Page 1

10/06

30-10-10-06-EN

Page 1 of 16

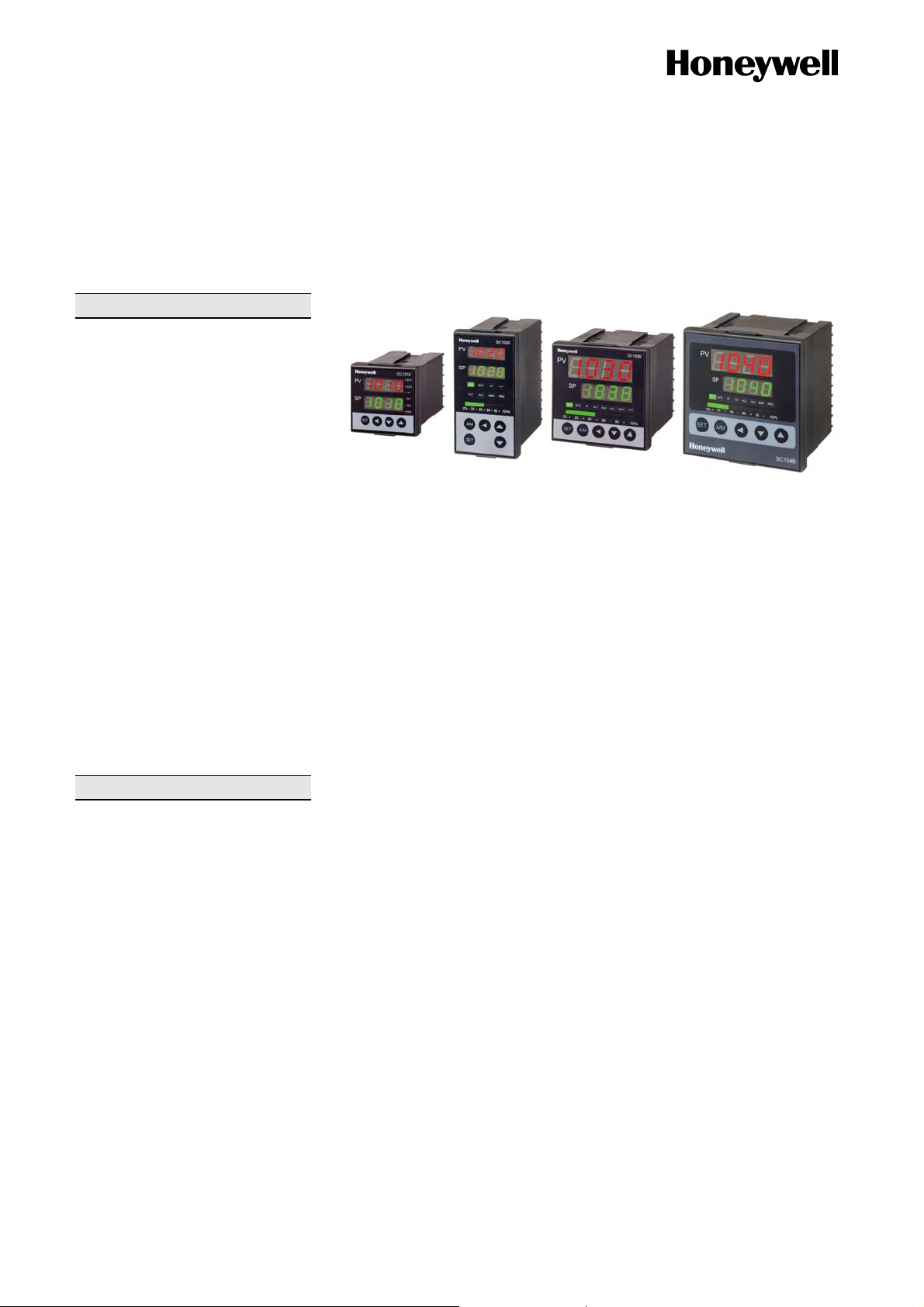

DC1010/DC1020/DC1030/DC1040

DIGITAL CONTROLLERS Specification

Overview

The DC1000 Series are microprocessorbased controllers designed with a high

degree of functionality and reliability at a

competitive price. The controllers are

available in different formats: 48x48

(1/16 DIN), 48x96 (1/8 DIN), 72x72

(3/16 DIN), 96x96 (1/4 DIN). This

controller series is ideal for the control of

temperature, humidity, pressure, flow etc.

in a variety of applications including:

z Plastic Processing

z Package Machinery

z Painting and coating

z Semiconductor packaging / Testing

z Dryers

Features

z Easy to Configure

Different configuration level s provide easy

access to parameters.

z Various Control Algorithm

Several different algorithms are available

as follows:

- PID or ON/OFF Control

- Heat/Cool Control with 2 PID sets

- Motor Position Control

(without slidewire feedback)

z Auto-Tuning Capability

Advanced auto-tuning function calculates

the optimized PID values for your specific

control system.

z Dual Display and Bar graph

Two large 4 digits display PV, SP and

configuration parameters. One 10 LED

bar-graph displays the control output

(MV), and up to 8 LEDs display the status

of the different outputs (Control, Alarm,

…) and also provide indication of the

Auto/Manual and programmer states.

z Setpoint Programming

Two programs are available with a

maximum of 8 segments. The 2 programs

can be linked together and perform as a

single 16 segment program.

z Extended Alarm Capability

Up to three different alarm outputs are

available per instrument and 17 kinds of

event modes can be assigned to each of

alarm output.

z Communications

RS232 or RS485 (with ASC II & Modbus

RTU Protocol) is optionally available with

a maximum communication speed of

38400 bps.

z IP65 Front Face Protection

IP65 rated front face permits use in

applications where it may be subjected to

moisture, dust conditions.

z Remote Setpoint Capability

The setpoint can be defined from a

remote PLC or other controller.

z Manual & Automatic Modes

The control mode can be switched

between Automatic and manual by

clicking A/M key. (The A/M key is

available with DC1020, DC1030 and

DC1040)

z Global Approvals – CE & cUL

All models are CE certified as a standard,

and UL approved version for all models

are available optionally.

z Parameter Lock

A 4-digit security code prevents any

unauthorized changes of parameters or

configurations. Parameters can be hidden

to user to prevent any mis-conf iguration

of the unit.

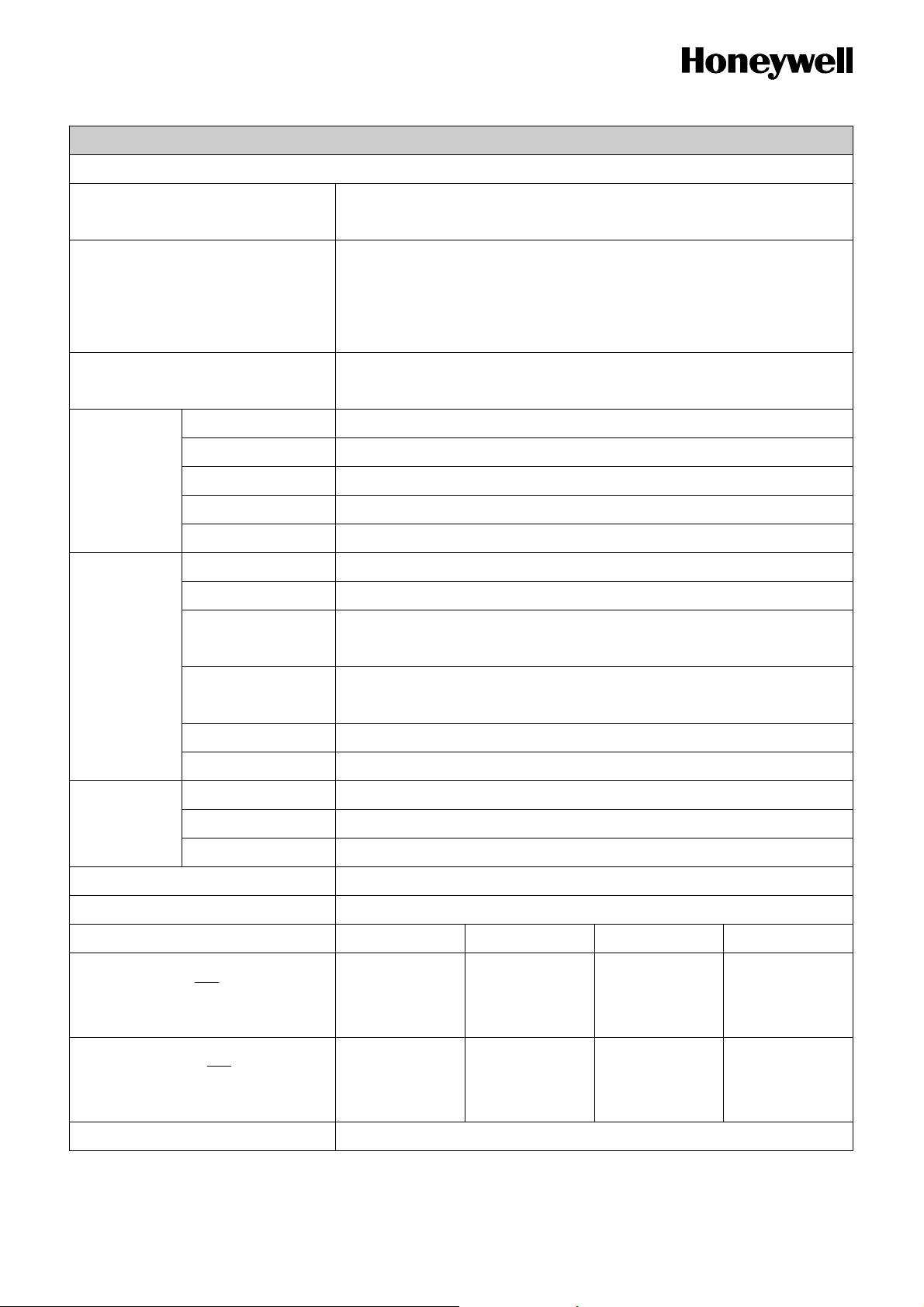

Page 2

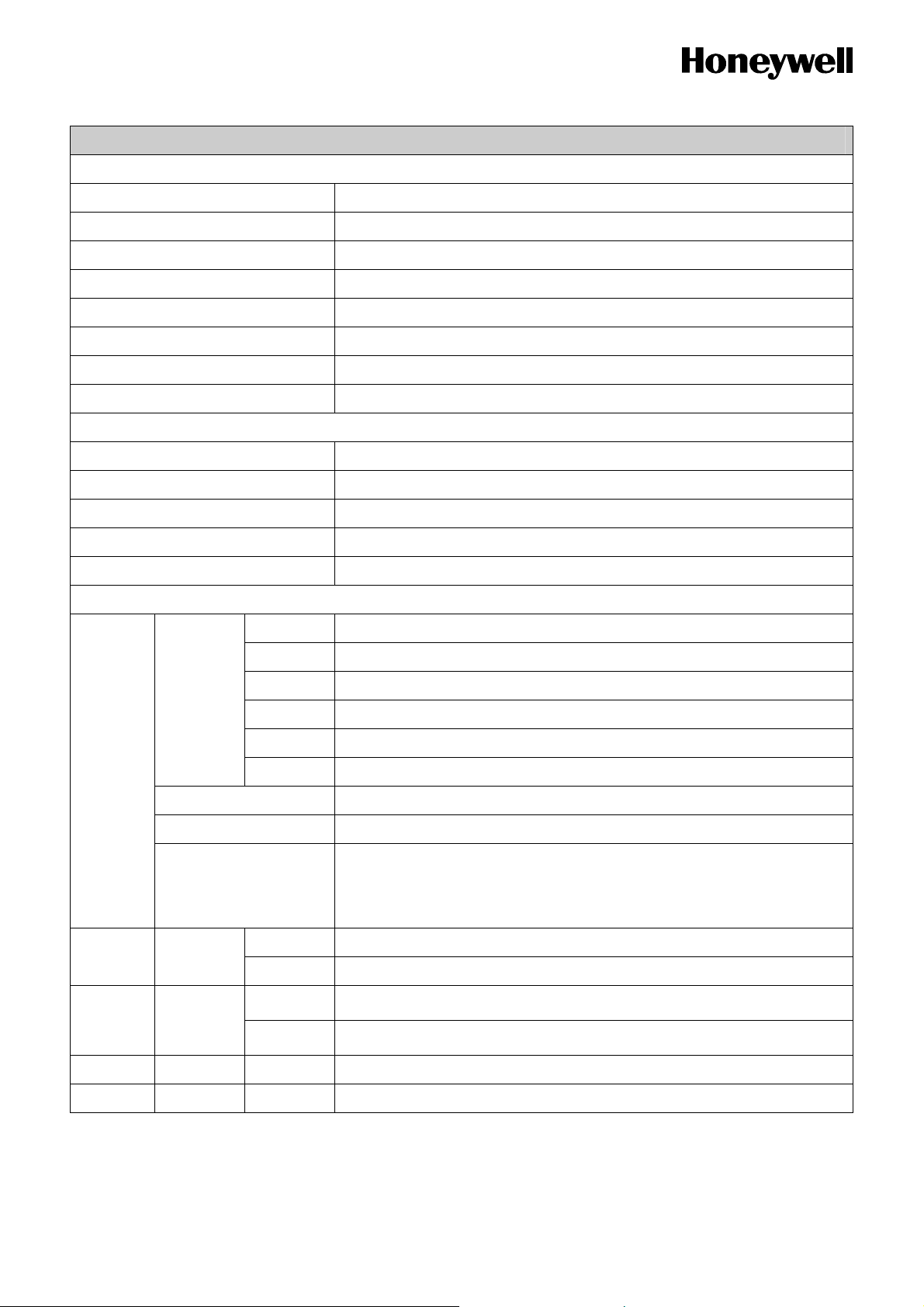

Specifications

General

Rated power supply voltage 100 to 240V AC 50/60Hz, 8VA max.

15 to 50V DC, 10VA max.

Insulation Resistance

Over 10㏁ under DC500V megger between input terminal and

case(ground).

Over 10㏁ under DC500V megger between output terminal and

case(ground).

Withstand voltage 1000V AC 50/60Hz for 1min across input terminal and case(ground)

1500V AC 50/60Hz for 1min across output terminal and case(ground)

Standard

Conditions

Ambient Temp.

Ambient Humi. 60 ± 5% RH

23 ± 2 °C

Rated Power Supply 110V AC

Power Frequency 50 ± 1Hz or 60 ± 1HZ

Operating

Conditions

Ambient Temp.

Ambient Humi. 20 to 90%RH (non-condensing)

0 to 50°C

Rated Power Supply 100 to 240V AC

20 to 50V DC

Allowable Power

85 to 264V AC

Supply

15 to 55VDC

Power Frequency 50 ± 2Hz or 60 ± 2Hz

2

(approx. 1G), 10 to 55Hz for 10min each X, Y, Z directions

-20 to +65 °C

2

(Approx. 2G), 10 to 55Hz for 2 hours each in X, Y, Z directions

Transportatio

n and storage

conditions

Vibration Resistance 10m/s

Ambient Temp.

Ambient Humi. 10 to +95% RH (non-condensing)

Vibration Resistance 20m/s

Exterior Case and front panel : plastic

Mounting Panel-mount

Model DC1010 DC1020 DC1030 DC1040

Exterior Size (unit:

mm

inch

)

50 X 50 X 97

(1.97X1.97X 3.82)

50 X 96 X 97

(1.97X3.78X3.82)

74 X 74 X 97

(2.91X2.91X3.82)

: W X H X D

Panel Cutout (unit:

mm

inch

)

44.5 X 44.5

(1.75 X 1.75)

44.5 X 90.5

(1.75 X 3.56)

68.5 X 68.5

(2.97 X 2.97)

: W X H

Global Approvals CE, cUL

96 X 96 X 97

(3.78X3.78X3.82)

90.5 X 90.5

(3.56 X 3.56)

Interval = 20.5mm (0.807 in)

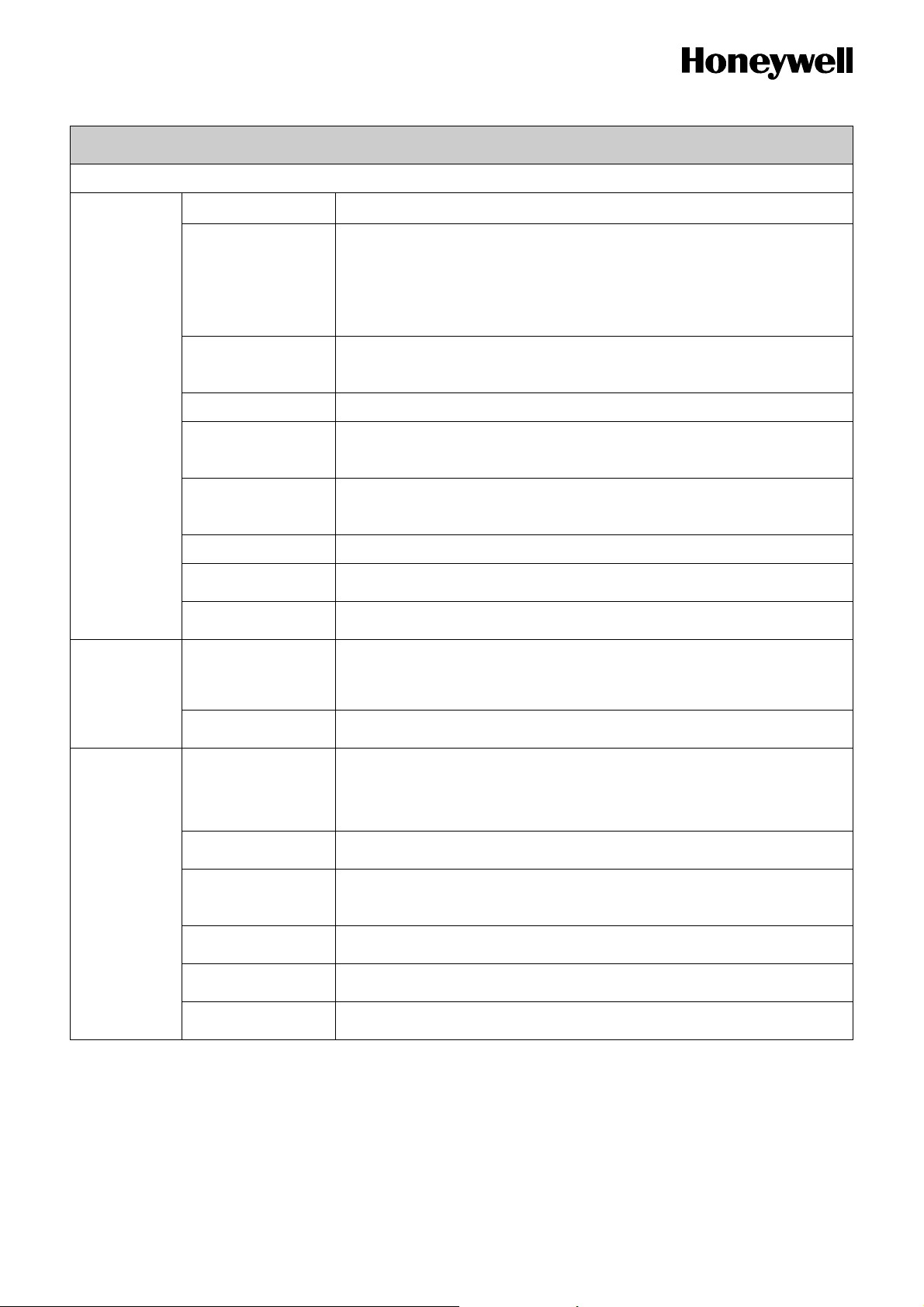

Page 3

Specifications

Input/Output

Analog

Input 1

Analog

Input 2

Number of Point 1 point (TC, RTD or Linear)

TC: K, J, R, S, B, E, T, N, W, U, PLII, L

RTD : DPt100, JPt100, JPt50

Type

Linear : 4~20mA / 1~5V / 2~10V * Note 1

0~20mA / 0~5V / 0~10V * Note 1

Refer to Table 1-1.

Range

* Temperature unit : ºC, ºF ( switchable)

Sampling cycle 250 ms

Indication

± 0.2% FS ± 1digit (for details Table1-1)

Accuracy

Cold junction

±1.0ºC (under standard conditions)

accuracy

Input bias (offset) LSPL ~ USPL

Digital Filter 0 - 200 sec (0: filter off)

Decimal Point 0000, 000.0, 00.00, 0.000

0~20mA / 0~5V / 0~10V

Type

4~20mA / 1~5V / 2~10V

Sampling Cycle 250ms

CT Input

Type

Sampling Cycle 500msec

Indication

Accuracy

Resolution 0.1A ac

Weight

Dielectric strength 2500Vac, for 1 min between terminal and case

Measure AC current of single phase

SC-80T : 0.0~80.0A

1% FS

12g

NOTE 1. When OUT1 is ON and CT input value is less than HBA set value for 5 seconds, AL1 is activated.

Otherwise, AL1 is not activated.

Page 4

Specification

Input/Output

Model DC1010 DC1020 DC1030 DC1040

Analog

Output 1

Analog

Output 2

(* Note 1)

Relay

Voltage Pulse

Linear

Relay

Voltage pulse

Linear

SPST SPDT SPST SPDT

3A, 220Vac, Resistive Load(100,000 time electrical life)

PWM(SSR drive), ON: 20 Vdc, OFF: 0 V (max. load current 20mA)

Open Time Terminal Voltage: 20 Vdc or less

Time Proportional Cycle Time: 0-150 sec

DC Current (mA) : 0~20mA, 4~20mA (load resistance 500Ω)

DC Voltage (V) : 0~5V, 0~10V, 1~5V, 2~10V (max. load current 20mA)

Accuracy ± 5% of Span

Update Cycle 500m sec

SPST SPST SPST SPST

3A, 220Vac, Resistive Load(100,000 time electrical life)

PWM(SSR drive), ON: 20 Vdc, OFF: 0 V (max. load current 20mA)

Open Time Terminal Voltage: 20 Vdc or less

Time Proportional Cycle Time: 0-150 sec

DC Current (mA) : 0~20mA, 4~20mA (load resistance 500Ω)

DC Voltage (V) : 0~5V, 0~10V, 1~5V, 2~10V (max. load current 20mA)

Accuracy ± 5% of Span

Update Cycle 500m sec

Output Direction (OUD) HEAT(Direct)/COOL(Reverse) (Selectable)

Auto/Manual operation is switchable.

Control Mode

Object SP, PV

No. of point 1 point

Transmission

Type 4-20mA, 0~20mA, 0~5V, 0~10V, 1~5V, 2~10V

Output

Accuracy +/- 0.2% of span

Update Cycle 500 ms

AL1 SPST SPDT SPST SPDT

AL2 SPST SPDT SPST SPDT

Digital Output Relay

AL3 - SPST SPST SPST

3A, 220Vac, Resistive Load(100,000 time electrical life)

*Manual output : Bumpless in normal mode

OUTL in abnormal mode

* For Heat/Cool Control Output only.

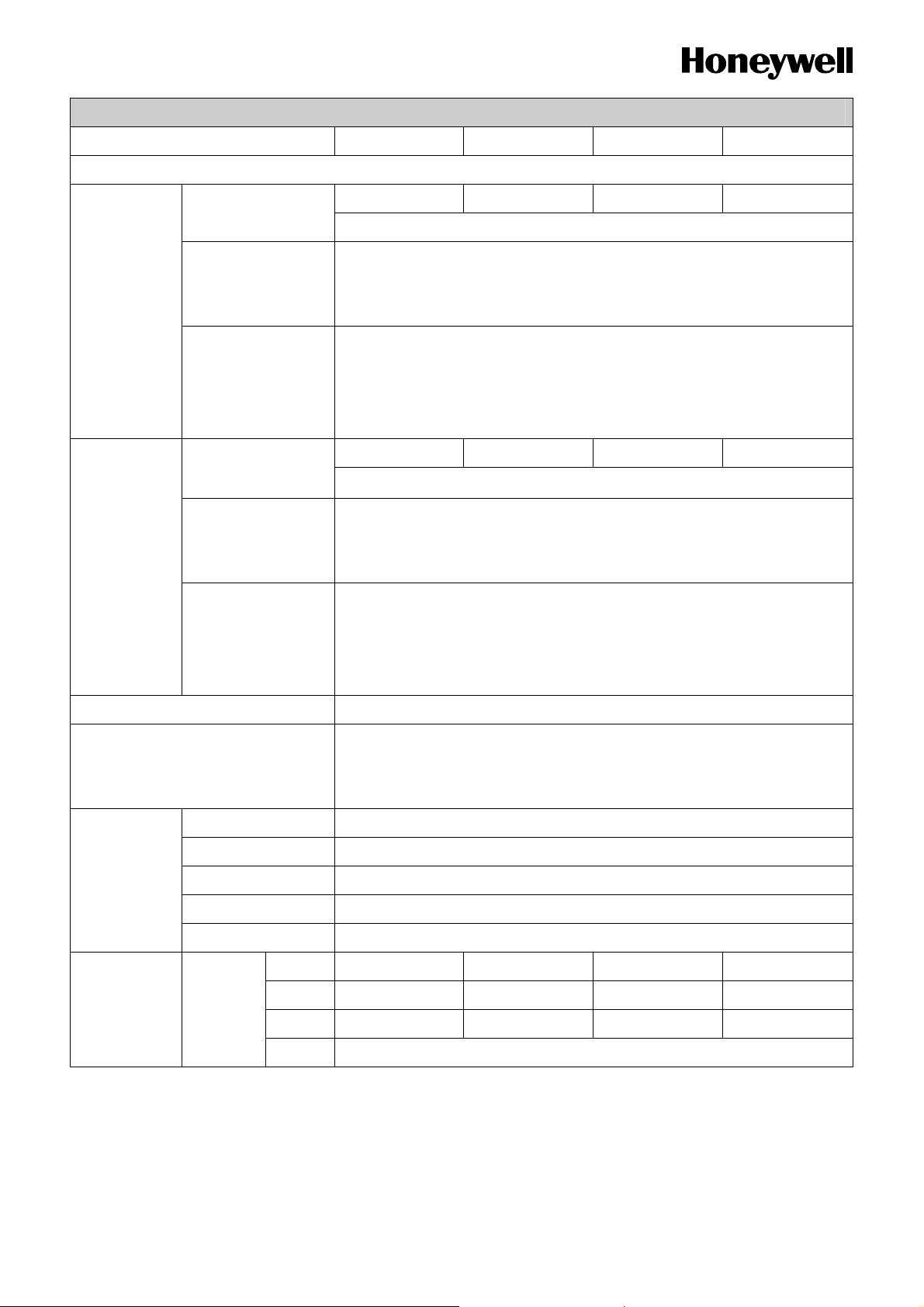

Page 5

Specification

PID Control & Auto-Tuning

Proportional Band (P1,P2) Proportional Band: 0.0 ~ 200.0%

Integral time (I1, I2) Integral time : 0 ~ 3600 sec

Derivative time (D1, D2) 0 ~ 900 sec

Auto-Tuning Value 0 ~ USPL

HYS1, HYS2 0 ~ 1000 (for ON/OFF control)

Dead Band (DB1) Not defined.

GAP1, GAP2 0 ~ 1000(for HEAT/COOL control)

Cycle Time 0 ~ 150 sec

Communication

Speed 1200, 2400, 4800, 9600, 19200, 38400 bps

Protocol ModBus RTU, ModBus ASCII

Parity check Odd / Even

Bit length 8

Communication RS232C, RS485

Events(ALARMS)

01 / 11 Deviation-High alarm (inhibit / no-inhibit)

02 / 12 Deviation-Low alarm (inhibit / no-inhibit)

Code

PV Event

SET VALUE -1999~ USPL (Absolute value, Deviation value)

Activation Hysterisis 0 ~ 1000

On Delay Time

Program Code

03 / 13 Deviation High/Low Limit alarm (inhibit / no-inhibit)

04 / 14 Deviation High/Low Limit range alarm (inhibit / no-inhibit)

05 / 15 Absolute High alarm by PV (inhibit / no-inhibit)

06 / 16 Absolute Low alarm by PV (inhibit / no-inhibit)

0 : Flicker

99M 59S : Continuance

00M 01S to 99M 58S : Time Delay

07 Segment End alarm(in progress of program)

17 Program RUN

08 System Error ON

System Code

18 System Error OFF

TIME Code 19 Delaying timer (00Hours 00Min ~ 99Hour 59Min)

HBA Code 09 Heater Break Alarm

Page 6

Specification

Program (Optional)

No. of programs 2 (Program 1 & Program 2)

No. of segments 8 segments/1 program

Program

section

Segment time

Control output

WAIT function

Repeat Repeat / Non-repeat

Program link When Program number is 0, Link program 1 and 2.

Program start

Segment time: Setting by set points(SP) and time

(Max. 99hours 59minutes)

0~100%

When OUT=0%, Program End.

Rear Wait

Time may exceed set time of the particular segment. In this case, remaining

time is set as 0 and pending; if the temperature that was measured does

not reach target value ± WAIT set point. It proceeds to the next segment

after it is confirmed that temperature reach the range of set point (target

value ± WAIT)

Setup range: ± 0 ~ 1000 by decimal point.

(1) Start from SP=0

(2) Start from PV

Power Failure Hot Start / Cold Start

TIME UNIT Hour. Minute / Minute. Second

Ramp & Soak

Slope(Ramp) Temperature : 0.0 to 99.99 / min

SOAK TIMER Max. 99 hours 59 min

POWER FAILURE It starts from PV.

Page 7

Table 1-1

Analog Input Range (Thermocouple)

Input Type Code

K1 0.0~200.0 0.0~392.0

K2 0.0 ~ 400.0 0.0~752.0

K

K3 0 ~ 600 0~1112

K4 0 ~ 800 0~1472

K5 0 ~ 1000 0~1832

K6 0 ~ 1200 0 ~ 2192

J1 0.0~200.0 0.0~392.0

J2 0.0 ~ 400.0 0.0~752.0

J

J3 0 ~ 600 0~1112

J4 0 ~ 800 0~1472

J5 0 ~ 1000 0~1832

J6 0 ~ 1200 0 ~ 2192

R1 0~1600 0~2912

R

R2 0~1769 0~3216

Temperature Range

ºC ºF

Indication

Accuracy

+/-0.2%FS

+/-0.2%FS

+/-0.2%FS

Remarks

+/-2 ºC under 100 ºC

+/-3.6 ºF under 212 ºF

TC

(Note1)

S

+/-0.2%FS

S2 0~1769 0~3216

S1 0~1600 0~2912

B1 0~1820 0~3308 +/-0.2%FS No guarantee at 0 ~ 400ºC

E

E1 0~800

E2 0~900

N1 0~1200

N

N2 0~1300

T1 -199.9~400.0

0~1472

0~1652

0~2192

0~2372

-199.9~752.0

+/-0.2%FS

+/-0.2%FS

+/-1 ºC under -100 ºC

+/-0.2%FS

T

T2 -199.9~200.0

T3 0.0~350.0

-199.9~392.0

0.0~662.0

+/-0.2%FS

+/-1.8 ºF under -148 ºF

0~2300 0~3632 W5Re/

+/-0.2%FS

W26Re

0~2320 0~4208

PL1 0~1300 0~2372

PLII

+/-0.2%FS

PL2 0~1390 0~2534

U1 -199.9~600.0

-199.9~999.9

+/-1 ºC under -100 ºC

+/-0.2%FS

U

U2 -199.9~200.0

-199.9~392.0

+/-1.8 ºF under -148 ºF

U3 0.0~400.0 0.0~752.0 +/-0.2%FS

L1 0~400 0~752

L

+/-0.2%FS

L2 0~800 0~1472

Page 8

Table 1-2

Analog Input Range (RTD)

Input Type Code

JPt100

DIN

RTD

Pt100

JPt50

Input Type

ºC ºF

JP1 -199.9~600.0 -199.9~999.9

JP2 -199.9~400.0 -199.9~752.0

JP3 -199.9~200.0 -199.9~392.0

JP4 0~200 0~392

JP5 0~400 0~752

JP6 0~600 0~1112

DP1 -199.9~600.0 -199.9~999.9

DP2 -199.9~400.0 -199.9~752.0

DP3 -199.9~200.0 -199.9~392.0

DP4 0~200 0~392

DP5 0~400 0~752

DP6 0~600 0~1112

JP.1 -199.9~600.0 -199.9~999.9

JP.2 -199.9~400.0 -199.9~752.0

JP.3 -199.9~200.0 -199.9~392.0

JP.4 0~200 0~392

Indication

Accuracy

+/-0.5 ºC under -100 ºC

+/-0.9 ºF under -148 ºF

+/-0.2%FS

+/-0.5 ºC under -100 ºC

+/-0.9 ºF under -148 ºF

+/-0.2%FS

+/-0.5 ºC under -100 ºC

+/-0.9 ºF under -148 ºF

+/-0.2%FS

Remarks

JP.5 0~400 0~752

JP.6 0~600 0~1112

Table 1-3

Analog Input Range (Linear)

Input Type Code Source Range

AN1 -10~10mV

AN2 0~10mV

Linear

AN3 0~20mV

AN4 0~50mV 0-20mA, 0-1V, 0-5V, 0-10V

AN5 10~50mV

-1999~9999 +/-0.1% of span

Indication

Remarks

Accuracy

4-20mA, 1-5V, 2-10V

Page 9

Picture 1.1

External Dimension

100%

60

20

40 80

0%

DC1030

200% 40 60 100%80

8040200% 60 100%

Page 10

(

)

A

Picture 1-2

Wiring Diagram – DC1010

N

POWER

L

AC 100 ~ 240V

50 / 60Hz

DC 15 ~ 50V

(option)

Noise

Filter

1

11

2

12

3

13

4

14

5 10

6

7

8

9

PV

Linear

ALARM

2

R

TD

7

8

9

10

7

B

8

9

B

10

A

AL1

11

T

C

7

8

9

10

AL2AL1

13

OUT2

OUTPUT

Relay

2

Volt

Linear

231

OUT1=5

11

G1

3

A,B,C,D

OUT1

Relay Volt

4

Linear

231

12

K1

13

G2

14

K2

5

A,B,C,D

OUT1=7

3

12

14

2

3

4

5

CLOSE

OPEN

COM

UX. OUT

TRS

CT INPUT

CT

COMM.

11

12

11

RS232

RD

SD

SG

COMM

COMM

RS485

11

12

13

D-

D+

11

12

13

12

Page 11

(

)

A

Picture 1-3

Wiring Diagram – DC1020

AC 100 ~ 240V

DC 15 ~ 50V

L

POWER

N

50 / 60Hz

(option)

Noise

Filter

1 11

2 12

3 13

4 14

5 15

6 16

7 17

8 18

9 19

10 20

PV

L

inear

17

18

19

20

R

TD

17

B

18

19

B

20

A

T

C

17

18

19

20

OUT2

OUT1

OUTPUT

Relay Volt

6

7

Relay Volt

8

Linear

231

A,B,C,D

Linear

NO

231

NC

9

10

COM

OUT1=7

6

7

CLOSE

A,B,C,D

LARM

AL1 AL2 AL3

NC

3

NO

4

5

COM

COM

NC

11

NO

12

13

6

7

AUX. OUT

11

TRS

12

13

8

OPEN

9

10

COM

INPU T2

14

15

16

COMM .

COMM

RS232

RD

14

SD

15

SG

16

COMM

RS485

14

D-

15

D+

16

CT INPUT

CT

14

15

Page 12

(

)

A

A

Picture 1-4

Wiring Diagram – DC1030

OUT2

OUT1

POWER

N

AC 100 ~ 240V

50 / 60Hz

DC 15 ~ 50V

(option)

OUTPUT

Relay

3

4

Relay Volt

NO

5

NC

6

7

COM

OUT1=7

3

4

CLOSE

L

Volt

231

231

Noise

Linear

A,B,C,D

Linear

A,B,C,D

Filter

OUT1=5

15

G1

17

G2

19

20

OUT1=8

15

G1

16

K1

1 15 8

2 16 9

3 17 10

4 18 11

5 19 12

6 20 13

7 21 14

PROT

PV

LARM

3

4

L

inear

11

12

13

14

COM

CT INPUT

CT

R

TD

11

B

12

13

B

14

A

UX. OUT

AL2AL1

8

NO

9

10

NC

TRS

15

16

T

C

11

12

13

14

18

19

5

OPEN

17

G2

18

6

7

COM

K2

20

PROT

21

INPUT2

Remote SP

9

10

COMM.

COMM

RS232

RD

15

SD

16

SG

17

COMM

RS485

15

D-

16

D+

17

Page 13

(

)

A

A

Picture 1-5

Wiring Diagram – DC1040

AC 100 ~ 240V

DC 15 ~ 50V

CT INPUT

POWER

50 / 60Hz

(option)

CT

L

Noise

Filter

1 31 11

2 32 12

N

3 33 13

4 34 14

5 35 15

6 36 16

7 37 17

8 38 18

14

15

9 39 19

10 40 20

COMM.

COMM

RS232

RD

31

SD

32

SG

33

UX. OUT

TRS

COMM

RS485

D-

D+

39

40

31

32

33

OUT2

OUTPUT

Relay

6

Volt

231

Linear

OUT1=6

31

RG

OUT1=5

31

G1

33

35

37

RG

TG1

TG2

33

39

40

G2

PROT

OUT1

7

Relay

8

A,B,C,D

Linear

Volt

NO

231

PV

Linear

17

18

19

20

R

TD

17

B

18

19

B

20

A

T

C

17

18

19

20

9

10

OUT1=7

6

7

CLOSE

8

OPEN

9

10

COM

NC

COM

A,B,C,D

39

40

OUT1=8

31

G1

32

K1

33

G2

34

K2

35

36

PROT

PROT

OUT1=9

31

G1

32

K1

33

G2

34

K2

35

G3

K3

36

39

40

PROT

LARM

AL1 AL2 AL3

NC

3

NO

4

5

COM

INPUT2

Remote SP

NC

NO

COM

COMM

11

12

13

COMM.

RS232

14

15

16

RD

14

SD

15

SG

16

6

7

COMM

RS485

14

D-

15

D+

16

Page 14

Model Interpretation

Page 15

Page 16

gap

Warranty / Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact your local

sales office for warranty information. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will

repair or replace without charge those items it finds defective. The foregoing is Buyer's sole remedy and is in lieu of all other

warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. Specifications may

change without notice. The information we supply is believed to be accurate and reliable as of this printing. However, we assume

no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it is up to the customer to

determine the suitability of the product in the application.

Honeywell Process Solution

IM&C Asia Pacific

Honeywell Building

17 Changi Business Park Central 1

ore 486073

Sin

Specifications are subject to chang e without notice.

www.honeywell.com/imc

Loading...

Loading...