Page 1

HONEYWELL

DC 1010 / 1020

1030 / 1040

DIGITAL CONTROLLER

PRODUCT MANUAL

51-52-25-113

06/02

Page 2

Before using this manual, please check to ensure the Model number, input type

Range and output match your requirements.

1. Front Panel Overview

1.1 Display

PV :Process Value, 4-digit display (Color Red)

SP :Set Point, 4-digit display (Color Green)

1.2 LED Indicators

OUT1 :Output 1, color green

OUT2 :Output 2, color green

AT :Auto-Tuning, color yellow

PRO :Program, color yellow

AL1 :Alarm 1, color red

AL2 :Alarm 2, color red

MAN :Manual, color yellow

1.3 Keys

SET :MODE & SET key

:SHIFT key

:DOWN key

:UP key

A/M :Auto/Manual key

2.2. Auto Tuning

2.1 When AT is set to ‘YES’, auto tuning can be initiated.

2.2 After completion of auto tuning, the PID parameter are automatically

Entered into memory.

2.3 ATVL = auto tuning offset, the off set value when entered will be calculated

and subtracted from the SP.

(It prevents over-shooting during auto tuning)

SP-ATVL = Auto-tuning value, ATVL = Auto tuning offset

Ex.) SP = 200°C, ATVL = 5, Auto tuning point is at 195°C

* ATVL means auto-tuning point (195°C) in the above example.

2.4 Auto tuning failure

2.4.1 ATVL is too large.

à If unsure, set ATVL = 0)

2.4.2 Process lag is to long for Auto Tune to function correctly.

à Set PID parameter manually.

DC1010/1020/1030/1040 PRODUCT MANUAL

2

Page 3

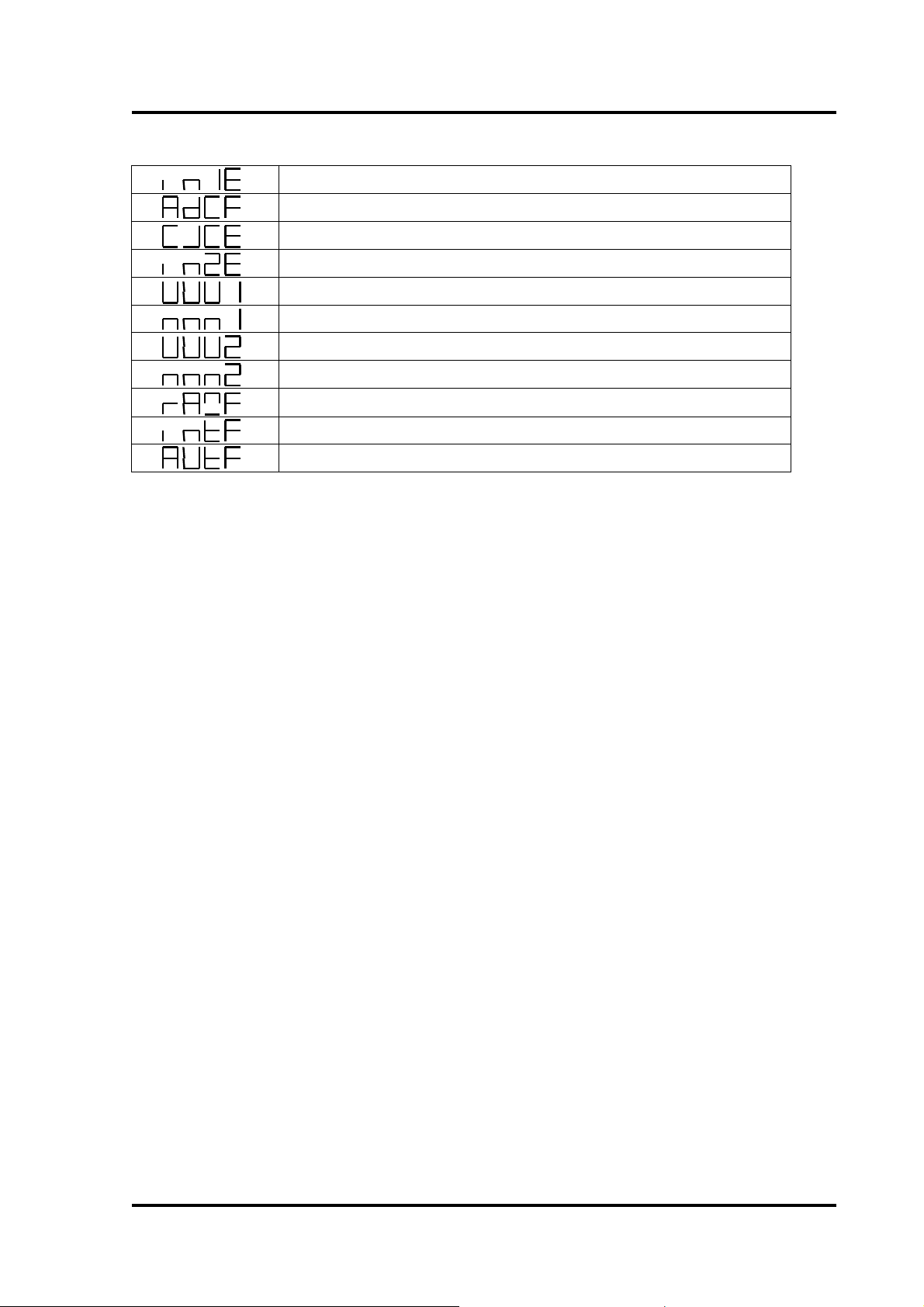

3.3. Error Information

Open circuit sensor input 1

* A/D converter failed

* Cold junction compensation failed

Open circuit of sensor input 2

PV exceeds USPL

PV under LSPL

Input 2 signal has exceeded the upper limit

Input 2 signal has exceeded the lower limit

* RAM failed

Interface failed

Auto tuning failed

Note) Error * code indicates critical failure unit must be replaced.

3

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 4

SET

SET

SET

SET

SET

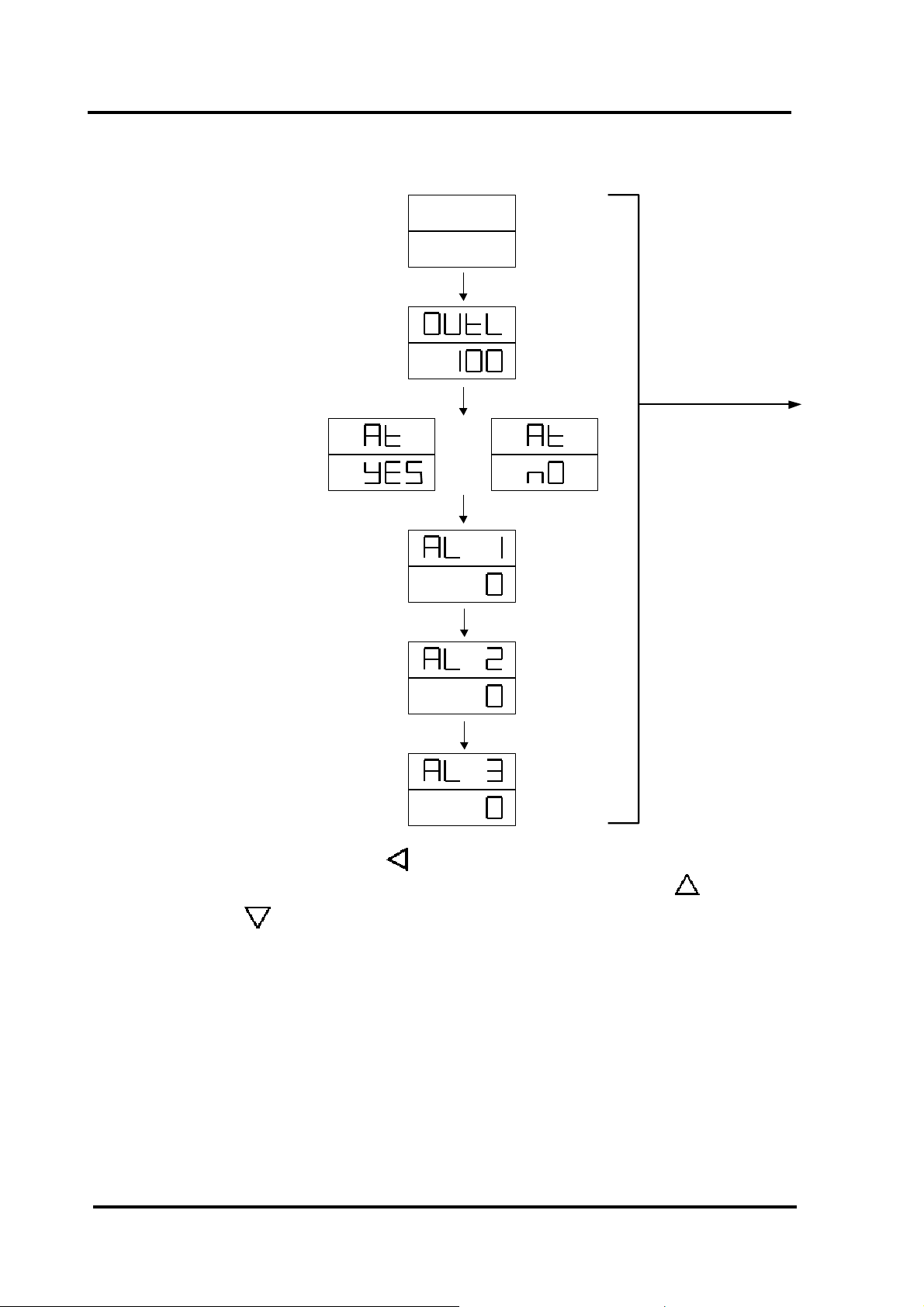

4.4. Operating Flow

Display PV

Display SP

Output

Percentage

Auto Tuning

Status

Alarm 1 Set

Alarm 2 Set

Alarm 3 Set

4.1 Level 1

PV

SP

Press SET key

for 5 sec

4.1.1 Press the SHIFT key ( ) to change the parameters, when the SHIFT key

is pressed, the first digit will start to blink. Press UP key ( ) or DOWN

key ( ) to increase or decrease the value of the digit, then press SHIFT

key again to go to the next digit, repeat the above procedure until the

required has been selected. Press the SET key to enter the desired value.

4.1.2 The SET key also has the function of changing MODEs. If SET key is

pressed, the display shows the next MODE.

4.1.3 Press SET key for 5 sec. The display goes to level 2, press the SET key

again to return to level 1.

4.1.4 If any key is not pressed for 1 minute the display will return to level 1.

4.1.5 If the A/M key is pressed the controller will switch to level 1.

4.1.6 If the output percentage is “0”, the controller output is off.

4

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 5

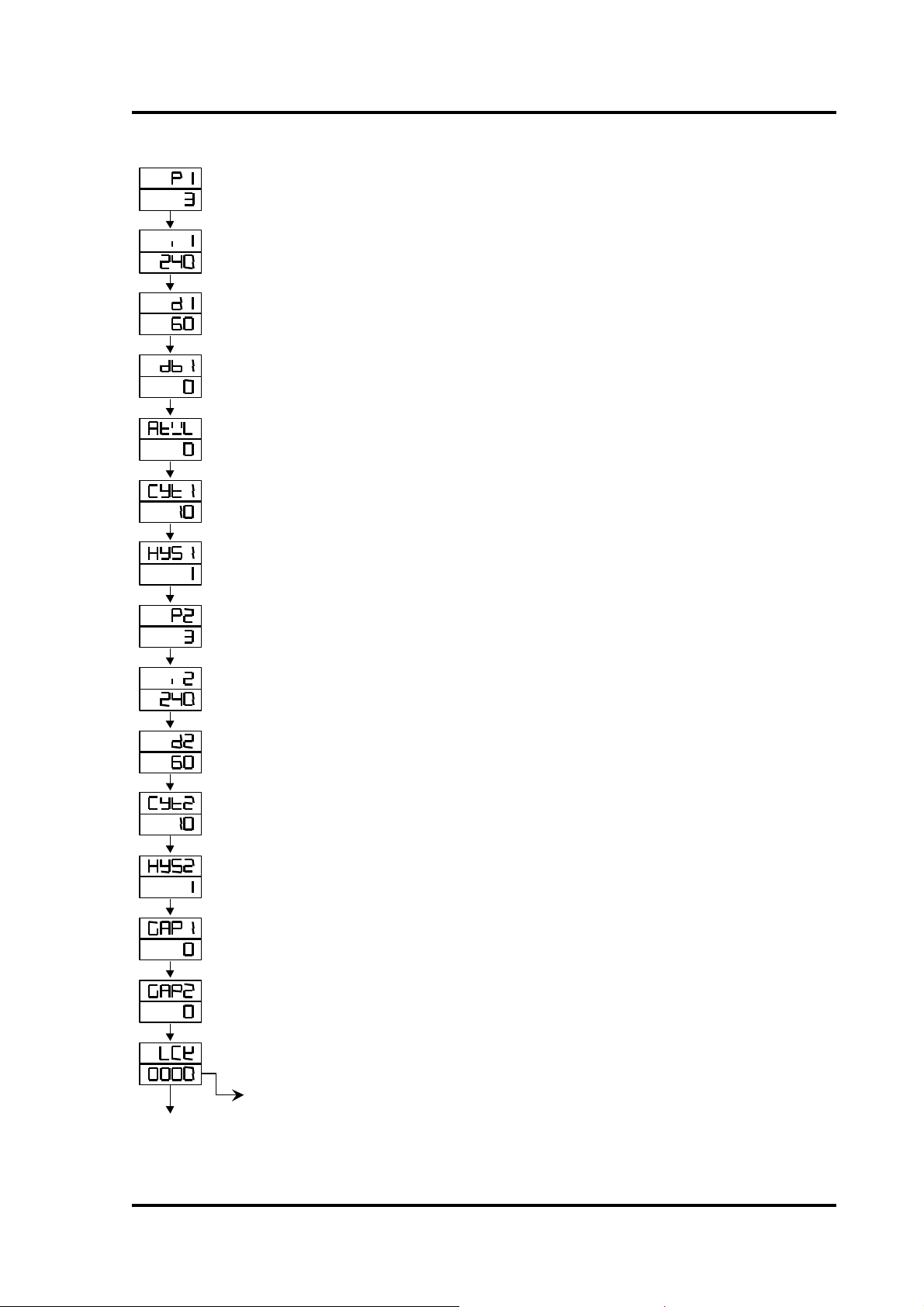

4.2 Level 2

Main Control

Proportional Band

Main Control

Integral Time

Main Control

Derivative Time

Main Control

Dead-band Time

Main Control

Auto Tuning off-set

Main Control

Proportional Cycle

Main Control

Hysterisis

Sub Control

Proportional band

Sub Control

Integral Time

Sub Control

Derivative Time

Sub Control

Proportional Cycle

Sub Control

Hysterisis

Main Control

Gap (Output 1)

Sub Control

Gap (Output 2)

Function Lock

Range: 0~200%

ON/OFF at P=0

Range: 0~3600 sec

Integral off at I=0

Range: 0~900 sec

Derivative off at D=0

Dead Time Compensation

Range: 0~1000 sec

Range: 0~USPL

Output (SSR à 1, 4~20mAà0, relayàover 10)

Range: 0~150 sec * Refer to 8.10 Cycle Time

For ON/OFF control only

Range: 0~1000

Same as P1

Same as I1

Same as D1

Same as CYT1

Same as HYS1

For output 2 use only, set the value turning

“OFF” early to SP

For output 2 use only, set the value turning

“ON” early to SP

LCK=0100, To enter Level 1 & 2 and to change their parameters allowed.

LCK=0110, To enter Level 1 & 2 and to change the parameters on Level 1 allowed.

LCK=0001, To enter Level 1 only and to change SP allowed.

LCK=0101, Nothing allowed except to change LCK.

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

Return to

‘P1’

5

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 6

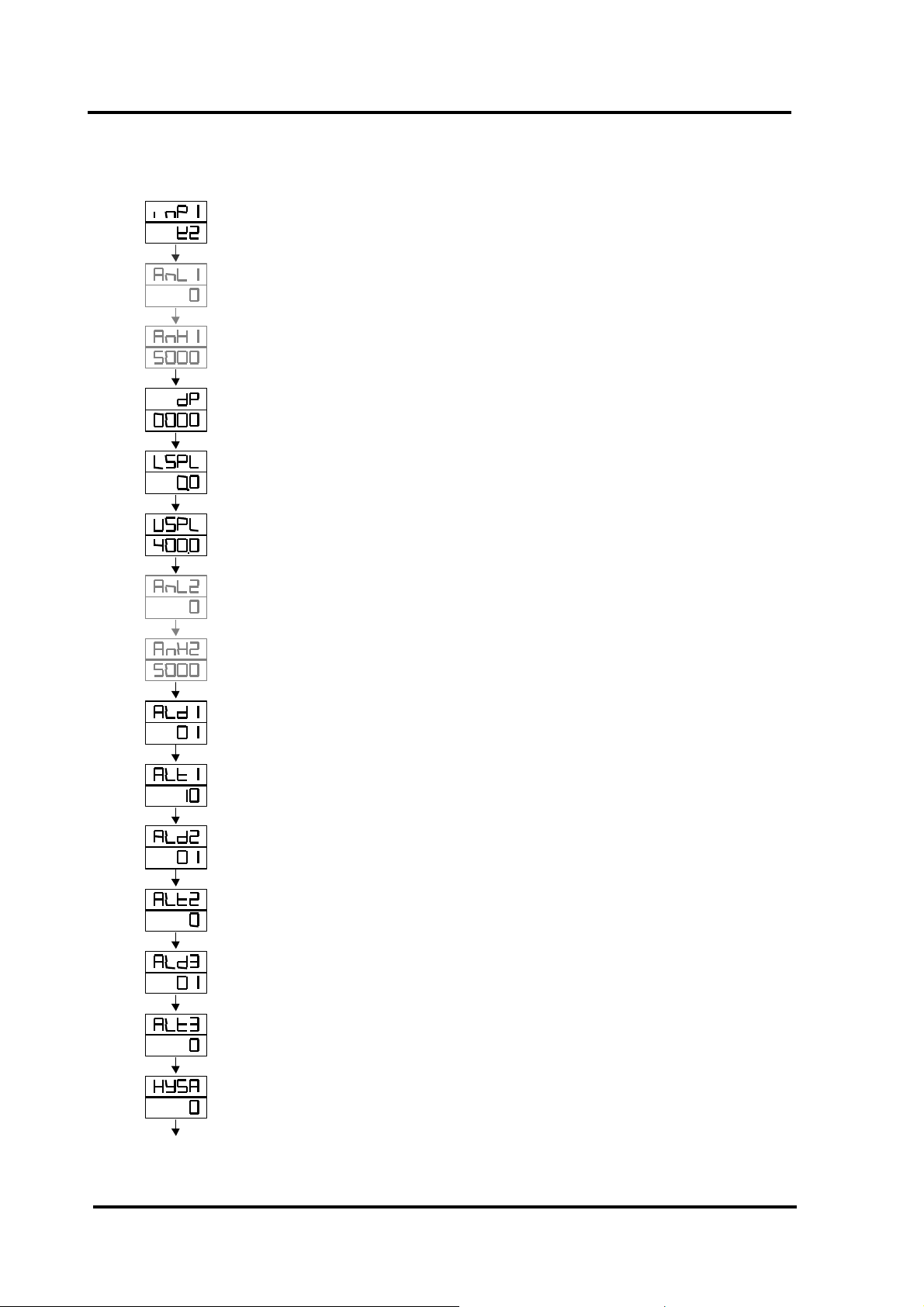

4.3 Level 3

Main Control

Input Selection

Main Control

Analog Zero set

Main Control

Analog Span set

Decimal point

Lower Set-point limit

Upper Set-point limit

Sub Control

Analog Zero set

Sub Control

Analog Span set

Alarm mode of AL1

Time set of Alarm 1

Alarm mode of AL2

Time set of Alarm 2

Alarm mode of AL3

Time set of Alarm 3

Hysterisis of Alarm

Select the input range.

Refer to 5.1 Input selection on P.13~P.14

Used as input code which are AN1 to AN5

Range: LSPL~USPL

Same as ANL1

To set the position of decimal point

To set the lowest point within INP1

To set the highest point within INP1

Used as input code which are AN1 to AN5

Range: LSPL~USPL

Same as ANL2

Range: 00~19

Refer to ‘6.1 Alarm Function Selection’ on P.15

Used in program function (Range: 0~99.59 min.)

Range: 00~19

Same as ALT 1

Range: 00~19

Same as ALT 1

Range: 0~1000

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

When LCK=0000, press the SET key and SHIFT key for 5 seconds to enter level 3.

0=switching, 99.59=continuous, others = on delay time

6

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 7

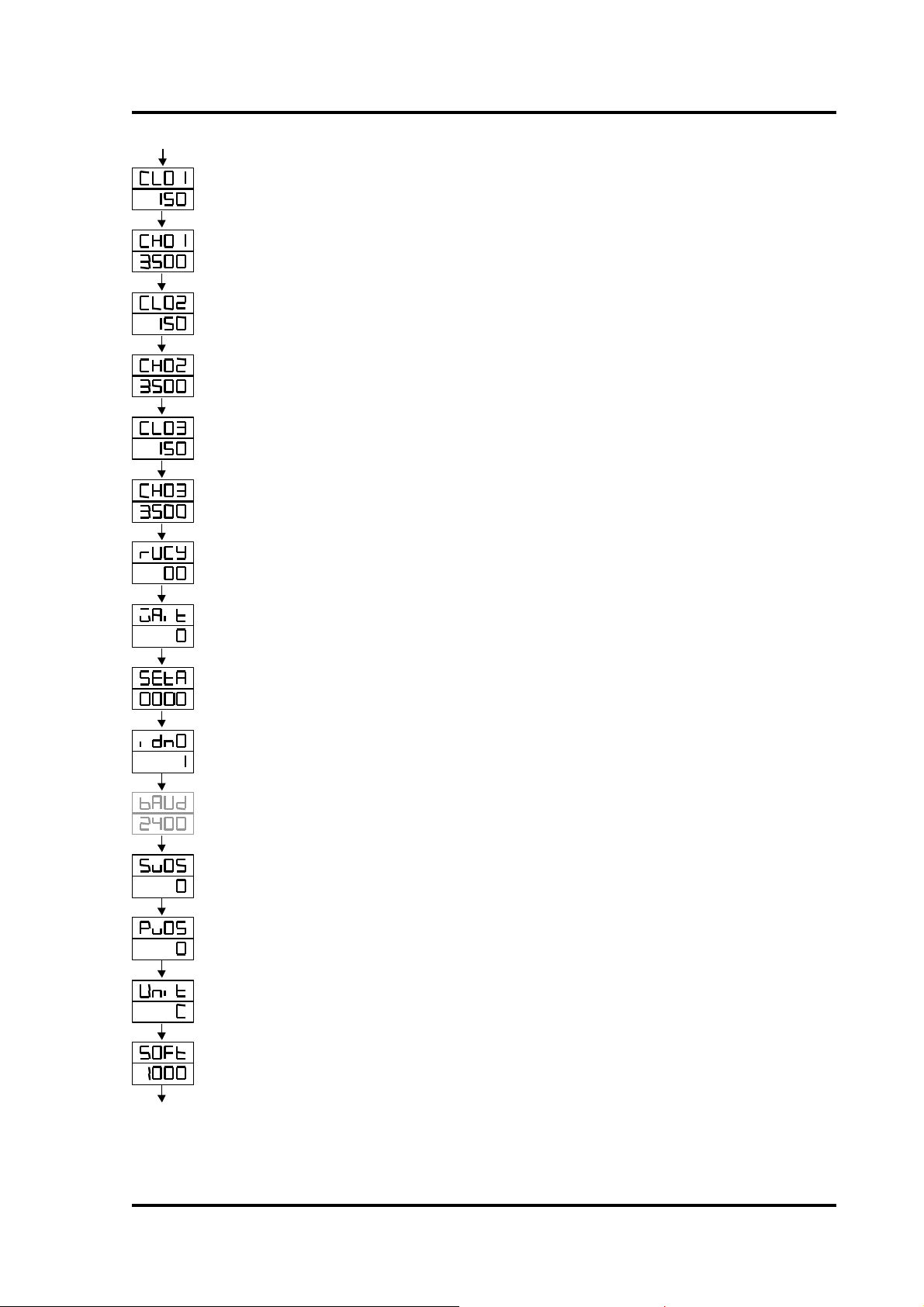

DC1010/1020/1030/1040 PRODUCT MANUAL

Main Control

Calibration

Main Control

Calibration high

Sub control

Calibration low

Sub Control

Calibration high

Transmitter control

Calibration low

Transmitter control

Calibration high

Timer for

Motor valve control

To use in program for

waiting continued operation

Relay Contact &

Program RUN & End ALM

ID number

(please skip this step)

Baud rate

(please skip this step)

Compensate SP

Compensate PV

Unit of PV & SP

Soft filter

(please skip this step)

To calibrate the low value of output

Range: LSPL~USPL (Current output only)

To calibrate the high value of output

Range: 0~9999 (Current output only)

Same as CL01

Same as CH01

Same as CL01

Same as CH01

Full run time of proportional motor (without potentiometer)

Range: 5~200 sec

0=No wait

Others = Wait time

0= “a” contact, 1= “b” contact

SET A.4=0 RUN alarm, SET A.4=1 END alarm

Communication ID number

UART band rate selection

Range: 110~9600 BIT/sec

Range: -1000~1000

Range: LSPL~USPL

Range: C, F, A (analog)

Adjust the response time of PV (the bigger, the faster)

Range: 0.05~1.00

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

7

Page 8

Return to ‘INP1’

Alternative: heat, cool

Alternative: PID, Fuzzy

Alternative: 50, 60Hz

PV

SP

0= lock (skip)

1= open (display)

Status definition

Please skip this step

Action mode

Control action

Frequency

* Check if the frequency is right. If not, change it, please.

SET

SET

SET

SET

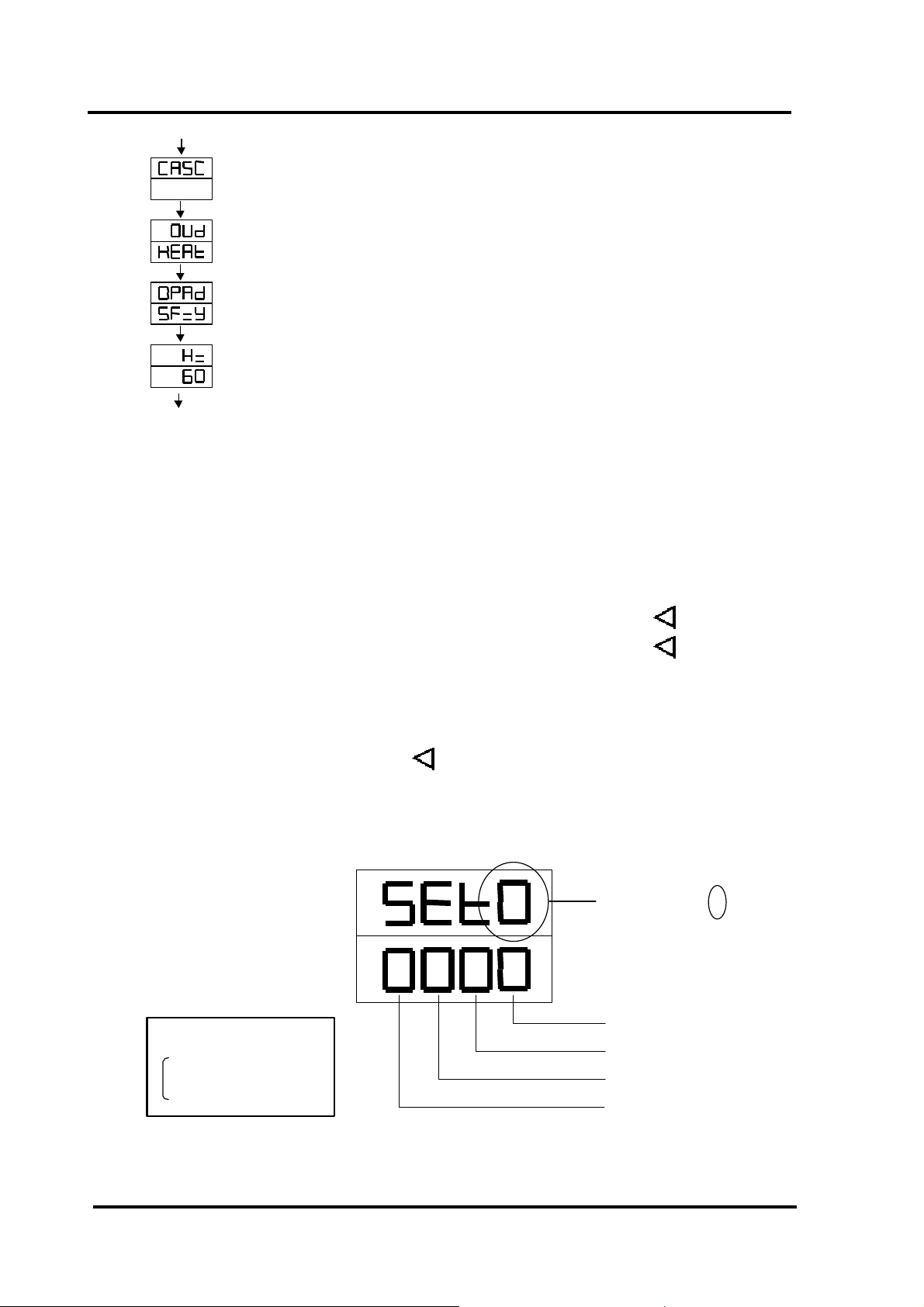

4.4 Level 4 (LOCK FUNCTION)

4.4.1 Functions of LCK

LCK=0100, To enter Level 1 & 2 and to change their parameters allowed.

LCK=0110, To enter Level 1 & 2 and to change the parameters on Level 1 allowed.

LCK=0001, To enter Level 1 only and to change SP allowed.

LCK=0000, To enter Level 3 allowed then press SET + SHIFT key ( )

LCK=1111, To enter Level 4 allowed then press SET + SHIFT key ( )

LCK=0101, Nothing allowed except to change LCK.

4.4.2 Let the display go to “LCK” in level 2, and set “1111” in LCK, then press

SET key and SHIFT key ( ) for 5 seconds to enter “SET” status. There

are SET0.1 to SET9.4 for use.

DC1010/1020/1030/1040 PRODUCT MANUAL

SET No. (SET 0 . ∗)

Status of SET ∗.1

Status of SET ∗.2

Status of SET ∗.3

Status of SET ∗.4

8

Page 9

4.4.3 Functions of SETs

SET Function SET Function

1.1 OUTL 5.1 CL02, CH02

1.2 AT 5.2 CL03, CH03

1.3 AL1 5.3 Rucy, WAIT, HYSM

1.4 AL2 5.4 IDNO, BAUD

2.1 AL3 6.1 SVOS

2.2 ANL1, ANH1, DP 6.2 PVOS

2.3 LSPL, USPL 6.3 UNIT

2.4 ANL2, ANH2 6.4 SOFT

3.1 ALD1 7.1 CASC

3.2 ALT1 7.2 OUD

3.3 ALD2 7.3 OPAD

3.4 ALT2 7.4 Hz

4.1 ALD3

4.2 ALT3

4.3 HYSA

4.4 CL01, CH01

SET Function Remarks

8.1

8.2

8.3

9.3 TRS SP

9.4 TRS PV

0.3

* Caution: Please don’t operate SET8.4, otherwise the process of the controller will

be in confusion.

0= No Repeat

1= Program Repeat

0= No Power Failure

1= With Power Failure

0= Start from 0

1= Start from PV

0= No Remote SP

1= Remote SP

Program Use

Auxiliary Output Use

9

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 10

Set point for Seg.5

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

4.5 Program Level

Level 1

Set program pattern

Range: 0~2

Program segment display

Range: (1-0)~(2-8)

Program timer display

Range: 99hour 59min

Set point for Seg.1

Range: LSPL~USPL

Set time for Seg.1

Range: 0~99H59M

Set output for Seg.1

Range: 0~100% (if out=0, no program)

Set point for Seg.2

Set time for Seg.2

Set output for Seg.2

Set point for Seg.3

Set time for Seg.3

Set output for Seg.3

Set point for Seg.4

Set time for Seg.4

Set time for Seg.5

Set output for Seg.5

Set point for Seg.6

Set time for Seg.6

Set output for Seg.6

Set point for Seg.7

Set time for Seg.7

Set output for Seg.7

Set point for Seg.8

Set time for Seg.8

Set output for Seg.8

Set output for Seg.4

Return to Normal(PV,SP)

DC1010/1020/1030/1040 PRODUCT MANUAL

10

Page 11

4.5.1 This program has 2 patterns, each pattern contains 8 segments. The

segment can be arranged a period of RAMP status or SOAK status.

4.5.2 Terminologies

Pattern : A program consists of some segments

Step : A RAMP status + a SOAK status

RAMP status : The status with changing SP

SOAK status : The status with fixed SP

4.5.3 Operating

1) Key functions (No changing parameters)

(START) : To start program procedure, PRO in panel flicker

(WAIT) : To suspend program procedure, PRO in panel will

stop flicker but light

+SET (JUMP) : To jump segment

+SET (RESET) : To reset program procedure, PRO in panel will be

“off”

2) Alarm function

If ALD1 to be set 07 (*refer to the selection),

AL1 to be set 2 (AL1=2, it means alarm in segment 2 end),

ALT1 to be set 00.10 (alarm time 10 sec.).

*In this case, when program proceeds to segment 2 end, ALM1 relay

will be on 10 sec.

3) End function

If ALD to be set 17 (* refer to the selection), this program will be end

in segment 8 or 16.

* In this case, PV and END will flicker in display window, and the

alarm relay acts.

This controller does not have END order if program procedure are less

than 8 segments. In this case, please set next segment’s out=0, then

this program will be end in last set segment. Otherwise, it will

proceed 8 or 16 segments.

4) Linking function

PTN=1, Proceed pattern1, which contains 8 segments

PTN=2, Proceed pattern2, which contains 8 segments

PTN=0, linking proceed pattern 1 and 2 ,totally 16 segments

(Set PTN1 and PTN2 first, then set PTN=0)

11

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 12

5) Other function (*refer to level 4)

SET8.1=1 Program repeat

SET8.2=0 No power failure

SET8.2=1 With power failure function

(If power suspended, the controller will keep the memory)

SET8.3=0 Program start from 0

SET8.3=1 Program start from PV

12

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 13

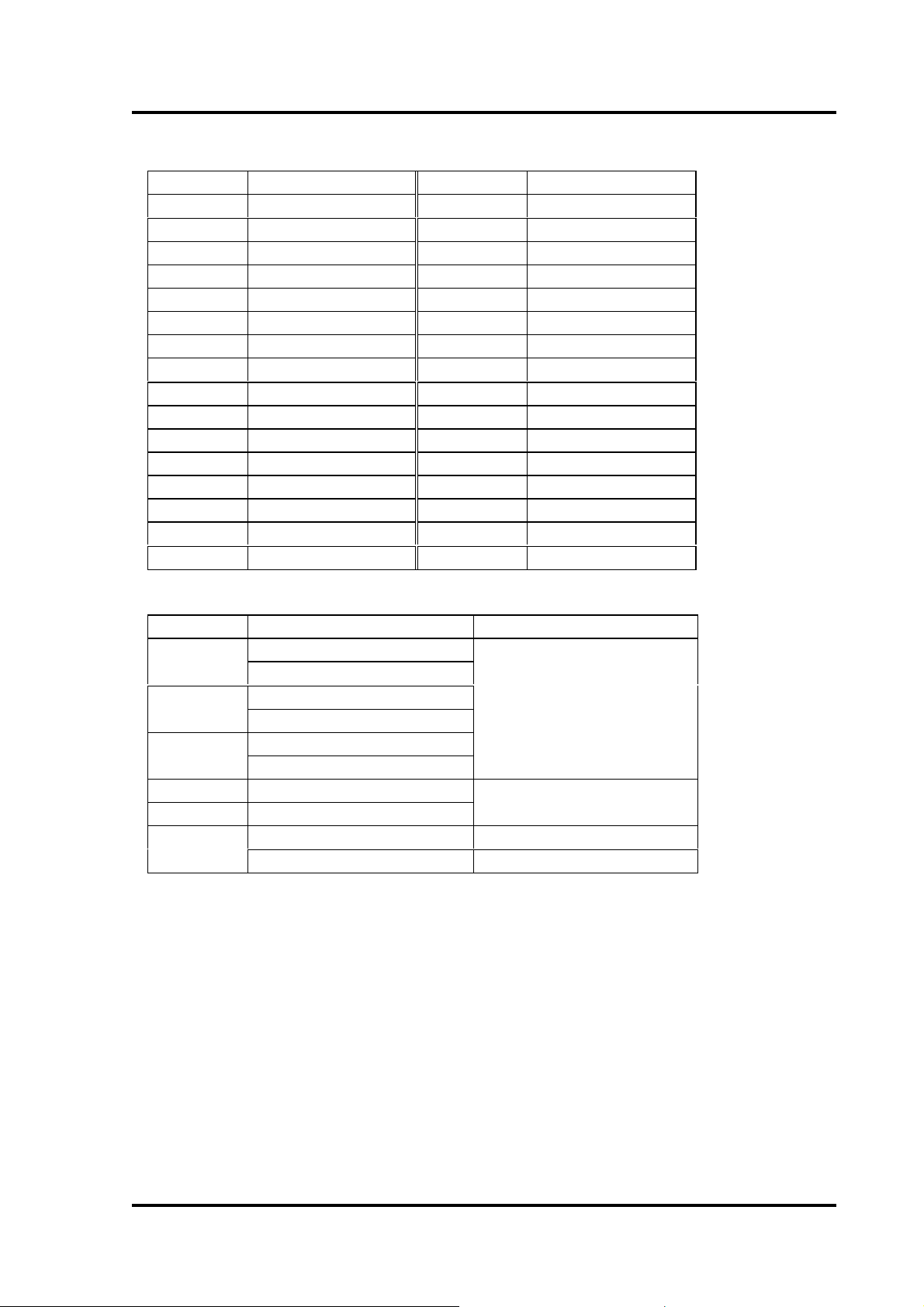

5.5. Input

5.1 Input selection (INP 1)

TYPE CODE RANGE HEX

0.0~200.0°C/0.0~392.0°F

0.0~400.0°C/0.0~752.0°F

K

J

R

S

B

0.0~600.0°C/0.0~1112.0°F

0.0~800.0°C/0.0~1472.0°F

0.0~1000.0°C/0.0~1832.0°F

0.0~1200.0°C/0.0~2192.0°F

0.0~200.0°C/0.0~392.0°F

0.0~400.0°C/0.0~752.0°F

0.0~600.0°C/0.0~1112.0°F

0.0~800.0°C/0.0~1472.0°F

0.0~1000.0°C/0.0~1832.0°F

0.0~1200.0°C/0.0~2192.0°F

0.0~1600.0°C/0.0~2912.0°F

0.0~1769.0°C/0.0~3216.0°F

0.0~1600.0°C/0.0~2912.0°F

0.0~1769.0°C/0.0~3216.0°F

0.0~1820.0°C/0.0~3308.0°F

01H

02H

03H

04H

05H

06H

07H

08H

09H

0AH

0BH

0CH

0DH

0EH

0FH

10H

11H

E

N

W

PLII

L

* The initial set in factory mode is K2 without any certain requirement.

0.0~800.0°C/0.0~1472.0°F

0.0~1000.0°C/0.0~1832.0°F

0.0~1200.0°C/0.0~2192.0°F

0.0~1300.0°C/0.0~2372.0°F

-199.9~400.0°C/-199.9~752.0°F

-199.9~200.0°C/-199.9~392.0°F

0.0~350.0°C/0.0~662.0°F

0.0~2000.0°C/0.0~3632.0°F

0.0~2320.0°C/0.0~2372.0°F

0.0~1300.0°C/0.0~2372.0°F

0.0~1390.0°C/0.0~2534.0°F

-199.9~600.0°C/-199.9~999.9°F

-199.9~200.0°C/-199.9~392.0°F

0.0~400.0°C/0.0~752.0°F

0.0~400.0°C/0.0~752.0°F

0.0~800.0°C/0.0~1472.0°F

12H

13H

14H

15H

16H

17HT

18H

19H

1AH

1BH

1CH

1DH

1EHU

1FH

20H

21H

13

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 14

TYPE CODE RANGE HEX

JIS

Pt100

DIN

Pt100

JIS

Pt50

-199.9~600.0°C/-199.9~999.9°F

-199.9~400.0°C/-199.9~752.0°F

-199.9~200.0°C/-199.9~392.0°F

0.0~200.0°C/0.0~392.0°F

0.0~400.0°C/0.0~752.0°F

0.0~600.0°C/0.0~1112.0°F

-199.9~600.0°C/-199.9~999.9°F

-199.9~400.0°C/-199.9~752.0°F

-199.9~200.0°C/-199.9~392.0°F

0.0~200.0°C/0.0~392.0°F

0.0~400.0°C/0.0~752.0°F

0.0~600.0°C/0.0~1112.0°F

-199.9~600.0°C/-199.9~999.9°F

-199.9~400.0°C/-199.9~752.0°F

-199.9~200.0°C/-199.9~392.0°F

0.0~200.0°C/0.0~392.0°F

0.0~400.0°C/0.0~752.0°F

22H

23H

24H

25H

26H

27H

28H

29H

2AH

2BH

2CH

2DH

2EH

2FH

30H

31H

32H

0.0~600.0°C/0.0~1112.0°F

AN1 -10~10mV/-1999~9999 34H

AN2 0~10mV/-1999~9999 35H

AN3 0~20mV/-1999~9999 36H

AN4 0~50mV/-1999~9999 37H

AN5 10~50mV/-1999~9999 38H

33H

14

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 15

6.6. Alarm

6.1 Alarm function selection

CODE DESCRIPTION Hold-On

/ None

Deviation high limit alarm Yes

Deviation high limit alarm No

Deviation low limit alarm Yes

Deviation low limit alarm No

Deviation high/low alarm Yes

Deviation high/low alarm No

/ Deviation high/low range alarm No

Absolute value high limit alarm Yes

Absolute value high limit alarm No

Absolute value low limit alarm No

Absolute value low limit alarm Yes

Segment end alarm (use for program only) Program run alarm (use for program only) System error alarm-on System error alarm-off On delay timer alarm -

* Note : “Hold-On” means the alarm does not work at the first time.

15

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 16

6.2 Alarm action description

6.1.1 CODE 00/10 : None

6.1.2 CODE 01 : Deviation high alarm inhibit

6.2.3 CODE 11 : Deviation high alarm no inhibit

6.2.4 CODE02 : Deviation low alarm inhibit

6.2.5 CODE12 : Deviation low alarm no inhibit

: SP

: Alarm set value

6.2.6 CODE03 : High/low alarm inhibit

6.2.7 CODE13 : High/low alarm no inhibit

6.2.8 CODE04/14 : Band alarm

6.2.9 CODE05 : Absolute high alarm inhibit

16

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 17

6.2.10 CODE15 : Absolute high alarm no inhibit

6.2.11 CODE06 : Absolute low alarm inhibit

6.2.12 CODE16 : Absolute low alarm no inhibit

6.2.13 CODE07 : Segment end alarm (program only)

i) ALD 1~3, set 07

ii) AL1~3, alarm segment no. set

iii) ALT1~3, if set 0 = flicker alarm

set 99.59 = alarm continued

set others = on delay time

6.2.14 CODE17 : Program run alarm (program only)

Program End

6.2.15 CODE08 : System Error- ON

17

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 18

6.2.16 CODE18 : System Error-OFF

6.2.17 CODE19 : on delay timer

when PV=alarm SP, it keeps a certain period (set time)

before alarm action (Range: 00H00M~99H59M)

18

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 19

7. Modification of HEAT/ALARM àHEAT/COOL (on PC board)

7.1 DC1010

7.2 DC1030

7.3 DC1020/1040

19

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 20

8. Special Function Description

SET 1

SET 0

INP2

OUTY

8.1 Level set

* Input 2 mode setting as below

8.1.1 Second input mode

INP 2 = 0, Non

INP 2 = 1, 1~5V/4~20mA/2~10V

INP 2 = 2, 0~5V/0~20mA/0~10V

8.1.2 Output mode

OUTY = 0, Single output

OUTY = 1, Double output

OUTY = 2, Non

OUTY = 3, Motor Postion Control

OUTY = 4, Single phase SCR (Single phase control)

OUTY = 5, Three phase SCR (Three phase control)

* Output mode setting as below

20

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 21

8.2 Ramp & Soak

PV

SP

PV

SP

°°C

t

8.2.1 RAMP

i) Set “SET2.1= 1”, “SET4.1= 1” at Set level

ii) Set “ALD 3 = 9” at Input level

iii) Then, “AL 3” menu will not be displayed

Range = 00.00~99.99 (°C/minute)

If RAMP not used, set ALD 3 = 0

8.2.2 SOAK

i) ALD1/ALD2 = 19

ii) Then, AL1/AL2 will be displayed

Range = 00.00~99.59 (hour/minute)

Example)

SP = 100°C, RAMP = 10.00 °C/minute

Time(minute) = 10 minute à AL1 = 00.10

PV = 25°C

100°°C

PV=25°°C

Time on

If PV SV(100°°C)

21

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 22

8.3 Remote SP

If SET A.1 = 1 set, AL1 relay reversed

If SET A.2 = 1 set, AL2 relay reversed

If SET A.3 = 1 set, AL3 relay reversed

If SET A.4 = 0 set, program run alarm

If SET A.4 = 1 set, program end alarm

Program model only

DC1010 is not available

‘a’ contact only

8.3.1 Hardware must be mounted

8.3.2 Set ‘INP2’ to 1or 2 (ANL2, ANH2 used for Cal.)

8.3.3 SET 0.3 = 1 means Remote SP from Input 2 channel

(*SET 0.3 = 0 means Local SP)

8.4 Alarm Timer ALT1/ALT2/ALT3 description

8.4.1 ALT 1 = 0 means Switching if AL 1 is ON

8.4.2 ALT 1 = 99.59 means ‘continuous alarm’ if AL 1 is ON

8.4.3 ALT 1 = 00.01~99.58 means AL 1 is on delay timer

8.5 Function SET A

PV

SP

8.6 Function SET 8

8.6.1 SET 8.1 = 0 Non

SET 8.1 = 1 Program Repeat

8.6.2 SET 8.2 = 0 Non (program model only)

SET 8.2 = 1 Power failure access

8.6.3 SET 8.3 = 0 Zero start (program model only)

SET 8.3 = 1 PV start

8.6.4 SET 8.4 = 0 Non

SET 8.4 = 1 Display will be transferred to single display.

(Don’t change this digit)

* SET 8 = 0000 can make return to double display

DC1010/1020/1030/1040 PRODUCT MANUAL

22

Page 23

8.7 Function SET 9

8.7.1 SET 9.1 = 0 Non

SET 9.1 = 1 PV/SP switching

* This is for the single display set (refer to SET 8.4)

8.7.2 SET 9.2 = 0 Non

SET 9.2 = 1 Non Program model : No display RAMP

Program model : Timer change from H.M to M.S

8.7.3 SET 9.3 = 0 Non

SET 9.3 = 1 Transmission SP

8.7.4 SET 9.4 = 0 Non

SET 9.4 = 1 Transmission PV

8.8 Function SET 0

8.8.1 SET 0.1 = 0 Non

SET 0.1 = 1 Non (function not available for DC1010/1020/1030/1040)

8.8.2 SET 0.2 = 0 Non

SET 0.2 = 1 Rate for AL3 (ALD 3 = 0)

8.8.3 SET 0.3 = 0 Non

SET 0.3 = 1 Remote SP

8.8.4 SET 0.4 = 0 Motor valve close = “b” out (contact normally close)

SET 0.4 = 1 Motor valve close = “a” out (contact normally open)

8.9 Input level wait

Wait = 0 means “no wait”. When used as a programmer, i the

Wait = 0 means “wait”

8.10 Cycle Time

Range: 0~150 sec

CYT1= 0 (i) mA

(ii) Phase control(SCR)

CYT1= 1 (i) SSR

(ii) Phase zero control(SCR)

CYT1= over 10 Relay output.

DC1010/1020/1030/1040 PRODUCT MANUAL

23

Page 24

Application 1. Single Phase Control, Phase angle control

-. Avalable models: DC1030/1040, DC1030P/1040P

-. Data Change: OUTY = 4

CYT = 0

CL01 = 0, CH01 = 5000 if used for resistance load

CL01 = 0, CH01 = 4000 if used for inductor load

S

K 2

G 2

U V

R

FAST

FUSE

SCR

Module

G 1

K1

CONTROLLER

G 1

K 1

G 2

K 2

Short

PROT

** Controller source phase must be same as load source phase

24

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 25

Application 2. Three Phase Control, Phase angle control

-. Available Models: DC1040/DC1040P

-. Data Change : OUTY = 5

CYT = 0

CL01 = 0, CH01 = 5000 only if used for resistance load

K 1

G 1

R

U

K 2

G 2

TS

CONTROLLER

Short

G 1

K 2

G 2

K 2

G 3

K 3

PROT

FAST

FUSE

K 3

G 3

V

DIODE/SCR

Module

W

3φ LOAD

25

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 26

Application 3. Single Phase Zero crossover Control

-. Available Models: DC1030/1040

DC1030P/1040P

-. Data Change: OUTY = 0

CYT1 = 1

R

G 1

U V

S

FAST

FUSE

SCR

Module

G 2

CONTROLLER

G 1

G 2

Short

PROT

TIME CHART:

ON

CYCLE TIME = 200 mSEC.

DC1010/1020/1030/1040 PRODUCT MANUAL

OFF

26

Page 27

Application 4. Three Phase Zero crossover Control

-. Available Models: DC1040/1040P

-. Data Change: OUTY = 0

CYT1 = 1

RG 1

R

RG 2

U

TIME CHART:

S

TG 1

V

WE CAN SUPPLY

HEATER SINK

T

FAST

FUSE

SCR

Module

TG 2

W

CONTROLLER

RG 1

RG 2

TG 1

TG 2

Short

PROT

OFF

ON

CYCLE TIME = 200 mSEC.

27

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 28

Application 5. Motor Valve Control

-. Available Models: DC1020/1030/1040

DC1020P/1030P/1040P

-. Data Change: OUTY = 3

CYT1 = 1~100 sec. (Normally, set 5 sec.)

RUCY = 5~200 sec.

* 1. CYT1 is the cycle time of Open/Close

2. RUCY is the running time of motor valve 0~100%

MOTOR VALVE

COM

CLOSE

OPEN

R

S

CONTROLLER

CLOSE

OPEN

COM

OUT2

Relay

OUT1

Relay

28

DC1010/1020/1030/1040 PRODUCT MANUAL

Page 29

Application 6. Single Phase Control ( for TRIAC module)

-. Available Models: DC1030/1040

DC1030P/1040P

-. Data Change: OUTY = 4

CLO1=0CHO1=5000 if use for resistance load

CLO1=0CHO1=4000 if use for inductor load

S

T2

U V

R

FAST

FUSE

TRIAC

Module

G1

T1

CONTROLLER

G1

K1

G2

K2

Short

PROT

** Controller source phase must be same as load source phase

VU

1/2W

100£[

DC1010/1020/1030/1040 PRODUCT MANUAL

M

M

0.1uf/630V

AC

29

Loading...

Loading...