Page 1

ENS7003R16 KO65 2013

1

DIGITAL BURNER CONTROLLER

DBC2000 SERIES

1. APPLICATION

The Honeywell DBC2000 is a microprocessor-based

integrated bur ner c ontroller for automatically fired

gas, oil or combination fuel industrial single bur ner

power burner appli c ations. The DBC2000 system

consists of the relay m odule and wir ing subbase.

The DBC2000 Standard Model pr ov ides the

minimum requirements to control an industrial

burner system, such as automatic burner

sequencing, fl am e supervision, system status

indicati on, system or self-diagnostics and

troubleshooting. The DBC2000 Enhanced Model

includes an integrated Valve Proofing System,

whilst the Ultimate model includes bus

communication on top of this.

The DBC2000 is programmed to provide a level of

safety, functi onal c apability and features beyond

the capacity of conventional controls.

2. FEATURES

•

Employs a plug-in mounting method

• Uses a microprocessor to improve performance

• Status and fault indication by indic ator LEDs

• A 4-wire firing rate switching circuit controls an air

damper motor or other auxiliary equi pm ent during

start-up of the bur ner .

• Safe start check before and dur ing pre-purge

• Dual flame amplifier for UV, IR or flam e rod sensor

• Automatic rec ycle once per 24h of uninterrupted

heat demand.

• Frontal jac k plug (Ø 3.5mm) to read the flame

signal with a microampere meter.

• An electrical sub base loc k ( r eset and safety limit

terminals are swapped) to avoid that a Standard

model is used systems wired for an Enhanced or

Ultimate model. The DBC2000 cannot start then.

• Safety shutdown occurs on

- malfuncti on of t he burner controller

- failure to ignite the pilot burner or main burner

- loss of flame duri ng r un peri od

- opening of air flow switch during pr e-pur ge, start-

up, run and post-purge period

- flame signal det ection during standby or pre-

purge period

• Integrated Valv e P r oofing System (Enhanced and

Ultimate models only)

• Remote bus communic ation (Ultimate m odel only)

Contents

1. Application 1

2. Features 1

3. Specifications 2

4. Dimensions 5

5. Installation and wiring 6

6. Operation 12

7. Trouble shooting 14

8. Approval s and Maint enanc e 23

Appendix: VPS calc ulation and diagrams 25

PRODUCT HANDBOOK

Importa nt no t e :

Subject to changes without notice.

Please check our web site

http://hic.emea.honeywell.com

for the most recent version of this document.

All rights reserv ed.

Page 2

ENS7003R16 KO65 2013

2

3. SPECIFICATIONS

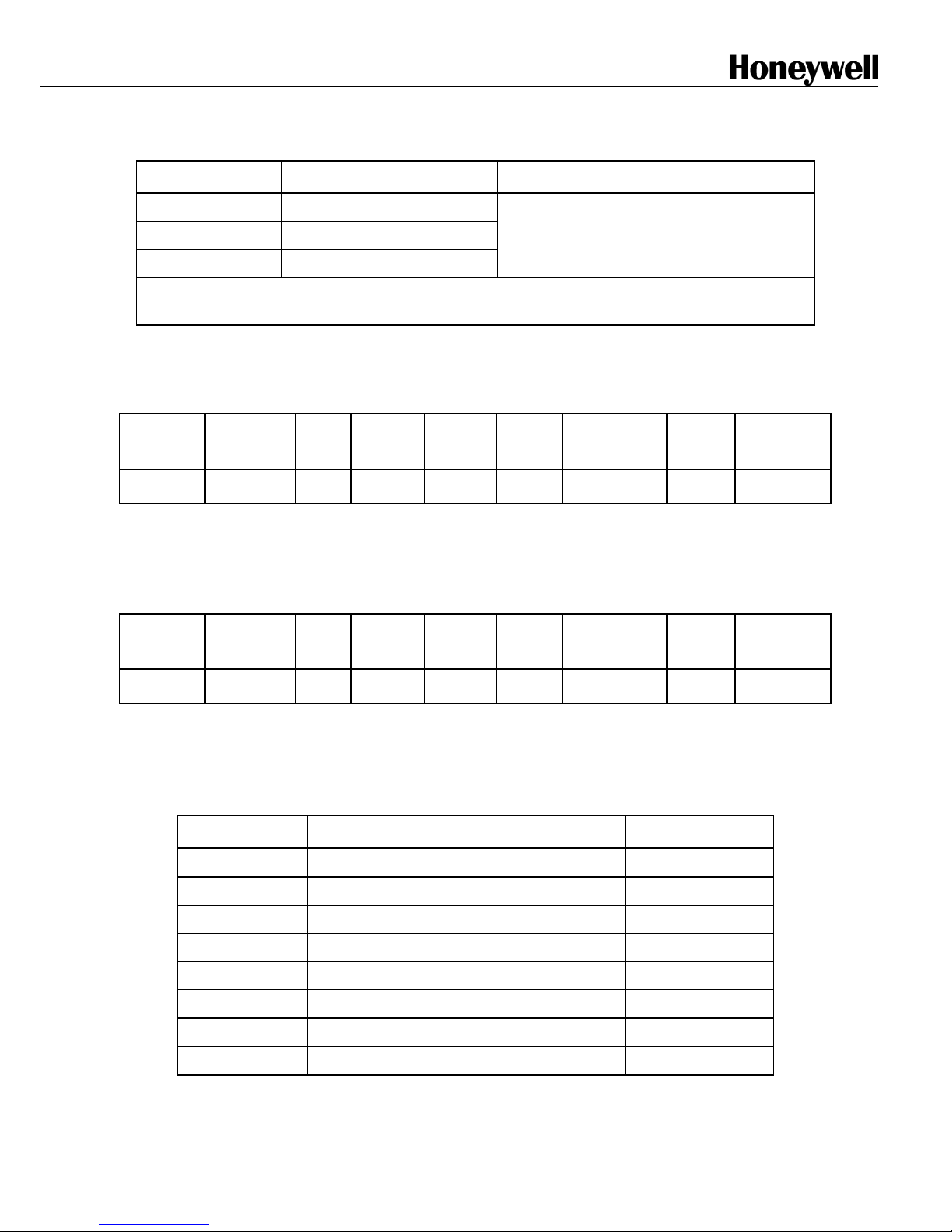

Table 1: Model Se le c t io n Guide

Model

Descr ipt io n / A pplicati on Supply voltage

DBC2000E10xx (*) Standard model

115V or 230V

(see detailed specs on page 4)

DBC2000E20xx (*) Enhanced model

DBC2000E30xx (*) Ultimate model (future release)

The Enhanced Model incl udes a Valve Proofing System.

The Ultimate model includes both r emote bus communication and a Valve Proofing System.

(*) xx depends on supply voltage and timings. For exact model num ber, plea se ref er to product selection m atrix ot

technical catalogue on http://products.ecc.emea.honeywell.com/europe.

Table 2: Sequence timing Standard Model

Waiting for

AFS

Waiting for

HF

Pre-

purge

Ignition

Pilotonly

Main

trial

Main

stabilization

Post-

purge

Flame

failure

response

300s (max) 300s (max) 35s1) 3s 5s

3s2) 4s2) 15s3) 1s (max)

1)

Default pre-purge time is 35s. Other timings on request, by OS number selection.

2)

Set to 0s. when DBI function is enabled (terminal 22 jumpered to line voltage).

3)

Set to 0s. when “no post-purge” feature is enabled (terminal 12 jumpered to line voltage).

Sequence at flame failure: immediat e lock out

Table 2a: Sequence timin g Enhanced and Ultimate Models

Waiting for

AFS

Waiting for

HF

Pre-

purge

Ignition

Pilotonly

Main

trial

Main

stabilization

Post-

purge

Flame

failure

response

300s (max) 300s (max) 35s1) 3s 5s

3s2) 4s2) 15s3) 1s (max)

1)

Default pre-purge time is 35s. Other timings on request, by OS number selection.

2)

Set to 0s. when DBI function is enabled using the DIP-switches on the front, at the bottom lef t corner (F ig 4-5).

3)

Set to 0s. when “no post-purge” feature is enabled using the DIP-switches on th e f ront, at the bottom left corner ( Fig 4-5).

Sequence at flame failure: immediate lock out

Table 3: Contact ratings

Terminal

Load Contact rating

3 Blower / Fan 3A @ cosφ=0.6

4 Ignition transformer 3A @ cosφ=0.6

5 Intermittent pilot or main (DBI) valves 3A @ cosφ=0.6

6 Interrupted pilot 3A @ cosφ=0.6

7 Main (PI) valves 3A @ cosφ=0.6

12 Main (PI) valve 2 (ENH/ULT models only) 3A @ cosφ=0.6

8, 9, 10, 11 Control motor 0.5A @ cosφ=0.6

21 Alarm 0.5A @ cosφ=0.6

Total load (based on set): Max 8A (Internal Fuse : 10A)

Total load (based on terminal 4,5,6,7): Max 5A (Internal Fuse : 6.3A)

Page 3

ENS7003R16 KO65 2013

3

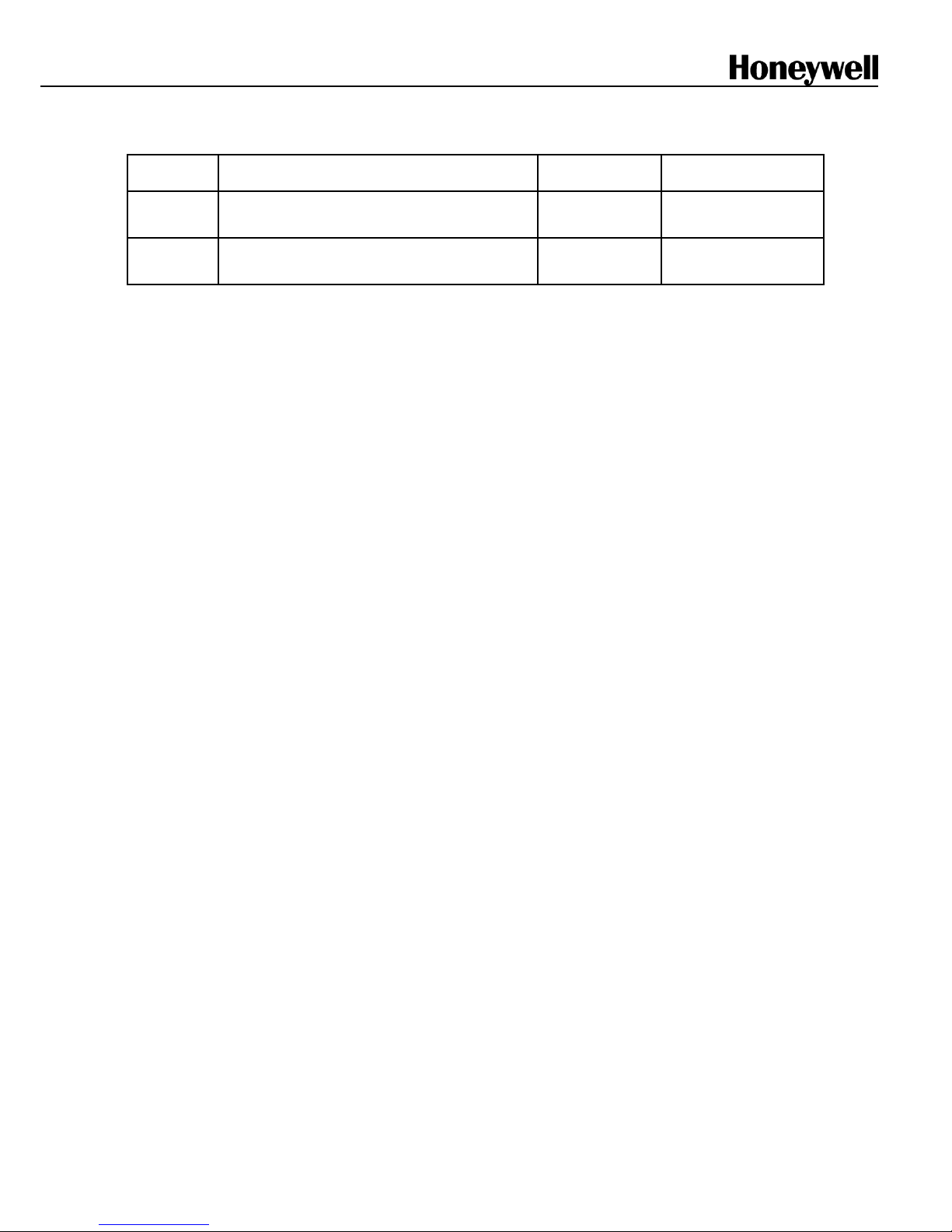

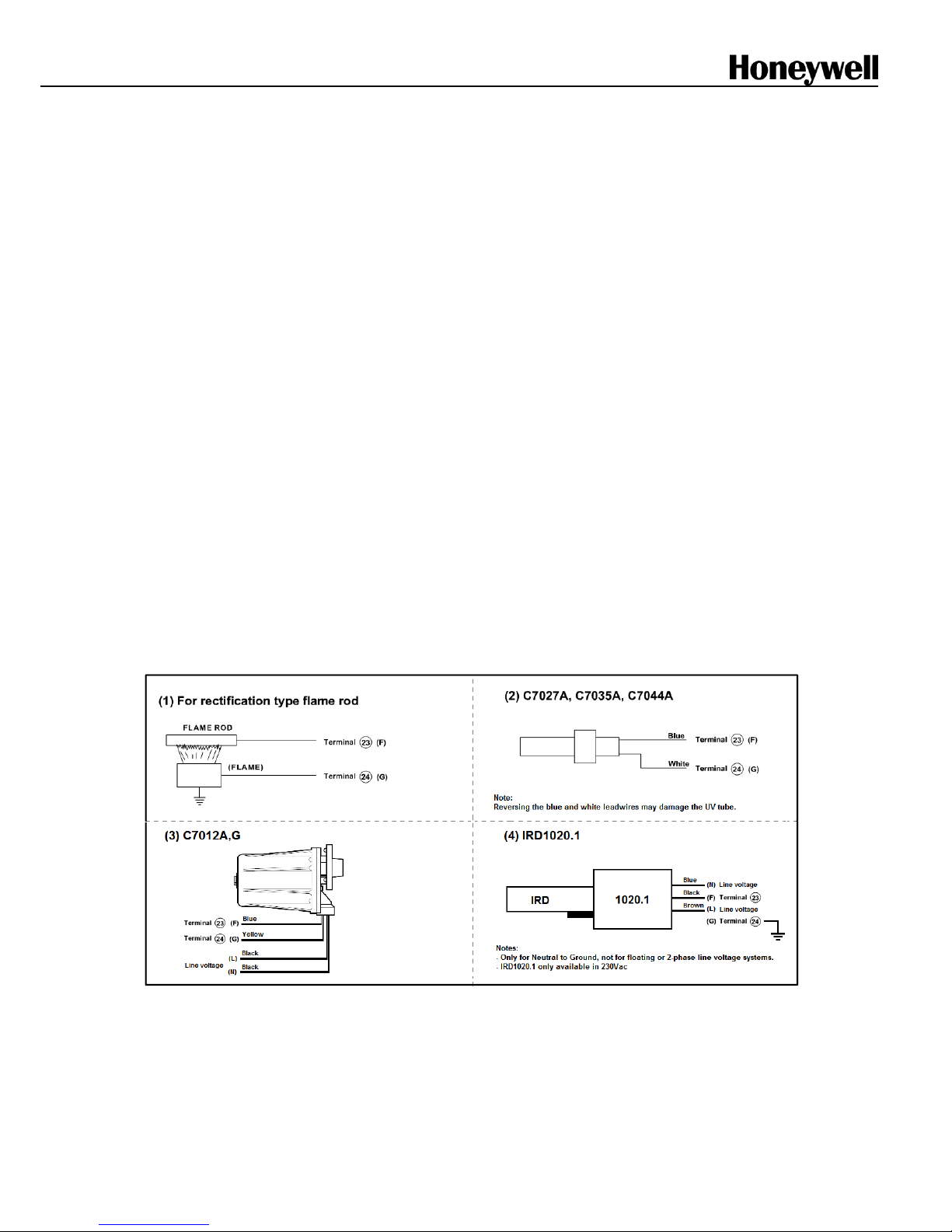

Table 4: Flame detection systems

Detector

type

Flame detector model no.

Max. lead wire

lengths

Standard stable flame

current on jack plug

UV detector C7027A, C7035A, C7044A < 100m 4µA (min)

14µA (max)

Flame rod Flame rod or rectifyi ng optical sensors,

C7012A,G (UV) or IRD1020.1 (IR)

< 15m 14µA (min)*

4µA (max)*

* When using a flame rod, the current on the flame jack plug is inverted. S ee also Fig 4-2.

Flame detector l eads are colour coded. The blue lead wire must be connected to the F terminal (T23) and the

white lead wire to the G terminal (T24). The UV sensing tube is polari ty sensit ive. Reversing the lead wires

even momentaril y will destr oy the UV sensing tube.

Page 4

ENS7003R16 KO65 2013

4

Mains input: Supply voltage

220 to 240Vac -15% +10% 50/60Hz or

110 to 120Vac -15% +10% 50/60Hz

Allowable ambien t Temperature & Humidity

-10 °C; +60°C

90% RH max. at 40°C (non-condensing)

Classificatio n to EN298 ( Chapter 4)

F/B/L/L/X/N

Where:

F = Fan assisted

B = Interrupted and Intermittent pilot capable

L (1

st

) = non-volatile lockout after flame loss

L (2

nd

) = non-volatile lockout after flame loss final stage

X = Fixed timings per model number

N = Intermittent operation (non-self-check)

Approvals

CE certification to EN298:2003 (gas, UV & flame rod)

CE certification to EN230:2005 (oil, UV only)

EN746-2 compliant

AGA certified

GOST-R listed

Power consumption

9VA

Protection class

IP40

Mounting

Plug-in mounting method using sub-base

Dimensions

103mm x 103mm x 124mm (W x D x H) incl. sub base

Status in dic a t or LEDs

- Standby

- Purge

- Ignition

- Pilot

- Main

- Modulate

- Flame On

- Alarm

The LEDs will shortl y blink as soon as power is appli ed to t he

DBC2000 and then as soon as there is a heat demand,

indicate the bur ner sequence.

The LEDs are also used to indicate faults. For example, if a

loss of flame signal oc c ur s during RUN, the LEDs for Alarm,

Flame and Main will blink the fault code.

Jack plug

The flame signal can be measured using the jack plug (Ø

3.5mm) on the front, using a microampere meter. The

measuring device m ust be c apable of reading microamperes

between 2 and 15~20 µA.

CAUTION

Although the v oltage on t he jac k pl ug is of low

voltage, it is not consi der ed to be safe when touching

the wires connected to t he jac k plug, in case of a

malfuncti on of t he devi c e. Therefor e av oid touching

the lead wires to avoid an electrical shock.

Reset switch

When the DBC2000 is in Lockout condition* press

the internal or remote reset button one time to reset

the DBC2000 and stop the alarm. The reset button

must be held for a minimum of 3 seconds.

If the heat demand is still present, the DBC2000 will

perform the start sequence normally when the fault

condition has been resolved. Otherwise the lockout

will repeat.

If during the lock out condition the DBC2000 is deenergized and power is reapplied afterwards, the

DBC2000 will rem ain in loc k out ( non-volatile lock

out).

A remote reset push button switc h c an be c onnec ted

between termi nals 15 and 19 (Standard Model) or

between termi nals 15 and 18 (Enhanc ed and

Ultimate Model s). The f unctionality of the remote

reset is the same as the red push butt on on the f r ont

of the device, with one exc eption; the remote reset

may occur only 5 times during 15 mi nutes of

operation, whilst the internal reset button is

unlimited.

* Remark:

Lockout condition refers to the state the DBC2000 is

in after a safety shut-down occurs and the lockout

timing (20 Seconds), plus the post purge timing (15

Seconds - if enabled) have been completed. For

safety reasons the reset button is disabled

immediately aft er a safety shut-down until both of

these above timings are completed.

The lockout timi ng is fixed at 20 seconds for all

models, to allow tim e for the air dampers to return to

the start position, and to allow a safety time between

ignition att em pts, for applications without pre- and

post-purge.

Note: The Alarm and LED’s will indicate the fault

immediately, but c annot be reset until the unit has

progressed to the Lockout Condition.

Remote communication

- Under construction

.

Page 5

ENS7003R16 KO65 2013

5

4. DIMENSIONS

Fig. 1: External Dimensions (in mm)

Fig. 2: Mounting dimensions of sub-base and terminal layout

Page 6

ENS7003R16 KO65 2013

6

5. INSTALLATION AND WIRING

CAUTION

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the produc t or cause a

hazardous condition.

2. Check the ratings giv en in the instructions and

marked on the product t o m ake sure the produc t

is suitable for the application.

3. Installer must be a trained, experienced, fl ame

safeguard service technician.

4. After installation is completed, check out the

product operation as provided in these

instructions.

WARNING

Fire or Explosion Hazard.

Can cause property damage,

severe injury, o r death.

Carefully f ollow safety requirements when installing a

burner control .

CAUTION

Electrical Shock Hazard or Equipment/

Control Damage.

Disconnect power supply before beginning installation,

to avoid electrical shock or equipment damage..

IMPORTANT

1. Wiring connections for the relay modules are

unique; refer to Fig. 3-2 or the appropriate

Specifications for individual subbase wiri ng.

2. Wiring must comply with all appli c able c odes,

ordinances and regulat ions.

3. Wiring must comply with NEC Class 1

(Line Voltage) wiri ng.

4. Loads connected to the DBC2000E must not

exceed those listed on the relay module label or the

Specificati ons; see Table 3.

5. Limits and interlock s must be rated t o

simultaneously c ar r y and break c ur r ent t o the

ignition transformer and fuel valve(s).

6. All external timer s must be listed or component

recognized by aut hori ties who have proper

jurisdiction.

7. For on-off gas-fired systems, some authorities

who have jurisdicti on pr ohibit the wiring of any

limit or operating contacts in series between the

flame safeguard control and the mai n fuel

valve(s).

8. Two UV flame detect or s can be connec ted in

parallel.

9. This equipment generat es, use s and can radiate

radio frequency ener gy and, if not installed and

used in accordance with the instructions, can

cause interfer enc e with radio communications. It

has been tested and found to comply with the

limits for a Class B computing device of Part 15 of

FCC rules, which are designed t o pr ov ide

reasonable protec tion against such interference

when operated in an industrial or commercial

environment. O per ation of this equipment in a

residential area c an c ause interference, in which

case, the users, at t heir own expense, may be

required to take whatever measures are required

to correct this interference.

10. T his digital apparatus complies with the

requirements as stated in the EN298 standard.

11. Do not install the Burner Controll er under any

circumstances in the following locations.

① Where chemicals or corrosiv e gases are

present, such as ammonia, sulfur, chlorine,

ethylene compounds, ac ids, etc.

② Install the relay module where the relative

humidity never reaches the satur ation point.

The relay module is designed t o oper ate in a

maximum 85% relative humi dity continuous,

noncondensing, moisture environment.

Condensing moistur e c an c ause a saf ety

shutdown or damage the devic e.

③ Where temperatures exceed the maximum

specificat ion for thi s device.

④ Where excessive continuous vi br ation exists.

12. Do not bundle power wiring and high voltage

ignition cable with the flame detector wiring, or run

them in parallel wit hin the same conduit. High

voltage cables must be k ept separated at least 10

cm from the Burner Controller.

13. Use proper grounding work in accor danc e with

the engineeri ng standar ds for electrical equipment

14. Connect the high voltage cabl e of t he ignition

transformer pr operl y to t he ignition electrode. A

poor connection c an c ause an el ectr ic al shock or

damage the equipment . Additionally the ignition

transformer must be properly grounded according

the standards.

Page 7

ENS7003R16 KO65 2013

7

REMOVE THE RELAY MODULE FRO M ITS

SUB BASE AND FIX THE SUB BASE

1. Loosen the M3 fixing screw as shown in F ig. 1 by

about eight turns using a Phili ps head screwdriver.

2. Take the subbase and cover with both hands and

unfold them gently. Fold the relay module

upwards, the turni ng point is on the top. Do not

apply excessive force, otherwise damage may

occur.

3. Punch out the needed conduit knockout holes for

the wiring as shown i n Figs 1 and 2, and install the

wiring conduit (s).

4. Using the fixing screws, mount the subbase in the

specified position.

Avoid to overtighten the fixat io n screw on the

front of the device, to avoid damaging the

(Phillips) head o f the screw.

WIRING TH E RELAY MODULE BOTTOM

TERMINALS

1. For applications with a UV detector, remov e the

jumper terminal located at the t erminal block on

the bo ttom of the relay module.

2. For applications using remote communicati on,

connect communication cable to “BUS” terminal

located at the terminal block on the bottom of the

relay module. In addition, set the communic ation

address uring the rotary switches at the bo ttom of

the relay module.

WIRING THE SUB BASE

1. Fig. 2 shows the lay out of the terminals on the

subbase, and Figs. 3-1 to 3-3 show examples of

connections to external equipment. Regarding the

wiring to the flame detector, refer to Fig. 4.

2. When using Intermittent Pilot, connect the pilot

valve to Terminal 5. Connect the main valves to

Terminal 7 (Enhanced and Ultimate models:

connect main valve 1 to Terminal 7 and main valve

2 to Terminal 12 for the VPS function)

3. When using Interrupted Pilot, connect the pilot

valve to Terminal 6. Connect the main valv es to

Terminal 7 (Enhanced and Ultimate models:

connect main valve 1 to Terminal 7 and main valve

2 to Terminal 12 for the VPS function)

4. When using direct ignition (DBI), jumper Terminals

15 and 22. And connect the Main(DB I) valves to

Terminal 5.

5. When not using purge positi on interlock, jumper

Terminals 15 and 16.

6. When not using start posi tion interlock, jumper

Terminals 13 and 17.

7. When not purge and start posi tion interlocks,

jumper Terminal s 15 and 16 as well as Termi nals

13 and 17 simultaneously.

8. Connect the safety switc h ci r c uit (lockout

interlocks) bet ween Terminals 15 and 18. The

safety switch cir c uit must be cl osed al way s,

otherwise a lockout oc c ur s immediately.

9. For non-floating mains power grids (Neutral to

Ground), connec t t he Line-L to Terminal 1 and t he

Line-N to Terminal 2. Use a corr ect fuse: 10A fast

bl ow maximum.

10. Check all wiring circuits and assure that the

correct fuse is installed. Check the correct voltage.

11. F inally plug the relay module on to its sub base

and fix it with the M3 fixing screw. Do not overtight

the screw.

12. When using a surge absorber, connect it between

Terminal 2 and application ground.

13. Connect the mains supply volt age usi ng 0.75mm

2

or larger lead wire.

14. Never connect blank stripped wir es to the wiring

sub base. Loose wire strands may c ause short

circuits to elec tric ally safe contacts which may

cause an electri c al shock haz ar d.

Always use cable lugs to attach the wires to th e

sub base.

See Fig 2-1 for do’s and don’ts about wiring.

Fig. 2-1: Wiring the sub base terminals

Page 8

ENS7003R16 KO65 2013

8

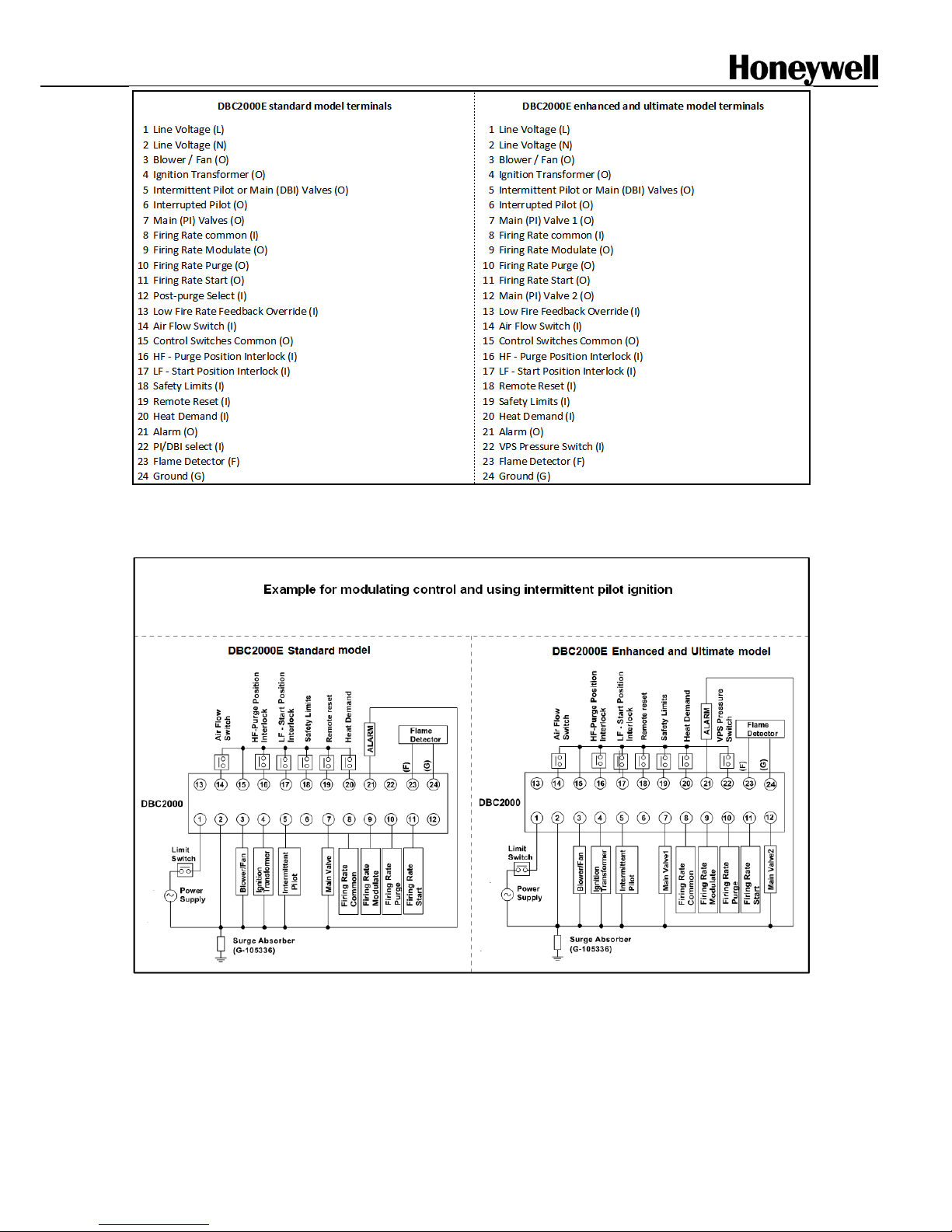

Note: terminals 18 and 19 are swapped for the Standard and Enhanced/Ultimate models.

This is to prevent that a Standard model can be used by mistake in a system that is wired for an Enhanced or Ultimate model.

Fig. 3-1: Terminal layout

Fig. 3-2: Example of wiring to external equipment (see fig 3-3 for more)

Page 9

ENS7003R16 KO65 2013

9

Fig. 3-3: More examples of wiring to external equipment

Fig. 4-1: Wiring a flam e detector

CAUTION

There is line voltage on fl am e sensor inputs. Don’t touch the lead wires of the UV detector or the flame sensing

electrode t o avoi d an electri c al shock.

Page 10

ENS7003R16 KO65 2013

10

Flame signal monitoring

Fig. 4-2: Real flame current versus reading on frontal jack plug.

Note:

The flame signal strengt h on the flame current jack plug is only for reference

and can vary between differ ent

DBC2000 devices.

When measuring the fl am e signal c ur r ent direc tly in the flame sensor wiring whilst:

1. Using a flame rod, the (multi -)meter will show the real flame current in µA.

2. Using a UV sensor (C7027, C7035 or C7044), the current in the sensor lead wires will be in the range of

20…25mA (inverted values).

Fig. 4-3: Measuring flame signal with multi meter (µA range selection) using a jack plug.

STD & ENH Models (flame detector sel ec t only) ULT Model (bus connector and address switches)

Fig. 4-4: Position of flame sensor selection jumpers and bus connector on the back of the DBC2000.

Page 11

ENS7003R16 KO65 2013

11

SETTING THE OPTIONAL FEATURES

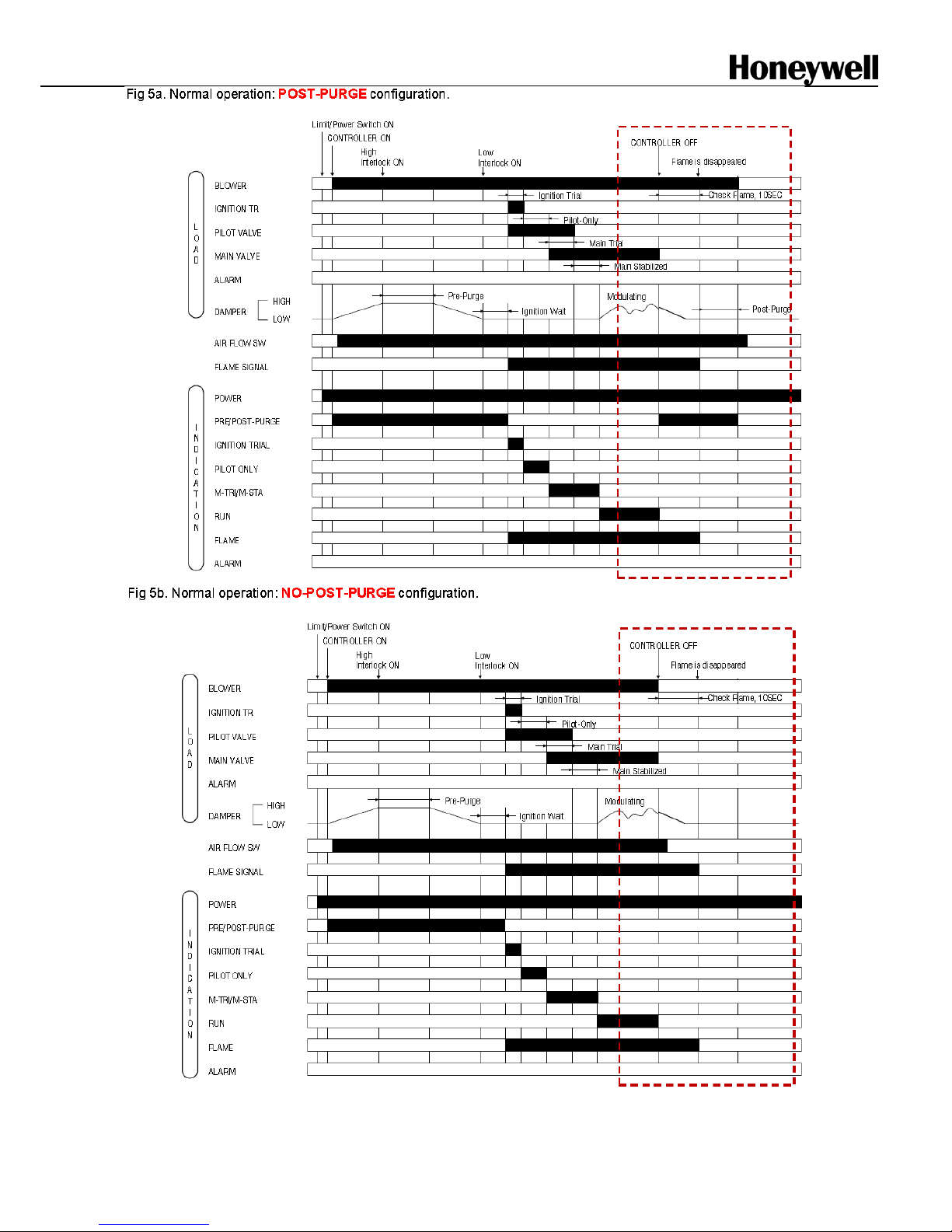

1. Post-purge or no post-purge

Post-purge mode

(default for all DBC2000E

models): before going to standby after heat

demand has ended, the DBC2000E performs a

15s post-purge cycle t o ventilate the burner

chamber, with the bl ower swit c hed on and the

firing rate in low positi on to save energy.

No post-purge mode

(selectabl e option): the

DBC2000E goes to standby with the blower

switched off immediately after heat demand ends

and the firing rate goes to low position.

STD model:

To enable no post-purge, apply line voltage to

terminal 12 on the wiring base. Practically this

means that a jumper is placed bet ween term inals

1 (L) and 12.

ENH/ULT models:

To enable no-post-purge, make the correct DIPswitch setti ng on the front of t he DB C2000E .

SW1 = POSTPURGE select.

Factory set to post-purge (SW1=off).

See fig. 4-5 to locate the DIP switches.

2. Pilot Ignition (PI) or Direct main

Burner Ig nit i on (DBI)

PI mode

(default): the main burner is ignited

indirectly by usi ng an interrupted or intermittent

pilot flame. Aft er the pilot is ignited and

stabelized, the DBC2000E goes for a second trial

of ignition (2

nd

safety and main stabilization are

3s) to ignite the mai n burner.

DBI mode

(selectabl e option): the intermittent

pilot ignition cycle is used to ignite the main

burner directl y via the spark igniter. The second

trial for ignition has become redundant in this

mode. In DBI mode the 2

nd

safety and main

stabilizati on times are 0s and DBC2000E goes

straight into running/modulate after pil ot

stabilization.

STD model:

To enable DBI mode, apply li ne v oltage to

terminal 22 on the wiring base. Practically this

means that a jumper is placed bet ween term inals

1 (L) and 22.

ENH/ULT models:

To enable DBI mode, make the correct DIP-switch

setting on the front of t he DBC2000E.

SW2 = DBI/PI select. Factory set to PI (SW2=off).

See fig. 4-5 to locate the DIP switches.

3. Valve Proofing System – VPS

(ENH/ULT models only)

Connect a gas pressure switc h ( such as the

C6097A2210) to terminal 22 on the wiring base

(N.O. contact).

Rule of thumb: adjust t he pr essure switc h to 0.5x

the inlet pressure.

Table 5: VPS function:

VPS enabled

SW3 = on

VPS is being perform ed

VPS disabled

SW3 = off

VPS is not used (default)

VPS pre-config

SW4 = on

SW5 = off

The VPS test cycle i s

performed duri ng pr e-purge

cycle, right aft er the heat

demand has started.

VPS post-config

SW4 = off

SW5 = on

The VPS test cycle i s

performed ri ght after the heat

demand has ended.

VPS both config

SW4 = on

SW5 = on

The VPS test cycle i s

performed before and after

the heat demand cycle.

Table 6: VPS timing:

VPS test time

25s

SW6=on

SW7=on

VPS test time

20s

SW6=on

SW7=off

VPS test time

15s

SW6=off

SW7=on

VPS test time

10s (default)

SW6=off

SW7=off

SW1: Post-p urg e use (default: off = post-purge enabled)

SW2: DBI/PI select

(default: off = PI enabled)

SW3: VPS use

(def ault: off = dis abled)

SW4: VPS pre-config

(default: off = dis abled)

SW5: VPS post-config

(default: off = disabled)

SW6: VPS test time

(default: off = see timing table)

SW7: VPS test time

(default: off = see timing table)

SW8: Not used (for future use)

Note for DIP switches:

on = upwards

off = downwards

Fig 4-5 Configurati on DIP switc hes (VPS) on the front of the DB C2000E (ENH/ ULT only)

Page 12

ENS7003R16 KO65 2013

12

6. OPERATION

NORMAL OPERATION

Table 7: Normal operation seq uence

Inputs

Operation of DBC2000 and device Indicator LED *

HEAT DEMAND SW OFF

AIR FLOW SW OFF

SAFETY LIMI T SW ON

The power supply voltage is appl ied across Terminal 1 and

2. When no flame signal is present, the combustion airflow

switch is opened (T14=OFF) and safety lockout

circuit is

closed (ON), it is possible t o star t.

●○○○○○○○

HEAT DEMAND SW ON

START Pos SW ON

PURGE Pos SW OFF

The blower is energiz ed (T3) . Fi ri ng r ate goes to PURGE

position. Air flow switch closes (T14=ON) as soon as air flow

is present.

●●○○○○○○

AIR FLOW SW ON

START Pos SW OFF

PURGE Pos SW ON

The pre-purge timer star ts counting as soon as PURGE

interlock is closed (T16=ON).

PURGE Pos SW OFF

After the completi on of pre-pur ge timing, firing rate goes to

START position.

The ignition wait timer star ts counting as soon as the START

position interlock is closed (T17=ON).

START Pos SW ON

After completion of the ignition wait timing, t he Igniti on

sequence starts. The I gnition transformer is energiz ed. The

Intermittent and Interrupted pilot valve out puts are energized

(T5 and T6).

●○●○○○○○

●○●○○○●○

FLAME ON

When a flame is detected after the ignition trial has ended

(Safety1), t he pilot stabilization tim e starts.

●○○●○○●○

After completion of the pilot-stabilization time, the Main

valves are energized (T7=ON). Note: Enhanced Model: also

(T12=ON).

The Main trial for igni tion takes place (Safety2).

●○○○●○●○

After completion of the main trial time, Interrupted pilot valve

is deenergized (T5=OFF). The Main stabilization time starts.

●○○○●○●○

PURGE & START Po s SW

IGNORED

After completion of the main stabilization time, the firing rate

goes to modulati on posi tion and releases control to an

external modulation device.

●○○○○●●○

HEAT DEMAND SW OFF

The intermittent pilot valve and main valves are deenergized

(T6=OFF and T7=OFF). Note: Enhanced Model: also

(T12=OFF). Firing rate moves to PURGE position.

The post-purge timi ng takes pl ac e.

●●○○○○○○

FLAME OFF

After the completi on of t he postpur ge time, the blower is

deenergized and firing rate moves to START position.

●○○○○○○○

AIR FLOW SW OFF

SAFETY L IMIT SW ON

After the air flow switch goes OFF, DBC2000E returns to the

STANDBY conditi on, wait ing for the next heat demand.

* For LED indic ation, ○ means ‘off’, ● means ‘illuminated’.

* Th e LEDs are arranged in the following order: Standby, Purge, Ignition, Pilot, Main, Modulate, Flame and Alarm at the left front

side of the DBC2000.

Page 13

ENS7003R16 KO65 2013

13

Page 14

ENS7003R16 KO65 2013

14

7. TROUBLE SHOOTING

ERROR T YPES AND SAFE SHUTDOWN

If a critical error related to safety operation (such as a l oss of flame, opening of the air flow switch during the

ignition trial and r un sequence) is detected, the DBC2000 instantly goes into lock-out and goes to pre-purge stat us.

If a non critical error is detected (such as opening of the air flow switch during post-purge), DBC2000 holds the

sequence during the lock-out time, allowing time for the error to rectify, and then goes into lock- out.

For all types of errors, the status LEDs indicate the status information to the operator.

Fig. 6 to Fig. 13 show the sequence of DBC2000 i n case of some err or. A nd Table 8 shows the statu s of LEDs for

each error.

The product handbook (E NS 7003) shows the different scenarios for possible failures.

Page 15

ENS7003R16 KO65 2013

15

Page 16

ENS7003R16 KO65 2013

16

Page 17

ENS7003R16 KO65 2013

17

Page 18

ENS7003R16 KO65 2013

18

Page 19

ENS7003R16 KO65 2013

19

Page 20

ENS7003R16 KO65 2013

20

Page 21

ENS7003R16 KO65 2013

21

Page 22

ENS7003R16 KO65 2013

22

Table 8: Error co ndition and LED stat us

Sequence

Error condition

Indicator LED

status (*1)

All

Safety limit s opened at any tim e (no voltage present at T18 (STD model) or

T19 (ENH/ULT model)

●○○○○○○◐

Standby (*2)

Air flow switch remains ON (closed) for more than 5 minutes, or

START position

interlock switch remains OFF(opened) for more than 5 minutes.

●◐○○○○○◐

Flame signal is present

●○○○○○◐◐

Blower motor is energized

●◐○◐◐○○◐

Pre-purge

Air flow switch remains OFF for more than 5 minutes after the heat demand has

started.

●◐○○○○○◐

PURGE pos ition int erlock swi tch remai ns OFF for more than 5 minutes after the heat

demand started.

●◐◐◐○○○◐

Both PURGE and START position interlocks ON at the same time during prepurge

period

●◐◐◐○○○◐

START position interlock remains OFF more than 5 minutes after pre-purge has

finished

●◐◐◐○○○◐

Air flow switch goes ON within 5 minutes after the heat demand started, but air flow

switch goes OFF again.

●◐○○○○○◐

Flame signal is present.

●◐○○○○◐◐

Ignition Standby

Air flow switch goes OFF

●◐○○○○○◐

Flame signal is present

●◐○○○○◐◐

Pilot Ignition

Air flow switch goes OFF

●◐◐○○○○◐

Ignition failure (flame signal is not present after ignition-trial).

●○◐○○○○◐

Pilot only

Air flow switch goes OFF

●◐○◐○○○◐

No flame signal

●○○◐○○◐◐

Main ignition

Air flow switch goes OFF

●◐○○◐○○◐

No flame signal

●○○○◐○◐◐

Main ignition

Stabilization

Air flow switch goes OFF

●◐○○◐○○◐

No flame signal

●○○○◐○◐◐

Run

Air flow switch goes OFF

●◐○○○◐○◐

No flame signal

●○○○○◐◐◐

Post-purge

No power is supplied to Ter minal 3 b ecause of intern al rel ay contac t fail ure.

●◐○◐◐○○◐

Flame signal is present for more than 10 seconds after heat demand has ended.

●○○○○○◐◐

Air f low switch keeps ON more than 5 minutes a f ter po st-purge.

●◐○○○○○◐

All

1. Line voltage out of specs for more than 2 seconds

2. Line frequency out of range for more than 2 seconds

3. Excessive noise on power line or in the ar ea

4. Internal device problem : CPU clock out of sync

●○○○○○○●

*1 : For LED indication, ○ means ‘off’, ● means ‘illuminat ed’, ◐ means ‘blinking’.

The LEDs are arranged in the following order: Standby, Purge, Ignition, Pilot, Main, Modulate, Flame and Alarm at the left

front side of the DBC2000.

*2 : If an error occurs during Standby, the DBC2000 will not lock-out but LEDs indicate the current error status.

In this case, the DBC2000 cannot start before the error is resolved.

Page 23

ENS7003R16 KO65 2013

23

8. Approvals and Maintenance

Declaration of Conformity

Honeywell Technologies Sàrl

Z.A. La Pièce 16

1180 Rolle

Switzerland

declares under it ’s sole respon si bility that the foll owing product family of burner controllers:

DBC2000 E 1xxx / DBC2000 E 2xxx

to which this statem ent relates, is:

• in conf ormit y with the essential requirements of the Gas Appliance Directive 2009/142/E C

based on EN 298

and in conformity with the type as described in the EC type-examination certificate issued

by DVGW CERT GmbH in Bonn with pin number

0085CM0138

• in conf ormity with the essential requirem ents of the Low Voltage Directive 2006/95/ E C

based on EN 60730-2-5

• in conf ormit y with the essential requirements of the EMC Direct ive 2004/108/EC on immunity

based on EN 298 immunity requir em ents

Conformity with the essential requirements of the EMC Directive 2004/108/EC on emission can only be

determined in the application.

This product is under surv eillance at KIWA Nederland BV.

Emmen, October 2011

Signed for and on behalf of Honeywell Technologies Sàrl,

A.Veld

Manager Standards & Approvals

Page 24

ENS7003R16 KO65 2013

24

Maintenan ce a nd service

The designed lifetime* of this product is 10 years, based on date code, or 1.000.000 cycles under norm al

conditions, accor ding to:

a) the standard EN 298

b) the table on designed lifetime as stated on the Afecor website http://www.afecor.org/

We cannot assume that the pr oduc t can be safely used beyond the mentioned designed lifetime. This lifetime is

based on use of the control accor ding m anufacturer’s instructions.

Regular inspection of the control by authorized per sonnel in ac c or danc e with guidelines of the applianc e

manufacturer is required.

After reaching the designed lifetime the product has to be repl ac ed by authorized personnel.

Note: * Warranty as opposed to design ed l ifet ime is described in the delivery terms.

Page 25

ENS7003R16 KO65 2013

25

APPENDIX: Calculations for VPS

General

The m aximum all owable lea k-rate (according EN676 and

EN746-2) is 0,1% of the maximum burner capacity. The test

time necessary to d etect a fail ing v alve is a fun c tion of:

- Inlet pr essur e

- Test volume

- Burner capacity

Wh en the v olume between two safety va lves i s big ger it takes

more time (in c ase of a l eaki ng val ve) to change the status of

the gas pressure swi tch (GPS) .

The switching point of the GPS is set to 50% of the maximum

inlet press ure. T he test peri od Tp i s calculat ed from the

inletpressure Pi, the test volume Vp (see Table a.) and

maximum burner capacity Qm. In a formula:

2 x Pi x Vp

Tp = --------------- [s]

Qm

Pi = inlet press ure [mbar]

Vp = test volume, s ee als o Table a [dm

3

]

Qm = burner capacity [dm

3

/h]

Tp = test time [s ]

Important

The total volume Vp h as to be c alculat ed with all volumes

betw een t he tested v alves : int ernal vol umes of valv es and all

pipes.

Calculation examp les

Example 1

Calculation of the minimum test time (per valv e) in a 2”

threaded pipe train.

Pi = 150 mbar

Qm = 60 dm

3

/h

Gas valv es used: 2” size with 0. 5 meter pip e.

To be calculated: Tp [s]

Calculation:

From Table a. :

2“ @ L=0.5m Vp = 2.3 dm

3

2 x 150 x 2.3

Tp = ---------------- [s]

60

Using the formula above, the minimum test time Tp = 11.5s

The DBC2000E2 must be set to 15s tes t time (see page 11 ).

Example 2

NOTE: to allow a 3-valve configuration, an external SPDT

relay needs to be added, when used incombination with VPS.

See schematic drawing below.

Calculation of the mini mum test time (per valve) in a DN80

flanged pipe train, where a 1” bypass valve is used.

Pi = 150 mbar

Qm = 100 dm

3

/h

Gas valv es used: DN8 0 s ize with 1 meter pipe (L1).

Byp ass valve: 1” valve with 0.5 met er pipe (L2).

To be calculated: Tp [s]

Calculation:

From Table a. :

DN80 @ L1=1m Vp1 = 6.9 dm

3

1” @ L2=0.5m Vp2 = 0.44 dm3

There is only 1” bypa ss valve, that r educes the total volume

by 0.5x the volum e @ L=0m Vp3 = 0.19 dm

3

Vp = Vp1 + Vp2 – (0.5 x Vp3) = 7.245 dm

3

2 x 150 x 7.15

Tp = ------------------ [s]

100

Using the formula above, the minimum test time Tp = 21.735s

The DBC2000E2 must be set to 25s test time (see page 11).

Page 26

ENS7003R16 KO65 2013

26

Tab le a.

Volumes in dm3 for ga s valves like Hon eywel l VE-series (Vp) with pipe length L (including V1 and V2). For combi blocks, like

VQ-M series and direct linked valves, use the values shown under L=0m.

Diameter

Length between valves [m]

0

0.5 1 1.5

2

per extra

meter

¼”

0.06

0.1

0.14

0.18

0.22

0.08

½”

0.06

0.15

0.24

0.33

0.42

0.18

¾”

0.12

0.28

0.43

0.59

0.74

0.31

1”

0.19

0.44

0.68

0.93

1.2

0.49

1¼”

0.69

1.1

1.5

1.9

2.3

0.8

1½”

0.71

1.4

2.0

2.7

3.3

1.3

2”

1.3

2.3

3.3

4.2

5.2

2.0

2½”

2.7

4.4

6.0

7.7

9.3

3.3

3”

2.9

5.4

7.9

10

13

5

DN65

3.2

4.9

7.5

8.2

9.8

3.3

DN80

4.4

6.9

9.4

12

14

5.0

DN100

6.5

10.5

14.4

18

22

7.9

Threaded connections: sizes in inches.

Flanged connections: sizes in DN

If L = 0m it means that valves are directly linked without pipe connections. Also applicable for combi-blocks (VQ-M series).

Page 27

ENS7003R16 KO65 2013

27

Page 28

ENS7003R16 KO65 2013

28

Page 29

ENS7003R16 KO65 2013

29

Page 30

ENS7003R16 KO65 2013

30

Page 31

ENS7003R16 KO65 2013

31

Page 32

ENS7003R16 KO65 2013

32

Page 33

ENS7003R16 KO65 2013

33

Page 34

ENS7003R16 KO65 2013

34

Loading...

Loading...