Page 1

DB7110U Universal Heat Pump

MENU

SETTING

SYSTEM

FAULT

M37637

DB7110U-DEFROST CONTROL

Defrost Controller

INSTALLATION INSTRUCTIONS

APPLICATION

The DB7110U Universal Heat Pump Defrost

Controller is a heat pump defrost control used in

single stage heat pump appliances. This product

replaces over 260 OEM and competitive controls and

can be easily programmed to meet the requirements

of virtually any single stage heat pump. See Table 2,

“Compatibility Chart.,” on page 5.

FEATURES

The DB7110U provides:

• Universal defrost control for single stage heat

pumps

• LED display for easy setup and configuration

• Small, square footprint for easier installation

• Demand and timed defrost modes

• System status and fault indication

• Selectable reversing delay to limit noise when

going in and out of a defrost cycle

• Fault history for easy troubleshooting

SPECIFICATIONS

Electrical Ratings

Input Voltage: 24VAC, 60Hz

Max. Input Current: 200mA

Compressor Contactor: 1A @ 24VAC

Outdoor Fan:

1/2HP motor

5A full load, 30A locked rotor, 240VAC.

Aux Heat: 1A @ 24VAC

Reversing Valve: 1A @ 24VAC

All outputs rated for 100,000 operations.

All terminals except FAN-IN and FAN-OUT are NEC

Class 2 low voltage.

Environmental Ratings

Operating Temperature Range: -40F to 150F

Humidity Limits: less than 95% (non-condensing)

Fig. 1. DB7110U1000.

INSTALLATION AND CONFIGURATION

Overview

When Installing This Product…

1. Read these instructions carefully. Failure to fol-

low instructions can damage the product or

cause a hazardous condition.

2. Check ratings given in these instructions and

on the product to make sure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. Use these instructions to check out the product

operation after installation.

34-00032-01

Page 2

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

WARNING

WARNING

M37663

M37664

Electrical Shock Hazard. Can cause severe

injury, death or property damage.

Disconnect power supply before beginning

installation to prevent electrical shock or

equipment damage. More than one disconnect

may be involved.

Control Location

1. Before removing the old control, make note of

the wire connections to ensure the wires will be

connected to the correct terminals of the

DB7110U.

2. Mount DB7110U inside the junction box on the

outdoor unit using the two included self-drilling

sheet metal screws.

3. Use the control as a template to drill new mounting holes if necessary.

4. If the mounting tabs interfere with other components in the junction box, break/cut off the

unused mounting tabs prior to tightening the

mounting screws.

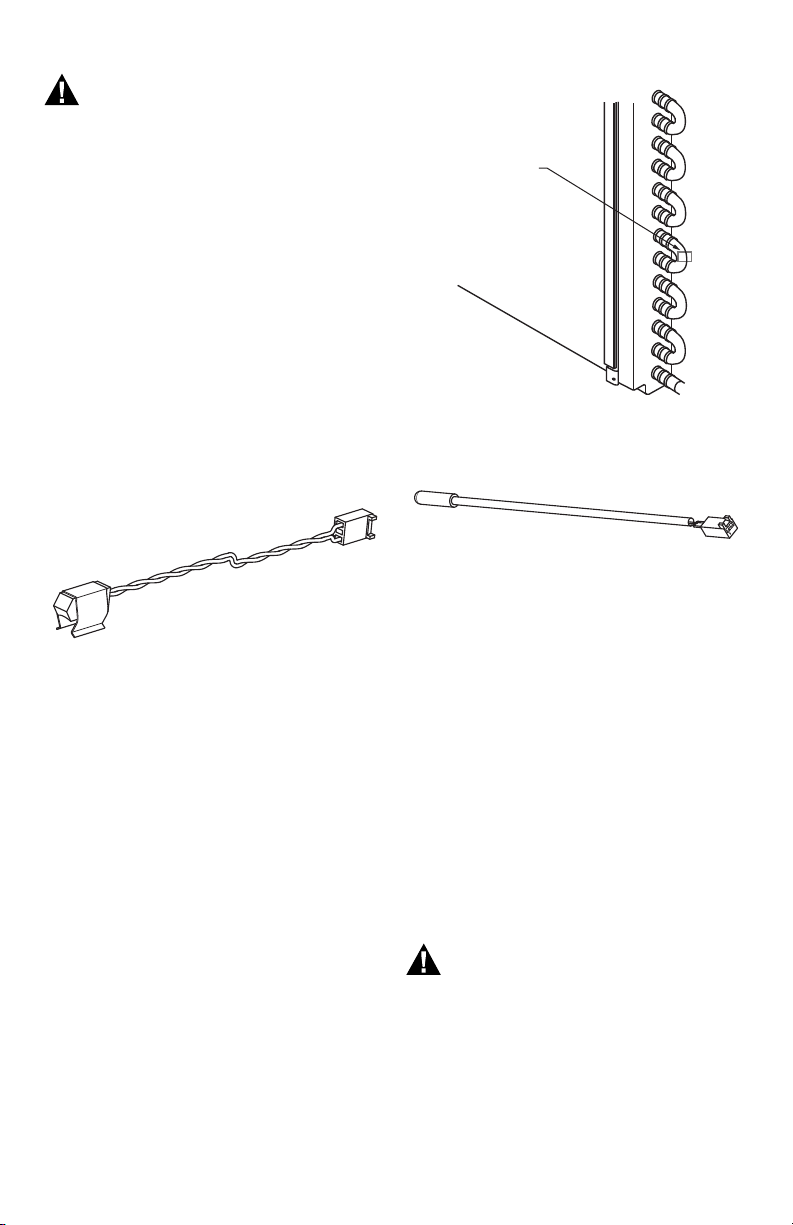

Coil Sensor Location

Fig. 2. Coil Sensor.

1. The outdoor coil sensor must be used. Without

the coil sensor, the DB7110U cannot determine

when to defrost. The coil sensor included with

the DB7110U replaces the existing defrost thermostat or coil sensor installed on the unit.

2. Place the sensor on the coil where the OEM sensor/thermostat was located. If replacing a

defrost thermostat, note the original settings for

proper adjustment of the termination and

enable temperatures on the DB7110U. They are

often marked with their open and close points. A

thermostat marked L60-25F for example would

correspond to a Termination Temperature of

60degF and an Enable Temperature of 35degF

(60deg-25deg).

3. If the location of the OEM sensor/thermostat is

inaccessible or difficult to access, place the new

coil sensor on the coil loop nearest the expansion valve where refrigerant is entering the coil

during the heating mode. This location gives the

largest temperature difference between the air.

4. Ensure the coil sensor is clamped tightly to the

coil. It may be desirable to add insulation to the

sensor to yield more accurate readings,

although this is generally not needed.

Wiring

SENSOR

M37638

Fig. 3. Coil Sensor Mounting.

OUTDOOR AIR SENSOR LOCATION

Fig. 4. Air Sensor.

1. The outdoor air sensor is optional. Using the

outdoor air sensor will enable the DB7110U to

implement a more advanced defrost algorithm

that determines to defrost based on the relationship between coil and air temperatures. Without

the air sensor, the DB7110U defrosts when the

coil temperature is below the Enable Temperature for the Defrost Cycle Time. It is advisable to

use the air sensor if possible as it may reduce the

number of unnecessary defrosts that are common among defrost timers.

2. Mount the air sensor such that the capsule is

hanging in air near the outdoor coil.

3. Do not locate the air sensor too close to the coil

that sensor readings are influenced by it.

4. Do not mount the air sensor in direct sunlight.

5. The air sensor capsule should not be in contact

with metal or some other material that may

change its readings.

Electrical Shock Hazard. Can cause severe

injury, death, or property damage.

Disconnect power supply before beginning

wiring to prevent electrical shock or equipment

damage. More than one disconnect may be

involved.

1. Make sure the wiring complies with all local

codes and ordinances.

2. If the low voltage wiring is bare wire with no terminals, wire nut them to the included wiring pigtails. Do not crimp terminals to solid wire.

34-00032—01 2

Page 3

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

A

LPC

HPC

CONTACTOR

AUX

REVERSING

VALVE

FAN-IN

FAN-OUT

R

C

O/B

W

Y

AIR

SENSOR

(OPTIONAL)

COIL

SENSOR

INDOOR

EQUIPMENT

OUTDOOR

EQUIPMENT

FAN

DB7110U

L1

L2

COMPR

RV

HIGH

PRESSURE

SWITCH

LOW

PRESSURE

SWITCH

AIRCOIL

IF THE PRESSURE SWITCH(ES) ARE IN SERIES

WITH THE CONTACTOR, JUMPER THE

ONBOARD CONNECTIONS. DO NOT BYPASS

ANY PROTECTIVE PRESSURE SWITCHES.

M37758

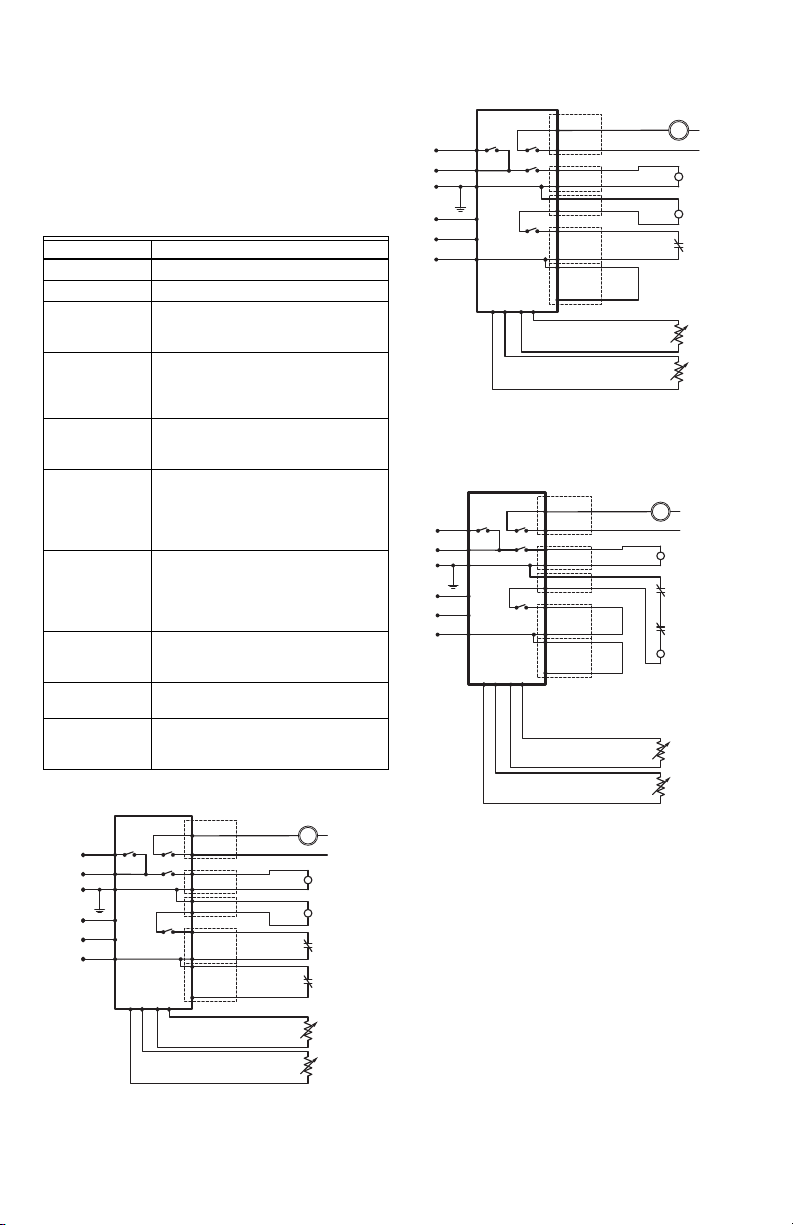

3. Check the line voltage connections on the fan

relay to ensure they are tight, in good connection, and more than 1/4" away from any part of

the appliance enclosure.

4. Plug in the outdoor sensor (if used) and the coil

sensor.

5. Reference the wiring diagrams in Figs. 5 to 8 to

aide in proper appliance wiring.

Table 1. Class 2 Low Voltage Terminations,

24V 60Hz.

Name Function

R (24V) 24V Hot

C (COM) 24V Common

W Aux/emergency heat request from

Y Compressor request from

O Reversing valve request from

HPC

(2 Terminals)

LPC

(2 Terminals)

AUX Output to auxiliary/emergency heat

COMPR

(2 Terminals)

RV

(2 Terminals)

thermostat – W requests will cause

the AUX output to be energized.

thermostat – Y requests will cause

the COMPR and FAN terminals to be

energized.

thermostat – controls the status of

the RV output.

High pressure cutout/switch – these

terminals must be shorted for

compressor operation. Never

bypass protective pressure

switches.

High pressure cutout/switch – these

terminals must be shorted for

compressor operation. Never

bypass protective pressure

switches.

– energized during a defrost cycle or

when requested by W input.

Output to compressor contactor –

energized by Y request.

Output to reversing valve –

energized by O input and as

required by a defrost cycle.

INDOOR

EQUIPMENT

UX

R

C

O/B

W

Y

Fig. 6. Wiring diagram for systems with no low

DB7110U

FAN-OUT

FAN-IN

RV

COMPR

HPC

LPC

AIRCOIL

pressure switch.

OUTDOOR

EQUIPMENT

FAN

REVERSING

CONTACTOR

PRESSURE

(OPTIONAL)

SWITCH

SENSOR

SENSOR

L2

L1

VALVE

HIGH

AIR

COIL

M37757

OUTDOOR

EQUIPMENT

FAN

REVERSING

CONTACTOR

PRESSURE

PRESSURE

(OPTIONAL)

SENSOR

L2

L1

VALVE

HIGH

SWITCH

LOW

SWITCH

AIR

SENSOR

COIL

INDOOR

EQUIPMENT

AUX

R

C

O/B

W

Y

Fig. 5. Wiring diagram with pressure switches

DB7110U

FAN-OUT

FAN-IN

RV

COMPR

HPC

LPC

AIR

COIL

connected to defrost control.

Fig. 7. Wiring diagram for systems with pressure

switches in series with the contactor and no

connection to the defrost control.

M37756

3 34-00032—01

Page 4

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

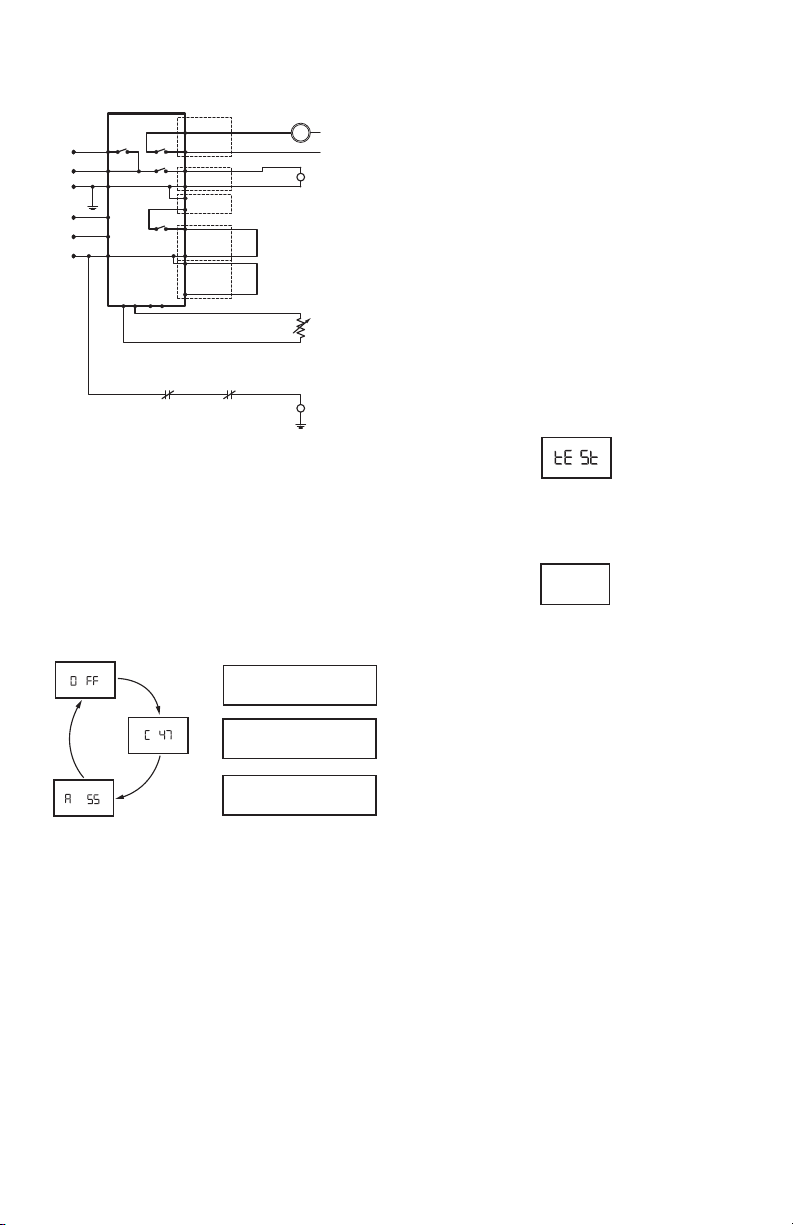

M37640

CURRENT MODE OF OPERATION

OFF, HEAT, COOL, DELAY, ETC.

OUTDOOR COIL TEMPERATURE

DEGREES FAHRENHEIT

OUTDOOR AIR TEMPERATURE

DEGREES FAHRENHEIT

INDOOR

EQUIPMENT

AUX

R

C

O/B

W

Y

DB7110U

FAN-OUT

FAN-IN

RV

COMPR

HPC

LPC

AIRCOIL

WHEN THE COMPRESSOR CONTACTOR IS POWERED DIRECTLY

FROM THE Y TERMINAL, SET THE REVERSING DELAY AND SHORT

CYCLE DELAY TO 0.

HIGH

PRESSURE

SWITCH

PRESSURE

SWITCH

OUTDOOR

EQUIPMENT

IF THE PRESSURE

SWITCH(ES) ARE IN SERIES

WITH THE CONTACTOR,

JUMPER THE ONBOARD

DO NOT BYPASS ANY

PROTECTIVE PRESSURE

LOW

FAN

L2

L1

REVERSING

VALVE

CONNECTIONS.

SWITCHES.

COIL

SENSOR

CONTACTOR

M37759

Fig. 8. Wiring diagram for simple timer applications.

CONFIGURATION

1. Connect power.

2. On power up the display will briefly flash the

software version of the DB7110U and then begin

cycling between the normal operating screens

showing the current mode and the values of the

two temperature sensors. Note that there is brief

startup delay following power up where compressor operation is prohibited.

Fig. 9.

The displayed coil and air temperature readings

can be very useful for optimizing and troubleshooting defrost performance.

3. There are several configurable options to optimize defrost performance. See “User Interface”

on page 7 for a detailed description of each

parameter/screen. Press the select (o) button

advance through the various screens and and

buttons to adjust the various parameters.

Table 4 below describes each parameter.

CHECKOUT

1. After the startup delay has expired, generate a

request for heat by shorting R to Y (and R to O if

configured as a “B” system, reversing valve energized in heating mode).

2. Verify the compressor, fan, and reversing valve (if

applicable) are energized.

3. Press and hold the button until “tESt” appears

on the display as shown below.

M37641

Fig. 10.

4. Verify the unit enters defrost mode

de Fr

M37642

Fig. 11.

The reversing valve will change states and the

aux heat will be energized. A few moments later

the fan will be turned off. If Reversing Delay is

enabled, the compressor will be turned off for

the selected time, and then turn back on to

reduce noise.

The DB7110U will remain in defrost for at least

one minute. After one minute has elapsed, the

DB7110U will exit defrost after the coil temperature has risen above the termination

temperature or after the selected defrost time,

whichever comes first.

Test mode can be terminated at any time by

pressing and holding the button again.

34-00032—01 4

Page 5

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

COMPATIBILITY CHART

Table 2. Compatibility Chart.

Amana C64301-1 C6431001

Arcoaire 32312-00 3232140

Armstrong 39840B001 44614-0001

44614-002 46257-001

47181-001 R46257-001

R46614-002 R47181-001

39840B002 37967B001

37967B002 R46K6701

R44614-001 R44614-002

Artesian 10321-00

Carrier 150-83-6A 621-xxxx

CES0110063-00 CES0110063-01

CES0110063-02A CES0130024-00

CES0130024-01 CES0130076

HK25SZ359A HK32EA001

HK32EA003 HK32EA007

HK32EA008 HK32FA003

HK32FA006

Coleman 3030A374 3030A364

3C30A374

Comfortmaker 1029-2 34332100

34332101

Evcon 9218-374

Fast 1093410

Goettl 305007

Goodman 1084-03-2022 1084-200D

20293901 B1226006

B1226008 LR4006 1

PCBDM101 PCBDM130

PCBDM133 PCBDM160

PCBDM101S PCBDM130S

Heil Quaker HQ1052727

Heil/Tempstar 1087952 1087953

1173636 CEPL130524-01

Honeywell ST74A1004 ST74A1020

ST74A1038 ST74A1053

ST74C1002

ICM DFORB24A21300 ICM300C

DFORB-AB1004 DFORF

DFOSP24A2 ICM301C

ICM302C ICM303C

ICM304 ICM307

ICM316 ICM317

ICM318 ICM319

ICM320 ICM321

ICM322 ICM323

W1001-4

ICP 1052757 1069364

Interthem 6208800

Table 2. Compatibility Chart. (Continued)

Lennox 100269-01 100269-02

100269-04 100269-05

11K7101 1507N170027

29M0101 29M0201

30W87 33G9501

34M6301 46K67

56M3701 68I2901

68J8401 78H6801

84W8801 86G1601

97M81 LB-101263A

LB-101263B 11K71

97M8101 30W8701

34M63 29M01

56M37 HPXB15

68I84 68I29

78H68

Nordyne 620880 621301A

621579B 621579C

624519A 624608

624626 624633

624644 624656

624700 917012

917178 917178A

920338 624644R

6246440 624633R

6246330

Ranco DT2

Rheem 47-102684-01 47-102684-02

47-102684-03 47-102684-04

47-102684-07 47-102684-08

47-102684-83 47-102685-01

47-102685-02 47-102685-03

47-102685-04 47-102685-05

47-102685-06 47-102685-84

47-21517-11 47-21517-13

47-21517-14 47-21517-16

47-21517-17 47-21517-18

47-21517-22 47-21517-23

47-21517-24 47-21517-82

47-21517-88 47-21517-92

47-21776-01 47-21776-06

47-21776-86 DDL-013002-0RH

DLL-013002-1RH DDL-0131020-1RH

DDL-017002-2RH DDL-017102-1RH

DDL-017702-1RH DDL-117702-3RH

DDL-122131-2RH 47-21517-12

47-21517-85 47-102685-87

47-102684-09 47-102685-07

47-21517-20

Robertshaw DT2-1000 TD-10

SnyderGeneral 1 395-329 CEBD430524-04B

5 34-00032—01

Page 6

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

Table 2. Compatibility Chart. (Continued)

Tempstar/ICP 1084-100 1084-83-1008

1087562

Therm-O Disc 26E-09

Trane 21C14501G18 21C1450127

21C1450136 21C1450137

21C1450138 21C1450142

21C1450144 21C1450145

21C1450153 21C1450154

21C1450155 21C1450160

21C14282G01 CNT01106

CNT01108 CNT01129

CNT01152 CNT01431

CNT01510 CNT01642

CNT01923 CNT01924

CNT01926 CNT02514

CNT02515 CNT02516

CNT02920 CNT02935

CNT03715 CNT03716

CNT04362 CNT04363

CNT04364 CNT04366

CNT04368 CNT04695

CNT05001 CNT05008

CNT05009 CNT05010

CNT05482 CNT05875

CNT1108 CNT01693

Weatherking 840-4-5548

White-Rodgers 840-4-5548 47D40-801

47D43-101 47D43-111

47D43-11102 47D43-811

90-621 47D01U-843

York 031-00872-001 031-00872-002

031-00872-002 031-00872-701

031-00872-702 031-00872-703

031-01222-000 031-01251-000

031-01268-000 031-01954-000

031-01975-000 031-09104-000

031-09170-000 331-01975-001

331-01975-102 331-09139-000

9218-3741 S1-03100872701

S1-03109170000 S1-33101954000

S1-33101975102

34-00032—01 6

Page 7

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

135

M37662

USER INTERFACE

The user interface consists of three buttons, two LED’s, and 4 7-segment digits. The two left digits generally

represent the category of what is being displayed while the two right digits represent the value or setting of the

category. The exception is in the event a value requires 3 digits such as a temperature higher than 99F as shown

below with two “termination temperature” values of 90F and 100F.

90

2

Fig. 12. Two example values of configuration option 2 (Termination Temperature).

The “o” button advances to the next screen while the and buttons are used to adjust the value of each

parameter.

Note that after one hour without a button press, the 7-segment display will turn off to save power. A button must

be pressed to turn the display on again.

Table 3. Status Screens.

Display Description

Current Fault(s) Present.

4

F

M37660

H 11

F

M37661

The configuration screens are numbered parameters where numbered parameter has a selectable value

according to the table below.

For example, would represent Parameter 1 (Defrost Enable Temperature) set to 35 (degF).

Right digits blank if there is no fault.

and to scroll through active faults.

Fault History

and to scroll through history.

Press an d hold for more than two seconds to clear all inactive faults.

2

1 00

M37659

Table 4. Configuration Screens.

Display Description Range Default

1 Defrost Enable Temperature

Coil temperature where defrost functionality is active.

2 Termination Temperature.

Coil temperature where defrost is terminated.

3 Defrost Cycle Time

Time the coil temperature is below the Defrost Enable

Temperature before a defrost is triggered if in timed mode

(no outdoor air sensor present).

4Short Cycle Delay Time

Minimum off time between compressor cycles.

5 Reversing Valve System Type

O = reversing valve energized in cool.

B = reversing valve energized in heat.

7 34-00032—01

30degF-36degF 35degF

70degF-100degF 70degF

30-120 minutes 30 minutes

0-5 minutes 3 minutes

O or B O

Page 8

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

Table 4. Configuration Screens. (Continued)

Display Description Range Default

6 Reverse Delay

Compressor off time when switching between heating and defrost

modes. Setting this to 0 will shorten the overall defrost time, but

may result in objectionably loud noises when entering/exiting

defrost (depending on compressor type).

7 Maximum Defrost Time

The maximum amount of time a defrost cycle can last. A defrost

cycle may be terminated earlier if the coil reaches the Termination

Temperature, but a defrost cycle should never last longer than this

time.

8 Aux Heat Lockout Temperature

W requests will be ignored if the outdoor temperature is higher

than this temperature. The Aux heat output will still function

normally during a defrost cycle regardless of this setting.

Do not set this temperature below the Compressor Lockout

Temperature or there will be a range of temperatures with no

heating operation.

9 Compressor Lockout Temperature

Y requests will be ignored if the outdoor temperature is lower than

this temperature.

Do not set this temperature above the Aux Heat Lockout

Temperature or there will be a range of temperatures with no

heating operation.

0-30 seconds 30 seconds

8-14 minutes 14 minutes

0degF-40degF No Lockout

-10degF-40degF No Lockout

(OF)

(OF)

Green LED: Indicates system power and operation.

Red LED: Indicates a fault is currently present and the user should inquire with the 7-segment display for more

information.

34-00032—01 8

Page 9

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

TROUBLESHOOTING AND MAINTENANCE

IMPORTANT

Due to the potential hazard of line voltage, only a trained experienced service technician should perform

the troubleshooting procedures.

This control contains no field-serviceable parts. Do not attempt to take it apart. Replace the entire control

if operation is not as described.

Table 5. Troubleshooting.

Condition Procedure Control Status Corrective Action

System does not

start with a call

for heat or cool

Compressor does

not stop when

the call for heat

or cool ends

System operates

in wrong mode,

heating when

cooling is

requested or vice

versa

Observe display for

current operational

mode.

Observe display for

current operational

mode.

Unplug Y wire from

control

Check O/B setup Control displays current

Display shows OFF • Verify call for heat or cool is present.

Control displays HEAT or

COOL but the system is

not operating.

Control displays DLY • The system is in a startup delay due

Control displays current

mode; OFF, HEAT, or

COOL.

Display shows OFF,

compressor turns OFF

Display shows OFF but

compressor remains ON

Display continues to show

shows HEAT or COOL

configuration:

• Check the wiring from thermostat and

indoor equipment

• Measure input terminals (W, Y, O) for

proper voltage.

• Verify cold weather compressor

lockout isn’t active. Adjust

“Compressor Lockout Temperature” if

necessary.

• Check wiring to outdoor equipment.

• Check contactor

• Measure output terminals for proper

voltage. WARN ING: fan terminals are

line voltage.

• Verify system pressure switches. The

onboard HPC and LPC terminals

must be shorted to run. Never bypass

protective pressure switches.

• Check coil sensor, the system will not

run without a coil sensor.

to short cycle protection, powerup, or

low voltage. Wait for the delay to

expire.

• If HEAT or COOL is shown after the

call ended, investigate thermostat

wiring.

• Investigate thermostat wiring to

ensure all wires are on the proper

terminals.

• Check the wiring between the control

and contactor.

• Check for a failed/stuck contactor.

•Unplug the COMPR wires and

measure voltage across the two

COMPR terminals. If they measure

24V while the display says OFF,

replace control.

• Replace the control.

• O means the control will be in

COOLING mode when there’s 24V on

the O terminal.

• B means the control will be in

HEATING mode when there’s 24V on

the O terminal. In most cases this will

only apply to Rheem units.

9 34-00032—01

Page 10

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

Table 5. Troubleshooting. (Continued)

Condition Procedure Control Status Corrective Action

System does not

defrost at all

System does not

defrost

completely

System defrosts

too much

No

Auxiliary/Emerg

ency Heat

Observe operational

mode while heating.

Observe defrost cycle Defrost starts too late. Too

Observe defrost cycle Defrost triggers too

Check configuration

parameters

Display shows COOL • O/b configured incorrectly. Verify

Display shows HEAT, but

no defrost is triggered.

much ice is built up before

starting a defrost cycle.

Defrost cycle ends too

soon. Not all the ice is

removed.

frequently, even with little

or no ice buildup.

Defrost cycle lasts too

long. Ice is melted long

before the cycle ends.

Active W request with no

Aux heat output

No Aux heat output during

defrost cycle

proper setting of O/b input for

reversing valve control. The control

won’t defrost if it “thinks” it’s in

cooling mode.

• Verify sensor placement and readings

are correct.

• Increase the “Enable Temperature” to

trigger defrost sooner. Defrost will

never be triggered if the coil

temperature does not fall below the

Enable Temperature. If the Enable

Temperature is too high, the system

may defrost when it’s not necessary.

• Verify sensor placement and readings

are correct.

• Increase the “Enable Temperature” to

trigger a defrost sooner.

• Lower the “Defrost Cycle Time” to

trigger a defrost sooner. Note this

parameter has no effect if an outdoor

air sensor is installed as the decision

would be made based on the

temperature difference between coil

and air.

• Verify sensor placement and readings

are correct.

• Increase the “Termination

Temperature” to allow the coil to get

hotter before a defrost cycle is

terminated.

• Increase the “Maximum Defrost

Time” to allow a defrost cycle to run

longer.

• Verify sensor placement and readings

are correct.

• Decrease the “Enable Temperature”

to force the coil to get colder before a

defrost is triggered. Increasing this

parameter too much can result in not

triggering a defrost at all. Verify coil

readings with respect to this

parameter.

• Increase the “Defrost Cycle Time” to

delay triggering a defrost. Note this

parameter has no effect if an outdoor

air sensor is installed.

• Verify sensor placement and readings

are correct.

• Decrease the “Termination

Temperature” to allow the defrost

cycle to end with a cooler coil

temperature.

• Decrease the “Maximum Defrost

Time” to force the defrost cycle to end

sooner.

• Verify warm weather aux heat lockout

isn’t active. Adjust “Aux Heat Lockout

Temperature” if necessary.

•Check wiring

•Replace control

•Check wiring

•Replace control

34-00032—01 10

Page 11

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

A

−−

M37655

A __

M37656

−−

C

M37657

Table 6. Fault Code Information.

Fault No. Description Corrective Action

1 Internal Communication Fault • Replace control

2 Internal Fault • Replace control

3 Low 24V • Measure 24V (R & C). There may be something in the

4 Corrupt Memory • Reset configuration options. Replace the control if the fault

5High Pressure Lockout – HPC

6 Low Pressure Lockout – LPC

7 High Pressure Cutout is currently

8 Low Pressure Cutout is currently

opened 3 times on a single

request.

opened 3 times on a single

request.

open

open

9 Coil Sensor Open Circuited • Check the sensor hasn’t become unplugged.

10 Coil Sensor Shorted • Check for pinched wires

11 Air Sensor Open Circuited • Check the sensor hasn’t become unplugged.

12 Air Sensor Shorted • Check for pinched wires

system loading the 24V transformer excessively. If voltage

is normal while the fault is currently active, replace the

control.

persists.

• Investigate refrigerant charge

• Check indoor coil for blockage

• Check outdoor coil for blockage

• Investigate refrigerant charge

• Investigate refrigerant charge

• Check indoor coil for blockage

• Check outdoor coil for blockage

• Investigate refrigerant charge

• Check sensor wiring

•Replace sensor

•Replace sensor

• Check sensor wiring

•Replace sensor

Note that this fault will only present itself if the sensor opens

after it has been detected. It will be cleared on a reset or power

cycle. Running without an air sensor causes the control to

operate in a timed defrost mode, which may be desired

operation.

•Replace sensor

Table 7. Sensor Diagnostics.

Display Description

Air sensor open circuit or unplugged

Air sensor shorted

Coil sensor open circuit or unplugged

__

C

Coil sensor shorted

M37658

11 34-00032—01

Page 12

DB7110U UNIVERSAL HEAT PUMP DEFROST CONTROLLER

Resideo Inc., 1985 Douglas Drive North,

www.resideo.com

©2018 Resideo Technologies, Inc. All rights reserved. Th e Honeywell Home trademark is used under license from Honeyw ell International Inc.

Golden Valley, MN 55422

34-00032—01 M.S. 12-18 | Printed in United States

Loading...

Loading...