Page 1

CPZ100,

CPZZOO,

CP2201,

Honeywell

CRZ150,

CRZZOO,

CR2201

.

PUNCHED

CARD

SUBSYSTEMS

SERIES

400/600/

6000

HARDWARE

Page 2

CPZ100,

CPZZOO,

CPZZO1,

Honeywell

CRZ150,

CRZZOO,

CR2201

A

PUNCHED

CARD

SUBSYSTEMS

SERIES

400/

600/

6000

SUBJECT:

h

Information,

Functional

Characteristics,

Operating

Instructions,

and

Characteristics

of

Series

400/600/6000

Punched

Card

Subsystems.

SPECIAL

INSTRUCTIONS:

This

manualisan

updateofCPB-12288A,

dated

October

1966

and

revised

December

1967.

The

new

order

number

is

consistent

with

the

HIS

publications

numbering

system.

Changes

and

additions

are

indicated

by

bars;

deletions

are

indicated

by

asterisks.

DATE:

December

1973

/\

ORDER

NUMBER:

B037,

Rev.

0

Page 3

PREFACE

This

manual

furnishes

general

information

and

specific

reference

material

for

customer

executives,

system

analysts,

operators,

programmers,

and

others

interested

in

punched

card

subsystems

available

with

the

Series

400/

600/

6000

Information

Processing

Systems

and

the

DATANET

communications

systems.

The

first

section

will

satisfy

the

needs

of

those

who

want

only

a

highlight

of

what

the

subsystems

do.

Section

H

describes

in

detail

the

functional

capabilities

of

the

subsystems.

This

chapter

will

be

of

prime

interest

to

system

operators

and

furnishes

background

information

for

programmers.

Detailed

descriptions

of

operating

controls

are

found

in

Section

III.

The

individual

subsystems

and

the

unique

features

of

each

are

described

in

Appendix

A.

When

the

subsystems

are

being

used

with

a

Series

400

system,

the

term

"processing

system"

refers

to

the

Central

processor;

for

the

Series

600/6000,

the

term

refers

to

the

Input/

Output

Controller.

©1966,

1968, 1973,

Honeywell

Information

Systems

Inc.

File

No.:

1503,

1603,

1703

Page 4

CONTENTS

GENERAL

INFORMATION

Physical

Characteristics

.............................

. .

. .

Usewiththe

Series

600/6000... ...... . . . . ...

. .............

Use

with

the

Series

400

..................................

FUNCTIONAL

CHARACTERISTICS

Readers

...........>.....................................

Punches

................................................

Data

Media

........_......................................

ModesofOperation

...............l.........................

Readers..............

...............................

Punches

...................l.........................

Input/

Output

Signals

........................................

End

Data

Transfer

Signal

.................................

Terminate

Signal

......................................

Special

Interrupt

Signal

..................................

Status

Information

.....‘....................................

PriorityofStatus

............i.........................

Resetting

Status

........................................

Status

and

Substatus

Descriptions

.....p.i.........................

Channel

Ready

...............l.........................

Device

Busy

(R)

........................................

Attention

...........................................

Data

Alert

.................i.........................

Instruction

Rejected

.....................................

Load

Operation

Complete

(R)..

. ...........................

Intermediate

(P)

(CPZlOO

only)...I.........................

Channel

Busy

..............y..i.........................

Channel

Absent

..............a.........................

Channel

Alert

(R)

.............a.........................

Card

Reader

Instructions

.....................................

Operational

Instructions

....................‘.............

No

-Op

Instructions

.....................................

Card

Punch

Instructions

.....................................

Operational

Instructions

.................................

No

-Op

Instructions

.....................................

OPERATING

INSTRUCTIONS

CareofPunch

Cards

......................|.................

'

Handling

Cards

...............,...'.....................

Storing

Cards

........................................

Preparing

Cards

for

Loading

.............................

iii

Page

(ANN

cooooo-J-aqoacaoaoacncn

21

21

22

Page 5

Alert

Conditions

and

Corrective

Action

...............'...........

Operator

Maintenance

.....................................

CRZZOI

Card

Reader

......................................

Operator's

Control

Panel

................................

Card

Handling.

Mechanism.. . . . .......

. ...

...............

Setup

.............................................

Loading

Cards

.......‘................................

ConvertingtoAlternate-Size

Cards.. ...................

.

. .

Summary

of SettingUpProcedures

.........................

Unloading

Cards

.....................................

Normal

Operation

....................................

Shutdown..

......................

.......

CRZZOO/CRDISO

Card

Reader

......................

. . .

.......

Operator's

Control

Panel

...............................

Input/

Output

Area

Switches

.......‘.......................

Card

Handling

Mechanism

..............................

Setup.

.........-..........................

. . . ...'

.

Loading

Cards

.................................

. .....

UnloadingCards...............§

...............‘......

Shutdown

......................~....................

CPZlOO

Card

Punch...y....................................

Operator's

Control

Panel

...............................

Card

Handling

Mechanism

...............................

Setup

..................................‘.........

. .

Adding

Cards

.......................................

Removing

Cards

.....................»................

Emptying

the

Chad

Box

.................................

Shutdown..........................................

CPZZOO

Card

Punch

......................................

Operator's

Control

Panel

...............................

Card

Handling

Mechanism.. ...

. . .......................

Setup...........

..........

Adding

Cards

.............'..........................

RemovingCards..

.....

...............

Emptying

the

Chad

Box

.................................

Manually

ReturningtoOperate

State

.............

.......

.

Shutdown....

............

......

..........

CPZZOl

Card

Punch

...........................

.............

Operator'5Control

Panel

...............

. ...

. .

.

.

......

CardHandlingMechanism.

.....

Setup

..........

.......................

AddingCards

....................

Removing

Cards

......................................

Emptying

the

Chad

Box

.................................

Manually

ReturningtoOperate

State

..........

. ..;.. . . . . .

; . .

.Shutdown

........................

......

iv

Page 6

APPENDIXES

SUBSYSTEM

CHARACTERISTICS

CRZZOl

Card

Reader

.......................................

Data

Medium

.........................................

Speeds

and

Capacity.....................................

Data

Formats

....................................-. ...

Checking

.................................. .i........

Operating

Speeds

......................................

Timing

Considerations

.................................

~

Status

Returns

.......................................

Instructions

.......................................

CRZZOO/CRD15O

Card

Reader

................................

Data

Medium....»....................................

Speeds

and

Capacities

..................................

Data

Formats...

.....................................

.

Checking

..........................................

Operating

Speeds.......-....._..

........................

Timing

Considerations

.................................

Status

Returns

.......................................

Instructions

.........................................

CPZlOO

Card

Punch

.......................................

Data

Medium

.......................................

Speeds

and

Capacities

..................................

Data

Formats

.......................................

Substatus

States..

.

Checking

................

...............

Timing

Considerations

.................................

Status

Returns

......................................

Instructions

.........................................

CPZZOO

Card

Punch

............................‘...........

Data

Medium

.......................................

Speeds

and

Capacities

...................................

Data

Formats

. .-......................................

Subsystem

States

...........-...........................

Checking

...........................................

Timing

Considerations

.........I.........................

Status

Returns

...............T.........................

Instructions

.................i.........................

Page 7

CPZZOl

Card

Punch

.......................................

Data

Medium

.......................................

Speeds

and

Capacities

..................................

Data

Formats

_

.................................

,

......

Subsystem

States

.....................................

Checking

...........

'

................................

Timing

Considerations

.................................

Status

Returns

.........

_

..............................

Instructions

..........................

,

...............

CHARACTER

SET;

........................................

GLOSSARYo-----------_

.................................

INDEX

................................................

vi

Page 8

Figure

9°99?”

ILLUSTRATIONS

Blocking

Small

Decks

..................................

Riffle

Each

End

of

Cards

................................

CRZ201

Control

Panel

.................................

CRZZOl

Card

Reader

Mechanism

..........................

‘

Track

Jam

Release

Mechanism

(Opened)

,,,,,,,,,,,,,,,,,,,,,

-

Stacker

Jam

Release

Mechanism

...........................

Card

RailinPlace

for

Reading

51-Column

Cards

...............

Card

Bumper

.......................................

CRZZOO

Control

Panel

.................................

CRZZOO

Input/

Output

Area

Switches

..........................

CRZZOO

Card

Reader

Mechanism

...........................

Adding

CardstoEmpty

HOpper

.............................

Inserting

First

CardinFeed

Throat

.........................

Adding

Cards

During

Feed

Operations

........................

Removing

Cards

During

Feed

Operations

......................

Blocking

CardsinStorage

Tray

............................

Removing

All

Cards

from

Stacker

...............i...........

CPZlOO

Control

Panel

.................................

CPZlOO

Card

Punch

Mechanism

...........................

CPZZOO

Control

Panel

.................................

CPZZOO

Card

Punch

Feed

Mechanism

(Left

Side

View)

............

CPZ201

Control

Panel

..................................

CPZZOI

Card

Feed

Mechanism

...........................

CRZ201

Card

Reader

Subsystem

...........................

CRZZOO/

CRD150

Card

Reader

Subsystem

.....................

CPZlOO

Card

Punch

Subsystem

...........

'

................

CPZZOO

Card

Punch

Subsystem

...........................

CPZZOI

Card

Punch

Subsystem

...........................

vii

54

59

62

68

73

'75

79

.83

Page 9

Page 10

1.

GENERAL

INFORMATION

The

Honeywell

Series400/

600/

6000

Information

Processing

Systems

are designed

to

give

the

user

versatility

of

operation

in

card

subsystem

equipment.

Card

reading

equipment

reads

information

punched

into

tabulating

cards

in

alphanumeric

or

binary

modes

and

feeds

it

into

the

core

store

of

the

central

processor

for

processing

or

storage.

‘The

user

has

a

choice

of

reading

speeds

from

900

to

1200

cards

per

minute

to

meet

his

requirements.

~

Card

readers

are

designed

to:

o

Handle

either

round-1

or

square-cornered

cards,

intermixed.

0'

Read

cards

punched

in

alphanumeric.

(binary-coded

decimal,

or

Hollerith)

and

12-row

binary,

formats.

0

Operate

simultaneously

with

central

processor

computation

and

other

input/

output

operations.

'

o

Readatvariable

speeds

(asynchronous).

o

Read

cards

serially,

column

by

column,

by

means

of

photocells

which

provide

reliable

and

accurate

reading

of

data

in

either

continuous

or

demand-type

operations.

0

Check

card

timing

and

synchronization,

proper

card

feeding

and

reading,

empty

homer,

and

full

stacker.

0

Check

for

the

presenceofinvalid

characters.

Card

punching

equipment

permits

information

from

the

central

processor

to

be

recorded

directly

on

cards

under

control

ofastored

program.

Punching

speeds

from

100to300

cards

per

minute

are

available.

Card

punches

are

designed

to:

0

Punch

cardsinalphanumeric

or

12-row

binary

formats.

0

Operate

simultaneously

with

central

processor

computation

and

other

peripheral

subsystems.

0

Punch

cards

rowbyrow,80columnsata

time.

0

Check

card

feeding

0

Check

punching

accuracybya

read-after-punch

hole

count.

-1-

Page 11

PHYSICAL

CHARACTERISTICS

The

punched

card

subsystems,

packaged

as

single,

freestanding

units,

are

on-line

devices,

each

consisting

of

a

card

handling

mechanism,

control

electronics,

and

a

power

supply.

Operator’s

control

panels

display

a

full

array

of

controls

and

indicators

for

observing

and

controlling

the

operation

of

the

subsystems.

The

power

supply

is

adequately

fused

against

overloads

and

provides

and

regulates

the

necessary

a.c.

and

d.c.

voltages

for

the

card

handling

mechanism

and

the

control

electronics.

The

control

electronics

interpret

and

transmit

to

and

from

the

processing

system

the

data

read

from

or

punched

into

cards

and

generate

and

transmit

timing

signals

and

information

on

the

operating

condition

of

the

subsystem.

USE

WITH

THE

SERIES

600/6000

Whenever

the

subsystem

operates

within

a

multiprogramming

environment,

its

operation

must

be

coordinated

to

mesh

efficiently

and

simultaneously

with

that of

other

peripheral

equipment

in

the

system.

The

General

Input/

Output

Supervisor

(GIOS)

program,

avail-

able

with

the

Series

600/

6000

systems,

does

this

for

the

programmer-

It

handles

the

details

that

arise

from

supervising

the

activities

and

status

of

many

peripherals

and

makes

the

most

efficient

use

of

them

in

conjunction

with

the

valuable

time

of

the

process-

ing

unit.

Whenever

use

of

the

subsystem

is

required,

GIOS

communicates

with

the Input/

Output

Controller

(ICC)

by

means

of

a

connect

instruction.

If

the

subsystem

is

busy

when

the

'

output

request

is

made,

GEIOS

queues

the

request

until

the

subsystem

becomes

ready.

When

the

subsystem

has

accepted

the

instruction

and

received

all

the

information

necessary

to

initiate

data

acceptance

and

punching

or

reading,

the

connect

sequence

ends

and

the

IOC.

data

service

sequence

begins.

This

sequence

controls

the

transfer

of

information

to

the

subsystem.

V

When

operation

stops,

either

because

of

a

normal

termination

or

because

an

alert

condition

occurred,

the

IOC

places

the

status

and

substatus

of

the

subsystem

in

the

proper

queue

and

sends

a

program

interrupt

signal

to

the

store

controller.

6108,

in

turn,

checks

each

queue

'

entry

to

be

sure

that

the

peripheral

operation

was

completed

free

of

errors.

If

it

was

not,

the

prOper

recovery

routines

are

called

in.

6108

also

returns

status

and

substatus

information

to

the

program

whenever

it

requests

it.

With

GIOS

efficiently

assuming

the

burden

of

responsibility

for

directing

peripheral

operations,

the

programmer

is

relieved

of

much

detailed

programming.

Programming

information

on

the

use

of

the

subsystem

with

the

Series

600/6000

is

containedinSeries

6000/

600

General

File

and

Record

Control

stem,

BN85,

and

Series

60007300

Em?

Macro

Esemfijl

firogram,

ENE.

.

.

l.,

Page 12

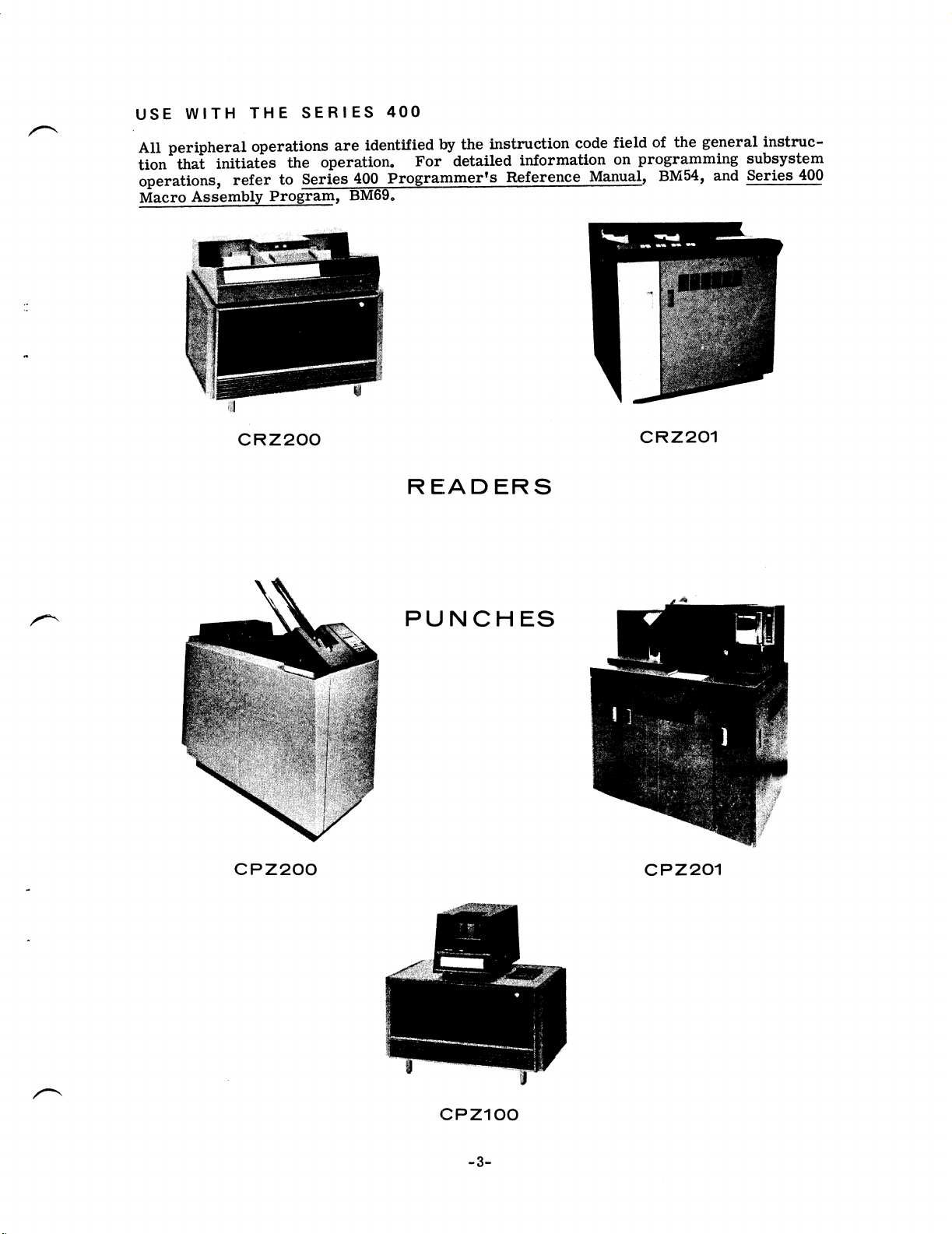

USE

WITH

THE

SERIES

400

A

~

All

peripheral

operations

are

identified

by

the

instruction

code

field

of

the

general

instruc-

tion

that

initiates

the

operation.

For

detailed

information

on

programming

subsystem

operations,

refer

to

Series

400

Programmer's

Reference

Manual,

BM54,

and

Series

400

Macro

Assemblx

Program,

BM69.

CRZZOO

CR2201

R

EIADERS

r“

P

U N

C

H

ES

CP2

200

CP2

201

/'\

'

CPZ1OO

-3-

Page 13

Page 14

2.

FUNCTIONAL

CHARACTERISTICS

READERS

Honeywell

card

readers

are

on-line

devices

consisting

of

a

card

reading

mechanism

and

the

control

logic

that

links

it

to

the

central

processor.

The

card

reading

mechanism

consists

of

the

card

input

hopper,

‘a

card

feed

mechanism,

a

reading

stations,

and

a

card

output

stacker.

The

reading

station

is

composed

of

a

lamp

and

12

light-sensitive

photocells.

The

reading

of

each

cardisinitiatedbya

specific

sequenceofinstruction

signals

received

by

the

card

reader.

If

no

Attention

conditions

exist,

the

card

reader

goes

intoabusy

state,

decodes

the

instruction,.checks

its

validity,

and

initiates

the

prOper.

control

functions.

The

first

card

is

released

from

the

input

hopper.

The

card

track

moves

the

Cardtothe

reading

station.

There,

the

photocells

read

the

card,

one

columnata

time.

The

photocells

detect

light

from

the

light

source

passing

through

the

punched

holesinthe

columns

and

send

an

electronic

signaltothe

control

electronics.

In

each

card

cycle,

the

Operation

of

the

photocells

in

the

read

station

is

checkedtodetermine

that

thereisno malfunction

and

that

the

card

has

not

been

unstableinits

passage

through

the

read

area.

The

transfer

of

data

continues

until

the

entire

card

is

read,

an

alert

condition

is

detected,

or

the

card

reader

receives

a

signal

telling

it

to

transfer

no

more

data.

When

reading

of

the

card

is

completed,

a

check

is

made

to

determine

whether

the

correct

number

of

columns

were

read.

If

not,

an

error

is

indicated.

The

card

reader

then

makes

available

information

on

its

status

and

generates

a

signal

indicating

termination

of

operation.

PUNCHES

Honeywell

card

punches

are

on-line

devices

consisting

of

a

card

punching

mechanism

and

the

control

logic

that

links

it

to

the

central

processor.

The

card

punching

mechanism

consists

of

the

card

input

hopper,

the

card

feed

mechanism,

a

punching

station,

a

reading

station,

and

a

card

output

stacker.

Before

punching

can

begin,

the

card

punch

mustbeproperly

loaded

and

freeofany

Attention

conditions.

The

subsystem

becomes

busy

and

card

punching

begins

whenapunch

instruction

is

received

and

accepted.

When

the

instruction

is

given

to

begin

card

punching,

the

bottom

card

of

the

stack

is

pushed

from

the

hopper

into

the

punching

station.

As

soon

as

the

punch

goes

into

the

busy

state,

it

requests

data

for

the

card.

Data

is

transmitted,

character

by

character,

from

-5-

Page 15

the

processing

system

to

the

buffer

of

the

punch’s

controller.

The

parity

of

each

character

is

checked

as

it

is

received.

If

the

instruction

requests

the

data

to

be

punched

in

the

Hollerith

code,

the

code

is

converted

by

the

controller

before

the

data

enters

the

buffer.

The

80

punching

dies

punch

the

card,

a

row

ata

time.

The

card

then

moves

into

the

reading

station,

where

80

wire

brushes

read

it

by

sensing

the

presence

or

absence

of

holes.

From

the

reading

station,

the

card

is

moved

to

the

output

stacker.

DATA

MEDIA

The

subsystems

accept

and

punch

or

read

data

into

or

from

punched

cards

in

a

variety

of

intermixed

card

stocks.

The

mechanism

of

the

subsystem

handles

cards

so

as

to

produce

the

least

possible

wear

both

to

the

cards

and

to

the

subsystem

itself.

Cards

should

meet

the

basic

requirements

specified

for

their

use

with

most

electronic

and

tabulating

equipment

in

order

to

provide

the

greatest

possible

amount

of

service.

The

subsystems

also

handle

cards

exposed

to

a

wide

range

of

temperature

and

humidity

conditions,

provided

the

cards

are

first

given

a

reconditioning

period.

MODES

OF

OPERATION'

Readers

ALPHANUMERIC

MODE.

The

contents

of

each

card

column

punched

in

the

Hollerith

format

are

converted

to

the

equivalent

6-bit

character

and

transmitted

with

an

odd

parity

bit.

In

addition,

a

check

is

made

to

see

that

the

punches

in

each

column

represent

a

valid

character

of

the

character

set.

(See

the

Appendix

B

of

this

manual

for

the

character

set

and

the

corresponding

punches

in

the

Hollerith

format.)

'

BINARY

MODE.

Data

punched

into

the

top

halfofeach

column

(row

12-row3)is

transmitted

as

the

first

character,

supplemented

by

an

odd

parity

bit.

Data

read

from

the

lower

half

of

the

column

(row

4-row9)is

transmittedasthe

second

character.

MIXED

MODE.

When

the

card

readerisoperatinginthe

mixed

mode,itis

readingadeck

composed

of

both

alphanumeric

and

binary

cards.

As

each

card

enters

the

reader,

column

1isexamined

to

determine

which

type

the

cardisand

thus,

how

the

dataistobehandled.

If

the

‘7'

and

“9"

of

column1are

punched,

regardlessofwhat

other

punches

occurinthe

column,

the

card

is

read

in

the

binary

mode.Ifeitherorbothofthese

two

punches

are

missing,

the

card

is

readinthe

alphanumeric

mode.

In

either

case,

the

full80columns

of

card

information

are

transmitted,

including

column

1.

Since

there

are no

alphanumeric

characters

represented

by

both

the7and9punches,

either

withorwithout

other

punches,

the

card

reader

cannot

accidentally

misinterpretastandard

Hollerith

punch

configuration

in

column1for

the

special

identifying7and9punchesofa

binary

card.

Punches

OD

Two

6-bit

binary

characters

are

punched

into

each

card

column.

The

first

character

goes

into

card

rows

12-3

(row

12

contains

the

most-significant

bit).

The

-3-

Page 16

second

character

is

punched

into

card

rows

4-9

(row

4

is

the

most-significant

bit).

The

third

and

fourth

characters

are

punchedl

in

column

2,

etc.

ALPHANUMERIC

MODE.

Each

6-bit

data

character

received

is

converted

into

Hollerith

code

and

punched

into

a

single

card

column.

The

character

set

and

the

corresponding

punches

in

the

alphanumeric

format

are

given

in

Appendix

B

of

this

manual.

EDITED

ALPHANUMERIC

MODE.

This

mode

of

operation

is

identical

to

the

alphanumeric

mode,

but

with

the

additional

feature

of

allowing

the

punch

to

delete

any

Ignore

characters

(octal

17)

which

it

may

receive.

Whenever

an

Ignore

character

is

deleted,

the

next

valid

character

received

is

punched

with

no

blank

column

intervening.

INPUT/OUTPUT

SIGNALS

Instructions

transmitted

to

the

subsystem

and

data

transmitted

to

or

received

from

the

subsystem

are

accompanied

by

signals

that

help

time

operations,

trigger

operations,

and

identify

information.

Some

signals

function

automatically,

while

others

can

be

accessed

or

caused

by

programmers

or

operators.

Those

signals

of

direct

concern

to

users

are:

EndData

Transfer

Terminate

Special

Interrupt

End

Data

Transfer

Signal

The

processing

system

transmits

the

End

Data

Transfer

signal

to

the

subsystem

to

indicate

that

no

more

data

is

to

be

transferred.

A

list

pointer

word

overflow

causes

this

signal

in

a

Series

400

system.

When

the

subsystem

receives

the

signal,

or

an

error

condition

is

detected,

data

transfer

is

terminated

for

the

remainder

of

the

card

operation

time.

The

two

error

conditions

that

cause

this

are

the

Attention,

Read

Alert,

and

the

Data

Alert,

Transfer

Timing

Alert,

conditions.

Both

are

defined

under

“Status,”

below.

Note

that

the

subsystem

remains

in

the

Channel

Busy

state

for

the

entire

operation

time.

Terminate

Signal

The

subsystem

transmits

the

Terminate

signal

to

the

processing

system

to

indicate

that

the

Channel

Busy

condition

was

terminated

for

one

of

the

following

reasons:

1.

Processingofa

cardiscomplete.

2.

A

card

jam

was

detected.

3.

A

data

alertisdetected.

-7-

Page 17

The

status

information

transmitted

with

the

Terminate

signal

identifies

the

specific

type

of

termination.

’

Special

Interrupt

Signal

The

subsystem

transmits

the

Special

Interrupt

signal

to

the

processing

system

to

call

attention

to

a

change

in

the

operating

state

of

the

subsystem.

The

signal

means

that

the

subsystem

was

manually

cleared

from

the

Attention

status.

STATUS

INFORMATION

The

punched

card

subsystem

transmits

status

information

about

its

Operating

condition

to

the

processing

system.

The

status

tells

the

processing

system

when

the

subsystem

is

ready

to

accept

an

instruction

or

is

busy,

whether

an

instruction

was

successfully

executed,

when

error

conditions

have

occurred,

etc.

Status

information

can

be

placed

in

core

store

and

interrogated

by

the

program.

When

used

in

this

way

by

the

program

or

Operating

system,

the

status

permits

detecting

and

attempting

to

recover

from

certain

error

conditions

under

program

control.

For

conditions

that

require

operator

intervention,

status

enables

the

program

or

operating

system

to

give

specific

instructions

to

the

operator

for

correcting

inoperable

conditions.

There

are

two

types

of

status

information--the

major

status

and

the

substatus.

Major

status

indicates

the

general

category

of

the

condition.

For

some

major

statuses,

there

are

substatuses

that

indicate

more

specific

reasons

for

the

existence

of

the

major

status.

In

the

following

discussions

of

major

status

and

substatus,

codes

are

interpreted

as

follows:

Bit

positions

———>

232221

2°

Major

Status

Code—p

O 0

0

0

Bit

positions

—————>25

242a22

2"1

2°

Substatus

Code—90

0

x

x

1

x

A

bit

shown

as

“0”

must

always

be

zero.Abit

shownas“x”

canbeeither

oneorzero.

A

l-bit

identifies

the

existing

condition.

The

patternofx’s,

1’s,

and

0’s

indicates

which

substatuses

can

occur

together.

.

The

major

statuses

that

may

be

encounteredbya

punched

card

subsystem

are

described

on

the

following

pages.

The

list

below

shows

the

4-bit

configuration

for

each

major

status

possible.

The

exact

statuses

returnedbyaparticular

subsystem

are

giveninthe

subsystem

descriptionsinAppendix

A.

-8-

Page 18

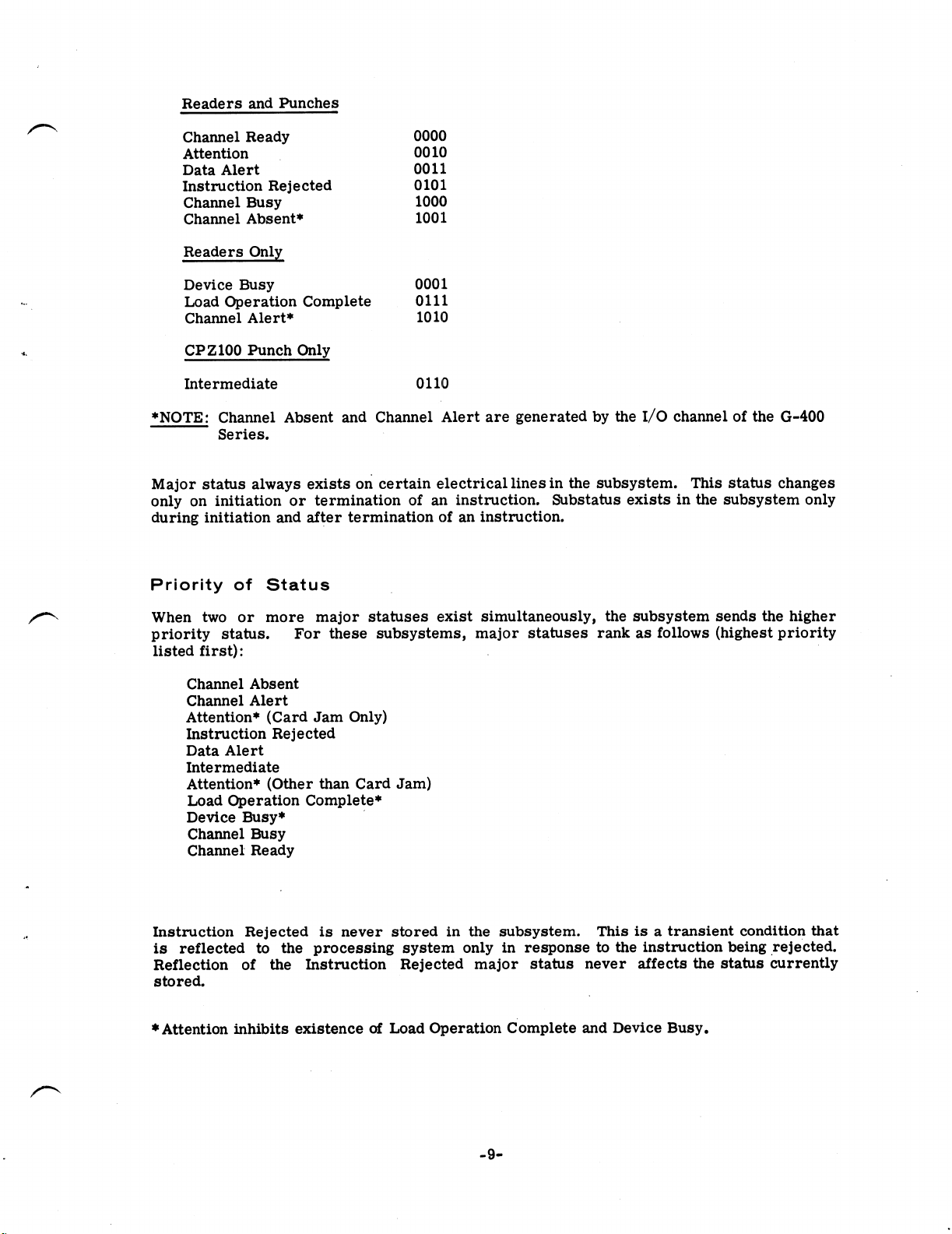

/A\

Readers

and

Punches

Channel

Ready

0000

Attention

.

0010

Data

Alert

0011

Instruction

Rejected

0101

Channel

Busy

1000

Channel

Absent*

1001

ReadersOnly

Device

Busy

0001

Load

Operation

Complete

0111

Channel

Alert*

1010

CPZlOO

Punch

Only

Intermediate

0110

*NOTE:

Channel

Absent

and

Channel

Alert

are

generatedbythe

I/O

channelofthe

G-400

Series.

~

Major

status

always

existsoncertain

electrical

linesinthe

subsystem.

This

status

changes

only

on

initiation

or

termination

of

an

instruction.

Substatus

existsinthe

subsystem

only

during

initiation

and

after

terminationofan

instruction.

Priority

of

Status

When

two

or

more

major

statuses

exist

simultaneously,

the

subsystem

sends

the

higher

priority

status.

For

these

subsystems,

major

statuses

rankasfollows

(highest

priority

listed

first):

.

'

Channel

Absent

Channel

Alert

Attention*

(Card

Jam

Only)

Instruction

Rejected

Data

Alert

Intermediate

Attention"

(Other

than

Card

Jam)

Load

Operation

Complete*

Device

Busy*

’

Channel

Busy

Channel

Ready

Instruction

Rejected

is

never

stored

in

the

subsystem.

Thisisa

transient

condition

that

is

reflected

to

the

processing

system

only

in

responsetothe

instruction

being

rejected.

Reflection

of

the

Instruction

Rejected

major

status

never

affects

the

status

currently

stored.

‘

*Attention

inhibits

existenceofLoad

Operation

Complete

and

Device

Busy.

-9-

Page 19

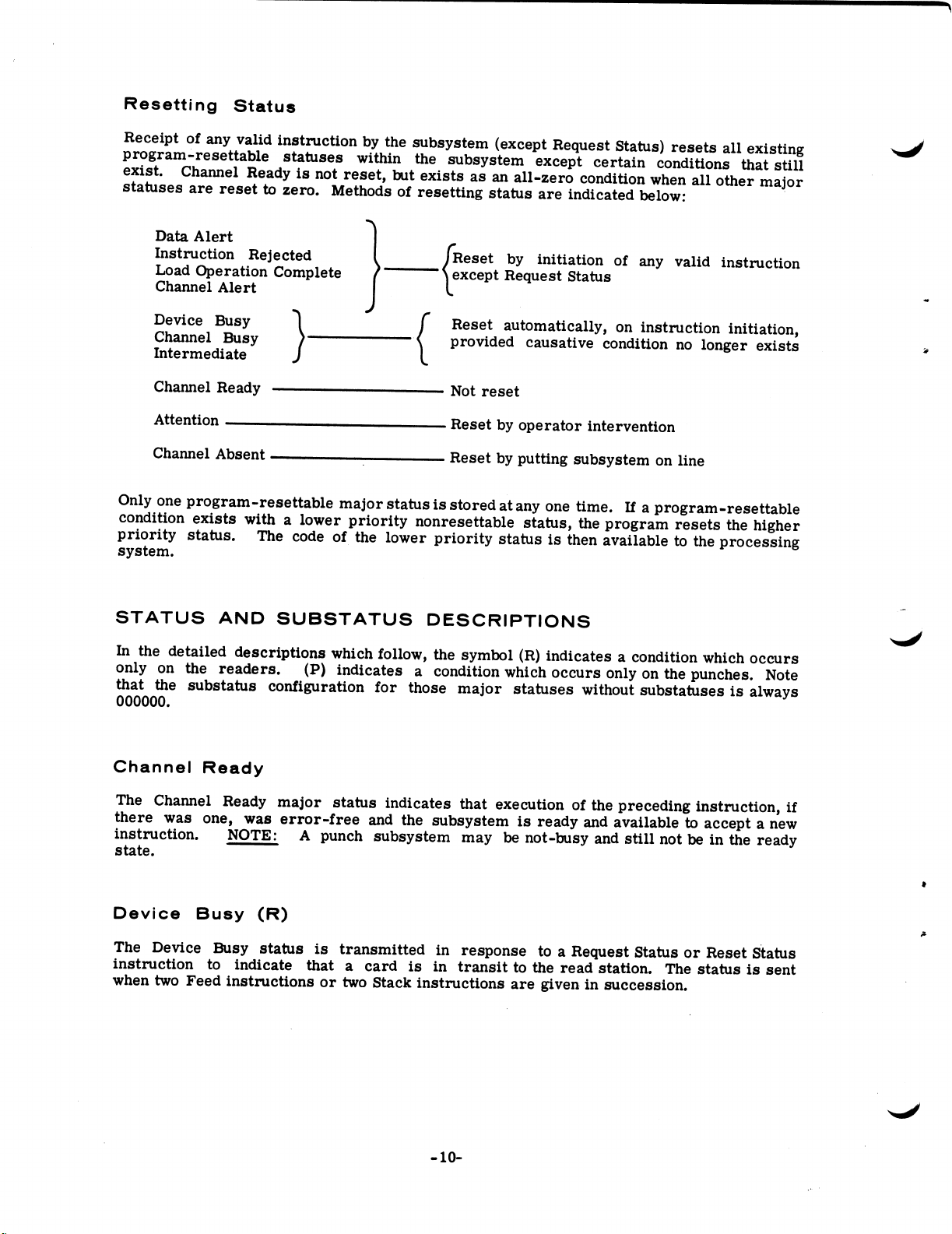

Resetting

Status

Receipt

of

any

valid

instruction

by

the

subsystem

(except

Request

Status)

resets

all

existing

program-resettable

statuses

within

the

subsystem

except

certain

conditions

that

still

exist.

Channel

Ready

is

not

reset,

but

exists

as

an

all-zero

condition

when

all

other

major

statuses

are

reset

to

zero.

Methods

of

resetting

status

are

indicated

below:

'

Data

Alert

Instruction

Rejected

Reset

by

initiation

of

any

valid

instruction

Load

Operation

Complete

except

Request

Status

Channel

Alert

Device

Busy

Reset

automatically,

on

instruction

initiation,

Channel

Busy

'

provided

causative

condition

no

longer

exists

Intermediate

Channel

Ready

Not

reset

Attention

Reset

by

operator

intervention

Channel

Absent

_

Reset

by

putting

subsystem

on

line

Only

one

program-resettable

major

status

is

stored

at

any

one

time.

If

a

program-resettable

condition

exists

with

a

lower

priority

nonresettable

status,

the

program

resets

the

higher

priority

status.

The

code

of

the

lower

priority

status

is

then

available

to

the

processing

system.

STATUS

AND SUBSTATUS

DESCRIPTIONS

In

the

detailed

descriptions

which

follow,

the

symbol

(R)

indicates

a

condition

which

occurs

only

on

the

readers.

(P)

indicates

a

condition

which

occurs

only

on

the

punches.

Note

that

the

substatus

configuration

for

those

major

statuses

without

substatuses

is

always

000000.

Channel

Ready

The

Channel

Ready

major

status

indicates

that

execution

of

the

preceding

instruction,

if

there

was

one,

was

error-free

and

the

subsystem

is

ready

and

available

to

accept

a

new

instruction.

NOTE:

A

punch

subsystem

may

be

not-busy

and

still

not

be

in

the

ready

state.

Device

Busy

(R)

The

Device

Busy

status

is

transmitted

in

response

to

a

Request

Status

or

Reset

Status

instruction

to

indicate

that

a

card

is

in

transit

to

the

read

station.

The

status

is

sent

when

two

Feed

instructions

or

two

Stack

instructions

are

given

in

succession.

-10-

Page 20

Attention

The

subsystem

sends

the

Attention

major

status

to

indicate

that

an

inoperable

condition

exists

that

requires

operator

correction.

The

subsystem

rejects

subsequent

instructions,

with

one

exception,

with

this

return

until

the

condition

is

corrected

and

the

logic

is

manually

reset.

However,

if

the

Attention

status

transmitted

at

terminate

time

was

caused

by

a

Hopper/

Stacker

Alert,

a

Manual

Halt,

the

Last-Batch,

condition,

or

a

Read

Alert

(all

described

below),

the

reader

can

accept

a

Stack

instruction

and

stack

the

card

for

which

the

respective

Terminate

signal

was

given.

One

or

more

substatuses

always

occur

with

the

Attention

major

status.

Unless

otherwise

noted

in

the

descriptions

below,

when

an

Attention

condition

is

detected

during

the

Channel

Busy

condition,

the

busy

stateisnot

terminated

until

normal

termination

time.

This

allows

cardsintransittobe

processed

before

feeding

halts.

The

substatuses

that

can

occur

with

the

Attention

major

status

are

described

below.

The

binary

code

for

each

substatusisshowninparentheses.

HOPPER/STACKER

ALERT

(xxxxxl)--Occurs

when

the

input

hopper

is

emptyorthe

output

stacker

is

full.

(See.

Appendix

A

for

additional

conditions

which

may

cause

this

conditiononthe

CRZZOI

Reader.)

MANUAL

HALT

(xxxxlx)--Occurs

when:

1.

The

MANUAL

HALT.

pushbutton

on

the

operator’s

control

panelisactuated.

2.

Poweristurnedonby

the

POWER

ON

pushbutton.

3.

The

field

engineer

goes

from

the

off-line

test

modetothe

on-line

mode.

4.

(P)

Blank

cards

have

not

been

loaded

into

the

prepunch

stations.

LAST

BATCH

(R)

(xxx1x1)--Occurs

when

the

input

hopper

goes

empty

while

the

LAST

BATCH

controlisin

theonstate.

FEED

ALERT

(OxlxnguOccurs

whenacard

failstofeed

from

the

hopper

into

the

card

trackinresponsetoa

FeedorPunch

instruction.

CARD

JAM

(x1xxxx)--Occurs

when

the

progress

ofacardonthe

card

track

becomes

impeded

to

the

poinTthat card

feeding

cannotbesuccessfully

completed.Ifthe

subsystem

is

in

the

Channel

Busy

state

at

this

time,

the

subsystem

interrupts

the

current

Operation

and

terminates

the

instruction

being:

executed.

If

the

subsystem

was

notinthe

Channel

Busy

stateattimeofdetecting

the

card

jam,

the

subsystem

revertstothe

Attention

condition

and

rejects

further

instructions

with

this

status.

On

detection

of

a

card

jam,

the

electrical

power

starts

cycling

down.

Note

that

Card

Jam

overrides

any

other

existing

statusinthe

subsystem.

-11-

Page 21

If

the

processing

system

recognized

the

last

data

character

sent

from

a

reader,

the

subsystem

sends

a

Terminate

signal.

If

the

card

reader

has

sent

a

character

that

was

not

recognized,

no

Terminate

signal

is

sent.

READ

ALERT

(R)

(1x0xxx)--Occurs

upon

failure

of

any

card

check

(light

check,

dark

check,

column

strobe

count

check,

or

internal

parity

check)

made

at

the

read

station

during

card

reading

time.

SNEAK

FEED

(R)

(lexxx)--Occurs

when

a

card

is

fed

without

the

reader

having

received

an

instruction

to

feed.

No

data

is

transmitted

from

the

card.

No

Terminate

signal

is

sent.

CHAD

BOX

FULL

(P)

(0xx1xx)--Occurs

when

too

much

chad

has

accumulated

and

chad

box

must

be

emptied

before

punching

can

continue,

or

the

chad

box

is

not

present.

Data

Alert

The

subsystem

returns

the

Data

Alert

major

status

to

the

processing

system

to

indicate

that

some

type

of

error

or

alert

condition

was

detected

during

the

processing

of

a

card.

One

or

more

of

the

substatuses

always

occur

with

Data

Alert.

Occurrence

of

a

Data

Alert

condition

does

not

cause

termination

of

the

Channel

Busy

condition.

The

operation

in

progress

is

allowed

to

come

to

its

normal

termination.

The

substatuses

that

can

occur

with

Data

Alert

are

described

below:

TRANSFER

TIMING

ALERT

(R)

(000001)--Occurs

when

the

card

reader

data

buffers

become

filled,because

the

processing

system

has

failed

to

recognize

a

transmitted

character,

or

it

can

mean

that

the

processing

system

has

not

accepted

all

characters

read

from

a

card

by

the

time

the

card

clears

the

read

station.

Transfer

of

data

to

the

processing

system

is

immediately

stopped,

but

the

Channel

Busy

state

is

not

terminated

until

card

reading

is

completed

and

all

checks

are

made.

TRANSFER

TIMING

ALERT

(P)

(000xx1)--Occurs

whenever

the

time

arrives

for

the

punch

dies

to

be

actuated

but

the

punch

has

not

yet

received

all

of

the

required

data.

The

Operation

terminates.

VALIDITY

ALERT

(R)

(000x10)--Occurs

when

the

subsystem

detects

an

invalid

character

while

reading

an

alphanumeric

card.

The

subsystem

sends

an

Ignore

character

(octal

17)

in

place

of

the

invalid

configuration

from

the

card

column.

Reading

continues

until

normal

termination

time;

then

the

subsystem

sends

the

substatus

and

the

Terminate

signal.

TRANSMISSION

PARITY

ALERT

(P)

(000x1x)--Occurs

whenever

a

parity

error

is

detected

on

the

data

characters

received

for

punching.

Operation

terminates.

-12-

Page 22

DUAL

READ

ALERT

(R)

(0001x0)--Occurs

when

the

two

outputs

of

the

dual

read

head

do

not

meet

the

compare

test

for

a

card

column.

In

the

binary

mode

of

Operation,

the

subsystem

transmits

two

Ignore

characters

in

place

of

thetwo

characters

in

the

card

column.

In

the

alphanumeric

mode,

the

subsystem

transmits

one

Ignore

character

in

place

of

the

Hollerith

character

in

the

card

column.

The

subsystem

continues

reading

the

card

and

sends

the

Data

Alert

at

normal

termination

time.

PUNCH

ALERT

(P)

(OOlex)--Occurs

whenever

the

row

parity

accumulated

from

the

read

Ration

does

not

agree

with

that

previously

established

when

the

data

entered

the

card

image

buffer

in

the

controller.

After

the

Punch

Alert

substatus

and

Data

Alert

status

information

has

been

transmitted,

the

punch

sendsaTerminate

signal.

Since

the

punch

check

is

made

by

the

read

head

while

the

following

cardisbeing

punched,

a

punch

alert,

if

there

is

one,

concerns

not

the

card

just

punched,

but

the

card

just

read

and

entering

the

stacker.

The

last

card

tobepunchedatany

time,

regardlessofwhetheritis

the

last

data

cardora

blank

card

following

the

data

deck,

is

automatically

transported

through

the

read

station

and

punch-checked.

The

only

indicationofa

punch

alertonthis

cardisthe

illumination

of

the

PUNCH

ALERT

indicatoron

the

operator’s

controlpanel.

Whenablank

cardisprovided

by

the

program,apunch

alert

on

the

last

data

cardisindicatedbyprogrammed

typeout;

but

a

punch

alert

on

the

blank

card

is

indicated

onlybythe

PUNCH

ALERT

indicator.

NO

READ

INSTRUCTION

(R)

(001000)--Occurs

whenacardisfedasthe

resultofa

Feed

instruction

and

enters

the

read

station

before

aRead

instructionisreceivedbythe

subsystem.

No

dataistransmitted

from

thecard.

Instruction

Rejected

The

subsystem

transmits

the

Instruction

Rejected

major

statustoindicate

that

the

received

instructionisbeing

rejected.

Oneofthe

following

substatuses

occuronthe

readertoshow

why

the

instructionisrejected.

Note

that

only

one

substatus

can

occuratany

time.

No

substatus

occursonthe

punch

subsystems.

INVALID

OPERATION

COD/E

(R)

(000001)--Occurs

when

the

operation

codeisnot

recog-

nizable

for

any

reason,

includingaparity

error.

NO

CARD

COMMITTED

(R)

(000010)--Occurs

whenaStack

instructionisreceived

when

no

card

isintransittothe

stacker.

The

substatusisreflected

onlytoStack

instructions.

LATE

READ

INSTRUCTION

(R)

(000100)--Occurs

when

a

Read

instruction

is.received

after

the

card

has

entered

the

read

station.

This

substatusisreflected

onlytoRead

instructions.

-13-

Page 23

Load

Operation

Complete

(R)

The

reader

returns

the

Load

Operation

Complete

major

status

to

indicate

the

termination

of

a

successful

program

load

operation.

Intermediate

(P)

(CPZ1OO

only)

The

Intermediate

major

status

indicates

that

the

punch,

although

not

currently

engaged

in

data

transfer

or

in

actual

punching,

is

not

at

the

end

of

the

card.

It

has

finished

punching

a

row

(other

than

the

9-row)

without

encountering

an

alert

condition

and

is

awaiting

the

instruction

to

punch

the

next

row

of

data.

This

status

is

always

automatically

set

between

rows.

Channel

Busy

The

subsystem

transmits

the

Channel

Busy

major

status

to

indicate

that

it

is

processing

a

card

and

receiving

or

transmitting

data.

Channel

Absent

The

1/0

channel

circuitry

of

the

Series

400

generates

the

Channel

Absent

major

status

to

indicate

that

the

processing

system

cannot

communicate

with

the

subsystem.

Reasons

can

be

that

the

subsystem

is

disconnected,

without

power,

or

absent.

Channel

Alert

(R)

The

1/0

channel

circuitry

of

the

Series

400

generates

the

Channel

Alert

major

status

to

indicate

that

during

the

card

reading

operation

just

ended,

the

processing

system

received

a

character

with

incorrect

parity.

CARD

READER

INSTRUCTIONS

The

General

Electric

card

readers

are

capable

of

executing

both

Operational

and

non-

operational

instructions.

A

6-bit

operation

code

in

the

instruction

informs

the

reader

of

the

operationtobe

performed.

Operation

Code

Function

000000

Sends

the

code

for

the

existing

statusofthe

subsystemtothe

processing

system.

000001

Reads

one

cardinthe

binary

mode.

000010

Reads

one

card

in

the

alphanumeric

mode.

000011

'

Reads

one

cardinthe

mixed

mode.

-14..

Page 24

Operation

COde

FunCtion

100000

Resets

all

resettable

statusesinthe

subsystem

and

sends

the

remaining

status

to

the

central

processor.

100100

Feeds

one

card

from

the

h0pper.

Operational

Instructions

An

on-line‘

instruction

is

one

whose

execution

requires

the

card

readertobeinthe

busy

state.

~

These

instructions

are:

Read

Card

Binary

Read

Card

Alphanumeric

Read

Card

Mixed.

INSTRUCTION

INITIATION.

When

the

card

reader

receives

any

oneofthese

three

instructions,

the

resettable

status

conditions

are

reset.

Major

status

then

either

indicates

the

card

reader

has

become

busyasa

resultofaccepting

the

instructionorthe

instruction

has

been

rejected.

If

the

instructionisrejected,

the

following

major

status

conditions

are

reflected:

Attention

Instruction

Rejected

.

INSTRUCTION

EXECUTION.

The

card

reader

completes

the

instruction

sequence

and

then

begins

execution

of

the

instruction

by

feeding

the

card

from

the

hopper

onto

the

card

track.

The

reader

goes

into

the

modeofoperation

indicatedbythe

instruction.

0

If

the

instruction

is

to

readabinary

card,

the

card

reader

goes

into

the

binary

mode

of

operation

and

handles

each

column

as

containing

two

binary

charactersofdata.

0

If

the

instruction

is

to

readacard

punchedinthe

Hollerith

format,

the

card

reader

goes

into

the

alphanumeric

mode

of

operation

and

handles

each

column

as

containing

only

one

characterofdata.

0

If

the

instruction

is

to

readacardinthe

mixed

modeofoperation,

the

card

reader

looks

for

the

identifying

7

and9punches

in

column1to

indicate

that

the

cardisto

be

read

in

the

binary

mode;ifthere

areno7

and9punches,

the

cardisreadinthe

alphanumeric

mode.

-15-

Page 25

INSTRUCTION

TERMINATION.

If

the

card

reader

successfully

executes

the

read

instruction

just

received

and

no

errors

or

inoperable

conditions

have

occurred,

when

the

Terminate

Signal

is

transmitted,

one

of

the

following

major

status

conditions

will

also

be

sent:

Channel

Ready

Load

Operation

Complete.

,

If

an

error

or

inoperable

condition

did

occur

after

the

card

reader

accepted

an

instruction

and

began

executing

it,

status

sent

at

the

time

of

the

Terminate

signal

will

be

one

of

the

following:

Data

Ale

rt

Attention

Appropriate

substatus

information

is

also

transmitted.

Rereading

of

the

card

may

be

attempted.

If

the

program

calls

for

data

from

only

part

of

the

card,

the

card

reader

receives

an

End

Data

Transfer

signal

when

all

the

desired

information

has

been

transmitted.

The

card

reader

remains

busy

and

continues

reading

the

rest

of

the

card,

but

none

of

the

remaining

data

is

transferred.

When

the

physical

end

of

the

card

is

reached,

the

Terminate

signal

is

sent,

along

with

the

appropriate

status

information.

No-op

Instructions

Request

Status

and

Reset

Status

are

instructions

which

do

not

directly

involve

media

or

imply

media

movement.

Thus,

these

instructions

do

not

require

the

card

reader

to

go

into

the

busy

state.

REQUEST

STATUS

INSTRUCTION.

When

the

card

reader

receivesaRequest

Status

instruction,

it

transmits

major

status

signals

identifying

the

following

various

conditions

which

may

exist:

Channel

Ready

Attention

Data

Alert

Load

Operation

Complete.

AlthoughaRequest

Status

instruction

may

be

rejectedbythe

card

reader,

the

status

shown

as

the

result

of

an

accepted

Request

Status

instruction

will

never

include

the

Instruction

Rejected

condition.

The

Instruction

Rejected

major

statusisreturned

onlyinresponse

to

the

specific

instruction

which

was

rejected

and

does

not

reflect

the

existing

stateofthe

card

readeratthat

time.

'

The

Request

Status

instruction

does

not

cause

any

status

conditionstobe

reset;

and

status,

therefore,

remains

unchangedbythis

instruction.

‘

-16-

Q!

Page 26

I'

Since thereisno

execution

sequencetoperforminreSponsetothe

Request

Status

instruction,

as

soonasthe

instruction

sequence

has

been

completed,

the

card

reader

returnstothe

ready

state.

RESET

STATUS

INSTRUCTION.

A

Reset

Status

instructionisone

methodbywhich

card

reader

status

canbereset

(see

the

explanationonresetting

status

under

“Status

Information”

in

the

preceding

pages

of

this

chapter).

It

causes

all

resettable

conditions--the

Data

Alert

substatuses

and

Load

Operation

Complete-40

be

reset.

Any

existing

status

conditions

not

resettable

by

this

instruction

are

reflected

in

the

major

status

code

configuration.

There

is

no

execution

sequence

with

the

Reset

Status

instruction,

consequently,assoon

as

the

instruction

sequenceiscompleted,

the

card

reader

returnstothe

ready

state.

CARD

"PUNCH INSTRUCTIONS

The

control

electronicsofthe

card

punches

recognize

and

accept

the

following

instructions.

Depending

on

whether

the

punch

has

an

80-character

row

bufferora

card

image

buffer,

a

single

punch

instruction

punches

one

row

oranentire

card,

one

rowata

time.

Operation

Code

.

Function

000000

Sends

the

code

for

the

existing

statusofthe

sub-

systemtothe

processing

system.

001001‘

Punches

one

row/

cardinthe

binary

mode.

001010

Punches

one

row/

cardinthe

alphanumeric

mode.

001011

Punches

one

row/

cardinthe

edited

alphanumeric

mode.

100000

Resets

all

resettable

statuses

in

the