Page 1

Controller Designer Software

Specifications

51

-52-03-43, November 2019

Description

Controller Designer software for the ControlEdge HC900

Controller is an easy-to-u se Windows-ba sed applic at io n

that is operable over Ethernet, a serial port or modem

connection to simplify controlle r configur ation. Designer

software supported in Engli sh and M andarin lan gua ge.

When used with the C70 series CPUs with dual Ethernet

capability, Controller Designer software supports

verification of both communication ports and may be used

with either port.

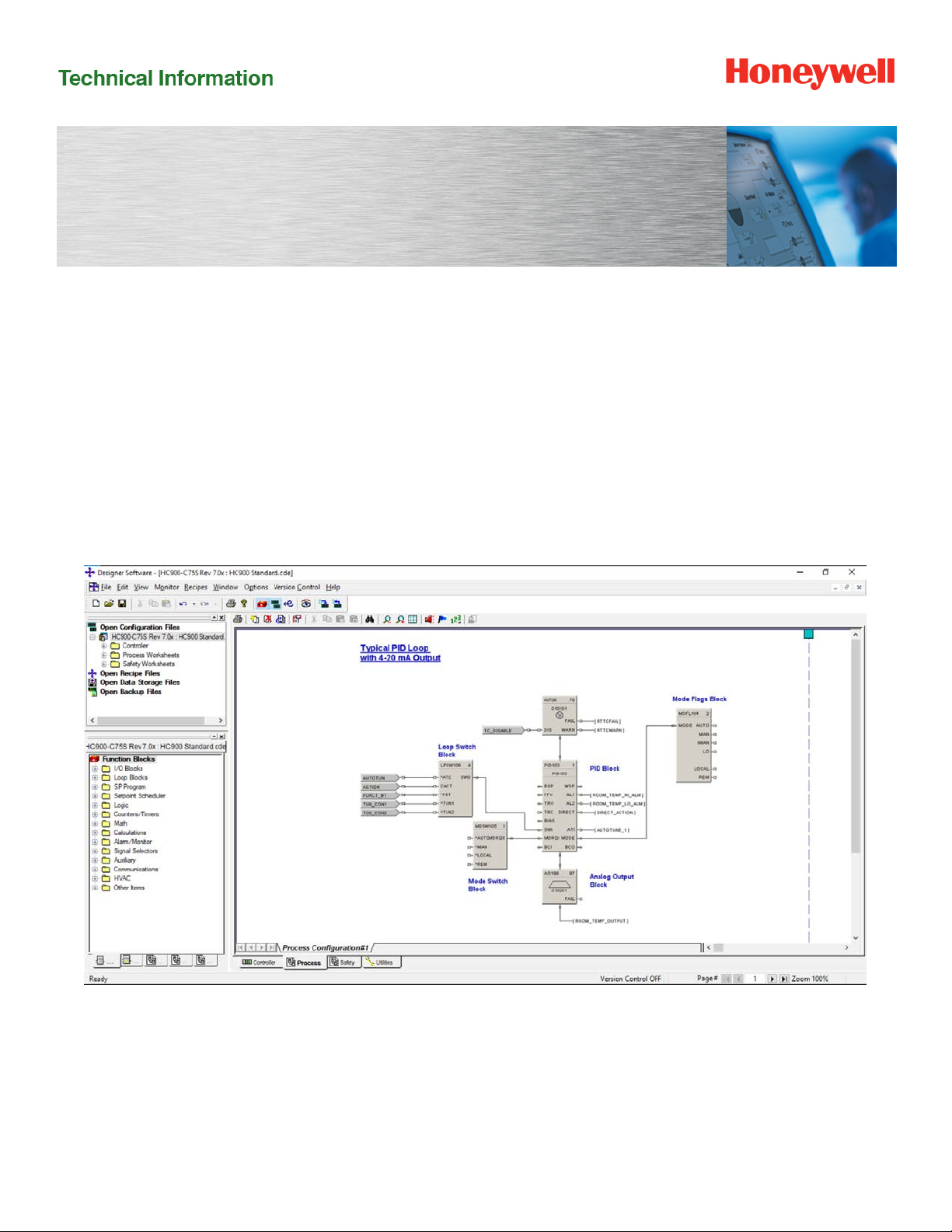

Figure 1 - Controller Designer Software

It provides advanced monitoring functions for debug,

allows RUN/PGM-mode configuration changes, uploads

the complete, annotated graphic controller control

strategy, plus supplies an array of reports for enhanced

documentation.

Page 2

Features

• Graphic drag and drop, soft-wire configuration

• Supports configuration edit downloads in RUN

mode

• Version Control System

• User Library Creation

• Configures:

Controller

Peer-to-peer data exchange (Peer and

safety peer communication)

Recipes, SP profiles,

SP Schedules, Sequences

Alarms, events, e-mail alarms/event s

Modbus Serial and Modbus TCP

Master communications

• Graphic function block configuration and

annotations

• Allows graphic configuration partitioning for

Process and Safety

• Extensive on-line monitoring features including:

User defined and pre-def ined watch

windows

Power flow indication

Function block pin values

Multiple function block access

Signal trace-back to source

• 5 Zoom levels for detail viewing

• On-line diagnostic windows for analyzing

controller, I/O, network host and controller peer

connections

• Supports Ethernet, RS 485 direct connection to

access controller

• Supported OS:

Windows™ 7 (32 and 64 bit OS)

Windows™ 8.1 (32 and 64 bit OS)

Windows 10 (32 and 64 bit OS)

The ControlEdge HC900 Controller Designer provides

separate functional tabbed worksheets for:

• Controller hardware setup

• 559 Operator interface setup

• Function block configuration for Process

• Function block configuration for Safety

• Utilities, communication ports setup and other

diagnostic support.

• Custom Modbus Map

The user-friendly graphic function block development

environment allows partitioning of the control strategy into

up to 160 (40 for version below 6.6) “worksheets” of 20

pages each.

This allows the configuration to be organized according to

Process and Safety fun ction, providing faster

configuration access, and improved documentation. In

addition, OEMs may apply additional security to specific

worksheets to prohibit access to proprietary operations

while allowing their customers to modify unprotected

worksheets. For maximum security, the default password

access feature for worksheets may be disabled.

Function Blocks are selected from a categorized list,

dropped on a selected worksheet page, and soft-wired to

other blocks directly or via tag references. Index numbers

allow users to read or write data within the block when

the data type is not brought to an output pin of the object.

Editing tools such as box copy and paste speed

development. You may also copy and paste portions of

strategies from other configurations. The Undo feature

provides a convenient method to reverse incorre ct or

undesired actions.

Configuration Management

The controller configuration file may be imported directly

into Station Designer software for configuring 900 Control

Station operator interfaces. Maintaining controller and

operator interface configuration files that match the actual

configuration being executed in the controller is a simple

task with Controller Designer’s configuration upload

capability. When a PC with Controller Designer software

is in communication with the controller, the Upload

feature reads the configuration from the controller’s

memory and back-builds an exact configuration file in the

PC, including all text annotations used to describe

functional areas. This file can then be saved to disk as a

back-up and downloaded when needed to simplify

maintenance.

New versions of Controller Designer software may be

used to develop configurations for older controller

versions. Configurations developed for early firmware

versions of ControlEdge HC900 Controllers are

automatically converted to be compatible with newer

controller versions when saved as the desired version

level. All controllers in the ControlEdge HC900 product

line are supported with the same software. Configurations

developed with Control Builder software version 5.0 for

UMC800 Controllers may also be converted for use with

ControlEdge HC900 controllers.

Page 3

Configuration Edits-RUN Mode

Configuration changes such as block additions or

substitutions and soft-wiring can be transferred to the

controller during the RUN/PRGM mode, avoiding

initialization. All outputs and status are held during a

minimal transfer time after which processing continues at

the start of a scan. Changes with I/O module updates

require additional time. The amount of time the outputs

will be held, typically several seconds, is presented to the

user at the time of download along with options to

proceed.

Configuration changes downloaded to the controller while

the controller is in the Program mode, or if cold start is

selected while in the Run mode, all controller outputs are

turned off and a re-initialization of the controller database

is executed.

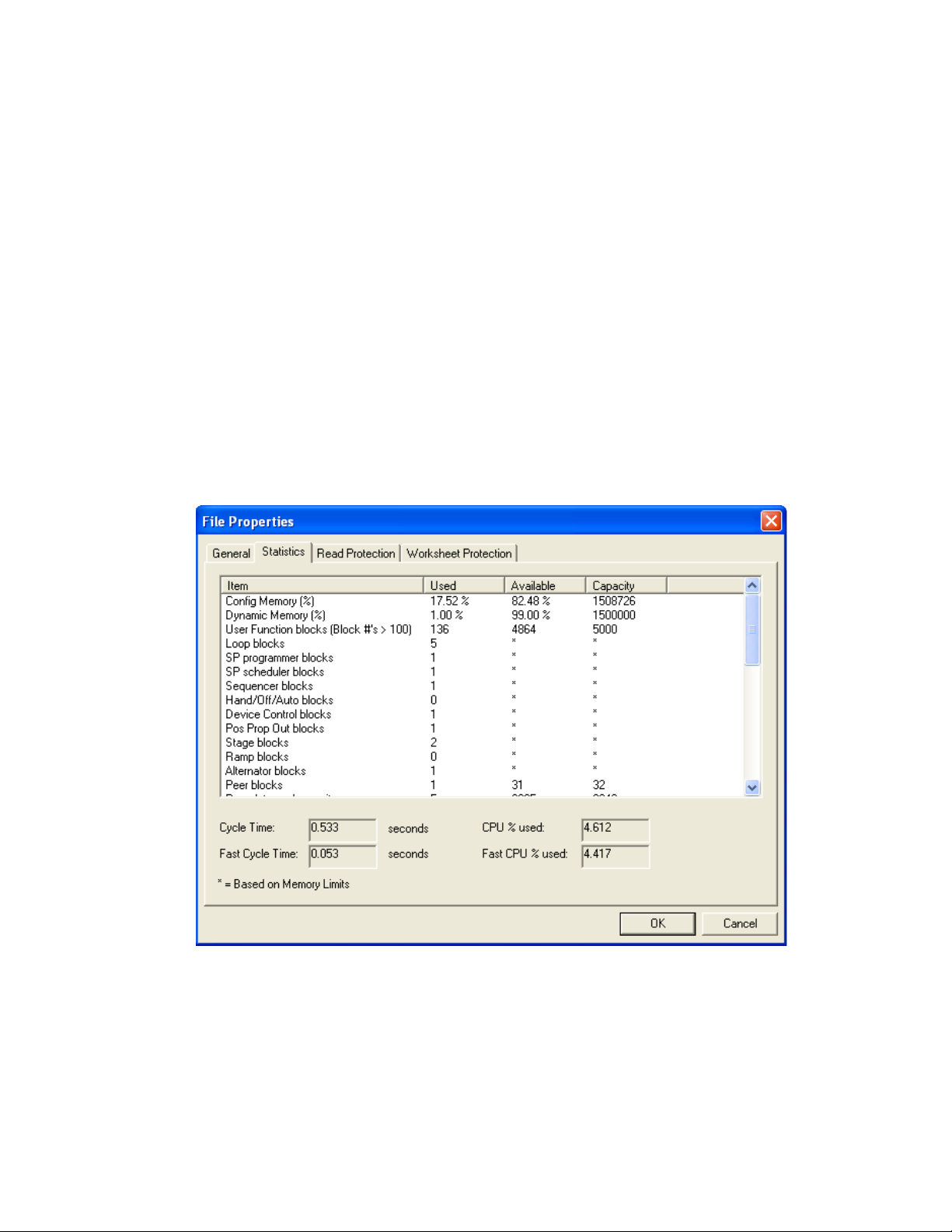

Configuration File Properties

Configuration file properties are maintained during

configuration development ide ntify ing the date of initial

file creation and the date of the last file modifi cati on.

Areas are provided to include a configuration name and

the name of the author. During configuration, a Statistics

summary (Figure 2) indicates the amount of controller

resources used by the configuration and the amount of

resources available. Security is provided via password

entry to limit access to the entire configuration or to only

user specified configuration wor ksheets.

Figure 2 - File properties

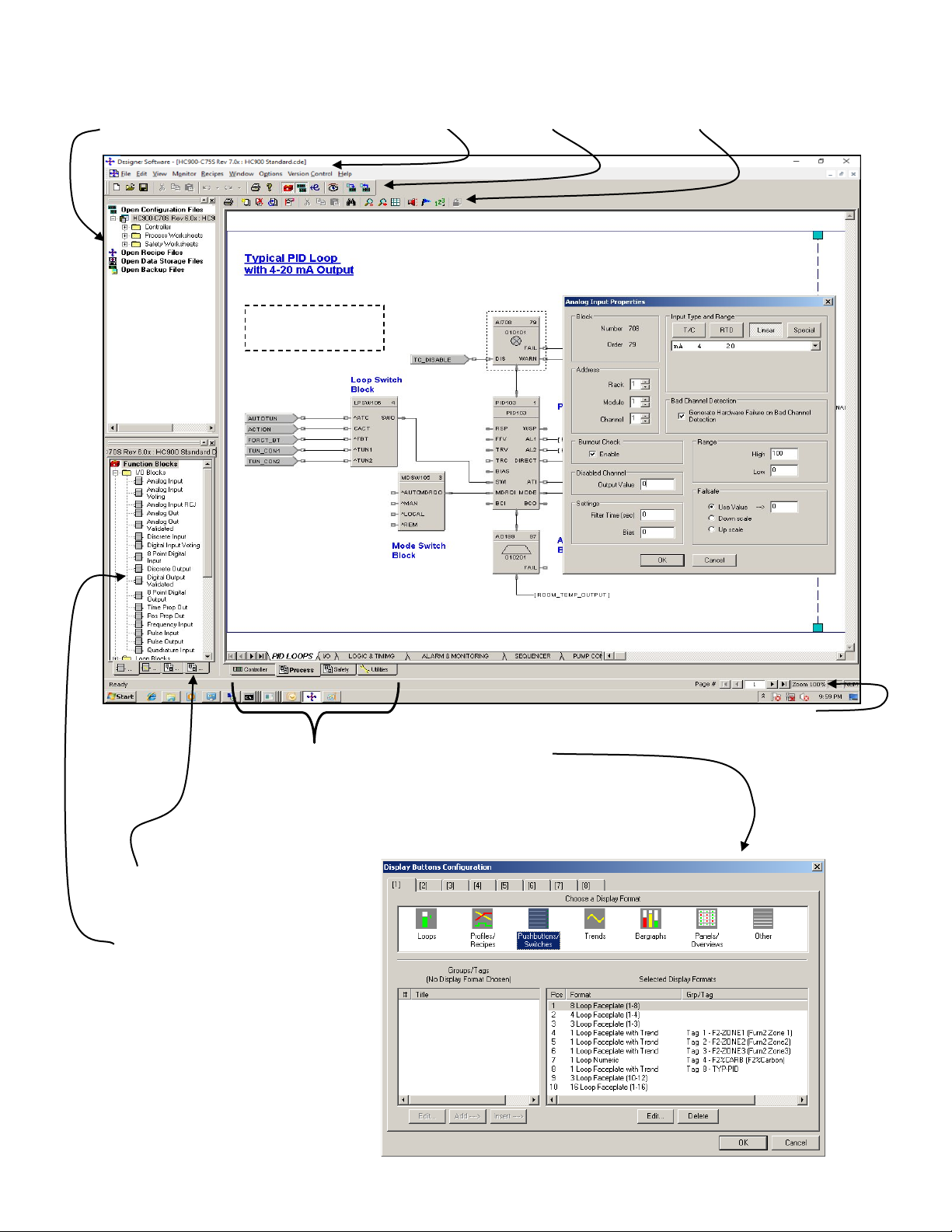

Page 4

File Browser shows all open files (configurations,

Main Menu

Main Tool Bar

Function-related Tool Bar

Config tab lists all configured blocks,

Status Bar

Functional Tabs (left to right) (see page 20 for details):

Double-click on

Edit mode Overview

recipes, data storage, and backup)

block for properties

Controller - lists I/O used, e-mail alarms

Display - format select, tag assignment , F-key assignment (limited to versions prior to 6.0)

Function Blocks - graphic configuration (shown above)

Modbus Map – shows custom Modbus addresses

Utilities - setup for ports, data storage, time, calibration and diagnostics

click on any block to find.

Worksheet Toolbox lists available

Function Blocks and software tools,

categorized by tabs Normal/Fast Scan &

by block type.

Page 5

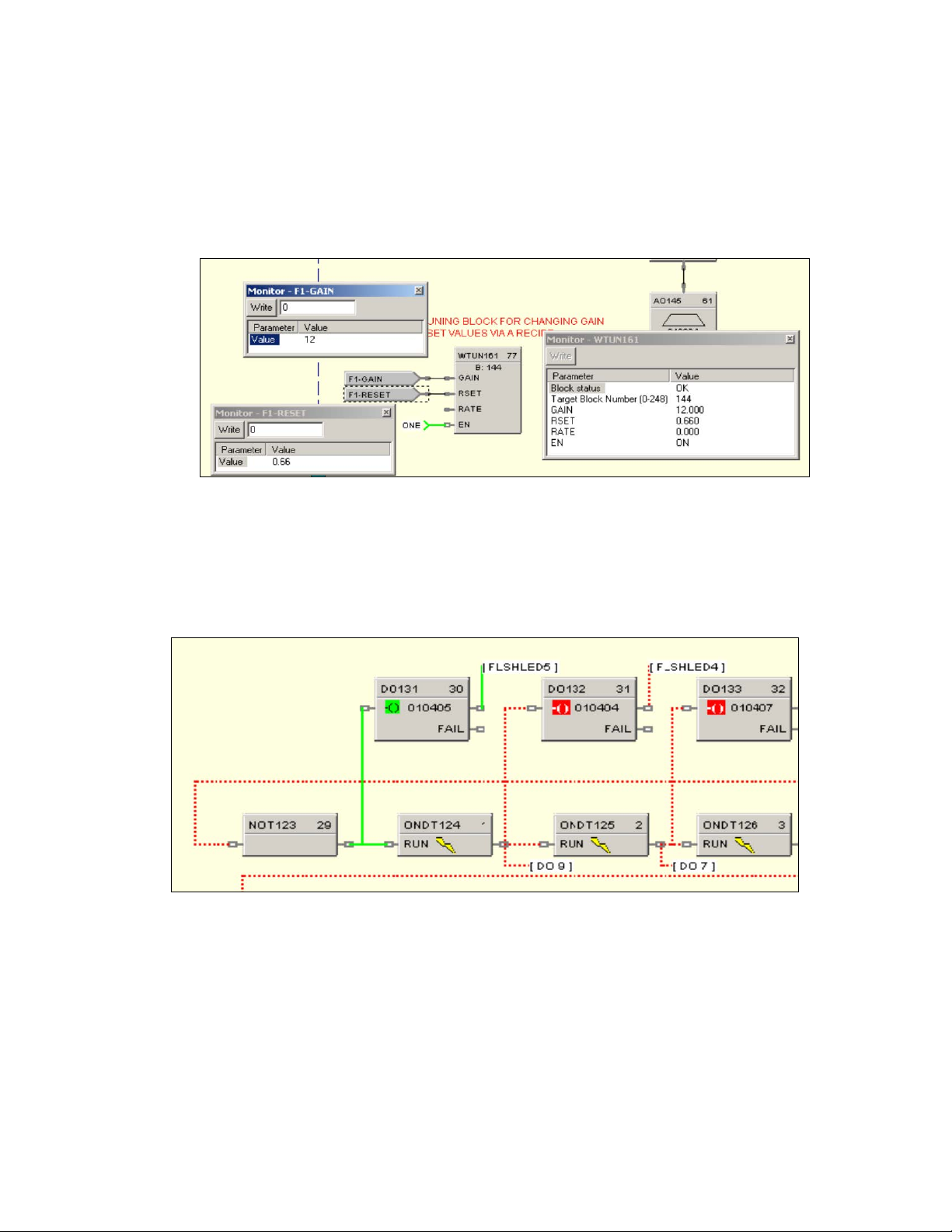

On-Line Monitoring Features

Controller Designer on-line monitoring tools allows quick analysis of configuration problems. Tools include:

1. Multiple function block monitor access on a single display from multiple worksheets. Most internal

parameters are available for read/write plus block outputs may be forced including I/O and logic blocks. Principle

blocks such as PID, Setpoint Programmer and Sequencers have dialog boxes to allow operation and test. Stored

profiles or sequences may also be selected on-line.

Figure 3 - Multiple function block monitoring

2. Logic Power Flow indication. You can choose solid green = ON/dotted red = OFF or solid red = ON/dotted green

= OFF to indicate power flow.

Figure 4 - Logic power fl ow

Page 6

On-Line Monitoring Features (cont’d)

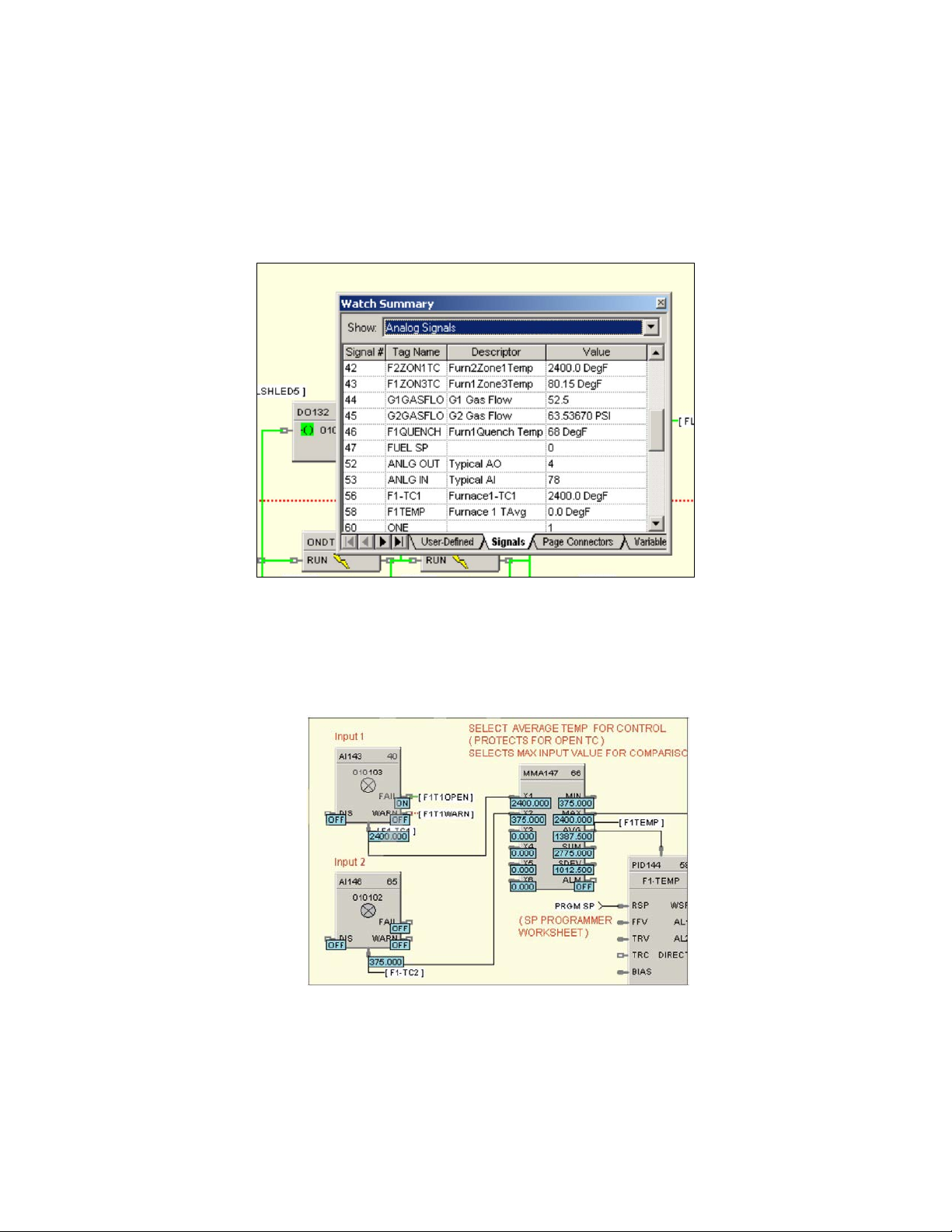

3. User-selected Watch Window. Allows access to digital and analog I/O, Signal Tags, Variables), and custom

display data groups by tab selection. A custom Watch Window may also be created by selecting parameters from

the configuration diagram. Write capability from Watch Windows is supported. Variables on the safety worksheet

must be enabled and restricted to non-critical safety functions for writing while operating in the safe mode. Writes

are then enabled utilizing the associated Write Variables function (WVAR) located on the process worksheet.

Figure 5 - User defined watch window

4. Dynamic function blocks input and output values. Provided when monitoring the function blocks of the

configuration diagram, the dynamic value presentation may be limited to a single pin, a single function block, or it

may encompass the entire display window.

Figure 6 - Dynamic function block values

5. Signal Trace-back for any function block input. Used to find the signal source for quick identification of potential

errors.

6. FIND. A FIND function allows location of multiple instances of specific tags across all worksheets.

Page 7

On-Line Monitoring Features (cont’d)

7. Recipe Management. A separate Recipe Management feature allows creating, editing, copying and exporting

recipes, profiles, schedules an d sequen ce s to allow transferr i ng th is infor mat ion between configurations and

controllers.

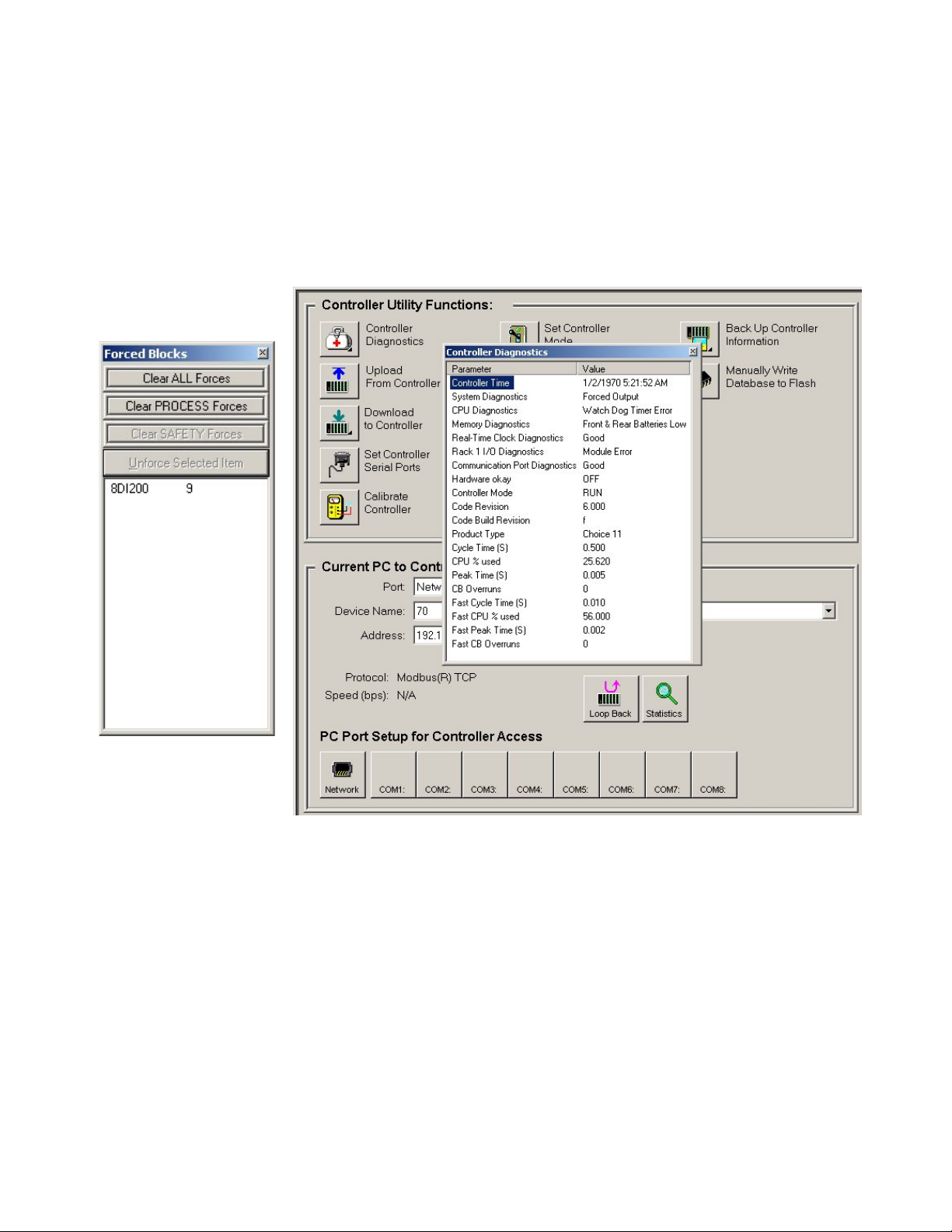

8. Diagnostic Monitoring. Provided in the Utilities section of the software to view controller status, I/O rack status

and communication port diagnostics sta tus for both serial and network ports. A search function to

locate/force/unforce function blocks is also provided.

Figure 7 - Forced blocks window (left), Diagnostic mon itor in g windo w

900 Control Station

When configuring 900 Control Station , the confi guration file from Controller Designer is imported into Station Designer

software to simplify database management when building displays. Database mismatches between the controller and

operator interface configurations are detected at run-time of the interface.

Page 8

Remote Access

Controller Designer software supports remote access to ControlEdge HC900 Controllers via Modem using Modbus Protocol

or Honeywell’s ELN Protocol. To support this function, an external modem must be connected to the serial port of the remote

controller. Controller Designer software provides a call ing lis t facility to simplify acce ss. Selecting Modem communications

from the Utilities tab and requesting a dial up operation provides the user with a calling list to access the appropriate

controller. Once communications is established, the configuration of the controller may be uploaded to the PC and edited or

monitored remotely.

Figure 9 - Remote access dialup

File Export for database transfer

When interfacing the ControlEdge HC900 controller to PC software programs or 3rd party operator interfaces, a time saving

service is provided to export tag and variable definitions in CSV or tab delimited formats. In addition, the Modbus addresses

of each configured data parameter may also be exported to a file.

Figure 10 - File Export

Page 9

Controller Designer Software Reports

Documenting your configuration is supported through a variety of report formats. Each can be print-previewed. A few of

these include a summary of the controller I/O used, function block worksheet selection (each page of diagram worksheet

printed as 8.5 x 11” sheet), function block properties, tag parameters, rec ipe lis ting s, set poi nt prof ile li stin gs, sequen cer

listings, setpoint scheduler listings, OI display groups, and controller setup. For signal tracing, a Where Used list is also

provided.

Figure 11 - Sample Where Used Report

Page 10

Version Control

The Version Control System provides capabilities to save changes made to the cde and non cde files over time and creates

repositories to manage differe nt versi ons.

This helps to manage, track, and compare differences between two revisions.

Page 11

Report summary

The report provides details of compared data between two files or versions. The data is classified and presented under

different categories such as Controller, Process, Safety, and Difference Summary. This report can be exported to Microsoft

Excel file and used for future references.

Paste special functionality

This window allows the user to find and replace text and add a prefix or suffix to the item names. This will help to maintain

consistency across the item names.

Page 12

Find and Replace

The Find and Replace feature allows the user to identify specific tags and replace them in all instances at the same time.

Library Functionality

This functionality helps to export a group of the control logic and thereby save to a location. These groups can be imported in

the worksheet whenever required. This saves time spent in recreating the control logics again. It is easy to share and reuse

by other users via the designer software.

Page 13

Help

Controller Designer provides extensive user help in the form of topical help information that may be accessed from the Help

selection on the main menu. Help information in this section cover subjects from how to get started to extensive detail on

each function block. See Figure 12.

Figure 12 - Topic help

Topic help specific to each function block is available. See Figure 13.

Figure 13 - Right-clicking on an AI block (L) to access its help (R)

Page 14

Help (Continued)

Popup help for entry fields is available. See Figure 14.

Figure 14 - Right-clicking on a recipe description to see its popup help

ControlEdge HC900 Controller Utilities Software

HC Utilities is a separate optional PC software application

that provides many of the user maintenance and

diagnostic functions of HC Designer software but restricts

configuration changes. This software is an ideal program

for OEMs and Integrators who wish to provide a

maintenance program to their customers without the risk

of unauthorized changes to the controller’s program.

Files created in HC Utilities for Recipes, and Data

Storage schedules may be loaded into the system via

serial communications, network communications.

The serial and network interface capabilities also allow

users to download new controller configurations or

perform equipment firmware upgrades.

Features include:

• Recipe development: (Variables, Setpoint

Profiles, Setpoint Schedules, Sequences)

• Data storage schedules

• Set controller communication ports

• Calibrate controller I/O

• Configuration reloads

• Firmware Upgrades

• View controller diagnostics

• Monitor controller configurations of unlocked

worksheets

Page 15

TABLE 1 – ControlEdge HC900 Controller Designer & Controller Utilities Software Specifications

Specifications

Design

PC Requirements Software runs on Windows™ 7 (32 & 64 bit OS) or Windows 10 (32 & 64 bit OS)

Minimum—Pentium Class 1.5 GHz with 1 GB of RAM (2.5 GHz with 4GB with multi core is

recommended for better performance)

Screen resolution – SVGA (1024x768 recommended) or better

Configuration (HC

Designer only)

Monitoring On-line monitoring allows user to test the developed configuration.

System

Interconnection

Modem PC Interface: Supports Microsoft Windows Telephony API (TAPI) device independent modem

Off-line configurations with optional on-line (Run mode) configuration download.

Connected to controller through its Ethernet 10/100 Base-T host ports, RS485 port.

Maximum Distance for Ethernet Connection: Not limited, per user network topology

Cable termination: RJ-45

communications. Baud rate = 1200 to 56.6KB selectable

Controller Interface: Connects to the controller configuratio n port . M ost commer c ial ly availa ble

modems with equivalent specifications to those validated should function with the ControlEdge

HC900 controller. The following modems have been validated: 3COM US Robotics 56K

Data/Fax External Modem, Zoom 56K Dual mode External Modem, Best Data 56SX Data Fax

External Modem

The modem must have the following capabilities:

• Auto answer

• Can operate at 1200 baud, 8 data bits, 1 stop bit, and no parity

• Hardware handshaking can be disabled

• Software handshaking can be disabled

• Data Terminal Ready (DTR) input can be disabled

• Result codes can be suppressed

• Echo can be disabled

• Must be equipped with non-volatile memory (NVRAM) so that settings that are

configured using command strings can be retained dur i ng a power-outage

• Must be able to load the NVRAM settings automatically on power-up

Page 16

TABLE 2 ControlEdge HC900 Controller Designer & Controller Utilities Software Functions

Controller CPUs

supported

Controller Firmware

Version Supported

Configuration File

Conversions

Recipe Development Recipes may be developed for Setpoint Profiles, Setpoint Schedules, Variables and

Data Storage

Schedules

C30, C50, C70 and C75

Software version number must be equal to or a higher number than the controller firmware

version number

Can convert between certain versions or CPU types.

Sequences.

Recipes may be stored as separate files, downloaded to a controller and/or printed for a hard

copy record.

Data Storage schedules in the controller may be developed using a dedicated type of function

block. Data files are accessed via communications using HC Historian software.

ControlEdge HC900 Supports History Backfill when used along with Experion HS

• Benefit: - Critical Data Protection and Compliance

• Target: - customers with critical data needs; aerospace manufacturing for complete

records of the complete manufacturing process, food & beverage where accurate data

on manufacturing and warehousing is required, pilot plants for accurate data retention

of processes for new product docu ment ati on, data ce ntr es .

• Secures critical customers from:

− Network outage or communication glit che s

− Experion HS server outages, shutdowns, MS updates

• At all other times, the Experion HS history database remains the master

• Backfills ONLY occur when plant data is missing

Security Password security may be applied to the entire configuration file and/or to individual

worksheets within a file. Default security may be disabled for worksheets.

Concurrent operation One instance of HC Designer or HC Utilities per PC at a time

Printing The following are available for printing: Controller (hardware and email assignments)

Function Block diagram (Process and/or Safety worksheets, block parameters, Modbus

registers, tags, where-used list, statistics)

Display (display settings, help screens, display key assignments, data storage schedule)

Recipes (variables, setpoint pr ofile s, setp oin t sche dule s, seq uenc es)

Alarm and Event groups

Export Files Format – CSV, Comma delimited or Tab delimited

Types: Controller – (I/O)

Function block Modbus Register Map

Function block tags

Recipes

Controller

maintenance

Calibration – Analog Input Modules

TC Cold junction

Analog Output Modules

Position Proportional Output function blocks

Set controller time

Serial Port setup

Perform controller firmware upgrades

Page 17

TABLE 3 Summary of ControlEdge HC900 Controller Designer & Controller Utilities Software Main Window Menu

Selections

Main Menu Selection Description

File • New: Provides dialog box

• Open: Opens an existing Controller Designer configuration.

• Close: Closes the active window.

• Save: Saves the active configuration.

• Save As: Can name the active configuration, select the target CPU type and revision and

select the directory where file is to be stored.

• Download: Alternate selection for download of saved configuration

• Upload: Alternate selection for upload of complete configuration in controller including

graphic pages, text annotations, stored recipes/profiles/schedules/sequences, OI display

assignments, OI data storage setup

• Upload Recipes: Uploads individual recipe files for variables, setpoint profiles, setpoint

schedules and sequences. (Allows print, save, edit or download.)

• Backup controller: Saves backup configuration file. cbk.

• Properties: File properties, statistics (capacity usage), file read protection, worksheet

protection (password access to individual worksheets)

• Write Protect File: Can enter and confirm a password for the selected file.

• Print Report: Provides report printout selections for documentation including configured I/O

list, worksheets, block parameters, tag list, display listing, recipes, SP profiles, SP

schedules, sequences, alarms and event list.

• Print Report Preview: Provides print preview of report selection plus print selection

• Printer Setup: Can select printer, paper type, and orientation.

• Exit: Exits the Controller Designer application.

Edit (HC Designer

only)

• Toolbar: Displays or hides the toolbar in the top of the Main window.

• Undo/redo: undo/redo last edit

• Cut, Copy, Paste: Editing functions for function block diagram items.

• Delete: Deletes the currently selec ted ite m on the fun ctio n block diagr am .

• Append FBD (Function Block Diagram) Worksheet: A dd s a wor ksheet

• Delete FBD Worksheet: Deletes a worksheet and its contents

• Reorder FBD: Allows the sequence of worksheets to be changed.

• Worksheet properties: Adds title and description for worksheet

• Unlock Worksheet: Allows entry of password to unlock protected worksheet

• Block and Tag Order: Shows list for ordering block sequen ce (fast and nor mal scan ra tes) ,

ordering of major blocks such as control loops for display purposes

• Loop Mode Priority: Lets you select which has priority: Manual Mode or Tracking Mode.

• Alarms: Displays alarm groups for setup or changes

• Events: Shows tag listing for assignment and annunciation as reportable events

• Edit Fixed Modbus Register Map: Allows limited editing of pre-assigned (fixed) Modbus

addresses.

• Configure Modbus Map Type: For extensive Modbus address editing, select this to change

from fixed map to custom map.

• Defragment Function Block List: Frees up memory consumed by previously deleted function

blocks.

• Find: Directs to area of diagram for tagged variables and blocks.

• Go To: Can enter the page number of Worksheet to which you want to go.

• Options: Warning Level: Can enable or disable the Open Input and Unassigned I/O

warnings on download. Default Annotation Attributes: Sets the default text attributes for

annotation entries.

Page 18

TABLE 3 Summary of ControlEdge HC900 Controller Designer & Controller Utilities Software Main Window Menu

Selections

View

• Status Bar: Displays or hides the status bar at the bottom of the Main window.

Main Menu Selection Description

• File Browser: Displays all open files (configurations, recipes, data storage)

• Worksheet Toolbox: Enables function block diagram tool category listing

• Trace Window: Shows listing of connection routing for selected input pin to function block

• Localization: For switching between supported languages by HCD tool

• Phone Book: Shows editable list of phone numbers

• Grid: Can place a grid in the function block diagram.

• Zoom Out: Can zoom out to see more of a document (5 levels).

• Zoom Normal: Returns object to normal size (Zoom In).

Monitor • Monitor Mode: Enables monitor mode. Enables toolbar for m onitor ing se lec tion s

• Monitor Toolbar: Disables/Enables monitoring toolbar

• Set Update Rate: Provides mo nitoring update rate selection – ¼ sec., ½ sec., 1 sec., and 5

sec.

• Set Logic State Colors: Se lec t a color sch eme for indicat ing the on/off status of digital wires,

digital signal tags, page connectors, and logic inversion.

• Watch Summary Window: Enables watch window with tabbed selection of I/O, Signal Tags,

Variables (write-capable), and display groups (write-capable). Writes are restricted from

running in Safe "RUN" mode unless enabled for non-critical safety functions located on the

safety worksheet. Writes are preformed using the Write Variable (WVAR) on the process

worksheet and connected to the associated variable in the safety worksheet.

• Controller Diagnostics: Displays controller diagnosti cs.

• Rack Diagnostics: Displays rack and I/O diagnostics.

• Controller Ports Diagnostics: Provides menu selection of all ports for displaying diagnostic

status including Ethernet port, RS-485 port, Host connections, Expansion Rack port, Peer

to peer connections

• Modbus Port Diagnostics

• Monitor Function Block: Alternate selection for enabling function block monitoring

• Forced Blocks: Displays all blocks with force conditions

• Show/Hide All Function Block Windows: Allows monitored blocks to be disabled/enabled for

viewing

• Show/Hide All Pin Data: Displays monitoring values (numeric or On/Off state) at any input

or output pin

• Show/Hide All Monitor Windows: Allows all monitoring windows to be disabled/enabled for

viewing

Page 19

TABLE 3 Summary of ControlEdge HC900 Controller Designer & Controller Utilities Software Main Window Menu

Selections

• Compare: Compares differences between two revisions of the cde file.

Main Menu Selection Description

Recipes • Allocate Recipe Memory: Allocates memory in controller to allow for more or fewer recipes

in the four pools below.

• Recipes (Variables): Displays recipe pool, allows stored recipe review, supports recipe

development, recipe printout is selectable

• Setpoint Profiles: Displays setpoint profile pool, allows stored profile review, supports profile

development, profile printout is selectable

• Setpoint Schedules: Displays setpoint schedules, allows stored schedule review, supports

schedule development, schedule printout is selectable

• Sequences: Displays sequence pool, allows stored sequencer review, supports sequencer

development, sequence printout is selectable

Window • Cascade: Arranges windows so that they overlap.

• Tile Horizontally: Arranges windows over and under each other. Each window is visible and

none overlap.

• Tile Vertically: Arranges windows side by side. Each window is visible and none overlap.

• Arrange All:

Version Control • Version Control Settings: Creates or uses existing repository and working folder.

• Version Control Explorer: Shows the folder structure and status of the files in the working

folder.

• Checkin To Version Control: Stores the changes from the working folder to repository

folder.

Help

• Help Topics: Calls up the top-level Help Contents page.

• About Help: Displays copyright and software version information.

Page 20

Description

TABLE 4 ControlEdge HC900 Controller Designer Functional Tabs

Tab

Controller Displays the I/O used in configuration by rack, module, channel. Supports conf iguration of:

• Controller name (for network peer addressing)

• E-mail alarm setup

Display (for support of

legacy 559 and 1042

OI functionality)

Available for

configurations prior to

version 6.000

Function Blocks Supports configuration of control and data acquisition strategy using function blocks available from

Modbus Map Appears when using a custom Modbus map. Custom Modbus map lets you assign blocks and

Utilities Supports configuration of:

Displays the 559 and 1042 operator interface setup. Supports configuration of:

• Operator interface displays (for example: trends, horizontal or vertical bars)

• Alarms

• Events

• Operator interface security

• Filenames

• Help displays

• Startup display

category tree. Up to 40 named worksheets with 20 pages each can be assigned.

parameters to custom addresses rather than pre-assigned fixed Modbus addresses.

• PC commu nications po rts (Com1 – Com8), selectable controller IP addresses

• Controller communications ports and IP address setup with auto-detect/ver ifi cat ion sel ect io n

• Real-time clock, cont roller mode

• Other functions:

• Controller, I/O, controller communications port, peer controller diagnostics

• Analog I/O calibration

• Slidewire calibration (Position Proportional Output)

• Show I/O force conditions (HC Designer only)

• Upload, Download and Loop-back check functions

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact your local

sales office for warranty information. If warranted goods are returned to Honeywell during the period of coverage, Honeywell

will repair or replace without charge those items it finds defective. The foregoing is Buyer's sole remedy and is in lieu of all

other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose.

Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this

printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the application.

Page 21

For more information

Process Solutions

1250 W Sam Houston Pkwy S

Honeywell Control Systems Ltd

2019 Honeywell International Inc.

Shanghai City Centre, 100 Jungi Road

www.honeywellprocess.com

Sales and Service

Fax: +(822) 792 9015

For application assistance, current specifications, pricing, or name of the nearest Authorized Distributor, contact one

of the offices below.

ASIA PACIFIC

Honeywell Process Solutions,

(TAC)

hfs-tac-

support@honeywell.com

Australia

Honeywell Limited

Phone: +(61) 7-3846 1255

FAX: +(61) 7-3840 6481

Toll Free 1300-36-39-36

Toll Free Fax:

1300-36-04-70

China – PRC - Shanghai

Honeywell China Inc.

Phone: (86-21) 5257-4568

Fax: (86-21) 6237-2826

Singapore

Honeywell Pte Ltd.

Phone: +(65) 6580 3278

Fax: +(65) 6445-3033

South Korea

Honeywell Korea Co Ltd

Phone: +(822) 799 6114

EMEA

Honeywell Process Solutions,

Phone: + 80012026455 or

+44 (0)1344 656000

Email: (Sales)

FP-Sales-Apps@Honeywell.com

or

(TAC)

hfs-tac-support@honeywell.com

AMERICA’S

Honeywell Process Solutions,

Phone: (TAC) 1-800-423-9883 or

215/641-3610

(Sales) 1-800-343-0228

Email: (Sales)

FP-Sales-Apps@Honeywell.com

or

(TAC)

hfs-tac-support@honeywell.com

Specifications are subject to change without notice

To learn more about ControlEdge HC900

Controller, visit www.honeywellprocess.com

Or contact your Honeywell Account Manager

Honeywell

Houston, TX 77042

Honeywell House, Skimped Hill Lane

Bracknell, England, RG12 1EB

Shanghai, China 20061

51-52-03-43

November 2019

Loading...

Loading...