Page 1

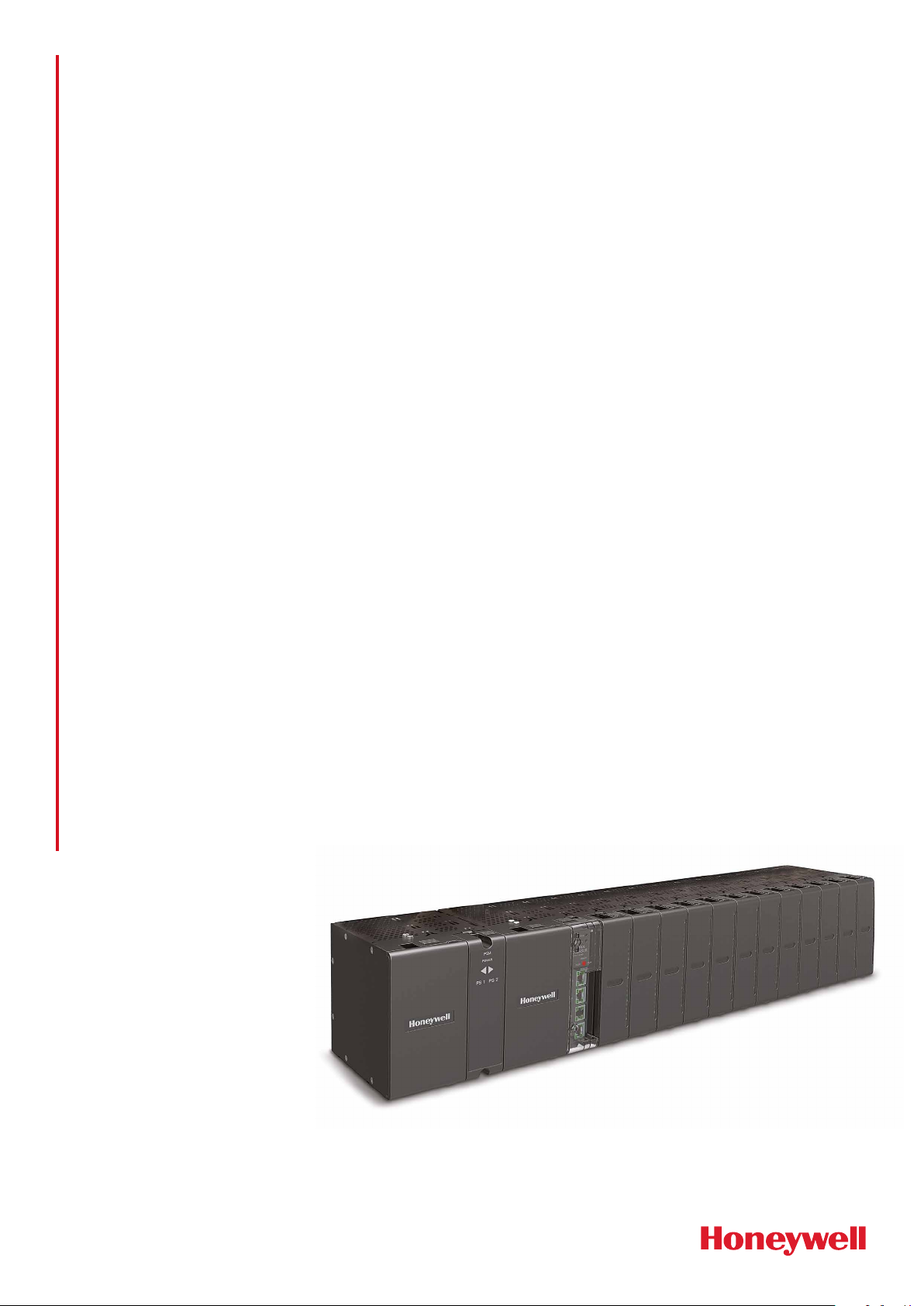

CONTROLEDGE PLC

SYSTEM INTEGRATORS

AND DISTRIBUTORS

ControlEdge programmable logic controller

(PLC) provides secure IIoT-ready connectivity

with tight integration to devices and systems from

multiple vendors. The first PLC to offer Universal

I/O, ControlEdge uses the OPC UA protocol and

has built-in cybersecurity. Designed to work

with any SCADA system, it becomes a superior

solution combined with any Experion® variant.

A NEW GENERATION

OF CONTROLLERS

Honeywell’s ControlEdge PLC is part

of the ControlEdge™ family, a next-

generation family of controllers providing

unprecedented connectivity through all

levels of process and business operations.

The result is optimized operations and

maintenance efficiencies that liberate

personnel from manual processes.

ControlEdge™ PLC provides secure

connectivity and tight integration to

devices and systems from multiple

vendors - with easy configuration, efficient

operations, and reduced maintenance.

Designed to work with any SCADA

system, it becomes a superior solution

using any variant of E xperion®, leveraging

common hardware and HMI, plus

LEAP™ project execution. ControlEdge

uses OPC UA, Profinet, and EtherNet /

IP protocols and built-in cybersecurity

for smooth integration to a range of

instruments, equipment and sof tware

from multiple vendors. The first PLC to

offer Universal I/O, ControlEdge provides

remote configuration and late design

change flexibility for improved project

implementation. Honeywell delivers

superior integration and efficiency

across both DCS and PLC applications.

SUPPORT

In addition, Honeywell supports you

with virtual product training. Moreover,

a 24x7 Global Technical Assistance

Center ( TAC) provides technical and

application support for faster problem

resolution, with remote diagnostics to

help pro-actively manage automation

systems. Honeywell provides the

confidence of a trusted supplier

with the largest installed base of

integrated systems and the greatest

longevity in the industr y. Rely on our

experience and expertise to reduce

risk and ensure performance.

Our Channel Par tner Portal is a private

and secure site designed to provide

authorized Honey well Channel Partners

with all the information they require to

successfully market, sell and support

Honeywell industrial automation

products. If you are interested in

becoming an authorized Honey well

Channel Partner to help your customers

improve their ef ficiency, reliabilit y,

safety and profitability, please email

us at HPSWeb@Honey well.com.

WHY CHOOSE

HONEYWELL?

Choosing Honeywell provides

distinct support advantages as well

as access to our broad portfolio.

Honeywell helps customers cost-

effectively manage their control

and safety infrastructure in the face

of constantly evolving technology

with extended lifecycle support,

flexible and easy migration paths,

and simplified upgrade capabilities.

Page 2

BENEFITS

OPC UA

Built on a proven and capable platform,

ControlEdge provides an IIoT-ready

open plat form that enables users

to better leverage data across their

assets. The OPC UA protocol offers

smooth integration while providing

built-in cybersecurity. Interoperable

multi-level and multiplatform open

communication provides flexible

and scalable design, enabling

standardization with less hardware.

An IIoT-ready platform enables

more direct access to cloud-based

applications for visualization and

analytics. With direct access and

reduced gateways, ControlEdge

provides investment protection

and easier maintenance, and

therefore reduced cost and risk.

Experion Integration

Designed to work with any SCADA

system, ControlEdge PLC becomes a

superior solution when combined with

any variant of Experion®. An additional

advantage to using Honeywell is that

we provide both process control and

PLC through a single vendor with

seamless support. Coordination is

easier with fewer teams and direct

access to system knowledge, resulting

in faster system setup, testing and

troubleshooting. The overall risk is

reduced with fewer elements to manage

and a single point of responsibilit y.

Reliable integration reduces both risk

and cost with fewer coordination errors,

less engineering, faster installation,

less training and reduced hardware.

For the end user, operator effectiveness

is increased and risk is diminished with

a leaner control room. Common HMI for

PLC and Experion means fewer operator

and engineering stations, less hardware

and wiring, reduced IT licensing and less

training with a common HMI tool and

operator interface. The end user benefits

from reduced cost over the lifecycle with

smaller footprint and easier maintenance.

Connectivity options

Built-in support for Industry standard

protocols such as Modbus, EtherNet /

IP, DNP3, PROFINET and HART-

IP provide smooth integration to a

range of instruments, equipment and

soft ware from multiple vendors.

Universal I/O

ControlEdge is the first PLC to offer

Universal I/O, providing remote

configuration and design change flexibility

for improved project implementation.

Universal I/O enables the entire cabinet

to become a standard part, with I/O

channels quickly configurable to allow

modules to serve as analog or digital

and as input or output. Engineers can

quickly accommodate late configuration

changes remotely using a simple

soft ware tool. Built-in HART-enabled

Universal I/O means no additional

hardware and costs to support HART.

By offering Universal I/O, ControlEdge

provides both configuration efficiency

and flexible design, thereby reducing

project schedule, cost and risk. Universal

Channel Technology eliminates

tedious documentation updates for

cabinet configurations and simplifies

maintenance. The reduction in types of

I/O modules minimizes the number of

spares needed and associated holding

costs for the end user. With reduced

or eliminated marshaling, there are

fewer cabinets, diminished footprint,

and lower infrastructure cost.

Cybersecurity

Our embedded cybersecurity supports

compliance, reduced risk, and availability.

Features include secure boot to prevent

uploading of unauthorized soft ware, a

built-in firewall to minimize exposure

to denial-of-service at tacks and

message flooding, and a certified

secure development lifecycle to ensure

securit y is built in from the star t.

In addition, Honeywell offers Industrial

Cybersecurity Solutions and Managed

Services that help protect the availability,

safety and reliability of industrial control

systems and site operations. Honey well

improves business performance by

reducing the risk of incidents, faults and

failures that disrupt normal operations.

For more information

Learn more about ControlEdge PLC, visit our

website www.HoneywellProcess.com/PLC or

contact your Honeywell account manager.

Honeywell Process Solutions

2101 CityWest Blvd, Houston, TX 77042

Honeywell House, Skimped Hill Lane

Bracknell, Berkshire, England RG12 1EB UK

Building #1, 555 Huanke Road

Zhangjiang Hi-Tech Industrial Park

Pudong New Area, Shanghai 201203

www.honeywellprocess.com

FL-21-01-ENG I 02/21

© 2021 Honeywell International Inc.

Loading...

Loading...