Page 1

LonWorks Bus I/O Modules Product Data

FEATURES

Plug-and-play functionality for easy maintenance.

Pluggable L

without rewiring. Further, the separate installation of

terminal sockets and electronic modules lower risk of

damage and theft in the construction phase.

Fast wiring with state-of-the-art push-in terminals (screw-

GENERAL

The CentraLine LONWORKS Bus I/O Modules communicate

via the L

These pluggable CentraLine L

consist of a terminal socket and a removable electronic

module, allowing the socket to be mounted and wired before

the electronic module is installed. All such electronic modules

can be swapped out without disrupting the power and bus

connections: Simply unplug the “old” and insert the “new”

module.

Risk of electric shock or equipment damage!

► Do not touch any live parts in the cabinet.

► Disconnect the power supply before you start to install

► Do not reconnect the power supply until you have

► Unused terminals must be closed (by completely

ONWORKS Bus.

ONWORKS Bus I/O modules

WARNING

the control system. More than one disconnect switch may

be required to de-energize the system.

completed the installation.

screwing in the terminal screws), thus preventing the

accidental touching of “live” parts.

type terminals also available) and bridge connectors.

Wide range of sensors supported (NTC20kΩ, NTC10kΩ,

PT1000-1/-2, Johnson A99 PTC, NI1000TK5000, PT3000,

Balco500, 0/2…10 V, 0/4…20 mA).

Binary input LEDs of the CentraLine L

Modules can be configured for status display (off / yellow)

or alarm display (green / red) per channel.

Configurable safety position for outputs, in case of loss of

communication with the controller.

Max. wiring flexibility due to optional accessories like

auxiliary terminals and cross-connectors.

Can be mounted in small installation housings

Flexible mix of L

your application requirements.

ONWORKS Bus I/O modules can be exchanged

ONWORKS Bus I/O

ONWORKS Bus I/O modules covering all

Software updates, configuration, and commissioning are all

done automatically by the controller for all L

Modules.

ONWORKS Bus I/O Modules may be used with any CPU

The L

supporting L

EAGLE, etc.).

Copyright © 2019 Honeywell GmbH ● All Rights Reserved EN0Z-0980GE51 R0119

ONWORKS Bus communication (e.g., the LION,

ONWORKS Bus I/O

Page 2

LONWORKS BUS I/O MODULES – PRODUCT DATA

X

X

X

X

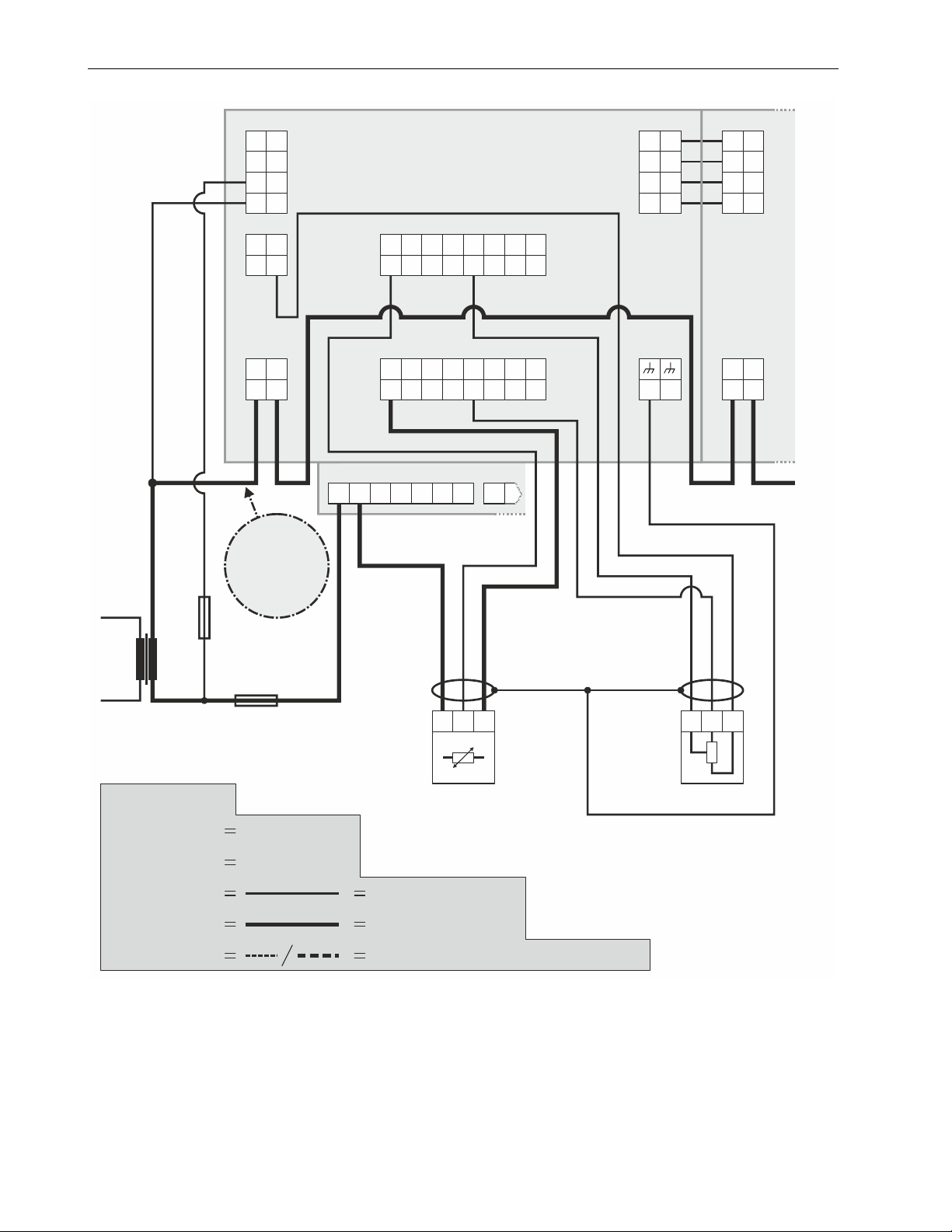

OVERVIEW

pluggable

ANALOG INPUT

pluggable

ANALOG OUTPUT

BINARY INPUT

pluggable

pluggable

RELAY OUTPUT

LonWorks

CLIOLR822A

CLIOLR824A

BUS MODULES

CLIOL821A

CONTROLLER

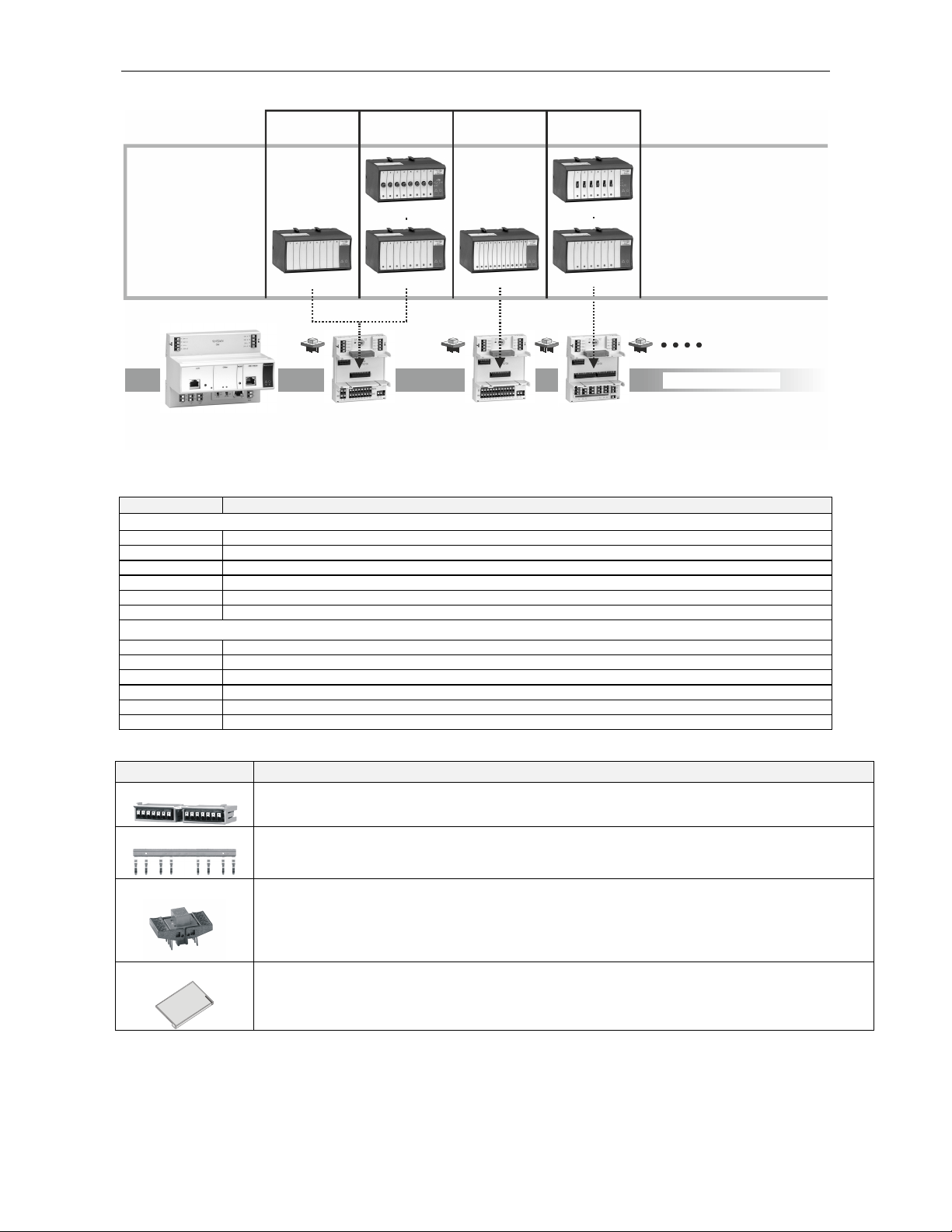

Fig. 1. Overview of CentraLine LonWorks Bus I/O Modules

Table 1. Overview of CentraLine LonWorks Bus I/O Modules

order number description

LonWorks Bus I/O Modules

L

CLIOL821A

CLIOL822A

CLIOLR822A

CLIOL823A

CLIOL824A

CLIOLR824A

ONWORKS Bus Bus Analog Input Module (with 8 analog inputs)

L

ONWORKS Bus Bus Analog Output Module (with 8 analog outputs)

L

ONWORKS Bus Bus Analog Output Module (with 8 analog outputs and manual overrides)

L

ONWORKS Bus Bus Binary Input Module (with 12 binary inputs)

L

ONWORKS Bus Bus Relay Output Module (with 6 relay outputs)

L

ONWORKS Bus Bus Relay Output Module (with 6 relay outputs and manual overrides)

Terminal Sockets

XS821-22

XSU821-22

XS823

XSU823

XS824-25

XSU824-25

Push-in terminal socket for AI/AO modules (incl. bridge connector, swivel label)

Screw-type terminal socket for AI/AO modules (incl. bridge connector, swivel label)

Push-in terminal socket for BI modules (incl. bridge connector, swivel label)

Screw-type terminal socket for BI modules (incl. bridge connector, swivel label)

Push-in terminal socket for relay/floating output modules (incl. bridge connector, cross connector, swivel label)

Screw-type terminal socket for relay/floating output modules (incl. bridge connector, cross connector, swivel label)

Table 2. Overview of auxiliary parts and spare parts

CLIOL822A CLIOL823A

XS821-22

XSU821-22

CLIOL824A

S823

SU823

order number description

XS814

Ten Auxiliary Terminal Blocks (for distribution of signals/power). Each terminal block includes two

groups with seven internally-connected push-in terminals.

XS815

20 Cross-Connectors for connection of six relay commons. One Cross-Connector is included in the

Terminal Socket package.

XS816

10 Bridge Connectors. One Bridge Connector is included in the Terminal Socket package.

LonWorks Bus

S824-25

SU824-25

XAL10

10 Swivel Labels Holders (for attaching the application-specific label printed with CARE / COACH AX /

COACH NX). One Swivel Label Holder is included in each Terminal Socket package. NOTE: Phased

out.

NOTE: The inputs and outputs of all CentraLine analog and binary I/O modules are protected against short circuit,

EN0Z-0980GE51 R0119

24 VAC +20%, and 40 VDC.

In the case of the relay outputs of other CentraLine I/O modules (i.e., relay output modules, floating output

modules, and mixed I/O modules), appropriate fusing must be provided to ensure that permissible load currents

are not exceeded. See also sub-section "Features" in section "Relay Output Modules" on pg. 14.

2

Page 3

LONWORKS BUS I/O MODULES – PRODUCT DATA

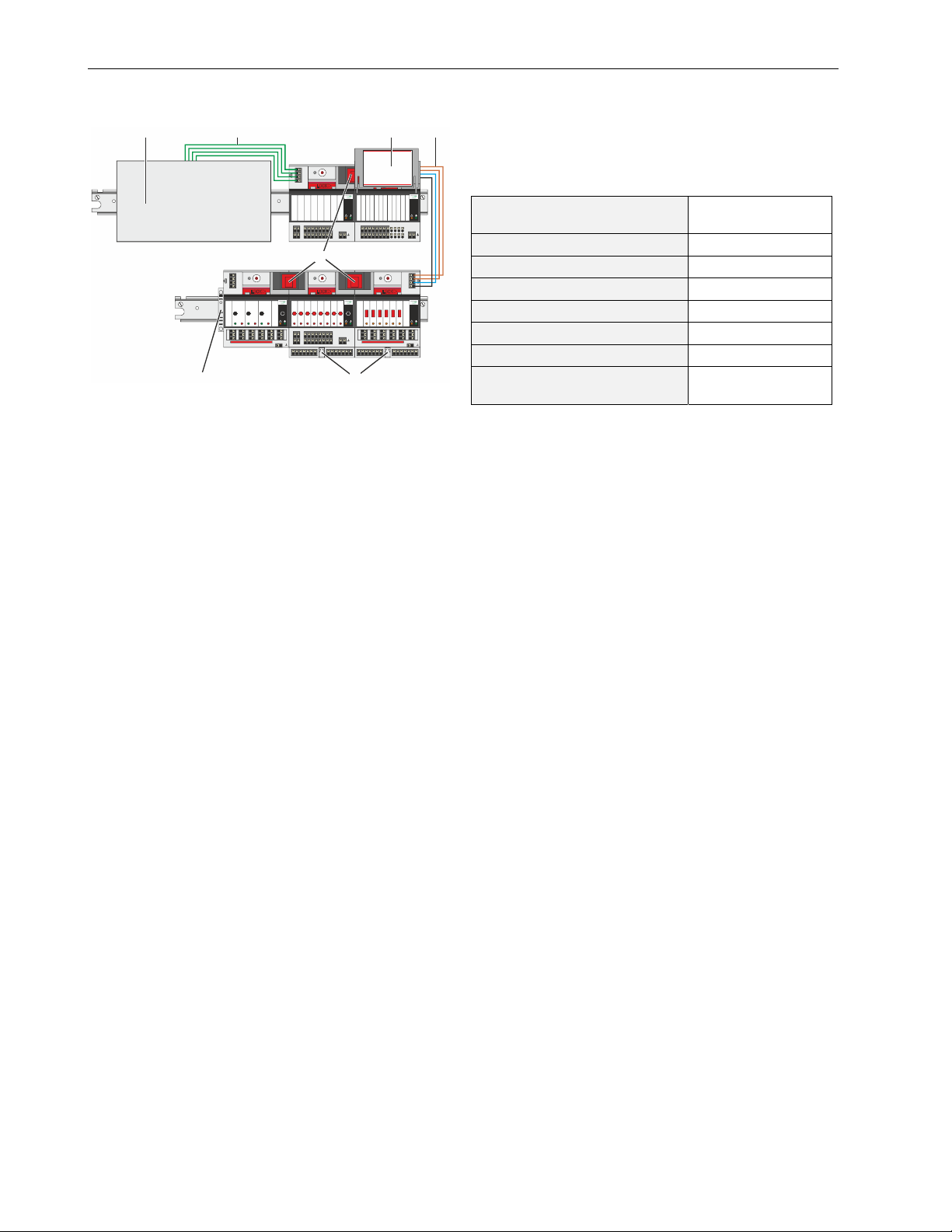

Table 3. Pluggable LonWorks Bus I/O Module specifications

Module

no. of I/Os 8 analog inputs 8 analog outputs 12 binary inputs

characteristics Linear Graph, 0...10 VDC with pull-

CLIOL821A CLIOL822A, CLIOLR822A CLIOL823A CLIOL824A, CLIOLR824A

up, 0(2)…10 VDC without pull-up

NTC20kΩ (-50…+150 °C, default)

NTC10kΩ (-30…+100 °C)

PT

1000-1

PT

1000-2

Johnson A99 PTC (-40…+120 °C)

NI1000TK5000 (-30…+130 °C)

PT

3000

BALCO

Also configurable as:

binary inputs

Linear graph (0…10 V with pull-up)

Features:

16-bit resolution

configurable offset per input

auxiliary voltage: 10 VDC, I

5 mA

Analog Input Analog Output Binary Input Relay Output

6 relay outputs

relay outputs (default)

Features:

Changeover relays

Voltage: 19…250 VAC,

1…29 VDC, P>50 mW

max. total current: 12 A

current per relay: N.O.: 4(4) A

(AC) or 4(1) A (DC),

N.C.: 2(1) A (AC) or 4(1) A

(DC)

Safety position (remain, 0%,

100%)

yellow LED per output

Version with manual override

(R):

1 switch per output

auto feedback signal (mode +

value)

blinking in manual override

position

(-50…150 °C)

(0…400 °C)

(-50…150 °C)

(-30…120 °C)

500

max

0…11 VDC / 1 mA

Also configurable as: floating

outputs or binary outputs (0 V

/ 10 V)

Features:

8-bit resolution (default)

Safety position (remain, 0%,

50%, 100%)

red LED per output

light intensity follows output

level in auto

Version with manual

override (R):

1 potentiometer per output

auto feedback signal (mode

=

+ value)

blinking in manual override

position

requiring a gold contact

or open collector

static binary input,

(default: dry contact)

Also configurable as:

totalizers (20 Hz)

Features:

1 LED per input

Color mode can be

set per input to

OFF/yellow or

green/red using

CARE / COACH AX /

COACH NX

ON: < 1.6 kΩ to GND

or < 2.5 V to GND,

OFF: > 90 kΩ to

GND or > 4 V to

GND

Manual Overrides as per EN ISO 16484-2:2004

The manual override switches and potentiometers of the output modules support direct operation as per EN ISO 164842:2004, section 5.4.3 "Local Priority Override/Indicating Units."

Specifically, the positions of the manual override switches and potentiometers directly control the outputs – independently

of the controller and HMI. When a manual override switch or potentiometer is not in its default position ("auto"), the

corresponding output LED will blink continuously, and the output module will send a feedback signal with the status

"manual override" and the given override position to the controller (which will then also store this information in its alarm

memory).

NOTE: When updating the firmware of output modules, their outputs are turned OFF – regardless of the position of their

manual override switches and/or potentiometers.

3

EN0Z-0980GE51 R0119

Page 4

LONWORKS BUS I/O MODULES – PRODUCT DATA

GENERAL FEATURES

3

1

1:ABCDFERTAQWESDERT1

2:ABCDFERTAQWESDERT2

3:ABCDFERTAQWESDERT3

4:ABCDFERTAQWESDERT4

5:ABCDFERTAQWESDERT5

6:ABCDFERTAQWESDERT6

PRESS

S1 S2

71 COM a

72 COM b

73 24V

~

74 24V0

~

12345678

21

22 1 234

AUX

GND GND

9

10 11 12 13 14 15 16 17 18 25 26

4

3

2

1

0

F

E

D

5678

5

6

7

8

9

A

B

C

Honeywell

!

AI/AOV

7:ABCDFERTAQWESDERT7

8:ABCDFERTAQWESDERT8

PRESS

1 234 5 6 7 8 9 10 11 12

5678910

1234

BI

GND

13 14 15 16 17 18 19 20 21 22 23 24 25 26

5

S1 S2

71 COM a

3

2

1

0

F

72 COM b

E

D

~

73 24V

74 24V0

~

1

2

AAA

21

31

11

22

32

12

23

33

13

14 4424 5434 64 25

4

5

6

7

8

9

A

B

C

3

PRESS

Honeywell

0

AUTO

!

41

51

42

52

43

53

100

AAAAAAAA

616261

62

AUX

6363

GND GND

S1 S2

4

5

3

6

2

7

1

8

0

9

F

A

E

B

C

D

PRESS

5678

1234

5678

21

22 1 234

9

10 11 12 13 14 15 16 17 18 25 26

AI/AOV

PRESS

Honeywell

0

100

AUTO

!

S1 S2

PRESS

1234

21

31

11

22

32

12

23

33

13

14 4424 5434 64 25

6 7

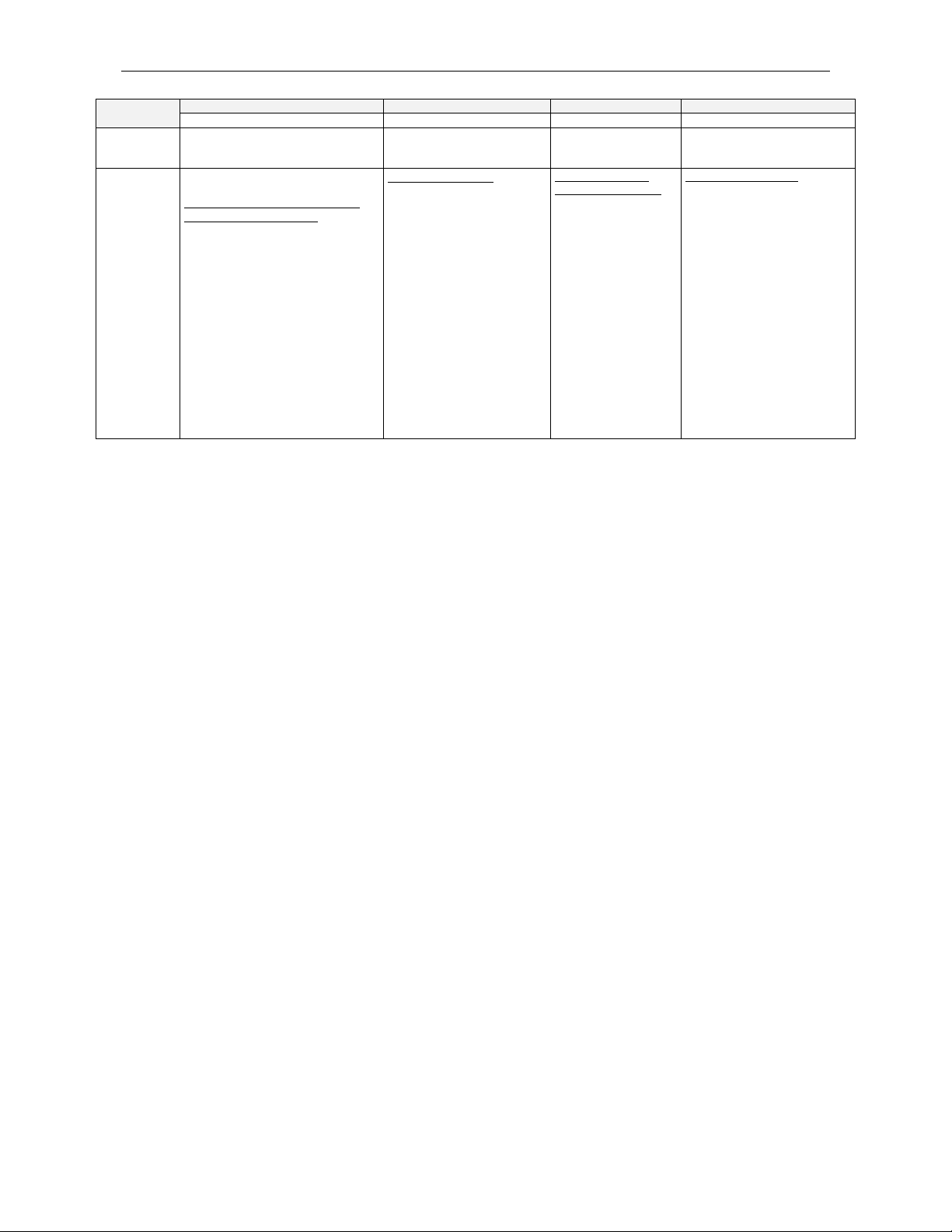

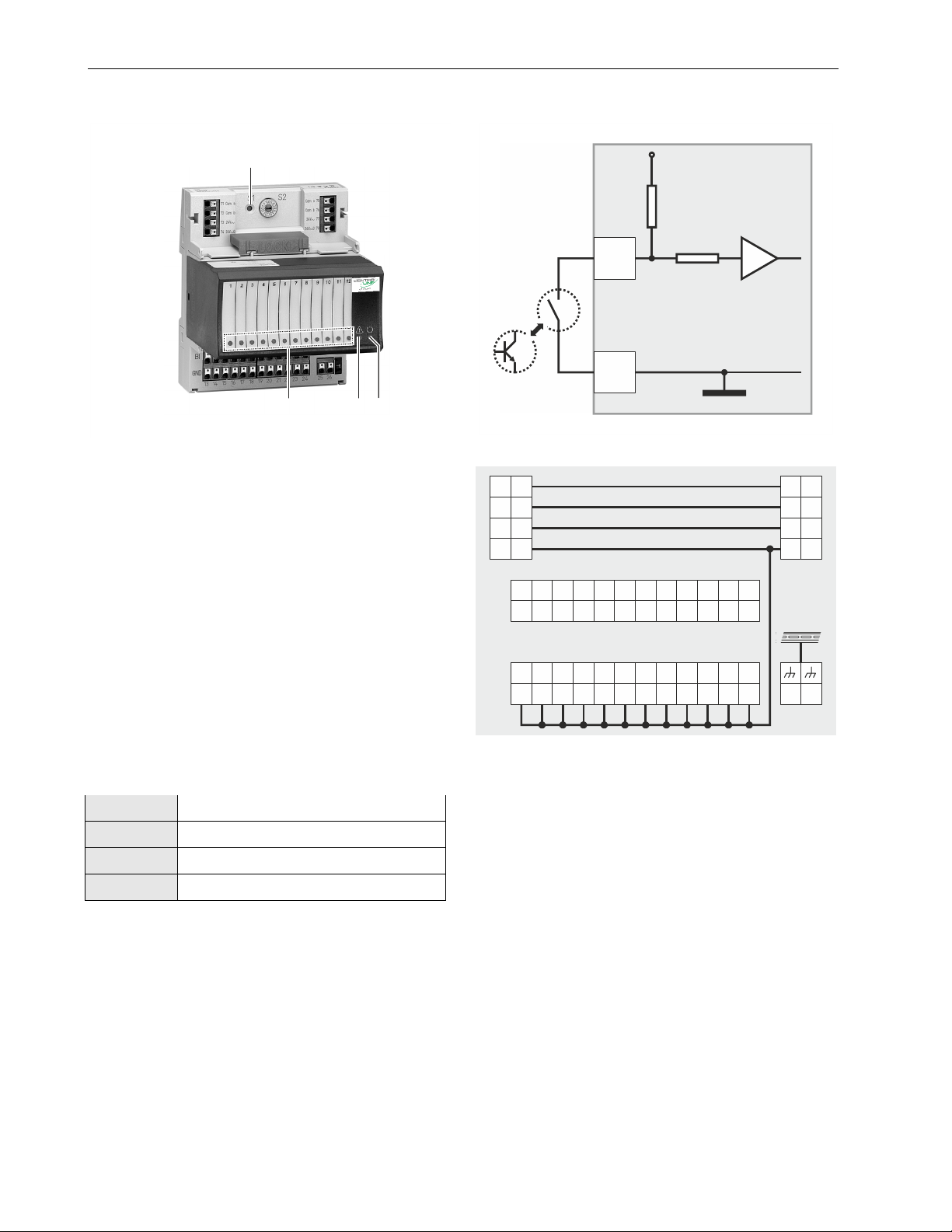

Fig. 2. LonWorks Bus I/O Modules on DIN rails

Legend

1 Controller (e.g., LION, EAGLE, HAWK, etc.)

2 Cable (power, L

L

ONWORKS Bus I/O Modules

ONWORKS) connection from controller to

3 Swivel label holder

4 Cable connection between L

ONWORKS Bus I/O Modules

on separate DIN rails

5 Bridge connectors between L

on same DIN rail

6 Stopper (from 3

rd

-party supplier)

ONWORKS Bus I/O Modules

7 Auxiliary terminal packages

LEDs

Each CentraLine LONWORKS Bus I/O Module is equipped

with:

one green power LED

one yellow service LED

Overvoltage Protection

The inputs and outputs of all CentraLine analog and binary

I/O modules are protected against short circuit, 24 VAC

+20%, and 40 VDC.

In the case of the relay outputs of other CentraLine I/O

modules (i.e., relay output modules, floating output modules,

and mixed I/O modules), appropriate fusing must be provided

to ensure that permissible load currents are not exceeded.

See also sub-section "Features" in section "Relay Output

Modules" on pg. 14.

Service LED

Each LONWORKS Bus I/O Module is equipped with a yellow

service LED (status: yellow/OFF) for easy diagnosis of

failures.

LonWorks Service Button

Each LONWORKS Bus I/O Module is equipped with a

L

ONWORKS service button.

Microprocessors

Each LONWORKS I/O Module is equipped with an FTT-10A

transceiver (link power-compatible) and can thus be used with

any L

ONWORKS controller.

42

Honeywell

!

11 12

71 COM a

4

5

3

6

2

7

1

8

0

9

F

A

72 COM b

E

B

C

D

~

73 24V

74 24V0

~

Honeywell

56

--1

--0

--AUTO

!

41

51

616261

42

52

62

43

53

6363

In addition to the main microprocessor, the L

I/O Modules also have their own Neuron chip (3120).

System Constraints

Max. no. of I/O modules (any

combination) per controller

Max. no. of I/O modules per row

Max. current (F1)

Max. current (F2)

Max. current (F3)

Max. row length

Max. distance between rows

Min. cross-section of GND

(terminal 9) (protected by F2)

Table 4. System constraints

depends upon

controller type

ONWORKS Bus

10

4 A

12 A

12 A

3 m

40 m

2

1.5 mm

EN0Z-0980GE51 R0119

4

Page 5

Analog Input Module

V

V

LONWORKS BUS I/O MODULES – PRODUCT DATA

1

3

2

Fig. 3. CLIOL821A LonWorks Bus AI Module (shown with

Legend

1 LONWORKS service button S1

2 Service LED

3 Power LED

NOTE: The hex switch S2 (located next to the L

The CentraLine L

analog inputs, is installed with the XS821-22 or XSU821-22

Terminal Socket.

service S1) has no function in combination with a

L

ONWORKS Bus I/O module. It is used with Panel

Bus I/O modules, only.

Fig. 4. Analog input low impedance (input circuit for

PT1000, Johnson A99 PTC, Balco500, PT3000,

NI1000TK5000, slow binary input)

terminal socket)

ONWORKS

ONWORKS Bus Analog Input Module, with 8

10 VDC

24.9 kOHM

AI

RTD

GND

AI

V

i

199.9 kOHM

10 VDC

24.9 kOHM

AI

GND

199.9 kOHM

(8.9 VDC IF

CONNECTION

INTERRUPTED)

V

i

Fig. 6. Analog input impedance setpoint (input circuit for

NTC10kΩ, NTC20kΩ, wall module setpoint)

COM

71

A

COM

72

B

24

73 77

V~

24

74

V~0

V

AUX

V

AUX

21

22101

GND GND GND GND GND GND GND GND GND GND

9

AI1 AI2

11

12

AI3

AI5 AI6

AI4

3

13

5156167178

4

14

2

AI8

AI7

18 25 26

Fig. 7. CentraLine LonWorks Bus Analog Input Module

(schematic)

Features

0…10 VDC, 2…10 VDC without pull-up

0…10 VDC with pull-up (linear graph, e.g., used for wall

module connection)

0/4…20 mA, needs 499 Ω resistor in parallel

NTC20kΩ (-50…+150 °C, default)

NTC10kΩ (-30…+100 °C)

PT1000-1 (-50…+150 °C)

PT1000-2 (0…+400 °C)

NI1000TK5000 (-30…+130 °C)

PT3000 (-50…+150 °C)

BALCO500 (-30…+120 °C)

Binary input

16-bit resolution

Configurable offset per input

Auxiliary voltage: 10 VDC, I

Sensor failure detection

MAX

= 5 mA

COM

COM

24

24

75

A

76

B

~

78

~0

GND

Fig. 5. Analog input high impedance (input circuit for

voltage input for active sensors)

5

EN0Z-0980GE51 R0119

Page 6

LONWORKS BUS I/O MODULES – PRODUCT DATA

A

AI5AI6AI7A

V

V

CLIOL821A ANALOG INPUT MODULE

COM

71 71

A

COM

72 72

B

24

73 7377

V~

24

74

V~0

V

AUXVAUX

21

22

GND GNDGND GNDGNDGNDGNDGND GND GND GNDGND

9 925

10 1026

OPT. AUX. TERMINAL MODULE XS814

A1 A2A3A4

AI1 AI2

1

2

11

12

AI3

3

13

A5 A6

AI4

4

14

5

15616

7 B1 B

7178

18

COM

75

A

COM

76

B

24

V~

24

78

~0

I8

74

COM

A

COM

B

24

V~

24

~0

CLIOL...

SHIELD

INTERNALLY

CONNECTED

TO DIN RAIL

LEGEND:

THIN LINES

THICK LINES

DASHED LINES

EXTERNAL

GROUND

REQUIRED TO

POWER

EXTERNAL

DEVICES

(24 VAC)

F1

F2

3 3

2 2

ACTIVE SENSOR

1: 24V POWER

2: 0...10 VDC SIGNAL

3: GND (24V 0)~~

F1

F2

MAX. 4 A

MAX. 12 A

MIN. 0.75 mm

MIN. 1.5 mm

SELECTED INTERNAL CONNECTIONS

Fig. 8. CLIOL821A LonWorks Bus AI Module, wiring example 1: Active sensor and potentiometer

1 1

AUX. VOLTAGE + POT.

1: SIGNAL

2: GND

3: 10 VDC AUX.

2

2

EN0Z-0980GE51 R0119

6

Page 7

LONWORKS BUS I/O MODULES – PRODUCT DATA

AI5AI6AI7A

V

V

S

COM

A

COM

B

24

V~

24

V~0

75

76

77

78

COM

71 71

A

COM

72 72

B

24

73 7377

V~

24

74

V~0

V

AUXVAUX

21

22

AI1 AI2

1

2

AI3

3

AI4

4

I8

5

7178

COM

COM

24

V~

24

74

COM

A

COM

B

24

V~

24

~0

75

A

76

B

78

~0

CLIOL821A ANALOG INPUT MODULE

CLIOL... CLIOL...

SHIELD

INTERNALLY

CONNECTED

TO DIN RAIL

GND GNDGND GNDGNDGNDGNDGND GND GND GND GND

9 925

10 1026

11

12

13

14

15616

18

DRY CONTACT

1: SIGNAL

2: GND

LEGEND:

THIN LINES

THICK LINES

DASHED LINES

Fig. 9. CLIOP821A LonWorks Bus AI Module, wiring example 2: Passive sensor and 0 (4) … 20 mA signal

DRY

CONTACT

F1

F2

(NTC20k or Pt1000)

MAX. 4 A

MAX. 12 A

2 22 1 11

TEMP. SENSOR

EXTERNAL

DC POWER

SUPPLY

MIN. 0.75 mm

MIN. 1.5 mm

2

2

0(4)...20 mA

1: IN

2: OUT

EXTERNAL 499 OHM

RESISTOR WITH

TWIN WIRE-END

REQUIRED.

ELECTED INTERNAL CONNECTIONS

FERRULES

7

EN0Z-0980GE51 R0119

Page 8

LONWORKS BUS I/O MODULES – PRODUCT DATA

V

V

Analog Output Modules

1

They are installed with the XS821-22 or XSU821-22 Terminal

Socket.

COM

71

A

COM

72

B

24

73 77

V~

24

74

V~0

COM

COM

24

24

75

A

76

B

~

78

~0

2

3

Fig. 10. CLIOPR822A LonWorks Bus AO Module (shown

with terminal socket)

5

4

Legend

1 LONWORKS service button S1

2 Manual overrides

3 Status LEDs

4 Service LED

5 Power LED

NOTE: The hex switch S2 (located next to the L

service S1) has no function in combination with a

L

ONWORKS Bus I/O module. It is used with Panel

Bus I/O modules, only.

The CentraLine L

ONWORKS Bus Analog Output Modules, with

8 analog outputs, are available in the following models:

CLIOL822A L

ONWORKS Bus Analog Output Module

(without manual overrides)

CLIOLR822A L

ONWORKS Bus Analog Output Module (with

manual overrides)

ONWORKS

AO1

NC NC

21

22101

GND GND GND GND GND GND GND GND GND GND

9

Fig. 11. CentraLine L

AO2 AO3 AO4AO5 AO6 AO7

3

5156167178

4

13

14

ONWORKS Bus Analog Output

11

2

12

AO8

18 25 26

Modules (schematic)

Features

0…11 VDC, +/-1 mA

Floating actuator (requires MCD3)

Binary output (0 V / 10 V)

red LED per output (brightness according to signal level)

Optional versions with manual override potentiometers

(Auto, 0…100%; LED flashes in override mode)

Feedback on manual override signal

8-bit resolution

Configurable safety position for outputs in case of

communication problems (remain, 0%, 50%, 100%)

EN0Z-0980GE51 R0119

8

Page 9

LONWORKS BUS I/O MODULES – PRODUCT DATA

A

V

V

X

A1A

S

CLIOL822A ANALOG OUTPUT MODULE

COM

71 71

A

COM

72 72

B

24

73 7377

V~

24

74

V~0

COM

COM

24

V~

24

75

A

76

B

78

~0

74

COM

A

COM

B

24

V~

24

~0

F1

NC NC

21

22 1

GND GND GNDGNDGNDGND GND GNDGND GND

9

10

A1 A2A3A4

EXT. GROUND

REQUIRED

TO POWER

EXT. DEVICES

AO1AO2 AO3AO4AO5AO6AO7AO8

5

3

2

4

11 121314

OPT. AUX. TERMINAL MODULE XS814

A5 A6

15 161718

7 B1

(24 VAC)

F2

6 7 8

B

SHIELD

INTERNALLY

CONNECTED

TO DIN RAIL

CLIOL...

GND GND

925

1026

S814

LEGEND:

THIN LINES

THICK LINES

DASHED LINES

231

M

2

2

F1

F2

MAX. 4 A

MAX. 12 A

~

24V DRIVE WITH

0...10 VDC SIGNAL

~

1: 24V POWER

~

2: GND (24V 0)

3: 0...10 VDC SIGNAL

MIN. 0.75 mm

MIN. 1.5 mm

ELECTED INTERNAL CONNECTIONS

Fig. 12. CLIOL822A LonWorks Bus AO Module, wiring example 1: Actuator

9

EN0Z-0980GE51 R0119

Page 10

LONWORKS BUS I/O MODULES – PRODUCT DATA

A

V

V

A

CLIOL822A ANALOG OUTPUT MODULE

COM

71 71

A

COM

72 72

B

24

73 7377

V~

24

74

V~0

COM

A

COM

B

24

V~

24

74

COM

A

COM

B

24

V~

24

~0

75

76

78

~0

F1

NC NC

21

22 1

GNDGND GNDGNDGNDGND GND GNDGND GND

9

10

A1 A2A3A4

EXT. GROUND

REQUIRED

TO POWER

EXT. DEVICES

AO1AO2AO3AO4AO5AO6AO7AO8

5

3

2

4

11 121314

OPT. AUX. TERMINAL MODULE XS814

A5 A6

15 161718

7 B1

(24 VAC)

F2

6 7 8

B

SHIELD

INTERNALLY

CONNECTED

TO DIN RAIL

CLIOL...

GNDGND

925

1026

XS814

A1

3

2

~

24V DRIVE WITH

0...10 VDC SIGNAL

~

1: 24V POWER

~

2: GND (24V 0)

3: 0...10 VDC SIGNAL

1

11 121314

M

LEGEND:

F1

F2

THIN LINES

THICK LINES

DASHED LINES

Fig. 13. CLIOL822A LonWorks Bus AO Module, wiring example 2: Relay Module MCD 3

The relay module facilitates the control of peripheral devices with high load via the analog outputs.

Input terminal 17 of MCD3 controls changeover contact K3.

Relay terminal 18 of MCD3 controls the N.O. contacts (floating outputs) K1, K2.

EN0Z-0980GE51 R0119

MAX. 4 A

MAX. 12 A

MIN. 0.75 mm

MIN. 1.5 mm

2

2

SELECTED INTERNAL CONNECTIONS

10

1 2

L

15 161718

MCD 3

5

K3

6 7 8

3

K1 K2

4

N

3

2

1

2 1

M

M

Page 11

LONWORKS BUS I/O MODULES – PRODUCT DATA

A

V

V

X

A

S

CLIOL822A ANALOG OUTPUT MODULE

COM

71 71

A

COM

72 72

B

24

73 7377

V~

24

74

V~0

COM

COM

24

V~

24

75

A

76

B

78

~0

74

COM

A

COM

B

24

V~

24

~0

F1

NC NC

21

22 1

GND GND GNDGNDGNDGND GND GNDGND GND

9

10

A1 A2A3A4

EXT. GROUND

REQUIRED

TO POWER

EXT. DEVICES

AO1AO2 AO3AO4AO5AO6AO7AO8

5

3

2

4

11 121314

OPT. AUX. TERMINAL MODULE XS814

A5 A6

15 161718

7 B1

(24 VAC)

F2

6 7 8

B

SHIELD

INTERNALLY

CONNECTED

TO DIN RAIL

CLIOL...

GND GND

925

1026

S814

1

~

24V DRIVE WITH

0...10 VDC SIGNAL

~

1: 24V POWER

~

2: GND (24V 0)

3: 0...10 VDC SIGNAL

231

11 121314

M

LEGEND:

F1

F2

THIN LINES

THICK LINES

DASHED LINES

Fig. 14. CLIOL822A Lonworks Bus AO Module, wiring example 3: Relay Module MCE 3

The relay module facilitates the control of peripheral devices with high load via the analog outputs.

Input terminal 16 of MCE3 controls the N.O. contact K3.

Input terminal 17 of MCE3 controls the changeover contact K2.

Input terminal 18 of MCE3 controls the changeover contact K1.

MAX. 4 A

MAX. 12 A

MIN. 0.75 mm

MIN. 1.5 mm

2

2

ELECTED INTERNAL CONNECTIONS

11

K1 K2

3

1 2

4

EN0Z-0980GE51 R0119

15 161718

MCE 3

K3

5

6 7 8

Page 12

LONWORKS BUS I/O MODULES – PRODUCT DATA

V

V

Binary Input Module

1

2

Fig. 15. CLIOP823A

Legend

1 LONWORKS service button S1

2 Status LEDs

3 Service LED

4 Power LED

NOTE: The hex switch S2 (located next to the L

The CentraLine L

binary inputs, is installed with the XS823 or XSU823 Terminal

Socket.

service S1) has no function in combination with a

L

ONWORKS Bus I/O module. It is used with Panel

Bus I/O modules, only.

LONWORKS Bus BI Module (shown w ith

XS823 terminal socket)

ONWORKS Bus Binary Input Module, with 12

3

4

ONWORKS

Configuration as Fast Totalizer

Using CARE / COACH AX / COACH NX, the binary inputs

can be configured as fast totalizers for operation in conjunction with devices equipped with an open collector output.

Table 5. Binary inputs used as fast totalizers

Frequency

Pulse ON

Pulse OFF

Bounce

max. 20 Hz

min. 25 ms

min. 25 ms

max. 5 ms

+V

18 VDC (NOT STABILIZED)

10 kOHM

150 kOHM

BI

DRY CONTACT

4 ... 40 VDC = OPEN

0 ... 2 VDC = CLOSED

FAS T

TOTALIZER

Fig. 16. Configuration of a binary input as a fast totalizer

COM

71

A

COM

72

B

24

73 77

V~

24

74

V~0

BI1 BI2

1

2

GND GND GND GND GND GND GND GND GND GND GND GND

13

14

Fig. 17. CentraLine L

GND

BI3

BI5 BI6

BI4

3

5156167178 9 10

4

ONWORKS Bus Binary Input Modules

BI8 BI9 BI10

BI7

18 19 20

(schematic)

BI11 BI12

11 12

21 222324

Features

Static binary input (dry contact)

Totalizer for up to 20 Hz

LEDs per binary input supporting alarm display mode

(red/green) or status mode (off/yellow).

Color mode of each LED can be set to OFF/yellow or

green/red in CARE / COACH AX / COACH.

COM

75

A

COM

76

B

24

~

24

78

~0

25 26

EN0Z-0980GE51 R0119

12

Page 13

V

V

F1

LONWORKS BUS I/O MODULES – PRODUCT DATA

CLIOL823A BINARY INPUT MODULE

COM

71 71

A

COM

72 72

B

24

73 7377

V~

24

74

V~0

BI3

BI1 BI2

1

2

BI5 BI6 BI7 BI8 BI9

BI4

5

3

4

7178 9 10

BI10

BI11BI12

11 12

COM

COM

24

V~

24

75

A

76

B

78

~0

74

CLIOL...

SHIELD

INTERNALLY

CONNECTED

TO DIN RAIL

GNDGND GND GND GNDGND GNDGND GNDGND GNDGND

25

13

14

15616

18 19 20

21 222324

26

COM

A

COM

B

24

V~

24

~0

LEGEND:

THIN LINES

THICK LINES

DASHED LINES

DRY CONTACT

1: SIGNAL

2: GND

F1

MAX. 4 A

Fig. 18. CLIOL823A L

21

DRY

CONTACT

TOTALIZER

1: SIGNAL

2: GND

MIN. 0.75 mm

MIN. 1.5 mm

2

2

21

MIN. 25 ms

TOTALIZER

SELECTED INTERNAL CONNECTIONS

ONWORKS Bus BI Module, wiring example: Dry contact and totalizer

13

EN0Z-0980GE51 R0119

Page 14

LONWORKS BUS I/O MODULES – PRODUCT DATA

V

Relay Output Modules

1

COM

71

A

COM

72 76

B

24

73 77

V~

24

74

V~0

RELAY BLOCK 1 RELAY BLOCK 2

NO

NC

COM

12

13

NO

11

NC

COM

NO

21

22

23

NC

COM

31

32

33

NO

NC

COM

42

43

41

NO

NC

COM

51

52

53

COM

COM

V~

A

B

24

24

~0

NO

NC

COM

75

78

61

62

63

2

3

Fig. 19. CLIOLR824A L

Module (shown with terminal socket)

Legend

1 LONWORKS service button S1

2 Manual overrides

3 Status LEDs

4 Service LED

5 Power LED

The CentraLine L

relay outputs, are available in the following versions:

CLIOP824A L

(without manual overrides)

CLIOPR824A L

manual overrides)

They are installed with the XS824-25 or XSU824-25 Terminal

Socket.

ONWORKS Bus Relay Output Modules, with 6

ONWORKS Bus Relay Output Module

ONWORKS Bus Relay Output Module (with

ONWORKS Bus Relay Output

5

4

REMOVABLE CROSS CONNECTOR (FACTORY-MOUNTED)

Fig. 20. CentraLine L

ONWORKS Bus Relay Output Modules

(schematic)

Features

- Cross-Connecter

- 1 yellow LED per output

- Optional versions with manual override switches (Auto, 0,

1; LED flashes in override mode)

- Feedback on manual override signal

- Configurable safety position for outputs in case of

communications problems (remain, OFF, ON)

- Permissible load per Relay Output Module (total)

Max. load (fuse F3):

19…250 VAC: 12 A

1…29 VDC: 12 A resistive, 3 A inductive

- Permissible load per normally-open contact:

Max. load:

19…250 VAC: 4 A resistive or inductive

1…29 VDC: 4 A resistive, 1 A inductive

Min. load: P > 50 mW

- Permissible load per normally-closed contact:

Max. load:

19…250 VAC: 2 A resistive, 1 A inductive

1…29 VDC: 4 A resistive, 1 A inductive

Min. load: P > 50 mW

25

EN0Z-0980GE51 R0119

14

Page 15

LONWORKS BUS I/O MODULES – PRODUCT DATA

V

V

F1

71

72

73

74

CLIOL824A RELAY OUTPUT MODULE

COM

A

COM

B

24

V~

24

V~0

NO

NC

COM

11

12

13

NO

NC

COM

22

23

21

NO

NC

COM

31

32

33

NO

NC

COM

41

42

43

COM

CROSS CONNECTOR XS815 (FACTORY-MOUNTED)

OPTIONAL AUX. TERMINAL PACKAGE XS814

A5 A6

A7

B1 B2B3B4

NO

NC

51

52

53

NO

NC

COM

B5 B6

61

62

63

COM

A

COM

B

24

V~

24

~0

SHIELD

INTERNALLY

CONNECTED

TO DIN RAIL

25

B7A1 A2A3A4

75

76

77

78

COM

71

A

COM

72

B

24

73

V~

24

74

~0

CLIOL...

LEGEND:

THIN LINES

THICK LINES

DASHED LINES

Fig. 21. CLIOL824A L

F1

F3

F3

POWER SUPPLY

230 VAC

MAX. 4 A

MAX. 12 A

NL

FIELD DEVICE

1: 230 V (N)

2: 230 V (L)

MIN. 0.75 mm

MIN. 1.5 mm - or less, as per F3

1 2

M

230 V

FIELD DEVICE

1: 230 V (N)

2: 230 V (L)

2

2

1 2

M

230 V

SELECTED INTERNAL CONNECTIONS

ONWORKS Bus RO Module, wiring example 1: Both relay blocks with line voltage

EN0Z-0980GE51 R0119

15

Page 16

LONWORKS BUS I/O MODULES – PRODUCT DATA

V

V

F1

71

72

73

74

CLIOL824A RELAY OUTPUT MODULE

COM

A

COM

B

24

V~

24

V~0

NO

NC

COM

11

12

13

NO

NC

COM

22

23

21

NO

NC

COM

31

32

33

NO

NC

COM

41

42

43

COM

CROSS CONNECTOR XS815 (FACTORY-MOUNTED)

OPTIONAL AUX. TERMINAL PACKAGE XS814

A5 A6

A7

B1 B2B3B4

NO

NC

51

52

53

NO

NC

COM

B5 B6

61

62

63

COM

A

COM

B

24

V~

24

~0

SHIELD

INTERNALLY

CONNECTED

TO DIN RAIL

25

B7A1 A2A3A4

75

76

77

78

COM

71

A

COM

72

B

24

73

V~

24

74

~0

CLIOL...

LEGEND:

THIN LINES

THICK LINES

DASHED LINES

Fig. 22. CLIOL824A L

F1

F3

F3

NL

POWER SUPPLY

230 VAC

FIELD DEVICE

1: 230 V (N)

2: 230 V (L)

1 2

M

230 V

FIELD DEVICE

1: 230 V (N)

2: 230 V (L)

1 2

M

230 V

FIELD DEVICE

1: 230 V (N)

2: 230 V (L)

MAX. 4 A

MAX. 12 A

MIN. 0.75 mm

MIN. 1.5 mm - or less, as per F3

2

2

SELECTED INTERNAL CONNECTIONS

ONWORKS Bus RO Module, wiring example 2: Relay blocks with low and line voltage

1 2

M

230 V

EN0Z-0980GE51 R0119

16

Page 17

Approvals, Certifications, and Standards

Approvals and Certifications

CE-approved

Conforms to EN 60730-1 and EN 60730-2-9

Investigated according to United States Standard

UL916 (USL-listed) as well as according to Canadian

National Standard(s) C22.2 (CNL-listed)

Classification according to EN60730-1

Environmental conditions: For use in home (residential,

Pollution degree: Class 2

Protection against shock: Class II

Software class: Class A

Overvoltage category: II

commercial, and light-industrial)

environments

Classification according to EN60529

(Degree of Protection Provided by Enclosures)

Classification: IP20

Ambient Environmental Limits

Operating temperature: 0 … +50 °C at 5…93% r.H.

Storage temperature: -20 … +70 °C at 5…93% r.H.

Humidity: 5 … 93% r.h. non-condensing

Current Requirement and Heat Dissipation

The LONWORKS Bus I/O Modules are equipped with highlyefficient switching power supplies which provide for relatively

uniform power consumption over a wide range of supply

voltages (see Table 6). The specific heat dissipation inside

the modules amounts to less than 2 W for all models.

Table 6. Current requirements at nominal voltage

devices powered

CLIOL821A 130 mA 80 mA

CLIOL822A, CLIOLR822A 150 mA 90 mA

CLIOL823A 180 mA 130 mA

CLIOL824A, CLIOLR824A 140 mA 80 mA

supply voltage

24 VAC 24 VDC

Mechanical

Housing Dimensions (H x W x D)

The LONWORKS Bus I/O Modules (mounted on Terminal

Sockets) all have the dimensions: 110 X 90 X 93 mm (see

also Fig. 23 on page 18).

Housing Material

Plastic, flame-retardant

Mounting Methods

DIN-rail mounting (e.g., in control cabinet).

Calculated Lifetime of Weakest Components

MTBF 13.7 years (under typical operating conditions)

LONWORKS BUS I/O MODULES – PRODUCT DATA

EN0Z-0980GE51 R0119

17

Page 18

LONWORKS BUS I/O MODULES – PRODUCT DATA

Dimensions

89.5 94.1

LOCK

110

SCREW-TYPE

TERMINALS

83

67.5

30.6

28

38

14

XS814 Aux. Terminal Package (optional)

Fig. 23. CentraLine LonWorks Bus I/O Modules (example shows Manual Overrides), incl. Terminal Socket, outside

dimensions (in mm)

SWIVEL LABEL HOLDER

51.5

45

Manufactured for and on behalf of the Connected Building Division of Honeywell Products and Solutions SARL, Z.A. La Pièce, 16, 1180 Rolle, Switzerland by its Authorized Representative:

CentraLine

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich, Germany

Phone +49 (0) 7031 637 845

Fax +49 (0) 7031 637 740

info@centraline.com

www.centraline.com

Subject to change without notice

EN0Z-0980GE51 R0119

Loading...

Loading...