Page 1

®

AutoSet 1500

Wintriss Two-channel Load Analyzer

1088500

Rev. C1 June 1998

®

Tech Support Hotline 800-586-8324 8-5 EST

®

Wintriss Controls Group

100 Discovery Way

Acton MA 01720-3648 USA

Phone (978) 264-9550 (800) 586-8324

Fax (978)263-2491

PRINTED IN USA DA45897

www.wintriss.com

Page 2

Thank you for purchasing a Honeywell Wintriss Product. We appreciate your business and want to do

whatever we can to ensure your satisfaction. Wintriss products are built to stay on the job day after day, and

are backed by an ironclad guarantee, international standards approvals, and unbeatable support. Whenever

you need assistance or service, we back all our products with excellent spare parts inventories, training

programs, and prompt repair service. We would like to share with you a list of service options– probably the

largest number of service options offered in the industry.

• Technical Assistance

We offer a toll-free line for technical assistance. Call our Wintriss Technical Support Hotline at

1-800-586-TECH (8324) should you have any questions about your equipment. Our technical staff

is ready to assist you Monday through Friday, 8 a.m. to 5 p.m. EST. In many cases our experienced

technical staff can resolve your inquiry right over the phone.

• Return Authorization

Please call our “800” number for a return authorization (RMA) number to return a product for repair.

Returned goods must arrive freight prepaid. In order to process your return quickly, we ask that you

provide us with the following pertinent information when you call: purchase order number, shipping

address, contact name and telephone number, and product type. The assigned RMA number should

appear on all packages returned to Wintriss Controls Group to ensure prompt service.

At the time of requesting an RMA, you will be quoted a flat-rate repair price for the product you are

returning. We ask that you either fax us a PO for that amount or enclose the PO with the returned

item. This will enable us to ship the item back to you as soon as the repair has been completed. If

the item cannot be repaired or there are additional charges, you will be contacted for approval.

Please be sure to carefully pack all returned items and ship to our Acton, MA location.

• Expedited Repair Program

Rush service providing 48 hour turnaround is available for most products upon request. An Expedite

Fee will be applied to our standard repair rate.

• Board Exchange Program

If your needs are urgent, you can take advantage of our Board Exchange (EX) program. Call our

“800” number between 8 a.m. and 5 p.m. EST and we will send a replacement to you overnight. A

fee does apply to this service. Contact Wintriss Technical Support at 800-586-8324 for details.

• Service Center

Our Service Center for product repairs is located at our headquarters in Acton MA. If your equipment

requires repair, please contact us at 800-586-8324 to obtain a return authorization number.

Nationwide field service is also available. Contact the Wintriss Service Manager at

800-586-8324, ext. 1949 or Wintriss Technical Support group at 800-586- 8324.

• Product Training

We also offer both product training and maintenance/troubleshooting courses at our Acton, MA and

Chicago-area facilities. On-site training is available from the factory or through your local Wintriss

representative.

• Restocking Charge

Returned goods are subject to a 20% restocking charge if returned for credit. The minimum charge

is $50, not to exceed $250 per item.

Whatever the product, we are committed to satisfying you with innovative engineering, quality

construction, reliable performance, and ongoing, helpful support. Call us whenever you need assistance.

Page 3

Changes for Revision C1 of the

AutoSet 1500 User Manual

(1088500)

Revision C1 of the AutoSet 1500 User Manual covers all AutoSet 1500

models.

Change(s) for Revision C1 include:

Label Switch 2 in location figure. (Figure 2-2, Chapter 2)

•

• Designate correct switch for “Zero Set”. (”Zeroing strain links”,

Chapter 3)

PROVIDE IMPORTANT INFO

DURING TROUBLESHOOTING WITH DI TECH SUPPORT!

Whenever you need to contact Data Instruments for technical assistance, be

ready to provide some important information to expedite a resolution to the

problem. Please supply: product name (e.g. AutoSet); model (e.g. 1500 or

1504); type (e.g. standard or plus); and firmware version number (e.g. Vs.

2.00). You can determine firmware version number from the chip on the

processor board (see "location of components" in Chapter 2).

Page 4

Table of Contents

Chapter 1 The AutoSet® 1500.........................................................................1

How AutoSet will benefit your operation..................................................................1

The AutoSet 1500 front panel....................................................................................2

How tonnage is recorded on the AutoSet displays....................................................3

Strain links.................................................................................................................3

Calibration .................................................................................................................3

How AutoSet 1500 works..........................................................................................4

Specifications.............................................................................................................6

Chapter 2 AutoSet 1500 Installation...............................................................7

Mounting the AutoSet control enclosure...................................................................7

Connecting AC wiring and stop circuit .....................................................................8

Mounting and connecting strain links........................................................................12

Connecting AC wires to power source ......................................................................16

Optional wiring connections......................................................................................17

Wiring a remote reset switch to AutoSet (optional)..................................................21

Wiring a strip chart recorder to AutoSet (optional)...................................................21

Final checkout for AutoSet 1500...............................................................................22

Chapter 3 AutoSet 1500 Calibration...............................................................23

Calibration .................................................................................................................23

Types of calibration kits you can use.........................................................................24

How many load cells to use.......................................................................................24

How to begin..............................................................................................................24

Zeroing strain links....................................................................................................24

Setting up and adjusting a Wintriss Load Analyzer (WLA) calibration kit..............26

Setting up and adjusting an AutoSet 1500 calibration kit .........................................29

Calibrating your AutoSet 1500..................................................................................33

Setting up the press..............................................................................................33

Setting full scale tonnage.....................................................................................35

Adjusting AutoSet to read the correct tonnage....................................................37

Linearity check ..........................................................................................................40

Chapter 4 AutoSet 1500 Operation.................................................................41

How to make settings on AutoSet..............................................................................41

Selecting the sample period.................................................................................41

Setting the percent tolerance selector ..................................................................42

Creating setpoints for the job....................................................................................44

When you may want to change the setpoint percentage.............................................................46

When you must recalculate setpoints.........................................................................46

When power is turned off and restored......................................................................46

Disabling AutoSet......................................................................................................46

AutoSet 1500 User Manual i TOC 1088500

Page 5

Table of Contents

Chapter 5 AutoSet 1500 Troubleshooting .....................................................47

AutoSet Alarms..........................................................................................................47

Before you reset AutoSet...........................................................................................47

When AutoSet displays a high setpoints fault...........................................................48

When AutoSet displays an offset error......................................................................49

Resetting AutoSet ......................................................................................................49

AutoSet Troubleshooting...........................................................................................50

When none of the load or setpoint LEDs are displayed ......................................50

When either of the load displays shows no tonnage............................................50

When the tonnage is lower than it should be.......................................................50

What happens when power is turned off and restored.........................................50

Appendix A AutoSet 1500 Panel Mount.........................................................51

Standard Enclosure versus Optional Panel Mount ....................................................51

Preparation for mounting AutoSet using your enclosure.............................................................51

Final assembly ...........................................................................................................51

Appendix B Modification for Selectable Sampling .......................................53

Index .................................................................................................................55

AutoSet 1500 User Manual ii TOC 1088500

Page 6

Table of Contents

How to use this manual

This is the installation and reference manual for AutoSet 1500. It has information about

how to install and use AutoSet 1500 to monitor load.

Chapter 1 introduces you to AutoSet 1500, tells how it works, lists features, and

explains how to use AutoSet.

Chapter 2 is the installation chapter. Use it to install AutoSet 1500 if you are

installing AutoSet yourself. Note that the 1500 processor board has changed. This is

covered in Chapter 2.

Chapter 3 talks about calibration. Read this chapter to calibrate AutoSet properly.

Chapter 4 explains how to use AutoSet. Use it to create and adjust setpoints.

Chapter 5 talks about what happens when AutoSet stops the press and what to do to

remedy the situation. It displays the alarms that AutoSet will provide, explains what

they mean, and how to correct them. This chapter also discusses how to troubleshoot

certain situations that may occur during normal press operation.

Appendix A explains how to install AutoSet 1500 as a panel mount. Mounting and

"cutout" dimensions are provided.

Appendix B is specifically included for specially modified AutoSet monitors with

custom selectable sampling. It explains how to use stroke sampling for 1, 15, 30,

and 60 strokes.

AutoSet 1500 User Manual iii TOC 1088500

Page 7

Table of Contents

Warranty

Data Instruments Inc. (D.I.) warrants that Data Instruments / Wintriss electronic

controls are free from defects in material and workmanship under normal use and

service for a period of one year (two years for Shadow light curtains) from date of

shipment. All software products (PACNet and RSR), electro-mechanical assemblies,

and sensors are warranted to be free from defects in material and workmanship under

normal use and service for a period of 90 days from date of shipment. D.I.'s

obligations under this warranty are limited to repairing or replacing, at its discretion

and at its factory or facility. Any products which shall, within the applicable period

after shipment, be returned to D.I. freight prepaid, and which are, after examination,

disclosed to the satisfaction of D.I., to be defective. This warranty shall not apply to

any equipment which has been subjected to improper installation, misuse,

misapplication, negligence, accident, or unauthorized modification. The provisions

of this warranty do not extend the original warranty of any product which has either

been repaired or replaced by D.I. No other warranty is expressed or implied. D.I.

accepts no liability for damages, including any anticipated or lost profits, incidental

damages, consequential damages, costs, time charges, or other losses incurred in

connection with the purchase, installation, repair or operation of our products, or any

part thereof.

Please note:

It is solely the user's responsibility to properly install and maintain Wintriss controls

and equipment. Data Instruments manufactures its products to meet stringent

specification and cannot assume responsibilities for those consequences arising from

their misuse. SmartPAC, AutoSet load monitors, DiPro 1500, IC Controllers,

ProCam 1500, Sensors, Spectrum Systems, and Wintriss Load Analyzers are not

designed or intended for use as personnel protection devices.

DATA INSTRUMENTS® AUTOSET® 1500

Wintriss® Controls Group USER MANUAL

75 Discovery Way Revision C1

Acton, MA 01720-3648 June 1998

Telephone: (800) 586-TECH (8234) ©1998, Data Instruments Inc.

(508)264-9550

Fax: (978) 263-2491

Internet: http://www.wintriss.com

AutoSet 1500 User Manual iv TOC 1088500

Page 8

Chapter 1

The AutoSet® 1500

Your AutoSet 1500 load monitor from Data Instruments is a simple, easy-to-use load

monitor. It protects your press and dies from overloads without the need to change or

readjust settings from die to die. That is because the AutoSet 1500 creates load limits (or

setpoints) automatically—for any job. You never have to calculate and enter settings

yourself. With AutoSet, you get overload protection, and you are freed from the

repetitive process of calculating and setting new setpoints every time you change dies.

How AutoSet will benefit your operation

AutoSet provides these benefits for any press operation:

1. It identifies machine overloading. AutoSet helps reduce unnecessary wear on

load bearing components.

2. While AutoSet cannot anticipate a bad stroke, it can signal the press to stop

after a bad stroke occurs. This eliminates successive bad hits that can cause

catastrophic damage.

3. Tooling setups are more accurate because of the actual tonnage information

AutoSet provides. The correct information about tonnage can be stamped on

the die shoe, per OSHA regulation 1910.217 (d) (6) (i).

4. AutoSet can detect die malfunctions through tonnage variations and can therefore monitor misfeeds, slug stacking, misuse of stop blocks, increases in material thickness and hardness, broken stripper springs, and broken punches in

the die. AutoSet makes it possible for one operator to monitor several presses

because it stops the press when these malfunctions are detected.

5. AutoSet helps you keep track of tonnage and tool wear so repairs to dies and

punches can be made on a schedule which permits more efficient use of the

press. This results in faster parts production and higher quality parts. You

know the tool is wearing if tonnage increases as the die is used again and

again.

6. AutoSet enables better matching of dies to press capacity since it tells you the

exact tonnage produced for each die. Therefore you can avoid using large capacity presses for smaller jobs.

AutoSet 1500 User Manual 1 Ch 1 1088500

Page 9

AutoSet 1500

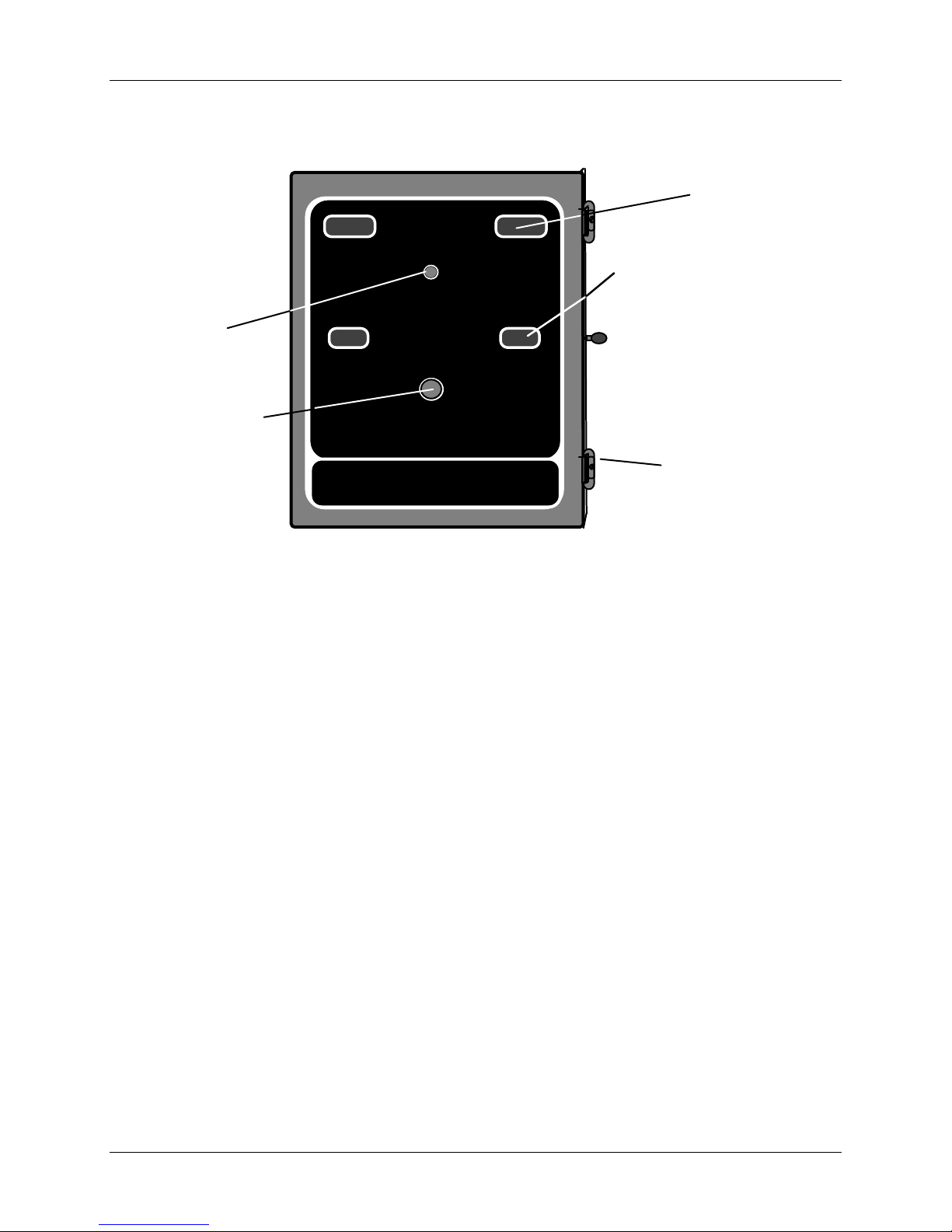

The AutoSet 1500 front panel

Tonnage

displays (for

forward or

reverse)

Zero

cam

LED

LEFT

LOAD

ZERO CAM

SETPOINTS

RIGHT

Setpoint

displays

®

1500

RESET

Cover latches

(keylock in between)

Reset button

AutoSet

WINTRISS LOAD ANALYZER

Figure 1-1. AutoSet front panel

Tonnage displays. Three-digit tonnage displays show the tonnage at each strain link.

Tonnage displays flash when an overload occurs.

Setpoint displays. Three-digit setpoint displays show the the upper load limits (or

setpoints). AutoSet creates setpoints automatically based on the load. AutoSet stops the

press if these limits are exceeded.

Reset button. This button has two functions. Pushing it momentarily (less than two sec-

onds) resets AutoSet after it signals an overload and stops the press. When an overload

occurs, the tonnage display for the strain link where the overload occurred will flash.

(Both displays will flash if an overload occurs on both sides of the press.) The press

stops. Once AutoSet is reset, the displays stop flashing. You can once again run the press.

Be sure to check for the cause of the overload first.

Holding the button down for more than two seconds signals AutoSet to recalculate

setpoints the next time the press is started. (This can be done while the press is running.)

To recalculate, the button should always be held down until the numbers in the setpoint

display blink once and change to 120% of the full scale tonnage set on AutoSet.

Complete instructions for using the reset button are in Chapter 4.

Zero Cam LED (optional). Illuminates when the zero cam is closed, generally through top

of stroke.

Keylock. AutoSet 1500 has a lock and key so the cover can be locked. This prevents

unauthorized changes to settings.

Cover latches. The two cover latches keep the AutoSet front panel door firmly closed. To

make settings on AutoSet, you unlock the box and loosen the two latches. Then swing the

front panel door open. All settings are made inside the box.

AutoSet 1500 User Manual 2 Ch 1 1088500

Page 10

AutoSet 1500

How tonnage is recorded on the AutoSet displays

The way AutoSet displays tonnage depends on the full scale tonnage of your press. (You

make the full scale tonnage setting during calibration.)

200 tons or less

If AutoSet is set to a full scale tonnage of 200 tons or less, it displays tonnage up to 100

tons in tenths of a ton ( 5.5, 6.0, 45.5, 90.1, 99.9, etc). Over 100 tons, it displays tonnage

in whole numbers only.

Between 200 and 1500 tons

For presses with full scale tonnage between 200 and 1500 tons, AutoSet displays only

whole numbers for tonnage (5, 10, 200 750, etc).

Over 1500 tons

For presses with full scale tonnage over 1500 tons, you must multiply the displayed tonnage by 10. For instance, a display of 5.5 tons would be 55 tons, a display of 105 tons

would be 1050 tons, and so on. (See "setting full scale tonnage" in Chapter 2 for more

details on how AutoSet displays tonnage.)

Strain links

Strain links are the sensors used by AutoSet to measure press tonnage. Strain links are

mounted to the press frame, or other structural members, where strain is proportional to

load and are wired to AutoSet. Two strain links are used. The strain links convert press

frame deflection into an electrical signal. They detect and measure the forces -- tension or

compression -- acting on the press frame.

When the press is loaded, the strain link is either stretched or compressed. On straight

side presses, strain links measure tension (stretching of the frame). On gap frame presses

(OBI or OBG), strain links can measure either tension (front mounted) or compression

(rear mounted). The tensile (or compressive) force changes the output signal of the

resistance bridge located inside the strain link body. The electrical signal sent to the

AutoSet 1500 is proportional to the force being exerted by the press.

The two strain links provided with the AutoSet 1500 are called differential strain links.

The part number on your links should be 9641601 (30' cable), 9641602 (100' cable), or

9641801 (with Hirschmann connector), depending on the cable length or connector you

choose. Contact Data Instruments before trying to use any other strain link.

Strain link mounting is described in Chapter 2– Installation.

Calibration

AutoSet must be calibrated before use. To calibrate, you first load the press to a certain

tonnage using load cells. You measure tonnage on an independent load monitor you

know will give correct readings. You then adjust the tonnage readings on AutoSet until

they match the tonnage readings of the independent load monitor. Calibration is covered

in Chapter 3.

AutoSet 1500 User Manual 3 Ch 1 1088500

Page 11

AutoSet 1500

How AutoSet 1500 works

AutoSet is so easy to use because it creates and displays load setpoints automatically.

You never have to calculate and enter setpoints.

Once AutoSet is installed and properly calibrated, there are only two settings you have to

make. You set the sample period and a percentage (the percent tolerance setting). The

sample period can be set to 1 or 15 strokes. The percentage tolerance setting tells AutoSet

how high above the load the setpoints should be. The percentages of load you can select

are 2%, 5%, 10%, 15%, 20%, 25%, 35%, 50%, or 100%. Settings are made using a

switch and dial indicator inside the box.

Once selected, these same settings can be used for any die (in most cases). You do not

have to change the setting from job to job. (See Chapter 4 for more details on when

changing settings may be necessary).

AutoSet calculates setpoints automatically based on a sample of the load just like you

would figure out setpoints yourself on paper. Here is how it does it:

1. Once the press is running, AutoSet begins measuring and recording the load (in

tons) at each strain link. It records the load for each stroke in the sample period.

2. After the sample period ends, AutoSet determines the highest load at each strain

link. It ends up with two numbers: the highest measured load at the right strain

link and the highest measured load at the left strain link.

3. It then calculates the setpoints using this formula:

highest measured load on each strain link during sample period +

percentage of load selected = high setpoint.

4. This calculation is performed for both strain links. The results are the setpoints for

each side of the press. See the following example. The setpoints are displayed in

the setpoint displays.

During the sample period (while AutoSet is recording tonnage), setpoints are maintained

at 120% of the full scale capacity of the press. Therefore, AutoSet offers protection from

overloads even during the sample period.

NOTE

AutoSet will not create setpoints greater than

120% of the full scale capacity of the press.

AutoSet will calculate new setpoints when you press the reset button and hold it for two

seconds or more. Afterwards, it will also change setpoints when you change the high

percentage setting switch. Complete instructions for making settings on AutoSet, how to

use the reset button, and a discussion of when you need to change settings is in Chapter

4—AutoSet 1500 Operation.

AutoSet 1500 User Manual 4 Ch 1 1088500

Page 12

AutoSet 1500

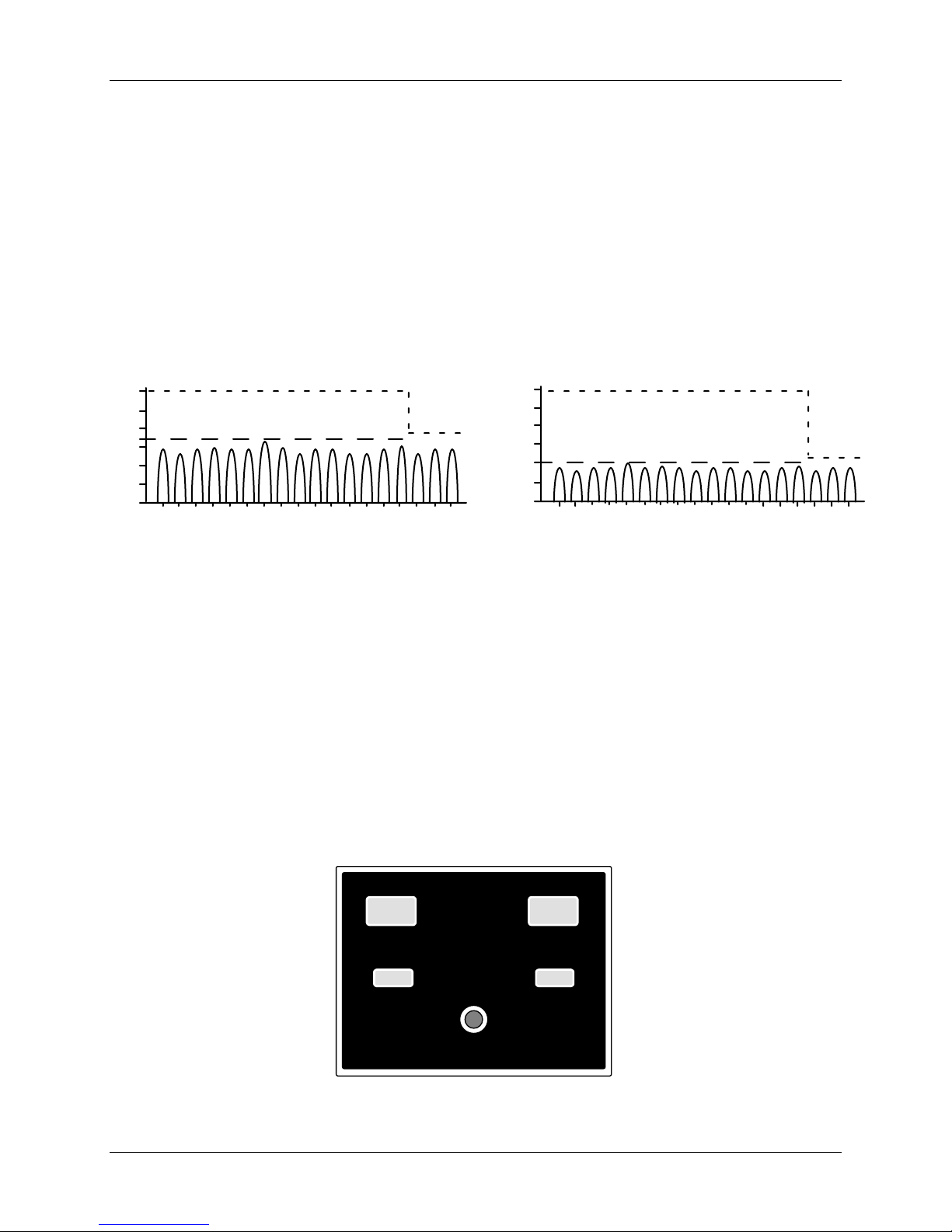

Example of how setpoints are calculated

To better understand how AutoSet 1500 automatically creates setpoints, let's look at an

example. Let's say AutoSet is installed on a 50 ton press. The percent tolerance setting is

at 10%, indicating that AutoSet will create setpoints 10% higher than the highest

measured load during the sample period. The sample period is set to 15 strokes.

The press is started. Then the reset button is pushed and held for at least two seconds.

This signals AutoSet to begin the calculation. It also changes the setpoint displays to 30.0

tons each (120% of 25 tons). 25 tons is the full scale tonnage on each side of the press.

Next, the press is run for 15 strokes. The highest measured tonnage on the left is 16 tons

and on the right is 10 tons. See Figure 1-2.

TONS

30

20

10

0

LEFT CHANNEL

30 tons

16 tons

1

23456789101112131415161718

STROKES

17.6 tons

TONS

30

20

10

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

RIGHT CHANNEL

30 tons

10 tons

STROKES

Figure 1-2. Tonnage produced at each strain link in example.

Highest load is on stroke 7 for left strain link and stroke 5 for right strain link. Tonnage

at far right on each graph is setpoint calculated by AutoSet after sample period.

Instantaneously after the 15 stroke sample period ends, setpoints are calculated as follows:

The setpoint for the left strain link is: 16 tons + (16 tons x 10%)

or 16 tons + 1.6 tons

or 17.6 tons

The setpoint for the right strain link is: 10 tons + (10 tons x 10%)

or 10 tons + 1 ton

or 11 tons

These setpoints are now shown in the setpoint display.

11 tons

Figure 1-3. Setpoints AutoSet created in example.

AutoSet 1500 User Manual 5 Ch 1 1088500

15.1

17.6 11.0

LOAD

RIGHTLEFT

SETPOINTS

RESET

9.6

Page 13

AutoSet 1500

Specifications

Equipment System enclosure 12" x 10.25" x 4"

(30.5 x 26 x 10.2 cm), NEMA 12,

shockmounted

Power 115 or 220 Vac ±15%, 50-60 Hz, 15 W

Operating temperature 32

Relay contact rating 5 amps @ 120 or 240 Vac

Normally open, held closed

Speed To 400 SPM without zero cam,

to 2000 SPM with optional zero cam

Display 2 3-digit .43" (1.1 cm) high for tonnages

2 3-digit .30" (.76 cm) high for setpoints

Strain links (two provided)

Size 3.75" x 1.19" x 0.75" (9.5 x 3 x 1.9 cm)

Cable 30 ft (9.1m) standard, other lengths optional

Drill fixture One provided

o

to 122o F (0o to 50o C)

AutoSet 1500 User Manual 6 Ch 1 1088500

Page 14

Chapter 2

AutoSet 1500 Installation

Installation of AutoSet involves mounting the AutoSet control box and connecting wiring

for power, strain links, and other devices. This chapter covers:

• Mounting the control box

• Connecting AC wiring and stop circuit

• Mounting and connecting strain links

• Connecting AC wires to power source

• Zero cam wiring (In some cases, installation of a zero cam switch is necessary)

• Optional connections.

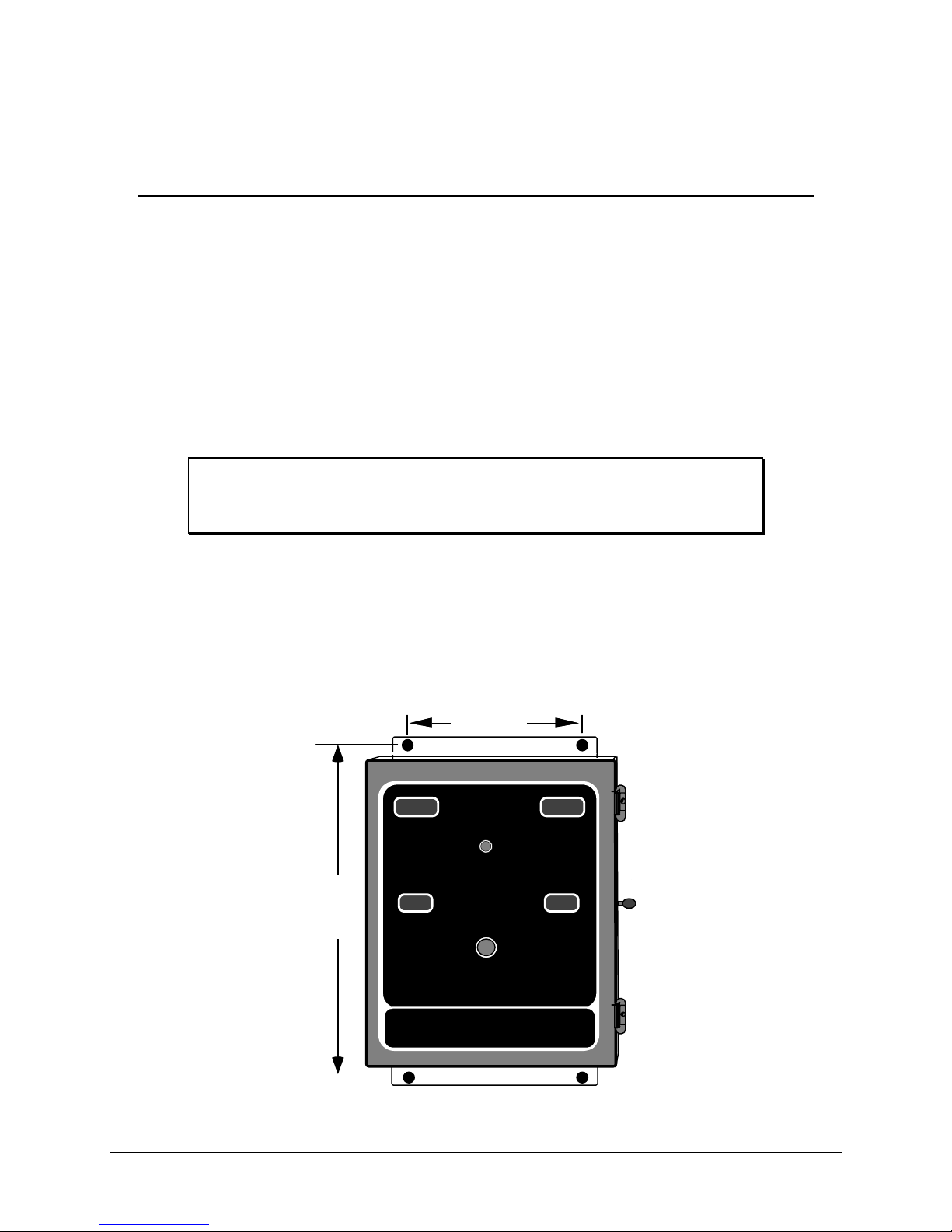

Mounting the AutoSet control enclosure

IMPORTANT!

If you have a panel mount, go to Appendix A for special installation

instructions, and mounting and cutout dimensions.

1. Determine a convenient place for the control box. Ideally it should be close to the

press control so operators and setup personnel can easily see the readouts and

reach the reset button. Also make sure the strain link cables will reach to the

mounting site selected. Leave enough room to open the door at least 120°. The

box can be mounted to the press or on a free-standing pedestal.

2. Drill holes for mounting (see dimensions in Figure 2-1). Shockmount studs are

1/4–20. Tap holes (if necessary) and mount the box using the enclosed shock

mounts. Use a No. 7 drill and 1/4–20 tap.

8 (20.32 )

LOAD

LEFT RIGHT

ZERO CAM

12.75

(32.39)

SETPOINTS

RESET

Figure 2-1. AutoSet mounting dimensions

AutoSet 1500 User Manual 7 Ch 2 1088500

AutoSet

WINTRISS LOAD ANALYZER

®

1500

Page 15

Installation

Connecting AC wiring and stop circuit

Wiring connections for AC power and for the stop circuit are on the same connector. To

wire the connector, follow these steps.

WARNING! PREVENT SHOCK!

Disconnect main power before installation. All power to the press, press control,

and other equipment used with the press must be off during installation. Also

"tag out" per OSHA 1910.147 Control of Hazardous Energy (Lockout/ Tagout).

Installation must be performed by qualified personnel only.

1. Determine how you will bring wiring from your 115 Vac power source (or 230V

source if applicable) to the control box. For 115 Vac, you need three wires—high

(black), neutral (white) and ground (green). No. 16 wire is recommended (No. 14

if local codes require it). For 230 Vac, wires are black and red with green or

green/yellow for ground.

2. Determine how you will connect the wires from AutoSet to your press control

stop circuit. You need two wires (No. 16 recommended, No. 14 if local codes require it). You should wire the AutoSet into the top stop circuit to avoid sticking

the press on bottom if AutoSet stops the press due to an overload.

NOTE: Top stop circuits are active only in continuous (automatic) operations on most

press controls. If overload protection is required during inch or single stroke mode,

you may have to install an additional control relay so AutoSet will stop the press.

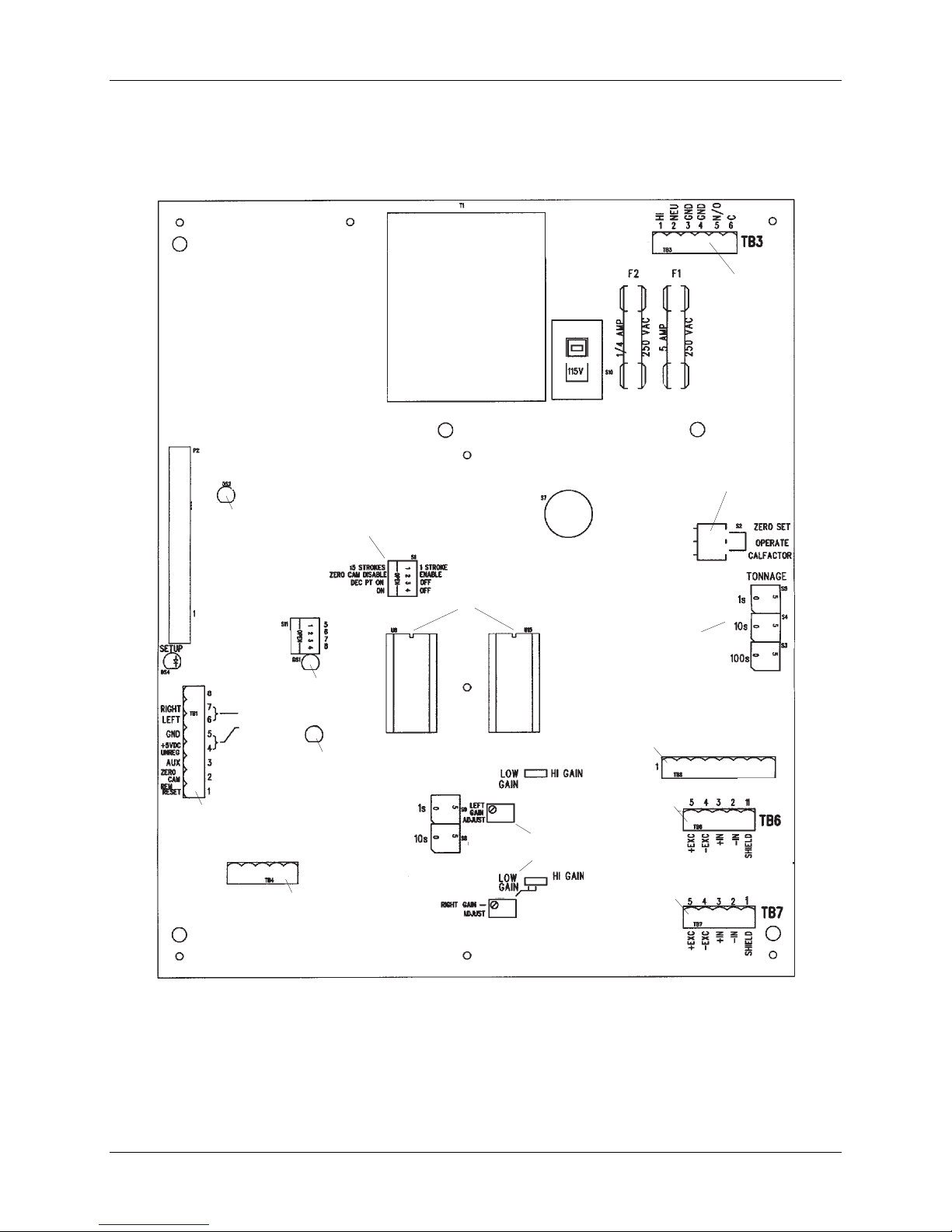

3. Open the cover of the control box. See Figure 2-2 for a drawing of the inside of

the box. Near the top of the enclosure, you will see a metal cover. This cover

protects the power supply. Remove it by first unsnapping the two white plastic

plugs at the bottom of the cover (pull plug straight up). Then loosen the screw on

top. Remove the cover. You will see the connector for AC power and the stop

circuit at right.

WARNING! SHOCK HAZARD!

Never apply power to AutoSet when the power supply cover is removed.

To prevent shock, always replace the cover before applying power.

4. Find the 115V-230V voltage selector switch. It's just below the power connection

to the left . It is a black rectangular box with a red handle and a cavity in the

middle. At the bottom of the cavity, you should see "115V." This is the factory

setting. This means AutoSet is set for 115 V operation.

If your AutoSet will be used with 230 Vac, push the red handle extending out of

the cavity towards you (away from top of the box). You will see 230 V displayed.

With the switch in this position, AutoSet will only work with 230 Vac power.

5. Run power and stop circuit wires through flexible liquid tight conduit to the box.

The AutoSet box is rated NEMA 12 (protected against dust and oil). You must

use conduit of the same rating and make proper connections to ensure NEMA 12

protection. Wires go through top right knockout hole. Leave a small service loop

inside box.

AutoSet 1500 User Manual 8 Ch 2 1088500

Page 16

Installation

Figure 2-2. Location of components in AutoSet 1500 (important components

shown and labeled)

CAUTION

POWER

POWER

TB3

TRANSFORMER

LINE

STOP CIRC.

FUSES

FOR

CALIBRATION

S2

COMMS

LED

DS2

MODE

SELECTOR

S1

VOLTAGE

SELECTOR

S7

% Tolerance

Selector

SETUP

TB1

Chart

Recorder

Zero

Cam

Power

COMMS

TB4

Zero LED

DS1

Remote Reset

LED

DS3

1

Notch

FIRMWARE

U8 U15

CPU NO.

S9

S8

RAM CHIP

J6

R17

J7

R25

Gain

Settings

Tonnage

Settings

Dialog

Station

TB8

LEFT INPUT

TB6

RIGHT INPUT

TB7

S5

S4

S3

AutoSet 1500 User Manual 9 Ch 2 1088500

Page 17

Installation

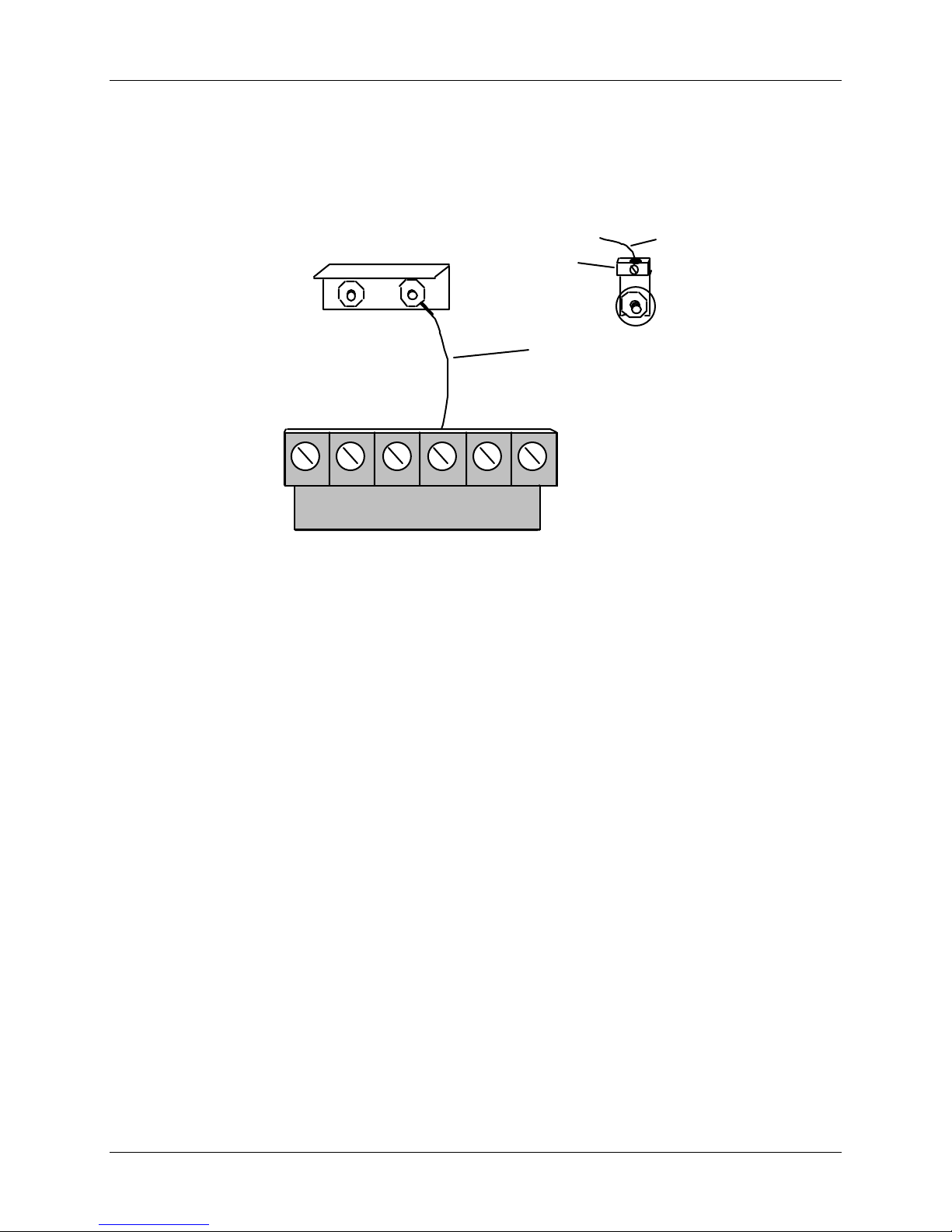

6. First connect the ground (green or green/yellow) wire. It must be connected to the

ground block as shown in Figure 2-3, not to "GND" terminal on the connector.

The ground block is located on the wall of the box at top right. To connect to

ground block, strip ground wire about 1/4" (6.4 mm) from end, loosen screw on

block, slide wire in hole, and tighten screw to pin wire in place.

ground wire (green)

Ground block

Connect ground

(green) wire here.

factory installed

ground wire to

case lug

HI NEU GND N/0 CGND

TB3

12345 6

Figure 2-3. Wiring connector and ground block for AC power and stop circuit.

7. Now find the connector TB3 for the other AC wires and stop circuit. It is at top

right. The connector consists of an L-shaped top section and base. Pull the Lshaped part away from its base. This is the part you will connect wiring to.

NOTE: A ground wire is attached from the connector to a case lug as shown in

Figure 2-3. Leave the ground wire attached to the connector while making

connections. If you remove this wire in order to pull the connector all the way out

of the box, be sure to replace it when done.

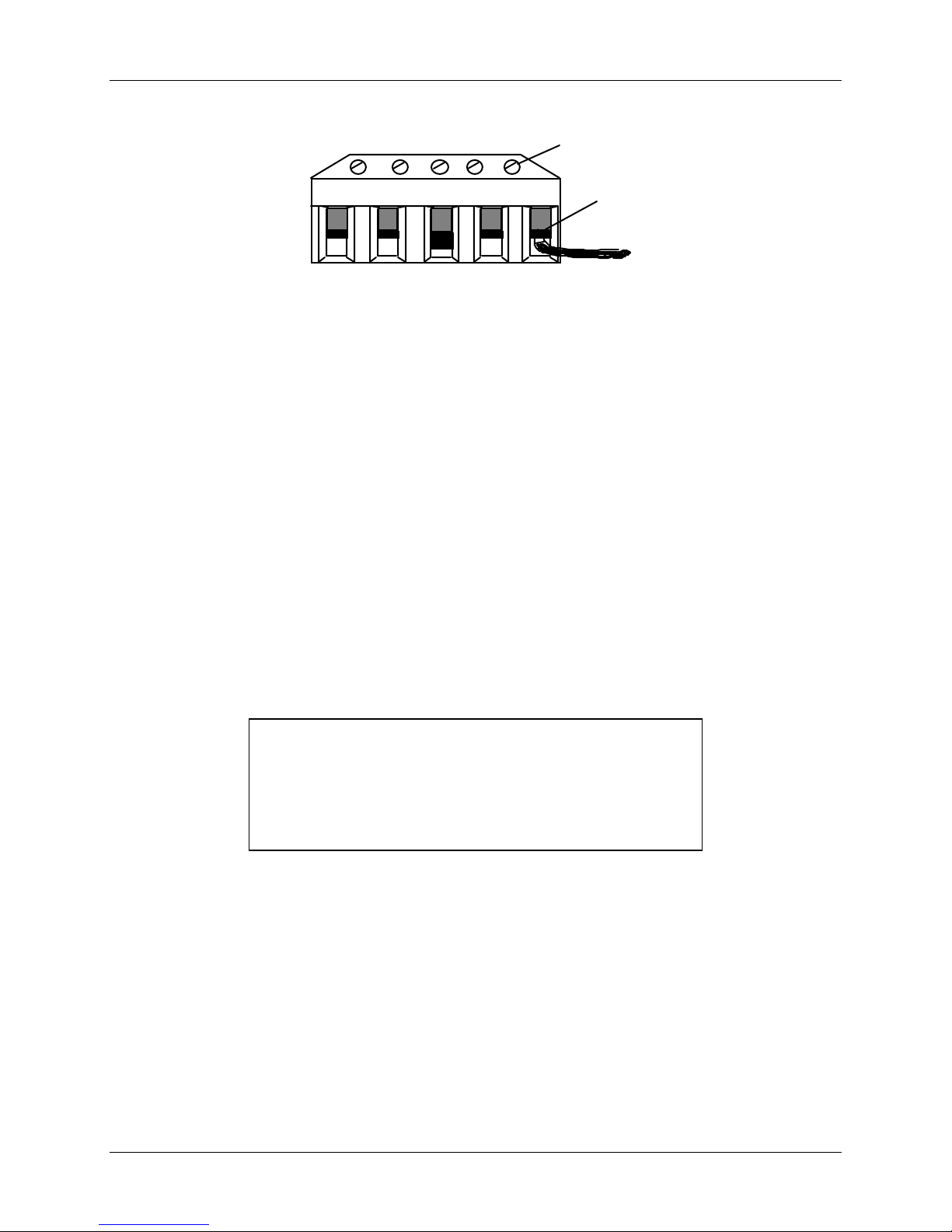

8. Connect wires to the L-shaped top section as shown in Figure 2-3. For 115 Vac,

connect black wire to HI slot and white wire to NEU. (For 230 Vac connect black

wire to HI slot and red wire to NEU). To connect a wire, find the correct slot and

loosen the screw over that slot by turning it counterclockwise (see Figure 2-4).

Strip the correct wire for this slot 1/4" (6.4 mm) from end. Insert bare wire into

slot 90% of the way. Tighten the screw. Metal tooth inside slot will clamp down

on the bare wire for a tight connection. Make sure the metal tooth is clamped

down on the bare part of the wire, not on the insulation. If on the insulation, you

will have a bad connection.

Connect both wires and double check connections when done.

NOTE: The connector can only plug in one way. Make sure you don't start at

the wrong end when connecting AC wires. Put the connector over the base the

way it will plug in and note wire marking next to base before starting.

AutoSet 1500 User Manual 10 Ch 2 1088500

Page 18

Installation

tightening screw

clamps wire in slot

slot for wire

Figure 2-4. Inserting wires into connector

9. Connect one of the wires from the press control stop circuit to the terminals

marked N/O (normally open) and the other wire to C (common). It does not

matter which wire goes to which terminal.

10. Plug the connector back into its terminal. Double check connections with

markings at the connector base to make sure you did not wire it backwards. (Note:

first "GND" from left in Figure 2-3 is not used).

11. Make all necessary conduit connections to ensure NEMA 12 protection.

12. Replace the power supply cover removed earlier. Snap in the white plastic plugs

at the bottom of the cover and tighten down screw at top.

13. Do not connect wires to AC power source until you are done with all other

installation procedures. Also make sure you number all wires in a way consistent

with your press's electrical prints.

WARNING

PREVENT SHOCK

Do not connect AC wires to the power source until

after all other installation procedures are finished.

14. Go on to the next procedure, mounting strain links.

AutoSet 1500 User Manual 11 Ch 2 1088500

Page 19

Installation

Mounting and connecting strain links

The two strain links provided with the AutoSet 1500 are called differential strain links.

The part number on your links should be 9641601, 9641602, or 9641603, depending on

the cable length or connector you chose. If you plan to use other strain links, contact Data

Instruments to find out if they will work with the AutoSet 1500.

To install strain links, follow these steps:

1. Select mounting sites on the press for the strain links. On straight side presses,

strain links are typically mounted on diagonal corners (one on front left, one on

back right). They measure tension (stretching of the frame). For gap frame (OBI

or OBG) presses, strain links can be mounted on the front of the press to measure

tension or on the back of the press to measure compression. Usually mounting on

back is better because the strain links are away from the work area. Typical strain

link locations for most gap frame and straight side presses are shown in Figures

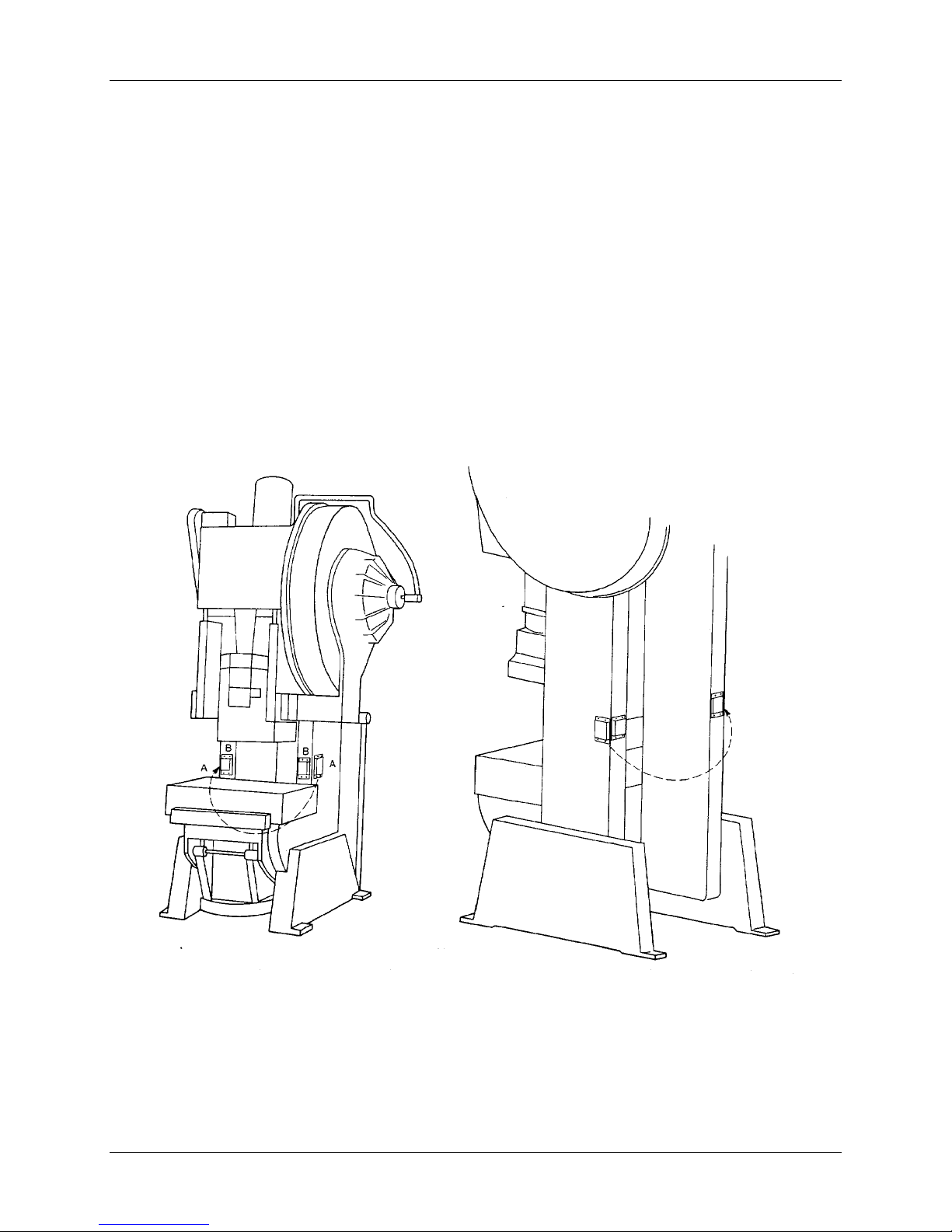

2-5 and 2-6.

D

D

C

C

A – Side of frame (arrow indicates second link D – Rear face of frame (similar to "A" but on rear of

mounted opposite) machine)

B – Front face of frame E – Similar to B but on rear face of frame

(A and B—forward load read as tension) (D and E—forward load read as compression)

Figure 2-5. Strain link mounting options on OBI/OBG presses

AutoSet 1500 User Manual 12 Ch 2 1088500

Page 20

Installation

2. Scrape the frame's surface to remove all paint or plastic filler which will affect

strain link readings. Cast frames may need light grinding to provide a flat surface.

Strain links must be mounted flat

There should be no imperfections, ridges, or cavities on the mounting surface.

Such imperfections will make it hard or impossible to zero the links later and

cause inaccurate tonnage readings.

WARNING

Use caution when determining an appropriate location for each

strain link! Do not mount any strain link under or above a hole

(1" in diameter or larger) on the press column. Avoid mounting

the strain link inside the die area where it would be subjected to

harsh chemicals. If necessary, use a cover to protect the strain

link.

A – Diagonal mounting. Right arrow indicates second

Middle arrows indicate strain links can be

Figure 2-6. Strain link mounting options on a straight side press

AutoSet 1500 User Manual 13 Ch 2 1088500

link mounted diagonally on opposite column.

(Forward load read as tension).

mounted either on front or side of columns when

using other placement methods.

Page 21

Installation

3. Select the area for the first mounting hole. Using a No. 7 drill bit, drill the hole

1/2" deep and bottom tap for a 1/4 x 20 thread.

WARNING

When drilling, make sure the holes are at right angles to

the surface. The strain link will not work if the mounting

holes are cocked or angled.

4. Mount the drill fixture supplied with the strain links, align it, and use the long

strain link screw to tighten it to the frame. Use the big hole in the fixture. The

screw will not fit through the other holes.

5. Using the drill fixture as a guide, drill the three remaining holes.

6. Remove the drill fixture and tap the three holes.

7. Mount the strain link (use semi-permanent Loctite—blue, no. 242 or equiv.—on

the mounting screws). Mark each strain link at the cable end to identify its

position on the press. Mark as "left" or "right."

Leave the mounting screws loose for now. Strain links must be properly zeroed

(set close to a 0 volt electrical output under no load) before mounting screws are

tightened. This zeroing procedure must be done as part of the calibration

procedure in Chapter 3.

Therefore, do not tighten links until you get to that part of the calibration

procedure.

8. Run the strain link cables through flexible conduit to the bottom right knockout

on control box. Use conduit rated NEMA 12.

CAUTION

Do not run strain link wires through the same conduit as power

wires. Strain link wires are sensitive to electrical noise. Separate

conduit will provide protection and shielding.

Plan to leave a service loop inside box. Measure cable for length and cut cable.

Strip outer cable 1" to 2" (2.5 to 5 cm) from end–enough to separate and work

with individual wires. Strip wires 1/4" (6.4 mm) from end.

9. The strain link connectors are at the lower right inside the box. They are marked

"right input" (TB6) and "left input" (TB5). Determine which connector each set of

strain link wires go to.

AutoSet 1500 User Manual 14 Ch 2 1088500

Page 22

Installation

10. Determine the correct wiring connections for your strain links. The way you connect the wires depends on whether you mounted the strain links to read tension or

compression forces on the press. Each wiring scheme is shown in Figure 2-7.

Wiring for tension Wiring for compression

-exc (blk)

+exc (red)

- in (grn)

+in (wht)

shield

+exc (red)

-exc (blk)

+in (grn)

- in (wht)

shield

1234512345

Figure 2-7. Wiring connections for strain links

11. Start with connector TB7 for the right strain link (marked right input). Strain link

connectors are the same L-shaped type as used for the AC wires. Pull the Lshaped top section of connector from base. Make wiring connections in the same

way as for AC wires.

12. Replace the connector. It only goes in one way. Double check connections.

13. Remove connector TB6 for the left strain link (marked left input). Connect wires

from second strain link.

14. Replace the second connector. Double check connections.

15. You are done installing the strain links and connecting them to the AutoSet. Go

on to next section—connecting AC wires to power source.

AutoSet 1500 User Manual 15 Ch 2 1088500

Page 23

Installation

Connecting AC wires to power source

Connect AC wires from the AutoSet control to your AC power source only when you're

finished connecting all wiring inside the control box. If you need to install a zero cam or

plan to make other optional connections to AutoSet (remote reset switch and chart

recorder), go to the sections that follow and do this wiring first. Then connect AC power.

WARNING

PREVENT SHOCK

Make sure main power is off when you connect AutoSet to

main power source.

WARNING

Make sure power supply cover is in place

Make sure you replaced the power supply cover (which fits

over the power supply near the top of the enclosure). The

power supply cover helps prevent shock if you're working

inside the box with power on.

What you should see when power is turned on

After connecting AutoSet to a power source, set switch S2 to "zero", close the cover, and

turn power on. The top LOAD displays should show 0's or other numbers. The bottom

setpoint displays should show either numbers, dashes (- - -) or the numbers "HI" or "LO".

It does not matter what at this point.

If the displays are not active, turn off power to AutoSet. Re-check connections for power

and strain links. Make sure the voltage selector switch is set correctly . Then turn power

on again. Make sure that the displays are active as noted above. If not, and AutoSet has

power, call Data Instruments or your sales representative.

Once all connections are made

Once you've made all connections and AutoSet has power, you are ready to begin

calibration. Calibration is covered in Chapter 3. Go to Chapter 3 and begin the calibration

procedure.

AutoSet 1500 User Manual 16 Ch 2 1088500

Page 24

Installation

Optional wiring connections

The following sections explain other connections you can make to AutoSet. Except for zero

cam wiring (required in some cases), these connections are optional.

The sections below cover:

• connecting a zero cam switch (installing an LMCS)

• connecting a remote reset switch

• connecting a strip chart recorder

Installing a zero cam switch (optional)

There will be instances where you will need a cam switch to signal AutoSet at the start of

each stroke. This signal is called the zero signal. In general, AutoSet zeroes automatically.

However, for high speed presses and for certain other applications, you must install a cam

switch to provide AutoSet with the zero signal. When you may need a zero cam switch is

discussed below.

Zero cam needed for high speed presses

For presses that operate over 400 strokes per minute, a zero cam must be wired to the AutoSet

1500. AutoSet cannot automatically zero itself fast enough at these press speeds. It must

signal AutoSet near top dead center of each stroke. AutoSet will then erase tonnage readings

from the previous stroke and get ready to record readings for the next stroke.

Other conditions when a zero cam is needed

For slower presses, a zero cam is not usually needed. AutoSet has enough time during the

stroke to zero itself automatically. However, in some instances, a zero cam may be needed

even for a slower press. Without a zero cam connected, AutoSet will not read tonnages less

than 5 percent of full scale tonnage. Therefore, if you will be using AutoSet on jobs where

less than five percent of press capacity is used, you will need a zero cam.

There are other instances where a zero cam may be needed. Some presses produce tonnage

over five percent of full scale at the beginning or end of a stroke. For instance, some presses

in single stroke operation will produce tonnages over five percent when they stop at top stop.

Also, some presses in continuous mode produce abnormally high or low tonnage at the

beginning or end of the stroke for the first few strokes only. This tonnage is produced by vibrations (also called ringing) or start-up torque.

A zero cam should be used in these cases. With a zero cam, AutoSet will record tonnage only

during the portion of the stroke when the zero signal is absent (off). When the zero signal is

set on between 240° and 30°, AutoSet will ignore tonnage produced during the beginning or

end of the stroke. Before installing a zero cam, be sure some other condition (loose wires,

improper calibration) is not causing erroneous tonnage readings. Also, do not hesitate to

contact Data Instruments if you need assistance in determining whether to install a zero cam.

AutoSet 1500 User Manual 17 Ch 2 1088500

Page 25

Installation

CORRECT ZERO SIGNAL SETTING

The zero signal must come on approximately at 240° and turn off at 30°. (The

zero signal is a closure to ground. That means during the zero signal the cam

switch must be closed. The closed switch makes a connection between the zero

cam terminal (pin 2) and GND (pin 5) on connector TB1 (see Figure 2-9).

If using a latching magnetic cam switch that uses magnets to turn the switch on

and off, make sure you install the magnets at 240° and 30°. See instructions with

switch for proper installation. Make sure that the zero signal does not turn off

until after top dead center (TDC). For other types of switches (like a Candy

switch), you can set the switch after wiring is complete.

Data Instruments provides a latching magnetic cam switch (LMCS) which you can obtain for

AutoSet. The following steps explain how to install the LMCS and magnets.

How to install the LMCS and magnets

1. Select a mounting site for the LMCS and the magnets so that the magnets rotate

1:1 with the crankshaft of the press. Ideally this is the crankshaft itself. However,

you might also use the pitman above the adjusting screw or a drive shaft to a feed

or other device.

2. Fabricate a bracket to position the LMCS 1/16" to 1/8" from the face of the

magnets. If possible, make the bracket adjustable. To aid in mounting, the

LMCS is supplied with a slotted mounting bracket. These slots are 1.5" apart,

and approximately .1875" (3/16) wide by .75" long. Use size 6-32 hardware and

lock washers. Install the LMCS as shown in Figure 2-8.

3. To mount the magnets, make sure that you use non-magnetic brass or nylon

screws, or epoxy adhesive. The magnets should be installed plastic side up with a

non-ferrous metal screw. It is important not to use a ferrous screw because it could

cause false signals. A brass screw (6-32) is supplied. Use a No. 36 drill and a 632 tap.

NOTE: FOR HIGH-SPEED PRESSES, DI RECOMMENDS THAT YOU USE

THE BRASS SCREW, NOT EPOXY OR NYLON SCREWS TO MOUNT

THE MAGNETS. IF THE EPOXY DOES NOT HOLD OR IF THE

NYLON SCREWS BREAK, THE MAGNETS CAN BECOME

DANGEROUS PROJECTILES.

Position the red magnet so that it closes the cam switch at 240° of stroke. Set the

blue magnet to open the cam switch at 30° of stroke. There should be a dwell of

150° between the two magnets across the top of the stroke, and the switch will be

open during the forming portion of the stroke.

AutoSet 1500 User Manual 18 Ch 2 1088500

Page 26

Installation

Press @ 240°

Red magnet

@ 240°

LMCS sensor

mounted

dead center

150° dwell

Blue

magnet

@ 30°

End View

forward

press

rotation

1/16" to 1/8"

gap between

magnet and

sensor

Crankshaft

Front View

rigid bracket to

press frame.

Red magnet

Figure 2-8. Installing the LMCS and magnets

4. Once the LMCS is installed, you are ready to wire it to the connector for TB1. Open

the AutoSet cover and find connector TB1 at the left center of the box. See Figure 2-9.

Black wire goes to terminal 5 (gnd); white or clear goes to terminal 2 (zero cam); red

goes to terminal 4 (sensor power).

5. Run wires from the cam switch through flexible, liquid-tight conduit to the bottom left

knockout on box. The control box is rated NEMA 12 (protected against dust and oil).

Therefore, you must use conduit rated NEMA 12 and make proper conduit connections

to ensure NEMA 12 protection.

6. Pull connector out of socket. How you wire the switch depends on the type used.

The LMCS will require power. Some other switches are mechanical so you do

not need to apply power to the switch. If you are using a programmable limit

switch (PLS) to supply the zeroing signal, you will not need power for the switch

either. See below for more information.

a. If your switch needs power, make connections to the terminals marked +12

Vdc (pin 4) and GND (pin 5). See the instructions for your switch to make

proper connections.

b. For all switches, connect the zero cam circuit by connecting the switch to the

terminals ZERO CAM (pin 2) and GND (pin 5).

c. Connections are made in the same way as for AC power and strain link

connections (see "Mounting and connecting strain links" and "Connecting AC

wires to power source" in this chapter). Make sure you did not get wiring

backwards due to turning connector the wrong way once removed from

socket.

AutoSet 1500 User Manual 19 Ch 2 1088500

Page 27

Installation

NOTE

Data Instruments' latching magnetic cam switch (LMCS) has no separate ground

connection for the zero signal. The ground for power and the ground for the signal

are the same. Other switches requiring power may be the same. Check instructions

for your switch.

TB1

UNUSED

8

RIGHT

LEFT

GND

+12 VDC

AUX–

OUT

ZERO

CAM

REMOTE

RESET

7

6

5

4

3

2

1

CHART

RECORDER

}

ZERO CAM

POWER

}

Figure 2-9. Connector for zero cam, remote reset and chart recorder

7. Plug the connector back into the socket. It only goes in one way. Verify the wiring.

8. If not done previously, adjust the cam switch so the zero signal comes on at 240°

and turns off at 30° (approximately). In other words, the switch should close to

ground between 240° and 30°.

9. The last thing you need to do is set DIP switch 2 on switch block S1 (refer to

location of components). You must set switch 2 to the right. With a ball point pen

(not a pencil) or your thumbnail, push the switch to the right—to the "zero cam

enable" position. See Figure 2-10. Make sure you push the switch all the way to

the right. Also, if power is on, press and hold the Reset button for at least two

seconds (toggle switch S2 must be set to "operate" before pushing Reset). This

must be done any time the switch is changed with power on. If power is off,

AutoSet automatically resets at start-up.

AutoSet 1500 User Manual 20 Ch 2 1088500

Figure 2-10. Zero cam enable switch.

Page 28

Installation

Wiring a remote reset switch to AutoSet (optional)

A remote reset switch allows you to reset AutoSet without using the RESET button on

the control box cover. A simple normally open momentary pushbutton switch can be

used.

NOTE: You can still use the reset button on AutoSet even when a remote switch is

connected.

To wire in a remote reset switch:

1. Choose a location for the switch and connect wires of appropriate length to it.

2. Run wires through conduit to bottom left knockout. (Use conduit rated NEMA 12

and make proper conduit connections to ensure NEMA 12 protection.)

3. Open the AutoSet cover and find the connector (TB1) for the switch. It is at the

left center of the box.

4. Run wires through the bottom left knockout to connector.

5. Pull the connector out of socket.

6. Connect one wire to pin 1 (RESET) and the other to pin 5 (GND). See Figure 2-9

for connections.

7. Replace the connector.

8. You are done installing the remote reset switch.

Wiring a strip chart recorder to AutoSet (optional)

You can connect a strip chart recorder to AutoSet to graphically plot tonnage produced at

both strain links. The AutoSet outputs for a strip chart recorder are -5V to +5Vdc.

To connect a strip chart recorder:

1. Open AutoSet front cover and find the connector (TB1) for the recorder. It is at

the left center of the box.

2. Run wires through the bottom left knockout. You need three wires. (Use conduit

rated NEMA 12 and make proper conduit connections to ensure NEMA 12

protection.)

3. Pull the connector out of socket. Connect the wire that will record tonnage at the

left strain link to pin 6 (LEFT). Connect wire for right strain link to pin 7

(RIGHT). See Figure 2-9 for connections.

4. Connect third wire to pin 5 (GND).

5. Replace the connector and close cover.

6. Connect wires to chart recorder. Follow manufacturer's instructions for your chart

recorder.

AutoSet 1500 User Manual 21 Ch 2 1088500

Page 29

Installation

Final checkout for AutoSet 1500

CAUTION

The Final Checkout needs to be performed after installation

(Chapter 2), and initialization/calibration procedures (Chapter 3)

have been completed. You should ensure that AutoSet 1500 will

properly stop the press before running parts.

You need to make a few test press runs to ensure that AutoSet 1500 is working properly and

will stop on a fault condition. You will have to load tonnage-related settings and then run a

test tool (refer to Chapter 4 (Operation) for more assistance). Here are the steps for the final

checkout:

• Set a high setpoint % value using the "% High Percent Tolerance Selector" on the

AutoSet board (see location of components - Figure 2-2). For simplicity, program the

high setting at 2% ("position 1" on the selector).

• Run a few parts.

• Check that the press top stops and that an error condition ("HI") flashes on the AutoSet

LED display and the display flashes the strain link input(s) affected.

• If AutoSet 1500 displayed a message but the press did not top stop, there is a problem in

your top stop circuit. Recheck all wiring and trace the cause of the problem. Do not

continue with this procedure until the press top stops when you trip the high setpoint.

• If you got to this step, and everything is working right, clear the error message by

pressing Reset. Change the high setpoint % to a proper value.

AutoSet 1500 User Manual 22 Ch 2 1088500

Page 30

Chapter 3

AutoSet 1500 Calibration

This chapter explains calibration of AutoSet. Calibration means adjusting AutoSet 1500

so tonnage readings are accurate.

After calibration, the tonnage AutoSet displays will indicate the true tonnage applied by

the press. You must calibrate the AutoSet after installation and any time you move the

strain links to a different location on the press, restres the tie rods, or perform major

repair work to the press frame.

The calibration procedure consists of the following general steps:

(1) Zeroing the strain links. This means you adjust the strain links until they provide a

"zero" signalwith no load on the press. Once the strain links are set for 0 tons at no

load, they can properly record the tonnage developed once the press is under load.

(2) Applying a load to the press and measuring this load using load cells and a separate

calibration unit. You can use either another AutoSet calibration kit as the calibration

unit or Data Instruments' Wintriss Load Analyzer (WLA) calibration kit. How to use

both units is described in this chapter.

NOTE: Calibration with a hydraulic jack is also possible, although much less

accurate than load cells. It is also not as easy a procedure as using load cells. Data

Instruments does not recommend hydraulic jack calibration, and it is not covered in

this manual. For more information on hydraulic jack calibration, contact a Data

Instruments service representative.

(3) Setting the full scale tonnage of AutoSet to equal the maximum tonnage capacity of

your press. This lets AutoSet know the highest tonnage it will be recording.

(4) Adjusting AutoSet until its tonnage display agrees with the tonnage recorded on

your calibration unit. Once you do that, your AutoSet is reading the proper tonnage,

and it is ready for use.

The exact procedures for calibration follow.

Calibration

Before starting calibration, make sure the press is adjusted to optimal condition – the

gib/ways adjustment should be correct and the ram should be parallel to the bed and tie

rod tension checked.

Data Instruments recommends calibrating the AutoSet at the tonnage the press will

normally operate. If you usually run between 60-90% of press capacity, for instance,

calibrate at 75% of capacity. For example, if the press is a 100 ton press, calibrate for 75

tons. Do not calibrate at less than 50% of press capacity.

AutoSet 1500 User Manual 23 Ch 3 1088500

Page 31

Calibration

Types of calibration kits you can use

As noted earlier, you must use a separate tonnage monitor with a calibration kit to calibrate

AutoSet. You first connect this tonnage monitor to the load cells. Then you apply tonnage

to the load cells and display the tonnage on this monitor. Finally, you adjust the AutoSet

until it displays the same tonnage. You can use either a Wintriss Load Analyzer (WLA)

with calibration kit or another AutoSet 1500 with calibration kit to read the tonnage applied

to the load cells. How to use each type of calibration kit is described below.

How many load cells to use

Use one load cell (single point calibration) if your press has only one connecting rod. The

load cell is placed under the rod. If your press has two (or more) connecting rods, use at

least two load cells (double point calibration). Both methods are covered below.

How to begin

The calibration procedure is divided into four parts:

• Zeroing your AutoSet Plus

• Setting up and adjusting the Wintriss Load Analyzer (WLA) calibration kit.

• Setting up and adjusting an AutoSet 1500 calibration kit.

• Calibrating your AutoSet 1500

First follow the procedure for setting up and adjusting the calibration unit you are using.

Then go directly to the section titled "Calibrating your AutoSet 1500".

Zeroing strain links

1. Before you can adjust the AutoSet 1500 to the tonnage on your calibration unit,

First, make sure there is no load on the load cells. Move the ram to top dead

2. Make sure the strain link mounting screws are loose. There can be no stress on the

NOTE: If you did not put Loctite no. 242 (or equivalent) on the mounting screws

3. Apply power to AutoSet if not already on.

4. Find the toggle switch S2, which is just above the three tonnage setting switches

5. Start with the left strain link. Remove its two cover screws and pull the cover off.

you have to set the strain links to read zero (0) at no load.

center if not already there.

link. You will zero and tighten links to the frame at the same time. (Remember

you left the strain links loose in the installation procedure—this is why.)

when following the installation procedure, do so now.

at the right side of the board. S2 is labeled “For Calibration” in Figure 2-2.

Switch it to the “Zero Set” position. The displays will be lit. The top load LED

displays will show numbers. The bottom setpoint LED displays will show dashes

or the letters "HI" or "LO."

AutoSet 1500 User Manual 24 Ch 3 1088500

Page 32

Calibration

6. Find the potentiometer for zeroing the link. It is a small cube on the circuit board

with a tiny screw on top as shown below.

circuit board

cover mounting

cable

bracket

adjusting screw on potentiometer

Figure 3-1. Zeroing screw for strain links

7. Turn the screw on the strain link. You will see the numbers in the upper left display

window change. Adjust the display by turning the screw one way or another until the

display reads between ±5. The setpoint display will now show dashes (- - -).

NOTE

If you cannot get the tonnage displays to read between ±5, make sure

strain link connections are tight and connector is firmly seated.

Loose connections can cause the problem. If nothing has worked, the

strain link is not working properly. Contact Data Instruments for assistance.

8. Now begin tightening the strain link screws evenly all around. As you tighten, check the

display. The numbers on the tonnage display will change. When the strain link is fully

tightened (150 inch-pounds), the number on the display must be between ±90.

If the number is not between ±90, loosen and adjust the mounting screws until you get it.

Make sure you get it right. By doing so, you ensure that there is no stress on the link at

no load.

If you cannot get the tonnage displays to read between ±90, you may

have drilled the holes crooked, or there may be some other problem with

the installation. Contact Data Instruments for assistance.

NOTE: At this point, the setpoint display may say "HI" or "LO" or show dashes ( - - -).

Ignore this display for now. A "HI" or "LO" means the setting is still too close to the

outer limits of the range, but we will take care of that in the next step.

AutoSet 1500 User Manual 25 Ch 3 1088500

NOTE

Page 33

Calibration

9. Once the strain link is tight, set the display as close to zero as possible, between ±50. Set

the display by turning the screw on the potentiometer on the strain link, as before. The

setpoint display will now show dashes ( - - -).

10. Replace the strain link cover. You are done zeroing the link.

11. Repeat Steps 5–10 for the remaining strain links.

Setting up and adjusting a Wintriss Load Analyzer

(WLA) calibration kit

Follow the steps below if you are using a Wintriss Load Analyzer 2000. You must obtain

a WLA2000 unit, up to two calibration modules, and up to two load cells and cables.

NOTE

For two load cell calibration: Ignore total tonnage readings displayed on

the WLA during calibration. Use left side reading for left tonnage and

right side reading for right tonnage.

For single load cell calibration: Disregard the total tonnage reading.

Make sure the load cell is centered under the connecting rod. Use the

left side readout and divide it by two for left and right side tonnage

readings.

Follow these steps to set up and adjust the WLA calibration unit:

1. Make sure the power to the Wintriss Load Analyzer is off. Then remove both

signal conditioning modules if installed. These modules are the ones which have

knobs for setting tonnage setpoints and a span adjustment. Loosen the screw at

the bottom of the module and pull it out. (Important: you must remove both

modules.)

2. Insert the calibration modules, which have a large, green Amphenol plug, in place

of the conditioning modules. (For single cell calibration, only insert the left

module.)

3. Remove the display module from the WLA. This is the module with the LED

display for tonnage readings. It is located between the two conditioning modules.

To remove, loosen the screw at the bottom of the module and slide module out.

You will see three dial switches with numbers on them.

For two cell calibration, set the tonnage switches to the sum of the load cell

capacities. For single cell calibration, set the tonnage switch to the load cell

capacity. To set the dial switches, use a screwdriver to aim the pointer at the

number you want. The switch for the most significant digit (the "1" in 100 for

instance) is at the left . When done, replace the display module.

AutoSet 1500 User Manual 26 Ch 3 1088500

Page 34

Calibration

4. Connect the cables to calibration modules—they attach to the front of the

module—and to the load cells. Make sure the left cell is connected to the left

module and the right cell to the right module. For one cell calibration, of course,

you are only connecting one module (the left module).

5. Plug in power cord and turn power on. (If your unit does not have a power cord,

refer to your WLA User Manual for instructions on connecting power.)

6. On the WLA computation module:

Set the mode switch to ZERO.

Set the TENSION/COMPRESSION switch to COMPRESSION.

Set the display switch to LEFT.

7. Use a screwdriver to adjust the span control on the left calibration module until

the display flickers between "00" and "L0."

8. For two cell calibration only:

Set the display switch to RIGHT.

Adjust the right calibration module span control with screwdriver until the display

flickers between "00" and "L0."

9. On the WLA:

Set the mode switch to CALFACTOR.

Set the display switch to LEFT.

Press and release the RESET button.

10. You should now see a number between 170 and 190 on the display.

If no calibration number appears, change the TENSION/COMPRESSION switch

to the opposite position.

If the calibration number is incorrect, stop the calibration procedure. Call Data

Instruments for help.

AutoSet 1500 User Manual 27 Ch 3 1088500

Page 35

Calibration

11. For two cell calibrations, set the display switch to RIGHT.

Press and release the RESET button.

12. You should now see a number between 170 and 190 on the display.

If no calibration number appears, change the TENSION/COMPRESSION switch

to the opposite position.

If the calibration number is incorrect, stop the calibration procedure. Call Data

Instruments for help.

13. On the WLA computation module:

Set the mode switch to OPERATE and the TENSION/COMPRESSION switch to

COMPRESSION.

Press and release the RESET button. Set the display switch to LEFT. The letters

"cA" will now appear in the displays.

14. If not already done, you must connect a switch to the WLA so you can zero it

after every complete stroke. Manually zeroing the WLA is required because it has

no zero cam connected to it which tells it when the press reaches top dead center.

Without a zero signal, the WLA does not know when to clear the readings for one

stroke and display readings for the next. You tell it when by manually zeroing it.

You should zero the WLA after every stroke of the press.

A normally open, momentary pushbutton switch is recommended. Install the

switch between terminals #1 and #4 on terminal TB2. TB2 is on the left end of the

WLA. Remove the screws on the left end panel and remove panel to see TB2. It is

on the edge of the circuit board. Connect the switch. Then re-assemble the end

panel.

15. Press the zero switch you just installed. The letters "cA" will disappear from the

displays and a zero will appear. Note: The status function light on the WLA will

light each time the switch is pressed.

16. You are done setting up the WLA calibration unit. The WLA will now read the

correct tonnage when you apply a load to the load cells. Go to the procedure titled

"Calibrating your AutoSet 1500" to set up the press and calibrate your AutoSet

1500.

AutoSet 1500 User Manual 28 Ch 3 1088500

Page 36

Calibration

Setting up and adjusting an AutoSet 1500 calibration kit

Follow the steps below if you are using another AutoSet 1500 with calibration kit for

calibrating your AutoSet 1500. The kit contains two load cells, calibration modules, and

cables. The steps below tell you how to set up and adjust the AutoSet to display the

correct tonnage applied to the load cells.

1. Find the calibration modules. They are small boxes with cables attached. The end

of each cable has a connector that fits into the strain link connector in the AutoSet

box. These modules also have a connector on the box where the load cell cable

connectors screw in.

2. Swing open the front cover of the AutoSet (the one you are using as the

calibration unit). If your unit does not have a plug, connect power to it as

described in Chapter 1—"Connecting AC power and stop circuit." (Do not

connect the stop circuit.)

WARNING

Make sure power supply cover is in place

If you remove the power supply cover to connect 115 Vac

wires, make sure you put the cover back on. The cover fits

over the power supply near the top of the enclosure. It

helps prevent shock if you are working inside the box with

power on.

3. For one cell calibration, take one calibration module and plug the cable into the

slot marked "left input" in the AutoSet box. This slot is at the lower right hand

corner of the box. The connector goes in one way only. If there already is a

connector plugged into this slot, remove it to plug in the connector to the

calibration module.

For two cell calibration, also plug the other calibration module into the slot

marked "right input."

For one cell calibration, you must attach a jumper wire to the connector on the

unused channel. So pull out the connector from the right input slot. If there is no

connector in this slot, you will have to put one in. Put a jumper wire between slots

2 and 3 (see Figure 2-7 in Chapter 2). Plug connector back in slot. This connector

should have no other wires attached to it.

NOTE: You can use either the right or left input for one cell calibration. We will

use the left in this procedure. The unused connector in the other slot must have

the jumper wires connected.

AutoSet 1500 User Manual 29 Ch 3 1088500

Page 37

Calibration

4. Get the load cells you are using (one or two). Screw the connector on each load

cell cable into the connector on the calibration module.

5. Plug in your AutoSet calibration unit if you have not done so. If your unit does

not have a plug, connect wiring to an AC outlet, then apply power. Make sure

power at outlet is off before connecting wires.

WARNING

PREVENT SHOCK

If your AutoSet does not have a plug and you wire it to a power

source, make sure power at that outlet is off before you connect the

wires.

6. Check the AutoSet displays. Once AutoSet has power, the displays will show

numbers, dashes, or letters (it does not matter what at this point). Recheck all

connections if displays do not light up.

7. Familiarize yourself with the location of the switches and dials inside the box. See

Figure 2-2 in Chapter 2 for a drawing of the components inside the box.

8. You must set the full scale tonnage on the AutoSet calibration unit to 2 times the

tonnage of one load cell. Even if you are using two load cells, you still set this

number to 2 times the tonnage of 1 load cell.

Determine the number you will use for your setting. Here are two examples of

how to determine the correct number:

Example 1. You are using one 100 ton load cell for calibration. The full scale

tonnage must be set to 200.

Example 2. You are using two 100 ton load cells for calibration. The full

scale tonnage must be set to 200.

9. Set full scale tonnage as follows:

Find the three blocks in a column with white dials on them. See Figure 3-2. They

are at the right middle of the box.

Figure 3-2. Blocks for setting full scale tonnage on calibration unit

AutoSet 1500 User Manual 30 Ch 3 1088500

Page 38

Calibration

The blocks are labeled 100's, 10's and 1's (for the 100's digit, 10's digit and 1's

digit in a number). These labels tell you how to dial in your number. For instance,

if your number is 250, you would set the blocks like this: 100's = 2, 10's = 5, 1's =

0. If your number is 50, you would do this: 100's = 0, 10's = 5, 1's = 0.

You set tonnage by turning the dial screw on each block until the arrow points at

the right number. Set your number on the calibration unit as instructed below:

If you are setting a number from 1 to 999

Set the 100's, 10's and 1's digits to the number. For load cells under 200 tons,

AutoSet will display tonnage in tenths of a ton (15.5 20.0, 99.9, etc) up to 100

tons. For 200 tons and above, AutoSet displays tonnage in whole numbers

only.

NOTE: Make sure the decimal point switch (No. 3 on S6) is set to the "on"

position. See Figure 3–2. If not set to "on", push switch all the way to the left

with a pen or your thumbnail.

If you are setting a number between 1000 and 1500

Leave out the least significant digit when setting the switches. For instance

1500 would be set as "1", "5", "0"—the same as if you were setting full scale

tonnage to 150 tons. You must also set DIP switch number 3 on Switch block

S6 to the closed position (decimal point off). Switch block S6 is located below

the full scale tonnage switches. See Figure 3-3. With a ball point pen (not a

pencil) or your thumbnail, push the switch to the right (away from the OPEN

position). Make sure you push it all the way to the right. This allows AutoSet

to display accurate readings within the 1000 to 1500 tonnage range.

NOTE: Changing this switch shuts off the decimal point. Tonnage will

only be displayed in whole numbers.

Figure 3-3. Setting decimal point switch on calibration unit

If you are setting a number more than 1500

Leave out the least significant digit when setting the switches. For instance

2000 would be set as "2", "0", "0"—the same as if you were setting full scale

tonnage to 200 tons. When your setting is greater than 1500, you must

multiply all tonnage readings on your displays by 10. For instance, 15.5 tons

would be read as 155 tons. A display of 150 tons would be read as 1500 tons.