Page 1

Automatic Pitch Trim

Installation Manual

8300-013 Rev K

Honeywell International,

Inc. 9201-B San Mateo Blvd N.E.

Albuquerque, New Mexico 87113 U.S.A.

Telephone: 855-250-7027 (Toll Free U.S.A./Canada)

Telephone: 602-365-7027 (International/Direct)

RESTRICTION ON USE, DUPLICATION, OR DISCLOSURE OF

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BENDIXKING. AND MAY NOT BE REPRODUCED, COPIED, DISCLOSED OR UTILIZED IN ANY

WAY, IN WHOLE OR IN PART, WITHOUT THE PRIOR WRITTEN CONSENT OF

BENDIXKING.

8300-013 1 Rev K

Page 2

8300-013 2 Rev K

Page 3

Table of Contents

1. Document Revision History ............................................................................. 4

Warning: ................................................................................................................... 5

2. Electrical Pinout ............................................................................................... 5

3. Retrofit to Existing Autopilot Harness ............................................................ 6

4. Pitch Auto Trim Block Diagram ...................................................................... 7

5. 28 Volt Aircraft with 12 Volt Trim System ..................................................... 8

6. Troubleshooting ............................................................................................... 9

7. Autotrim Installation ....................................................................................... 9

8. Autotrim Ground Setup .................................................................................... 9

9. Autotrim Ground Checkout ........................................................................... 10

10. Autotrim Status Lamp Indications ............................................................ 10

11. Autotrim Checkout Flowchart ................................................................... 11

12. Autotrim Troubleshooting ......................................................................... 12

13. Autotrim Dimensions ................................................................................. 14

8300-013 3 Rev K

Page 4

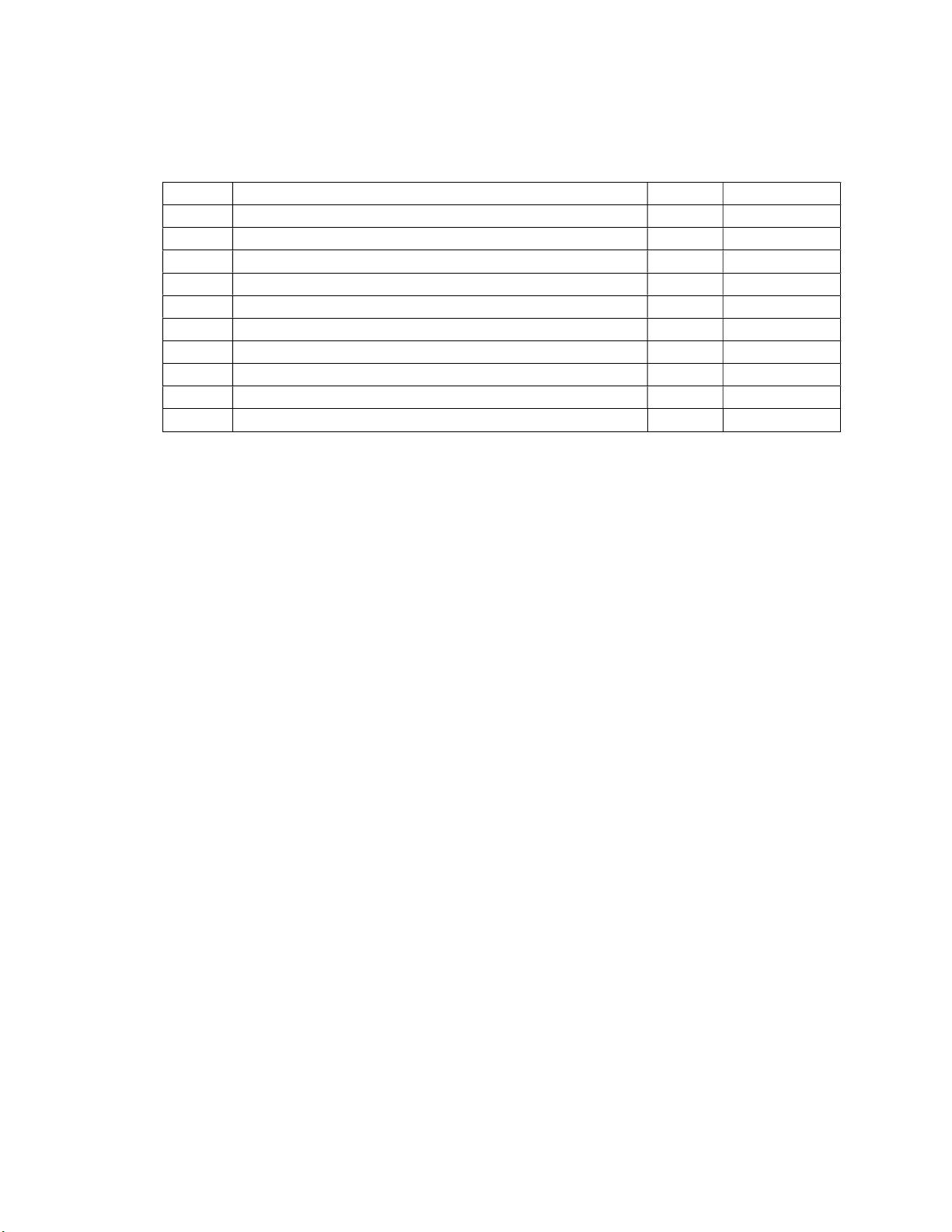

1. Document Revision History

Rev Description Pages Date

C New Auto Trim Module All

D Updated Trouble Guide 1, 5& 6

E Updated for new autotrim design All

F Corrected Diagrams for LED 4-6 3/2/2015

G Corrected setup procedure 9 3/30/2015

H Added note to diagrams for LED polarity 4-6 7/13/2017

I Corrected Pin 16 Connection 4 10/23/2017

J Corrected Flow Chart 9 10/30/2017

K Updated for BendixKing All 2/15/2021

12/22/2009

6/3/2011

2/23/2015

8300-013 4 Rev K

Page 5

Warning:

IT IS THE INSTALLERS RESPONSIBILITY TO ENSURE THAT THE TRIM

SYSTEM DOES NOT EXCEED THE ABILITY OF THE PILOT TO CONTROL

THE AIRCRAFT AT ANY SPEED WITH THE TRIM TAB AT FULL

DEFLECTION IN EITHER POSITION.

IF UNABLE TO MAINTAIN FLIGHT CONTROL WITH THE TRIM TABS AT

FULL DEFLECTION THEN STOPS WILL BE NEEDED IN THE AIRCRAFT

TRIM SYSTEM.

2. Electrical Pinout

The Trim motor control from the pilot trim switch system will pass through the

Auto Trim module when the Auto Pilot is NOT ENGAGED through a normally closed

relay internally. Once the Auto Pilot is engaged the Auto Trim will open the relay

and pulse the voltage that is applied to pin 12 / 13 and ground on pins 9 and 10

according to which direction the sense voltage from the Pitch Servo indicates to

drive the trim motor. This control voltage and ground MUST be connected to the

trim motor ONLY, it will not drive the trim relay system.

8300-013 5 Rev K

Page 6

3. Retrofit to Existing Autopilot Harness

8300-013 6 Rev K

Page 7

4. Pitch Auto Trim Block Diagram

8300-013 7 Rev K

Page 8

5. 28 Volt Aircraft with 12 Volt Trim System

The Voltage that is supplied to the Auto Trim system will drive the trim motor with

the same voltage when the Auto Trim system is in operation. The pitch servo and the

auto trim system do NOT need to be supplied with the same voltage to work correctly.

8300-013 8 Rev K

Page 9

6. Troubleshooting

7. Autotrim Installation

The autotrim module can be mounted in any location, in any orientation. Generally it

is installed near the pitch servo to minimize the wire length required for installation.

The LED status lamp can also be installed in any location desired. However, it must

be visible for the setup procedure. The lamp will also indicate a failure so having it

visible even during normal operation is beneficial.

NOTE: The status lamp is NOT the LED on the side of the autotrim module itself.

8. Autotrim Ground Setup

The autotrim ground setup is a simple process outlined below. The autotrim module

pulses the trim motor instead of

running it continuously. This prevents a rapid trim runaway in case the ground check

was not completed properly. This

ground setup process describes

1) Power up the autopilot system. The LED status lamp should illuminate and

stay lit for no more than five seconds. Once the lamp goes out, move to step 2.

2) Engage the autopilot then press and hold one direction on the aircraft trim

switch for 10 seconds. After 10 seconds, the status lamp will illuminate again

and stay lit until the trim switch is released. Release the trim switch.

3) The status lamp will now flash at the currently selected autotrim speed.

Tapping one of the trim switches will adjust the speed slower, tapping the

other switch will adjust it faster. Which is which depends on how it was wired,

so it is not a constant. The speed of the lamp flash will adjust with each switch

tap.

8300-013 9 Rev K

Page 10

4) Once the desired speed is set, simply do not press any trim switch for 10

seconds. The status lamp will stop flashing. This indicates the autotrim is no

longer in setup mode and the desired trim speed has been saved.

5) Setup is complete, disengage the autopilot and proceed to Autotrim Ground

Checkout.

9. Autotrim Ground Checkout

Once installation and setup is complete, follow the below checkout procedure before

flying with the autotrim for the first

time. Following this procedure will prevent runaway trim conditions in flight.

1) Verify that the manual trim control moves the trim tab in the appropriate

direction.

2) Center the elevator control then engage the autopilot.

3) Gently apply pressure downward on the elevator, not from the stick but from

the actual elevator.

4) The trim tab should move downward as well. If the trim tab moves up, the

autotrim direction is reversed so the switch on the side of the autotrim will

need to be flipped. Once it is flipped, repeat steps 2-4.

10. Autotrim Status Lamp Indications

The LED status lamp four different indications:

1) Steady On at Power Up: This is the self-test of the autotrim module. This lasts

no more than five seconds right as power is applied to the autopilot system.

2) Steady On during Ground Setup: This indicates that the autotrim is entering

setup mode so the autotrim speed can be adjusted.

3) Flashing during Ground Setup: This flashing indicates the speed the autotrim

will pulse the trim motor.

4) Steady On during Normal Flight Operation: This indicates that the autotrim

has detected an internal failure and will no longer function. Manual trim

control will be restored if this occurs.

8300-013 10 Rev K

Page 11

11. Autotrim Checkout Flowchart

All tests performed at the elevator surface, not at the stick/yoke.

Note: If the above technique has been completed and the automatic trim module still

does not run the trim, then first try applying more force to the system when holding

the up elevator. If the pitch servo slips easily when holding the force, ensure that the

pitch servo torque is set at the maximum value and hold as much force as possible

without slipping the servo. If the torque is set at the maximum and the system still

does not function, check automatic trim wiring. See trouble shoot guide in back

The switch in the first slot of the controller is to switch trim motor direction, see

above diagram.

Two small slots are control indication LEDs, see above.

8300-013 11 Rev K

Page 12

12. Autotrim Troubleshooting

Does the Trim bar always show on the display with the Auto pilot programmer

engaged?

Does the Auto trim drive the trim motor with no pressure on the elevator?

AUTO PILOT PROGRAMMER TEST

Disconnect Auto trim harness 25 pin connector.

Insert test contact pin into pin location 3 (Trim Sense 2.5v no control surface load)

Insert test pin contact into pin location 15 (Ground)

Apply power to Autopilot system

Engage Autopilot

Check for trim sense voltage at (pin 3) to ground (pin 15) should be 2.5 volts. This

should be checking the voltage on the trim

sense wire from the autopilot programmer.

If yes, continue Programmer test good.

Reconnect Auto trim harness

AUTO TRIM MODULE TEST

Disconnect Pitch servo harness 9 pin connector

Insert test contact pin into pin location 9 of servo connector (Ground)

Insert test contact pin into pin location 7 of servo connector (Trim Sense 2.5v)

Apply power to Auto pilot system

Engage Auto pilot

Check for trim sense voltage at (pin 7) to ground (pin 9) should be 2.5 volts. This

should be checking the voltage on the trim

sense wire from the Auto trim module.

If yes, continue Module test good.

Reconnect Pitch servo harness

SERVO TRIM SENSE TEST

Remove cover from Pitch servo 9 pin connector to access pin contacts.

Connect volt meter to aircraft ground. (confirm good ground by check for resistance

to pin 9 of servo connector). Must be 0 ohms.

Connect volt meter to pin 7 of servo connector.

Apply power to autopilot system

Engage autopilot

Test voltage at pin 7 of servo, Must be @ 2.5 with no load on elevator. Apply pressure

to elevator in both directions. Should be able to vary voltage up or down according to

amount of force applied. Voltage range 0-5 volts.

If yes, continue Servo test good.

Reassemble connector shell.

TRIM MOTOR CONTROL TEST

Disconnect Auto Trim Module harness connector

8300-013 12 Rev K

Page 13

Insert test contact pin into pins 8 & 11

Connect volt meter across pins, there should be aircraft voltage when trim system is

actuated with pilot trim control. This voltage must be positive one direction and

negative in the other. If a Relay Deck is installed in the Trim System it MUST be

wire BEFORE the Auto Trim Module and Trim motor.

Reconnect Auto Trim Module harness

Connect volt meter across Trim motor output pins 9 & 10

Engage auto pilot, there should be pulsing voltage when trim system is actuated with

pressure on the elevator. This voltage must be positive one direction and negative in

the other.

This concludes the trim system testing

8300-013 13 Rev K

Page 14

13. Autotrim Dimensions

8300-013 14 Rev K

Page 15

8300-013 15 Rev K

Loading...

Loading...