Page 1

ENGINEERING MANUAL of

AUTOMATIC

CONTROL

COMMERCIAL BUILDINGS

SI Edition

for

Page 2

Copyright 1989, 1995, and 1997 by Honeywell Inc.

All rights reserved. This manual or portions thereof may not be reporduced

in any form without permission of Honeywell Inc.

Library of Congress Catalog Card Number: 97-77856

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis MN 55408-0524

Honeywell Latin American Region

480 Sawgrass Corporate Parkway

Suite 200

Sunrise FL 33325

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 3N7

Honeywell Europe S.A.

3 Avenue du Bourget

1140 Brussels

Belgium

Printed in USA

ii

Honeywell Asia Pacific Inc.

Room 3213-3225

Sun Hung Kai Centre

No. 30 Harbour Road

Wanchai

Hong Kong

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 3

FOREWORD

The Minneapolis Honeywell Regulator Company published the first edition of the Engineering Manual of

Automatic Control in l934. The manual quickly became the standard textbook for the commercial building

controls industry. Subsequent editions ha ve enjoyed ev en greater success in colleges, univ ersities, and contractor

and consulting engineering offices throughout the world.

Since the original 1934 edition, the building control industry has experienced dramatic change and made

tremendous advances in equipment, system design, and application. In this edition, microprocessor controls are

shown in most of the control applications rather than pneumatic, electric, or electronic to reflect the trends in

industry today. Consideration of configuration, functionality, and integration plays a significant role in the

design of building control systems.

Through the years Honeywell has been dedicated to assisting consulting engineers and architects in the

application of automatic controls to heating, ventilating, and air conditioning systems. This manual is an outgro wth

of that dedication. Our end user customers, the building owners and operators, will ultimately benef it from the

efficiently designed systems resulting from the contents of this manual.

All of this manual’s original sections have been updated and enhanced to include the latest developments in

control technology and use the International System of Units (SI). A ne w section has been added on indoor air

quality and information on district heating has been added to the Chiller, Boiler, and Distribution System

Control Applications Section.

This third SI edition of the Engineering Manual of Automatic Control is our contribution to ensure that we

continue to satisfy our customer’s requirements. The contr ib utions and encouragement receiv ed from pre vious

users are gratefully acknowledged. Further suggestions will be most welcome.

Minneapolis, Minnesota

December, 1997

KEVIN GILLIGAN

President, H&BC Solutions and Services

ENGINEERING MANUAL OF AUTOMATIC CONTROL

iii

Page 4

iv

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 5

PREFACE

The purpose of this manual is to provide the reader with a fundamental understanding of controls and how

they are applied to the many parts of heating, ventilating, and air conditioning systems in commer cial buildings.

Many aspects of control are presented including air handling units, terminal units, chillers, boilers, building

airflow , water and steam distribution systems, smoke management, and indoor air quality . Control fundamentals,

theory, and types of controls provide background for application of controls to heating, ventilating, and air

conditioning systems. Discussions of pneumatic, electric, electronic, and digital controls illustrate that applications

may use one or more of several different control methods. Eng ineering data such as equipment sizing, use of

psychrometric charts, and conversion formulas supplement and support the control information. To enhance

understanding, definitions of terms are provided within individual sections.

Building management systems have ev olved into a major consideration for the control engineer when evaluating

a total heating, ventilating, and air conditioning system design. In response to this consideration, the basics of

building management systems configuration are presented.

The control recommendations in this manual are general in nature and are not the basis for any specific job or

installation. Control systems are furnished according to the plans and specifications prepared by the control

engineer. In many instances there is more than one control solution. Professional expertise and judgment are

required for the design of a control system. This manual is not a substitute for such expertise and judgment.

Always consult a licensed engineer for advice on designing control systems.

It is hoped that the scope of information in this manual will provide the readers with the tools to expand their

knowledge base and help develop sound approaches to automatic control.

ENGINEERING MANUAL OF AUTOMATIC CONTROL

v

Page 6

vi

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 7

ENGINEERING MANUAL of

AUTOMATIC

CONTROL

CONTENTS

Foreward ............................................................................................................ iii

Preface ............................................................................................................ v

Control System Fundamentals .......................................................................................... 1

Control Fundamentals ............................................................................................................ 3

Introduction.......................................................................................... 5

Definitions............................................................................................ 5

HVAC System Characteristics ............................................................. 8

Control System Characteristics ........................................................... 15

Control System Components .............................................................. 30

Characteristics and Attributes of Control Methods .............................. 35

Psychrometric Chart Fundamentals ............................................................................................................ 37

Introduction.......................................................................................... 38

Definitions............................................................................................ 38

Description of the Psychrometric Chart............................................... 39

The Abridged Psychrometric Chart ..................................................... 40

Examples of Air Mixing Process.......................................................... 42

Air Conditioning Processes ................................................................. 43

Humidifying Process............................................................................ 44

Process Summary ............................................................................... 53

ASHRAE Psychrometric Charts .......................................................... 53

Pneumatic Control Fundamentals ............................................................................................................ 57

Introduction.......................................................................................... 59

Definitions............................................................................................ 59

Abbreviations....................................................................................... 60

Symbols............................................................................................... 61

Basic Pneumatic Control System ........................................................ 61

Air Supply Equipment.......................................................................... 65

Thermostats ........................................................................................ 69

Controllers ........................................................................................... 70

Sensor-Controller Systems ................................................................. 72

Actuators and Final Control Elements................................................. 74

Relays and Switches ........................................................................... 77

Pneumatic Control Combinations........................................................ 84

Pneumatic Centralization .................................................................... 89

Pneumatic Control System Example................................................... 90

Electric Control Fundamentals ............................................................................................................ 95

Introduction.......................................................................................... 97

Definitions............................................................................................ 97

How Electric Control Circuits are Classified ........................................ 99

Series 40 Control Circuits.................................................................... 100

Series 80 Control Circuits.................................................................... 102

Series 60 Two-Position Control Circuits............................................... 103

Series 60 Floating Control Circuits...................................................... 106

Series 90 Control Circuits.................................................................... 107

Motor Control Circuits.......................................................................... 114

ENGINEERING MANUAL OF AUTOMATIC CONTROL

vii

Page 8

Electronic Control Fundamentals ............................................................................................................ 119

Introduction.......................................................................................... 120

Definitions............................................................................................ 120

Typical System .................................................................................... 122

Components ........................................................................................ 122

Electronic Controller Fundamentals .................................................... 129

Typical System Application.................................................................. 130

Microprocessor-Based/DDC Fundamentals .................................................................................................... 131

Introduction.......................................................................................... 133

Definitions............................................................................................ 133

Background ......................................................................................... 134

Advantages ......................................................................................... 134

Controller Configuration ...................................................................... 135

Types of Controllers............................................................................. 136

Controller Software.............................................................................. 137

Controller Programming ...................................................................... 142

Typical Applications ............................................................................. 145

Indoor Air Quality Fundamentals ............................................................................................................ 149

Introduction.......................................................................................... 151

Definitions............................................................................................ 151

Abbreviations....................................................................................... 153

Indoor Air Quality Concerns ................................................................ 154

Indoor Air Quality Control Applications................................................ 164

Bibliography ......................................................................................... 170

Smoke Management Fundamentals ............................................................................................................ 171

Introduction.......................................................................................... 172

Definitions............................................................................................ 172

Objectives............................................................................................ 173

Design Considerations ........................................................................ 173

Design Priniples .................................................................................. 175

Control Applications ............................................................................ 178

Acceptance Testing ............................................................................. 181

Leakage Rated Dampers .................................................................... 181

Bibliography ......................................................................................... 182

Building Management System Fundamentals................................................................................................. 183

Introduction.......................................................................................... 184

Definitions............................................................................................ 184

Background ......................................................................................... 185

System Configurations ........................................................................ 186

System Functions................................................................................ 189

Integration of Other Systems............................................................... 196

viii

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 9

Control System Applications .......................................................................................... 199

Air Handling System Control Applications...................................................................................................... 201

Introduction.......................................................................................... 203

Abbreviations....................................................................................... 203

Requirements for Effective Control...................................................... 204

Applications-General ........................................................................... 206

Valve and Damper Selection ............................................................... 207

Symbols............................................................................................... 208

Ventilation Control Processes ............................................................. 209

Fixed Quantity of Outdoor Air Control ................................................. 211

Heating Control Processes.................................................................. 223

Preheat Control Processes ................................................................. 228

Humidification Control Process ........................................................... 235

Cooling Control Processes.................................................................. 236

Dehumidification Control Processes ................................................... 243

Heating System Control Process ........................................................ 246

Year-Round System Control Processes .............................................. 248

ASHRAE Psychrometric Charts .......................................................... 261

Building Airflow System Control Applications ............................................................................................... 263

Introduction.......................................................................................... 265

Definitions............................................................................................ 265

Airflow Control Fundamentals ............................................................. 266

Airflow Control Applications................................................................. 280

References .......................................................................................... 290

Chiller, Boiler, and Distribution System Control Applications....................................................................... 291

Introduction.......................................................................................... 295

Abbreviations....................................................................................... 295

Definitions............................................................................................ 295

Symbols............................................................................................... 296

Chiller System Control......................................................................... 297

Boiler System Control.......................................................................... 327

Hot and Chilled Water Distribution Systems Control ........................... 335

High Temperature Water Heating System Control............................... 374

District Heating Applications................................................................ 380

Individual Room Control Applications ............................................................................................................ 395

Introduction.......................................................................................... 397

Unitary Equipment Control .................................................................. 408

Hot Water Plant Considerations .......................................................... 424

ENGINEERING MANUAL OF AUTOMATIC CONTROL

ix

Page 10

Engineering Information .......................................................................................... 425

Valve Selection and Sizing ............................................................................................................ 427

Introduction.......................................................................................... 428

Definitions............................................................................................ 428

Valve Selection .................................................................................... 432

Valve Sizing ......................................................................................... 437

Damper Selection and Sizing ............................................................................................................ 445

Introduction.......................................................................................... 447

Definitions............................................................................................ 447

Damper Selection................................................................................ 448

Damper Sizing..................................................................................... 457

Damper Pressure Drop ....................................................................... 462

Damper Applications ........................................................................... 463

General Engineering Data ............................................................................................................ 465

Introduction.......................................................................................... 466

Conversion Formulas and Tables ........................................................ 466

Electrical Data ..................................................................................... 473

Properties of Saturated Steam Data ................................................... 476

Airflow Data ......................................................................................... 477

Moisture Content of Air Data ............................................................... 479

Index .......................................................................................... 483

x

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 11

SMOKE MANAGEMENT FUNDAMENTALS

CONTROL

SYSTEM

FUNDAMENTALS

ENGINEERING MANUAL OF AUTOMATIC CONTROL

1

Page 12

SMOKE MANAGEMENT FUNDAMENTALS

SMOKE MANAGEMENT FUNDAMENTALS

2

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 13

CONTROL FUNDAMENTALS

Control Fundamentals

ENGINEERING MANUAL OF AUTOMATIC CONTROL

CONTENTS

Introduction ............................................................................................................ 5

Definitions ............................................................................................................ 5

HVAC System Characteristics ............................................................................................................ 8

General................................................................................................ 8

Heating ................................................................................................ 9

General ........................................................................................... 9

Heating Equipment ......................................................................... 10

Cooling ................................................................................................ 11

General ........................................................................................... 11

Cooling Equipment.......................................................................... 12

Dehumidification.................................................................................. 12

Humidification...................................................................................... 13

Ventilation ............................................................................................ 13

Filtration............................................................................................... 14

Control System Characteristics ............................................................................................................ 15

Controlled V ariables ............................................................................ 15

Control Loop........................................................................................ 15

Control Methods .................................................................................. 16

General ........................................................................................... 16

Analog and Digital Control .............................................................. 16

Control Modes ..................................................................................... 17

Two-Position Control ....................................................................... 17

General ....................................................................................... 17

Basic Two-Position Control ......................................................... 17

Timed Two-Position Control ........................................................ 18

Step Control .................................................................................... 19

Floating Control............................................................................... 20

Proportional Control ........................................................................ 21

General ....................................................................................... 21

Compensation Control ................................................................ 22

Proportional-Integral (PI) Control .................................................... 23

Proportional-Integral-Derivative (PID) Control ................................ 25

Enhanced Proportional-Integral-Derivative (EPID) Control............. 25

Adaptive Control.............................................................................. 26

Process Characteristics....................................................................... 26

Load ................................................................................................ 26

Lag .................................................................................................. 27

General ....................................................................................... 27

Measurement Lag....................................................................... 27

Capacitance................................................................................ 28

Resistance .................................................................................. 29

Dead Time .................................................................................. 29

Control Application Guidelines ............................................................ 29

ENGINEERING MANUAL OF AUTOMATIC CONTROL

3

Page 14

CONTROL FUNDAMENTALS

Control System Components ............................................................................................................ 30

Sensing Elements ............................................................................... 30

Temperature Sensing Elements...................................................... 30

Pressure Sensing Elements............................................................ 31

Moisture Sensing Elements ............................................................ 32

Flow Sensors .................................................................................. 32

Proof-of-Operation Sensors ............................................................ 33

Transducers......................................................................................... 33

Controllers ........................................................................................... 33

Actuators ............................................................................................. 33

Auxiliary Equipment............................................................................. 34

Characteristics and Attributes of Control Methods .............................................................................. 35

4

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 15

INTRODUCTION

CONTROL FUNDAMENTALS

This section describes heating, ventilating, and air

conditioning (HV A C) systems and discusses characteristics and

components of automatic control systems. Cross-references are

made to sections that provide more detailed information.

A correctly designed HVAC control system can provide a

comfortable environment for occupants, optimize energy cost

and consumption, improve employee productivity, facilitate

efficient manufacturing, control smoke in the event of a fire,

and support the operation of computer and telecommunications

equipment. Controls are essential to the proper operation of

the system and should be considered as early in the design

process as possible.

Properly applied automatic controls ensure that a correctly

designed HVAC system will maintain a comfortable

environment and perform economically under a wide range of

operating conditions. Automatic controls regulate HVA C system

output in response to varying indoor and outdoor conditions to

maintain general comfort conditions in office areas and provide

narrow temperature and humidity limits where required in

production areas for product quality.

DEFINITIONS

Automatic controls can optimize HVAC system operation.

They can adjust temperatures and pressures automatically to

reduce demand when spaces are unoccupied and regulate

heating and cooling to provide comfort conditions while limiting

energy usage. Limit controls ensure safe operation of HVAC

system equipment and prevent injury to personnel and damage

to the system. Examples of limit controls are low-limit

temperature controllers which help prevent water coils or heat

exchangers from freezing and flow sensors for safe operation

of some equipment (e.g., chillers). In the event of a fire,

controlled air distribution can provide smoke-free evacuation

passages, and smoke detection in ducts can close dampers to

prevent the spread of smoke and toxic gases.

HVAC control systems can also be integra ted with security

access control systems, fire alarm systems, lighting control

systems, and building and facility management systems to

further optimize building comfort, safety, and efficiency.

The following terms are used in this manual. Figure 1 at the

end of this list illustrates a typical control loop with the

components identified using terms from this list.

Analog: Continuousl y variable (e.g., a faucet controlling water

from off to full flow).

Automatic contr ol system: A system that reacts to a change or

imbalance in the variable it controls by adjusting other

variables to restore the system to the desired balance.

Algorithm: A calculation method that produces a control output

by operating on an error signal or a time series of error

signals.

Compensation control: A process of automatically adjusting

the setpoint of a given controller to compensate for

changes in a second measured variable (e.g., outdoor

air temperature). For example, the hot deck setpoint

is normally reset upward as the outdoor air temperature

decreases. Also called “reset control”.

Control agent: The medium in which the manipulated variable

exists. In a steam heating system, the control agent is

the steam and the manipulated variable is the flow of

the steam.

Control point: The actual value of the controlled variable

(setpoint plus or minus offset).

Controlled medium: The medium in which the controlled

variable exists. In a space temperature control system,

the controlled variable is the space temperature and

the controlled medium is the air within the space.

Controlled V ariable: The quantity or condition that is measured

and controlled.

Controller: A device that senses changes in the controlled

variable (or receiv es input from a r emote sensor) and

derives the proper correction output.

Corrective action: Control action that results in a change of

the manipulated variable. Initiated when the controlled

variable deviates from setpoint.

Cycle: One complete e xecution of a repeatable process. In basic

heating operation, a cycle comprises one on period

and one off period in a two-position control system.

Cycling: A periodic change in the controlled v ariable from one

value to another. Out-of-control analog cycling is

called “hunting”. T oo frequent on-off c ycling is called

“short cycling”. Short cycling can harm electric

motors, fans, and compressors.

Cycling rate: The number of cycles completed per time unit,

typically cycles per hour for a heating or cooling system.

The inverse of the length of the period of the c ycle.

ENGINEERING MANUAL OF AUTOMATIC CONTROL

5

Page 16

CONTROL FUNDAMENTALS

Deadband: A range of the controlled variable in which no

corrective action is taken by the controlled system and

no energy is used. See also “zero energy band”.

Deviation: The difference between the setpoint and the value

of the controlled variable at any moment. Also called

“offset”.

DDC: Direct Digital Control. See also Digital and Digital

control.

Digital: A series of on and off pulses arranged to convey

information. Morse code is an early example.

Processors (computers) operate using digital language.

Digital control: A control loop in which a microprocessor-

based controller directly controls equipment based on

sensor inputs and setpoint parameters. The

programmed control sequence determines the output

to the equipment.

Droop: A sustained deviation between the control point and

the setpoint in a two-position control system caused

by a change in the heating or cooling load.

Enhanced proportional-integral-derivative (EPID) contr ol:

A control algorithm that enhances the standard PID

algorithm by allowing the designer to enter a startup

output value and error ramp duration in addition to

the gains and setpoints. These additional parameters

are configured so that at startup the PID output varies

smoothly to the control point with negligible overshoot

or undershoot.

Electric control: A control circuit that operates on line or low

voltage and uses a mechanical means, such as a

temperature-sensitive bimetal or bellows, to perf orm

control functions, such as actuating a switch or

positioning a potentiometer. T he controller signal usually

operates or positions an electric actuator or may switch

an electrical load directly or through a relay.

Electronic control: A control circuit that operates on low

voltage and uses solid-state components to amplify

input signals and perform control functions, such as

operating a relay or providing an output signal to

position an actuator. The controller usually furnishes

fixed control routines based on the logic of the solidstate components.

Final control element: A device such as a valve or damper

that acts to change the value of the manipulated

variable. Positioned by an actuator.

Hunting: See Cycling.

Load: In a heating or cooling system, the heat transfer that the

system will be called upon to provide. Also, the work

that the system must perform.

Manipulated variable: The quantity or condition regulated

by the automatic control system to cause the desired

change in the controlled variable.

Measured variable: A variable that is measured and may be

controlled (e.g., discharge air is measured and

controlled, outdoor air is only measured).

Microprocessor -based control: A control circuit that operates

on low voltage and uses a microprocessor to perform

logic and control functions, such as operating a relay

or providing an output signal to position an actuator.

Electronic devices are primarily used as sensors. The

controller often furnishes flexible DDC and energy

management control routines.

Modulating: An action that adjusts by minute increments and

decrements.

Offset: A sustained deviation between the control point and

the setpoint of a proportional control system under

stable operating conditions.

On/off control: A simple two-position control system in which

the device being controlled is either full on or full off

with no intermediate operating positions available.

Also called “two-position control”.

Pneumatic control: A control circuit that operates on air

pressure and uses a mechanical means, such as a

temperature-sensitive bimetal or bellows, to perform

control functions, such as actuating a nozzle and

flapper or a switching relay. The controller output

usually operates or positions a pneumatic actuator,

although relays and switches are often in the circuit.

Process: A gener al term that describes a change in a measurable

variable (e.g., the mixing of return and outdoor air

streams in a mixed-air control loop and heat transfer

between cold water and hot air in a cooling coil).

Usually considered separately from the sensing

element, control element, and controller.

Proportional band: In a proportional controller, the control

point range through which the controlled variable must

pass to move the final control element through its full

operationg range. Expressed in percent of primary

sensor span. Commonly used equivalents are

“throttling range” and “modulating range”, usually

expressed in a quantity of Engineering units (degrees

of temperature).

Lag: A delay in the effect of a changed condition at one point in

the system, or some other condition to which it is related.

Also, the delay in response of the sensing element of a

control due to the time required for the sensing element

to sense a change in the sensed variable.

Proportional control: A control algorithm or method in which

the final control element moves to a position

proportional to the deviation of the value of the

controlled variable from the setpoint.

6

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 17

CONTROL FUNDAMENTALS

Proportional-Integral (PI) control: A control algorithm that

combines the proportional (proportional response) and

integral (reset response) control algorithms. Reset

response tends to correct the offset resulting from

proportional control. Also called “proportional-plusreset” or “two-mode” control.

Proportional-Integral-Derivative (PID) control: A control

algorithm that enhances the PI control algorithm by

adding a component that is proportional to the rate of

change (derivative) of the deviation of the controlled

variable. Compensates for system dynamics and

allows faster control response. Also called “threemode” or “rate-reset” control.

Reset Control: See Compensation Control.

Sensing element: A device or component that measures the

value of a variable.

Setpoint: The value at which the controller is set (e.g., the

desired room temperature set on a thermostat). The

desired control point.

Short cycling: See Cycling.

Step control: Control method in which a multiple-switch

assembly sequentially switches equipment (e.g.,

electric heat, multiple chillers) as the controller input

varies through the proportional band. Step controllers

may be actuator driven, electronic, or directly activ ated

by the sensed medium (e.g., pressure, temperature).

Throttling range: In a proportional controller, the control point

range through which the controlled variable must pass

to move the final control element through its full

operating range. Expressed in values of the controlled

variable (e.g., Kelvins or degrees Celsius, percent

relative humidity, kilopascals). Also called

“proportional band”. In a proportional room

thermostat, the temperature change required to drive

the manipulated variable from full off to full on.

Time constant: The time required for a dynamic component,

such as a sensor, or a control system to reach 63.2

percent of the total response to an instantaneous (or

“step”) change to its input. Typically used to judge

the responsiveness of the component or system.

Two-position control: See on/off control.

Zero energy band: An energy conservation technique that

allows temperatures to float between selected settings,

thereby preventing the consumption of heating or

cooling energy while the temperature is in this range.

Zoning: The practice of dividing a building into sections for

heating and cooling control so that one controller is

sufficient to determine the heating and cooling

requirements for the section.

MEASURED

VARIABLE

OUTDOOR

AIR

-2

OUTDOOR

AIR

CONTROLLED

MEASURED

VARIABLE

HOT WATER

RETURN

TEMPERATURE

MEDIUM

RESET SCHEDULE

15

-15

OA

CONTROLLED

VARIABLE

HOT WATER

SUPPLY

64

AUTO

55

90

HW

SETPOINT

CONTROL

POINT

HOT WATER

SUPPLY

TEMPERATURE

71

Fig. 1. Typical Control Loop.

70

SETPOINT

INPUT

PERCENT

OPEN

VALVE

SETPOINT

OUTPUT

41

FLOW

ALGORITHM IN

CONTROLLER

FINAL CONTROL

ELEMENT

STEAM

CONTROL

AGENT

MANIPULATED

VARIABLE

M15127

ENGINEERING MANUAL OF AUTOMATIC CONTROL

7

Page 18

CONTROL FUNDAMENTALS

HVAC SYSTEM CHARACTERISTICS

GENERAL

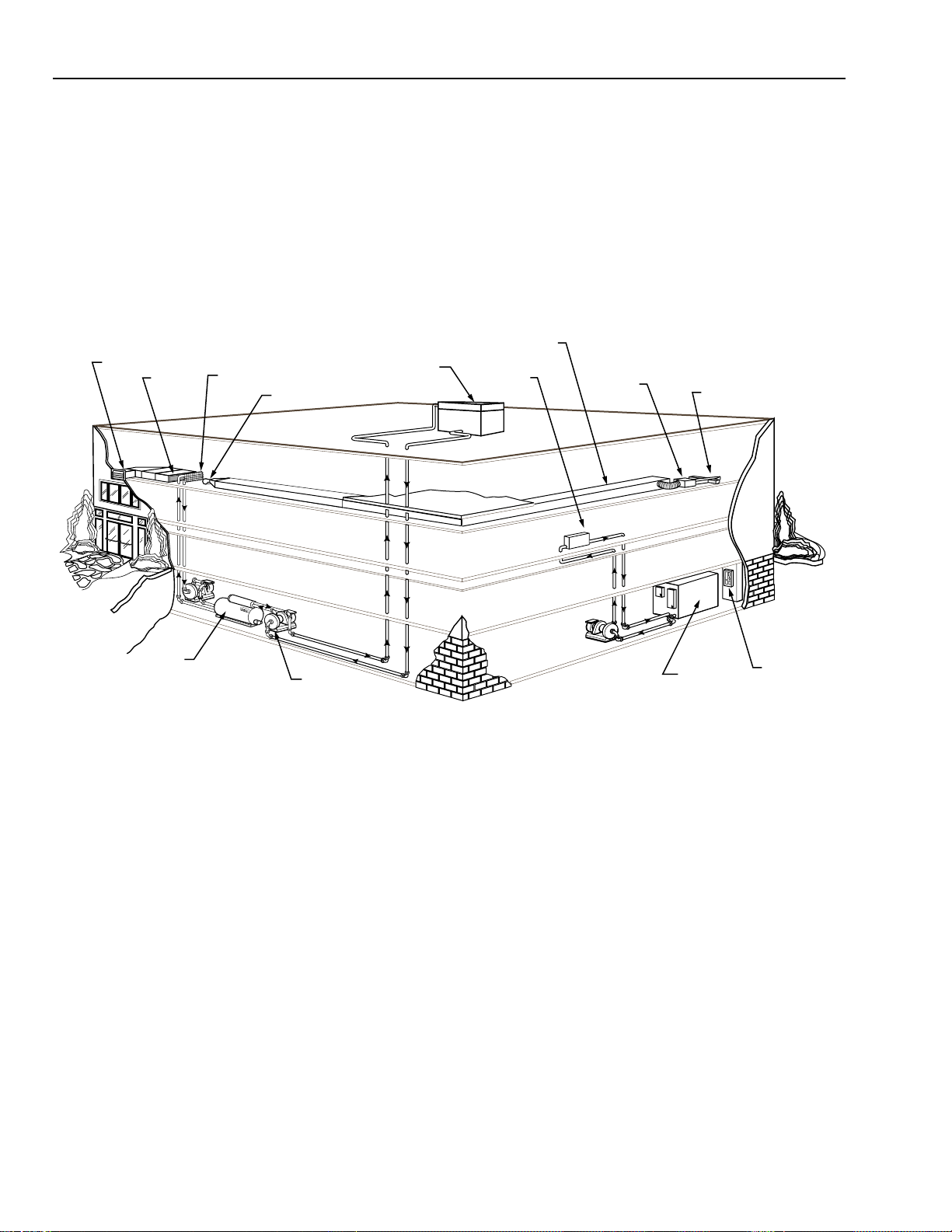

An HVAC system is designed according to capacity

requirements, an acceptable combination of first cost and operating

costs, system reliability, and available equipment space.

DAMPER

AIR

FILTER

COOLING

COIL

FAN

COOLING

TOWER

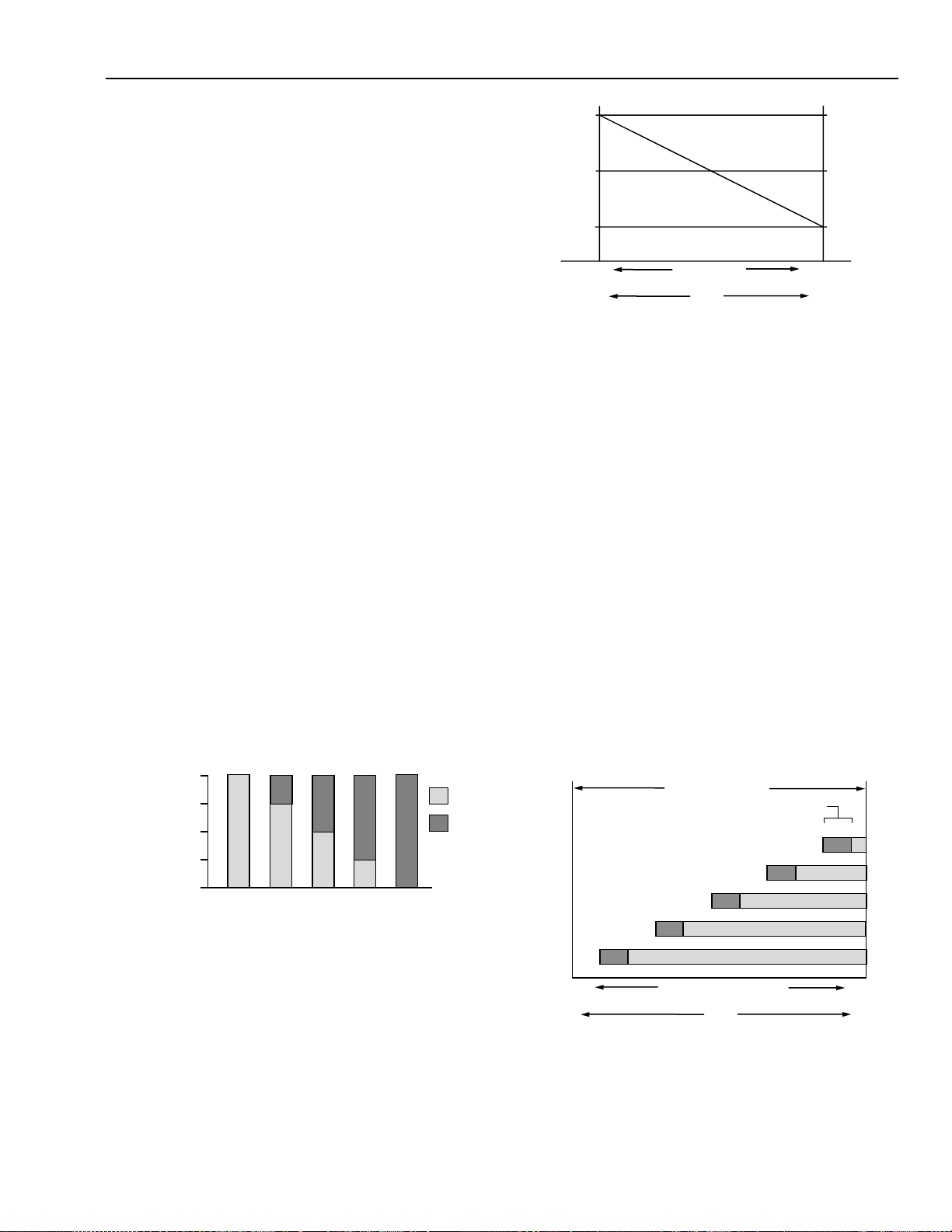

Figure 2 shows how an HVAC system may be distributed in

a small commercial building. The system control panel, boilers,

motors, pumps, and chillers are often located on the lower lev el.

The cooling tower is typically located on the roof. Throughout

the building are ductwork, fans, dampers, coils, air filters,

heating units, and variable air volume (VAV) units and dif fusers.

Larger buildings often hav e separate systems for groups of floors

or areas of the building.

DUCTWORK

HEATING

UNIT

VAV BOX

DIFFUSER

CHILLER

PUMP

Fig. 2. Typical HVAC System in a Small Building.

The control system for a commercial building comprises

many control loops and can be divided into central system and

local- or zone-control loops. For maximum comfort and

efficiency, all control loops should be tied together to share

information and system commands using a building

management system. Refer to the Building Management System

Fundamentals section of this manual.

BOILER

CONTROL

PANEL

M10506

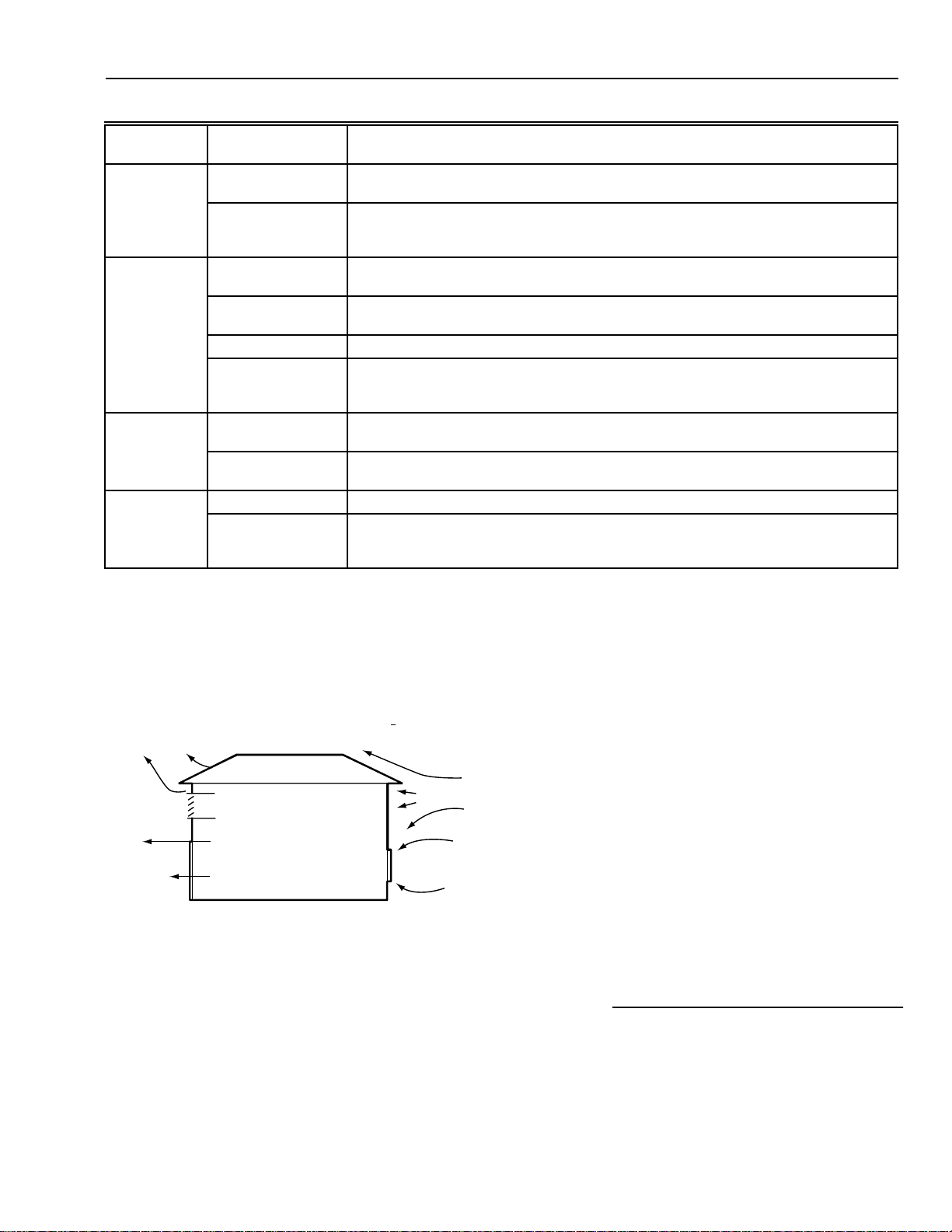

The basic control loops in a central air handling system can

be classified as shown in Table 1.

Depending on the system, other controls may be required

for optimum performance. Local or zone controls depend on

the type of terminal units used.

8

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 19

CONTROL FUNDAMENTALS

Table 1. Functions of Central HVAC Control Loops.

Control

Loop Classification Description

Ventilation Basic Coordinates operation of the outdoor, return, and exhaust air dampers to maintain

Better Measures and controls the volume of outdoor air to provide the proper mix of

Cooling Chiller control Maintains chiller discharge water at preset temperature or resets temperature

Cooling tower

control

Water coil control Adjusts chilled water flow to maintain temperature.

Direct expansion

(DX) system control

Fan Basic Turns on supply and return fans during occupied periods and cycles them as

Better Adjusts fan volumes to maintain proper duct and space pressures. Reduces system

Heating Coil control Adjusts water or steam flow or electric heat to maintain temperature.

Boiler control Operates burner to maintain proper discharge steam pressure or water temperature.

the proper amount of ventilation air. Low-temperature protection is often required.

outdoor and return air under varying indoor conditions (essential in variable air

volume systems). Low-temperature protection may be required.

according to demand.

Controls cooling tower fans to provide the coolest water practical under existing

wet bulb temperature conditions.

Cycles compressor or DX coil solenoid valves to maintain temperature. If

compressor is unloading type, cylinders are unloaded as required to maintain

temperature.

required during unoccupied periods.

operating cost and improves performance (essential for variable air volume systems).

For maximum efficiency in a hot water system, water temperature should be reset as

a function of demand or outdoor temperature.

HEATING

GENERAL

Building heat loss occurs mainly through transmission,

infiltration/exfiltration, and ventilation (Fig. 3).

TRANSMISSION

VENTILATION DUCT

EXFILTRATION

DOOR

Fig. 3. Heat Loss from a Building.

The heating capacity required for a building depends on the

design temperature, the quantity of outdoor air used, and the

physical activity of the occupants. Prevailing winds affect the

rate of heat loss and the degree of infiltration. The heating

system must be sized to heat the building at the coldest outdoor

temperature the building is likely to experience (outdoor design

temperature).

ROOF

20°C

-7°C

WINDOW

PREVAILING

WINDS

INFILTRATION

C3971

Transmission is the process by which energ y enters or leaves

a space through exterior surfaces. The rate of energy

transmission is calculated by subtracting the outdoor

temperature from the indoor temperature and multiplying the

result by the heat transfer coefficient of the surface materials.

The rate of transmission varies with the thickness and

construction of the exterior surfaces but is calculated the same

way for all exterior surfaces:

Energy Transmission per

Unit Area and Unit Time = (TIN - T

OUT

) x HTC

Where:

TIN= indoor temperature

T

= outdoor temperature

OUT

HTC = heat transfer coefficient

HTC

=

Unit Time x Unit Area x Unit Temperature

joule

ENGINEERING MANUAL OF AUTOMATIC CONTROL

9

Page 20

CONTROL FUNDAMENTALS

Infiltration is the process by which outdoor air enters a

building through walls, cracks around doors and windows, and

open doors due to the difference between indoor and outdoor

air pressures. The pressure differential is the result of

temperature difference and air intake or exhaust caused by f an

operation. Heat loss due to infiltration is a function of

temperature difference and volume of air moved. Exfiltration

is the process by which air leaves a building (e.g., through walls

and cracks around doors and windows) and carries heat with it.

Infiltration and exfiltration can occur at the same time.

Ventilation brings in fresh outdoor air that may require

heating. As with heat loss from inf iltration and exfiltration, heat

loss from ventilation is a function of the temperature difference

and the volume of air brought into the building or exhausted.

HEATING EQUIPMENT

Selecting the proper heating equipment depends on many

factors, including cost and availability of fuels, building size

and use, climate, and initial and operating cost trade-offs.

Primary sources of heat include gas, oil, wood, coal, electrical,

and solar energy . Sometimes a combination of sources is most

economical. Boilers are typically fueled by gas and may have

the option of switching to oil during periods of high demand.

Solar heat can be used as an alternate or supplementary source

with any type of fuel.

STEAM OR

HOT WATER

SUPPL Y

FAN

COIL

UNIT HEATER

STEAM TRAP

(IF STEAM SUPPLY)

CONDENSA TE

OR HOT WATER

RETURN

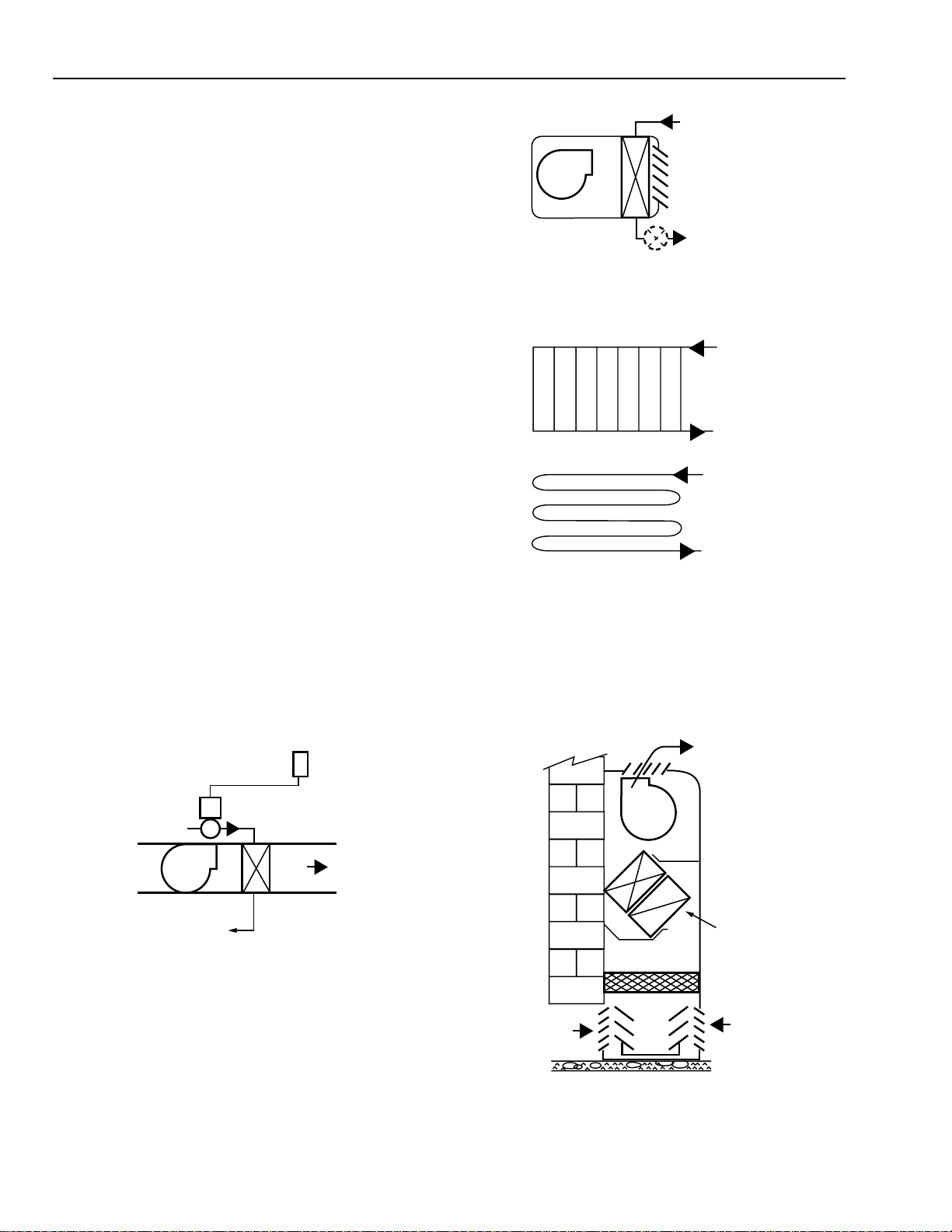

Fig. 5. Typical Unit Heater.

GRID PANEL

SERPENTINE PANEL

C2703

HOT WATER

SUPPL Y

HOT WATER

RETURN

HOT WATER

SUPPL Y

HOT WATER

RETURN

C2704

Figure 4 shows an air handling system with a hot water coil.

A similar control scheme would apply to a steam coil. If steam

or hot water is chosen to distribute the heat energy, highefficiency boilers may be used to reduce life-c ycle cost. Water

generally is used more often than steam to transmit heat energy

from the boiler to the coils or terminal units, because water

requires fewer safety measures and is typically more eff icient,

especially in mild climates.

THERMOSTAT

HOT WATER

SUPPLY

FAN

VALVE

HOT WATER

RETURN

DISCHARGE

AIR

C2702

Fig. 4. System Using Heating Coil.

An air handling system provides heat by moving an air stream

across a coil containing a heating medium, across an electric

heating coil, or through a furnace. Unit heaters (Fig. 5) are

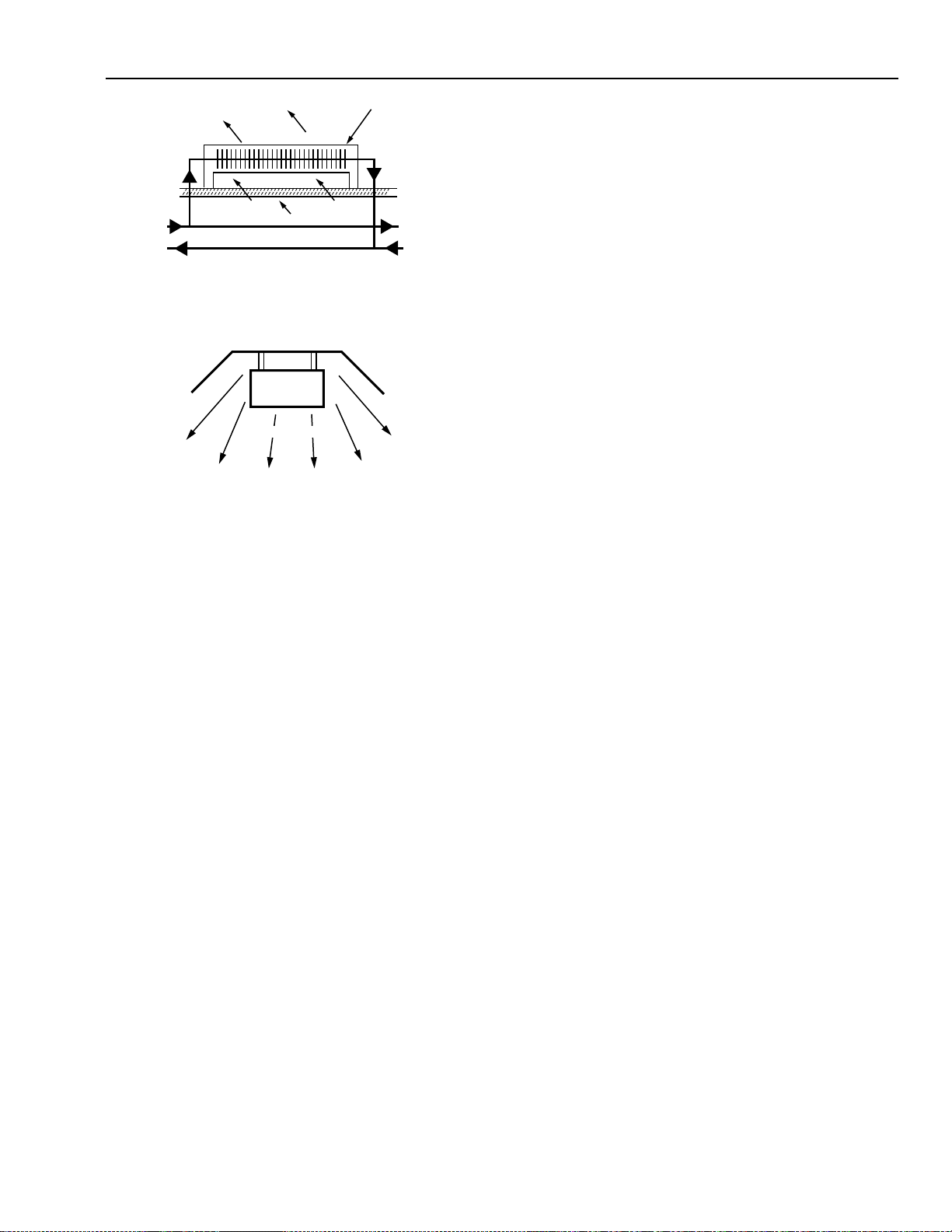

typically used in shops, storage areas, stairwells, and docks.

Panel heaters (Fig. 6) are typically used for heating floors and

are usually installed in a slab or floor structure, but may be

installed in a wall or ceiling.

Fig. 6. Panel Heaters.

Unit ventilators (Fig. 7) are used in classrooms and may

include both a heating and a cooling coil. Convection heaters

(Fig. 8) are used for perimeter heating and in entries and

corridors. Infrared heaters (Fig. 9) are typically used for spot

heating in large areas (e.g., aircraft hangers, stadiums).

FAN

DISCHARGE

AIR

COOLING

COIL

RETURN

AIR

C3035

WALL

OUTDOOR

AIR

HEATING

COIL

DRAIN PAN

MIXING

DAMPERS

Fig. 7. Unit Ventilator.

10

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 21

CONTROL FUNDAMENTALS

FINNED TUBE

WARM AIR

RETURN AIR

SUPPLY

RETURN

FLOOR

TO OTHER

HEATING UNITS

FROM OTHER

HEATING UNITS

C2705

Fig. 8. Convection Heater.

REFLECTOR

INFRARED

SOURCE

RADIANT HEAT

C2706

Fig. 9. Infrared Heater.

In mild climates, heat can be provided by a coil in the central

air handling system or by a heat pump. Heat pumps have the

advantage of switching between heating and cooling modes as

required. Rooftop units provide packaged heating and cooling.

Heating in a rooftop unit is usually by a gas- or oil-fired furnace

or an electric heat coil. Steam and hot water coils are available

as well. Perimeter heat is often required in colder climates,

particularly under large windows.

A heat pump uses standard refrigeration components and a

reversing valv e to pro vide both heating and cooling within the

same unit. In the heating mode, the flow of refrigerant through

the coils is reversed to deliver heat from a heat source to the

conditioned space. When a heat pump is used to exchange heat

from the interior of a building to the perimeter, no additional

heat source is needed.

A heat-recovery system is often used in buildings where a

significant quantity of outdoor air is used. Several types of heatrecovery systems are av ailable including heat pumps, runaround

systems, rotary heat exchangers, and heat pipes.

In a runaround system, coils are installed in the outdoor air

supply duct and the exhaust air duct. A pump circulates the

medium (water or glycol) between the coils so that medium heated

by the exhaust air preheats the outdoor air entering the system.

A rotary heat exchanger is a large wheel filled with metal

mesh. One half of the wheel is in the outdoor air intake and the

other half, in the exhaust air duct. As the wheel r otates, the

metal mesh absorbs heat from the exhaust air and dissipates it

in the intake air.

A heat pipe is a long, sealed, finned tube charged with a

refrigerant. The tube is tilted slightly with one end in the outdoor

air intake and the other end in the exhaust air. In a heating

application, the refrigerant vaporizes at the lower end in the

warm exhaust air , and the vapor rises toward the higher end in

the cool outdoor air, where it gi v es up the heat of v aporization

and condenses. A wick carries the liquid refrigerant back to the

warm end, where the cycle repeats. A heat pipe requires no

energy input. For cooling, the process is rev ersed by tilting the

pipe the other way.

Controls may be pneumatic, electric, electronic, digital, or a

combination. Satisfactory control can be achieved using

independent control loops on each system. Maximum operating

efficiency and comfort levels can be achieved with a control

system which adjusts the central system operation to the

demands of the zones. Such a system can save enough in

operating costs to pay for itself in a short time.

Controls for the air handling system and zones are specifically

designed for a building by the architect, engineer, or team who

designs the building. The controls are usually installed at the job

site. T erminal unit controls are typically factory installed. Boilers,

heat pumps, and rooftop units are usually sold with a factoryinstalled control package specifically designed for that unit.

COOLING

GENERAL

Both sensible and latent heat contribute to the cooling load

of a building. Heat gain is sensible when heat is added to the

conditioned space. Heat gain is latent when moisture is added

to the space (e.g., by vapor emitted by occupants and other

sources). To maintain a constant humidity ratio in the space,

water vapor must be removed at a rate equal to its rate of addition

into the space.

Conduction is the process by which heat moves between

adjoining spaces with unequal space temperatures. Heat may

move through exterior walls and the roof, or through floors,

walls, or ceilings. Solar radiation heats surfaces which then

transfer the heat to the surrounding air. Internal heat gain is

generated by occupants, lighting, and equipment. Warm air

entering a building by infiltration and through ventilation also

contributes to heat gain.

Building orientation, interior and exterior shading, the angle

of the sun, and prevailing winds af fect the amount of solar heat

gain, which can be a major source of heat. Solar heat received

through windows causes immediate heat gain. Areas with large

windows may experience more solar gain in winter than in

summer. Building surf aces absorb solar energy , become heated,

and transfer the heat to interior air. The amount of change in

temperature through each layer of a composite surface depends

on the resistance to heat flow and thickness of each material.

Occupants, lighting, equipment, and outdoor air ventilation

and infiltration requirements contribute to internal heat gain.

For example, an adult sitting at a desk produces about 117 watts.

Incandescent lighting produces more heat than fluorescent

lighting. Copiers, computers, and other office machines also

contribute significantly to internal heat gain.

ENGINEERING MANUAL OF AUTOMATIC CONTROL

11

Page 22

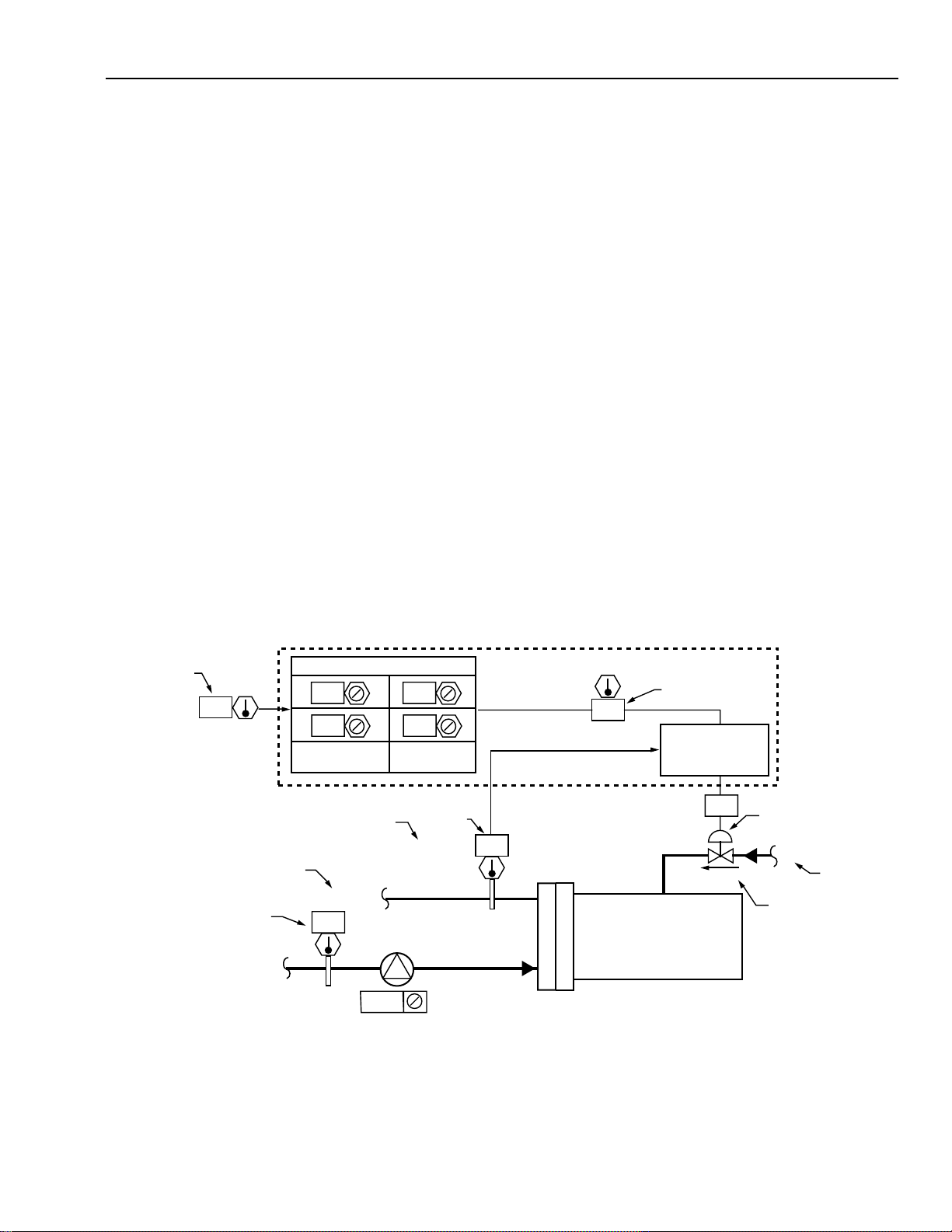

CONTROL FUNDAMENTALS

COOLING EQUIPMENT

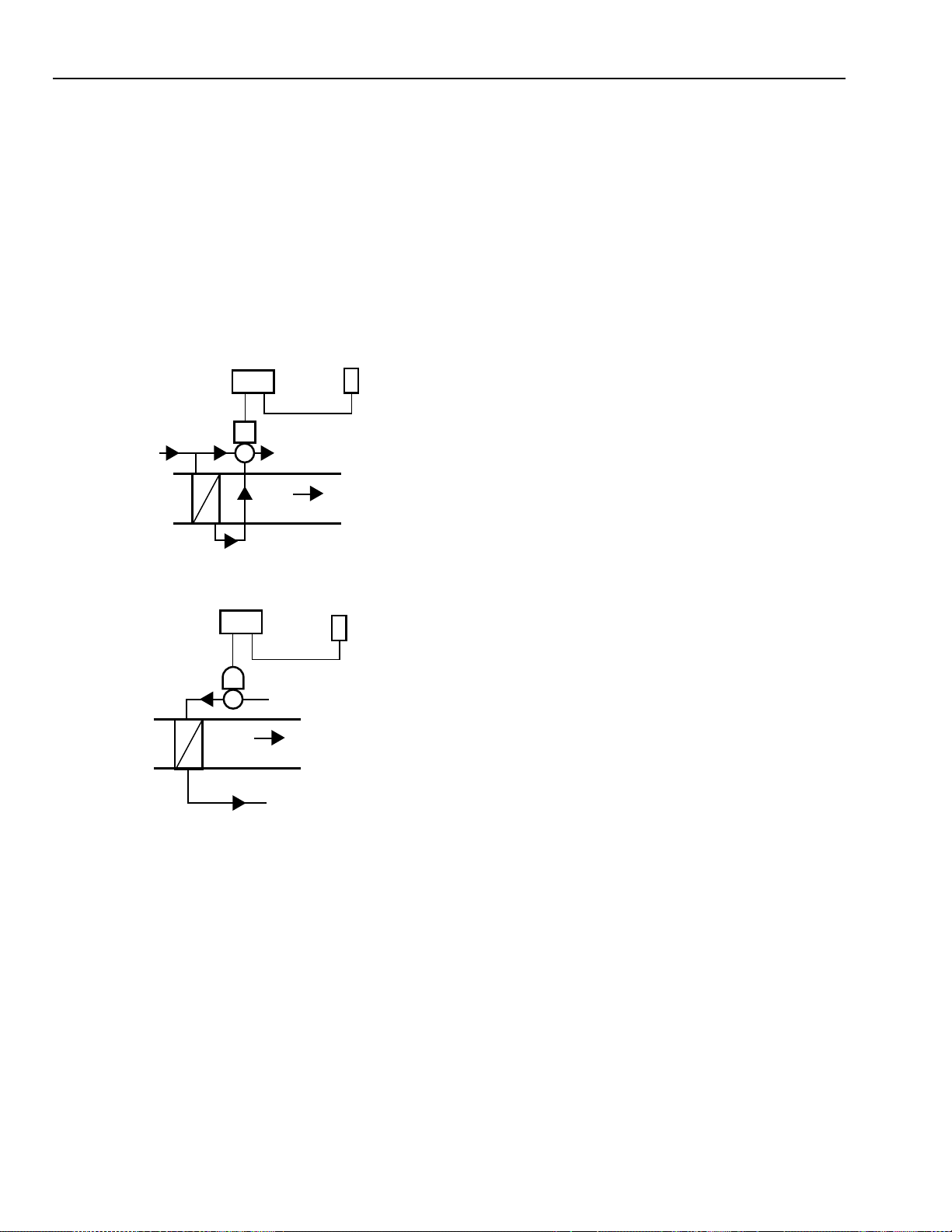

An air handling system cools by moving air across a coil

containing a cooling medium (e.g., chilled water or a

refrigerant). Figures 10 and 11 show air handling systems that

use a chilled water coil and a refrigeration evaporator (direct

expansion) coil, respectively. Chilled water control is usually

proportional, whereas control of an evaporator coil is twoposition. In direct expansion systems having more than one

coil, a thermostat controls a solenoid valve for each coil and

the compressor is cycled by a refrigerant pressure control. This

type of system is called a “pump down” system. Pump down

may be used for systems having only one coil, but more often

the compressor is controlled directly by the thermostat.

CHILLED

WATER

SUPPLY

TEMPERATURE

CONTROLLER

CONTROL

VALVE

CHILLED

WATER

COIL

SENSOR

CHILLED

WATER

RETURN

COOL AIR

C2707-2

Fig. 10. System Using Cooling Coil.

Compressors for chilled water systems are usually centrifugal,

reciprocating, or screw type. The capacities of centr ifugal and

screw-type compressors can be controlled by varying the

volume of refrigerant or controlling the compressor speed. DX

system compressors are usually reciprocating and, in some

systems, capacity can be controlled by unloading cylinders.

Absorption refrigeration systems, which use heat energy directly

to produce chilled water, are sometimes used for large chilled

water systems.

While heat pumps are usually direct expansion, a large heat

pump may be in the form of a chiller. Air is typically the heat

source and heat sink unless a large water reservoir (e.g., ground

water) is available.

Initial and operating costs are prime factors in selecting

cooling equipment. DX systems can be less expensive than

chillers. However, because a DX system is inherently twoposition (on/off), it cannot control temperature with the accuracy

of a chilled water system. Low-temperature control is essential

in a DX system used with a variable air volume system.

For more information control of various system equipment,

refer to the following sections of this manual:

— Chiller, Boiler, and Distribution System

Control Applications.

— Air Handling System Control Applications.

— Individual Room Control Applications.

TEMPERA TURE

CONTROLLER

EVAPORATOR

COIL

SOLENOID

VALVE

D

X

COOL AIR

SENSOR

REFRIGERANT

LIQUID

REFRIGERANT

GAS

C2708-1

Fig. 11. System Using Evaporator

(Direct Expansion) Coil.

Two basic types of cooling systems are available: chillers,

typically used in larger systems, and direct expansion (DX)

coils, typically used in smaller systems. In a chiller, the

refrigeration system cools water which is then pumped to coils

in the central air handling system or to the coils of fan coil

units, a zone system, or other type of cooling system. In a DX

system, the DX coil of the refrigeration system is located in

the duct of the air handling system. Condenser cooling for

chillers may be air or water (using a cooling tower), while DX

systems are typically air cooled. Because water cooling is more

efficient than air cooling, large chillers ar e always water cooled.

DEHUMIDIFICATION

Air that is too humid can cause problems such as condensation

and physical discomfort. Dehumidification methods circulate

moist air through cooling coils or sorption units.

Dehumidification is required only during the cooling season.

In those applications, the cooling system can be designed to

provide dehumidification as well as cooling.

For dehumidification, a cooling coil must have a capacity

and surface temperature sufficient to cool the air belo w its dew

point. Cooling the air condenses water, which is then collected

and drained away. When humidity is critical and the cooling

system is used for dehumidification, the dehumidified air may

be reheated to maintain the desired space temperature.

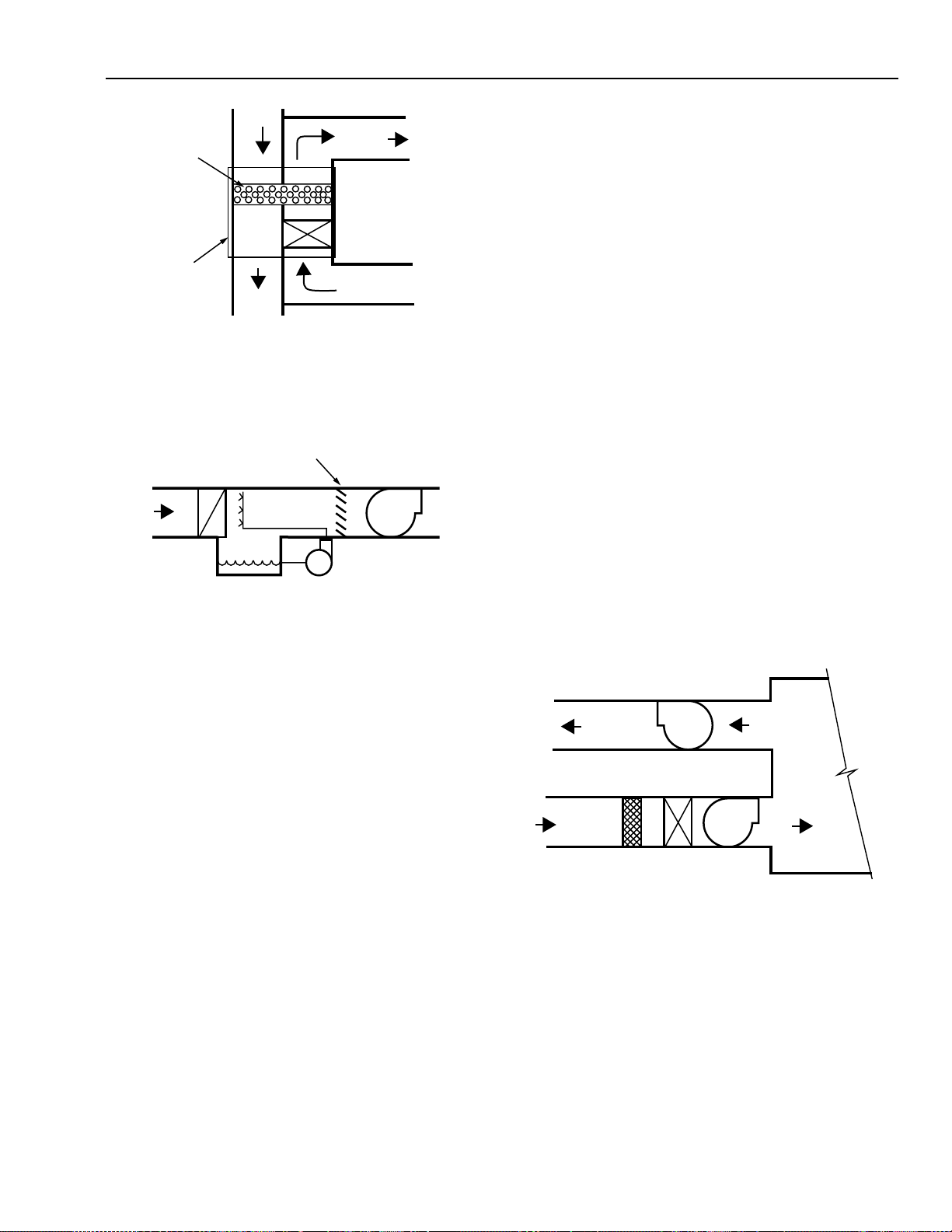

When cooling coils cannot reduce moisture content

sufficiently, sorption units are installed. A sorption unit uses

either a rotating granular bed of silica gel, activated alumina or

hygroscopic salts (Fig. 12), or a spray of lithium chloride brine

or glycol solution. In both types, the sorbent material absorbs

moisture from the air and then the saturated sorbent material

passes through a separate section of the unit that applies heat

to remove moisture. The sorbent material gi v es up moisture to

a stream of “scavenger” air , which is then exhausted. Scavenger

air is often exhaust air or could be outdoor air.

12

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 23

CONTROL FUNDAMENTALS

HUMID

ROTATING

GRANULAR

BED

SORPTION

UNIT

AIR

DRY AIR

HUMID AIR

EXHAUST

HEATING

COIL

SCAVENGER

AIR

C2709

Fig. 12. Granular Bed Sorption Unit.

Sprayed cooling coils (Fig. 13) are often used for space humidity

control to increase the dehumidifier eff iciency and to provide yearround humidity control (winter humidification also).

MOISTURE

COOLING

COIL

ELIMINATORS

SPRAY

PUMP

M10511

Fig. 13. Sprayed Coil Dehumidifier.

For more information on dehumidification, refer to the

following sections of this manual:

— Psychrometric Chart Fundamentals.

— Air Handling System Control Applications.

VENTILATION

Ventilation introduces outdoor air to replenish the oxygen

supply and rid building spaces of odors and toxic gases.

Ventilation can also be used to pressurize a building to reduce

infiltration. While ventila tion is required in nearly all buildings,

the design of a ventilation system must consider the cost of

heating and cooling the ventilation air. Ventilation air must be

kept at the minimum required level except when used f or free

cooling (refer to ASHRAE Standard 62, Ventilation for

Acceptable Indoor Air Quality).

To ensure high-quality ventilation air and minimize the

amount required, the outdoor air intakes must be located to

avoid building exhausts, vehicle emissions, and other sources

of pollutants. Indoor exhaust systems should collect odors or

contaminants at their source. The amount of ventilation a

building requires may be reduced with air washers, high

efficiency f ilters, absorption chemicals (e.g., activ ated charcoal),

or odor modification systems.

Ventilation requirements vary according to the number of

occupants and the intended use of the space. For a breakdown

of types of spaces, occupancy levels, and required v entilation,

refer to ASHRAE Standard 62.

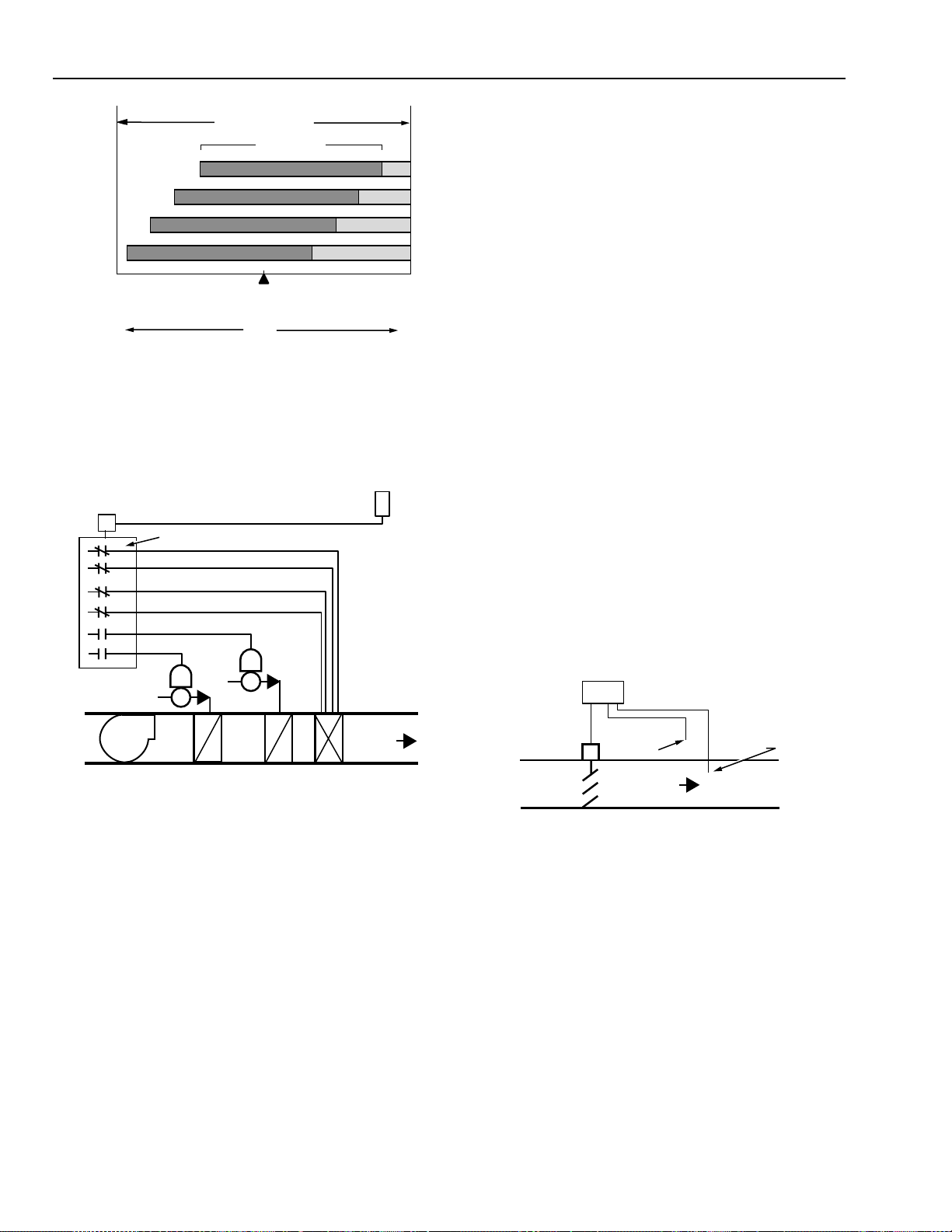

Figure 14 shows a ventilation system that supplies 100 percent

outdoor air. This type of ventilation system is typically used

where odors or contaminants originate in the conditioned space

(e.g., a laboratory where exhaust hoods and fans remove fumes).

Such applications require make-up air that is conditioned to

provide an acceptable environment.

EXHAUST

HUMIDIFICATION

Low humidity can cause problems such as respiratory

discomfort and static electricity. Humidifiers can humidify a

space either directly or through an air handling system. For

satisfactory environmental conditions, the relati ve humidity of

the air should be 30 to 60 percent. In critical areas where

explosive gases are present, 50 percent minimum is

recommended. Humidification is usually required only during

the heating season except in extremely dry climates.

Humidifiers in air handling systems typically inject steam

directly into the air stream (steam injection), spray atomized

water into the air stream (atomizing), or evaporate heated w ater

from a pan in the duct into the air stream passing through the

duct (pan humidification). Other types of humidifiers are a water

spray and sprayed coil. In spray systems, the water can be heated

for better vaporization or cooled for dehumidification.

For more information on humidification, refer to the following

sections of this manual:

— Psychrometric Chart Fundamentals.

— Air Handling System Control Applications.

SUPPLY

FAN

RETURN

AIR

MAKE-UP

AIR

SPACE

C2711

TO

OUTDOORS

OUTDOOR

AIR

SUPPLY

FILTER

EXHAUST

FAN

COIL

Fig. 14. Ventilation System Using

100 Percent Outdoor Air.

In many applications, energy costs make 100 percent outdoor

air constant volume systems uneconomical. For that reason,

other means of controlling internal contaminants are available,

such as variable volume fume hood controls, space

pressurization controls, and air cleaning systems.

A ventilation system that uses return air (Fig. 15) is more

common than the 100 percent outdoor air system. The returnair ventilation system recirculates most of the return air from

the system and adds outdoor air for ventilation. The return-air

system may have a separate fan to overcome duct pressure

ENGINEERING MANUAL OF AUTOMATIC CONTROL

13

Page 24

CONTROL FUNDAMENTALS

losses. The exhaust-air system may be incorporated into the air

conditioning unit, or it may be a separate remote exhaust. Supply

air is heated or cooled, humidified or dehumidified, and

discharged into the space.

DAMPER RETURN FAN

EXHAUST

AIR

RETURN

AIR

FILTER COIL SUPPLY FAN

MIXED

AIR

SUPPLY

AIR

C2712

OUTDOOR

AIR

DAMPERS

Fig. 15. Ventilation System Using Return Air.

Ventilation systems as shown in Figures 14 and 15 should

provide an acceptable indoor air quality , utilize outdoor air for

cooling (or to supplement cooling) when possible, and maintain

proper building pressurization.

For more information on ventilation, refer to the following

sections of this manual:

— Indoor Air Quality Fundamentals.

— Air Handling System Control Applications.

— Building Airflow System Control Applications.

FILTRATION

Air filtration is an important part of the central air handling

system and is usually considered part of the ventilation system.

Two basic types of filters are available: mechanical filters and

electrostatic precipitation filters (also called electronic air

cleaners). Mechanical filters are subdivided into standard and

high efficiency.

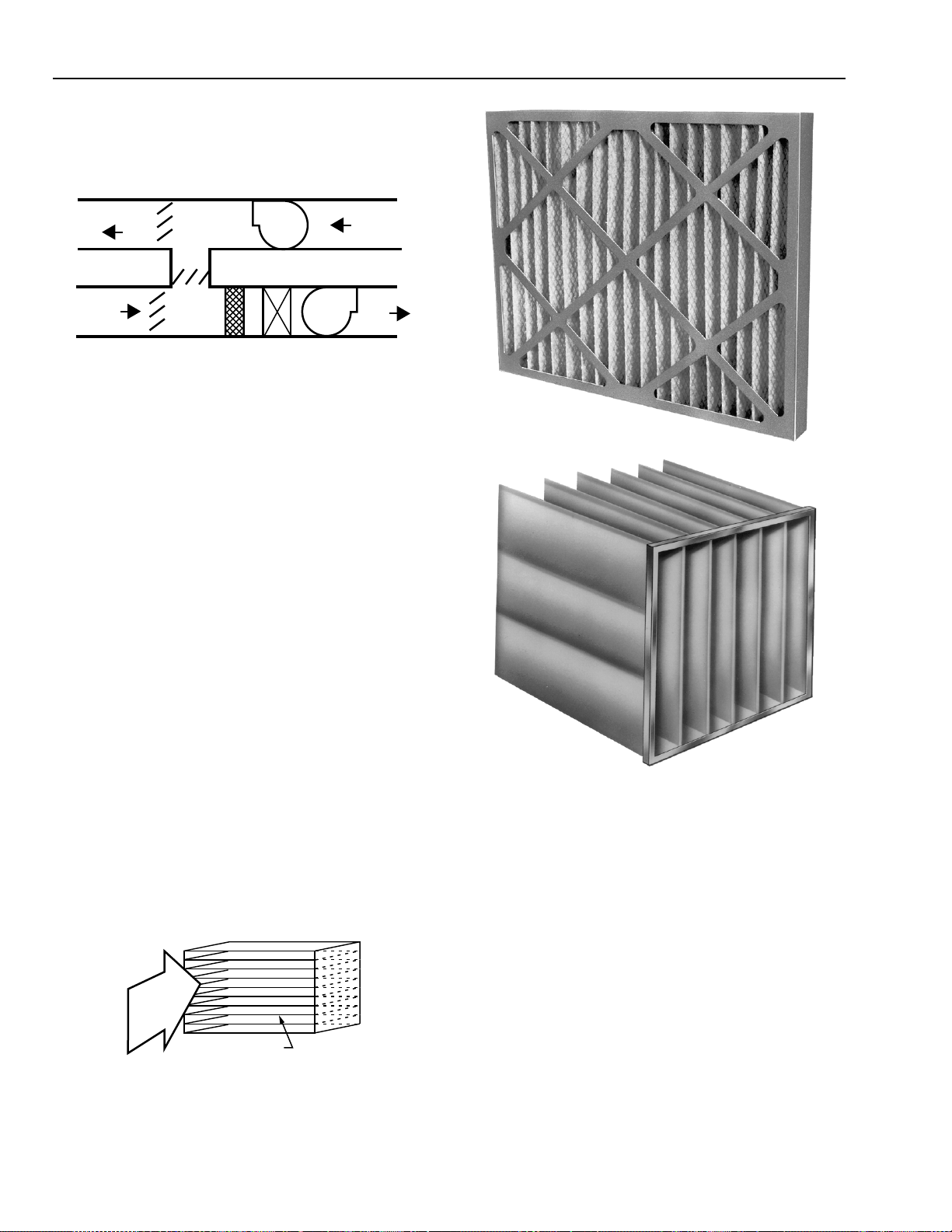

PLEATED FILTER

Filters are selected according to the degree of cleanliness

required, the amount and size of particles to be removed, and

acceptable maintenance requirements. High-efficiency

particulate air (HEP A) mechanical filters (Fig. 16) do not release

the collected particles and therefore can be used for clean rooms

and areas where toxic particles are released. HEPA filters

significantly increase system pressure drop, which must be

considered when selecting the fan. Figure 17 shows other

mechanical filters.

CELL

AIR FLOW

PLEATED PAPER

C2713

Fig. 16. HEPA Filter.

BAG FILTER

Fig. 17. Mechanical Filters.

Other types of mechanical filters include strainers, viscous

coated filters, and diffusion f ilters. Straining removes particles

that are larger than the spaces in the mesh of a metal filter and

are often used as prefilters for electrostatic filters. In viscous

coated filters, the particles passing through the filter fibers

collide with the fibers and are held on the fiber surface. Dif fusion

removes fine particles by using the turbulence present in the

air stream to drive particles to the fibers of the filter surface.

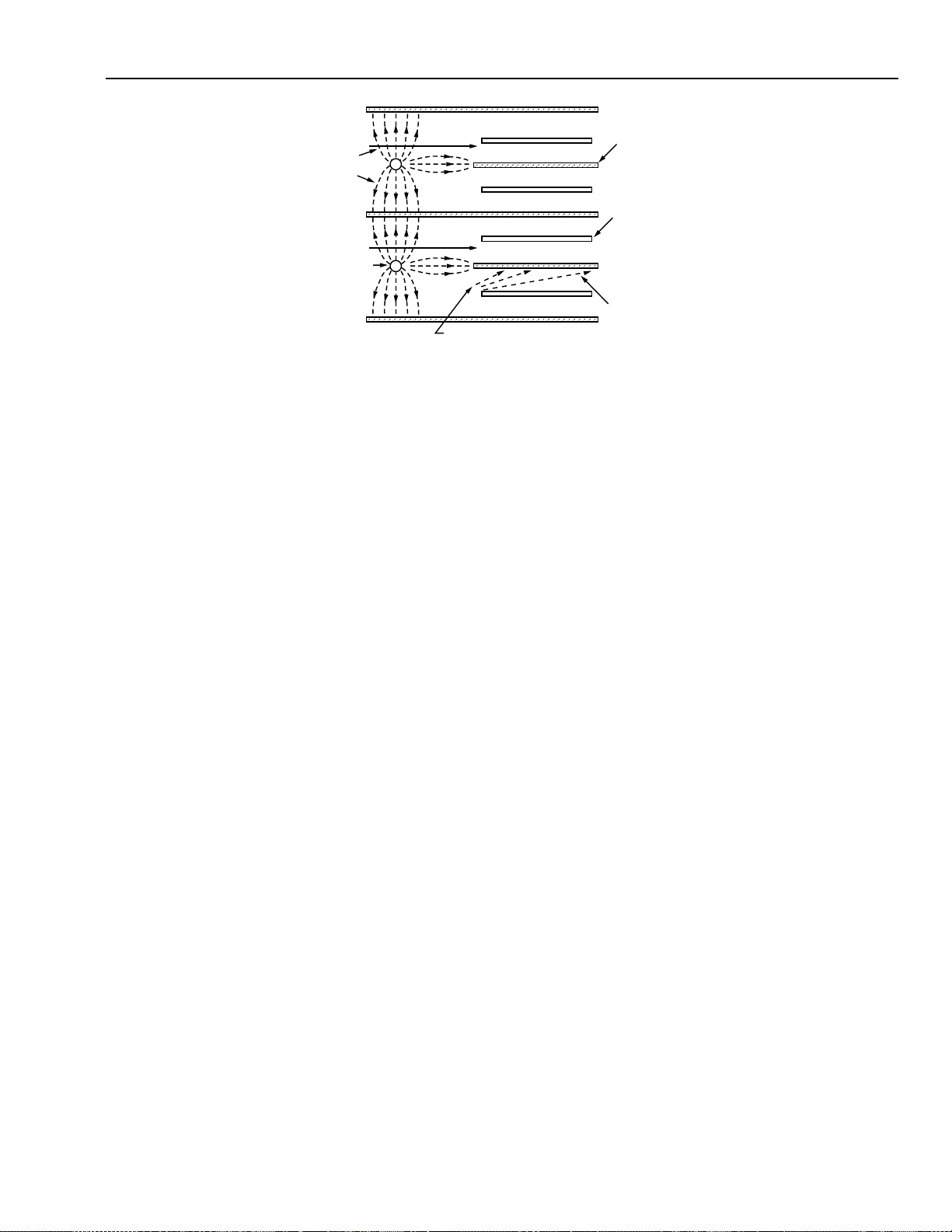

An electrostatic filter (Fig. 18) provides a low pressure drop

but often requires a mechanical prefilter to collect lar ge particles

and a mechanical after-filter to collect agglomerated particles

that may be blown off the electrostatic filter. An electrostatic

filter electrically charges particles passing through an ionizing

field and collects the charged particles on plates with an opposite

electrical charge. The plates may be coated with an adhesive.

14

ENGINEERING MANUAL OF AUTOMATIC CONTROL

Page 25

CONTROL FUNDAMENTALS

–

PATH

OF

IONS

WIRES

AT HIGH

POSITIVE

POTENTIAL

SOURCE: 1996 ASHRAE SYSTEMS AND EQUIPMENT HANDBOOK

AIRFLOW

AIRFLOW

POSITIVELY CHARGED

PARTICLES

Fig. 18. Electrostatic Filter.

CONTROL SYSTEM CHARACTERISTICS

Automatic controls are used wherever a variable condition

must be controlled. In HVAC systems, the most commonly

controlled conditions are pressure, temperature, humidity, and

rate of flow. Applications of automatic control systems range

from simple residential temperature regulation to precision

control of industrial processes.

CONTROLLED VARIABLES

The sensor can be separate from or part of the controller and

is located in the controlled medium. The sensor measures the

value of the controlled variable and sends the resulting signal

to the controller. The controller receives the sensor signal,

compares it to the desired value, or setpoint, and generates a

correction signal to direct the operation of the controlled device.

The controlled device varies the control agent to regulate the

output of the control equipment that produces the desired

condition.

+

ALTERNATE

PLATES

–

GROUNDED

+

–

INTERMEDIATE

PLATES

+

CHARGED

TO HIGH

POSITIVE

–

POTENTIAL

+

THEORETICAL

PATHS OF

–

CHARGES DUST

PARTICLES

C2714

Automatic control requires a system in which a controllable

variable exists. An automatic control system controls the

variable by manipulating a second variable. The second v ariable,

called the manipulated variable, causes the necessary changes

in the controlled variable.

In a room heated by air moving through a hot water coil, for

example, the thermostat measures the temperature (controlled

variable) of the room air (controlled medium) at a specified

location. As the room cools, the thermostat operates a valve

that regulates the flow (manipulated variable) of hot water

(control agent) through the coil. In this way, the coil furnishes

heat to warm the room air.

CONTROL LOOP

In an air conditioning system, the controlled variable is

maintained by varying the output of the mechanical equipment

by means of an automatic control loop. A control loop consists

of an input sensing element, such as a temperature sensor; a

controller that processes the input signal and produces an output

signal; and a final control element, such as a valve, that operates

according to the output signal.

HVAC applications use two types of control loops: open and

closed. An open-loop system assumes a fixed relationship

between a controlled condition and an external condition. An

example of open-loop control would be the control of perimeter

radiation heating based on an input from an outdoor air

temperature sensor. A circulating pump and boiler are energized

when an outdoor air temperature drops to a specified setting,

and the water temperature or flow is proportionally controlled

as a function of the outdoor temperature. An open-loop system

does not take into account changing space conditions from

internal heat gains, infiltration/exfiltration, solar gain, or other

changing variables in the building. Open-loop control alone

does not provide close control and may result in underheating

or overheating. For this reason, open-loop systems are not

common in residential or commercial applications.

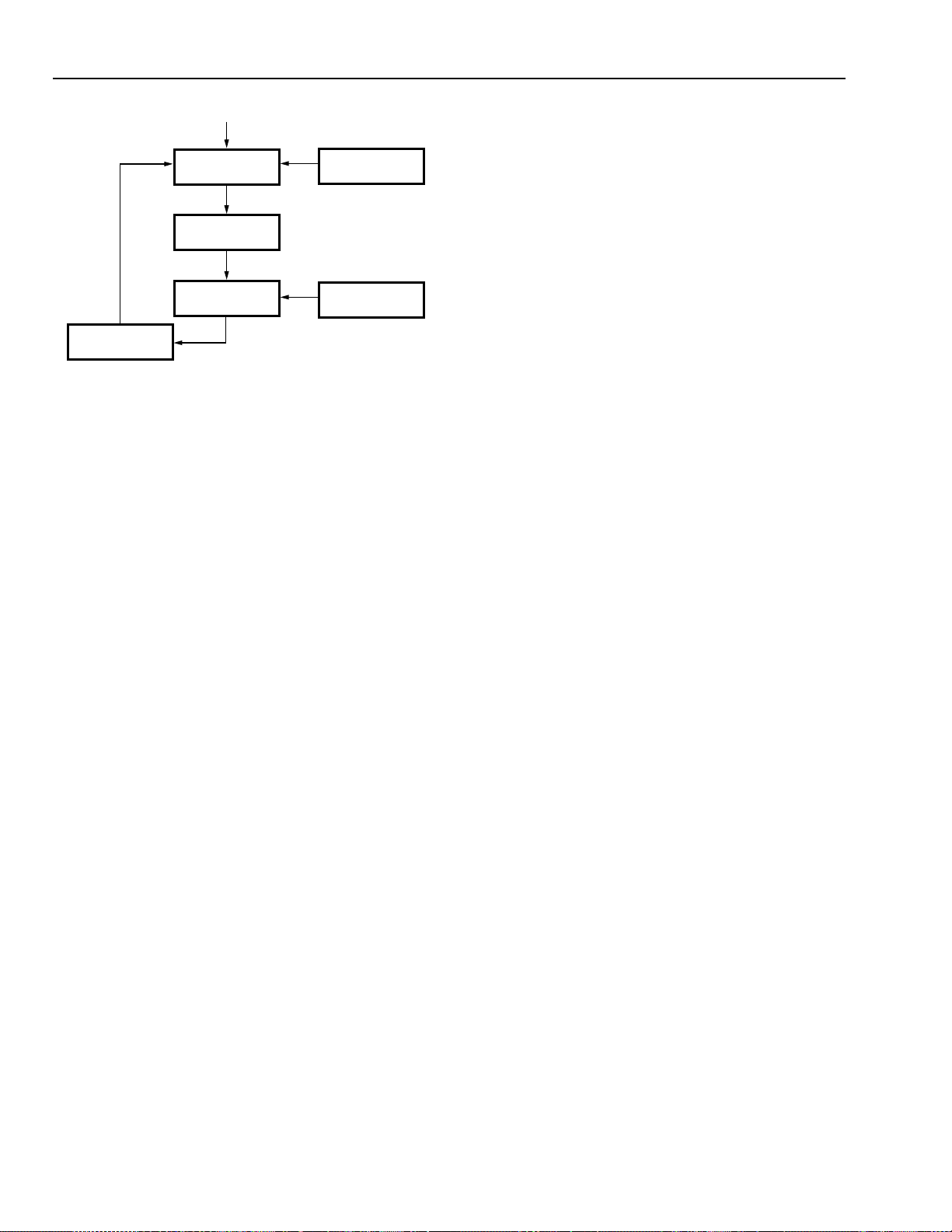

A closed-loop system relies on measurement of the controlled

variable to vary the controller output. Figure 19 sho ws a block

diagram of a closed-loop system. An example of closed-loop

control would be the temperature of discharge air in a duct

determining the flow of hot water to the heating coils to maintain

the discharge temperature at a controller setpoint.

ENGINEERING MANUAL OF AUTOMATIC CONTROL

15

Page 26

CONTROL FUNDAMENTALS

SETPOINT

FEEDBACK

SENSING

ELEMENT

CONTROLLER

CORRECTIVE

SIGNAL

FINAL CONTROL

ELEMENT

MANIPULATED

VARIABLE

PROCESS

CONTROLLED

VARIABLE

SECONDARY

INPUT

DISTURBANCES

C2072

Fig. 19. Feedback in a Closed-Loop System.

In this example, the sensing element measures the discharge

air temperature and sends a feedback signal to the controller.

The controller compares the feedback signal to the setpoint.

Based on the difference, or deviation, the controller issues a

corrective signal to a valve, which regulates the flow of hot

water to meet the process demand. Changes in the controlled

variable thus reflect the demand. The sensing element continues

to measure changes in the discharge air temperature and feeds

the new condition back into the controller for continuous

comparison and correction.

Automatic control systems use feedback to reduce the

magnitude of the deviation and produce system stability as

described above. A secondary input, such as the input from an

outdoor air compensation sensor, can provide information about

disturbances that affect the controlled variable. Using an input in

addition to the controlled variable enables the controller to

anticipate the effect of the disturbance and compensate for it, thus

reducing the impact of disturbances on the controlled variable.

CONTROL METHODS

GENERAL

An automatic control system is classified by the type of

energy transmission and the type of control signal (analog or

digital) it uses to perform its functions.

Self-powered systems are a comparatively minor but still

important type of control. These systems use the power of the

measured variable to induce the necessary corrective action.

For example, temperature changes at a sensor cause pressure

or volume changes that are applied directly to the diaphragm

or bellows in the valve or damper actuator.

Many complete control systems use a combination of the

above categories. An example of a combined system is the

control system for an air handler that includes electric on/off

control of the fan and pneumatic control for the heating and

cooling coils.

Various control methods are described in the following

sections of this manual:

— Pneumatic Control Fundamentals.

— Electric Control Fundamentals.

— Electronic Control Fundamentals.

— Microprocessor-Based/DDC Fundamental.

See CHARACTERISTICS AND ATTRIBUTES OF

CONTROL METHODS.

ANALOG AND DIGITAL CONTROL

Traditionally , analog de vices have performed HVA C control.

A typical analog HVAC controller is the pneumatic type which

receives and acts upon data continuously. In a pneumatic

controller, the sensor sends the controller a continuous

pneumatic signal, the pressure of which is proportional to the

value of the variable being measured. The controller compares

the air pressure sent by the sensor to the desired value of air

pressure as determined by the setpoint and sends out a control

signal based on the comparison.

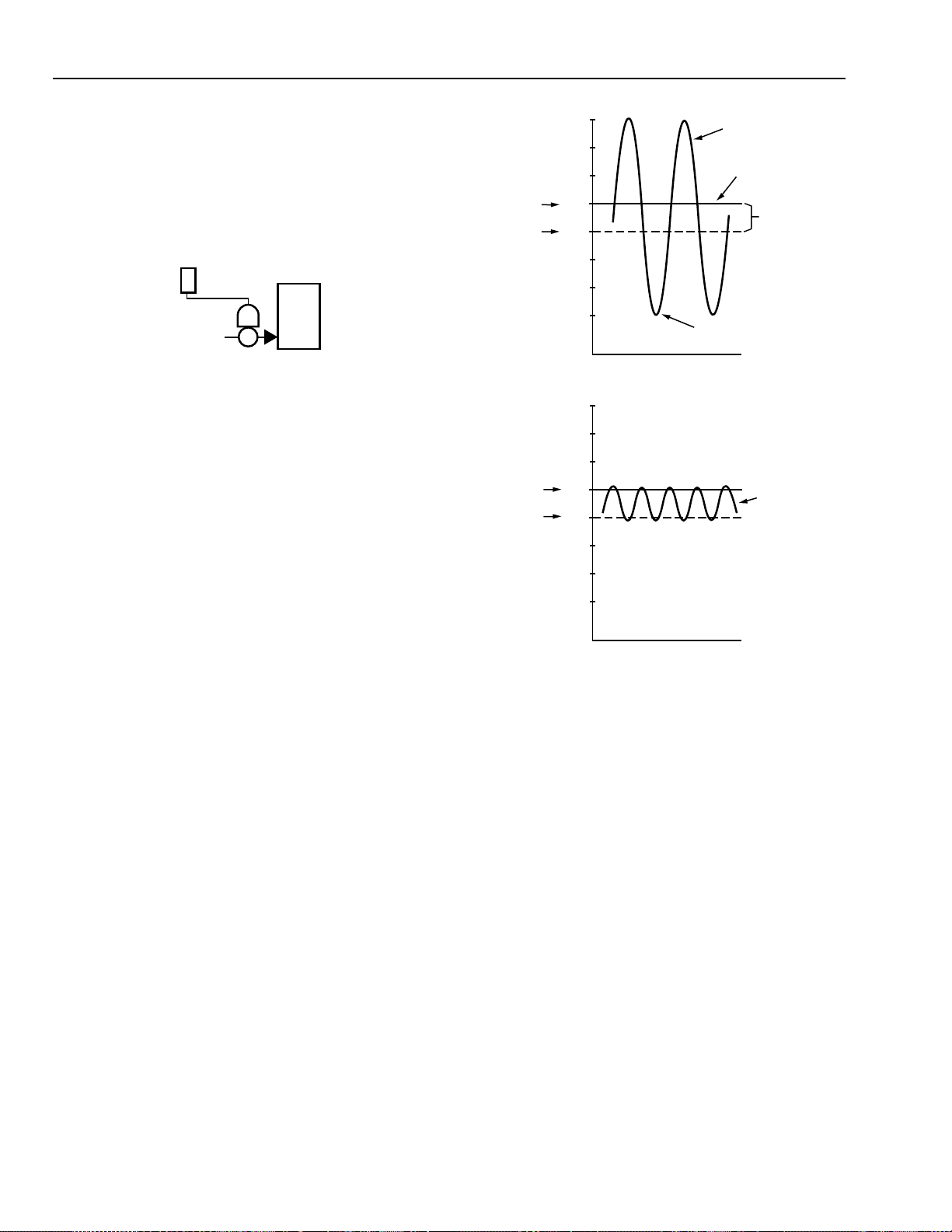

The digital controller receives electronic signals from sensors,

converts the electronic signals to dig ital pulses (values), and

performs mathematical operations on these values. The

controller reconverts the output value to a signal to operate an

actuator. The controller samples digital data at set time intervals,

rather than reading it continually . The sampling method is called

discrete control signaling. If the sampling interval for the digital

controller is chosen properly, discrete output changes pr ovide

even and uninterrupted control performance.

The most common forms of energy for automatic control

systems are electricity and compressed air. Systems may

comprise one or both forms of energy.

Systems that use electrical energy are electromechanical,

electronic, or microprocessor controlled. Pneumatic control

systems use varying air pressure from the sensor as input to a

controller, which in turn produces a pneumatic output signal to

a final control element. Pneumatic, electromechanical, and

electronic systems perform limited, predetermined control

functions and sequences. Microprocessor-based controllers use