Page 1

Intelligent Power Supply

AMPS-24/E

Manual

Document 51907

02/26/2014 Rev:

P/N 51907:J2 ECN 14-0161

J2

Page 2

Fire Alarm & Emergency Communication System Limitations

While a life safety system may lower insurance rates, it is not a substitute for life and property

insurance!

An automatic fire alarm system—typically made up of

smoke detectors, heat detectors, manual pull stations, audible

warning devices, and a fire alarm control panel (FACP) with

remote notification capability—can provide early warning of a

developing fire. Such a system, however, does not assure

protection against property damage or loss of life resulting

from a fire.

An emergency communication system—typically made up

of an automatic fire alarm system (as described above) and a

life safety communication system that may include an autonomous control unit (ACU), local operating console (LOC), voice

communication, and other various interoperable communication methods—can broadcast a mass notification message.

Such a system, however, does not assure protection against

property damage or loss of life resulting from a fire or life

safety event.

The Manufacturer recommends that smoke and/or heat

detectors be located throughout a protected premises

following the recommendations of the current edition of the

National Fire Protection Association Standard 72 (NFPA 72),

manufacturer's recommendations, State and local codes, and

the recommendations contained in the Guide for Proper Use of

System Smoke Detectors, which is made available at no

charge to all installing dealers. This document can be found at

http://www.systemsensor.com/appguides/. A study by the

Federal Emergency Management Agency (an agency of the

United States government) indicated that smoke detectors

may not go off in as many as 35% of all fires. While fire alarm

systems are designed to provide early warning against fire,

they do not guarantee warning or protection against fire. A fire

alarm system may not provide timely or adequate warning, or

simply may not function, for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls, on

roofs, or on the other side of closed doors. Smoke detectors

also may not sense a fire on another level or floor of a building.

A second-floor detector, for example, may not sense a firstfloor or basement fire.

Particles of combustion or “smoke” from a developing fire

may not reach the sensing chambers of smoke detectors

because:

• Barriers such as closed or partially closed doors, walls,

chimneys, even wet or humid areas may inhibit particle or

smoke flow.

• Smoke particles may become “cold,” stratify, and not reach

the ceiling or upper walls where detectors are located.

• Smoke particles may be blown away from detectors by air

outlets, such as air conditioning vents.

• Smoke particles may be drawn into air returns before

reaching the detector.

The amount of “smoke” present may be insufficient to alarm

smoke detectors. Smoke detectors are designed to alarm at

various levels of smoke density. If such density levels are not

created by a developing fire at the location of detectors, the

detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing

limitations. Detectors that have photoelectronic sensing

chambers tend to detect smoldering fires better than flaming

fires, which have little visible smoke. Detectors that have ionizing-type sensing chambers tend to detect fast-flaming fires

better than smoldering fires. Because fires develop in different

ways and are often unpredictable in their growth, neither type

of detector is necessarily best and a given type of detector

may not provide adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate

warning of fires caused by arson, children playing with

matches (especially in bedrooms), smoking in bed, and violent

explosions (caused by escaping gas, improper storage of

flammable materials, etc.).

Heat detectors do not sense particles of combustion and

alarm only when heat on their sensors increases at a predetermined rate or reaches a predetermined level. Rate-of-rise

heat detectors may be subject to reduced sensitivity over time.

For this reason, the rate-of-rise feature of each detector

should be tested at least once per year by a qualified fire protection specialist. Heat detectors are designed to protect

property, not life.

IMPORTANT! Smoke detectors must be installed in the

same room as the control panel and in rooms used by the system for the connection of alarm transmission wiring, communications, signaling, and/or power. If detectors are not so

located, a developing fire may damage the alarm system,

compromising its ability to report a fire.

Audible warning devices such as bells, horns, strobes,

speakers and displays may not alert people if these devices

are located on the other side of closed or partly open doors or

are located on another floor of a building. Any warning device

may fail to alert people with a disability or those who have

recently consumed drugs, alcohol, or medication. Please note

that:

• An emergency communication system may take priority

over a fire alarm system in the event of a life safety emergency.

• Voice messaging systems must be designed to meet intelligibility requirements as defined by NFPA, local codes, and

Authorities Having Jurisdiction (AHJ).

• Language and instructional requirements must be clearly

disseminated on any local displays.

• Strobes can, under certain circumstances, cause seizures

in people with conditions such as epilepsy.

• Studies have shown that certain people, even when they

hear a fire alarm signal, do not respond to or comprehend

the meaning of the signal. Audible devices, such as horns

and bells, can have different tonal patterns and frequencies. It is the property owner's responsibility to conduct fire

drills and other training exercises to make people aware of

fire alarm signals and instruct them on the proper reaction

to alarm signals.

• In rare instances, the sounding of a warning device can

cause temporary or permanent hearing loss.

A life safety system will not operate without any electrical

power. If AC power fails, the system will operate from standby

batteries only for a specified time and only if the batteries have

been properly maintained and replaced regularly.

Equipment used in the system

may not be technically compatible with the control panel. It is essential to use only equipment listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a

premises to a central monitoring station may be out of service

or temporarily disabled. For added protection against telephone line failure, backup radio transmission systems are recommended.

The most common cause of life safety system malfunction is

inadequate maintenance. To keep the entire life safety system

2 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 3

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be

connected to the fire alarm control panel. Disconnect all

sources of power before servicing. Control unit and associated equipment may be damaged by removing and/or inserting cards, modules, or interconnecting cables while the unit is

energized. Do not attempt to install, service, or operate this

unit until manuals are read and understood.

CAUTION - System Re-acceptance Test after Software

Changes: To ensure proper system operation, this product

must be tested in accordance with NFPA 72 after any programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or

deletion of system components, or after any modification,

repair or adjustment to system hardware or wiring. All components, circuits, system operations, or software functions known

to be affected by a change must be 100% tested. In addition,

to ensure that other operations are not inadvertently affected,

at least 10% of initiating devices that are not directly affected

by the change, up to a maximum of 50 devices, must also be

tested and proper system operation verified.

This system meets NFPA requirements for operation at 0-49º

C/32-120º F and at a relative humidity . However, the useful

life of the system's standby batteries and the electronic components may be adversely affected by extreme temperature

ranges and humidity. Therefore, it is recommended that this

system and its peripherals be installed in an environment with

a normal room temperature of 15-27º C/60-80º F.

Verify that wire sizes are adequate for all initiating and indicating device loops. Most devices cannot tolerate more than a

10% I.R. drop from the specified device voltage.

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to lightning induced transients. Although no system is completely

immune from lightning transients and interference, proper

grounding will reduce susceptibility. Overhead or outside aerial

wiring is not recommended, due to an increased susceptibility

to nearby lightning strikes. Consult with the Technical Services Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or

inserting circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make

all cable entries from the sides or rear. Before making modifications, verify that they will not interfere with battery, transformer, or printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs. Overtightening may damage threads, resulting in reduced terminal

contact pressure and difficulty with screw terminal removal.

This system contains static-sensitive components.

Always ground yourself with a proper wrist strap before handling any circuits so that static charges are removed from the

body. Use static suppressive packaging to protect electronic

assemblies removed from the unit.

Follow the instructions in the installation, operating, and programming manuals. These instructions must be followed to

avoid damage to the control panel and associated equipment.

FACP operation and reliability depend upon proper installation.

Precau-D1-9-2005

FCC Warning

WARNING: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with the instruction manual may

cause interference to radio communications. It has been

tested and found to comply with the limits for class A

computing devices pursuant to Subpart B of Part 15 of

FCC Rules, which is designed to provide reasonable

protection against such interference when devices are

operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference, in which case the user will be required to correct

the interference at his or her own expense.

Canadian Requirements

This digital apparatus does not exceed the Class A limits

for radiation noise emissions from digital apparatus set

out in the Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant les limites applicables aux appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

HARSH™, NIS™, and NOTI•FIRE•NET™ are all trademarks; and Acclimate® Plus, FlashScan®, NION®, NOTIFIER®, ONYX®, ONYXWorks®, UniNet®,

VeriF ire® , and VIEW® are all registered trademarks of Honeywell International Inc. Echelon® is a registered trademark and LonWorks™ is a trademark of

Echelon Corporation. ARCNET® is a registered trademark of Datapoint Corporation. Microsoft® and Windows® are registered trademarks of the Microsoft

Corporation.

©Wednesday, February 26, 2014 by Honeywell International Inc. All rights reserved. Unauthorized use of this document is strictly prohibited.

AMPS-24 Manual — P/N 51907:J2 02/26/2014 3

Page 4

Software Downloads

In order to supply the latest features and functionality in fire alarm and life safety technology to our customers, we make

frequent upgrades to the embedded software in our products. To ensure that you are installing and programming the latest

features, we strongly recommend that you download the most current version of software for each product prior to

commissioning any system. Contact Technical Support with any questions about software and the appropriate version for

a specific application.

Documentation Feedback

Your feedback helps us keep our documentation up-to-date and accurate. If you have any comments or suggestions about

our online Help or printed manuals, you can email us.

Please include the following information:

•Product name and version number (if applicable)

•Printed manual or online Help

•Topic Title (for online Help)

•Page number (for printed manual)

•Brief description of content you think should be improved or corrected

•Your suggestion for how to correct/improve documentation

Send email messages to:

FireSystems.TechPubs@honeywell.com

Please note this email address is for documentation feedback only. If you have any technical issues, please contact

Technical Services.

4 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 5

Table of Contents

Section 1: Introduction.............................................................................................................7

1.1: Features..........................................................................................................................................................7

1.2: Specifications.................................................................................................................................................7

1.2.1: CPS-24 Board......................................................................................................................................7

1.2.2: AMPS-K2 Board .................................................................................................................................8

1.3: Installation Standards and Codes...................................................................................................................9

1.3.1: UL 9th Edition Compliance.................................................................................................................9

1.4: Related Documentation ...............................................................................................................................10

1.5: Notes, Cautions, and Warnings ....................................................................................................................10

1.6: Board Layout ...............................................................................................................................................11

1.7: LED Indicators.............................................................................................................................................12

Section 2: Installation ............................................................................................................14

2.1: In a CAB-4 Series Backbox.........................................................................................................................14

2.2: In an EQ Series Backbox.............................................................................................................................15

2.3: In a BB-25 Cabinet ......................................................................................................................................16

2.4: In a BB-100 Cabinet ...................................................................................................................................16

2.5: In a BB-200 Cabinet ....................................................................................................................................17

2.6: Cabinet Wiring Examples............................................................................................................................18

2.7: Wiring the AMPS-24/E ..............................................................................................................................20

2.7.1: Overview ...........................................................................................................................................20

2.7.2: Connecting TB1 MAIN 24V .............................................................................................................21

2.7.3: Connecting to the AUX 24 Output....................................................................................................23

2.7.4: Connecting to the SLC ......................................................................................................................23

2.7.5: Connecting the Trouble Bus ..............................................................................................................24

2.7.6: Connecting the Accessories Output on the CPS-24 ..........................................................................24

2.7.7: Connecting the Power Supply to AC Power .....................................................................................24

2.8: Installing and Connecting the Batteries .......................................................................................................25

2.8.1: Setting the Charger ............................................................................................................................26

2.8.2: Connecting the Power Supply to Two Batteries:...............................................................................26

2.8.3: Connecting the Power Supply to Four Batteries: ..............................................................................26

2.8.4: Connecting Multiple Power Supplies/Products (Separate Batteries) ................................................28

2.8.5: Connecting Multiple Power Supplies/Products (One Set of Batteries) .............................................29

Section 3: Configuring the AMPS-24 ....................................................................................30

3.1: SLC Addressing...........................................................................................................................................30

3.1.1: Determining Address Consumption .................................................................................................30

3.1.2: Setting the Base Address (SLC Enabled) .........................................................................................31

3.2: Programming the AMPS-24 ........................................................................................................................32

3.2.1: Installing the Configuration Software ...............................................................................................32

3.2.2: Establishing the Hardware Connection .............................................................................................33

3.2.3: Working Offline ................................................................................................................................33

3.2.4: Working Online .................................................................................................................................34

3.2.5: Downloading to the AMPS-24 ..........................................................................................................34

3.2.6: AMPS-24 Configuration ...................................................................................................................34

3.3: Configuring the Network Annunciator ........................................................................................................37

3.3.1: Programming .....................................................................................................................................37

3.3.2: Display...............................................................................................................................................37

3.4: Configuring the FACP .................................................................................................................................37

3.4.1: Programming .....................................................................................................................................37

3.4.2: Software Type ID Codes ...................................................................................................................38

3.4.3: Panel Display.....................................................................................................................................38

Section 4: Power Supply Calculations..................................................................................41

4.1: Calculating the System Current Draws........................................................................................................41

4.1.1: How to Use the Calculating Tables ...................................................................................................41

AMPS-24 Manual — P/N 51907:J2 02/26/2014 5

Page 6

Table of Contents

4.1.2: Calculation for Main Supply Current ................................................................................................42

4.1.3: Calculating the Maximum Secondary Power Non-Fire Alarm Current Draw ..................................43

4.1.4: Calculating the Maximum Secondary Power Fire Alarm Current Draw ..........................................43

4.2: Calculating the Battery Requirements .........................................................................................................44

4.2.1: Calculating the Battery Capacity .......................................................................................................44

4.2.2: Calculating the Battery Size ..............................................................................................................45

Appendix A: Compatibility with Other Systems .................................................................. 46

A.1: XLS3000 .....................................................................................................................................................46

A.1.1: Power Supply Calculations...............................................................................................................46

A.1.2: Calculation for Main Supply Current ...............................................................................................47

Index ........................................................................................................................................48

6 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 7

The AMPS-24/E is an intelligent power supply and battery charger with one 5VDC and three 24

VDC outputs. It can connect directly to a CPU2-3030*, NCA-2 or DS-DB via a harness cable with

EIA-485 connections. For other systems it can operate in FlashScan or CLIP (Classic Loop

Interface Protocol) mode and reside on the SLC. The AMPS-24 includes a battery charger capable

of charging up to 200 AH batteries.

*Note that the CPU2-3030 must connect to the SLC as well to get correct trouble status reporting. Refer to “SLC Addressing” on

page 30.

The AMPS-24/E may be installed remotely from an ONYX Series panel, connected as an SLC

device in either FlashScan or CLIP mode to provide system supervision. In this configuration, it

can simultaneously charge batteries and power remote devices. (See block diagram Figure 2.12 on

page 22.)

1.1 Features

• SLC Addressable by any CLIP or FlashScan Fire Alarm Control Panel (FACP)

• Remote charger/general purpose power supply

• Charges 7 to 200 AH batteries

• Isolated Signaling Line Circuit (SLC) interface

• Brownout detection

• Battery/battery charger supervision

• Disconnect of deeply-discharged battery (low battery disconnect)

• Selectable charger current

• AC loss detection and AC loss delay reporting

• Five-point trouble reporting

• Two models available: AMPS-24 (120 VAC, 50/60 Hz) or AMPS-24E (220-240 VAC, 50/60

Section 1: Introduction

Hz)

1.2 Specifications

The AMPS-24 is comprised of two boards; the CPS-24 board (the smaller front board), and the

AMPS-K2 (the larger rear board). See Figure 1.1.

1.2.1 CPS-24 Board

AC Power - TB1

120 VAC 50/60 Hz input, 5.0 A maximum

220 - 240 VAC 50/60 Hz input, 2.5 A maximum

Maximum 12 AWG (3.31 mm

Fuse: 8 amps, 250V, 5 x 20 mm, Fast-Acting, ceramic. Notifier P/N 12117

Secondary Power 5V and 24V AUX outputs - TB2

Power-limited (Class 2): 24V @ 0.5A, 5V @ 0.15A

Utilizes wire sizes 12-18 AWG (3.31 mm

Secondary Power (Battery) Charging Circuit - TB3

Sealed lead-acid battery charger which wll charge 7 - 200 AH batteries

Utilizes wire sizes 10-14 AWG (5.26 mm

2

) with 600 VAC insulation

2

- 0.821 mm2 )

2

- 2.08mm2 )

AMPS-24 Manual — P/N 51907:J2 02/26/2014 7

Page 8

Introduction Specifications

Charging current: 1.0A, 2.0A, 5.0A, or OFF (Software selectable)

Based on battery size programming (See “Outputs Current Settings” on page 35)

Charging voltage: 27.6 VDC (nominal)

To calculate expected standby operating times, see Section 4 on page 41.

When AC power is lost, the deeply-discharged battery cutoff protection will be invoked at 17 volts.

The power supply will be disconnected from the batteries. The power supply’s normal operation

will be restored when AC power returns.

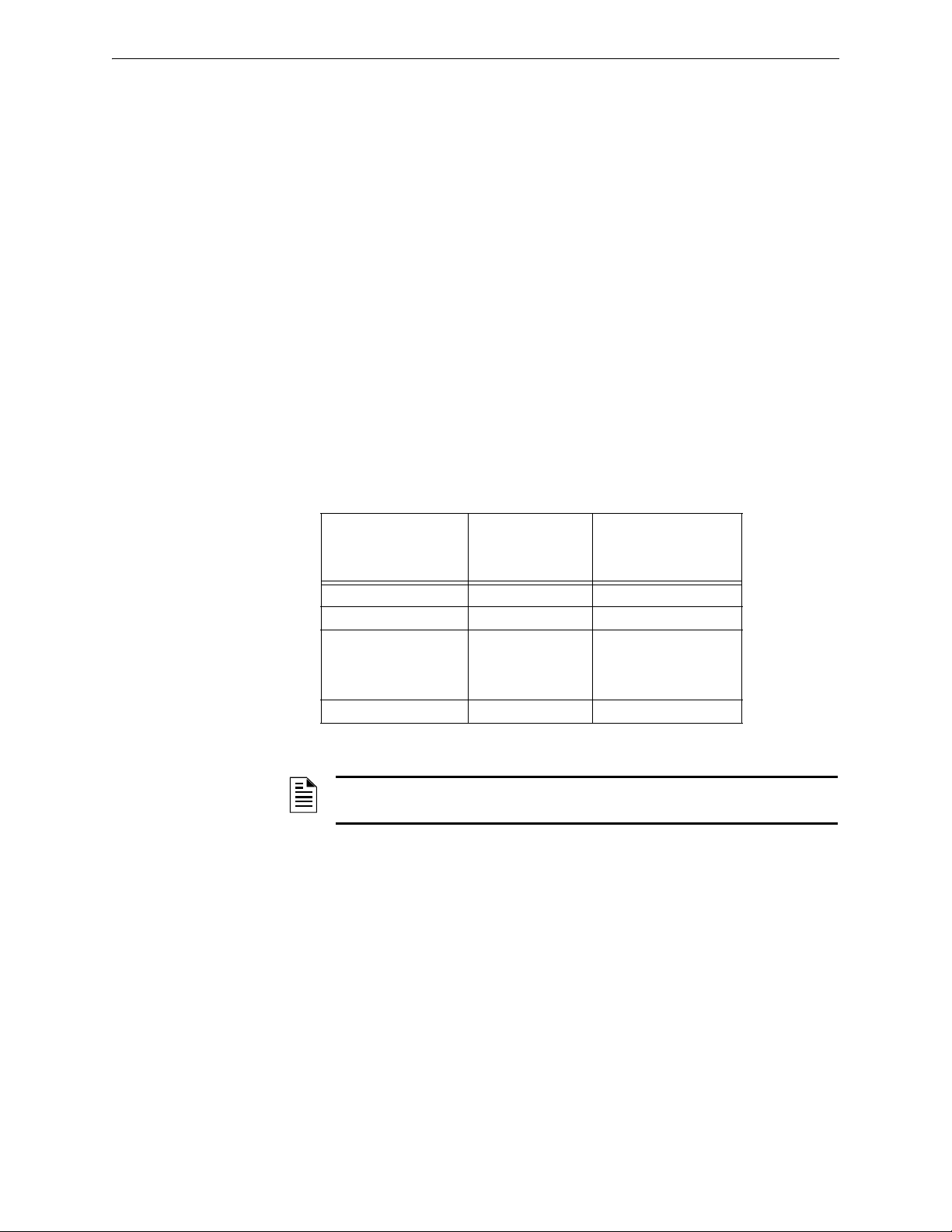

1.2.2 AMPS-K2 Board

Main 24V Output Circuit - TB1

Main 24V output provides filtered power-limited (Class 2) power when set for 3A. Otherwise it

provides filtered, non-power limited power. Refer to Table 1.1 below for maximum current settings

for the various configurations.

Aux 24V Output Circuit - TB3

Auxiliary 24V output provides filtered power-limited (Class 2) power when set for less than

5A.Otherwise, it provides filtered, non-power limited power. Refer to Table 1.1 below for

maximum current settings for the various configurations.

Charger

Setting/Battery Size

1A / 7 - 26AH Batteries 5A 3A

2A / 12 - 60AH Batteries 5A 3A

5A / 55 - 200 AH

Configuration 1 5A OFF

Configuration 2 3 A 1 A

Disabled 5A 5A

Main 24V (TB1 on

AMPS-K2 board)

Maximum Current

Total AUX 24V (TB3 on

AMPS-K2 board plus

TB2 on CPS-24)

Maximum Current

Table 1.1 Output Current for Each Configuration

NOTE: The AMPS-24 can provide up to 3A for releasing applications, limited

by the FCM-1-REL.

SLC Circuit - TB2

Average SLC current is 1.0 mA. The maximum resistance of the SLC wiring from any device to the

FACP should not exceed 50 ohms.

Utilizes wire sizes 12-18 AWG (3.31 mm

2

- 0.821 mm2 ).

Trouble Bus - TB4

Trouble bus input is designed to receive trouble signals from any normally-open dry contacts or

open-collector circuit.

Utilizes twisted-pair wire sizes 12-22 AWG (3.31 mm

2

- 0.326 mm2 ).

Full Speed USB 2.0 - J3

USB Type B connector for programming installation parameters.

8 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 9

Installation Standards and Codes Introduction

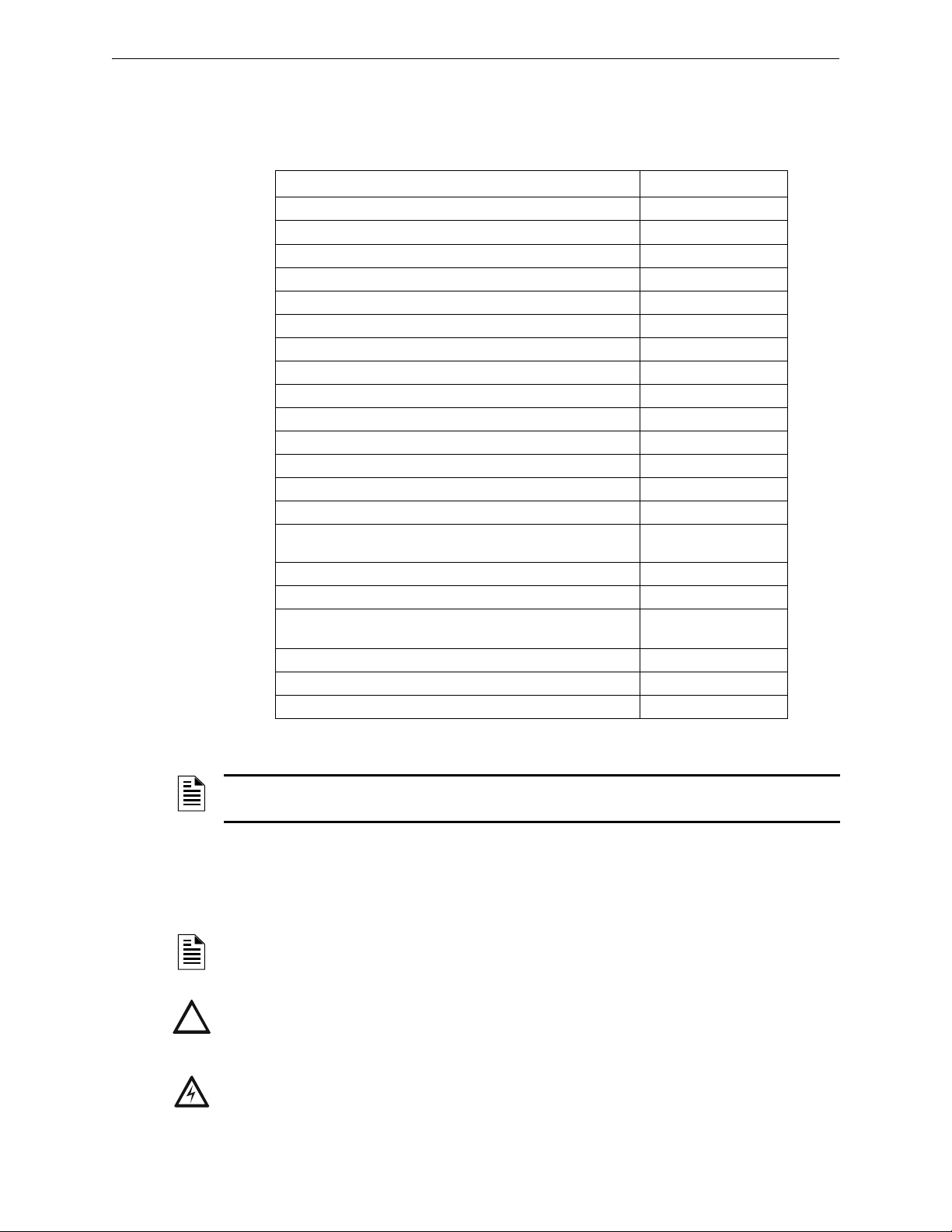

1.3 Installation Standards and Codes

The AMPS-24/E complies with the following standards:

NFPA 72 National Fire Alarm Code

Underwriters Laboratories:

• UL 864 Standard for Control Units and Accessories for Fire Alarm Systems

• UL 2572 Standard for Mass Notification Systems

Underwriters Laboratories of Canada (ULC):

• ULC-S527-99: Standard of Control Units for Fire Alarm Systems

• ULC-S524: Standard for the Installation of Fire Alarm Systems

In addition, the installer should be familiar with the following standards:

• NEC Article 300 Wiring Methods

• NEC Article 760 Fire Protective Signaling Systems

• Applicable Local and State Building Codes

• Requirements of the Local Authority Having Jurisdiction

• The Canadian Electrical Code, Part 1

1.3.1 UL 9th Edition Compliance

This product has been certified to comply with the requirements in the Standard for Control Units

and Accessories for Fire Alarm Systems, UL 864 9th Edition.

The following products have not received UL 864 9th Edition certification and may only be used in

retrofit applications. Operation of the AMPS-24/E with products not tested for UL 864 9th Edition

has not been evaluated and may not comply with NFPA 72 and/or the latest edition of UL 864.

These applications will require the approval of the local Authority Having Jurisdiction (AHJ).

• NFS-3030 Fire Alarm Control Panel

• AMG-1 Audio Message Generator

•ICM-4/E

•NCA

AMPS-24 Manual — P/N 51907:J2 02/26/2014 9

Page 10

Introduction Related Documentation

!

!

1.4 Related Documentation

To obtain a complete understanding of specific features of the AMPS-24, or to become familiar

with functions in general, make use of the documentation listed in Table 1.2.

Title Document Number

NFS2-3030 Installation, Operation, and Programming Manuals 52544, 52546, 52545

NFS-3030 Installation, Operation and Programming Manuals 51330,51344, 51345

NCA-2 Network Control Annunciator Manual 52482

NCA Network Control Annunciator Manual 51482

DS-DB Manual 53622

DVC/DAA Manual Manual 52411

ACM Series Annunciators Manual Manual 15842

LDM Series Lamp Driver Modules Manual 15885

SCS Series Smoke Control Annunciators Manual 15712

UDACT Manual 50050

UZC Universal Zone Coding Installation & Programming Manuals 15216, 15976

BB-100/200 Cabinet Installation Instructions 51981

CAB-3/CAB-4 Series Installation Instructions 15330

EQ Cabinet Series Installation Instructions 53412

Heat Dissipation Calculation Document for Cabinets with Digital

Audio Products

BB-25 Cabinet Installation Instructions 50898

NFS-LBB Cabinet Installation Instructions 50295

PK-PPS Power Supply Programming Utility Installation CD PK-PPS Power Supply

VeriFire™ Tools Online Help VeriFire-TCD

SLC Wiring Instruction Manual 51253

Device Compatibility Document 15378

53645

Programming Utility CD

Table 1.2 Related Documentation

NOTE: Unless otherwise indicated, when used in this manual, NFS2-3030 refers to both the NFS-

3030 and NFS2-3030E and AMPS-24 refers to both the AMPS-24 and AMPS-24E.

1.5 Notes, Cautions, and Warnings

This manual contains notes, cautions, and warnings to alert the reader as follows:

NOTE: Supplemental information for a topic, such as tips and references.

CAUTION: A brief identifier stating the nature of the hazard.

Information about procedures that could cause programming errors, runtime errors, or equipment

damage.

WARNING: A brief identifier stating the nature of the hazard.

Indicates information about procedures that could cause irreversible equipment damage, irreversible loss

of programming data or personal injury.

10 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 11

Board Layout Introduction

Rotary Switch SW2

A

–

+

–

+

BAT

BAT

amps24_CPS24andMaina.wmf

Slide Switch SW3

AC Fuse F4

HOT

NEUT

EARTH

GROUND

+ 24V

COM

COM

+ 5V

Ground Fault

Switch SW1

Accessories

Outputs (TB2)

USB Port J3

Type B

–

+

B

–

+

TBL

BUS

(TB4)

MAIN 24

(TB1)

AUX 24

TB3

+24V

COM

+485

-485

COM

+24V

+24V

COM

COM

+24V

SLC (TB2)

Battery

Connections

(TB3)

AC (TB1)

Use supplied

harness cable for

direct connection to

CPU2-3030, NCA2, or DS-DB.

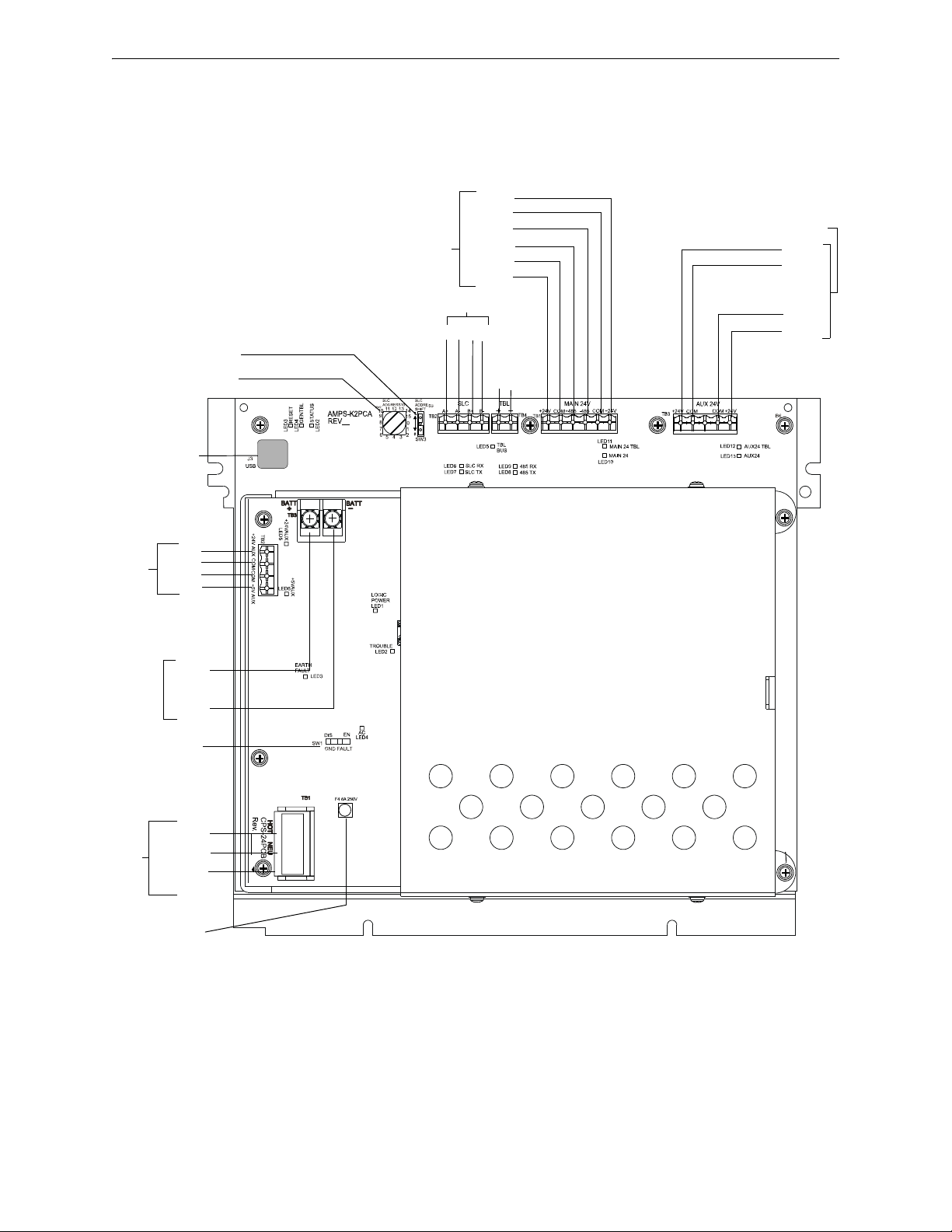

1.6 Board Layout

The AMPS-24 is comprised of two boards; the AMPS-K2 (the larger rear board), and the CPS-24

(the smaller front board). Figure 1.1 below illustrates the layouts for these boards. Figure 1.2

illustrates the positions of the LEDs.

Figure 1.1 The AMPS-24 Board Layout

AMPS-24 Manual — P/N 51907:J2 02/26/2014 11

Page 12

Introduction LED Indicators

amps24_CPS24andMain.wmf

SLCRX

LED 6

SLCTX

LED 7

485RX

LED 9

485TX

LED 8

TBL BUS

LED 5

MAIN 24 TBL

LED 11

MAIN 24

LED 10

AUX 24 TBL

LED 12

AUX 24

LED 13

STATUS

LED 2

GEN TBL

LED 4

RESET

LED 3

+24V AUX

LED 5

+5V AUX

LED 6

LOGIC POWER

LED 1

TROUBLE

LED 2

EARTH FAULT

LED 3

AC

LED 4

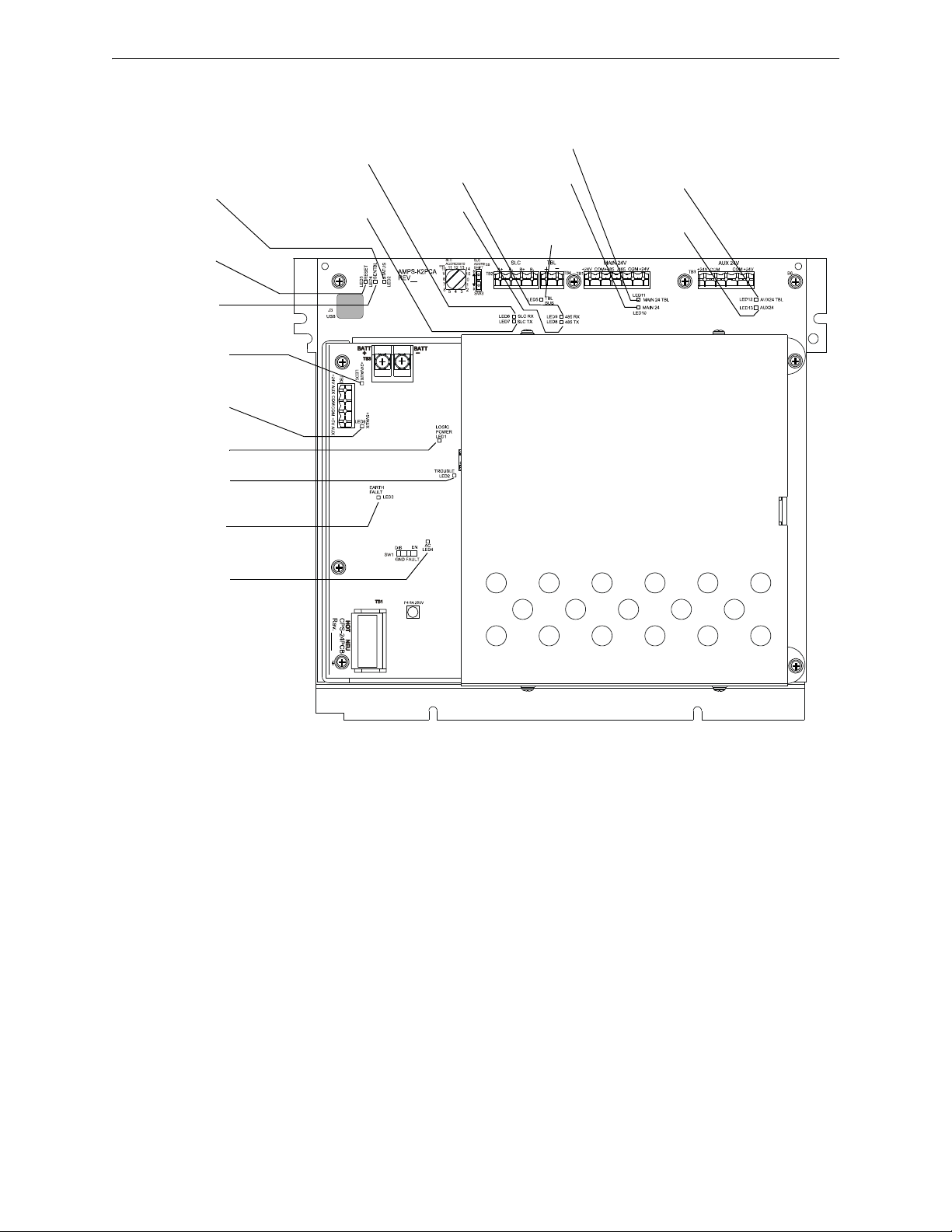

1.7 LED Indicators

Figure 1.2 Locations of LED Indicators

12 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 13

LED Indicators Introduction

There are eighteen LEDs that indicate various conditions and troubles. The following table lists and

describes each.

Reference LED Name Color Description

•

+5V logic power and software indication

2 STATUS Green

• Normally slow blink (1 blink/sec)

• Off in self-test failure or SLC address = 0 (bootloader)

• Steady on memory Flashing and POR (+5V check)

3 RESET Yellow

4 GEN TBL Yellow

RESET active.

Slow blink (1 blink/sec) if SLC address = 0 (bootloader)

•

• Blinks once then pause in CPS communication failure

• Fast blink (5 blinks/sec) in self-test failure or programming

• Steady in any other trouble, POR and memory Flashing

Steady when external trouble bus signal received (trouble bus shorted)

SLC incoming data

485 outgoing data

485 incoming data

+24V at Main output

Steady if in current-limit

•

• Fast blink (5 blinks/sec) in hardware failure

AMPS-K2

Board

5 TBL BUS Yellow

6 SLCRX Green

7 SLCTX Green SLC outgoing data

8 485TX Green

9 485RX Green

10 MAIN 24V Green

11 MAIN 24V TBL Yellow

• Steady on memory Flashing, or RAM self-test failure

• Medium blink (3 blinks/sec) on application code CRC self-test failure

Steady if in current-limit

12 AUX 24V TBL Yellow

•

• Fast blink (5 blinks/sec) in hardware failure

• Steady on memory Flashing, PCB rev test failed

• Medium blink (3 blinks/sec) on application code CRC self-test failure

13 AUX 24V Green +24V at AUX output

+5V logic power

Coded trouble indicator: 1 blink = AC failure; 2 blinks - high battery; 3

blinks = low battery; 4 blinks = charger failure

AC is on

+24V Auxiliary power

+5V Auxiliary power

CPS-24

Board

1 LOGIC POWER Green

2 TROUBLE Yellow

3 EARTH FAULT Yellow Ground fault detected

4 AC Green

5 +24V AUX Green

6 +5V AUX Green

Table 1.3 LED Indicators

AMPS-24 Manual — P/N 51907:J2 02/26/2014 13

Page 14

Section 2: Installation

!

!

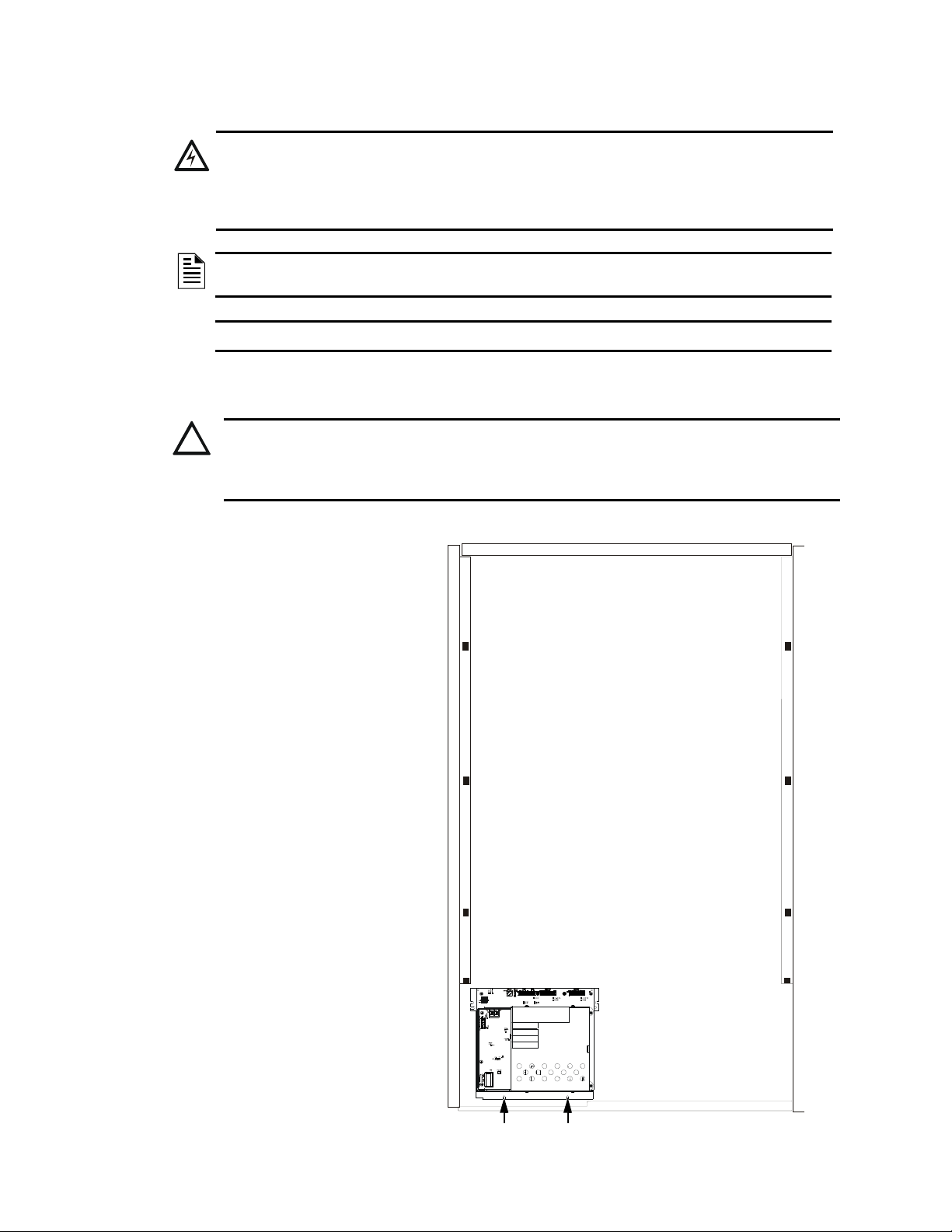

Figure 2.1 CAB-4 Series Backbox

Install the AMPS-24 in the lower

left of any CAB-4 Series cabinet.

Lower the power supply over the

cabinet’s support brackets and

fasten to the backbox with two

self-threading #6-32 screws, at the

indicated positions.

The AMPS-24 may also be

installed in a CHS-6 chassis in a

CAB-4 Series cabinet. (Refer to

Figure 2.2 on page 15.)

amps24cab3b.wmf

WARNING: High Voltages Present!

Use extreme caution when working with the AMPS-24. High voltage and AC line-connected circuits are

present in this power supply. Turn off and remove all power sources. To reduce the risk of electric shock,

make sure to properly ground the AMPS-24.

Install the snap-on cover for TB1 after wiring.

NOTE: A surge suppressor, model EDCO HSP121BT-1RU (for 120VAC operations) is required when using the

FCM-1-REL for releasing applications. The AMPS-24E power supply is not suitable for releasing applications.

NOTE: Test wire to wire faults with 0 ohm impedance.

2.1 In a CAB-4 Series Backbox.

WARNING: Risk of equipment damage!

Due to heat dissipation, total battery capacity must not exceed 26 amp-hours when the AMPS-24 is

charging in a CAB-4 series cabinet. Refer to the Heat Dissipation PID to determine the acceptable

heat dissipation in the cabinets when digital audio products are present.

The AMPS-24 mounts in the lower left of a CAB-4 Series enclosure.

14 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 15

In an EQ Series Backbox Installation

!

Figure 2.2 EQ Series Backbox

Fasten the power supply to the chassis

with two # 4-40 hex nuts, included.

(P/N 36045) at these positions.

CHS-6 Chassis

EQ Series Cabinet

2.2 In an EQ Series Backbox

WARNING: Risk of equipment damage!

Refer to the Heat Dissipation Calculation Document to determine the acceptable heat dissipation in

the EQ Series cabinets when digital audio products are present.

The AMPS-24 mounts on a CHS-6 chassis into any EQ Series cabinet row. It will require the left

two of the three chassis spaces.

AMPS-24 Manual — P/N 51907:J2 02/26/2014 15

Page 16

Installation In a BB-25 Cabinet

Figure 2.3 BB-25 Cabinet Mounting

Fasten the power supply to the backbox with (2)

#8-32 self-threading screws (p/n 38132) at the

indicated positions.

amps24_bb25b.CDR

Figure 2.4 BB-100 Mounting

BB100_AMPS24_2Batta.wmf

Fasten the AMPS-24 chassis to the backbox using the two

supplied #4-40 keps nuts (p/n 36045) at these positions.

!

2.3 In a BB-25 Cabinet

The AMPS-24 mounts in the left side of a BB-25 cabinet. Two 26 amp-hour batteries fit into the

right side of the cabinet. A BB-100 or BB-200 cabinet is required for batteries larger than 26

amp-hour.

2.4 In a BB-100 Cabinet

The AMPS-24 mounts in a BB-100 cabinet. Two 55 or 100 amp-hour batteries fit into the bottom of

this cabinet under the AMPS-24. The power supply is fastened directly to the the backbox using the

two provided keps nuts.

WARNING: Heavy Load!

The total weight of a fully loaded BB-100 will exceed 175 pounds. Additional support may be required

when mounting this cabinet to a wall.

See BB-100/200 Cabinet Installation Instructions for more information.

16 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 17

In a BB-200 Cabinet Installation

BB200_AMPS24_4Battb.wmf

Figure 2.5 BB-200 Mounting

Fasten the AMPS-24 chassis to the backbox using the two

supplied #4-40 keps nuts (p/n 36045) at these positions.

!

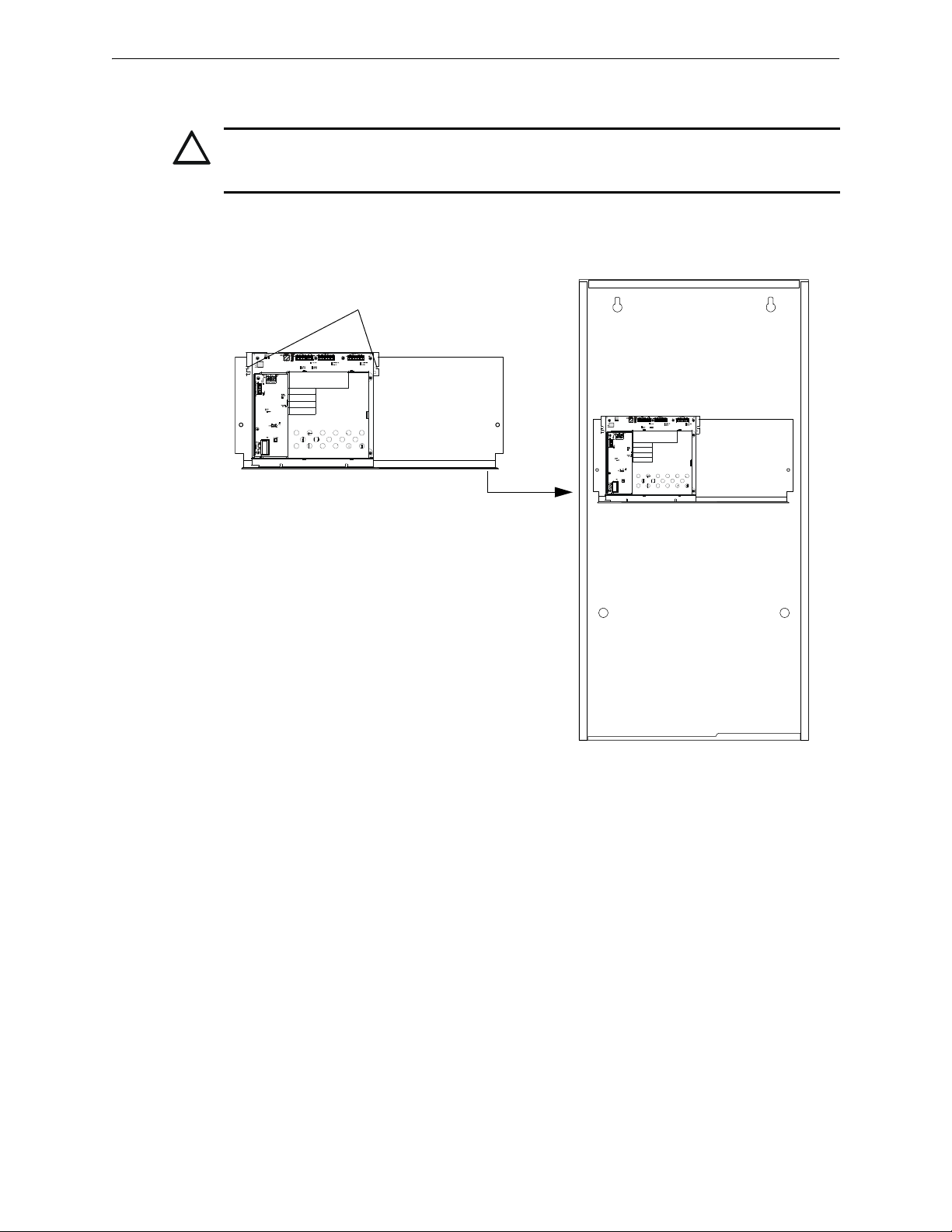

2.5 In a BB-200 Cabinet

The AMPS-24 mounts in a BB-200 cabinet with four 100 amp-hour batteries (two on the top shelf

and two on the bottom). The power supply is fastened directly to the unpainted section of the

backbox with two keps nuts.

WARNING: Heavy Load!

The total weight of a fully loaded BB-200 will exceed 300 pounds. Additional support may be required

when mounting this cabinet to a wall.

See BB-100/200 Cabinet Installation Instructions for more information.

AMPS-24 Manual — P/N 51907:J2 02/26/2014 17

Page 18

Installation Cabinet Wiring Examples

TB1: AC Primary Power

Wiring Nonpower-limited and

supervised

TB1: Main 24V Wiring Power-limited (Class 2) and filtered.

(See page 21.)

amps24_BB25_pwrlmtdb.wmf

When the BB-25 cabinet contains batteries

only, it must be located within 20 feet (6.1

m) of the enclosure housing the power

supply, and all connections must be

contained in conduit.

TB3: AUX 24V Wiring Power-limited (Class 2) and filtered

TB2: SLC Circuit Wiring Power-limited (Class 2) and supervised

Grounding Wire

TB4: Trouble Bus Wiring Power-limited (Class 2) and

non-supervised

TB2: Accessories Output Wiring (5V,

24V) - Power-limited (Class 2) and

filtered. (See page 24.)

Affix battery cables as

necessary to maintain

appropriate distance between

nonpower and power-limited

(Class 2) wiring.

Power-li

mited

(Class 2)

circuits

Grounding Wire

TB1: AC Primary

Power Wiring Nonpower-limited

and supervised

TB2: Accessories

Output Wiring (5V,

24V) - Power-limited

(Class 2) and

filtered. (See

page 21.)

TB1: Main 24V

Wiring Power-limited

(Class 2) and

filtered. (See

page 24.)

TB3: AUX 24V Wiring

-Power-limited (Class

2), supervised, filtered

NFS2-3030

AC

Side-View

Affix battery cables

as necessary to

maintain appropriate

distance between

nonpower and

power-limited (Class

2) wiring.

2.6 Cabinet Wiring Examples

The terminal block and pin connections are illustrated in Figure 1.1. Power-limited (Class 2) wiring

must remain separated from nonpower-limited wiring by at least 0.25 in. (6.4 mm), and must enter

an enclosure through different knockouts. TB1 (Main 24V) and TB3 (AUX 24) on the AMPS-K2

board are power-limited (Class 2) when set for 3A maximum current in the programmed database.

Install tie wraps and adhesive squares to secure the wiring. Figures 2.6 through 2.9 show samples

of power-limited (Class 2) and nonpower-limited wiring configurations in different cabinets.

Figure 2.6 BB-25 Cabinet: Power-limited (Class 2) Wiring Example, with Two Battery

Wiring

Figure 2.7 CAB-4 Series Cabinet: Power-limited (Class 2) Wiring Example

18 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 19

Cabinet Wiring Examples Installation

The BB-100 cabinet must be

located less than 20 feet (6.1

m) from the enclosure

housing the control panel and

all connections must be

contained in conduit.

TB3 - Nonpower-limited

and supervised

TB3 - 24V Auxiliary power.

Power-limited (Class 2).

TB2 - Secondary Power 5V and

24V Auxiliary outputs.

Power-limited (Class 2).

Grounding

Wire

TB1 - AC Primary

Power Wiring Nonpower-limited and

supervised

TB1 - Main 24V power to panel.

Power-limited (Class 2).

TB2 - SLC Circuit Wiring - Power-limited

(Class 2) and supervised.

TB4 - Trouble Bus Wiring - Power-limited

(Class 2) and non-supervised.

BB100_AMPS24_PowerLimitedd.wmf

TB1 - Main 24V power to panel. Power-limited (Class 2).

TB2 - SLC Circuit Wiring - Power-limited (Class 2) and

supervised.

TB4:Trouble Bus Wiring - Power-limited (Class 2),

non-supervised.

Grounding

Wire

TB1 - AC Primary

Power Wiring Nonpower-limited

and supervised.

TB2 - Secondary Power

5V and 24V Auxiliary

outputs. Power-limited

(Class 2).

The BB-200 cabinet must

be located less than 20

feet (6.1 m) from the

enclosure housing the

control panel and all

connections must be

contained in conduit.

TB3 Nonpower-limite

d and

supervised.

TB3 - 24V Auxiliary

power. Power-limited

(Class 2).

Figure 2.8 BB-100 Cabinet: Power-limited (Class 2) Wiring Example with Two Battery Wiring

Figure 2.9 BB-200 Cabinet: Power-limited (Class 2) Wiring Example with Four Battery Wiring

AMPS-24 Manual — P/N 51907:J2 02/26/2014 19

Page 20

Installation Wiring the AMPS-24/E

!

!

2.7 Wiring the AMPS-24/E

WARNING: Risk of electrical shock!

Remove all power sources to equipment while connecting electrical components. Leave the external,

main power breaker OFF until installation of the entire system is complete.

WARNING: Risk of equipment damage!

Several sources of power can be connected to the control panel and/or power supply. Before servicing

the control panel, disconnect all sources of input power including the battery. While energized, the control

panel and associated equipment can be damaged by removing and/or inserting cards, modules, or

interconnecting cables.

2.7.1 Overview

Complete all mounting procedures and check all wiring before applying power. Electrical

connections are listed below and are detailed in the following paragraphs:

AMPS-K2 (rear board)

TB1 - MAIN 24V

Main output, 5 A, 24VDC (nominal), output.

•5A

1) with 5A charger and AUX 24V output disabled, or

2) with 1A charger and 3A AUX 24V, or

3) with 2A charger and 3A AUX 24V,

OR

• 3A (with 5A charger and 1A AUX 24V)

These values are described in table format in Table 1.1 on page 8.

TB3 - AUX 24V

Auxiliary 24V output provides filtered power-limited (Class 2) power for additional components.

• 5A (charger disabled)

• 3A (1A/2A charger)

• 1A (5A charger and 3A Main 24V output)

These values are described in table format in Table 1.1 on page 8.

TB2 - SLC Wiring

Connect to panel Signaling Line Circuit. This terminal is not used when the AMPS-24 is connected

to a panel or DS-DB via the EIA-485 connection.

TB4 - TBL BUS

Trouble bus input is designed to receive trouble signals from any normally open dry contacts or

open collector circuit.

J3 - USB

USB Type B connector for Power Supply configuration using a PC.

CPS-24 (front board)

TB1 - AC

Primary AC Power Source - 120 VAC, 50/60 Hz, 5A (AMPS-24E uses 220-240 VAC, 50/60 Hz,

2.5 A) from line voltage source.

20 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 21

Wiring the AMPS-24/E Installation

COM — Black Wire

COM — Black Wire

24V — Red Wire

24V — Red Wire

485– — Orange Wire

485+ — Brown Wire

}

P/N 75637 only

+24V

+24V

COM +485

- 485

COM

TB1

MAIN 24V

TB2 - Accessories Output

Power-limited (Class 2); 24V @ 0.5A, 5V @ 0.15A.

TB3 - Secondary Output Source (Batteries)

24VDC from batteries installed in the appropriate enclosure. Secondary (battery) power is required

to support the system during loss of primary power.

2.7.2 Connecting TB1 MAIN 24V

To a Control Panel, Network Annunciator, or DS-DB

This output provides filtered, power-limited (Class 2)(when set for less than 5A) 24VDC power to

a control panel, network annunciator, or DS-DB. Use a four-wire harness (P/N 75591) when

connecting the power supply to a CPU-3030. Use a six-wire harness (P/N 75637 — supplied panel,

network annunciator, and DS-DB) when connecting the power supply to a CPU2-3030, NCA-2, or

DS-DB. (All six wires must be connected, even if SLC trouble reporting is selected in

programming.) If not installed in the same enclosure as the control panel; the power supply must be

located in the same room, total wire length must be less than 20 feet (6.1 meters), and all external

connections must be in conduit. Do not splice or otherwise extend P/N 75591 or P/N 75637.

Connect wiring with all power sources off.

Figure 2.10 Connecting to the Main 24 Output TB1, Example 1

As General Purpose Power

When used as general purpose power, this output provides filtered, power-limited (Class 2) (when

set for less than 5A) 24VDC general purpose (non-NAC) power. If not installed in the same

enclosure as the devices it powers; the power supply must be located in the same room, total wire

length must be less than 20 feet (6.1 meters), and all external connections must be in conduit.

Examples of devices that may utilize this power provided by an AMPS-24 mounted remotely from

the fire alarm control panel include:

AMPS-24 Manual — P/N 51907:J2 02/26/2014 21

• All current Notifier annunciators including

- ACM Series annunciators

- LDM Series lamp driver modules

- SCS Series annunciators

- UDACT

• Remote LEDs or incandescent lights supported by an LDM series annunciator

• 4-wire smoke detector (requires external reset control relay)

• 2-wire smoke detectors connected to FZM-1 module

• Solenoids (refer to the Device Compatibility Document for acceptable models)

Page 22

Installation Wiring the AMPS-24/E

+24V

+24V

COM

COM

+24V

+24V

COM +485

- 485

COM

TB1

MAIN 24V

ONYX

Panel

SLC

Battery

Battery

Non-charging

device such as

DAA-75 or

AA-Series

AC power

AMPS-24

24 VDC

General

Purpose

Power

AC power

• DVC Series

•NCM-W/F

• DS-DB Digital Series board (+/- 485 terminals must be connected).

Figure 2.11 Connecting to the Main 24 Output TB1, Example 2

Figure 2.12 is a block diagram representing an application where an AMPS-24 is used as a general

purpose remote power supply and battery charger.

Figure 2.12 AMPS-24 as Battery Charger/General Purpose Remote Power Supply

22 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 23

Wiring the AMPS-24/E Installation

+24V

+24V

COM

COM

+24V

+24V

COM

COM

TB3

AUX 24V

To SLC

Interface

+

–

+

–

SLC B

SLC A

Optional 4-wire

Return Loop

Style 6 (Class A)

A+ B-A- B+

TB2

SLC

2.7.3 Connecting to the AUX 24 Output

TB3 - This output supplies one non-resettable, power-limited (Class 2) (when set for less than 5A),

filtered 24VDC circuit available to power external devices. It may be used to power the DS-DB when

connected to TB24 on the DS-DB. This application requires that the AMPS-24 be monitored by an

FACP.

The output can be configured to provide 3A or 5A maximum current, or it can be disabled. Refer to

Section 3.2.6 on page 34.

Figure 2.13 Connecting to the AUX 24V Output TB3

2.7.4 Connecting to the SLC

TB2 - Supervised and power-limited (Class 2). With all power sources off, connect the power

supply from TB2 to the SLC interface.

NOTE: Do not connect the AMPS-24 to the SLC if the AMPS-24 is communicating via 485

trouble reporting. (Refer to “Trouble Reporting” on page 36.)

See

“SLC Addressing” on page 30.

Refer to the SLC Wiring Manual for more information.

Figure 2.14 Connecting to the SLC Interface TB2

AMPS-24 Manual — P/N 51907:J2 02/26/2014 23

Page 24

Installation Wiring the AMPS-24/E

Figure 2.15 Trouble Bus Connection

+

TB4

TBL BUS

COM — Black Wire

24V — Brown Wire

COM — Green Wire

5V — Red Wire

AMPS24_TB2access.wmf

+24V AUX

TB2

COMCOM +5V AUX

2.7.5 Connecting the Trouble Bus

Trouble bus input is designed to receive

trouble signals from any normally-open dry

contacts or open-collector circuit.

2.7.6 Connecting the Accessories Output on the CPS-24

TB2 - Supplies one (1) non-resettable, power-limited (Class 2) 24 VDC circuit and one

non-resettable power-limited (Class 2) 5 VDC circuit available to power external devices. UZC

applications on the 5V connection to the Accessories Output must be within 10 feet (3.658 meters)

of the power supply and should use the supplied cable, P/N 75595. Do not splice or otherwise

extend P/N 75595. Refer to the “Wire Requirements” section of the panel installation manual for all

applications requiring a 24V connection. The wiring must remain within the same enclosure, or it

must be in conduit. Connect wiring with all power sources off.

• 24 VDC (nominal) @ 0.5 A max.

• 5 VDC (nominal) @ 0.15 A max.

Refer to the Device Compatibility Document for compatible devices and notification appliances.

Figure 2.16 Connecting to the Accessories Output TB2 on CPS-24

2.7.7 Connecting the Power Supply to AC Power

TB1 (CPS-24) - Primary AC power source - 120 VAC, 50/60 Hz, 5.0A (AMPS-24E uses 220-240

VAC, 50/60 Hz, 2.5A) from line voltage source.

The AMPS-24 requires connection to a separate dedicated AC branch circuit. Follow these

24 AMPS-24 Manual — P/N 51907:J2 02/26/2014

guidelines when connecting the AC branch circuit:

• Label the branch circuit “Fire Alarm”.

• Connect the branch circuit to the line side of the main power feed of the protected premises.

• Do not power other equipment from the fire alarm branch circuit.

• Run the AC branch circuit wire continuously, without any disconnect devices, from the

power source to the power supply.

Page 25

Installing and Connecting the Batteries Installation

Figure 2.17 AC Power Connection

cps24_ac.cdr

!

!

!

Figure 2.18 Terminal Bolt Installation

• Overcurrent protection for the AC branch circuit must comply with Article 760 of the

National Electrical Codes, as well as local codes.

• Use 12–14 AWG (3.31 mm

2

– 2.08 mm2) or larger wire with 600 VAC insulation for the AC

branch circuit.

Connect primary power as follows:

1.Turn off the circuit breaker at the main power

distribution panel.

2.Connect the earth ground terminal (TB1-

EARTH) to a solid earth ground (a metallic, cold

water pipe may be suitable in some installations).

This connection is vital in reducing the panel’s

susceptibility to transients generated by lightning

and electrostatic discharge.

3.Connect the primary power neutral line to

terminal marked

AC line to terminal marked

NEUTRAL and the primary power

HOT.

2.8 Installing and Connecting the Batteries

WARNING: Risk of severe burns!

Batteries contain sulfuric acid which can cause severe burns to the skin and eyes, and can destroy

fabrics. If contact is made with sulfuric acid, immediately flush skin or eyes with water for 15 minutes

and seek immediate medical attention.

WARNING: Risk of equipment damage!

Do not connect the battery interconnect cables (P/N 75560, 75561, or 71070) at this time. Leave the

battery interconnect cables disconnected until after initial system power-up.

WARNING: Risk of equipment damage!

To avoid contact with metal cabinet, always install terminal bolts towards the center of the battery. See

Figure 2.18.

AMPS-24 Manual — P/N 51907:J2 02/26/2014 25

Page 26

Installation Installing and Connecting the Batteries

cps24_2batt.wmf

TB3

Certain system designs may require connecting two or four batteries to the power supply,

connecting multiple power supplies to each other, or connecting one set of batteries to multiple

power supplies. Always use wire size 12-18 AWG (3.25 mm

2

– 0.75 mm2), and install the power

supply and the batteries in the appropriate enclosures, as described in Sections 2.4 and 2.5.

2.8.1 Setting the Charger

The AMPS-24 battery charger will charge 7 to 200 AH lead-acid batteries. Use PK-PPS to select

the appropriate battery charger current for the system’s battery capacity from these settings:

5A, or DISABLE CHARGER. Select 1A to charge 7 to 26 AH batteries. Select 2A to charge 12 to 60

1A, 2A,

AH batteries. Set the charger to 5 A when the power supply will be charging a system that requires

55 to 200 AH. Select

DISABLE CHARGER when the batteries will be charged by an external charger.

See Section 3.2, “Programming the AMPS-24”, on page 32 for more information on programming

via PK-PPS. Refer to Section 4.2, “Calculating the Battery Requirements”, on page 44 for more

information on determining your system’s battery capacity.

2.8.2 Connecting the Power Supply to Two Batteries:

1. Use PK-PPS to set the charger to the appropriate current for the system’s battery capacity.

2. Connect one cable from TB3 (

one battery.

3. Connect another cable from TB3 (

of the other battery.

4. Only after initial system power-up, connect a battery interconnect cable between the

negative (-) terminal on the first battery to the positive (+) terminal on the second battery.

BATT IN +) on the power supply to the positive (+) terminal of

BATT IN -) on the power supply to the negative (–) terminal

To determine battery requirements, refer to Section 4 of this manual.

Figure 2.19 Connecting Two Batteries to the Power Supply

2.8.3 Connecting the Power Supply to Four Batteries:

1. Use PK-PPS to set the charger to the appropriate battery charger current for the system’s

battery capacity.

2. Continue the connection from the occupied positive (+) battery terminal to the positive (+)

terminal of the next unconnected battery.

3. Continue the connection from the occupied negative (–) battery terminal to the negative (–)

terminal of the remaining unconnected battery.

4. Only after initial system power-up, connect the two pairs of batteries. Use two battery

interconnect cables to tie each unoccupied negative (–) terminal to an unoccupied positive (+)

terminal, as shown in Figure 2.20.

26 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 27

Installing and Connecting the Batteries Installation

TB3

cps24_4Batt.wmf

To determine battery requirements, refer to Section 4 of this manual.

Figure 2.20 Connecting Four Batteries to the Power Supply

NOTE: Use a ring terminal to attach two cables to one battery terminal.

AMPS-24 Manual — P/N 51907:J2 02/26/2014 27

Page 28

Installation Installing and Connecting the Batteries

!

AMPS-24

Compatible UL/ULC–Listed

Power Supply/Product

To Batteries

To Batteries

acps-610_MultiPS.wmf

2.8.4 Connecting Multiple Power Supplies/Products (Separate Batteries)

Follow these guidelines when connecting multiple power supplies and products that use batteries

(such as the DS-AMP and DAX):

• Disable Ground Fault detection on all products except one power supply. See Figure 1.1 on

page 11.

For proper supervision the power supply with the enabled ground fault detection must be

connected to the SLC or to the EIA-485.

• Connect common bond wire between these products.

• All connections must be in conduit and the total battery connection must be less than 20 feet

(6.1 meters) from the enabled power supply.

• Confirm that enabled chargers have the capacity to charge the total load of the selected

battery configuration.

• Connect battery interconnect cables only after initial system power-up. Refer to

“Installing and Connecting the Batteries” on page 25.

To determine AMPS-24 battery requirements, refer to Section 4.2 on page 44 in this manual.

Refer to the specific product manual(s) and/or Device Compatibility Document for further

information and instructions.

CAUTION: Risk of possible equipment damage.

To maintain proper supervision, auxiliary supplies used to power Panel Circuits, such as the ICM-4/E,

must be connected to the same batteries as the main power supply. Failure to do so may result in

equipment damage.

Figure 2.21 Connecting Multiple Power Supplies/Products with Common Bond Wire

28 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 29

Installing and Connecting the Batteries Installation

!

AMPS-24

Internal Charger enabled

Refer to “Outputs Current Settings”

on page 35.

Compatible

UL/ULC–Listed

Power

Supply/Product

Internal Charger disabled

AMPS24_MultiPS-BAT.wmf

Internal Charger disabled

Compatible

UL/ULC–Listed

Power

Supply/Product

2.8.5 Connecting Multiple Power Supplies/Products (One Set of Batteries)

Certain system designs may require connecting multiple power supplies and products that use

batteries (such as the DS-AMP and DAX) to one set of batteries. Follow these connection

guidelines:

• For proper supervision, enable only the charger directly connected to the batteries. Disable

all other chargers.

• Confirm that the enabled charger has the capacity to charge the total load of the selected

battery configuration.

• Use PK-PPS to set the charger to the appropriate battery charger current for the system’s

battery capacity.

• Disable Ground Fault detection on all power supplies/products except the one that is

charging the batteries. See Figure 1.1 on page 11.

For proper supervision the power supply with the enabled ground fault detection must be

connected to the SLC, or to the EIA-485 to the CPU2-3030, NCA-2 or DS-DB.

• All power supply to power supply connections must be in conduit and the total battery

connection must be less than 20 feet (6.1 meters).

• Connect battery interconnect cables only after initial system power-up. Refer to

“Installing and Connecting the Batteries” on page 25.

To determine battery requirements, refer to Section 4.2, “Calculating the Battery Requirements” in

this manual.

Refer to the specific power supply manual(s) and/or Device Compatibility Document for further

information and instructions.

CAUTION: Risk of possible equipment damage.

To maintain proper supervision, auxiliary supplies used to power Panel Circuits, such as the

ICM-4/E, must be connected to the same batteries as the main power supply. Failure to do so

may result in equipment damage.

Figure 2.22 Connecting Multiple Power Supplies/Products (One Set of Batteries)

AMPS-24 Manual — P/N 51907:J2 02/26/2014 29

Page 30

Section 3: Configuring the AMPS-24

!

3.1 SLC Addressing

NOTE: An AMPS-24 communicating over the EIA-485 protocol will not require an SLC address

block. See Section 3.3, “Configuring the Network Annunciator” for more information.

When the AMPS-24 communicates via the SLC, the installer must reserve sequential SLC

addresses (an address block) equal to the number of addresses that will be consumed by the

AMPS-24. Determining the size of the address block and setting the SLC base address is

described in this section.

3.1.1 Determining Address Consumption

CAUTION:

Always select “SLC Trouble Reporting” when connecting the AMPS-24 to an NFS2-3030.

Software determines the AMPS-24 address consumption. An AMPS-24 can occupy either one or

five addresses on an SLC. The AMPS-24 will consume five addresses on the SLC if configured for

five-point trouble reporting. If trouble reporting is not selected, the AMPS-24 will only consume

one address. Table 3.1 details address consumption.

AMPS-24

Addresses

PK-PPS Setting

Monitor General

Monitor AC Fail

Monitor Battery

Monitor Earth Fault

Monitor Charger

Fault

EIA-485 or SLC

Five Point

Trouble Reporting

NOT SELECTED

“SLC” Interface Type “EIA-485” Interface Type

??

Total: 1 Address No address when SLC is

EIA-485

Trouble Reporting

SELECTED

disabled.

SLC

Trouble Reporting

*

SELECTED

†

SLC

Address

• “SLC” Interface Type

• “Five-Point Monitoring”

Trouble Reporting

‡

B

?

?

?

?

Total: 5 Addresses

Assign 5 sequential SLC

addresses for this

configuration.

B + 1

B + 2

B + 3

B + 4

Table 3.1 SLC Address Consumption

* Required for use with NCA-2

† Required for use with NFS2-3030 and when used as a remote power supply.

‡ B = SLC Base Address

30 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 31

SLC Addressing Configuring the AMPS-24

rotarysw.CDR

acps-610_SW3.wmf

3.1.2 Setting the Base Address (SLC Enabled)

The base address is the first address used in an SLC address block. Combine rotary switch (SW2)

and address switch (SW3) settings to determine the base address (B). The base address will be a

number that ends in zero or five and the rest of the address block will progress sequentially from

that number until all the addresses in the block are consumed.

NOTE: The lowest base address for the AMPS-24 is 05. Do not use FACP addresses 00 through 04

for the AMPS-24.

The Rotary Switch

The rotary switch SW2 determines the address decade. Each number on the dial represents the ten

addresses of a decade. Turning the arrow until it points at a number selects that number’s decade.

For example:

Pointing the arrow at the 1 selects the “one” address decade, beginning at 10.

Pointing the arrow at the 12 selects the “twelve” address decade, beginning at

120.

The SLC Address Slider Switch (SW3)

Use the slider switch, SW3, to further define the SLC base address. While an address’ decade is

defined by the rotary switch, the slider determines whether the base address (B) will end in a zero

or a five. Sliding the switch towards the 0 selects a base address that ends with a zero. Sliding the

switch towards the 5 selects a base address that ends with a five.

For example:

Slide the switch towards the 0, as shown in the illustration to the left, to select

an initial address that ends in zero. Since the rotary switch defines the decade, if

the rotary switch were to point at 8, the base address in this address block would

be 80.

Slide the switch towards the 5, as shown in the illustration to the left, to select

an initial address that ends in five. Since the rotary switch defines the decade, if

the rotary switch were to point at 8, the base address in this address block would

be 85.

AMPS-24 Manual — P/N 51907:J2 02/26/2014 31

Page 32

Configuring the AMPS-24 Programming the AMPS-24

ROTARY

SWITCH

SETTING

SW3

SLIDER SWITCH

POSITION

acpsaddrot1.CDR

acpsaddrot3.CDR

SLC

BASE

ADDRESS

5

120

SLC ADDRESSES

SELECTED

with

five AMPS-24 Addresses

5-9

120-124

acps610_sw32.wmf

acps610_sw31.wmf

Figure 3.1 below gives two examples of setting the base address with both rotary and slider switch

settings.

Figure 3.1 SLC Address Selection

3.2 Programming the AMPS-24

Use PK-PPS to program the charger current and trouble reporting. With PK-PPS, the AMPS-24

database can be configured and downloaded, and firmware updated. The power supply’s

configuration can be modified online, while the PC is connected to the power supply; or offline, on

a database that can be downloaded at a later date.

3.2.1 Installing the Configuration Software

Minimum Requirements

• Windows XP Professional with SP2, or Windows 2000 with SP4.

• PC or Laptop with USB 2.0 port.

Installation

1. Log in. The user must have Administrative privileges.

2. Exit out of the NFN Gateway if it is running in the system tray.

3. Insert the CD into the PC’s CD drive.

4. Double click on the file PPS.exe on the CD.

5. Follow the instructions of the PPS installation wizard to completion.

6. Connect the AMPS-24 to the PC via the USB cable. (See Section 3.2.2.) Wait for the

operating system to detect the new hardware.

7. Follow the set of steps in Table 3.2 below that are specific to your operating system.

32 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 33

Programming the AMPS-24 Configuring the AMPS-24

!

!

Figure 3.2 The AMPS-24 USB Interface (J3)

AMPS24_USBa.wmf

.

Windows XP Professional with SP2 Windows 2000 with SP4

1. On the Found New Hardware Wizard window, select “No,

not this time”. Click Next.

2. Select “Install from a list or specific location”. Click Next.

3. Select “Search for the best driver in these locations”.

Clear the check box next to “Search removable media”

and set the check mark next to “Include this location in the

search”. Click Browse.

4. On the Browse For Folder pop-up window, select the

folder C:\ProgrammingKit\PowerSupply\USB Drivers.

Click OK.

5. Click Next.

6. On the Hardware Installation window that warns “The

software has not passed Windows Logo testing...”, click

Continue Anyway.

7. Click Finish.

Table 3.2 Operating System Instructions

WARNING: Power Supply Disabled!

The power supply is out of service during database/firmware upload and downloads.

WARNING: Risk of Irreversible Loss of Programming Data!

Steady STATUS, GENERAL and OUTPUT TROUBLE LEDS indicate that a database/firmware

download is STILL in process. Do not disconnect power or the USB cable during this time!

Disonnect USB cable only after programming is complete.

1. On the Found New Hardware Wizard window, click Next.

2. Select “Search for a suitable driver for my device”. Click

Next.

3. Under optional search locations, select “Specify a

location”. Clear all other check boxes. Click Next.

4. On the window that pops up, click the Browse button and

select the file

C:\ProgrammingKit\PowerSupply\USB Drivers\HfsUsb.inf.

Click Open.

5. Click OK on the pop-up window.

6. Click Next. This will install the driver.

7. Click Finish.

3.2.2 Establishing the Hardware Connection

NOTE: Before connecting PK-PPS to the power supply, exit out of the NFN Gateway if it is

running in the system tray.

Connect a standard USB cable from the

PC’s USB port to the AMPS-24’s USB

interface (J3). When the download is

complete, the unit automatically reboots

and returns to normal operation.

3.2.3 Working Offline

If the PC is not connected to a power supply, it can be used to create or edit AMPS-24 databases.

These databases can be saved and downloaded at a later date.

AMPS-24 Manual — P/N 51907:J2 02/26/2014 33

Page 34

Configuring the AMPS-24 Programming the AMPS-24

Select AMPS-24

from drop-down

menu.

To create a new database, select NEW from the FILE menu, then select AMPS-24.

To edit an existing database, select

OPEN from the FILE menu, then select AMPS-24.

Refer to Figure 3.3 below.

Figure 3.3 Power Supply Selection

3.2.4 Working Online

NOTE: Before connecting PK-PPS to the power supply, exit out of the NFN Gateway if it is

running in the system tray.

In addition to creating and opening databases on the PC’s local drive, modifications may be made

to any AMPS-24 that is directly connected to the PC with the PK-PPS programming utility. When

PK-PPS is open and the PC is connected via the USB to a power supply, that power supply is

represented by the icon in the left window. Click on this icon to see the power supply’s current

configuration and version information.

Right-clicking on the AMPS-24 icon provides three work options:

SAVE Select this option to save the power supply’s current configuration as a database file

(*.pdb) on the PC’s local drive.

MODIFY Select this option to edit the power supply’s current configuration. When all changes

are made, the new database will overwrite the one in the AMPS-24. The new database can also

be saved to the local drive.

DOWNLOAD Select this option to download a database, application, or bootloader file to the

power supply. See Section 3.2.5.

3.2.5 Downloading to the AMPS-24

1. Check to make sure that the PC is connected to the AMPS-24 (Section 3.2.2).

2. Right click on the AMPS-24 icon, select

you wish to download or select Download from the Operation menu.

You may download a program database file (*.pdb), an application file (*.hex), or a

bootloader file (*.hex).

3. Use the Browse button to navigate to the file you wish to download.

4. Open the file to download it to the AMPS-24.

5. Disconnect USB cable AFTER programming is complete.

DOWNLOAD and choose the type of application

3.2.6 AMPS-24 Configuration

PK-PPS sets parameters for the AMPS-24, outputs/charger current and trouble reporting type.

Selections must be made in order shown below. Lower level options will not be available until

upper level options have been selected.

34 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 35

Programming the AMPS-24 Configuring the AMPS-24

PKPPS Label.bmp

PKPPS Charger.bmp

The worksheet’s summary section displays all selections. When programming is complete, PK-PPS

displays the SLC address consumption that is the result of your selections.

Figure 3.4 PK-PPS: Label

Label

For greater ease of identification, you may create a label for each power supply. Labels may have a

maximum of 40 characters.

Figure 3.5 PK-PPS: Battery Charger/Outputs Current Setup

Outputs Current Settings

Choose the appropriate battery charger current for the system’s battery capacity. Refer to

Section 4.2, “Calculating the Battery Requirements”, on page 44 for more information on

determining your system’s battery capacity.

There are three charger current options. Select

to 26 AH batteries. Select

5A CHARGE to charge 55 to 200 AH batteries. Select DISABLE CHARGER

1A CHARGE for 7 to 26AH, 2A CHARGE to charge 12

when the batteries will be charged by an external charger (See “Setting the Charger” on page 26.).

NOTE: The charger current option “1A CHARGE” is not approved for ULC applications.

AMPS-24 Manual — P/N 51907:J2 02/26/2014 35

Page 36

Configuring the AMPS-24 Programming the AMPS-24

PKPPS Interface.bmp

PKPPS Trouble.bmp

Figure 3.6 PK-PPS: Interface Type

Interface Type

Select the interface type.

SLC: This must be selected when the AMPS-24 is used as the power supply for a CPU2-3030 or as

a remote power supply.

EIA-485: This must be selected when the AMPS-24 is used with an NCA-2.

Figure 3.7 PK-PPS: Trouble Reporting

Trouble Reporting

Select the trouble reporting option.

Five Point Monitoring: When the power supply is configured for Five Point Monitoring

(trouble reporting over the SLC), the panel will report a trouble message beginning at the base

SLC address. This selection must be made if the power supply is being used to power a CPU23030 or as a remote power supply. Reporting at the base address (“Monitor General”) includes

current limit, hardware failure, trouble bus active, and CPS communication trouble. Refer to

“SLC Addressing” on page 30.

When the power supply is configured for Five Point Monitoring, the panel displays a specific

trouble message for AC Fail, Battery, Earth Fault, and Charger Fail addresses (See Table 3.1).

In CLIP mode, the labels for the “Base + x

” addresses must be entered manually. In FlashScan

mode, device labeling is automatic.

36 AMPS-24 Manual — P/N 51907:J2 02/26/2014

Page 37

Configuring the Network Annunciator Configuring the AMPS-24

PK-PPS Summary.jpg

!

US AC Fail Delay time: Make a selection (0, 2 HOURS, 8 HOURS, or 16 HOURS) from the dropdown menu.

Figure 3.8 PK-PPS: Summary

Summary

The Summary screen displays all of your previous selections and the resulting SLC address

consumption. Review this summary screen before downloading and ensure that the proper

number of consecutive addresses are reserved. You may use the

your selections. Click the

FINISH button to save your changes to the database.