Page 1

ACUIX™

High Speed Dome

User Manual

Document 800-01023 – Rev A – 02/08

Page 2

Revisions

Issue Date Revisions

1.00 05/07 New document

1.01 05/07 Revised document (HJZTP privacy zone revision)

A 02/08 Document p/n changed from 900.0849 rev 1.01. Removed 23X WDR & TDN (Hitachi

VK-S454R) camera, added 18X Color (Sony FCB-48C), 18X TDN (Sony FCB-490D)

and 26X WDR & TDN (Sony FCB-990D) cameras. Added Class A warning to p. 3.

Page 3

FCC Compliance Statement

Information to the User: This equipment has been tested and found to comply with the limits for a Class B digital device.

Pursuant to Part 15 of the FCC Rules, these limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference. For example, try orienting or

relocating the receiving antenna, increasing the separation between the equipment and receiver, or connecting the

equipment to an outlet on a different circuit.

Caution Changes or modifications not expressly approved by the party responsible for compliance could void the

user's authority to operate the equipment.

Users of the product are responsible for checking and complying with all federal, state and local

laws and statutes concerning the monitoring and recording of video and audio signals.

Honeywell Video Systems shall not be held responsible for the use of this product in violation of

current laws and statutes.

Canadian Compliance Statement

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Manufacturer’s Declaration of Conformance

The manufacturer declares that the equipment supplied with this guide is compliant with the essential protection

requirements of the EMC directive 89/336/EEC and the Low Voltage Directive LVD 73/23 EEC, conforming to the

requirements of standards EN 55022 for emissions, EN 50130-4 for immunity, and EN 60065 for Electrical Equipment

safety.

Document 800-01023 Rev A 3

02/08

Page 4

Explanation Of Graphical Objects

The lightning flash with arrowhead symbol within an equilateral triangle is intended to alert the user to the

presence of uninsulated "dangerous voltage" within the enclosure of the product that may be of sufficient

magnitude to constitute a risk of electric shock to the person.

The exclamation point within an equilateral triangle is intended to alert the user to the presence of

important operating and maintenance servicing instructions in the literature accompany the product.

Important Safety Instructions

READ INSTRUCTIONS - All safety and operating instructions should be read before the unit is operated.

1. RETAIN INSTRUCTIONS - The safety and operating instructions should be retained for future reference.

2. HEED WARNINGS - All warnings on the unit and in the operating instructions should be adhered to.

3. FOLLOW INSTRUCTIONS - All operating and use instructions should be followed.

4. CLEANING - Unplug the unit from the outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use

a damp cloth for cleaning.

5. ATTACHMENTS - Do not use attachments not recommended by the product manufacturer as they may result in

the risk of fire, electric shock, or injury to persons.

6. ACCESSORIES - Only use accessories specified by the manufacturer. Do not place this product on an unstable

cart, stand, tripod, bracket, or table. The product may fall, causing serious injury to a child or adult and serious

damage to the equipment. Use only with a cart, stand, tripod, bracket, or table recommended by the

manufacturer, or sold with the product. Any mounting of the product should follow the manufacturer's

instructions and should use a mounting accessory recommended by the manufacturer. Wall or shelf mounting

should follow the manufacturer's instructions and should use a mounting kit approved by the manufacturer.

7. A product and cart combination should be moved with care. Quick stops, excessive force, and uneven surfaces

may cause the product and cart combination to overturn.

8. POWER SOURCES - This product should be operated only from the type of power source indicated on the

marking label. If you are not sure of the type of power supplied to your facility, consult your product dealer or

local power company.

9. OVERLOADING - Do not overload outlets and extension cords as this can result in a risk of fire or electric shock.

10. POWER-CORD PROTECTION - Power supply cords should be routed so that they are not likely to be walked on

or pinched by items placed upon or against them, paying particular attention to cords, plugs, and convenience

receptacles.

11. SERVICING - Do not attempt to service this unit yourself as opening or removing covers may expose you to

dangerous voltage or other hazards. Refer all servicing to qualified service personnel.

4

Page 5

12. DAMAGE REQUIRING SERVICE - Unplug the unit from the outlet and refer servicing to qualified service

personnel under the following conditions:

a. When the power-supply cord or plug is damaged.

b. If liquid has been spilled, or objects have fallen into the unit.

c. If the unit has been exposed to rain or moisture.

d. If the unit does not operate normally by following the operating instructions. Adjust only those controls that

are covered by the operating instructions as an improper adjustment of other controls may result in damage

and will often require extensive work by a qualified technician to restore the unit to its normal operation.

e. If the unit has been dropped or the enclosure has been damaged.

f. When the unit exhibits a distinct change in performance - this indicates a need for service.

13. REPLACEMENT PARTS - When replacement parts are required, be sure the service technician has used

replacement parts specified by the manufacturer or have the same characteristics as the original part.

Unauthorized substitutions may result in fire, electric shock or other hazards.

14. SAFETY CHECK - Upon completion of any service or repairs to this unit, ask the service technician to perform

safety checks to determine that the unit is in proper operating condition.

15. LIGHTNING AND POWER LINE SURGES - For added protection of this unit when it is left unattended and unused

for long periods of time, unplug it from the wall outlet and disconnect the cable system. This will prevent damage

to the unit due to lightning and power-line surges.

16. HEAT - The product should be situated away from heat sources such as radiators, heat registers, stoves, or other

products (including amplifiers) that produce heat.

17. INSTALLATION - Install in accordance with the manufacturer’s instructions. Do not install the unit in an extremely

hot or humid location, or in a place subject to dust or mechanical vibration. The unit is not designed to be

waterproof. Exposure to rain or water may damage the unit.

Prior to installation and use of this product, please observe the following cautions and warnings.

Caution

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK).

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

Document 800-01023 Rev A 5

02/08

Page 6

Warning

Warning! Installation and servicing must be performed by qualified personnel in accordance

with current IEE wiring regulations.

Warning! The PSU must be wired to a double pole fuse spur with 3mm separation. The 3A

fuse spur must be located close to the PSU.

Warning! Using replacement parts or accessories other than the original manufacturers may

invalidate the warranty.

Warning! To prevent injury, this apparatus must be securely attached to the wall/ceiling in

accordance with the installation instructions.

6

Page 7

ACUIX High Speed Dome User Manual

Contents

About This Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overview of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1 Installing the Pan and Tilt Camera Assembly and Lower Dome . . . . . . . . . . . . . . . . . . 17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing the Pan and Tilt Camera Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installing the Lower Dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Indoor or Outdoor Pendant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Protocol Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Baud Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Sample Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Honeywell Diamond . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

VCL - RS485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

IntelliBus™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Camera Address Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Address Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DIP Switch Address Override. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Restore Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

RJ45 Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3 Operation and Programming with Honeywell Diamond Protocol . . . . . . . . . . . . . . . . . . 29

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

HEGS5000/5001 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Reset ACUIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

18X Color Camera (FCB-EX48C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

18X True Day/Night Camera with Wide Dynamic Range (FCB-EX490D) . . . . . . . . . . . . 33

26X True Day/Night Camera with Wide Dynamic Range (FCB-EX990D) . . . . . . . . . . . . 33

35X True Day/Night Camera with Wide Dynamic Range, Progressive Scanning and Image Stabi-

lization (VK-S654) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Freeze and Unfreeze Video. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Flashback Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

NightShot Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Alarm Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Find Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Preset Tours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Rev A Document 800-01023

7

02/08

Page 8

Contents

Mimic Tours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Sector IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Privacy Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

HJTZP Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Reset ACUIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Freeze/Unfreeze Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Flashback Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

NightShot Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Alarm Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Find Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Preset Tours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Mimic Tours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Sector IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Privacy Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4 Operation and Programming with Honeywell VCL Protocol . . . . . . . . . . . . . . . . . . . . 61

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Reset ACUIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Lens Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Freeze/Unfreeze Video—Preset 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Flashback Operation—Preset 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

NightShot Mode—Preset 94 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Find Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Program Preset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Recall Preset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Preset Tours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Run Preset Tour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Stop a Preset Tour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Sector IDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Privacy Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Mimic Tours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Programming Mimic Tours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Mimic Tour Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Deleting Privacy Zones, Presets, Preset Tours, and Sectors . . . . . . . . . . . . . . . . . . 72

5 Operation and Programming with IntelliBus™ Protocol. . . . . . . . . . . . . . . . . . . . . . . 75

Factory Default Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Configuration Upload/Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Configuration Default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Configuration Data Saving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

6 ACUIX Password Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Enabling the Password Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Logging On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Changing the 4-Digit PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Resetting Privacy Zone Password (Diamond or IntelliBus Protocols) . . . . . . . . . . . . . . . . . . . 81

Delete Privacy Zone Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7 On-Screen Setup Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Rev A Document 800-01023

8

02/08

Page 9

ACUIX High Speed Dome User Manual

Control/Video Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Honeywell Diamond Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Honeywell VCL Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Honeywell VCL Coax Control Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3rd Party Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Selecting the Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Control Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Diagnostic Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Camera Options, 18X WDR & True Day/Night and 26X WDR, True/Day Night Camera

(FCB-EX490D and FCB-EX990D Respectively) . . . . . . . . . . . . . . . . . . . . . . . . 105

Camera Options, 35X WDR & True Day/Night Camera with Image Stabilization and Motion De-

tection

(VK-S654) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Function Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Enhanced Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Appendix A Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Problem: No Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Problem: General Video Problems (Video Over UTP Only) . . . . . . . . . . . . . . . . . . . . . . . 128

Video is Inverted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Video is Poor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Problem: Video, But No Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Problem: Lens Out of Optical Focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Problem: Cannot Find Home or Does Not Go to a Preset. . . . . . . . . . . . . . . . . . . . . . . . 130

Problem: Pan and Tilt is Jerky . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Problem: Video Zooms For No Reason . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Appendix B Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

ACUIX Housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

ACUIX Cameras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Pan and Tilt Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Operating/Programming Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

ACUIX Lower Dome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Regulatory Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Appendix C Pelco Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

ACUIX Mimic Tour Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Appendix D Digital Video Recorder Integration . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

DVR and Camera protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Rev A Document 800-01023

9

02/08

Page 10

Contents

Rev A Document 800-01023

10

02/08

Page 11

ACUIX High Speed Dome User Manual

Figures

Figure 1-1 ACUIX Pan and Tilt Camera Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 1-2 ACUIX Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 1-3 ACUIX Pan and Tilt Camera Assembly Locking Rails. . . . . . . . . . . . . . . . . . . . . 19

Figure 1-4 Pendant Lower Dome Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2-1 ACUIX Pan and Tilt Camera Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2-2 Location of DIP and Rotary Switches on Main Board . . . . . . . . . . . . . . . . . . . . . 21

Figure 3-1 Sectors IDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 3-2 Sector ID Coordinates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Rev A Document 800-01023

11

02/08

Page 12

Figures

Rev A Document 800-01023

12

02/08

Page 13

ACUIX High Speed Dome User Manual

Tables

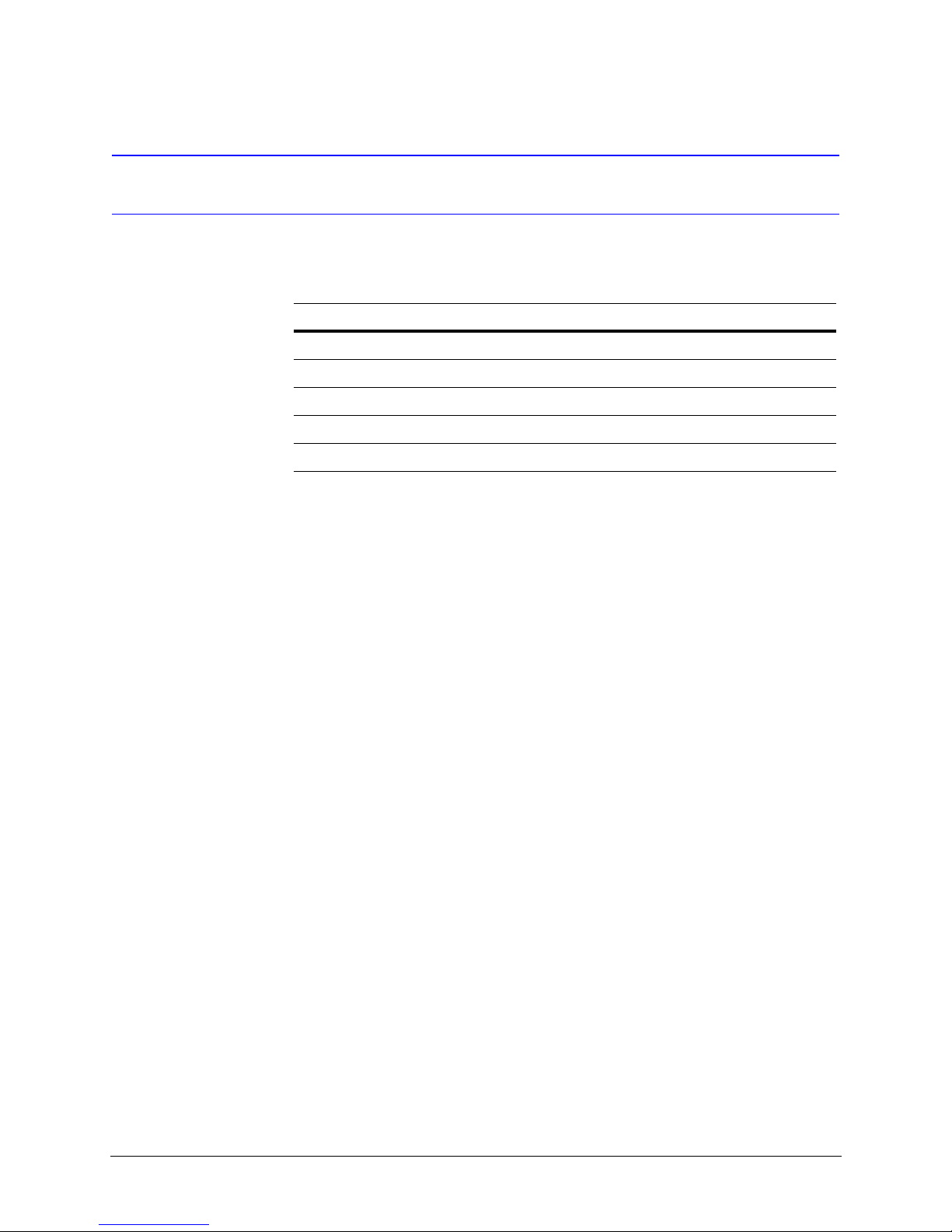

Table 1-1 ACUIX Pan and Tilt Camera Assembly Model Numbers. . . . . . . . . . . . . . . . . . . . 17

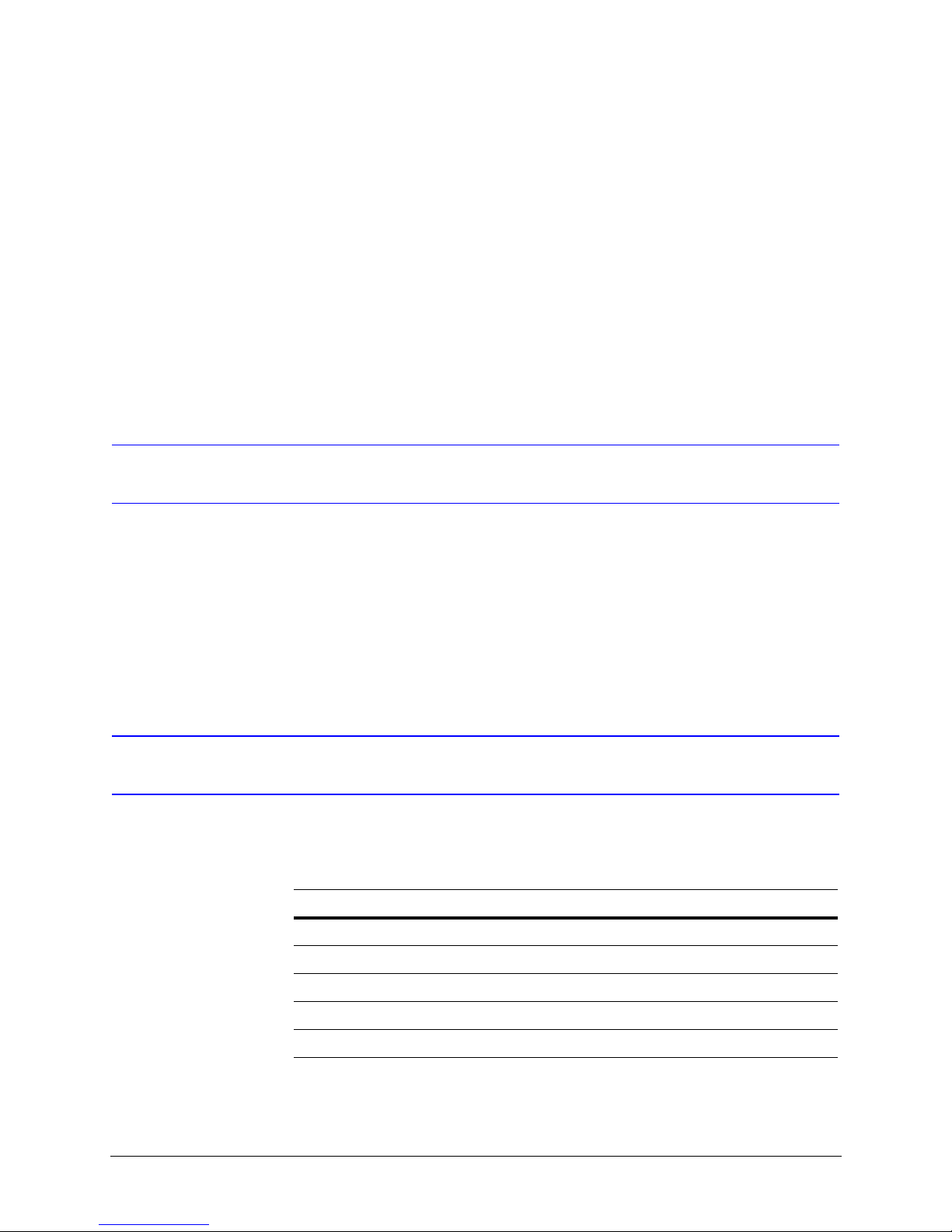

Table 2-1 DIP Switch SW5 ACUIX Protocol Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 2-2 DIP Switch SW6 ACUIX Baud Rate Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 2-3 DIP Switch SW6 ACUIX Parity Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 2-4 ACUIX Camera Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 3-1 HEGS5000 Joystick Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 3-2 HEGS5000/5001 Camera Lens Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 3-3 35X Camera Feature Dependencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 3-4 Pre-programmed Presets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 3-5 Program Preset Menu Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 3-6 Preset Title Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 3-7 Still Preset Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 3-8 Preset Tour Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 3-9 Sector ID Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 3-10 Privacy Zone Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 3-11 HJZTP Joystick Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 4-1 HJZTP Joystick Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 4-2 Pre-programmed Presets ACUIX (VCL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 4-3 Preset Tour Programming Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 6-1 Default User PINs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 7-1 Program Alarm Field Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 7-2 Alarm States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 7-3 Alarm Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 7-4 Pan and Tilt Reverse Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 7-5 Find Home Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table 7-6 Default Function Field Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 7-7 Default Function Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 7-8 Auto Focus Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 7-9 Preset Tour Auto Focus Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 7-10 Cx Code Last Hexadecimal Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Table 7-11 High Light White Balance Mode Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 7-12 Still Preset Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 7-13 Auto Exposure Control Mode Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 7-14 Manual Exposure Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 7-15 Auto Slow Shutter Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Rev A Document 800-01023

13

02/08

Page 14

Tables

Table 7-16 Still Preset Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Table 7-17 Preset Tour Field Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Table 7-18 Recommended Lift Settings for Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . 123

Table 7-19 Recommended Gain Settings for Cable Lengths . . . . . . . . . . . . . . . . . . . . . . 124

Table B-1 Housing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Table B-2 Camera Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Table B-3 Pan and Tilt Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Table B-4 Lower Dome Light Loss Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Table B-5 Regulatory Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Table C-1 ACUIX Mimic Tours Mapped to Pelco Pattern Tours. . . . . . . . . . . . . . . . . . . . . 139

Table D-1 Protocol settings for ACUIX PTZ dome camera system . . . . . . . . . . . . . . . . . . . 141

Rev A Document 800-01023

14

02/08

Page 15

About This Document

This document introduces the ACUIX™, a high-performance PTZ (pan/tilt/zoom) camera

system, and describes how to install, configure, and operate the PTZ dome.

This document demonstrates how to install the camera assembly and lower dome into

the housing and then program and operate the camera using one of the available

protocols. Troubleshooting and Specifications reference sections are also included.

ACUIX High Speed Dome User Manual

Overview of Contents

This document contains the following chapters and appendixes:

• Chapter 1, Installing the Pan and Tilt Camera Assembly and Lower Dome, introduces

the ACUIX dome and describes the camera assembly and lower dome installation.

• Chapter 2, Switch Settings, explains the different DIP and rotary switches available

and their uses.

• Chapter 3, Operation and Programming with Honeywell Diamond Protocol, provides

instruction for programming and operation of an ACUIX set to Honeywell Diamond

protocol and controlled by an HEGS5000/HEGS5001 controller.

• Chapter 4, Operation and Programming with Honeywell VCL Protocol, demonstrates

the programming and operation of an ACUIX set to Honeywell VCL protocol and

controlled by an HJZTP controller.

• Chapter 5, Operation and Programming with IntelliBus™ Protocol, describes

additional features that are provided by the IntelliBus™ protocol.

• Chapter 6, ACUIX Password Feature, provides an overview of the ACUIX password

protection feature and its options.

• Chapter 7, On-Screen Setup Menus, covers the on-screen setup menus, and setting

up the control, camera and special features.

• Appendix A, Troubleshooting, provides answers for common technical issues.

• Appendix B, Replacement Parts, lists the materials that may assist when installing

and servicing the ACUIX product line.

• Appendix B, Specifications, shows the ACUIX specifications.

• Appendix C, Pelco Emulation, describes the operation of ACUIX Mimic Tours when

set for Pelco protocol and controlled by a Pelco keyboard.

• Appendix D, Digital Video Recorder Integration, describes the required protocols for

using an ACUIX PTZ camera with a Honeywell DVR.

Document 800-01023 Rev A 15

02/08

Page 16

Related Documents

For more information about topics that are relevant to ACUIX, see the documents listed

below.

Document title Part number

ACUIX Housing Installation Guide 800-01760

ACUIX Quick Set-Up Poster 800-00248

HDPRM2 Parapet Mount Install Guide 900.0877

HDXWM1 Decorative Wall Mount Install Guide 900.0868

HDCM1 Indoor Pendant Mount Install Guide 900.0869

16

Page 17

ACUIX High Speed Dome User Manual

1

Installing the Pan and Tilt Camera Assembly

and Lower Dome

Introduction

Models

This chapter describes installing the ACUIX pan and tilt camera assembly in the housing

and installing the lower dome on the housing. Installation of the camera assembly is the

same regardless of the housing type. The following instructions assume the housing

mount has been installed and the housing has been installed on the mount. See Related

Documents on page 16 for the names and part numbers of the mount and housing

installation guides.

Refer to the following table for the ACUIX pan and tilt camera assembly model numbers.

Table 1-1 ACUIX Pan and Tilt Camera Assembly Model Numbers

Model Number Description

HDCAN0000 ACUIX Pan and Tilt with 18X Color, NTSC Camera

HDCAP0000 ACUIX Pan and Tilt with 18X Color, PAL Camera

HDCJN0000 ACUIX Pan and Tilt with 18X WDR & TDN, NTSC Camera

HDCJP0000 ACUIX Pan and Tilt with 18X WDR & TDN, PAL Camera

HDCFN0000 ACUIX Pan and Tilt with 26X WDR & TDN, NTSC Camera

Document 800-01023 Rev A 17

02/08

Page 18

Installing the Pan and Tilt Camera Assembly and Lower Dome

Table 1-1 ACUIX Pan and Tilt Camera Assembly Model Numbers

Model Number Description

HDCFP0000 ACUIX Pan and Tilt with 26X WDR & TDN, PAL Camera

HDCGN0000 ACUIX Pan and Tilt with 35X WDR & TDN w/ EIS, NTSC Camera

HDCGP0000 ACUIX Pan and Tilt with 35X WDR & TDN w/ EIS, PAL Camera

Installing the Pan and Tilt Camera Assembly

1. Set the switches on the printed circuit board as required for your system

configuration. See Chapter 2, Switch Settings.

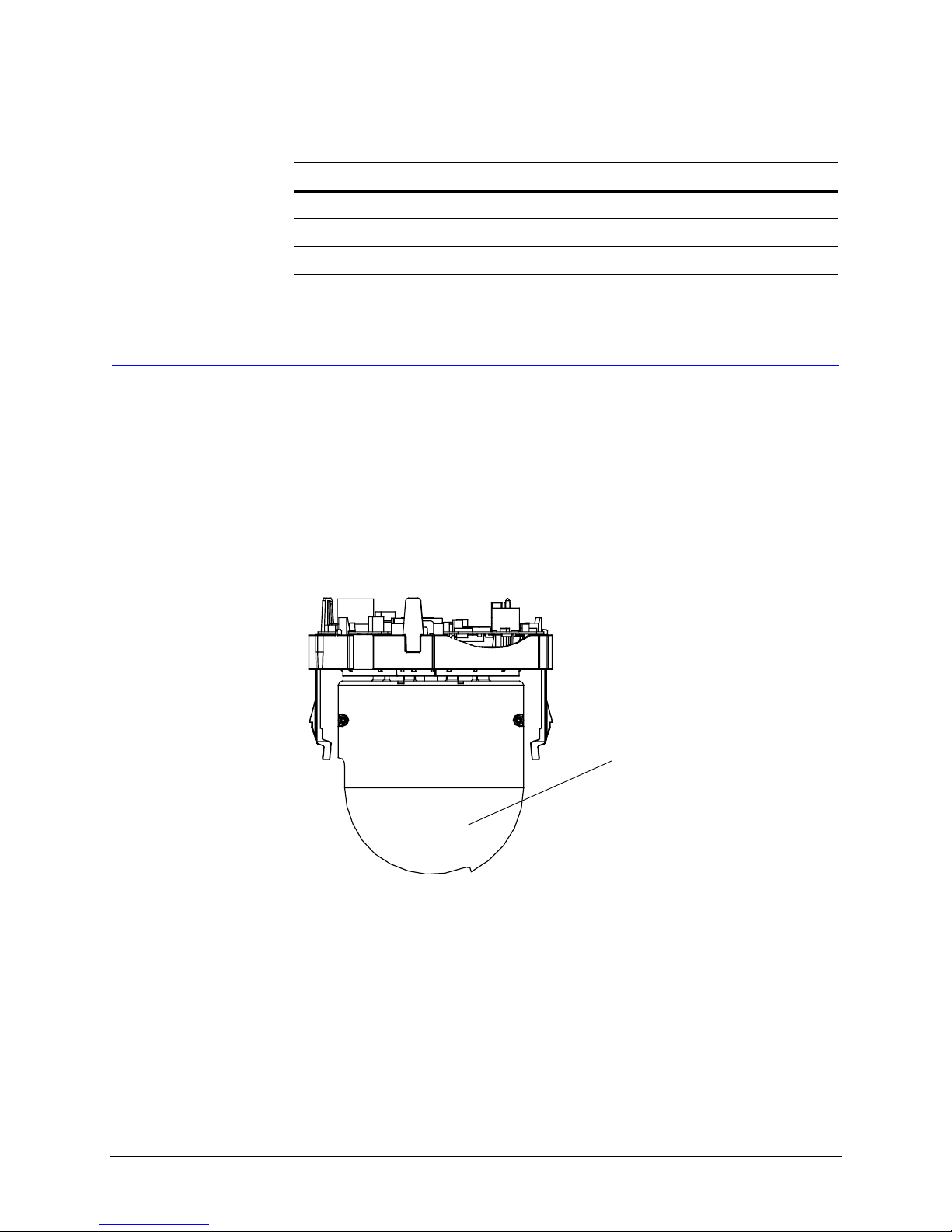

Figure 1-1 ACUIX Pan and Tilt Camera Assembly

Printed Circuit Board (Set Switches)

Camera

2. Line up the alignment label (yellow label with black dot) below the locking guide in

the housing with the alignment label (yellow label with black dot) on the locking rail

on the pan and tilt camera assembly.

18

Page 19

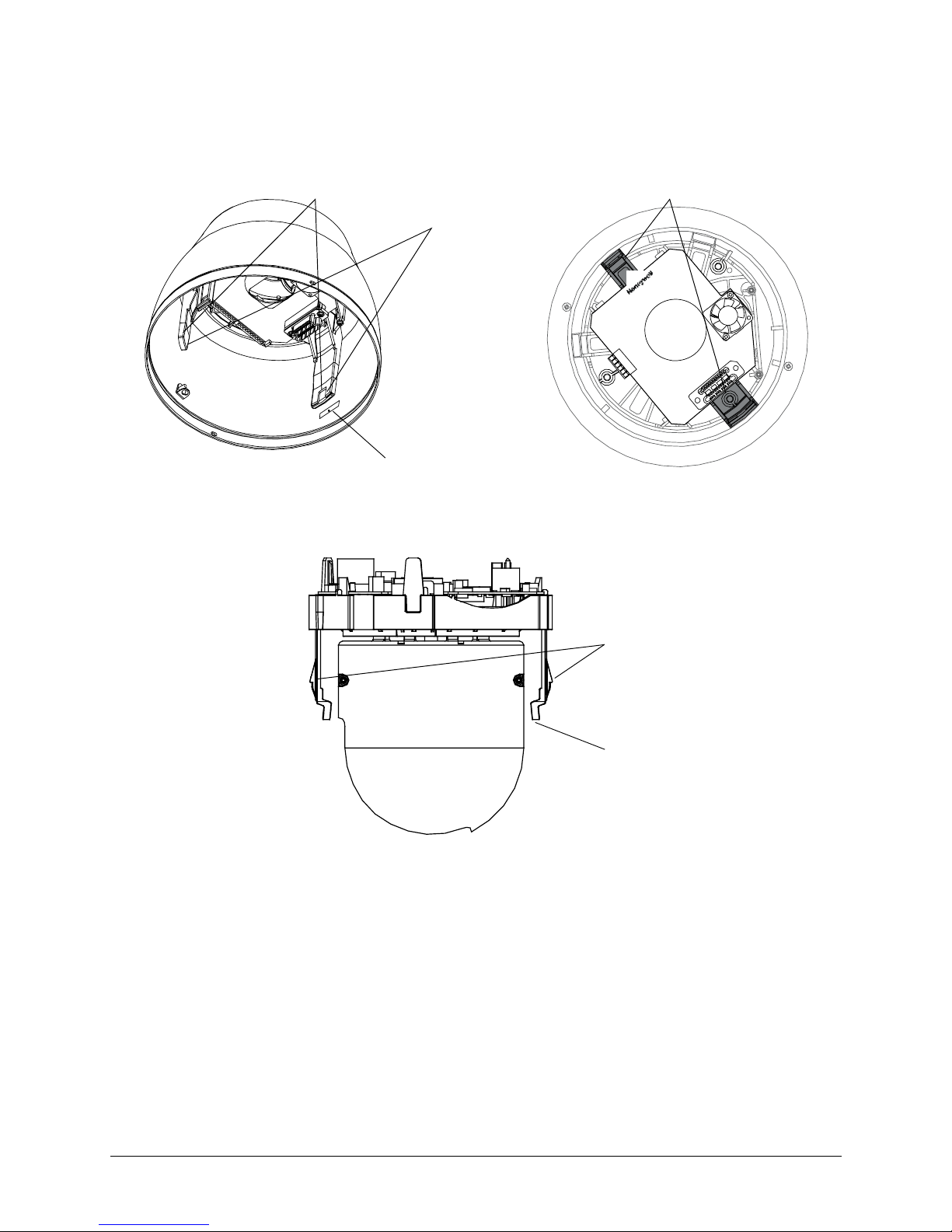

Figure 1-2 ACUIX Housing

ACUIX High Speed Dome User Manual

Locking guide

(2 places)

Locking guide

(2 places)

Ensure the rails on the

pan and tilt assembly

lock into the holes on

the housing guides

Alignment label (yellow

label with black dot)

Figure 1-3 ACUIX Pan and Tilt Camera Assembly Locking Rails

Ensure the 2 rails on the

camera assembly lock

into the holes on the

housing guides

Alignment label

(yellow label with

black dot)

3. Push the camera assembly into the housing until it snaps into place.

Document 800-01023 Rev A 19

02/08

Page 20

Installing the Pan and Tilt Camera Assembly and Lower Dome

Installing the Lower Dome

Indoor or Outdoor Pendant

1. Hook the lanyard attached to the lower dome on the retaining bracket in the

housing.

Figure 1-4 Pendant Lower Dome Installation

Hook lanyard from

lower dome to retaining

bracket in housing

Trim ring

2. Ensure the trim ring is in place around the lower dome.

3. Press the lower dome into the housing.

4. Secure the lower dome to the housing by installing the two screws provided with the

lower dome.

20

Page 21

Switch Settings

The ACUIX has two DIP switches (SW5 and SW6) on the pan and tilt printed circuit board

(PCB) for setting the protocol, baud rate, and parity. These settings must match the

control equipment settings.

There are four rotary switches (SW1, SW2, SW3, and SW4) for setting the ACUIX logical

address for control purposes.

A DIP switch can also be used to restore the default settings and another DIP switch to

override the switch settings for the logical address.

ACUIX High Speed Dome User Manual

2

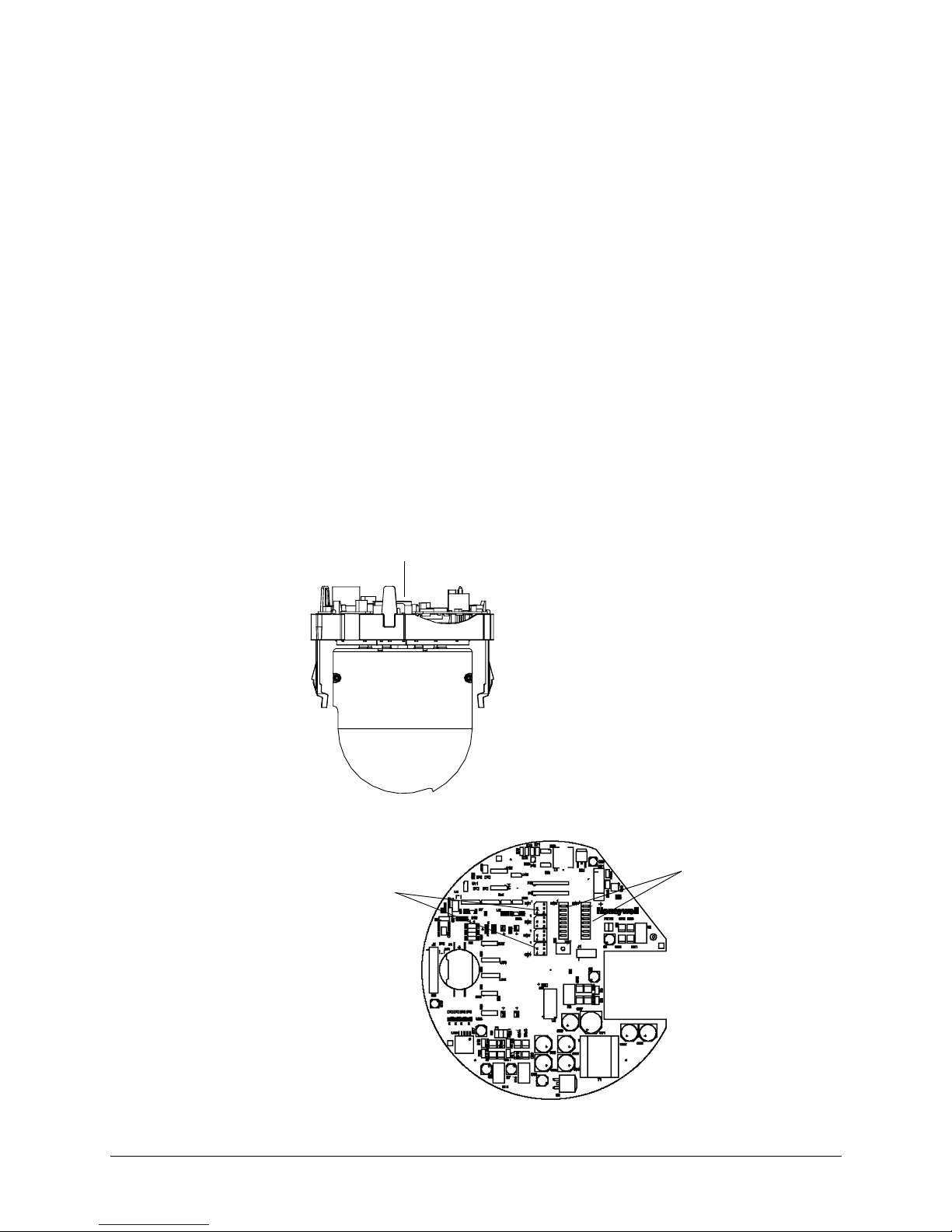

Figure 2-1 ACUIX Pan and Tilt Camera Assembly

Printed circuit board

Figure 2-2 Location of DIP and Rotary Switches on Main Board

Rotary switches

SW1, SW2,

SW3, & SW4

DIP switches

SW5 and SW6

Document 800-01023 Rev A 21

02/08

Page 22

Switch Settings

Protocol Settings

DIP switch SW5 is used to select the protocol setting for your ACUIX. See Table 2-1 for

more information. The default protocol setting for the ACUIX is the Honeywell Diamond

protocol.

Note If there are invalid settings on SW5 or SW6 regarding protocol or baud rate,

Table 2-1 DIP Switch SW5 ACUIX Protocol Settings

Protocol Name

the system defaults to Diamond protocol at 9600 baud rate.

Switch Position

12345678

IntelliBus™ OFF OFF OFF OFF OFF OFF OFF OFF

Diamond ON OFF OFF OFF OFF OFF OFF OFF

MAXPRO Mode OFF ON OFF OFF OFF OFF OFF OFF

VCL - RS485 ON ON OFF OFF OFF OFF OFF OFF

VCL Video Telemetry

(Control over Coax)

Pelco P ON OFF ON OFF OFF OFF OFF OFF

Pelco D OFF ON ON OFF OFF OFF OFF OFF

OFF OFF ON OFF OFF OFF OFF OFF

22

Page 23

Baud Rate

ACUIX High Speed Dome User Manual

DIP SW6, position 1 through 4 are used to set the baud rate. The baud rate of the ACUIX

and the control equipment must be the same.

Note If there are invalid settings on SW5 or SW6 regarding protocol or baud rate,

the system defaults to Diamond protocol at 9600 baud rate.

Table 2-2 DIP Switch SW6 ACUIX Baud Rate Settings

Switch Position

Baud Rate

1234

600 OFFOFFOFFOFF

1200 ON OFF OFF OFF

2400 OFF ON OFF OFF

4800 ON ON OFF OFF

9600 OFF OFF ON OFF

19200 ON OFF ON OFF

38400 OFF ON ON OFF

57600 ON ON ON OFF

115200 OFF OFF OFF ON

Document 800-01023 Rev A 23

02/08

Page 24

Switch Settings

Parity

DIP Switch SW6, positions 5 and 6 are used to set the parity.

Table 2-3 DIP Switch SW6 ACUIX Parity Settings

Switch Position

Parity

None OFF OFF

Even ON OFF

Odd OFF ON

Note SW6, position 7 should be kept OFF. This switch is only used during

development for debugging purposes.

56

Sample Switch Settings

Legend for the following samples:

1 = On/ 0 = Off

Honeywell Diamond

For Honeywell Diamond protocol, the commonly used setting is 9600 baud, even parity.

SW5 - 10000001 (positions 1–8).

In above SW5–8 is ON to force reading from DIP switches. See DIP Switch Address

Override, page 26, for more information on setting SW5–8.

SW6 - 00101000 (positions 1–8) sets the ACUIX to 9600 baud with even parity.

24

Page 25

VCL - RS485

IntelliBus™

ACUIX High Speed Dome User Manual

For VCL - RS485 protocol, the commonly used setting is 9600 baud, no parity.

SW5 - 11000001 (positions 1–8).

In above SW5–8 is ON to force reading from DIP switches. See DIP Switch Address

Override, page 26, for more information on setting SW5–8.

SW6 - 00100000 (positions 1–8) sets the ACUIX to 9600 baud with no parity.

SW5 - 00000001 (positions 1–8).

In above SW5–8 is ON to force reading from DIP switches. See DIP Switch Address

Override, page 26, for more information on setting SW5–8.

SW6 - 01100000 (positions 1–8) sets the ACUIX to 38400 baud with no parity.

Camera Address Settings

Address selection is via rotary switches SW1, SW2, SW3, and SW4.

Table 2-4 ACUIX Camera Addresses

Address Value

SW1 Units digit

SW2 Tens digit

SW3 Hundreds digit

SW4 Thousands digit

Caution The ACUIX can be addressed from 0000 to 9999. The addressing

scheme may be restricted due to the limitations of the controller

being used to control the ACUIX. For example, the

HEGS5000/HEGS5001 controllers can control camera addresses 1

to 256. The HJZTP can control camera addresses 1 to 128.

Document 800-01023 Rev A 25

02/08

Page 26

Switch Settings

Address Examples

1. To set the camera address to 1, set SW1 = 1, SW2 = 0, SW3 = 0, SW4 = 0

(CAM - 0001).

2. To set the camera address to 125, set SW1 = 5, SW2 = 2, SW3 = 1, SW4 = 0

(CAM - 0125).

Note If the ACUIX is set to address 0000, it will respond to control commands for

any address. That is, if the ACUIX is set to address 0000 and the operator

sends control commands for address 2, the ACUIX addressed 0000 will

perform the commands for address 2. No validation is performed on the

addresses by the ACUIX.

DIP Switch Address Override

DIP Switch SW5–8 can be set so the ACUIX sets the camera address based on the rotary

switch settings or from memory. SW5–8 should be kept ON during normal operation so that

the logical address can be changed from the on-screen setup menus.

SW5–8

OFF Logical address stored in memory overrides the DIP Switch settings.

ON The ACUIX is forced to read from the rotary switches and overrides the logical

Factory Defaults

The factory default settings are as follows:

Protocol Honeywell Diamond

Baud rate 9600

address stored in memory.

Parity No parity

Address Even

Termination None

26

Page 27

Restore Factory Defaults

SW5–7 is looked at only when the ACUIX is powered up. If this switch is ON at the time of

power up, the factory defaults will be restored. For an already powered dome, you must

place switch SW5–7 in the ON position, and then cycle the power to the ACUIX for the

factory default settings to be restored.

SW5–7

OFF Normal Operation.

ON Restore Factory Default settings.

Note It is not advisable to keep this DIP switch (SW5–7) in the ON position. Once

ACUIX High Speed Dome User Manual

the factory default is achieved after a single power cycling, place SW5–7

back to the OFF position.

RJ45 Ethernet Connection

The RJ45 connector located on the ACUIX interface board is used for production use and

testing only and has no functionality during normal dome use. This will not damage your

ACUIX dome, but may affect your network. Honeywell recommends you DO NOT connect

your network to the RJ45 connector.

Document 800-01023 Rev A 27

02/08

Page 28

Switch Settings

28

Page 29

ACUIX High Speed Dome User Manual

3

Operation and Programming with Honeywell

Diamond Protocol

Introduction

The availability of the ACUIX features and the way the ACUIX features are controlled is

governed by the controller being used and the ACUIX protocol setting. This chapter

describes the operation of the ACUIX set to Honeywell Diamond protocol and controlled

by a model HEGS5000, HEGS5001 or HJZTP joystick controller.

HEGS5000/5001 Controller

Power Up

Upon power up of the ACUIX, a start up

screen displays the protocol, baud rate,

parity, data bits, camera model, and

software (VXWorks and FPGA) release

dates and versions. If the Honeywell

startup screen has been turned off in the

setup menus, an X displays in its place.

---- ACUIX Dome ----

Protocol ........... Diamond

9600 baud no parity -8bits

Camera ............... Model

Honeywell Video Systems

DOMEApp date version B0

FPGABit date version B1

Please wait......_8

Document 800-01023 Rev A 29

02/08

CAM-0006 M

Page 30

Operation and Programming with Honeywell Diamond Protocol

If the ACUIX is set to find home on startup, the message Finding Home... displays on

the monitor. Once the ACUIX has found home, the message Home Found... is briefly

displayed.

If the ACUIX is not set to find home on startup, the ACUIX finds home when it receives the

first control command. After the ACUIX finds home, the operator can control the ACUIX.

Reset ACUIX

To reset an ACUIX using an HEGS5000/5001 controller you must be logged in as a Master

user on the controller. This reset is the same as if power was removed from the ACUIX and

then restored.

1. Press Dome Menu. Dome Setup Menu displays in the controller’s LCD window. If

Dome Setup Menu is not displayed, press + or - until it displays.

2. Press Enter to access the Dome Setup Menu.

3. Press 4 for Diagnostic Options.

4. Press 7 for Scan and Camera Reset.

Manual Control

You can also press Clear/Manual on the HEGS5000/5001 controller four times to reset the

ACUIX.

Note To restore the ACUIX to factory default settings, you can access the

on-screen setup menus or make use of the DIP switches as described in

Restore Factory Defaults on page 27.

Manual control of an ACUIX dome includes pan, tilt, zoom, focus, and iris. To manually

control an ACUIX, the address of the ACUIX must be selected as the control camera. When

an operator performs a command at the controller, the controller sends out the control

command with the control camera address.

Example: The operator has camera 2 selected as the control camera on the controller. The

operator performs the tilt function on the controller. The controller sends out the tilt

command to camera address 2. All the ACUIX domes on the control loop receive the

command, but only the ACUIX with address 2 performs the tilt command. If the ACUIX is

set to address 0, CAM-0000, the ACUIX responds to commands for all addresses.

When the ACUIX is being manually controlled the letter

M (manual) is added to the camera ID. The camera

message must be turned on in the Display Options

menu for it to be added to the video signal and viewed

on a monitor.

30

CAM-0001 M

Page 31

ACUIX High Speed Dome User Manual

Pan and Tilt

The joystick on the HEGS5000/5001 controller is used to control the pan and tilt functions

of the ACUIX. The maximum pan speed is selectable between 120°, 240°, or 480° per

second. The maximum tilt speed is one-half the maximum pan speed. If the maximum pan

speed is set to 240° per second, the maximum tilt speed is set to 120° per second. The pan

and tilt speeds are set in the on-screen setup menus under Control Options.

Table 3-1 HEGS5000 Joystick Operation

Action Function

Joystick up Tilt up

Joystick down Tilt down

Joystick left Pan left

Joystick right Pan right

Note If the pan and/or tilt functions of the ACUIX are reversed through the

on-screen setup menus, joystick up performs tilt down, joystick down

performs tilt up, joystick left performs pan right and joystick right performs

pan left.

Note The HEGS5000/HEGS5001 controller will not function properly if the polarity

of the 2-wire RS485 lines is reversed.

Lens Control

The camera/lens package in the ACUIX provides automatic exposure control. The lens iris,

camera video gain, and camera shutter speed adjust automatically to the brightness of the

scene (unless manual exposure, or iris, is selected at the controller).

Under normal conditions the camera shutter is set to 1/60s for NTSC and the video gain is

set to 1 (0dB). As the light level varies in this normal area the lens iris is opened and closed

to compensate for the variations in the light level.

If the light level increases beyond the level that can be compensated for by closing the lens

iris the camera will begin to decrease the time that the electronic shutter is opened down to

a minimum of 1/10000s.

If the light level decreases when the camera is operating at a shutter speed of less than

normal (see above) the shutter time will increase until it reaches the normal time and if the

light level decreases beyond the level that can be compensated for by opening the lens iris

the camera will begin increasing its video gain.

Document 800-01023 Rev A 31

02/08

Page 32

Operation and Programming with Honeywell Diamond Protocol

If the camera is operating with the video gain higher than the minimum and the light level

increases the video gain will be decreased until it reaches the minimum value.

If the camera has auto slow shutter mode and it is set to auto and the light level continues

to decrease beyond the point where the camera’s maximum video gain is reached, then the

time that the electronic shutter is open will increase beyond 1/60s for NTSC until it reaches

the maximum shutter time (1/2 to 2s depending on the camera). This will cause blurred

motion and slow updating of the picture.

If the camera is in the slow shutter mode and the light level increases the shutter time will

decrease until it reaches the normal setting (see above).

If the camera has True Day Night (TDN) functionality the IR block filter will be removed and

the picture switched to black and white at a preselected increased gain and shutter time

point. This point is either detected by the camera or by the ACUIX depending on the camera

type and can be modified in either case. The details of the operation of the TDN feature

depends on the specific camera being used.

If the camera has TDN and the IR block filter has been removed and the light level increases

beyond the TDN transition point set by the camera or the ACUIX the IR block filter will be

inserted and the picture is returned to color.

For all cameras with manual exposure control (also referred to as manual iris control) the

same sequence is followed when increasing and decreasing manual exposure control.

When in manual exposure control the TDN function is also controlled manually, however, it

remains independent of the manual exposure control.

If the unit is powered down then back up, the ACUIX comes back up in the iris mode it was

in when it was powered down.

The lens auto focus feature can be set to adjust automatically when the zoom setting

changes or when the pan, tilt, or zoom settings change. The lens auto focus can also be

disabled so the operator has to manually focus the lens. If the ACUIX is programmed for

either of the two auto focus settings, the operator can manually control the lens focus. The

minimum focus distance is set at 1.0 meter (3.3 ft) from the camera lens in both manual and

automatic focus modes.

Refer to Table 3-2 for information on manually controlling the camera lens features using

the HEGS5000/5001.

Table 3-2 HEGS5000/5001 Camera Lens Control

Control Function

Joystick Knob Rotate the joystick knob clockwise and counterclockwise

for zoom in and out functions, respectively. The manual

speed of the zoom function is set through the on-screen

setup menus under Camera Options.

Auto Iris Places the lens in auto exposure mode.

Iris Open Manually increases exposure to lighten the scene.

Iris Close Manually decreases exposure to darken the scene.

Focus Near/Focus Far Manually focuses the lens.

32

Page 33

ACUIX High Speed Dome User Manual

18X Color Camera (FCB-EX48C)

The 18X color camera has an 18X optical zoom lens with a digital zoom function up to 216X.

The White Balance can be set to manual mode. If the unit is in manual mode, the red and

blue gain settings can be set between 0 (low) and 255 (high).

The 18X color camera features motion detection. There are four default motion detection

zones. If motion detection is set to ON, and the camera detects motion in any one of the

four zones, the message Motion Detected displays on the video. The message remains

on the video until the ACUIX either is controlled by the operator, responds to an alarm, or

performs the default function. Once motion is detected, the ACUIX automatically disables

motion detection. The user must re-enable motion detection through the setup menus.

18X True Day/Night Camera with Wide Dynamic Range (FCB-EX490D)

The 18X True Day/Night (TDN) camera has a feature called Wide Dynamic Range (WDR)

that can be enabled or disabled. The wide dynamic range is only functional if the camera is

in auto iris mode. When the wide dynamic range is enabled, the camera scans the scene

and sets the exposure level so both the dark areas and bright areas in a scene can be

viewed.

When the controller is in manual iris mode the wide dynamic range is disabled and the auto

digital shutter does not go below 1/60s for NTSC or 1/50s for PAL. The exposure setting

(iris, gain or shutter) that is controlled when the camera is in manual exposure mode is

selectable, while the other two will be in auto mode.

The White Balance can be set to manual mode. If the unit is in manual mode, the red and

blue gain settings can be set between 0 (low) and 255 (high).

The 18X color camera features motion detection. There are four default motion detection

zones. If motion detection is set to ON, and the camera detects motion in any one of the

four zones, the message Motion Detected displays on the video. The message remains

on the video until the ACUIX either is controlled by the operator, responds to an alarm, or

performs the default function. Once motion is detected, the ACUIX automatically disables

motion detection. The user must re-enable motion detection through the setup menus.

26X True Day/Night Camera with Wide Dynamic Range (FCB-EX990D)

The 26X True Day/Night (TDN) camera has a feature called Wide Dynamic Range (WDR)

that can be enabled or disabled. The wide dynamic range is only functional if the camera is

in auto iris mode. When the wide dynamic range is enabled, the camera scans the scene

and sets the exposure level so both the dark areas and bright areas in a scene can be

viewed.

When the controller is in manual iris mode the wide dynamic range is disabled and the auto

digital shutter does not go below 1/60s for NTSC or 1/50s for PAL. The exposure setting

(iris, gain or shutter) that is controlled when the camera is in manual exposure mode is

selectable, while the other two will be in auto mode.

Document 800-01023 Rev A 33

02/08

Page 34

Operation and Programming with Honeywell Diamond Protocol

The White Balance can be set to manual mode. If the unit is in manual mode, the red and

blue gain settings can be set between 0 (low) and 255 (high).

The 26X color camera features motion detection. There are four default motion detection

zones. If motion detection is set to ON, and the camera detects motion in any one of the

four zones, the message Motion Detected displays on the video. The message remains

on the video until the ACUIX either is controlled by the operator, responds to an alarm, or

performs the default function. Once motion is detected, the ACUIX automatically disables

motion detection. The user must re-enable motion detection through the setup menus.

35X True Day/Night Camera with Wide Dynamic Range, Progressive

Scanning and Image Stabilization (VK-S654)

The 35X camera has a feature called Wide Dynamic Range (WDR) that can be enabled or

disabled. The wide dynamic range is only functional if the camera is in auto iris mode. When

the wide dynamic range is enabled, the camera scans the scene and sets the exposure

level so both the dark areas and bright areas in a scene can be viewed.

When the controller is in manual mode the wide dynamic range is disabled and the auto

digital shutter does not go below 1/60s for NTSC. The exposure setting (iris, gain or shutter)

that is controlled when the camera is in manual exposure mode is selectable, while the

other two will be in auto mode.

The White Balance can be set to manual mode. If the unit is in manual mode, the red and

blue gain settings can be set between 0 (low) and 511 (high).

The 35X camera also features progressive scanning, image stabilization, and motion

detection. When the default interlace scanning is set to the default ON, the camera scans

all the odd lines and then all the even lines of video. If the interlace scanning is set to OFF,

the camera is in progressive scan mode and scans all the lines of video. When the interlace

scanning is set to ON, the wide dynamic range and motion detection features are disabled.

The 35X camera features electronic Image Stabilization (EIS) to eliminate blurry and jumpy

video when the camera is bumped or jostled due to wind or traffic vibration. If the Image

Stabilization is set to ON, the motion detection feature is disabled. When EIS is enabled, the

camera reduces the area of the CCD that is scanned. This causes the video displayed on

the monitor to appear to have zoomed in. When the dome undergoes a pan or tilt operation,

electronic Image Stabilization is disabled while the camera moves, and then re-enables

after the camera has stopped moving for a five second period.

The 35X camera features motion detection. There are eight default motion detection zones.

If motion detection is set to ON, and the camera detects motion in any one of the eight

zones, the message Motion Detected displays on the video. The message remains on

34

Page 35

ACUIX High Speed Dome User Manual

the video until the ACUIX either is controlled by the operator, responds to an alarm, or

performs the default function. Once motion is detected, the ACUIX automatically disables

motion detection. The user must re-enable motion detection through the setup menus.

Table 3-3 35X Camera Feature Dependencies

If: Then:

Motion detection is enabled Interlace scanning and image stabilization are

disabled.

Image stabilization is enabled Motion detection is disabled.

Interlace scanning is enabled Wide Dynamic Range (WDR) and motion detection

are disabled.

Wide Dynamic Range (WDR)

is enabled

Freeze and Unfreeze Video

Press Freeze Video on the controller to toggle between

freezing and unfreezing the current video scene. When

the video is frozen, an asterisk displays on the same line

as the camera ID, and the video remains frozen on the

current scene until the operator unfreezes the video.

If the camera ID display is turned off, the asterisk displays by itself.

An operator can manually control the camera or send

the camera to a Preset, but the video display does not

change. When the video is unfrozen, the scene the

camera is viewing is outputted on the video signal.

Flashback Operation

Interlace scanning must be disabled and the

ACUIX must be in auto iris mode.

* CAM-0001 M

*

The patented flashback function enables the user to quickly return to a scene of interest.

Initially pressing Flashback when viewing a scene saves that scene as a flashback scene.

Moving to a subsequent scene and pressing Flashback both saves that scene and returns

the camera to the previously saved flashback scene.

For instance, after the ACUIX has found home (initialized), the operator finds a scene of

interest. The operator presses Flashback and ACUIX stores that scene (Scene A). If the

operator then moves to another scene (Scene B) and presses Flashback, ACUIX saves

Scene B and returns to Scene A. Pressing Flashback again returns the camera to Scene

B. If the operator then manually moves to another scene (Scene C) and presses Flashback

the ACUIX returns to Scene A. This occurs because the last time Flashback was pressed

the camera was at Scene A, therefore, saving that scene in the Flashback memory.

The only exception is during a Preset Tour operation. For example, Flashback is pressed

and the ACUIX returns to Scene A. After that, a Preset Tour is started. During the Preset

Tour, the ACUIX moves from Preset 2 to Preset 3. If Flashback is pressed while the ACUIX

is at Preset 3, the Preset Tour will be terminated and the ACUIX will go back to Preset 2.

Document 800-01023 Rev A 35

02/08

Page 36

Operation and Programming with Honeywell Diamond Protocol

Each time Flashback is pressed thereafter, the ACUIX toggles between Presets 2 and 3

until the ACUIX is manually controlled. After manual control, the flashback feature returns

to normal operation. The next time Flashback is pressed, the current scene (Scene D) is

stored and the ACUIX returns to the last Flashback scene (in this case, Scene A) prior to

the start of the Preset Tour. Once at Scene A, if Flashback is pressed, the ACUIX goes back

to Scene D.

NightShot Mode

The NightShot feature is only available on ACUIX units with cameras that have a removable

IR block filter. These cameras are often referred to as true day/night (TDN) cameras. When

the IR block filter is removed (NightShot on), the camera sensitivity for viewing dark scenes

is increased and the video is converted to black and white.

Note NightShot mode must be set to manual in the setup menus to control it from

the controller.

Alarm Operation

To toggle between standard operation and NightShot mode:

1. Press Run Menu continuously until NightShot displays on the controller’s LCD.

2. Press Enter.

A message (NightShot On or NightShot Off) displays on the monitor where the ACUIX

video is viewed.

The NightShot mode can also be toggled on and off using Preset 99. Refer to Recall

Presets on page 41 for more information on sending the ACUIX to a Preset.

The ACUIX has 4 alarm inputs that can be configured as normally open or closed. If the

contact deviates from normal, an alarm occurs. The ACUIX can be programmed (through

the on-screen setup menus) to activate a Preset, a Preset Tour, or Mimic Tour in response

to an alarm. Refer to Program Alarms, page 93, in Chapter 7, On-Screen Setup Menus for

more information on programming alarms.

The alarms are sampled 16 times per second. After the alarm has been activated, the ACUIX

determines if a function has been programmed for that alarm, and if that alarm is enabled.

If either of those conditions are not met, the alarm will be discarded. If both conditions are

met, the alarm is considered triggered. If no other alarm is in service, the alarm is serviced.

The function assigned to the alarm is performed. The ACUIX stays in this alarm state until

the alarm is acknowledged. Any additional alarms that are triggered are not serviced until

the first alarm is acknowledged. If there is more than one alarm waiting to be serviced, they

are serviced in order of alarm number, starting with the lowest.

An alarm cannot be reactivated until it has been both acknowledged, and the contact

returned to normal. After acknowledgment and the contact change of state, the cycle can

begin again.

36

Page 37

ACUIX High Speed Dome User Manual

There are three ways to acknowledge an alarm:

• The first way is to press the key on the controller that represents the ESC key

(Clear/Manual on the HEGS5000/HEGS5001 controller). This sends a Return to

Manual command to the ACUIX. When the ACUIX receives this command, it

acknowledges any alarm that is currently active.

• The second way to acknowledge an alarm is to take manual control. This will

acknowledge ALL the alarms that are present—even those waiting to be serviced. To

acknowledge alarms sequentially: press a PTZ button to acknowledge the first alarm,

then press another PTZ button to acknowledge the second alarm, and so on.

• The final way is to use the default function. The default function runs a Preset, Preset

Tour, or Mimic Tour after a user-programmable amount of inactive time. It also

auto-acknowledges an alarm after the programmable delay. It acknowledges each

active alarm until all alarms are inactive. At that point, the default function runs. If any

new alarms come in after this, the cycle starts again.

The alarm status displays on-screen on the same text line set aside for the Camera ID

number. The Camera ID does not have to be displayed in order to view the alarm status. If

any alarms are active, the ACUIX displays AL-. After the AL-, the ACUIX lists all active

alarms in order. Thus, if alarms 1, 3, and 4 are active, the ACUIX displays AL-1 3 4. There

is no on-screen indication as to which alarm is currently being serviced. That can be

determined by what function is active.

Find Home

The ACUIX has a mechanical “Home” position. The home position is a pan and tilt position

used as a reference point for controlling and programming the ACUIX. Upon power-up of

the unit, the ACUIX must find its home position before it responds to any control

commands.

The ACUIX can be sent to its home position from the HEGS5000 controller as follows:

1. Press Run Menu until Find Home displays on the controller’s LCD screen.

2. Press Enter. The controller sends out the data to send the control camera to its

mechanical home position.

The message, Home Found... displays. If the message, Homing Failed, displays, the

ACUIX can be manually controlled, but cannot be programmed and automatic functions

(Presets, Mimic Tours, Preset Tours, and Privacy Zones) are not operational.

Document 800-01023 Rev A 37

02/08

Page 38

Operation and Programming with Honeywell Diamond Protocol

Presets

A Preset is a programmed scene (pan, tilt, zoom, focus, and iris setting) that can be recalled

by an operator, in response to an alarm, or set as the default function when the ACUIX is

idle for a specified time. There are 161 (0–160) Presets in each ACUIX dome. Presets 71 –79

and 98–99 are pre-programmed for special functions and cannot be re-programmed.

Table 3-4 Pre-programmed Presets

Preset Function

72 Recover encrypted PIN

75 Administrator Login screen

98 Camera reset

99 NightShot On/Off

Preset 99 is reserved for manually controlling the NightShot mode on cameras with IR block

filters. Preset 99 toggles between standard operation and the NightShot mode. The

NightShot mode must be manual for this Preset to function. The NightShot mode causes

the camera to pull the IR block filter and go to black and white to increase the sensitivity of

the video.

Program Preset

There are two methods for programming and saving Presets when using the

HEGS5000/HEGS5001 controller. The first method quickly saves the current camera scene

and assigns a predefined title. For example, Preset 1 is titled PS1, Preset 2 is titled PS2, and

so forth. The second method allows the user to program a 24-character title.

Note The HEGS5000/5001 controller allows operators to program Presets 1–10. To

program Preset 0 and 9, you must log in as a Master user.

Program Preset Method 1 (PSn Title)

1. Position the camera (pan, tilt) and the lens (zoom, focus, iris) to the desired scene.

2. Press Run Menu until Quick Prg Preset displays on the LCD screen and then

press Enter.

3. Using the numeric keys, enter the desired Preset number (refer to Table 3-4 for

reserved Presets) and press Enter. The current PTZ position and lens settings are

saved for the Preset number entered.

Example: To save Preset 5 with the default title PS5.

1. Position the camera and lens as desired.

2. Press Run Menu until Quick Prg Preset displays.

3. Press Enter.

38

Page 39

ACUIX High Speed Dome User Manual

4. Press 5.

5. Press Enter.

The current scene is saved as Preset 5 with the title PS5.

Program Preset Method 2 (User-defined Title)

1. Press Dome Menu.

2. Press + or - until PreShot Menu displays.

3. Press Enter.

4. Press + or - until Program displays.

5. Press Enter. The following displays in the

controller’s LCD window.

6. Follow the on-screen prompts that appear

on the monitor where the ACUIX video is

viewed.

a. Enter the Preset number (see Table 3-4 for reserved Presets) using the numeric

keypad and press Enter. If the selected Preset number has already been

programmed, the Preset title displays. To accept the existing title, press Enter. To

change the current title proceed to step b.

< Select Function >

A

Note The HEGS5000 is limited to Preset numbers 0–99.

Note Preset 99 is reserved for controlling the NightShot mode if this feature is

available on the camera and cannot be programmed. For domes without the

NightShot feature, Preset 99 can be programmed.

b. Press + or - until the desired character displays on the controller’s LCD screen,

and press Character Select. The controller sends the character to the ACUIX.

Continue selecting characters and pressing Character Select until the desired

title displays on the monitor.

c. Press Enter. The following commands are displayed on the monitor:

Table 3-5 Program Preset Menu Commands

Action Required Steps

C to Change name

location

Press + or - until C displays on the LCD and press Character

Select. Use the up or down arrow keys to reposition the Preset

title on the monitor screen.

E to Edit Preset Press + or - until E displays on the LCD and press Character

Select. Reposition the PTZ and/or change the lens settings,

then repeat step 6.

D to Delete Preset Press + or - until D displays on the LCD and press Character

Document 800-01023 Rev A 39

02/08

Select. The Preset number entered in step 6 is deleted.

Page 40

Operation and Programming with Honeywell Diamond Protocol

Table 3-5 Program Preset Menu Commands

Action Required Steps

S to Save Preset Press + or - until S displays on the LCD and press Character

Select. The current PTZ and lens (focus and iris) settings are

saved for the Preset number entered in step 6.

N to Save name only Press + or - until N displays on the LCD and press Character

Select. This option is used for retitling Presets. Only the title

entered in step 6b is saved for the Preset number entered. The

current PTZ and iris settings of the dome are not saved.

7. Program another Preset by repeating step 6 or press Clear/Manual to exit the Preset

programming menu.

8. Press Dome Menu or press Menu ESC three times to exit the menu on the controller

LCD.

Example: Program Preset 1, titled Front Door in Camera 1.

1. Select Camera 1.

a. Press 1.

b. Press Camera.

2. Position camera 1 to the desired Preset position (pan, tilt, zoom, focus, iris).

3. Press Dome Menu.

4. Press + or - until PreShot Menu displays on the LCD and press Enter.

5. Press + or - until Program displays on the LCD and press Enter.

6. Press 1 and press Enter.

7. Program the title.

a. Press + or - until an upper case F displays on the controller LCD and then press

Character Select.

b. Press + or - until a lower case r displays and then press Character Select.

c. Press + or - until a lower case o displays and then press Character Select.

d. Press + or - until a lower case n displays and then press Character Select.

e. Press + or - until a lower case t displays and then press Character Select.

f. Press + or - until Space displays and then press

g. Press + or - until an upper case D displays and then press Character Select.

h. Press + or - until a lower case o displays and then press Character Select.

i. Press + or - until a lower case o displays and then press Character Select.

j. Press + or - until a lower case r displays and then press Character Select.

k. Press Character Select.

8. Press + or - until an upper or lower case S displays on the controller LCD and then

press Character Select.

9. Program another Preset or press Clear/Manual to exit.

10. Press Dome Menu or press Menu ESC three times to exit the menus on the controller

LCD display.

Character Select.

40

Page 41

ACUIX High Speed Dome User Manual

Recall Presets

To recall a Preset:

1. Using the numeric keypad, enter the Preset number to recall (see Table 3-4 for

reserved Presets).

Note The HEGS5000 is limited to recalling Presets 0–99.

2. Press PreShot.

Example: Recall Preset 11.

1. Press 1.

2. Press 1 again.

3. Press PreShot.

Note If the ACUIX has not already found its home position, it will first find its home

position and then go to the preset.

The ACUIX goes to the pan, tilt, zoom, iris, and focus

positions programmed in the Preset. While the ACUIX is

going to a Preset position, the title of the Preset is added

to the video signal and the letter A (automatic) is added

to the camera ID. The Preset title and the letter A remain

on the video until the ACUIX gets another command.

Table 3-6 Preset Title Operation

If: Then:

Preset title is on The Preset title displays on the monitor.

Camera message is on The Camera ID and the letter A are

displayed on the monitor.

An operator sends the ACUIX to a Preset

that has not been programmed

The message DOES NOT EXIST displays

on the monitor.

CAM-0001 A

Document 800-01023 Rev A 41

02/08

Page 42

Operation and Programming with Honeywell Diamond Protocol

The ACUIX has a Still Preset feature that can be enabled or disabled through the Camera

Options menu.

Table 3-7 Still Preset Operation

If: Then:

Still Preset is on (video is frozen) Video is frozen between Presets. Video from the

Still Preset is off (video is unfrozen) Video returns to normal operation.

Still Preset

If the camera installed in the ACUIX has the Still Preset feature, and it is set to ON in the

Camera Options menu, the ACUIX freezes the video between Presets. When the ACUIX is

viewing a Preset and receives a command to go to another Preset, the video remains at the

current Preset until the ACUIX arrives at the next Preset and then switches the video to the

new Preset. While traveling between Presets, an asterisk displays to the left of the camera

ID. If Still Preset is set to OFF, the ACUIX displays the actual video as it travels from one

Preset to the next. If turned on and video is recording, this feature saves storage space

old position remains until the scan arrives at the

new Preset, then switches to the video from the

new Preset. While video is frozen, an asterisk (*)

appears on the same line as the Camera ID.

List Programmed Presets

A list of the programmed Presets can be viewed for each ACUIX. To view a listing of the

programmed Presets, perform the following steps. This display cannot be edited; it is for

viewing purposes only.

1. Press Dome Menu.

2. Press + or - until PreShot Menu displays on the controller LCD.

3. Press Enter.

4. Press + or - until List displays on the controller LCD.

5. Press Enter. A list of the programmed Presets displays on the monitor (where the

ACUIX video can be viewed).

6. The controller LCD display shows the command Page Down. Press Enter to view

more pages of the listing. When you have reached the end of the listing, End of

Directory displays on the monitor. To go back to the first page of the listing, press

Enter.

7. When you are finished viewing the Preset listing, press Clear/Manual.

8. To exit the menu on the LCD controller, press Dome Menu or press Menu ESC.

42

Page 43

Preset Tours

ACUIX High Speed Dome User Manual

Sixteen Preset Tours (1–16) can be programmed for each ACUIX. Up to 64 Presets, with

velocity settings and dwell times for each Preset, can be programmed into every Preset

Tour. Preset Tours can be started by an operator, started in response to an alarm, or

programmed as a default function when the ACUIX is idle for a specified amount of time.

When an ACUIX receives a command to run a Preset Tour, the ACUIX goes to the first

Preset programmed in the Preset Tour at maximum velocity (480°/second) and remains at

the Preset for the programmed dwell time, then goes to the next Preset in the Preset Tour

at the programmed velocity and remains at that Preset for the specified dwell time, and so

forth for all other programmed Presets.