Page 1

7. CERTIFICATION 8. SPECIFICATIONS 8. SPECIFICATIONS 9. ACCESSORIES AND SPARE PARTS

Technical Services

EMEAI:

US:

AP:

Asia Pacific

Honeywell Analytics Asia Pacific

#701 Kolon Science Valley (1)

43 Digital-Ro 34-Gil, Guro-Gu

Seoul 152-729

Korea

Tel: +82 (0)2 6909 0300

Fax: +82 (0)2 2025 0328

analytics.ap@honeywell.com

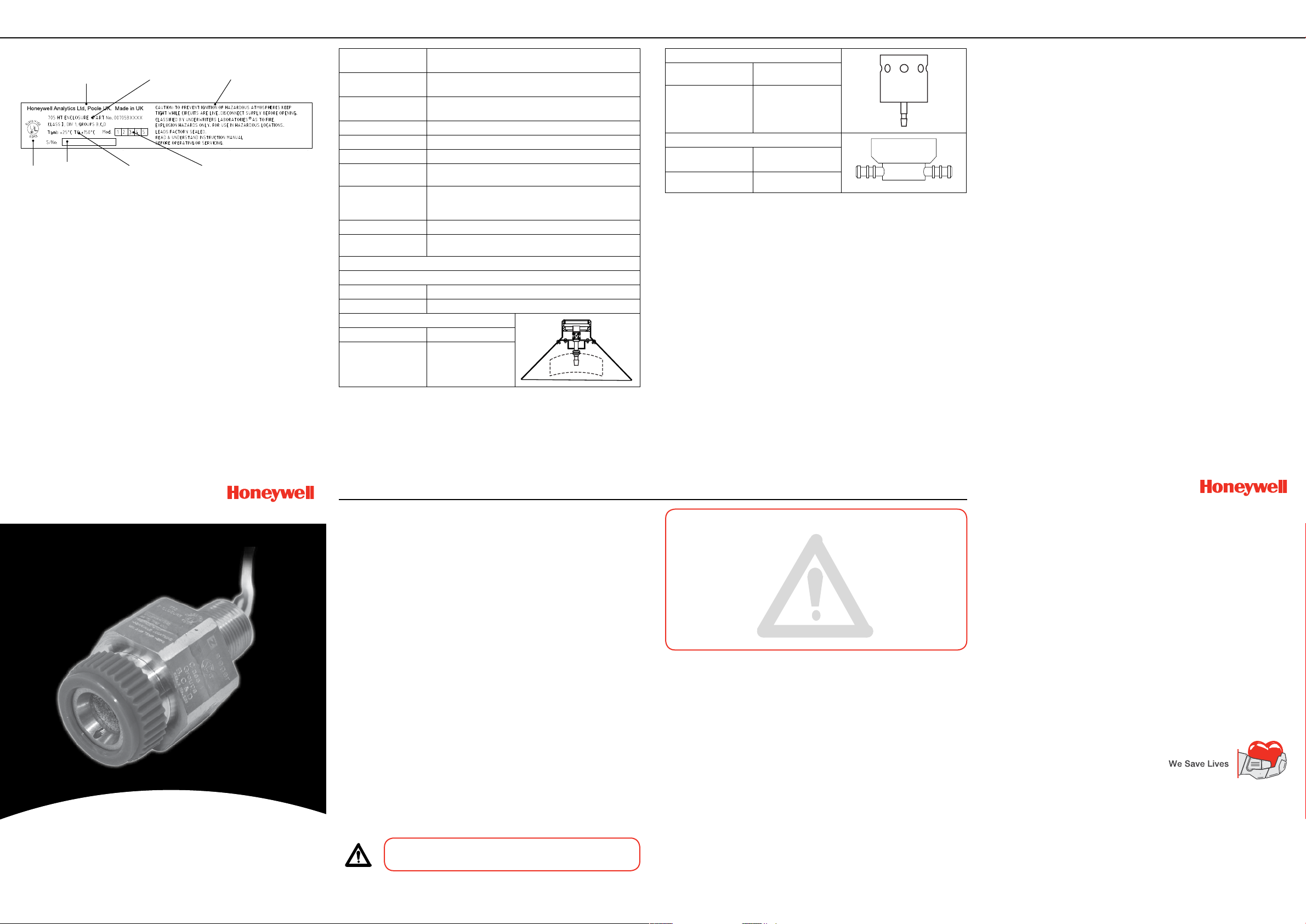

The following UL certication information is imprinted on the sensor body.

Manufacturer’s Trademark,

Name and Address

UL Control Number

Serial Number

Product Name

and Part Number

Certied Ambient

Temperature Range

Cautions

Modication

Status

Operating

temperature range

Storage temperature

range

Operating humidity

range

Drive current 200mA +/- 2mA (from control equipment)

Power consumption 0.7W

Calibration ow rate Recommended 1.5 l/min +/- 0.1 l/min

Response time T60 - less than 6 sec.

Temperature

coefcient of

zero point

Line resistance Refer to control system documentation

UL Certication Class I, Div 1, Groups B, C, D

Dimensions and weights

Sensor

Dimensions 78mm x 55mm (51mm or 47.2mm across ats)

Weight 200g

Collecting Cone

Dimensions 87mm x 165mm dia.

Weight 175g

-25°C to +150°C

-25°C to +150°C

20% to 90% RH continuous - non condensing

10% to 100% RH intermittent -non-condensing

T90 - less than 10 sec.

o

Approximately 0.05% LEL Methane per

Tamb -25

o

C to +150oC

C (maximum)

Weather Protection Housing

Dimensions 76.5mm x 50.8mm

Weight 52.4g

Sample Flow Housing

Dimensions 61mm x 45mm x

Weight 110g

dia.

31mm

When ordering accessories and parts, always quote the complete part number.

Where a component part number is not listed or known, state type, material, cable

entry size and other relevant details.

Complete replacement 705 HT sensor (Part No: 00705-A-1735)

Identify the gas to be detected when ordering a complete replacement sensor.

Collecting Cone (Part No: 00780-A-0032)

Used for the detection of lighter than air gases. A lter must be tted. A nozzle on

the cone (6.5mm O.D.) permits gassing of the Sensor with the cone in position.

Test gas is applied either direct to the nozzle or via a permanently connected

pipe-line when the sensor is in an inaccessible location.

Weather Protection Housing (Part No: 00780-A-0076)

This accessory, tted to a sensor installed in an exposed location, protects the

sensor from driving rain from vertical to 30° below horizontal. When mounted close

to the ground, it protects from heavy rain rebounding off the ground. It also reduces

contamination from industrial waste and enables the application of test gas in high

wind speeds without signicant error.

Incorporated in the housing is a nozzle to facilitate gassing of the sensor with the

housing in position, either by direct application to the nozzle or via a permanently

connected pipeline. The nozzle is free to rotate within the housing to allow removal

from the sensor without disconnecting a permanently connected pipeline, when

changing the lter and cleaning the sensor.

Sample Flow Housing (Part No: 00780-A-0035)

This accessory allows sampling of a closed system by means of two pipes.

The housing is tted to the sensor accessory thread by a locking ring that enables

the housing to be removed without disconnecting the pipeline. The lter is retained

by the housing and interfaces with a gasket bonded to the housing

(Part No: 00780-A-0048).

Stainless Steel Filter (Part No: 00780-F-0018)

Two layers of stainless steel mesh in the form of a disc with a rubber rim to provide

mechanical protection of the sinter and exclude large dust particles.

Quick Start Guide

Type 705 High Temperature

Combustible Gas Sensor

11 12 13

1. INTRODUCTION

The 705 High Temperature (HT) Combustible Gas Sensor is a gas detector that is

UL certied for Class I, Division 1, Groups B, C and D for installation in a hazardous

area.

It employs a catalytic pellistor sensor device which is used as part of a bridge

measuring circuit. The sensor must be mounted on a suitably UL approved hightemperature junctionbox in the hazardous area and connected to control equipment

situated in a non-hazardous area to form part of a combustible-gas detection system.

The sensor comprises an aluminium housing containing a pair of poison resistant

detector elements, with a sintered stainless steel disc forming the face of the

sensor. The sensor contains two elements which are heated by a supply derived

from the associated control equipment. One element is sensitive to the presence

of combustible gas, the element temperature increasing in response to catalytic

oxidation of the gas. The resultant rise in resistance of the sensitive element,

proportional to gas concentration, is processed by the associated control module.

The non-sensitive element compensates for effects of changes in ambient

temperature. The sensor drive current is set to a value appropriate to the type of

elements used.

The housing has a 51mm or 47.2mm AF body with a 3/4 NPT mounting thread at one

end and an M36 accessory thread on the other end. The following accessories are

available for use with the sensor (also see Accessories & Spare Parts):

• Collecting Cone

• Weather Protection Housing

• Sample Flow Housing

• Hydrophobic Barrier

• Gassing Point Assembly

When delivered a disposable plastic Filter Housing with protective disc for the sinter

is tted to the M36 accessory thread.

Note: The protective disc should not be removed until after the sensor is installed.

Refer to Installation for different Honeywell Analytics System 57 components to

which the 705 Sensor can be connected and to the associated control system

documentation for external wiring and connection information.

If information outside the scope of these instructions is required please contact

Honeywell Analytics. The types of information notices used throughout this document

are as follows:

WARNING

Indicates hazardous or unsafe practice which could result in severe

injury or death to personnel.

Caution: Indicates hazardous or unsafe practice which could result in minor injury to

personnel, or product or property damage.

Note: Provides useful/helpful/additional information.

1. This apparatus is not suitable for use in oxygen enriched atmospheres

(>21%V/V). Oxygen decient atmospheres (<10%V/V) may suppress sensor

output.

2. Refer to local or national regulations relative to installation at the site.

3. Operators should be fully aware of the action to be taken if the gas

concentration exceeds the alarm level.

4. Atmospheres above 100% LEL may suppress the sensor reading.

5. The catalytic detector element is resistant to catalyst poisons, however,

abnormally high concentrations of halogenated hydrocarbons, vapours of

heavy metals or compounds, some silicone compounds and sulphur

compounds may cause loss of sensitivity.

1. Do not modify or alter the sensor construction as essential safety requirements

may be invalidated.

2. Install using suitably approved and certied high temperature junction box,

connectors and glands.

3. Installation should consider not only the best placing for gas leakage related to

potential leak points, gas characteristics and ventilation, but also where the

potential of mechanical damage is minimized or avoided.

4. The sintered disc on the sensor assembly must be kept free from

contaminants, e.g. oil and dirt.

5. The Code of Practice covering Selection, installation, use and maintenance

of detectors for ammable gases and oxygen, IEC 60079-29-2, should be

complied with at all times. Refer to the appropriate local/national regulations

relative to the installation site.

7. Dispose of in accordance with local/national disposal regulations.

Materials used - Stainless Steel.

2. SAFETY

WARNINGS

CAUTIONS

1 2

Find out more

www.honeywellanalytics.com

Contact Honeywell Analytics:

Europe, Middle East, Africa, India

Life Safety Distribution AG

Javastrasse 2

8604 Hegnau

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

India Tel: +91 124 4752700

gasdetection@honeywell.com

Americas

Honeywell Analytics Inc.

405 Barclay Blvd.

Lincolnshire, IL 60069

USA

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8210

detectgas@honeywell.com

HAexpert@honeywell.com

ha.us.service@honeywell.com

ha.ap.service@honeywell.com

www.honeywell.com

14

Please Note:

While every effort has been made to ensure accuracy in this

publication, no responsibility can be accepted for errors or

omissions. Data may change, as well as legislation, and you are

strongly advised to obtain copies of the most recently issued

regulations, standards, and guidelines. This publication is not

intended to form the basis of a contract.

Issue 2 09/2013

H_MAN0625_EMEAI

00705M5010_ECO A04169

© 2013 Honeywell Analytics

Page 2

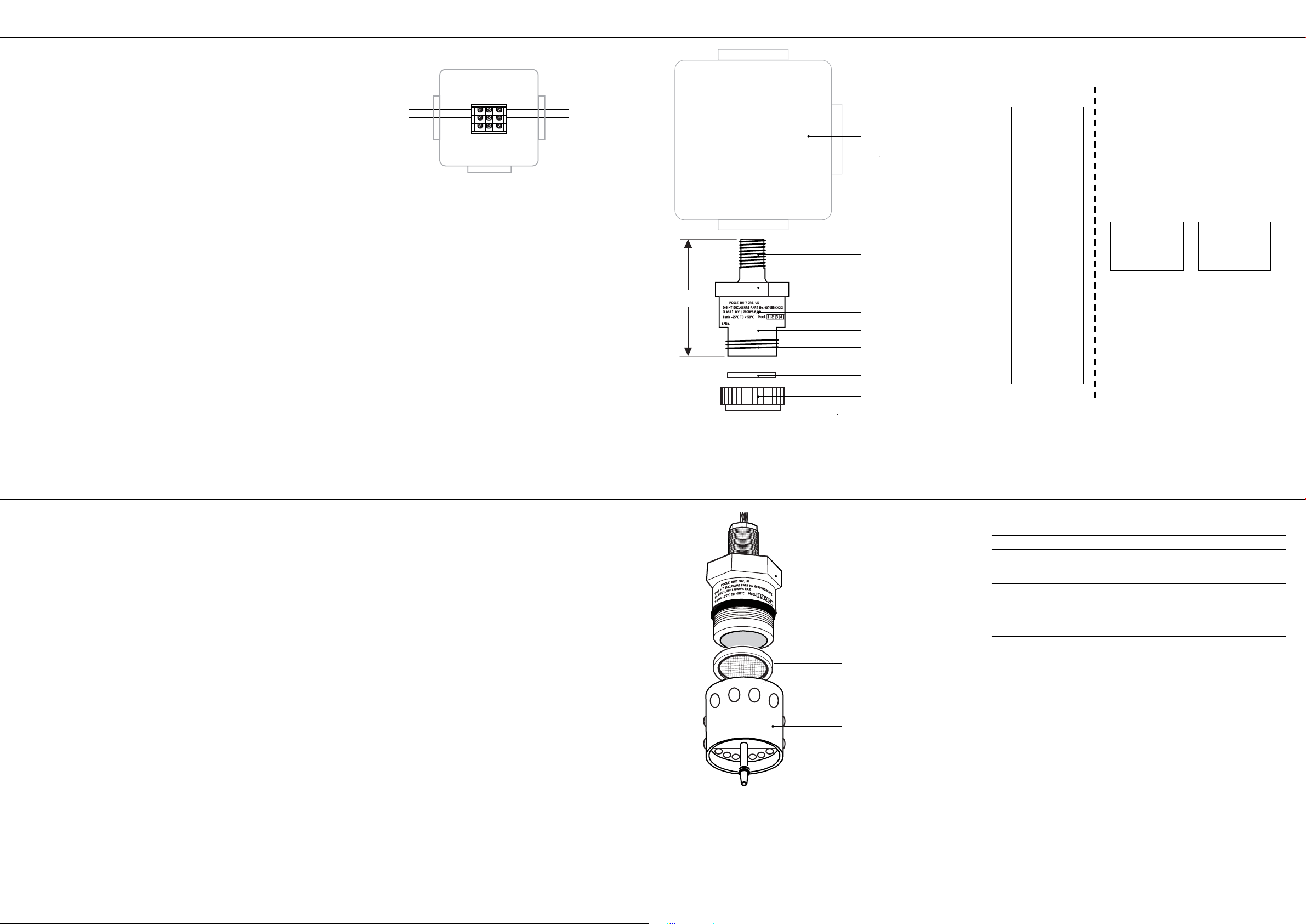

3. INSTALLATION

3. INSTALLATION

3. INSTALLATION 3. INSTALLATION

The 705 HT sensor must be tted into a suitable UL approved high temperature

junction box tted with an approved cable gland for external wiring. The sensor

requires a 200mA current supply, nominal 3V, derived from a suitable control card.

Only a qualied installation engineer should install the sensor.

Install the sensor in a location free from direct heat sources and t it so that it either

points downwards or horizontally. It is not recommended that the sensor points

upwards.

1. Isolate all associated power supplies and ensure that they remain OFF during the

installation procedure. Ensure a gas free atmosphere.

2. Install a suitably approved UL high temperature junction box.

See the manufacturer’s instructions. The box provides a mounting point for

the sensor.

3. Remove the junction box lid.

4. Fit the 705 HT sensor to the junction box.

Ensure that the junction box thread and the sensor thread are compatible.

The mounting threads should be coated with an approved anti-seize compound,

such as a light petroleum grease.

Push the sensor wires through the cable entry in the junction box and screw the

sensor body rmly home into the entry. To comply with certication requirements,

a minimum of ve threads must be engaged.

5. Connect the sensor wiring to the junction box terminal strip.

See the subsequent wiring diagram. Use multicore cable, three wire minimum,

of conductor size 2.5mm2 (14AWG) max.

6. Fit a suitable gland/conduit to the box, secure the control system cable and

connect the cable wiring to the terminal strip.

7. Ret the junction box lid.

8. Unscrew the lter housing from the sensor body and remove the lter from the

lter housing.

Discard the lter housing with protective disc. The lter housing material cannot

withstand high temperatures. Keep the lter.

Sensor wiring Control system

Brown Sensitive (S)

Blue

White

10. If required, t an accessory to the sensor.

See subsequent instructions. In a clean atmosphere, and where no accessories

are to be tted, a lter is not needed.

11. Power-up the system, calibrate the sensor (if required), and check for correct

operation of the gas detector.

Fitting the Weather Housing and Collecting Cone Accessories

1. Fit the previously removed lter to the accessory.

The lter must be tted to these accessories.

2. Firmly screw the accessory to the body of the sensor.

Note: When tting a lter, keep it free from oil and dirt and other contaminants.

Fitting the Flow Housing Accessory

1. Ensure the gasket (Part No: 00780-C-0048) is tted to the Flow Housing.

2. Apply a thin coating of anti-seize compound, such as a light petroleum grease, to

the sensor accessory thread.

3. Firmly screw the accessory to the body of the sensor.

Note: When tting a lter, keep it free from oil and dirt and other contaminants.

Suitably approved UL

HT Junction Box

eld wiring

Non-Sensitive (NS)

Common - Linked (01)

82.5mm

Suitably Approved

UL High Temperature

Junction Box

3/4 NPT thread

51mm or 47.2mm

across ats

Certication data

705 HT Combustible

Gas Sensor 0-100%LEL

M36 thread

for accessories

Filter (only used

with accessories)

Filter Housing (discard not suitable for high

temperature operation)

Sensor installation with System 57 components

NON-HAZARDOUS AREA

SYSTEM 57

COMPONENTS

CONTROL

CARDS

05700-A-0311

05700-A-0313

05700-A-0321

05700-A-0323

05700-A-0401

TO

05700-A-0409

05700-A-3000

INTERFACE

CARDS

05700-A-0950

05700-A-0951

05700-A-0952

05700-A-0953

INTERFACE

MODULES

05700-A-0201

05700-A-0202

05700-A-0211

05700-A-0212

05700-A-0221

05700-A-0231

SUITABLY

APPROVED UL

CERTIFIED

JUNCTION BOX

705 HT SENSOR

00705-A-1735

3

4. CALIBRATION

Sensors should be calibrated at concentrations representative of those to be

measured. It is always recommended that 705 HT is calibrated with the target gas

it is to detect. Gassing is carried out at the sensor and adjustments are made at

the control card.

5.1 No accessories tted

Where there are no accessories tted to the sensor, it is recommended that the

Sample Flow Housing accessory is used when gassing the sensor (see 5.3).

Where this is not possible, a suitable plastic bag may be used.

Caution: Calibration should only be attempted by qualied service personnel.

5.2 Collecting Cone or Weather Protection Housing Fitted

1. Using rubber tubing, connect the test gas to the gassing nozzle or to the

permanently connected tubing if tted to the accessory.

Cautions:

1. Spring pressure on the gassing nozzle of the Weather Protection Housing

accessory forces the nozzle against the sinter. Rotation of the nozzle may

damage the sinter if a lter is not tted.

2. Direct gassing of the sensor via the nozzle on the Collecting Cone accessory in

wind speeds greater than 5m/s may cause errors.

2. Set the ow rate to 1.5 ± 0.1 litres per minute and test the system in

accordance with the instructions in the relevant system equipment manual.

3. On completion, shut off the test gas and disconnect the rubber tubing.

5.3 Sample Flow Housing Fitted

1. Shut off the sample ow to the Flow Housing.

2. Disconnect the input pipeline from the input nozzle of the Flow Housing.

3. Using rubber tubing, connect the test gas to the Flow Housing input nozzle.

4. Set the ow rate to 1.5 ± 0.1 litres per minute and test the system in

accordance with the instructions in the relevant system equipment manual.

5. On completion, shut off the test gas and disconnect the rubber tubing.

6. Reconnect the input pipeline to the Flow Housing input nozzle and restore the

sample ow.

4 5

5. MAINTENANCE

Only a qualied installation engineer should service the sensor. Ensure power is off

before carrying out any maintenance procedures.

Maintenance consists of cleaning the sensor and accessories and replacing the lter.

Both these can be carried out without removing the sensor from the junction box.

Sensor and accessories may be cleaned using an industrial grade of Methanol,

providing the appropriate safety precautions are taken when handling this solvent.

Whenever cleaning takes place, a new lter must be tted.

To change a lter carry out the following procedure:

1. Remove the accessory (if tted) from the sensor.

2. Remove the old lter and replace with a fresh lter.

3. Replace the accessory (if tted).

Ensure any seals are retted/correctly located. The diagram shows the sensor with

the Weather Protection accessory tted.

5. MAINTENANCE

Sensor body

Weather Protection Seal

Filter

Weather Protection

6

6. FAULT FINDING

The following table provides a list of possible faults related to the sensor together

with possible causes and remedies.

Fault Cause/Remedy

Sensor reads non-zero all the time Gas could be present, ensure

Sensor reads non-zero when no gas is

present

Sensor reads low when gas is applied Adjust the control system span setting

Sensor reads high when gas is applied Adjust the control system span setting

Sensor reads zero when gas is applied 1. Check the wiring

In the event of exposure to contaminant, e.g. silicones or silicone based products,

or prolonged exposure to high concentration of gas, the sensor should be operated

for 24 hours in a clean environment and then recalibrated.

If the sensor is found to be faulty, or cannot be calibrated, the complete sensor

must be discarded and replaced.

there is no combustible gas in the

atmosphere

Adjust the control system zero setting

2. Check that the protective disc has

been removed from the lter housing

3. Check that the lter is not dirty/

obstructed

4. Replace the sensor if poisoning is

suspected

7

8 9

10

Loading...

Loading...