Page 1

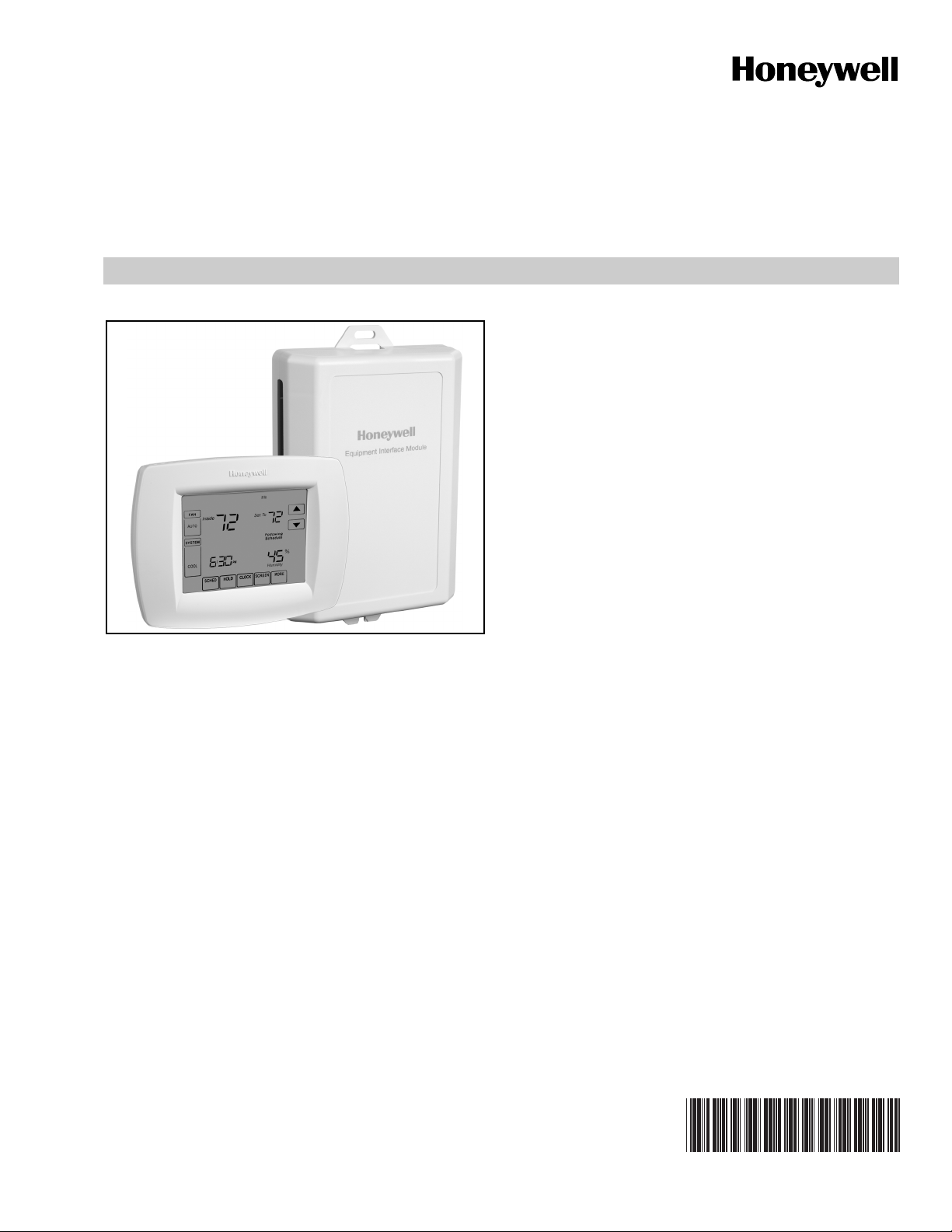

VisionPRO® IAQ

Total Home Comfort System

FEATURES

• Large, clear display with backlight shows the current

and set temperature and time—even in the dark.

• Touchscreen interaction

• Real-time clock keeps time during power failures and

automatically updates to daylight savings.

• Change/check reminders let you know when to service

or replace filters.

• Various Hold options allow you to override the

program schedule, as desired.

• Controls humidification to increase homeowner

comfort while protecting woodwork and furnishings.

• Controls dehumidification using air conditioner with

high or low speed fan or a whole house dehumidifier.

• Controls ventilation with other HRV, ERV, or Freshair

damper. Vent on demand and automatically using

patented advanced ventilation control.

APPLICATION

The VisionPRO® IAQ Total Home Comfort System features an

effortless, 7-Day programmable touchscreen thermostat that

provides control of temperature, humidification,

dehumidification, and ventilation.

• Advanced heat pump control featuring balance point

plus temperature droop control to increase

homeowner comfort.

PRODUCT DATA

Contents

Application/Features.......................................................... 1

Specifications/Ordering Information .................................. 2

Installation ........................................................................ 4

Wiring ............................................................................... 5

Power the Thermostat ...................................................... 8

Installer Setup .................................................................. 12

Operation .......................................................................... 20

Programming .................................................................... 26

Troubleshooting ................................................................ 36

68-0287-04

Page 2

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

SPECIFICATIONS

Thermostat Description:

Feature Description

Powering method • Common wire only

System types (up to

4 heat/2 cool)

• Gas, oil or electric heat with air

conditioning

• Warm air, hot water, high-efficiency

furnaces, heat pumps, steam and

gravity

• Heat only with fan

• Cool only

Changeover Manual or Auto changeover selectable

System setting Heat-Off-Cool-Auto

Fan setting Auto-On-Circ

Electrical Ratings:

Terminal Voltage (50/60 Hz) Running Current

W1 Heating 20 - 30 Vac .02 - 1.0A

W2/Aux Heating 20 - 30 Vac .02 - 1.0A

W3/Aux2 Heating 20 - 30 Vac .02 - 1.0A

Y Cooling 20 - 30 Vac .02 - 1.0A

Y2 Cooling 20 - 30 Vac .02 - 1.0A

G Fan 20 - 30 Vac .02 - 1.0A

Temperature Setting Range:

Heating: 40°F to 90°F(4.5°C to 32°C).

Cooling: 50°F to 99°F (10°C to 37°C).

Operating Ambient Temperature:

VisionPRO

®

IAQ Thermostats: 0°F to 120°F

(-18°C to 49°C).

THM5421C1008: -30°F to 150°F (-34°C to 66°C).

C7089U1006: -40°F to 120°F (-40°C to 49°C).

C7189U1005: 45°F to 88°F (7°C to 32°C).

Shipping Temperature:

VisionPRO

®

IAQ Thermostats: -30°F to 150°F

(-34°C to 66°C).

THM5421C1008: -30°F to 150°F (-34°C to 66°C).

Operating Relative Humidity (Non-condensing):

VisionPRO

®

IAQ Thermostats: 5% to 90%.

THM5421C1008: 5% to 90%.

C7089U1006: 5% to 95%.

C7189U1005: 5% to 95%.

Humidification Setting Range:

Heating: 10% to 60% RH.

Dehumidification Setting Range:

Heating: 40% to 80% RH.

Humidity Display Range:

0% to 99%.

Finish:

VisionPRO

THM5421C1008: Premier White

C7189U1005 Wall Mount Remote Indoor Sensor: Premier

White

®

IAQ Thermostats: Premier White® color.

®

color.

®

color.

Clock Accuracy: +/- 1 minute per year.

Resistance Characteristics of Remote Sensors:

C7089U1006 Outdoor Sensor: Negative temperature coeffi-

cient (NTC) means that resistance decreases as the temperature increases. See Table 12 in the Operation section

for sensor resistance characteristics.

C7189U1005 Remote Indoor Sensor: Negative temperature

coefficient (NTC), means that resistance decreases as the

temperature increases. See Table 13 in the Operation section for sensor resistance characteristics.

Cool Indication:

VisionPRO

®

IAQ Comfort Systems show “Cool On” on the

thermostat screen when Cool is activated.

Heat Indication:

VisionPRO

®

IAQ Comfort Systems show “Heat On” on the

thermostat screen when Heat is activated.

Auxiliary Heat Indication:

VisionPRO

®

IAQ Comfort Systems show “Aux. Heat On” on

the thermostat screen when Auxiliary Heat is activated.

Calibration:

C7089U1006, C7189U1005 and VisionPRO® IAQ Comfort Sys-

tems are factory-calibrated and require no field calibration.

Interstage Differential:

VisionPRO

®

IAQ Comfort Systems operate with droopless

control. Once the thermostat senses that 1st stage is running at 90% capacity, the thermostat energizes 2nd stage.

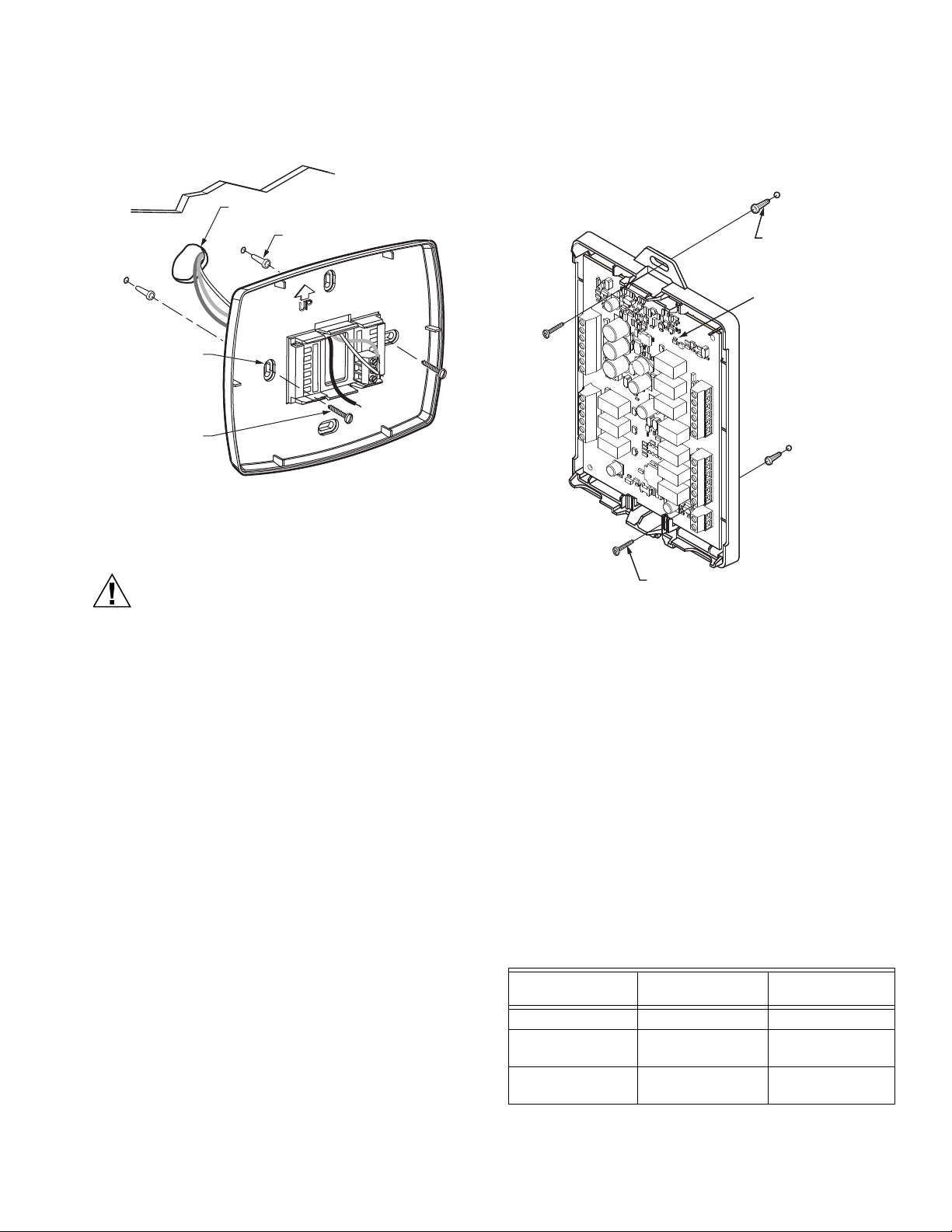

Mounting Means:

VisionPRO

®

IAQ Comfort System: Thermostat mounts directly

on the wall in the living space using mounting screws and

anchors provided. Fits a vertical or horizontal 2 x 4 in. junction box.

THM5421C1008 Equipment Interface Module (EIM) mounts on

HVAC equipment or on a wall in the equipment room.

C7089U1006 Outdoor Sensor: Mounts outside of living space

with mounting clip and screws provided.

C7189U1005 Remote Indoor Sensor: Mounts directly on the

wall using mounting screws and anchors provided.

Cover Plate:

32003796-001 Cover Plate is used to cover marks left on the

wall by the old thermostat.

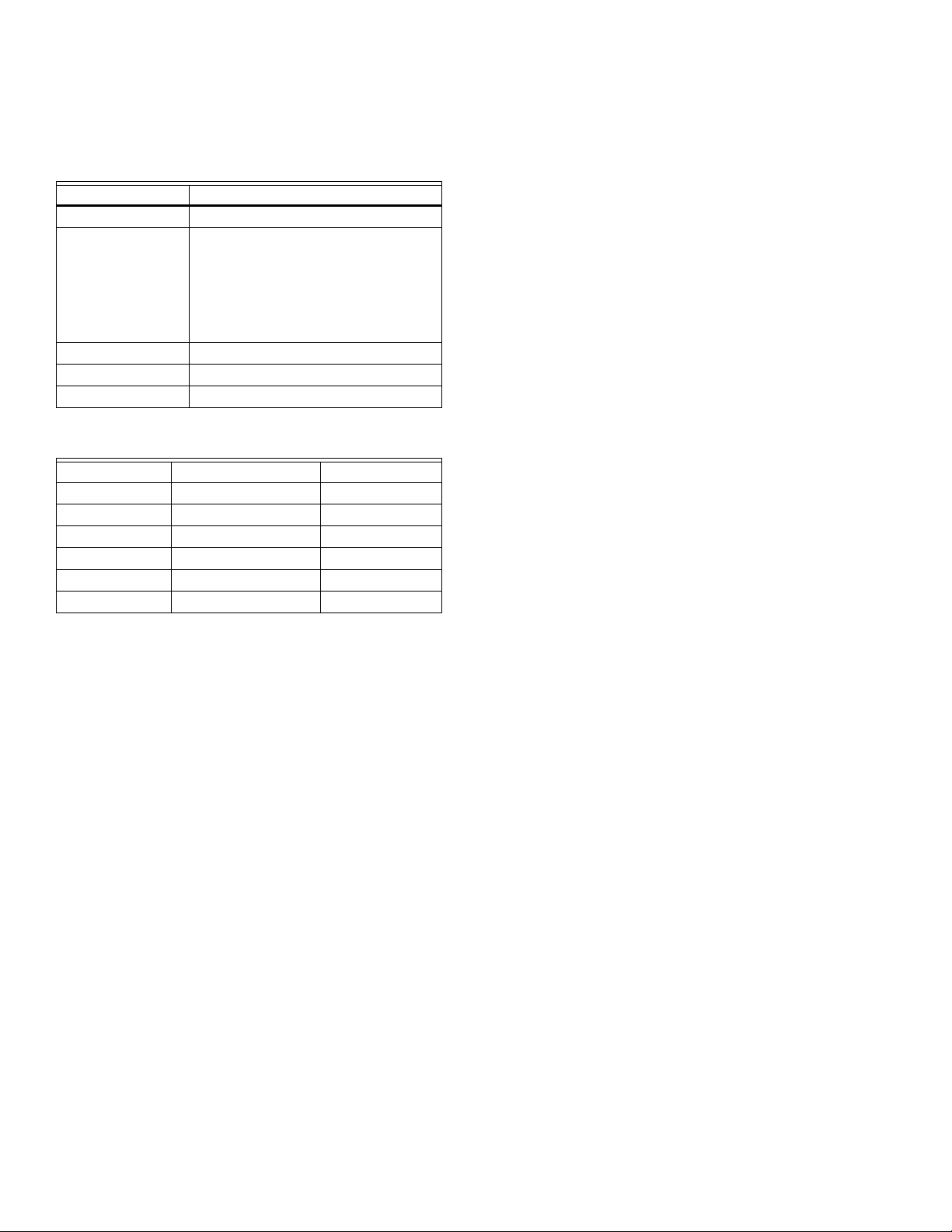

Dimensions:

VisionPRO

®

IAQ Comfort System: see Fig. 1.

THM5421C1008: see Fig. 2

C7089U1006 Outdoor Sensor Mounting Clip: see Fig. 3.

32003796-001 Cover Plate: see Fig. 4.

C7189U1005 Remote Indoor Sensor: see Fig. 5.

Cycle Rates (at 50% Load):

Heating: Selectable 1 - 12 cycles per hour.

Cooling: Selectable 1 - 6 cycles per hour.

68-0287—04 2

Page 3

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

WALLPLATE

3-3/8 (86)

THERMOSTAT

6 (152)

3-3/8 (86)

THERMOSTAT

AND WALLPLATE

4-9/16

(116)

1-3/8 (35)

M23539

1-1/2 (38)

M4488

Fig. 3. C7089U1006 Outdoor Sensor Mounting Clip

dimensions in in. (mm).

7-7/8 (200)

3-5/16 (84)

5-1/2

(140)

3-5/16

(84)

Fig. 1. VisionPRO® IAQ Comfort System

dimensions in in. (mm).

7-9/32

(185)

6-57/64

(175)

4-35/64

(116)

FRONT VIEW SIDE VIEW

1-21/64

(34)

M22139

Fig. 4. 32003796-001 Cover Plate dimensions in in. (mm).

M23544

Fig. 2. THM5421C1008 Equipment Interface Module

dimensions in in. (mm).

3 68-0287—04

Page 4

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

CAUTION

5 FEET

[1.5 METERS]

YES

NO

NO

NO

M19925

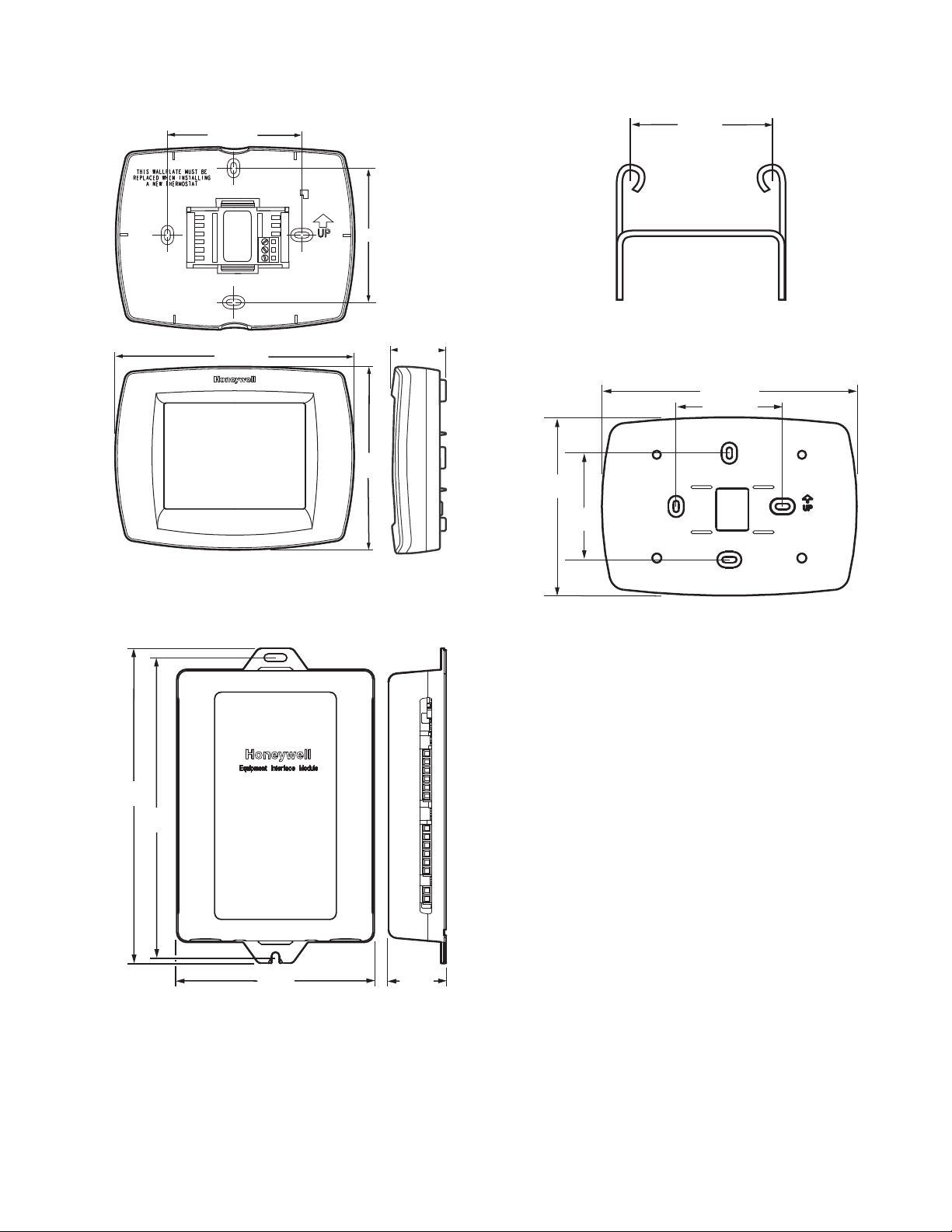

2-9/32

(58)

1-1/2 (38)

M23522

FRONT VIEW SIDE VIEW FRONT VIEW (COVER OFF)

Fig. 5. C7189U1005 Remote Indoor Sensor dimensions in in. (mm).

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow the

instructions can damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions to make sure

the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After completing installation, use these instructions to

verify the product operation.

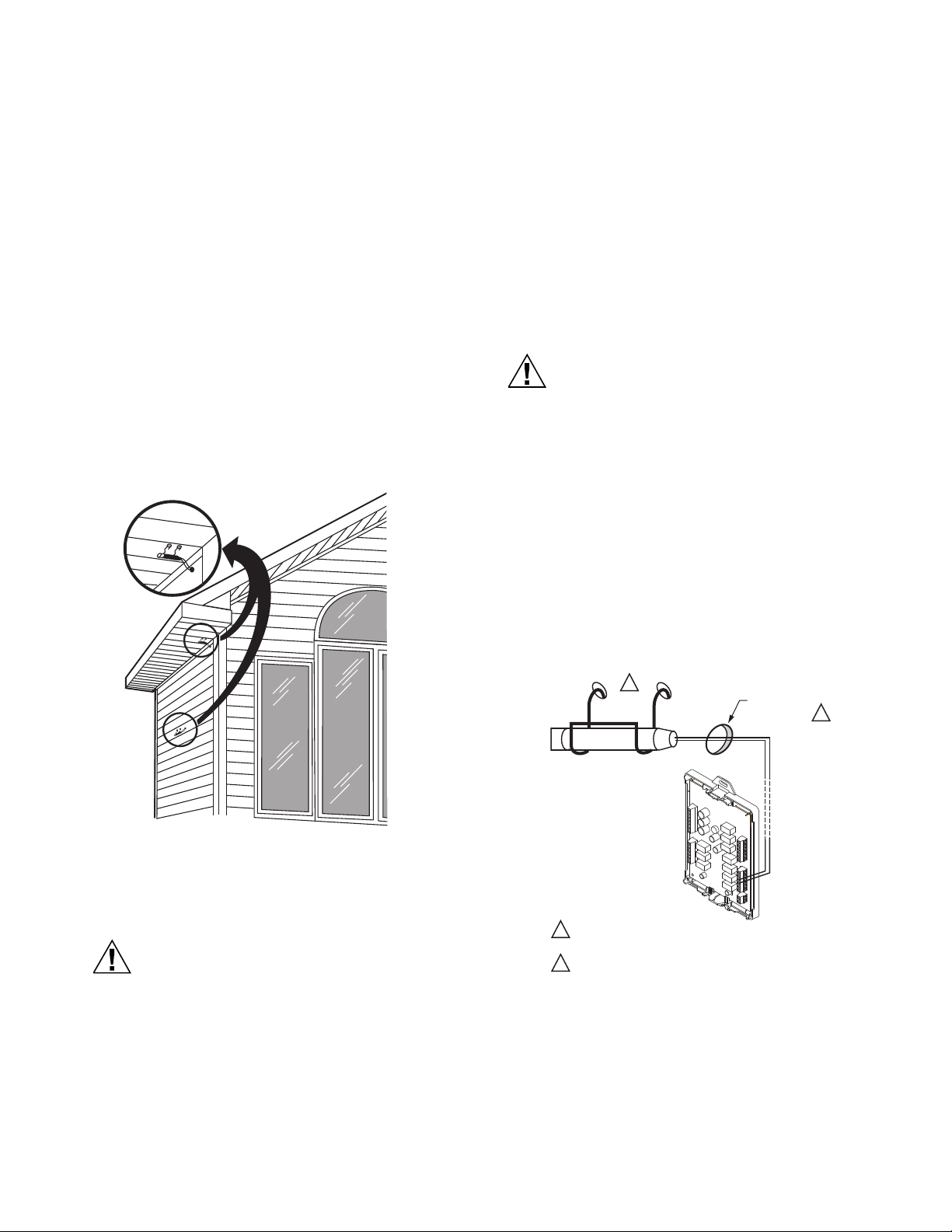

Selecting Location

Install the thermostat about 5 ft. (1.5m) above the floor in an area

with good air circulation at average temperature. See Fig. 6.

2-9/32

(58)

45/64

(18)

1-1/2 (38)

Do not install the thermostat where it can be affected by:

— Drafts or dead spots behind doors and in corners.

— Hot or cold air from ducts.

— Radiant heat from sun or appliances.

— Concealed pipes and chimneys.

— Unheated (uncooled) areas such as an outside wall behind

the thermostat.

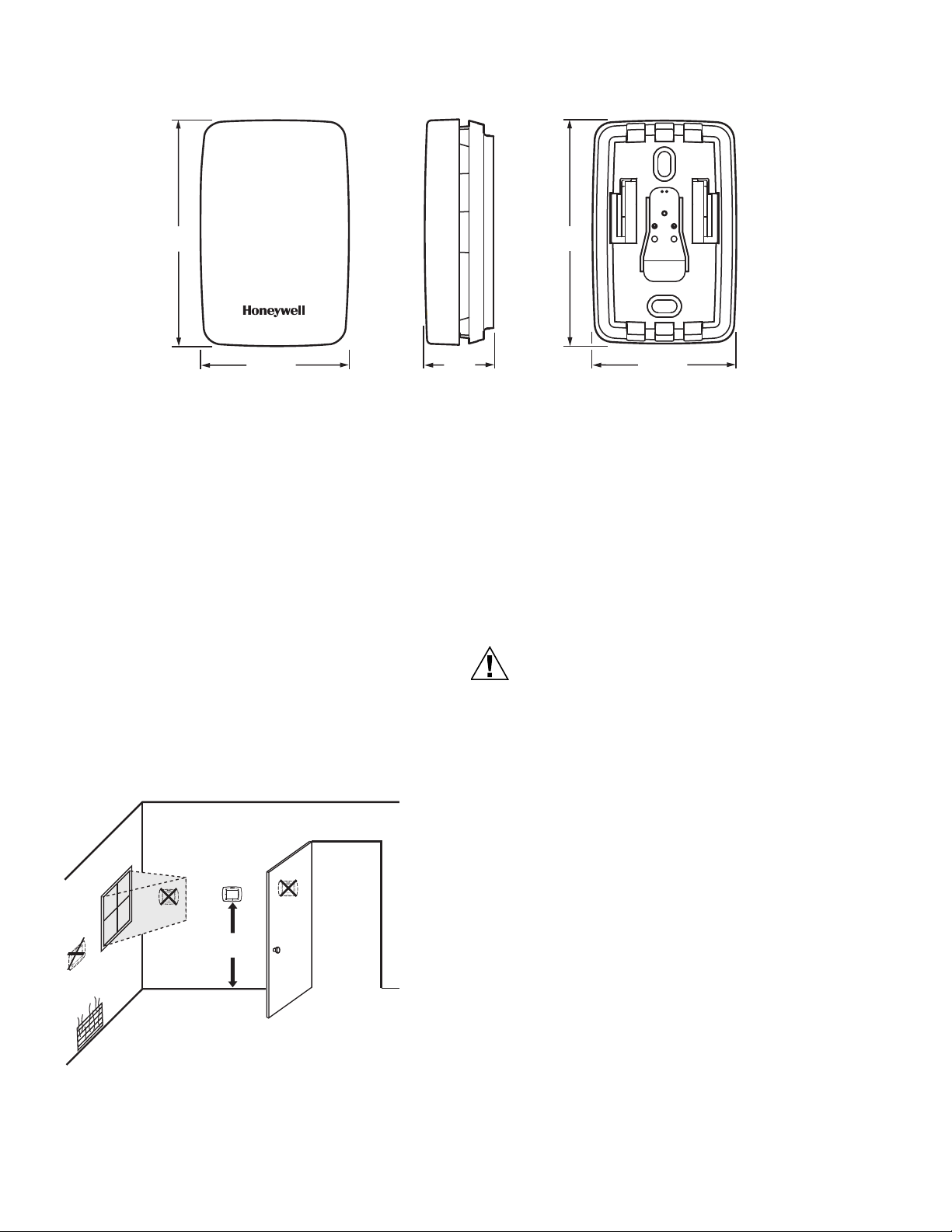

Installing Wallplate

Electrical Hazard.

Can cause electrical shock or equipment damage.

Disconnect power before wiring.

The thermostat can be mounted horizontally on the wall or on a

4 in. x 2 in. (101.6 mm x 50.8 mm) wiring box.

68-0287—04 4

Fig. 6. Selecting thermostat location.

1. Position and level the wallplate (for appearance only).

2. Use a pencil to mark the mounting holes.

3. Remove the wallplate from the wall and, if drywall, drill

two 3/16-in. holes in the wall, as marked. For firmer

material such as plaster, drill two 7/32-in. holes. Gently

tap anchors (provided) into the drilled holes until flush

with the wall.

Page 5

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

CAUTION

WALL

MOUNTING

HOLES

M23543

MOUNTING

SCREWS (2)

WALL ANCHORS (2)

WIRES THROUGH WALL

AND WIRE SLOT

M23541

4. Position the wallplate over the holes, pulling wires

through the wiring opening. See Fig. 7.

5. Insert the mounting screws into the holes and tighten.

Fig. 7. Mounting wallplate.

Installing Equipment Interface Module (EIM)

NOTE: It is normal for the LED to blink continuously during

startup, and while checking equipment status (Auto

Discover mode).

WALL ANCHOR

COMMUNICATION LED

DRILL 3/16 IN. HOLES

FOR DRYWALL. DRILL

7/32 IN. HOLES FOR

PLASTER

Electrical Hazard.

Can cause electrical shock or equipment damage.

Disconnect power before wiring.

The EIM can be mounted vertically on the HVAC equipment or

on a wall in the equipment room.

1. Position the EIM.

2. Use a pencil to mark the mounting holes.

3. Remove the wallplate from the wall and, if drywall, drill

two 3/16-in. holes in the wall, as marked. For firmer

material such as plaster, drill two 7/32-in. holes. Gently

tap anchors (provided) into the drilled holes until flush

with the wall.

4. Position the wallplate over the holes, pulling wires

through the wiring opening.

5. Insert the mounting screws into the holes and tighten.

See Fig. 8.

Communication LED

The EIM has an LED (see Fig. 8) that communicates the EIM

status as follows.

• LED blinks rapidly: Normal information transfer.

• LED blinks once: Incoming message to EIM.

• LED blinks continuously: Wiring problem. Check wiring to

terminals 1, 2, 3.

• LED always off: Wiring problem. Check wiring to terminals

1, 2, 3.

• LED always on: EIM may need replacement.

MOUNTING SCREW

M23484

Fig. 8. Mounting EIM.

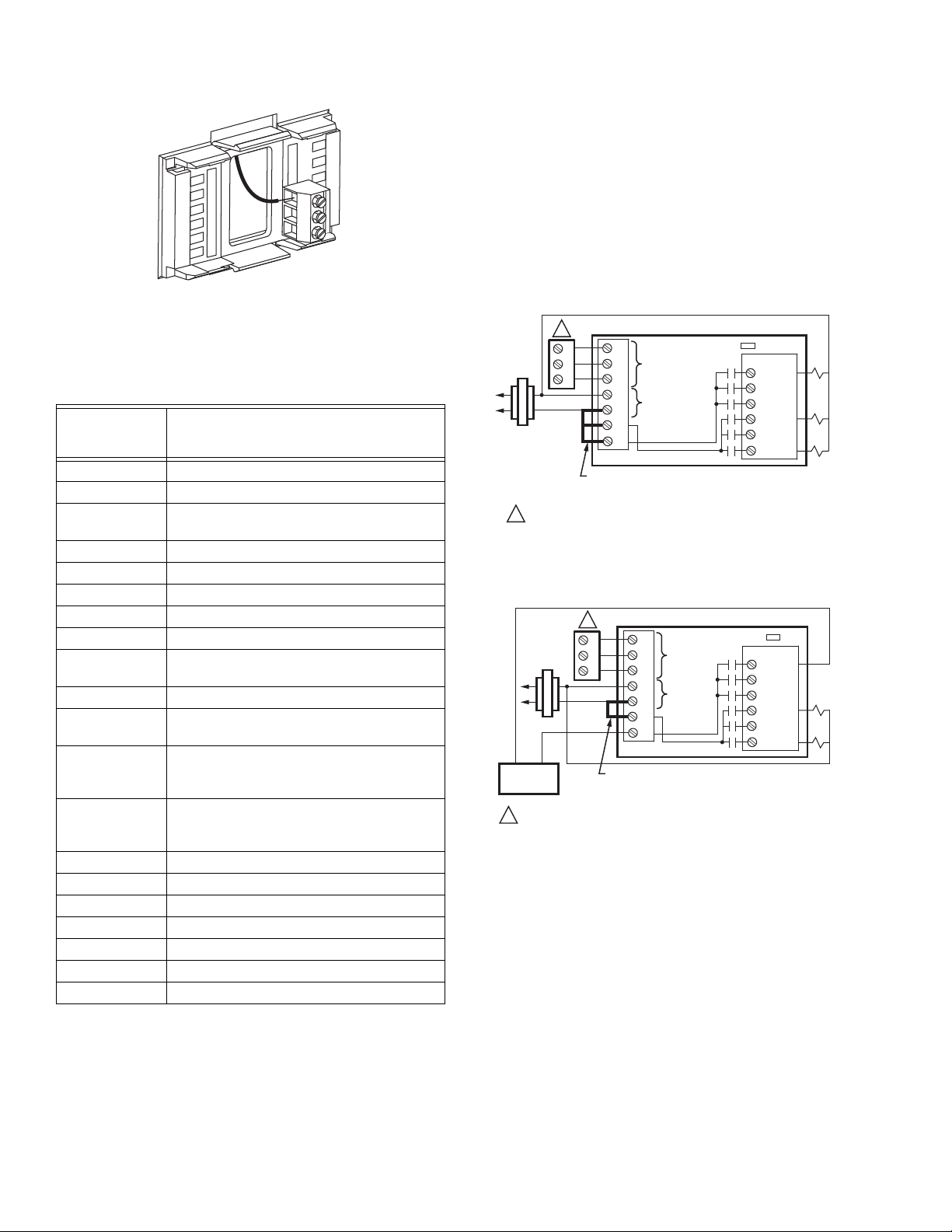

WIRING

All wiring must comply with local electrical codes and

ordinances. See Fig. 10–20.

1. Select set of terminal identifications (Table 1) that corre-

sponds with system type.

2. Loosen the screws for the appropriate system type

selected; see Table 1. See Table 2 for terminal designation descriptions. Insert wires in the terminal block under

the loosened screw. See Fig. 9.

3. Securely tighten each screw.

4. Push excess wire back into the hole.

5. Plug the hole with nonflammable insulation to prevent

drafts from affecting the thermostat.

6. See Fig. 10–20 for typical wiring hookups.

Table 1. Selecting Terminal Identifications for System Type.

Wallplate Terminal

System Type

Identifications

Standard Heat/Cool Conventional 10, 11

Standard Multistage

Conventional 12

up to 3 Heat/2 Cool

Heat Pump with

Heat Pump 13

Auxiliary Heat

Wiring Diagram

Reference

5 68-0287—04

Page 6

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

M23541

M23485

FACTORY INSTALLED

JUMPER BETWEEN R,

RC AND RH

1

2

3

C

R

RC

RH

COMMUNICATION

TERMINALS

COMMUNICATION LED

W1

W2

W3

Y

Y2

G

24 VAC

O/B

AUX

AUX2

Y

Y2

G

1

2

3

WIRE TO TERMINALS ON THERMOSTAT.1

1

CONV. HP

M23486

FACTORY INSTALLED JUMPER BETWEEN R,

AND RC (REMOVE FACTORY INSTALLED

JUMPER BETWEEN RC AND RH

1

2

3

C

R

RC

RH

COMMUNICATION

TERMINALS

COMMUNICATION LED

W1

W2

W3

Y

Y2

G

24 VAC

O/B

AUX

AUX2

Y

Y2

G

1

2

3

OIL PRIMARY/

AQUASTAT

WIRE TO TERMINALS ON THERMOSTAT.1

1

CONV. HP

Fig. 9. Inserting wires in terminal block.

IMPORTANT

Use 18-gauge thermostat wire.

Table 2. Terminal Designation Descriptions.

THM5421C1008

Terminal

Designations Function

1 Terminal 1—data to/from thermostat

2 Terminal 2—power from thermostat (24Vac)

3 Terminal 3—common from thermostat

(24Vac)

C 24 Vac Transformer Common

R 24 Vac Transformer

RC 24 Vac Cooling Transformer

RH 24 Vac Heating Transformer

HUM1/HUM2 Humidification Connection (normally open)

DHM1/DHM2 Dehumidification Connection (normally

open or closed based on installer setup)

VNT1/VNT2 Ventilation connection (normally open)

W1/O/B Stage 1 Heating Relay (Conventional)

Change-over Relay (Heat Pump)

W2/AUX Stage 2 Heating Relay (Conventional)

Auxiliary Heat (fossil fuel or electric) (Heat

Pump)

W3/AUX2 Stage 3 Heating Relay (Conventional)

Auxiliary Heat (fossil fuel or electric) (Heat

Pump)

Y Stage 1 Compressor Relay

Y2 Stage 2 Compressor Relay

GFan Relay

L Heat Pump Equipment Monitor

OUT1/OUT2 Outdoor Temperature Sensor

IN1/IN2 Remote Indoor Temperature Sensor

DATS1/DATS2 Discharge Air Temperature Sensor

NOTES:

1. When used in a single-transformer system, leave

the metal jumper wires in place between R and Rc,

and Rc and Rh. If used on a two-transformer system, remove metal jumper wire between Rc and Rh.

2. If thermostat is configured for a heat pump system

in the Installer Setup, configure changeover valve

for cool (O-factory setting) or heat (B).

For wiring to a W8835 Zone panel please refer to the product

data sheet included with the panel.

Fig. 10. Typical hookup of conventional single-stage heat

and cool system with single transformer

(1H/1C conventional).

Fig. 11. Typical hookup of conventional single-stage heat

and cool system with oil primary (1H/1C conventional).

68-0287—04 6

Page 7

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

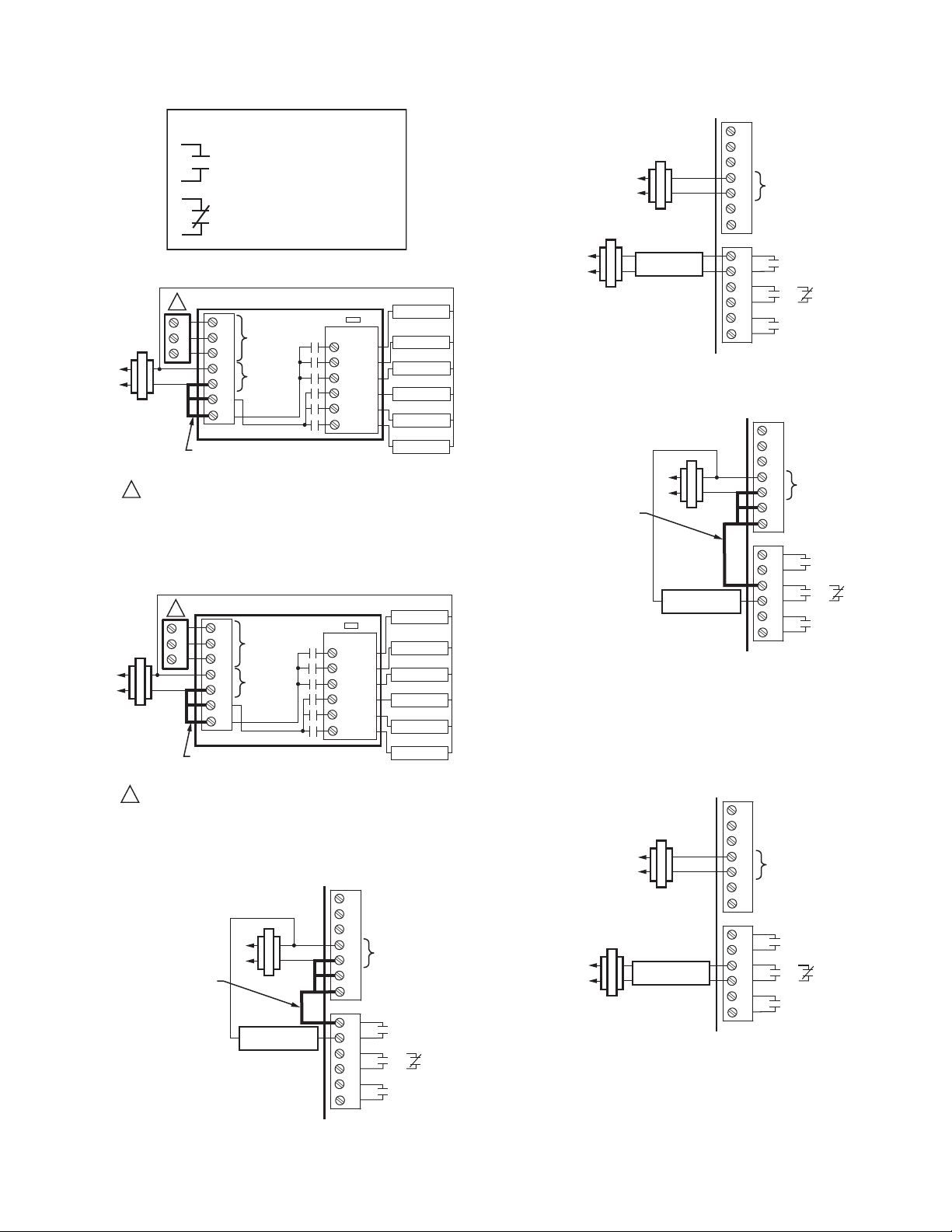

M23685

KEY

= NORMALLY OPEN, DRY CONTACTS

= NORMALLY CLOSED, DRY CONTACTS

M23487

FACTORY INSTALLED

JUMPER BETWEEN R,

RC AND RH

1

2

3

C

R

RC

RH

COMMUNICATION

TERMINALS

COMMUNICATION LED

W1

W2

W3

Y

Y2

G

24 VAC

O/B

AUX

AUX2

Y

Y2

G

1

2

3

CONV. HP

HEAT 1 RELAY

HEAT 2 RELAY

HEAT 3 RELAY

COOL 1 RELAY

COOL 2 RELAY

FAN RELAY

WIRE TO TERMINALS ON THERMOSTAT.

1

1

M23488

FACTORY INSTALLED

JUMPER BETWEEN R,

RC AND RH

1

2

3

C

R

RC

RH

COMMUNICATION

TERMINALS

COMMUNICATION LED

W1

W2

W3

Y

Y2

G

24 VAC

O/B

AUX

AUX2

Y

Y2

G

1

2

3

CONV. HP

CHANGEOVER

AUX 1 (HEAT 3)

AUX 2 (HEAT 4)

COMP 1

COMP 2

FAN RELAY

WIRE TO TERMINALS ON THERMOSTAT.

1

1

M23489

FIELD INSTALLED

JUMPER BETWEEN

R AND HUM 1

1

2

3

C

R

RC

RH

24 VAC

H1

U

M2

D1

H

M2

V1

N

T2

OR

NON-POWERED

HUMIDIFIER

M23491

FIELD INSTALLED

JUMPER BETWEEN

R AND DHM 1

1

2

3

C

R

RC

RH

24 VAC

H1

U

M2

D1

H

M2

V1

N

T2

OR

NON-POWERED

DEHUMIDIFIER

M23492

1

2

3

C

R

RC

RH

24 VAC

H1

U

M2

D1

H

M2

V1

N

T2

OR

POWERED

DEHUMIDIFIER

1

2

3

C

24 VAC

R

RC

RH

Fig. 12. Typical hookup of conventional system with up to

three-stage heat and two-stage cool with one transformer

(3H/2C, 2H/2C, 2H/1C, 1H/2C, 1H/1C conventional).

POWERED

HUMIDIFIER

H1

U

M2

D1

H

M2

V1

N

T2

OR

M23490

Fig. 15. Typical hookup of powered humidifier.

Fig. 16. Typical hookup of variable speed blower for

dehumidification in low speed (contacts normally closed).

Fig. 13. Typical hookup of heat pump system

Fig. 14. Typical hookup of non-powered humidifier.

(up to 4H/2C heat pump).

NOTE: Connect DHM2 to low-speed fan terminal on air han-

dler for dehumidification with air conditioner and a

low-speed fan.

7 68-0287—04

Fig. 17. Typical hookup of powered whole house

dehumidifier (contacts normally open).

Page 8

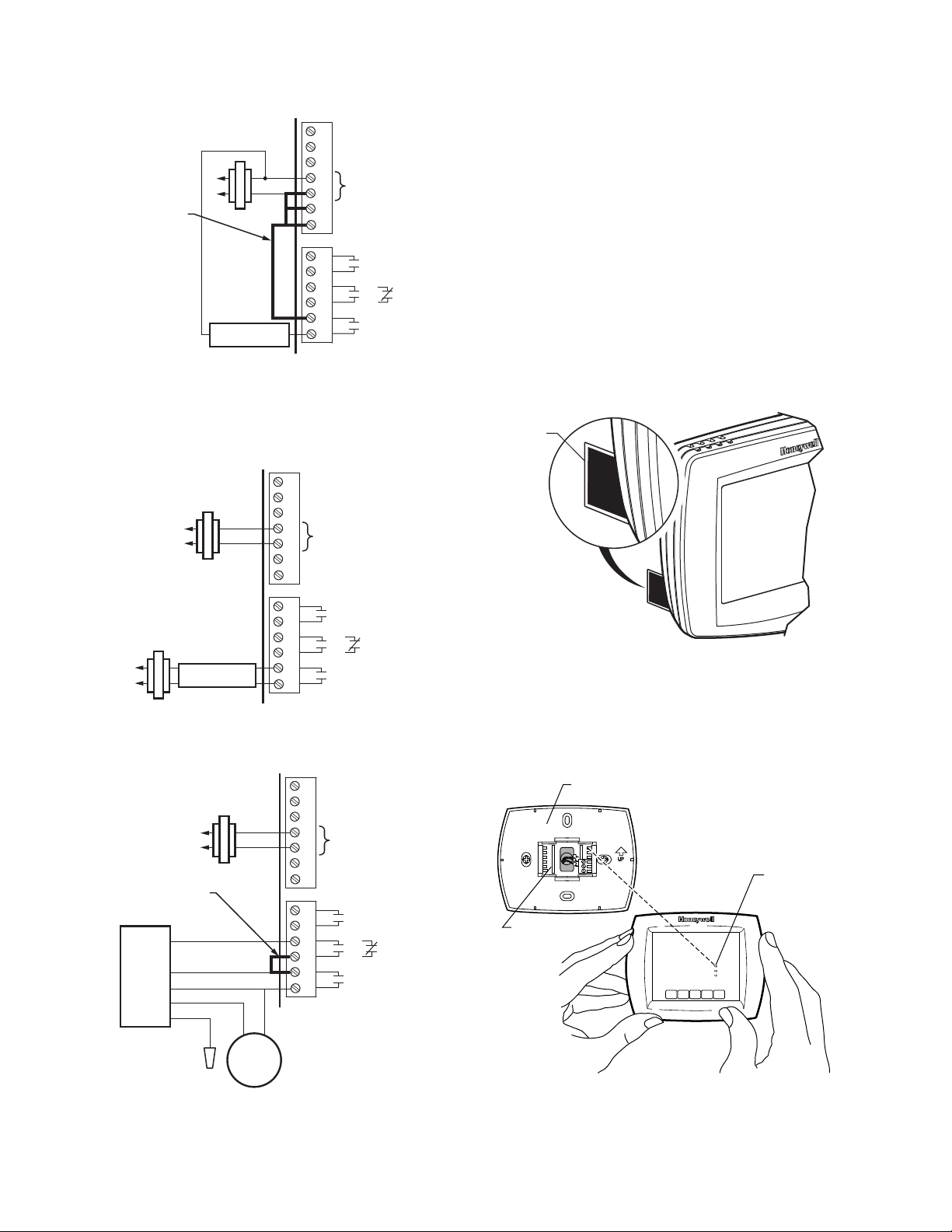

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

M23493

FIELD INSTALLED

JUMPER BETWEEN

R AND VNT 1

1

2

3

C

R

RC

RH

24 VAC

H1

U

M2

D1

H

M2

V1

N

T2

OR

NON-POWERED

VENTILATOR

M23494

1

2

3

C

R

RC

RH

24 VAC

H1

U

M2

D1

H

M2

V1

N

T2

OR

POWERED

VENTILATOR

M23495

1

2

3

C

R

RC

RH

24 VAC

H1

U

M2

D1

H

M2

V1

N

T2

OR

FRESH

AIR

DAMPER

DH90

BLUE

GREEN

YELLOW

RED

WHITE

FIELD INSTALLED

JUMPER BETWEEN

DHM 1 AND VNT 1

REMOVE DURING

INSTALLATION

M19920

REMOVE

TAB

REMOVE DURING

INSTALLATION

POWER THE THERMOSTAT

• 24 Vac common wire only to EIM or zone panel.

Wiring 24 Vac Common

• Single-Transformer System—Connect the common side of

the transformer to the C screw terminal of the EIM. Leave

the metal jumper wires in place between R, Rc, and RH.

• Two-Transformer System—Connect the common side of

the cooling transformer to the C screw terminal of the EIM.

Remove the metal jumper wire between Rc and Rh.

Connect the hot side of heating transformer to Rh and leave

the jumper wire between R and Rc and connect the hot side

of cooling transformer to R or Rc.

Fig. 18. Typical hookup of fresh air damper.

NOTE: Use this hookup for ventilation using a fresh air

damper.

Fig. 19. Typical hookup of powered ventilation.

1. Locate and remove the tab labeled, Remove, in the

lower left corner on the thermostat back. See Fig. 21.

Fig. 21. Remove tab labeled, Remove, on thermostat back

Mount Thermostat to Wallplate

1. Align the terminal screw blocks with the pins on the back

of the thermostat. Push the thermostat straight onto the

wallplate until it snaps into place. See Fig. 22.

WALLPLATE

Fig. 20. Hookup of Honeywell DH90 with fresh air intake for

68-0287—04 8

ventilation.

PINS ON

BACK OF

THERMOSTAT

TERMINAL

SCREW

BLOCK

M23542

Fig. 22. Mount thermostat to wallplate.

Page 9

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

CAUTION

CAUTION

M7514

1

2

2

1

USE APPROPRIATE MOUNTING MEANS FOR THE

TYPE OF STRUCTURE.

PLUG WIRING HOLE WITH NON-HARDENING CAULK

OR PUTTY.

C7089

WIRING HOLE

THROUGH

STRUCTURE

M23525

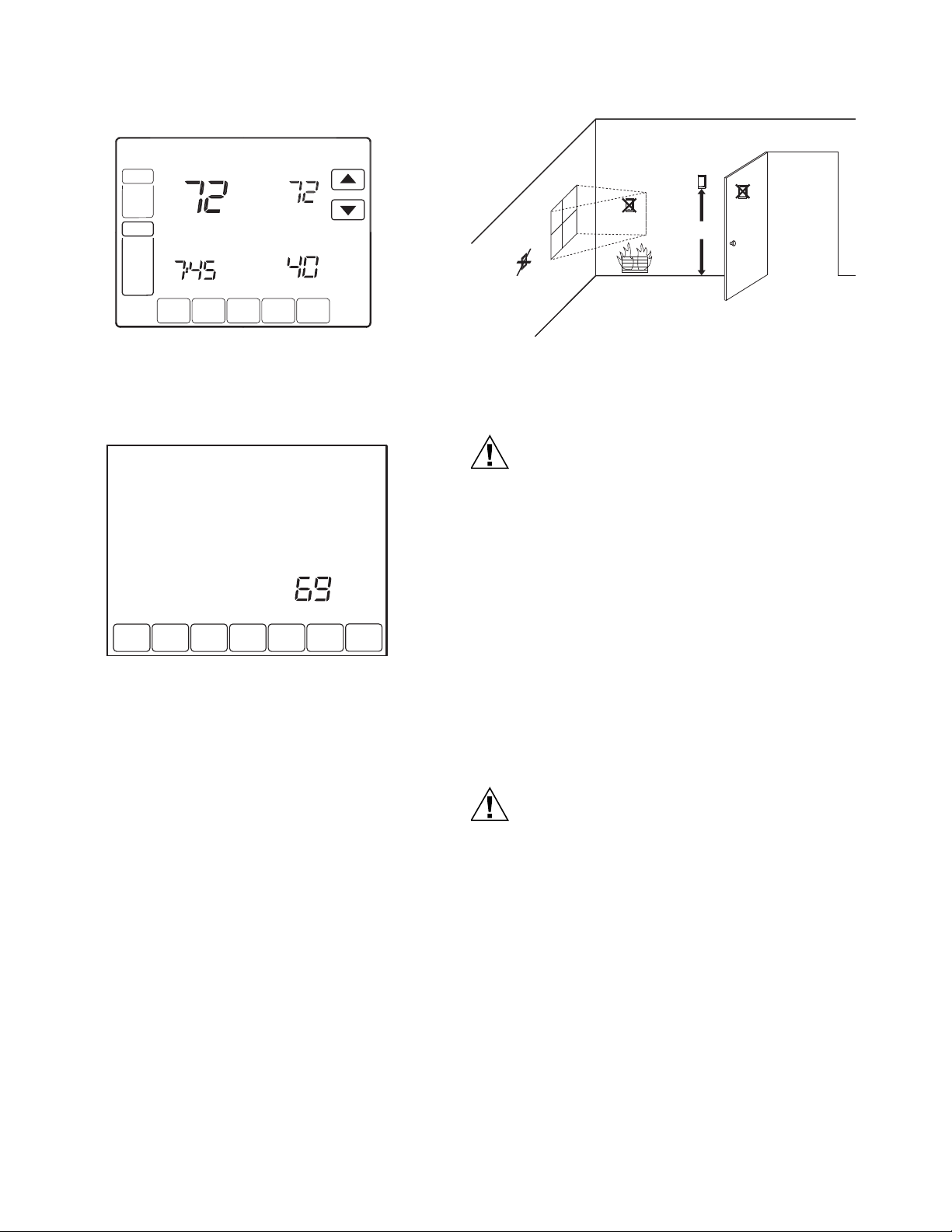

Locate and Mount C7089U1006 Outdoor Temperature Sensor (Optional)

Mount the sensor where (see Fig. 23):

• cannot tamper with settings.

• there is good air circulation.

• it can measure true outdoor ambient temperature.

• surface is flat.

• wire distance between C7089U1006 and EIM is less than

200 feet.

Do not mount the sensor:

• in direct sunlight.

• where hot or cold air blows on the sensor. Discharge line

from an outdoor compressor unit, vent or fan causes

inaccurate temperature readings.

• where snow, ice or debris can cover it.

Use the following steps to mount the sensor:

1. Remove the sensor from the mounting clip.

2. Mark the area on the location selected for mounting the

sensor mounting clip.

3. Mount the clip.

IMPORTANT

Erratic temperature readings from a sensor can occur

as a result of any of the wiring practices described

below. Avoid these practices to assure correct operation. Use shielded cable to reduce interference if

rerouting sensor wiring is not possible.

— Be sure wires have a cable separate from the thermo-

stat cable.

— Do not route temperature sensor wiring with building

power wiring, next to control contactors or near light

dimming circuits, electric motors or welding

equipment.

— Avoid poor wiring connections.

— Avoid intermittent or missing building earth ground.

Electrical Shock Hazard.

Can cause electrical shock or equipment damage.

Disconnect power supply before connecting wiring.

Wiring must comply with applicable codes, ordinances and

regulations:

1. Wire C7089U1006 Outdoor Sensor to OUT1and OUT2

terminals on the EIM. If leadwire provided is not long

enough (60 in.), run a cable to a hole at C7089U1006

location.

a. Using color-coded, 18-gauge thermostat wire is

recommended. For example of general wiring of

C7089U1006, see Fig. 24.

b. Pigtail wiring can be used.

2. Mount C7089U1006 in its mounting clip.

3. Plug wiring hole using nonhardening caulk or putty.

Fig. 23. Typical locations for C7089U1006 Outdoor Sensor.

Wire C7089U1006 Outdoor Sensor

Electrical Interference (Noise) Hazard.

Can cause erratic system operation.

Keep wiring at least one foot away from large inductive

loads such as motors, line starters, lighting ballasts and

large power distribution panels.

Use shielded cable to reduce interference when

rerouting is not possible.

Fig. 24. Wire C7089U1006 Outdoor Sensor to the EIM.

If an outdoor temperature sensor is installed, the thermostat

displays the outside temperature in the lower right corner of the

Home Screen.

9 68-0287—04

Page 10

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

CAUTION

CAUTION

SCHED HOLD CLOCK SCREEN MORE

MON

UE

THUSASUN

AM

O

SYSTEM

HEAT

Following

Schedule

de

Outside

Se

o

M22453

SCHED

HOLD

5 FEET

(1.5 METERS)

YES

NO

NO

NO

M4476

T

Insi

AUT

t T

If thermostat is set to Auto Changeover System mode, press

the More key until the outside temperature is shown on the

screen.

TUE WED THU FRI SAT SUN

MON

Outside

SCHED

HOLD

CLOCK SCREEN

DONE

WAKE

LEAVE RETURN SLEEP CANCEL

M22448

Locate and Mount C7189U1005 Remote Indoor Temperature Sensor (Optional)

1. Choose a location (see Fig. 25) for mounting the sensor

on an inside wall about 5 ft (1.5m) above the floor.

2. Be sure wire distance between C7189U1005 and EIM is

less than 200 feet.

3. Make sure there is good air circulation at average tem-

perature at the chosen location. Avoid the following locations because they can introduce errors in sensor

measurements. See Fig. 25.

a. Hot areas caused by:

(a)Concealed pipes or ducts.

(b)Drafts from fireplaces or other heat sources.

(c)Convection or radiant heat from the sun or

electrical equipment.

b. Cold areas caused by:

(a)Concealed pipes or ducts.

(b)Drafts from windows and doors.

(c)Unheated areas on the other side of the wall

c. Dead air areas:

4. Mark the area on the wall selected for mounting the

C7189U1005 Sensor.

5. Run wire cable to a hole at the selected wall location.

Pull approximately three inches of wire through the

opening. Color-coded, 18-gauge thermostat wire is

recommended.

location.

(a)Behind doors, furniture and curtains.

(b)In corners and alcoves.

Fig. 25. Typical location for C7189U1005 Indoor Sensor.

Wire C7189U1005 Indoor Sensor

Electrical Interference (Noise) Hazard.

Can cause erratic system operation.

Keep wiring at least one foot away from large inductive

loads such as motors, line starters, lighting ballasts and

large power distribution panels.

IMPORTANT

Erratic temperature readings from a sensor can occur

as a result of any of the wiring practices described

below. Avoid these practices to assure correct

operation.

— Be sure wires have a cable separate from the thermo-

stat cable.

— Do not route temperature sensor wiring with building

power wiring, next to control contactors or near light

dimming circuits, electric motors or welding equipment.

— Avoid poor wiring connections.

— Avoid intermittent or missing building earth ground.

Electrical Shock Hazard.

Can cause electrical shock or equipment damage.

Disconnect power supply before connecting wiring.

Wiring must comply with applicable codes, ordinances and

regulations.

1. Wire C7189U1005 Indoor Sensor to IN1and IN2 termi-

nals on the EIM. For an example of general wiring of

C7189U1005, see Fig. 26 to wire one sensor and Fig. 27

to wire multiple sensors.

2. Push excess wire back into the hole. Plug the hole using

nonhardening caulk, putty or insulation to prevent drafts

from affecting performance.

3. Remove C7189U1005 cover.

4. Mount C7189U1005 to the wall using the screws and

anchors provided.

5. Level the C7189U1005 for appearance only. Device

functions correctly even when not level.

6. Install C7189U1005 cover.

68-0287—04 10

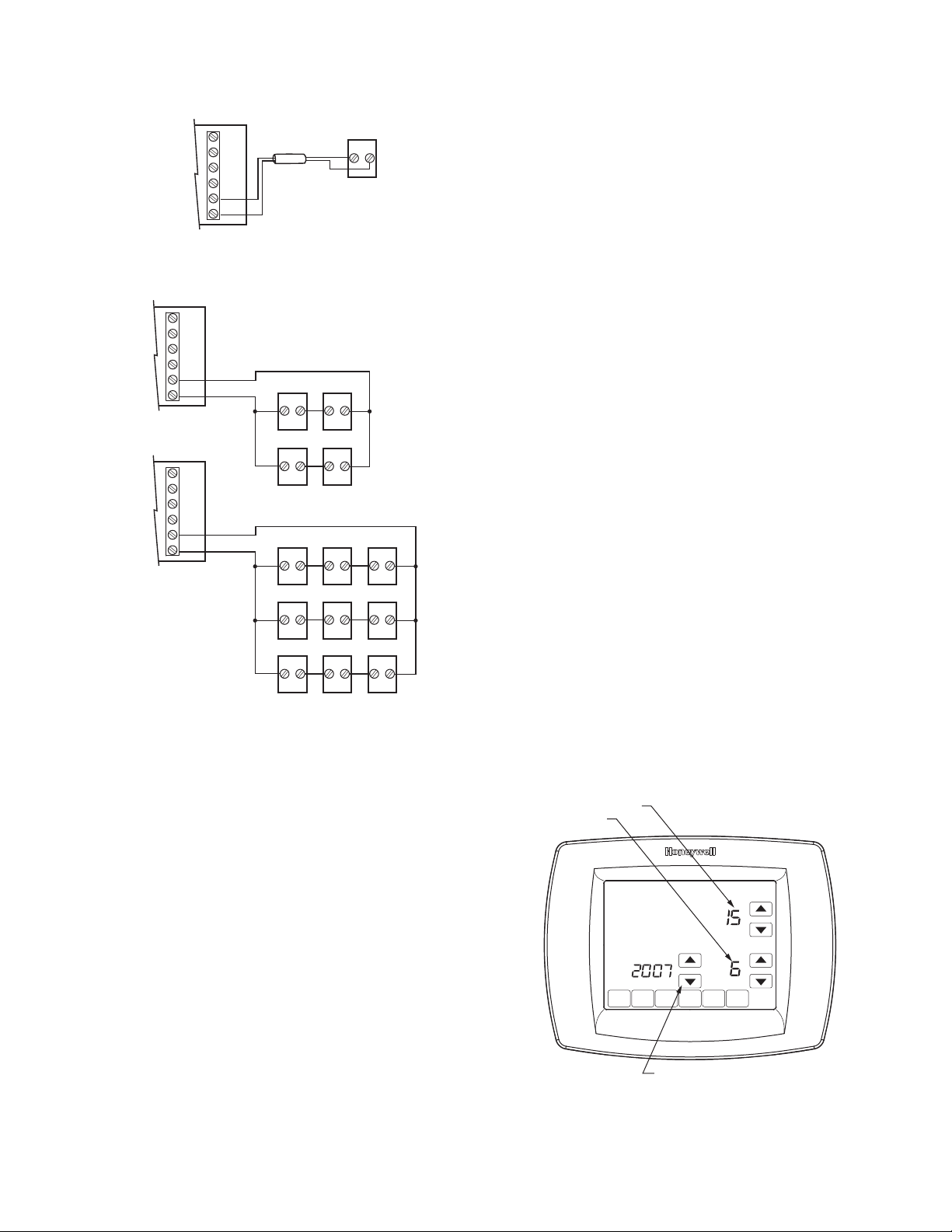

Page 11

L

M23524

C7189 C7189

C7189 C7189

C7189 C7189

C7189 C7189

C7189

C7189

C7189 C7189 C7189

1 OUT

L

2 IN

1 IN

2 OUT

1 OUT

L

2 IN

1 IN

2 OUT

MO

1 OUT

2 OUT

1 IN

2 IN

C7189

M23523

Fig. 26. Wiring a single C7189U1005 Indoor Sensor.

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

• The thermostat will display the temperature measured at

the sensor locations (internal thermostat sensor is

disabled). Sensors must be in square numbers (e.g., 4, 9,

16, and so on) and the displayed temperature will be an

average of the temperatures measured at each location.

• The thermostat will display a 50-50 average of the

temperature measured at the thermostat location and the

average of the temperatures measured at the remote indoor

sensor locations. In this case, the thermostat sensor still

carries a 50% weighting of the displayed temperature.

Install Discharge Air Temperature Sensor (Optional):

Prior to installing Discharge Air Temperature Sensor (DATS)

refer to the installation instructions included with the product for

more information on placement and wiring.

When using a DATS with network zoning the DATS will monitor

the duct air temperature and communicate with the thermostat

and will disable the heating and/or cooling if installer set high or

low temperature limits are reached.

When using a DATS with an Equipment Interface Module the

DATS is for testing only. When the installer is in any of the

Installer Tests pressing the “More” button will display the

temperature measured at the DATS. This allows the installer

to view the temperature of each stage of heating and or

cooling. The DATS will not be used for control and will not

disable heating or cooling based on duct air temperature.

Fig. 27. Wiring Multiple C7189U1005 Sensors.

If a remote indoor temperature sensor is installed, the

thermostat has several options for displaying the current indoor

temperature. This is configured in ISU 340. The thermostat can

display either the temperature measured at the thermostat

location, the sensor location, or a 50-50 average of both.

ONE REMOTE INDOOR SENSOR INSTALLED (OPTIONAL)

If one remote indoor temperature sensor is used, based on

configuration during installer setup, either of the following

options are available:

• The thermostat will display the temperature measured at

the sensor location (internal thermostat sensor is disabled).

• The thermostat will display a 50-50 average of the

temperature measured at the thermostat location and the

remote indoor sensor location.

MULTIPLE REMOTE INDOOR SENSORS INSTALLED (OPTIONAL)

If more than one remote indoor sensor is used, based on

configuration during installer setup, either of the following

options are available:

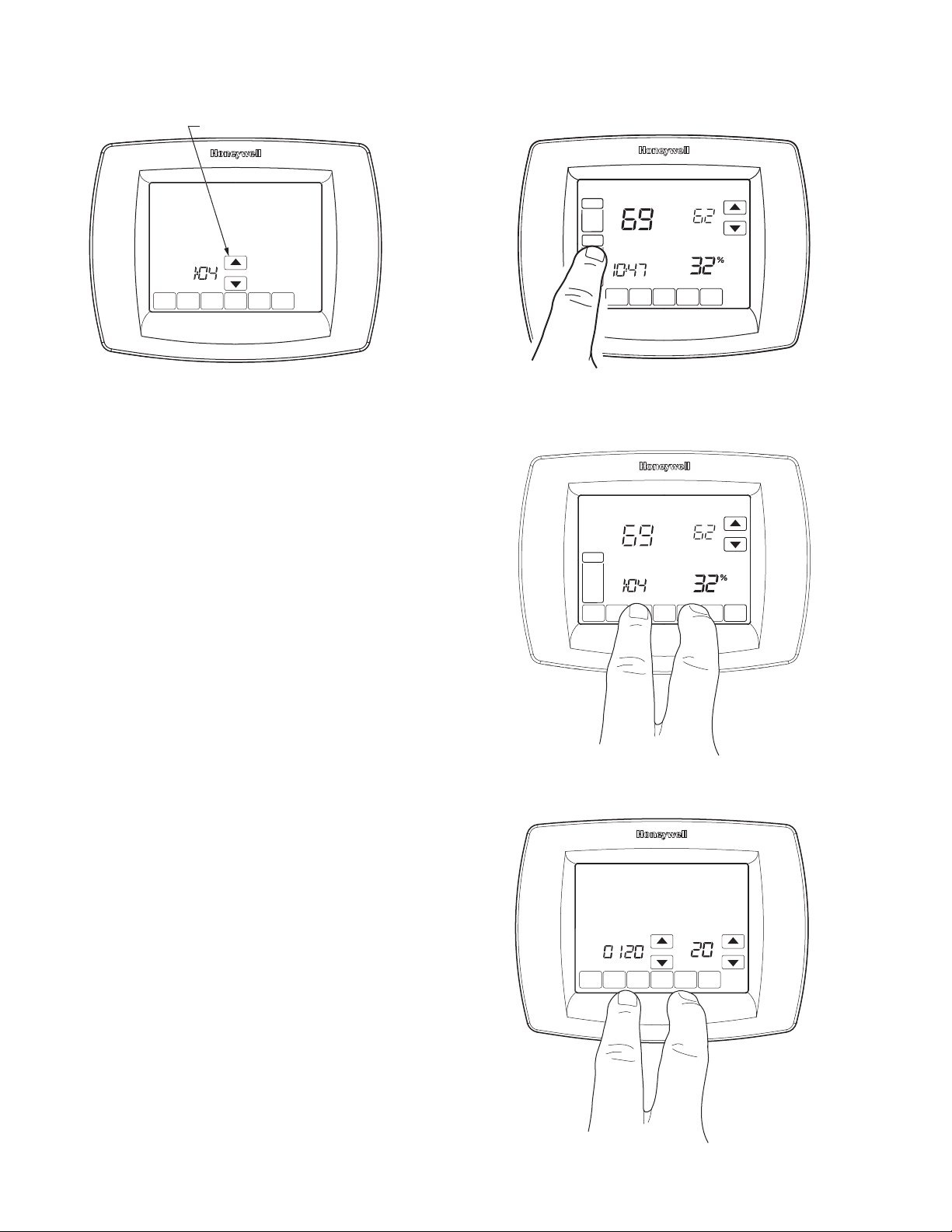

Set Calendar and Time

Thermostat keeps current time and day for up to ten years

under normal use after the calendar is set.

When the thermostat is first powered, the display is ready to

set the calendar and time.

NOTE: Calendar can also be set in the Installer Setup.

1. Press the arrow keys to set the year, month and day.

2. Press the Done key.

SET CURRENT DAY

SET MONTH

MO

DONE

WEWETHTHFRFRSSAASU

OK TO PICK MULTIPLE DAYS SCREEN LOCKED

CHANGE FILTER UV LAMP

USE ARROWS TO SET YEAR AND TIME

M22424

3. Press the arrow keys to set the current time.

4. Press the Done Key.

11 68-0287—04

Page 12

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

E

MO

SA

SU

SCHED HOLD CLOCK

SCREEN

FAN

ON

AUTO

A

M

THU

SYSTEM

EM HEAT

OFF

COOL

Following

Schedule

Inside

M23498

Humidity

MO

USE ARROWS TO SET YEAR AND TIME

DON

M22425

INSTALLER SETUP

Auto Discover is available when the TH9421C thermostat is

connected to an EIM. The EIM communicates information to

the thermostat. Thermostat settings can be specified using the

up and down arrow keys on the screen or set to Auto Discover.

Using Auto Discover

Some Installer setups are defaulted to Auto Discover. If not

defaulted, the installer can change the option to Auto Discover,

however, it is always important that the installer verify that the

auto discovered values are correct for the system that is

present.

1. Press and release the System Key.

2. Press and hold the two blank keys on either side of the

center blank key for approximately five seconds until

screen changes.

TU WEWETHTHFRFRSSAASU

MO

OK TO PICK MULTIPLE DAYS SCREEN LOCKED

CHANGE FILTER UV LAMP

SYSTE

EM

HEAT

OFF

DONE

Inside

M

Set

Following

Schedule

Humidity

CANCEL

When using the thermostat with an equipment interface

module, Auto Discover will discover factory default settings

and will not receive communications as to proper system

settings. The equipment interface module is preprogrammed at

the factory as a one heat one cool product and the thermostat

will “auto discover” those settings. The equipment interface

module will be reprogrammed when the installer manually

changes the configuration in the installer set up. It is not

recommended to use Auto Discover with an equipment

interface module.

When using the VisionPRO® IAQ thermostat with a W8835

zone panel, configure the zone panel, using the DIP switches

on the panel, for the proper system settings. Enter the installer

setup on each thermostat and assign zone numbers, and

change the system settings (ISU 172–180) to Auto Discover

(E) then press the discover button on the zone panel. The zone

panel will then communicate those settings back to the

thermostats and the thermostats will automatically configure

the ISU settings in Auto Discover, again it is important to verify

that the auto discovered values are correct.

NOTE: When a VisionPRO® IAQ thermostat is being added

to an existing zoning system with T8635 Thermostats

the new VisionPRO® IAQ must be set up as the Zone

One Thermostat (master zone controller), and can

only be used with a W8835 zone panel.

Follow these steps to enter the Installer Setup:

M23499

3. Release the two blank keys when the screen on the ther-

mostat matches the screen below.

DONE

M22442

68-0287—04 12

Page 13

4. See screen below to review how the thermostat keys are

DONE

MON

THUSASUN

A

used during Installer Setup. See Table 3–4 for the

Installer Setup Numbers and Settings.

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

ADVANCE TO NEXT

INSTALLER

SETUP

NUMBER

INSTALLER SETUP

CURRENT

SETTING

ISU

Parameter

Number

Installer Setup

Name

110 Zone Number 0

120

USU

130

USU

140

Date (Year

Upper)

Date (Year

Lower)

Date (Month) 1-12 Default = 06

USU

150

USU

160

USU

165

USU

Date (Day) 1-31 Default = 15

Schedule Options 4

Restore energy

saving default

schedule

172 System Selection 1

173 Heat Pump Type 0

174 Number of Cool/

Compressor

Stages

176 Number of

Conventional

Heat or Heat

Pump Aux Stages

180 Fan Operation

Conventional

heat only

PRESS TO EXIT

INSTALLER SETUP

CHANGE THE

CURRENT

SETTING

M22443

5. Press the Done key to exit the Installer Setup screen.

Table 3. Installer Setup Menu.

(Factory Defaults Shown in Bold) Notes

Not zoned

1–9

20

21

Zone number

01-99 Default = 06 Select last two digits of current calendar year (2006

Select number that represents current

calendar month.

Select number that represents current

calendar date.

0

0

1

2

3

E

1

1

0

2

E

1

0

2

3

E

0

1

2

E

Seven-day programmable

Non-programmable

No

Yes

Conventional

Heat Pump

Heat Only No Fan

Auto Discover

Air to Air heat pump

Geothermal heat pump

1

none

2

Auto Discover

1

none

2

3

Auto Discover

Gas or oil furnace equipment controls fan

in heating

Electric furnace—thermostat controls fan in

heating

Equipment controls stage 1; thermostat

controls stage 2+

Auto Discover

Settings

Select zone number.

Zone 0 = not zoned

Zone 1 = master zone controller*

Zone 2–9 = satellite thermostat*

*Only change if used with Envirazone Panel.

Select first two digits of current calendar year (2006

for example) - (2001-2178 available).

for example) - (2001-2178 available).

Selection of a specific system setting will

automatically modify some default settings and/or

hide other installer setup options that follow.

Not shown if ISU172 = 3.

Conventional systems = number of cooling stages.

Heat Pump systems = number of compressor

stages.

Conventional systems = number of heating stages

(maximum of 3).

Heat Pump systems = number of auxiliary heat

stages (maximum of 2).

Only shown if ISU172 = 1 (conventional system).

Use 0 for fossil fuel systems (equipment controls

fan).

Use 1 for electric systems (thermostat controls fan).

Use 2 if stage 1 is radiant heating and stage 2+ is a

hot water fan coil.

13 68-0287—04

Page 14

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

Table 3. Installer Setup Menu. (Continued)

ISU

Parameter

Number

190 Reversing Valve

200 Back-up Heat

210 External Fossil

220 CPH for 1st

230 CPH for 2nd

240 CPH for 1st

250 CPH for 2nd

260 CPH for 3rd

270 CPH for

280

USU

300 Changeover 0

310 Deadband

320

USU

330

USU

Installer Setup

Name

O/B

Source Applies to

both Aux and

EmHeat

Fuel Kit

Stage Cool/

Compressor

Stage Cool/

Compressor

Stage

Conventional

Heat or Auxiliary

Stage

Conventional

Heat or 2nd

Stage Auxiliary

Stage Heat

Emergency Heat91-12

Continuous

Backlight

Temperature

Indication Scale01

Daylight Saving 2

0

1

E

0

1

1

0

1-6

E

1-6

E

1-12

E

1-12

E

1-12

E

0

1

1

32.0

21.5

42.5

53.0

63.5

74.0

84.5

95.0

0

1

(Factory Defaults Shown in Bold) Notes

Changeover valve—O/B terminal is

energized in cooling

Changeover valve—O/B terminal is energized

in heating

Auto Discover

Electric backup heat

Fossil fuel backup heat

External Fossil Fuel kit controls backup

heat*

Thermostat controls backup heat

3—cph recommended for compressors

1, 2, 4, 5, 6—other cycle rate settings

Auto Discover

3—cph recommended for compressors

1, 2, 4, 5, 6—other cycle rate settings

Auto Discover

1—1 cph used for steam and gravity

3—3 cph used for hot water system and high

efficiency (90% or better) furnaces

5—5 cph used for standard fossil fuel forced

air (less than 80% efficient) systems

9—9 cph used for electric furnaces

2, 4, 6, 7, 8, 10, 11, 12—other cycle rate

settings

Auto Discover

1—1 cph used for steam and gravity

3—3 cph for hot water systems and high

efficiency (90% or better) furnaces

5—5 cph for standard fossil fuel forced air (less

than 90% efficient) systems

9—9 cph used for electric furnaces or electric

auxiliary heat for heat pump systems

2, 4, 6, 7, 8, 10, 11, 12—other cycle rate

settings

Auto Discover

1—1 cph used for steam and gravity

3—3 cph for hot water systems and high

efficiency (90% or better) furnaces

5—5 cph for standard fossil fuel forced air (less

than 90% efficient) systems

9—9 cph used for electric furnaces or electric

auxiliary heat for heat pump systems

2, 4, 6, 7, 8, 10, 11, 12—other cycle rate

settings

Auto Discover

Default

Only shown if heat pump is selected.

Backlight not on continuously. Thermostat

backlight comes on with each key press.

Backlight is on continuously.

Manual

Auto

3°F 2.0°C

2°F 1.5°C

4°F 2.5°C

5°F 3.0°C

6°F 3.5°C

7°F 4.0°C

8°F 4.5°C

9°F 5.0°C

Note: degrees C is not same as degrees F

Fahrenheit temperature display

Celsius temperature display

Enabled (US 2007)

Disabled

Enabled (US 1987)

Settings

Only shown if ISU172 = 2.

Only shown if ISU172 = 2 and ISU176 = 1 or

greater.

*Cannot control dual fuel when used with W8835

Envirazone Panel.

Only shown if ISU172 = 2 and ISU200 = 1.

Only shown if ISU174 = 2.

Only shown if ISU172 = 2 and ISU176 = 1 or higher.

Default varies based on types of heating.

Only shown if ISU176 = 2 or for Heat Pump systems

with 2 stages of Auxiliary Heat.

Default varies based on types of heating.

Only shown if ISU176 = 3.

Default varies based on types of heating.

If backlight is on continuously, it is low-intensity.

Light changes to full brightness after pressing any

key.

Auto Changeover allows user to choose heat, cool,

off or auto. When set to Auto the thermostat will

automatically choose heat or cool based on room

temperature and heat/cool set points. Manual

changeover allows the user to manually toggle

between heat, cool and off.

Only shown if ISU300 = 0. The deadband indicates

the minimum number of degrees that are allowed

between the heat and cool settings when in auto

changeover. For example, if the deadband is set to

3°F and the cool setpoint is 75°F the warmest heat

setpoint allowed would be 72°F.

Set to 0 in areas that do not follow daylight savings

time.

68-0287—04 14

Page 15

ISU

Parameter

Number

340 Indoor Temp

342 Outdoor Temp

345 Dual Fuel Heat

346 Dual Fuel Heat

347 Droop

350 Heat Pump

360 Heat Pump

365 Discharge Temp

366 Zoning High

367 Zoning Low

Installer Setup

Name

Sensor

Sensor

Pump Control10

Pump Upstage to

Furnace Timer (in

hours)

Temperature

Balance Point

(also compressor

lockout)

Temperature

Auxiliary Heat

Lockout

Temperature

Sensor

Temperature

Limit

Temperature

Limit

Table 3. Installer Setup Menu. (Continued)

(Factory Defaults Shown in Bold) Notes

0

1

2

E

0

1

2

1

0

0.5

1.5

2

3

4

5

6

8

10

12

14

16

2

3

4

5

40 4.5

0

5-15

10 -12

15

20 -6.5

25 -4

30 -1

35 1.5

45 7

50 10

55 13

60 15.5

0

5-15

10 -12

15 -9.5

20 -6.5

25 -4

30 -1

35 1.5

40 4.5

45 7

50 10

55 13

60 15.5

65 18.5

E

0

1

160

0

110–170

40

0

35-50

Thermostat location only

Remote indoor sensor(s) location(s) only

Average between thermostat and sensor

locations

Auto Discover

None

Yes

Droop Control

No Droop Control

Droop Control with Auxiliary heat lockout

1 hr.

Disabled

0.5 hrs.

1.5 hrs.

2 hrs.

3 hrs.

4 hrs.

5 hrs.

6 hrs.

8 hrs.

10 hrs.

12 hrs.

14 hrs.

16 hrs.

2°F 1.0°C

3°F 1.5°C

4°F 2.0°C

5°F 2.5°C

40°F 4.5°C

No heat pump compressor lockout

5°F -15.0°C

10°F -12.0°C

15°F -9.5°C

-9.5

20°F -6.5°C

25°F -4.0°C

30°F -1.0°C

35°F 1.5°C

45°F 7.0°C

50°F 10.0°C

55°F 13.0°C

60°F 15.5°C

(Show 1/2 degree C)

No heat pump auxiliary lockout

5°F -15.0°C

10°F -12.0°C

15°F -9.5°C

20°F -6.5°C

25°F -4.0°C

30°F -1.0°C

35°F 1.5°C

40°F 4.5°C

45°F 7.0°C

50°F 10.0°C

55°F 13.0°C

60°F 15.5°C

65°F 18.5°C

(Show 1/2 degree C)

Auto Discover

None

Remote

160°F (71°C)

Disabled

110°F to 170°F (43.5°C to 76.5°C)

160°F (71°C)

Disabled

35°F to 50°F (1.5°C to 10°C)

Settings

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

Indoor temperature sensors will display the

temperature at the sensor location or an average of

two indoor temperature sensors, not including the

temperature sensor in the thermostat. The

temperature sensor in the thermostat is disabled

when using remote indoor temperature sensor(s).

An outdoor temperature sensor is required for heat

pump compressor lockout (ISU350), heat pump

auxiliary lockout (ISU360), dual fuel heat pump

balance point (ISU360) and Humidification with

Frost Protection (ISU372).

See Dual Fuel Heat Pump control on page 23.

See Dual Fuel Heat Pump control on page 23.

The fossil fuel will turn on when the outdoor

temperature is above the balance point if the room

temperature droops below the selected droop

temperature setting, and the compressor will be

disabled.

Only shown for heat pump applications with an

outdoor temperature sensor present.

If electric backup is selected then the default is No

Compressor lockout.

Only shown for heat pump applications with an

outdoor temperature sensor present.

Only Shown if ISU110 = 1 (Master Zone Controller)

and Discharge Temperature Sensor is available.

Only Shown if ISU110 = 1 (Master Zone Controller)

and Discharge Temperature Sensor is available.

15 68-0287—04

Page 16

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

Table 3. Installer Setup Menu. (Continued)

ISU

Parameter

Number

368 Staging

369 Staging

370 Indoor Humidity

372 Indoor

374 Hum Fan Action 0

379 Dehumidification

382 Dehumidification

383 Over-Cooling

384 Dehumidification

386 Whole house

390 Southern

391 Southern

392 Southern

393 Southern

Installer Setup

Name

Discharge

Temperature

High Limit

Discharge

Temperature

Low Limit

Sensor

Humidification

Control

Control

system modes

Limit

Fan Action

dehumidification

lockout

Dehumidification

Away Mode

Dehumidification

Away Mode Fan

Setting

Dehumidification

Away Mode Low

Limit

Temperature

Setting

Dehumidification

Away

Temperature

Setting

(Factory Defaults Shown in Bold) Notes

110

0

80-130

55

0

50-60

1

0

2

E

E

0

1

3

8

9

1

2

3

0

1

3

0

2

3

31.5

10.5

21.0

0

1

0

1

0

1

0

1

2

76

70-80

85

70-99

110°F (43.5°C)

Disabled

80°F to 130°F (26.5°C to 54.5°C)

55°F (13°C)

Disabled

50°F to 60°F (10°C to 15.5°C)

Internal—sensor in thermostat

Disabled

Remote

Auto Discovered

Auto Discover

Off

Humidify (no frost protection)

Humidify (with frost protection)

Desert Humidity Control on heat, cool, and off

(no frost protection)*

Desert Humidity Control on heat, cool, and off

(with frost protection)*

Humidify only while fan or heat is on

Humidify will force fan on

Humidify only when heat is on

Humidifier operates independent of fan

None

Dehumidify with Air Conditioning

Whole house Dehumidifier

Dehumidifier in Cool or Auto (when last call

was for cooling)

Dehumidifier in Cool, Off, Heat, EmHeat, or

Auto

Dehumidifier in Cool, Off, or Auto (when last

call was for cooling)

3°F 1.5°C

1°F 0.5°C

2°F 1.0°C

(Show 1/2 degree C)

System fan turns on with dehumidifier

Dehumidifier operates independent of system

fan

Disabled

Enabled

No

Yes

Fan Auto

Fan On

Fan Circulate

Default = 76°F

70°F–80°F

Default = 85°F

70°F–99°F

Settings

Only Shown if ISU110 = 1 (Master Zone Controller)

and ISU174 = 2 or more. Must have Discharge

Temperature Sensor present.

Only Shown if ISU110 = 1 (Master Zone Controller)

and ISU176 = 2. Must have Discharge Temperature

Sensor present.

If there is a remote sensor installed and the setting

is either auto discover or “remote” the internal

thermostat humidity sensor is disabled. If set to

“internal” the internal thermostat sensor is

presented on the screen. If set to “disabled” the

internal sensor and any remote sensors are

disabled, there will be no humidity displayed and will

have no humidification/dehumidification control.

Shown only if ISU370 = 1, 2 or E.

* DATS required for Desert Humidification

Setting 0 will run the humidifier only during a call for

heat or if the fan is running.

Setting 1 will force the fan to run if there is a call for

humidification.

Setting 2 will humidify only during a call for heat.

Setting 3 assumes the humidifier has it own internal

fan and will not require the system fan or heat to be

operating during a call for humidification.

Option 1 uses dehum terminal as a normally closed

relay to wire to a low-speed fan terminal.

Option 3 uses dehum terminal as a normally open

relay to wire to a whole-house dehumidifier.

Only shown if ISU379 = 1.

Only shown if ISU379 = 3.

Not shown if ISU379 = 0.

ISU 391-394 will only be shown if ISU390 = 1.

If ISU391 = 1 or 2 to help remove condensation

from the air handler and the A-coil, some humidity

may be re-introduced into the living space.

The air conditioner will be allowed to cool the living

space to this temperature to meet the humidity

setting that set in ISU394.

The A/C will maintain this temperature provided the

humidity setting is satisfied. This temperature

setting can not be set lower than the temperature

set in ISU 392.

68-0287—04 16

Page 17

ISU

Parameter

Number

394 Southern

400 Ventilation control 0

401 Number of

402 Total house

403 Ventilation CFM 160

404 Max ventilation

405 Ventilation Fan

406 Ventilation in

430 Ventilation

431 Ventilation

432 Ventilation

450 DATS Inhibit 0

500

USU

502 Furnace filter

Installer Setup

Name

Dehumidification

Away

Dehumidification

Setting

bedrooms

Sq. Ft.

percentage limit5030-60

Action

High Humidity10

lockout

lockout high

temperature

lockout low

temperature

Furnace Filter

Change

Reminder

reminder run time

equipment counts

65

40-70

1

2

3

4

2

1-6

10

10-50

30-195

100

1

2

0

1

2

3

100 38

90 32

95 35

105 40.5

110 43.5

-10 -23.5

-20 -29

-15 -26

-5 -20.5

-0 -18

35 1.5

40 4.5

45 7

50 10

55 13

60 15.5

65 18.5

E

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

0

1

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

Table 3. Installer Setup Menu. (Continued)

(Factory Defaults Shown in Bold) Notes

Default = 65%

40%–70% relative humidity

No ventilation

Ventilation on at all times

Ventilation on except during sleep period

Vent all with lockouts

Vent off sleep with lockouts

Default = 2

1–6 bedrooms

Default = 1000 sq. ft.

1000–5000 sq. ft. in increments of 100

Default = 160 CFM

30–195 CFM in increments of 5

Default = 50%

30%–60%

unlimited

Vent on will force fan on also

Vent will not force fan ON

On

Off

Disabled

Lockout for high temperatures

Lockout for low temperatures

Lockout for high and low temperatures

100°F 38°C

90°F 32°C

95°F 35°C

105°F 40.5°C

110°F 43.5°C

-10°F -23.5°C

-20°F -29.0°C

-15°F -26.0°C

-5°F -20.5°C

0°F -18.0°C

Disabled

35°F 1.5°C

40°F 4.5°C

45°F 7.0°C

50°F 10.0°C

55°F 13.0°C

60°F 15.5°C

65°F 18.5°C

Auto Discover

Disabled

10 R.T. Days

30 R.T. Days

60 R.T. Days

90 R.T. Days

120 R.T Days

180 R.T. Days

270 R.T. Days

365 R.T. Days

30 C Days

60 C Days

90 C Days

120 C Days

180 C Days

365 C Days

Counts runtime Heat and Cool

Counts runtime Cool only

Settings

Set the desired humidity level to maintain within the

living space

If ISU300 = 0, ISU401-405 will not be shown.

Not ASHRAE

Not ASHRAE

The thermostat will determine if ventilation is

meeting ASHRAE standard 62.2. The display will

show a P above the setup number if the setting

passes the ASHRAE standard, or F if it does not.

Best practice is to move the setting down until F is

displayed, then move up one setting to the minimum

passing value.

Only shown if ISU372 and ISU400 are not set to 0.

When set to On will use ventilation to remove

humidity when thermostat is in the heat mode.

Outdoor temperature sensor required for high and

low temperature lockouts.

The DATS will cycle the cooling off at the selected

temperature to prevent coil freezing.

17 68-0287—04

Page 18

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

Table 3. Installer Setup Menu. (Continued)

ISU

Parameter

Number

510

USU

520

USU

530

USU

540

USU

550 Number of

560 Number of

580 Min Compressor

600 Heat Temp

610 Cool Temp

640

USU

650 Extended Fan on

660 Extended Fan on

670

USU

680 Temp Control

690 Temp Control

700 Temperature

Installer Setup

Name

Humidifier Pad

Replacement

Reminder

UV Lamp

Replacement

Reminder

Adaptive

Intelligent

Recovery

Number of

Periods

Periods:

Weekdays

Periods:

Weekend Days

Off Time

Range Stops9040-90

Range Stops6060-99

Clock Format 12

time Heat (Blower

Off Delay Heat)

time Cool (Blower

Off Delay Heat)

Keypad Lockout 0

Heat

Cool

Display Offset

E

0

1

2

3

E

0

1

2

1

0

4

2

4

2

4

2

5

0

1

2

3

4

24

0

30

60

90

120

0

30

60

90

120

1

2

2

1

3

2

1

3

0

-3

-2

-1

1

2

3

(Factory Defaults Shown in Bold) Notes

Auto Discover

Disabled

90 C Days or 30 R.T. Days

180 C Days or 60 R.T. Days

365 C Days or 90 R.T. Days

Auto Discover

Disabled

365 Days

730 Days (2 years)

Adaptive

Conventional

4 Periods

2 Periods

4 Periods

2 Periods

4 Periods

2 Periods

5 minutes

Off

1 minute

2 minutes

3 minutes

4 minutes

Default = 90°F

40°F–90°F (Show 1/2 degree C)

Default = 60°F

60°F–99°F (Show 1/2 degree C)

12 Hour

24 Hour

Off

30 seconds

60 seconds

90 seconds

120 seconds

Off

30 seconds

60 seconds

90 Seconds

120 Seconds

Unlocked

Partial Locked

Full Locked

Standard (recommended)

Less Aggressive temp control (may cause

temp undershoot)

More Aggressive temp control (may cause

temp overshoot)

Standard (recommended)

Less Aggressive temp control (may cause

temp undershoot)

More Aggressive temp control (may cause

temp overshoot)

0°F 0 °C — (no difference in

displayed temperature and actual room

temperature)

-3°F -1.5°C

-2°F -1°C

-1°F -.5°C

1°F .5°C

2°F 1°C

3°F 1.5°C

Settings

Display will show Calendar Days if ISU372 = 0; Run

Time Days if ISU372 = 1 or 3.

See Temperature Recovery on page 32.

4 periods = Wake, Leave, Return, and Sleep

2 periods = Wake and Sleep

This can be used to remove condensation from Acoil; however, could re-introduce humidity into the

living space.

68-0287—04 18

Page 19

CAUTION

ISU

DONE

Parameter

Number

701 Humidity Display

710 Restore Factory

Installer Setup

Name

Offset

Defaults

0

-12

-11

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

1

2

3

4

5

6

7

8

9

10

11

12

0

1

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

Table 3. Installer Setup Menu. (Continued)

(Factory Defaults Shown in Bold) Notes

0%

-12%

-11%

-10%

-9%

-8%

-7%

-6%

-5%

-4%

-3%

-2%

-1%

1%

2%

3%

4%

5%

6%

7%

8%

9%

10%

11%

12%

No

Yes

Settings

Restoring factory defaults will re-set installer setup

and programming.

INSTALLER SYSTEM TEST

Use the Installer System Test to test the heating, cooling and

fan (and emergency heat for heat pump systems).

Equipment Damage Hazard.

Minimum compressor off time is bypassed during

Installer System Test

Avoid cycling compressor quickly.

How to Use the Installer System Test

The Installer Test is part of the Installer Setup Menu.

1. Enter the Installer System Test by entering the Installer

Setup.

2. Note that the test appears at the end of the Installer

Setup Numbers.

3. See Fig. 28 to review how the thermostat buttons are

used during the Installer System Test. See Table 6 for

available Installer System Tests.

4. If installed with a Discharge Air Temperature Sensor

(ISU365=1) press the “MORE” button to view the discharge temperature, and press Cancel to return to the

Installer test screen.

SYSTEM TEST

NUMBER

DONE KEY

EXITS INSTALLER

SYSTEM TEST

SYSTEM STATUS

NUMBER

UP ARROW KEY

ADVANCES TO

NEXT SYSTEM

TEST NUMBER

UP ARROW

TURNS THE

SYSTEM ON

DOWN ARROW

TURNS THE

SYSTEM OFF

M22428

Fig. 28. Review thermostat buttons used during Installer

System Test.

19 68-0287—04

Page 20

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

SCHED HOLD CLOCK SCREEN MORE

TUE

AM

FAN

AUTO

SYSTEM

HEAT

Following

Schedule

Inside

Set To

M23500

FAN

SELECTS

ON/AUTO/CIRC

SYSTEM

SELECTS EM.

HEAT/HEAT/OFF/COOL

UP ARROW

RAISES

TEMPERATURE

SETTING

DOWN ARROW

LOWERS TEMPERATURE

SETTING

SCHED

ENTERS

SCHEDULING

MODE

MORE

SHOWS ADDITIONAL

ACCESSORY AND

MAINTENANCE

OPTIONS

SCREEN

LOCKS OUT THE

SCREEN TO ALLOW

FOR CLEANING

CLOCK

SETS THE

TIME

FORWARD

OR BACK

HOLD

SETS A PERMANENT

HOLD AND ACTIVITIES

VACATION HOLD

Humidity

SCHED HOLD CLOCK SCREE MORE

TU

A

M

FAN

AUTO

SYSTEM

HEAT

Following

Schedule

Inside

Set To

M23501

FAN

SHOWS FAN

SETTING

TUE

SHOWS CURRENT DAY

OF THE WEEK

SYSTEM

SHOWS

CURRENT

SYSTEM

POSITION

TIME

DISPLAY CURRENT

TIME OF DAY, HOLD

TIME REMAINING OR

NUMBER OF VACATION

DAYS REMAINING

INSIDE TEMPERATURE

SHOWS THE CURRENT INSIDE

TEMPERATURE

SET TO

TEMPERATURE

SHOWS THE

CURRENT SET

TEMPERATURE

FOLLOWING

SCHEDULE

SHOWS THE

THERMOSTAT IS

FOLLOWING THE

PROGRAMMED

SCHEDULE

Humidity

Installer System Tests

Table 4. Installer System Test.

System Test Number Test Type ISU Value System Status Number and Description

Test 1 Installer Test Cool 0

1

2

Test 2 Installer Test Fan 0

1

Test 3 Installer Test Heat 0

1

2

3

4

Test 4 Emergency Heat Test 0

1

2

Test 5 Installer Test Humidifier 0

1

Test 6 Installer Test Dehumidifier 0

1

Test 7 Installer Test Ventilator 0

1

Err Diagnostic Recall 00-99 See “Communication Error Codes” on page 35

Press the Next button to go to the beginning of the Installer Setup or press the Done button to exit the Installer System Test.

Off

Cool Stage 1

Cool Stages 1 & 2

Off

Fan On

Off

Heat Stage 1

Heat Stages 1, 2

Heat Stages 1,2,3

Heat Stages 1,2,3,4

Off

AUX Heat Stage 1

AUX Heat Stages 1 and 2

Off

Humidifier On

Off

Dehumidifier On

Off

Ventilator On

When VisionPRO® IAQ is used in a zoning system you must exit the installer test on one thermostat before entering the installer

test on another thermostat.

OPERATION

Thermostat Keys

Thermostat Display

68-0287—04 20

Page 21

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

MORE

DONE CANCEL

DEHUMIDIFIER

Inside

Humidity

FROST

M23518

MORE

DONE CANCEL

DEHUMIDIFIER

Inside

Humidity

M23496

CURRENT

INDOOR

HUMIDITY

DEHUMIDIFIER

SETTING

(AUTO/OFF)

HUMIDITY SET

POINT

DONE CANCEL

DEHUMIDIFIER

Inside

M23514

System and Fan Settings

System

The System key selections vary based on your heating and/or

cooling system type.

Heat — Thermostat controls the heating system.

Off — Both heating and cooling systems are off.

Cool — Thermostat controls the cooling system.

Auto — Thermostat automatically changes between heating

and cooling operation, depending on indoor temperature.

Em. Heat — Emergency heat cycles to maintain temperature.

Compressor is locked out and auxiliary heat turns on as

needed.

Fan

The Fan key selections vary based on the heating and/or

cooling system type.

On — Fan runs continuously. Use this setting for improved air

circulation or for more efficient central air cleaning.

Auto — fan follows the fan program schedule.

Circ — fan runs randomly approximately 35% of the time. Use

this setting for improved air circulation or for more efficient

central air cleaning when you do not want the fan running

continuously.

1. Press the More key until the inside humidity level set-

point is shown.

2. Use Up and Down arrow keys, located to the right of the

humidity setpoint, to set desired humidity level.

3. Press Done key.

Control Dehumidification Level

The VisionPRO® IAQ Touchscreen Thermostat reads the

inside humidity level and allows for a dehumidification setting,

and can be set to dehumidify using the air conditioner or a

whole house dehumidifier.

Control Humidification Level

The VisionPRO® IAQ Touchscreen Thermostat reads the

inside humidity level and allows for a humidification setting with

or without frost protection.

WITH FROST PROTECTION

Controlling humidification with frost protection requires an

outdoor temperature sensor. The Frost Index (scale 1–10) will

limit the amount of humidity added to the air based on outdoor

temperature, with 1=most dry and 10=most humid. This

prevents frost from accumulating on windows.

WITHOUT FROST PROTECTION

The frost setpoint is not displayed, but a humidity setpoint can

still be set.

With Air Conditioner

The set range for dehumidification is 40 to 80%, and can be set

in 5% increments. The thermostat must be in Cool mode or

Auto mode when the previous call was a call for cooling.

Dehumidifying in this manner runs the air conditioner longer

than simply cooling the house would require, and can be set to

run 1, 2, or 3°F below the temperature setpoint. This feature is

called Dehumidification Droop Control.

NOTE: You must use this setting if:

— No powered, whole house dehumidifier is present,

and

— The system uses the air conditioner as the

dehumidifier.

21 68-0287—04

Page 22

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

MORE

DONE CANCEL

DEHUMIDIFIER

Inside

Humidity

M23515

DONE

M23520

DEHUMIDIFICATION DROOP CONTROL

In extremely high humidity conditions, the thermostat keeps

the air conditioner running (energizing Y/Y2 and G) for up to

3°F below the temperature setpoint. It does this while trying to

achieve the desired humidity setpoint and balancing that with

the temperature setpoint. The thermostat controls up to 3° F

below the temperature setting until either the humidity setpoint

is satisfied or conditions change.

With Whole House Dehumidifier

Controls humidity levels in the house by dehumidifying without

the use of the air conditioner. This setting requires a dedicated

unit for dehumidification. Dehumidification with a whole house

dehumidifier will take place when the thermostat is in the Cool,

Off, Auto, Heat or Em.Heat modes. If the system is installed

with a whole house humidifier, dehumidification with a whole

house dehumidifier will only take place when the thermostat is

in Cool, Off or Auto modes (Auto only if the previous call was a

call for cooling).

When controlling a whole-house dehumidifier the user can

toggle between auto (dehumidify when needed based on

setpoint and current humidity level) and off (see Fig. 29).

Ventilation occurs two ways:

AUTOMATIC

Uses installer setup to determine amount of ventilation

required based on house and equipment size. To disable

automatic ventilation, switch the ventilation setting to Off. The

user can still use the timer to request ventilation.

ON DEMAND

User can also set a vent timer that will circulate fresh air into

the home for a set period of time from 20 to 180 minutes in 20minute increments. The vent timer is enabled whether

ventilation is set to “Auto” or “Off.”

Fig. 29. Display when controlling a whole-house

dehumidifier.

1. Press the More key until the inside humidity percent and

dehumidification setpoint are shown.

2. Use Up and Down arrow keys, located to the right of the

dehumidifier setpoint, to set desired humidity level for

dehumidification in the summer.

3. Press Done key.

Ventilation Control

Ventilation setup options include ISUs 400, 401, 402, 403, and

404. Combined, these will determine a percentage of

maximum ventilation limit. The thermostat will calculate

whether or not this level of ventilation meets ASHRAE

standard 62.2. If ASHRAE 62.2 is met a P will appear in the

display above the setup number. If ASHRAE 62.2 is not met an

F will appear in the display above the setup number.

Passing ASHRAE 62.2 is only applicable when vent is running.

For example, if installer has set to not vent during sleep period,

ASHRAE 62.2 would be met at all times except during sleep

period.

68-0287—04 22

VENT

Minutes

MORE

DONE CANCEL

M23519

VENTILATION IN HIGH HUMIDITY CONDITIONS (SETUP FUNCTION 0406)

If Ventilation Control is available (setup function 0400 set to 1

or 2), this allows the ventilation equipment to turn on if the

humidity rises approximately 10% above the RH setting in

heating mode to exhaust the extra humidity.

HEAT PUMP OPERATION

Heat Pump LED Indication

A red LED indication is located in the upper right corner of the

thermostat. It is only visible when lighted.

When the L terminal is wired to an equipment monitor, the LED

signals when a check or fail signal is sent to the thermostat

from the system. This is operational in the Heat, Off, Cool or

Auto positions.

Page 23

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

30

M22441

BALANCE

POINT

COMPRESSOR ONLY

FOSSIL FUEL ONLY

OUTDOOR TEMPERATURE

50

35

OUTDOOR TEMPERATURE

BALANCE

POINT

AUX.

LOCKOUT

COMPRESSOR ONLY

COMPRESSOR+2 °F

DROOP UPSTAGE TO

FURNACE

FURNACE ONLY

M23497

Heat Pump Emergency Heat LED Indication

The thermostat uses a red LED indicator that lights when the

thermostat is in the Emergency Heat mode. The LED is located

in the upper right corner of the thermostat. It is visible only

when on.

Heat Pump Temperature Lockouts

Dual Fuel Heat Pump and Outdoor Temperature

Sensor

In this operation, there is no external fossil fuel kit (dual fuel kit)

installed; the thermostat controls this function.

1. Choose correct heat pump application in Installer Setup

Number 0172.

2. Choose Fossil Fuel Option as the backup heat source

in Installer Setup Number 0200.

3. Choose No External Fossil Fuel Kit Option is control-

ling back up heat in Installer Setup Number 0210.

4. Choose Outdoor Temperature Sensor for Heat Pump

Temperature Lockouts in Installer Setup Number 0342.

5. Choose appropriate Balance Point Temperature in

Installer Setup Number 0350.

Dual Fuel Heat Pump Control

Balance Point Only (ISU345 = 0)

NOTE: System must have an outdoor temperature sensor.

When the outdoor temperature is above the selected balance

point temperature, only the compressor operates and the fan

(G terminal) energizes when the thermostat calls for heat. See

Fig. 30. When the outdoor temperature is below the selected

balance point temperature, only the fossil fuel (auxiliary heat)

operates and the fan (G terminal) does not energize when the

thermostat calls for heat.

Balance Point/Auxiliary Heat Lockout Plus Droop

(ISU 345 = 2)

When the outdoor temperature is above the Auxiliary Heat

Lockout Temperature only the compressor operates; below the

balance point temperature (setup function 0360) only the fossil

fuel operates. Between the balance point temperature and

auxiliary heat lockout temperature the compressor will operate.

However, the fossil fuel will turn on if the room temperature

droops below the selected droop temperature setting,

compressor will be disabled.

Fig. 31. Balance Point with Auxiliary Lockout Temperature.

AUXILIARY LOCKOUT FOR ELECTRIC HEAT BACKUP

Heat Pump systems with electric heat backup can select a

compressor lockout temperature (function 0350) and/or

auxiliary heat lockout temperature (function 0360). When the

outdoor temperature is below the compressor lockout

temperature, only the auxiliary heat operates. When the

outdoor temperature is between the compressor and auxiliary

lockout temperatures, both the compressor and auxiliary heat

can operate.

NOTE: System must have an outdoor temperature sensor.

Heat Pump with Electric Auxiliary (Backup) Heat and

Outdoor Temperature Sensor

1. Choose correct heat pump application in Installer Setup

Number 0172.

2. Choose Electric as Auxiliary (Backup) Heat Source in

Installer Setup Number 0200.

3. Choose Outdoor Temperature Sensor in Installer

Setup Number 0342.

4. Choose Compressor Lockout Temperature in Installer

Setup Number 0350.

5. Choose Auxiliary Lockout Temperature in Installer

Setup Number 0360.

Fig. 30. Dual Fuel Heat Pump Operation in Heat mode with

Balance Point Plus Droop (ISU345 = 1)

The fossil fuel will turn on when the outdoor temperature is

above the balance point if the room temperature droops below

the selected droop temperature setting, and the compressor

will be disabled.

Balance Point Set.

NOTE: There is a 5°F deadband between the Compressor

and Auxiliary Heat Lockout Temperatures.

Operation in Heat Mode

When the outdoor temperature is below the Compressor

Lockout Temperature, only the Auxiliary Heat operates.

When the outdoor temperature is above the Auxiliary Lockout

Temperature, only the Compressor operates. See Fig. 32.

23 68-0287—04

Page 24

VISIONPRO® IAQ TOTAL HOME COMFORT SYSTEM

COMPRESSOR ONLY

50

BOTH COMPRESSOR AND

AUXILIARY HEAT

35

AUXILIARY ONLY

OUTDOOR TEMPERATURE

AUXILIARY

LOCKOUT

TEMPERATURE

COMPRESSOR

LOCKOUT

TEMPERATURE

M19950

Fig. 32. Heat Pump Operation with Lockout

Temperatures Set.

When the outdoor temperature is between the two

temperatures, both the Compressor and Auxiliary Heat operate.

Table 5. Sequence of Operation for Conventional Systems.

System Setting Fan Setting Call for Action Energize Terminals Screen Message

Off Auto None None None

Cool or Auto Auto None None None

Cool or Auto Auto Stage 1 Cooling Y, G Cool On

Cool or Auto Auto Stage 1 and Stage 2 cooling

Heat or Auto Auto None None None

Heat or Auto Auto Stage 1 heating

Heat or Auto Auto Stage 1 and Stage 2 heating

Heat or Auto Auto Stage 1, Stage 2 and Stage 3 heating

a

G energizes only if Installer set up number 180 is set to Option 1 (Electric Heat).

b

If installer setup (ISU174) is configured for two stages of cooling.

c

If installer setup (ISU 176) is configured for two or more stages of heating.

d

If installer setup (ISU 176) is configured for three stages of heating.

e

G energizes only if Installer set up number 180 is set to Option 1 (Electric Heat) or 2 (Hot water coil).

Once the thermostat is placed into the Emergency Heat mode,

the compressor and auxiliary lockout features are turned off. In

the Emergency heat mode, the compressor is locked out. The

first stage of heat is whatever is connected to the AUX

terminal. The second stage of heat is connected to the AUX2.

terminal.

Operating Sequence

The thermostat energizes specific terminal(s), depending on

the demand for heating, cooling or fan. The thermostat screen

shows the time, inside temperature, system and fan selections.

Additional indicators are shown when the heating, cooling or

fan is energized. See Table 5 and 6 for specification

information.

b

, G

Y, Y 2

a

W1, G

W1, W2c, G

c

W1, W2

, W3d, G

e

e

Cool On

Heat On

Heat On

Heat On

Operation in Emergency Heat Mode