Page 1

LIMITED WARRANTY

ADEMCO 5817

L

R

Honeywell International Inc., acting through its Security & Custom Electronics business

("Seller") 165 Eileen Way, Syosset, New York 11791, warrants its product(s) to be in

conformance with its own plans and specifications and to be free from defects in materials

and workmanship under normal use and service for 24 months from the date stamp control

on the product(s) or, for product(s) not having a manufacturer’s date stamp, for 12 months

from date of original purchase unless the installation instructions or catalog sets forth a

shorter period, in which case the shorter period shall apply. Seller's obligation shall be

limited to repairing or replacing, at its option, free of charge for materials or labor, any

product(s) which is proved not in compliance with Seller's specifications or proves defective in

materials or workmanship under normal use and service. Seller shall have no obligation

under this Limited Warranty or otherwise if the product(s) is altered or improperly repaired

or serviced by anyone other than Honeywell factory service. For warranty service, return

product(s) transportation prepaid, to Honeywell Factory Service, 165 Eileen Way, Syosset,

New York 11791.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, OF MERCHANTABILITY, OR

FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, WHICH EXTEND BEYOND

THE DESCRIPTION ON THE FACE HEREOF. IN NO CASE SHALL SELLER BE LIABLE

TO ANYONE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR BREACH

OF THIS OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED, OR UPON ANY OTHER

BASIS OF LIABILITY WHATSOEVER, EVEN IF THE LOSS OR DAMAGE IS CAUSED BY

THE SELLER'S OWN NEGLIGENCE OR FAULT.

Seller does not represent that the product(s) it sells may not be compromised or

circumvented; that the product(s) will prevent any personal injury or property loss by

burglary, robbery, fire or otherwise; or that the product(s) will in all cases provide adequate

warning or protection. Customer understands that a properly installed and maintained

alarm system may only reduce the risk of a burglary, robbery, fire, or other events occurring

without providing an alarm, but it is not insurance or a guarantee that such will not occur or

that there will be no personal injury or property loss as a result. CONSEQUENTLY,

SELLER SHALL HAVE NO LIABILITY FOR ANY PERSONAL INJURY, PROPERTY

DAMAGE OR OTHER LOSS BASED ON A CLAIM THAT THE PRODUCT(S) FAILED TO

GIVE WARNING. HOWEVER, IF SELLER IS HELD LIABLE, WHETHER DIRECTLY OR

INDIRECTLY, FOR ANY LOSS OR DAMAGE ARISING UNDER THIS LIMITED

WARRANTY OR OTHERWISE, REGARDLESS OF CAUSE OR ORIGIN, SELLER'S

MAXIMUM LIABILITY SHALL NOT IN ANY CASE EXCEED THE PURCHASE PRICE OF

THE PRODUCT(S), WHICH SHALL BE THE COMPLETE AND EXCLUSIVE REMEDY

AGAINST SELLER.

This warranty replaces any previous warranties and is the only warranty made by Seller on

this product(s). No increase or alteration, written or verbal, of the obligations of this Limited

Warranty is authorized.

165 Eileen Way, Syosset, New York 11791

Copyright © 2004 Honeywell International, Inc.

www.honeywell.com/security

¬19Ql

N6483V3 4/98 Rev. B

N6483V3 4/98 Rev. B

MULTI-POINT UNIVERSA

TRANSMITTE

INSTALLATION AND SETUP GUIDE

GENERAL INFORMATION

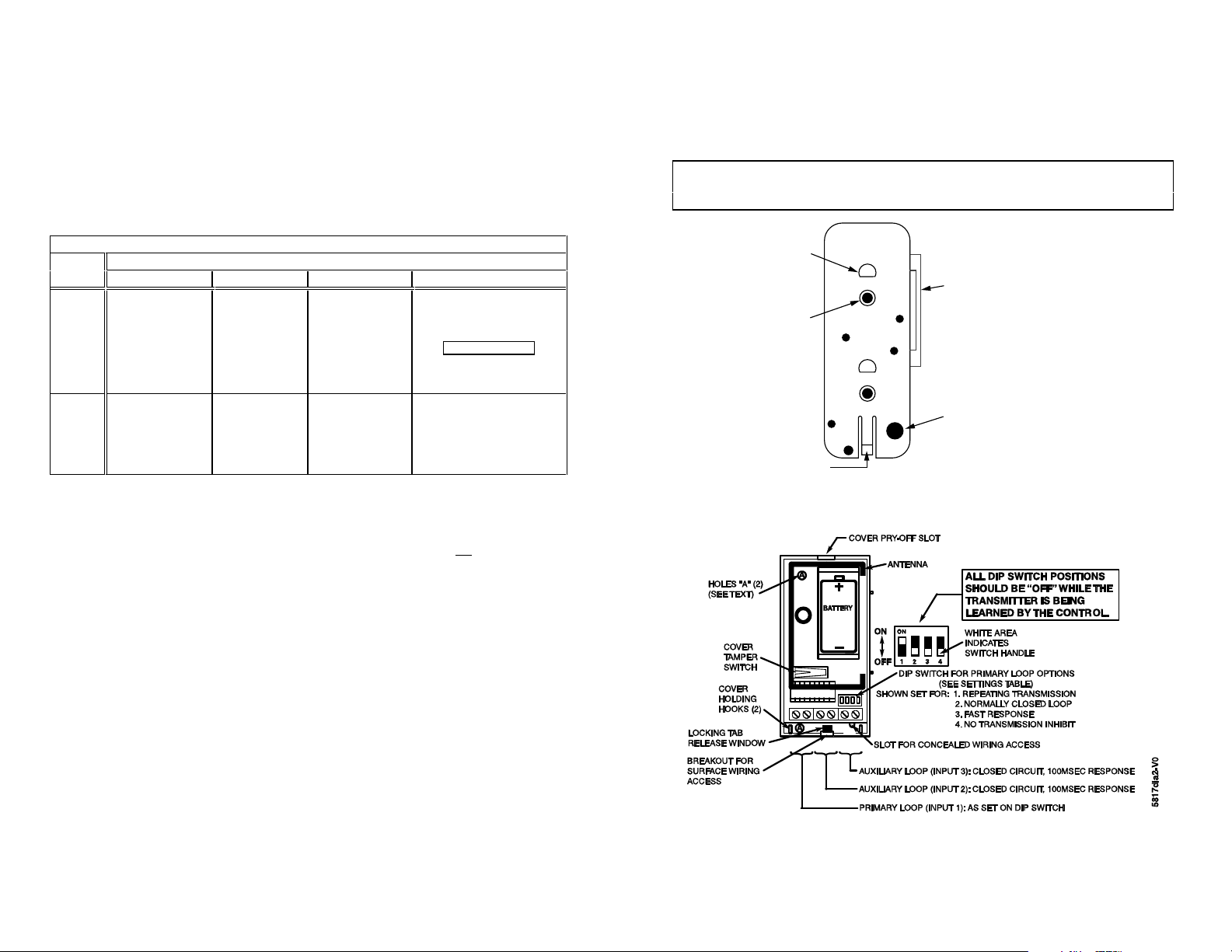

The 5817 Multi-Point Universal Transmitter may have three contact loops connected to it. Each

loop transmits a unique ID code to a 5800 wireless system receiver connected to the system

control panel. The Primary Loop has several DIP switch selectable options that determine its

connection requirements, response, and transmission characteristics (see DIP switch setting

table on next page). The two Auxiliary Loops are closed-circuit, with a nominal response time of

100mSec. For UL installations, no contact in any of the loops may be more than 3 feet from the

transmitter.

A built-in cover tamper switch is activated when the cover is removed.

ENROLLING THE TRANSMITTER IDs

The 5817 has its own unique identification codes permanently assigned during manufacture. It is

not necessary to program the transmitter IDs during installation. Instead, the control unit is

required to "enroll" the transmitter IDs at some point prior to the transmitter’s usage in the alarm

system.

The control unit’s installation manual contains general information on the "enrolling" procedure,

but the information given herein pertains specifically to the 5817.

1. Place a 3V battery in the battery holder, as described later in BATTERY

INSTALLATION/REPLACEMENT and as shown in Diagram 2. Observe polarity!

2. Make sure that the DIP switch’s 4 positions (see Diagram 2) are all OFF.

3. Set the system ready for enrolling the ID code of one of the 5817’s loops (inputs) to be

used, as described in the control’s instructions. The 5817 should be treated as "RF" (i.e.,

supervised RF) Type (mandatory for UL installations).

4. Proceed with enrolling the inputs of the loops to be used, as described in the control’s

instructions.

INSTALLATION

Mounting

For proper orientation of the unit in relation to its wall mounting plate and the loop wiring, read all

of this section before installing the unit.

The description that follows assumes that the unit will be mounted as shown in the diagrams. The

unit may, however, be installed in any direction, as long as the relationship of the unit to its

mounting plate is maintained.

Although two holes are provided in the unit that would permit mounting directly to a surface (holes

"A" in Diagram 2), it is recommended that the mounting plate be used, as described below, for

ease in removing the unit for servicing should it become necessary.

Before mounting the transmitter permanently, conduct Go/No Go tests (see control’s instructions)

to verify adequate signal strength and reorient or relocate the transmitter if necessary. When a

satisfactory location is found, remove the battery and proceed with installation.

1. Remove the transmitter’s cover by inserting the flat blade of a small screwdriver into the

pry-off slot at the end of the unit farthest from the cover’s decorative ribs, and twisting the

blade. Note: The open slot at the other end of the unit cannot be used as a cover pry-off.

2. Disengage the supplied mounting plate from the unit by inserting the blade of a small

screwdriver into the locking tab release window (see Diagram 2) and pressing it against the

case locking tab (see Diagram 1) while sliding the plate downward along the case back. Note:

For this application, the alignment guide strip along one edge of the plate serves no function

and may be broken away, if desired.

Page 2

3. If concealed wiring is to be used, feed the wires through the concealed wiring entry hole at

one corner of the plate (surface wiring is mentioned in Step 5 below).

4. Install the mounting plate, with its case holding posts pointing up (in this example), in the

location selected as described in the control unit’s installation instructions. Use the flat-head

screws supplied.

5. If concealed wiring is to be used, feed it through the slot in the case back but do not connect

to the terminal block yet. Surface wiring should enter via the thin "breakout" area provided in

the case wall.

6. Attach the case back to the mounting plate by sliding the keyhole slots in the case back down

onto the mounting plate’s hooks. The locking tab will click as the case back locks in place.

7 Set the DIP switch (after the control has enrolled the transmitter’s input IDs) for the desired

primary loop characteristics, as described in the table below.

SWITCH

P R I M A R Y L O O P O P T I O N S T A B L E

D I P S W I T C H P O S I T I O N

SETTING 1 2 3 4

ON

OFF

REPEATING

TRANSMISSION

(every 4 sec.)

UPON PRIMARY

LOOP FAULT

Use for high-priority

alarm, such as fire.

SINGLE

TRANSMISSION

PER PRIMARY

LOOP

CHANGE-OF-

STATE

NORMALLY

OPEN CIRCUIT

PRIMARY LOOP

NORMALLY

CLOSED

CIRCUIT

PRIMARY

LOOP

SLOW

PRIMARY LOOP

RESPONSE

(Approx. 200mSec

Normally Closed

Response Time)

FAST

PRIMARY LOOP

RESPONSE

(Approx. 5mSec

Normally Closed

Response Time)

3 MINUTE, ALL LOOP

TRANSMISSION INHIBIT

AFTER RESTORE OF

PRIMARY LOOP

See Note c.

This affects the Aux. loops as

well. Use on frequently used

doors, etc. to conserve battery.

NO

TRANSMISSION

INHIBIT

Notes: a. While the transmitter is being enrolled by the control, all DIP switch positions should

be OFF.

b. Except in the case of the position 4 ON setting, the Auxiliary loops are not affected by

the DIP switch settings.

c. For UL installations with fire zones, the position 4 ON setting must not

be used.

WIRING CONNECTIONS

With the battery still not inserted, connect the loop wiring to the unit’s terminals (see Diagram 2).

Note: If a contact loop is not to be used, no connection is needed across its terminals.

BATTERY INSTALLATION/REPLACEMENT

1. Remove the transmitter’s cover (if not already off) as described in Mounting Step 1.

2. Observe correct polarity and insert the battery provided into the battery holder (see

Diagram 2). Take care not to bend the antenna.

Note: Replace battery only with: Duracelll DL123A, Sanyo CR123A,

Panasonic CR123A, ADEMCO 466, or Varta CR123A.

CAUTION: Risk of fire, explosion, and burns. Do not recharge, disassemble, heat above

212°F (100°C), or incinerate. Dispose of used batteries promptly. Keep away

from children.

3. To replace the cover, engage the hooks along one edge and snap shut.

SPECIFICATIONS

Dimensions 1-9/16"W x 3-1/2"H x 1-3/16"D (40mm x 89mm x 30mm)

Battery 3V Lithium (see BATTERY INSTALLATION/REPLACEMENT).

Regular maintenance and inspection (at least annually) by the installer and frequent testing by

the user are vital to continuous satisfactory operation of any alarm system.

The installer should assume the responsibility of developing and offering a regular maintenance

program to the user, as well as acquainting the user with the proper operation and limitations of

the alarm system and its component parts. Recommendations must be included for a specific

program of frequent testing (at least weekly) to ensure the system’s operation at all times.

REFER TO THE CONTROL'S INSTALLATION INSTRUCTIONS FOR THE

RECEIVER/CONTROL WITH WHICH THIS DEVICE IS USED, FOR DETAILS ON

LIMITATIONS OF THE ENTIRE ALARM SYSTEM.

CASE

HOLDING

POSTS (2)

PLATE

MOUNTING

HOLES (2)

CASE LOCKING TAB

ALIGNMENT GUIDE STRIP

(NOT USED IN THIS APPLICATION.

BREAK AWAY, IF DESIRED.)

CONCEALED WIRING

ENTRY HOLE

Diagram 1: MOUNTING PLATE

TO THE INSTALLER

Diagram 2: 5817 (SHOWN WITH COVER REMOVED)

— 2 — — 3 —

Loading...

Loading...