Table of Contents

CHAPTER 1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Product Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Target Audience for this Manual . . . . . . . . . . . . . . . . . 1-2

CHAPTER 2 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Safety Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Safety Instructions for the WFI . . . . . . . . . . . . . . . . . . 2-2

2.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.1.1 EC declaration of conformity (for EU) . . . . . . . . . . . . . . . . . . . .2-3

2.2.1.2 Control Drawings for FM and CSA . . . . . . . . . . . . . . . . . . . . . .2-3

2.2.1.3 Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1.4 Additional information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.1.5 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.2 Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.2.1.1 Repairs and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.2.1.2 Opening of the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.2.1.3 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.2.2.1.4 Working Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.2.2.1.5 Required Skills . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.2.2.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.2.2.3 Maintenance and troubleshooting . . . . . . . . . . . . . . . . . . . . . . .2-5

2.2.2.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.2.3 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.2.3.1 Safety Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.2.3.2 Accordance to Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.3.3 Explosion Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.3.4 Compliance to FCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.3.5 Low-Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.3.6 Reference of Applicable Standards. . . . . . . . . . . . . . . . . . . . . .2-6

2.2.3.7 WFI Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3 Liability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

CHAPTER 3 SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Part No.: Rev01 Wireless Field Interface

Installation & Operation Manual i

Table of Contents

3.3 FlexConn Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3.2 Grounding Concept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.3 Enclosure Earth Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.3.4 Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.5 PCB Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.5.1 CAN-1WL Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3.3.5.2 CAN-BPM module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.3.5.2.1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.3.5.2.2 Terminal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3.3.5.3 FII-SMV (HMI-TSI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.3.5.3.1 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3.3.5.3.2 Terminal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.3.6 CAN-PSX module - Power Supply . . . . . . . . . . . . . . . . . . . . . 3-12

3.3.6.1 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3.3.6.1.1 Terminal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

CHAPTER 4 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Mounting the Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Mounting Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Wireless Field Interface Part No.: Rev01

ii Installation Manual

General - Product Introduction

CHAPTER 1 GENERAL

1.1 Product Introduction

The Wireless Field Interface (WFI) adds a wireless capability to the

existing servo or the radar gauge by supporting the GPU protocol which

is compliant with the ISA100 standards. It consists of multiple electronic

boards, an antenna cable, and an antenna. The WFI communicates

with the servo or the radar gauge through the Honeywell Enraf field bus

Bi-Phase Mark, processes the data, and forwards the information

wirelessly to the Wireless Device Manager (WDM) which is compliant

with the ISA100 standards. The complete network including the WFI is

based on the ISA100 wireless field device network.

Also, there are different ways of communication which are as follows:

The protocol tunnel (Engauge and Entis)

Function blocks (Experion integration)

FIGURE 1-1 Wireless Field Interface (WFI)

Part No.: Rev01 Wireless Field Interface

Installation Manual 1 - 1

General - Target Audience for this Manual

1.2 Target Audience for this Manual

This manual is intended for engineers and technicians, who are

assigned to install, commission, and service the WFI. Also, all

Honeywell Enraf customers who use wireless.

Wireless Field Interface Part No.: Rev01

1 - 2 Installation Manual

Safety - Safety Conventions

CHAPTER 2 SAFETY

2.1 Safety Conventions

2.1.1 Warnings

The following warning mark is used within this document to urge

attention in order to prevent personal injuries or dangerous

situations, further described in this document.

Symbol Description Remark

General warning Will always be explained by text.

2.1.2 Cautions

The following caution mark is used within this document to urge

attention in order to prevent damages to the equipment, further

described in this document.

Symbol Description

General caution sign

Electrostatic Discharge (ESD) sensitive device

Part No.: Rev01 Wireless Field Interface

Installation Manual 2 - 1

Safety - Safety Instructions for the WFI

2.2 Safety Instructions for the WFI

The WFI device is used for converting the wired communication of

various Honeywell Enraf equipment into a wireless transmission.

FIGURE 2-1 Wireless Field Interface (WFI)

2.2.1 General

WARNING! You must strictly follow the safety instructions

mentioned in this manual and the safety instructions

shipped with the WFI device for installation, commissioning, operation, and maintenance, for the safe

operation of the WFI device.

Wireless Field Interface Part No.: Rev01

2 - 2 Installation Manual

Safety - Safety Instructions for the WFI

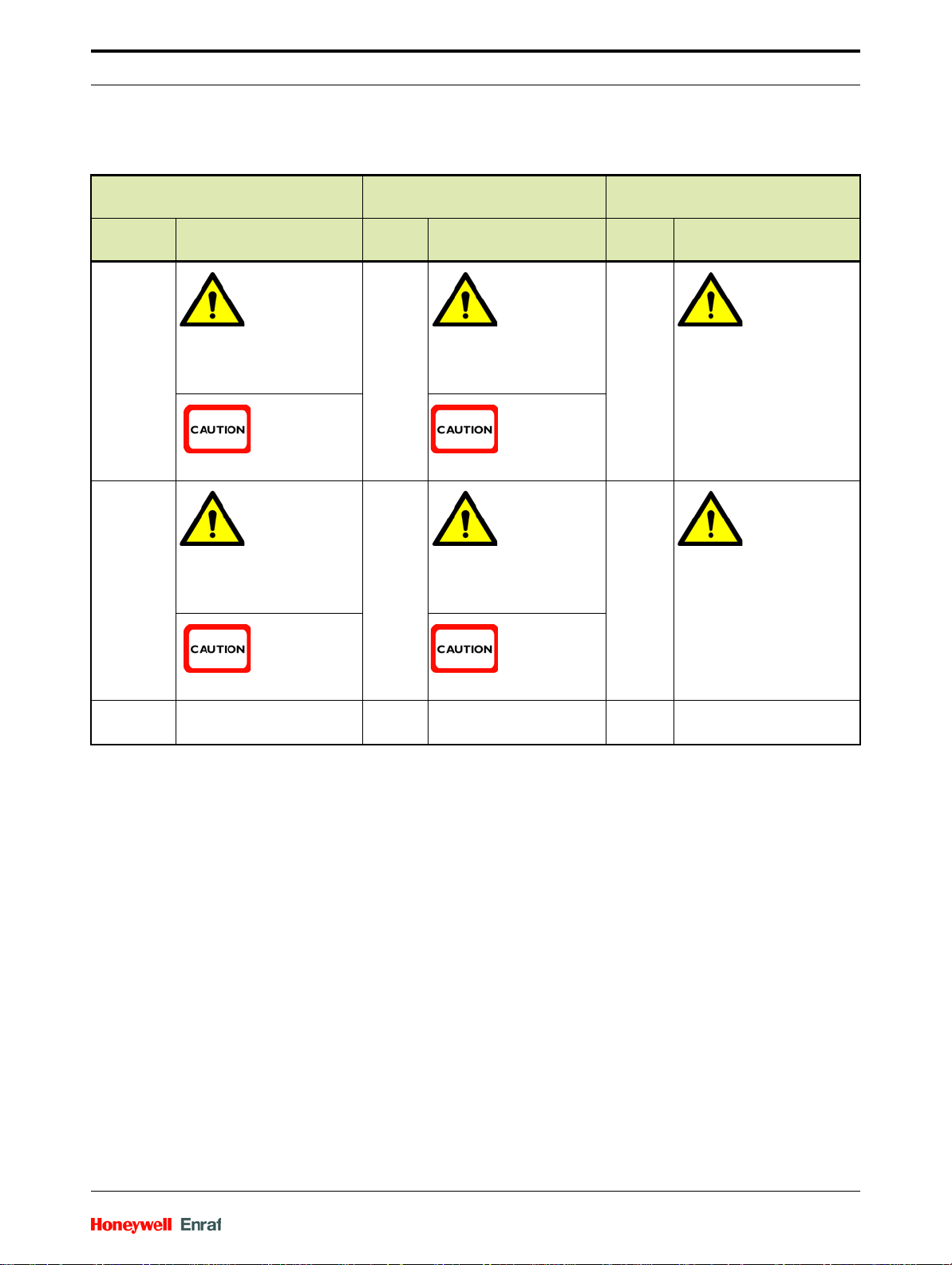

The WFI may be located in explosion safety areas as follows:

USA (FM) and Canada (CSA) Canada (CSA)

Safety

level

Class 1,

Division 1

Class 1,

Division 2

Remarks

WARNING!

Do NOT open

when an

explosive

atmosphere

may be

present.

CAUTION!

Seal conduit

within 18

inches.

WARNING!

Do NOT open

when an

explosive

atmosphere

may be

present.

CAUTION!

Seal conduit

within 18

inches.

Safety

level

Zone 1 WARNING!

Zone 2 WARNING!

Remarks

Do NOT open

when an

explosive

atmosphere

may be

present.

CAUTION!

Seal conduit

within 18

inches.

Do NOT open

when an

explosive

atmosphere

may be

present.

CAUTION!

Seal conduit

within 18

inches.

Rest of the World

(ATEX / IECEx)

Safety

level

Zone 1 WARNING!

Zone 2 WARNING!

Remarks

Do NOT open

when an

explosive

atmosphere

may be

present.

Do NOT open

when an

explosive

atmosphere

may be

present.

Safe Area - Safe

Zone

2.2.1.1 EC declaration of conformity (for EU)

Refer to the EC declaration of conformity and the ATEX certificate(s),

shipped with the WFI device for EC declarations.

2.2.1.2 Control Drawings for FM and CSA

Refer to the control drawings shipped with the WFI for FM and CSA.

2.2.1.3 Users

The mechanical and electrical installation must be performed only by

trained people with the knowledge of the requirements for installation of

explosion proof equipment in hazardous areas.

The entire installation procedure for the WFI must be implemented in

accordance with national, local, and company regulations.

The entire electrical installation may be performed in accordance with

the national requirements for electrical equipment to be installed in

hazardous areas.

- Safe

Zone

-

Part No.: Rev01 Wireless Field Interface

Installation Manual 2 - 3

Safety - Safety Instructions for the WFI

NOTE: See EN IEC 60079-14 document for more infor-

mation.

2.2.1.4 Additional information

For additional information about Honeywell Enraf solutions, see the

back cover of this manual to contact Honeywell Enraf or its

representative.

2.2.1.5 Environmental Conditions

The environmental conditions regarding the permissible operating

temperature for the WFI is -40 °C to +65 °C (-40 °F to +149 °F). The

relative humidity is RH 5 to 95%, non-condensing.

2.2.2 Personal Safety

WARNING! In hazardous areas, it is compulsory to use personal

protection and safety gear.

Safety can be achieved by using the following

equipment:

1. Safety helmet

2. Fire-resistive overall

3. Safety shoes

4. Safety glasses

5. Working gloves

6. LEL-meter

Pay attention to the kind of product involved. If there

is any danger to your health, wear a gas mask and

take all the necessary precautions.

WARNING! Take appropriate precautions when chemical or toxic

2.2.2.1 General

2.2.2.1.1 Repairs and Maintenance

WARNING! Any repairs or parts replacements must be

2.2.2.1.2 Opening of the Device

product vapors are present (compressed air,

chemical protection suit, detection equipment).

performed by the manufacturer or its appointed

repair agent.

WARNING! It is forbidden to open the WFI device within an

explosive hazardous environment in power, unless

otherwise stated on the safety label.

WARNING! Treat the flange surface of the cover and the housing

with care.

Keep the flange surface free of dirt.

The O-ring must be present and undamaged.

Wireless Field Interface Part No.: Rev01

2 - 4 Installation Manual

Safety - Safety Instructions for the WFI

2.2.2.1.3 Tools

WARNING! Use non-sparking tools and explosion-proof testers.

2.2.2.1.4 Working Environment

WARNING! Avoid generation of static electricity. Make sure the

2.2.2.1.5 Required Skills

WARNING! The technician must have technical skills to be able

2.2.2.2 Commissioning

Use suitable explosion-proof tools (for example,

testing devices).

explosive gas mixtures are not available in the

working area.

to safely install the WFI device. The technician also

must be trained to work in accordance with the

national requirements for electrical equipment in

hazardous areas.

The commissioning of the device is conducted by qualified engineers

trained by Honeywell Enraf and with the knowledge of the (local and

national) requirements for electrical equipment in (potentially) explosive

atmospheres.

2.2.2.3 Maintenance and troubleshooting

If the WFI device does not function accurately, only a qualified service

engineer, trained by Honeywell Enraf and with the knowledge of safety

regulations for working in (potentially) explosive atmospheres are

allowed to repair the WFI device.

2.2.2.4 Grounding

Make sure the housing of the device is properly connected to ground

reference. See FIGURE 3-5.

Make sure the electrical resistance of the ground connections is below

the maximum prescribed by local requirements.

2.2.3 Electrical

2.2.3.1 Safety Standards

The entire electrical installation must be in accordance with the Inter-

national Standard EN IEC 60079-14 for electrical equipment in

hazardous areas.

The stopping plugs, cable glands, and reducers must be installed in

accordance with the appropriate IP requirements.

Use the bolts that are property class A2-70 or better captured types

and are not user replaceable. Contact Honeywell Enraf if you need to

replace the bolts.

Use suitable flameproof (Ex d) compound cable glands or conduit

seals.

Part No.: Rev01 Wireless Field Interface

Installation Manual 2 - 5

Safety - Safety Instructions for the WFI

Improper installation of cable glands, threaded adaptors, stopping

plugs, and their interface invalidates the Ex approval of the WFI

device.

Accurate dimensions of the flameproof joints must be used. Contact

Honeywell Enraf for information regarding the dimensions of the

flameproof joints.

2.2.3.2 Accordance to Regulations

2.2.3.3 Explosion Safety

Approval Certificate no. Type of protection identification

ATEX Approval pending II 2 G

Ex d [ia] IIB T6 Gb

IECEx Approval pending Zone 1

FM Approval pending Class I, Division 1 group C, D T6

Class I, Division 1 group C, D T6

CSA Approval pending

Zone 1 Ex d [ia] IIB T6

= -40 °C ... +65 °C

T

a

(-40 °F ... +149 °F)

2.2.3.4 Compliance to FCC

This device complies with Part 15 of the FCC Rules. The WFI device

does not cause any harmful interference and accepts any interference

received.

2.2.3.5 Low-Voltage Directive

The device is suitable for 2006/95/EC.

The applicable standard value is IEC 61010-1 (3rd Edition).

2.2.3.6 Reference of Applicable Standards

Standard Description

ATEX 95 Applicable for manufacturers of equipment used in places

where explosion danger may exist.

IECEx The IECEx System is an International Conformity System

where a Mark of Conformity is granted by approved IECEx

certifiers (ExCBs) located in IECEx participating countries for

equipment that is covered by an IECEx Certificate of Conformity and hence has been tested and manufactured under

systems that are under ongoing surveillance by ExCBs.

FM Factory Mutual Approvals Division

The Factory Mutual Approvals Division determines the safety

and reliability of equipment, materials, or services utilized in

hazardous locations in the United States and elsewhere.

CSA Canadian Standards Association

The standards generated by CSA are the cornerstone for

determining a product's eligibility for certification in

hazardous locations in Canada.

Wireless Field Interface Part No.: Rev01

2 - 6 Installation Manual

Safety - Safety Instructions for the WFI

NOTE to FM label:

Ta = -40 °F to +149 ºF

2.2.3.7 WFI Labels

FIGURE 2-2 Identification labels with Safety note on the WFI

Part No.: Rev01 Wireless Field Interface

Installation Manual 2 - 7

Safety - Liability

2.3 Liability

The information in this installation guide is the copyright property of

Honeywell International Inc. Honeywell International Inc. disclaims any

responsibility for personal injury or damage to equipment caused by:

Deviation from any of the prescribed procedures.

Execution of activities that are not prescribed.

Neglect of the safety regulations for handling tools and use of elec-

tricity.

The contents, descriptions, and specifications in this manual are subject

to change without notice. Honeywell International Inc. accepts no

responsibility for any errors that may appear in this manual.

WARNING! Only certified technicians are authorized to make

changes to the WFI configuration. All modifications

must be in accordance with the guidelines as set

forth by Honeywell International Inc. Modifications

not authorized by Honeywell International Inc. invalidates the approval certificates.

Wireless Field Interface Part No.: Rev01

2 - 8 Installation Manual

System Description - Introduction

Entis

CIU

WDM

Engauge service tool

FDAP

WFI

Servo Gauge

BPM Interface

ISA100 Wireless

Interface

Experion

CHAPTER 3 SYSTEM DESCRIPTION

3.1 Introduction

3.2 System Architecture

The WFI is a box that can be installed next to an installed Servo/Radar

gauge. The WFI retrieves the information from this gauge and sends the

information wirelessly to the supervisory level.

This is an ISA100 compliant solution that supports transducer blocks for

transferring basic process values to the supervisory level and supports

the GPU tunnel to connect to the Engauge (maintenance) and Entis

(inventory management package) systems. See FIGURE 3-1.

FIGURE 3-1 WFI architecture overview

Part No.: Rev01 Wireless Field Interface

3.3 FlexConn Modules

3.3.1 General

One of the main characteristics of the FlexConn architecture is the

placement flexibility of the FlexConn modules. The backbone of this

Installation Manual 3 - 1

System Description - FlexConn Modules

FII-SMV/SPARE HCW-1WL FCW-BPM CAN-PSX

CAN-L

CAN-H

= terminating resistor

concept is the serial CAN1 bus to which each FlexConn module

connects.

FIGURE 3-2 FlexConn CAN bus concept

Inside the enclosure, the following modules are available.

FII-SMV or Spare Module

HCW-1WL

FCW-BPM

The stack of modules are mounted on the DIN Rail and placed vertically

inside the enclosure as illustrated in FIGURE 3-3.

1. Controller Area Network.

Wireless Field Interface Part No.: Rev01

3 - 2 Installation Manual

System Description - FlexConn Modules

FII-SMV/SPARE

Radio Board

FCW-BPM

CAN-PSX

DIN rail

FIGURE 3-3 FlexConn board sequencing

Module Description

Radio Board Includes the circuit of 1WL Main Board and Carrier

CAN-PSX Generates the power of 15 V DC with auxiliary supply.

CAN-BPM Provides an interface to a BPM based Enraf field bus to

FII-SMV Connects the display type SmartView with a standard

3.3.2 Grounding Concept

Each printed circuit board has 2 grounding points. These grounding

points are used to electrically connect every board with the metal

housing. This is performed by means of metal spacers, which are

pressed into the boards. See FIGURE 3-4.

Boards. It is assembled with DFSS Radio or LCRB and

Barrier Boards.

communicate with Servo/Radar Gauge.

CAN bus.

Part No.: Rev01 Wireless Field Interface

Installation Manual 3 - 3

System Description - FlexConn Modules

Grounding points

FIGURE 3-4 Grounding concept

3.3.3 Enclosure Earth Details

Inside the enclosure, 2 Protected Earthing (PE) or Mains input earth

points and 1 external point is available to connect to the field earth

point.

See FIGURE 3-5.

Wireless Field Interface Part No.: Rev01

3 - 4 Installation Manual

System Description - FlexConn Modules

FIGURE 3-5 The grounding connections for the WFI

3.3.4 Field Wiring

The mains input and the CAN-BPM signal lines enter the enclosure

through different glands from one side of the enclosure.

The mains input (Line and Neutral) cable wires terminate on the PSX

module connector. The mains input earth wire terminates on one of the

PE points provided inside the enclosure. From the PE point inside the

enclosure, the PSX gets the PE connection through the wire terminated

on the PSX connector.

The CAN-BPM signals cable from the servo gauge enters the enclosure

with the gland and terminates on the CAN-BPM module connector. The

CAN-BPM module then gets the earth wire from the PE point inside the

enclosure. See FIGURE 3-6.

Part No.: Rev01 Wireless Field Interface

Installation Manual 3 - 5

System Description - FlexConn Modules

FII-SMV cable

Field Earth

(External)

Mains Input

BPM Interface cable

Ground Points

Antenna Coaxial Cable

FIGURE 3-6 Field wiring

Wireless Field Interface Part No.: Rev01

3 - 6 Installation Manual

System Description - FlexConn Modules

3.3.5 PCB Details

3.3.5.1 CAN-1WL Board

The CAN-1WL board is used to interface data between a FlexConn

system and the OneWireless network (including the antenna).

The 1WL main board occupies a single slot in the FlexConn rail and the

other three boards (1WL carrier board, 1WL radio board, and 1WL

barrier board) are mounted together to form the second FlexConn

board. See FIGURE 3-7.

FIGURE 3-7 CAN-1WL board layout

The functions of the CAN-1WL board are as follows:

1WL main board

• FlexConn electronics

Part No.: Rev01 Wireless Field Interface

Installation Manual 3 - 7

System Description - FlexConn Modules

• 3V3 power supply

• SD card interface

• 5V / 3V3 level converter

1WL carrier board

• Filter the 3V3 power supply

1WL radio board

• OneWireless radio board

1WL barrier board

• Barrier board

3.3.5.2 CAN-BPM module

3.3.5.2.1 Functions

The CAN-BPM module provides an interface to a BPM based Enraf field

bus. It is a communication print that is based on Flexconn and can be

installed in a SmartLink (new CIU) or in a new instrument such as a

Flexconn based radar or servo gauge. The CAN-BPM print in a

SmartLink is called FCM-BPM module. See FIGURE 3-8.

FIGURE 3-8 CAN-BPM board layout

Wireless Field Interface Part No.: Rev01

3 - 8 Installation Manual

System Description - FlexConn Modules

3.3.5.2.2 Terminal Descriptions

CN2 - BPM

Pin no. Name/Signal

1TL1

2TL2

3n.c/spare

4 PE (optional)

LEDs

Items Description

LE1 Error indication

LE2 Follows TxD on BPM line (TXEFB1)

LE3 Follows RxD on BPM line (RXEFB)

3.3.5.3 FII-SMV (HMI-TSI)

3.3.5.3.1 Functions

The FII-SMV (HMI-TSI) module is intended to connect the display type

SmartView with a standard CAN bus. The display is an intrinsic safe

device. The interface module is located within an Ex d enclosure or in a

safe area and provides intrinsic safe circuits for the supply and

communication to the display module. See FIGURE 3-9.

The module implements the following functions.

Function Description

Supply 10 V Safe_+ = 10V for the SmartView display module, isolated (Ex certified)

RS485 RS485 for the SmartView display module, isolated (Ex certified)

Local service Software, processing messages from/to the SmartView display unit and

CAN-BUS

Display interface Software, processing messages from/to the SmartView display unit and

CAN-BUS

Part No.: Rev01 Wireless Field Interface

Installation Manual 3 - 9

System Description - FlexConn Modules

CN2

CN3

CN1

TR1

FIGURE 3-9 FII-SMV board layout

3.3.5.3.2 Terminal Descriptions

LE1 is connected to the V

Connectors

Connectors Description

CN1 CAN-BUS

CN2 Display output

CN3 Display output

CN4 Program Header

Wireless Field Interface Part No.: Rev01

3 - 10 Installation Manual

output signal.

dc

System Description - FlexConn Modules

CN1

Pin no. Name/Signal

1W&M

2CAN_H

3CAN_L

4V

5GND

= + 15 V

dc

CN2

Pin no. Name/Signal Description

1 SGND Isolated secondary ground

2 Vsafe_+ Isolated DC supply output

3 Safe_A Isolated RS485 A input/output

4 Safe_B Isolated RS485 B input/output

CN4

Pin no. Name/Signal

1P00

2P01

3MD0

4MD2

5RST

6SIN0

7SOT0

8SCK0

9V

10 GND

cc

LEDs

Items Description

LE1 Error indication

LE2 Application specific

LE3 Application specific

Jumpers

Items Description

JP1 W&M entities protection

JP2 Password read protection

JP3 Write protection all entities

Part No.: Rev01 Wireless Field Interface

Installation Manual 3 - 11

System Description - FlexConn Modules

Items Description

JP4 Spare

JP5 Spare

JP6 Termination of CAN-bus

3.3.6 CAN-PSX module - Power Supply

3.3.6.1 Functions

The CAN Power supply (+15V DC) is intended to power up the

FlexConn modules. It can be used within the application and also within

an Ex-d enclosure. See FIGURE 3-10.

The module implements the following specifications.

Item Specification

AC Input Voltage Range 65 V - 240 V AC (+10% to -15%)

Input Frequency 50 Hz to 60 Hz ±10%

Input Fuse Value 1.25 A

Isolation Voltage 4.3 KV

DC Input Voltage Range 24 V - 65 V DC (+10% to -15%)

Output Voltage 15 V DC ± 4%

Continuous current 1 A

Wireless Field Interface Part No.: Rev01

3 - 12 Installation Manual

System Description - FlexConn Modules

CN2

Switch board

Main board

Storage

Heatsink

Boost coil

TX1

FIGURE 3-10 CAN-PSX board layout

3.3.6.1.1 Terminal Descriptions

LE1 is connected to the V

Connectors

Connectors Description

CN1 CAN-BUS

CN2 Mains/DC input

CN3 Not placed

CN1

Pin no. Name/Signal Description

1n.c.

2 CAN_H Interconnected by 120Ω 1206

3CAN_L

4V

5GND

= + 15 V

dc

a

output signal.

dc

Internally connected to CN2, earth PE

Part No.: Rev01 Wireless Field Interface

Installation Manual 3 - 13

System Description - FlexConn Modules

a. CN1 pin 5 may not be used as an

extension on the protective earth.

However, it may be used as a functional

earth pin.

CN2 (AC/DC input)

Pin no. Name / signal Description

1V

2V

in_a

in_b

3 PE Earth = PE = GND

4n.c

Mains or DC + / - input

Mains or DC + / - input

Wireless Field Interface Part No.: Rev01

3 - 14 Installation Manual

Installation - Mounting the Antenna

CHAPTER 4 INSTALLATION

4.1 Mounting the Antenna

The antenna is placed on top of the WFI enclosure as shown in the

following figure.

FIGURE 4-1 WFI antenna

To mount the communication antenna on the WFI device, screw the

communication antenna clockwise on the lightning arrestor. See

FIGURE 4-2.

Part No.: Rev01 Wireless Field Interface

Installation Manual 4 - 1

Installation - Mounting the Antenna

FIGURE 4-2 Mounting the communication antenna

NOTE: The lightning arrestor protects the inside electronics

from the lightning damage. Although it protects

against multiple discharges, it can be replaced as a

preventive maintenance action. Preve nt i ve maintenance interval depends on the location, position of

the equipment, grounding, and other protection

measures installed.

4 dBi and 8 dBi integral antenna’s are supported in WFI.

For more information about the antenna types supported, refer to the

SmartRadar FlexLine Service Manual.

Wireless Field Interface Part No.: Rev01

4 - 2 Installation Manual

Installation - Mounting Dimensions

4.2 Mounting Dimensions

NOTE: This section will be updated when the mounting

dimensions for the WFI is finalized.

Part No.: Rev01 Wireless Field Interface

Installation Manual 4 - 3

Installation - Mounting Dimensions

Wireless Field Interface Part No.: Rev01

4 - 4 Installation Manual

Loading...

Loading...