OneWireless

XYR 6000 Transmitters

Quick Start Guide

34-XY-25-21

R100

7/23/07

Release 100

Notices and Trademarks

Copyright 2007 by Honeywell International Inc.

Release 100 July 23, 2007

While this information is presented in good faith and believed to be accurate, Honeywell disclaims the implied

warranties of merchantability and fitness for a particular purpose and makes no express warranties except as may

be stated in its written agreement with and for its customers.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The information and

specifications in this document are subject to change without notice.

Honeywell, PlantScape, Experion PKS, and TotalPlant are registered trademarks of Honeywell International Inc.

Other brand or product names are trademarks of their respective owners.

Honeywell International

Process Solutions

2500 West Union Hills

Phoenix, AZ 85027

1-800 343-0228

ii OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

About This Document

This document describes mounting, installation and wiring of the XYR 6000 Wireless Transmitters and antennae.

Configuration, authentication and ope rat i on are covered in other documents.

Honeywell does not recommend using devices for critical control where there is a single point of failure or where

single points of failure result in unsafe conditions. The initial release of OneWireless (R100) is targeted at open

loop control, supervisory control, and controls that do not have environmental or safety consequences. As with any

process control solution, the end-user must weigh the risk s and benefits to determine if the products used are the

right match for the application based on security, safety, and performance. Additionally, it is up to the end-user to

ensure that the control strategy sheds to a safe operating condition if any crucial segment of the con trol solution

fails.

Release Information

Document Name Document ID

XYR 6000 Transmitters Quick Start Guide 34-XY-25-21 100 7/23/07

Release

Number

Publication

Date

References

The following list identifies all documents that may be sources of reference for material discussed in this

publication.

Document Title

Getting Started with Honeywell OneWireless Solutions

OneWireless Wireless Builder User’s Guide

OneWireless Builder Parameter Reference

OneWireless XYR 6000 Pressure Transmitter User's Manual

OneWireless XYR 6000 Temperature Transmitter User's Manual

OneWireless XYR 6000 SmartCET Corrosion Transmitter User's Manual

OneWireless XYR 6000 HLAI Transmitter User's Manual

Support and contact info

United States and Canada

Contact: Honeywell Solution Support Center

Phone: 1-800 822-7673. In Arizona: 602- 313-5558

Calls are answered by dispatcher between 6:00 am and 4:00 pm Mountain Standard Time.

Emergency calls outside normal working hours are received by an answering service and

returned within one hour.

Facsimile: (602) 313-3293

Mail: Honeywell TAC, MS P13

2500 West Union Hills Drive

Phoenix, AZ, 85027

R100 OneWireless XYR 6000 Transmitters Quick Start Guide iii

7/23/07

Europe

Pacific

India

Contact: Honeywell TAC-EMEA

Phone: +32-2-728-2732

Facsimile: +32-2-728-2696

Mail: TAC-BE02

Hermes Plaza

Hermeslaan, 1H

B-1831 Diegem, Belgium

Contact: Honeywell Global TAC – Pacific

Phone: 1300-300-4822 (toll free within Australia)

+61-8-9362-9559 (outside Australia)

Facsimile: +61-8-9362-9564

Mail: Honeywell Limited Australia

5 Kitchener Way

Burswood 6100, Western Australia

Email: GTAC@honeywell.com

Contact: Honeywell Global TAC – India

Phone: +91-20- 6603-9400

Facsimile: +91-20- 6603-9800

Mail: Honeywell Automation India Ltd.

56 and 57, Hadapsar Industrial Estate

Hadapsar, Pune –411 013, India

Email: Global-TAC-India@honeywell.com

Korea

Contact: Honeywell Global TAC – Korea

Phone: +82-2-799-6317

+82-11-9227-6324

Facsimile: +82-2-792-9015

Mail: Honeywell Co., Ltd

17F, Kikje Center B/D,

191, Hangangro-2Ga

Yongsan-gu, Seoul, 140-702, Korea

Email: Global-TAC-Korea@honeywell.com

People’s Republic of China

Contact: Honeywell Global TAC – China

Phone: +86- 21-5257-4568

Mail: Honeywell (China) Co., Ltd

33/F, Tower A, City Center, 100 Zunyi Rd.

Shanghai 200051, People’s Republic of China

Email: Global-TAC-China@honeywell.com

iv OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

Singapore

Contact: Honeywell Global TAC – South East Asia

Phone: +65-6580-3500

Facsimile: +65-6580-3501

+65-6445-3033

Mail: Honeywell Private Limited

Honeywell Building

17, Changi Business Park Central 1

Singapore 486073

Email: GTAC-SEA@honeywell.com

Taiwan

Contact: Honeywell Global TAC – Taiwan

Phone: +886- 7- 536-2567

Facsimile: +886-7-536-2039

Mail: Honeywell Taiwan Ltd.

17F-1, No. 260, Jhongshan 2nd Road.

Cianjhen District

Kaohsiung, Taiwan, ROC

Email: Global-TAC-Taiwan@honeywell.com

Japan

Contact: Honeywell Global TAC – Japan

Phone: +81-3-6730-7160

Facsimile: +81-3-6730-7228

Mail: Honeywell Japan Inc.

New Pier Takeshiba, South Tower Building,

20th Floor, 1-16-1 Kaigan, Minato-ku,

Tokyo 105-0022, Japan

Email: Global-TAC-JapanJA25@honeywell.com

World Wide Web

Honeywell Solution Support Online:

http://www.honeywell.com/ps

Elsewhere

Call your nearest Honeywell office.

Training Classes

Honeywell Automation College:

http://www.automationcollege.com

R100 OneWireless XYR 6000 Transmitters Quick Start Guide v

7/23/07

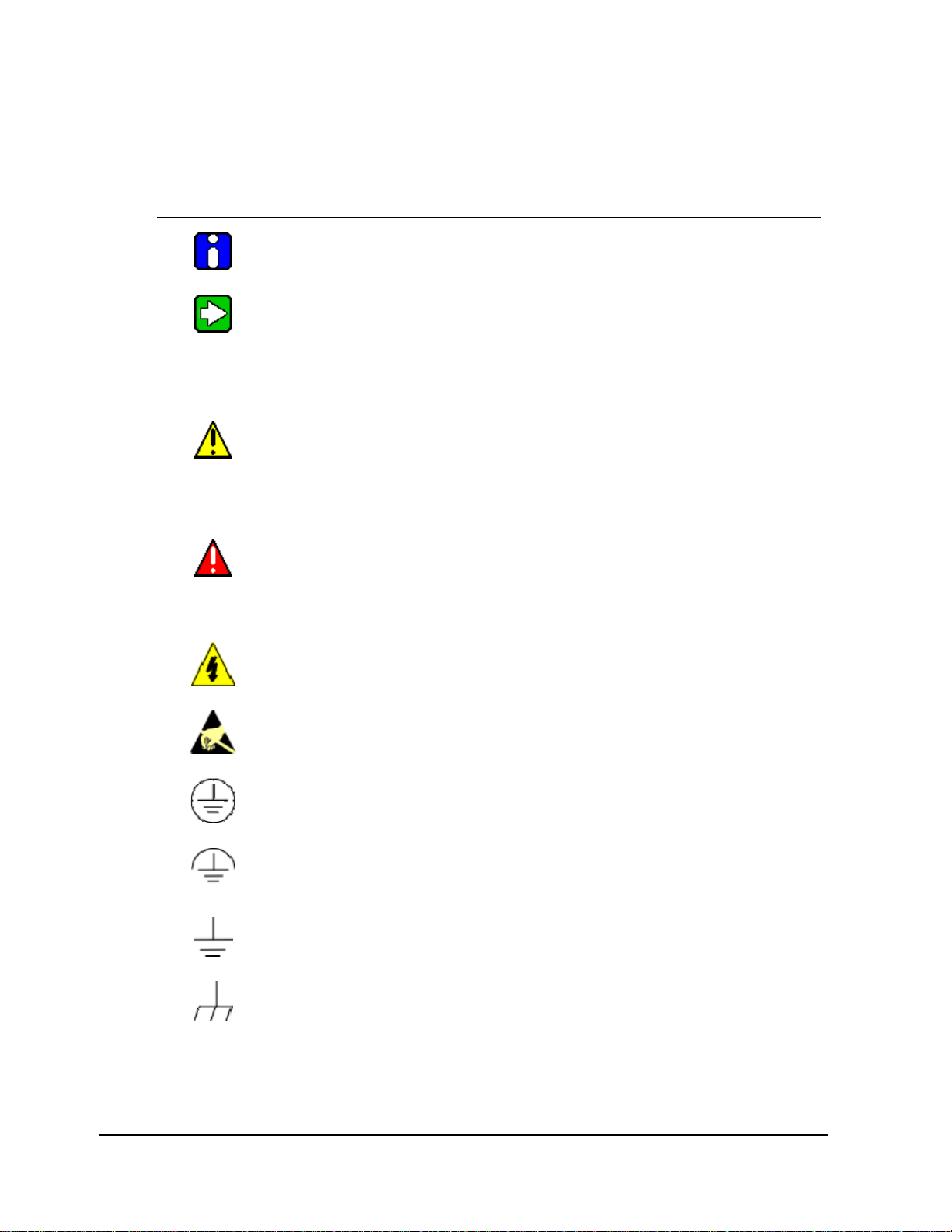

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Symbol Definition

CAUTION

ATTENTION: Identifies information that requires special consideration.

TIP: Identifies advice or hints for the user, often in terms of performing a task.

Indicates a situation which, if not avoided, may result in equipment or work (data) on

the system being damaged or lost, or may result in the inability to properly operate

the process.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe

practices.

CAUTION symbol on the equipment refers the user to the product manual for

additional information. The symbol appears next to required information in the

manual.

WARNING: Indicates a potentially hazardous situation, which, if not avoided, could

result in serious injury or death.

WARNING symbol on the equipment refers the user to the product manual for

additional information. The symbol appears next to required information in the

manual.

WARNING, Risk of electrical shock: Potential shock hazard where HAZARDOUS

LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60 VDC may be accessible.

ESD HAZARD: Danger of an electro-static discharge to which equipment may be

sensitive. Observe precautions for handling electrostatic sensitive devices.

Protective Earth (PE) terminal: Provided for connection of the protective earth

(green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to Protective Earth at the

source of supply in accordance with national local electrical code requirements.

Earth Ground: Functional earth connection. NOTE: This connection shall be

bonded to Protective Earth at the source of supply in accordance with national and

local electrical code requirements.

Chassis Ground: Identifies a connection to the chassis or frame of the equipment

shall be bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requirements.

vi OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

Contents

Support and contact info........................................................................................................................iii

1. INTRODUCTION....................................................................................................1

1.1 Site preparation.............................................................................................................................1

1.2 Certifications and approvals........................................................................................................1

Hazardous location certifications ............................................................................................................................1

Radio certifications .................................................................................................................................................1

Approval ratings .....................................................................................................................................................2

2. TRANSMITTER MOUNTING .................................................................................3

2.1 Weight ............................................................................................................................................3

2.2 Dimensions....................................................................................................................................3

2.3 Transmitter location......................................................................................................................4

Pressure models.....................................................................................................................................................4

2.4 Bracket mounting..........................................................................................................................4

Attach bracket to pipe.............................................................................................................................................4

Attach transmitter to bracket...................................................................................................................................5

2.5 Rotate transmitter housing..........................................................................................................6

2.6 Rotate display................................................................................................................................6

Tools required ........................................................................................................................................................6

Procedure...............................................................................................................................................................6

3. PROCESS INSERTION .........................................................................................9

3.1 Pressure models ...........................................................................................................................9

Piping .....................................................................................................................................................................9

Process connections ............................................................................................................................................11

General piping guidelines .....................................................................................................................................11

3.2 Temperature models...................................................................................................................12

Insert probe into process ......................................................................................................................................12

Integral probe wiring .............................................................................................................................................12

Remote probe wiring ............................................................................................................................................12

3.3 HLAI models ................................................................................................................................13

Connect wiring......................................................................................................................................................13

3.4 Corrosion models........................................................................................................................14

Probe mounting locations .....................................................................................................................................14

Probe installation..................................................................................................................................................17

Connect wiring......................................................................................................................................................18

4. ANTENNA ADJUSTMENT AND MOUNTING .....................................................19

4.1 Requirements ..............................................................................................................................19

Radio installation requirements ............................................................................................................................19

4.2 Integral antenna...........................................................................................................................19

Elbow....................................................................................................................................................................20

R100 OneWireless XYR 6000 Transmitters Quick Start Guide vii

7/23/07

Contents

Symbol Definitions

Straight................................................................................................................................................................. 20

4.3 Remote antenna ..........................................................................................................................21

Outdoor installation warnings............................................................................................................................... 21

Directional mounting procedure ........................................................................................................................... 23

Omnidirectional mounting procedure ...................................................................................................................24

Connect antenna to transmitter............................................................................................................................ 24

5. START UP ...........................................................................................................25

5.1 Connect batteries........................................................................................................................25

Display sequence................................................................................................................................................. 26

Authentication ...................................................................................................................................................... 26

6. CSA CERTIFIED DIVISION 2 / ZONE 2 INSTALLATION DRAWINGS ..............27

viii OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

Contents

Tables

Tables

Table 2-1 Display adjustment ........................................................................................................................7

R100 OneWireless XYR 6000 Transmitters Quick Start Guide ix

7/23/07

Contents

Figures

Figures

Figure 1 Common bracket orientations .........................................................................................................4

Figure 2 Rotating transmitter housing ...........................................................................................................6

Figure 3 Display rotation................................................................................................................................7

Figure 4 Typical 3-valve manifold and blow-down piping arrangment ..........................................................9

Figure 5 Typical Arrangement for ½” NPT Process Connection Piping ......................................................10

Figure 6 Temperature probes......................................................................................................................12

Figure 7 HLAI connection ............................................................................................................................13

Figure 8 Voltage input wiring .......................................................................................................................13

Figure 9 Current input wiring .......................................................................................................................13

Figure 10 Corrosion transmitter with remote probe.....................................................................................18

Figure 11 Elbow antenna adjustment ..........................................................................................................20

Figure 12 Integral straight antenna..............................................................................................................20

Figure 13 Directional antenna mounting......................................................................................................23

Figure 14 Omnidirection antenna mounting ................................................................................................24

Figure 15 Battery assembly.........................................................................................................................26

x OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

1. Introduction

1.1 Site preparation

Wireless devices require proper site preparation to ensure optimum performance and safety compliance.

Do not proceed until you have done the proper planning described in the Wireless Planning Guide.

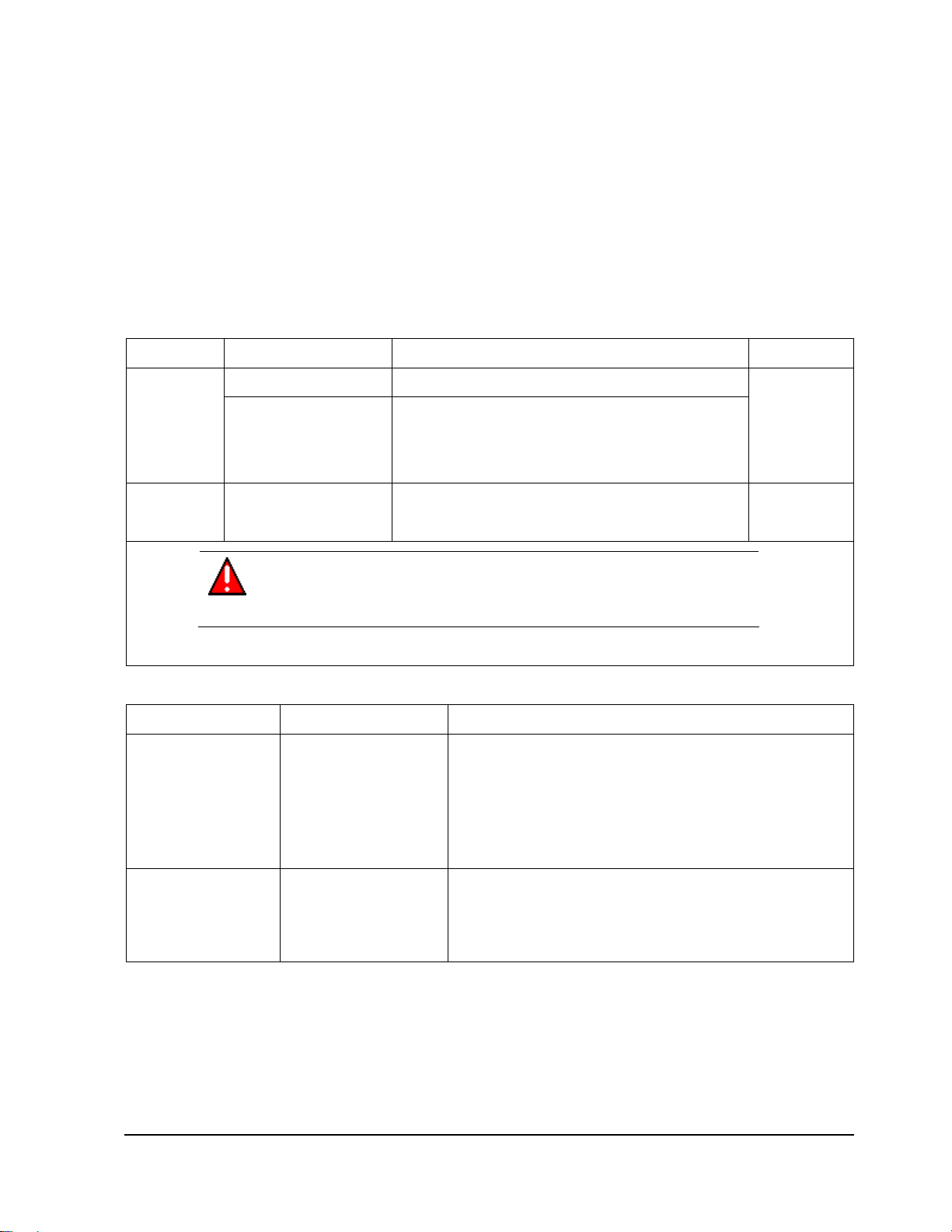

1.2 Certifications and approvals

Hazardous location certifications

Agency Approval Type Location or Classification Model Code

Nonincendive Nonincendive, CL I, Div 2, Groups A,B,C & D,

cCSAus

ATEX Non-Sparking

Non-Sparking

WARNING

Division 2 / Zone 2 apparatus may only be connected to a non-hazardous

process.

Radio certifications

Agency Certification Description

Federal

Communications

Commission (FCC)

FCC ID: S5750016517

CL II & III, Div 2, Groups F & G, T4 Ta = 85°C

2N

Class I, Ex/AEx nC IIC; T4, Ta ≤ 85°C, Zone 2;

IP 66

Ex II 3 GD; Ex nA IIC; T4, Ta ≤ 85°C, Zone 2;

3N

IP 66

The XYR 6000 Wireless Transmitters comply with part 15 of

the FCC rules. Operation is subject to the following two

conditions.

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

The installer of this radio equipment must ensure that the

antenna is located or pointed such that it does not emit RF

Industry Canada (IC) IC: 573I-50016517

fields in excess of Health Canada limits for the general

population; consult Safety Code 6, obtainable from Health

Canada’s web site www.hc-sc.gc.ca/rpb.

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 1

7/23/07

1. Introduction

1.2. Certifications and approvals

Approval ratings

Pressure

Transmitter

Temperature transmitter Approval / Item Ratings / Description

Integral

Probe

Remote

Inputs

High Level

Analog

Input HLAI

Corrosion

Transmitter

w/Remote

Probe

Nonincendive*

Non-Sparking CL I, Ex/AEx nA IIC T4; Ta = 85°C, Zone 2

Ex II 3 GD, EEx nA IIC T4; Ta = 85°C, Zone 2 X X X X X

Process

Connections

Temperature

Limits

Enclosure

Type*

CRN Canadian Registration Number X X n/a n/a X

Entry Plugs 1/2 NPT or M20 as required, quantity required 2 2 1 1 1

Field Wiring

(Supplied by

others)

*Class II and III installations and for Type 4X/IP66 applications require that all cable and unused entires be sealed with an NRTL

Nonincendive, CL I, Div 2, Groups A,B,C & D,

CL II & III, Div 2, Groups F & G, T4 Ta = 85°C;

WARNING – Division 2 / Zone 2 apparatus

may only be connected to a non-hazardous

process.

Max Process Temperature +125°C +85°C Sensor Rating n/a n/a

Ambient Temperature Limits Cold: –40°C –40°C –40°C –40°C –30°C

Ambient Temperature Limits Hot: +85°C +85°C +85°C +85°C +85°C

4X / IP 66/67 X n/a X X X

4 / IP 66 n/a X n/a n/a n/a

Conduit (Explosionproof Not Required) n/a X X X n/a

Cable Gland* n/a X X X X*

listed cable gland or seal fitting. Cable glands and seal fittings are not supplied by Honeywell.

X X X X X

X n/a n/a n/a X

2 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

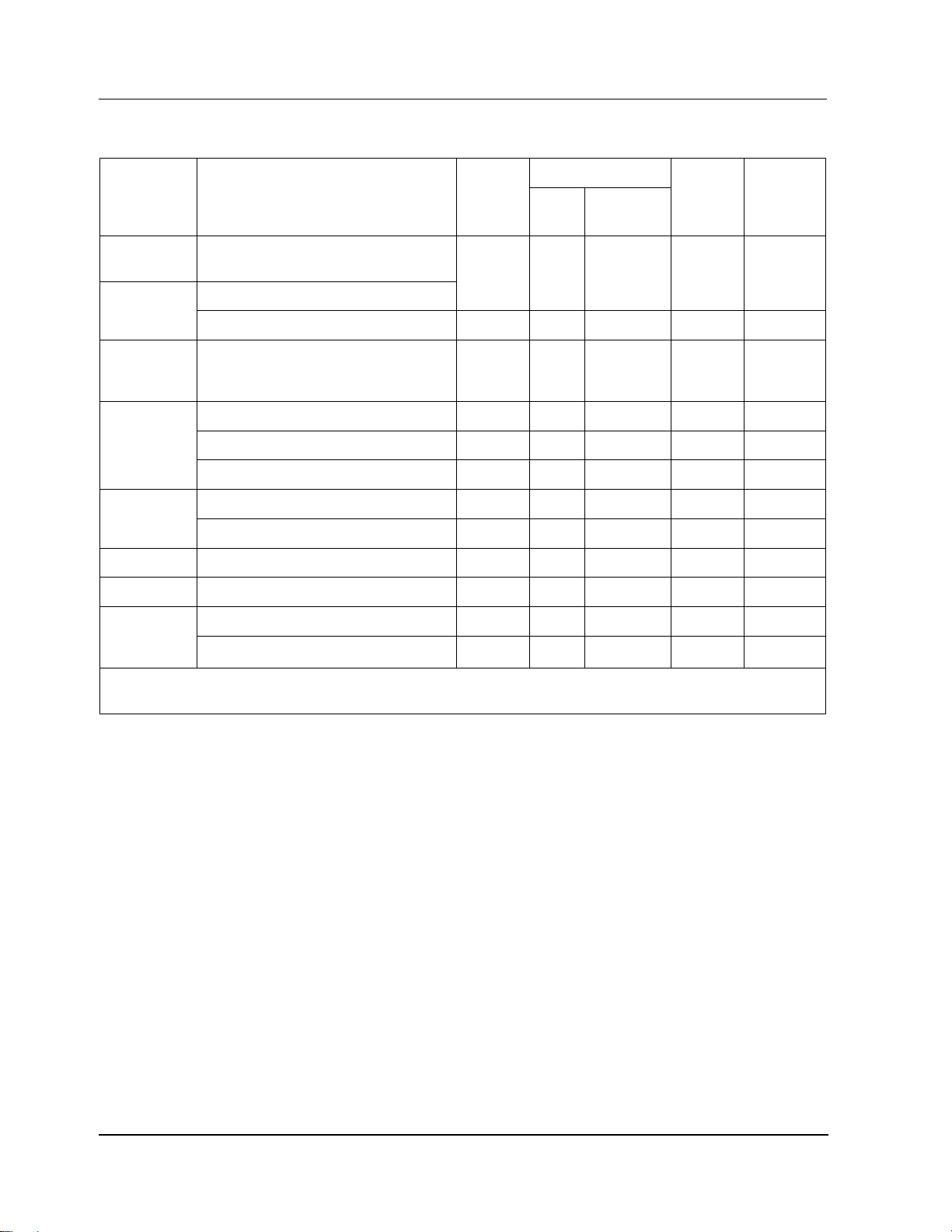

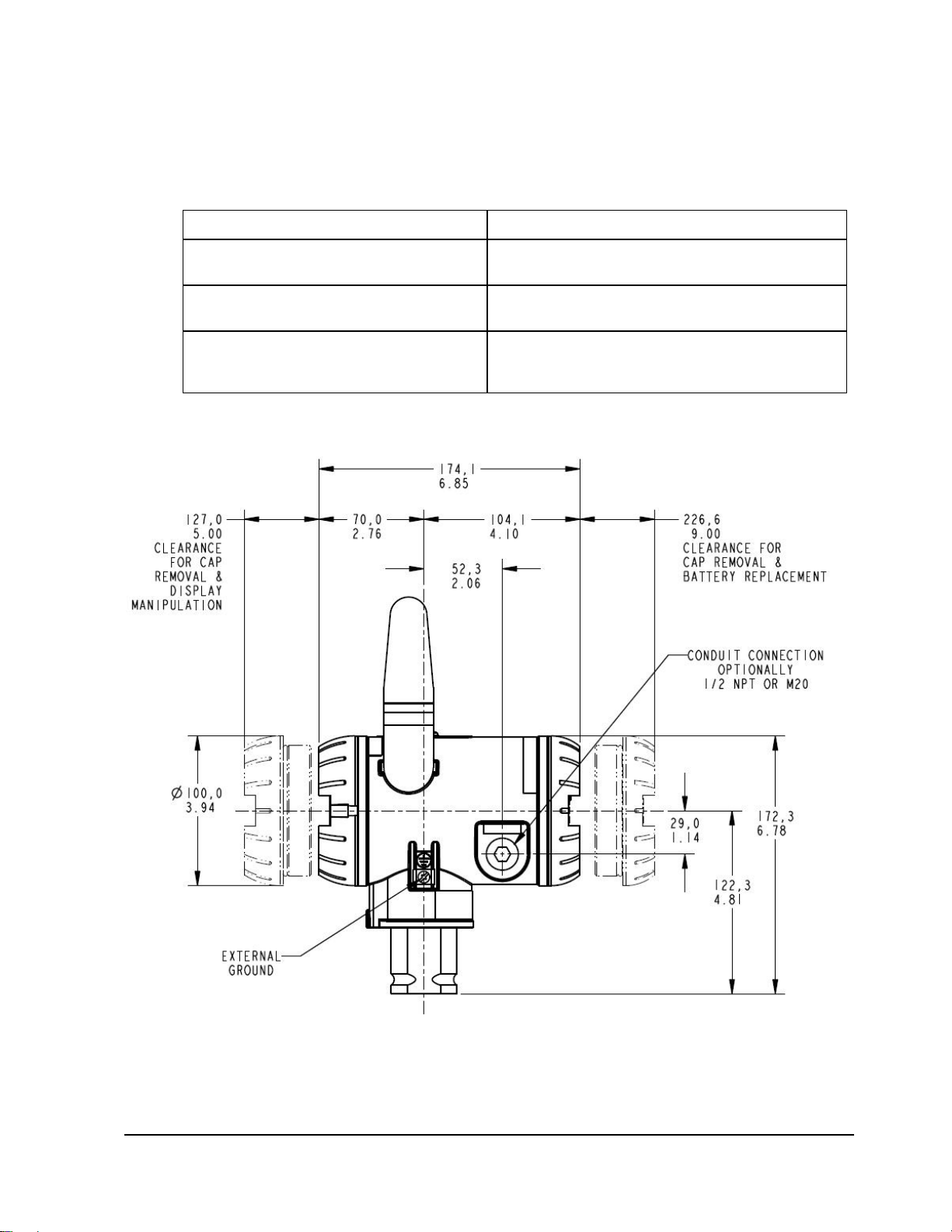

2.1 Weight

2. Transmitter Mounting

Transmitter model Weight

STDW9xx

STGW9x4

STGW9xL

STAW94L

STIW400

STTW400

CETW6000M

2.2 Dimensions

11 lbs (5 kg)

7 lbs (3.2 kg)

6 lbs (2.7 kg)

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 3

7/23/07

2. Transmitter Mounting

2.3. Transmitter location

2.3 Transmitter location

Pressure models

Process Suggested location Explanation

Gases Above the gas line

Liquids

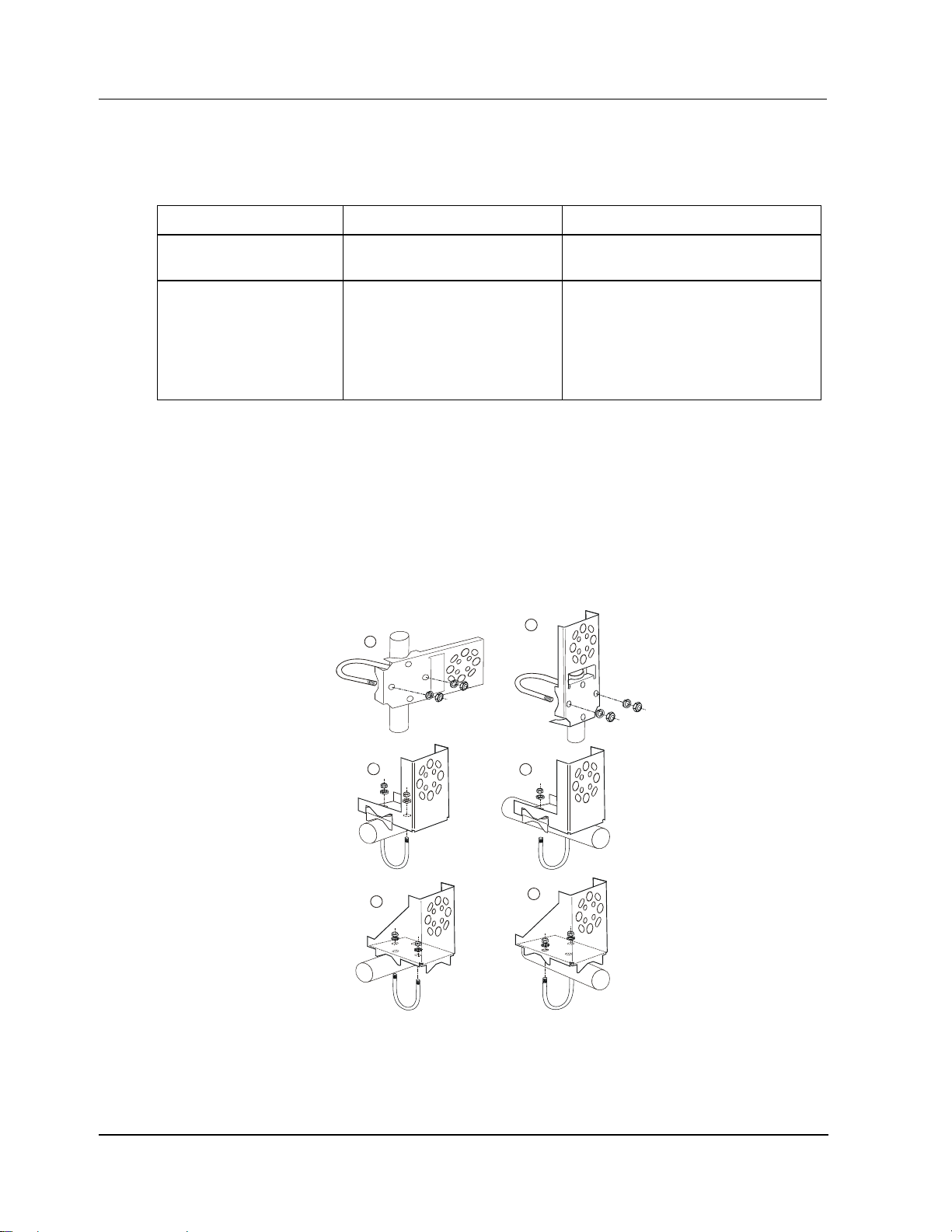

2.4 Bracket mounting

Attach bracket to pipe

Figure 1 shows some commonly used bracket and pipe orientations. Not all possibilities are shown; you

can use any bracket (flat or angle) and orientation (parallel or transverse) to get the desired transmitter

positioning.

Position bracket on 2-inch (50.8 mm) pipe and install “U” bolt around pipe and through holes in bracket.

Secure with nuts and lockwashers provided.

• Below but close to the

elevation of the process

connection.

• Level with or above the

process connection.

A

The condensate drains away from the

transmitter.

• This minimizes the static head

effect of the condensate.

• This requires a siphon to protect

the transmitter from process

steam. The siphon retains water as

a “fill fluid.”

B

C

E

D

F

Figure 1 Common bracket orientations

4 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

Attach transmitter to bracket

Align appropriate mounting holes in transmitter with holes in bracket and secure the transmitter to the

bracket with bolts and washers provide d.

If the meter body is hexagonal, you must use the additional bracket supplied. If meter body is round,

discard the bracket.

Transmitter type Attachment to bracket Example

2. Transmitter Mounting

2.4. Bracket mounting

DP type with double-ended

process heads and/or remote

seals

Dual head GP

Alternate mounting holes

in end of heads.

Mounting holes in end of

A

B

C

process head

In-line GP and AP (LGP

model)

Smaller “U” bolt.

C

B

D

Temperature Smaller “U” bolt.

High Level AI Smaller “U” bolt.

A

Corrosion Smaller “U” bolt.

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 5

7/23/07

2. Transmitter Mounting

2.5. Rotate transmitter housing

2.5 Rotate transmitter housing

You can rotate the transmitter for better viewing, access, or antenna position. Loosen set screw (see A in

Figure 2) on outside neck of transmitter one full turn. Rotate transmitter housing up to 180 degrees in

either direction to desired position.

CAUTION

Tighten set screw.

Do not rotate the housing past 180 degrees in any direction or you

could damage the internal wiring.

CAUTION:

Do not rotate

more than 180

A

0

2.6 Rotate display

If the transmitter’s mounting is such that the display is not horizontal, you can rotate the display 90 degrees

for horizontal viewing.

Tools required

• #1 Phillips Screwdriver or 1/8” Slotted Screwdriver

• Torque Screwdriver

• 1.5 mm hex key

Procedure

WARNING

Risk of death or serious injury by explosion. Do not open transmitter

enclosure when an explosive gas atmosphere is present.

Figure 2 Rotating transmitter housing

6 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

2. Transmitter Mounting

1

2.6. Rotate display

CAUTION

Take precautions against electrostatic discharge to prevent damaging the

display/sensor module.

Table 2-1 Display adjustment

Step Action

1

Honeywell recommends that the transmitter be removed from service and moved to a clean

area before servicing.

2

Loosen the M3 locking set screw on the display end-cap. See item 1 in Figure 3. Unscrew and

remove the end cap.

3

Loosen the two captive screws on the display/sensor module. See items 2 in Figure 3.

4

Rotate the display 90 degrees in either direction so the screws line up with the threaded holes.

Do not rotate more than 90 degrees or you could damage the wires behind the display.

5

Re-attach the two captive screws.

2

2

Figure 3 Display rotation

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 7

7/23/07

2. Transmitter Mounting

2.6. Rotate display

8 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

3. Process insertion

3.1 Pressure models

Piping

The actual piping arrangement will vary depending upon the process measurement requirements and the

transmitter model. Except for flanged and remote diaphragm seal connections, process connections are

made to ¼ inch or ½ inch NPT female connections in the process head of the transmitter’s meter body. For

example, a differential pressure transmitter comes with double ended process heads with ¼ inch NPT

connections but they can be modified to accept ½ inch NPT through optional flange adapters. Some gauge

pressure transmitters may have a ½ inch NPT connection which mounts directly to a process pipe.

The most common type of pipe used is ½ inch schedule 80 steel pipe. Many piping arrangements use a

three-valve manifold to connect the process piping to the transmitter. A manifold makes it easy to install

and remove or rezero a transmitter without interrupting the process. It also accommodates the installation

of blow-down valves to clear debris from pressure lines to the transmitter.

Figure 4 shows a diagram of a typical piping arrangement using a 3-valve manifold and blow-down lines

for a differential pressure transmitter being used to measure flow.

To Upstream TapTo Downstream Tap

Blow-Down

Piping

To WasteTo Waste

Blow-Down

Valve

21010

Blow-Down

Valve

Blow-Down

Piping

To Low Pressure

Side of Transmitter

3-Valve

Manifold

To High Pressure

Side of Transmitter

Figure 4 Typical 3-valve manifold and blow-down piping arrangment

Another piping arrangement uses a block-off valve and a tee connector in the process piping to the

transmitter as shown in Figure 5.

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 9

7/23/07

3. Process insertion

3.1. Pressure models

Tank Wall

1/2" NPT

Connection

Block-off Valve

Figure 5 Typical Arrangement for ½” NPT Process Connection Piping

ATTENTION

For liquid or steam, the piping should slope a minimum of 25.4 mm (1 inch) per 305 mm (1

foot). Slope the piping down towards the transmitter if the transmitter is below the process

connection so the bubbles may rise back into the piping through the liquid. If the transmitter is

located above the process connection, the piping should rise vertically above the transmitter;

then slope down towards the flowline with a vent valve at the high point. For gas

measurement, use a condensate leg and drain at the low point (freeze protection may be

required here).

CAUTION

Property damage may result if operating temperature limits of transmitter are exceeded.

Electronics housing must not exceed 85° C [185° F], meterbody temperature limit may be

rated higher. Consult transmitter nameplate for meterbody temperature limits. To reduce

the temperature of the process that comes into contact with the transmitter meter body, install

impulse piping. As a general rule there is a 56 degree C drop (100 degrees F) in the

temperature of the process for every foot (305 mm) of ½ inch uninsulated piping.

10 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

Process connections

Transmitter Type Process Connection

Differential Pressure Process heads with ¼ inch NPT female connection

Gauge Pressure Process head with ½ inch NPT female connection

Absolute Pressure Process head with ½ inch NPT female connection

3. Process insertion

3.1. Pressure models

Flange adapters and manifolds with ½ inch female connection are

optional

In-line ½ inch NPT female connection

In-line ½ inch NPT male

9/16 Aminco

DIN19213n

Process heads with ¼ inch NPT female connection

Flange adapters and manifolds with ½ inch female connections are

optional

General piping guidelines

When measuring fluids containing suspended solids, install permanent valves at regular intervals to blowdown piping.

Blow-down all lines on new installations with compressed air or steam and flush them with process fluids

(where possible) before connecting these lines to the transmitter’s meter body.

Be sure all the valves in the blow-down lines are closed tight after the initial blow-down procedure and

each maintenance procedure after that.

In-line ½-inch NPT male

9/16 Aminco

DIN19213n

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 11

7/23/07

3. Process insertion

3.2. Temperature models

3.2 Temperature models

Insert probe into process

ATTENTION

It is your responsibility to supply a suitable sealing method or gasket and mounting hardware

for the probe’s service conditions.

Inte gra l

Ri g i d

Integral probe wiring

The integral probe is pre-wired to the transmitter at the factory.

Remote probe wiring

Step Action

1

See Figure 6. Open the transmitter’s rear end cap (opposite end from

display).

2

Open the cable gland (on right side below antenna).

3

Feed wiring (6 to 8 mm allowed diameter) through the cable gland and

connect to terminal block. See page 27 for terminal connections.

4

Plug battery connector into batteries.

Inte g ra l

Sp r i n g

Re m o t e

Ri g i d

loaded

Figure 6 Temperature probes

Re m o t e

Sp r i n g

loaded

5

Close rear end cap and cable gland.

12 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

3.3 HLAI models

Connect wiring

Step Action

1

See Figure 7. HLAI transmitter is shown at left. Open the rear end cap

(opposite end from display).

2

Open the cable gland (on right side below antenna).

3

Feed wiring (allowed diameter 6 to 8 mm) from other transmitter through the

cable gland and connect to terminal block using either voltage or current but

not both. See Figure 8 or Figure 9. For hazardous locations see page 27.

4

Plug battery connector into batteries.

5

Close rear end cap and cable gland.

3. Process insertion

3.3. HLAI models

Figure 7 HLAI connection

+

+

+

4

4

1

1

5

5

2

2

3

3

-

-

6

6

+

-

-

0-5V

0-5V

1-5V

1-5V

Figure 8 Voltage input wiring

0-20 mA

0-20 mA

0-20 mA

4-20mA

4-20mA

4-20mA

+

-

-

+

+

+

-

-

-

4

4

4

1

1

1

5

5

5

2

2

2

6

6

6

3

3

3

+

Figure 9 Current input wiring

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 13

7/23/07

3. Process insertion

3.4. Corrosion models

3.4 Corrosion models

Probe mounting locations

The corrosion probe must be installed in a location that is most susceptible to corros ion. In most cases,

corrosion tends to occur where water is trapped or stagnant. However, it can also accelerate at the bend of

the pipe or where corrosion has occurred previously, but is accelerated by high flow or turbulence.

Location Picture

Incorrect probe location

The probe should not be mounted in a

pipe drop since the corrosive liquid

may not be in full contact with the

electrodes.

Correct probe location

The probe should be mounted in the

riser of a pipe near an elbow where

the velocity is the highest. In general,

probe should be mounted in pipes or

tanks at locations of highest liquid

velocity and constant immersion.

Correct Pipeline Position

Probe can be located at any point on

the pipeline but should always be

immersed in the corrosive material.

14 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

Location Picture

Located in Tee

Probe can be located at any point on

the pipeline but should always be

immersed in the corrosive material.

3. Process insertion

3.4. Corrosion models

Located in Bypass Loop

Probe should be located downstream

of a control valve for best performance

and can also be located in the deadleg

portion of a by-pass.

Note that the probe located in the bypass leg should be mounted before

the valve for best performance. This

guarantees the electrodes will always

be immersed in the corrosive material.

Mounted with Different Electrodes

Installing with different electrode

materials on the suction side of the

pump will ensure monitoring of the

pump impeller and the pipe.

Installed in a Condensate Flash Tank

A condensate flash tank is also a good

application.

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 15

7/23/07

3. Process insertion

3.4. Corrosion models

Mounted in Y-Strainer

The probe is shown in the blow down

of a Y-strainer.

Location Picture

Mounted in Basket Strainer

The probe is shown in the discharge

side of the basket strainer.

The electrodes should be selected to reflect the same metal properties as the piping or other components

that might be susceptible to corrosion. For example, in applications where the pipe is made of stainless

steel and the water pump’s impeller is made of carbon steel, the impeller will corrode faster than the pipe.

In this case it is advisable to select the electrodes to be the same material as the pump’s impeller.

16 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

Probe installation

Step Action

3. Process insertion

3.4. Corrosion models

WARNING

If the pipe or vessel into which the probe is to be inserted is under pressure

and/or contains any hazardous substance, such as steam, caustic solutions,

acids, toxins or other substances specified by OSHA as physical or health

hazards, the pipe or vessel must first be depressurized and any hazardous

substance purged there from, and appropriate lockout/tagout procedures

observed in accordance with Section 1910.147 of the OSHA Regulations,

before the probe can be installed. Failure to follow these procedures may

result in serious injury or death.

1

1/16”

1/16”

1

1

Hex Flat

Hex Flat

1/8”

1/8”

1

1

Hex Flat

Hex Flat

Pipe

Pipe

Some probes are supplied with an adjustable, compression NPT fitting (e.g.

Swagelok). With this fitting, follow this tightening sequence to ensure a tight

seal.

a) The Swagelok fitting should be held onto place with a plastic zip-tie

around the probe body. The zip-tie should be removed.

b) Determine the depth that the probe should extend into the pipe.

c) Tighten the larger upper nut until the tubing will not rotate freely by hand.

d) Make a mark on the nut. This mark will serve as a reference as the 6

o’clock position.

e) While holding fitting body steady, tighten the large upper nut 1 + 1⁄4 turns

to the 9 o’clock position.

f) This tightening sequence will crimp the internal ring onto the probe body

and should lock the fitting in place now.

g) Tighten the lower nut onto the pipe nipple or access point.

For fixed type probes (without the adjustable compression fitting) only the

1 1/16 hex nut needs to be tightened and the safety bracket is not required.

2

Ensure the flow rate of the process fluid does not exceed 20 feet per second

(fps). Stronger flow might damage probes with three finger electrodes and

interfere with the reading. If the flow rate exceeds the recommendation, a

different probe style may be required.

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 17

7/23/07

3. Process insertion

3.4. Corrosion models

Connect wiring

Step Action

1

See Figure 10. Open the transmitter’s rear end cap (opposite end from

display).

2

Open the cable gland (on right side below antenna).

3

Feed probe wiring through the cable gland and connect to terminal block. See

Figure 10. See page 27 for terminal connections.

4

Plug battery connector into batteries.

5

Close rear end cap and cable gland.

Figure 10 Corrosion transmitter with remote probe

18 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

4. Antenna adjustment and mounting

4.1 Requirements

Radio installation requirements

ATTENTION

Professional Installation is required to insure conformity with Federal Communications

Commission (FCC) in the USA, Industry Canada (IC) in Canada and the Radio and

Telecommunications Terminal Equipment Directive, 1999/5/EC (R&TTE), in the European

Union (EU).

Professional installation is required for the selection and installation of approved antennas and

setup of the maximum allowable radiated power from the XYR 6000 Wireless Transmitter as

configured for the particular installation site.

The antennae used for this transmitter must be installed to provide a separation distance of at

least 20 cm (8 inches) from all persons and must not be co-located or operating in conjunction

with any other antenna or transmitter.

For remote antenna, see antenna installation requirements to satisfy FCC RF exposure

requirements.

ATTENTION

Federal Communications Commission (FCC):

The XYR 6000 Wireless Transmitters comply with part 15 of the FCC rules. Operation is

subject to the following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause

undesired operation.

Industry Canada (IC):

The installer of this radio equipment must ensure that the antenna is located or pointed such

that it does not emit RF fields in excess of Health Canada limits for the general population;

consult Safety Code 6, obtainable from Health Canada’s web site www.hc-sc.gc.ca/rpb.

4.2 Integral antenna

WARNING

POTENTIAL ELECTROSTATIC CHARGING HAZARD

The integrally mounted antenna shroud is made of Teflon® and has a surface

resistance greater than 1Gohm per square. When the XYR 6000 transmitter

is installed in potentially hazardous locations care should be taken not to

electrostatically charge the surface of the antenna shroud by rubbing the

surface with a cloth, or cleaning the surface with a solvent. If electrostatically

charged, discharge of the antenna shroud to a person or a tool could possibly

ignite a surrounding hazardous atmosphere.

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 19

7/23/07

4. Antenna adjustment and mounting

4.2. Integral antenna

Elbow

If your model has the integral elbow anntena you can adjust it to improve operation. Typically, pointed

straight up gives best performance but your installation may vary. Loosen the 1.5mm set screw located

near the antenna base. Rotate antenna for best reception. Do not rotate antenna more than 180 degrees

either direction or you could damage internal wiring. Tighten set screw.

Figure 11 Elbow antenna adjustment

Straight

Figure 12 Integral straight antenna

20 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

If your model has the integral straight anntena (Figure 12) you can adjust its position by rotating the

transmitter housing. (See page 6.) Typically, pointed straight up gives best performance but your

installation may vary.

4.3 Remote antenna

Outdoor installation warnings

WARNING

LIVES MAY BE AT RISK! Carefully observe these instructions and any special instructions

that are included with the equipment you are installing.

WARNING

Contacting power lines can be lethal.

Look over the site before beginning any installation, and anticipate possible hazards,

especially these:

Make sure no power lines are anywhere where possible contact can be made. Antennas,

masts, towers, guy wires or cables may lean or fall and contact these lines. People may be

injured or killed if they are touching or holding any part of equipment when it contacts electric

lines. Make sure there is NO possibility that equipment or personnel can come in contact

directly or indirectly with power lines.

4. Antenna adjustment and mounting

4.3. Remote antenna

Assume all overhead lines are power lines.

The horizontal distance from a tower, mast or antenna to the nearest power line should be at

least twice the total length of the mast/antenna combination. This will ensure that the mast will

not contact power if it falls either during installation or later.

WARNING

To avoid falling, use safe procedures when working at heights above ground.

Select equipment locations that will allow safe, simple equipment installation.

Don’t work alone. A friend or co-worker can save your life if an accident happens.

Use approved non-conducting ladders and other safety equipment. Make sure all equipment is

in good repair.

If a tower or mast begins falling, don’t attempt to catch it. Stand back and let it fall.

If anything such as a wire or mast does come in contact with a power line, DON’T TOUCH IT

OR ATTEMPT TO MOVE IT. Instead, save your life by calling the power company.

Don’t attempt to erect antennas or towers on windy days.

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 21

7/23/07

4. Antenna adjustment and mounting

4.3. Remote antenna

WARNING

MAKE SURE ALL TOWERS AND MASTS ARE SECURELY GROUNDED, AND

ELECTRICAL CABLES CONNECTED TO ANTENNAS HAVE LIGHTNING ARRESTORS.

This will help prevent fire damage or human injury in case of lightning, static build-up, or short

circuit within equipment connected to the antenna.

The base of the antenna mast or tower must be connected directly to the building protective

ground or to one or more approved grounding rods, using 1 OAWG ground wire and

corrosion-resistant connectors.

Refer to the National Electrical Code for grounding details.

Lightning arrestors for antenna feed coaxial cables are available from HyperLink

Technologies, Inc.

WARNING

If a person comes in contact with electrical power, and cannot move:

DON’T TOUCH THAT PERSON, OR YOU MAY BE ELECTROCUTED.

Use a non-conductive dry board, stick or rope to push or drag them so they no longer are in

contact with electrical power.

Once they are no longer contacting electrical power, administer CPR if you are certified, and

make sure that emergency medical aid has been requested.

22 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

Directional mounting procedure

Step Action

1

Secure mast mounting bracket to mast as shown using 2 U-bolts and supplied hardware.

2

Attach antenna to mast mounting bracket as shown using supplied hardware.

3

Adjust antenna to desired tilt and lock into place using the antenna tilt adjustment nut.

4. Antenna adjustment and mounting

4.3. Remote antenna

Figure 13 Directional antenna mounting

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 23

7/23/07

4. Antenna adjustment and mounting

4.3. Remote antenna

Omnidirectional mounting procedure

Step Action

1

Secure mast mounting bracket to mast as shown using 2 U-bolts and supplied hardware.

2

Remove antenna mounting bolt and washer from antenna base.

3

Insert antenna into mounting bracket and secure with washer and antenna mounting bolt. Do

not overtighten.

4

Any drain holes in the antenna base must be kept clear for proper operation.

Figure 14 Omnidirection antenna mounting

Connect antenna to transmitter

Using coaxial cable, connect the antenna base to the transmitter’s remote antenna connector (located at top

right as you face the transmitter display). A lightning arrestor may be required between the antenna and the

transmitter, using two cables up to 10m long each. Without lightning arrester, total cable length must not

exceed 10m (33 ft.). With lightning arrester total cable length must not exceed 20m (66 ft.). Antenna cable

shield shall be bonded to earth ground.

See page for cable types and connection information.

24 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

5.1 Connect batteries

WARNING

Risk of death or serious injury from explosion or fire.

Connection and disconnection of the batteries should be done only when the

area is non-hazardous.

ATTENTION

Both batteries must be the same model from the same manufacturer. Mixing

old and new batteries or different manufacturers is not permitted.

Use only the following 3.6V lithium thionyl chloride (Li-SOCl2) batteries (nonrechargeable), size D. No other batteries are approved for use in XYR 6000

Wireless Transmitters.

• Xeno Energy XL-205F

5. Start up

5.1. Connect batteries

5. Start up

• Eagle Picher PT-2300H

• Tadiran TL-5930/s

• Honeywell p/n 50026010-001 (Two 3.6V lithium thionyl chloride

batteries)

• Honeywell p/n 50026010-002 (Four 3.6V lithium thionyl chloride

batteries)

• Honeywell p/n 50026010-003 (Ten 3.6V lithium thionyl chloride batteries)

Step Action

1

Loosen the M3 locking set screw on the battery end-cap (opposite end from display). See item

1 in Figure 15. Unscrew and remove the end cap.

2

Attach connector to batteries as shown.

3

Screw the end cap back on and tighten the M3 locking screw.

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 25

7/23/07

5. Start up

1

5.1. Connect batteries

-

+

+

Display sequence

After power up, the transmitter does a brief self-test of the LCD display. Then it proceeds to Power-On

Message, which is the model name of the transmitter. The name is displayed for 2 seconds after which the

transmitter displays the process variables and associated status.

Authentication

Before the transmitter can be configured it must be unlocked with a security key so it can join the network.

Use the Authentication Device Pocket PC software to receive security keys from the Key Server manager,

then aim the Pocket PC at the transmitter and transmit a key.

-

4

2

Figure 15 Battery assembly

3

26 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

6. CSA Certified DIVISION 2 / ZONE 2 Installation Drawings

Use the following drawings and accompanying notes and text for hazardous locations. For non-hazardous

locations you can use the same drawings without the accompanying notes and text.

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 27

7/23/07

6. CSA Certified DIVISION 2 / ZONE 2 Installation Drawings

28 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

6. CSA Certified DIVISION 2 / ZONE 2 Installation Drawings

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 29

7/23/07

6. CSA Certified DIVISION 2 / ZONE 2 Installation Drawings

30 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

6. CSA Certified DIVISION 2 / ZONE 2 Installation Drawings

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 31

7/23/07

6. CSA Certified DIVISION 2 / ZONE 2 Installation Drawings

32 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

6. CSA Certified DIVISION 2 / ZONE 2 Installation Drawings

R100 OneWireless XYR 6000 Transmitters Quick Start Guide 33

7/23/07

6. CSA Certified DIVISION 2 / ZONE 2 Installation Drawings

34 OneWireless XYR 6000 Transmitters Quick Start Guide R100

7/23/07

Honeywell International

Process Solutions

2500 West Union Hills

Phoenix, AZ 85027

Loading...

Loading...