Page 1

™

4600rp, 4600g/4600r, 4800i

Commercial/Retail/Industrial Area Imager

User’s Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information contained in this document without prior notice,

and the reader should in all cases consult HII to determine whether any such

changes have been made. The information in this publication does not represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained

herein; nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material.

This document contains proprietary information that is protected by copyright.

All rights are reserved. No part of this document may be photocopied, reproduced, or translated into another language without the prior written consent of

HII.

© 2007-2011 Honeywell International Inc. All rights reserved.

Other product names or marks mentioned in this document may be trademarks

or registered trademarks of other companies and are the property of their

respective owners.

Web Address:

www.honeywellaidc.com

Product Agency Compliance

USA

FCC Part 15 Subpart B Class A

This device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference

that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at his own expense.

Use only shielded data cables with this system.

Page 3

Caution: Any changes or modifications made to this equipment not expressly

approved by Honeywell may void the FCC authorization to operate this

equipment.

UL Statement

UL listed: UL60950-1.

Canada

Industry Canada ICES-003

This Class A digital apparatus complies with Canadian ICES-003. Operation

is subject to the following conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference

that may cause undesired operation.

Conformité à la règlementation canadienne

Cet appareil numérique de la Classe A est conforme à la norme NMB-003 du

Canada. Son fonctionnement est assujetti aux conditions suivantes :

1. Cet appareil ne doit pas causer de brouillage préjudiciable.

2. Cet appareil doit pouvoir accepter tout brouillage reçu, y compris le

brouillage pouvant causer un fonctionnement indésirable.

C-UL Statement

C-UL listed: CSA C22.2 No.60950-1-03.

Europe

The CE marking indicates compliance to 2004/108/EC EMC Directive

with Standards EN55022 CLASS A, EN55024, EN61000-3-2,

EN61000-3-3. In addition, complies to 2006/95/EC Low Voltage

Directive, when shipped with recommended power supply.

For further information contact:

Honeywell Imaging & Mobility Europe BV

Nijverheidsweg 9-13

5627 BT Eindhoven

The Netherlands

Honeywell International Inc. shall not be liable for use of our product with

equipment (i.e., power supplies, personal computers, etc.) that is not CE

marked and does not comply with the Low Voltage Directive.

Page 4

Waste Electrical and Electronic Equipment

Information

Honeywell complies with Directive 2002/96/EC OF THE EUROPEAN

PARLIAMENT AND OF THE COUNCIL of 27 January 2003 on waste

electrical and electronic equipment (WEEE).

This product has required the extraction and use of natural resources for its

production. It may contain hazardous substances that could impact health

and the environment, if not properly disposed.

In order to avoid the dissemination of those substances in our environment

and to diminish the pressure on the natural resources, we encourage you to

use the appropriate take-back systems for product disposal. Those systems

will reuse or recycle most of the materials of the product you are disposing in

a sound way.

The crossed out wheeled bin symbol informs you that the product

should not be disposed of along with municipal waste and invites you to use

the appropriate separate take-back systems for product disposal.

If you need more information on the collection, reuse, and recycling systems,

contact your local or regional waste administration.

You may also contact your supplier for more information on the

environmental performances of this product.

Germany

GS marked to EN60950-1:2001.

Australia/NZ

C-Tick Statement

Conforms to AS/NZS 3548.

South Korea

This product meets Korean agency approval.

Page 5

Mexico

!

Conforms to NOM-019.

International

LED Safety Statement

LEDs have been tested and classified as “EXEMPT RISK GROUP” to the

standard: IEC 62471:2006.

CB Scheme

Certified to CB Scheme IEC 60950-1, Second Edition.

Power Source

Use only a Listed Limited Power Source (LPS) or a Class 2 type power supply

compatible with these models.

Patents

For patent information, refer to www.honeywellaidc.com/patents.

Solids and Water Protection

The 4600g/4600r has a rating of IP41, immunity of foreign particles and dripping

water.

The 4800i has a rating of IP54, immunity of windblown dust penetration and

splashing water.

Warning

To reduce the possibility of heat-related injuries, avoid touching sections

of the scanner that feel warm.

Page 6

Page 7

Table of Contents

Chapter 1 - Getting Started

About This Manual ...................................................... 1-1

Unpacking the Imager ................................................. 1-1

Imager Models ............................................................ 1-2

Imager Identification.................................................... 1-3

Connecting the Imager with Keyboard Wedge............ 1-4

Connecting the Imager with USB ................................ 1-5

Connecting the Imager with RS-232 Serial Port ......... 1-6

Connecting the Imager with RS-232 Wedge............... 1-6

Programming the Interface - Plug and Play ................ 1-8

Keyboard Wedge Connection ..................................... 1-8

Laptop Direct Connect........................................... 1-8

USB Connection.......................................................... 1-9

IBM SurePos ......................................................... 1-9

USB PC or Macintosh

USB HID.............................................................. 1-10

USB COM Port Emulation................................... 1-10

RS-232 Serial Port Connection ................................. 1-11

Serial Wedge Data Transmission Port ...................... 1-12

IBM 4683 Ports 5B, 9B, and 17 Connection ............. 1-12

Wand Emulation Connection..................................... 1-13

Menu Bar Code Security Settings ............................. 1-14

Reading Techniques ................................................. 1-15

®

Keyboard ....................... 1-10

Chapter 2 - Terminal Interfaces

Terminal ID.................................................................. 2-1

Supported Terminals................................................... 2-2

Keyboard Country ....................................................... 2-4

Keyboard Style............................................................ 2-6

i

Page 8

Keyboard Modifiers......................................................2-7

RS-232 Baud Rate............................................... 2-10

RS-232 Word Length: Data Bits, Stop Bits,

and Parity .......................................................2-10

RS-232 Receiver Time-Out .................................2-11

RS-232 Handshaking........................................... 2-12

Wand Emulation Connection ............................... 2-12

Wand Emulation ........................................................2-13

Data Block Size ...................................................2-13

Delay Between Blocks .........................................2-14

Overall Checksum ...............................................2-14

Wand Emulation Transmission Rate ...................2-15

Wand Emulation Polarity .....................................2-15

Wand Emulation Idle............................................ 2-16

Chapter 3 - Output

Good Read Indicators..................................................3-1

Beeper – Good Read.............................................3-1

Beeper Volume – Good Read................................ 3-1

Beeper Pitch – Good Read....................................3-2

Beeper Duration – Good Read .............................. 3-2

LED – Good Read .................................................3-2

Number of Beeps – Good Read ............................3-2

Good Read Delay ........................................................3-3

User-Specified Good Read Delay................................3-3

Trigger Modes..............................................................3-4

Manual/Serial Trigger ............................................3-4

In-Stand Sensor Mode (4600r only).............................3-5

Scan Stand Mode ........................................................3-6

Scan Stand Symbol ............................................... 3-6

Presentation Mode.......................................................3-7

Presentation LED Behavior after Decode..............3-7

Presentation Sensitivity .........................................3-8

Streaming Presentation™ Mode..................................3-8

Image Snap and Ship ..................................................3-9

Hands Free Time-Out.................................................. 3-9

ii

Page 9

Reread Delay .............................................................. 3-9

User-Specified Reread Delay.................................... 3-10

LED Power Level ...................................................... 3-10

Illumination Lights ..................................................... 3-11

Imager Time-Out ....................................................... 3-12

Aimer Delay............................................................... 3-12

User-Specified Aimer Delay ................................ 3-12

Aimer Mode............................................................... 3-13

Centering................................................................... 3-13

Decode Search Mode ............................................... 3-15

Preferred Symbology ................................................ 3-15

Output Sequence Overview ...................................... 3-17

Output Sequence Editor...................................... 3-20

Require Output Sequence................................... 3-20

Multiple Symbols ....................................................... 3-20

No Read .................................................................... 3-21

Print Weight............................................................... 3-21

Video Reverse........................................................... 3-22

Working Orientation .................................................. 3-22

Chapter 4 - Data Editing

Prefix/Suffix Overview ................................................. 4-1

To Add a Prefix or Suffix: ...................................... 4-2

To Clear One or All Prefixes or Suffixes:............... 4-3

To Add a Carriage Return Suffix

to all Symbologies............................................ 4-3

Prefix Selections.................................................... 4-4

Suffix Selections.................................................... 4-4

Function Code Transmit........................................ 4-4

Intercharacter, Interfunction,

and Intermessage Delays ......................................... 4-5

Intercharacter Delay.............................................. 4-5

User Specified Intercharacter Delay...................... 4-5

Interfunction Delay ................................................ 4-6

Intermessage Delay .............................................. 4-7

iii

Page 10

Chapter 5 - Data Formatting

Data Format Editor Introduction...................................5-1

To Add a Data Format ........................................... 5-1

Other Programming Selections.............................. 5-2

Data Format Editor Commands .............................5-2

Data Format Editor ................................................5-5

Data Formatter....................................................... 5-5

Alternate Data Formats.......................................... 5-6

Chapter 6 - Secondary Interface

Secondary RS-232 Connection ...................................6-2

Secondary Code 39 Wand Emulation..........................6-2

Wand Emulation Multi Block........................................ 6-3

Delay Between Blocks ...........................................6-3

Overall Checksum .................................................6-4

Wand Emulation Transmission Rate .....................6-4

Wand Emulation Polarity .......................................6-5

Wand Emulation Idle.............................................. 6-5

Data Block Size .....................................................6-5

Secondary Trigger Mode .............................................6-6

Manual/Serial Trigger ............................................6-6

Hands Free Time-Out.................................................. 6-7

Scan Stand Mode ........................................................6-8

Scan Stand Symbol ............................................... 6-8

Presentation Mode.......................................................6-8

Chapter 7 - Symbologies

All Symbologies ..........................................................7-2

Message Length Description .......................................7-2

Codabar ......................................................................7-3

Codabar Concatenation.........................................7-4

Code 39 ......................................................................7-5

Code 32 Pharmaceutical (PARAF) ........................7-7

Full ASCII............................................................... 7-7

Code 39 Code Page .............................................. 7-8

iv

Page 11

Interleaved 2 of 5 ....................................................... 7-8

Code 93 .................................................................... 7-10

Straight 2 of 5 Industrial ........................................... 7-11

Straight 2 of 5 IATA (Two-Bar Start/Stop) ................ 7-12

Matrix 2 of 5 ............................................................. 7-13

Code 11 .................................................................... 7-13

Code 128 .................................................................. 7-15

ISBT 128 Concatenation ..................................... 7-15

Telepen .................................................................... 7-17

UPC-A ...................................................................... 7-18

UPC-A/EAN-13

with Extended Coupon Code ................................. 7-20

UPC-E0 .................................................................... 7-20

UPC-E1 .................................................................... 7-22

EAN/JAN-13 ............................................................. 7-23

ISBN Translate.................................................... 7-25

EAN/JAN-8 ............................................................... 7-25

MSI ........................................................................... 7-27

Plessey Code ........................................................... 7-28

GS1 DataBar Omnidirectional .................................. 7-29

GS1 DataBar Limited ............................................... 7-29

GS1 DataBar Expanded ........................................... 7-29

PosiCode .................................................................. 7-31

Trioptic Code ............................................................ 7-32

Codablock F ............................................................. 7-32

Code 16K ................................................................. 7-33

Code 49 .................................................................... 7-34

PDF417 .................................................................... 7-35

MicroPDF417 ........................................................... 7-36

GS1 Composite Codes ............................................ 7-36

UPC/EAN Version ............................................... 7-37

GS1 Emulation ......................................................... 7-37

TCIF Linked Code 39 (TLC39) ................................. 7-38

v

Page 12

Postal Codes ............................................................7-38

Intelligent Mail Bar Code...................................... 7-38

Postal-4i...............................................................7-39

Postnet................................................................. 7-39

Planet Code .........................................................7-40

British Post........................................................... 7-41

Canadian Post ..................................................... 7-41

Kix (Netherlands) Post.........................................7-41

Australian Post..................................................... 7-41

Japanese Post .....................................................7-43

China Post ........................................................... 7-43

Korea Post ...........................................................7-44

QR Code ...................................................................7-45

Data Matrix ...............................................................7-46

MaxiCode ..................................................................7-47

Aztec Code ...............................................................7-48

Chinese Sensible (Han Xin) Code ............................7-49

Chapter 8 - Imaging Commands

Single-Use Basis .........................................................8-1

Command Syntax ........................................................8-1

Image Snap - IMGSNP................................................ 8-2

IMGSNP Modifiers .................................................8-2

Image Ship - IMGSHP .................................................8-5

IMGSHP Modifiers .................................................8-6

Intelligent Signature Capture - IMGBOX....................8-14

IMGBOX Modifiers...............................................8-15

Chapter 9 - OCR Programming

OCR Fonts ..................................................................9-1

OCR.............................................................................9-1

U.S. Currency Font ..................................................... 9-2

MICR E13 B Font ........................................................9-2

SEMI Font ...................................................................9-3

vi

Page 13

OCR Templates .......................................................... 9-3

Creating an OCR Template................................... 9-3

Stringing Together Multiple Formats

(Creating “Or” Statements) .............................. 9-5

OCR User-Defined Variables ...................................... 9-6

Reading Multi-Row OCR....................................... 9-7

OCR Check Character ................................................ 9-7

OCR Modulo 10 Check Character......................... 9-8

OCR Modulo 36 Check Character......................... 9-8

OCR User-Defined Check Character .......................... 9-8

Weighting Options................................................. 9-9

OCR ISBN Application Example ............................... 9-11

OCR Template Codes............................................... 9-13

Chapter 10 - Interface Keys

Keyboard Function Relationships ............................. 10-1

Supported Interface Keys.......................................... 10-3

Chapter 11 - Utilities

To Add a Test Code I.D. Prefix to All Symbologies... 11-1

Show Decoder Revision............................................ 11-1

Show Engine Revision .............................................. 11-1

Show Scan Driver Revision....................................... 11-2

Show Software Revision ........................................... 11-2

Show Data Format .................................................... 11-2

Resetting the Standard Product Defaults.................. 11-2

Test Menu ................................................................. 11-3

2D PQA (Print Quality Assessment) ......................... 11-3

2D PQA Reporting............................................... 11-3

Visual Xpress Introduction ........................................ 11-4

Installing Visual Xpress from the Web................. 11-5

Quick*View................................................................ 11-6

Installing Quick*View from the Web .................... 11-6

vii

Page 14

Chapter 12 - Serial Programming Commands

Conventions...............................................................12-1

Menu Command Syntax ............................................12-1

Query Commands......................................................12-2

Concatenation of Multiple Commands.................12-2

Responses...........................................................12-2

Examples of Query Commands...........................12-3

Trigger Commands.................................................... 12-4

Resetting the Standard Product Defaults ..................12-4

Menu Commands ......................................................12-4

Chapter 13 - Product Specifications

4600g and 4600r........................................................13-1

4800i.......................................................................... 13-2

Standard Cable Pinouts.............................................13-3

Keyboard Wedge .................................................13-3

Wand Emulation ..................................................13-4

Serial Output .......................................................13-5

USB .....................................................................13-6

Chapter 14 - Maintenance

Repairs ......................................................................14-1

Maintenance ..............................................................14-1

Cleaning the Device............................................. 14-1

Inspecting Cords and Connectors .......................14-1

Replacing the Interface Cable .............................14-2

Troubleshooting......................................................... 14-4

Chapter 15 - Customer Support

Technical Assistance................................................. 15-1

Online Technical Assistance................................ 15-1

Product Service and Repair.....................................15-2

Online Product Service and Repair Assistance ...15-3

Limited Warranty........................................................15-3

viii

Page 15

Appendix A - Reference Charts

Sample Symbols

OCR Programming Chart

Programming Chart

ix

Page 16

x

Page 17

1

Getting Started

About This Manual

This User’s Guide provides installation and programming instructions for the

4000 Series imagers. Product specifications, dimensions, warranty, and customer support information are also included.

Honeywell bar code imagers are factory programmed for the most common terminal and communications settings. If you need to change these settings, programming is accomplished by scanning the bar codes in this guide.

An asterisk (*) next to an option indicates the default setting.

Unpacking the Imager

After you open the shipping carton, take the following steps:

• Check for damage during shipment. Report damage immediately to the

carrier who delivered the carton.

• Make sure the items in the carton match your order.

• Save the shipping container for later storage or shipping.

1 - 1

Page 18

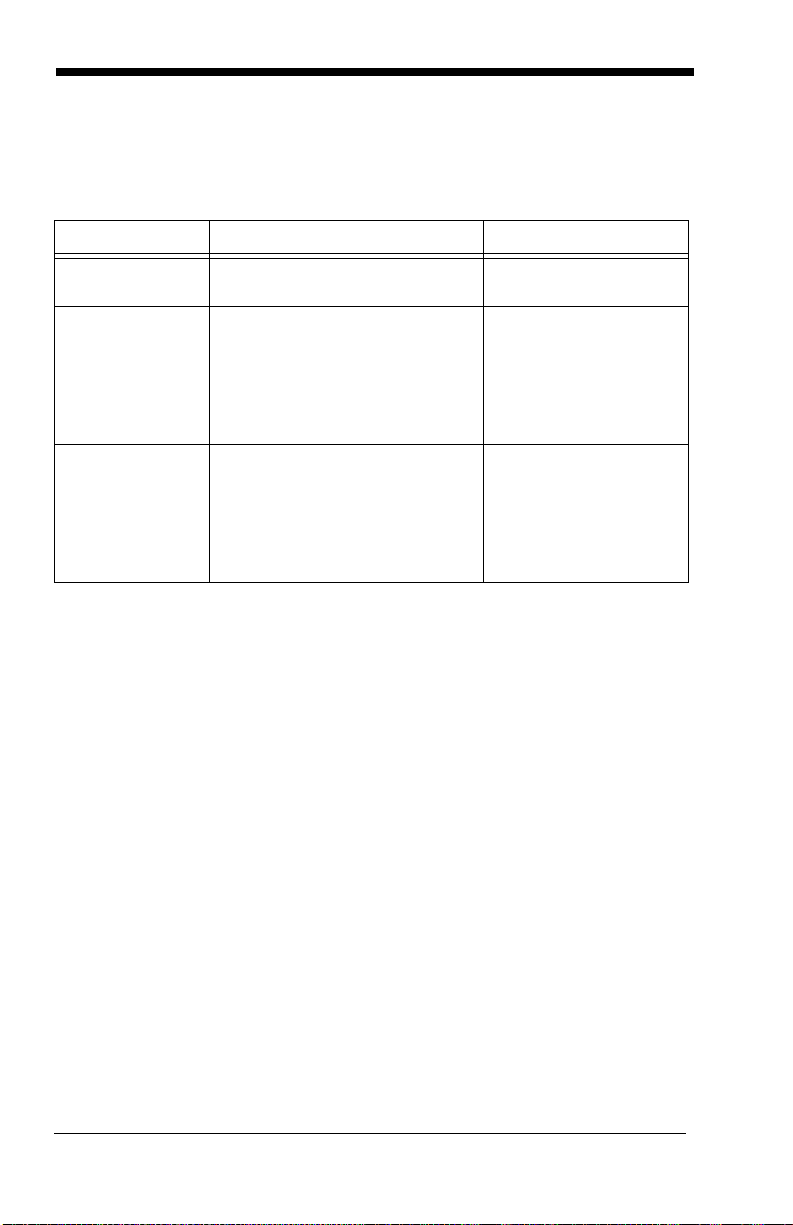

Imager Models

The chart below lists the interfaces that can be used with your imager. Refer to

Chapter 6 for programming information regarding secondary interfaces.

Models Primary Secondary

4600gXX03XX

4800iXX03XX

4600gXX05XX

4800iXX05XX

4600rXX05XX

4600rpXX05XX

True RS-232 True RS-232

Keyboard wedge, TTL level

232, TTL level 232 serial

wedge, IBM 4683, wand emulation, USB keyboard, USB HID,

USB retail (IBM SurePOS),

USB COM port emulation

Keyboard wedge, TTL level

232, TTL level 232 serial

wedge, IBM 4683, USB keyboard, USB HID, USB retail

(IBM SurePOS), USB COM

port emulation

Wand Emulation, TTL

level 232

TTL level 232

1 - 2

Page 19

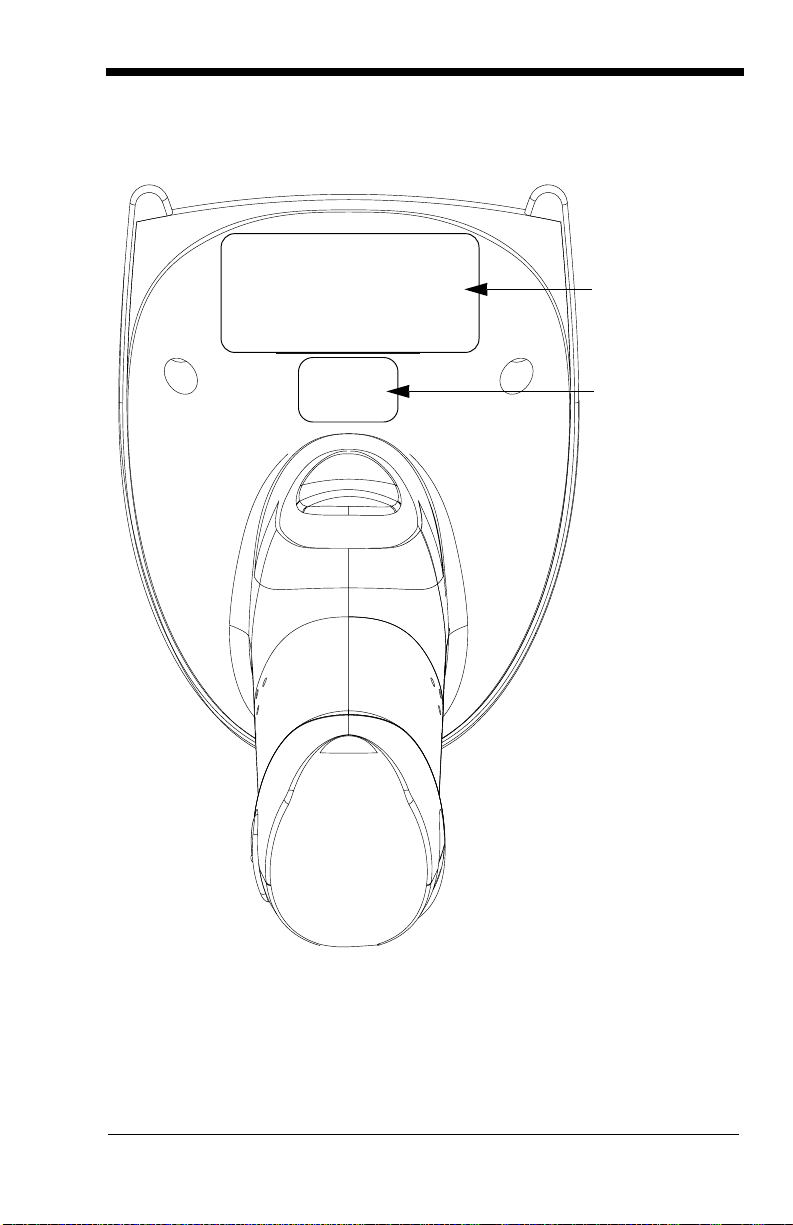

Imager Identification

Compliance

Label location

Item Number,

Serial Number

and Revision

Information

location

1 - 3

Page 20

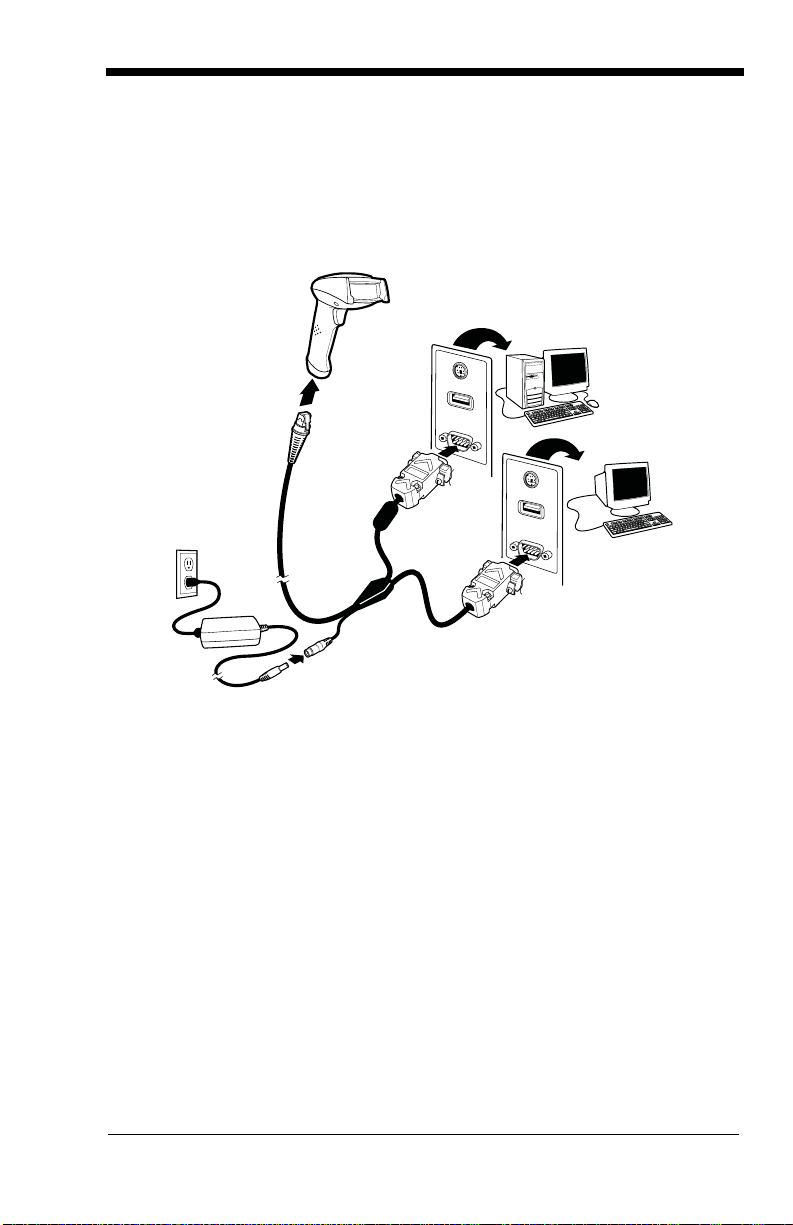

Connecting the Imager with Keyboard Wedge

Note: See "Imager Models" on page 1-2 to determine which interfaces apply to

your imager.

An imager can be connected between the keyboard and PC as a “keyboard

wedge,” plugged into the serial port, or connected to a portable data terminal in

wand emulation or non decoded output mode. The following is an example of a

keyboard wedge connection:

1. Turn off power to the terminal/computer.

2. Disconnect the keyboard cable from the back of the terminal/computer.

3. Connect the appropriate interface cable to the imager and to the terminal/

computer.

4. Turn the terminal/computer power back on. The imager beeps.

5. Program the imager for a keyboard wedge interface using the Plug and Play

bar codes beginning on page 1-8.

6. Verify the imager operation by scanning a bar code from the Sample

Symbols in the back of this manual. The imager beeps once.

Your imager is factory programmed for a keyboard wedge interface to an IBM

PC AT with a USA keyboard. If this is your interface and you do not need to

modify the settings, skip to Chapter 3 - Output.

1 - 4

Page 21

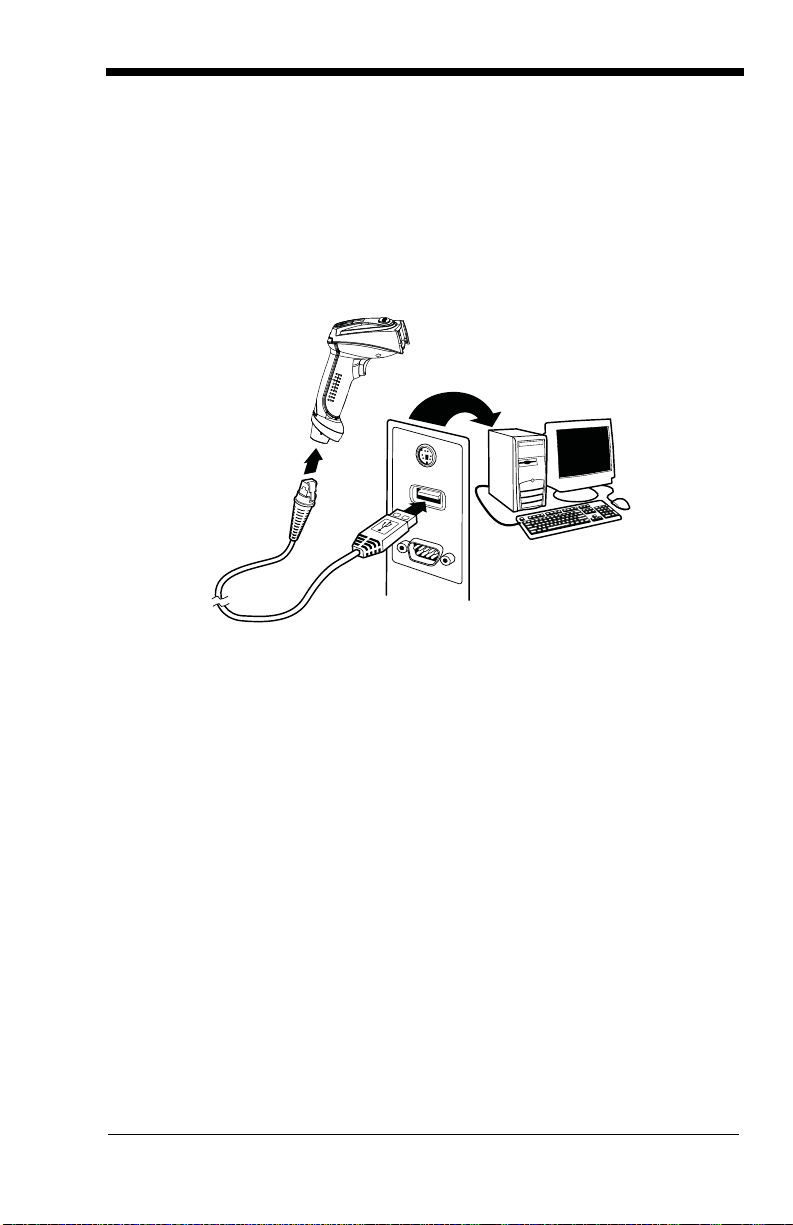

Connecting the Imager with USB

Note: See "Imager Models" on page 1-2 to determine which interfaces apply to

your imager.

An imager can be connected to the USB port of a computer.

1. Connect the appropriate interface cable to the imager first, then to the computer.

2. Program the imager for a USB interface using the Plug and Play bar codes

beginning on page 1-9.

3. The imager beeps.

4. Verify the imager operation by scanning a bar code from the Sample

Symbols in the back of this manual.

For additional USB programming and technical information, refer to “USB Application Note,” available at

www.honeywellaidc.com.

1 - 5

Page 22

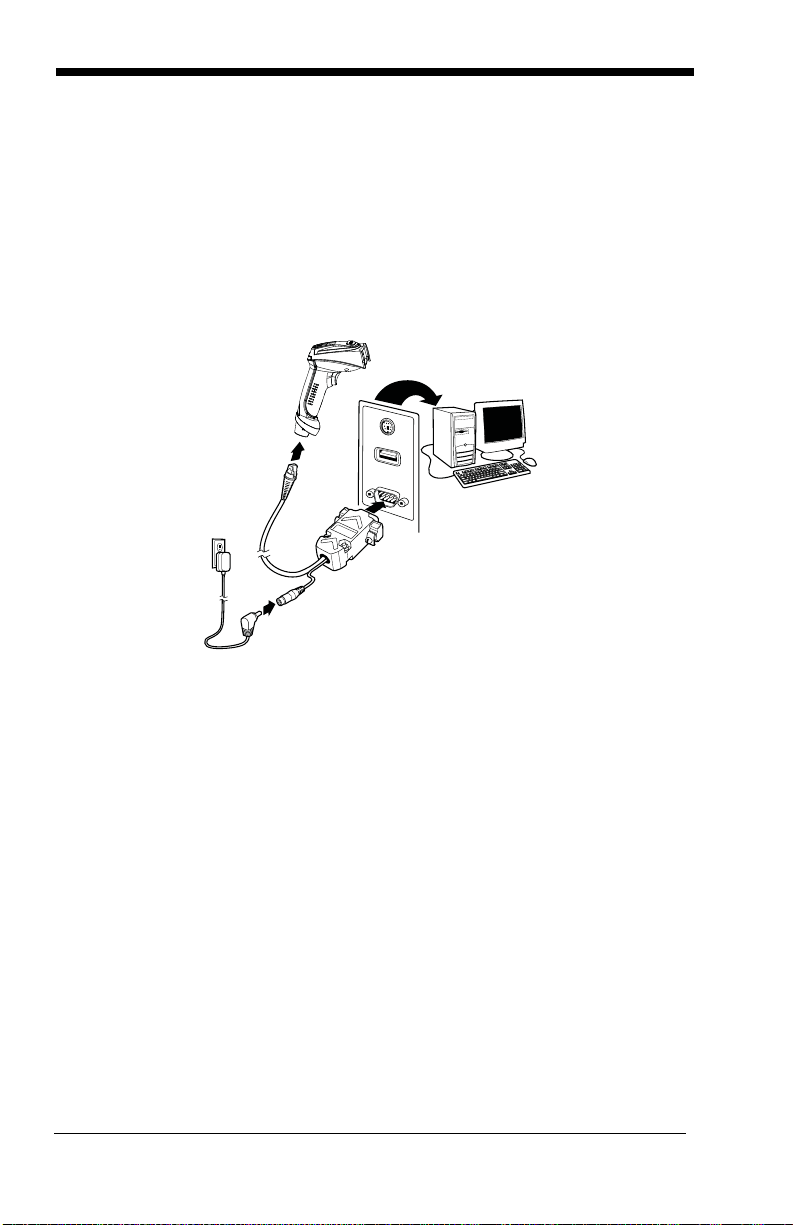

Connecting the Imager with RS-232 Serial Port

Note: See "Imager Models" on page 1-2 to determine which interfaces apply to

your imager.

1. Turn off power to the terminal/computer.

2. Connect the appropriate interface cable to the imager.

Note: For the imager to work properly, you must have the correct cable for your

type of terminal/computer.

3. Plug the serial connector into the serial port on your computer. Tighten the

two screws to secure the connector to the port.

4. Plug the power supply into the cable.

5. Once the imager has been fully connected, power up the computer.

6. Program the imager for an RS-232 Serial Port interface using the Plug and

Play bar code on page 1-11.

Connecting the Imager with RS-232 Wedge

Note: See "Imager Models" on page 1-2 to determine which interfaces apply to

your imager.

Your imager uses True and TTL signal levels to wedge into an RS-232 serial

network. Use only serial wedge cables to prevent damage to the imager. Refer

to RS-232 Baud Rate on page 2-10 to set the baud rate and communications

protocol.

1 - 6

Page 23

1. Turn off power to the computer.

2. Disconnect the existing serial cable from the computer.

3. Connect the appropriate interface cable to the imager.

Note: For the imager to work properly, you must have the correct cable for your

type of computer.

Host

Terminal

4. Plug the serial connector into the serial port on your computer. Tighten the

two screws to secure the connector to the port.

5. Plug the other serial connector into the host connection and tighten the two

screws.

6. Plug the power pack cable into the receptor on the imager cable.

7. Plug the power pack into a power source.

8. Once the imager has been fully connected, power up the computer.

9. To set up the serial wedge terminal ID, use the serial terminal ID 050 and

follow the instructions on page 2-1.

10. Program the port for data transmission using the bar codes on page 1-12.

1 - 7

Page 24

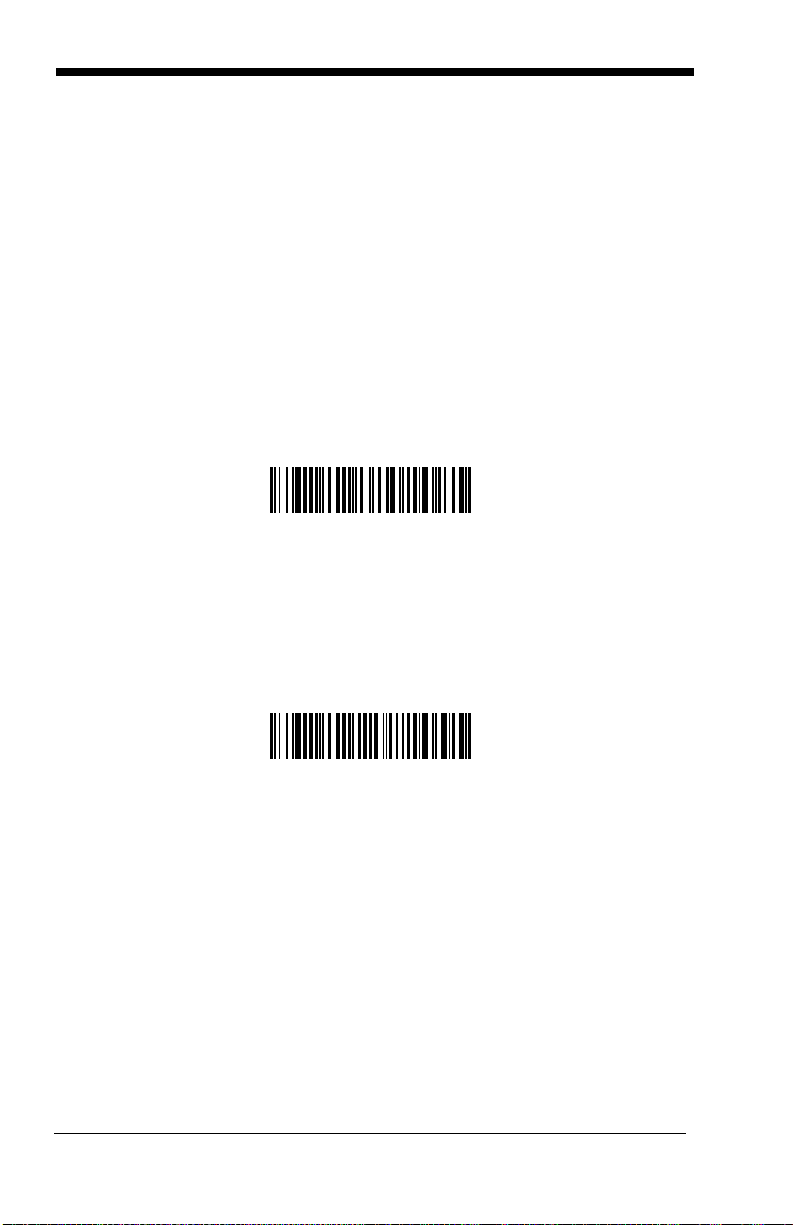

Programming the Interface - Plug and Play

IBM PC AT and Compatibles

with CR suffix

Laptop Direct Connect

with CR suffix

Plug and Play bar codes provide instant imager set up for commonly used interfaces.

Note: After you scan one of the codes, power cycle the host terminal to have

the interface in effect.

Note: See "Imager Models" on page 1-2 to determine which interfaces apply to

your imager.

Keyboard Wedge Connection

If you want your system programmed for an IBM PC AT and compatibles keyboard wedge interface with a USA keyboard, scan the bar code below. Keyboard wedge is the default interface.

Laptop Direct Connect

For most laptops, scanning the

tion of the imager in parallel with the integral keyboard. The following Laptop

Direct Connect bar code also programs a carriage return (CR) suffix, and turns

on Emulate External Keyboard (page 2-7).

Laptop Direct Connect

bar code allows opera-

1 - 8

Page 25

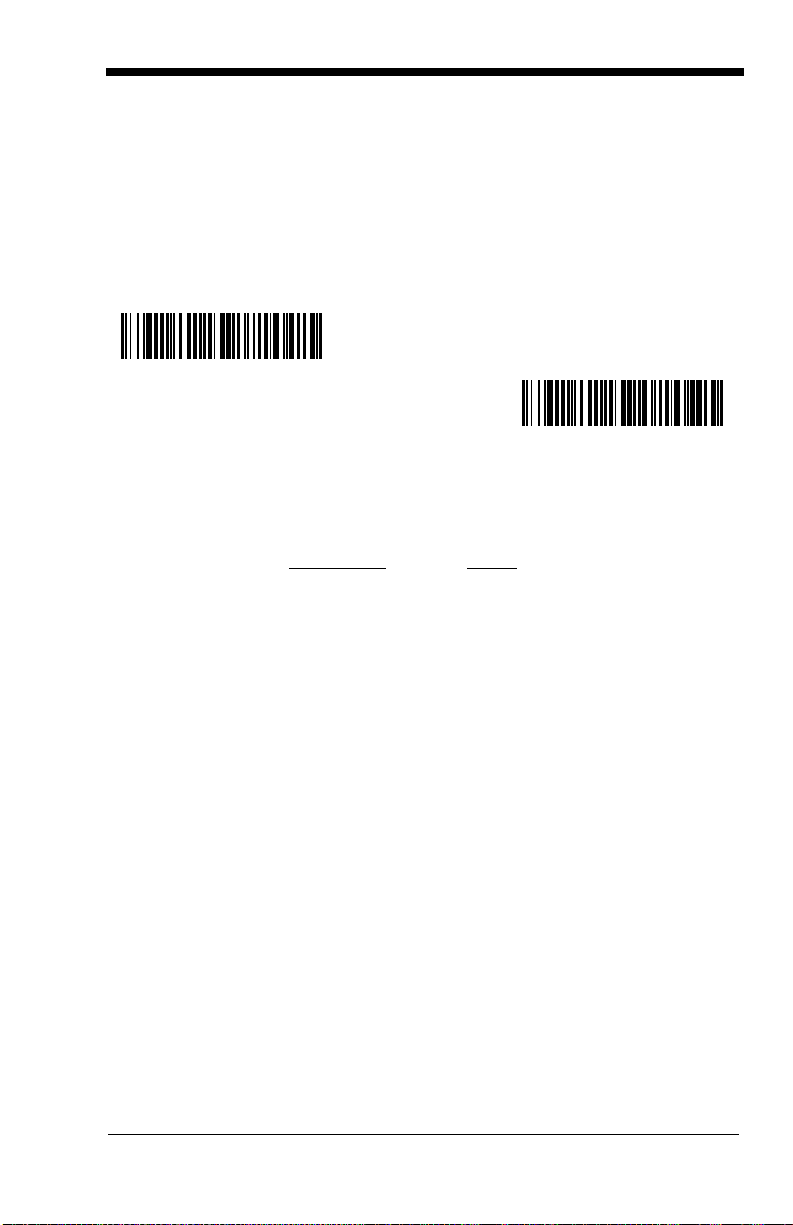

USB Connection

IBM SurePos

(USB Handheld Imager)

Interface

IBM SurePos

(USB Tabletop Imager)

Interface

IBM SurePos

Scan one of the following “Plug and Play” codes to program the imager for IBM

SurePos (USB handheld imager) or IBM SurePos (USB Tabletop imager).

Note: After scanning one of these codes, you must power cycle the cash

register.

Each bar code above also programs the following suffixes for each symbology:

Symbology

EAN-8 0C

EAN-13 16

UPC-A 0D

UPC-E 0A

Code 39 00 0A 0B

Interleaved 2 of 5 00 0D 0B

Code 128 00 18 0B

Suffix

1 - 9

Page 26

USB PC or Macintosh® Keyboard

USB Keyboard (PC)

USB Keyboard (Mac)

USB Japanese Keyboard (PC)

USB HID Bar Code Imager

USB COM Port Emulation

Scan one of the following codes to program the imager for USB PC Keyboard or

USB Macintosh Keyboard. Scanning these codes adds a CR and selects the

terminal ID (USB PC Keyboard - 124, USB Macintosh Keyboard - 125).

USB HID

Scan the following code to program the imager for USB HID bar code imagers.

Scanning this code changes the terminal ID to 131.

USB COM Port Emulation

Scan the following code to program the imager to emulate a regular RS-232based COM port. If you are using a Microsoft® Windows® PC, you will need to

download a driver from the Honeywell website (

driver will use the next available COM port number. Apple® Macintosh computers recognize the imager as a USB CDC class device and automatically use a

class driver. Scanning the code below changes the terminal ID to 130.

www.honeywellaidc.com). The

Note: No extra configuration (e.g., baud rate) is necessary.

1 - 10

Page 27

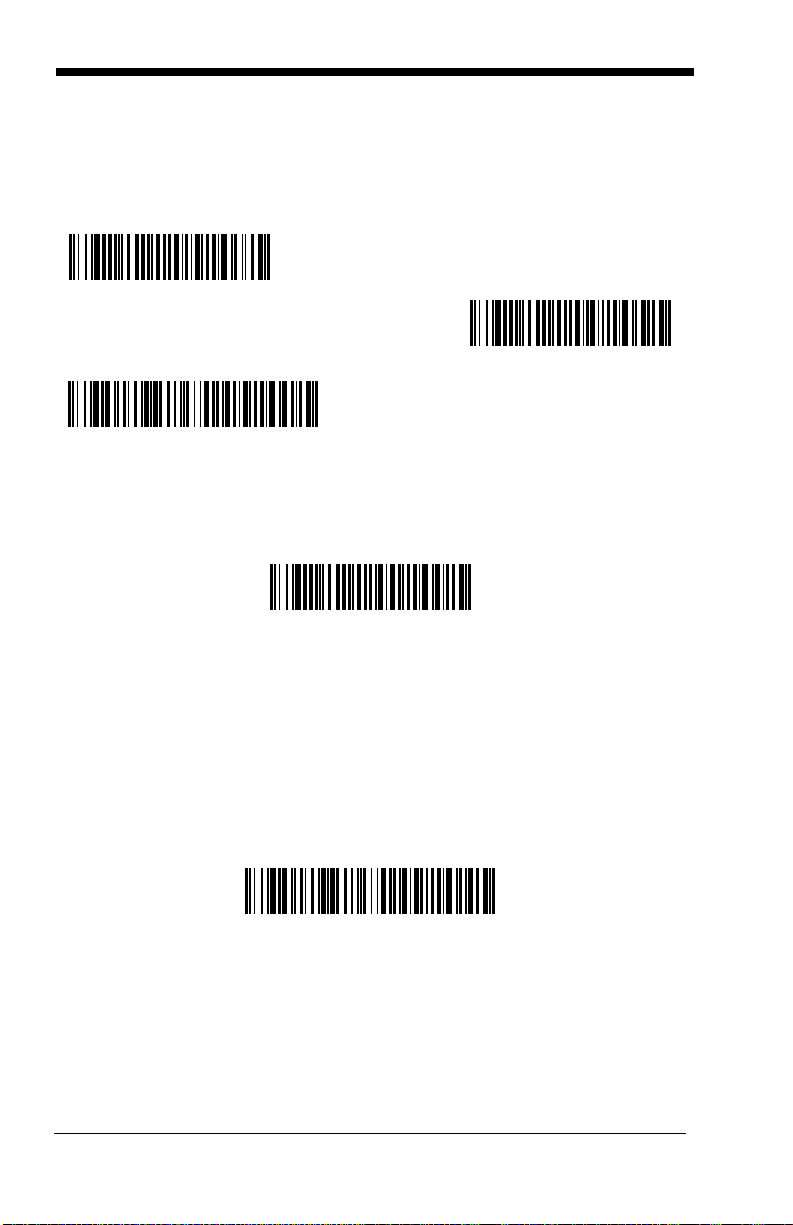

CTS/RTS Emulation

On

* Off

On

* Off

RS-232 Interface

ACK/NAK Mode

RS-232 Serial Port Connection

All communication parameters between the imager and terminal must match for

correct data transfer through the serial port using RS-232 protocol. Scanning

the RS-232 interface bar code programs the imager for an RS-232 interface at

38,400 baud, parity–none, 8 data bits, 1 stop bit, and adds a suffix of a CR LF.

1 - 11

Page 28

Serial Wedge Data Transmission Port

* P1

P2

Both P1 and P2

IBM 4683 Port 5B Interface

IBM 4683 Port 9B

HHBCR-1 Interface

IBM 4683 Port 17 Interface

Using the following bar codes, set the port to which you want the scanned data

to transmit. Port 1 corresponds to P1 on the output cable and Port 2 corresponds to P2 on the output cable. Choosing Both sends scanned data to P1

and P2.

Default = P1.

IBM 4683 Ports 5B, 9B, and 17 Connection

Note: See "Imager Models" on page 1-2 to determine which interfaces apply to

your imager.

Scan one of the following “Plug and Play” codes to program the imager for IBM

4683 Port 5B, 9B, or 17.

Note: After scanning one of these codes, you must power cycle the cash

register.

1 - 12

Page 29

Each of the previous bar codes also programs the following suffixes for each

IBM 4683 Port 9B HHBCR-2 Interface

symbology:

Symbology

EAN-8 0C

EAN-13 16

UPC-A 0D

UPC-E 0A

Code 39 00 0A 0B

Interleaved 2 of 5 00 0D 0B

Code 128 00 0A 0B

.

The IBM 4683 Port 9B HHBCR-2 Interface bar code also programs the following suffixes for each symbology:

Symbology

EAN-8 0C

EAN-13 16

UPC-A 0D

UPC-E 0A

Code 39 00 0A 0B

Interleaved 2 of 5 00 0D 0B

Code 128 00 18 0B

Suffix

Suffix

Wand Emulation Connection

Note: See "Imager Models" on page 1-2 to determine which interfaces apply to

your imager.

In Wand Emulation mode, the imager decodes the bar code then sends data in

the same format as a wand imager. The Code 39 Format converts all symbologies to Code 39.

The Same Code Format transmits UPC, EAN, Code 128, Codabar, and Interleaved 2 of 5 without any changes, but converts all other symbologies to Code

39. 2D symbologies are converted to Code 128.

Wand Emulation Plug & Play (Code 39 Format)

The

terminal ID to 61. The

sets the terminal ID to 64. These bar codes also set the Transmission Rate to

Wand Emulation Plug & Play Same Code

bar code below sets the

bar code

1 - 13

Page 30

25 inches per second, Output Polarity to black high, and Idle State to high. (If

Wand Emulation

Plug & Play

Same Code

Wand Emulation

Plug & Play

(Code 39 Format)

you want to change the terminal ID

tings, refer to Terminal ID on page 2-1.)

only

, without changing any other imager set-

Menu Bar Code Security Settings

Honeywell 2D imagers are programmed by scanning menu bar codes or by

sending serial commands to the imager. If you want to restrict the ability to

scan menu codes, you can use the Menu Bar Code Security settings. Contact

the nearest technical support office (see Technical Assistance on page 15-1)

for further information.

1 - 14

Page 31

Reading Techniques

Linear bar code 2D Matrix symbol

The imager has a view finder that projects a bright red or green aiming beam

that corresponds to the imager’s horizontal field of view. The aiming beam

should be centered over the bar code, but it can be positioned in any direction

for a good read.

The aiming beam is smaller when the imager is closer to the code and larger

when it is farther from the code. Symbologies with smaller bars or elements (mil

size) should be read closer to the unit. Symbologies with larger bars or elements (mil size) should be read farther from the unit. To read single or multiple

symbols (on a page or on an object), hold the imager at an appropriate distance

from the target, pull the trigger, and center the aiming beam on the symbol. If

the code being scanned is highly reflective (e.g., laminated), it may be necessary to tilt the code +

5° to prevent unwanted reflection.

1 - 15

Page 32

1 - 16

Page 33

2

Terminal ID

Save

Terminal Interfaces

Terminal ID

If your interface is not covered by a Plug and Play bar code from Chapter 1,

then refer to Supported Terminals on page 2-2 through page 2-3, and locate the

Terminal ID number for your PC. Scan the Terminal ID bar code below, then

scan the numeric bar code(s) from the Programming Chart inside the back

cover of this manual to program the imager for your terminal ID. Scan Save to

save your selection.

For example, an IBM AT terminal has a Terminal ID of 003. You would scan the

Terminal ID bar code, then 0, 0, 3 from the Programming Chart inside the back

cover of this manual, then Save. If you make an error while scanning the digits

(before scanning Save), scan the Discard code on the Programming Chart,

scan the Terminal ID bar code, scan the digits, and the Save code again.

Note: After scanning one of these codes, you must power cycle your computer.

2 - 1

Page 34

Supported Terminals

Note: See "Imager Models" on page 1-2 to determine which interfaces apply to

your imager.

Terminal Model(s)

DDC 3496, 3497, 122 key

DDC 3496, 3497, 102 key

DEC VT510, 520, 525 (PC style)

DEC VT510, 520, 525 (DEC style

LK411)

Esprit 200, 400

Heath Zenith PC, AT

Heath Zenith

HP Vectra

HP Vectra

IBM XT

IBM PS/2 25, 30, 77DX2

IBM AT, PS/2 30–286, 50, 55SX, 60,

70, 70–061, 70–121, 80

IBM 102 key 3151, 3161, 3162, 3163, 3191,

3192, 3194, 3196, 3197, 3471,

3472, 3476, 3477

IBM 122 key 3191, 3192, 3471, 3472

IBM 122 key 3196, 3197, 3476, 3477, 3486,

3482, 3488

IBM 122 key 3180

IBM 122 key 3180 data entry keyboard

IBM DOS/V 106 key PC & Workstation

IBM SurePOS USB Handheld Imager

IBM SurePOS USB Tabletop Imager

IBM Thinkpad 360 CSE, 340, 750

IBM Thinkpad

IBM Thinkpad 365, 755CV

I/O 122 key 2676D, 2677C, 2677D

ITT 9271

Lee Data IIS

NEC 98XX Series

Olivetti M19, M200

Olivetti M240, M250, M290, M380,

P500

RS-232 True

RS-232 TTL

Terminal

ID

005

071

084

104

005

003

090

003

023

001

002

003 *

006

007

008

024

114

102

128*

129*

097

106

003

008

007

007

103

001

003

000**

000

2 - 2

Page 35

Supported Terminals

Note: See "Imager Models" on page 1-2 to determine which interfaces apply to

your imager.

Terminal Model(s)

Serial Wedge

Silicon Graphics Indy, Indigoll

Telex 88 key 078, 078A, 79, 80, 191, 196,

Telex 88 key Data Entry Keyboard

Telex 102 key 078, 078A, 79, 80, 191, 196,

Telex 122 key 078, 078A, 79, 80, 191, 196,

USB COM Port Emulation

USB Japanese Keyboard

(PC)

USB PC Keyboard

USB Mac Keyboard

USB HID POS

Wand Emulation (Code 39

Format)

Wand Emulation (Same

Code Format)

* Default for 4600g/4600r/4600rp/4800iXX 05XX models. It is best to use the Plug and

Play bar codes, beginning on page 1-9, to program these interfaces, rather than scanning the terminal ID listed in this table.

** Default for 4600g/4800iXX 03XX models

1191,1192, 1471, 1472, 1476,

1477, 1483

1191,1192, 1471, 1472, 1476,

1477, 1483

1191,1192, 1471, 1472, 1476,

1477, 1482, 1483

Terminal

ID

050

005

025

112

045

046

130

134

124*

125*

131*

061

064

2 - 3

Page 36

Keyboard Country

* United States

Brazil

Czech Republic

Denmark

Finland (Sweden)

France

Germany/Austria

Greece

Hungary

Belgium

Canada (French)

Israel (Hebrew)

Scan the appropriate country code below to program the keyboard for your

country. As a general rule, the following characters are supported, but need

special care for countries other than the United States:

@ | $ # { } [ ] = / ‘ \ < > ~

2 - 4

Page 37

Keyboard Country (continued)

Latin America

Norway

Poland

Portugal

Romania

Russia

SCS

Slovakia

Italy

Netherlands (Dutch)

Spain

Sweden

Switzerland (German)

2 - 5

Page 38

Keyboard Country (continued)

Turkey Q

U.K.

Turkey F

Program Keyboard Country

* Regular

Caps Lock

Refer to the Honeywell website (www.honeywellaidc.com) for complete keyboard country support information and applicable interfaces. If you need to program a keyboard for a country other than one listed above, scan the Program

Keyboard Country bar code below, then scan the numeric bar code(s) for the

appropriate country from the inside back cover, then the Save bar code.

Keyboard Style

This programs keyboard styles, such as Caps Lock and Shift Lock.

Regular.

Regular is used when you normally have the Caps Lock key off.

Caps Lock

is used when you normally have the Caps Lock key on.

2 - 6

Default =

Page 39

Shift Lock is used when you normally have the Shift Lock key on (not common

Shift Lock

Automatic Caps Lock

Autocaps via NumLock

Emulate External Keyboard

to U.S. keyboards).

Automatic Caps Lock

The software tracks and reflects if you have Caps Lock on or off (AT and PS/2

only). This selection can only be used with systems that have an LED which

notes the Caps Lock status.

Autocaps via NumLock

many, France) where the Caps Lock key cannot be used to toggle Caps Lock.

The NumLock option works similarly to the regular Auotcaps, but uses the NumLock key to retrieve the current state of the Caps Lock.

Emulate External Keyboard should be scanned if you do not have an external

keyboard (IBM AT or equivalent).

is used if you change the Caps Lock key on and off.

bar code should be scanned in countries (e.g., Ger-

Note: After scanning the Emulate External Keyboard bar code, you must power

cycle your computer.

Keyboard Modifiers

This modifies special keyboard features, such as CTRL+ ASCII codes and

Turbo Mode.

:

Control + ASCII Mode On

trol characters for values 00-1F. Windows is the preferred mode. All keyboard

country codes are supported. DOS mode is a legacy mode, and it does not

The imager sends key combinations for ASCII con-

2 - 7

Page 40

support all keyboard country codes. New users should use the Windows mode.

Windows Mode Control + ASCII

Mode On

* Control + ASCII Mode Off

DOS Mode Control + ASCII Mode On

Turbo Mode On

* Turbo Mode Off

Numeric Keypad Mode On

* Numeric Keypad Mode Off

Refer to Keyboard Function Relationships, page 10-1 for CTRL+ ASCII Values.

Default = Off.

Turbo Mode: The imager sends characters to a terminal faster. If the terminal

drops characters, do not use Turbo Mode.

Default = Off.

Numeric Keypad Mode:Sends numeric characters as if entered from a

numeric keypad.

2 - 8

Default = Off.

Page 41

Automatic Direct Connect Mode: This selection can be used if you have an

Automatic Direct

Connect Mode On

* Automatic Direct Connect

Mode Off

IBM AT style terminal and the system is dropping characters.

Default = Off.

2 - 9

Page 42

RS-232 Baud Rate

300

2400

600

1200

4800

* 38400

9600

19200

115,200

57,600

Baud Rate sends the data from the imager to the terminal at the specified rate.

The host terminal must be set for the same baud rate as the imager.

Default = 38,400.

RS-232 Word Length: Data Bits, Stop Bits, and Parity

Data Bits sets the word length at 7 or 8 bits of data per character. If an applica-

tion requires only ASCII Hex characters 0 through 7F decimal (text, digits, and

punctuation), select 7 data bits. For applications which require use of the full

ASCII set, select 8 data bits per character.

Stop Bits sets the stop bits at 1 or 2.

Default = 8.

Default = 1.

2 - 10

Page 43

Parity provides a means of checking character bit patterns for validity.

7 Data, 1 Stop, Parity Even

7 Data, 1 Stop, Parity None

7 Data, 1 Stop, Parity Odd

7 Data, 2 Stop, Parity Odd

7 Data, 2 Stop, Parity Even

7 Data, 2 Stop Parity None

* 8 Data, 1 Stop, Parity None

8 Data, 1 Stop, Parity Even

8 Data, 1 Stop, Parity Odd

Default = None.

RS-232 Receiver Time-Out

The unit stays awake to receive data until the RS-232 Receiver Time-Out

expires. A manual or serial trigger resets the time-out. When an RS-232

receiver is sleeping, a character may be sent to wake up the receiver and reset

the time-out. A transaction on the CTS line will also wake up the receiver. The

receiver takes 300 milliseconds to completely come up. Change the RS-232

2 - 11

Page 44

receiver time-out by scanning the bar code below, then scanning digits from the

RS-232 Receiver Time-Out

RTS/CTS On

* XON/OFF Off

* RTS/CTS Off

XON/XOFF On

ACK/NAK On

* ACK/NAK Off

inside back cover of this manual, then scanning

seconds.

Default = 0 seconds (no time-out - always on).

Save

. The range is 0 to 300

RS-232 Handshaking

RS-232 Handshaking allows control of data transmission from the imager using

software commands from the host device. When this feature is turned

data flow control is used. When Data Flow Control is turned On, the host

device suspends transmission by sending the XOFF character (DC3, hex 13) to

the imager. To resume transmission, the host sends the XON character (DC1,

hex 11). Data transmission continues where it left off when XOFF was sent.

Default = RTS/CTS, XON/XOFF and ACK/NAK Off

.

Off

, no

Wand Emulation Connection

The Wand Emulation Connection bar codes should be used if you want to

change the terminal ID

recommend using Wand Emulation Plug & Play bar codes to program your

imager to emulate a wand reader. The Wand Emulation Plug & Play bar codes

change other parameters, in addition to changing the terminal ID.

In Wand Emulation mode, the imager decodes the bar code then sends data in

the same format as a wand imager. The Code 39 Format converts all symbologies to Code 39.

2 - 12

only

, without changing any other imager settings. We

Page 45

The Same Code Format transmits UPC, EAN, Code 128, Codabar, and Inter-

Code 39 Format

Same Code Format

20

80

* 40

60

leaved 2 of 5 without any changes, but converts all other symbologies to Code

39. 2D symbologies are converted to Code 128.

The Code 39 Format bar code below sets the terminal ID to 61, and the Same

Code Format bar code sets the terminal ID to 64.

Default = Code 39 Format.

Wand Emulation

Note: See "Imager Models" on page 1-2 to determine which interfaces apply to

your imager.

Note: Changing primary wand emulation settings also changes the secondary

wand emulation settings (see Secondary Code 39 Wand Emulation on

page 6-2).

Data Block Size

This transmits the data in smaller blocks to prevent buffer overflow.

40.

Default =

2 - 13

Page 46

Delay Between Blocks

5ms

500ms

* 50ms

150ms

On

* Off

This sets the delay time between data blocks.

Default = 50ms.

Overall Checksum

When this option is turned on, a computed check character is added at the end

of the entire message. The check character is the character which when Exclusive-OR’d with every preceding character of the message yields a result of 0x00

(00H).

Default = Off.

2 - 14

Page 47

Wand Emulation Transmission Rate

10

80

* 25

40

120

150

200

* Black High

White High

The Transmission Rate is limited by the terminal’s ability to receive data without

dropping characters.

Default = 25 inches/second.

Wand Emulation Polarity

The Polarity can be sent as standard with black bars high, or reversed with

white bars high.

Default = Black High.

2 - 15

Page 48

Wand Emulation Idle

* Idle High

Idle Low

The idle describes the state of the imager when no data is being transmitted.

When in Wand Emulation mode, you must set the imager’s idle state to match

the idle state for the device to which the imager is connected.

.

High

Default = Idle

2 - 16

Page 49

3

* On

Off

High

Medium

Off

Low

Output

Good Read Indicators

Beeper – Good Read

The beeper may be programmed On or

this option off, only turns off the beeper response to a good read indication. All

error and menu beeps are still audible.

Beeper Volume – Good Read

The beeper volume codes modify the volume of the beep the imager emits on a

good read.

Default = Medium for the 4600g/4600r/4600rp; High for the 4800i.

Off

in response to a good read. Turning

Default = On.

3 - 1

Page 50

Beeper Pitch – Good Read

Low (1600 Hz)

* Medium (3250 Hz)

High (4200 Hz)

* Normal Beep

Short Beep

* On

Off

The beeper pitch codes modify the pitch (frequency) of the beep the imager

emits on a good read.

Default = Medium.

Beeper Duration – Good Read

The beeper duration codes modify the length of the beep the imager emits on a

good read.

Default = Normal.

LED – Good Read

The LED indicator can be programmed On or

Default = On.

Off

in response to a good read.

Number of Beeps – Good Read

The number of beeps of a good read can be programmed from 1 - 9. The same

number of beeps will be applied to the beeper and LED in response to a good

read. For example, if you program this option to have five beeps, there will be

five beeps and five LED flashes in response to a good read. The beeps and

3 - 2

Page 51

LED flashes are in sync with one another. To change the number of beeps,

Number of Pulses

* No Delay

Short Delay (500 ms)

Medium Delay (1,000 ms)

Long Delay (1,500 ms)

User-Specified Good Read Delay

scan the bar codebar code below and then scan a digit (1-9) bar code and the

Save bar code on the Programming Chart inside the back cover of this manual.

Default = One.

Good Read Delay

This sets the minimum amount of time before the imager can read another bar

Default = No Delay.

code.

User-Specified Good Read Delay

If you want to set your own length for the good read delay, scan the bar code

below, then set the delay (from 0-30,000 milliseconds) by scanning digits from

the inside back cover, then scanning Save.

3 - 3

Page 52

Trigger Modes

* Manual/Serial Trigger

Read Time-Out

Manual Trigger, Low Power

Manual/Serial Trigger

You can activate the imager either by pressing the trigger, or using a serial trigger command (see Trigger Commands on page 12-4). When in manual trigger

mode, the imager scans until a bar code is read, or until the trigger is released.

When in serial mode, the imager scans until a bar code has been read or until

the deactivate command is sent. The imager can also be set to turn itself off

after a specified time has elapsed (see Read Time-Out, which follows).

Read Time-Out

Use this selection to set a time-out (in milliseconds) of the imager’s trigger when

using serial commands to trigger the imager, or if the imager is in manual trigger

mode. Once the imager has timed out, you can activate the imager either by

pressing the trigger or using a serial trigger command. After scanning the Read

Time-Out bar code, set the time-out duration (from 0-300,000 milliseconds) by

scanning digits from the inside back cover, then scanning Save.

30,000.

Default =

Manual Trigger, Low Power

Note: Does not apply to the 4600r.

The imager powers down until the trigger is pulled. When the trigger is pulled,

the imager powers up and operates until there is no triggering for the time set

with the Low Power Time-Out bar code below. There is a delay of up to one

second in operation when the imager is first triggered, but there is no delay

when operating in low power time-out mode.

Note: Manual Trigger, Low Power cannot be used with keyboard wedge

applications.

3 - 4

Page 53

Low Power Time-Out Timer

Low Power Time-Out

Sensor On

* Sensor Off

Scan the Low Power Time-Out bar code to change the time-out duration (in

seconds). Then scan the time-out duration (from 0-300 seconds) from the

inside back cover, and Save.

If the unit remains idle during the low power time-out interval, the unit goes into

low power mode. Whenever the trigger is enabled, the low power time-out timer

is reset.

Note: This time-out does not begin until the imager time-out setting has expired.

Default = 120 seconds.

In-Stand Sensor Mode (4600r only)

Note: This feature is only applicable to the flex stand with sensor

(HFSTAND5RSE) used with a 4600r, software revision 31205480-118 or

higher. To determine whether you have the correct hardware and

software, scan the Sensor On bar code. If it triple beeps, your device

does not have this capability.

This feature tells a 4600r to sense when the scanner is removed from the stand

and to begin manual triggering. When you scan Sensor On, the imager goes

into manual trigger mode when it is removed from the stand. For example, if

the 4600r is programmed for Presentation Mode (page 3-7), it would be in presentation mode whenever it is in the stand, and in manual trigger mode whenever it is removed from the stand.

Default = Sensor Off.

3 - 5

Page 54

Scan Stand Mode

Scan Stand Mode

Scan Stand Symbol

When a unit is in Scan Stand mode, it remains idle as long as it sees the Scan

Stand symbol (see below). When a different code is presented, the imager is

triggered to read the new code.

Note: The imager automatically adjusts the illumination LEDs to the lowest light

level possible to maintain a good lock on the Scan Stand symbol. When

a symbol is presented, the imager’s light levels adjust to the saved setting

(see LED Power Level on page 3-10). This mode requires at least 50 lux

of ambient light to operate correctly.

Scan Stand Symbol

When a unit is in Scan Stand mode, the LEDs shine at the Scan Stand symbol

on the base of the stand which tells it to remain idle.

symbol is covered, the imager turns the LEDs on at the configured power level

(default setting is high) and attempts to find and decode bar codes in its field of

view.

When the Scan Stand

3 - 6

Page 55

Presentation Mode

Presentation Mode

Non-Advanced

Illumination Unit

Advanced

Illumination Unit

* LEDs On

LEDs Off

This programs the imager to work in Presentation mode. The LEDs are either

off or at the lowest power for ambient conditions until a bar code is presented to

the imager. Then the LEDs turn on automatically to read the code. Presentation Mode uses ambient light to detect the bar codes. If the light level in the

room is not high enough, Presentation Mode may not work properly.

Note: The operation of advanced illumination units and non-advanced

illumination units differs slightly. When an advanced illumination unit is in

Presentation Mode and idle, the illumination LEDs go dim, but never go

out. When a non-advanced illumination unit is in Presentation Mode and

idle, the illumination LEDs go out completely.

Presentation LED Behavior after Decode

When an imager is in presentation mode, the LEDs remain on and continue

scanning for a short time after a bar code is decoded. If you wish to turn the

LEDs off immediately after a bar code is decoded, scan the LEDs Off bar code,

below.

Default = LEDs On.

3 - 7

Page 56

Presentation Sensitivity

Sensitivity

Streaming Presentation Mode

Non-Advanced

Illumination Unit

Advanced

Illumination Unit

Presentation Sensitivity is a numeric range that increases or decreases the

imager's reaction time to bar code presentation. To set the sensitivity, scan the

Sensitivity bar code, then scan the degree of sensitivity (from 0-20) from the

inside back cover, and Save. 0 is the most sensitive setting, and 20 is the least

sensitive.

Default = 1.

Streaming Presentation™ Mode

When in Streaming Presentation mode, the imager’s aimer goes out after a

short time, but the scan illumination remains on all the time to continuously

search for bar codes.

When using Preferred Symbology (page 3-15), a lower priority symbol must be

centered on the aiming pattern to be read in Streaming Presentation Mode.

Note: Streaming Presentation Mode applies only to advanced illumination units.

3 - 8

Page 57

Image Snap and Ship

Image Snap and Ship

Hands Free Time-Out

Image Snap and Ship tells the imager to take a picture (rather than read a bar

code) when the trigger is pressed. Once the picture is snapped, it is shipped to

the host system as a jpeg file by default. To revert to bar code reading, you

must change to a different trigger mode (see Trigger Modes beginning on page

3-4).

Hands Free Time-Out

The Scan Stand, and Presentation, and Streaming Presentation Modes are

referred to as “hands free” modes. If the imager’s trigger is pulled when using a

hands free mode, the imager changes to manual trigger mode. You can set the

time the imager should remain in manual trigger mode by setting the Hands

Free Time-Out. Once the time-out value is reached, (if there have been no further trigger pulls) the imager reverts to the original hands free mode.

Scan the Hands Free Time-Out bar code, then scan the time-out duration

(from 0-300,000 milliseconds) from the inside back cover, and Save.

5,000 ms.

Default =

Reread Delay

This sets the time period before the imager can read the

ond time. Setting a reread delay protects against accidental rereads of the

same bar code. Longer delays are effective in minimizing accidental rereads.

Use shorter delays in applications where repetitive bar code scanning is

required.

Default = Medium.

same

bar code a sec-

3 - 9

Page 58

Reread Delay only works when in Presentation Mode or Streaming

Short (500 ms)

* Medium (750 ms)

Long (1000 ms)

Extra Long (2000 ms)Extra Long (2000 ms)

User-Specified Reread Delay

Presentation™ Mode (page 3-8).

User-Specified Reread Delay

If you want to set your own length for the reread delay, scan the bar code below,

then set the delay (from 0-30,000 milliseconds) by scanning digits from the

inside back cover, then scanning Save.

LED Power Level

This selection allows you to adjust LED and aimer brightness. Off is used when

no illumination is needed. Low is used if low illumination is sufficient. High (the

default) is the brightest setting.

3 - 10

Page 59

If you have an aimer delay programmed (see Aimer Delay on page 3-12), the

Off

Low (50%)

* High (100%)

Lights Off

* Lights On

aimer will be at 100% power during the delay, regardless of the LED Power

Level.

Note: If you scan the Off bar code, both the aimer and illumination lights turn

off, making it impossible to scan bar codes in low light. To turn the LED

Power Level back on, move to a brightly lit area and scan either the Low

or the High bar code below.

Illumination Lights

If you want the illumination lights on while reading a bar code, scan the Lights

On bar code, below. However, if you want to turn just the lights off, scan the

Lights Off bar code.

Note: This setting does not affect the aimer light. The aiming light can be set

using Aimer Mode (page 3-13).

Default = Lights On.

3 - 11

Page 60

Imager Time-Out

Imager Time-Out

400 milliseconds

* Off

(no delay)

200 milliseconds

Delay Duration

Imager Time-Out powers down the imager after the unit has been idle for the

specified time. To prevent the imager from powering down, set this time-out to

0. Scan Imager Time-Out, then set the time-out by scanning digits (from 0 999,999 ms) from the inside back cover, then scanning Save.

ms.

Note: The default applies to firmware with a base number of 31205480. Refer

to the Show Software Revision on page 11-2 for information on

determining the firmware revision in your unit.

Default = 60,000

Aimer Delay

The aimer delay allows a delay time for the operator to aim the imager before

the picture is taken. Use these codes to set the time between when the trigger

is pulled and when the picture is taken. During the delay time, the aiming light

will appear, but the LEDs won’t turn on until the delay time is over.

Off.

Default =

User-Specified Aimer Delay

If you want to set your own length for the duration of the delay, scan the bar

code below, then set the time-out by scanning digits (0 - 4,000 ms) from the

Programming Chart inside the back cover of this manual, then scan Save.

3 - 12

Page 61

Aimer Mode

Off

*Interlaced

Bar Code 1

Bar Code 2

This feature allows you to turn the aimer on and off. When the Interlaced bar

code is scanned, the aimer is interlaced with the illumination LEDs.

Interlaced.

Default =

Centering

Use Centering to narrow the imager’s field of view to make sure the imager

reads only those bar codes intended by the user. For instance, if multiple codes

are placed closely together, centering will insure that only the desired codes are

read. (Centering can be used in conjunction with Aimer Delay, page 3-12, for

the most error-free operation in applications where multiple codes are spaced

closely together. Using the Aimer Delay and Centering features, the imager can

emulate the operation of older systems, such as linear laser bar code imagers.)

In the example below, the gray area is the full imager field of view and the white

area is the centering window. Bar Code 1 will not be read, while Bar Code 2 will

be.

The default centering window is a 128x96 pixel area in the center of the

3 - 13

Page 62

imager’s field of view. The following diagram illustrates the default top, bottom,

0

100%

100%

Default

Center

40% 60%

40%

60%

Left

Right

Bottom

Top

Left of Centering Window

Top of Centering Window

Right of Centering Window

Bottom of Centering Window

* Centering Off

Centering On

left, and right pixel positions, measured from the top and the left side of the

imager’s field of view, which is 640 by 480 pixels.

If a bar code is not within the predefined window, it will not be decoded or output

by the imager. If centering is turned on by scanning Centering On, the imager

only reads codes that intersect the centering window you specify using the Top,

Bottom, Left, or Right bar codes.

Scan Centering On, then scan one of the following bar codes to change the

top, bottom, left, or right of the centering window. Then scan the percent you

want to shift the centering window using digits on the inside back cover of this

manual. Scan Save.

Default Centering = 40% for Top and Left, 60% for Bot-

tom and Right.

3 - 14

Page 63

Decode Search Mode

Full Omnidirectional

Quick Omnidirectional

Advanced Linear Decoding

There are three selectable decode (scanning) modes:

Full Omnidirectional

of an image, and searches to the image’s limits. This mode reads all symbologies (including OCR), in any orientation. The Full Omnidirectional search is

very thorough which may slow performance time.

Note: This search mode is the default setting.

- Searches for bar code features beginning at the center

Quick Omnidirectional

around the center region of an image. This mode quickly reads all symbologies

in any orientation. The Quick Omnidirectional mode may miss some off-center

symbols, as well as larger Data Matrix and QR Code symbols.

Advanced Linear Decoding

ter band of the image. This mode is

linear and stacked bar codes. Advanced Linear Decoding cannot read 2D,

OCR, or Postal symbols.

- This is an abbreviated search for bar code features

- Performs quick horizontal linear scans in a cen-

not

omnidirectional, but does quickly read

Preferred Symbology

Note: This selection does not apply to OCR.

The imager can be programmed to specify one symbology as a higher priority

over other symbologies in situations where both bar code symbologies appear

on the same label, but the lower priority symbology cannot be disabled.

For example, you may be using the imager in a retail setting to read UPC symbols, but have occasional need to read a code on a drivers license. Since some

licenses have a Code 39 symbol as well as the PDF417 symbol, you can use

Preferred Symbology to specify that the PDF417 symbol be read instead of the

Code 39.

3 - 15

Page 64

Preferred Symbology classifies each symbology as high priority, low priority,

* Preferred Symbology Off

Preferred Symbology On

High Priority Symbology

Low Priority Symbology

or as an unspecified type. When a low priority symbology is presented, the

imager ignores it for a set period of time (see Preferred Symbology Time-out on

page 3-17) while it searches for the high priority symbology. If a high priority

symbology is located during this period, then that data is read immediately.

If the time-out period expires before a high priority symbology is read, the

imager will read any bar code in its view (low priority or unspecified). If there is

no bar code in the imager’s view after the time-out period expires, then no data

is reported.

Note: A low priority symbol must be centered on the aiming pattern to be read.

Scan a bar code below to enable or disable Preferred Symbology.

Default =

Preferred Symbology Off.

High Priority Symbology

To specify the high priority symbology, scan the High Priority Symbology bar

code below. On the Symbology Chart on page A-1, find the symbology you

want to set as high priority. Locate the Hex value for that symbology and scan

the 2 digit hex value from the Programming Chart (inside back cover). Scan

Save to save your selection.

Default = None

Low Priority Symbology

To specify the low priority symbology, scan the Low Priority Symbology bar

code below. On the Symbology Chart on page A-1, find the symbology you

want to set as low priority. Locate the Hex value for that symbology and scan

the 2 digit hex value from the Programming Chart (inside back cover).

If you want to set additional low priority symbologies, scan FF, then scan the 2

digit hex value from the Programming Chart for the next symbology. You can

program up to 5 low priority symbologies. Scan Save to save your selection.

Default = None

3 - 16

Page 65

Preferred Symbology Time-out

Preferred Symbology Time-out

Preferred Symbology Default

Once you have enabled Preferred Symbology and entered the high and low priority symbologies, you must set the time-out period. This is the period of time

the imager will search for a high priority bar code after a low priority bar code

has been encountered. Scan the bar code below, then set the delay (from 1003,000 milliseconds) by scanning digits from the inside back cover, then scanning Save.

Default = 500 ms.

Preferred Symbology Default

Scan the bar code below to set all Preferred Symbology entries to their default

values.

Output Sequence Overview

Require Output Sequence

When turned off, the bar code data will be output to the host as the imager

decodes it. When turned on, all output data must conform to an edited

sequence or the imager will not transmit the output data to the host device.

Note: This selection is unavailable when Multiple Symbols (page 3-20) is

enabled.

Output Sequence Editor

This programming selection allows you to program the imager to output data

(when scanning more than one symbol) in whatever order your application

requires, regardless of the order in which the bar codes are scanned. Reading

the Default Sequence symbol programs the imager to the Universal values,

shown below. These are the defaults. Be

formats before you read the Default Sequence symbol.

Note: To make Output Sequence Editor selections, you’ll need to know the code

I.D., code length, and character match(es) your application requires. Use

the Alphanumeric symbols (inside back cover) to read these options.

You must hold the trigger while reading each bar code in the sequence.

To Add an Output Sequence

1. Scan the Enter Sequence symbol (see Require Output Sequence, page 3-

20).

2. Code I.D.

On the Symbology Chart on page A-1, find the symbology to which you want

certain

you want to delete or clear all

3 - 17

Page 66

to apply the output sequence format. Locate the Hex value for that symbol-

A - Code 39

B - Code 128

C - Code 93

ogy and scan the 2 digit hex value from the Programming Chart (inside back

cover).

3. Length

Specify what length (up to 9999 characters) of data output will be acceptable

for this symbology. Scan the four digit data length from the Programming

Chart. (Note: 50 characters is entered as 0050. 9999 is a universal number, indicating all lengths.) When calculating the length, you must count any

programmed prefixes, suffixes, or formatted characters as part of the length

(unless using 9999).

4. Character Match Sequences

On the ASCII Conversion Chart (Code Page 1252), page A-4, find the Hex

value that represents the character(s) you want to match. Use the Programming Chart to read the alphanumeric combination that represents the ASCII

characters. (99 is the Universal number, indicating all characters.)

5. End Output Sequence Editor

Scan F F to enter an Output Sequence for an additional symbology, or Save

to save your entries.

Other Programming Selections

•Discard

This exits without saving any Output Sequence changes.

Output Sequence Example

In this example, you are scanning Code 93, Code 128, and Code 39 bar codes,

but you want the imager to output Code 39 1st, Code 128 2nd, and Code 93

3rd, as shown below.

Note: Code 93 must be enabled to use this example.

You would set up the sequence editor with the following command line:

SEQBLK62999941FF6A999942FF69999943FF

The breakdown of the command line is shown below:

3 - 18

Page 67

SEQBLK sequence editor start command

62 code identifier for Code 39

9999 code length that must match for Code 39, 9999 = all lengths

41 start character match for Code 39, 41h = “A”

FF termination string for first code

6A code identifier for Code 128

9999 code length that must match for Code 128, 9999 = all lengths

42 start character match for Code 128, 42h = “B”

FF termination string for second code

69 code identifier for Code 93

9999 code length that must match for Code 93, 9999 = all lengths

43 start character match for Code 93, 43h = “C”

FF termination string for third code

To program the previous example using specific lengths, you would have to

count any programmed prefixes, suffixes, or formatted characters as part of the

length. If you use the example on page 3-18, but assume a <CR> suffix and

specific code lengths, you would use the following command line:

SEQBLK62001241FF6A001342FF69001243FF

The breakdown of the command line is shown below:

SEQBLK sequence editor start command

62 code identifier for Code 39

0012 A - Code 39 sample length (11) plus CR suffix (1) = 12

41 start character match for Code 39, 41h = “A”

FF termination string for first code

6A code identifier for Code 128

0013 B - Code 128 sample length (12) plus CR suffix (1) = 13

42 start character match for Code 128, 42h = “B”

FF termination string for second code

69 code identifier for Code 93

0012 C - Code 93 sample length (11) plus CR suffix (1) = 12

43 start character match for Code 93, 43h = “C”

FF termination string for third code

3 - 19

Page 68

Output Sequence Editor

Enter Sequence

Default Sequence

Required

On/Not Required

*Off

Require Output Sequence

When an output sequence is Required, all output data must conform to an

edited sequence or the imager will not transmit the output data to the host

device. When it’s On/Not Required, the imager will attempt to get the output

data to conform to an edited sequence but, if it cannot, the imager transmits all

output data to the host device as is.

When the output sequence is Off, the bar code data is output to the host as the

imager decodes it.

Note: This selection is unavailable when the Multiple Symbols Selection is

turned on.

Default = Off.

Multiple Symbols

Note: This feature does not work when the imager is in Low Power mode.

When this programming selection is turned On, it allows you to read multiple