Page 1

K0315 12/02 Rev. D

INSTALLATION AND SETUP GUIDE

GENERAL INFORMATION

The ADEMCO 269R/270R Holdup Switch (Figure 1) is a fingeroperated switch for activating the holdup signal at the control

and/or any other security application. The 269R adds a protective

steel cover. The Holdup Switch is typically mounted under a

counter for inconspicuous operation. The device comes standard as

a latching type switch that is easily converted to a non-latching

type.

If the switch is used as a latching type switch, the supplied reset

key is used to reset the device. Additional reset keys may be

obtained separately by ordering ADEMCO part number K4563.

PROGRAMMING

For Honeywell controls, program the unit like any other zone,

according to the control’s installation and setup guide. Enter the

following information when prompted for in zone programming:

“ZONE TYPE” = “06”

“INPUT TYPE” = “01”

For other manufacture controls, refer to the controls instructions

for specific programming instructions.

MOUNTING

Refer to the steps and figures that follow for typical mounting

installation. If required, convert the latching device to a nonlatching device as shown in figure 2.

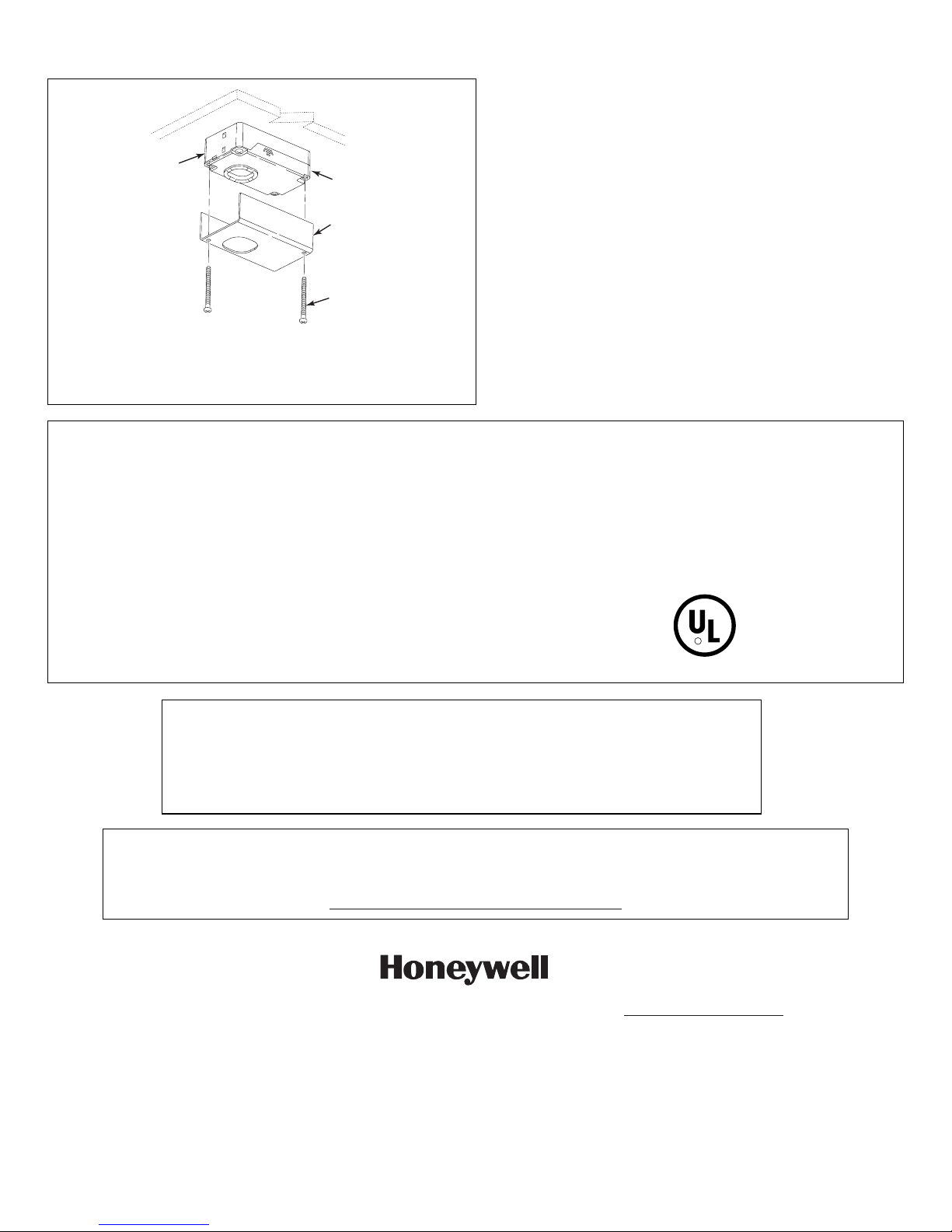

RESET KEY

(K4563 SUPPLIED)

COVER

ATTA CH

HOLE

MOUNTING

HOLE

COVER

+

COVER

SCREW

Figure 1

COVER

SCREW (2)

No. 6x7/8

+

PROTECTIVE

STEEL

COVER

(269R ONLY)

MOUNTING

SCREW (2)

No. 6X1 3/4

269R-001-V1

TRIGGER

CIRCUIT

BOARD

MOUNTING

HOLE

COVER

ATTACH HOLE

ADEMCO 269R/270R

Holdup Switch

1. Run the wiring from the control panel to the device, through

the opening in the case back as shown in Figure 3.

2. Wire the device for a normally closed or a normally open loop

with no EOL resistor or for a normally-closed or a normally

open loop with an EOL resistor as shown in figure 3, detail A

and B, respectively. Where Form C wiring is required,

providing full supervision of the loop refer to figure 3, detail C.

3. Secure the cover to the case with two screws (No. 6 x 7/8) as

shown in figure 1. Note the cover screws are noticeably

shorter than the mounting screws. Be sure to use the correct

holes. The holes opposite these are used to secure the device to

the counter.

IMPORTANT: To prevent damage to the case do not

over tighten the cover screws.

4. Peel the backing from the double stick tape strips on the back

of the device and position the device in its mounting location.

IMPORTANT: The double stick tape is provided to

temporarily hold the assembly in place while drilling

the pilot holes. The device must be permanently

mounted with the screws supplied.

5. Using the case as a drill template, drill a 1/16” diameter pilot

hole at the two case mounting holes (Figure 1).

6. Secure the assembled case with the protective cover (if

required) to the counter with two screws (No. 6 x 1-3/4)

supplied. (Figure 4).

ARROW

(CUT POINT)

TRIGGER

ASSEMBLY

TO CONVERT TO MOMENTARY (NO LATCHING) SWITCH

OPERATION, REMOVE THE TRIGGER ASSEMBLY FROM THE

CASE. USING A PAIR OF CUTTERS, CUT THE TRIGGER LATCH

AT THE POINT THE "ARROW" IS STAMPED ON THE CASE.

Figure 2

TRIGGER

LATCH

269R-004-V0

DETAIL A

WIRE AS SHOWN FOR

A NORMALLY-CLOSED

LOOP WITH NO EOL

RESISTOR.

NO

C

NC

EOL

EOL

NC

C

NO

WIRE AS SHOWN FOR

A NORMALLY-OPEN

LOOP WITH NO EOL

RESISTOR.

269R-007-V1

DETAIL B

WIRE AS SHOWN FOR

A NORMALLY-CLOSED

LOOP WITH AN EOL

RESISTOR.

NO

C

NC

EOL

EOL

NC

C

NO

WIRE AS SHOWN FOR

A NORMALLY-OPEN

LOOP WITH AN EOL RESISTOR.

NOTE THAT THE EOL

TERMINAL IS NOT USED

IN A NORMALLY OPEN LOOP.

Figure 3

269R-008-V1

DETAIL C

FORM "C"

WIRING PROVIDES

FULL SUPERVISION

OF THE LOOP

CONTROL PANEL

ZONE TERMINALS

NO

C

NC

EOL

EOL

NC

C

NO

269R-012-V1

Page 2

MOUNTING

HOLE

MOUNTING

HOLE

PROTECTIVE

STEEL COVER

(269R ONLY)

HOLDUP SWITCH SHOWN MOUNTED

IN TYPICAL UNDER COUNTER APPLICATION

SPECIFICATIONS

Physical:

Electrical:

Contact

Rating:

Operating

Temperature:

Agency:

Reset Key:

Regular maintenance and inspection (at least annually) by the installer and frequent testing by the user are

vital to continuous satisfactory operation of any alarm system.

The installer should assume the responsibility of developing and offering a regular maintenance program

to the user, as well as acquainting the user with the proper operation and limitations of the alarm system

and its component parts. Recommendations must be included for a specific program of frequent testing (at

least weekly) to insure the system's operation at all times.

ÊK0315ÈŠ

K0315 12/02 Rev. D

IMPORTANT:

THIS DEVICE MUST

BE PERMANENTLY

MOUNTED WITH THE

SCREWS SUPPLIED

MOUNTING

SCREW (2)

No. 6X1 3/4

(SUPPLIED)

269R-010-V0

Figure 4

2"W x 3-1/2"H x 1-1/4"D

(51mm x 89mm x 32mm)

0.2 A @ 30 VDC (MAX)

WARNING: Observe contact rating limitations.

Do not use to switch Line Voltage AC current.

14°F to 140°F

-10°C to 60°C

UL 636 – Holdup alarm units and systems

Supplied, Part Number K4563 to order separately

TO THE INSTALLER

WARRANTY INFORMATION

For the latest warranty information, please go to:

www.honeywell.com/security/hsc/resources/wa

R

C

LISTED

US

2 Corporate Center Drive, Suite 100

P.O. Box 9040, Melville, NY 11747

Copyright © 2010 Honeywell International Inc.

www.honeywell.com/security

Loading...

Loading...