Page 1

Figure

1

EVORA Switch

Confidential

Copyright © 2012 INNCOM

EVORA Series Datasheet

Overview

The EVORA family of switches offers an elegantly designed, easy to use,

feature-rich user interface and control system providing a state-of-the-art

guestroom automation experience. EVORA allows guest control of multiple

lighting loads, temperature, drapes, and guest annunciation from multiple

switch locations in the guestroom. EVORA offers three different user interface

modules and multiple different Load Assemblies that include wired and

wireless communications, dimmers, and programmable controls designed to

operate within INNCOM’s Integrated Room Automation System (IRAS). The

EVORA system brings all guestroom control features into a sleekly designed

traditional keypad user interface.

Features

• Up to 7 key configurations with up to 5 position key pad for programmable control of any IRAS feature

• Nightlight configuration with 2 key positions

• Doorbell configuration with 2 key positions

• Optional multifunction key for up to 10 grouped features per device

• Backlight illuminated keys and text

• TRIAC dimmer

• FET dimmer

• Relay actuator

• Master contactor application

• 12VDC power supply

• Low-voltage adapter for load center applications

• 2.4Ghz 802.15.4 wireless RF network communications

• S5bus wired network communications

• Digital input for door switch contact / integration with the INNCOM energy management system (EMS)

• Software programmable for any CBL feature

Application

EVORA was developed to extend INNCOM switch capabilities beyond those offered in the well-established SSeries (S217 and S5XX) product families and the innovative MODEVA series. The EVORA series uses a modular,

cross functional hardware platform that allows each of the three main products (multifunctional switch,

nightlight, and doorbell ) to share features in both hardware and software that were previously available only as

uniquely designed sub-assemblies in the legacy S-Series products.

EVORA has at its core the same Load Assembly (WBI) architecture used by INNCOM’s MODEVA line. The Load

Assembly is available in six configurations—500W relay, 500W TRIAC dimmer, 350W FET dimmer, 30A master

contactor, 200mA power supply, and a low-voltage adapter (LVA)—that provide the mechanical platform and load

bearing capability for the EVORA system. The EVORA series differs from MODEVA in several ways. It uses a

Page 2

E V O R A D a t a s h e e t P a g e 2 o f 1 0

standard dimension mounting bracket, for instance, allowing EVORAs to be ganged with other products (similar to

the S-Series). EVORA products come factory assembled.

Categories of Load Assembly Load Switching

• TRIAC dimmer provides dimming control of resistive light loads such as incandescent, halogen, and

TRIAC dimmable LEDs. The TRIAC dimmer can dim 100–120VAC loads up to 500W.

• FET dimmer dims capacitive loads such as dimmable fluorescent lamps and electronic ballasts. It can also

dim resistive loads such as incandescent, halogen, and dimmable LEDs. The FET dimmer is designed to

dim 100–120VAC up to 350W.

• Relay power supply switches capacitive, inductive, resistive, and general purpose loads up to 500W.

• Master contactor controls 30A relay at 120–240VAC.

• 200mA power supply used for applications where EVORA must be line powered but does not require

load dimming or switching.

• Low-voltage adapter allows the EVORA products to run in a +12VDC powered device that does not

actuate a load. This is very similar to the legacy S5XX product.

Load Assembly Parallel Power Supplies

The WBI actuators operate in parallel to supply a higher load capacity on the +12VDC rail than that achievable by a

single actuator. The total output power of the actuators in parallel is based on the voltage specifications at maximum

load versus the output current at maximum load and nominal recovery time after a foldback condition occurs. This

design can aggregate up to 6 actuators into a system that permits up to a combined 990mA (~1A) +12VDC output.

See Class 2 Output table below.

Additional Load Assembly Technical Features

• Air-gap relay required (for dimmers meeting UL 508). Where solid state dimmers are used, disengages

the load from the line power in the event that a failed actuator causes a short or a closed circuit (as with a

FET dimmer), a possible electric shock risk during routine maintenance or lamp replacement.

• Additional overload detection circuit for FET dimmer that senses a catastrophic overload / short and

shuts down the dimmer to protect the solid state circuitry.

• Dimming linearization curve may be set by application engineer to calibrate the duty cycle of a Pulse

Width Modulated signal driving the various lamp types that could be used.

• Self contained actuator that can be used without the user interface. This is useful during installation (with

EVORA) and in repair to isolate symptoms related specifically to the actuator.

Load Assembly Installation

Locate the fuse panel and remove fuses or ensure the breaker is in the OFF position before installing the Load

Assembly.

1. Pull the class-2 wires for Ground (Brown), +12VDC (Red) and S5bus (Orange) and digital inputs into the

wall box (See Wiring Diagrams). Make the connections using a dolphin DC-1000P Super B connector or

equivalent type connector to the S5bus or digital input harnesses and connect them to the appropriate

header on the Load Assembly.

2. Prepare the line voltage wiring by stripping back the insulation 16mm (5/8th inch).

3. Connect the Green (Earth) Cable attached to the Load Assembly Strap to Earth.

Page 3

E V O R A D a t a s h e e t P a g e 3 o f 1 0

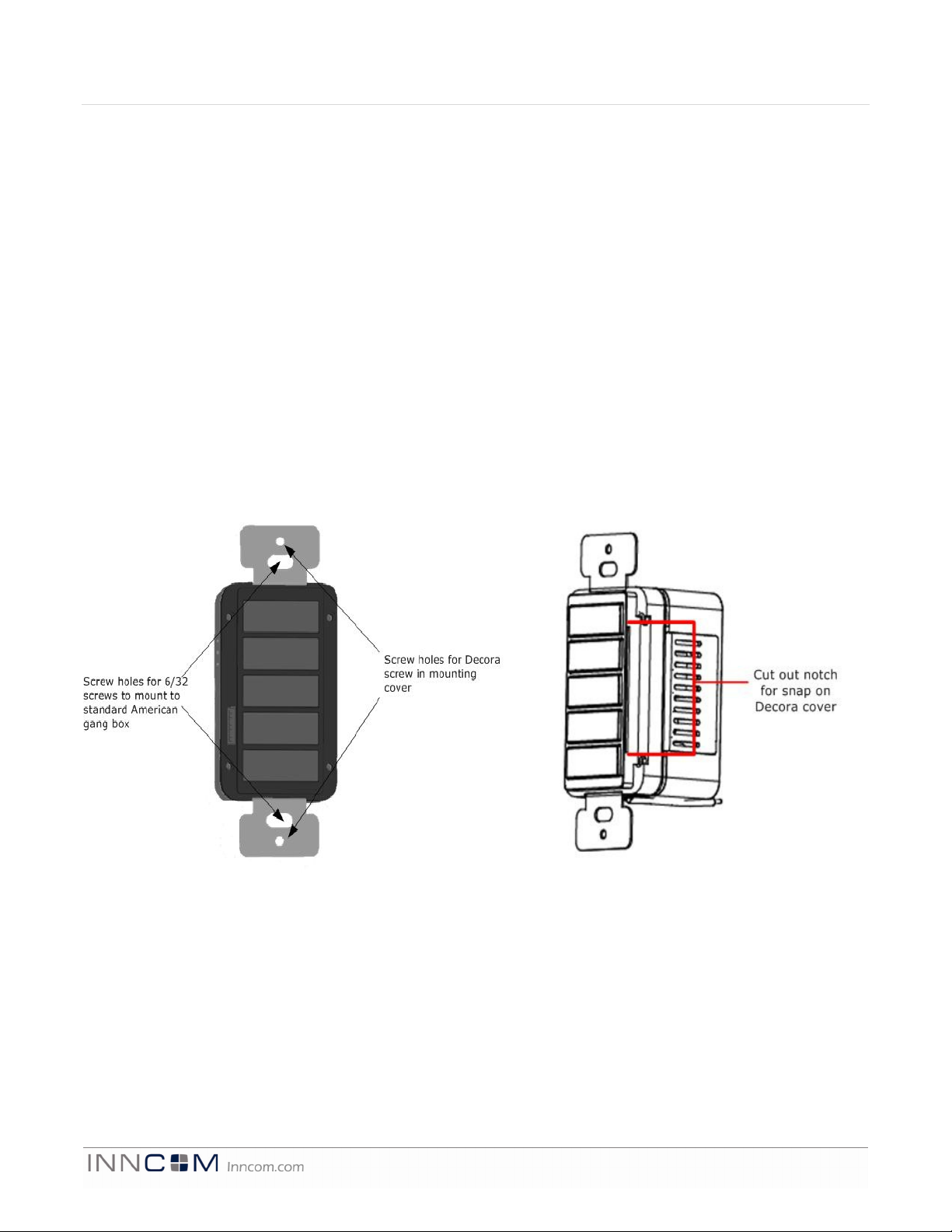

Figure

2

Mounting Screw Holes

4. Wire the Load Assembly as described in the Wiring Diagrams. Depending on gang assembly using the

appropriate 10, 12, 14, 16, or 18 AWG wire nut.

5. Push all wires back into the wall box and fasten the control to the wall box using the supplied mounting

screws. Be sure not to pinch or disconnect any of the wires.

6. Ensure the intended load(s) are connected to the circuit.

7. Replace the fuses in the fuse panel or move the breaker to ON before continuing.

Note: EVORA self test may require that an I/O map is configured. The following steps are general

guidance only. Installers should refer to the property-specific install and commissioning

documents for further guidance.

8. Allow the EVORA switch to power up. To verify power, observe whether indicator light or backlight

illuminate or blink.

9. Testing EVORA depends on the specific software configuration.

10. The EVORA User Interface will display start up behavior (refer to the property-specific installation and

commissioning guide(s) and then enter a self test mode for the first 20 seconds of operation.

Figure 3 Decora Notch

Page 4

E V O R A D a t a s h e e t P a g e 4 o f 1 0

The EVORA and Load Assembly is supplied with two 1¼" 6/32 screws, two 3-pin S5bus harnesses and a two-pin

pig-tail harness for the digital input.

Wiring Diagrams

Figure 4 EVORA WBI Single Wiring

Figure 5 EVORA WBI Double Wiring

Page 5

E V O R A D a t a s h e e t P a g e 5 o f 1 0

Figure 6 EVORA WBI Triple Wiring

In double and triple configurations, refer to the wiring diagram for S5bus and digital input connections. Daisy

chaining is required only if all EVORA units need to be on the same S5bus or a parallel power design is needed

for higher load capacity (See Class 2 Output table below).

Master Contactor

Use for master contactor applications up to 30A. This assembly requires an external +12VDC source.

Figure 7 EVORA WBI Master Contactor Wiring

Page 6

E V O R A D a t a s h e e t P a g e 6 o f 1 0

WBI Power Supply

Use for applications where EVORA must be line powered but does not require load dimming or switching.

200mA DC output.

Figure 8 EVORA WBI Power Supply Wiring

Low Voltage Adapter

The EVORA can be equipped with the Low Voltage Adapter (LVA). This allows the EVORA to act as a remote,

+12VDC powered device only.

Figure 9 EVORA WBI Low Voltage Adapter Wiring

Page 7

E V O R A D a t a s h e e t P a g e 7 o f 1 0

Technical Specifications

User Interface Tactile input

Maximum # of inputs 1-7 tactile keys

Alternate User Interface Keypad—traditional mechanical switches

Communications Wired S5bus

2.4Ghz RF

Input Power 12VDC, up to 250mA*

Audio 8 ohm, 0.5W speaker for door bell chime

Micro controller 16Mhz, 32-bit ARM based MCU

Dimensions 1 3/4” W x 1 3/4” D x4” H (including brackets)

45 mm W x 45 mm D x 100 mm H (including brackets)

FCC ID: GTC202111TXR

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one of the following measures:

— Reorient or relocate the receiving antenna.

— Increase the separation between the equipment and receiver.

— Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

— Consult the dealer or an experienced radio/TV technician for help.

Any changes or modifications not expressly approved by the party responsible for compliance could void the

user's authority to operate this equipment.

IC: 1609A-201217TXR

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following two

conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including interference

that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d’industrie Canada applicables aux appareils radio exempts de licence.

L’exploitation est autorisée aux deux conditions suivantes: (1) l’appareil ne doit pas produire de brouillage, et (2) l’utilisateur

de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le

fonctionnement.

Page 8

E V O R A D a t a s h e e t P a g e 8 o f 1 0

Load Specifications

Single Gang Installation

The following table provides the load ratings at absolute maximum based on the load type in a single gang wall box.

Actuator Ratings

SMPS

Relay Actuator

TRIAC Dimmer

MOSFET Dimmer

Master Contactor

Voltage Frequency Power / Amperes Load Type

120-240Vac 50/60Hz 200mA +12VDC Output

Only

120-240 Vac 50/60 Hz 4.1 A Resistive

120-240 Vac 50/60 Hz 4.1 A General Purpose

120-240 Vac 50/60 Hz 500 W Tungsten / ELV

120-240 Vac 50/60 Hz 250 VA Electric Ballast

120 Vac 50/60 Hz 1/10 HP Motor

120 Vac 60 Hz 2.9 A Resistive

120 Vac 60 Hz 500 W Tungsten / ELV

120 Vac 60 Hz 250 VA Electronic Ballast

120 Vac 60 Hz 1/10 HP Motor

120 Vac 60 Hz 2.9 A Resistive

120 Vac 60 Hz 2.9 A General Purpose

120 Vac 60 Hz 350 W Tungsten / ELV

120 Vac 60 Hz 250 VA Electronic Ballast

120-240 Vac 50/60 Hz 7200VA General Purpose

120-240 Vac 50/60 Hz 960W Tungsten / ELV

120-240 Vac 50/60 Hz 800VA Electronic Ballast

120-240 Vac 50/60 Hz 30A Resistive

Class-2 Output

The Load Assembly has been designed to provide +12VDC power to devices connected to the S5bus. The Load

Assemblies can operate in parallel to supply a higher total load capacity than that achievable by a single Load

Assembly. However, the total output is derated as per the table below for accommodating the stability of the

power supply circuitry. The total available output power must be shared with the EVORA User Interface. Refer to

the following table for Class-2 Output ratings.

Number of Load

Assemblies

1 +12VDC +11.0VDC 200mA

2 +12VDC +11.0VDC 375mA

3 +12VDC +11.1VDC 550mA

4 +12VDC +11.1VDC 660mA

5 +12VDC +11.2VDC 880mA

6 +12VDC +11.2VDC 990mA

Nominal Voltage Voltage at Maximum

Load

Output Rating

Page 9

E V O R A D a t a s h e e t P a g e 9 o f 1 0

Operating Conditions

Table Header Table Header

Storage 68-176 degrees F; 20–80 degrees C, non-condensing

Operating 50-122 degrees F; 10–50 degrees C, non-condensing

Ordering Information

The highly configurable EVORA product line features many options for function (programmable control, doorbell,

nightlight), appearance, user interface, and Load Assembly. The Ordering Guide below is for the EVORA final

assembly. For detailed ordering information for all EVORA components, see the EVORA Ordering Guide.

Final Assembly

Description OPN Part Number

Multifunction/Doorbell 201-217

Nightlight 201-564

Power Supply

Description OPN Part Number

500W TRIAC Dimmer T5 03-7051

350W FET Dimmer F3 03-7052

500W Relay Actuator R5 03-7050

30A Master Contactor 3M 03-0310

200mA Power Supply PS 03-7053

Low Voltage Adapter LVA 03-7073

Page 10

E V O R A D a t a s h e e t P a g e 1 0 o f 1 0

Logic

Description OPN Part Number

1–5 button logic board w/radio MB 202-111

2 button nightlight logic board w/

radio

2 button logic board w/radio DB 202-114

Description OPN Part Number

1, 2, 3, 3b, 4, 4b, 5 button (Nightlight

and Doorbell are 2 button only)

Description OPN Part Number

White WH

Black BK

Light Almond LA

Eagle Almond EA

NL 202-113

Button

- -

Housing Color

Document Revision History

Revision Date Issued Reason

0.1

0.2

0.3

1.0

1.01

2.0

10-Mar-2012 First draft

15-Mar-2012 Incorporated R&D review comments

22-Mar-2012 Updated drawings and Load Assembly text

23-Mar-2012 Incorporated Marketing comments and released

29-Jun-2012 Incorporate new load assemblies, order guide, IC statement

07-Sep-2012 Incorporate FCC statement changes and republish

Loading...

Loading...