Honda WSP33 Owner's Manual

OPERATOR'S MANUAL

BY:

SUBMERSIBLE PUMP

WSP33AA•WSP53AA•WSP73AA

© 2004-2011 American Honda Motor Co., Inc.

All Rights Reserved

BY:

POM31WSP611

AHM.2000.2011.02

Printed in USA

Thank you for purchasing this Honda Stainless Steel

Sump Pump. We hope you are pleased with your

purchase and that our pumps will provide you with long

service life and exceptional performance.

To ensure satisfactory service life, there are several

considerations regarding proper installation, operation,

and power source. Please review the recommendations

outlined within this operator's manual.

Please contact your supplier (supplying dealer or

contractor) if service is necessary or if you have any

questions or need further assistance.

Please retain the following information for your records

and to help expedite service:

Purchase Date: ___________________________

Purchased From: ___________________________

___________________________

Serial No: ___________________________

(Located on the pump nameplate)

Important Safeguards

To reduce risk of injury, always follow these instructions and safety precautions when

using this pump and to maintain warranty.

Read All Instructions Prior to Installation

(SAVE THESE INSTRUCTIONS)

Installation/Operation

• Never lift or carry the pump by the electrical cord. Use a chain or rope affixed to the

handle to install or remove the pump. To reduce potential damage to the pump from

inadvertent lifting by the electrical cord, refer to “Proper Lifting” on page 2

• This pump must be operated fully submerged. Pump must be shutdown if the sump,

pit, or pond level drops below the motor housing.

• Pump is designed to pump clean water (maximum temperature of 122

suspended solids up to 3/16 of an inch. Larger solids will clog the suction strainer plate

leading to dry running and subsequent failure. (Note: Pumping sand, gravel, and other

hard debris will shorten the life of the pump.) Elevate the pump with bricks or other

support above the sump, pit or pond bottom if debris is present.

• Clean the filter basin when cleaning the inlet filter media when the pump is shut down.

• If used with a float switch, the float must have a full range of motion to operate properly

without obstruction. Refer to “Submersible Pump Installation” on page 9

• Pump should be mounted upright only (vertical). Never lay the pump on its side.

Electrical Requirements

• Pump must be operated with a GFCI breaker of at least 15 amps.

• High OR Low Voltage can damage the pump. Power from your utility or generator set

cannot be more or less than 10% of the rated voltage shown on the pump.

• Maximum distance from power source and pump must not exceed 100 feet using 16/3

electrical cables. This distance is from the breaker box and includes the pump cord. If

the run is longer, consult a qualified electrician or your dealer.

• Lightning strikes can destroy the capacitor in your pump. Ensure proper protection is

provided.

• Consult this manual for additional operation and application information.

.

°F) with

.

1

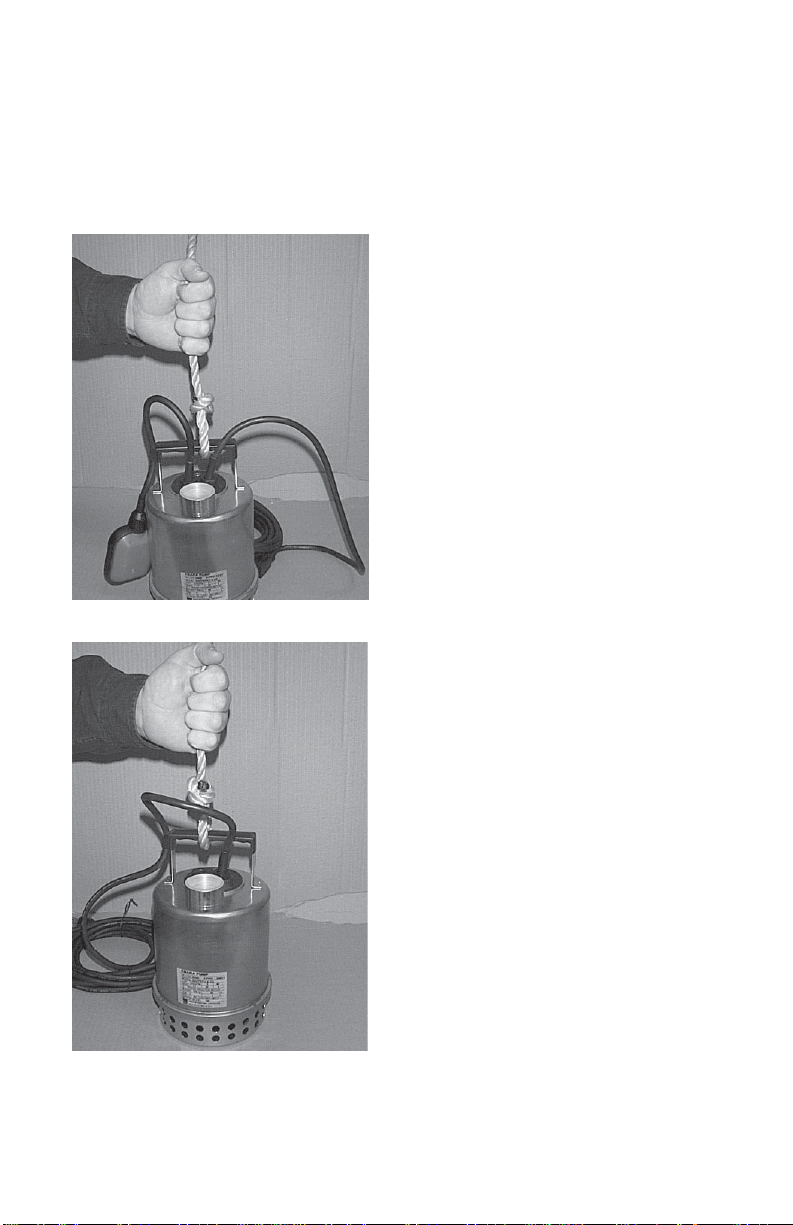

Proper Lifting

A separate chain or rope should be attached to the handle for normal lifting.

Note that this will help prevent damage due to inadvertent lifting of the pump by the

power cord.

Rope attached to the automatic pump for lifting

and installation.

Rope attached to the manual pump for lifting

and installation.

2

Contents

Section Page

General Application Information 3

Safety Information and Introduction 5

General Specifications 6

Tools Needed 6

Materials Needed 6

Installation Instructions 7

Electrical Information 8

Submersible Pump Installation 9

Performance Table (Capacity in Gallons per Minute) 10

WSP Submersible Pump Installation Diagram 11

Motor Wiring Diagram 12

Operation 14

Technical Specifications 15

Troubleshooting Checklist 16

Maintenance and Service 17

Sectional View – WSP33K1AA 18

Sectional View – WSP53AA, WSP73AA 20

Disassembly and Assembly 21

Customer Service Information 22

General Application Information

The Sump and Installation

If your basement does not currently have a sump installed, it will be necessary to check

local plumbing codes as to the acceptable type of sump that may be used. Materials

commonly specified are: clay tile, fiberglass, steel, concrete, and polyethylene. It may be

necessary to cut a hole in the basement floor and excavate for the sump. Plumbing and

electrical contractors can advise on proper installation of drain tiles, sump, pump, and

electrical service. Honda recommends that a solid sump base be provided. The sump is

fed by drain tile placed around the outside and/or inside basement walls at the footings. In

applications where a gravel base must be used to relieve hydraulic pressure under the

basement floor, be sure to provide a permanent and solid base for the pump (bricks or a

steel plate). A sump cover capable of supporting 200 pounds should be employed to

contain odors and for obvious safety reasons.

3

Electrical Installation

Electrical service for any sump pump installation must be grounded and separately fused

or breakered directly from the entrance box with a single grounding type receptacle at the

pump. The receptacle should not be less than four feet above the basement floor for

safety reasons. Y ou should never touch a sump pump or discharge piping while the pump

is connected to electrical power and water is present. The pump should be disconnected

from the electrical source before handling in all cases.

Discharge Piping Installation

To assure the maximum performance from your sump pump, the discharge pipe size and

piping fittings should not be smaller than the discharge port of the pump. Smaller pipe will

add to friction losses and reduce the capacity of the pump. Normally accepted materials

are galvanized pipe, rigid plastic pipe, or acceptable flexible pipe or hose. A piece of

flexible hose between the pump discharge and the discharge piping will provide for ease

in alignment, reduce vibration and noise, and will act as a union when it is necessary to

remove the pump. Where the discharge pipe is long, a check valve is often employed to

prevent the water from flowing back into the sump when the pump turns off. If the

discharge is directed into a sanitary sewer, a suitable anti-siphon device or a free flow

check valve should be inserted in the line to prevent backflow into the pit. Sump pumps

are not designed to handle raw sewage (see “Septic Tank Installation” on page 7

attempt to adapt one for this type of application. A sewage ejector pump especially

designed to handle solids must be used.

Pump Installation

When the sump, electrical and discharge plumbing installation is complete and ready for

the pump, clean all solid debris from the pit. Complete the plumbing connection to the

pump and then plug the pump into the electrical outlet. A few extra minutes to test the

sump pump installation are now in order. Fill the sump with water, note the turn on and

turn off level of the pump, and the pumping cycle. This will allow you to calculate the

approximate discharge flow of the pump system. If everything is operating properly, install

the sump cover.

Pump Selection

). Do not

The pump should be of sufficient capacity and head to satisfy anticipated use

requirements.

Basement perimeter water intrusion varies by area and region. Typically a 1/3 HP or 1/2

HP DRAINAGE PUMP WILL EVACUATE MOST HOME SUMP PITS. Commercial and

industrial drainage applications require that calculations of pumping volume and pumping

head be performed to determine the proper size pump is applied.

NOTE: Pumping volume may vary seasonally due to rainfall and area run-off.

4

Basin and Cover

The basin should not be less than 18 inches in diameter and 24 inches deep. Larger

diameters are advisable in instances of increased pump capacity requirements:

Required Pump Capacity Minimum Basin Diameter

Up to 35 GPM 18"

Over 35 GPM 24"

Over 60 GPM 30"

Over 100 GPM 36"

Over 150 GPM 48"

The basin should be located such that all water flows into the basin due to gravity.

Outdoor installations should be at a sufficient depth to ensure protection from freezing.

Maintenance Tips

• Every three or four months:

1) Clean the pump screen or inlet opening. If your sump collects the discharge from an

automatic washing machine, cleaning will be required more often. (Before removing

the pump, be sure to disconnect the unit from electrical power; and reconnect after

completion of cleaning).

2) Pour enough water into the sump to cycle the pump and assure its proper

functioning.

• Annually:

Remove and clean the pump. Clean the sump pit also.

Safety Information and Introduction

B WARNING

Before handling this pump, always disconnect The power

first.

This pump should only be serviced by a qualified person or a factory

trained person.

B CAUTION

This instruction manual includes necessary items for installation, operation, and

maintenance. Read this manual carefully to ensure correct installation, operation, and

maintenance. Be sure to keep this instruction manual on hand for future reference

5

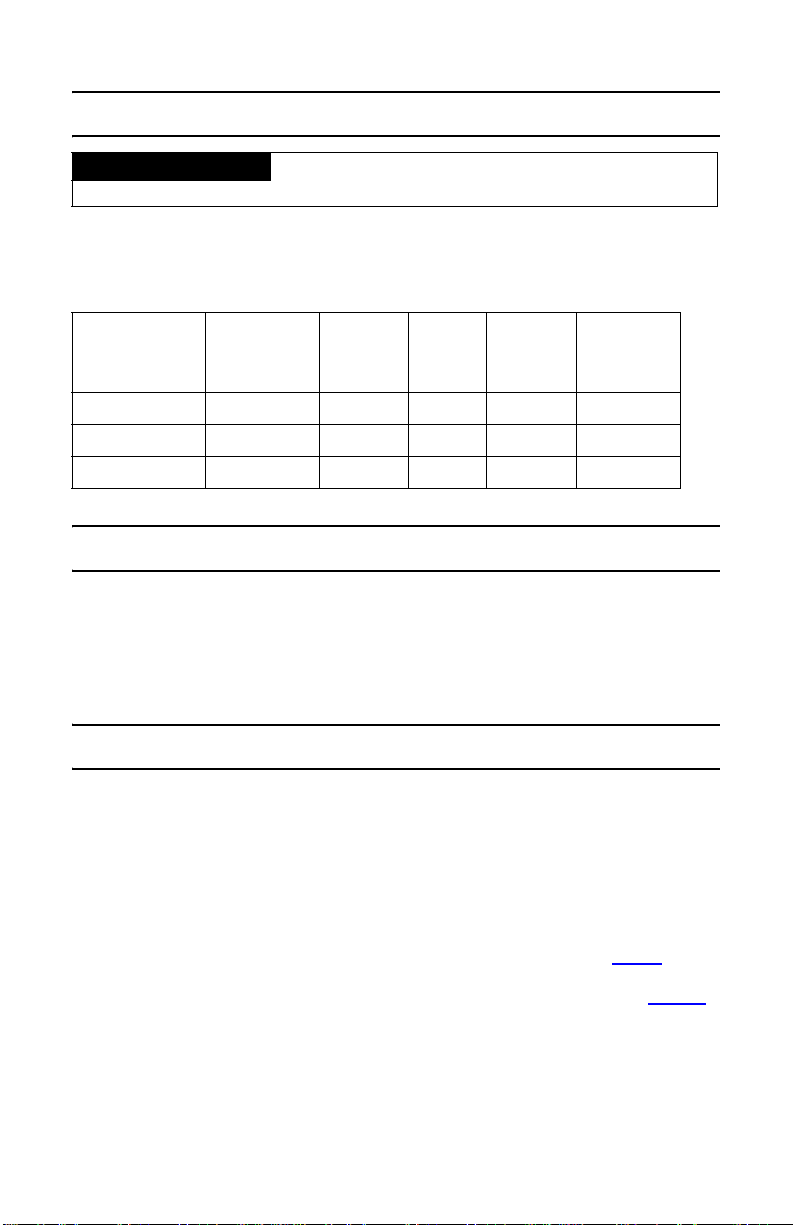

General Specifications

B CAUTION

Be careful not to exceed the given specifications in the use of your products.

Check the nameplate for your pump’s head (HEAD), discharge volume (CAPACITY),

speed (SPEED), motor voltage, and current. Other specifications are noted in the chart

below:

Discharge

Model

WSP33K1AA 1-1/4 1/3 1 115 11

WSP53AA 1-1/2 1/2 1 115 27

WSP73AA 1-1/2 3/4 1 115 27

Diameter

(inch)

Motor

Output

(HP)

Motor

Phase

Voltage

Weight

(lb)

Tools Needed

• Screwdriver

• Pipe wrench

• Adjustable wrench (medium-large)

• Hacksaw with 24-tooth blade for cutting plastic pipe

• Knife or round file for smoothing inside of all plastic pipe connections

Materials Needed

• PVC or ABS pipe cement (read manufacturer’s instructions carefully)

• PVC or ABS pipe;

– 1-1/4" for WSP33K1AA

– 1-1/2" for WSP53AA, WSP73AA

• PVC adapter

– 1-1/4" for WSP33K1AA

– 1-1/2" for WSP53AA, WSP73AA

• In-line check valve

• Sump basin 18" or larger diameter plastic, fiberglass, or concrete. (See page 5

minimum diameter basin size by pump capacity.)

• Optional: gate valve (see “WSP Submersible Pump Installation Diagram” on page 11

for

).

6

Loading...

Loading...