INTRODUCTION

Thank you for purchasing an

This

attachments:

For your convenience,

NOTE:

information available

reserves

incurring any obligation.

No

Pay

manual covers

0

QH6000 Subframe

0

DB6560 60" Dozer Blade

0

DK6000 Drive kit

0

SB6557 57"

0

FS6560 60" Rotary Broom

The information

the

part

of

special

this

attention

Indicates

are

the

assembly, operation and maintenance of

with

Two

Stage Snowblower

a

parts

in

at

right

publication may be reproduced without

not followed.

to

make changes

to

the

that

HTA

attachment for your Honda Tractor.

Quick

guide

this

the

time

statements preceded by

serious injury

Hitch

is

publication

of

System

also included in

printing.

at

any

or

is

American

time

death

the

following

this

publication.

based

written

the

WILL

on

the

latest

Honda Motor

without notice and without

permission.

following symbols:

result

if

product

Co.,

instructions

HTA

Inc.

Indicates

result if instructions

m:

Indicates

are

not

:

Indicates

instructions

NOTE

HTA attachments

operated according to instructions.

If

a

problem should

consult an authorized Honda compact Tractor dealer.

OM

0179

:

Gives helpful information.

are

a

strong possibility

are

not followed.

a

possibility

followed.

that

are

designed to give safe and dependable service if assembled and

arise,

equipment

not followed.

or if you have any questions about your attachment(s1,

that

minor injury can result if instructions

or

1

that

serious injury

or

death can

property damage can result

if

comENT!3

PAGE

INTRODUCTION

SAFETY PRECAUTIONS

0

QH6000

0

DB6560

0

SB6557

FS6560

PARTS GUIDE

QH6000

DK6000

DB6560

SB6557

FS6560

Decals

TORQUE SPECIFICATION TABLE

WARRANTY SERVICE

............................................................

......................................................

-

QUICK

-

60" FRONT DOZER

.

57" TWO

.

60" FRONT

.

Two

Subframe with Quick Hitch System

.

Drive

.

Blade Angling Cylinder

60" Front

.

57" Two Stage Snowblower

.

60

ATTACH SUBFRAME WITH

SAFETY

OPERATION

ASSEMBLY

DISMOUNTING

SAFETY DECALS

OPERATION

MAINTENANCE

ASSEMBLY

STAGE SNOWBLOWER

SAFETY DECALS

OPERATION

MAINTENANCE

ASSEMBLY

SAFETY DECALS

OPERATION

MAINTENANCE

ASSEMBLY

DISMOUNTING

Spool Valve

Kit

Components

"

Front Rotary Broom

Components

............................................................

.....................................

&

INSTRUCTIONAL DECALS

QUICK

HITCH SYSTEM

...........................

...............................................

.

Step 1: Subframe assembly

Step 2: Mid PTO kit

Step 3: Valve & hose

Step 4: Tractor

Step

5:

&

REMOUNTING

BLADE

Attaching frame

................................

installation

installation

preparation

....................

..................

to

tractor

...........................................

.

Operating

&

-

Step

Step

Step 3:

DISMOUNTING

1:

2:

controls

&

adjustment

...............................

Blade

Hydraulic angling installation

Blade

assembly

installation

.......................

...................

...........................................

.

Preparing for

Operating

Snow

removal

snow

controls

methods

removal

&

adjustments

..................

........................

.............................................

.

Step

Step 2: Chute

Step 3: Attaching snowblower

BROOM

1:

Snowblower assembly

and

hydraulic

..................

rotation

to

...........................................

.

Operating

Applications

.

General

.

Brush

.

Step

Step

Step 3: Optional dolly wheel

1:

2:

controls

&

adjustments

................................

...................................

replacement

Broom

Broom

preparation

installation

.........................

....................

...................

installation

.............................................

..........................................

.........................

................................................

...................................

Dozer

Blade

....................................

.................................

..............................................

....................................

..............................................

...............................................

(inside back

.............

............

...........

.............

.......

............

.........

quick hitch

............

cover)

..

....

1

3

6

7

8

9

10

11

12

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

31

32

33

34

35

36

37

39

40

41

42

46

49

50

52

54

60

63

69

71

OM

0179

2

A

CAREFUL OPERATOR IS THE BEST

-

OPERATOR

MOST ACCIDENTS CAN

BY OBSERVING CERTAIN PRECAUTIONS

BE

AVOIDED

-

READ

AND TAKE THE FOLLOWING PRECAUTIONS

BEFORE

HELP PREVENT ACCIDENTS

SHOULD BE OPERATED ONLY BY

ARE

THE ATTACHMENT

1.

2.

OPERATING THESE A!WACEMENTS

-

RESPONSIBLE

AND

INSTRUCTED

(S)

Read

this

manual carefully

yourself

as

the

Working

can lead to accidents.

familiar

proper

how

the

Keep

tighten

with

the

equipment

tractor operator's manual.

to

with

use

stop

unfamiliar equipment

Be

with

the controls and

of

the

equipment. Know

the

unit and disengage

controls quickly.

all

shields

all

in

place

mounting hardware.

To

EQUIPMENT

THOSE

To

to

WHO

DO SO-

acquaint

as

well

thoroughly

and properly

SAFETY PRECAUTIONS

2.

Clothing worn by

the

operator should

be fairly tight and belted. Loose

clothing can easily become caught

on moving

3.

Prolonged exposure to loud noise can

parts

cause impairment

Wear

a

suitable hearing protective

device such

or controls.

or

loss

of hearing.

as

earmuffs or earplugs

to protect against objectionable or

uncomfortable noises.

OPERATING THE ATTACHMENT(S)

To

tIELP PREVENT ACCIDENTS THE FOLLOWING

PRECAUTIONS SHOULD

OPERATING EACH

1.

Never allow anyone to

OF

BE

TAKEN BEFORE

THESE ATTACHMENTS.

ride

attachment.

on

the

3.

Periodically

for

service

of

4.

Replace

wear

parts

wear

and

inspect

replace

all

with

moving

authorized

if an excessive amount

is

present.

all

missing, illegible, or

damaged safety and warning decals.

See

your

5.

Do

or any of

list

attachment(s1 section(s).

not modify or

of

its

decals

alter

at

this

the

equipment

components , or any

equipment function without first

consulting an authorized Honda

compact tractor

6.

Keep

safety decals clean

dealer.

of

grime.

GENERAL PREPARATION

1.

Be

sure

before starting

the

PTO

is

the

in

OFF

engine.

parts

end of

dirt and

position

2.

Clear

the

area

of people and debris

before commencing operation.

3.

Never allow children to operate

equipment. Never allow

adults

operate equipment without proper

instruction.

4.

Always keep

the

attachment discharge

directed away from people and objects

which

5.

Never

6.

Never leave attachment in raised

could be struck

allow

anyone in front

by

debris.

position.

7.

Never

operate

the

attachment without

good visibility and lighting.

8.

Never clean or adjust PTO

equipment

with

the

tractor engine

running.

of

unit.

-

driven

to

OM

0179

3

SAFETY

9.

PRECAUTIONS

When operating PTO-driven equipment,

shut

off

always

for

the

PTO to stop turning before

getting off

unplugging

the

the

the

collector/impeller

housing or discharge chute and

before making any

or

inspections.

10.

Take

all

leaving

Disengage

possible precautions when

the

repairs,

vehicle unattended.

the

PTO, lower

attachment, shift into neutral,

the

parking brake, stop

the

and remove

11.

Disengage power

transporting

key.

to

or

when not in use.

12. The operator must never

tractor

while

it

is

engine and

wait

tractor, before

adjustments

the

set

the

engine

attachment when

get

off

the

in motion.

19.

Use

care

when backing

up.

20. After striking a foreign object, stop

the

engine,

to stop,

attachment for

the

damage before restarting and

operating

the

21. If

start

sweeper

to vibrate abnormally, stop

engine immediately and check for

cause. Vibration

wait

for

all

movements

thoroughly inspect

the

attachment.

damage

and

or snowblower should

is

generally

the

repair

the

the

warning of trouble.

22.

Do not

slopes.

clear

snow

across

the

face of

Exercise extreme caution when

changing direction on slopes. Do not

attempt

to

clear

steep

slopes.

a

13.

Exercise

extreme caution when

operating on or crossing gravel

drives, walks or roads. Stay

for

the

hidden hazards of traffic.

14.

Do not put hands or feet near rotating

parts.

at

15.

Do not use hands or feet

all

Keep

times.

clear

of discharge opening

to

spout.

16.

Keep a careful

could enter

watch

the

for debris

blower

operating.

17. Never operate

guards, shields and

protective devices in

18.

Never operate machine

transport speeds on

ace.

surf

the

attachment without

other

phce.

a

alert

unplug

that

while

safety

at

high

slippery

23 Escaping

hydraulic/diesel fluid under

pressure can penetrate

serious injury.

Do

not use your hands to check

for leaks.

cardboard or

for

leaks.

Stop engine and relieve pressure

by moving valve handles back

and forth before connecting or

disconnecting lines.

0

Tighten

starting engine or pressurizing

lines.

If

any fluid

skin,

the

within

familiar

it

fluid

a

may result in gangrene if

is

few hours by

with

the

skin causing

Use

a

piece

paper

all

connections before

is

injected into

to

of

search

the

not surgically removed

a

doctor

this

form of injury.

OM

0179

4

THE

TRACTOR

1.

Read

the

Operator's

Manual carefully

before using tractor. Lack of

operating knowledge can lead

accidents.

to

10.

11.

Keep

downhi

Use

for

the

11.

of

tire

better

tractor

traction and stability

recommended. See

recommended weighing.

in

gear

chains and

Tractor

SAFETY

when going

wheel

Manual for

PRECAUTIONS

weights

is

2.

Do

not

to ride

permit

on

anyone but

the

tractor.

the

There

operator

is

no compatible

12. Always drive

safe.place for extra riders. when

I

OPERATING THE TRACTOR MAINTENANCE

I

1. Never

beside

tractor

or operating controls.

2.

Never run

closed building without adequate

ventilation

are

4.

Never

fuel tank

5.

Use

emblem and

lamps

roads, day or night,

by

start

the

engine while standing

the

tractor. Always

seat

while

the

tractor

as

starting

the

very dangerous.

allow

a

an open flame near

or

battery. maintenance when

slow moving vehicle

the

flasher warning

when traveling on

law

in your

state.

sit

on

the

engine raised position.

engine in

exhaust fumes

(SMV)

public

unless

prohibited

the

the

1.

2.

a

3.

4.

the

with

operating

tractor

safety, especially

over rough ground,

at

speeds

crossing ditches, or when turning.

AND

STORAGE

Provide adequate blocking before

working under an attachment when in

Make certain

all

moving

parts

have

stopped before cleaning, repairing

or

inspecting.

Do

not run engine indoors.

Do

not

attempt

is

running, or when

is

raised.

to

repair

the

or

tractor engine

the

attachment

perform

6.

Make

when using PTO

always

I

7. Always bring

stop and shut off

getting off

8.

Never park

incline.

Use

9.

grades to maintain proper stability.

OM

0179

sure

replace

care

the

PTO shield

-

driven equipment and

is

PTO shield if damaged.

the

tractor to a complete

the

engine before

the

tractor.

the

tractor on

when operating on

installed

a

steep

steep

5

SUBFRAME

-

SAFETY

DECALS

~~6000

I

I

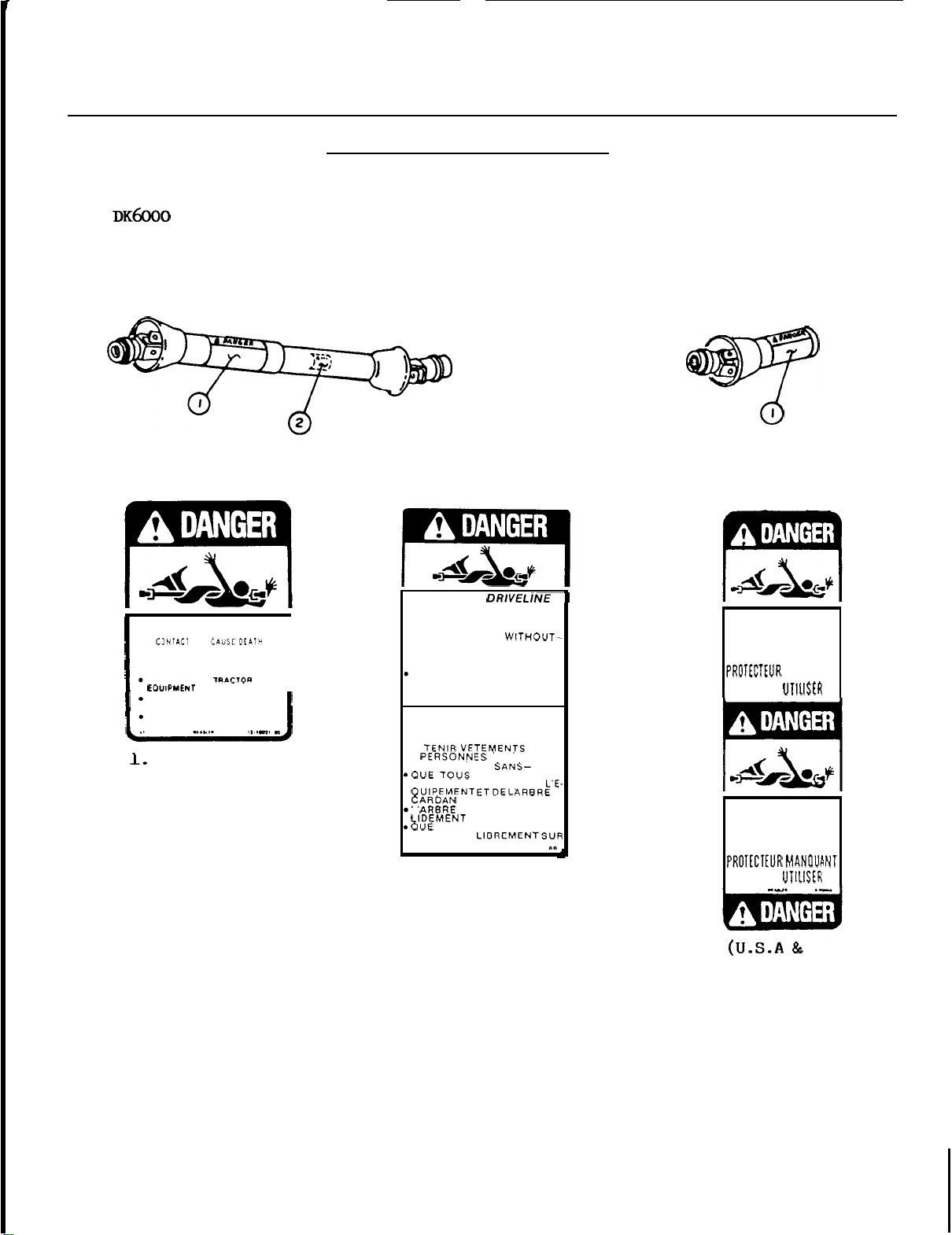

1.

(drive

ROTATING DRIVELINE

CONIAtl CAN

DO

NOT

ALL DRIVLLINE. TRACIOR AND

EQUIPMENT SHIELDS IN PLACE

DRIVELINES SECURELV

ATTACHED AT BOTH ENDS

DRIVELINE SHIELDS THAT TURN

FREELY ON DRIVELINE

CIUSI

KEEP AWAY!

OPERATE

(U.S.A.

kit)

OtAIH

WITHOUT

only)

-

I

REPLACE

IMMEDIATELY

ROTATING DRIVELibE-

CONTACT CAN CAUSE DEATH

KEEP PEOPLE AND CLOTHING

WELL CLEAR

DO

NOT OPERATE WITHOUT-

*ALL DRIVELINE. TRACTOR

AND EQUIPMENT SHIELDS

IN PLACE

DRIVELINES SECURELY

ATTACHED AT BOTH ENDS

*DRIVELINE SHIELDS THAT

TURN FREELY

TRANSMISSION ROTATIVE

A CARDAN

TOUT CONTACT PEUT

CAUSER LA MORT

TENlR VETEMENTS ET

PERSONNES A L'ECART

NE PAS OPERER SANS-

*QUE TOUS LES PROTEC

TEURSDU TRACTEUR.DE

OUIPEMENTETDELARBRE A

C,ARDAN SOIENT EN PLACE

L ARBRE A CARDAN FIXE

LIDEMENT A CHAQUE BOUT

*QUE LES PROTECTEURS

TOURNENT

L'ARBRE A CARDAN

1.

(CANADA

IF

DAMAGED

ON

DRIVELINE

L'E.

SO

LIBREMENTSUR

Llll

only)

d

SHIELD

DO

PROTtCTEUR

SHIELD

DO

PROTtClEUR

MISSING

NOT OPERATE

MANOUANT

Nt

PAS

UilllSER

MISSING

NOT OPERATE

MAN[IUANT

NE

PAS

UTlllStR

OM

0179

6

2.

(U.S.A

Visible

shield

&

CANADA)

only

is

missing.

if

'

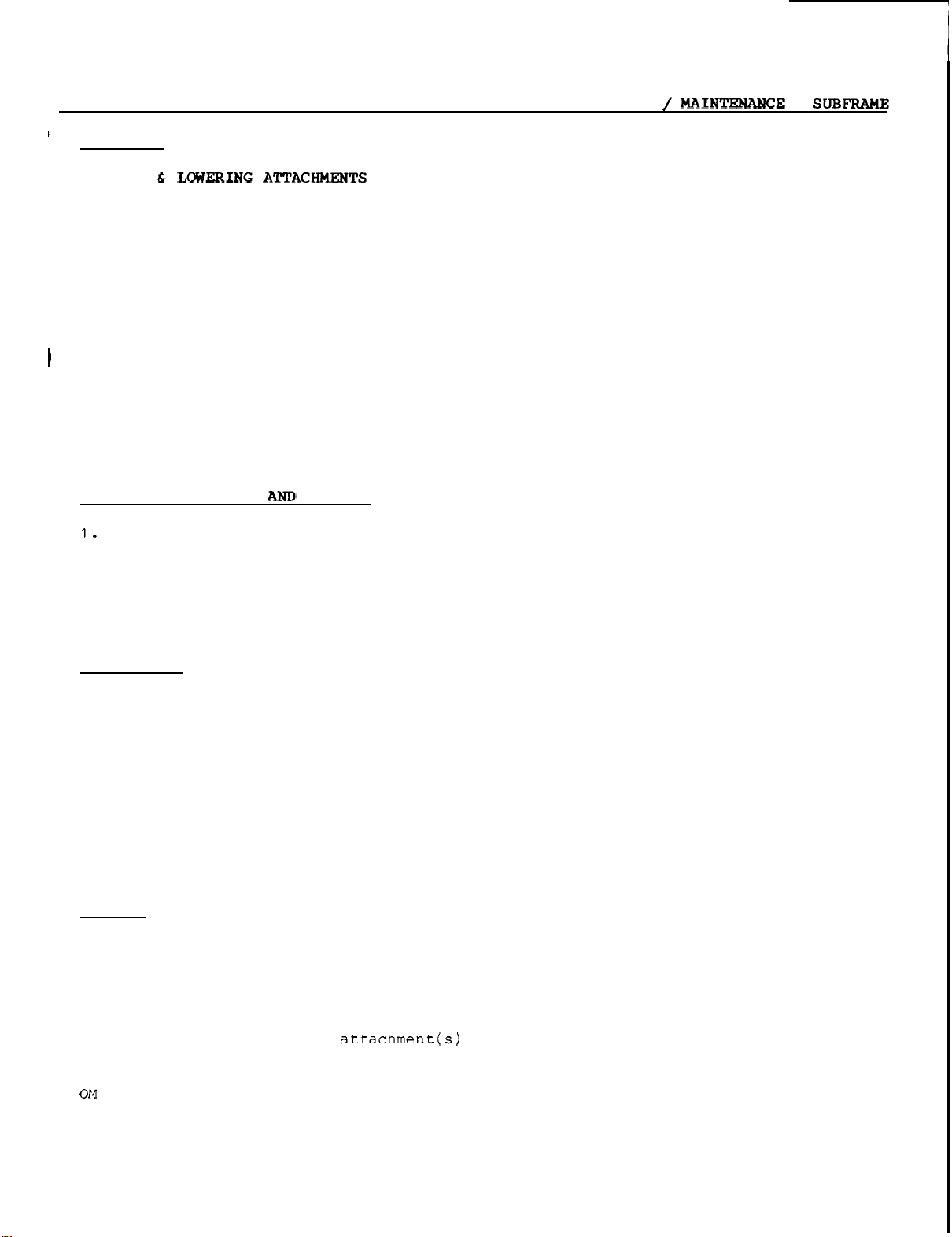

OPERATION

OPERATION / MA1-E

-

SUBFRAME

RAISING

(Dozer

Attachments

the

valve handle: Float position

pushing

AUXILIARY

This

either

and 'on

rotation on

&

LOWWING

Blade, Snowblower, Rotary

can

AT!I?ACHMENTS

broom)

be

raised or lowered using

right hand (farthest from operator)

is

obtained by

the

right handle fully forward.

VALVE

valve (closest to operator)

for power angling on

the

dozer blade or for

the

snowblower. If motion

the

is

used

rotary broom

the

chute

contrary to attachment operation instructions,

simply

switch

attachment

male

quick coupler

locations.

MAINTENANCE SERVICE

1.

Never store

the

AND

STORAGE

tractor

with

fuel in

the

fuel tank inside a building where open

flame or sparks

engine

to

cool before storing in any

present. Allow

the

are

enclosure.

is

LUBRICATION

1

.

DRIVELINE:

every

shaft

with

2.

SUBFRAME:

8

apart

grease every

Grease

each

u-joint fitting

hours of operation.

and coat sliding surfaces

24

hours

Grease

all

fittings on lift

of

and on subframe attaching points every

hours of operation.

STORAGE

1

.

2.

3.

4.

5.

Ol4

Clean

Repaint

When

parts.

Lubricate

Store

a

01

dry

79

the

subframe thoroughly.

all

the

the

place.

parts

subframe

the

subframe and attachment(s) in

from

is

subframe

which

dry,

as

paint

oil

instructed

Slide

drive

operation.

has

worn.

all

moving

above.

8

7

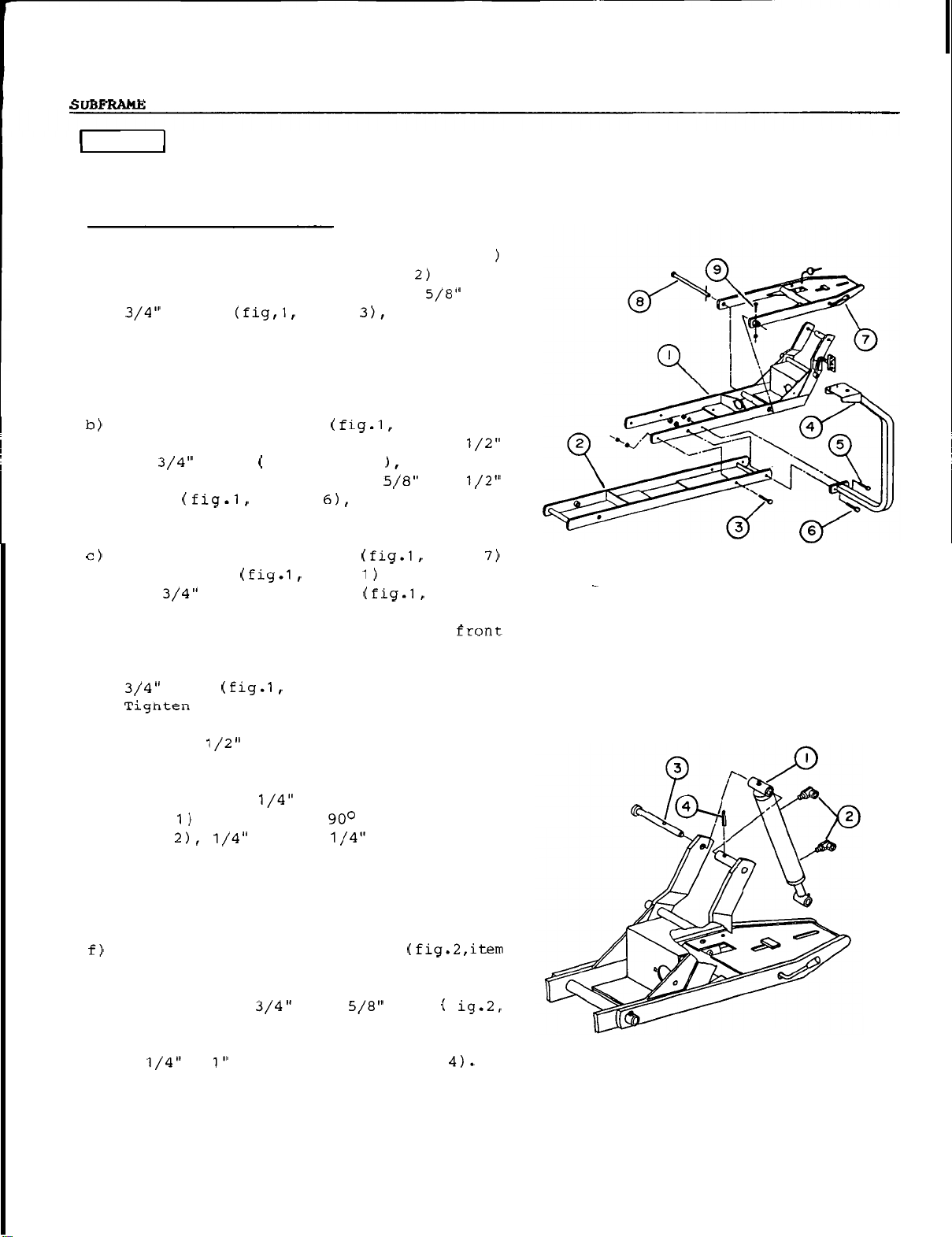

SUBFRAME

I

NOTICE I Before beginning assembly

through completely and familiarize yourself

assembly,

-

ASSEMBLY

torque

all

bolts according to

of

this

the

subframe,

with

torque

all

specification table on page 71.

please

the

read

parts.

the

instructions

After completing

STEP

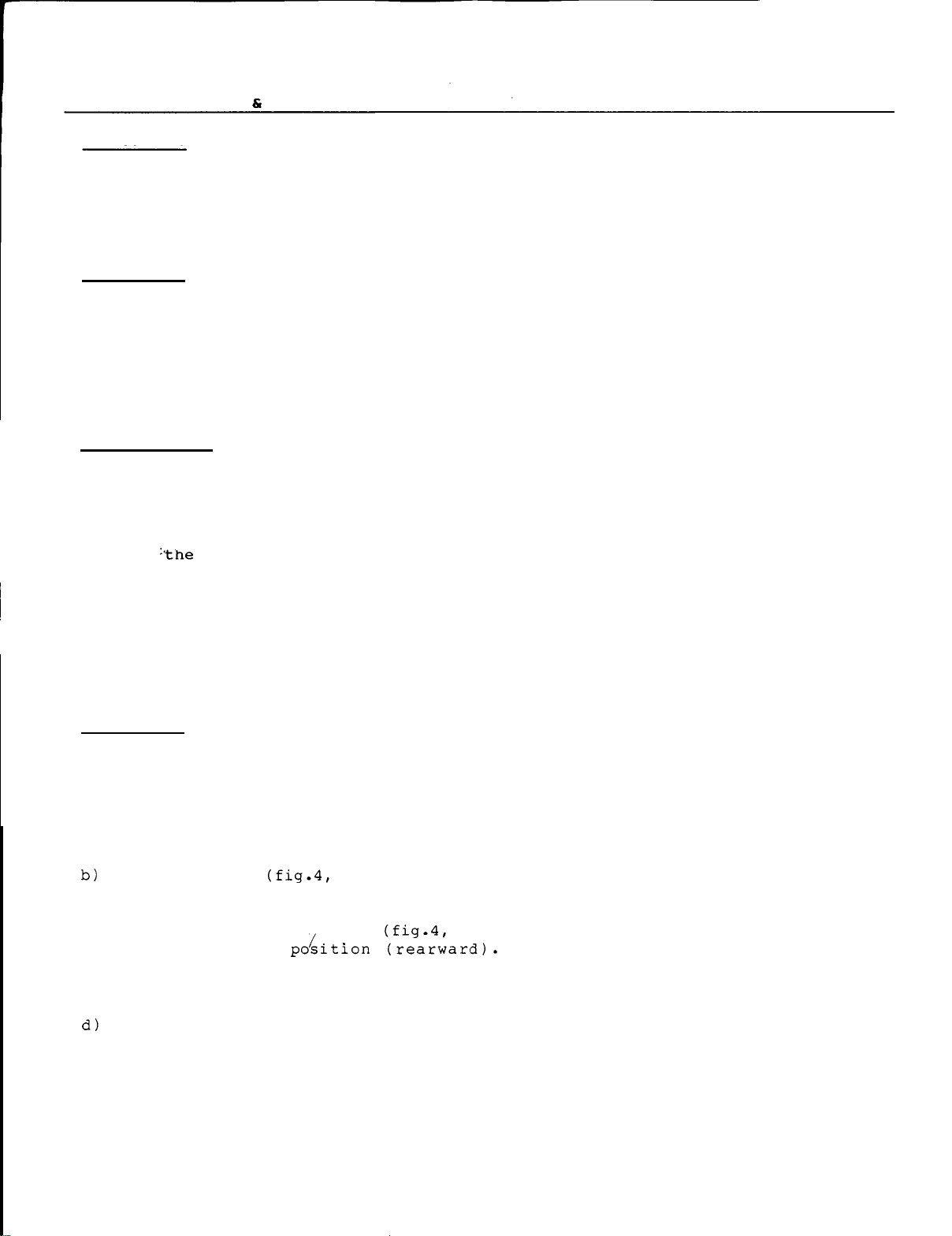

a)

NOTE:

with

b)

c)

1

:

SUBFRAME

Assemble front section (fig.

and

rear

subframe together, using

3/4" bolts (fig,l,

and nuts. Tighten securely.

Rear

section of subframe must be installed

reinforcement

Attach

right hand

x

1

and

bolt (fig.1,

nut.

Attach

to

the

through

hitch

section. Lock

hand side of subframe using

3/4"

Tighten securely.

valve support (fig.1,

3/4" bolts ( fig.

nut

in front hole and

Tighten securely.

male

subframe (fig.1,

3/4"

the

and through

bolt

ASSEMBLY

section (fig.

item

plates

side

of

subframe using one 1/2"

1

,

item

quick

hitch

item

x

11

13/16" pin (fig.1,

left hand side of

the

pin in

(fig.1,

item

1

,

i

1,

item

three

31, lockwashers

on bottom side.

2) of

5/8"

item

item

5

1,

lockwasher

a

5/8"

x

61,

lockwasher and

(fig.1,

1)

by inserting

item

item

the

the

subframe front

place

9)

and nylon nut.

on right

a

5/16

tem

the

x

4) 'to

2 1/2"

quick

"

x

1

)

1

7)

8)

1

FIGURE

-

1

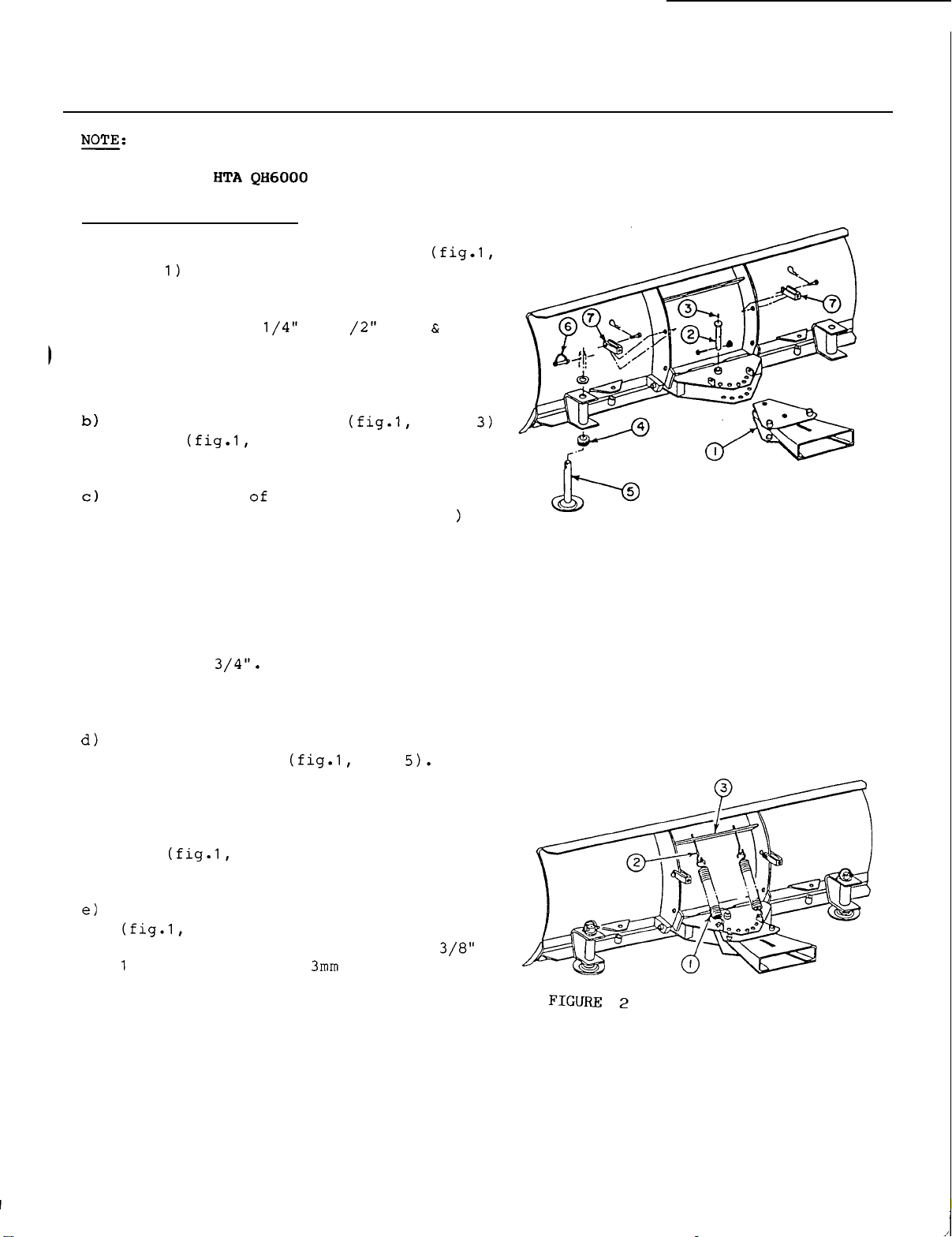

d) Install

quick

e)

On

the

item

item

in cylinder

Cylinder base end being 12 o'clock,

base end

and rod end elbow

f)

Install

1

)

between

of subframe.

place

item

is

vertical. Lock

a

1/4"

OM

0179

1/2"

hitch

2

" x 6 1/4" lift cylinder (fig.2,

1)

install

2),

elbow

lift cylinder

with

3)

making sure

x

x

3" handle

lever.

two

1/4"

male

port

at

x

using thread sealant.

approximately

at

the

welded tube and side

Attach

a

3/4"

1"

roll pin (fig.2,

cylinder

x

the

the

90°

1/4" female swivel

12 o'clock.

base

6

5/8"

pin in

grip

elbows (fig.2,

end (fig.2,item

on

10

o'clock

male

place

plate

base

pin

hole in

place

item

end in

(

f

ig.2,

the

using

4).

pin

8

FIGURE

2

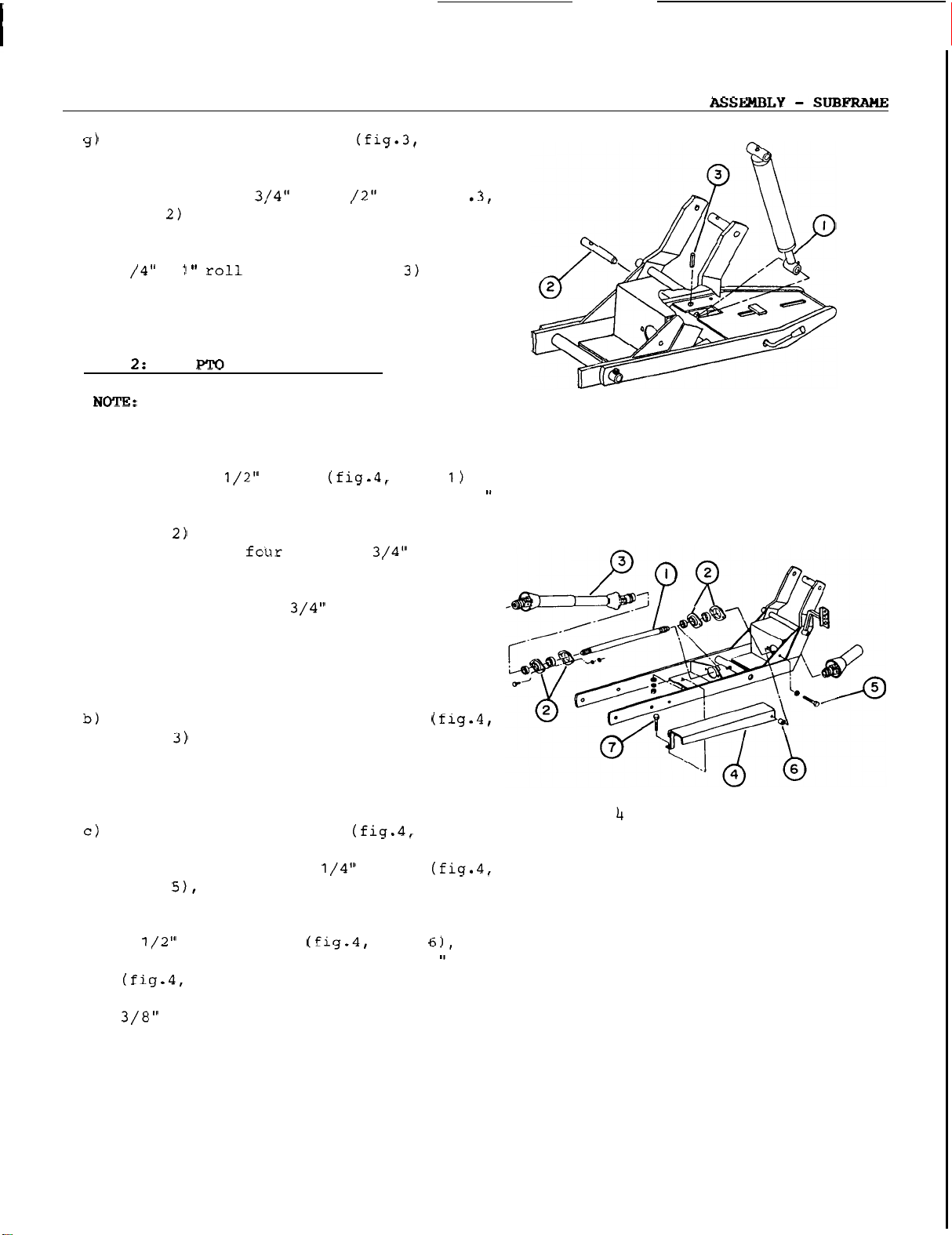

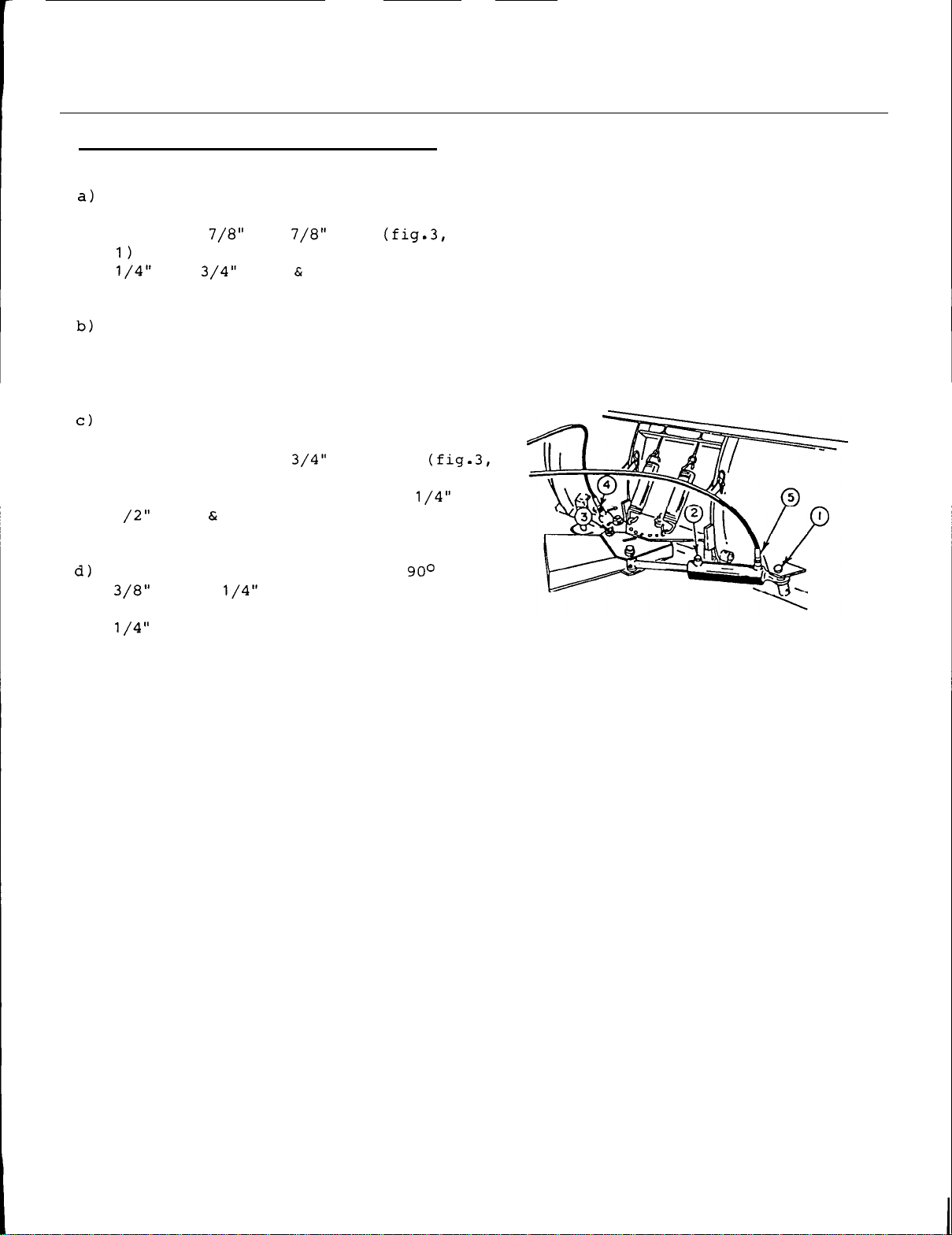

g) Install cylinder

into

the

secure

item

quick

the

male

quick

grease fitting

with

2) on

hitch

a

3/4" x 4

the

right hand

(make sure

vertical). Lock

1

/4"

x

1

I'

roll

pin (fig.

the

right

quick

hand

hitch.

rod

is

the

pin in

welded

end (fig.3,

hitch,

making sure

on front

1

/2"

pin (fig .3,

side

of

hole

in pin

place

3,

item

tube

in

item

1)

side,

the

and

male

is

with'

3) through

the

male

a

STEP

a)

2:

NWE:

Install

MID

PTO

If you

over

Step

KIT INSTALLATION

do

not require

this

3.

19

section and go directly to

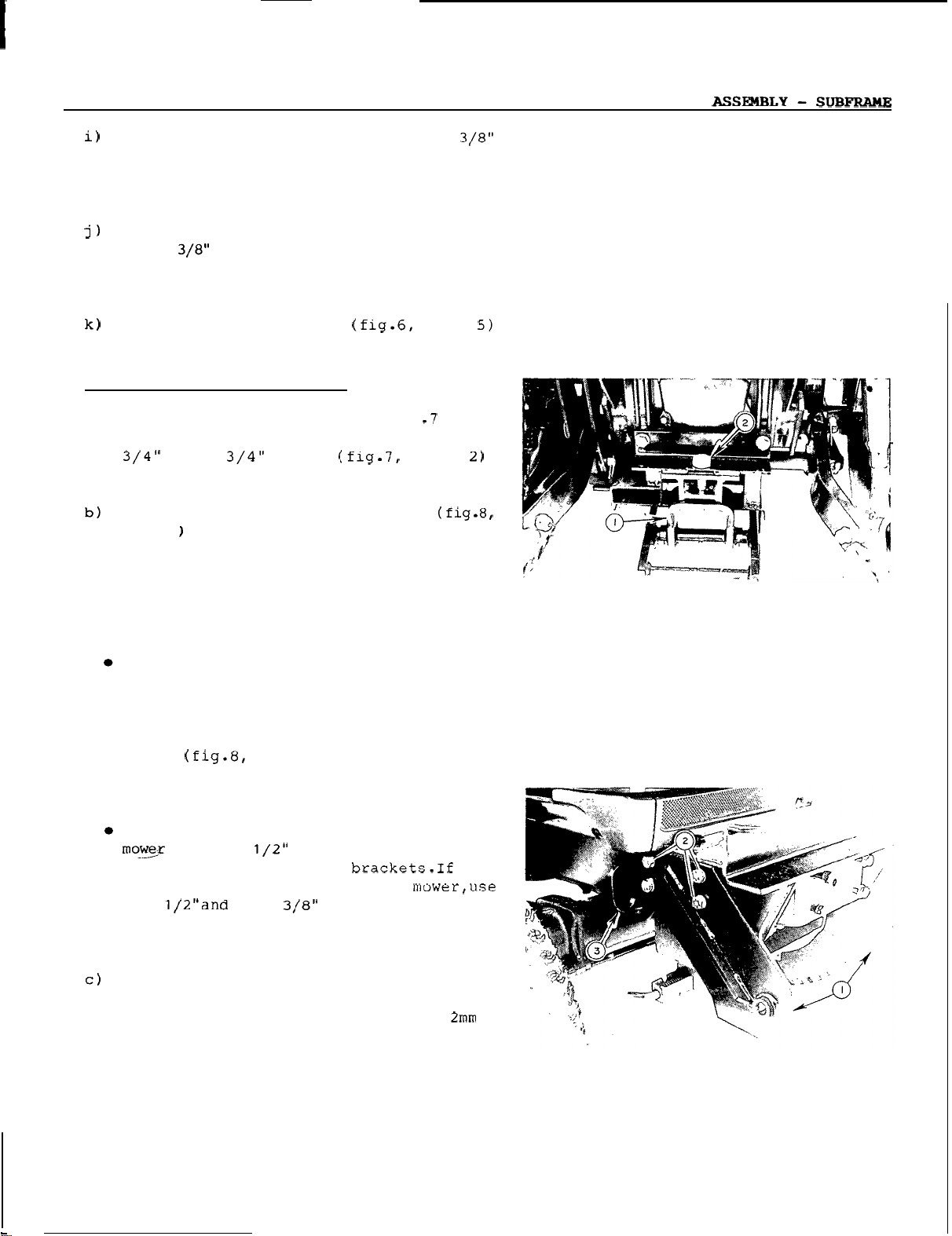

1/2" shaft (fig.4,

this

item

front section of subframe, using

bearings, four bearing retainers (fig.4,

item

plates)

bolts,

two bearings and locking

shaft

rear

place

2)

(placed on

,

and four 5/16

rear

side of

" x 3/4" carriage

lockwashers and nuts. Install

collars.

so

that

cross

by turning

3

plate.

3/4" extends from the

Lock

the

the

eccentric

in a clockwise direction (viewed from

rear

of subframe).

b)

Attach

item

sliding back

long end of driveline (fig.4,

3)

to

the

the

shaft

locking

in

subframe by

collar

and pushing driveline yoke over

shaft

c)

Install driveline guard (fig.4,

on

using one 5/16

item

lockwasher on

bolt

a

through

(fig.4,

bracket

3/8" f

until

the

51,

through

the

locking

collar

front section of the subframe

"

x 1 1/4"

in

the

the

the

front

bolt,

subf

hole,

then placing

rame

1/2" long sleeve (fig.4,

the

guard.

item

to

7)

the

latwasher

Use

a

to

attach

subframe, securing

,

lockwasher

snaps

bolt

placing

,

then through

item

5/16

"

the

rear

Tighten securely.

kit, skip

1)

in

two

1

"

cross

the

Adjust

shaft in

collars

on yoke

the

back.

item

4)

(fig.4,

a

the

61,

and

x

1

"

bolt

guard

with

and

a

nut.

FIGURE

FIGURE

3

4

OM

01

79 9

SUBFRAME

-

ASSEMBLY

STEP

3:

VALVE

Thread

male

1/2"

connectors

NPT male

(fig.5,

ports,

Install

of valve support

three

and nuts. Tighten securely.

Thread both handles on

as

in figure 1 on page

Place two rubber grommets

inside

support, and route

described below through

Install one

base

end

the

short bend

to

the

fitting in

AND

HOSE

the

four

(fig

x

item

using thread sealant.

valve (fig.5,

5/16

the

2) in

"

x

2 1/4" bolts, lockwashers

two lower holes

1/4" x 76" hose in

elbow,

routing

to

the

INSTALLATION

3/8"

NPT

male

.5,

item

9/16

"

male

the

appropriate valve

item

3)

(fig.5,

valve(simu1taneously)

the

the

right hand front port.

item

24.

Tighten nuts.

(fig.6,

two 1/4" hoses

the

the

other

valve, and connect

x

7/16

1

1

and two

connectors

on underside

4) using

item

of

the

grommets.

the

cylinder

end

"

1)

hose

with

FIGURE

5

1/4"

x

78

"

Install one

rod end elbow. Route other end

long bend

fitting

Place straight end of 62" hose (fig.6,item

2) through

the

of

washer

female quick coupler

ring over threaded portion) using thread

sealant. Route

short bend to

the

fitting in

Place straight end of

item

3)

bracket.

end, and install female quick coupler(fig.6,

item

threaded portion) using thread sealant.

Route

to

the

in

the

to

the

in

the

ri9h.t

the

hole second from

coupler bracket. Place

on

the

hose end, and install

the

the

the

through

Place

4)(with

the

valve, connecting

left hand rear port.

the

a

the

other end

hose in

valve and connect

hand

(with

other end

valve, connecting to

left hand front port.

the

top

hole

nylon

washer

green

with

the

cylinder

with

rear

port

the

yellow

with

64" hose (fig.6,

of

the

on

I.D.

the

short bend

to

the

ring over

the

to

the

-

the

top

a

nylon

I.D.

the

Coupler

the

hose

fitting

a

I/

F

I

G

UR

E

6

I

OM

0179 10

i)

Install

x

30" hose

connect

in

j)

Install a female quick coupler

of

the

Connect

in

a

male

using

other

the

right hand inlet

3/8" x 30

other

the

left hand outlet

end of

"

end of

quick coupler on

thread

hose

using thread sealant.

hose

hose

sealant and

to

the

port

on valve.

at

to

the

port

on valve.

the

3/8"

fitting

one end

fitting

k) Install dust

in

small

STEP

4:

TRACTOR

a)

Install

1)

3/4"

under

x

rear

3 3/4"

cap

hole

of coupler bracket.

PREPARATION

hitch

the

tractor

rings (fig.6,

bracket (fig .7

drawbar, using

bolt

(fig.7,

lockwasher and nut. Tighten lightly.

b)

Install quick

item

1

)

on

NOTES:

If equipped

mower

If equipped

or

loader

and

mower

If your

tractor

loader and mid mount

existing eight

on

the

engine

time,

bolts

and

(fig.8,

placing two quick

the

on

outside of

hitch

the

front brackets (fig.8,

tractor

with

engine

mid mount mower,

bracket remains on

with

the

mower

only,

the

loader subframe

brackets remain on

is

already equipped

mower,

bolts

side

replace

item

from

rails,

with

2)

hitch

the

the

seven

and lockwashers,

front brackets

loader brackets.

Tighten lightly.

If your

,

moy2r only, use 1/2"

the

tractor

the

each

and quick

tractor

mower

and quick

has

1/2"and

neither loader nor mowerfuse

the

side between

hitch

is

equipped

shims

hitch

3/8"

the

bracket.

provided between

brackets.If your

shims

engine

item

,

item

item

side

rails.

the

tractor.

and loader

the

tractor.

with

remove

front brackets

one

side

12mm

with

mid

at

x

50mm

mount

provided

side

rail

5)

2)

the

the

to

a

,

,

FIGURE

a

7

c)

Install one

item

3) on right hand front support bracket,

the

in

hose

lowest

support bracket (fig.8,

rear

hole , using

60mm bolt and lockwasher through support

OM

bracket

0179

and

tractor

frame.

a

1

2mm

x

FIGURE

11

8

SUBFRAME

-

ASSEMBLY

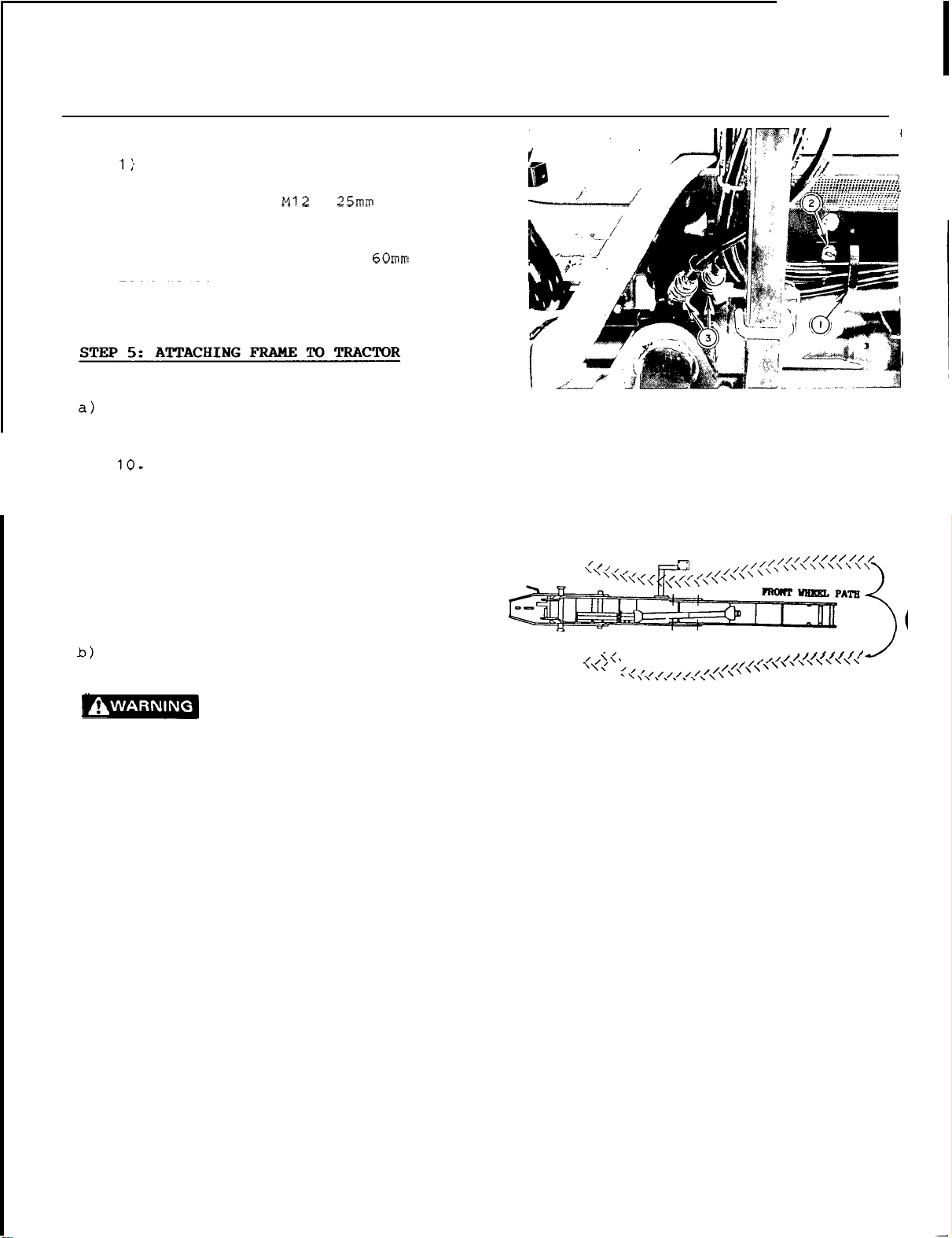

d) Install second hose bracket (fig.9,

1)

in

the

engine side

lower hole

rear

of

bracket, using an

item

does not have

has

2)

and lockwasher if

a

a

loader, use an

rail,

the

front right attaching

MI2

x

loader. If

M12

in

25mm bolt (fig.9,

the

the

x

60mm

iockwasher.

a)

Carefully

assembly running

over

the

10.

Do

hydraulic hoses.

place

valve support

not run

the

tractor

the

front

tractor

Place

over subframe

right

as

shown in figure

wheels

hydraulic

front right hand wheel. Make sure

section of

subframe

is

in between

the

front support brackets and

attaching point

The

subframe must be

length in

the

is

under

parallel

center of

rear

the

hitch

tractor.

the

tractor

tractor

bolt and

hand

over

hoses

the

the

plate.

to

tractor

item

first

tire

the

over

front

the

rear

---A,--/'

~

FIGURE

I

..

'.................:I

..._

................,..

i

A

::::!::~::::::I:.?.Y::

9

b)

With

to

the

engine turned off, connect valve

tractor

oil

Escaping hydraulic fluid

under

pressure

causing serious injury.

0

Do

not use

0

leaks.

paper

Stop

Use

to

search

engine and relieve

moving valve handles back and forth

before connecting

lines

0

Tighten

engine

.

all

or

If any fluid

it

may result in gangrene if the fluid

is

not surgically removed within

a

hours by

doctor familiar

of injury.

OM

0179

supply (fig.9,

can penetrate

your

a

piece

for

hands

of

leaks.

item

the

to

check

cardboard

3).

(oil)

pressure

or

disconnecting

connections before starting

pressurizing lines.

is

injected into the skin,

a

with

this

skin

for

or

by

few

form

12

<</

\(\\\\\\\\\\

FIGURE

,/,//////,~~~~~~~~~\\\'\'\\

10

///I////

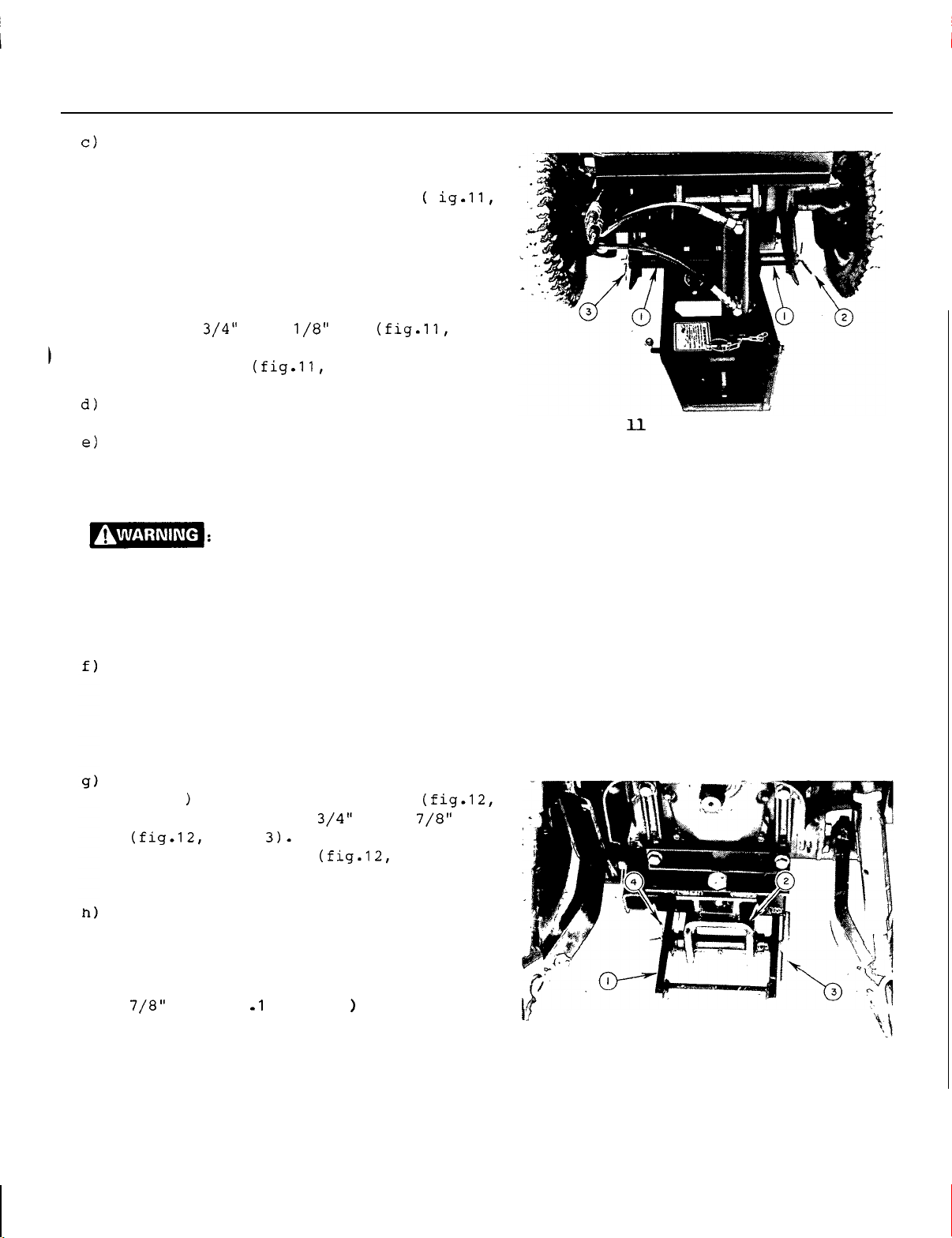

c)

Sitting on

set

parking brake and, using

valve lever carefully lower front end of

rame

subf

item

raise

brackets. Lower front section until

weight

engine off.

subframe to

with

the

2). Lock

80mm

hair

the

so

1)

on

into

is

off

3/4" x 17

the

pin (fig.11,

tractor

that

the

the

place

the

Attach

the

front attaching brackets

pin in

seat,

welded tube ( f ig.11,

subframe front section

inside

front

the

1/8"

place

start

the

the

tires.

front end of

pin (fig.11,

with a 4mm

item

3).

engine,

hydraulic

support

the

Turn

the

item

x

ASSEMBLY

-

SUBFRAME

d) Install hoses in

e)

If using drive kit, connect mid drive

line to tractor mid

sure yokes

m:

RPM.

end

can fly

If

in subf

is

causing serious injury

Before installing

the

subf

hydraulically

the

implement

engine off.

Attach

item

1

item

(fig.12,

4mm

x

are

This

the

rame,

not secured properly, the driveline

loose

rame,

rear

)

to

2)

using

item

80mm

the

hose support brackets.

PTO

shaft, making

well

collar

or

with great

start

section of subframe (fig. 12,

the

hair

secured to shafts.

shaft turns at very high

is

not locked

if the yoke

the

the

the

front

if installed. Turn

rear

hitch

the

3/4"

3). Lock

pin (fig.12,

force

or

death.

rear

tractor

male

plate

x

the

at

the tractor

capable of

section of

8

pin

item

to

shaft

and lift

hitch

(f ig.12,

7/8" pin

or

the

with

4).

a

FIGURE

ll

Tighten bolts on support brackets and

rear

hitch

Specification

tighten

the

to

7/8" pin (fig

easily. If

adjust

OM

0179 13

bracket, according to Torque

Table

all

bolts

Torque Table. Make sure

the

on

-1

2,

it

does not move easily,

front attaching brackets.

on page 71. Then

the

subframe according

item

3

can

be

the

removed

re

8

I

?

-

FIGURE

12

SUBFRAME

-

ASSEMBLY

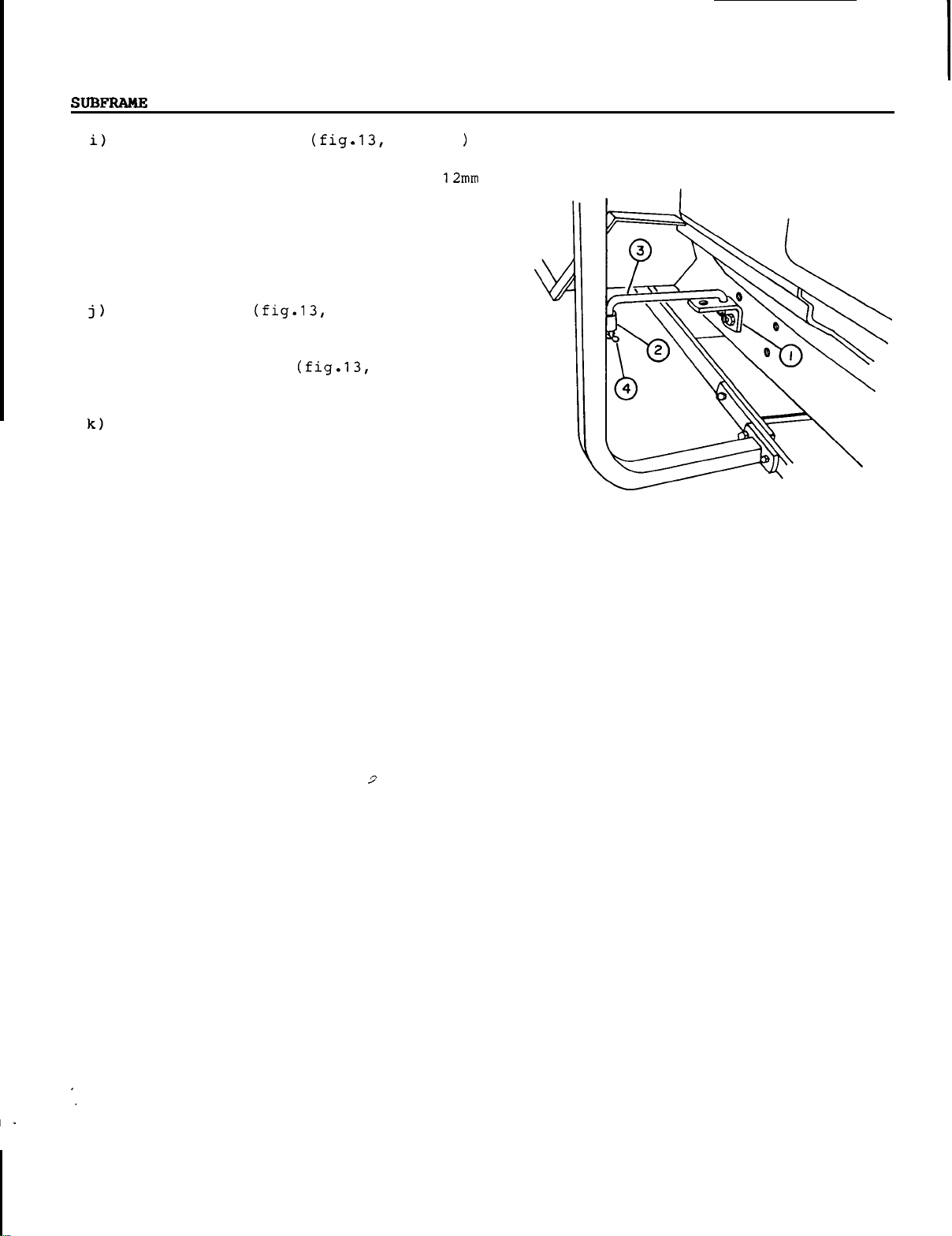

Attach

tractor right hand engine side

line

L-bracket (fig.13,

with

valve support using 12mm

item

1

rail

)

to

in

30mm bolt with a lockwasher if tractor

does

bolt

not

with

have

loader

or a 12mm

lockwasher if equipped

x

70mm

with

loader.

Insert link

sleeve (fig. 13,

in

and

x

65mm

L-bracket. Secure using

hair

Secure

provided nylon

the two

between

first

hose

(fig.13,

pins (fig.13,

hoses

together using

ties,

hose

the

coupler

bracket.

item

item

2)

3) in welded

on valve support

item

placing one between

brackets and

support

4).

the

and

two

the

3mm

two

other

the

x

FIGURE

13

'.

OM

01

79

1.

P

14

DISMOUNTING

&

REMOUNTING

-

SUBFRAME

DISMOUNTING

Sitting on

the

attachment to transport position.

Turn engine off

to stop, and

Remove link

the

,

set

(fig.13,

tractor

wait

for

seat,

all

parking brake.

item

movement

3) from

bracket on tractor.

Remove

pin under

remove

Sitting on

the

hairpin from

the

the

8

7/8"

the

the

tractor drawbar and

pin.

tractor

seat

with

engine running, carefully lower

attachment by applying light

to

the

valve lever, until

section of

ground and

front

tires

Disconnect

place

along

Remove

Place

(fully forward)

is

flat on

Move

the

and forth

pressure. Disconnect

hoses from

tractor.

supports on

Connect

connecting

the

subframe touches

the

weight

are

off

the

the

mid driveline and

the

centre of

the

17" front pin.

the

valve in float position

,

so

that

the

ground.

hydraulic valve levers back

to

relieve

the

quick couplers on

Remove

the

the

the,

two hoses together by

the

the

the

hoses

engine side

male

pressure

the

is

off

ground.

the

subframe.

the

subframe

hydraulic

hydraulic

from

and female

couplers. Install dust plugs on

tractor couplers.

raise

8

their

rail.

7/8"

the

the

rear

the

the

the

REMOUNTING

Carefully drive tractor over subframe,

running

the

Figure

subf

the

the

line

engine off and

Remove

the

front right hand

valve support bracket

11.

rame

Place

front pin points

tractor

as

so

wheel

shown

that

are

front support brackets, and

subframe

with

the

rear

the

dust plugs from

pin point

tractor drawbar. Turn

set

parking brake.

the

couplers,

and connect valve inlet and outlet hoses

to

the

tractor oil outlet coupler.

Sitting on

the

tractor

Seat,

engine, and carefully lower

hitch

(&

attachment), using

hydraulic valve lever, until subframe

front pin points

brackets, and until

the

front

Attach

the

to

the

place

3/4"

tires.

the

front end of

Stop

front attaching brackets

x

17" pin. Lock

with

a

4mm

x

Install hoses in

inside

the

the

80mm

the

the

weight

engine.

the

subframe

the

hair

hose support

are

brackets.

the

Connect

mid PTO,

e

on page 13.

Sitting on tractor

running, carefully

(&

attachment) completely using

mid driveline to

as

per

instructions of section

seat

raise

the

with

male

the

hydraulic valve lever. Turn engine

wait

for

all

off and

movements to stop.

over

in

the

under

that

is

in

start

male

the

front

is

off

with

pin in

pin.

tractor

engine

hitch

the

Carefully back

subframe

running

over

the

not back over

hydraulic hoses.

OM

0179

the

tractor over

as

shown in Figure

the

front right hand

valve support bracket.

the

driveline

or

the

11,

tire

Do

the

Attach

pin through

attachment.

Attach

bracket and

hair

15

rear

section using

the

Secure

link (fig.13,

secure

pin.

the

8

7/8"

subframe and drawbar

with

the

hair

pin.

on

underside

item

3) to

with

-

1

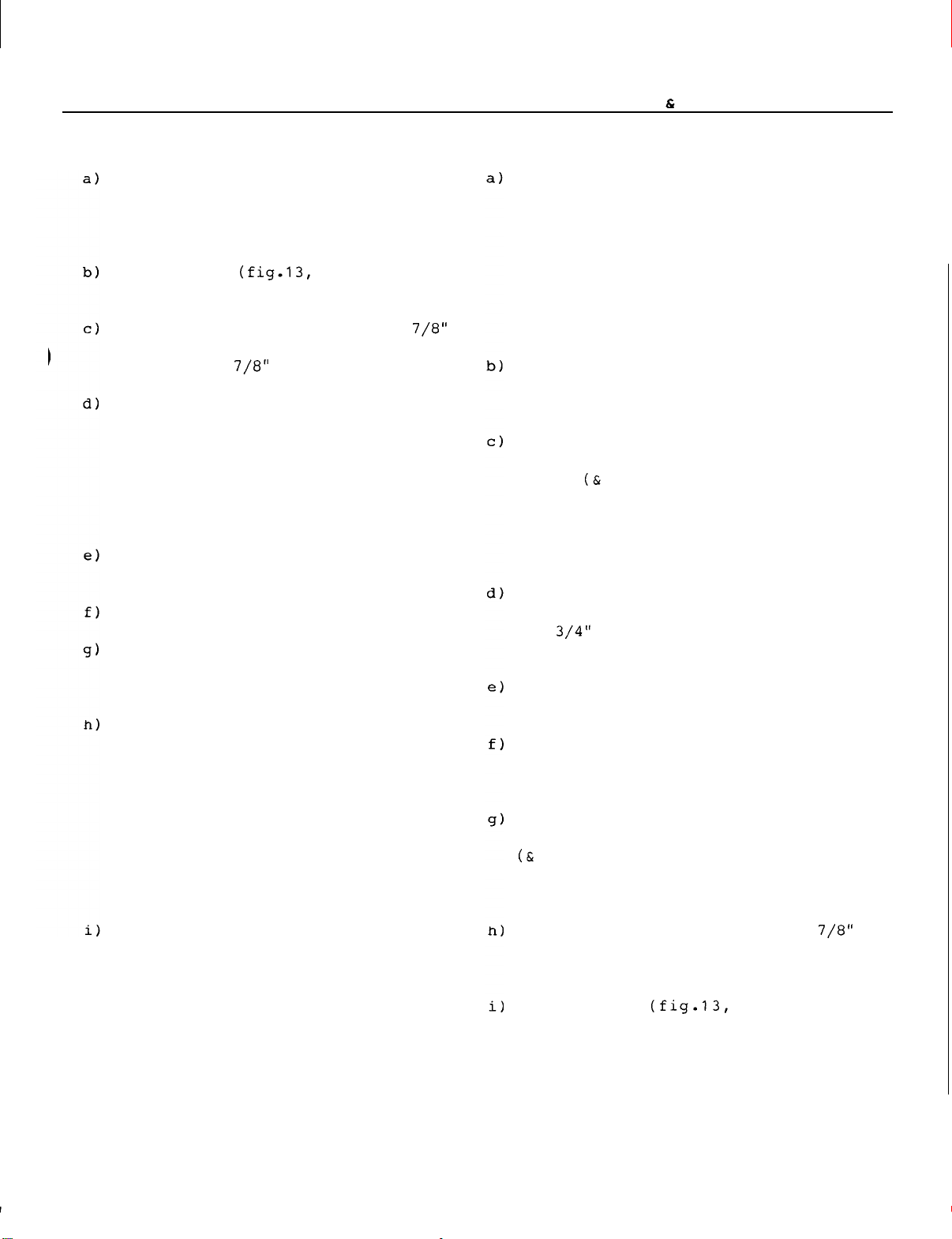

BLADE

I

1.

-

SAFETY

a

(U.S.A.

DM3ALS

I

&

CANADA)

AVOID

FRAME

Keep

REPLACE

INJURY

F

IMMEDIATELY

R

O

M

PIVOT AND STOPS:

hands

and

feet

away.

IF

2.

DAMAGED

(CANADA

C

only)

H

A

S

SIS

PIVOTANT.

IMPORTANT

.TO

PREVENT BLADE DAMAGE MAKE SURE

BLADE ANGLE ADJUSTMENT PIN

THROUGH THE BOTTOM PLATE.

.

.~~

DO

NOT USE BLADE

WHEN PLOWING SNOW. WHEN

OR

ROUGH CONOITIONS. ETC.

0

-ATE

3.

(U.S.A.

OM

0179

?

TRIP

SPRING

.[

&

IS

SPRING LOCK OUT

USING IN ROCKY

lRlP

OPERATION

SPRtNG

TRIP

LOCK

CANADA)

INSERTED

OUT

I

111

16

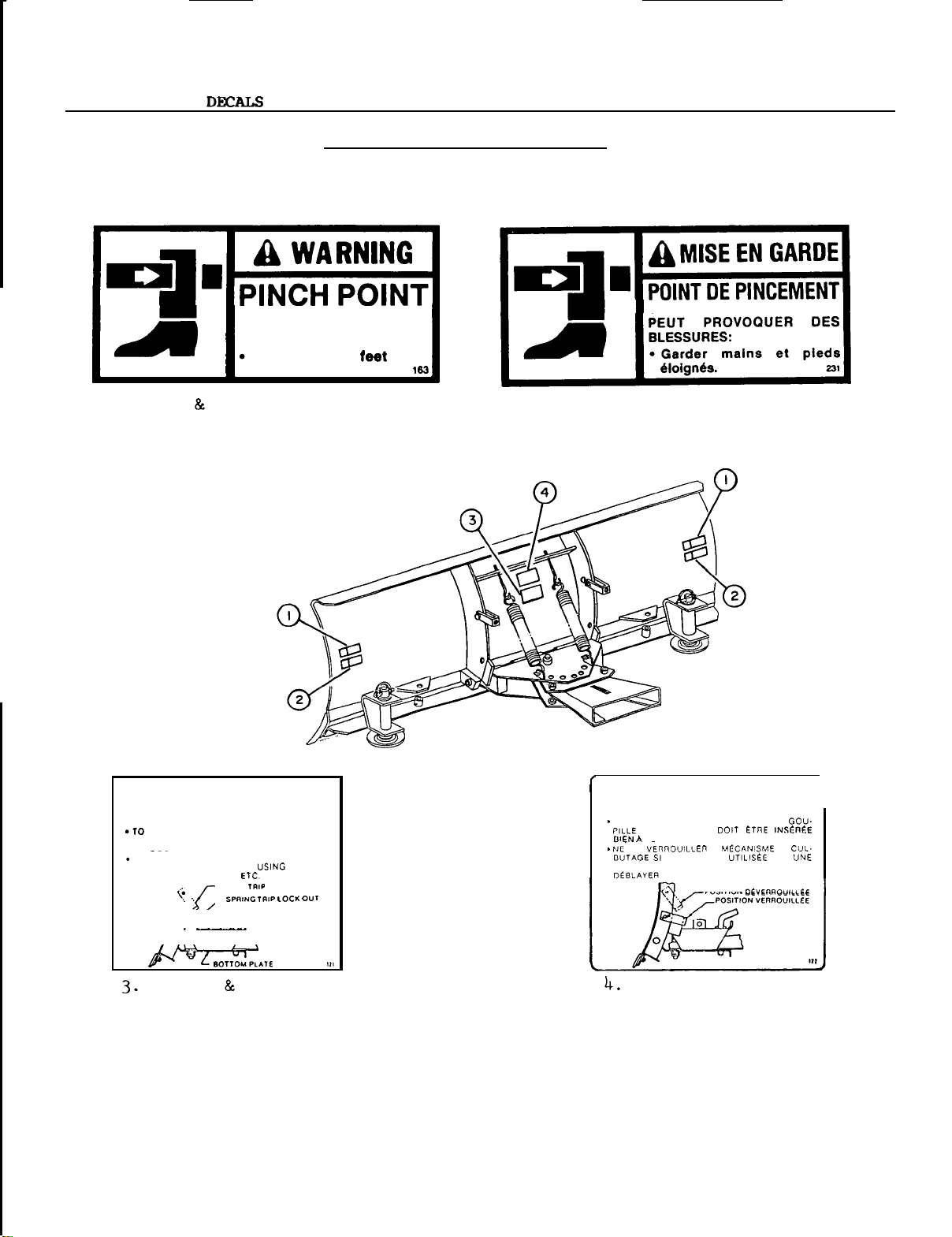

IMPORTANT

D

POUR NE PAS ENOOMMAGER LA LAME. LA GOU-

PlLLE D'AJUSTEMENT DOlT ETnE

WEN A FOND

__

~

B

NC

PAS VEnnOUILLEn LE MECANISME

OUTAOE

SI

LA

LAME

SURFACE ROCHEUSE. RUGUEUSE OU POUR

DEBLAYER LA NEIGE.

4.

(CANADA

EST

POSITION DEVERAOUILLEE

only)

UTILISEE

INSCnEE

DE

sun

CUL-

UNE

I

OPERATION

-

BLADE

OPERATING

1.

RAISING

See

page

2.

HYDRAULIC

When

the blade rotates

direction to

CONTROLS

AND

LOWERING

'RAISING

7.

&

LOWERING

ANGLING

the valve handle

the

left, and pulling back

FRONT

in

BLADE

ATTACHMENTS'

is

pushed forward,

a counterclockwise

on handle rotates the blade to the right.

See subframe or tractor operator's manual

for accessory valve location.

Before

turn

brake

making any adjustment,

engine

off

and

set

.

on

parking

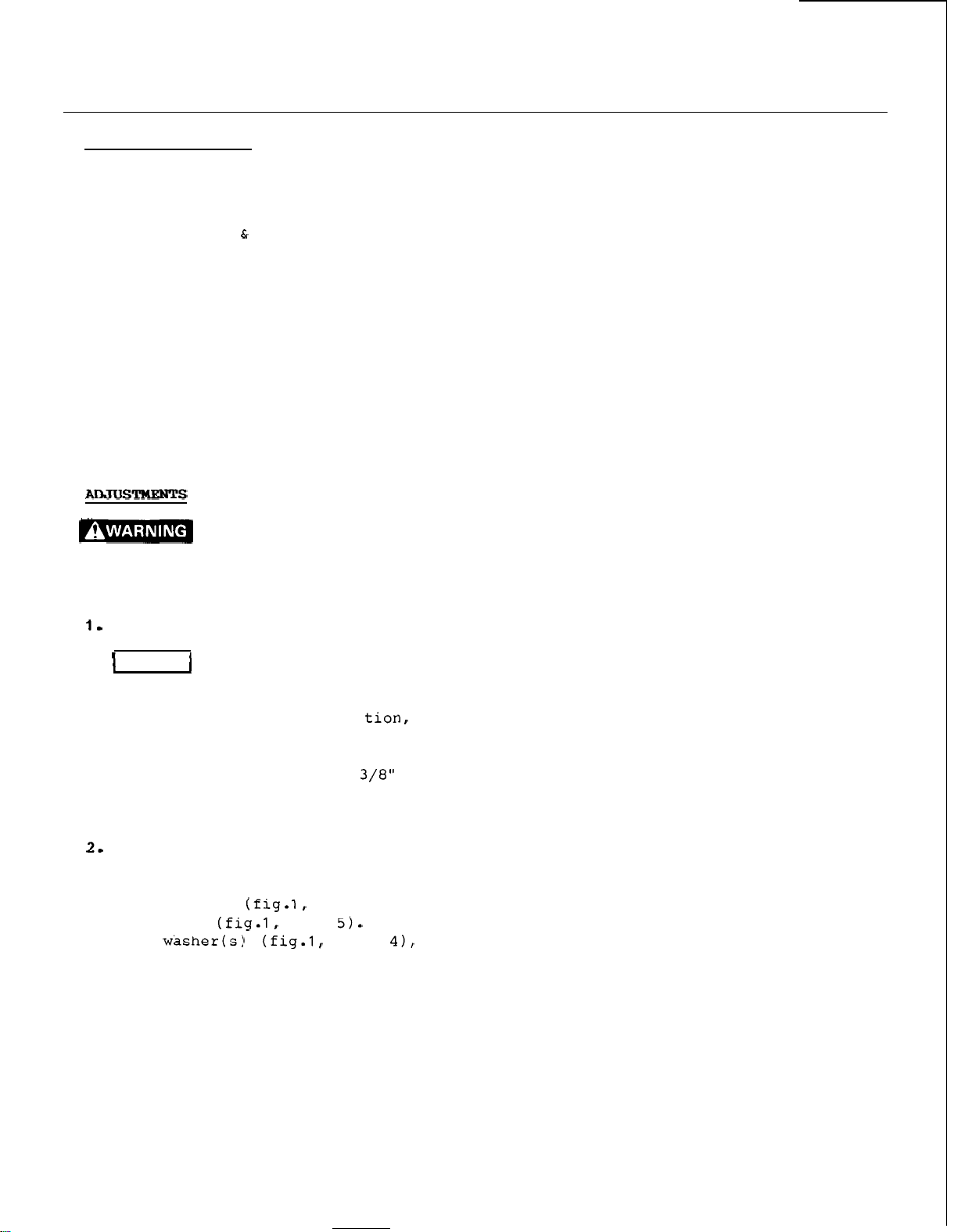

1.

RIGID

I

NOTICE

ground

To

trip spring lockout brackets

holes, hooking over

Attach

pins and secure

2.

SKID

BLADE

OPERATION

1

Use

speeds

rigid blade

up

to

2

mph.

obtain rigid blade opera

the

in

SHOE

place

ADJUSTMENT

with

With

the 3/8"

3mm

x

only

tion, move

to

the

blade frame.

x

65mm hairpins.

Raise blade to transport position. Remove

the linchpin

skid

shoes (fig.1,

shim

washer(s) (fig.1, item

(fig.1, item 6) from both

item

5).

Remove or add

41,

washers on under side of support brackets

for more clearance (there

at least one

shim

washer on top side

must

always be

support bracket). Reinstall linchpins.

for

low

the

lower

1

7/16

placing

"

of

OM

0179

17

BLADE

-

MAINTENANCE

Maintenance

1.

Remove dirt from pivot points and angling

cylinders every 4 hours of operation,

especially in cold

Lubrication

1.

Grease

the

of operation.

2.

Oil

Before storage

1

.

Clean

2.

Repaint

3.

When

parts.

against rust.

the

rod end of

all

moving

the

blade

all

:the

Apply

ti

DISMOUNTING

weather.

fitting on pivot pin and

each

cylinder every

parts

thoroughly.

parts

blade

oil

every month.

from

which

is

dry,

liberally

paint

oil

to

has

all

8

hours

worn.

moving

protect

at

4. Store blade in

a

dry

place.

DISMOUNTING

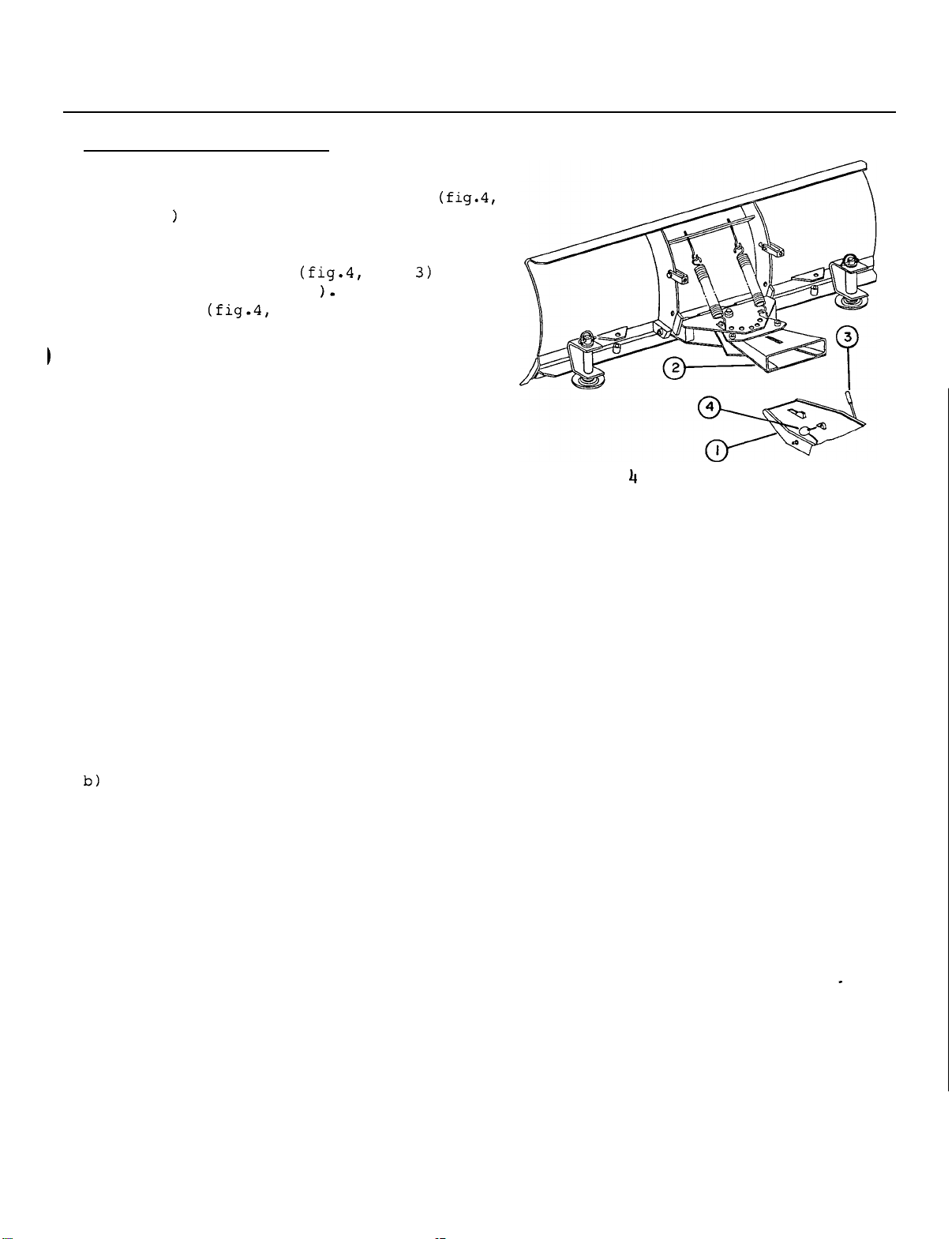

a)

Set

tractor

and remove ignition key. Place lift lever

in

float

pressure by moving valve handles back and

forth.

b)

Remove linchpin (fig.4,

quick

c)

Move

3)

Disconnect blade cylinder

to

hitch

the

the

parking brake,

position

and relieve hydraulic

item

stop

4)

from

latch.

quick

hitch

unlock posltlon (rearward).

lever (fig.4,

/’

’

hoses

tractor.

d) Remove blade from subframe.

engine

the

item

from

OM

0179

18

ASSEMBLY

-

BLADE

NOTE:

STEP

a)

Before

tractor,

with

1:

Install

item

on

top

long pin (fig.

in

place

lock nut on the underside of

attachment.

Install grease fitting

on pin (fig.1,

Hook

attaching brackets (fig.

the

bolt

each

the

(fig.2,

Secure

Adjust eye

lengthens

other

mounting

your

a

EITA

BLADE

1)

ASSEMBLY

the

inside

side) using a 23/32

with

tractor

QH6000

female quick

the

1

,

a

1/4"

item

one end

blade

(fig.2,

spring. Insert

holes

item

the

5/16" nuts.

of

the

frame . Place a 5/16

item

in

the

upper

3)

eye

bolts

bolts

3/4". Lock eye

this

blade

item

x

2) on

the

as

so

attachment on your

must

subf

attachment

"

2) . Lock

1 1

/2"

(fig.1,

2).

two springs

the

eye

blade

shown in figure

with

that

be

rame.

hitch

dia.

x

bolt

the

2,

item

" x 5" eye

other

bolts

cross

5/16" nuts.

the

bolts

with

mounted

(fig.1,

4

the

&

item

to

end of

through

member

spring

(slot

11/16

pin

nylon

blade

the

1

)

on

two

"

3)

2.

0

FIGURE

1

d)

Place four

over

each

one skid

underside.

each

bracket and secure skid

pins

e)

Install

(fig.1,

the

1

OM

skid

(fig.1,

blade.

7/16" pins and

0179

shim washers

skid

shoe

shoe

in

Place

shoe

item

the

trip

item

7) in

Lock in

(fig.

1

,

item

(fig.1,

each

two

on

top

6).

spring lockout brackets

the

place

the

3mm

item

5). Insert

support bracket from

shim

upper

washers

side of support

shoes

x

with

holes

with

the

65mm hairpins.

over

linch

behind

3/8"

4)

x

19

BLADE

-

ASSEMBLY

STEP

a)

b)

c)

d) Using thread

2:

HYDRAULIC ANGLING INSTALLATION

Install base end of

the

blade (cylinder ports on top side)

using two

1)

.

Lock

1/4"

Place

the

rod end port of

thread sealant.

Attach

female quick

outward) using

item

of

the

1

/2"

bolt & nylon lock nut.

3/8"

male

quick coupler

1/4"

end of each hose, placing

dust

cap

7/8"

the

x

1

3/4" bolt & nylon lock nut.

a breather plug (fig.3,

rod end of

3). Lock

female quick

x

ring on

the

two cylinders on

x

2

7/8" pins (fig.3,

pins on

hitch

the

the

sealant,

1/4" pivoting female and male

with

the

the

underside

item

each

each

3/4"

pins

hitch

rubber dust

hose before connecting.

cylinder using

cylinder to

(grease fittings

x

3

"

pins (fig.3,

on the upper side

with

attach

a

90°

cap

the

1/4"

elbow

at

rubber

item

with

2)

x

in

the

the

1

P

.

FIGURE

3

e)

Install

the

(fig .3,

and identify

plastic

33

"

hand cylinder (fig.3,

thread sealant, and identify

with

OM

0179

the

base

end port of

hose

the

other end

the

item

ring. Attach

to

yellow

4)

using thread sealant,

this

the base end

hose

plastic

of

the

40

"

hose to

left hand cylinder

with

the

item

ring.

the

green

other end of

port

of right

5)

using

this

hose

20

1

3:

STEP

a)

BLADE INSTALLATION

Insert

item

quick hitch (fig.4,

off and

by

position (fully forward

linchpin (fig.4,

the

1

)

on

moving

male

the

set

the

Escaping hydraulic fluid (oil)

under pressure can penetrate

causing

0

serious

Do

not use your hands

leaks.

paper

0

Stop

engine and relieve pressure

moving valve handles back and

before

lines.

0

Tighten

starting

If

any fluid

it

may

result

is

not surgically 'removed within

hours

by

a

of injury.

quick

tractor into

parking brake. Lock in place

lever (fig.4,

item

hitch

item

1.

section (fig.4,

the

blade female

2)

,

item

Secure

4).

turn engine

3)

to lock

latch

the

with

skin

injury.

to

Use

a

piece

to

search for leaks.

of

check

cardboard

for

or

by

forth

connecting

all

engine

is

injected into

in gangrene

doctor familiar

or

disconnecting

connections before

or

pressurizing

if

with

the

the

this

lines.

skin,

fluid

a

few

form

FIGURE

4

ASSEMBLY

-

BLADE

b) Connect left hand cylinder hose

second from

the

and

top female quick coupler on

hand side of tractor.

OM

0179

top

female quick coupler,

right hand cylinder hose to

the

to

right

the

the

21

Loading...

Loading...