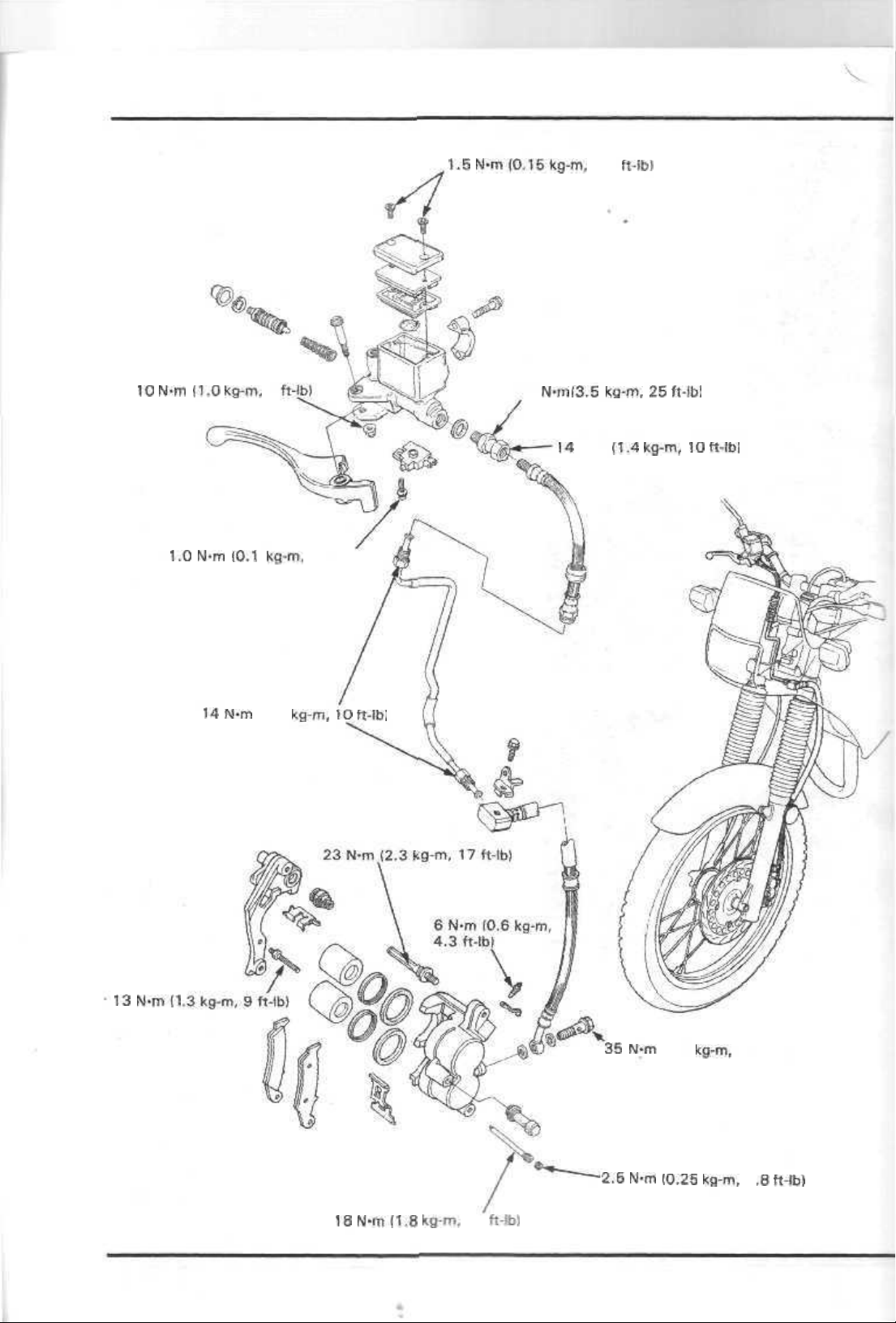

Honda NX 250 Service Manual 14

HYDRAULIC BRAKE

10

N-m

11.0

kg-m,

7

1.0

NTTI

10.1

kfl-rp>.

0.7 ft-ib|

l.S

N*mfCM5fcg-m,

35

Nw f3.5

14

N-m

1,1

ko-m,

fl,4

it-ibl

kg-m,

25

fl-Ui!

10 fi-lbl

13

N*m{1

14

N-rn

(1.4

kg-mH )0 ft-ihl

3£

2.6

N*m

N-m

{3.5

(Or25

kg-m.

kq-mr 1

25 ft-tbl

,S ft-lb}

14-0

IS

N'ittfi.8

kffm,

13

fi-to)

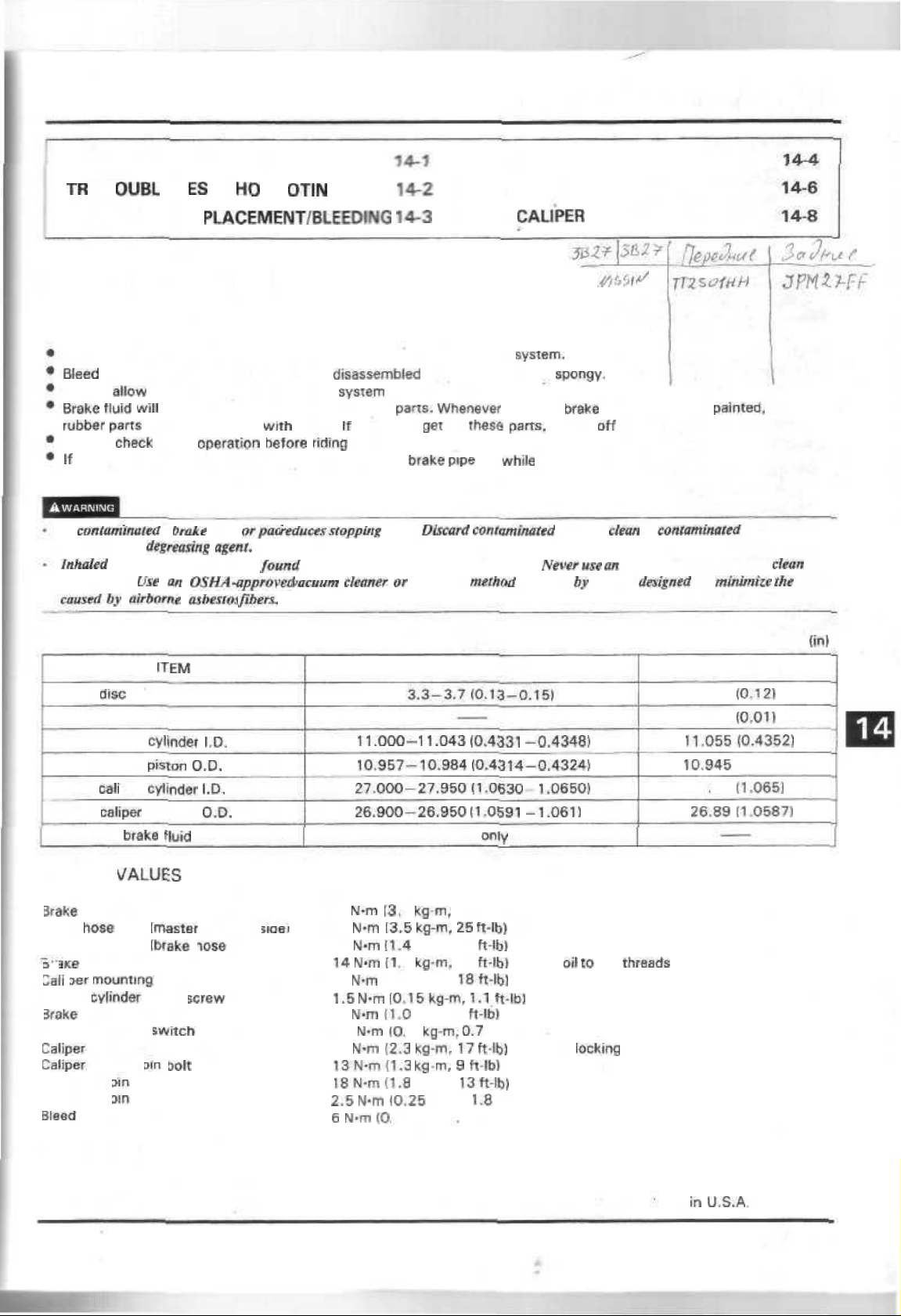

14. HYDRAULIC BRAKE

SERVICE INFORMATION

TR

OUBL

BRAKE FLUID RE

SERVICE INFORMATION

GENERAL

The brake pads can be removed without disconnecting the hydraulic

Bleed

the hydraulic system if it has been

Do not

allow

Brake

tluid

rubber

parts

Always

check

If

the metal brake pipe has to be removed, loosen the

hose or brake hose stay from tivistrng or bending.

A

ciif"nrt;sfsii/i',.'

Quality brake

inhaied

asbestos fibers have been

assemblies.

by airborne aihestot

ES

HO OTIN

PLACEMENT/BLEEDING

***'

foreign material to enter the

will

damage painted, plastic and rubber

by covering them

brake

operation

{•r.tkf

disc

degreasing

Dse

an

agent-

OSHA-approved

with

hefore

orpad

found

fiheix.

a rag.

riding

reducesstopping

to cause respiratory disease and cancer.

vacuum

G

14-2

14-3

disassembled

system

If

cleaner

when filling the reservoir.

pans.

fluid does

the motorcycle.

brake

power.

or

alternate

BRAKE PAD/DISC

MASTER CYLINDER

BRAKE

or if the brake fesls

Whenever

get

on

pipe

Discard

CALIPER

system.

handling

Thes£

parts,

nut

while

contaminated

methfd

approved

spongy.

brake

fluid, protect the

wipe it

holding the brake hose nut to prevent the brake

Never me

padi and

b/

OSHA

off

with a clean cloth.

clean a cottiamirtated

an

air hose or dry brush to

designed

painted,

disc with a high

to

minimize ihe

plastic and

dean

brake

hazard

SPECIFICATIONS

ITEM

Front

dfsc

thickness

Front disc runout

Front master

Front master

Front

call

Front

caliper

Specified

TORQUE

Brafce

hose oil bolt

Brake

hose

-^

,."0

pipe nut

Call

per

mounting

Master

cyHnder

Brake

lever pivot nut

Front brake light

Caliper

pin bolt

Caliper

bracket

Brake pad

Brake pad

Blged

valve

cylinder

piston

per

cylinder

cylinder

brake

Muid

VALUES

joint

jrnaster

'brake

bolt

cover

suvitch

pin

pin

pin

plug

bolt

LD.

OrD,

I.D,

0rD.

cylinder

hose

sciew

screw

tida]

siaei

STANDARD

11.000-

10.957^10.984

27.000-27.950(1,0630

26.900-26,950

35

N*m

35

N-m

14

NTH

14

N-m

25

W-fn

1.5

N-m

10

W'm

1.0

N*m

23

N-m

13N'm{l,3

lSN-m(1.a

2,5

N-m

6

N-m

11.043

DOT 4

13 5 kg-m,

13.5

11.4

^l 4 kgmr TO

|2.5kg-m,

(0.15kg-m,

H1.0

10 1 kg-mr 0.7

{2.3

10.25

10

6 kg-m, 4 3 ft-lbl

25 fl-4b]

kg-mF 25

kg-m, 10

18+t-lb)

kg-m, 7

kg-m,

17

kg

m, 9 h-lbl

kg-m,

13ft-lb|

kg-m.

10.4331

(0.4314-0.4324)

(1.0591

ft-lb>

ft-lh)

1.1

ft-lb)

ft*>)

1.8

ori]y

ft-lbl

tt-lb)

ft-lb)

tt-lb)

-0,4348)

1.0650)

-1.06T1

Apply

Apply a

oi'

locking

to

the

threads

agent to the threads

Unit: mm

SERVICE LIMIT

3.0

(0.121

0.3

(Q,01t

11.055(0.4352)

10,945

(0.4309)

2706

(1.065]

26.39 (10567)

lint

TOOL

Special

Snap ring pliers

07914-3230001 or equivalent commercially available

in

U.S.A

14-1

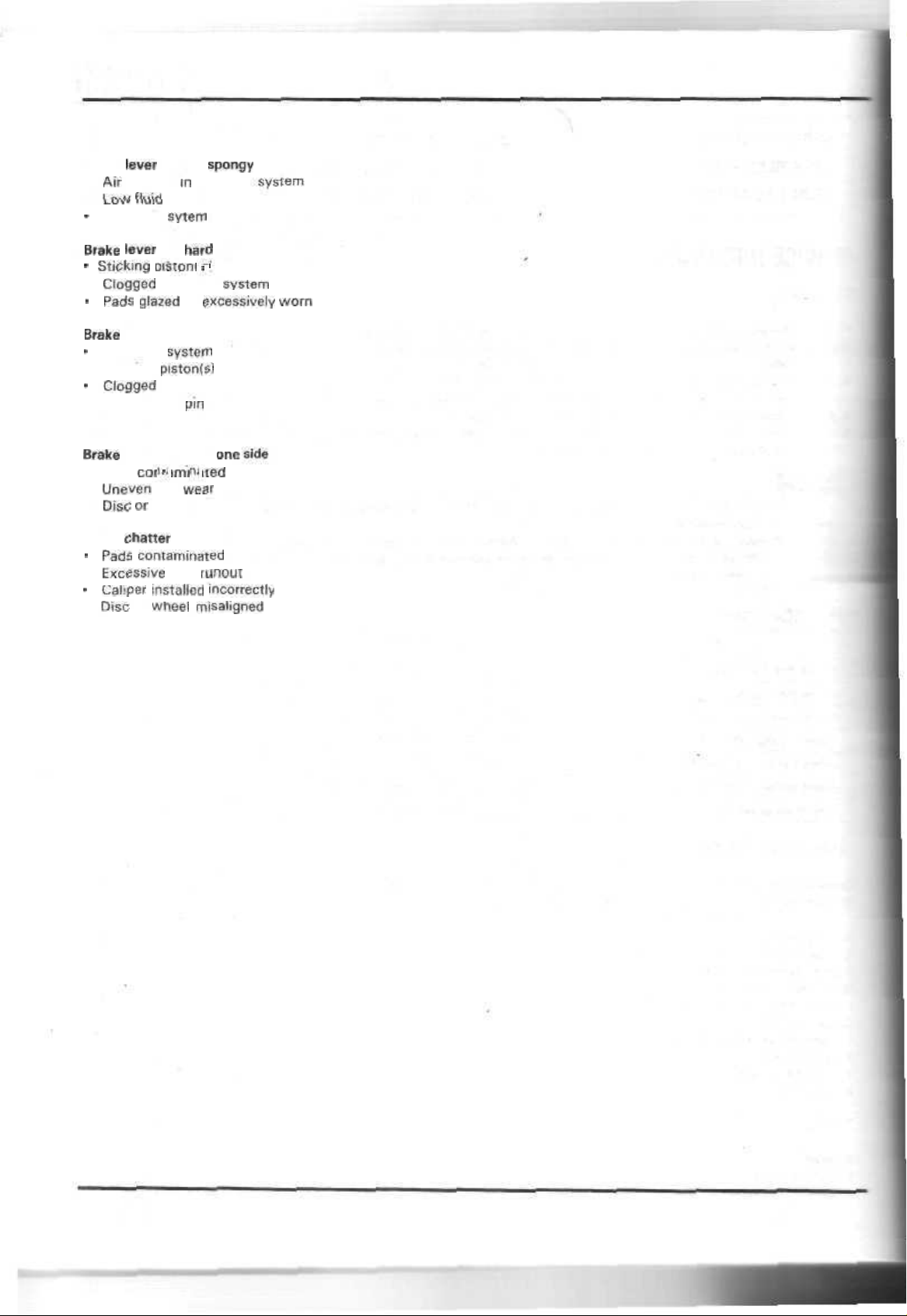

HYDRAULIC BRAKE

TROUBLESHOOTING

Brake

\ever

soft or

-

Air

bubbles

•

Low fluid

-

Hydraulic

Brake

'eve/

too

' Sticking

•

Clogged

• Pads glazed

Brake

*

Hydraulic

• Sticking

* Clogged

• Caliper slide

• Disc or wheel misaligned

Brake

• Pads

•

Uneven

*

Disc or

Brake

1

Pads contaminated

•

txcesaive

*

Calipe*

•

fJisc

n.s'onl

hydraulic

drag

pietonls)

grab or pull to

cor '

pad

wheel misaligned

chatter

insiallcrj rncorrecily

or

wheel misaligned

spongy

in

hydraulic

level

sylem

leaking

hard

• •

system

or

excessively worn

System

hydraulic system

,IVI

disc

sticking

pm

slicking

one

niV

wear

or squeal

mnoui

14-2

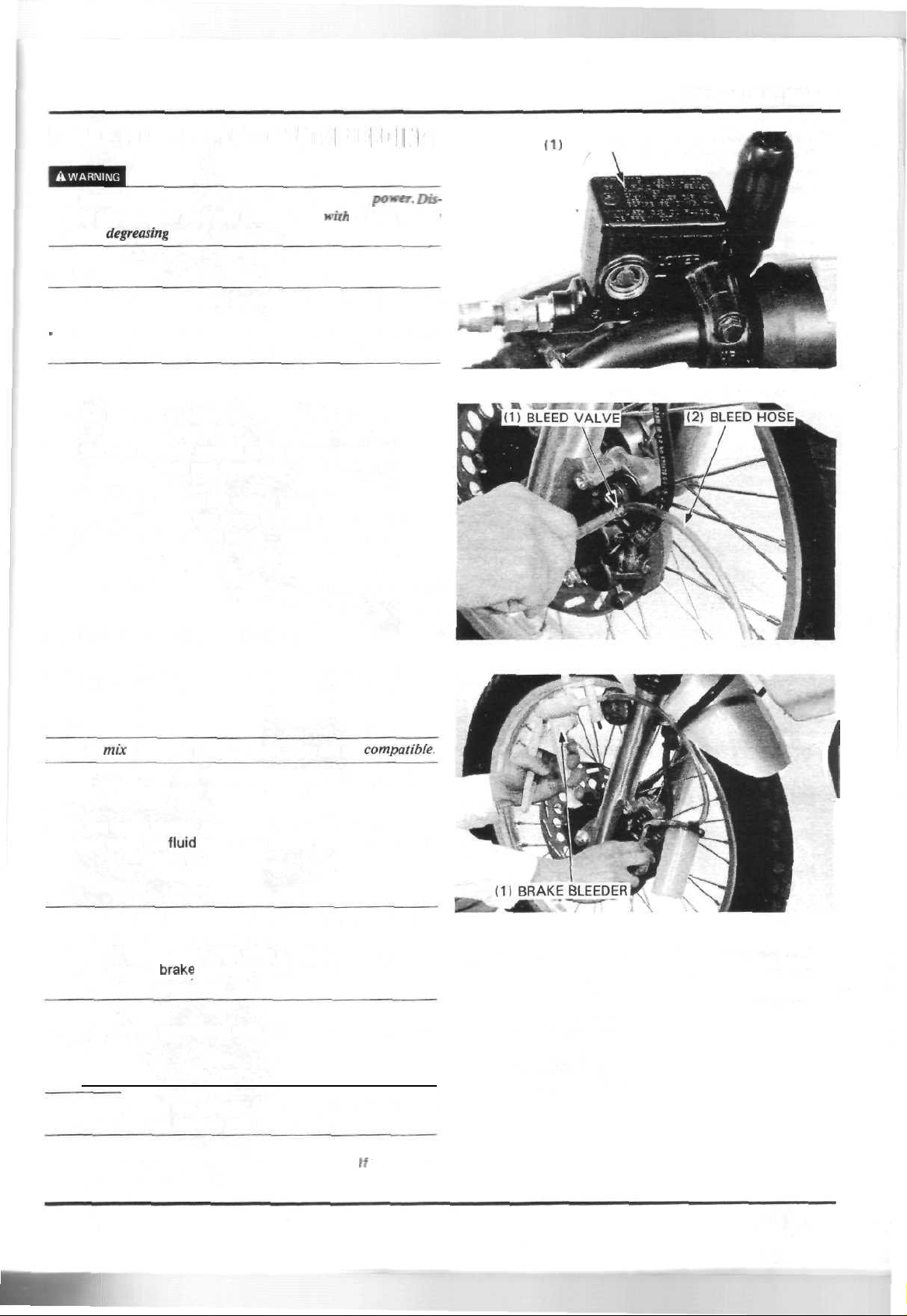

HYDRAULIC BRAKE

BRAKE FLUID REPLACEMENT/BLEEDING

• A contaminated brake disc or pad reduces stopping

card contaminated pads and clean the disc

brake

degreasing

CAUTION

• Do not let foreign material to enter the system when filling the

reservoir.

•

Avoid spilling fluid on painted, plastic or rubber parts. Place a

rag over these parts whenever the system is serviced.

agent.

with

BRAKE FLUID DRAINING

With the fluid reservoir parallel to the ground, remove the reservoir cover, set plate and diaphragm.

Connect a bleed hose to the caliper bleed valve.

Loosen the bleed valve and pump the brake lever until no more

fluid flows out of the bleed valve.

pov*r.

Dis-

a high quality

(1)

RESERVOIR COVER

BRAKE FLUID FILLING/BLEEDING

Fill the master cylinder reservoir with DOT 4 brake fluid from a

sealed container.

CAUTION

• Do not

Connect a commercially available brake bleeder to the bleed

valve.

Pump the brake bleeder and loosen the bleed valve.

Add fluid when the

low.

NOTE

• Check the fluid level often while bleeding the brake to pre-

• Use only DOT 4 brake fluid from a sealed container.

• When using a

Repeat the above procedures until air bubbles do not appear in

the plastic hose.

NOTE

• If air is entering the bleeder from around the bleed valve

mix

different types of fluid. They are not

fluid

level in the master cylinder reservoir is

vent air from being pumped into the system.

brake

bleeding tool, follow the manufactur-

er's operating instruction.

threads, seal the threads with teflon tape.

compatible.

I

Close the bleed valve and operate the brake lever.

spongy, repeat the above procedure.

If

rt still feels

14-3

Loading...

Loading...