Honda CH250 (1989), ELITE 250 (1989) Service Manual

I Index

Charging System/Alternator

1-"

I~

Introduction

This

service

manual

describes

the

service

procedures

for

and

technical

featuresofthe

CH250.

This

Model

Specific

Manual

includes

every

service

pro-

cedure

thatisofaspecific

nature

to

this

particular

model.

Basic

service

procedures

that

are

common

to

other

Honda

Motorcycle/Motor

Scooter/ATVs

are

cov-

eredinthe

Common

Service

Manual.

This

Model

Spe-

cific

Service

Manual

shouldbeused

together

with

the

Common

Service

Manualinordertoprovide

complete

service

information

on

all

aspectsofthis

motorcycle.

Follow

the

Maintenance

Schedule

(Section

3)

recom-

mendationstoensure

that

the

vehicleisin

peak

operat-

ing

condition

and

the

emission

levels

are

within

the

standards

set

by

the

U.S.

Environmental

Protection

Agency

and

the

California

Air

Resources

Board.

Performing

the

first

scheduled

maintenanceisvery

im-

portant.Itcompensates

for

the

initial

wear

that

occurs

during

the

break-in

period.

Section1and3applytothe

whole

motorcycle,

Section

2

illustrates

procedures

for

removal/installation

of

com-

ponents

that

may

be

requiredtoperform

service

de-

scribedinthe

following

sections.

While

Section4through18describe

partsofthe

motor-

cycle,

grouped

accordingtolocations.

Find

the

section

you

wantonthis

page,

then

turntothe

tableofcontentsonthe

first

pageofthe

section.

Most

sections

describe

the

service

procedure

through

a

system

illustration.

Refertothe

next

page

for

details

on

holl}'touse

this

manual.

If

you

don't

know

the

sourceofthe

trouble,goto

Sec-

tion19TROUBLESHOOTING.

ALL

INFORMATION,

ILLUSTRATIONS, DIREC-

TIONS

AND

SPECIFICATIONS INCLUDED

IN

THIS PUBLICATION ARE BASED ON THE LATEST

PRODUCT

INFORMATION

AVAILABLE

AT

THE

TIME

OF

APPROVAL FOR PRINTING.

HONDA

MOTOR CO., LTD. RESERVES THE RIGHT

TO

MAKE CHANGES

AT

ANY

TIME

WITHOUT

NOTICE AND

WITHOUT

INCURRING

ANY

OBLI-

GATION

WHATEVER.

NO PART OF

THIS

PUBLI-

CATION

MAY

BE

REPRODUCED

WITHOUT

WRITTEN PERMISSION.

THIS

MANUALISWRIT-

TEN

FOR

PERSONS

WHO

HAVE

ACQUIRED

BASIC KNOWLEDGE OF

MAINTENANCE

ON

~~~~~~_~OTORCYCLES,

MOTOR

SCOOTERS

.I

HONDA

MOTOR

CO., LTD.

SERVICE PUBLICATION OFFICE

DateofISSue:

May,

1989

©

HONDA

MOTOR

CO.,

LTD.

Contents

l.

General

Informa-tio-n---

-

--

_~_-

..

~ame/BOdY

Panels/Exhaust

System--

---1fJI

~intenanc~

-iii

I.§

Ii

~::;i:::~:mSYstem

-

-=

I-

r---

~

~

LCooling

System_..-:.I'

'':::

~

[Engine

Removal/Installation

==-

~

LCYlinder Head/Cylinder/Piston -----=__

UJ

~I

~

I

L

Crankcase/Crankshaft

..

~e

Trai~

__

.

~~~_-_~-~=-

!

IJJ

In

Front

Whe-e-I/-S-usp~nsion/Steering

__

~

! 5

l

~

=:=:=:=~=eW=s=:=:=::-::-~~-~S--p-.

e_ns_io_n

.

---~-It

-~_DI

-=all

~_-m

III

lEI

___

..

-m

-

--m

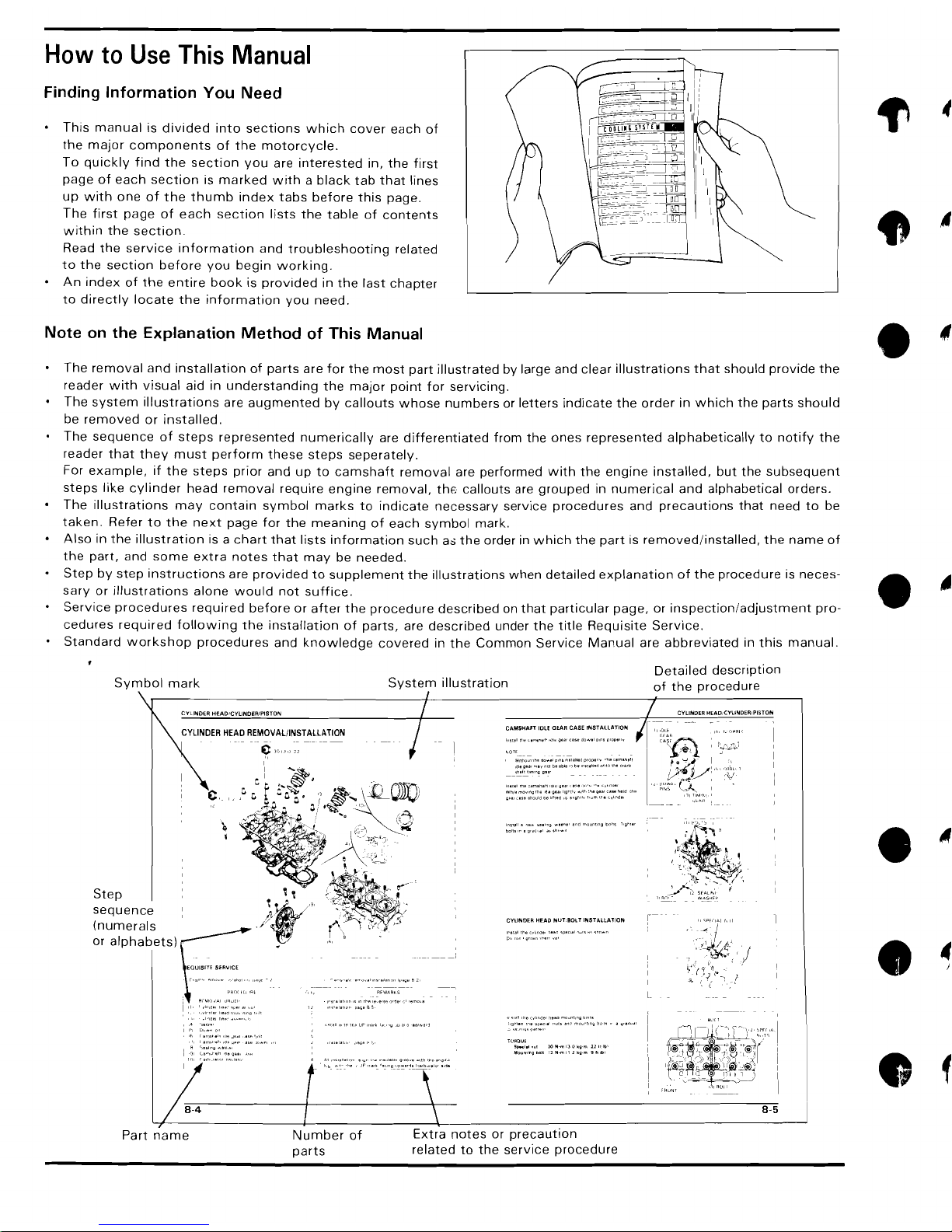

How

to

Use

This

Manual

Finding Information You Need

This

manual

is

divided

into

sections

which

cover

each

of

the

major

components

of

the

motorcycle.

To

quickly

find

the

section

you

are

interested

in,

the

first

page

of

each

section

is

marked

with a black

tab

that

lines

up

with

one

of

the

thumb

index

tabs

before

this

page.

The

first

page

of

each

section

lists

the

table

of

contents

within

the

section

Read

the

service

information

and

troubleshooting

related

to

the

section

before

you

begin

working.

An

index

of

the

entire

book

is

provided

in

the

last

chapter

to

directly

locate

the

information

you

need.

Note

on

the Explanation

Method

of This Manual

The

removal

and

installation

of

parts

are

for

the

most

part

illustrated

by large and

clear

illustrations

that

should

provide

the

reader

with

visual

aid in

understanding

the

major

point

for

servicing.

The

system

illustrations

are

augmented

by

callouts

whose

numbers

or

letters

indicate

the

order

in

which

the

parts

should

be

removed

or

installed.

The

sequence

of

steps

represented

numerically

are

differentiated

from

the

ones

represented

alphabetically

to

notify

the

reader

that

they

must

perform

these

steps

seperately.

For

example,

if

the

steps

prior

and

up

to

camshaft

removal

are

performed

with

the

engine

installed,

but

the

subsequent

steps

like

cylinder

head

removal

require

engine

removal,

the

callouts

are

grouped

in

numerical

and

alphabetical

orders.

The

illustrations

may

contain

symbol

marks

to

indicate

necessary

service

procedures

and

precautions

that

need

to

be

taken.

Refer

to

the

next

page

for

the

meaning

of

each

symbol

mark.

Also

in

the

illustration

is a

chart

that

lists

information

such

as

the

order in

which

the

part

is

removed/installed,

the

name

of

the

part,

and

some

extra

notes

that

may

be

needed.

Step

by

step

instructions

are

provided

to

supplement

the

illustrations

when

detailed

explanation

of

the

procedure

is

neces-

sary

or

illustrations

alone

would

not

suffice.

Service

procedures

required

before

or

after

the

procedure

described

on

that

particular

page,

or

inspection/adjustment

pro-

cedures

required

following

the

installation

of

parts,

are

described

under

the

title

Requisite

Service.

Standard

workshop

procedures

and

knowledge

covered

in

the

Common

Service

Manual

are

abbreviated

in

this

manual.

Detailed

description

Symbol

mark

System

illustration

of

the

procedure

CAMSHAFT

IDLE ClEAR CASE rNSTALLATlOJilj

- I

In"." , 00"

".',og

",una'

sod

moun"ng

boilS

"~hr.'

boll"e,g"'J".,.,.h,,,,

..

,,

Step

sequence

CYLINDER

HEAD

REMOVAL/INST

ALLATION

CVLINDER HEAD/CYUNDER/PiSTON

CYUNDER HEAD

NUT:80l

T INSTALLATION

(numerals

or

alphabets)

H)~aUE

~~I.'""'

lO'-l"m

IJOkg-m

II

"·1.'

J,loum1ng

Mlt

12

~·m

II"kg-m

9 h

Ib'

8-5

•

•

•

•

•

Part

name

Number

of

Extra

notes

or

precaution

parts

related

to

the

service

procedure

I

--

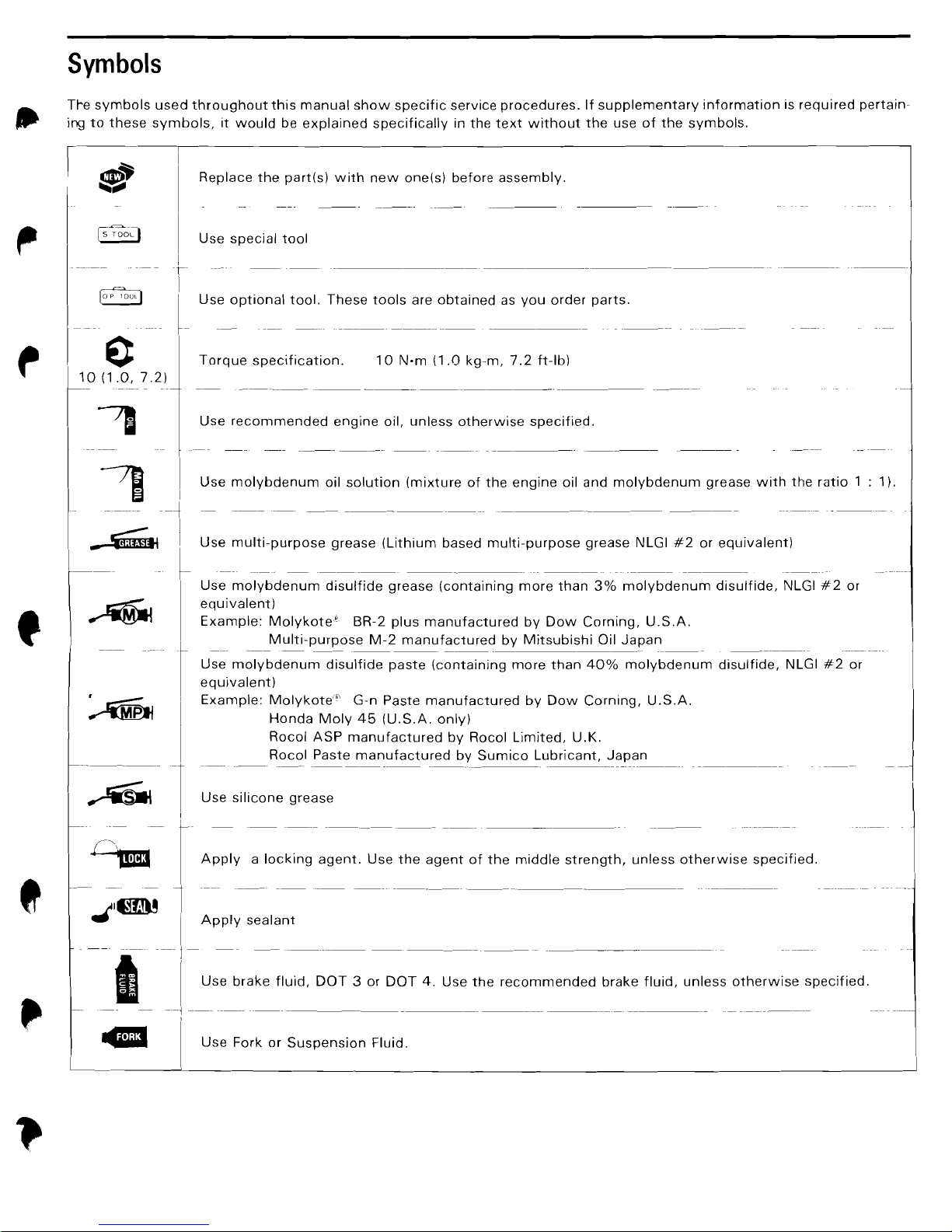

Symbols

Tre

symbols

used

throughout

this

manual

show

specific

service

procedures.

If

supplementary

information

is

required

pertain-

ing

to

these

symbols,

it

would

be

explained

specifically

in

the

text

without

the

use

of

the

symbols.

I

~~

lIlIIiiijlll

[5"

TOOL)

~

0

10

(1.0,7.2)

~

II

-~

.....

f

Replace

the

part(s)

with

new

one(s)

before

assembly.

Use

special

tool

Use

optional

tool.

These

tools

are

obtained

as

you

order

parts.

Torque

specification.

10

N·m

(1.0

kg-m,

7.2

ft-Ib)

Use

recommended

engine

oil,

unless

otherwise

specified.

Use

molybdenum

oil

solution

(mixture

of

the

engine

oil and

molybdenum

grease

with

the

ratio

: 1).

Use

multi-purpose

grease

(Lithium

based

multi-purpose

grease

NLGI

#2

or

equivalent)

Use

molybdenum

disulfide

grease

(containing

more

than

3%

molybdenum

disulfide,

NLGI

#2

or

equivalent)

Example:

Molykote'

BR-2

plus

manufactured

by

Dow

Corning,

U.S.A.

Multi-purpose

M-2

manufactured

by

Mitsubishi

Oil

Japan

---

..

_-

---

-----

---.

--------

Use

molybdenum

disulfide

paste

(containing

more

than

40%

molybdenum

disulfide,

NLGI

#2

or

equivalent)

I

Example:

Molykote'"'

G-n

Paste

manufactured

by

Dow

Corning,

U.S.A.

Honda

Moly

45

(U.S.A.

only)

Rocol

ASP

manufactured

by

Rocol

Limited,

U.K.

I

Rocol

Paste

manufactured

by

Sumico

Lubricant,

Japan

_._--------

~,--r

~

I Use

silicone

grease

IApply

"acking

,gent.

U"

tho

'·9::'

tho

middle

""o9th,

001",

athmW":::C~"od

~I~

1

..

I

Apply

sealant

I

1-

U"

b"ko

f1oid,

D~T

3

a,

DO~U"

tho

"cammondod

b"ko

f1oid,

oolm

athmwl"

,peclfi,d

--,---

[

U"

Fmk m S",pon"ao

Floid.

I

1.

General

Information

General

Safety

1-1

Model

Identification

1-2

Specifications

1-3

Torque

Values

1-10

Tools

1-12

General

Safety

Carbon

Monoxide

If

the

engine

must

be

running

to

do

some

work,

make

sure

the area is

well

ventilated.

Never

run

the

engine in an en-

closed area.

~s

poisonous

carbon

monoxide

gas

that

can

cause

loss

of

consciousness

and

may

~todeath.

Run

the

engine in an

open

area or

with

an

exhaust

evacua-

tion

system

in an

enclosed

area.

Gasoline

Work

in a

well

ventilated

area. Keep

cigarettes,

flames

or

sparks

away

from

the

work

area

or

where

gasoline is

stored.

Gasoline is

extremely

flammable

and is

explosive

under

certain

conditions.

KEEP

OUT

OF REACH OF

, I CHILDREN.

Hot

Components

Engine and

exhaust

system

parts

become

very

hot

I

and

remain

hot

for

some

time

after

the

engine

is run.

Wear

insulated

gloves

or

wait

until

the

engine

and

exhaust

system

have

cooled

before

handling

these

Lparts.

Battery

Hydrogen

Gas &

Electrolyte

• The

battery

gives

off

explosive

gases;

keep

sparks,

flames

and

cigarettes

away.

Provide

adequate

venti-

lation

when

charging.

• The

battery

contains

sulfuric

acid

(electrolyte).

Con-

tact

with

skin

or

eyes

may

cause severe

burns.

Wear

protective

clothing

and a

face

shield.

-

If

electrolyte

gets

on

your

skin,

flush

with

water.

-

If

electrolyte

gets

in

your

eyes,

flush

with

water

for

at

least

15

minutes

and

call a

physician.

•

Electrolyte

is

poisonous.

-

If

swallowed,

drink

large

quantities

of

water

or

I

,

milk

and

follow

with

milk

of

magnesia

or

vegeta-

ble

oil

and

call a

physician.

KEEP OUT OF REACH

OF CHILDREN.

Lubrication

& Seal

Points

1-13

III

Cable &

Harness

Routing

Emission

Control

Systems

Emission

Control

Information

Labels

(U.S.A.

Only)

1-14

1-19

1-21

Used

Engine/Transmission

Oil

• Used engine oil (or

transmission

oil in

two-strokesl

may

cause skin

cancer

if

repeatedly

left

in

contact

with

the

skin

for

prolonged

periods.

Although

this

is

unlikely

unless

you

handle

used oil

on a daily

basis,

it

is still advisable

to

thoroughly

wash

your

hands

with

soap and

water

as

soon

as possible

after

handling

used oil.

KEEP

OUT

OF REACH OF CHILDREN.

Brake

Dust

Never use an air hose or

dry

brush

to

clean brake assemb-

lies. Use an

OSHA-approved

vacuum

cleaner or alternate

method

approved

by

OSHA,

designed

to

minimize

the

hazard caused by airborne

asbestos

fibers.

Inhaled

asbestos

fibers

have

been

found

to

cause

"---

respiratory

disease and cancer.

Coolant

Under

some

conditions,

the

ethylene

glycol

in engine cool-

ant

is

combustible

and

its

flame

is

not

visible.

If

the

ethyl-

ene

glycol

does

ignite,

you

will

not

see

any

flame,

but

you

can be burned.

•

Avoid

spilling

engine

coolant

on

the

exhaust

system

or

engine

parts.

They

may

be

hot

enough

to

cause

the

coolant

to

ignite

and

burn

without

a visible

flame.

•

Coolant

(ethylene

glycol)

can

cause

some

skin irrita-

tion

and is

poisonous

if

swallowed.

KEEP

OUT

OF

REACH OF CHILDREN.

•

Do

not

remove

the

radiator

cap

when

the

engine is

hot.

The

coolant

is

under

pressure and could scald

you.

• Keep hands and

clothing

away

from

the

cooling

fan,

as

it

starts

automatically.

'I

If

it

contacts

your

skin,

wash

the

affected

areas

immedi-

ately

with

soap and

water.

If

it

contacts

your

eyes, flush

them

thoroughly

with

fresh

water

and

get

immediate

medi-

cal

attention.

If

it

is

swallowed,

the

victim

must

be

forced

to

vomit

then

rinse

mouth

and

throat

with

fresh

water

before

obtaining

medical

attention.

Because

of

these

dan-

gers,

always

store

coolant

in a

safe

place,

away

from

the

reach

of

children.

1-1

L

General Information

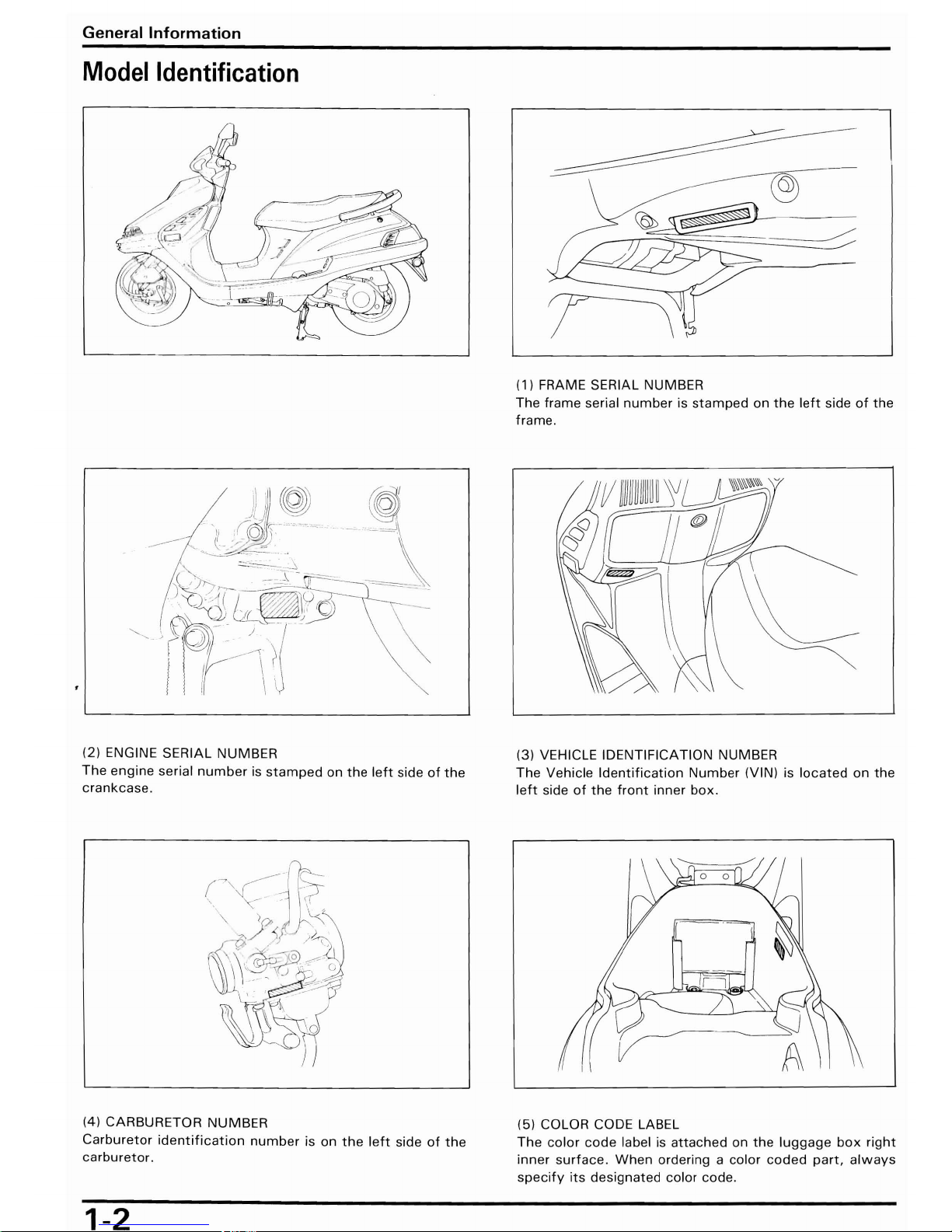

Model

Identification

(1) FRAME SERIAL NUMBER

The frame serial

number

is

stamped

on

the

left

side

of

the

frame .

......

~

.~\

(2) ENGINE SERIAL NUMBER

The

engine

serial

number

is

stamped

on

the

left

side

of

the

crankcase.

(3) VEHICLE IDENTIFICATION NUMBER

The Vehicle

Identification

Number

(VIN) is

located

on

the

left

side

of

the

front

inner

box.

(4) CARBURETOR NUMBER

(5) COLOR CODE LABEL

Carburetor

identification

number

is

on

the

left

side

of

the

The

color

code

label is

attached

on

the

luggage

box

right

carburetor.

inner

surface.

When

ordering a color

coded

part,

always

specify

its

designated color code.

1-2

-----

General

Information

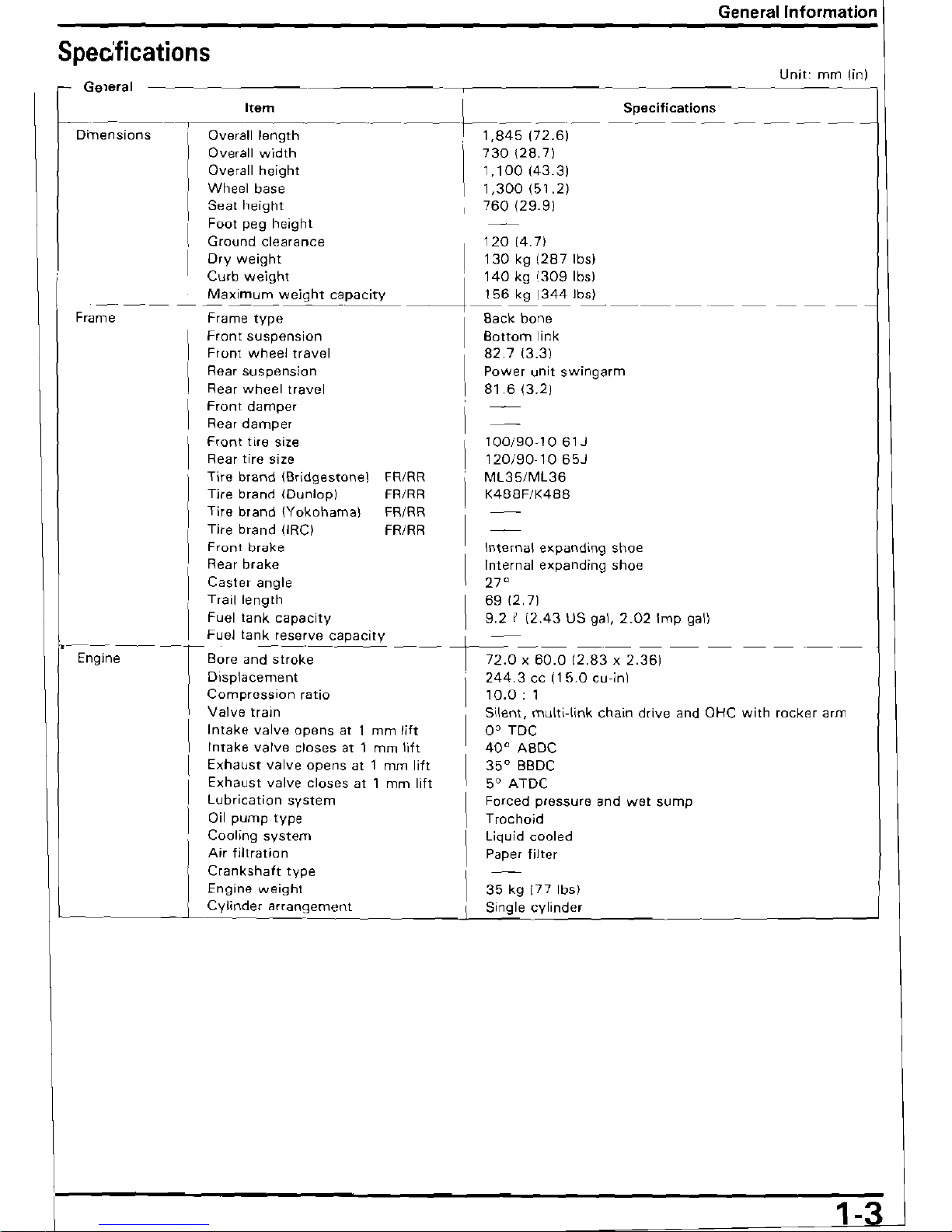

Speo'fications

Unit:

mm

(in)

,....

Geleral

Specifications

_.

;~

It_e_m~~~

~

__

~--

__.__

ornensions

Overall

length

'

1,845

(72.6)

Overall

width

730

(28.7)

Overall

height

1,100

143.31

Wheel

base

1,300151.21

Seat

height

760

129.91

Foot

peg

height

Ground

clearance

12014.71

Dry

weight

I

130

kg

[287

Ibsl

Curb

weight

.

140

kg

1309 Ibsl

Maximum

weight

capacity

~

156

kg

!344

Ibsl

---~-

------

------_._-

----

Frame

Frame

type

Back

bone

Front

suspension

Bottom

link

I

Front

wheel

travel

82.7

13.31

Rear

suspension

Power

unit

swing

arm

I

Rear

wheel

travel

I

81.6

13.21

Front

damper

Rear

damper

I

Front

tire

size

100/90·10

61J

Rear

tire

size

120/90·1065J

I

Tire

brand

(Bridgestonel

FRIRR

ML35/ML36

Tire

brand

(Dunlop)

FR/RR

K488F/K488

I

Tire

brand

IYokohamal

FR/RR

Tire

brand

IIRel

FR/RR

Front

brake

I

Rear

brake

Caster

angle

I

Trail

length

Fuel

tank

capacity

\

Fuel

tank

reserve

capacity

-En-g-ine--

-r

Bore

an-d-st-ro-ke

Displacement

Compression

ratio

Valve

train

Intake

valve

opens

at 1 mm

lift

Intake

varve

closes

at 1 mm

lift

Exhaust

valve

opens

at 1 mm

lift

Exhaust

valve

closes

at 1 mm

lift

Lubrication

system

Oil

pump

type

Cooling

system

Air

filtration

Crankshaft

type

Engine

weight

35

kg

177

Ibs)

Cylinder

arrangement

Single

cylinder

1-3

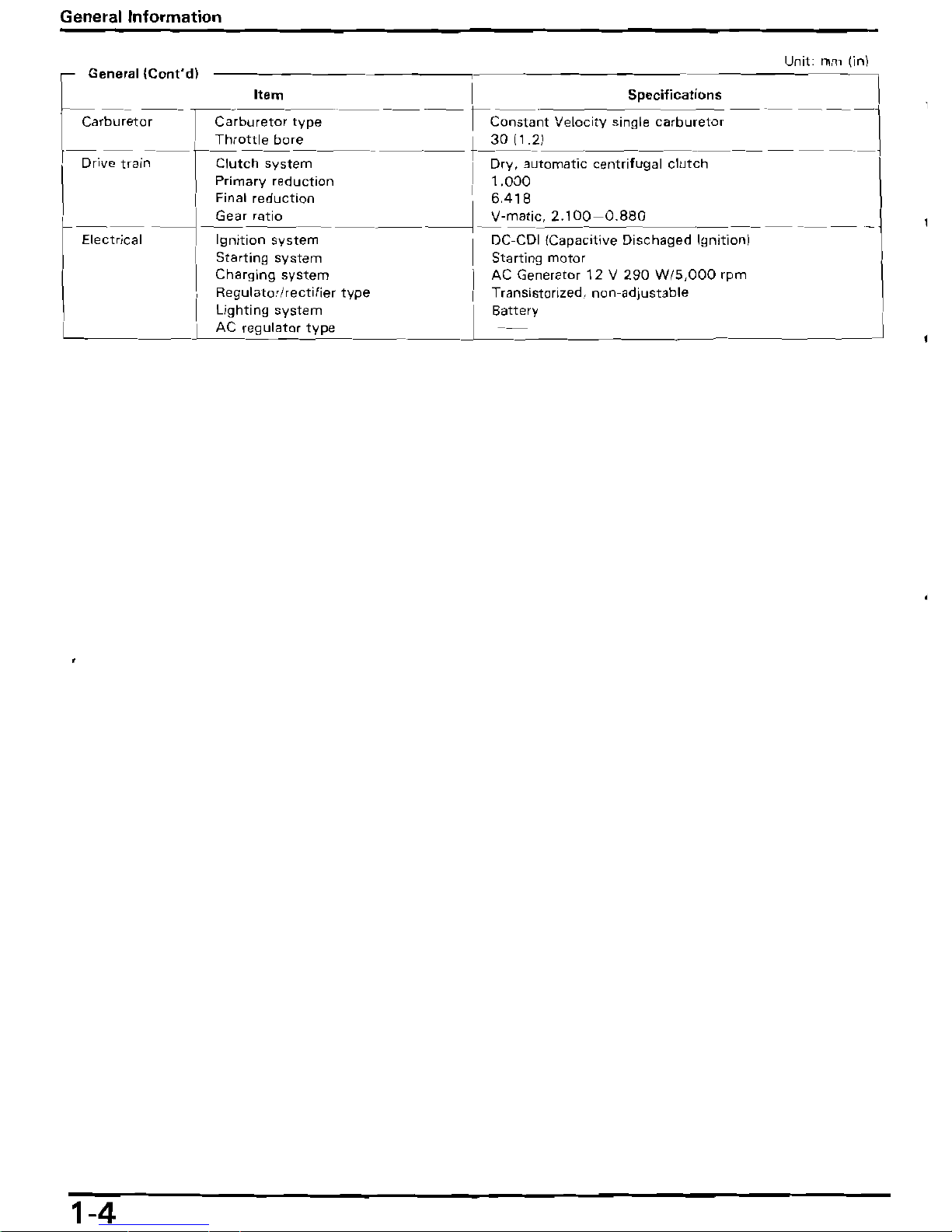

General

Information

Unit:

111m

(in)

r-

General

(Cant'd)

b

,

Item

I

Specifications

Carburet~-

I

Carburetor

type

--

---

r

Constant

Velocity single

carburetor

--

--

-

---

I

Throttle

bore

21

t-

30

(1

-------1

-Dry,

~tomatlc

centrlfug~

clutch--

-~I:;~al~--

r~tCh

sy';tem

---

--

--

---

l

Primary

reduction

I Final

reduction

_____

----J~r

ratio

Electncal

I

Ignition

system

-

1.000

6

418

---l_v-matlc,

2.100-0.880

I DC-COl (CapacItIve

Dischaged

Ignition)

_

II

Starting

system

Charging

system

i

Starting motor

AC Generator

12 V 290

W/5,OOO

rpm

I

Hegulator/rectifier

type

I

Transistorized,

non-adjustable

I

Lighting

system

I

Battery

I

AC

regulator

type

I

~

1-4

••

General

Information

Unit:

mm

(in)

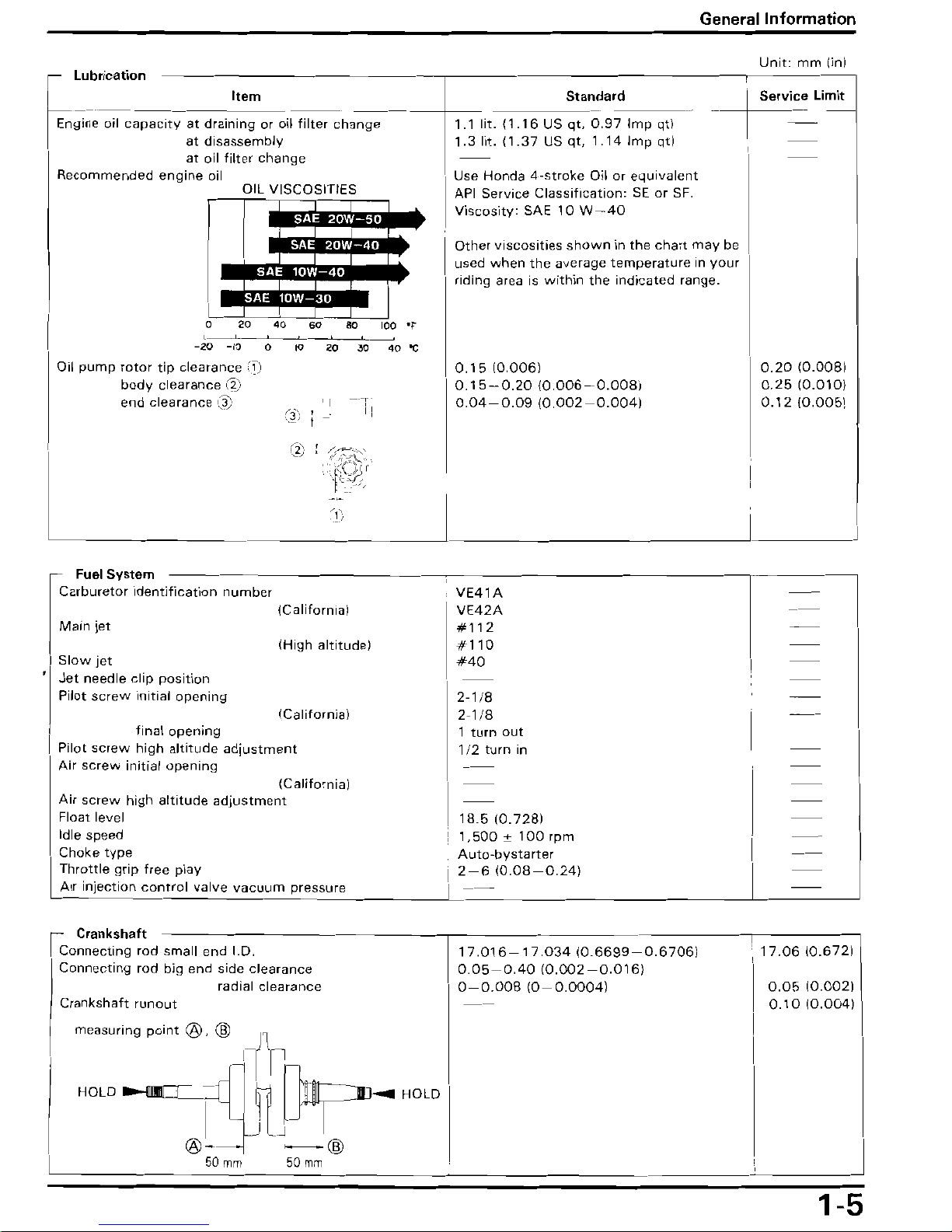

En:::ri:~t~:~acity

at

dra;:::;

or

oil

filter

change

-*

1 lit. 11.16 US

::~:d:r;

Imp qtl

at

disassembly

~:3Iit.

11.37 US qt,

1.141mp

qtlI

at

oil

filter

change

Recommended

engine

oil

Use

Honda

4-stroke

Oil

or

eqlJivalent

OIL

VISCOSITIES

m

API Service

Classification:

SE

or

SF.

Viscosity:

SAE

10

W-40

.,

Other

viscosities

shown

in

the

chart

may

be

used

when

the

average

temperature

in

your

riding

area is

within

the

indicated

range.

o

20

40

60

80

loo-r

-20

-10

0

to

20

30

40"C

Oil

pump

rotor

tip

clearance

0.15

10.0061

body

clearance

\~)

0.15-0.2010.006-0.0081

end

clearance

I't'

,

0.04-0.0910.002--0.0041

I -

I'i

I:

Fuel

System

Carburetor

identification

number

VE41A

(California)

VE42A

Main

jet

#112

(High

altitude)

#110

Slow

jet

#40

Jet

needle

clip

position

Pilot

screw

initial

opening

2-1/B

(California)

2-1/8

final

opening

1

turn

out

Pilot

screw

high

altitude

adjustment

1/2

turn

in

Air

screw

initial

opening

(California)

Air

screw

high

altitude

adjustment

Float

level

18.5

10.7281

Idle

speed

1,500 ± 100

rpm

Choke

type

Auto-bystarter

Throttle

grip

free

play

I

2-610.08-0.241

Air

injection

control

valve

vacuum

pressure

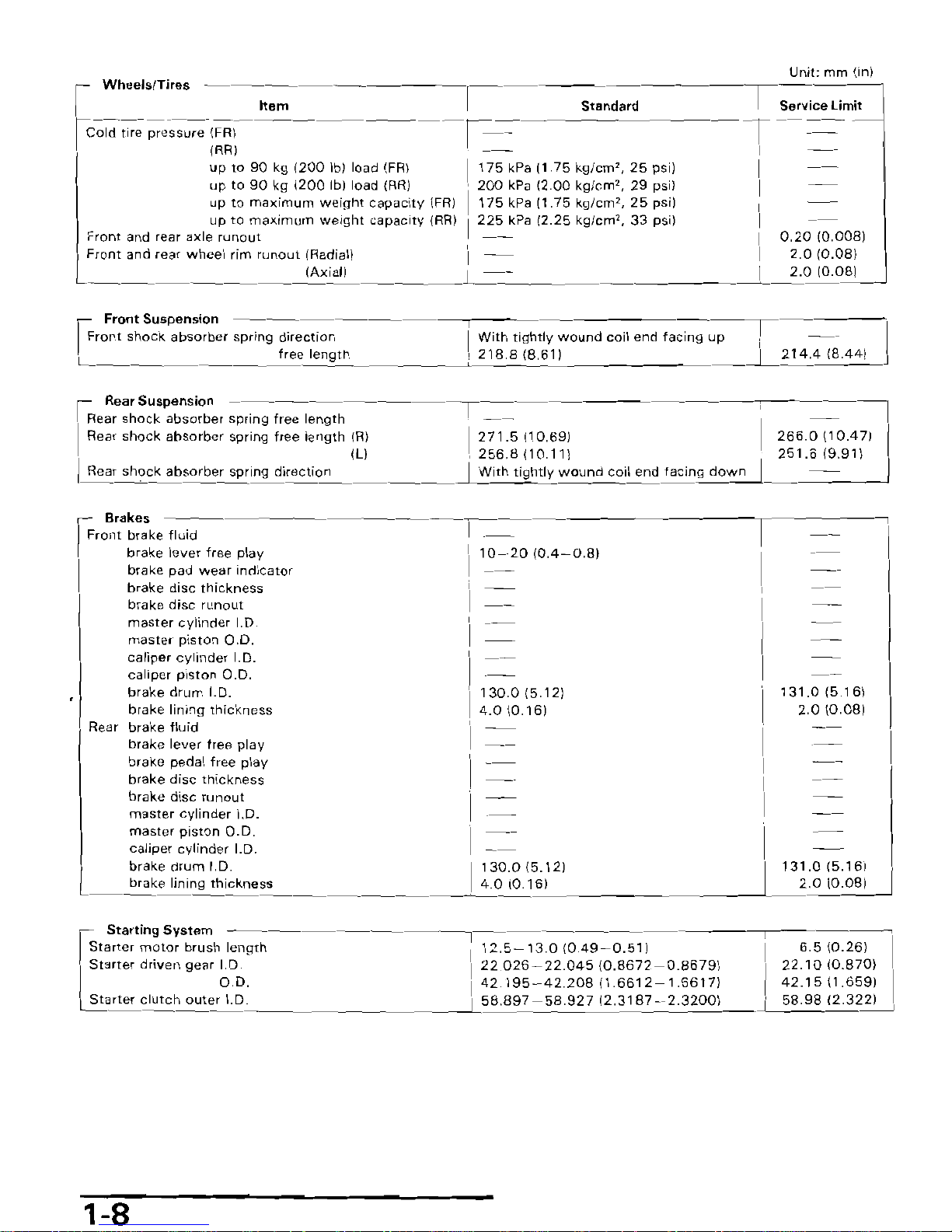

Crankshaft

Connecting

rod

small

end

I.D.

17.016-17.03410.6699-0.67061

Connecting

rod

big

end

side

clearance

0.05-0.4010.002-0.0161

radial

clearance

O-O.OOB

10-0.00041

Crankshaft

runout

measuring

point

®,

@

HOLD

~@

50

mm

0.20

10.00BI

0.25

(0.0101

0.12

10.0051

17.0610.6721

0.05

10.0021

0.10

10.0041

1-5

General Information

Unit:

mm

lin)

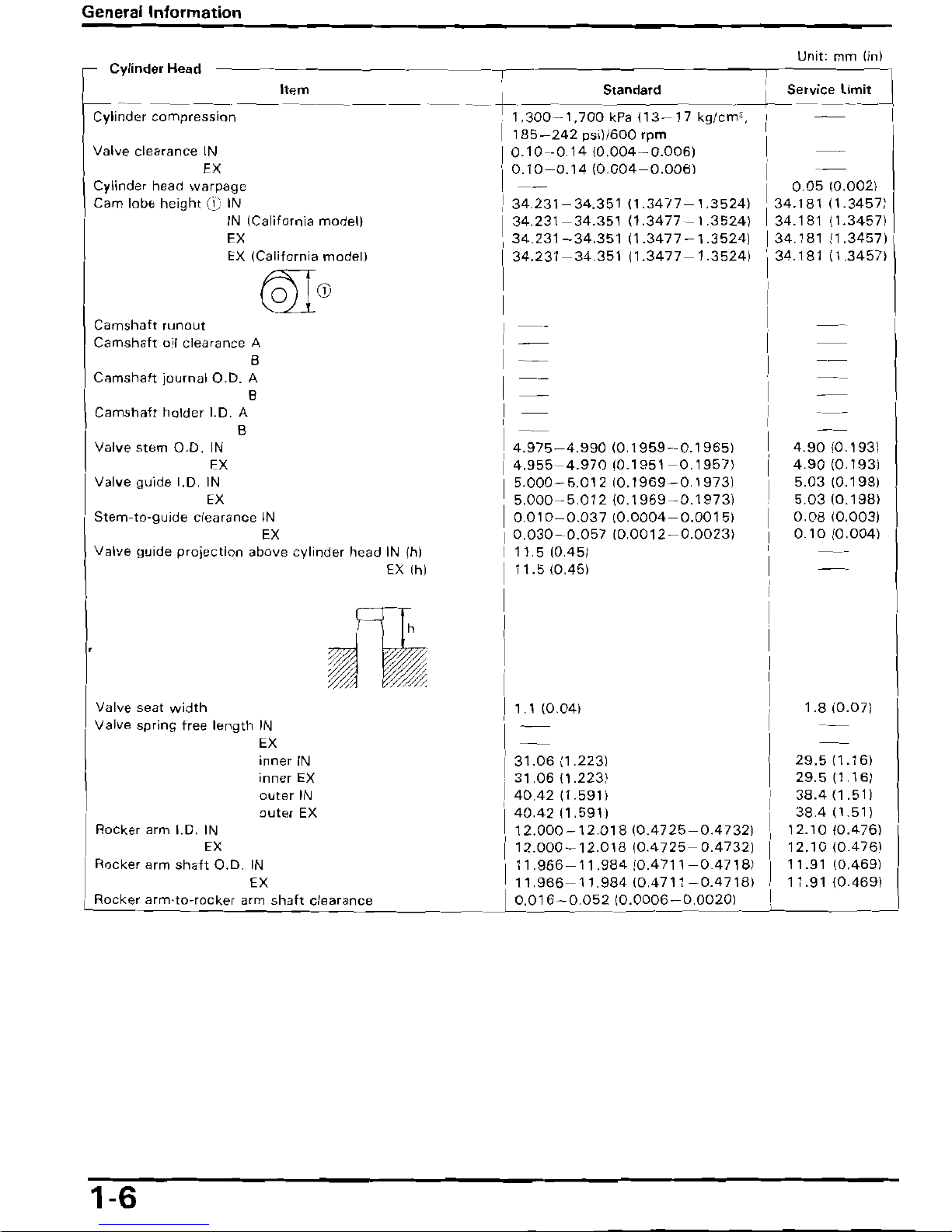

Cylinder

He.d

I I

~

Item Standard

~

Service limit

Cylinder

compression--

--------

--

--+I~

1,300-1,700

kPa

113-

17

kg/cm

2 ,

I--~--

185-242

psil/600

rpm 1

Valve clearance IN

10.10

-0.1410.004-0.0061

--

EX

10.10-0.1410.004-0.0061

1

Cylinder head

warpage

.

--

I

0.05

10.0021

Cam lobe

height(i)/N

134.231-34.35111.3477-1.35241

34.18111.34571

IN ICalifornia model) I

34.231-34.351

11.3477-1.35241

I

34.181

11.34571

EX

34.231-34.351

[1.3477-1.3524i

1

34.181

11.34571

EX

ICaliforni.

model)

134.231-34.35111.3477-1.35241

134.18111.34571

@lCD

i

Camshaft

run

out

Camshaft

oil

clearance

A

I

B

I

Camshaft journal

0.0.

A

B I

Camshaft

holder 1.0. A

B

1

Valve stem

0.0.

IN

I

4.975-4.99010.1

959-0.1

9651

4.9010.1931

EX

I

4.955-4.970

10.1951-0.19571

49010.1931

Valve guide 1.0.

IN

I

5000-

5.012

10.1969-0.19731

5.03

10.198!

EX

5.000-

5.012

10.1969 -O.

19731

5.03

10.1

981

Stem-ta-guide

clearance

IN

I

0.010-0.037

10.0004-

0.00151

0.0810.0031

EX

0.030-0.057

10.0012-0.00231

0.10

10.0041

Valve

guide projection above cylinder head

IN

{hl

I

11.510,451

EX Ihi

I

11.5

10,451

I

h

'j/

~W

::::~~

Valve seat width

1.1 10.041

1.8

10.071

Valve

spring free length IN

EX

inner

IN

31.0611.2231

29.511.161

inner

EX

31.0611.2231

29.511.161

outer

IN

40,42

11.5911

38,411.511

outer

EX

40,4211.5911

38.411.511

Rocker arm

1.0.

IN

12.000-12.018

10,4725-0.47321

12.1010.4761

EX

12.000-12.01810,4725-0.47321

12.1010.4761

Rocker arm

shafIO.D.

IN

11.966-11.98410,4711-0,47181

11.91 10.4691

EX

11.966-11.98410.4711-0,47181

11.91

10.4691

e..:.~r

a::.n:..:c..:e

L..::0~.

0:.:1

6 -

0.052

(0.0006 -0.0020)

~

--.J

L-R_o.:.ck.:.e:..r.:.a:..r:..m:..-

t:..:o_-r:..:o:..:c:..:ke:cr_a:cr~m~sh~a:cf:..'

..:c:..:1

1-6

----

--

--

I

Unit: mm

(in)

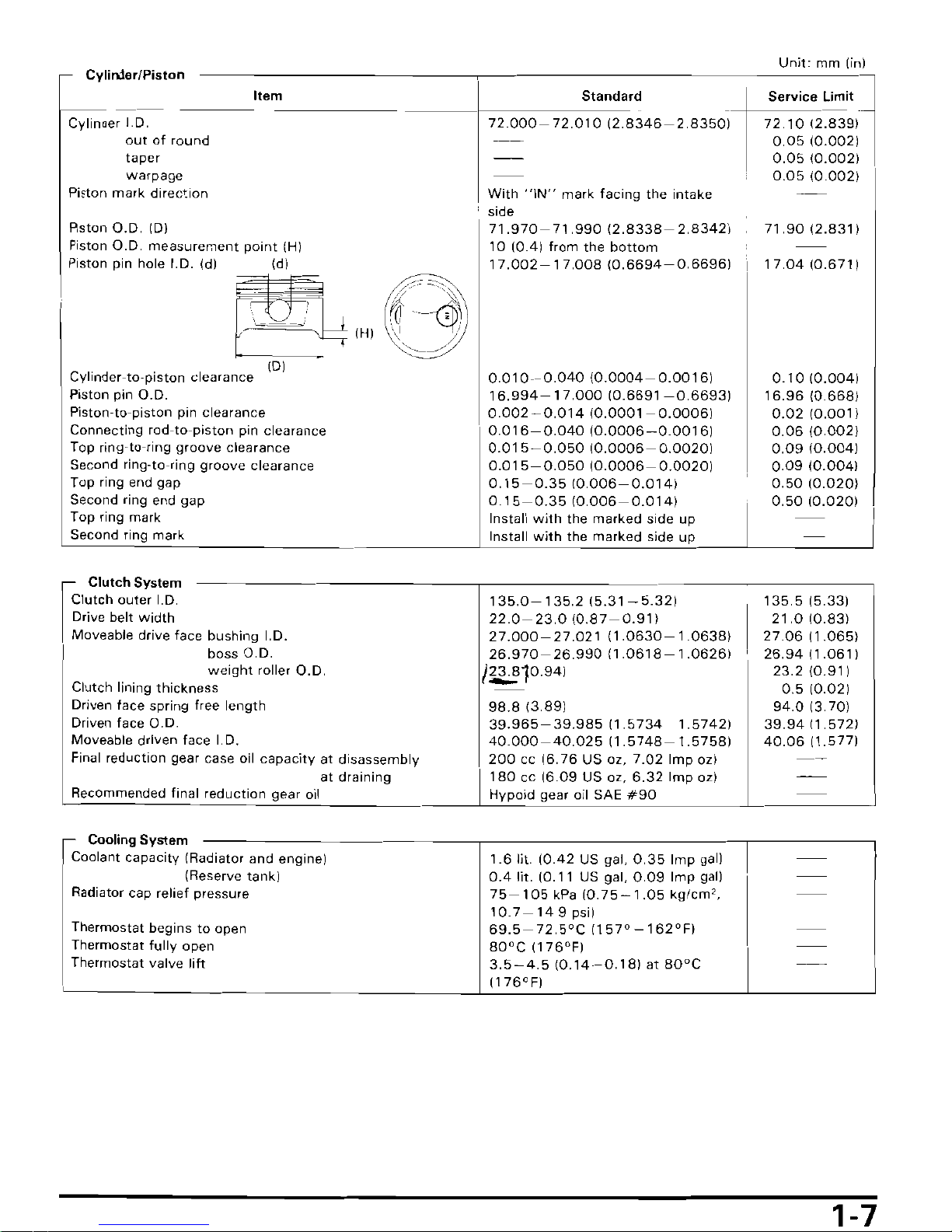

- Cylin:ter/Piston

Item

Standard Service Limit

ttl

Cylinller

J.D.

out

of round

taper

warpage

Pi~ton

mark direction

Rston

a.D.

IDI

Piston

O.D.

measurement

point

(H)

Piston pin hole I.D. Idl Idl

~

~IHI

d'

IDI

C

I

·

er-to-plston clearance Yin

Piston pin

O.D.

Piston-to-piston

pin

clearance

Connecting rod-to-piston

pin

clearance

Top ring-to-ring groove clearance

Second ring-to-ring groove clearance

Top ring end gap

Second ring end gap

Top ring mark

Second ring mark

Clutch System

Clutch outer

I.

D.

Drive belt width

Moveable drive face bushing 1.0.

boss

0.0.

weight

roller

0.0.

Clutch lining thickness

Driven face spring free length

Driven face

0.0.

Moveable driven face

I.

D.

Final reduction gear case

oil

capacity at disassembly

at draining

Recommended final reduction gear

oil

r

Cooling System

Coolant capacity (Radiator and engine)

(Reserve tank)

Radiator cap relief pressure

Thermostat begins to open

Thermostat fully open

Thermostat valve lift

72.000-72.01012.8346-2.8350"1

-

With

"IN"

mark facing the intake

side

71.970-71.99012.8338-2.83421

10

10AI from

the

bottom

17.002-17.00810.6694-0.66961

0.010-0.040

10.0004-0.00161

16.994-17.00010.6691-0.66931

0.002--0.01410.0001-0.00061

0.016-0.04010.0006-0.00161

0.015-0.05010.0006-0.00201

0.015-0.05010.0006-0.00201

0.15-0.3510006-0.0141

0.15-0.3510.006-0.0141

Install

with

the marked side up

Install

with

the marked side up

135.0-135.2

15.31 - 5.321

22.0-23.010.87-0.911

27.000-27.02111.0630-1.06381

26.970-2699011.0618-1.06261

1~10941

98.8

13.891

39.965-

39.98511.5734

1.57421

40.000-40.02511.5748-1.57581

200

ee

[6.76

US oz,

7.02

Imp ozl

180

ee

[6.09

US oz,

6.32

Imp ozl

Hypoid gear

oil

SAE

#90

1.6

lit.

[OA2

US

gal.

0.35

Imp gall

OA

lit. [0.11

US

gal,

0.09

Imp gall

75-105

kPa

[0.75-1.05

kg/em',

10.7-14.9

psil

69.5-72.5'C

1157'

-162'FI

80'C

1176'FI

3.5-4510.14-0.181

at

80'C

[176'FI

721012.839)-

0.0510.0021

0.05

10.0021

,

0.05

10.0021

71.9012.831

I

17.0410.6711

0.10

10.0041

16.96

106681

0.02

10.0011

0.06

10.0021

0.09

10.0041

0.09

10.0041

0.5010.0201

0.50

10.0201

135.515.331

21.0

10.831

27.0611.0651

26.9411.0611

23.210.911

0.5

[0.021

94.0

[3.701

39.9411.5721

40.06

[1.5771

I

I,

1-7

Unit: mm lin)

Wheels/Tires

Item

Standard

Service

limit

Cold

tire

preSS~(FR)-~-----------r--=-

T-

~

IRRJ

~-

up

to

90

kg

1200

Iblload

IFRI

1175

kPa 11.75

kg/cm',

25

psil

up

to

90

kg

1200

Ibl

load

IRRI

200

kPa 12.00

kg/cm',

29

psi!

\

up to

maximum

weight capacity

(FR) \ 175

kPa

\1.75

kg/cm

2

,

25

psi)

up to

maximum

weight capacity

(RR) I 225

kPa

(2.25

kg/cm

2

,

33

psi)

I

Front and rear axle runaut

0.2010.0081

Front and rear wheel rim runout (Radial) \

I

2.0

(0.081

IAxiall

I

I

2.010.081

Front Suspension

Front shock absorber spring direction

With

tightly wound coil end facing up

~_~_~

f_re_e_l_e_ngc_t_h

__

~

~

218.8

1.-=8::.6=--lccl

-"--__2_1_4_A_18_._4_4c-I

--'

Rear Suspension

T---

Rear shock absorber spring free length \

Rear shock absorber spring free length

\R}

1271.5

\10.69}

2660

(100471

ILl

256.8110.111

251.619.911

Rear sh?ck absorber

sprlng_d_i_re_c_t_i

o_n

~

~LW:..i-=t::h-:t"i

g"h::t"ly_wLo::L:..,":..dLco,_il

::e::n_d_t::a_c_in-'g=-d::o_w_n_-'-

-'

Brakes

Front brake fluid

brake lever free play

10-2010A-0.BI

brake pad

wear

indicator

brake disc thickness

brake disc runout

master cylinder

1.

D.

master piston

0.0.

caliper cylinder

I.

O.

caliper piston

0.0.

brake drum 1.0.

130015.121

131.015.161

brake lining thickness

4.0

10.161

2.010.081

Rear brake fluid

brake lever free play

brake pedal free play

brake disc thickness

brake disc runout

master cylinder 1.0.

master piston

0.0.

caliper cylinder 1.0.

brake drum 1.0.

130.015.121

131.015.161

brake lining thickness

4.010.161

2.010.081

Starting

System

Starter

motor

brush length

112.5-13010049-0.511

6.510.261

Starter

driven

gear

I.D.

22.026-22.04510.8672-0.86791

22.1010.8701

00.

142.195-4220811.6612-166171

42.1511.6591

Starter

clutch

outer__I._D

------l.

58.897 -58.927

12.31 B7 -2__

.3_2_0_0-'1__--L_58_.

9_8.....:.12_._3_2_2_1-"

1-8

General

Information

Unit:

mm

(in)

r-

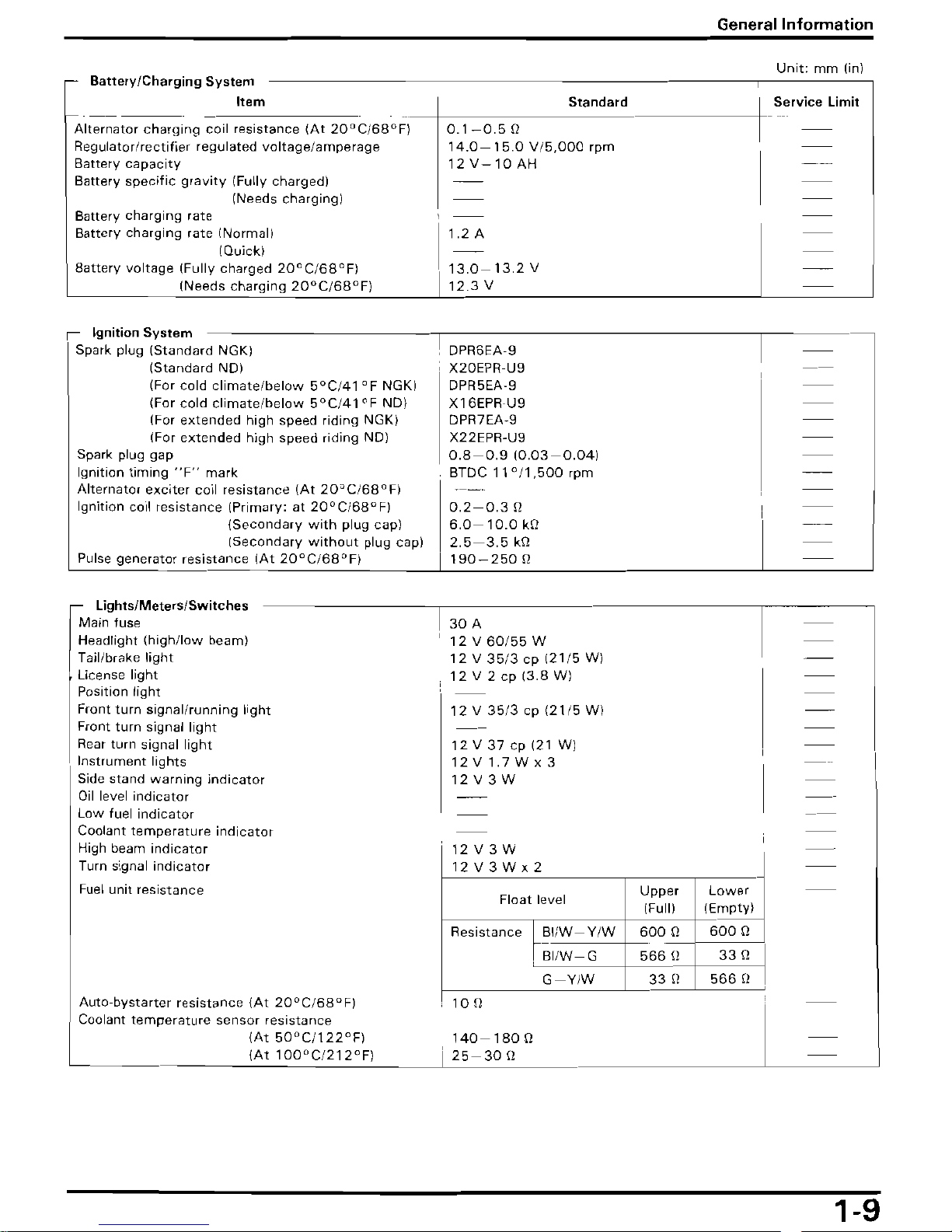

Battery/Charging

System

~

__

Item

_-+

Alternator charging coil resistance

(At

20 D C/68°F)

Regulator/rectifier regulated

voltage/amperage

Battery

capacity

Battery specific

gravity

(Fully charged)

(Needs charging)

Battery charging rate

Battery charging rate (Normal)

(Quickl

Battery voltage (Fully charged

20°C/68°F)

(Needs charging

20o CJ68°F)

S_t_a_n_d_a_'_d

---iL_

~_~rvice

Limit

0.1-0.5

n I

14.0

- 1

5.0 V/5,

000

rpm

12 V-10

AH

1.2

A

13.0-13.2

V

12.3

V

Ignition

System

-----------------,--------------------

------_

Spark plug (Standard NGKI

(Standard NDI

(For cold

climate/below

5°C/41°F

NGKI

(For cold

climate/below 5°C/41

°F NDI

(For extended high speed riding NGK}

(For extended high speed riding NO)

Spark plug gap

Ignition timing

"F"

mark

Alternator exciter coil resistance

(At

20o CJ68°Fl

Ignition coil resistance (Primary: at

20°C/68°F)

(Secondary

with

plug cap)

(Secondary

without

plug cap)

Pulse generator resistance

(At

20°C/68°F)

Lights/Meters/Switches

Main fuse

Headlight

(high/low

beaml

Tail/brake light

License light

Position light

Front turn signal/running light

Front turn signal light

Rear turn signal light

Instrument lights

Side stand warning indicator

Oil

level indicator

Low fuel indicator

Coolant temperature indicator

High beam indicator

Turn signal indicator

Fuel

unit resistance

Auto-bystarter resistance {At

20°C/68°F)

Coolant

temperature

sensor resistance

(At

50 0 C1122°FI

IAt

100°C/212°FI

DPR6EA·9

X20EPR·U9

DPR5EA·9

X16EPR·U9

DPR7EA-9

X22EPR-U9

0.8-0.9

(0.03-0.041

BTDC

11°/1

,500

rpm

I

0.2-0.3

Q

6.0-10.0

kQ

2.5-3.5

kQ

190-250

Q

30

A

12 V 60/55

W

12 V 35/3

cp

(21/5

WI

12

V 2 cp

(3.8

WI

12 V 35/3

cp

(21/5

WI

12 V

37

cp

121

WI

12V1.7Wx3

12

V 3 W

12

V 3 W

12V3Wx2

Float level

Resistance

hB'/W-Y/W

,

BI/W-G

G-Y/W

10

n

Upper

(Full)

600

Q

566

Q

33

[)

Lower

(Emptyl

600

Q

33

Q

566

[)

140-180

Q

25-30

Q

1-9

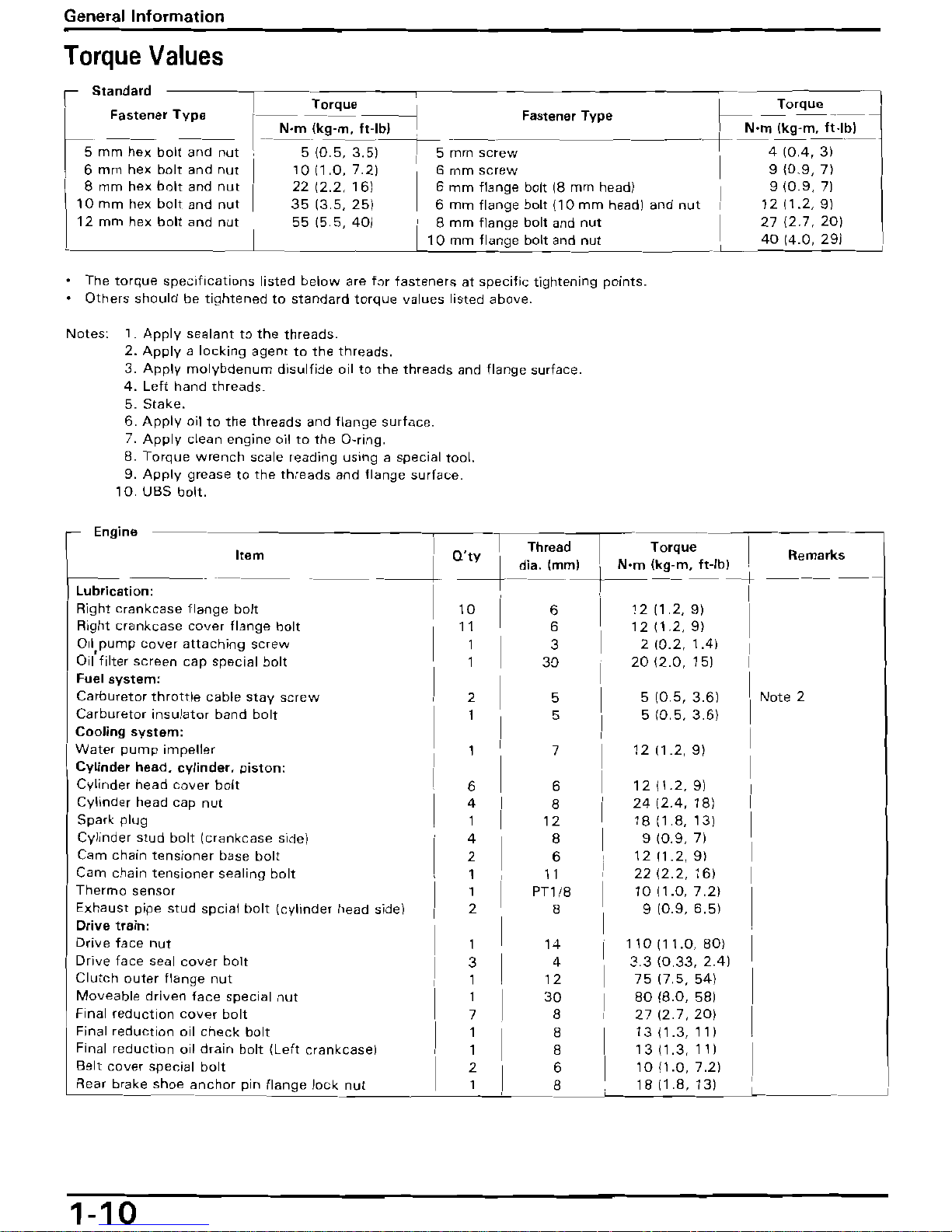

General

Information

Torque

Values

Standard

1-

Torque

'I

I

Torque

Fastener

Type

L_

----

--_

Fastener

Type

f--

-

--

----

I

N'm

Ikg-m.

It-Ib)

" -+

N'm

Jkg-m---!t~b_l_

5

mm

hex

bolt

and

nut

,---S-{O.5,

i51--TS rnrn

sc~ew

--------

I 4 (004,

3)

6

mm

hex

bolt

and

nut

10

(1.0,

7.2)

6

mm

screw

9 {D.9,

7l

I

8

mm

hex

bnlt

and

nut

22 12.2.

161

6

mm

flange

bolt

18

mm

headl

910.9.

71

10

mm

hex

bolt

and

nut

3513,5.251

6

mm

flange

bolt

110

mm

head I and

nut

1211.2,91

12

mm

hex

bolt

and

nut

55

(5,5,

40)~mm

flange

bolt

and

nut

27

(2.7,

20)

I

10

mm

flange

bolt and

nut

40

14.0,

291

--~~---

The

torque

specifications

listed

below

are

for

tasteners

at

specific

tightening

points.

Others

should

be

tightened

to

standard

torque

values

listed

above.

Notes:

1.

Apply

sealant

to

the

threads.

2.

Apply a locking

agent

to

the

threads.

3.

Apply

molybdenum

disulfide

oil

to

the

threads

and

flange

surface.

4.

Left

hand

threads.

5.

Stake.

6.

Apply

oil

to

the

threads

and

flange

surface.

7.

Apply

clean

engine

oil

to

the

a-ring.

8.

Torque

wrench

scale

reading

using a special

tool.

9.

Apply

grease

to

the

threads

and

flange

surface.

10.

UBS

bolt.

\ Engine

Item

____ I ---l

Q'

I Threed

~+

di.~ml

Torque

I

N'm

(kg-m,

ft-Ibl

+--------t

Remarks

Lubrication:

I

Right

crankcase

flange

bolt

I

10

I

6

1211.2,91

Right

crankcase

cover

flange

bolt

I

11

I

6

1211,2,91

I

Oil

pump

cover

attaching

SCrew

oil'

filter

screen

cap

special

bolt

I

~

I

3

30

2 10.2. 1.41

20

12,0,

151

I

Fuel

system:

Carburetor

throttle

cable

stay

screw

I 2 I 5 5 10.5, 3.61

Note

2

Carburetor

insulator

band

bolt

5

510,5.3,61

Cooling

system:

I 1

'I

Water

pump

impeller

7

1211.2,91

Cylinder

head,

cylinder.

piston:

Cylinder

head

cover

bolt

I 6 I 6

1211.2.91

Cylinder

head

cap

nut

Spark

plug

I

~

I

8

12

24

12.4.

181

1811,8,131

Cylinder

stud

bolt

(crankcase

side)

B

910.9.71

Cam

chain

tensioner

base

bolt

~

I

6

1211.2,91

Cam

chain

tensioner

sealing

bolt

11

22 12,2,

161

Thermo

sensor

~

I

PTl/8

1011.0,7.21

Exhaust

pipe

stud

spcial

bolt

(cylinder

head side)

2

8

910.9.6.51

Drive

train:

Drive

face

nut

1

I

14

110111.0,801

Drive

face

seal

cover

bolt

Clutch

outer

flange

nut

3

1

I

4

12

33

10,33. 2.41

7517,5.541

Moveable

driven

face

special

nut

1

30

8018.0,

581

Final

reduction

cover

bolt

7

8

27127.201

Final

reduction

oil

check

bolt

1

8

1311.3,111

Final

reduction

oil

drain

bolt

(Left

crankcase)

1

8

1311,3,111

Belt

cover

special

bolt

2

6

1011.0,7.21

Rear

brake

shoe

anchor

pin

flange

lock

nut

1 8

1811.8.131

1-10

1-11

Loading...

Loading...