Page 1

Page 2

Page 3

Page 4

FRONT WHEEL/SUSPENSI

ON/

STEERING

Install the oil seal

its marked

with

side facing up.

Before assembly, wash all parts

non

-flammable

Install a

been removed.

I NO

• Be ca

new

TI

refulnot to

forktube

CE I

solvent

damage

and

wipe

bushingifthe

the fork t

coating.

• Do

not

open

the

fork

tube

bushing

necessary.

• Remove the

being

Install the new s

da

mage

rem oved.

Remove

being careful

Install

seal o

nto

careful

the

the

burrs fr om th e

the

slider

the

burrs

from

nottopeel

lider

coat

ing

not

to peel

bushing,

fork

slider.

the

bushing

off

bushing being careful

of th e

bush

bush

off

the coating.

back-up

withahigh

them

tube

ube

more

mating

the

coating

ing if it has been

ing mating surface,

ring

flash or

dry.

bushing has

bush

ing

than

surface,

.

and new

not

oil

to

BACK-UP RING

~

If the fork damper

turns together

wit

h the socket

bolt, temporarily

install the fork

sonnq. spring

seat.onto cof/ar

and fork bolt.

tube

sealing

specif

Ibf.f

.

tools

t)

.

bolt

washer

ied

torque.

threads.

.

Install the fork slider into the fork

Drive

the

oil seal in usi ng

TOOL:

Fork sealdriver

Fork

seal

Apply

a locking agent to

Install

the

Hold the axle holder in a vise w ith soft jaws or a shop

towel.

Tighten

TORQUE: 20 N

the

driver

socket

fork

weight

attachme

bolt

socket

·m

12.0 kgf-rn, 14

the

special

07947-KA50100

07947-KA40200

nt

the

fork socket

withanew

bolt

to the

l.

ATTACH~M~

EN~T

~

o

U;

\ SOCKET BOLT/SEALING WASHR

S

\

SLIDER BUSHING

ATTACHMENT

I

I

I

\

\

\

13-21

Page 5

FRONT WHEEL/SUSPENSION/STEERING

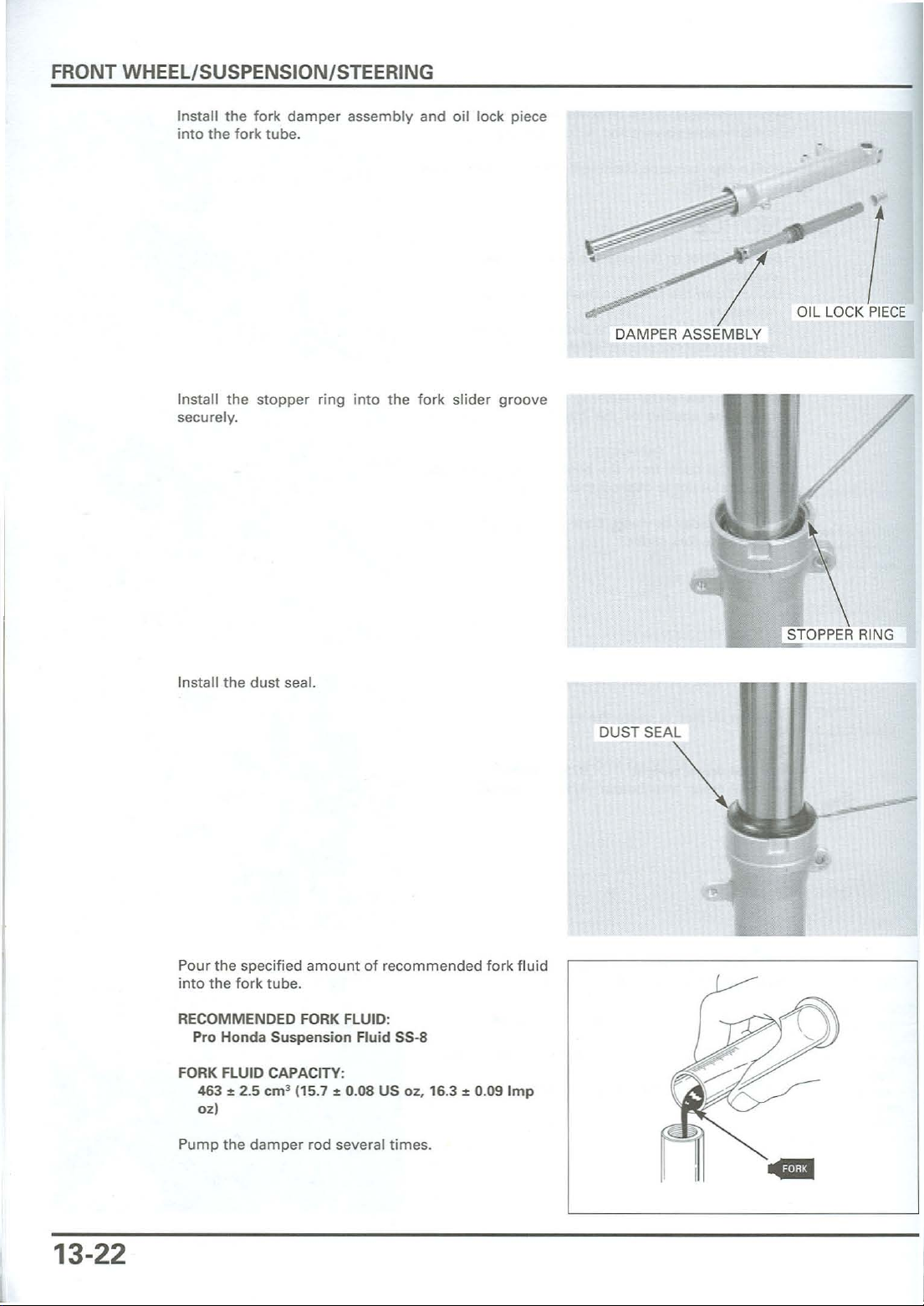

Install the fork damper assembly and oil lock piece

into the fork tube.

-

Install the stopper ring into the fork slider groove

securely.

Install the

dust

seal.

/"

DAMPER ASSEMBLY

DUST SEAL

_ _

OIL LOCK

....S..

TOPPER RING

/

PIECE

13-22

Pour the specified amount of recom

into the fork tube.

RECOMMENDED FORK FLUID:

Pro Honda Suspension Fluid

FORK FLUID CAPACITY:

e 2.5 em' 115.7

463

oz)

Pump the dampe r rod several times.

~

55-8

0.08 US oz, 16.3~0.09

men

ded fork fluid

-.

Imp

Page 6

FRONT WHEEL/SUSPENSION/STEERING

Be sure the oil

is the same

level

both

in

forks.

Measure

while

the

damper

FORK OIL LEVEL: 155 mm 16.1 in)

Pull

the tapered end facing

Screw the

the oil level

compressing

fork

tubeslowly

rod

more

the

damper

damper

from

the

tube

morethan5times

than10times

rod up

and

install

down

rod end

nut

the

all

.

the

fully

topofthe

way

.

the

forkspring

by hand.

after

fork

stroking

and the

tube

with

-

...

NUT

~

OIL

LEVEL

Insta ll

Install a

Apply

Hold

the

dampe

Hold the

ified

torque

the

spring

seat and

newO-ringonto

fork f

luid

to the

damper

r rod

fork

rod

unti

litseats on the

bolt and

.

the

new

and sc

tighten

spring

fork bolt.

O-ring.

rew

the lock

collar

the

fork bolt o

damper

.

rod lock nut.

nut

to the spec-

nto

FORK SPRING

SPRING COLLAR

<.

SPRING SEAT

the

TORQUE: 22 Nom 12.2

kgf

om. 16 Ibfoft)

13-23

Page 7

FRONT WHEEL/SUSPENSI

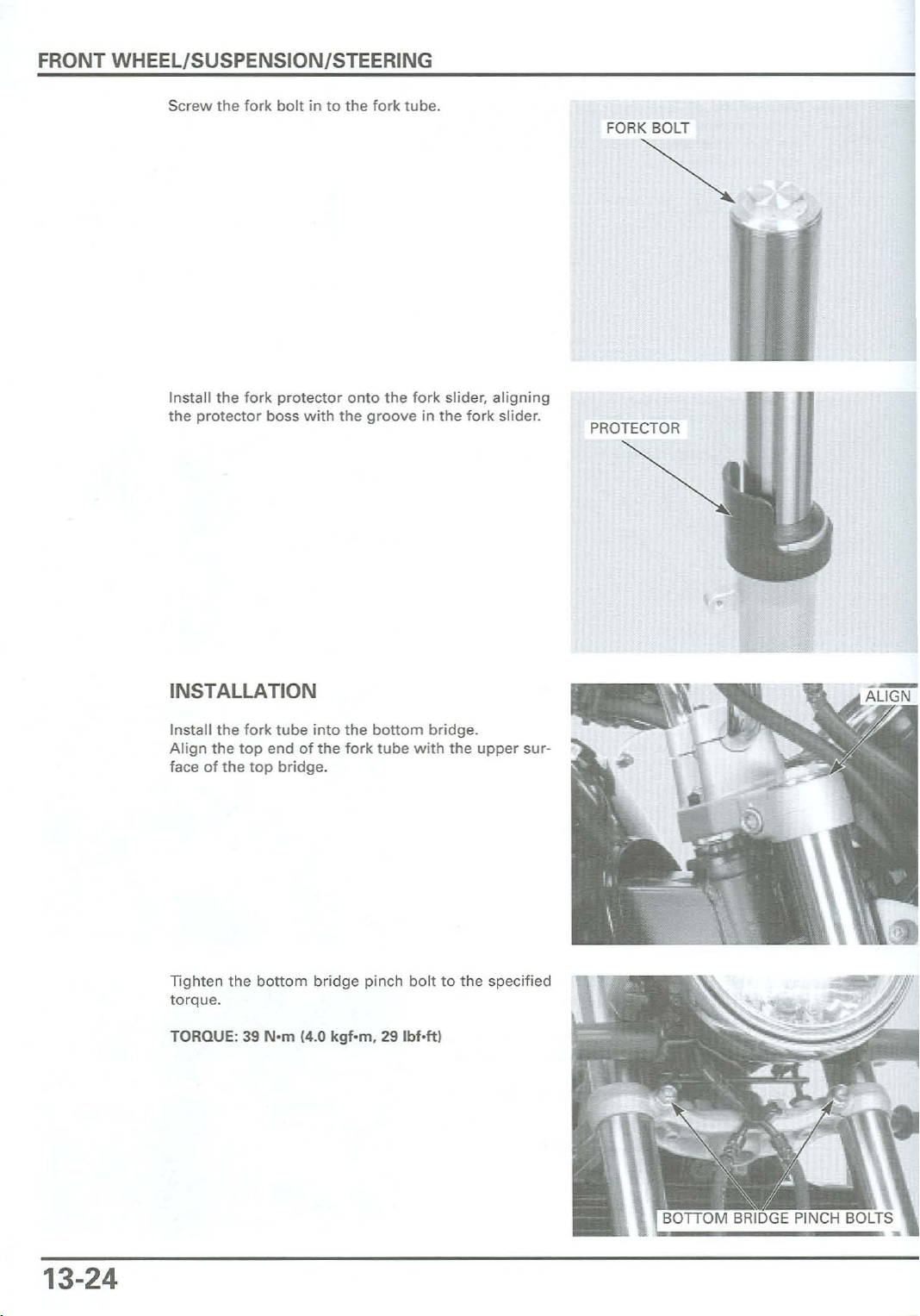

Screw the fork bolt in to the fork tube.

Install the fork protector onto the fork slider, aligning

the protector boss with the groove in the fork slider.

ON/

STEERING

FORK BOLT

-.

PROTECTOR

~

INSTALLATION

Install the

Align the top end of the for k tube with the upper sur-

face of the top

Tighten the

torque.

TORQUE: 39 N'm(4.0 kgf·m. 29 Ibf·ft)

fork

bottom

tube

into

thebottom

bridge

.

bridge pinch bolt to the specified

bridge.

•

13-24

Page 8

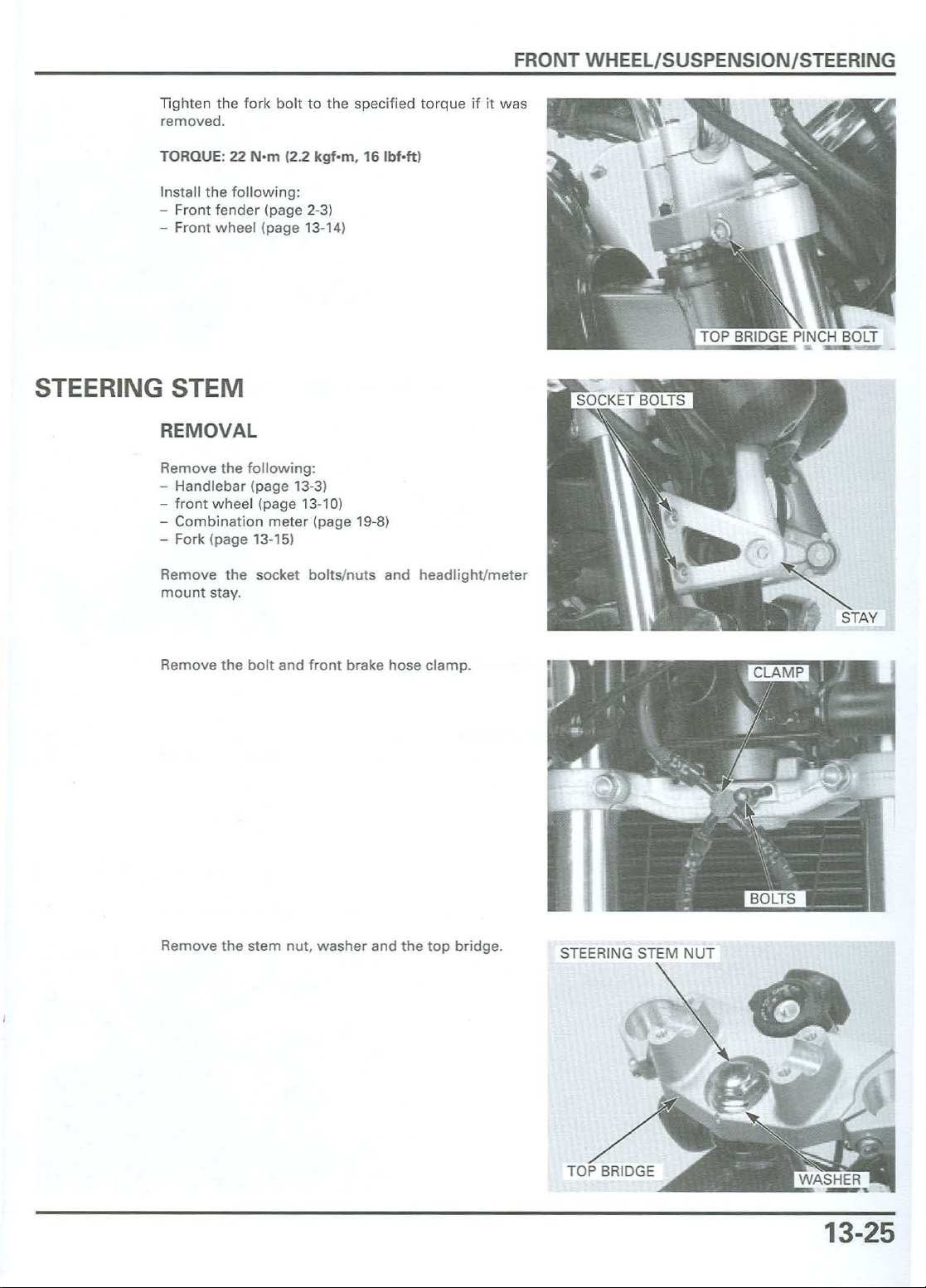

Tighten the fork bolt to the specified torque if it was

removed.

FRONT WHEEL/SUSPENSION/STEERING

TORQUE: 22

Install th e foll

ont

- Fr

- Front wheel (page 13-14)

fender (pag e 2-31

STEERING STEM

REMOVAL

Remove the followi ng:

- Handl ebar (page 13-3)

-

front

wheel

- Combin ation meter (page 19-8)

- Fork (page 13-151

Remove the socket bolts/nuts and headl ight/meter

mount stay.

N·m

(2.2

owing

:

(page 13-10)

kqf-m

, 16

Ibf·ftl

Remove the bolt and front brake hose clamp.

Remove the stem nut, washer and the top bridge.

STEERING STEM NUT

13-25

Page 9

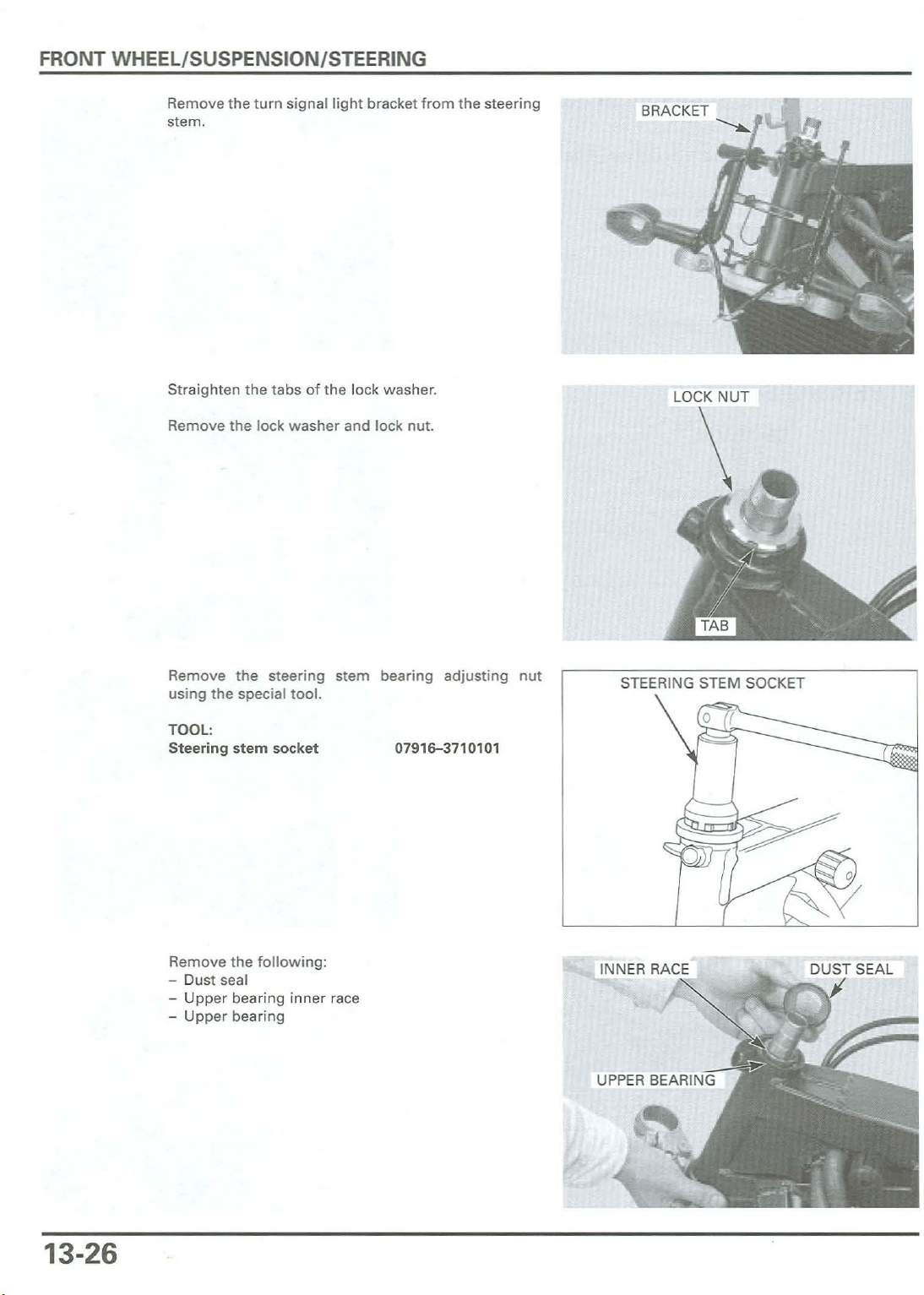

FRONT WHEEL/SUSPENSION/STEERING

Remove the

stem.

Straighten the tabs of the lock

Remove the lock washer and lock nut.

turnsignal

light

bracket from the steering

washe

r.

LOCK NUT

\

Remove the steering stem bearing adjusting nut

using

the special

TOOL:

Steering

Remove th e

- Oust seal

-

- Upper bearing

Upp

er bearin g

stem

tool.

socket

followin

inner

07916-3710101

g:

race

STEERING STEM SOCKET

13-26

Page 10

FRONTWHEEL/SUSPENSI

ON/

STEERING

Note the installa -

tion direction

the

assembly

base.

Always replace

the bearing races

as a

set

- Steering stem

of

- Lo

wer

bearing

BEARING RACE REPLACEMENT

Replace

ciaI to ol.

TOOLS:

Ball race remover

Ball race remover set

- Remover

.

- Driver s

the

upp

attachment

haft

er bearing outer races

07953

07953

07946

07946

using

the

-4250002

-MJ10000

-MJ

10100

- M

J1020

0

spe-

or

~

,--

__

ATTACHMENT

DRIVER SHAFT

/

Replace the

cial

tool.

TOOLS:

Ball race remo ver

Ball race remover

Tempo

stemtoprevent

when

lower

rarily

removing

install

stem.

Removethe

equivalent

Remove

the

lower

tool,

dust

bearing

the

the

bearing

being

seal.

the

threads

lower

careful

outer

steering

frombeing

bear

ing

inner

nottodamage

races

using

07953

-3710500

07953-4250002

stem

nut

onto

damaged

inner

race f

race

with

a chisel or

the

the

rom

spe-

the

the

stem.

REMOVER

LOWER

INNER RACE

13-27

Page 11

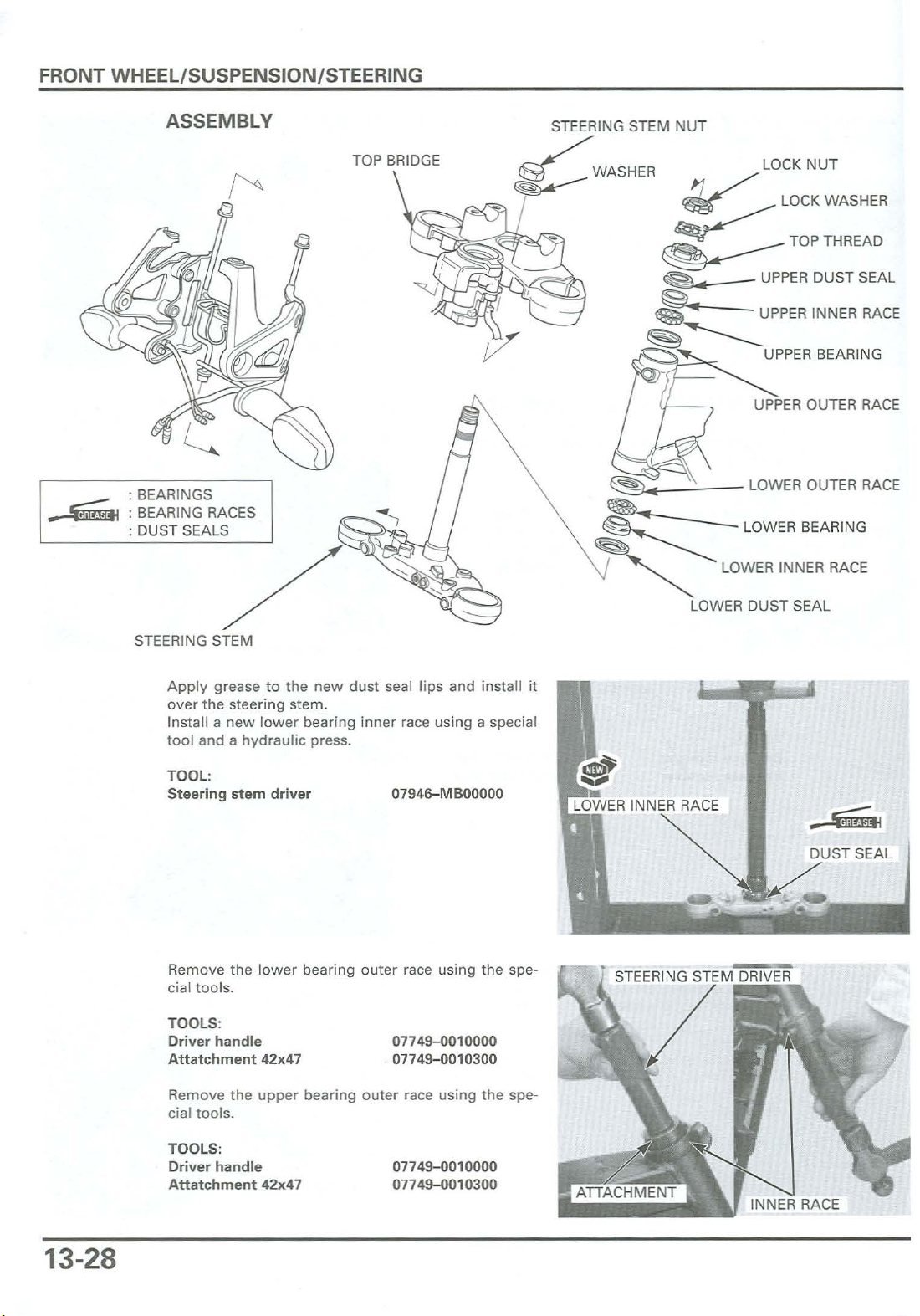

FRONT WHEEL/SUSPENSION/STEERING

I"-

~

ASSEMBLY

: BEARINGS

: BEARING RACES

: DUST SEALS

TOP BRIDGE

STEERING STEM NUT

~WASHER

~

_

~

LOCK NUT

LOCK WASHER

~TOPTHREAD

~

• UPPER DUST SEAL

Jfi

. UPPER INNER RACE

UPPER BEARING

UPPER OUTER RACE

- LOWER BEARING

LOWER INNER RACE

~

~

~

~

~

------

• LOWER OUTER RACE

..

LOWER DUST SEAL

STEERING STEM

Apply grease to the

over the steering stem.

Install a new lower bearing inner race using a special

tool and a hydraulic press.

TOOL:

Steering stem driver 0794

Remove the lower bearing outer race using the spe-

cial tools.

TOOLS:

Driver handle

Attat

chment

Remove the upper bearing outer race using the spe-

cial tools.

42x47

new

dust seal lips and install it

6-M

BOOOOO

07749-0010000

07749-0010

DUST SEAL

300

13-28

TOOLS:

Driver handle

Attatchment

42x47

0

7749-0010000

07749-0010

300

INNER RACE

Page 12

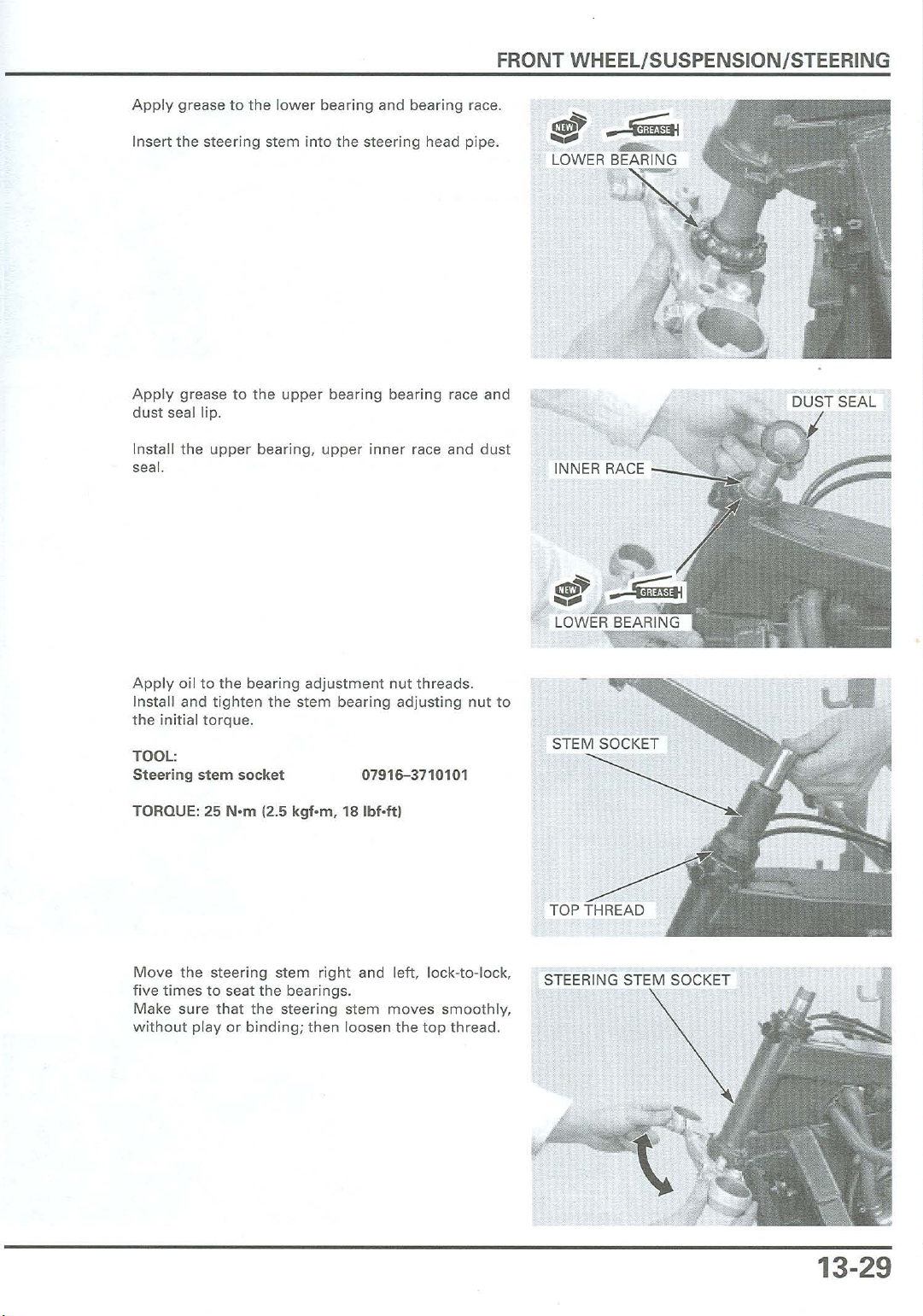

Apply

Insert

grease to the

the

steering stem

lower

bearing and bear

into

the steering head pipe.

ing

FRONT WHEEL/SUSPENSION/STEERING

race.

~

LOWER BEARING

..

-$iiiffi

~

Apply

grease to the

dust

seal lip .

Instal l the

seal.

Apply

oil to the bearing

Install and

the initial

upper

tighten

torque.

upper

bearing bearing race and

bearing,

the stem bearing

upper

adjustment

inner

nut

race and

threads.

adjust

ing

nut

dust

to

~

J

INNER RACE --_

I

--:c

TOOL:

Steering stem

TORQUE: 25

Move

the steering

fivetimes

Make sure

w

ithout

to seat the bearings .

that

play

soc

ket

N'm

(2.5 kqf-rn, 18

stem

the steering stem

or b

inding;then

07916-3710101

Ibf·ll)

right

and left, lock-to-lock,

moves

loosen the

smoothly,

top

thread.

STEERING STEM SOCKET

13-29

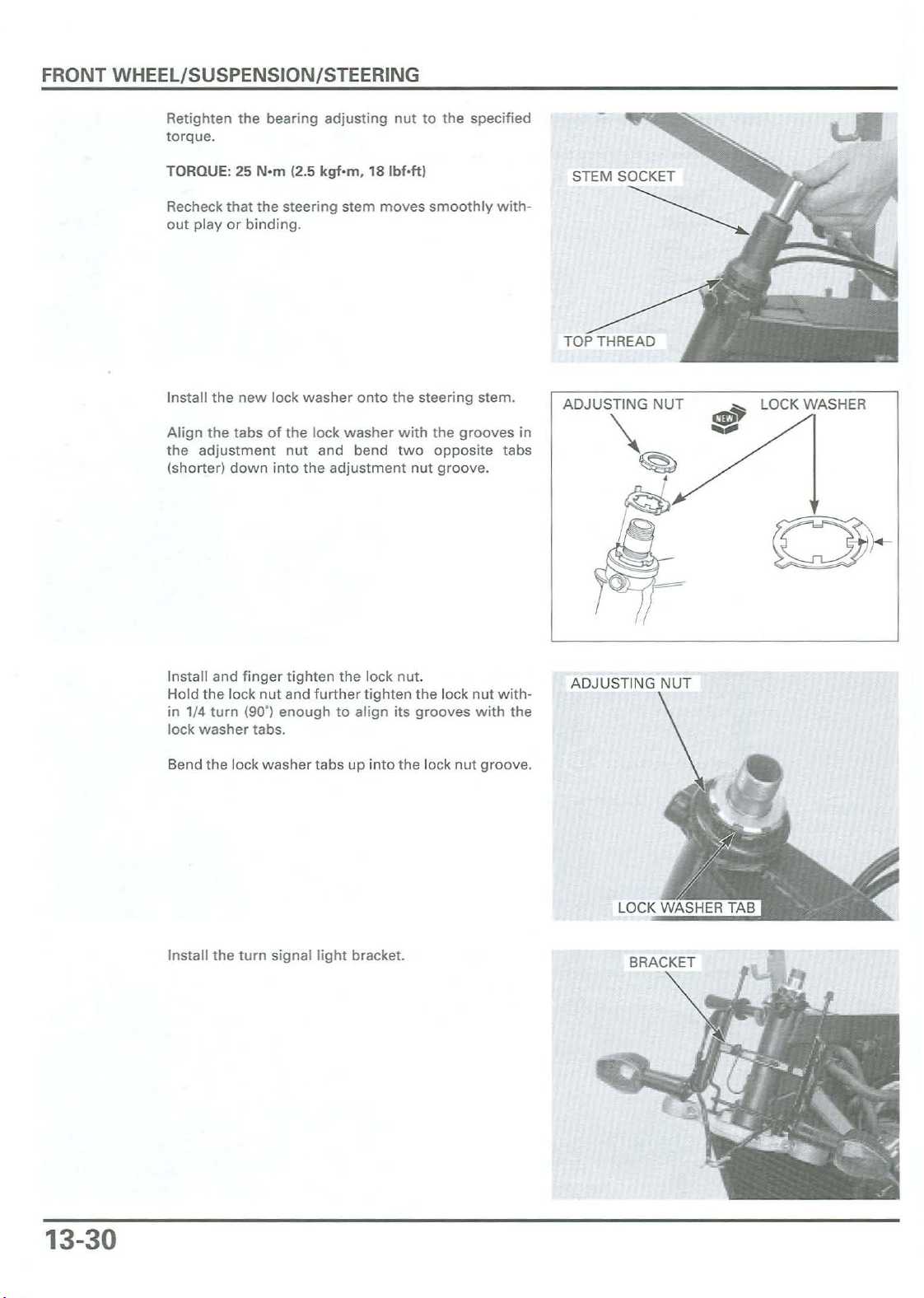

Page 13

FRONT WHEEL/SUSPENSION/STEERING

Retighten the bearing adjusting nut to the specified

torque.

TORQUE: 25 N·m12.5 kqf -m, 18 Ibf-ttl

Recheck that the stee ring stem

out play or binding.

Install the new lock washer onto the steering stem.

Align the tabs of the lock washer with the grooves in

the adju stment nut and bend two opposite tabs

(shorter) down into the adjustment nut groove.

Install and

Hold the lock nut and

in 1/4 turn (90·) enough to align its grooves w ith the

lock

washer

fing

er tighten the lock nut.

furt

tabs.

her

tig

moves

smoothly

hten the lock

with-

nutwith-

ADJUSTI NG NUT

~

~

e

~

LOCK WASHER

Bend the lock washer tabs up into the lock nut groove.

Install the turn signal light bracket.

BRACKET

13-30

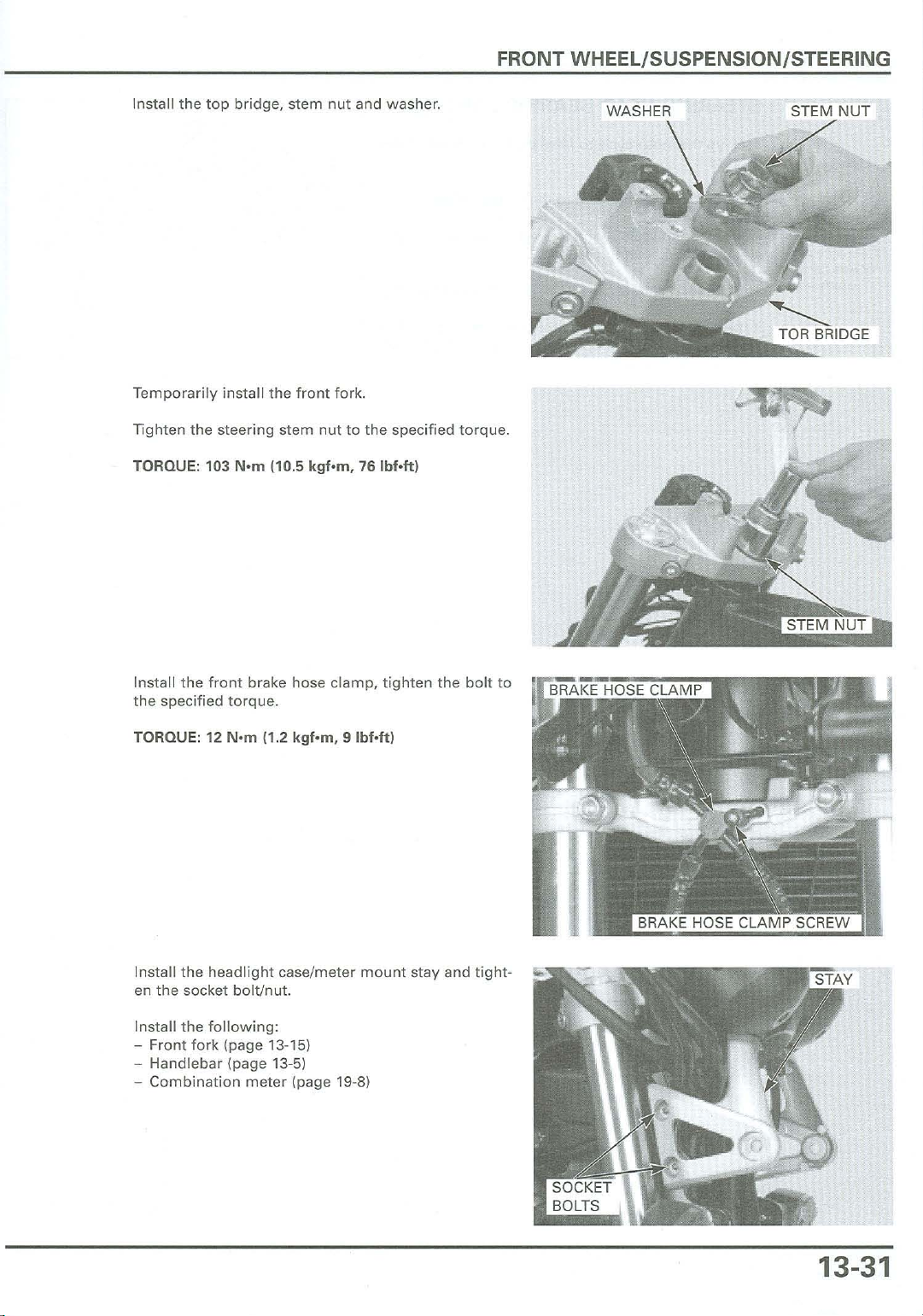

Page 14

FRONT WHEEL/SUSPENSION/STEERING

Install the top bridge, stem nut and washer.

Temporarily install the front fork.

Tighten the steering stem nut to the specified torque.

TORQUE: 103

N'm

(10.5

kqf-m,

761bf·1t)

WASHER STEM

..

NUT

Install the

the specified torque.

TORQUE: 12

Install the headlight case/meter mount stay and

en the socket bolt/nut.

Install the

- Front fo rk (page 13-15)

- Handlebar (page

-

Combination

front

brake hose clamp,

N'm

(1.2

following

:

13-51

meter

kgf.m,9Ibf·ltl

(page 19-8)

tighten

the

bolt

tiqht

to

-

13-31

Page 15

FRONT WHEEL/SUSPENSION/STEERING

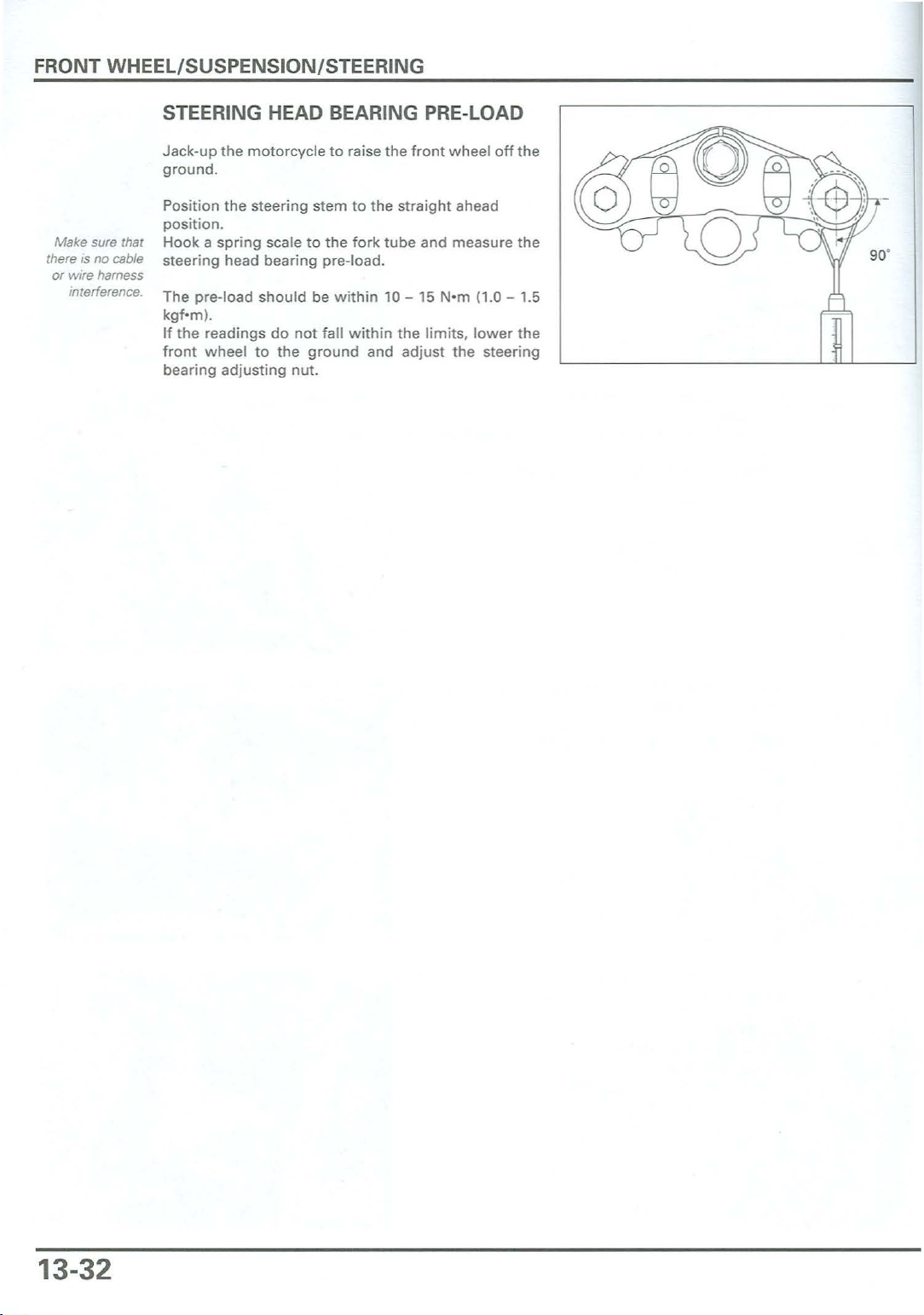

STEERING HEAD BEARING PRE-LOAD

Make sure that

no cable

there is

or wire harness

interference.

Jack-up

g

Positi on th e stee

posi

Hook

steering

The pre

kqf

If

front

bearing

the

motorcycle to raise th e

rou

nd.

ring

stemtothe

tion

.

a sp ring scaletothe fo rk tube and

head bearing pre

-load

-m ),

the

readingsdonot

wheel

adj

usting

shouldbewithin

to the

nut.

gro

-load

fall

und

front

w heel offthe

straig

ht ahead

measure

,

10 - 15 Nom (1.0 - 1.5

withinthe

and

limits.

adjust

the

lower

stee

the

the

ring

13-32

Page 16

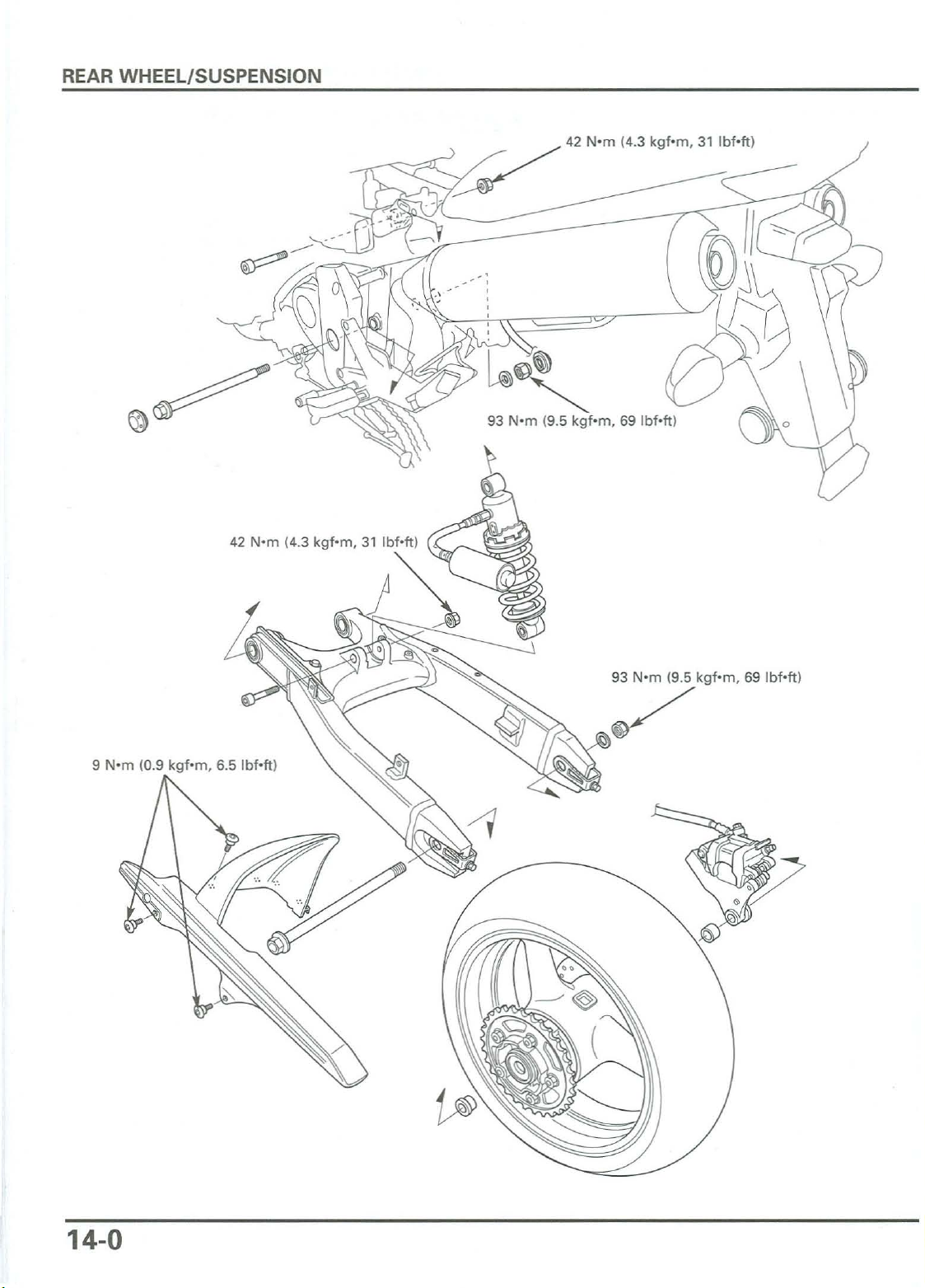

REAR WHEEL/SUSPENSION

____

-<::-~

~

42 Nom (4.3 kqf-m, 31 IbfO"ft).-

...-fYCI

9 Nom (0.9 kgfom, 6.5 lbf-ft)

93 Nom (9.5 kqf-rn , 69 lbf-ft)

~

/

14-0

Page 17

14.

REAR

WHEEL/SUSPENSION

SERVICE INFORMATION

TROUBLESHOOTING

REAR WHEEL

14-1

14-2

14-3

SHOCK ABSORBER

SWINGARM

SERVICE INFORMATION

GENERAL

A contaminated brake disc or pad reduces s

withahigh

After

The shock

Before disposalofthe shock abso rber, release the nit

When

Use only tires marked "TUBELESS·and tubeless valves on rims marked "TUBELESS TIRE APPLICABLE:'

Use

genu

Refer to section 15

quality

the rear wheel insta llat

abso

servicing the rear

ine Honda replaceme nt

brake degreasing a

rber contains nitrogen

whee

for

brake sys

ion

. check

l and suspens

bolts

tem

information.

topp

gent

.

the

brake o

und

er high pres

ion,support

and

nuts

ing power. Discard con

perationbyapplying

sur

roge

for

all suspens

e. Do not a

n (page 14-13).

the

motorcycle

ion

llow

pivot

tam

inated pads and clean a contaminated disc

the brake pedal.

fire or heat near

usingasafety

and

mount

stand or

ingpoint

the

shockabso

hoist

.

14

-10

14-14

rber.

.

SPECIFICATIONS

Minimum

Cold tire pressure Driver

Axlerunout

Wheelrim

Wh

Drive c

tir

e tread depth

runout

eel balanceweight

hain

Dr

Radial

Axial

Sizellink DID DID525VM2-112LE

Slack 25 - 35 (1 - 1-3/8)

Unit:mm

ITEM STANDARD SERVICE LIMIT

only

iver

and passenge r

--

290 kPa (2.90 kgf/em' , 42 psi)

290 kPa (2.90 kgf/em', 42 psi)

--

- -

--

--

2.0 (0.08)

--

--

0.2 (0.01)

2.0 (0.08)

2.0 (0.08)

50g (2.1oz)max.

--

RK

RKGB525R

Ol

1-112LE

--

--

(in)

14-1

Page 18

REAR WHEEL/SUSPENSI

TORQUEVALUES

ON

Rear brake disc

Final driven sprocket nut

Rear axle nut

Rear shock absorber mounting nut

Drive chain slider flange bolt

Swingarm pivot nut

bolt

TOOLS

Bearing

Bearing remover head, 20

Driver

Attachment, 32 X 35

Attachment, 42 X 47

Attachment

Attachment, 37 X 40

Attachment,

Pilot. 17

Pilot, 20

Pilot, 28

Attachment,

Bearing remover hand le

Bearing remover head

Remover we ight

Outer driver, 37

TROUBLESHOOTI

remov

, 52 X 55

22 X 24

mm

mm

mm

28 X 30

er shaft

mm

mm

mm

mm

mm

mm

mm

mm

NG

42 Nom (4.3 kqf-rn, 31 lbf-ft}

108 Nom (11.0 kqf-rn, 80 lbf-tt)

93 Nom (9.5 kg10m, 69 lbf-ft )

42 Nom (4.3 kglom, 31

kqf

9 Nom (0.9

93 Nom (9.5 kqf-rn , 69

07GGD-0010100

0774EHl050600

07749-0010000

0

774EHlOl0l00

0774EHlO10300

0774EHlOl0400

0774EHlOl0 200

0774EHlOl0800

0774EHl040400

0774EHl040500

0774EHl041100

07

94607936-3710100

07936-371060 0

07741-0010201

D-M

07ZM

-rn, 6.5 lbf-ft)

1870100

BW0200

Ibl

lbf

olt)

-ft)

Al

o e bolt: replace

U-nut

If-nut

U-nut

AlO

e bolt: replace with a

If-n ut

withanew

new

one

one

Soft

suspension

Weak shock abso rber

Incorrect suspension adjustment

Oil leakage from

Insufficient tire pressure

Hard suspension

Incorrect suspension adjustment

Damaged rear suspension pivot bearings

Bent

damper

Incorrect swingarm pivot fasteners tightening

Tire pressure too high

Rear w heel

Bent rim

Wornordamaged

Faulty rear tire

Unbalanced rear tire and

Insufficient rear tire pressure

Faulty swingarm pivot bearings

Rear

whee

Faulty rear w hee l bearings

Bent rear axle

Rear brake drag

Drive chain too tight

rod

wobbl

l turns hard

damper

ing

rear

spring

unit

wheel

wheel

bearings

Rear suspension noise

Faulty rear shock absorber

loose

rear suspension fasteners

Worn rear suspension pivot bearings

14-2

Page 19

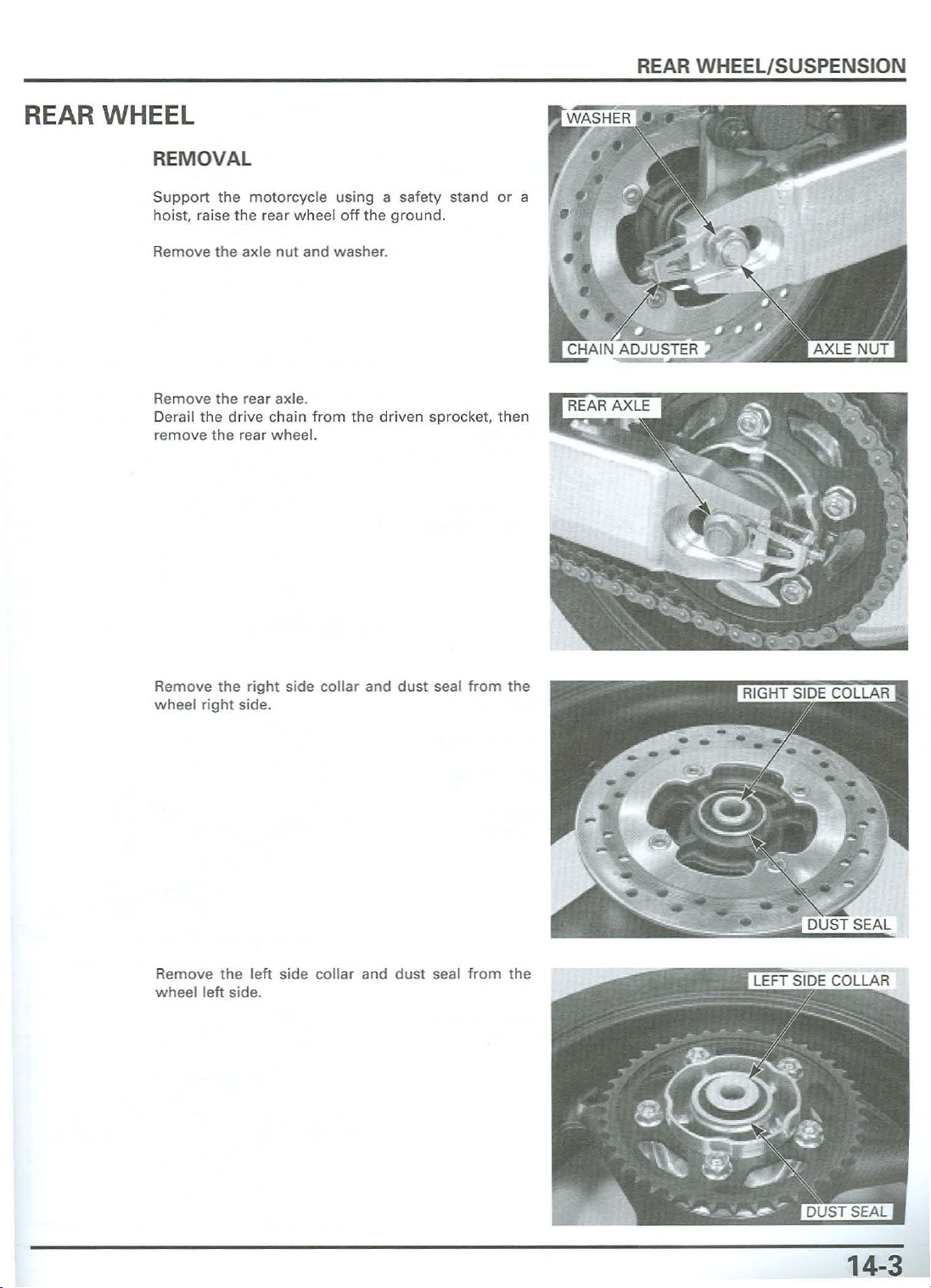

REAR WH EEL

REM

Supp

hoist, raise the rear

OVAL

ort

themotorcycle using a safety stand or a

whe

el off the ground.

REAR WHE

EL/

SUSPENSION

Remove

Remove

Derail thedrive chain

remove the rear w heel.

Remove the right side collar and

wheelright

the

the

axle

nut

rear axle .

side.

and

washe

from

thedriven sprocket,

r.

then

dust

seal

from

the

Remove the

wheel left side.

left

side collar and dust seal f

rom

the

14-3

Page 20

REAR WHEEL/SUSPENSION

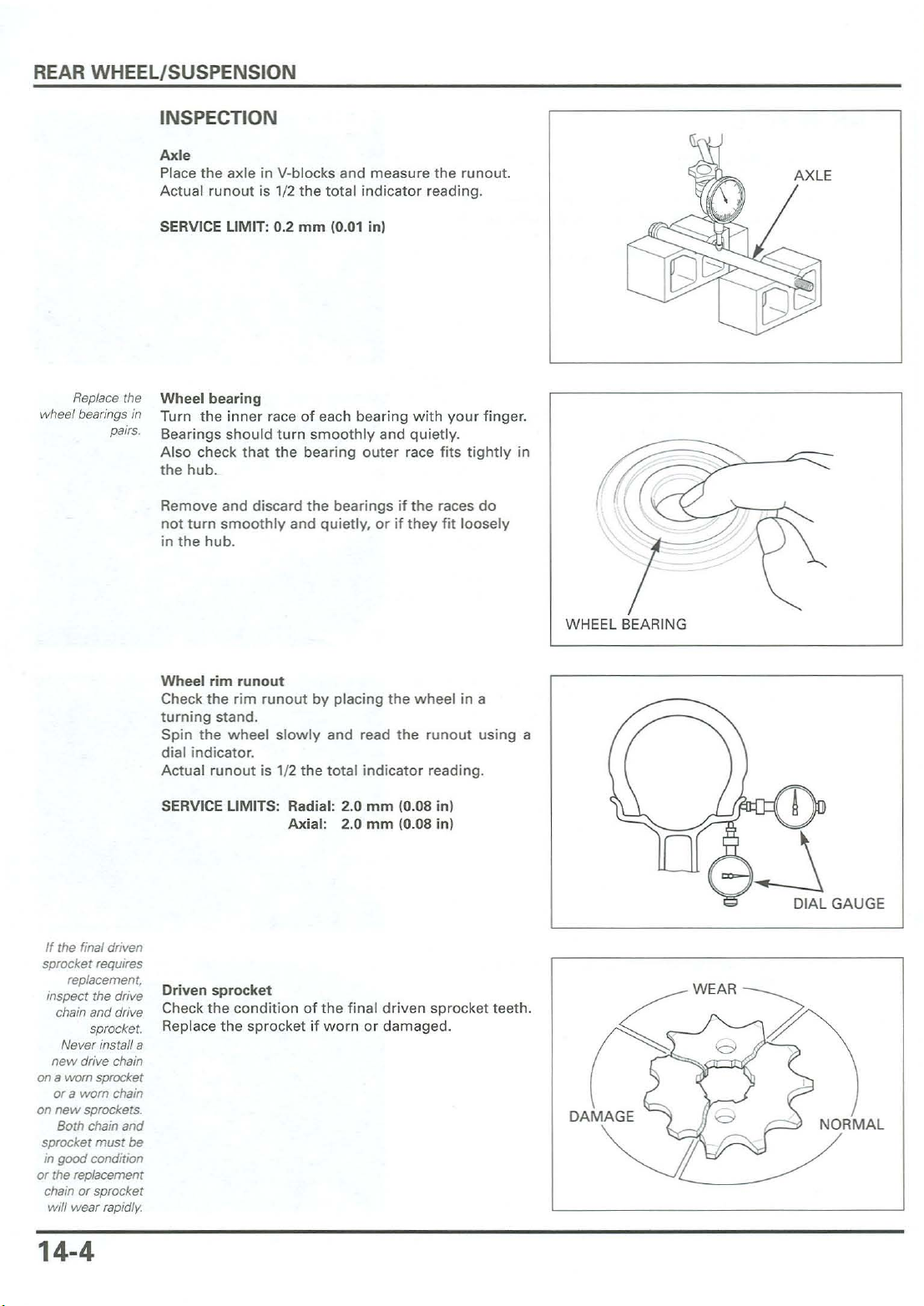

INSPECTION

Axle

Place the axle in V-blocks and measure the

Act

ual run out is 1/2 the

tota

l indicatorreading.

runo

ut.

Replace the

wheel bearings

pairs.

SERVICE LIMIT: 0.2

Wheel

in

bearing

Turn

the

inn

Be

arings

should turn smoo

Also check t hat

the hu b.

Remove and discard the bearings

not

turn smooth ly and quiet ly, or if they fit

in the

hub

.

Wheelrim

Check

turn ing stand.

Spin

dial indica

Actual runout is 1/2 the total indicator reading.

runout

the

rimrunout

the

w heel slowly and read the run out using a

tor

mm

10.01

in)

er raceofeach bearing

thl

y and qu

the

bearing oute r race

by pla cing th e wheel in a

.

if the races do

withyour

ietly

.

fit

s t i

loosely

finger

ghtl

.

y in

WHEEL BEARING

the final driven

If

sprocket requires

replacement

inspect the drive

chain and drive

sprocket.

N

ever

install a

new

driv

ona

on

sprocket

in

or the replacement

chain

will

e chain

Il\Iom

sprocket

or a worn chain

new

sprockets.

Both

chain

and

must

good

orsprocket

wearrapidly.

be

condition

14-4

SERVICE LIMITS: Radial: 2.0

Axial: 2.0

Driven

Check

sprocket

the

con

ditionof

Replace the sprocket

the final d

if

wornordamage

mm

10.08in )

mm

10.08 in)

riv

en sprocket teeth.

DIAL GAUGE

d.

(i

DAM

~R

W

'

:~

M

AL

Page 21

DISASSEMBLY

REAR WHEEL/SUSPE NSION

If you will be

disassembling the

driven flange.

loosen the driven

sprocket nuts

before removing

the driven flange

from the

wheel

hub.

Remove

Remove

wheel

hub

the

bolts

the

drivenflange

.

and brake disc.

assemblyfrom

the

left

Remove the

Remove

Driven

Loosen the

Remove the driven flange f

r

emove

Remove the

the

flange

the

wheel

Ocrinq.

bearing

driven

driven

driven

damper

removal

sprocket nuts.

sprocket

flange

rubbers

bearing and colla r.

.

rom

the w heel hub, then

nuts

and sprocket.

14

-5

Page 22

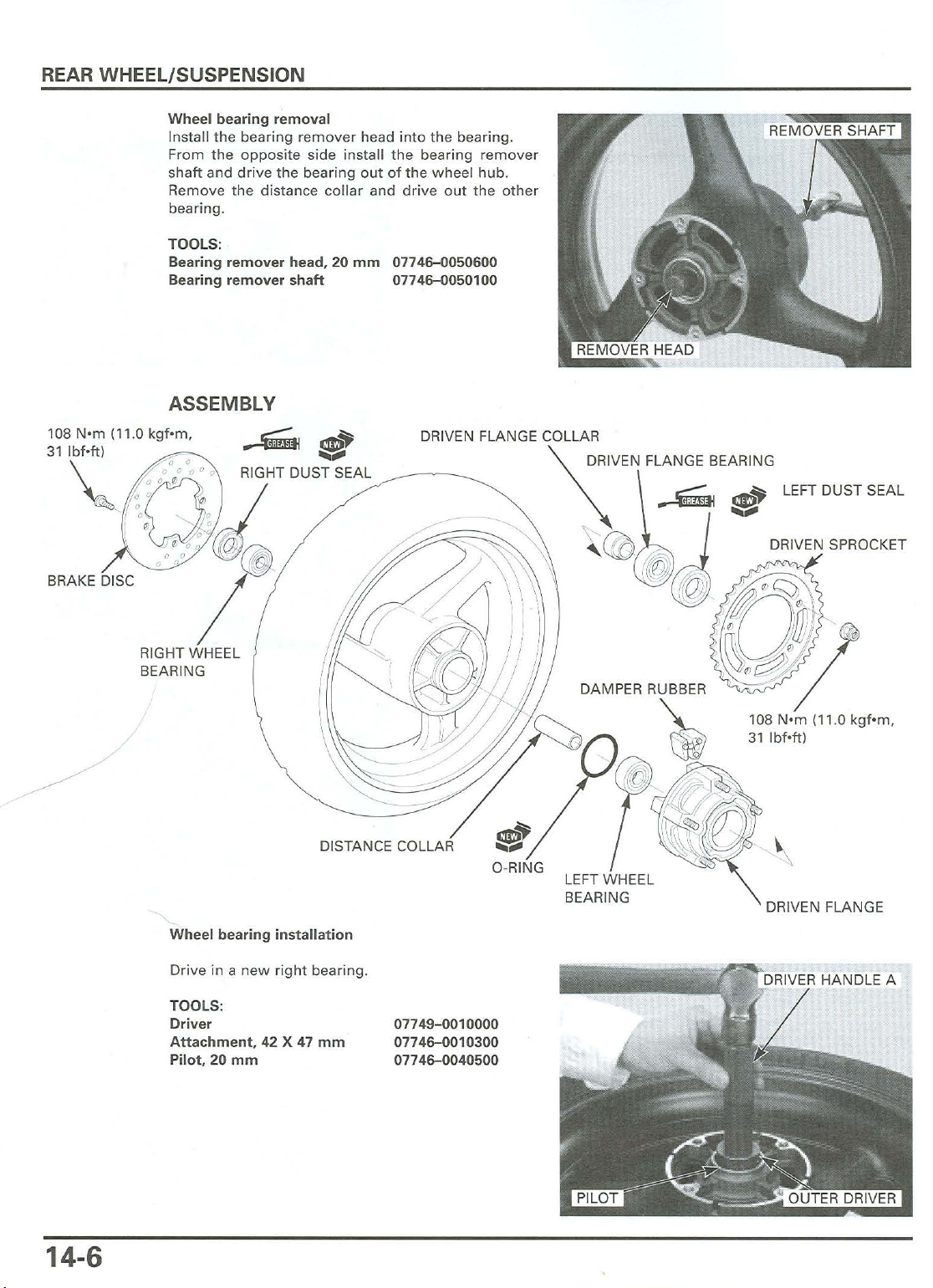

REAR WHEEL/SUSPENSION

Wheel bearing removal

Install the bearing remover head into the bearing.

From the opposite side install the bearing remover

shaft and drive the bearing out of the wheel hub.

Remove the distance collar and drive out the other

bearing .

TOOLS:

Bearing remover head, 20

Bearing

remover

shaft

ASSEMBLY

108 Nom (11.0 kqf-rn.

31 Ibfoftl

-,

mm

07746-0050600

07746-0050100

DRIVEN SPROCKET

BRAKE DISC

DISTANCE COLLAR

Wheel bearing installation

Drive in a new right bearing .

TOOLS:

Driver

Attachment,

Pilot,20mm

42 X 47

mm

07749-0010000

07746-0010300

07746-0040500

~

S

O-RING

LEFT WHEEL

BEARING

DRIVEN FLANGE

14-6

Page 23

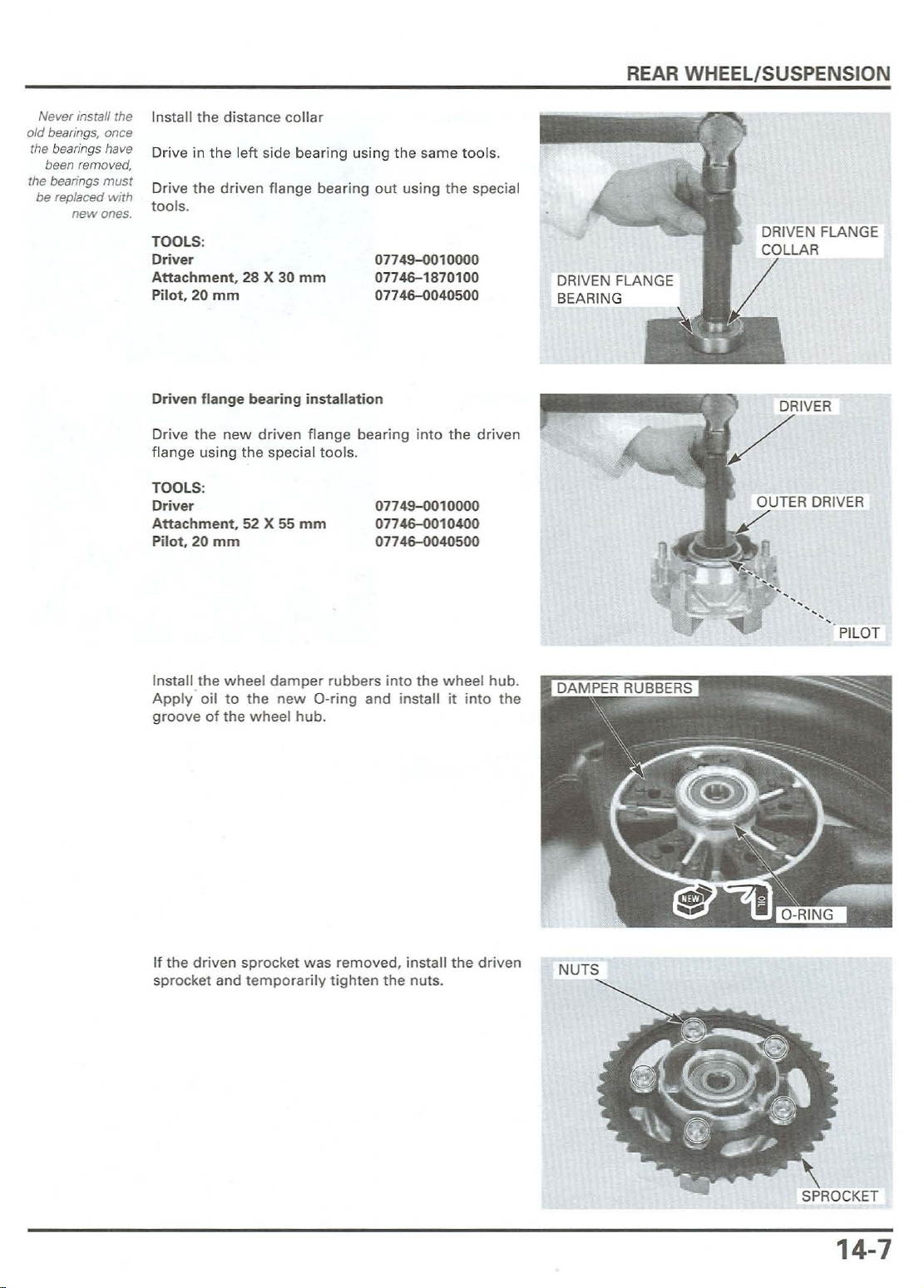

REAR WHEEL/SUSPENSION

Never install the

old bearings, once

the bearings have

been removed,

the bearings

be replaced

must

with

newones.

Install

the

Driv

dista nce

e in t he l

eft

side

colla

bear

r

ing using

the

same

too

ls.

Drive the driven flange bearing out using the special

too

ls.

TOOLS:

Driver

Attachment. 28 X 30 mm

Pilot, 20

Driven flangebearing

Drive t he

flange using th e spec ial

TOOLS:

Driver

mm

new

installat

driven flange

Attachmen1.52 X 55 mm

Pilot . 20

mm

too

0774~010000

07746-1870100

07746-0040500

ion

bearinginto

ls.

0774~010000

07746-0010400

07746-0040500

the

driven

OUTER DRIVER

the

Install

Apply

wheel

'

oil

to the

groove of the

If

the

driven

sprocket

and

damper

new

whee

l hub.

sprocket

temporarily

rubbe

rs into

the

O-ring and install it

wasremoved,

tighten

the

insta

nuts

wheel

ll the

.

into

driven

hub

the

PILOT

.

SPROCKET

14

-7

Page 24

REAR WHE

EL/

SUSPENSION

Install the d

wheel

TORQUE: 108

Install the brake

facing

Install and

to

rque.

TORQUE: 42 N·m

hub

out

riven

.

N'

.

tig

flange

assembly

m 111.0kgf·m. 80 Ibf·ft)

disc

with

its

hten the

14.

3 k

new

gf.m.

into the left

rotating

boltstothe

31 Ibf·ft)

direction

specified

mark

WHEEL BALANCE

The

wheel

remounted

For

optimum

dot

on the s

stem

. Rem ount the

Note

the

tire .

balance

.

ide

rotatingdirection

must

balance, the

wall)

must

tire

be checked w hen the tire is

tire

balance

be located

if necessary.

marks on

mark(apaint

nexttothe

the

wheel

valve

and

BALANCE

MARK

14-8

ROTATING DIRECTION MARKS

Page 25

Mount

the

wheel,tire

inspection stand.

Spin

the

wheel,

est(heaviest)

Do

this

twoorthree

the

wheel

If

the

same

To balance

l

ightest

Add

stopinthe

Do

sideofrim,

just

not

add

enough

allow

partofthe

is balanced, it

position

the

same

more

wheel,

.

weightsothe

posit

than

INSTALLATION

Apply

right

grease and

side.

install

and

brake disc

it to stop, and

wheel

w ith chalk.

timestoverify

will

not

install

balance

the

side

opposite

wheel

ion

when

it is

60 9 (2.1 oz)tothe

the

new

assembly

mark

the

heaviest

stop

consistently

weightsonthe

the chalk marks.

willnolonger

spun.

rear

dust

seal to

the

wheel.

the

REAR WHEEL/SUSPENSION

on an

low-

area.

in

Apply

grease and

install

the

dust

seal to

the

left

side.

/

Apply

grease to the side collars inside and grooves.

Install

the

side

collars

.

14-9

Page 26

REAR

WHEEL/SUSPENSION

Install the rear brake caliper bracket onto the guide of

the swingarm.

Be careful

damage the brake

not

pads.

to

Place the rear wheel into the swingarm.

Install the drive chain over the driven sprocket.

Install the rear axle from the left side.

Install the washer and axle nut.

Adjust

thedrive chain slack (page 3-10).

Tighten the axle nut to the specified torque .

TORQU E: 93

N'm

(9.5 kq

f-m,69lb

f-ft]

SHOCK ABSORBER

REMOVAL

Remove

Remove the side cover (page 2-2).

Secure the motorcycle using a hoist or an equivalent.

Loosen the shock absorber reservoir band screw and

remove the reservoir from the inner fender.

the

seat (page 2-21.

14-10

BAND

SCREW

Page 27

REAR

WHEEL/

SUSPENSION

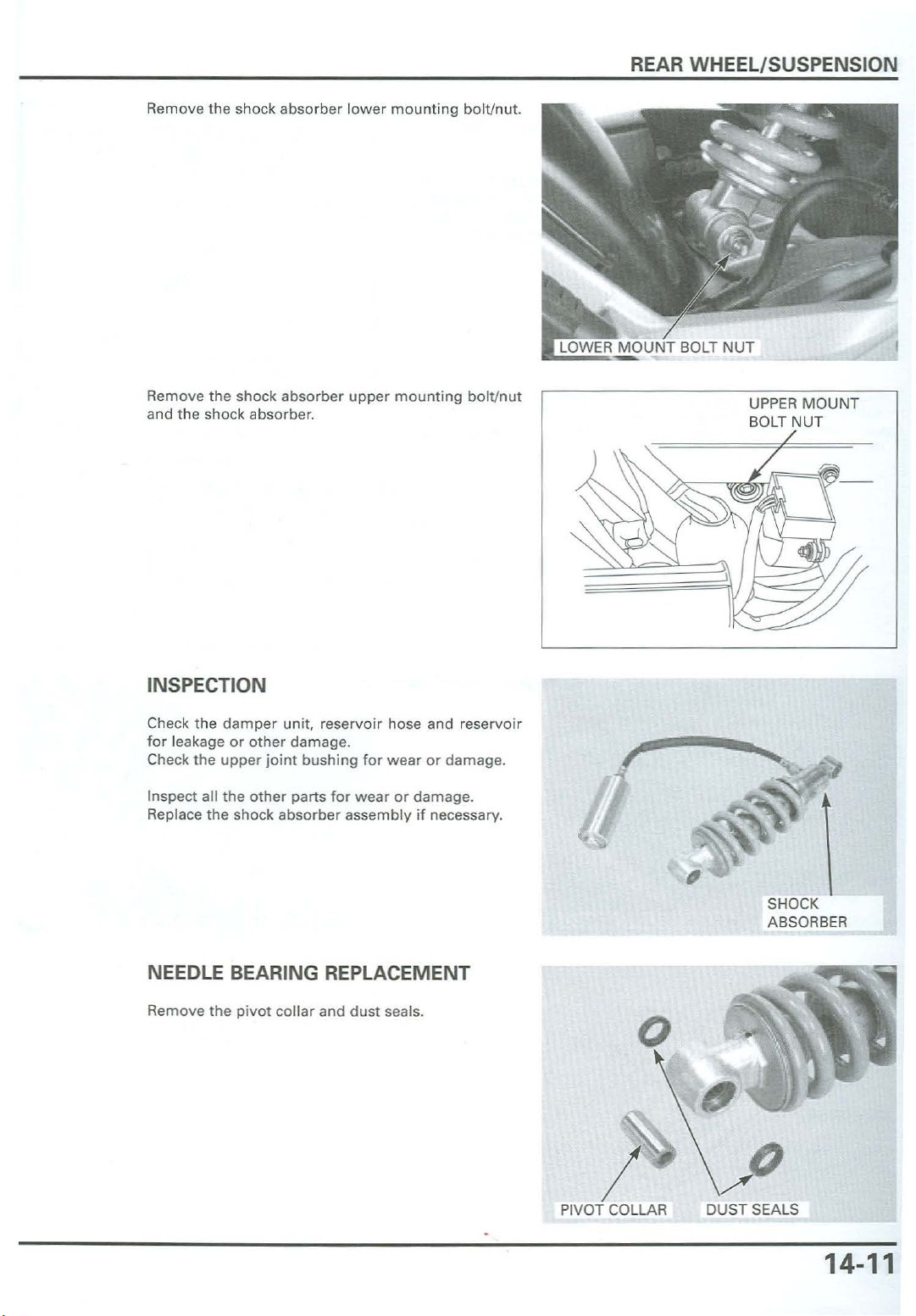

Remove the shock abso rber

Remove the shock

and

the

shock absorber.

absorber

lower

mou

nting

uppermounting

bolt/nut.

bol

t/nut

UPPER

BOLT NUT

MOUN

T

INSPECTION

Check the

for

Check the

Inspect all the

Replace the shock

NEEDLE BEARING REPLACEMENT

Remove the

damper

leakage or

upper

unit, reservoir hose and reservoir

other

other

pivot

damage

joint

parts

absorber

collar

.

bushing

for

wearordamage

for

wear

or damage.

assembly if necessary.

and

dust

seals.

.

r

\

/

SHOCK

ABSORBER

(J

SEALS

o

I

PIVOT COLLAR

"

DUST

14

-11

Page 28

REAR

WHEEL/SUSPE NSION

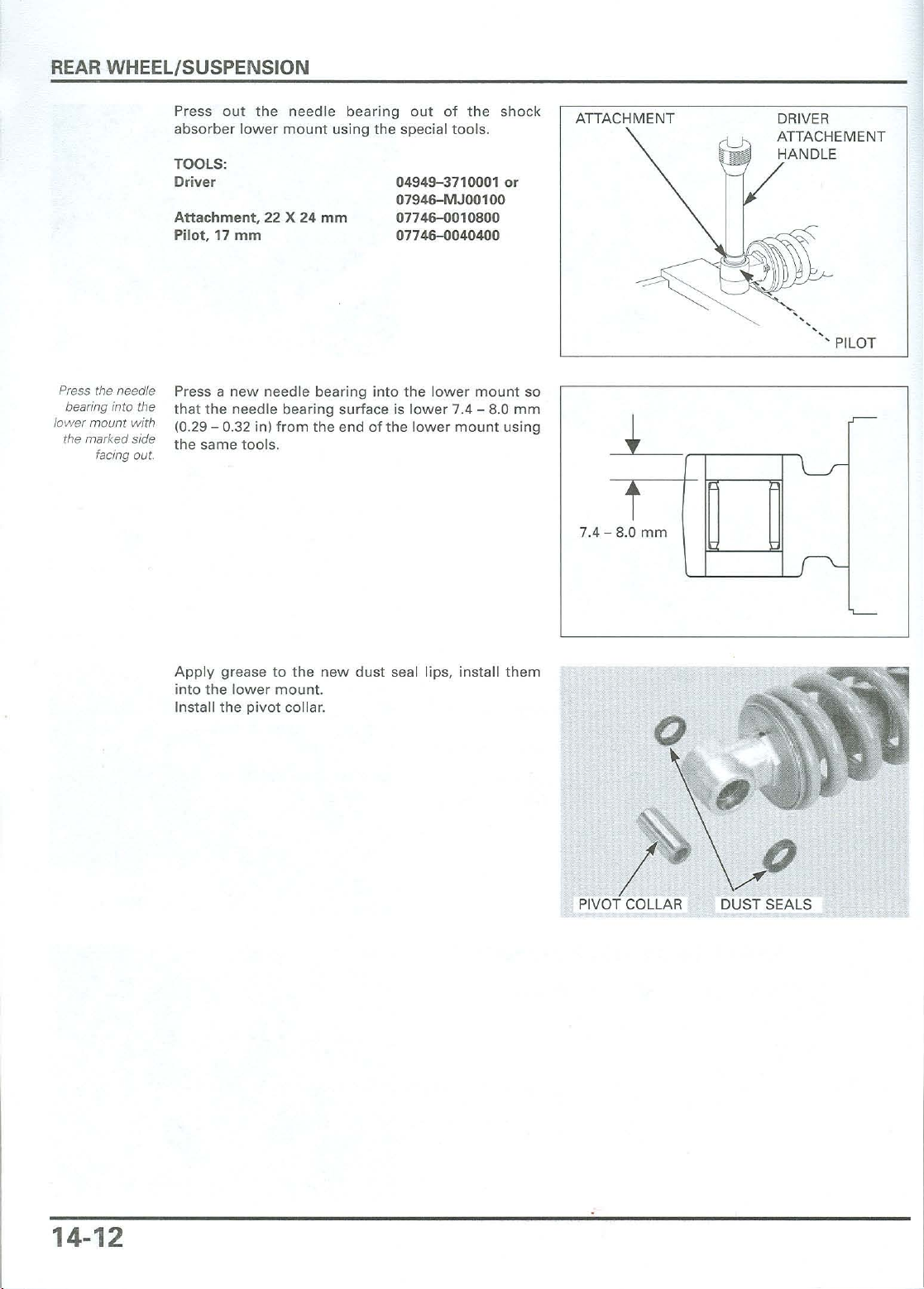

Press the needle

bearing into the

lower mount with

the marked side

facing out.

Press out the

absorber

TOOLS:

Driver

Atta

chment, 22 X 24 mm

Pilot, 17

Press a new needle bearing into the lower

that the needle bearing surface is lower 7.4 - 8.0

10.29- 0.32 in)

the s

mm

ame

needle

lower

mount using the special tools .

from

tools.

bearing out of the shock

the

endofthe

04949-3710001 or

0794

6-MJ00100

07746-00

07746-0040400

lower

10800

mount

mount

so

mm

using

ATTACHM ENT DRIVER

ATTACHEMENT

HANDL

,

...........

7.4 - 8.0

mm

E

PILOT

Apply grease to the

into the lower

Install

the

pivot

mount

collar

new

dust seal lips, install

.

.

them

o

/ D

DUST SEALS

14-12

Page 29

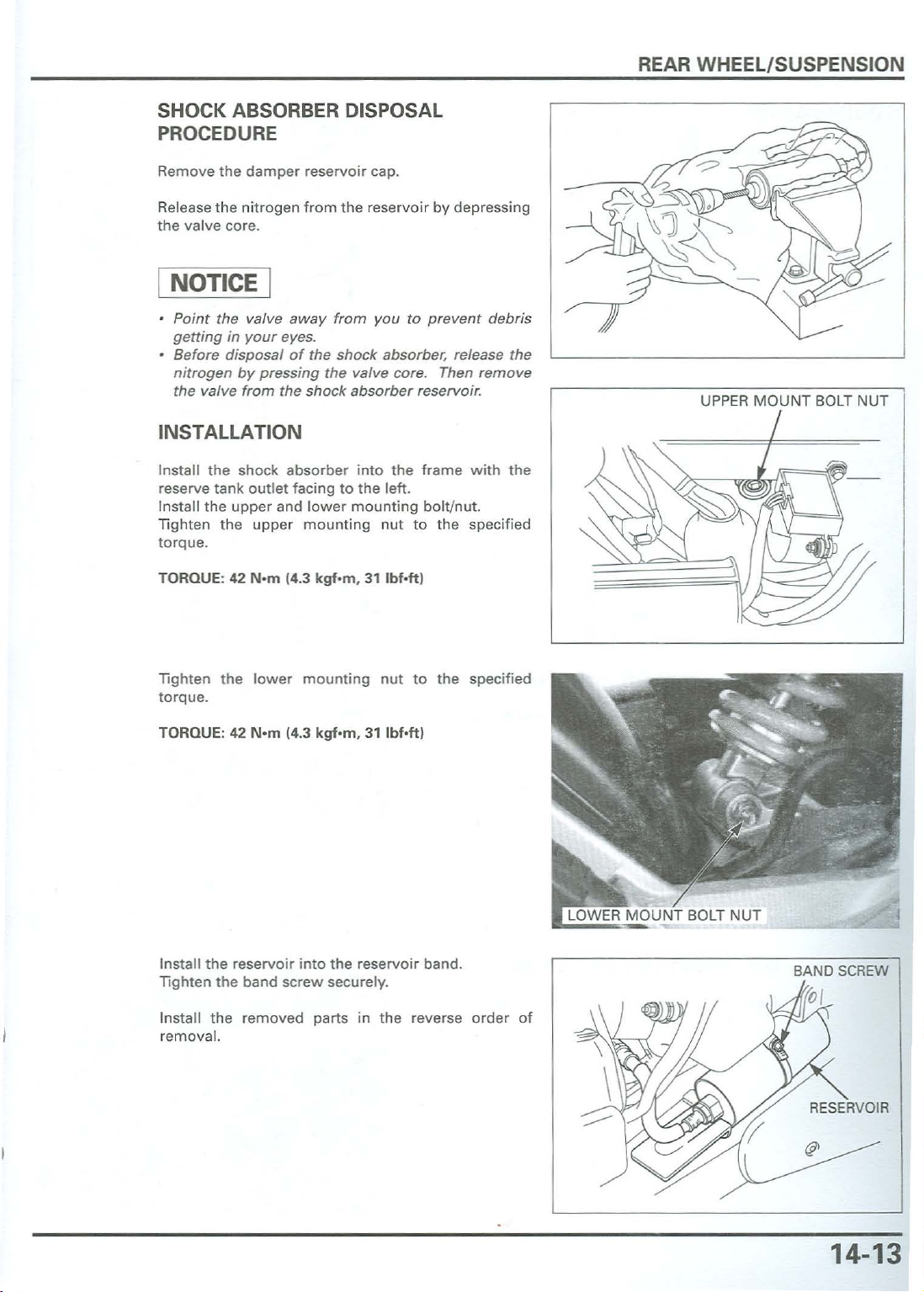

SHOCK ABSORBER DISPOSAL

PROCEDURE

REAR WHEEL/SUSPENSION

Remove the da

Release the nitrogen

the valve

I

NOTICE

Po

int

g

ett

ing in your eyes.

Before

core

.

mperreservo

from

ir cap.

the res

ervoir

I

the

valveaway

dispo

salofthe shock absorber, release th e

fro m you to

by depressing

pre

vent

nitrogenbypressing the valve core. Then remove

the

valvefrom

the shock

absorber

res

ervoir

.

INSTALLATION

Install

the

shock absorbe r int o

reserve tan k

Install the upper and

Ti

ght

en the upper

torqu

e.

TORQUE: 42

outlet

N'm

14.3

facing to the left.

lowermounting

mount

kqf-m,

ing

nut

31

the

frame with

bolt/n ut.

to the spe

Ibf

·ftl

debris

the

cified

UPPER

MOUNT

BOLT NUT

Tighten the low er

mountingnut

to

the specifi ed

to rque.

TORQUE: 42 Nsm 14.3

Insta ll

the

rese

rvo

ten the

Tigh

Install the removed parts in the reverse order of

removal.

band screwsecur

kgf'm,

31

lbf-ft}

ir intothe reservoir band.

ely

.

BAND SCREW

14-13

Page 30

REAR WHEEL/SUSPENSION

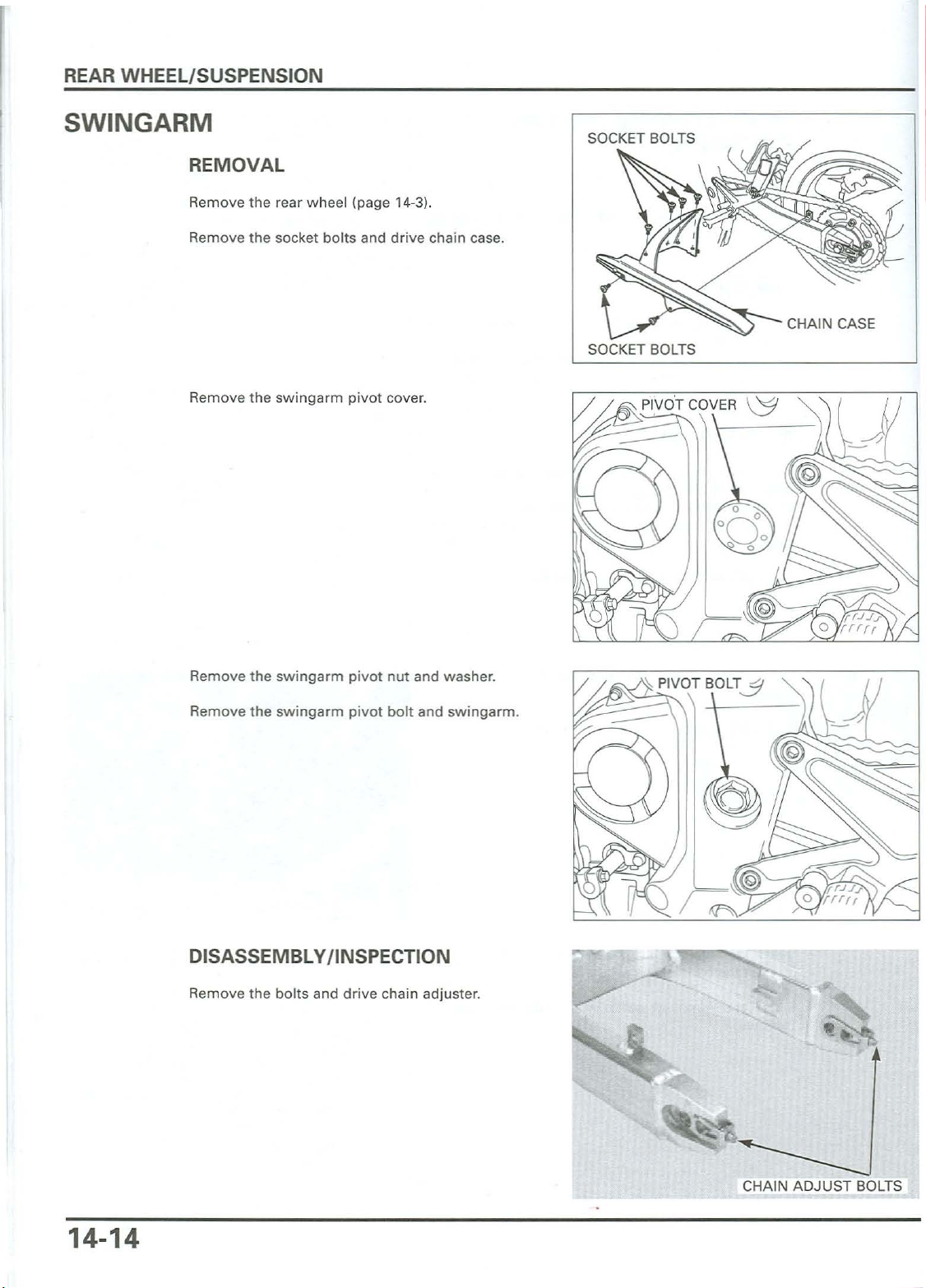

SWINGARM

REMOVAL

Remove the rear wh eel (page 14-31.

Remove the socket bolts and drive chain case.

Remove the swingarm pivot cover.

CHAIN CASE

SOCKET BOLTS

Remove the swingarm pivot nut and was her.

Remove the swingarm pivot bolt and swingarm.

DISASSEMBLY/ INSPECTION

Remove the bolts and drive chain adjuster.

14-14

~

CHAIN

ADJUST

BOLTS

Page 31

REAR WHEEL/SUSPENSION

Remove the

Check the

Remove

swinga

Check

fatigue .

the

rm left

the

bolts

drive

dust

chain

pivot

pivot

seals and

and

.

drive

slider

collar

chain slider.

for

wearordamage

and

dust

collars

seals

for

from

damage

CHAIN SLIDER -

.

the

or

-~

DUST SEALS ·

BOLT

o

p

Turn

the

inner raceofright

finger

that

.

smoothly

.

the

should

bearing

and

quietly,orifthey

your

The bearings

check

hub

Remove and discard the bearings if the races do

turn

pivot.

turn

pivot

smooth

outer

bearings w ith

ly and quietly. Also

race

fits

tightlyinthe

fit

looselyinthe

not

SIDE COLLARS

\

DISTANCE COLLAR

14

-15

Page 32

REAR WHEEL/SUSPENSION

P

IVOT

BEARING REPLACE

MENT

LEFT

PI

DISTANCE

COLLAR

DUST SEAL

(28x 37 x 41

VOT NEEDLE BEARING

~~;;:;:;;;:;:;iiC

Remove the snap ring.

=if

!-

DUST SEAL

-

(28x 37 x 4)

SIDE COLLAR

DUST SEAL

(27 x 34 x 4)

RIGHT PIVOT BEARING (20

x 37 x 91

DUST SEAL

(28x 37 x 4)

SNAP RING

14-16

Remove the right pivot radial ball bearing using the

special tools .

TOOLS:

Bearing remover handle

Bearing remover shaft set, 20mm

Removerweight

07936-3710100

07936-3710600

07741-ll010201

Page 33

REAR

WHEEL/SUSPENSION

Press the

cial

tools

and a hydraulic press.

TOOLS:

Driver

Attachment

Pi

lot

, 28

mm

ASSEMBLY

NEEDLE BEARING

left

pivot

, 32 X 35

DUST SEAL

needle

mm

COLLAR

bear

ing

out using the spe-

07949-3710001

07746-001000

07746-0041

BALL BEARINGS

1

100

COLLAR DUST SEAL

l'

~~""

""

SWING ARM

DRIVER

OUTER

DRIVER

PILOT

ousr

CHAIN SUDER

Press the needle

bearing into the

pivot

with

marked side

the

facing out.

ssxt,

~

\a:

~

Pack

Press

until

press.

TOOLS:

Driver

Attachment.37mm

Pilot, 28

COLLAR

the

new

the

needle

it seats using

mm

BOLTS

need le bearing w ith grease.

bea

ring

the

into th e

specia l

swingar

tools

andahydra

07749-0010000

07ZMD-MBW0200

07746-0041100

,/

CHAIN ADJUSTER

m left pivot

ulic

OUTER

DRIVER

14-17

Page 34

REAR WHEEL/SUSPENSION

Press the radial ball bearing in using the special too ls

and a hydraulic press.

TOOLS:

Driver

Attac

hment

, 32 X 35

P

ilot,20mm

Install the snap ring into the groove securely.

mm

0774~010000

0774lHlOl0l00

0774lHl040500

OUT

ER

DRIVER

PILOT

Apply

grease to the

seals into the left swingarm pivot.

Fill the grease up between the inner dust seal and

need le bearing.

Install the pivot distance colla r.

Apply grease to the dust seal lips, then install the dust

seals and pivot collar into the right swingarm pivot.

Install the bolts and drive chain adjusters.

dust

seal lips,

then

install the

dust

SIDE COLLARS

p

DISTANCE COLLAR

"

14-18

Page 35

REAR WHEEL/SU SPENSION

Install t he

boss on

Install the

swingarm

Install and t

ing

TORQUE: 9 Nsm (0.9

drive

the

swingarm

drive

.

igh

boltstothe

chain

chain

ten

specified

the

slider

.

slider

new

torque

kqf-rn,

, a

lign

ing

bosses into

drive

chain s

6.5 Ib

f.f

tl

theslitwith

the

hole

lider

mount-

the

in the

~~

;trZBOLT

INSTALLATION

Apply

a

thin

coatofgrease to theswingarm

slid

ing

surface.

Insta ll

the

swingarmonto

Install

theswi

swingarm

Install and

ified

to rque.

TORQU E: 93

Install

the

pivot.

tighten

N'm

pivot

ngarm

theswinga rm

(9.5

bolt

the

frame.

pivot

bolt

kqf-m,69Ibf.ftl

collar

.

to

pivot

pivot

the

frame

nuttothe

bolt

and

spec-

14-19

Page 36

REAR WHEEL/SUSPENSION

Install the socket bolts and drive chain case.

Install th e rear w heel (page 14-9),

CHAIN CASE

SOCKET BOLTS

14-20

Page 37

HYDRAULIC BRAKE

FRO

NT:

15-0

(3 1 kqf-m, 22 lbf-ft)30 Nom .

Page 38

15. HYDRAULIC BRAKE

SERVICE INFORMATION

TROUBLESHOOTING

BRAKE

AIR BLEEDING

BRAKE PAD/DISC

REAR:

flUID

REPLACEMENT/

15-2

15-3

15-4

15-7

FRONT MASTER CYLINDER

REAR MASTER CYLINDER

FRONT BRAKE CALIPER

REAR BRAKE CALIPER

BRAKE PEDAL

10 Nem (1.0 kqf-rn, 7

lbf

15-10

15-15

15-19

15-23

15-26

-ft)

10 N-m (1.0 kqf-rn, 7 lbf-ft l

~

? o.s kqf-rn,

c-:

.f . .

"'"'"'"

15-1

Page 39

HYDRAULIC BRAKE

SERVICE INFORMATION

GENERAL

A

CAUTION

Frequent inhalation of brake pad dust, regardless of material composition could be hazardous to your health.

Avoid breathing dust particles.

• Never use an air hose or brush to clean brake assemblies. Use an OSHA-approved vacuum cleaner.

A contaminated brake disc or pad reduces stopping power. Discard contaminated pads and clean a contam inated discwith

a high quality brake digreasing agent.

Check the brake syste m by appl ying

Spilled brake fluid w ill severely damage instrument lenses and painted surfaces. It is also harmful to some rubber parts. Be

careful whenever you remove the reservoir cap; make sure the front reservoir is horizontal first.

Never allow contaminates (dirt, water,

Once the hydraulic system has been opened, or if the brake feels spongy, the system must be bled.

Always use fresh DOT

as they may not be compatible .

Always check brake operation before riding the moto rcycle.

4 brake fluid from a sealed container when servicing the system. Do not mix different types of fluid

the

brake lever or pedal after the air bleeding .

etc.) to get into an open reservoir.

SPECIFICATIONS

ITEM STANDARD SERVICE LIMIT

Front Specified brake fluid DOT 4

Brake disc thickness

Brake disc runout

Master cylinder I.D.

Master piston O.D. 13.957 - 13.984 10.5495 - 0.5506) 13.945 (0.5490)

Caliper cylinder I.D. A 30.230 - 30.280 11.1902 - 1.1921)

B

Caliper piston 0 .0 . A

B

Rear Specifie d brake fluid DOT 4

Brake disc thickness

Brake disc runout

Master cylinder 1.0. 12.700 - 12.743 (0.49999

Master piston 0 .0 . 12.657 - 12.684 10.4983 - 0.4994) 12.645 10.49781

Caliper cylinder I.D. 38.180 - 38.230

Caliper piston O.D. 38.098 - 38.148 11.4999 - 1.5019) 38.09 (1

4.3 - 4.7 10.17 - 0

14.000

27.000 - 27.050 (1.0630 - 1.0650) 27.06 (1.065)

30.148 - 30.198 (1.1869 - 1.1889) 30.14 (1.18

26.918 - 26.968 (1.0598 - 1.0617) 26.91 (1.059)

4.8 - 5.2 (0.19 - 0.20) 4.0 (0.16)

-14.04310

Unit

: mm (in)

--

.191

- -

.5512 - 0.5529) 14.055 (0.5533)

3.5 10

.141

0.310.012)

30.29 11.193)

--

0.30 (0.012)

38.24

11.5061

.5001

11

.053 - 1

- -

-0

.5017) 12.755 10.5022)

.5051

71

15-2

Page 40

TORQUE VALUES

Front

mastercylinder

Brake lever pivot

Brake lever pivot nut

Front bra ke light switch screw

Front

maste

r cylinder mou nting bolt

Front brake caliper

Front brake caliper

Rear

maste

r cylinder joint

Rear

master

Rear brake caliper bolt

Rear brake

cylinder

caliper

reservoir cap screw

bolt

assembly

mounting

nut

mounting

pin

bolt

Pad pin

Pad pin plug

Brake hose oil bolt

Brake caliper bleeder valve

mount

Footpeg brac ket

Rear

master

cylinde r hose joint sc

ing bolt

TOOL

torx bolt

flange bolt

bolt

rew

1 Nom (0.1 kqf-rn, 0.7 lbf-ft]

1 Nom (0.1 kgfom, 0.7

lbf-

ft]

6 Nom (0.6 kqf-rn, 4.3 lbf-ft)

1 Nom 10.1 kqf-m, 0.7 lb

f-ft

12 Nom (1.2 kqf-m, 9 lbf-tt)

32 Nom (3.3 kqf-rn, 24 Ibf°ft)

30 Nom (3.1

kqf-rn, 22 lbf-ft)

17 Nom (1.7 kqf-m, 12 lbf-ft)

10 Nom (1.0 kqf-m, 7

23 Nom (2.3 kqf-m, 17

Ibf

lbt

-ft)

-tt)

27 Nom (2.8 kqf-rn, 20 lbf-ft)

17 Nom (1.7 kqf-m, 12

3 Nom (0.3 kqf-rn, 2.2

lbf

lbf

-ft)

-ft)

34 Nom (3.5 kgfom, 25 lbf-tt l

6 Nom (0.6 kqf-rn . 4.3 lbf- ft )

27Nom12.7 kgfom, 2.0 lbf-ft)

1 Nom (0.1 kgfom, 0.7 lbf-ft)

HYDRAULIC BRAKE

]

Appl

y a lock ing agent to

ALOC bolt

the

thr

eads

Snap ring pliers

TROUBLESHOOTING

Brake lever/ pedal soft or spongy

Air in hydraulic system

Leaking hyd raulic system

Contaminated brake pad/disc

Worn caliper piston seal

master

Worn

Worn brake pad/disc

Contaminated ca

Caliper not sl

Low brake fluid level

Clogged fluid passage

Warped/defor med brake disc

Sticki

ng/

Sticking

Contaminated

Bent brake

Brake leve

Clogged/restricted brake system

Sticking

Caliper

Clogged/restricted fl uid passage

Worn caliper piston seal

Sticking

Bent brake

cylinder piston cups

liper

iding

prope

worn

caliper piston

/worn

mas

ter

maste

r cylinder

lever

/pedal

r/pedal

/wo

notsliding

/worn

hard

rn calipe r piston

proper ly (rear)

maste r cylinder piston

lever

/pedal

rly (rear)

cylinder piston

07914

-SA

50001

Brake

drags

Con

taminated

ligned

Misa

Clogged/restricted brake hose joint

Warped

Cal

iper

Clogged/restricted brake hydraulic system

Sticking/w orn calipe r piston

Clogged

wheel

/defo

rmed

not

sliding

mast

er cyl inder po rt

brake pad/disc

brake

disc

properly

(rear)

15-3

Page 41

HYDRAULIC

BRAKE

BRAKE FLUID REPLACEMENT

BLEEDING

I NOTICE I

• Do

not

all

ow fo

reign

material

when

filli

ng the reservoir.

•

Avoid

spilling

part

s. Place a rag

system is serviced.

BRAKE

For the

voir is parallel to the

reservoir ca p.

Remove

Remove the

fron

thescrew

FLUID

t brake,

diaphrag

fluid

on

painted,plas

over

these

DRAINING

turn

the handlebar until the reser-

ground

, before removing the

s and reservoir cap.

m plate and diap

/AIR

to enter the

tic,orrubber

parts

whenever

hragm

system

.

the

SCREWS

\

PLATE/

DIAPHRAGM

=

(0~

I

CAP

the

Remove

Remove th e diaphrag m plate and

reservoir cap.

diap

RESERVOIR CAP

hragm.

15-4

Page 42

HYDRAULIC BRAKE

Connect

Loosen

pedal.

Stop

pumping

flows

a bleed hose to

the

bleed

the

outofthe

bleed valve.

valve

lever

the

caliper

and

pump

or pedal

bleed

valve

the

brake

lever

whennomore

.

or

fluid

Check the fluid

leve!

often

while

bleeding the

brakes to

pum

prevent

air from being

ped

into the

system.

If

air is entering

the bleeder from

around the bleed

valve threads,

seal the threads

with teflon tape.

BRAKE FLUID FILLING/BLEEDING

Close

the

bleed valve.

Fill

the

reservoir

container

.

NOTE:

Use

only

Do

not

compatible

Connectacommercially

the

bleed

Pump

the

adding

der

When

turers

Repeat

do

Close

fluid

reservoirislow

using

operating

the

not

appearinthe

the

or pedal.

If it still feels

with

DOT 4 brake

mix

different

.

valve

.

brake

bleeder

when

a brake

instructions.

previous

bleed

valve

spongy,

DOT 4 brake

fluid

from

typesoffluid.They

available

and loosen

the

fluid

level in

.

bleeding

step

tool,

procedures

plastic hose.

and

operate

bleed

the

system

fluid

from

a sealed

brake

the

the

master

follow

until

the

brake

again.

bleeder

bleed

the

air

a sealed

container

are

not

valve,

cylin-

manfac-

bubbles

lever

.

to

15-5

Page 43

HYDRAULIC BRAKE

If a brake bleeder is not available, use the following

procedure.

Pump up the system pressure with the lever or pedal

until lever or pedal resistance is felt.

Do not release

the brake lever or

pedal until the

bleed valve has

been closed.

Connect a bleed hose to

system as follows:

1.Squeeze the brake lever or depress the brake pedal,

open the bleed valve 1/2 turn and then close

2. Release the brake lever or pedal until the bleed

valve has been closed.

Repeat steps 1 and 2 until bubbles cease to appear in

the fluid coming out of the bleed valve.

the

bleed valve and bleed the

it.

Tighten the bleed valve .

N·m

(0.6

kqf-m,

4.3

TORQUE: 6

Fill the fluid reservoir to the upper level.

Reinstall the

diaphragm

and

IbHt)

diaphragm

plate. PLATE/DIAPHRAGM

UPPERLEVEL

15-6

On the front brake, install the reservoir cap, and tighten the screws to the specified torque.

TORQUE: 2

On the rear brake, install the reservoir cap securely,

N'm

(0.2

kqf-m

, 1.4

Ibf·ftl

REAR FRONT

RESERVOIR

CAP

SCREWS

Page 44

BRAKE PAD/DISC

Al

ways

the brakepads in

replace

paris to assure

disc pressure.

FRONT BRAKE PAD REPLACEMENT

Remove the pad pin

even

plug

HYDRAULIC BRAKE

.

Check the brake

fluid level in the

brake master

cylinder reservoir

as this operation

causes the level

to rise.

Loosen th e pad pin s.

Remove the bolts and brake caliper.

Push the cali per pis

installation of n

Remove the pad pin and pad spring.

Remove

the

tons

ew

brake pads.

brake pads.

all the

way

in to allow

Inst

all the

Ins

tall

shown

new

brake pads.

the

pad spr ing w ith its ar

.

row

mark facing up as

15-7

Page 45

HYDRAULIC

BRAKE

Push

the

pad sp

ring

, th en

install

the

pad

pin

.

Tighten

TORQUE : 17 Nom

Install and t

TORQUE: 3 Nom 10.3 kgfom ,

the

pad

pin

.

11.7 kgfom , 12 Ibfof1)

ighten

the

pad

pin

plug.

2.2 Ibfof1)

Always

the brake pads

Check the brake

cylinder reservoir

as this operation

replace

paris to assure

even disc

pressure.

fluid level in the

brake ma

ster

causes the leve'

to rise.

REAR

in

Push

BRAKE

the

caliper

PAD REPLACEMENT

pistons

all

the

wayinby

caliper body inwa rd to allow installation of

pads.

the

Remove

pad pin plug.

pus

hing

new

the

brake

15-8

Page 46

HYDRAULIC BRAKE

Remove

Remove

Pivot the calipe r up.

Remove

Install

the

the

the

the

new

pad pin.

caliper

pad

pin

brakepads

bracket

bolt

.

and brake pads.

.

Make sure the

brake pad spring

is in place.

Low er

the

cal

iperwhile

springsothat

pad

the retainer on

Install

the

pad

the

tighten

pad pin.

Install and

TORQUE: 23 N'm12.3

Tighten

TORQUE: 17 N

the pad

the

cal

pin

.

the caliper bracket bo lt.

'm

11.7 kqf-rn, 12

pushing

ipe

r bracket.

kqf-m,17Ibf·h)

ends

the

are

Ibf·h

pads

posi

l

agai

tio

nst

ned on

• •

the

to

15-9

Page 47

HYDRAULIC BRAKE

Install and tighten the pad pin plug.

N·m

(0.3

kgf.m

. 2.2

Ibf

TORQUE: 3

·ft)

BRAKE DISC INSPECTION

Visually

Measure the brake disc thickness with a micrometer.

SERVICELIMITS:

Replace the brake disc if th e sma

less than the service

inspect th e bra ke disc

FRONT: 3.5

REAR: 4.0

mm

mm

(0.14 in)

(0.16 in)

lim

it.

for

damageorcracks.

llest

meas

ure

ment

,.. PAD PIN PLUG

is

Measure

SERVICELIMITS:

Check

warpage

disc if the wheel bearings are

the

brake

FRONT: 0.30

REAR: 0.30

the

wheel

exceeds

disc

wa rpage

mm

10.012 in)

mm

10.012 in)

bearing s for excessive play. If

the

service

FRONT MASTER CYLINDER

REMOVAL

Avoid spilling fluid

on painted, plas-

tic, orrubber

parts. Place a rag

over these parts

whenever the

system is

setvicea.

Drain th e front hydraulic system (page 15-4).

Disc

onn

ect

the

brak

e light

swi

Remove the brake hose

oil

bolt, sealing

brake hose eye let.

limit.

nor

tch

wit

h a dial in

replace

mal.

wire

dicator

the

brake

connectors.

washers

.

the

and

15-10

.

~

...

£ IL BOLT

Page 48

HYDRAULIC BRAKE

Remove the bolts from the master cylinder holder and

remove the master cylinder assembly.

DISASSEMBLY

Remove the pivot bolt/nut and brake lever assembly.

MA

STER CYLNDER

HOLDER

PIVOT BOLT

Remove the screw and brake light switch.

Remove the boot.

BRAKE LEVERASSEMBLY PIVOT NUT

SCREW

BRAKE LIGHT SWITCH

<.

PISTON BOOT

15-11

Page 49

HYDRAULIC BRAKE

Remove the snap ring from the maste r cylinder body

using the special tool as shown .

TOOL:

Snap ring pliers

Remove the master piston and spring.

Clean the inside of the cylinder and reservoir with

brake flu id.

07914-SA50001

SNAP RING

.>

PRIMARY CUP /

PISTON CUP

SNAP RING PLIERS

I

SPRING

MASTER

PISTON

SNAP

RING

I

cf

INSPECTION

Check the piston boot, primary cup and secondary

cup for fatigue or damage.

Check the maste r cylinder and piston for abnormal

scratches.

Measure the master cylinderJ.D.

SERVICE LIMIT: 14.055 mm (0.5533 in)

Measure the master cylinder piston

SERVICE LIMIT: 13.945 mm (0.5490 inl

0.

0.

15-12

Page 50

HYDRAULIC BRAKE

ASSEMBL

MAS

TER PISTON 0.7 lbf-ft )

Y

SPRING

I

PRIMARY CUP ;

1 Nem (0.1 kqf-rn.

_____

RESERVOIR CAP

SET PLATE

DIAPHRAGM

PIVOT

BRAKE LEVERASSEMBLY

BRAKE LIGHT SW ITCH

Keep the piston.

cups, spring, snap

ring and

set;

boot

do nor substi-

tute

individual

parts.

When instaffing

the cups, do not

allow

the lips to

turn inside

Be certain the

snap ring

is firmly

seared in the

groove.

as a

out

Coat all parts

Dip the p

Install the

Install

the

Insta ll the snap

TOOL:

Snap ring pliers 07914-SA50001

iston

spring

piston

with

clean brake

in brake

into

the p

assemblyinto

ring

.

flu

id.

iston

fluid

.

the

before as

master

sembly

cyl

inde

.

SPRING

1

r.

PRIMARY CAP

--,

~

_

//

_

1

-:

MASTER PISTON

SNA

SNAP

RING

P RING

PLIERS

15-13

Page 51

HYDRAULIC BRAKE

Apply silicon grease to the boot inside.

Install the

boot

.

- §

:00

Install th e brake light

the specified torque.

TORQUE: 1 Nom 10.1 kgfom. 0.7 Ibfoft)

Apply silicone grease to the contact surfaces of the

brake lever and piston tip.

switc

h and ti

ght

en the sc

rew

~.~t;f···}J;

- -

to

.

\9

..-._",0

-'

""""-

-

SCREW

-

PIVOT BOLT

Install the brake lever assembly, tighten the pivot bolt

to the specified torque .

TORQUE: 1 Nom 10.1 kgfom. 0.7 Ibfoft)

Hold the

specified torque.

TORQUE: 6 Nom 10.6 kgfom. 4.3

pivot

bolt and tig hten the

Ibf·ftl

pivot

nut to th e

I

BRAKE LEVER ASSEMBLY

~PI

VOTNUT

15-14

Page 52

HYDRAULIC BRAKE

Place the master cylinder assembly on the handlebar.

Align the end of the master cylinder with the punch

mark on the handlebar.

Install the master cylinder holder with the "UP" mark

facing up.

Tighten the

specified torque .

TORQUE: 12

Install the brake hose eyelet with the oil bolt and

sealing washers.

Push the eyelet joint against the stopper, then tighten

the oil bolt to the specified torque.

TORQUE: 34 N·m(3.5

Connect the brake light switch wire connectors.

Fill the reservoir to the upper level and bleed the

brake

system

upper

bolt

N·m

(1.2

(page 15-4).

first,

kqf-m,

kqf-m,

then

9 Ibfoft)

25 Ibfoft)

the

lower

bolt

to the

new

MASTER CYLINDER

HOLDER

SEALING

WASHERS

REAR MASTER CYLINDER

REMOVAL

Avoid spilling fluid

on painted, plas-

tic. or rubber

parts. Place

over these parts

whenever the

a rag

system is

serviced.

Drain the rear

Disconnect the brake light switch 2P connector.

Remove the rear master cylinder reservoir mounting

bolt/nut

Remove the brake hose oil bolt, sealing washers and

brake hose.

Loosen the rear master cylinder mounting bolts.

Remove the socket bolts and footpeg bracket

assembly.

.

hydraulic

system (page

15-41

RESERVOIR

.

SWITCH CONNECTOR

15-15

Page 53

HYDRAULIC BRAKE

Remove

Remove

Remove

guard

DISASSEMBLY

Disconnect

joint.

Remove

master

and

the

the

and

master

the

cylinder

discard

joint

master

the

screw

pin .

reservoir

.

the

cylinder

cylinder

and

brake pedal

mounting

.

hose

from

reservoir

the

hose

joint

reservoir

joint

cotte r pin.

bolts,

step

hose

from

the

RESERVOIR

JOINT

Remove

Remove

using

TOOL:

Snap ring pliers

Remove

spring

Clean

the

the

the

special

the

.

the

insideofthe

boot.

snap

push

ring

from

the

toolasshown

rod,

master

cyl

inder

master

.

07914-SA50001

piston,

w ith brake

cylinder

primary

cup and

fluid

body

.

BOOT

SNAP RING

SPRING

-.

~

SNAP RINGPLIERS

I

,

J

'

,,,8'\

15-16

#'(

PUSH ROD Assy.

\

MAST

ER PITON

Page 54

INSPECTION

HYDRAULIC BRAKE

RESERVOIR CAP

PLATE

DIAPHRAG M

Check the

cup

Check the

scratches.

Measure

SERVICE LIMIT: 12.755

Measure the

SERVICE LIM IT: 12.645 mm 10.4978 in)

for

piston

fatigue

master

the

boot,primary

or damage.

cylinder

master

mas

ter

and

cylinder1.0.

mm

10.5022 inl

cylinder p

cup and

piston

iston0.0

ASSEMBLY

RESERVOIR JOINT

PUSH ROD

secondary

for

.

~A

e

abnormal

Ii

O·RING

I

MAS

TER CYLIND ER

Keep the piston. Coat all parts w ith clean brake

cups, spring. snap

ring and boot as a

set; do not substi·

tute individual

parts.

When installing

the cups. do

alfow the lips to

turn inside out.

not

thepiston

Dip

Install the

Install

assembly

App

ly si

push rod.

the

.

licone

in brake

spring

to the

spring

grease to the

fluid

primary

/primary

J

.

cup

piston

fluid

cup .

before

and

contact

assemb

master

areaofthe

LOWER

piston

JOINT

ly.

~

1 Nom 10.1

kqf

lbf-ftl

MAS

-rn, 0.7

TER PISTON

--

- MASTER PISTON

- SECONDARY CUP

e--

.

----S

SNAP RING

OOT

15-17

Page 55

HYDRAULIC BRAKE

Be certain the

snap ring is firmly

seared in the

groov

Install the push rod into the

Install the snap ring .

TOOL:

e.

Snap ring pliers

App

ly silicone grease to the boot inside.

Install the

Apply brake fluid to a new O

the reservoir joint.

Install the reservoir joint into the maste r cylinder.

boo

t.

maste

r cylinder.

07914-SA50001

·rin

g and install it onto

SNAP RING

PLIERS

/

SNAP RING

RESERVOIR HOSE JOINT

/

Install and tighten the screw securely.

Connect the reservoir hose to the reservoir joint.

II the push rod is disassembled, adj ust the push rod

length as shown .

After adjustme nt. tighten th e lock nut to the specified

torque.

TORQUE: 17 Nom

11.7

kglom, 12 Ibfoft)

LOCK NUT LOWER JO NT

15-18

67.5

mm12.66 in)

Page 56

INSTALLATION

HYDRAULIC BRAKE

Place the

bracket, install the

Connect the brake peda l to the push rod low er joint.

Install th e jo int pin and secure

Install the

en the socket

TORQUE: 27 Nom (2.8

li

ghten

specified to rque.

TORQUE: 10 Nom (1.0 kgfom, 7 Ibfo

Install the brake hose

ing w ashers .

Push th e eyelet join t aga

the oil bolt to the specified torqu e.

dr

the

master

iver

bolts

mas

cyl

inder

onto

the main f

master

footpeg

ter cyli

cylinder

it

with

bracket o

to the specified torque.

kqf-m

nder

with

inst

nto

, 20 Ibfoft l

moun

ft)

the oil bolt and new seal-

the s

top

oot

mounting

a new

the frame.

bolts.

cotter

tig

ting bolts to th e

per, then tig hten

peg

pin.

ht-

TORQUE: 34 Nom (3.5 k

Install

bolt/nut to the specified

TORQUE: 10 Nom (1.0

Connect

Fill the reservoi rtothe

brake sys

andtighte

the

brake

tem

(page 15-4).

n the brake reservoirmou nting

lightswit

FRONT BRAKE CALIPER

REMOVAL

Drain

Avoid spilling fluid

on painted, otes-

tic, or rubber

parts. Place a rag

over these parts

whenever the

system is

serviced.

thefront

Remove th e oil bolt. seali ng w ashers and brake hose

eyelet j

R

Remove the brake pads (page 15-7).

oint

emove

brake

.

the cali per

hydraulicsystem

mountingbolt

gf

om, 25 Ibfoftl

torque

.

kqf-rn, 7 Ibfoftl

ch 2P (Black)

uppe

r level

s and cali per.

connector

and

ble

ed th e

(page 15-41.

RESERVOIR SWITCH CONNECTOR

.

15-19

Page 57

HYDRAULIC BRAKE

DISASSEMBLY

Do not use high

pressure

bring the nozzle

too close to the

81f or

inlet.

Install

betw een the pistons.

Apply

remove

Remove

the

corrugated

small

the

caliper

squirtsofair

pistons

the

fourcaliper

halves

.

cardboard

pressureto

.

assembly

or

soft

the

bolts

wood

fluid

and

sheet

inlet

to

separate

ASSEMBLY BOLTS

Mark the pistons

toensure

Be careful

correct

reassembly.

not

damage the

piston sliding

surface.

Remove the

-

Joint

- Caliper piston A

- Caliper pis

to

Push the

them

out

Clean th e seal

following:

seals

ton

B

dust

seals and piston seals in and

.

grooves

with

clean brake

fluid

PISTONS

lift

.

15-20

PISTON SEAL

Page 58

HYDRAULIC BRAKE

INSPECTION

kthe

damage.

ure the caliper cylinder 1.0.Meas

SERVICE LI m i1.192 in)

A: 30.29 m (1 065 in)

B: 27.060

other damage.

SERVICE LI

A: 30 .14 m

B: 26.91

. c Iinder for scor

caliper

MITS'

re the caliper piston 0 .0.Measu

MIT

yChec

mm

S'

m i1.1S7 in)

(105

mm

.

.

9

in)

Ingorother

scoring orfor scratches.k the caliper pistonsChec

......~tA

~

... JOINT SEALS

.II

~I

·

e

e

PISTON SEAL

~~

ASSEMBLY

°0

nQ)

JlI)

//

DUST SEAL

I CALIPER PISTON A

~~

[)

I

=-----==

~

CALIPER PISTON B

32 Nom (3.3 kg ' ,

f m 24 lbf-ft]

KE BLEED VALVEBRA

15-21

Page 59

HYDRAULIC BRAKE

Coat the

Coat the new dust seals with silicone grease.

Install the piston and dust seal into the groove of the

calipe r body.

Coat the calipe r pistons w ith clean brake fluid and

install them into the caliper cylinder with their open-

ing ends

Install the

the caliper.

new

piston seals with clean brake fluid.

towa

rd the pad.

new

joint seals into the fluid passages on

PISTON

mble

Asse

Apply

threads.

Install and tighte n the caliper assembly bolts to the

specified to rque.

TORQUE: 32 Nom13.3 kgfom. 24 Ibfoft)

the caliper halves.

a locking agent to

the

caliper assembly

bolt

INSTALLATION

Install the brake pads (page 15-6).

fork

Install the brake caliper onto the

Install and tighten the new caliper mounting bolts to

the specified torque.

TORQUE: 30 Nom13.1 kgfom. 22 Ibfoft)

tall

the brake hose eyelet to the calip er

Ins

two

new sealing washers and the oil bolt.

leg.

body

with

ASSEMBLY BOLTS

SEALING

15-22

Page 60

Push

the

brakehose

caliper,thentightenthe

torque

.

eyelet

to the stopper on

oil bolt to th e spe

cif

HYDRAULIC BRAKE

the

ied

TORQUE: 34 Nsm 13.5

Fill and bleed the

(page 15-4).

front

REAR BRAKE CALIPER

REMOVAL

Drain

the

rear brake

Avoid

spifJing fluid

on painted, plas-

tic. or rubber

parts. Place a rag

over these parts

whenever the

system

is serviced.

Loosen

Remove the rear w heel (page 14-3).

Remo

eyeletjoint

the

caliper bracke t bolt.

ve th e oil b

olt,

.

kgf

.m.

25 Ibfoft)

brake hyd r

hydraulicsystem

sealing

aulicsys

was

hers and brake hose

tem

(page 15-5).

00 not use high

pressure alf or

bring the nozzle

too close to

the

inlet.

DISASSEMBLY

Remove

(page 15

Remove the pad spri ng , co

caliper body.

Remove the cal

Remove th e ret

Place a s

Position th e calipe r

appl

rem

the

caliper bracket

-81

.

ipe

r bod y

from

ainer

from

th e cal

hop

towe

l over the

bod

y w it h the piston downand

y sma ll squirts of air press ure to

ove th e pi

sto

n.

bolt

llar

pisto

and

and

the ca

iperbra

n.

the

brake

bootfrom

liperbra

cket.

the

flui

cket.

d in

pads

the

let

RETAINE R

•

•

•

•

•

•

•

•

to

15-23

Page 61

HYDRAULIC BRAKE

Be careful not to Push the

damage the

piston sfiding Clean the seal grooves w

surface.

dust

seal and pis

INSPECTION

Check the

other

Measure

SERVICE LIMIT: 38.24 mm (1.506 inl

calipercylinder

damage.

the cali per cylin

ton

seal in and lift

ith

clean brake

for

scoring

der

I.D.

them

out

.

fluid

.

or

PISTON SEAL

DUST SEAL

for

Check the calipe r pistons

other

damage.

Measu re the ca

SERVICE LIMIT: 38.09 mm (1.500 in)

liperpiston0.0.

scratches, scoring or

/

/

15-

24

Page 62

ASSEMBLY

BRAKE PADS

PAD PIN PLUG

~

COLLAR - /

BOOT

r-

-.;:

2\

\0

PAD PIN

~~.

......

II

PISTON SEAL

HYDRAU LIC BRAKE

CALIPER PISTON

~

~

,

S~

DUST SEAL

PAD SPRING

CALIPER PIN BOLT

Coat

Coat th e new

Install the pis

the caliper body.

Coat

insta ll

tow

If the ca

orated, repla ce

Ap ply si

boo

Install the bra cket

Install the pad

App

ca liper

the

new

the

caliper piston

it into

ard

the pad.

liperand

lico

t.

ly sil icone

bod

y to

~

/

BRACKET BOLT

pisto

n seal w ith clean brake f

dust

seal w ith silicone grease.

to

n seal

and

dust seal

with

thecalipe

ne greasetothe

retainer

greasetothecaliper

bracket

them

pinboot

the

r c

with

into

bracket.

ylinder

pin

new ones .

luid

.

into

thegroove

clean bra ke fluid and

w ith its opening end

boots are hard or deteri-

insid e of th e bracket pin

and co llar

the bracket.

int

o th e caliper.

pin

and insta ll the

BRACKET

of

~~,

S~

COLLAR

DUST SEAL

PAD

RETAINER

Install

the

Install

the cal

(page 15-BI.

pad spring into the cali

iper

bracket bolt and brake pads

per

bracket.

15-25

Page 63

HYDRAULIC BRAKE

INSTALLATION

Install the wheel (page 14·9).

Install the brake caliper/bracket assembly onto the

guideofthe

Install and tighten the caliper bracket bolt to the spec-

ified torque.

TORQUE: 23 N' m (2.3 kgf' m, 17 Iblott)

swingarm (page 14·10).

Install the brake hose eyelet to the caliper

two new sealing washers and oil bolt.

Push the brake hose eyelet to the stopper on the

caliper, then tighten the oil bolt to the specified

torque.

TORQUE: 34N'm (3.5 kgf· m. 25

Fill and bleed the rear brake hydraulic system

(page 15·4).

BRAKE PEDAL

REMOVAL

Remove the footpeg bracket mounting bolts and

bracket assembly from the frame.

Ibf·ft

body

with

)

15-26

Remove and discard the brake pedal joint cotter pin.

Remove the joint pin.

Unhook the return spring and remove the brake light

switch

from

the step

Unhook

Remove the snap ring and thrust washer.

Remove the brake peda l from the pivot.

the brake pedal return spring .

holder

.

BRAKE LIGHT SWITCH

SWITCH SPRING

MOUNT

SNAP RING/

WASHER

BOLTS

Page 64

HYDRAULIC BRAKE

~

S

COTTER PIN

INSTALLAT

JOIN

T PIN

STOPPER RING

ION

7'

THRUST WAS HER

BRAKE PEDAL

]J

r SWITCH

I .

/

I

~

//

/ '''-'''"--0

~

BRAKE LIGHT

SW

ITCH SPRING

~

2 7

/ kgfom, 20

o

Nom12.7

lbf-ftl

STEP HOLDER BOLT

A

pply

grease to th e slid ing surface of

and footpeg .

Install the brake pedal and

pivot.

Secure the pedal pivot with a snap ring.

Hook the brake pedal return spring.

Install the brake

spring.

Connect the brake pedal to the push rod

Install the joint pin and secure it with a

Install the right driver footpeg bracket assembly onto

the frame .

light

thrust

switch and hook the switch

the

washer

new

brake pedal

to the pedal

lower

joint .

cotter pin.

BRAKE

10 Nom 11.0 kqf-m . 7 lbf-

~

:

O

~

L1

GHT SWITCH

tt

)

THRUST

ASHER

SNAP RING

COTTER PIN/

JOIN

T PIN

15-27

Page 65

HYDRAULIC

BRAKE

Install and tighten the right

bolts to the specified torque.

TORQUE: 27 Nom (2.8 kg/om. 20 Ibfoll)

footp

eg bracket socket

15-28

Page 66

BATTERY/CHARGING SYSTEM

SYSTEM DIAGRAM

AC GENERATOR

BATTERY

8

MA

IN FUSE 130A)

REGULATOR/RECTIFIER

G

il

G G R R

REGULATOR/RECTIFIER

Y Y Y

Y Y Y

16-0

AC GENERATOR

Page 67

16. BATTERY/CHARGING SYSTEM

SYSTEM DIAGRAM

SERVICE INFORMATION

TROUBLESHOOTING

BATTERY

SERVICE INFORMATION

GENERAL

The

battery

cha

rging

The

battery

cloth

ing

- If elect

- If electrol

Electrolyte is

- If swa

immediate

A

lw

ays turn

Som e electr ical co

tionswitch is ON and current is present.

F

or

extended storage,

charge

F

orabattery

The maintenance free

The batte ry can be

ditions

det

erio

Battery

ly die out . F

problems in the

and battery

tio

ns,

the

efore

B

fr

equentl

m

oto

rcycl e.

The

battery

revent

p

When checking the chargi ng

F

or

battery cha

rgin

cha

gives

off

exp

.

contains

and a face sh

rolyte

yte

poisonous

llowed,dri

ly.

off

the

stored

remai

contribute

rates after 2-3years.

voltage

or

this

voltage

elect

rolyte

trou bleshoot ing

y under he

will

sulfat

ion

rging,

g tim e may da

sulfur

ield

getsonyour

gets

in yo ur eyes, flu shwith

.

nk large

the ignition s

mp

onents may be da

remove

battery

to sh

may

battery

self-discharge

from

every

ning

in a

battery

dam

agedifovercha rgedorunderc

ort

recover a

reason,

itself,

does

not

level

the

avy

load, such as ha

occurr

do not exceed t he c

mage

losive

gases; keep sparks. flam es and

ic acid (electrolyte). Contact

.

skin, flush

quantitiesofwateror

witch

beforedisco

the

battery,give

two

weeks

stored

motor

must

be replaced

ening

the"life span"of

fter

battery

the

charging

which

may

increase,

goes

dow

charg

when

ing

system,alwaysfoll

the battery.

n quickly.

ing

.

the

sys

the

16-0

16-1

16-3

CHARGING SYSTEM INSPECTION

ALTERNATOR CHARGING COIL

REGULATOR/RECTIFIER

16-5

A

WARNING

cigarettes

with

skinoreyes m ay cause severe

withwater

mag

.

cycle, disconnect

charg ing, but u

systemisoftensuspectedasthe

appea rtobe an overcharg

reg