Page 1

2005 CB900F

SET-UP

INSTRUCTIONS

Set-up and pre-delivery service

must be performed by an authorized

Honda motorcycle dealer.

©2005 American Honda Motor Co., Inc. - All Rights Reserved

MPD 10969 (0501)

Issued: March 2005

Page 2

IMPORTANCE OF PROPER SET-UP AND PRE-DELIVERY SERVICE

FOR YOUR CUSTOMER'S SAFETY

Proper set-up and pre-delivery service are essential to rider safety and the reliability of the

machine. Any error or oversight made by the technician assembling and servicing a new machine

can result in faulty operation, damage to the machine, or injury to the rider.

WARNING

Improper set-up or pre-delivery service can

create an unsafe condition that can cause

your customer to be seriously hurt or killed.

Follow the procedures and precautions in

this manual and the service manual carefully.

FOR YOUR SAFETY

Some of the most important safety precautions are given below. However, we cannot warn you of

every conceivable hazard that can arise in performing set-up and pre-delivery service. Only you

can decide whether or not you should perform a given task.

WARNING

Failure to properly follow instructions and

precautions can cause you to be seriously

hurt or killed.

Follow the procedures and precautions in this

manual carefully.

IMPORTANT SAFETY PRECAUTIONS

Make sure you have a clear understanding of all basic shop safety practices and that you are

wearing appropriate clothing and safety equipment. When performing the set-up or pre-delivery

service, be especially careful of the following:

• Read the instructions before you begin, and make sure you have the tools and skills required to

perform the tasks safely.

• To prevent the machine from falling on you, park it on a firm, level surface, using the proper

stand(s) to provide firm support.

Make sure the engine is off before you begin any servicing procedures. This will help eliminate

several potential hazards:

• Carbon monoxide poisoning from engine exhaust—be sure there is adequate ventilation

whenever you run the engine.

• Burns from hot parts—let the engine and exhaust system cool before touching.

• Injury from moving parts—do not run the engine unless the instruction tells you to do so.

Even then, keep your hands, fingers, and clothing away.

To reduce the possibility of a fire or explosion, be careful when working around gasoline or

batteries. Use only a nonflammable solvent, not gasoline, to clean parts. Keep all cigarettes,

sparks and flames away from the battery and all fuel-related parts.

©2005 American Honda Motor Co., Inc. - All Rights Reserved i

Page 3

2005 CB900F

How To Use This Manual

Follow the complete sequence of steps as shown. Do not short-cut any steps. The sequence has

been established to ensure the unit is properly assembled.

The individual steps are composed of three components:

• Sub-heading—The large sub-headings are a brief description of the step. They are intended

to be used by the experienced technician, one who only needs a brief reminder of the

set-up sequence.

• Descriptive text—The descriptive text explains in detail what is to be done during that step.

This explanation is intended as a guide for the technician needing additional information.

• Photographs/Line art—The photographs or line art support both the sub-headings and the

detailed text.

Indicates the Set-up section Indicates the Pre-delivery section

Modifications and Accessories

Modifications that you may have made, or should make in the future, to any Honda product, shall

be deemed by our company to have been performed at your sole risk and responsibility, and

without our company's or the manufacturer's approval, or consent, implied or expressed. We

further disclaim any and all liability, obligation, or responsibility for any defects of modified parts

or of the modified product, and for any claims, demands, or causes of action for damage to

property or for personal injuries resulting from the modification of said Honda product.

To r qu e Tab l e

ITEM SIZE TORQUE

Handlebar bolts 8 mm 27 N·m (2.8 kgf·m, 20 lbf-ft)

Handlebar weight 6 mm 10 N·m (1.0 kgf·m, 7 lbf-ft)

Master cylinder holder bolts 6 mm 12 N·m (1.2 kgf·m, 9 lbf-ft)

Clutch lever holder bolts 6 mm 12 N·m (1.2 kgf·m, 9 lbf-ft)

Footpeg socket bolts 8 mm 27 N·m (2.8 kgf·m, 20 lbf-ft)

Rear axle nut -------- 93 N·m (9.5 kgf·m, 69 lbf-ft)

ii ©2005 American Honda Motor Co., Inc. - All Rights Reserved

Page 4

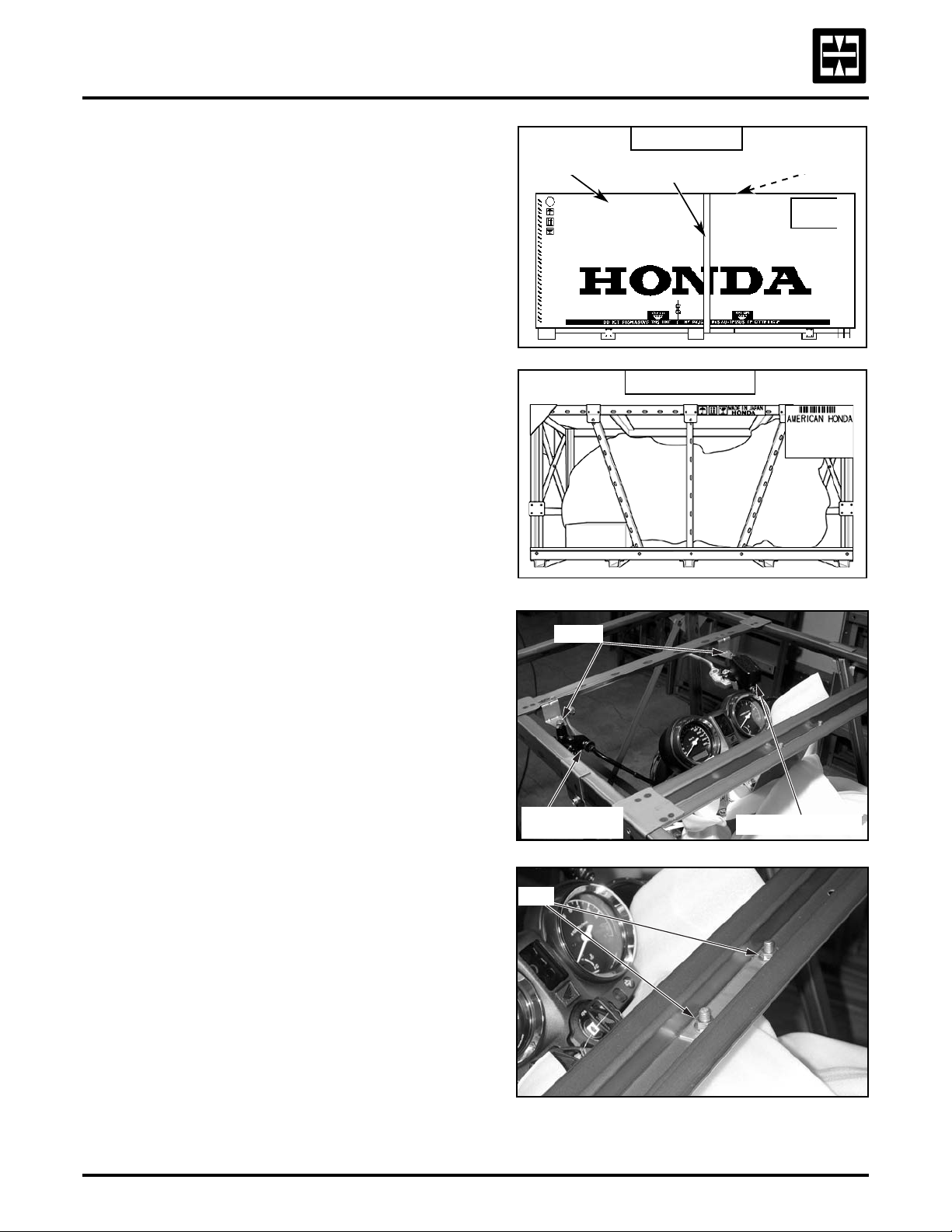

1. Remove the carton cover and check

for damage.

The CB900F is crated at the factory in either a

covered or uncovered crate. You may receive

either one.

Covered crate:

Cut the strap and remove the carton cover.

Remove the cardboard top.

CARTON COVER

COVERED CRATE

STRAP

CARDBOARD TOP

Uncovered crate:

When stacking, protect the motorcycle from

falling objects and bad weather.

Check the motorcycle for hidden damage.

If you find damage, follow the instructions

on the Delivery and Damage Claims

Guidelines wall chart (Reorder No. S0477)

before proceeding.

2. Remove the master cylinder and the

clutch lever assembly.

Remove the bolt and the front brake

master cylinder.

Do not allow the master cylinder to hang by

its hose. The weight of the assembly could

damage the hose.

Remove the bolt and the clutch

lever assembly.

BOLTS

CLUTCH LEVER

ASSEMBLY

UNCOVERED CRATE

MASTER CYLINDER

3. Remove the front shipping brace.

Remove the nuts and the front

shipping brace.

©2005 American Honda Motor Co., Inc. - All Rights Reserved 1

NUT

Page 5

2005 CB900F

4. Remove the crate frame and the

loose parts carton.

Remove the bolts and braces. Using two

people lift off the crate frame, being careful

not to damage the motorcycle.

Cut the strap and remove the loose

parts carton.

Keep the You and Your Motorcycle - Riding

Tips & Practice Guide booklet separate and

hand-deliver to the customer at the time

of delivery.

PARTS

CARTON

STRAP

BOLTS

BOLTS

BRACES

2 ©2005 American Honda Motor Co., Inc. - All Rights Reserved

Page 6

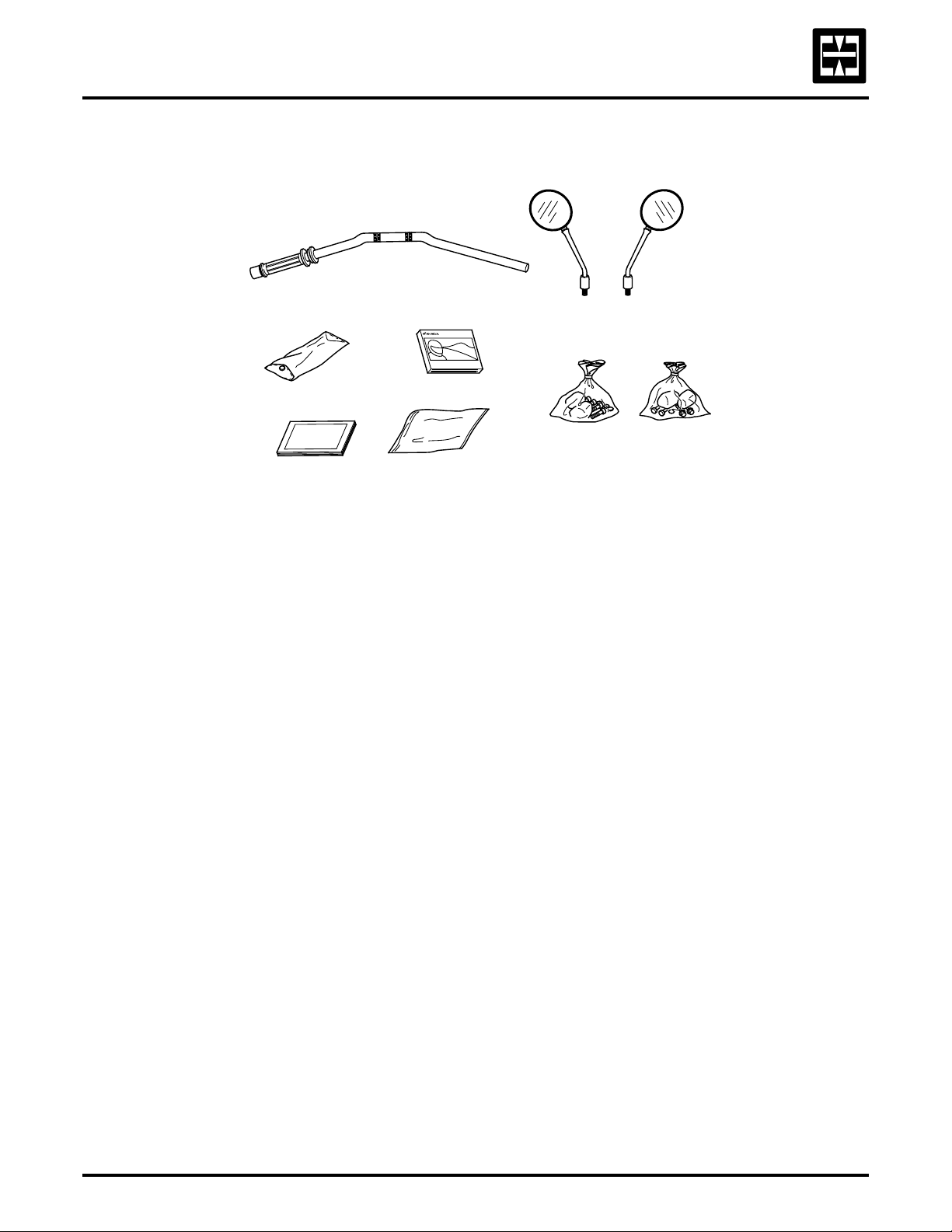

5. Loose Parts Information.

Unpack the remaining loose parts and check them against this illustration and list.

1.

4.

3.

5.

DESRIPTION QTY PART NUMBER STEP

1. Handlebar 1 53100-MCZ-000 8

2. Mirrors 2 88210-MCC-000 14

3. Tool kit 1 89010-MCZ-000 15

4. Owner’s Manual 1 31MCZ630* 15

5. Riding Tips & Practice Guide 1 G0045** 4

6. Manual bag 1 77251-342-000 15

7. Attaching Parts:

Screw/washer, 5 x 20 mm 1 93892-05020-07 7

Screw/washer, 5 x 25 mm 1 93892-05025-07 7

Handlebar Holder 2 53131-MCZ-000 8

Socket bolt, 8 x 32 mm 4 96600-08032-10 8

Socket bolt cap, 8 mm 4 91455-KEA-000 8

Handlebar weight 1 53105-MK4-620 9

Oval crew, 6 x 65 mm 1 90191-KBG-000 9

Master cylinder holder 2 45517-166-006 10 & 12

Flange bolt, 6 x 22 mm 2 90101-MBZ-G00 10

Screw/washer, 5 x 45 mm 1 93892-05045-07 11

Screw/washer, 5 x 35 mm 1 93892-05035-07 11

Flange bolt, small head, 6 x 22 mm (clutch side) 2 96001-06022-07 12

Socket bolt, 8 x 22 mm 2 90157-ME9-000 13

6.

2.

7.

*If missing, order from Helm Inc.

**If missing, order from Resolve Corp.

Missing Parts or Shipping Damage

Identify missing parts by referring to the Loose Parts Information section. Order the parts using

normal parts ordering procedures. Claims for missing loose parts or those damaged during

transit should be submitted to American Honda, not the carrier. After completing repairs, submit

a Transportation Claim via iN. For complete details, please refer to the Warranty Policy and

Procedures Manual.

©2005 American Honda Motor Co., Inc. - All Rights Reserved 3

Page 7

2005 CB900F

6. Remove the front shipping bracket.

Remove the bolts and front shipping bracket

from the handlebar mount.

7. Install the throttle grip.

Remove the protective wrap from the throttle

grip/switch assembly.

Slide the throttle grip/switch assembly onto

the right side of the handlebar. Move the grip

until the pin in the switch assembly drops into

the hole in the handlebar.

Close the bottom half of the switch assembly

and secure the halves using a 5 x 20 mm

screw/washer in the front hole and a

5 x 25 mm screw/washer in the rear hole.

Torque the screw/washers, starting with the

front one.

BOLTS

FRONT SHIPPING BRACKET

PIN

HOLE

5 x 20 mm

SCREW/WASHER

5 x 25 mm

SCREW/WASHER

Torque: 4 N·m (0.4 kgf·m, 3 lbf-ft)

8. Install the handlebars.

Align the handlebar punch mark with the top

edge of the lower holder.

Set the upper holders onto the handlebar

with their punch marks to the front.

Attach the handlebar using four 8 x 32 mm

socket bolts. Torque the four bolts starting

with the front two.

Torque: 27 N·m (2.8 kgf·m, 20 lbf-ft)

Attach the socket bolt caps to the

handlebar bolts.

PUNCH MARK

PUNCH MARK

HANDLEBAR

PUNCH MARK

BOLTS

4 ©2005 American Honda Motor Co., Inc. - All Rights Reserved

Page 8

9. Attach the handlebar weight.

Align the tab on the handlebar weight with

the recess in the handlebar.

Insert the weight into the handlebar and

attach it with a 6 x 65 mm oval head screw.

Torque the screw.

Torque: 10 N·m (1.0 kgf·m, 7 lbf-ft)

HANDLEBAR WEIGHT

10. Install the front brake

master cylinder.

Place the master cylinder assembly on the

handlebar. Align the edge of the assembly

with the punch mark on the handlebar.

Set the master cylinder holder, with its UP

mark facing up, on the assembly.

Attach it using two 6 x 22 mm flange bolts.

Torque the two bolts, starting with the

top one.

Torque: 12 N·m (1.2 kgf·m, 9 lbf-ft)

Connect the brake light wires to the master

cylinder terminals.

11. Install the turn signal switch.

Position the switch assembly on the

handlebar by inserting its pin into the hole in

the handlebar and aligning the end cap with

the groove in the switch assembly.

FRONT BRAKE

MASTER CYLINDER

HOLE

UP MARK

SWITCH

CONNECTORS

6 x 22 mm

FLANGE BOLTS

END CAP

Attach the switch assembly using a 5 x 45 mm

screw/washer in the front hole and a

5 x 35 mm screw/washer in the rear hole.

Torque the screw/washers, starting with the

front one.

Torque: 4 N·m (0.4 kgf·m, 3 lbf-ft)

©2005 American Honda Motor Co., Inc. - All Rights Reserved 5

PIN

5 x 35 mm

SCREW/WASHER

5 x 45 mm

SCREW/WASHER

Page 9

2005 CB900F

12. Install the clutch lever assembly.

Position the clutch lever assembly on the left

side of the handlebar. Loosely attach it using

its holder and two 6 x 22 mm small head

flange bolts. Be sure the holder's UP mark is

facing up.

Align the split between the holder and

lever assembly with the punch mark on

the handlebar.

PUNCH MARK

UP MARK

BOLTS

Torque the two bolts, starting with the top

bolt first.

Torque: 12 N·m (1.2 kgf·m, 9 lbf-ft)

Connect the clutch switch connectors to the

switch terminals.

13. Remove the motorcycle from the

crate base.

Route a sling under the steering stem. Be sure

not to trap any cables, hoses or wires

between the sling and the frame.

CONNECTORS

SLING

Route another sling through the rear wheel.

Attach the slings to a fork lift or similar lifting

device and apply just enough tension to the

slings to support the motorcycle.

Use a spreader board, if needed, to prevent

the sling from rubbing on the rear body.

SLING

6 ©2005 American Honda Motor Co., Inc. - All Rights Reserved

Page 10

13. Remove the motorcycle from the

crate base (cont.).

Remove the 6 and 8 mm bolts and right crate

shipping brace.

Re move the 6 a nd 8 mm bol ts an d l eft c rat e

shipping brace.

Discard the bolts.

RIGHT SIDE:

BRACE

LEFT SIDE:

BRACE

Install and torque the 8 x 22 mm socket bolts

securing the footpeg brackets.

Torque: 27 N·m (2.8 kgf·m, 20 lbf-ft)

Lower the side stand and place the

motorcycle on a level surface.

Remove the slings.

Clean both sides of all the brake discs using

Pro Honda Brake Cleaner or equivalent and a

clean shop towel.

14. Install the mirrors.

Thread the mirrors into their mounts and

secure them by tightening their lock nuts.

BOLTS

RIGHT SIDE SHOWN:

MIRROR

BOLTS

BOLT

LOCK NUT

15. Store the Owner’s Manual and

tool kit.

SEAT

Insert the ignition key into the seat lock. Turn

the key clockwise to release the seat. Pull the

seat back and off the motorcycle.

KEY

©2005 American Honda Motor Co., Inc. - All Rights Reserved 7

Page 11

2005 CB900F

15. Store the Owner’s Manual and

tool kit (cont.).

Place the tool kit in the holder and secure it

with the rubber restraining strap.

Place the Owner's Manual in its bag and

secure it in the holder located on the bottom

of the seat.

If the pre-delivery inspection is to be

completed directly after set-up, leave the seat

off. If not, reinstall the seat.

STRAP

TOOL KIT

BAG

OWNER’S MANUAL

8 ©2005 American Honda Motor Co., Inc. - All Rights Reserved

Page 12

16. Check the cables, hoses, and wire harness routing.

THROTTLE CABLES

RIGHT HANDLEBAR SWITCH WIRE

FRONT BRAKE HOSE

NEGATIVE (-)

BATTERY CABLE

CLUTCH CABLE

LEFT HANDLEBAR SWITCH WIRE

POSITIVE (+)

BATTERY CABLE

BATTERY

©2005 American Honda Motor Co., Inc. - All Rights Reserved 9

Page 13

2005 CB900F

17. Service and install the battery.

Service the battery only if the motorcycle

has been sold or is to be used as a

demonstration vehicle.

Remove the seat (see step 15).

Remove the bolt, then pull back the right side

cover from the motorcycle.

Follow the instructions included on the

battery case and in Service Letter #48.

The battery used in this motorcycle is a

pre-charged, maintenance-free type. The

electrolyte has already been added to

the battery.

Do not connect the motorcycle battery cables

to the battery terminals until the motorcycle is

ready for delivery.

Place the ignition in the OFF position.

Remove the battery hold-down strap

and battery.

Remove the protective cap from the positive

(+) battery terminal.

Slide the battery terminal nut into the battery

positive (+) terminal. Connect the battery

positive (+) cable to the positive (+) battery

terminal, tighten the bolt, coat the terminal

with dielectric grease, then pull the red cover

over the positive terminal.

Set the battery into the battery box. Install the

battery hold-down strap.

Slide the battery terminal nut into the battery

negative (-) terminal. Connect the battery

negative (-) cable to the negative (-) battery

terminal, tighten the bolt, coat the terminal

with dielectric grease, then pull the cover over

the negative terminal.

SIDE COVER

POSITIVE (+) CABLE

STRAP

NUT

BOLT

BOLT

NUT

BATTERY

BOLT

Reinstall the side cover and seat.

10 ©2005 American Honda Motor Co., Inc. - All Rights Reserved

NEGATIVE (-)

CABLE

Page 14

18. Check the throttle operation.

Check the throttle cable for damage.

Check that the throttle returns from all

open positions to the fully closed position

smoothly and automatically in all

steering positions.

Measure the throttle grip free play.

Throttle grip free play: 2 – 4 mm

(1/16 – 3/16 in.)

To adjust free play:

• Make small adjustments at the throttle

grip adjuster. Loosen the lock nut and

turn the adjuster. Tighten the lock nut

after adjusting.

• Make large adjustments at the throttle body

end. Loosen the lock nut and the adjuster

nut. Tighten the lock nuts after adjusting.

2 – 4 mm (1/16 – 3/16 in.)

LOCK NUT

ADJUSTER

ADJUSTER

LOCK NUTS

©2005 American Honda Motor Co., Inc. - All Rights Reserved 11

Page 15

2005 CB900F

19. Check the clutch lever free play.

Measure the clutch lever free play at the

lever tip.

Clutch lever free play: 10 - 20 mm

(3/8 - 13/16 in)

10 – 20 mm (3/8 – 13/16 in)

To adjust the free play:

• Make small adjustments at the lever end

of the cable. Loosen the lock nut and

turn the adjuster. Tighten the lock nut

after adjusting.

• Before making any large adjustments,

loosen the lever adjuster lock nut, turn the

adjuster in completely, then turn it out one

or two turns.

• Make large adjustments at the engine end

of the cable. Loosen the lock nut and turn

the adjustment nut. Tighten the lock nut

after adjusting.

LOCK NUT

ADJUSTING NUT

ADJUSTER

LOCK NUT

20. Adjust the brake light switch.

Turn on the ignition switch.

Adjust the rear brake light switch so the light

comes on as the brake begins to engage.

Avoid turning the switch body. Turning the

switch body will twist the wires and could

cause a short circuit.

To adjust, turn the adjuster, not the body.

ADJUSTER

12 ©2005 American Honda Motor Co., Inc. - All Rights Reserved

Page 16

21. Check the engine oil.

Before starting the engine, remove the antirust coating from the engine and exhaust

system using a mild detergent and water.

Rinse with clean water.

FILLER CAP

Support the motorcycle in an upright position

on a firm, level surface.

Check the oil inspection window to be sure

the engine has oil.

If no oil is present in the window, remove the

oil filler cap and add the recommended oil to

bring the level up to between the upper and

lower level marks.

• Oil recommendation: Pro Honda GN4

or HP4 (without molybdenum

additives) 4-stroke oil, or an equivalent

motorcycle oil.

• Viscosity (weight): SAE, 10W-40

• API classification: SF or higher. Do not

use oils labeled as energy conserving

on the circular API service label.

• JASO T 903 standard: MA

• Crankcase capacity: 3.5 Liters

(3.7 US Quarts)

UPPER

LEVEL

MARK

LOWER

LEVEL

MARK

Start the engine and let it idle for 3 - 5

minutes, then shut it off. Wait 2 - 3 minutes

and, supporting the motorcycle in an upright

position, check the oil inspection window. The

oil level should be between the upper and

lower level marks. If the level is low, add the

recommended oil as detailed above. Do not

add oil above the upper level mark.

22. Check the coolant level.

Check the coolant level at the reserve tank

located behind the side cover on the left side.

If required, add Pro Honda HP coolant or

an equivalent high quality ethylene glycol

antifreeze containing silicate-free corrosion

inhibitors to restore the level to the

UPPER mark.

UPPER LEVEL

©2005 American Honda Motor Co., Inc. - All Rights Reserved 13

Page 17

2005 CB900F

23. Check the idle speed.

Support the motorcycle on its side stand on a

firm, level surface.

Connect a tachometer to the engine. Place the

transmission in neutral.

Start the engine and warm it to the normal

operating temperature. Verify the engine

idle speed.

Idle speed: 1,200 ± 100 rpm

U s e o n l y t h e th r ot tl e st o p s c r ew t o m a k e i dl e

speed adjustments.

24. Verify the drive chain slack.

Place the motorcycle on the side stand and

put the transmission in neutral.

Check the drive chain slack midway on the

lower chain run.

Drive chain slack:

THROTTLE STOP SCREW

30 – 40 mm (1 3/16 – 1 9/16 in.)

Adjust the slack by loosening the axle nut and

the adjustment lock nuts. Turn the adjustment

bolts to set the proper chain slack.

Set the wheel alignment using the alignment

marks on the swingarm and the notches on

the axle holders. Be sure both sides are set to

the same position.

Torque the axle nut and tighten the lock nuts

on both sides.

Torque: 93 N·m (9.5 kgf·m, 69 lbf-ft)

25. Check the tire pressure.

Front: 36 psi Rear: 41 psi

26. Complete the Set-Up/

Pre-Delivery Checklist.

Complete an On-Road Set-Up/Pre-Delivery

Checklist (Reorder No. S0299) by checking the

boxes confirming that the steps were done.

30 – 40 mm (1 3/16 – 1 9/16 in.)

14 ©2005 American Honda Motor Co., Inc. - All Rights Reserved

Page 18

Wiring Diagram

STOP

ENGINE

STARTER

ECM

SERVICE

SWITCHSWITCH

CHECK

CONNECTOR

B 22P Light Gray22P BlA

MINI

IG

HL

BAT4

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

21G/P

20

19

17G/Bu

16

15

14

12

9Y/Bu

8

7

5

4

3

2P/Bu

1

3P Bl

FAN MOTOR

BAT2

ST

IG

Y

G/W

P

P/G

P/W

W/Y

Gr

G/R

R/Y

Lg/Y

Bl/W

Y/R

G/O 22

Bu/Y

Y/G

O/Bl 18

G

P/Y 13

P/G

G11

G/P 10

Y/Bl

Br/Bl 6

Y/Bl

Br

P/Bl

Br

G

(0030Z-MCZ-L100)

Gr/Bu

W/Bu

FAN

FRONT BRAKE

Bl

W/Bl

Bu/W

Y/R

Bl

Bl/R

CONTROL

PURGE

SOLENOID

VALVE

WPC

2P Bl

Y/Bl

Bl/W

Bl/Bu

2P Bl

Bl/Bu

Bl/Bu

Bl

LIGHT SWITCH

G/Y

W/G

Y/Bl

Bl/W

WPC

Y/Bl

Bl/W

G

Bl

Bl

G/Y

W/Bl

W/G

Y/R

Bu/W

Bl/RBl/R

LICENSE LIGHT

12V5W

TURN SIGNAL LIGHT

RIGHT REAR

TURN SIGNAL LIGHT

12V23W

SENSOR

MAP

IAT

SENSOR

SENSOR

TP

EXHAUST AIR INJECT

SOLENOID VALVE

SOLENOID VALVE

INTAKE AIRDUCT CONTROL

O/Bl

Bl/W

WPC

2P Bl

2P NAT

O/Bl

Bl/W

2P

W/Y

Gr

MINI

Bl/W

Bu/Y

Bl/W

Y/Bu

IGNITION

COILS

INJECTOR 3

INJECTOR 2

INJECTOR 1

2P 2P

2P

2P

P/Y

P/G

P/Bu

Bl/W

Bl/W

Bl/W

P/Y

Y/R

R/Y

P/G

G/O

P/Bu

Bl/W

Bl/W

WPC

Gr

8P

P/Y

R/Y

Y/R

P/G

G/O

P/Bu

Bl/W

Bl/W

Bl/W

Bl/W

Br/Bl

CUT

FUEL

0/3)4)/.

3%.3/2

CAM

2-31-4

SIDE STAND

Bl

G/Y

W/Bl

W/G

Y/R

MINI

Bu/W

9P Br

Bl/W

Br

RELAY

INJECTOR 4

P/Bl

SWITCH

Bl

Y/R

G/O

Gr/Bu

Y/R

R/Y

G/O

G

Br

R/G

Bl/W

Br/Bl

G/Bu

Bl/Bu

MINI

Bl

3P

FUEL

PUMP

MOTOR

FAN

RELAY

SENSOR

FUEL

REVERSE

G/W

G/W G/W

G

G

UP

DOWN

MINI 2P G

G

G

Lb

G/O

Lg/Y

2P

G

Lb

O

Lb

LEFT REAR

12V23W

12V21W/5Wx2

BRAKE AND TAILLIGHTS

G

G

G

O

G

Bl/Br

MINI

2P

2P

G

O

Bl/Br

Bl/Br

2P R

W/Y

Y

MINI

Bl

G/Y

Bl W/G

MINI 2P NAT

G

G

Br

Br

G/Y

G/Y

G

Br

G/Y

MINI

3P NAT

G

G/Y

Bl/Br

GENERATOR

PULSE

IGNITION

W/Y

Y

FUSE MAIN (A) 30A

R/Y

SWITCH

STARTER RELAY

Y/R

G/R

R

R/Y

G

G

G

G/P

G/P

G/Bl

P/G

P

G/Bl

G

Bl/Br

Bl

3P NAT

REAR

BRAKE

SWITCH

LIGHT

G/O

P/W

G/Bu

2P Bu

Bu/R

Bu/R

Lg

MINI

Lg

ECT

BATTERY

12V 10AH

6%()#,%

SENSOR

/),

4P

SPEED

SENSOR

PRESSURE

SWITCH

SWITCH

NEUTRAL

PINK

GRAY

O ORANGEYELLOWY

Lb LIGHT BLUEBLUEBu

GrWHITEW

Bl BLACK BROWNBr

G GREEN LIGHT GREENLg

R RED P

R

G/R

Y/R

STARTER

MOTOR

R

R

R

R

NAT

G

G

G

G

4P

Y

Y

Y

REGULATOR/

RECTIFIER

Y

Y

Y

Y

Y

Y

3P W

ALTERNATOR

R

BAT1

R

ILLUMINATION

12V1.7Wx2

INDICATOR

SIGNAL

RIGHT TURN

LEFT TURN

SIGNAL

INDICATOR

12V1.7W 12V1.7W

TACHO

TEMPERATURE

COOLANT

SPEEDO

1

Y/G

G/Bl

METERGAUGE

Bl/Br

G

G/Bu

Lb

G

Bl/Br

Br/Bl

W/Bu

Bu/R

Lg/R

Bu

G

23456

O

G

Bl/Br

G

R/G

P/G

METER

DISPLAY

LCD

OIL PRESSURE INDICATOR

FI INDICATOR

NEUTRAL INDICATOR

HIGH BEAM INDICATOR

TRIPMETER/ODOMETER

FUEL RESERVE INDICATOR

12354

6

SWITCH

IGNITION

BANK

Bu/R

Bu

Lb

R/G

O

Y/G

G/Bl

G/Bu

Bl/Br

Br/Bl

Lg/R

P/G

G

W/Bu

IG

Vz

ANGLE

SENSOR

NAT

MINI

6P

Bl

MINI

9P

R/Bl

ENGINE

STOP

Lb

O

G

Bu/O

RELAY

W/Bu

Bu/R

Bu

R/G

Y/G

G/Bl

G/Bu

Bl/Br

Br/Bl

Lg/R

P/G

R/BlR/Bl

Bu/O

4P NAT

G

W

R/W

MINI

R

P

G

G

W/Bl

R/O

4P

R/O

Bl

Bl/W

R/W

G

W

12V23/8W

TURN SIGNAL LIGHT

RIGHT FRONT

Bu

(HI)

(LO)

12V60/55W

HEADLIGHT

G

Lb

Lb/W

R/Bl

R

R/Y

R/W

R/G

W/Bl

W/G

FUSE

Bl/Br

Bl/R

G/R

Lg

Lg/R

CLUTCH

DIODE

Gr

Gr

Bl6P

W/Bl

W/G

Bu/W

Bu/W

MINI

Lg

Bl

Bl/Br Bl/Br

Lb

Lb

O

O

Bl

G/W

Bu

Bu

MINI

Bl G/R

G

G

6P Bu

Bl

Bl

HORN

GLbOO

G

G

Lb

O/W O/W

Lb/W Lb/W

Gr

W/G

O

G

O/W

LEFT FRONT

TURN SIGNAL LIGHT

12V23/8W

FAN MOTOR, ODOMETER

FI IGN, PUMP

R/G 20A

R/W 20A

FUSE

Ho

Lg

Bl/Br

BAT3

Bu/W

HORNDIMMERTURN SIGNAL

Bu

Hi

W

HL

Lo

R

Lb

W

Gr

O

L

PL

O/W

P

W/Bl

POSITION SWITCH

Lb/W

PR

Bl

Bl

CLUTCH

TURN

SIGNAL

RELAY

SWITCH

3P Bl

MINI

HZ

R/Bu

Gr

POBAT3 W

W/G W/RCOLOR

ON

OFF

STARTER, BANK ANGLE SENSOR

TURN, STOP

HEADLIGHTS, PASS.

HL

Bu/WBl/R

BAT4

10A

10A

10A

10A

IG

Bl/R

W/G

W/Bl

Bl/Br METER, IND, HORN, TAIL, (PO), LICENSE

STARTER SWITCH HAZARD SWITCH

FREE

PUSH

IG BAT2

OFF

RUN

SWITCH

ENGINE STOP

BAT3

Ho ST

HORN

FREE

PUSH

COLOR Lg Bl/Br COLOR W/BlBl COLOR Y/R Bl

HiLoHL

Bu

W

Bu/W

Hi

Lo

(N)

PL

O/W

PR

Lb/W

P

Gr

LRW

L

R

N

COLOR Gr Lb O COLOR

KEYBAT1

KEY ON

KEY OFFOFF

LOCK PIN

KEY OFF

IG DIODE

IGNITION SWITCH TURN SIGNAL SWITCH DIMMER SWITCH SWITCH

ON

LOCK

COLOR R/Bl R Bu/O

©2005 American Honda Motor Co., Inc. - All Rights Reserved 15

Loading...

Loading...