Page 1

GB OWNERS MANUAL & PARTS LIST

4-CYCLE ENGINE DRIVEN PORTABLE PUMPS 1 1/2" AND 2"Models

F MANUEL DE L’UTILISATEUR ET LISTE DES PIÈCES

DE RECHANGE

POMPES PORTATIVES À MOTEUR À QUATRE TEMPS MODÈLES DE

1 1/2 et DE 2 POUCES

E MANUAL DEL PROPIETARIO Y LISTA DE

PIEZAS

BOMBAS PORTATILES ACCIONADAS POR MOTORES DE 4 CICLOS

Modelos de 1 1/2” y 2”

G B CORROSION RESISTANT, LIGHTWEIGHT, HIGH LIFT, FAST PRIME, HIGH VOLUME

F RÉSISTANCE À LA CORROSION, LÉGÈRETÉ, HAUTE PRESSION,AMORÇAGE RAPIDE, GROS

DÉBIT

E RESISTENTE CONTRA LA CORROSION, PESO LIGERO, ALTURA DE IMPULSION ELEVADA,

CEBADO RAPIDO, VOLUMEN ALTO

AP215 1 UT01516

AP215 1A UT01548

AP220 1 UT01517

AP220 1A UT01549

AP220 1B UT01549A, UT01549B, UT01549C

AP220 2A UT01113

AP315 1 UT01510

AP315 1A UT01550

AP320 1 UT01511

AP320 1A UT01551

AP320 1B UT01551A, UT01551B, UT01551C

AP320 D UT01551D

AP520 UT01552, UT01552A, UT01552B

GB FIRST EDITIONGB FIRST EDITION

GB FIRST EDITION

GB FIRST EDITIONGB FIRST EDITION

Printed in U.S.A.

F PREMIÉRE ÉDITIONF PREMIÉRE ÉDITION

F PREMIÉRE ÉDITION

F PREMIÉRE ÉDITIONF PREMIÉRE ÉDITION

Imprime aux. E.-U.

E PRIMERA EDICIONE PRIMERA EDICION

E PRIMERA EDICION

E PRIMERA EDICIONE PRIMERA EDICION

Impreso en los EE.UU.

P/N PS01130

Page 2

GB SAFETY PRECAUTIONS

WARNING

1. This pump is designed for pumping water and general farm

liquid fertilizers, herbicides and pesticides. Flammable materials

such as gasoline should not be pumped with this pump.

Explosion might result, causing serious injury. Corrosive

materials should be handled with caution, taking into consideration the handling instruction for the particular material.

2. Before starting the pump, study all of the instructions in this

booklet and the Engine Operating and Maintenance Instructions

supplied with the unit. Make sure you thoroughly understand

how to operate the machine. Proper preparation, operation and

maintenance will result in operator safety, optimum performance and long unit life.

3. Be sure each person who operates the machine is properly

instructed in its safe operation.

PREPARING THE PUMP FOR OPERATION

UNCRATING THE PUMP

When uncrating the pump, loosen any shipping blocks, clamps and

packing material from the unit. Look the unit over carefully for shipping

damage. If you find any damage, report it immediately to your dealer or

the shipper.

Read these instructions and the 4-cycle engine instructions carefully until

you are sure you can prepare the engine and pump properly for use, and

can operate it safely and correctly.

WARRANTY

The pump is warranted for the period and under the conditions stated on

the warranty card packaged with the pump. Fill out the card and mail it.

ENGINE PREPARATION

The engine is lubricated by engine oil in the crankcase. The engine is

governed to operate at speeds close to 3600 rpm and the governor

setting

must not be changed

by the operator or owner.

4. Never operate the machine in an explosive atmosphere, near

combustible materials or where ventilation is not sufficient to

carry away exhaust fumes.

5. Always be sure that the machine is on secure footing so that it

cannot slide or shift around, endangering workers.

6. Keep the immediate area free of all bystanders.

7. When starting the machine, be sure that nothing is in a position

to be hit by the operator’s hand or arm, or the starting rope.

8. Never operate this machine with any guard removed.

9. Observe all safety regulations for the safe handling of fuel in

safety containers. If container does not have a spout, use a

funnel. Do not refill engine while it is running or hot. Fill the tank

only on an area of bare ground. While filling the tank, keep heat,

sparks and open flame away. Carefully clean up any spilled fuel

before starting engine.

10. Avoid contacting the hot exhaust manifold, muffler or cylinder.

Keep clear of all rotating parts.

11. Always keep the machine and all associated equipment clean,

properly serviced and maintained.

12. Before working on any part of the machine, shut off the engine

and disconnect the spark plug wire to prevent accidental

starting.

13. Never run pump in an enclosed area.

14. Use only product manufacturer’s genuine replacement parts.

Failure to do so may cause poor fit and possible injury.

NOTE

The fuel for this 4-cycle engine is regular grade gasoline 87 Octane

(average) minimum. No oil should be mixed with the gasoline.

However, engine lubricating oil in the crankcase should be checked

before use. Follow instructions in the Briggs & Stratton instruction

manual in all matters of 4-cycle engine preparation, engine oil

selection, operation, maintenance and trouble-shooting.

Do not leave gasoline in the engine tank for long periods of time because

gasoline breaks down as it ages. The peroxides and gums in old stale

gasoline can attack the interior surfaces of the fuel system and engine,

clog the carburetor, and prevent starting. The “freshness” of fresh

gasoline can be prolonged for several months by treating the newly

purchased gasoline with an anti-oxidant type of fuel stabilizer (such as

STA-BIL®, available from Gold Eagle Laboratories, Chicago, Illinois

60632) according to instructions on the stabilizer can.

PUMP PREPARATION

CAUTION

Do not run the pump dry. There must be liquid in the pump to

lubricate the pump shaft seal.

Always fill the pump body with water (or the liquid to be pumped) before

starting the pump. It is not necessary to drain the pump body after use,

unless there is a danger of freezing.

The pump shaft seal is lubricated by the liquid being pumped. The seal is

designed to handle clean or dirty liquids. No other points on the pump

require lubrication.

ELBOW AND NIPPLE INSTALLATION: (AP220-1B, AP315-1, AP3151A, AP320-1, AP320-1A, AP320-1B & AP520)

Wrap the male threads with Teflon sealing tape. This tape gives a more

superior seal than pipe joint compound without making the connections so

tight as to damage the threads. Assemble nipple into the pump body. The

proper tightness is hand tight plus one full turn with a pipe wrench (no

tighter).

©1998, John Deere Consumer Products, Inc.

2

Page 3

OPERATING

INSTRUCTIONS

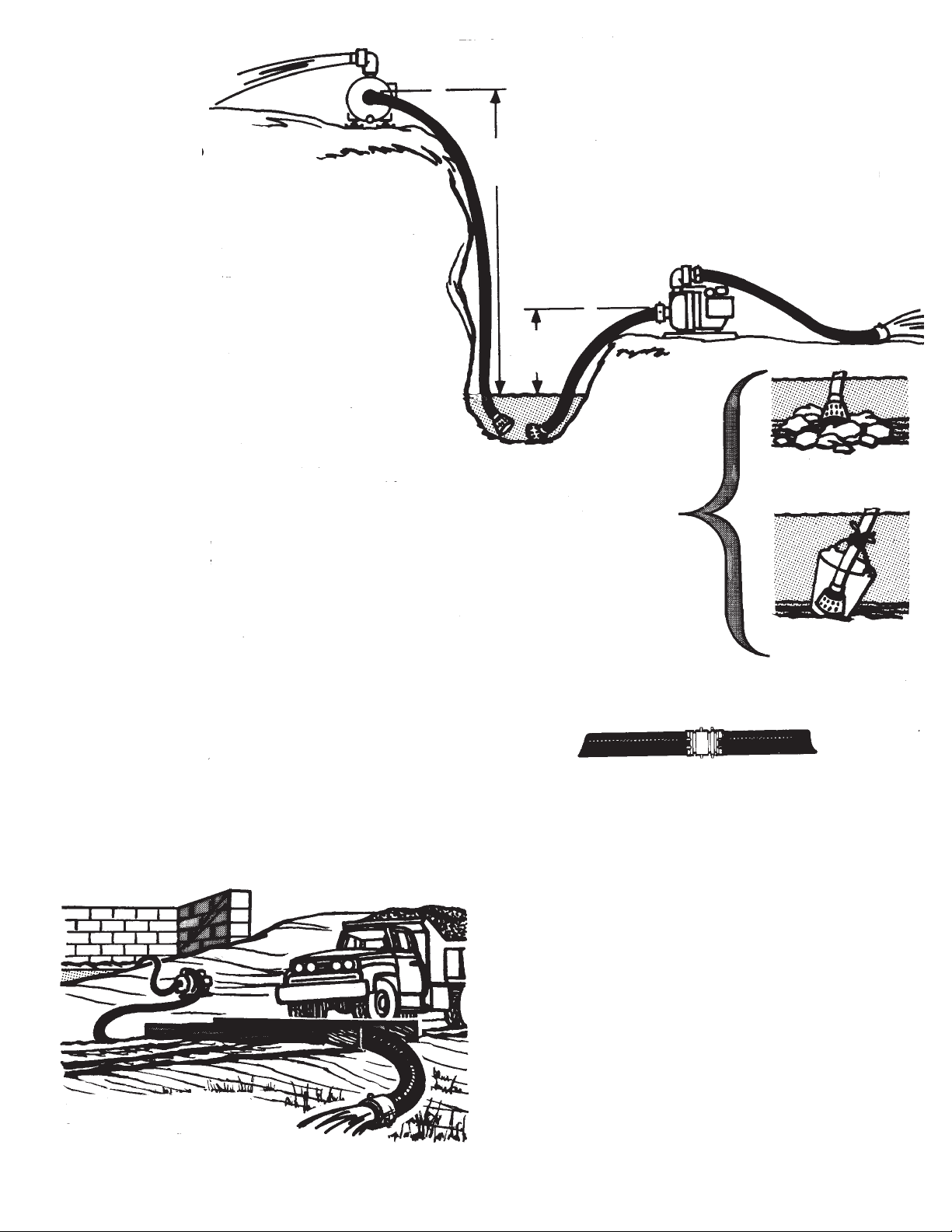

1. When pumping dirty water or liquids

containing solids, always use a pump strainer on the end of

the suction line.

2. Make sure that all hose and pipe connections are air tight. An air

leak in the suction line may prevent priming and will reduce the

capacity of the pump. Also be sure that the filler plug on top of

the pump and the drain plug at bottom rear are air tight.

3. Always place the pump as close to the liquid to be pumped as

possible but not in an enclosed area. Keep the pump and

engine on a level foundation. When the suction

hose is hanging down a steep bank or into a hole, the weight

of the hose and the liquid in it can pull the pump into the liquid. To

prevent “walking” and possible loss of the pump, tie it

down.

4. Always be sure the pump contains liquid before you start the

engine. In freezing weather, always drain liquid from the pump after

use. After refilling pump in freezing weather, crank engine very

slowly so you can feel whether pump is free to run before you crank

to start the engine. If pump is frozen, thaw it out slowly. (Do not use

fire to thaw pump).

5. If pumping liquid is contaminated with mud or detergents (many

rivers and lakes contain detergents) which will churn into suds in the

pump, it may be necessary to prime the pump with clean water (tap

water). Once primed, the pump will handle the contaminated liquid.

25 FOOT SUCTION LIFT IS

THE MAXIMUM

5 FOOT

SUCTION

LIFT

WAYS TO KEEP

STRAINER OUT OF

RIVER SILT

KEEP PUMP FAR ENOUGH

FROM BANK THAT SUCTION

HOSE WILL NOT PULL IT INTO

THE WATER. TIE PUMP DOWN

IF NECESSARY.

PUMP CAN LIFT TO A MAXIMUM

OF 25 FEET, BUT IT IS BETTER

TO USE THE SMALLEST

SUCTION LIFT DISTANCE YOU

CAN.

PLACE ON BED OF

STONES

6. Maximum volume is achieved by:

(a ) Keeping lines as straight as possible, and avoiding kinks and sharp

bends in the hoses.

(b ) Making the vertical suction lift distance as short as possible (see

illustration).

(c ) Using large diameter suction and discharge lines (The larger the

diameter the lower the friction).

(d ) Using as few connectors, elbows and adapters as you can get away

with.

(e ) Maintaining the pump and associated equipment in good operable

condition.

7. If flexible hose must be laid across a roadway, protect it with

planking. Instantaneous shut-off pressures, applied when a vehicle

runs across an unprotected hose, will cause pounding. Pounding

TIE INSIDE OLD PAIL

OR BASKET

NOTE: ALL CONNECTIONS ON SUCTION SIDE OF

PUMP MUST BE AIR TIGHT.

can split the pump body or damage the hose.

8. When the suction strainer is likely to clog with muck and roots,

prepare a bed of stones on which to rest the strainer; or tie the

strainer so that it stays off the bottom; or tie it in a basket or pail (see

illustration).

9. When pumping liquids (such as Liquid Fertilizer) containing solids,

the time required to prime will increase and the pumping volume

(gallons per minute) will decrease as the proportion of solid matter in

the liquid to be pumped is increased. The viscosity or thickness of

the liquid also will affect the priming time and the pumping volume.

Any consistency of liquid which increases friction and drag in the

pump and lines will retard the output.

10. The rubber molded check valve in the “chimney” of the pump volute

will seal off the pump to retain liquid in the suction line so that the

pump will start pumping immediately after short periods of shutdown.

PROTECT FLEXIBLE HOSE WITH

PLANKING ACROSS ROADWAYS

11. When the pump is used only now and then, it is a good idea to check

that the unit is ready for operation by (a) checking the level of oil in

the engine crankcase and (b) filling the pump with liquid.

3

Page 4

ENGINE MAINTENANCE AND UNIT STORAGE

1. Follow instructions in the Briggs & Stratton Instruction Manual in

all matters of engine maintenance. The air filter must be cleaned

regularly, the proper level of oil maintained in the crankcase,

and the engine oil must be changed at regular intervals.

2. After every 100 hours of operation, the cylinder head should be

removed and the engine deposits removed carefully from the

combustion chamber and the top of the piston. We recommend

that engine work such as carbon removal be done by a Briggs

& Stratton or Homelite Construction Equipment Service Station.

The engine can be inspected, repaired if necessary, and tuned

for optimum performance at this time.

3. When the engine is to be idle for a long period of time, both

pump and engine should be prepared for storage as given

below:

(a ) If the engine tank contains anti-oxidant-treated gasoline you

may store the pump for as long as two months with the tank

filled to the top. If the gasoline is untreated, drain the tank

and use up your reserve fuel supply in another engine. Start

and run the pump engine until it dies from lack of fuel.

(b ) Drain the pump. If the pump contains liquids which could

dry out and cake up, it is a good idea to pump a little clear

water before draining the pump.

(c) Leave the filler and drain plugs out of the pump.

(d ) Wipe down the exterior of the unit. It must be stored in a

dry, well ventilated area, away from fertilizers and corrosive

salts. Try to keep the unit in a cold or cool area where the

temperature changes very little. Dampness and heat will

accelerate rust of the engine parts, so cold, dry area

storage is your best bet for long engine life.

PUMP TROUBLE-SHOOTING AND REPAIR

DIAGNOSIS TREATMENT

1. DOES NOT PRIME OR DOES NOT PUMP

25 INCHES (MAX.)

2. OUTPUT O.K. AT LOW LIFTS, BUT FALLS OFF AT

MEDIUM HEIGHT SUCTION LIFTS.

• Fill pump with clean liquid and try priming again.

• Disconnect suction and discharge lines at pump. Check pump

suction by holding palm of hand over suction opening (or use a

vacuum gauge). Maximum vacuum should be about 25" Hg on

vacuum gauge. You can live with less vacuum as long as

satisfied with lower performance. If dissatisfied, disassemble

and check the impeller, wear plate and seal.

• If pump suction tests O.K., attach suction line and check

suction at end of suction line. Failure to get suction here

indicates leaking connections or leaking or collapsing lines.

Liners of damaged suction hose will often be sucked shut inside

the hose.

• If good intake suction, put on the discharge line. The only thing

which could interfere with pumping here would be a blockage.

• Worn pump can handle low lifts. Lower the lift distance, if

possible, or check pump out as below.

• Body screws have loosened to permit an interior air leak.

Recheck after tightening.

NOTE

Failure of pump to perform satisfactorily, i.e. pump heavy liquids or

negotiate high lifts up to its expected ability, may not be the

pump’s fault. If you find nothing wrong with the pump, have the

engine inspected, overhauled if necessary, and tuned for the

altitude range you expect to use the pump.

4

• Worn or damaged pump parts. Disassemble. Check rubber

wear plate, impeller volute and shaft seal. Replace any broken

or worn components; check clearance between impeller blades

and wear plate. Reassemble using all new “0” rings. Shim to

.015" impeller to volute clearance during reassembly.

Page 5

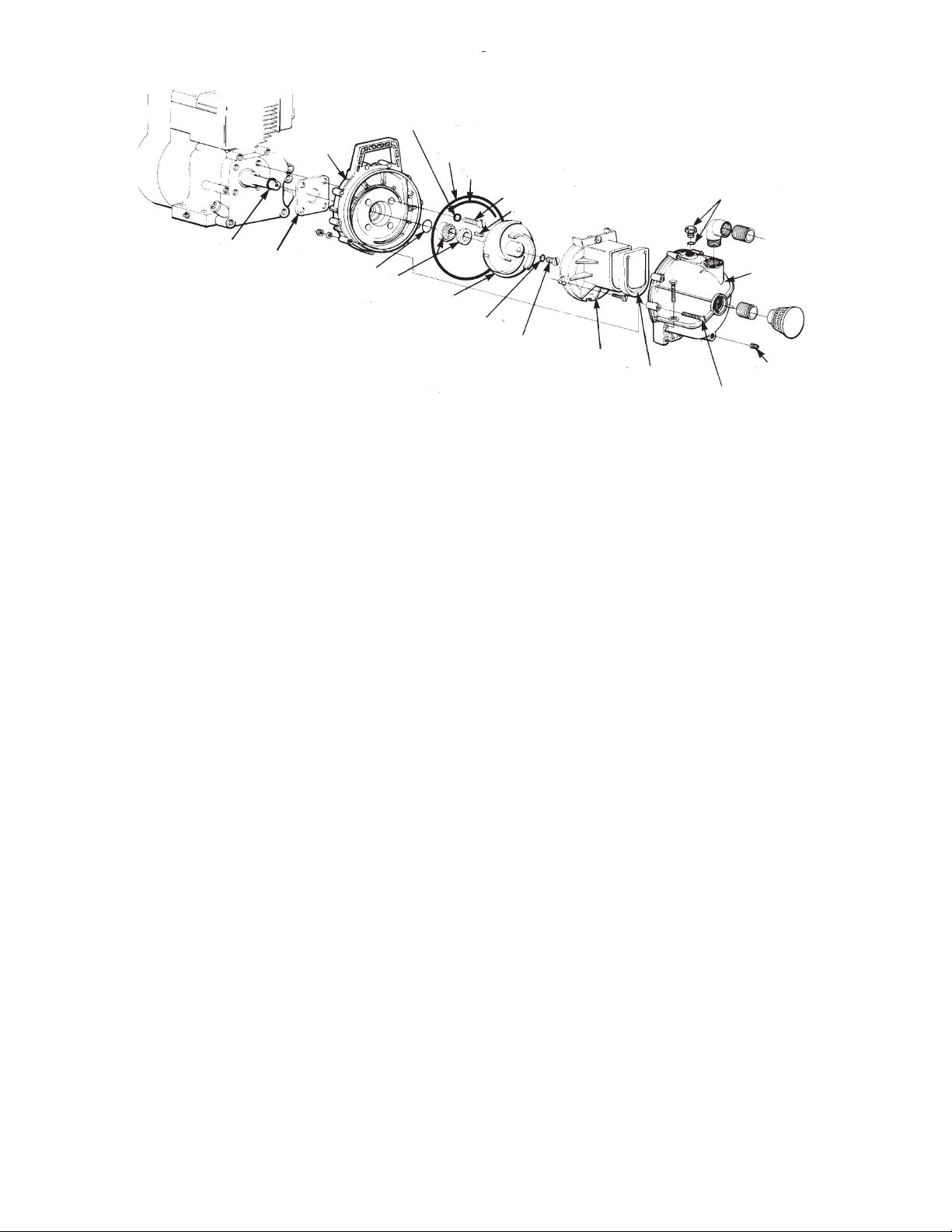

HOW TO DISASSEMBLE AND REPAIR THE PUMP

IMPELLER

SMALL "O" RING (4)

HOUSING

LARGE "O" RING

"O" RING SEGMENT

SLINGER

.015" SHIM AS

REQUIRED

"O" RING

SEAL

IMPELLER

PUMP MAY BE DISASSEMBLED

SMALL "O" RING (1)

AND REASSEMBLED USING

ONLY A PIPE WRENCH AND

LARGE SCREWDRIVER

1. Using a large screwdriver to remove the 1/4" screws, lock

washers and nuts, remove the pump body from the impeller

housing.

2. Remove the rubber check valve from the “chimney” of the

volute.

3. Remove the large self-tapping screw at the top of the volute and

the two smaller self-tapping screws at the sides of the volute.

4. Unscrew the 5/16-24 x 3/4 (fine thread) impeller screw and

remove it along with the small “0” ring. Slide the impeller off the

shaft and key.

5. One half of the shaft seal is in the impeller hub, the other half is

on the shaft inside the back plate. Remove both halves.

6. Remove the four steel screws (and small “0” rings) and pull the

impeller housing off the engine.

7. See that the key fits the shaft groove snugly. If it doesn’t,

replace the key with a wider one.

8. The clearance between the impeller blades and the volute must

be about .015" for good pumping. If the impeller blades and

volute are worn, there may be too much “front” clearance. You

can reduce the clearance by taking out one or more of the

shims between the impeller housing and the engine. After locking

the impeller back in place temporarily, check the impeller bladeto-volute clearance with a feeler gauge. Continue (below) with

reassembly.

CAUTION:

When reassembling pump, (as in steps 10 through 15) after

adjustment of the clearance (as above) you must check that there is

no contact between the volute and impeller. Rotate shaft slowly by

hand and listen for scraping noises. If you hear no noises, put

priming liquid into the pump and start up the engine. If there is no

scraping noise, your assembly is probably O.K.

"CHIMNEY"

OF VOLUTE

HOUSING SCREWS (4)

SHAFT KEY

FILLER PLUG

AND "O" RING

PUMP BODY

IMPELLER

SCREW

VOLUTE

CHECK

VALVE

12. When assembling nipples, fittings, and elbows into the pump

body, wrap the male threads with Teflon® sealing tape. This

tape gives a more superior seal than pipe joint compound

without making the connections so tight as to damage the

threads. The proper tightness is

with a pipe wrench.

13. The four 5/16"-24 x 1-1/8" screws (with an “0” ring on each)

holding impeller housing to engine should be tightened securely

with a large screwdriver. When your rebuilding is completed, fill

the pump with liquid and test whether its full capacity has been

restored.

14. The screws holding the volute in place do not have to be

tightened any more than needed to secure the volute during

assembly. Overtightening may cut the “0” rings. The impeller

and the outside body screws should be made moderately tight

to insure against air leaks.

BODY SCREWS (10)

(No tighter than that, please.)

DRAIN PLUG

hand tight plus

one

full turn

9. If you cannot get a clearance reasonably close to .015" between

the impeller and wear plate, install new parts as required.

10. During final assembly, be sure to change all of “0” ring seals

unless you are positive they are in good condition.

11. Put all of the parts back together in the reverse of the order

used in disassembly.

WARNING

Do not use any petroleum oil or grease in the assembly and do not

pump petroleum products with this pump.

5

Page 6

F MESURES DE SÉCURITÉ

AVERTISSEMENT

1. Cette pompe est conçue pour le pompage de l’eau et d’engrais,

herbicides et pesticides agricoles liquides d’usage général.

Cette pompe ne doit pas être utilisée pour le pompage de

l’essence ou de tout autre substance inflammable. L’explosion

pouvant en résulter est susceptible d’occasionner des

blessures graves. Les substances corrosives doivent être

manipulées avec précaution, en respectant les instructions

relatives à la substance en question.

2. Avant de faire démarrer la pompe, étudier soigneusement les

instructions fournies par ce manuel et par le manuel d’utilisation

et d’entretien du moteur fourni avec l’appareil. S’assurer que

l’on comprend parfaitement le mode d’utilisation de la machine.

Une bonne préparation, une utilisation correcte et un bon

entretien sont essentiels pour la sécurité de l’utilisateur, le bon

fonctionnement de l’appareil et sa longue durée de vie.

3. S’assurer que toute personne se servant de la machine est

correctement formée pour une utilisation en toute sécurité.

4. Ne jamais faire fonctionner la machine dans une atmosphère

explosive, à proximité de substances combustibles ou dans

des endroits où la ventilation est inadéquate pour l’élimination

des gaz d’échappement.

5. Toujours vérifier que la machine est positionnée de façon

stable et qu’elle ne peut pas mettre le personnel en danger en

glissant ou en se déplaçant d’une manière ou d’une autre.

6. Interdire la présence de spectateurs à proximité immédiate de

la machine.

PRÉPARATION DE LA POMPE AVANT

UTILISATION

DÉBALLAGE DE LA POMPE

Pour le déballage de la pompe, détacher les blocs, brides et matériaux

d’emballage de l’appareil. Bien examiner l’appareil pour vérifier l’absence

de dommages dus à son transport. En cas de dommage, notifier

immédiatement le distributeur ou l’expéditeur.

Lire soigneusement ces instructions et les instructions relatives au

moteur à quatre temps afin de pouvoir préparer correctement le moteur

et la pompe en vue de leur utilisation, et les faire fonctionner correctement

en toute sécurité.

GARANTIE

La pompe est garantie pour la durée et sous les conditions stipulées sur

la carte de garantie emballée avec la pompe. Remplir la carte de garantie

et la renvoyer par la poste.

PRÉPARATION DU MOTEUR

Le moteur est lubrifié par l’huile moteur du carter. Le moteur est réglé de

manière à fonctionner à des vitesses proches de 3600 t/mn, et le réglage

du régulateur de vitesse ne doit être changé ni par l’utilisateur, ni par le

propriétaire.

NOTA

Le carburant de ce moteur à quatre temps est de l’essence

ordinaire à indice d’octane minimum (moyen) de 87. Ne pas

mélanger d’huile à l’essence. Cependant, l’huile de graissage dans

le carter doit être vérifiée avant toute utilisation. Suivre les instructions du manuel Briggs & Stratton pour tout ce qui concerne la

préparation du moteur à quatre temps, le choix de l’huile,

l’utilisation du moteur, son entretien et son dépannage.

7. Au moment du démarrage de la machine, s’assurer que rien ne

fait obstacle au déplacement de la main ou du bras de

l’utilisateur, ni à la course du cordon du démarreur.

8. Ne jamais utiliser cette machine si l’un des dispositifs de

protection n’est pas en place.

9. Respecter tous les règlements de sécurité relatifs à la

manipulation du carburant dans des récipients de sécurité.

Utiliser un entonnoir si le récipient n’a pas de bec verseur. Ne

pas rajouter de carburant lorsque le moteur est en marche ou

lorsqu’il est chaud. Ne remplir le réservoir que dans un endroit

ou le sol est dénudé. Pendant le remplissage du réservoir, ne

permettre la présence d’aucune flamme, étincelle ni source de

chaleur à proximité. Nettoyer soigneusement le carburant

répandu avant de faire démarrer le moteur.

10. Éviter tout contact avec le collecteur d’échappement, le

silencieux et le cylindre lorsqu’ils sont chauds. Se maintenir à

l’écart de toute pièce en rotation.

11. Toujours veiller à la propreté et au bon entretien de la machine

et du matériel connexe.

12. Avant d’effectuer des travaux sur un élément de la machine,

arrêter le moteur et débrancher le fil de la bougie afin

d’empêcher un démarrage accidentel.

13. Ne jamais faire fonctionner la pompe dans un endroit confiné.

14. N’utiliser que des pièces de rechange authentiques provenant

du fabricant afin d’éviter la possibilité d’un mauvais assemblage

et de blessures corporelles.

Ne pas laisser d’essence dans le réservoir pour de longues périodes, car

l’essence se dégrade avec le temps. Lorsque l’essence est trop vieille,

les peroxydes et les substances gommeuses peuvent attaquer les

surfaces intérieures du dispositif d’alimentation en carburant et du

moteur, encrasser le carburateur, et empêcher le démarrage. La

« fraîcheur » de l’essence peut être maintenue pendant plusieurs mois en

traitant de l’essence qui vient d’être achetée avec un stabilisant de

carburant de type antioxydant (par exemple, STA-BIL® de Gold Eagle

Laboratories, Chicago, Illinois 60632) conformément aux indications

présentes sur le bidon du stabilisant.

PRÉPARATION DE LA POMPE

ATTENTION

Ne pas faire fonctionner la pompe à sec. Du liquide doit être

présent afin de lubrifier le joint d’étanchéité de l’arbre de la pompe.

Avant de démarrer la pompe, toujours remplir le corps de pompe avec de

l’eau (ou avec le liquide à pomper). En l’absence de risque de gel, il n’est

pas nécessaire de vider le corps de pompe après usage.

Le joint d’étanchéité de l’arbre de la pompe est lubrifié par le liquide

pompé. Le joint est conçu pour fonctionner avec des liquides propres ou

sales. Aucun autre élément de la pompe ne nécessite de lubrification.

INSTALLATION D’UN COUDE ET D’UN RACCORD FILETÉ (AP2201B, AP315-1, AP315-1A, AP320-1, AP320-1A, AP320-1B ET AP520)

Enrober le filetage mâle de ruban d’étanchéité à base de Téflon®. Ce

ruban fournit une étanchéité supérieure à la pâte à joints sans nécessiter

un serrage susceptible d’endommager le filetage. Assembler le raccord

sur le corps de pompe. Le serrage correct correspond à un serrage à la

main suivi d’un tour complet effectué à l’aide d’une clé (ne pas serrer

davantage).

6

Page 7

MODE D’EMPLOIMODE D’EMPLOI

MODE D’EMPLOI

MODE D’EMPLOIMODE D’EMPLOI

1. Pour le pompage d’eau sale

ou de liquides contenant

des solides, toujours

placer une crépine à l’extrémité

de la conduite d’aspiration.

2. Vérifier que les conduites et les raccords sont étanches à l’air.

Une fuite d’air dans la conduite d’aspiration peut empêcher

l’amorçage de la pompe et réduit ses performances. Vérifier

également que le bouchon de remplissage à la partie

supérieure de la pompe et le bouchon de vidange à sa partie

inférieure sont étanches à l’air.

3. Toujours placer la pompe aussi près que possible du liquide à

pomper, mais pas dans un endroit confiné. Maintenir la pompe

et le moteur en position horizontale. Lorsque la conduite

d’aspiration repose sur du terrain très incliné, ou pend dans un

trou, le poids de la conduite et du liquide qu’elle contient peut

entraîner la pompe dans le liquide. Attacher la pompe pour

l’empêcher de « s’échapper » et éviter de la perdre.

4. Toujours vérifier que la pompe est remplie de liquide avant de

faire démarrer le moteur. Par temps de gel, toujours vider la

pompe de son liquide après utilisation. Par temps de gel, après

avoir remis du liquide dans la pompe, faire tourner le moteur

très lentement à la main afin de vérifier que la pompe peut

tourner avant de faire démarrer le moteur. Lorsque la pompe

est gelée, la faire dégeler lentement. (Ne pas utiliser de flamme

pour faire dégeler la pompe).

5. Lorsque le liquide à pomper est contaminé par de la boue ou

des détergents (beaucoup de rivières et de lacs contiennent

des détergents) susceptibles de mousser dans la pompe, il

peut être nécessaire d’amorcer la pompe avec de l’eau propre

(eau potable). Une fois amorcée, la pompe peut fonctionner en

présence du liquide contaminé.

6. Pour obtenir un débit maximal :

(a) maintenir les conduites aussi rectilignes que possible et

éviter les noeuds et coudes brusques,

(b) réduire au minimum la hauteur d’aspiration (voir figure),

(c) utiliser des conduites d’aspiration et de refoulement de gros

diamètre (plus le diamètre est gros, plus la friction est

faible),

(d) utiliser le moins possible de raccords et de coudes,

(e) maintenir la pompe et le matériel connexe en bon état de

fonctionnement.

HAUTEUR D’ASPIRATION

MAXIMALE DE 7,5 MÈTRES

(25 PIEDS)

DÉNIVELLATION

DE 1,5 MÈTRE

(5 PIEDS)

MANIÈRE DE

PROTÉGER LA

CRÉPINE

CONTRE LE

LIMON DES

RIVIÈRES

TOUS LES RACCORDS SUR LE CÔTÉ ASPIRATION

DOIVENT ÊTRE ÉTANCHES À L’AIR.

MAINTENIR LA POMPE SUFFISAMMENT

LOIN DU BORD POUR QUE LA

CONDUITE D’ASPIRATION NE PUISSE

L’ENTRAÎNER DANS L’EAU. ATTACHER

LA POMPE LE CAS ÉCHÉANT.

LA POMPE PEUT FONCTIONNER AVEC

UNE DÉNIVELLATION ALLANT JUSQU’À

7,5 MÈTRES (25 PIEDS), MAIS IL EST

PRÉFÉRABLE D’UTILISER LA

DÉNIVELLATION LA PLUS FAIBLE

POSSIBLE.

PLACER SUR UN

LIT DE CAILLOUX

ATTACHER À

L’INTÉRIEUR D’UN

VIEUX PANIER OU

D’UN VIEUX SEAU

7. Si une conduite flexible doit traverser une voie d’accès,

protéger la conduite à l’aide de planches. Les surpressions

instantanées résultant du passage d’un véhicule sur une

conduite non protégée causent un effet de bélier. L’effet de

bélier peut fendre le corps de pompe ou endommager la

conduite.

PROTÉGER LES CONDUITES

FLEXIBLES TRAVERSANT LES VOIES

D’ACCÈS À L’AIDE DE PLANCHES.

8. Lorsque la crépine d’aspiration est susceptible d’être colmatée

par de la boue ou des racines, préparer un lit de cailloux sur

lequel la crépine pourra reposer, ou attacher la crépine de

manière à la maintenir au-dessus de la surface du sol, ou

l’attacher dans un panier ou un seau (voir figure).

9. Le pompage de liquides contenant des solides (tels les engrais

liquides) est caractérisé par un temps d’amorçage plus long et

un débit plus faible au fur et à mesure que la proportion de

solides augmente dans le liquide à pomper. La viscosité ou

épaisseur du liquide affecte également le temps d’amorçage et

le débit. Toute viscosité ou épaisseur du liquide augmente la

friction ou résistance au mouvement dans la pompe et les

conduites, et réduit le débit.

10. Le clapet antiretour en caoutchouc moulé dans la « cheminée »

d’une pompe à volute colmate la pompe pour retenir le liquide

dans la conduite d’aspiration, de telle sorte que la pompe

puisse immédiatement recommencer à pomper après de

courtes périodes d’arrêt.

11. Lorsque la pompe n’est utilisée que de façon intermittente, il est

recommandé de vérifier que l’appareil est prêt à fonctionner en

(a) vérifiant le niveau d’huile dans le carter, et (b) remplissant la

pompe de liquide.

7

Page 8

ENTRETIEN DU MOTEUR ET ENTREPOSAGE DE L’APPAREIL

1. Suivre les instructions de la notice d’entretien Briggs & Stratton

pour tout ce qui concerne l’entretien du moteur. Le filtre à air doit

être nettoyé régulièrement, l’huile moteur doit être maintenue à

un niveau correct dans le carter et doit être changée à

intervalles réguliers.

2. Toutes les 100 heures de fonctionnement, démonter la culasse

et enlever soigneusement les dépôts dans la chambre de

combustion et sur la partie supérieure du piston. Nous

recommandons que les travaux d’entretien, tel l’enlèvement des

dépôts de carbone, soient effectués par une station-service de

matériel de construction Briggs & Stratton ou Homelite. À cette

occasion, le moteur peut être inspecté, réparé le cas échéant et

réglé de manière à obtenir le meilleur fonctionnement.

3. Lorsqu’il est prévu de ne pas utiliser l’appareil pendant de

longues périodes, la pompe et le moteur doivent être préparés

en vue de leur stockage de la manière suivante :

DÉTECTION DES PANNES ET RÉPARATION DE LA POMPE

(a )si le réservoir de carburant du moteur contient de l’essence traitée

avec un antioxydant, il est possible de stocker la pompe

pendant deux mois avec un réservoir

complètement rempli ; Si l’essence n’est pas traitée,

vider le réservoir et utiliser le carburant dans un autre moteur ; Faire

démarrer le moteur et le laisser tourner jusqu’à ce qu’il s’arrête de lui-

même par manque d’essence ;

(b) vidanger la pompe ; Si la pompe contient des liquides pouvant sécher

et former des dépôts solides, il est recommandé de pomper un

peu d’eau propre avant de vidanger la pompe ;

(c) enlever les bouchons de remplissage et de vidange de la pompe ;

(d) essuyer l’extérieur de l’appareil et entreposer celui-ci dans un endroit

sec, bien ventilé et éloigné de tout engrais ou sel corrosif ; Faire son

possible pour ranger l’appareil dans un endroit froid ou frais où la

température varie très peu ; Comme l’humidité et la chaleur accélèrent

l’oxydation des éléments du moteur, un emplacement froid et

se c présente les meilleures garanties de

longue vie pour le moteur.

DIAGNOSTIC

1. PAS D’AMORÇAGE OU PAS DE POMPAGE

7,5 MÈTRES (25 PIEDS) MAX.

2. LE DÉBIT EST ACCEPTABLE POUR DE FAIBLES

DÉNIVELLATIONS, MAIS DÉCROÎT RAPIDEMENT

POUR DES DÉNIVELLATIONS MOYENNES.

REMÈDE

• Remplir la pompe avec un liquide propre et essayer de

nouveau d’amorcer.

• Débrancher les conduites d’aspiration et de refoulement au

niveau de la pompe. Vérifier l’aspiration de la pompe en

maintenant la paume de la main contre l’orifice d’aspiration (ou

utiliser un manomètre). Le manomètre doit indiquer une

dépression maximale d’environ 25 pouces (65 cm) Hg. Une

dépression inférieure peut être tolérable si l’on est prêt à

accepter des performances plus faibles. Si les performances

ne sont pas satisfaisantes, démonter l’appareil et vérifier la

roue, la plaque d’usure et le joint d’étanchéité.

• Si l’aspiration de la pompe est correcte, brancher la conduite

d’aspiration et vérifier l’aspiration à l’extrémité de la conduite.

Un manque d’aspiration à ce niveau indique une fuite dans un

raccord ou dans la conduite, ou un affaissement de la

conduite. Les revêtements intérieurs de conduites d’aspiration

endommagées bloquent fréquemment l’intérieur des conduites.

• En cas de bonne aspiration, installer la conduite de

refoulement. À ce niveau, la seule interférence possible avec le

pompage proviendrait d’une obstruction dans la conduite.

• Une pompe usée ne peut fonctionner qu’avec de faibles

dénivellations. Réduire la dénivellation si cela est possible, ou

vérifier la pompe de la manière indiquée ci-dessous.

• Les vis du corps de pompe se sont desserrées au point de

permettre des fuites d’air. vérifier de nouveau après les avoir

resserrées.

• Des éléments de la pompe sont usés ou endommagés.

Démonter l’appareil. Vérifier la plaque d’usure en caoutchouc,

la volute de la roue et le joint d’étanchéité de l’arbre. Remplacer

tout élément cassé ou usé ; vérifier le dégagement entre les

pales de la roue et la plaque d’usure. Remonter l’appareil en

utilisant de nouveaux joints toriques. Pendant le remontage,

utiliser des cales pour obtenir un dégagement de 0,4 mm

(.015”) entre la volute et la roue.

NOTA

Lorsqu’une pompe ne fonctionne pas de façon satisfaisante compte tenu des

résultats que l’on attend d’elle pour le pompage de liquides lourds ou en présence de

dénivellations importantes, il est possible que la pompe n’en soit pas responsable. Si

l’on ne peut identifier les raisons du problème, faire inspecter le moteur, le faire

remettre en état le cas échéant, et le faire régler en fonction de l’altitude d’utilisation.

8

Page 9

CARTER

DE ROUE

BAGUE D’ÉTANCHÉITÉ

CALE DE .015”(0,4 mm) SELON LE

BESOIN

ON PEUT DÉMONTER ET RÉASSEMBLER LA

POMPE EN UTILISANT SEULEMENT UNE CLÉ À

TUBE ET UN GROS TOURNEVIS

JOINT TORIQUE

BAGUE D’ÉTANCHÉITÉ

PETIT JOINT TORIQUE (4)

GROS JOINT TORIQUE

SEGMENT DE BAGUE

TORIQUE

VIS DE CARTER (4)

ROUE

PETIT JOINT TORIQUE (1)

VIS DE FIXATION DE LA ROUGE

CLAVETTE D’ARBRE

VOLUTE

CLAPET ANTIRETOUR

« CHEMINÉE » DE LA

VOLUTE

BOUCHON DE

REMPLISSAGE

CORPS DE POMPE

BOUCHON DE VIDANGE

VIS DE CARTER (10)

1. En utilisant un gros tournevis pour enlever les vis de 1/4”, les

rondelles d’arrêt et les écrous, séparer le corps de pompe du

carter de roue.

2. Enlever le clapet antiretour en caoutchouc de la « cheminée »

de la volute.

3. Enlever la grosse vis autotaraudeuse à la partie supérieure de

la volute et les deux plus petites vis autotaraudeuses sur les

côtés de la volute.

4. Dévisser et enlever la vis de fixation de la roue de 5/16-24 x 3/

4 (filetage à pas fin) ainsi que son petit joint torique. Sortir la

roue en la faisant glisser le long de l’arbre et de la clavette.

5. Une moitié du joint d’étanchéité de l’arbre se trouve dans le

moyeu de la roue, l’autre moitié se trouve sur l’arbre à

l’intérieur de la plaque arrière. Enlever les deux moitiés.

6. Enlever les quatre vis en acier (et leurs petits joints toriques)

et séparer le carter de roue du moteur en le tirant.

7. Vérifier que la clavette est bien ajustée dans la rainure de

l’arbre. Dans le cas contraire, remplacer la clavette avec une

plus large.

8. Pour un pompage efficace, le dégagement entre les pales de

roue et la volute doit être d’environ 0,4 mm (.015”). En cas

d’usure des pales de roue et de la volute, il peut y avoir trop de

dégagement « avant ». Le dégagement peut être réduit en

enlevant une ou plusieurs des cales se trouvant entre le carter

de roue et le moteur. Après avoir de nouveau bloqué la roue

temporairement en place, vérifier le dégagement entre les

pales de roue et la volute avec une jauge d’épaisseur à lame.

Continuer le remontage de la pompe conformément aux

indications ci-dessous.

9. S’il n’est pas possible d’obtenir un dégagement suffisamment

proche de 0,4 mm (.015”) entre la roue et la plaque d’usure,

installer de nouvelles pièces selon le besoin.

10. Pendant le montage final, ne pas oublier de remplacer tous les

joints toriques, à moins d’être sûr qu’ils sont en bon état.

11. Remonter toutes les pièces dans l’ordre inverse de celui de leur

démontage.

AVERTISSEMENT

Ne pas utiliser d’huile minérale ni de graisse au cours du

remontage, et ne pas pomper de produits pétroliers avec cette

pompe.

12. Au cours du montage des raccords et des coudes sur le corps

de pompe, enrouler les filetages mâles de ruban d’étanchéité à

base de Téflon®. Ce ruban fournit une étanchéité supérieure à la

pâte à joints sans nécessiter un serrage susceptible

d’endommager les filetages. Le serrage correct correspond à

un serrage à la main suivi d’un tour complet effectué à l’aide

d’une clé (ne pas serrer davantage).

13. Les quatre vis 5/16”-24 x 1-1/8” (chacune munie d’un joint

torique) retenant le carter de la roue sur le moteur doivent être

bien serrées à l’aide d’un gros tournevis. Lorsque le remontage

est terminé, remplir la pompe de liquide et vérifier que la pompe

a retrouvé toutes ses capacités.

14. Au cours du montage, ne pas serrer les vis retenant la volute

plus qu’il n’est nécessaire pour juste retenir la volute. Un

serrage excessif peut entailler les joints toriques. Les vis de la

roue et les vis extérieures du corps de pompe doivent être

suffisamment serrées pour empêcher les fuites d’air.

ATTENTION

Pendant le remontage de la pompe (étapes 10 à 15) après le

réglage du dégagement (étapes précédentes), vérifier que la

volute et la roue ne sont pas en contact. Faire lentement pivoter

l’arbre avec la main et écouter pour la présence de bruits de

frottement. En l’absence de bruits de frottement, verser du liquide

d’amorçage dans la pompe et faire démarrer le moteur. L’absence

de bruits de frottement indique que le montage est probablement

correct.

9

Page 10

E PRECAUCIONES DE SEGURIDADE PRECAUCIONES DE SEGURIDAD

E PRECAUCIONES DE SEGURIDAD

E PRECAUCIONES DE SEGURIDADE PRECAUCIONES DE SEGURIDAD

ADVERTENCIA

PREPARACION DE LA BOMBA PARA SUPREPARACION DE LA BOMBA PARA SU

PREPARACION DE LA BOMBA PARA SU

PREPARACION DE LA BOMBA PARA SUPREPARACION DE LA BOMBA PARA SU

UTILIZACIONUTILIZACION

UTILIZACION

UTILIZACIONUTILIZACION

1. Esta bomba ha sido diseñada para bombear agua y fertilizantes

líquidos, herbicidas y pesticidas generales para granjas. Esta

bomba no se debería utilizar para bombear materiales

inflamables tales como gasolina. Se pueden producir

explosiones, dando origen a lesiones serias. Los materiales

corrosivos se deben manejar con cuidado, teniendo en cuenta

las instrucciones de manipulación aplicables al material de que

se trate.

2. Antes de poner en marcha la bomba, estudie todas las

instrucciones que se indican en el presente folleto y las

instrucciones de Funcionamiento y Mantenimiento del Motor

que se suministran con la unidad. Asegúrese de que entiende

completamente la operación de la máquina. La preparación,

operación y mantenimiento adecuados traerán consigo un

funcionamiento seguro para el operario, un rendimiento óptimo

y una vida útil larga de la unidad.

3. Asegúrese de que todas las personas que operen la unidad

hayan recibido las instrucciones apropiadas relativas a la

utilización segura de la misma.

4. No opere nunca esta unidad en una atmósfera donde haya

explosivos presentes, cerca de materiales combustibles ni en

lugares donde no exista una ventilación adecuada para

evacuar los gases de escape.

5. Asegúrese siempre de que la máquina esté apoyada

firmemente de manera que no pueda deslizarse o desplazarse

de un lado a otro, poniendo en peligro a los trabajadores.

6. Asegúrese de que no haya personas alrededor del área

inmediata del lugar donde vaya a utilizar la unidad.

DESEMBALAJE DE LA BOMBA

Cuando proceda a desembalar la unidad, afloje los soportes,

abrazaderas y material de embalaje utilizado para transportar la unidad.

Inspeccione la unidad cuidadosamente para ver si se han producido

daños durante el transporte. Si encuentra cualquier tipo de daño,

comuníqueselo inmediatamente a su distribuidor o a la compañía de

transportes.

Lea detenidamente estas instrucciones y las instrucciones relativas al

motor de 4 ciclos hasta que esté seguro de que puede preparar el motor

y la bomba adecuadamente para su utilización posterior y puede operar

la unidad segura y correctamente.

GARANTIA

La bomba se encuentra garantizada de conformidad con las condiciones

establecidas en la tarjeta de garantía que se envía con la bomba y

durante el período de tiempo indicado en la misma. Rellene la tarjeta y

envíela por correo.

PREPARACION DEL MOTOR

El motor se encuentra lubricado por el aceite del motor existente en el

cárter. El motor ha sido regulado para operar a velocidades próximas a

3600 rpm. Ni el operario ni el propietario

regulador automático.

El combustible adecuado para este motor de 4 ciclos es gasolina

de grado normal de 87 octanos (media) como mínimo. No se

debería mezclar aceite con la gasolina. No obstante, se deberá

comprobar el aceite para lubricar el motor que se encuentra en el

cárter antes de utilizar la unidad. Siga las instrucciones existentes

en el manual de instrucciones de Briggs & Stratton en todo lo

relativo a preparación del motor de 4 ciclos, selección del aceite del

motor, funcionamiento, mantenimiento y resolución de problemas.

NOTA

deben cambiar

el ajuste del

7. Cuando proceda a poner en marcha la máquina, asegúrese de

que no haya ningún objeto alrededor que pueda ser golpeado

por la mano o el brazo del operario o la cuerda para poner en

marcha la unidad.

8. No opere nunca la unidad cuando la protección no se

encuentre en su sitio.

9. Cumpla todos los reglamentos de seguridad relativos a la

manipulación segura del combustible en recipientes de

seguridad. Si el recipiente no tiene tubo, utilice un embudo. No

llene el depósito de combustible mientras el motor esté en

marcha. Llene el depósito únicamente en un área donde el

terreno sea llano. Manténgase alejado de las chispas, el calor

y las llamas abiertas mientras esté llenando el depósito. Limpie

cuidadosamente el combustible que se haya derramado antes

de poner en marcha el motor.

10. Evite el contacto con el colector de salida de humos, el

silenciador o el cilindro cuando estén calientes. Manténgase

alejado de todas las piezas giratorias.

11.Mantenga la máquina y el equipo relacionado limpio en todo

momento y lleve a cabo las tareas de servicio y mantenimiento

que resulten necesarias.

12. Antes de llevar a cabo tareas de servicio en cualquier parte de

la máquina, apague el motor y desconecte el cable de la bujía

con el fin de evitar que se ponga en marcha accidentalmente.

13. No ponga nunca en marcha la bomba en un área cerrada.

14. Utilice únicamente las piezas de repuesto originales del

fabricante. El hecho de no hacerlo puede dar origen a una

adaptación inadecuada y es posible que se produzcan

lesiones.

10

No deje gasolina en el depósito del motor durante períodos de tiempo

largos ya que la gasolina pierde propiedades con el transcurso del

tiempo. Los peróxidos y gomas existentes en la gasolina que llevan

demasiado tiempo en el depósito pueden atacar las superficies interiores

del sistema de combustible y del motor, obstruir el carburador y evitar

que la unidad se ponga en marcha. La “condiciones óptimas” de la

gasolina recién salida del surtidor se pueden prolongar durante varios

meses tratando la gasolina comprada recientemente con algún tipo de

estabilizador antioxidante (como, por ejemplo STA-BILâ, disponible a

través de Gold Eagle Laboratories, Chicago, Illinois 60632), de

conformidad con las instrucciones que aparecen en la lata del

estabilizador.

PREPARACION DE LA BOMBA

PRECAUCION

No ponga la bomba en marcha en seco. Es necesario que haya

algún tipo de líquido en la bomba que lubrique el sello del eje de la

bomba.

Llene siempre el cuerpo de la bomba con agua ( o el líquido que se vaya

a bombear) antes de poner en marcha la bomba. No es necesario

drenar el cuerpo de la bomba después de utilizarla, a menos que exista

peligro de que se congele.

El líquido que se está bombeando lubrica el sello del eje de la bomba. El

sello se encuentra diseñado para funcionar con líquidos limpios o sucios.

No existe ningún otro punto en la bomba que requiera lubricación.

INSTALACION DEL CODO Y EL ACOPLADOR: (AP220-1B, AP315-1,

AP315-1A, AP320-1, AP320-1A, AP320-1B y AP520)

Envuelva las roscas macho con cinta obturadora de Teflon. La

hermeticidad que proporciona esta cinta es mejor que la del compuesto

para juntas de tubos, sin que sea necesario que las conexiones estén

excesivamente apretadas y se dañen las roscas. Monte el acoplador en

el cuerpo de la bomba. La forma adecuada de hacerlo es apretarlo con

la mano y darle una vuelta adicional haciendo uso de una llave de tuerca

para tubos (no más apretado).

Page 11

INSTRUCCIONES DE

FUNCIONAMIENTO

1. Cuando bombee agua

sucia o líquidos que

contengan sólidos, utilice siempre

una alcachofa de aspiración en el

extremo de la línea de succión.

2. Asegúrese de que todas las conexiones de las mangueras y

los tubos estén selladas herméticamente. Las fugas de aire en

la línea de succión pueden impedir que se cebe la unidad y

reducen la capacidad de la bomba. Asegúrese también de que

el tapón de llenado que se encuentra encima de la bomba y el

tapón de drenaje existente en la parte posterior trasera estén

cerrados herméticamente.

3. Coloque siempre la bomba lo más cerca posible del líquido

que se esté bombeando, teniendo presente en todo momento

que no se debe colocar en un área cerrada. Mantenga la

bomba y el motor sobre una base nivelada. Tenga en cuenta

que cuando la manguera de succión cuelga hacia abajo en un

desnivel empinado o se introduce en un orificio, el peso de la

manguera y del líquido existente en su interior pueden tirar de

la bomba en dirección al líquido. Fíjela al suelo para evitar el

“desplazamiento” o la pérdida posible de la bomba.

4. Asegúrese siempre de que la bomba contenga líquido antes de

poner en marcha el motor. Cuando el clima sea muy frío y

hiele, drene siempre el líquido para que salga de la bomba

después de utilizarla. Después de rellenar la bomba cuando

hiela, dele vueltas al motor muy lentamente de manera que

pueda ver si la bomba funciona normalmente antes de poner

en marcha el motor. En el supuesto de que la bomba esté

congelada, deje que se deshiele lentamente. (No utilice fuego

para descongelar la bomba).

5. En aquellos casos en los que el líquido de la bomba esté

contaminado con lodo o detergentes (muchos ríos y lagos

contienen detergentes), los cuales crean espuma cuando se

agitan en la bomba, puede resultar necesario cebar la bomba

con agua limpia (agua del grifo). Una vez que haya cebado la

unidad, la bomba tendrá capacidad para funcionar con líquido

contaminado.

6. El máximo volumen se consigue:

a) manteniendo las líneas lo más rectas posible y evitando

que la manguera se retuerza o se doble de forma excesiva.

b) Reduciendo al máximo la altura de impulsión de succión

vertical (consulte la ilustración).

c ) Utilizando líneas de succión y descarga de gran diámetro

(cuanto mayor es el diámetro menor es la fricción).

d) Utilizando el menor número posible de conectores, codos y

adaptadores.

e) Manteniendo la bomba y el equipo relacionado en buenas

condiciones de funcionamiento.

7. En caso de que se deba utilizar una manguera flexible que

atraviese una carretera, se deberá proteger con tablones de

madera. Las presiones de cierre instantáneo, aplicadas

cuando un vehículo pasa por encima de una manguera que no

se encuentra protegida, provocan la afluencia súbita de agua.

Esta afluencia súbita de agua puede separar el cuerpo de la

bomba o dañar la manguera.

MANTENGA LA BOMBA LO

SUFICIENTEMENTE ALEJADA DE LA

ORILLA DE MANERA QUE LA

MANGUERA DE SUCCION NO TIRE

DE LA UNIDAD HACIA EL AGUA.

LA MAXIMA ALTURA DE

IMPULSION DE SUCCION ES

25 PIES

FIJE LA BOMBA AL SUELO SI

RESULTA NECESARIO.

LA BOMBA PUEDE IMPULSAR A

UNA ALTURA MAXIMA DE HASTA

25 PIES, AUNQUE ES PREFERIBLE

UTILIZAR LA MENOR DISTANCIA

POSIBLE DE IMPULSION DE

SUCCION

ALTURA DE

IMPULSION DE

SUCCION DE 5

PIES

COLOCAR SOBRE

UN LECHO DE

MANERAS DE

PIEDRAS

MANTENER LA

ALCACHOFA DE

ASPIRACION

ALEJADA DE LOS

SEDIMENTOS DEL RIO

ATELA DENTRO DE

UN CUBO VIEJO O

UNA CESTA

NOTA: TODAS LAS CONEXIONES DEL

LADO DE SUCCION DE LA BOMBA DEBEN

SER HERMETICAS.

8.Hvis det er fare for at inntaksfilteret kan tettes til med

jordmasse og røtter, kan du lage en steinhaug der

inntaksfilteret skal ligge, eller binde filteret slik at det holdes

over bunnen, eller binde det fast i en kurv eller en bøtte (se

illustrasjonen).

9. Ved pumping av væsker (som flytende gjødsel) som inneholder

tørrstoff, vil det ta lengre tid å fjerne luft i systemet, og

pumpevolumet (liter per minutt) vil avta ettersom andelen av

tørrstoff i væsken som pumpes øker. Væskens viskositet, eller

tykkelse, virker også inn på tiden det tar å fjerne luft, og på

pumpevolumet. All væskekonsistens som øker friksjon og

motstand i pumpen og i rørene, vil forsinke utslippet.

PROTEJA LA MANGUERA FLEXIBLE

CON TABLONES DE MADERA QUE

ATRAVIESEN LA CARRETERA

10. Den gummistøpte sikkerhetsventilen i “skorsteinen” av

pumpevolutten stenger av pumpen slik at den holder væsken i

sugerøret. Pumpen vil derfor begynne å pumpe umiddelbart

etter den har vært slått av i korte perioder.

11. Hvis pumpen ikke er i bruk så ofte, er det en god idé å

kontrollere at den er klar for bruk ved å (a) undersøke

oljenivået i motorens veivhus, og (b) fylle pumpen med væske.

11

Page 12

MANTENIMIENTO DEL MOTOR Y ALMACENAMIENTO DE LA UNIDAD

1. Siga las instrucciones existentes en el manual de instrucciones

de Briggs & Stratton en todo lo relativo a mantenimiento del

motor. El filtro del aire se debe limpiar regularmente. Se deberá

mantener asimismo el nivel adecuado de aceite en el cárter. El

aceite del motor debe cambiarse a intervalos de tiempo

regulares.

2. Después de cada 100 horas de funcionamiento se debería

retirar la culata del cilindro y quitar cuidadosamente los

depósitos del motor existentes en la cámara de combustión y

en la parte superior del pistón. Recomendamos que las

operaciones de servicio del motor, tales como la retirada del

carbón, se lleven a cabo en un Centro de Servicio de Briggs &

Stratton o Homelite. Este es el momento adecuado para

inspeccionar, reparar (en caso de que resulte necesario) y

poner a punto el motor para que ofrezca un rendimiento óptimo.

3. Cuando el motor vaya a estar parado durante un período de

tiempo largo, se deberán preparar tanto la bomba como el

motor con el fin de almacenarlos, tal y como se indica a

continuación:av bensinen kan brukes i en annen motor. Start

pumpemotoren, og la den gå til den stopper av seg selv.

RESOLUCION DE PROBLEMAS Y REPARACION DE LA BOMBA

DIAGNOSTICO

1. NO SE CEBA O NO BOMBEA

a) Si el depósito del motor contiene gasolina tratada con antioxidantes,

usted puede almacenar la bomba con el depósito lleno hasta arriba

durante un período de tiempo de hasta dos meses. Si la gasolina no

ha sido tratada, deberá vaciar el depósito y usar el suministro de

combustible de reserva en otro motor. Ponga en marcha el motor

de la bomba y déjelo funcionar hasta que se pare por falta de

combustible.

b) Vacíe la bomba. Si la bomba contiene líquidos que pueden secarse

y solidificarse, se recomienda bombear un poco de agua limpia

antes de vaciar la bomba.

c ) Deje los tapones de llenado y vaciado fuera de la bomba.

d) Limpie el exterior de la unidad. La unidad se debe almacenar en un

área seca y bien ventilada que se encuentre alejada de fertilizantes

y sales corrosivas. Intente guardar la unidad en un área fría donde

haya cambios mínimos de temperatura. La humedad y el calor

aceleran la oxidación de los componentes del motor de manera que

lo mejor es almacenar la unidad en áreas frías y secas para que el

motor dure el máximo tiempo posible.

TRATAMIENTO

• Llene la bomba con un líquido limpio e intente cebarla nuevamente.

25 PULGADAS (MAX.)

2. CAUDAL ADECUADO A ALTURAS DE

IMPULSION BAJAS, PERO CAE A

ALTURAS DE IMPULSION DE

SUCCION MEDIAS

• Desconecte las líneas de succión y descarga en la bomba. Compruebe

la succión de la bomba poniendo la palma de la mano en la abertura de

succión ( o use un manómetro). El manómetro debería indicar una

aspiración de aproximadamente 25 pulgadas Hg. La aspiración puede

ser menor siempre y cuando el rendimiento resulte adecuado para sus

necesidades. En caso contrario, se deberán desmontar y comprobar

el impulsor, la placa de desgaste y el sello.

• Si las pruebas de succión de la bomba son adecuadas, conecte la línea

de succión y compruebe la succión en el extremo de la línea de succión.

El hecho de que la succión aquí no sea la adecuada indica la existencia

de conexiones con fugas o líneas que tienen fugas o están dobladas.

Los revestimientos de las mangueras de succión que están dañadas

quedan aspirados a menudo, cerrando el paso dentro de la manguera.

••

• Si la succión de entrada es adecuada, coloque la línea de descarga. Lo

••

único que puede interferir en el cebado en este momento sería una

obstrucción.

••

• Las bombas desgastadas pueden funcionar a alturas de impulsión

••

bajas. Reduzca la altura de impulsión, si resulta posible, o compruebe

la bomba tal y como se indica a continuación.

••

• Los tornillos se han aflojado y esto ha dado origen a una fuga de aire

••

interna. Vuelva a comprobar el funcionamiento después de apretarlos.

••

• Las piezas de la bomba están desgastadas o dañadas. Desmóntela.

••

Compruebe la placa de desgaste de caucho, la voluta del impulsor, y el

sello del eje. Reemplace los componentes que estén rotos o desgastados;

compruebe la separación existente entre las paletas del impulsor y la

placa de desgaste. Vuelva a ensamblarla utilizando anillos tóricos

nuevos. Ajuste con una cuña dejando una separación de .015” entre

impulsor y la voluta durante el ensamblaje.en.

NOTA

La falta de rendimiento satisfactorio de la bomba (es decir, bombear líquidos densos o funcionar a alturas de impulsión elevadas de

conformidad con la capacidad prevista) puede deberse a causas ajenas a la bomba. Si no observa ningún problema en la bomba, llévela a

un centro de servicio para que la inspeccionen, la reparen (en caso de que resulte necesario) y la pongan a punto de conformidad con la

gama de altitudes a las que usted espera utilizar la bomba.

12

Page 13

COMO DESMONTAR Y REPARAR LA BOMBA

ANILLO TORICO

ARMAZON DEL

IMPULSOR

ESLINGADOR

CUÑA DE .015” SEGUN

SEA NECESARIO

LA BOMBA SE PUEDE DESMONTAR Y VOLVER A MONTAR

USANDO UNICAMENTE UNA LLAVE DE TUERCA DE TUBOS Y

UN DESTORNILLADOR GRANDE

1. Utilizando un destornillador grande para sacar los tornillos de 1/4”,

las arandelas y las tuercas de seguridad, extraiga el cuerpo de la

bomba del armazón del impulsor.

2. Saque la válvula de retención de caucho de la “chimenea” de la

voluta.

3. Retire los tornillos de auto-roscado que se encuentran a los lados

de la voluta.

ANILLO

TORICO

ANILLO TORICO PEQUEÑO (1)

PEQUEÑO (4)

SELLO

IMPULSORL

ANILLO TORICO GRANDE

SEGMENTO DEL ANILLO TORICO

TORNILLOS DEL ARMAZON (4)

CUÑA DE AJUSTE DEL EJE

TORNILLO DEL

IMPULSOR

rozaduras quiere decir que el ensamblaje es probablemente

correcto.

VOLUTA

VALVULA DE

RETENCION

9. Si no puede conseguir una separación entre el impulsor y la

placa de desgaste que sea razonablemente próxima a .015”,

deberá instalar las piezas nuevas que resulten necesarias.

10. Durante el ensamblaje final, asegúrese de cambiar todos los

sellos de los anillos tóricos a menos que esté completamente

seguro de que están en buenas condiciones.

“CHIMENEA” DE VOLUTA

TAPON DE LLENADO Y

TORNILLOS

DEL

CUERPO (10)

ANILLO TORICO

CUERPO DE LA BOMBA

TAPON DE

DRENAJE

4. Desatornille el tornillo del impulsor de 5/16-24 x 3/4 (rosca fina) y

sáquelo junto con el anillo tórico pequeño. Saque el impulsor del

eje y de la cuña de ajuste.

5. Una de las mitades del sello del eje se encuentra en la parte

central del impulsor y la otra mitad se encuentra en el eje

existente dentro de la placa posterior. Saque ambas mitades.

6. Retire los cuatro tornillos de acero (y los anillos tóricos pequeños)

y saque el armazón del impulsor del motor.

7. Asegúrese de que la cuña de ajuste se adapte a la ranura del eje

y quede bien ajustada. Si no es así, reemplace la cuña de ajuste

por una más ancha.

8. La separación que debe haber entre las paletas del impulsor y la

voluta para que el bombeo sea adecuado es .015”

aproximadamente. El hecho de que las paletas del impulsor y la

voluta estén desgastadas puede dar origen a que la separación

“frontal” sea excesiva. Usted puede reducir esta separación

sacando una de las cuñas existentes entre el armazón del

impulsor y el motor, o varias. Una vez que haya vuelto a fijar el

impulsor en su sitio de forma provisional, compruebe la

separación paleta-voluta existente en el impulsor con un

calibrador de separaciones. Continúe con el ensamblaje tal y

como se indica a continuación.

PRECAUCION:

Cuando vuelva a ensamblar la bomba (tal y como se indica en los

pasos 10-14) después de haber ajustado la separación (tal y como se

indica más arriba), deberá asegurarse de que no haya ningún tipo de

contacto entre la voluta y el impulsor. Gire el eje lentamente con la

mano y preste atención para ver si escucha ruidos de rozaduras. Si

no escucha ruidos, ponga el líquido de cebado en la bomba y ponga

el motor en marcha. El hecho de que no escuche ruidos de

11. Vuelva a colocar todas las piezas en el orden inverso al

seguido para desmontar la unidad.

ADVERTENCIA

No utilice ningún tipo de aceite o grasa de petróleo durante el

ensamblaje y no bombee productos de petróleo con esta bomba.

12. Cuando proceda a montar acopladores, adaptadores y

codos en el cuerpo de la bomba, envuelva las roscas macho

con cinta obturadora de Teflonâ. La hermeticidad que

proporciona esta cinta es mejor que la del compuesto para

juntas de tubos, sin que sea necesario que las conexiones

estén excesivamente apretadas y se dañen las roscas. La

forma adecuada de hacerlo es

apretarlas con la mano y

darles una vuelta adicional haciendo uso de una llave de

tuerca de tubo

13. Los cuatro tornillos de 5/16”-24 x 1-1/8” (con un anillo tórico

en cada uno de ellos) que sujetan el armazón del impulsor al

motor deberían apretarse firmemente con un destornillador

grande. Una vez que haya terminado de montar la unidad,

llene la bomba de líquido y compruebe si se ha restaurado su

capacidad máxima.

14. Los tornillos que mantienen la voluta en posición se deben

apretar lo suficiente como para fijar la voluta durante el

ensamblaje. Apretarlos excesivamente puede provocar el

corte de los anillos tóricos. Los tornillos del impulsor y del

cuerpo exterior se deberían apretar moderadamente para

asegurarse de que no existan fugas de aire.

(Por favor no las apriete más).

13

Page 14

30

31

30

28

34

31

31

30

28

32

27

27

29

33

35

32

1

2

4

5

34

32

3

10

9

7

6

11

8

12

13

15

14

7

17

16

19

21

18

31

22

32

31

20

32

23

24

24

25

26

REPLACEMENT PARTS & ACCESSORY KITS

FOR AP SERIES PUMPS

KEY

NO. DESCRIPTION PART NO. OTY.

1 ENGINE * 1 x x x x x x x x x

MOTEUR / MOTOR

2 SHIM 43269 A/R ¤¤¤¤¤¤ ¤¤¤¤

SHIM (.010) (Not Shown) 42382 A/R xxxxxx xxxx

SHIM(.015) (NotShown) 42383 A/R xxxxxx xxxx

CALE / CUÑA

3 HOUSING- Impeller 43270 B 1 xxxxxx xxxx

CARTER DE ROUE / ARMAZON DEL IMPULSOR

4 NUT- Hex 1/4 - 20 81172 B 10 xxxxxx xxxx

ÉCROUS / TUERCAS DE SEGURIDAD

5 WASHER- Lock 1/4 83051 B 10 xxxxxx xxxx

RONDELLES D'ARRÊT / ARANDELAS

6 “O”RING (BunaN) 43751 1 x 0 x 0 0 x x 0

“O” RING (EPDM) 43752 1 x x x ‡ ‡ ‡ ‡ x

JOINT TORIQUE / ANILLO TORICO

7 “O”RING,Screw (BunaN) 67900 5 x 0 x 0 0 x x x x 0

“O” RING, Screw (EPDM) 43313 5 ‡ x ‡ x x ‡ ‡ ‡ ‡ x

JOINT TORIQUE / ANILLO TORICO

8 SCREW, Bracket, impeller hsg. 43302B 4 xxxxxx xxxx

VIS / TORNILLO

9 “O” RING,Segment (BunaN) 43272 1 x 0 x 0 0 x x x x 0

“O” RING,Segment (EDPM) 43314 1 ‡ x ‡ x x ‡ ‡ ‡ ‡ x

JOINT TORIQUE / ANILLO TORICO

10 “O” RING, Body (Buna N) 43273 1 x 0 x 0 0 x x x x 0

“O” RING, Body (EPDM) 43312 1 ‡ x ‡ x x ‡ ‡ ‡ ‡ x

JOINT TORIQUE / ANILLO TORICO

11 SHAFT SEAL (Buna N) 43271 1 x 0 x 0 0 x x x x 0

SHAFT SEAL (EPDM) 43303 A 1 ‡ x ‡ x x ‡ ‡ ‡ ‡ x

BAGUE D’ÉTANCHÉITÉ / SELLO

12 KEY,3/16 x 3/16 x 1 43301 A 1 xxxxxx xxxx

CLAVETTE D’ARBRE / CUÑA DE AJUSTE DEL EJE

13 IMPELLER 43274 B 1 xxxxxx xxxx

ROUE / IMPULSOR

14 SCREW, Impeller, rd. hd. 43284 B 1 xxxxxx xxxx

5/16-24 x 3/4

VIS-ROUE / TORNILLO-IMPULSOR

15 VOLUTE 43324 A 1 xxxxx¤ ¤¤¤x

VOLUTE (BunaN) PA00094 1 x x x x

VOLUTE / VOLUTA

16 SCREW-Volute (stainless) 43285 C 2 xxxxxx xxxx

6-32 x 1/2 rd. hd.

VIS-VOLUTE / TORNILLOS-VOLUTA

17 SCREW- Volute top 46044 A A/R ¤¤¤¤¤¤ ¤¤¤¤

(10-24 x 1 1/2) rd. hd.

VIS-VOLUTE / TORNILLOS-VOLUTA

AP215-1

AP215-1A

AP220-1

AP220-1A, -1B

AP220-2A

AP315-1

AP315-1A

AP320-1

AP320-1A, -1B, D

AP520

14

Page 15

KEY

NO. DESCRIPTION PART NO. OTY.

AP215-1

AP215-1A

AP220-1

AP220-1A, -1B

AP220-2A

AP315-1

AP315-1A

AP320-1A, -1B, D

AP320-1

AP520-1

18 CHECK VALVE (Buna N) 43276 B 1 x 0 x 0 0 x x x x 0

19 BODY 1 1/2" 43277 A 1 x x x x

20 SCREWS- Body fil. PS46045 A 10 x x x x x x x x x x

21 “0” RING- Fil. plug (Buna N) 43316 1 x 0 x 0 0 x x x x 0

22 PLUG- Filler 43311 A 1 x x x x x x x x x x

23 ELBOW- Street, 1 1/2" 43304 1 ¤ ¤ x x

24 NIPPLE- 1 1/2" 03041 2 ¤ ¤ x x

25 STRAINER, 1 1/2" 43306 1 ¤ ¤ x x

26 PLUG- Drain 46317 A 1 x x x x x x x x x x

27 SCREW- Hex 5/16-18 x 1 46053 A 3 x x x x

28 SCREW- 5/16-18 x 1 3/4" 82504 A 2 x x x x

29 BAR- Mounting 43262 1 1 † † † † † x x x x †

30 WASHER-Lock 5/l6 heavy 83003 3 † † † † † x x x x †

31 NUT- Hex hd., 5/16-18 81132 5 † † † † † x x x x †

32 WASHER- FIat, 5/16 84046 8 † † † † † x x x x †

33 SKID A43263 2 † † † † † x x x x †

34 SPRING- Foot 50389 4 † † † † † x x x x †

35 SLINGER 02964 1 x x x x x x x x x x

CHECKVALVE (EPDM) 43300 B 1 ‡ x ‡ x x ‡ ‡ ‡ ‡ x

CLAPET ANTIRETOUR / VALVULA DE RETENCION

BODY 2" 43278 A 1 x x x x x x

CORPS DE POMPE / CUERPO DE LA BOMBA

(1/4-20 x 2 1/2)

VIS/ TORNILLOS

“0” RING- Fil. plug (EPDM) 43315 1 ‡ x ‡ x x ‡ ‡ ‡ ‡ x

JOINT TORIQUE / ANILLO TORICO

BOUCHON / TAPON DE LLENADO

ELBOW- Street, 2" 43305 1 ¤ ¤ ¤ x x ¤

COUDE / CODO

NIPPLE- 2" 03040 2 ¤ ¤ ¤ x x ¤

RACCORD FILETÉ / ACOPLADOR

STRAINER, 2" 43307 1 ¤ ¤ ¤ x x ¤

CRÉPINE / ALCACHOFA

BOUCHON DE VIDANGE / TAPON DE DRENAJE

SCREW- Hex 5/16-18 x 7/8" 82598 3 † † † † † †

VIS / TORNILLO

SCREW- 5/16-18 x 1 1/2" 80087 2 † † † † † †

VIS / TORNILLO

BARRE – de montage / BARRA DE REFUERZO

RONDELLES D'ARRÊT / ARANDELAS

ÉCROUS / TUERCAS DE SEGURIDAD

RONDELLES / ARANDELAS

PATINS / CALZO

Includes:

RESSORT - Pied / Resorte de base

RIVET (not shown) 85025 4 † † † † † x x x x †

RIVET / REMACHE

LABEL- Warning (not shown) 43265 1 x x x x x x

ÉTIQUETTE / ETIQUETA

DECAL- EPDM (not shown) 43880 A 1 x x x † † † x

DÉCALQUE / CALCOMANÍA

BAGUE D’ÉTANCHÉITÉ / ESLINGADOR

GB ) x Standard equipment on these models

† Found in accessories Skid Kit A 43318

‡ Found in optional EPDM Repair Kit A 43297 C (see note)

¤ Optional equipment on these models

0 Found in Buna-N Repair Kit A 47832 A

F) x Matériel de série sur ces modèles

† Fait partie des accessoires Skid-Kit (A 43318)

‡ Fait partie du lot de réparation en option EPDM A 43297 C

(Voir Nota)

¤ Matériel en option sur ces modèles

0 Fait partie du lot de réparation Buna-N A 47832 A

E) x Equipo estándar en estos modelos

† En los accesorios del Conjunto de Calzo A 43318

‡ En Equipos opcionales de Reparación EPDM A 43297 C (ver

nota)

¤ Equipo opcional en estos modelos

0 En Equipos de Reparación Buna-N A 47832 A

15

Page 16

DESCRIPTION PART NO.

GB ACCESSORIES:

EPDM Repair Kit (See Note) A 43297 C ¤¤¤¤¤¤¤¤¤¤

Skid Kit A 43318 ¤¤¤¤¤xxxx¤

Viton Repair Kit (opt.) A 48298 A ¤¤¤¤¤¤¤¤¤¤

Buna-N Repair a Kit A 47832 A ¤¤¤¤¤xxxx¤

Steel Fittings (2") 75663 1 ¤ ¤ ¤ ¤ ¤

(1 1/2”) 75959 1 ¤ ¤ ¤

Viton Seal 48299 ¤¤¤¤¤¤¤¤¤¤

S TILLBEHÖR

Lot de réparation EPDM A 43297 C ¤¤¤¤¤¤¤¤¤¤

(Voir Nota ci-dessous)

Lot de patins A 43318 ¤¤¤¤¤xxxx¤

Lot de réparation Viton (en option) A 48298 A ¤¤¤¤¤¤¤¤¤¤

Lot de réparation Buna-N A 47832 A ¤¤¤¤¤xxxx¤

Raccords en acier (2”) 75663 1 ¤ ¤ ¤ ¤ ¤

(1 1/2”) 75959 1 ¤ ¤ ¤

Viton d’étanchéité 48299 ¤¤¤¤¤¤¤¤¤¤

E ACCESORIOS

Equipo de Reparación EPDM A 43297 C ¤¤¤¤¤¤¤¤¤¤

(Ver Nota)

Conjunto de Calzo A 43318 ¤¤¤¤¤xxxx¤

Equipo de Reparación Viton (opc.) A 48298 A ¤¤¤¤¤¤¤¤¤¤

Equipo de Reparación Buna-N A 47832 A ¤¤¤¤¤xxxx¤

Adaptadores de acero (2”) 75663 1 ¤ ¤ ¤ ¤ ¤

(1 1/2”) 75959 1 ¤ ¤ ¤

Viton sello 48299 ¤¤¤¤¤¤¤¤¤¤

AP215-1

AP215-1A

AP220-1

AP220-1A, -1B

AP220-2A

AP315-1

AP315-1A

AP320-1

AP320-1A, -1B, D

AP520-1

Torque Specs

Item In/Lbs Nm Required

No Loctite

8 70-90 7.9-10.2 Red 262

14 20-25 2.3-2.8 Red 262

16 15-20 1.7-2.3

17 15-20 1.7-2.3

20 20-25 2.3-2.8

27 140-160 15.8-18.1

28 140-160 15.8-18.1

GB) NOTE: When using EPDM Kit or Viton Kit on AP315 & AP320, you must change Volute to number 43324-A.

*For engine replacement parts locate the engine brand name, model number, and type number and consult the appropriate dealer in your area.

F) NOTA: Pour l’utilisation des lots de réparation EPDM ou Viton sur les modèles AP315 et AP320, il faut remplacer la volute par une

volute de type 43324-A.

∗Pour les pièces de rechange du moteur, identifier la marque, le modèle et le type de moteur, et appeler le distributeur local approprié.

E) NOTA: Cuando utilice el Equipo EPDM o el Equipo Viton con los modelos AP315 y AP320, deberá cambiar la Voluta al número 43324-

A.

*En el caso de las piezas de repuesto del motor, localice la marca del motor, el número de modelo y el número de tipo y consulte al distribuidor

apropiado de su área.

16

Page 17

GB

SYMBOL DEFINITION

F

DÉFINITION DES SYMBOLES

E

DEFINICIONES DE LOS SIMBOLOS

GB

DANGER

F

DANGER

E

PELIGRO

GB

Read your product literature.

F

Lire les imprimés sur le produit.

E

Lea el manual del producto.

GB

Disconnect spark plug before performing maintenance, adjustment, lubrication

and storage.

F

Débrancher la bougie avant de procéder à l’entretien, le réglage, la lubrification ou

le remisage de la pompe.

E

Desconecte la bujía antes de efectuar el mantenimiento, ajuste, lubricación y

almacenamiento de la bomba.

17

Page 18

THIS PRODUCT HAS BEEN REMANUFACTURED BY

JERRY B LEACH CO.

FOR WARRANTY AND SERVICE INFORMATION PLEASE CONTACT

JERRY B. LEACH CO.

P.O. BOX 71

CHERAW S. C. 29520

PHONE 800-845-9005

FAX 843-537-6990

DO NOT CONTACT HOMELITE OR ANY OTHER ORIGINAL

COMPONENT MANUFACTURER.

••

• 647 STATE ROAD

••

P.O. BOX 71 • 647 STATE ROAD

CHERAW, SC 29520

1-800-845-9005 F AX 843-537-6990

www.jerrybleach.com

07/13/98/E1

Loading...

Loading...