HT1621

RAM Mapping 32´4 LCD Controller for I/O mC

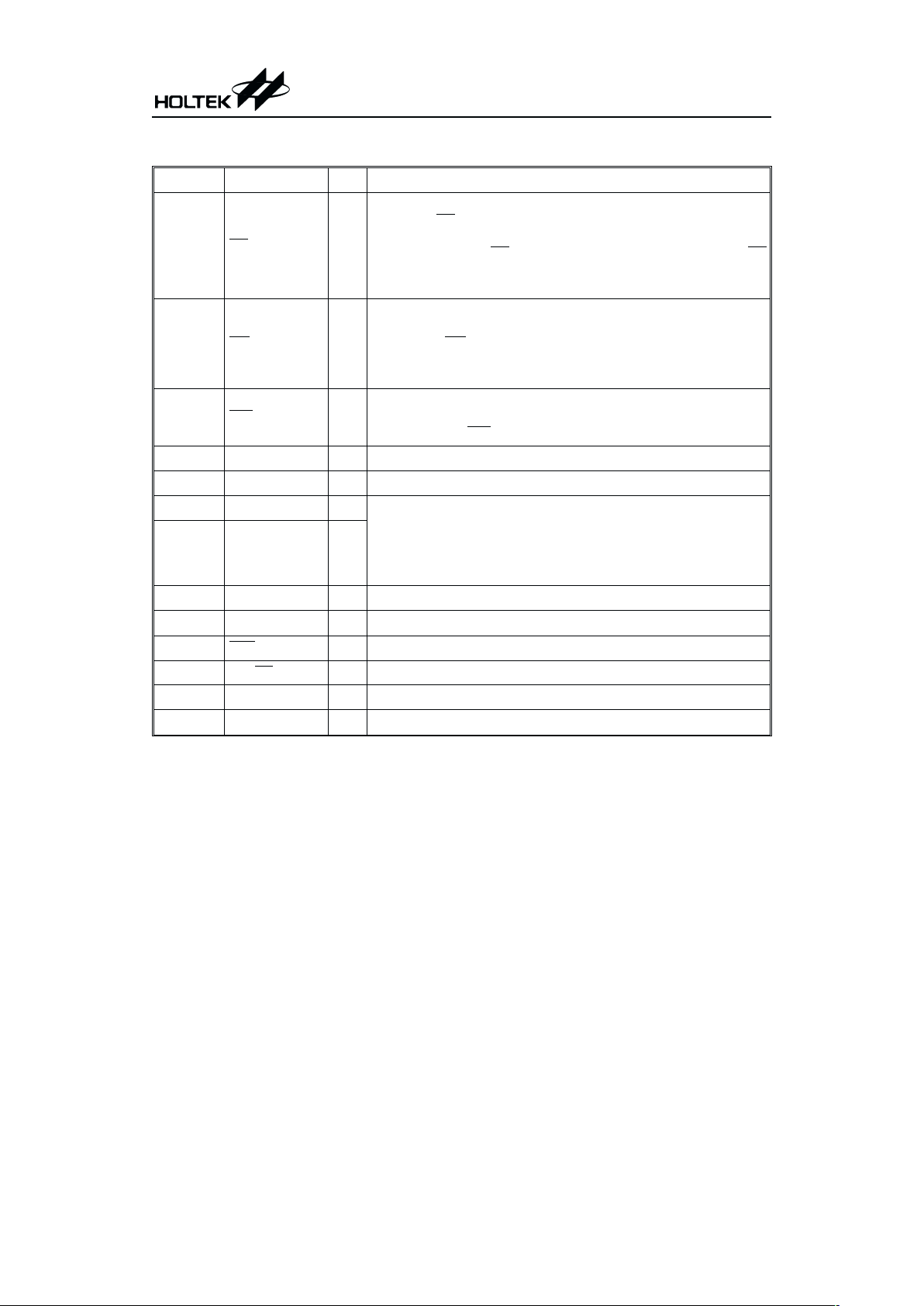

Selection Table

HT162X HT1620 HT1621 HT1622 HT16220 HT1623 HT1625 HT1626 HT1627 HT16270

COM 4 4 8888161616

SEG 32 32 32 32 48 64 48 64 64

Built-in Osc.

Ö

Ö ÖÖÖÖ

Crystal Osc.

Ö

Ö

Ö ÖÖÖ Ö

1 April 21, 2000

Features

·

Operating voltage : 2.4V~5.2V

·

Built-in 256kHz RC oscillator

·

External 32.768kHz crystal or 256kHz

frequency source input

·

Selection of 1/2 or 1/3 bias, and selection of

1/2 or 1/3 or 1/4 duty LCD applications

·

Internal time base frequency sources

·

Two selectable buzzer frequencies

(2kHz/4kHz)

·

Power down command reduces power

consumption

·

Built-in time base generator and WDT

·

Time base or WDT overflow output

·

8 kinds of time base/WDT clock sources

·

32´4 LCD driver

·

Built-in 32´4 bit display RAM

·

3-wire serial interface

·

Internal LCD driving frequency source

·

Software configuration feature

·

Data mode and command mode

instructions

·

R/W address auto increment

·

Three data accessing modes

·

VLCD pin for adjusting LCD operating

voltage

General Description

The HT1621 is a 128 pattern (32´4), memory

mapping, and multi-function LCD driver. The

S/W configuration feature of the HT1621

makes it suitable for multiple LCD applica

-

tions including LCD modules and display sub-

systems. Only three or four lines are required

for the interface between the host controller

and the HT1621. The HT1621 contains a power

down command to reduce power consumption.

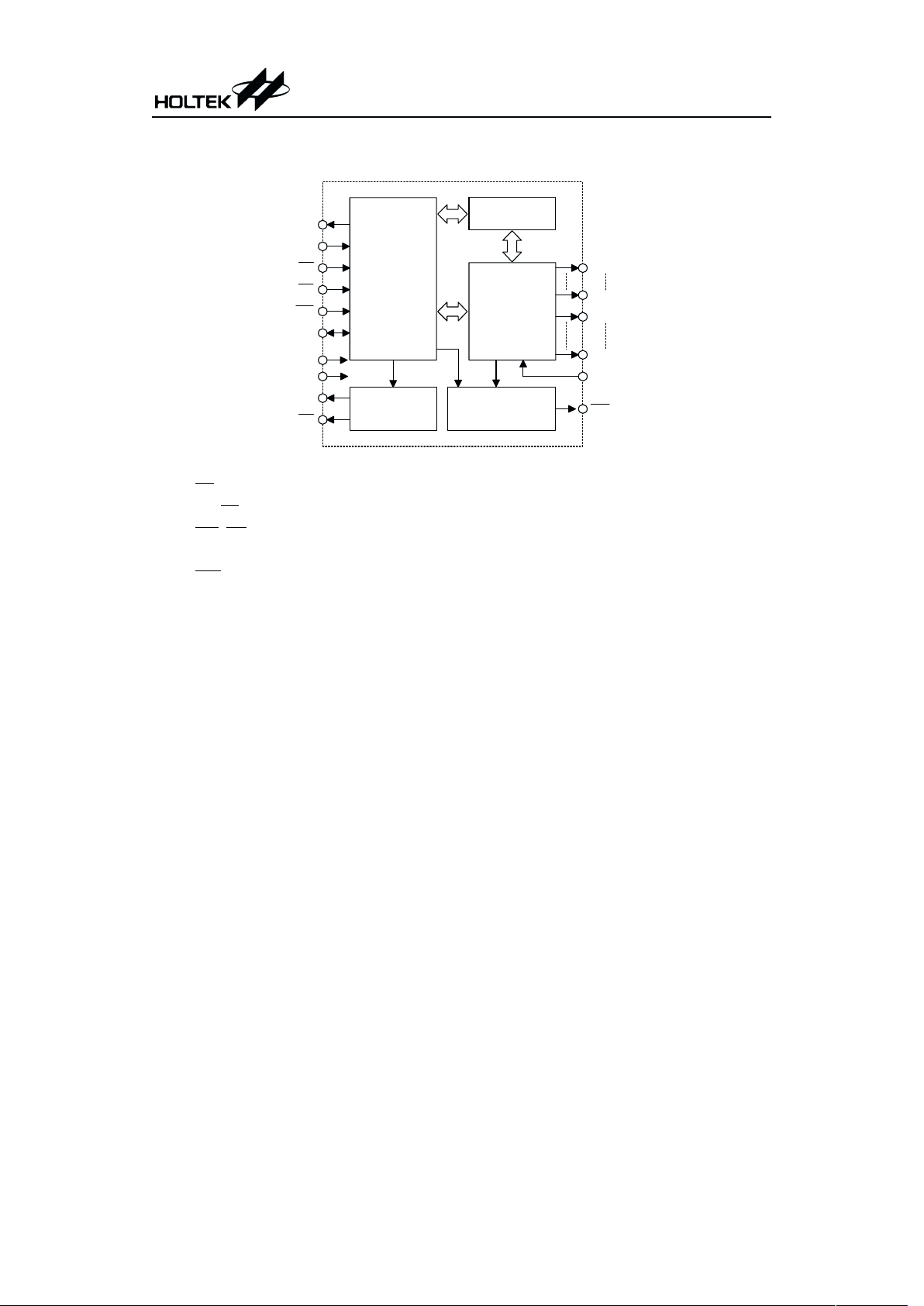

Block Diagram

Note: CS: Chip selection

BZ, BZ

: Tone outputs

WR

,RD, DATA: Serial interface

COM0~COM3, SEG0~SEG31: LCD outputs

IRQ

: Time base or WDT overflow output

HT1621

2 April 21, 2000

W atchdog Tim er

and

Tim e B ase G enerator

D ispla y R A M

LCD Driver/

Bias Circuit

C ontrol

and

Tim ing

Circuit

DATA

WR

OSCO

OSCI

CS

RD

COM 0

COM 3

SEG0

SEG31

Tone F requency

G enerator

BZ

BZ

IR Q

VSS

VDD

VLCD

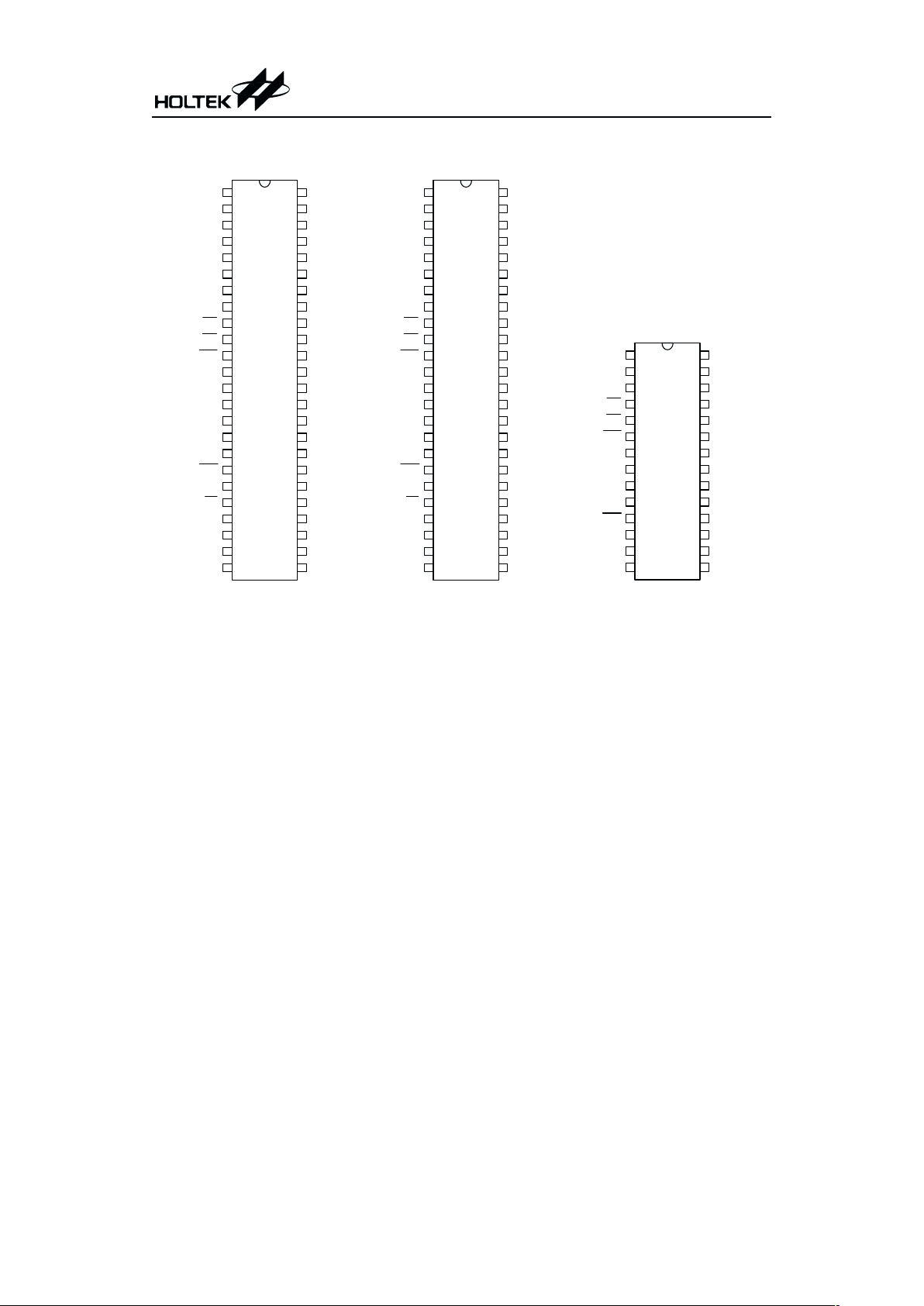

Pin Assignment

HT1621

3 April 21, 2000

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

CS

RD

WR

DATA

VSS

OSCO

NC

OSCI

VDD /VLCD

IR Q

BZ

BZ

COM 0

COM 1

COM 2

COM 3

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

SEG31

H T 1621

-

48 S S O P

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

CS

RD

WR

DATA

VSS

OSCO

OSCI

VLCD

VDD

IR Q

BZ

BZ

COM 0

COM 1

COM 2

COM 3

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

SEG31

H T 1621B

-

4 8 S S O P /D IP

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

SEG5

SEG3

SEG1

CS

RD

WR

DATA

VSS

VLCD

VDD

IR Q

BZ

COM 0

COM 1

H T 1621D

-

28 S kinny

SEG7

SEG9

SEG11

SEG13

SEG15

SEG17

SEG19

SEG21

SEG23

SEG25

SEG27

SEG29

SEG31

COM 2

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

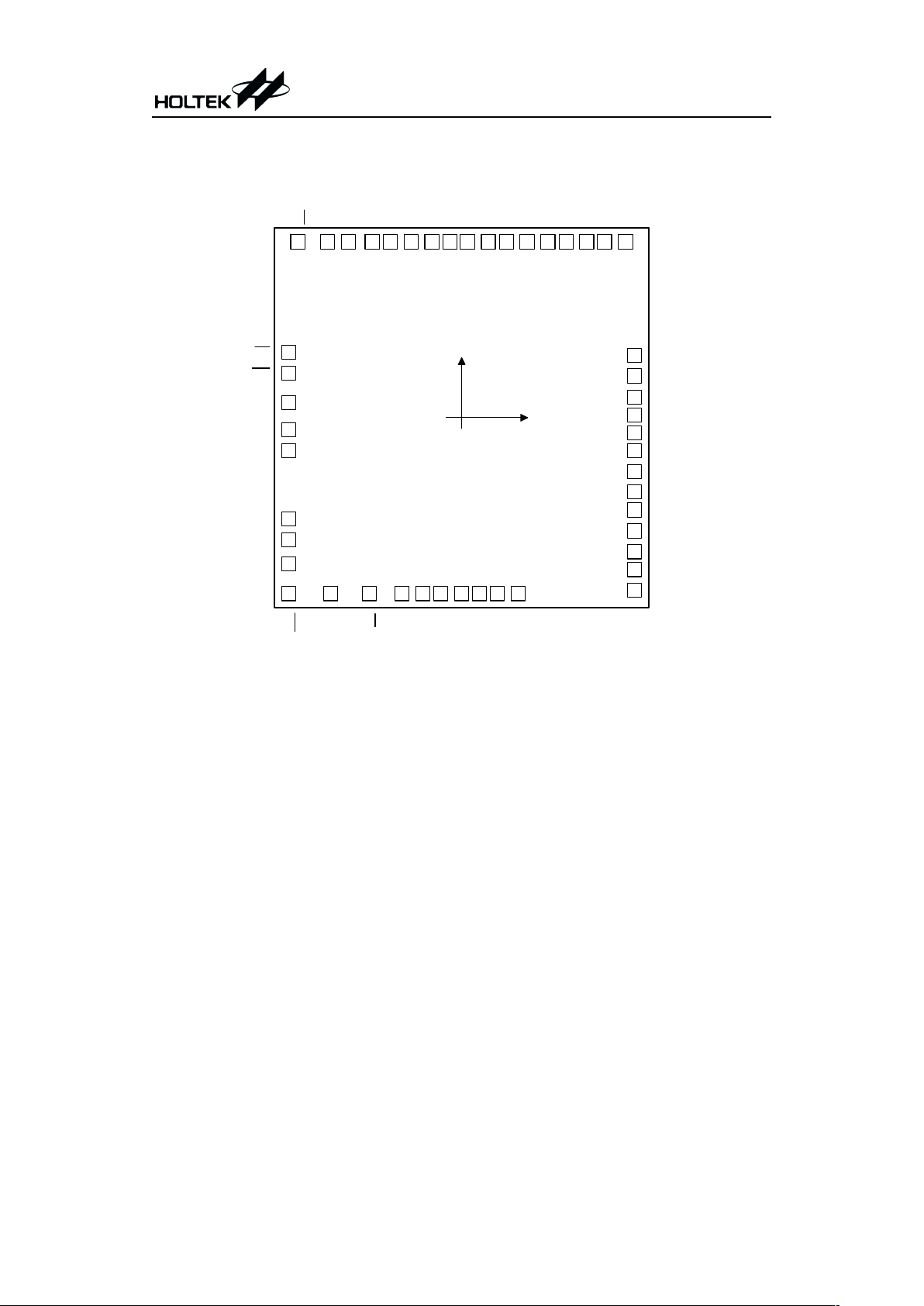

Pad Assignment

Chip size: 127 ´ 129 (mil)

2

* The IC substrate should be connected to VDD in the PCB layout artwork.

HT1621

4 April 21, 2000

IR Q

BZ

CS

1

2

3

4

5

6

7

8

9

10

11

12 13

14 15 16 17 18 19

20

21

22

23

24

25

26

27

28

29

30

31

32

3334353637383940

41

4243

44

45464748

(0 ,0 )

RD

WR

DATA

VSS

OSCO

OSCI

VLCD

VDD

BZ

COM 0

COM 1

COM 2

COM 3

SEG31

SEG30

SEG29

SEG28

SEG27

SEG26

SEG25

SEG24

SEG23

SEG22

SEG21

SEG20

SEG19

SEG18

SEG17

SEG16

SEG15

SEG14

SEG13

SEG12

SEG11

SEG10

SEG9

SEG8

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

Pad Coordinates Unit:mil

Pad No. X Y Pad No. X Y

1

-55.04

59.46 25 58.14

-25.29

2

-58.52

22.18 26 58.14

-18.66

3

-58.52

15.56 27 58.14

-11.94

4

-58.52

5.36 28 58.14

-5.31

5

-58.52 -4.51

29 58.14 1.32

6

-58.52 -11.14

30 58.14 7.95

7

-58.52 -34.76

31 58.14 14.58

8

-58.52 -41.90

32 58.14 21.21

9

-58.52 -49.13

33 55.55 59.46

10

-58.52 -59.08

34 48.92 59.46

11

-44.07 -59.08

35 42.29 59.46

12

-31.58 -59.08

36 35.66 59.46

13

-20.70 -59.08

37 29.03 59.46

14

-13.98 -59.08

38 22.40 59.46

15

-7.05 -59.08

39 15.77 59.46

16

-0.34 -59.08

40 9.14 59.46

17 6.33

-59.08

41 2.42 59.46

18 12.96

-59.08

42

-4.21

59.46

19 19.59

-59.08

43

-10.84

59.46

20 58.14

-58.44

44

-17.47

59.46

21 58.14

-51.81

45

-24.10

59.46

22 58.14

-45.18

46

-30.73

59.46

23 58.14

-38.55

47

-38.17

59.46

24 58.14

-31.92

48

-45.39

59.46

HT1621

5 April 21, 2000

Pad Description

Pad No. Pad Name I/O Function

1CS

I

Chip selection input with pull-high resistor

When the CS

is logic high, the data and command read from or

written to the HT1621 are disabled. The serial interface circuit

is also reset. But if CS

is at logic low level and is input to the CS

pad, the data and command transmission between the host con

-

troller and the HT1621 are all enabled.

2RD

I

READ clock input with pull-high resistor

Data in the RAM of the HT1621 are clocked out on the falling

edge of the RD signal. The clocked out data will appear on the

DATA line. The host controller can use the next rising edge to

latch the clocked out data.

3WR

I

WRITE clock input with pull-high resistor

Data on the DATA line are latched into the HT1621 on the ris

-

ing edge of the WR

signal.

4 DATA I/O Serial data input/output with pull-high resistor

5 VSS

¾

Negative power supply, ground

7 OSCI I The OSCI and OSCO pads are connected to a 32.768kHz crystal

in order to generate a system clock. If the system clock comes

from an external clock source, the external clock source should

be connected to the OSCI pad. But if an on-chip RC oscillator is

selected instead, the OSCI and OSCO pads can be left open.

6 OSCO O

8 VLCD I LCD power input

9 VDD

¾

Positive power supply

10 IRQ

O Time base or WDT overflow flag, NMOS open drain output

11, 12 BZ, BZ

O 2kHz or 4kHz tone frequency output pair

13~16 COM0~COM3 O LCD common outputs

48~17 SEG0~SEG31 O LCD segment outputs

Absolute Maximum Ratings

Supply Voltage.................................-0.3V~5.5V

Storage Temperature....................-50

o

C~125oC

Input Voltage ....................V

SS

-0.3V~VDD+0.3V

Operating Temperature..................-25

o

C~75oC

Note: These are stress ratings only. Stresses exceeding the range specified under Absolute Maxi

-

mum Ratings may cause substantial damage to the device. Functional operation of this de

vice at other conditions beyond those listed in the specification is not implied and prolonged

exposure to extreme conditions may affect device reliability.

HT1621

6 April 21, 2000

D.C. Characteristics

Ta=25°C

Symbol Parameter

Test Conditions

Min. Typ. Max. Unit

V

DD

Conditions

V

DD

Operating Voltage

¾¾

2.4

¾

5.2 V

I

DD1

Operating Current

3V

No load/LCD ON

On-chip RC oscillator

¾

150 300

mA

5V

¾

300 600

mA

I

DD2

Operating Current

3V

No load/LCD ON

Crystal oscillator

¾

60 120

mA

5V

¾

120 240

mA

I

DD3

Operating Current

3V

No load/LCD ON

External clock source

¾

100 200

mA

5V

¾

200 400

mA

I

STB

Standby Current

3V

No load

Power down mode

¾

0.1 5

mA

5V

¾

0.3 10

mA

V

IL

Input Low Voltage

3V

DATA, WR,CS,RD

0

¾

0.6 V

5V 0

¾

1.0 V

V

IH

Input High Voltage

3V

DATA, WR,CS,RD

2.4

¾

3.0 V

5V 4.0

¾

5.0 V

I

OL1

DATA, BZ, BZ, IRQ

3V

V

OL

=0.3V

0.5 1.2

¾

mA

5V

V

OL

=0.5V

1.3 2.6

¾

mA

I

OH1

DATA, BZ, BZ

3V

V

OH

=2.7V

-0.4 -0.8 ¾

mA

5V

V

OH

=4.5V

-0.9 -1.8 ¾

mA

I

OL2

LCD Common Sink

Current

3V

V

OL

=0.3V

80 150

¾mA

5V

V

OL

=0.5V

150 250

¾mA

I

OH2

LCD Common Source

Current

3V

V

OH

=2.7V

-80 -120 ¾mA

5V

V

OH

=4.5V

-120 -200 ¾mA

I

OL3

LCD Segment Sink

Current

3V

V

OL

=0.3V

60 120

¾mA

5V

V

OL

=0.5V

120 200

¾mA

I

OH3

LCD Segment Source

Current

3V

V

OH

=2.7V

-40 -70 ¾mA

5V

V

OH

=4.5V

-70 -100 ¾mA

R

PH

Pull-high Resistor

3V

DATA, WR,CS,RD

40 80 150

kW

5V 30 60 100

kW

HT1621

7 April 21, 2000

A.C. Characteristics

Ta=25°C

Symbol Parameter

Test Conditions

Min. Typ. Max. Unit

V

DD

Conditions

f

SYS1

System Clock 3V On-chip RC oscillator

¾

256

¾

kHz

5V

¾

256

¾

kHz

f

SYS2

System Clock

3V

Crystal oscillator

¾

32.768

¾

kHz

5V

¾

32.768

¾

kHz

f

SYS3

System Clock

3V

External clock source

¾

256

¾

kHz

5V

¾

256

¾

kHz

f

LCD

LCD Clock

¾

On-chip RC oscillator

¾

f

SYS1

/1024

¾

Hz

¾

Crystal oscillator

¾

f

SYS2

/128

¾

Hz

¾

External clock source

¾

f

SYS3

/1024

¾

Hz

t

COM

LCD Common Period

¾

n: Number of COM

¾

n/f

LCD

¾

s

f

CLK1

Serial Data Clock (WR pin)

3V

Duty cycle 50%

¾¾

150 kHz

5V

¾¾

300 kHz

f

CLK2

Serial Data Clock (RD pin)

3V

Duty cycle 50%

¾¾

75 kHz

5V

¾¾

150 kHz

f

TONE

Tone Frequency

¾

On-chip RC oscillator

¾

2.0 or 4.0

¾

kHz

t

CS

Serial Interface Reset Pulse

Width (Figure 3)

¾

CS

¾

250

¾

ns

t

CLK

WR,RDInput Pulse Width

(Figure 1)

3V

Write mode 3.34

¾¾

ms

Read mode 6.67

¾¾

5V

Write mode 1.67

¾¾

ms

Read mode 3.34

¾¾

t

r,tf

Rise/Fall Time Serial Data

Clock Width (Figure 1)

3V

¾¾

120

¾

ns

5V

t

su

Setup Time for DATA to WR,

RD

Clock Width (Figure 2)

3V

¾¾

120

¾

ns

5V

t

h

Hold Time for DATA to WR,

RD

Clock Width (Figure 2)

3V

¾¾

120

¾

ns

5V

t

su1

Setup Time for CS to WR,RD

Clock Width (Figure 3)

3V

¾¾

100

¾

ns

5V

t

h1

Hold Time for CS to WR,RD

Clock Width (Figure 3)

3V

¾¾

100

¾

ns

5V

HT1621

8 April 21, 2000

HT1621

9 April 21, 2000

Functional Description

Display memory - RAM

The static display memory (RAM) is organized

into 32´4 bits and stores the displayed data.

The contents of the RAM are directly mapped to

the contents of the LCD driver. Data in the

RAM can be accessed by the READ, WRITE,

and READ-MODIFY-WRITE commands. The

following is a mapping from the RAM to the

LCD pattern:

System oscillator

The HT1621 system clock is used to generate

the time base/Watchdog Timer (WDT) clock fre

-

quency, LCD driving clock, and tone frequency.

The source of the clock may be from an on-chip

RC oscillator (256kHz), a crystal oscillator

(32.768kHz), or an external 256kHz clock by

the S/W setting. The configuration of the system oscillator is as shown. After the SYS DIS

command is executed, the system clock will

stop and the LCD bias generator will turn off.

That command is, however, available only for

the on-chip RC oscillator or for the crystal oscillator. Once the system clock stops, the LCD display will become blank, and the time base/WDT

lose its function as well.

The LCD OFF command is used to turn the

LCD bias generator off. After the LCD bias gen

-

erator switches off by issuing the LCD OFF

command, using the SYS DIS command re

-

duces power consumption, serving as a system

power down command. But if the external clock

source is chosen as the system clock, using the

SYS DIS command can neither turn the oscilla

-

tor off nor carry out the power down mode. The

crystal oscillator option can be applied to con

-

nect an external frequency source of 32kHz to

the OSCI pin. In this case, the system fails to

SEG0

SEG1

SEG2

SEG3

SEG31

COM 0COM 1COM 2COM 3

D 3 D 2 D 1 D 0

Data

Addr

31

0

1

2

3

Address 6 bits

(A 5 , A 4 , ..., A 0 )

Data 4 bits

(D3, D 2, D 1, D0)

RAM mapping

90%

50%

10%

GN

D

W

R, RD

Clock

t

f

t

r

t

CLK

t

CLK

V

DD

Figure 1

50%

VALID DATA

50%

DB

W R , R D

Clock

GND

t

su

t

h

V

DD

V

DD

GND

Figure 2

CS

GND

50%

50%

FIRST

Clock

LAST

Clock

GND

WR, RD

Clock

t

su1

t

h1

t

CS

V

DD

V

DD

Figure 3

HT1621

10 April 21, 2000

enter the power down mode, similar to the case

in the external 256kHz clock source operation.

At the initial system power on, the HT1621 is at

the SYS DIS state.

Time base and Watchdog Timer (WDT)

The time base generator is comprised by an

8-stage count-up ripple counter and is designed

to generate an accurate time base. The watch

dog timer (WDT), on the other hand, is com

posed of an 8-stage time base generator along

with a 2-stage count-up counter, and is de

signed to break the host controller or other sub

systems from abnormal states such as

unknown or unwanted jump, execution errors,

etc. The WDT time-out will result in the setting

of an internal WDT time-out flag. The outputs

of the time base generator and of the WDT

time-out flag can be connected to the IRQ

out

put by a command option. There are totally

eight frequency sources available for the time

base generator and the WDT clock. The fre

quency is calculated by the following equation.

f

WDT

=

32kHz

2

n

where the value of n ranges from 0 to 7 by com

mand options. The 32kHz in the above equation

indicates that the source of the system fre

quency is derived from a crystal oscillator of

32.768kHz, an on-chip oscillator (256kHz), or

an external frequency of 256kHz.

If an on-chip oscillator (256kHz) or an external

256kHz frequency is chosen as the source of the

system frequency, the frequency source is by de

fault prescaled to 32kHz by a 3-stage prescaler.

Employing both the time base generator and

the WDT related commands, one should be

careful since the time base generator and WDT

share the same 8-stage counter. For example,

invoking the WDT DIS command disables the

time base generator whereas executing the

WDT EN command not only enables the time

base generator but activates the WDT time-out

flag output (connect the WDT time-out flag to

the IRQ

pin). After the TIMER EN command is

transferred, the WDT is disconnected from the

IRQ

pin, and the output of the time base generator

is connected to the IRQ

pin. The WDT can be

cleared by executing the CLR WDT command,

and the contents of the time base generator is

cleared by executing the CLR WDT or the CLR

1/8

OSCI

OSCO

C rystal O scillator

32768H z

E x te rn a l C lo c k S o u rc e

256kHz

O n - c h ip R C O s c illa t o r

256kHz

S ystem

Clock

System oscillator configuration

TIM ER E N/DIS

W D T E N /D IS

V

DD

IR Q

IR Q E N /D IS

D

CK

Q

R

CLR W DT

S ystem C lock

f=32kH z

/256

/4

WDT

Tim er/W D T

C lock S ources

/2

n

n=0~7

Timer and WDT configurations

HT1621

11 April 21, 2000

TIMER command. The CLR WDT or the CLR

TIMER command should be executed prior to

the WDT EN or the TIMER EN command re

-

spectively. Before executing the IRQ

EN com

mand the CLR WDT or CLR TIMER command

should be executed first. The CLR TIMER com

mand has to be executed before switching from

the WDT mode to the time base mode. Once the

WDT time-out occurs, the IRQ

pin will stay at a

logic low level until the CLR WDT or the IRQ

DIS command is issued. After the IRQ output is

disabled the IRQ

pin will remain at the floating

state. The IRQ

output can be enabled or dis

-

abled by executing the IRQ

EN or the IRQ DIS

command, respectively. The IRQ

EN makes the

output of the time base generator or of the WDT

time-out flag appear on the IRQ

pin. The configuration of the time base generator along with

the WDT are as shown. In the case of on-chip

RC oscillator or crystal oscillator, the power

down mode can reduce power consumption

since the oscillator can be turned on or off by

the corresponding system commands. At the

power down mode the time base/WDT loses all

its functions.

On the other hand, if an external clock is se

lected as the source of system frequency the

SYS DIS command turns out invalid and the

power down mode fails to be carried out. That

is, after the external clock source is selected,

the HT1621 will continue working until system

power fails or the external clock source is re

moved. After the system power on, the IRQ

will

be disabled.

Tone output

A simple tone generator is implemented in the

HT1621. The tone generator can output a pair

of differential driving signals on the BZ and BZ,

which are used to generate a single tone. By ex

ecuting the TONE4K and TONE2K commands

there are two tone frequency outputs

selectable. The TONE4K and TONE2K com

mands set the tone frequency to 4kHz and

2kHz, respectively. The tone output can be

turned on or off by invoking the TONE ON or

the TONE OFF command. The tone outputs,

namely BZ and BZ

, are a pair of differential

driving outputs used to drive a piezo buzzer.

Once the system is disabled or the tone output

is inhibited, the BZ and the BZ

outputs will re-

main at low level.

LCD driver

The HT1621 is a 128 (32´4) pattern LCD driver.

It can be configured as 1/2 or 1/3 bias and 2 or 3

or 4 commons of LCD driver by the S/W configuration. This feature makes the HT1621 suitable

for multiply LCD applications. The LCD driving

clock is derived from the system clock. The value

of the driving clock is always 256Hz even when it

is at a 32.768kHz crystal oscillator frequency, an

on-chip RC oscillator frequency, or an external

frequency. The LCD corresponding commands

are summarized in the table.

The bold form of100,namely 100, indicates

the command mode ID. If successive commands

have been issued, the command mode ID except

for the first command, will be omitted. The LCD

Name Command Code Function

LCD OFF

10000000010X

Turn off LCD outputs

LCD ON

10000000011X

Turn on LCD outputs

BIAS & COM

1000010abXcX

c=0: 1/2 bias option

c=1: 1/3 bias option

ab=00: 2 commons option

ab=01: 3 commons option

ab=10: 4 commons option

HT1621

12 April 21, 2000

OFF command turns the LCD display off by dis

abling the LCD bias generator. The LCD ON

command, on the other hand, turns the LCD

display on by enabling the LCD bias generator.

The BIAS and COM are the LCD panel related

commands. Using the LCD related commands,

the HT1621 can be compatible with most types

of LCD panels.

Command format

The HT1621 can be configured by the S/W set

ting. There are two mode commands to configure

the HT1621 resources and to transfer the LCD

display data. The configuration mode of the

HT1621 is called command mode, and its com

mand mode ID is 100. The command mode con

sists of a system configuration command, a

system frequency selection command, a LCD con

figuration command, a tone frequency selection

command, a timer/WDT setting command, and

an operating command. The data mode, on the

other hand, includes READ, WRITE, and

READ-MODIFY-WRITE operations. The follow

ing are the data mode IDs and the command

mode ID:

Operation Mode ID

READ Data 1 1 0

WRITE Data 1 0 1

READ-MODIFY-WRITE Data 1 0 1

COMMAND Command 1 0 0

The mode command should be issued before the

data or command is transferred. If successive

commands have been issued, the command

mode ID, namely 100, can be omitted. While

the system is operating in the non-successive

command or the non-successive address data

mode, the CS

pin should be set to "1" and the

previous operation mode will be reset also.

Once the CS

pin returns to "0" a new operation

mode ID should be issued first.

Interfacing

Only four lines are required to interface with

the HT1621. The CS

line is used to initialize the

serial interface circuit and to terminate the com

munication between the host controller and the

HT1621. If the CS

pin is set to 1, the data and

command issued between the host controller and

the HT1621 are first disabled and then initial

ized. Before issuing a mode command or mode

switching, a high level pulse is required to initial

ize the serial interface of the HT1621. The DATA

line is the serial data input/output line. Data to

be read or written or commands to be written

have to be passed through the DATA line. The RD

line is the READ clock input. Data in the RAM

are clocked out on the falling edge of the RD

sig

nal, and the clocked out data will then appear on

the DATA line. It is recommended that the host

controller read in correct data during the interval

between the rising edge and the next falling edge

of the RD

signal. The WR line is the WRITE clock

input. The data, address, and command on the

DATA line are all clocked into the HT1621 on the

rising edge of the WR

signal. There is an optional

IRQ

line to be used as an interface between the

host controller and the HT1621. The IRQ

pin can

be selected as a timer output or a WDT overflow

flag output by the S/W setting. The host controller can perform the time base or the WDT function by being connected with the IRQ

pin of the

HT1621.

Timing Diagrams

READ mode (command code:110)

READ mode (successive address reading)

HT1621

13 April 21, 2000

RD

DATA

WR

1

1

0A5A4A3 A2

A1A0D0D1

D2

D3

M em ory Address 1 (M A1) D ata (M A 2)

1

1

0A5A4A3 A2

A1A0D0D1

D2

D3

D ata (M A 1) M em ory Address 2 (M A2)

CS

RD

DATA

CS

WR

1

1

0A5A4A3 A2

A1A0D0D1

D2

D3

M e m o ry A d d re s s ( M A ) D a ta (M A )

D0D1

D2

D3

D0D1

D2

D3

D0D1

D2

D3

D0

D a ta (M A + 1 ) D a ta (M A + 2 ) D a ta (M A + 3 )

WRITE mode (command code:101)

WRITE mode (successive address writing)

HT1621

14 April 21, 2000

DATA

CS

WR

1

0

1A5A4A3 A2

A1A0D0D1

D2

D3

M em ory Address 1 (M A1)D ata (M A 1)

1

0

1A5A4A3 A2

A1A0D0D1

D2

D3

M em ory Address 2 (M A2)D ata (M A 2)

DATA

CS

WR

1

0

1A5A4A3 A2

A1A0D0D1

D2

D3

M e m o ry A d d re s s ( M A ) D a ta (M A )

D0D1

D2

D3

D0D1

D2

D3

D0D1

D2

D3

D0

D a ta (M A + 1 ) D a ta (M A + 2 ) D a ta (M A + 3 )

READ-MODIFY-WRITE mode (command code:101)

READ-MODIFY-WRITE mode (successive address accessing)

HT1621

15 April 21, 2000

DATA

CS

WR

1

0

1A5A4A3 A2

A1A0D0D1

D2

D3

M em ory Address 1 (M A 1)D ata (M A 1)

A5A4A3 A2

A1A0D0D1

D2

D3

M em ory Address 2 (M A 2)D ata (M A 2)

1

0

1

RD

D0D1

D2

D3

D a ta ( M A 1 )

DATA

CS

WR

1

0

1A5A4A3 A2

A1A0D0D1

D2

D3

M e m o r y A d d r e s s (M A ) D a ta ( M A )

D0D1

D2

D3

D0D1

D2

D3

D0D1

D2

D3

D0

D a ta ( M A ) D a ta (M A + 1 ) D a ta (M A + 1 )

RD

D1

D2

D3

D0

D a ta ( M A + 2 )

Command mode (command code:100)

Mode (data and command mode)

Note: It is recommended that the host controller should read in the data from the DATA line

between the rising edge of the RD

line and the falling edge of the next RD line.

HT1621

16 April 21, 2000

DATA

CS

WR

1

0

0C8C7C6 C5

C4C3C2C1

C0

C om m and 1

C8C7C6 C5

C4C3C2C1

C0

C om m and iC om m and... C om m and

or

D a ta M o d e

RD

DATA

CS

WR

Address & D ata

C om m and

or

D a ta M o d e

Address and D ata

C om m and

or

D a ta M o d e

Address and D ata

C om m and

or

D a ta M o d e

Application Circuits

Host controller with an HT1621 display system

Note:

The connection of IRQ

and RD pin can be selected depending on the requirement of the mC.

The voltage applied to V

LCD

pin must be lower than VDD.

Adjust VR to fit LCD display, at V

DD

=5V, V

LCD

=4V, VR=15kW±20%.

Adjust R (external pull-high resistance) to fit user s time base clock.

HT1621

17 April 21, 2000

IR Q

DATA

*

O n-chip O S C

OSCI

OSCO

C lock O u t

E x te rn a l C o lc k 1

E x te rn a l C o lc k 2

CS

RD

WR

m

C

C rystal

32768H z

H T 1621B

LCD P anel

BZ

BZ

CO M 0 ~ COM 3 SEG 0~SEG31

Piezo

1/2 or 1/3 B ias; 1/2, 1/3 or 1/4 Duty

R

*

VR

*

VDD

VLCD

Command Summary

HT1621

18 April 21, 2000

Name ID Command Code D/C Function Def.

READ

110

A5A4A3A2A1A0D0D1D2D3 D Read data from the RAM

WRITE

101

A5A4A3A2A1A0D0D1D2D3 D Write data to the RAM

READMODIFYWRITE

101

A5A4A3A2A1A0D0D1D2D3 D READ and WRITE to the RAM

SYS DIS

100

0000-0000-X C

Turn off both system oscillator

and LCD bias generator

Yes

SYS EN

100

0000-0001-X C Turn on system oscillator

LCD OFF

100

0000-0010-X C Turn off LCD bias generator Yes

LCD ON

100

0000-0011-X C Turn on LCD bias generator

TIMER DIS

100

0000-0100-X C Disable time base output

WDT DIS

100

0000-0101-X C

Disable WDT time-out flag

output

TIMER EN

100

0000-0110-X C Enable time base output

WDT EN

100

0000-0111-X C

Enable WDT time-out flag

output

TONE OFF

100

0000-1000-X C Turn off tone outputs Yes

TONE ON

100

0000-1001-X C Turn on tone outputs

CLR TIMER

100

0000-11XX-X C

Clear the contents of time base

generator

CLR WDT

100

0000-111X-X C Clear the contents of WDT stage

XTAL 32K

100

0001-01XX-X C

System clock source, crystal

oscillator

RC 256K

100

0001-10XX-X C

System clock source, on-chip RC

oscillator

Yes

EXT 256K

100

0001-11XX-X C

System clock source, external

clock source

BIAS 1/2

100

0010-abX0-X C

LCD 1/2 bias option

ab=00: 2 commons option

ab=01: 3 commons option

ab=10: 4 commons option

BIAS 1/3

100

0010-abX1-X C

LCD 1/3 bias option

ab=00: 2 commons option

ab=01: 3 commons option

ab=10: 4 commons option

TONE 4K

100

010X-XXXX-X C Tone frequency, 4kHz

TONE 2K

100

011X-XXXX-X C Tone frequency, 2kHz

IRQ

DIS

100

100X-0XXX-X C Disable IRQ output Yes

HT1621

19 April 21, 2000

Name ID Command Code D/C Function Def.

IRQ

EN

100

100X-1XXX-X C Enable IRQ output

F1

100

101X-X000-X C

Time base/WDT clock

output:1Hz

The WDT time-out flag after: 4s

F2

100

101X-X001-X C

Time base/WDT clock

output:2Hz

The WDT time-out flag after: 2s

F4

100

101X-X010-X C

Time base/WDT clock

output:4Hz

The WDT time-out flag after: 1s

F8

100

101X-X011-X C

Time base/WDT clock

output:8Hz

The WDT time-out flag after: 1/2 s

F16

100

101X-X100-X C

Time base/WDT clock

output:16Hz

The WDT time-out flag after: 1/4 s

F32

100

101X-X101-X C

Time base/WDT clock

output:32Hz

The WDT time-out flag after: 1/8 s

F64

100

101X-X110-X C

Time base/WDT clock

output:64Hz

The WDT time-out flag after: 1/16 s

F128

100

101X-X111-X C

Time base/WDT clock

output:128Hz

The WDT time-out flag after: 1/32 s

Yes

TEST

100

1110-0000-X C Test mode, user don't use.

NORMAL

100

1110-0011-X C Normal mode Yes

Note: X : Don,t care

A5~A0 : RAM addresses

D3~D0 : RAM data

D/C : Data/command mode

Def. : Power on reset default

All the bold forms, namely 110, 101, and 100, are mode commands. Of these, 100indicates

the command mode ID. If successive commands have been issued, the command mode ID ex

cept for the first command will be omitted. The source of the tone frequency and of the time

base/WDT clock frequency can be derived from an on-chip 256kHz RC oscillator, a 32.768kHz

crystal oscillator, or an external 256kHz clock. Calculation of the frequency is based on the

system frequency sources as stated above. It is recommended that the host controller should

initialize the HT1621 after power on reset, for power on reset may fail, which in turn leads to

the malfunctioning of the HT1621.

HT1621

20 April 21, 2000

Copyright Ó 2000 by HOLTEK SEMICONDUCTOR INC.

The information appearing in this Data Sheet is believed to be accurate at the time of publication. However, Holtek

assumes no responsibility arising from the use of the specifications described. The applications mentioned herein are

used solely for the purpose of illustration and Holtek makes no warranty or representation that such applications

will be suitable without further modification, nor recommends the use of its products for application that may pres

ent a risk to human life due to malfunction or otherwise. Holtek reserves the right to alter its products without prior

notification. For the most up-to-date information, please visit our web site at http://www.holtek.com.tw.

Holtek Semiconductor Inc. (Headquarters)

No.3 Creation Rd. II, Science-based Industrial Park, Hsinchu, Taiwan, R.O.C.

Tel: 886-3-563-1999

Fax: 886-3-563-1189

Holtek Semiconductor Inc. (Taipei Office)

5F, No.576, Sec.7 Chung Hsiao E. Rd., Taipei, Taiwan, R.O.C.

Tel: 886-2-2782-9635

Fax: 886-2-2782-9636

Fax: 886-2-2782-7128 (International sales hotline)

Holtek Semiconductor (Hong Kong) Ltd.

RM.711, Tower 2, Cheung Sha Wan Plaza, 833 Cheung Sha Wan Rd., Kowloon, Hong Kong

Tel: 852-2-745-8288

Fax: 852-2-742-8657

Loading...

Loading...