Page 1

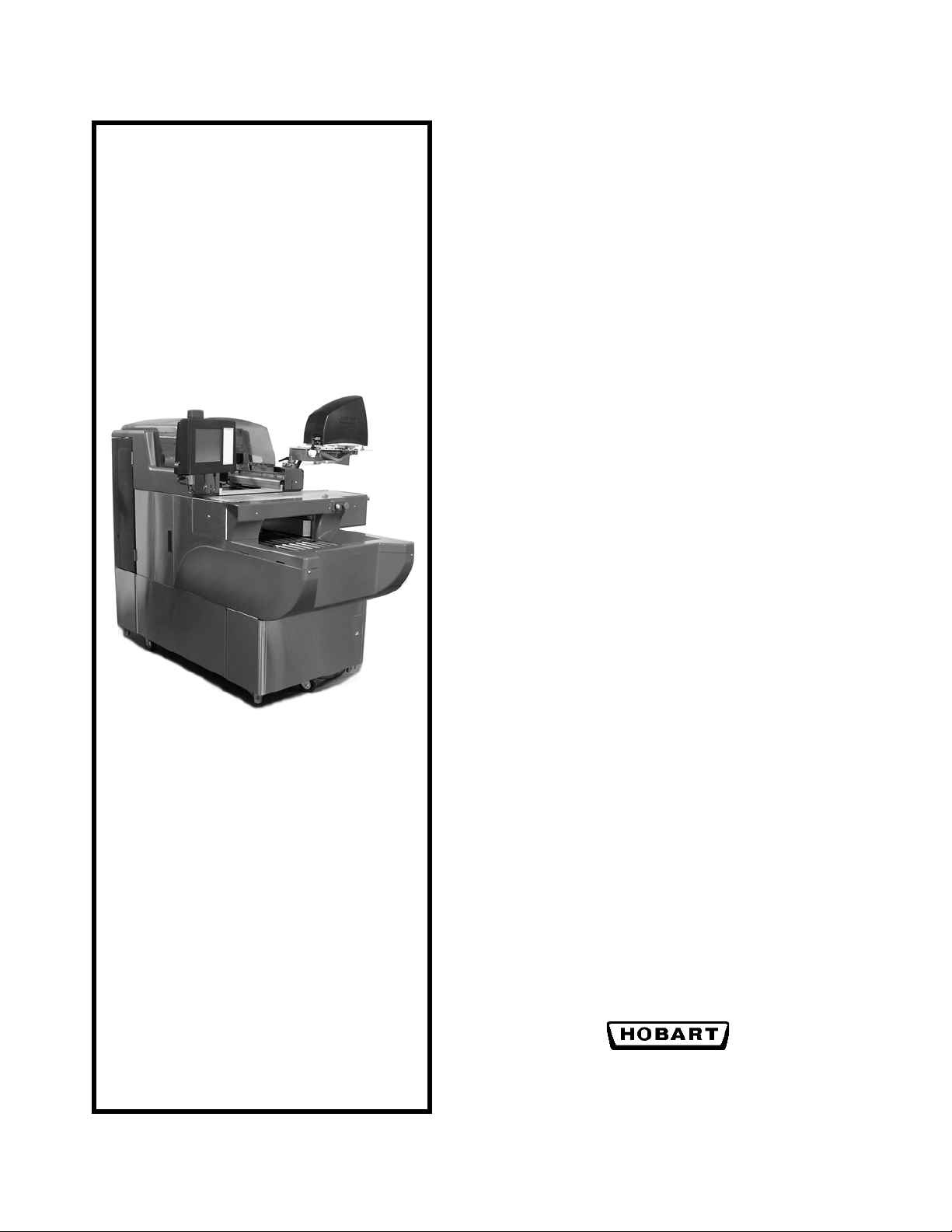

Access AWS-1B

Wrapping System

Operator Manual

ML-44216 AWS-1B (L-R)

ML-44217 AWS-1B (R-L)

701 S. RIDGE AVENUE

TROY, OHIO 45374

www.hobartcorp.com

F-35538 (April 2010)

Page 2

Page 3

Access AWS-1B Wrapping System Operator Manual

TABLE OF CONTENTS

Chapter 1: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Welcome. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

FCC Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Verify Correctness of

Weight and Price . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Operator Manual Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Important Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Chapter 2: Understanding the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Console Communication

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Operator Start Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Understanding the Wrapper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Loading Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Chapter 3: Using the Access Wrapping System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Power Up the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Logging onto the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Shutting Down the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Operator Start Screen

Menu Buttons and Flashkeys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Run Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Modifying the Run Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Automatic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Using Automatic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Running a Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Using the Operator Run Screen Drop-Down Menus . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Product Drop-Down Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Settings Drop-Down Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Help Drop-Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Chapter 4: Maintenance & Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

About Proper Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Cleaning Each Component. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Removing Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Loading Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Setting the Label Size Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Cleaning the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

F-35538 (April 2010) i Table of Contents

Page 4

Access AWS-1B Wrapping System Operator Manual

Chapter 5: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Reviewing System Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Possible System Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Table of Contents ii F-35538 (April 2010)

Page 5

Access AWS-1B Wrapping System Operator Manual

Chapter 1: Introduction

Introduction

Welcome The Access Wrapping System was designed as a meat room or

produce back room wrapper. It gives you merchandising capabilities with multiple fonts, graphics, and label types.

Access Wrapping System

All necessary operator data appears on the touch screen.

FCC Note

F-35538 (April 2010) 1-1 Introduction

This scale has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection

against harmful interference when the scale is operated in a commercial environment. This scale generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this scale in a

residential area is likely to cause harmful interference; in which

case, the user will be required to correct the interference at their

own expense.

Page 6

Access AWS-1B Wrapping System Operator Manual

Verify Correctness of

Weight and Price

Routinely verify label information. Check the multiplication of

price per pound times weight, and check the scale weight against

printed label weight. Weigh the same package several times to

verify outcome consistency. Packages that weigh near the middle

of the 0.01 lb. increment will normally vary up or down by

0.01 lb. Greater variation than 0.01 lb indicates the system needs

adjustment. In such a case, or whenever necessary, contact your

local Hobart Representative.

Operator Manual Terminology

This manual uses the following terminology for keystrokes and

data manipulation procedures:

• The word TYPE means to touch a series of keys on the

Operator Screen Numeric Keypad or the Operator Screen

Alpha Keyboard.

• The word TOUCH means to activate an entry shown on the

Operator Screen.

• The word SELECT means to choose an item from a list

brought up on the Operator Screen.

• The word PRESS means to press a button on the Wrapper.

The following special instructions are used in the manual:

Note

A Note is information that you need to know , but is not an actual

step in the process.

Tip

A Tip is additional information that may be useful when you are

using the system.

Look At This

Look At This is information to alert you that you may be doing

something that will permanently alter your system.

Introduction 1-2 F-35538 (April 2010)

Page 7

Important Information

Access AWS-1B Wrapping System Operator Manual

The following warnings and notices are provided for your

protection:

Fluorescent lamp in display panel contains a small amount

of mercury. Please dispose of according to local, state, or

federal laws.

The Model AWS wrapper must be connected to a grounded,

metal, permanent wiring system; or an equipment-grounding

conductor must be run with the circuit conductors and connected

to the equipment-grounding lead on the product.

Online Viewing

If you are viewing this manual online or from a CD, you have the

advantage of using the cross-referencing feature that is built into

the document. Links are shown in italicized text and are crossreferenced.

For example, the text may say:

Shutting Down the System

When you move your mouse directly over the text, the cursor

changes to a pointing hand. This indicates a cross-reference. If

you click on this text, you will be taken to that section of the

document.

Use the back arrow on the top of your screen to return to your

starting point.

F-35538 (April 2010) 1-3 Introduction

Page 8

Access AWS-1B Wrapping System Operator Manual

Introduction 1-4 F-35538 (April 2010)

Page 9

Chapter 2: Understanding the System

Understanding the System

Access AWS-1B Wrapping System Operator Manual

The Access Wrapping System is the solution you need to address

your back room packaging needs. This state-of-the-art weighing/

wrapping system can handle a broad variety of products.

The Access Wrapping System can store information on thousands

of products. Retail store information required for product handling and processing, such as PLU number, UPC number, Pricing, Tare, and Shelf Life is included. Consumer information

describing products, such as NutriFacts, Safe Handling,

Expanded Text, Health Tips, Meal Planners, Recipes, Cooking

Instructions, and Merchandising Graphics is also included.

The scale should be installed and moved only by qualified

Hobart Service Technicians. The system can operate in a temperature range from 32°F to 82°F (0°C to 28°C).

The following topics are discussed in this chapter:

Electrical Connections

Console Communication Connections

Loading Film

Operator Start Screen

F-35538 (April 2010) 2-1 Understanding the System

Page 10

Access AWS-1B Wrapping System Operator Manual

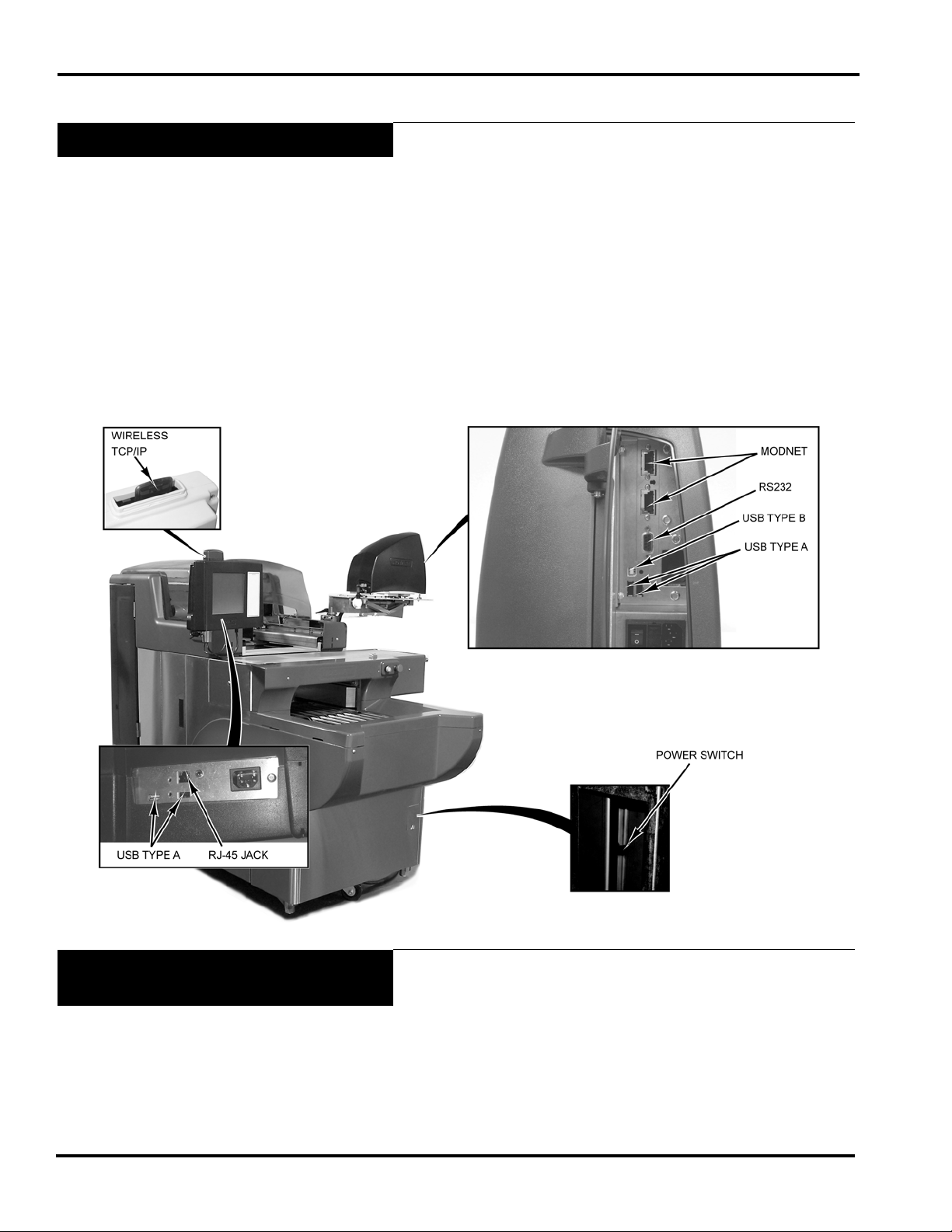

Electrical Connections

The Console has power, if plugged in, as soon as the power connections are made at the wrapper. The Printer must be switched

on, using the power switch located on the back of the printer. The

wrapper and label applier do not have power until the power

switch is in the On position. The power switch is located just

inside the small access door on the right-hand side of the

lower front panel of the wrapper.

Power runs to the Console through 110 VAC cable, which is connected in the back of the printer to the bottom of the console.

A dedicated circuit, rated 208-240 volts, 60 Hz, Phase 1 (3-wire

plus ground) is required. Twenty (20) amp circuit protection is

also required.

Console Communication

Connections

On the Access Wrapping System, in addition to the electrical connections, there are several ports that can be configured:

• RJ-45 Jack for an Ethernet Connector (TCP/IP)

–OR–

• Wireless TCP/IP (located on the top of the console).

• 2 Type A USB Ports

Understanding the System 2-2 F-35538 (April 2010)

Page 11

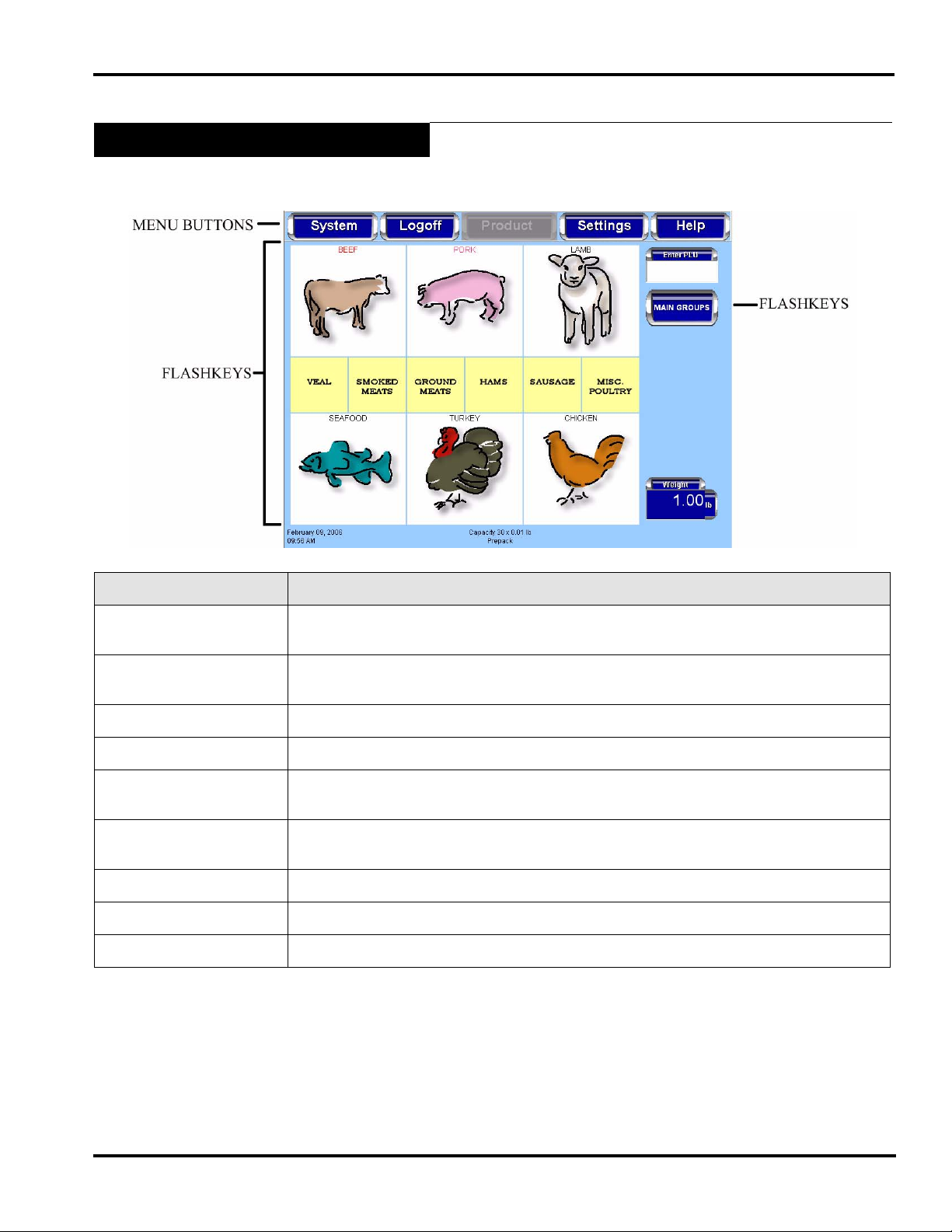

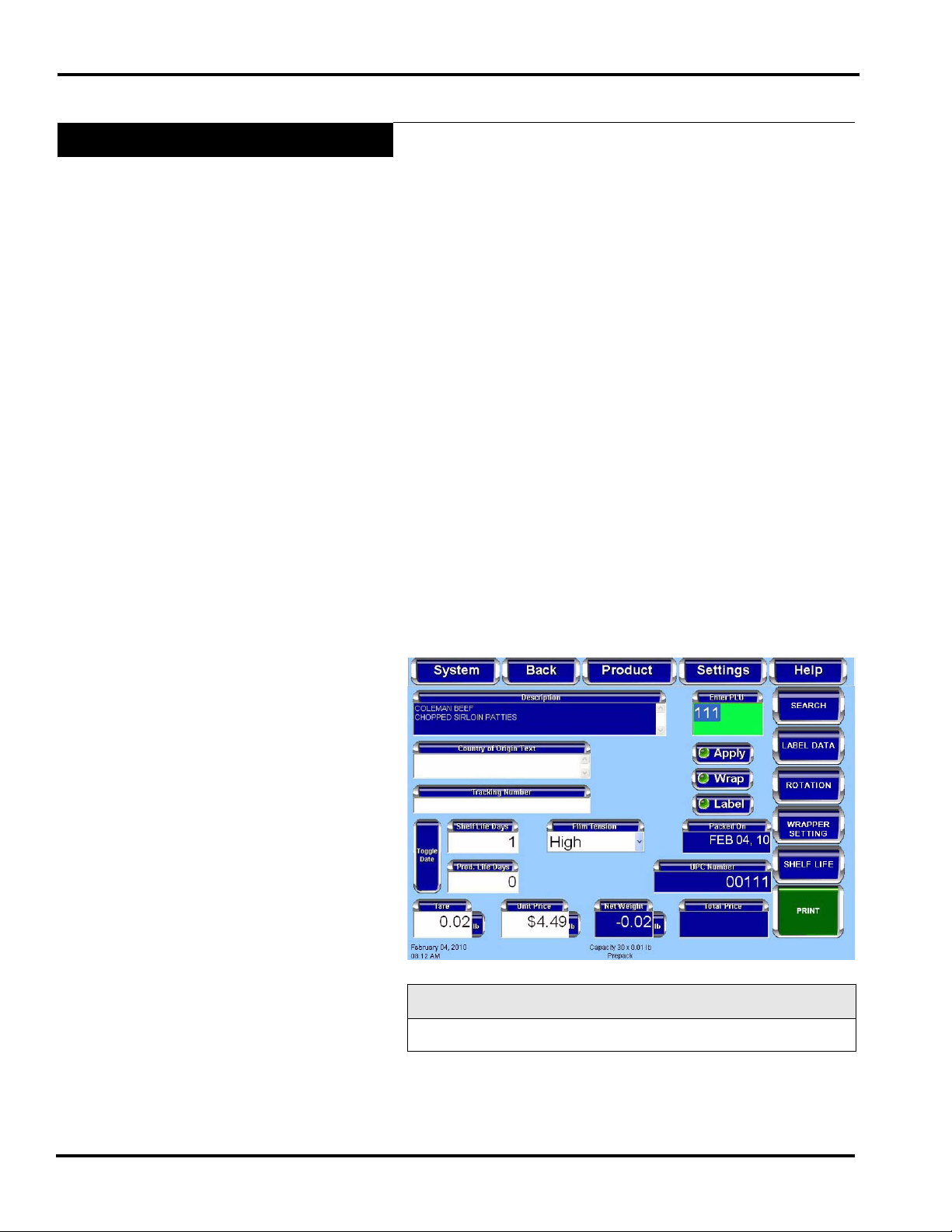

Operator Start Screen

Access AWS-1B Wrapping System Operator Manual

The Operator Start Screen is a touch screen that enables you to

enter information and move through the display screens.

Attributes Functions

Menu Buttons The menu buttons on the Operator Start Screen are used to access the drop-down

menus, which show the subcategories of data available for selection.

Check Box A check box enables or disables optional functions. A check mark or circle appears in

the box when a function is enabled.

Text Box A text box is a field into which you enter data.

Grayed Field A grayed field indicates the field is not available for the current screen or transaction.

Flashing Cursor The flashing cursor in a text box indicates that the field is currently activated and is

available for data entry.

Light Blue Highlighted

Drop-Down Menu

A drop-down menu, shown in light blue, indicates the menu h as been activ ated and a

subcategory may be selected.

Flashkeys The Flashkeys provide quick access to frequently used products and functions.

Numeric Keypad The numeric keypad appears on the screen when numeric data is to be entered.

Alpha Keyboard The alpha keyboard appears on the screen when alpha data is to be entered.

F-35538 (April 2010) 2-3 Understanding the System

Page 12

Access AWS-1B Wrapping System Operator Manual

Understanding the Wrapper

The wrapper is an automatic stretch wrapper designed to utilize

rolled stretch film. The package size is automatically sensed by

the wrapper, which then selects the length required to properly

wrap each package.

Selecting Film

Storing Film

Using Trays

The wrapping material required is rolled machine stretch film.

This wrapper is capable of using 13

of film required is determined by the size of the package being

wrapped. The film must be on 3

diameter is 9.5

Access Wrapping System is 60.

Film widths should allow a 1

age between flaps. Excessive film width should be avoided

because it can cause poor sealing, due to too many folded layers

of film under the package.

Film should be stored at temperatures between 50°F and 70°F

(10°C and 21°C) with a relative humidity of 50% to 85%. Storage

temperatures outside this range can adversely affect film performance and life expectancy.

All products must be contained within a tray in order to be

wrapped. The tray design and material must be strong enough

and rigid enough to be used for machine wrapping. Damp or soft

trays will not work properly and can cause package jams and loss

of product.

For best results, the bottom of the tray should be flat. T rays which

are distorted or have irregular bottoms cause problems with package movement and film sealing. Trays must have an angled edge

of not less than 15

package while wrapping the film under the tray.

. The minimum recommended gauge for the

to allow the rear underfolder to roll under the

to 20 film (width). The size

cores, and the maximum roll

overlap on the bottom of the pack-

The maximum tray width is 15

The minimum tray width is 5

Trays less than 1/2

paper stripping are not acceptable containers.

Understand Package Weight, Size,

Shape and Range Guidelines

Understanding the System 2-4 F-35538 (April 2010)

The performance of your wrapping system is partially dependent

on the package size and shape. Bulky or odd shaped packages

tend to roll and do not wrap properly.

Package length is defined as the length of the package based on

which direction it travels through the machine. Package width

must always exceed package height. If the package is high, but

short, it may roll over as it travels through the wrapper.

Uneven distribution of product weight in a package may result in

improper sealing or packages turning over. If the package is

heavy on one side, it should be placed in the machine with the

heavy side away from the operator.

Product must be completely within the tray. Overhanging or projecting parts could cause package jams resulting in damage to the

system and loss of time and product.

high are not recommended. Flat boards or

and the maximum length is 10.

and the minimum length is 4.

Page 13

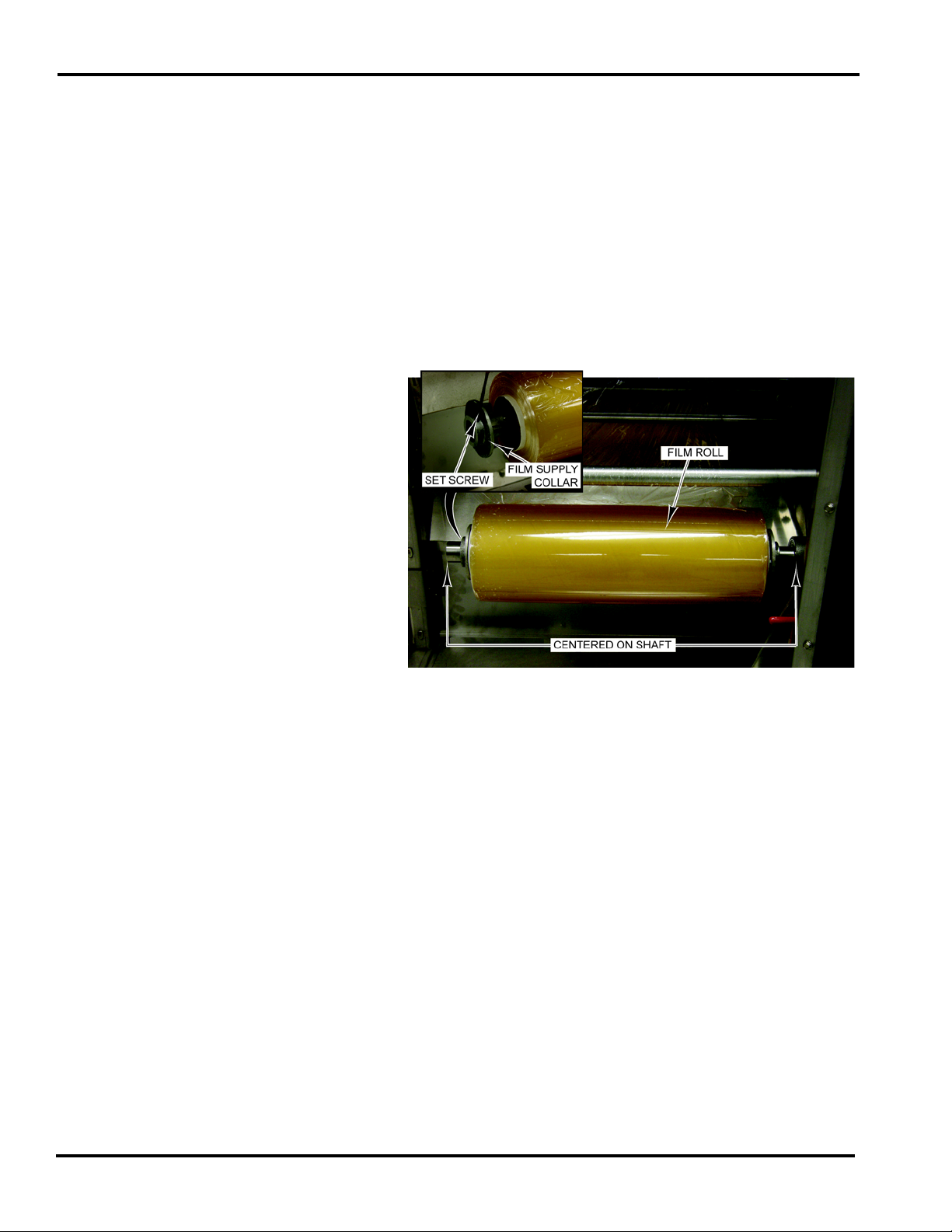

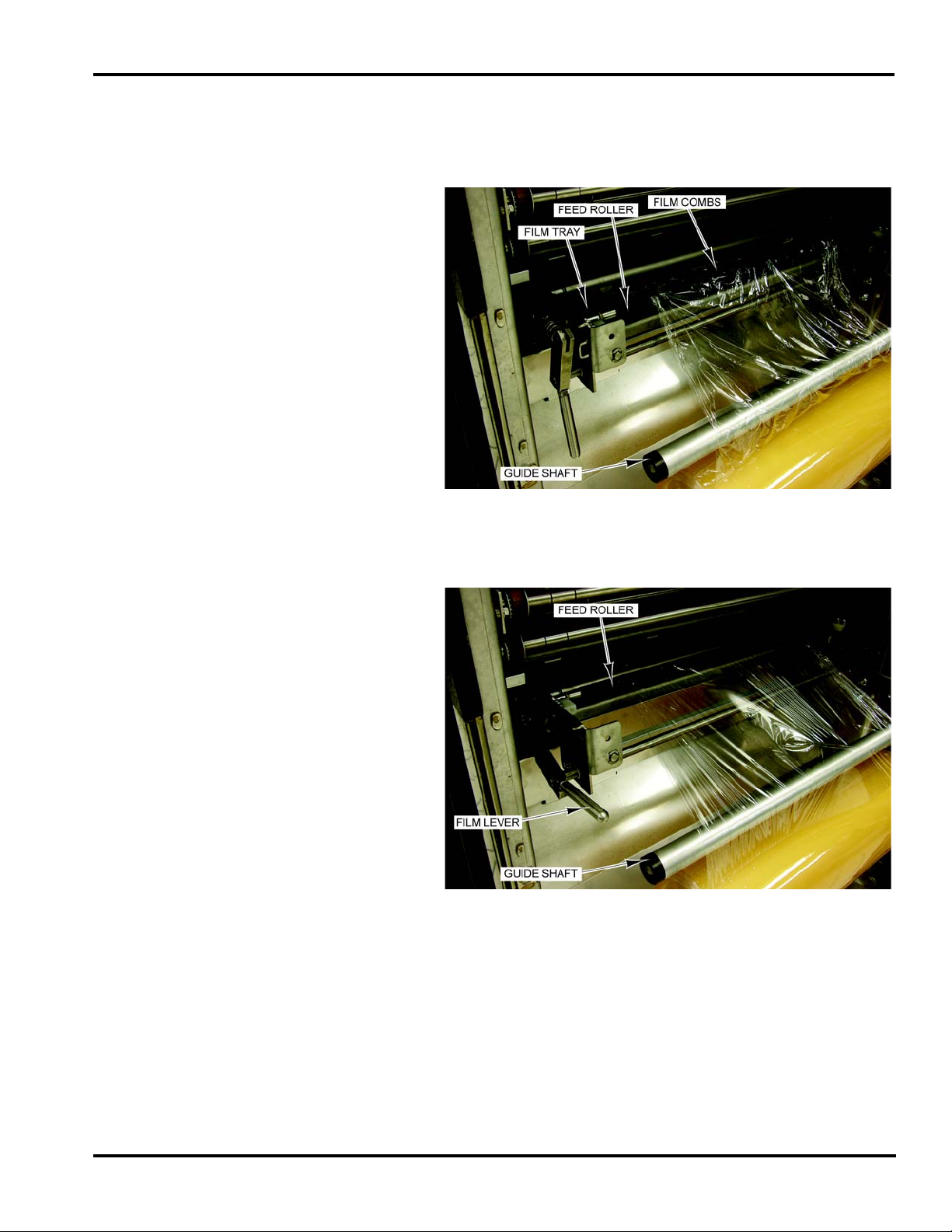

Loading Film

Access AWS-1B Wrapping System Operator Manual

Keep the film as straight as possible through the threading

process. The following diagram shows the different ways to load

film.

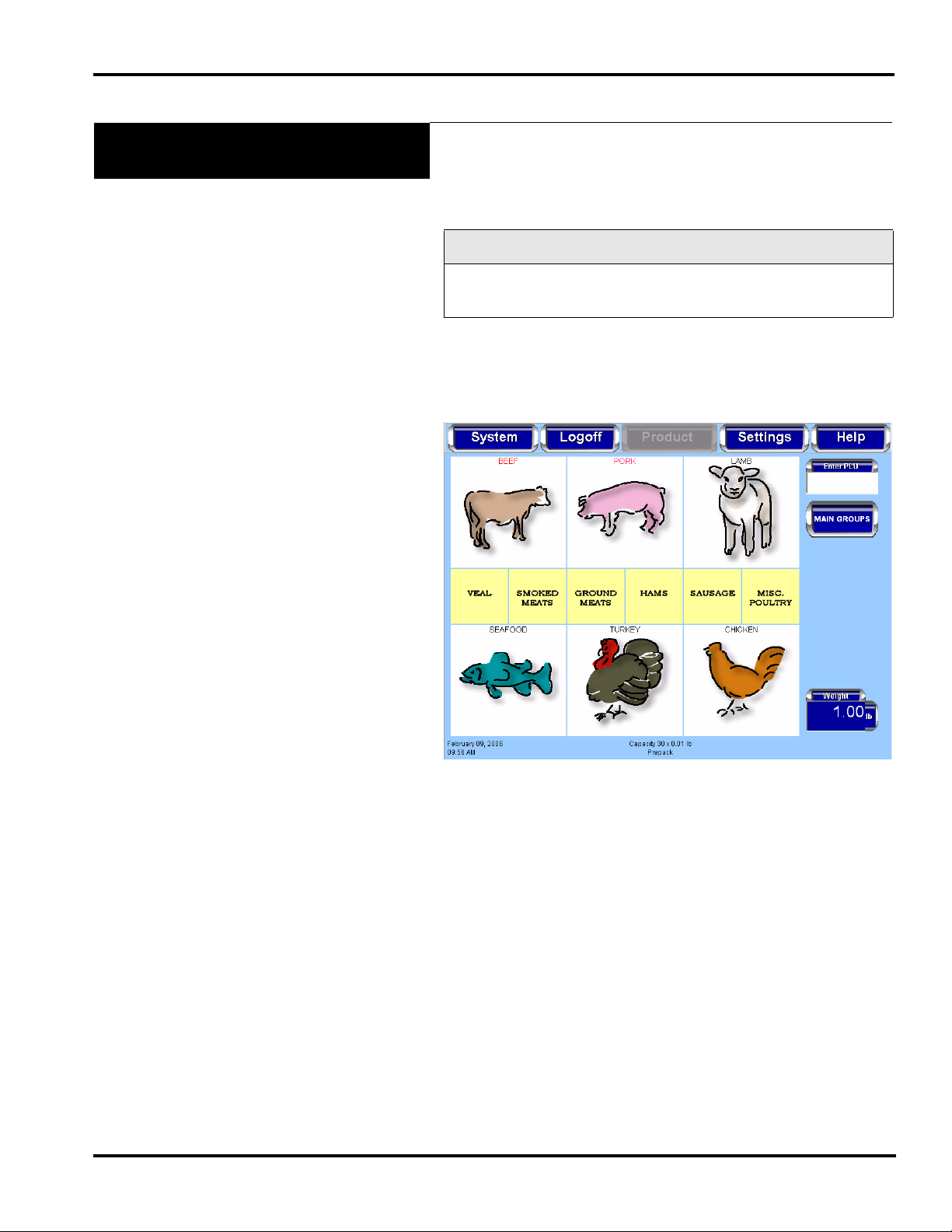

To thread film:

1. PRESS the STOP (red) button and allow the machine to stop.

2. Open the rear doors.

3. Release feed rollers by pulling the film lever down.

F-35538 (April 2010) 2-5 Understanding the System

Page 14

Access AWS-1B Wrapping System Operator Manual

4. Loosen 2 set screws on the film supply collar. (A T-Handled

Allen wrench is located on the inside of the machine for this

purpose.

5. If applicable, remove the empty film core.

6. Install the film roll on the shaft.

7. Install the film supply collar. Be sure both collars are flush

with the film roll. You may need to tap the film collar into

place with the old film core.

8. Verify that the film is centered on the shaft. (You may have

to loosen the other set screw to center.) Once centered,

tighten the set screws on both collars.

Understanding the System 2-6 F-35538 (April 2010)

Page 15

Access AWS-1B Wrapping System Operator Manual

9. Slide the film tray out, exposing the film combs.

10. Pull the film end upward to the front of the guide shaft

continuing around the shaft toward the extended film tray.

11. Put the film over the rubber feed roller and make sure the

film gets to the ends of the film combs, securing the film end

down over the combs.

12. Push the feed tray in and lift the film lever up.

F-35538 (April 2010) 2-7 Understanding the System

Page 16

Access AWS-1B Wrapping System Operator Manual

13. Close the rear doors.

14. PRESS the ON (green) button. Wait for a steady light, no

blink mode.

15. From the Operator Start Screen, TOUCH Settings. TOUCH

Wrapper. You should now be on the Wr apper Screen.

16. If the film width installed is different than the displayed

width, TOUCH Upper Film Width field to set film width.

17. TOUCH Load Film and the wrapper will position film, cut

any excess film and set itself (home) for operation.

18. TOUCH Back to exit this screen.

19. PRESS the STOP (red) button and allow the machine to stop.

20. Lift the canopy and remove excess film.

21. Close canopy.

22. PRESS the ON (green) button. It will be a steady light, no

blink mode. Ready for operation.

Understanding the System 2-8 F-35538 (April 2010)

Page 17

Chapter 3: Using the Access Wrapping System

Using the Access Wrapping System

Access AWS-1B Wrapping System Operator Manual

Power Up the System

Logging onto the System

To power up the system, use the ON/OFF switch located at the

back of the printer.

1. Verify that the breaker is on, located behind small access

door on the right-hand side of the lower panel.

2. PRESS the ON (green) button.

3. Remove any objects from the scale platter/weigher.

4. Turn printer on.

The Access Wrapping System may require each operator to login

before use. Not all systems are setup to have operator’s login.

The instructions for using this system are detailed in this chapter.

To login to the system you should be at the Operator Login

Screen shown below.

To Login to the System

TYPE your Operator ID. You should now be on the Operator

Start Screen.

: TOUCH the Operator ID field and

To Logoff the Operator Start Screen

Operator Start Screen. No further action is required. The Operator

Login Screen will be displayed.

F-35538 (April 2010) 3-1 Using the Access Wrapping System

: TOUCH Logoff on the

Page 18

Access AWS-1B Wrapping System Operator Manual

Shutting Down the System

The Shutdown feature is designed to stop all internal functions.

Shutdown is required before power can be disconnected from the

system.

To Shutdown the System:

1. From the Operator Start Screen, TOUCH System.

2. From the System Menu, TOUCH Shutdown. A screen will

appear and ask, “Are you sure you want to shutdown?”

3. TOUCH OK. A screen will appear and say, “The scale is

shutting down. Please wait....”

Shutdown may take a few minutes to complete depending on the

size of the database in the scale. DO NOT disconnect power to

the system during shutdown.

4. When the shutdown is complete, a screen will appear and

say, “The scale has been shutdown. You may remove power

from the scale.

–OR–

Press REBOOT to reboot now.”

5. Remove power by using the on/off switch on th e back of the

printer.

Do not remove power from the system by unplugging it. Always

use the on/off switch on the back of the printer to power down

the system. Failure to comply with will result in a service call.

Note

The Access Wrapping System is equipped with an automatic

sleep/start feature. When all packages clear the machine it will

only continue to run for a specified period of time. The machine

shuts off, but the green light remains on. When you place a

package on the intake, the machine automatically re-starts. The

PLU remains the same.

6. Lift small access door on the right-hand side of the lower

front panel of the wrapper and switch the power switch off.

Using the Access Wrapping System 3-2 F-35538 (April 2010)

Page 19

Access AWS-1B Wrapping System Operator Manual

Operator Start Screen

Menu Buttons and Flashkeys

The Operator Start Screen Menu Buttons provide access to dropdown menus showing available functions. The use of these keys,

the screens accessed, and the functions performed through these

keys are described in next section of this manual.

Note

The Product Menu Buttons will only be available when a PLU is

entered.

Flashkeys are the keys located below the Operator Start Screen

menu buttons. These keys are configured individually for each

system to provide quick access to products and functions

frequently used.

F-35538 (April 2010) 3-3 Using the Access Wrapping System

Page 20

Access AWS-1B Wrapping System Operator Manual

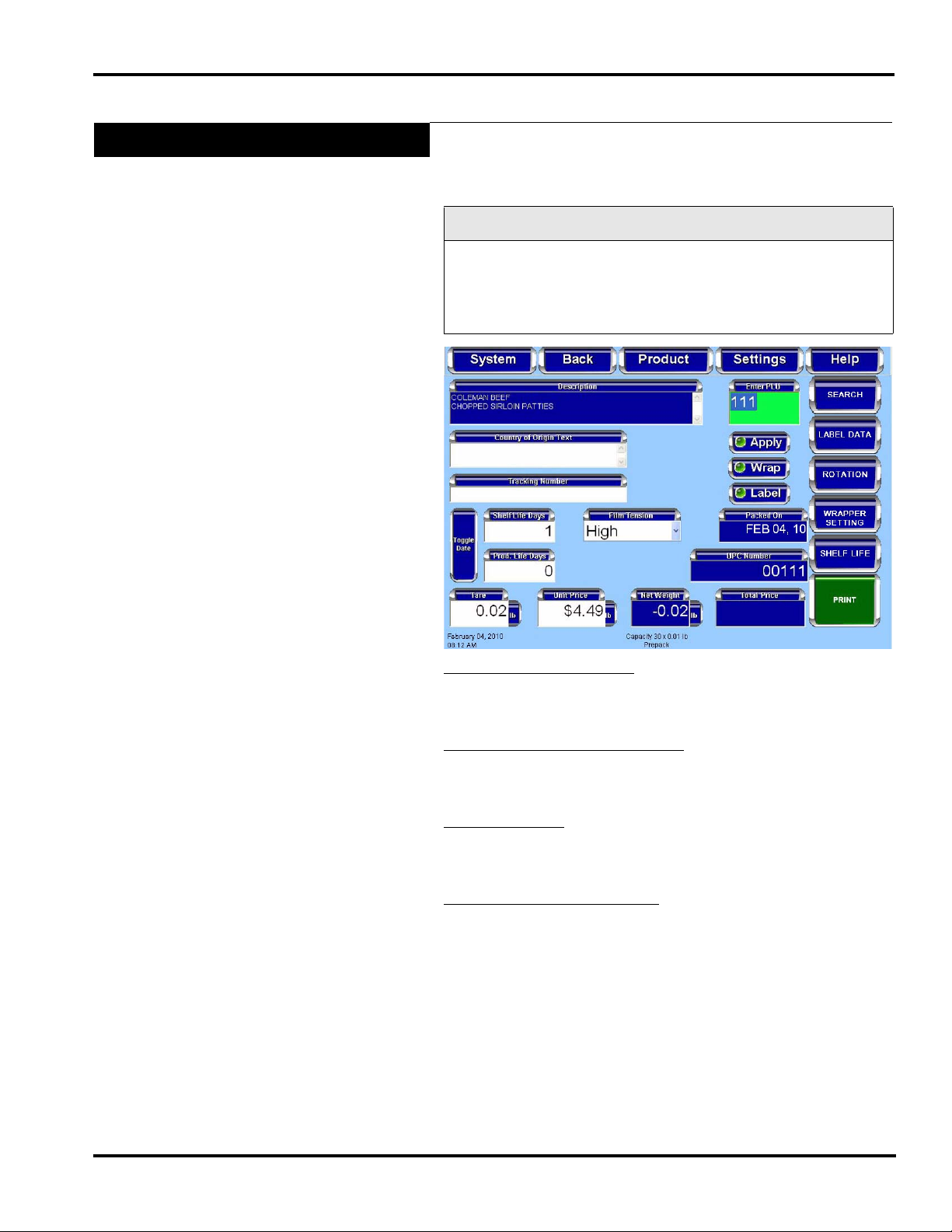

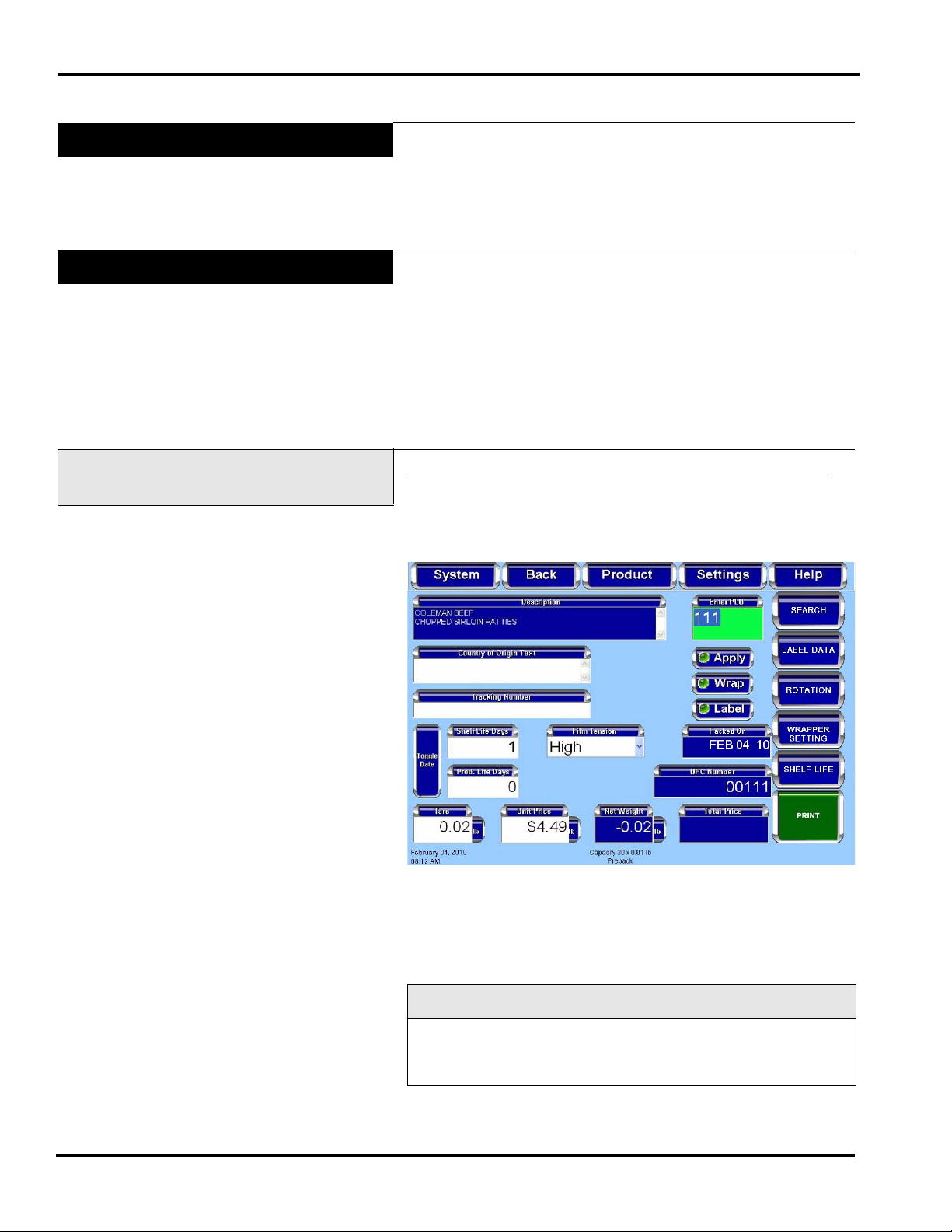

Run Screen

The Run Screen displays product information for the PLU that is

entered. The type of data displayed depends upon the product

weigh type of the PLU.

The Run Screen displays the following product information, if

applicable:

• Enter PLU Number

• Product Description

• Shelf Life Days (toggles to Sell By Date)

• Product Life Days (toggles to Best Before Date)

• Country of Origin Text (COOL)

•Tracking Number

• Product Image (optional)

•UPC Number

•Net Weight

•Total Price

•Print

• Film Tension

• Automatic Label Apply (toggles on/off)

• Automatic Wrap (toggles on/off)

• Automatic Label Print (toggles on/off)

• Tare (if applicable)

• Unit Price (if applicable)

• By Count (if applicable)

• Exception Price (if applicable)

• Volume (if applicable)

Note

System configuation may show different options.

Using the Access Wrapping System 3-4 F-35538 (April 2010)

Page 21

Modifying the Run Screen

Access AWS-1B Wrapping System Operator Manual

The operator can modify certain settings that display on the Run

Screen. Only text fields with a white background can be

modified. Text fields with a blue background cannot be edited

and provide information only.

Note

Changes made at the Run Screen, other than certain COOL and

Film Selection information will be in effect for the current

product only . The scale will revert to the system default settings

when a different PLU is entered.

T o change Text Field values: TOUCH the text field and SELECT

the setting from the list –OR– TYPE the change on the pop-up

Numeric Keypad or Alpha Keyboard. TOUCH Enter. The value

change will be displayed in the text field.

To change the Film Tension setting

: TOUCH the Film Tension

field. The settings of High, Medium, and Low will be displayed.

SELECT the desired setting. The setting selected will be

displayed in the Film Tension field.

T o change COOL

: TOUCH the Country of Origin T ext field. You

should now be on the COOL Screen. See Product Drop-Down

Menu - COOL Screen for information about modifying COOL.

The setting changes made will be displayed on the Run Screen.

To change Automatic functions

: TOUCH the automatic buttons

on the screen to turn them on or off. If the indicator is green the

function is enabled. If the indicator is red, then the function is

disabled. See Automatic Settings for more information about the

automatic functions available on the Access Wrapping System.

F-35538 (April 2010) 3-5 Using the Access Wrapping System

Page 22

Access AWS-1B Wrapping System Operator Manual

Automatic Settings

The Run Screen has settings for automatic or manual modes. In

Automatic Mode the operation will be performed without the

operator touching PRINT, as is required in Manual Mode. Automatic Mode is changed with the Apply , Wrap, and Label buttons.

The function is enabled when the indicator is green (Automatic

Mode) and is disabled when the indicator is red (Manual Mode).

Using Automatic Mode

Automatically Wrap, Print and

Apply Label

There are different automatic modes available for use with the

Access Wrapping System.

The automatic functions are:

Automatically Wrap, Print and Apply Label

Automatically Print Label Only

Automatically Print and Apply Label, No Wrap (Prepackaged

Products)

Automatically Wrap Only

To wrap the product and print and apply a label automatically:

TOUCH the Apply, Wrap, and Label buttons until the indicators

are green. The Enter PLU text background color is green.

TOUCH a Flashkey or TOUCH the Enter PLU field and TYPE

the product number on the numeric keypad.

A product is placed on the wrapper scale. The product will run

through the wrapper and will be wrapped. A label will be printed

when a stable weight has been sensed by the scale. The label will

be applied to the product as the product emerges from the

wrapper.

Note

Some pre-wrapped items, such as turkey or chicken, have a

cardboard band around the package. Do not run these through

the wrapper.

Using the Access Wrapping System 3-6 F-35538 (April 2010)

Page 23

Automatically Print Label Only

Access AWS-1B Wrapping System Operator Manual

To print a label without applying the label in Automatic Mode:

TOUCH the Label button until the indicator is green. TOUCH the

Apply and Wrap buttons until the indicators are red. The Enter

PLU text background color is white.

TOUCH a Flashkey or TOUCH the Enter PLU field and TYPE

the product number on the numeric keypad.

Place the product on the wrapper scale. A label will print

automatically when a stable weight has been sensed by the scale.

The label will not be applied to the product. Manually remove the

label from the printer and apply to the product.

F-35538 (April 2010) 3-7 Using the Access Wrapping System

Page 24

Access AWS-1B Wrapping System Operator Manual

Automatically Print and Apply

Label, No Wrap (Prepackaged

Products)

To print and apply a label to the product in Automatic Mode:

TOUCH the Apply and Label buttons until the indicators are

green. TOUCH the Wrap button until the indicator is red. The

Enter PLU text background is yellow.

TOUCH a Flashkey or TOUCH the Enter PLU field and TYPE

the product number on the numeric keypad.

Place the product on the wrapper scale. A label will print

automatically when a stable weight has been sensed by the scale.

The product will travel through the wrapper and the label will be

applied. The product will not be wrapped.

Note

Some pre-wrapped items, such as turkey or chicken, have a

cardboard band around the package. Do not run these through

the wrapper.

Using the Access Wrapping System 3-8 F-35538 (April 2010)

Page 25

Automatically Wrap Only

Access AWS-1B Wrapping System Operator Manual

To wrap a product without printing or applying a label in

Automatic Mode: TOUCH the Wrap button until the indicator is

green. TOUCH the Apply and Label buttons until the indicators

are red. The Enter PLU text background color is white.

A product is placed on the wrapper scale. The product will run

through the wrapper and will be wrapped.

F-35538 (April 2010) 3-9 Using the Access Wrapping System

Page 26

Access AWS-1B Wrapping System Operator Manual

Manual Mode

To use Manual Mode: TOUCH the Apply, Wrap, and Label

buttons until the indicators are red. The enter PLU text

background color is white.

A product is placed on the wrapper scale. TOUCH Print to print a

label.

Using the Access Wrapping System 3-10 F-35538 (April 2010)

Page 27

Running a Product

Access AWS-1B Wrapping System Operator Manual

Running a product is the basic function of the operator. This

function allows the operator to select the PLU, weigh, wrap,

print, and apply the label.

From the Operator Start Screen, TOUCH a Flashkey –OR–

TOUCH the Enter PLU field and TYPE the product number on

the Numeric Keypad. TOUCH Enter. You should now be on the

Run Screen.

Select the automatic setting for this run. See Using Automatic

Mode.

Note

Make sure the product settings are correct before starting a run.

To modify product settings, see Modifying the Run Screen.

To run in Automatic Mode

label will print automatically when a stable weight has been

sensed by the scale.

T o run in Manual Mode

Print to print a label. The label will print when a stable weight has

been sensed by the scale.

: Place the product on the scale. The

: Place the product on the scale. TOUCH

F-35538 (April 2010) 3-11 Using the Access Wrapping System

Page 28

Access AWS-1B Wrapping System Operator Manual

Using the Operator Run Screen

Drop-Down Menus

Additional information is available through a menu button;

Product, Settings, and Help are located on the Operator Screen

menu bar as shown on the Operator Run Screen.

The Operator Run Screen drop-down menus include:

Note

The Product Menu button will only be available when a PLU is

entered.

For Product

•Label Data

• Label Placement

• Product Note

• Product & Shelf Life

• COOL

• Void Transaction

For Settings

• Wrapper Settings

• Printer Settings

• Date and Time

• Total Types

• Rezero Weigher

For Help

•Search

• Describe this Page

• Questions

• Operator Note

• Weights & Measures

• About Access

Using the Access Wrapping System 3-12 F-35538 (April 2010)

Page 29

Product Drop-Down Menu

Access AWS-1B Wrapping System Operator Manual

The Product Drop-Down Menu has the following selections:

Label Data Screen

Label Placement Screen

Product Note Screen

Product & Shelf Life Screen

COOL Screen

Void Transaction

Product Drop-Down Menu Label Data Screen

From the Operator Run Screen, TOUCH Product. TOUCH

Label Data. You should now be on the Label Data Screen.

T o change the Lab el Type

Numeric Keypad will be displayed. TYPE the label number or

TOUCH clear to delete the label number and enter another one,

then TOUCH enter to complete the label number entry. The width

and length of the label will automatically be displayed below the

Label Type text box.

: TOUCH the Label T ype text box. The

Note

If in manual mode, TOUCH Print.

To change the Graphic

from the list.

To exit this screen

F-35538 (April 2010) 3-13 Using the Access Wrapping System

: TOUCH the graphic field and SELECT

: TOUCH Back.

Page 30

Access AWS-1B Wrapping System Operator Manual

Product Drop-Down Menu Label Placement Screen

From the Operator Run Screen, TOUCH Product. TOUCH

Label Placement. You should now be on the Label Placement

Screen.

To change the Printer Selected

: TOUCH the Printer field. The

printer drop-down selections of Primary and Secondary will be

displayed. SELECT the printer. The default settings for the

selected printer will be displayed.

Note

If only a Primary printer is available the Primary printer text box

will be disabled.

To change the Label Rotation

until the label shown on the screen is in the desired orientation.

Then, set the rotation lever to the position indicated in green.

: TOUCH the Label Rotation field

To change Label Position

: TOUCH the Label Position field. The

label position drop down selections of right and left will be

displayed. SELECT a label position.

To exit this screen

Using the Access Wrapping System 3-14 F-35538 (April 2010)

: TOUCH Back.

Page 31

Product Drop-Down Menu Product Note Screen

Access AWS-1B Wrapping System Operator Manual

From the Operator Run Screen, TOUCH Product. TOUCH

Product Note. You should now be on the Product Note Screen.

Note

Not all PLU’s have an associated Product Note.

To exit this screen

: TOUCH Back.

F-35538 (April 2010) 3-15 Using the Access Wrapping System

Page 32

Access AWS-1B Wrapping System Operator Manual

Product Drop-Down Menu Product & Shelf Life Screen

From the Operator Run Screen, TOUCH Product. TOUCH

Product & Shelf Life. You should now be on the Product & Shelf

Life Screen.

To change the Shelf Life Days:

TOUCH the Shelf Life Days box

to activate it. The numeric keypad will be displayed. TYPE in the

number of days. TOUCH enter on the keypad. The number of

days will appear in the Shelf Life Days box. The Sell By Date

will be calculated automatically and the date will be highlighted

in the calendar.

To change the Sell By Date

: TOUCH the Sell By Date box to

activate it. The numeric keypad will be displayed. TYPE in the

date using two digits each for the day, month, and year. TOUCH

enter on the keypad. The new date will appear in the Sell By Date

box as well as be highlighted in the calendar.

T o ch ange the Produ ct Life Days:

TOUCH the Product Life Days

box to activate it. The numeric keypad will be displayed. TYPE

in the number of days. TOUCH enter on the keypad. The number

of days will appear in the Product Life Days box. The Best

Before Date will be calculated automatically and the date will be

highlighted in the calendar.

Using the Access Wrapping System 3-16 F-35538 (April 2010)

Page 33

Access AWS-1B Wrapping System Operator Manual

To change the Best Be fore Date: TOUCH the Best Before Date

box to activate it. The numeric keypad will be displayed. TYPE

in the date using two digits each for the day, mont h, and year.

TOUCH enter on the keypad. The new date will appear in the

Best Before Date box as well as be highlighted in the calendar.

To change the Shelf/Product Life Hours:

TOUCH the S helf or

Product Life Hours box to activate it. The numeric keypad will be

displayed. TYPE in the number of days. TOUCH enter on the

keypad. The number of hours will appear in the Shelf or Product

Life Hours box. The Sell By and/or Best Before Date will be

calculated automatically and the date will be highlighted in the

calendar.

T o change the Don't print check boxes:

TOUCH the check box to

turn the function on.

Note

You can also use the calendar to change the best before or sell

by date. TOUCH the sell by or best before date field. TOUCH

cancel, then SELECT the date on the calendar.

To change the Month

: TOUCH the arrow keys to the right and

left at the top of the calendar.

To exit this screen

: TOUCH Back.

Note

The Best Before Date changes reflect a change in the Sell By

Date.

F-35538 (April 2010) 3-17 Using the Access Wrapping System

Page 34

Access AWS-1B Wrapping System Operator Manual

Product Drop-Down Menu COOL Screen

From the Operator Run Screen, TOUCH Product. TOUCH

COOL. You should now be on the COOL Screen.

To exclude COOL Data

To create COOL text

: TOUCH the Cool Not Required button.

: TOUCH the Create COOL Text button.

You should now be on the Create COOL Text Screen.

SELECT the appropriate production step from those listed in the

Production Steps box. Repeat this procedure to SELECT the

country from the list in the Country box in which the production

step was performed. The production step and country selected

will be displayed in the COOL Text box. If needed, TOUCH the

Start Over button to delete the COOL text. The created COOL

text should now appear in the COOL Short List.

To use text from the COOL Short List:

TOUCH the text in the

COOL Short List field. The text selected should now appear in

the Current COOL Text field. This is the COOL text that will be

used for this run only.

T o create COOL Tracking Number:

TOUCH the COOL Tracking

Number field to activate it. The alpha keyboard will be displayed.

TYPE in the tracking number.

To exit this screen

: TOUCH Back.

Using the Access Wrapping System 3-18 F-35538 (April 2010)

Page 35

Product Drop-Down Menu Void Transaction

Access AWS-1B Wrapping System Operator Manual

From the Operator Run Screen, TOUCH Product. TOUCH Void

Transation.

The current transaction will be voided. There will be no further

indication on the screen that the transaction has been completed.

Settings Drop-Down Menu

Settings Drop-Down Wrapper Screen

The Setting Drop-Down Menu has the following selections:

Wrapper Screen

Printer Settings Screen

Date and Time Screen

Total Type Screen

Rezero Weigher Screen

From the Operator Run Screen, TOUCH Settings. TOUCH

Wrapper. You should now be on the Wrapper Screen.

To change the Intake Mode

bring up the Intake Mode drop-down selections either Normal,

Default, or Gentle.

To turn on/off the Sealer Belt

field and SELECT either On or Off.

The sealer belt is hot. Do not touch.

: TOUCH the Intake Mode field and

: TOUCH the Sealer Belt power

Tip

Allow the sealer belt to warm up for 10-15 minutes; it must be

hot enough to seal properly. You will need to do this anytime

you change the temperature or if the circuit breaker is turned on

after being off.

F-35538 (April 2010) 3-19 Using the Access Wrapping System

Page 36

Access AWS-1B Wrapping System Operator Manual

To change the Belt Temperature: TOUCH the Belt Temperature

Setting field. The Numeric Keypad will be displayed. TYPE the

Belt T emperature Setting on the Numeric Keypad. TOUCH Enter.

To change Film Tension

: TOUCH the Film Tension field and

SELECT either High, Medium, or Low.

To change Film Tension - Front to Back

: TOUCH the Tension Front to Back field and SELECT from a range of -5 to +5;

negative allowing less tension; positive allowing more tension.

None is the default value.

To change Film Tension - Left to Right

: TOUCH the Tension Left to Right field and SELECT from a range of -5 to +5;

negative allowing less tension; positive allowing more tension.

None is the default value.

To load Film

To Cut Film

To change Film Width

: TOUCH the Load Film button.

: TOUCH the Cut Film button.

: TOUCH the Upper Film Width button.

SELECT the appropriate width.

To exit this screen

: TOUCH Back.

Using the Access Wrapping System 3-20 F-35538 (April 2010)

Page 37

Settings Drop-Down Menu Printer Settings Screen

Access AWS-1B Wrapping System Operator Manual

From the Operator Run Screen, TOUCH Settings. TOUCH

Printer Settings. You should now be on the Printer Settings

Screen.

To change the Printer Type

: TOUCH the Printer Type field and

SELECT Primary, Second, Third, or None.

To change the Printer Contras t

: TOUCH the Printer Contrast

field and SELECT a number from 0-7. TOUCH the Apply

Changes & Print Label button to save changes and print a sample

label.

Note

Use the lowest contrast level that allows for acceptable print.

To change Label Width

SELECT the desired width. TOUCH the Apply Changes & Print

Label button to save changes and print a sample label.

To change the Horizontal Print Position

Right buttons on either side of the Horizontal Print Position field

to move the print to the left or the right on the label. TOUCH the

Apply Changes & Print Label button to save changes and print a

sample label.

To change the Vertical Print Position

buttons on either side of the Vertical Print Position field to move

the print up or down on the label. TOUCH the Apply Changes &

Print Label button to save changes and print a sample label.

: TOUCH the Label Width field and

: TOUCH the Left or

: TOUCH the Up or Down

To exit this screen

F-35538 (April 2010) 3-21 Using the Access Wrapping System

: TOUCH Back.

Page 38

Access AWS-1B Wrapping System Operator Manual

Settings Drop-Down Menu Date and Time Screen

The current date and time set for the Access Wrapping System is

shown on the Operator Run Screen in the lower left-hand corner.

From the Operator Run Screen, TOUCH Settings. TOUCH Date

and Time. You should now be on the Date and Time Screen.

T o change the Month

month.

To change the Year

: TOUCH the year field and SELECT the

year.

To change the Day

T o change the Hour

: TOUCH the day on the calendar.

: TOUCH the HH field and TOUCH the up or

down arrow.

To change the Minute

up or down arrow.

To change AM/PM

: TOUCH the AM/PM field to toggle between

AM and PM.

To exit this screen

: TOUCH Back.

: TOUCH the month field and SELECT the

: TOUCH the MM field and TOUCH the

Using the Access Wrapping System 3-22 F-35538 (April 2010)

Page 39

Settings Drop-Down Menu Total Type Screen

Access AWS-1B Wrapping System Operator Manual

From the Operator Run Screen, TOUCH Settings. TOUCH T otal

Type. You should now be on the Total Type Screen.

Settings Drop-Down Menu Rezero Weigher Screen

To select a Total Type

: TOUCH the Total Type field and

SELECT a Total Type.

To exit this screen

: TOUCH Back.

Ensure that nothing is on the scale. From the Operator Main

Menu Screen, TOUCH Settings. TOUCH Rezero Weigher. A

process box will appear briefly; no other action is required.

F-35538 (April 2010) 3-23 Using the Access Wrapping System

Page 40

Access AWS-1B Wrapping System Operator Manual

Help Drop-Down Menu

The Help Drop-Down Menu has the following selections:

Search Screen

Describe this Page Screen

Questions Screen

Operator Note Screen

About Access Screen

Weights & Measures Screen

Help Drop-Down Menu Search Screen

From any screen, TOUCH Help. TOUCH Search. You should

now be on the Search Screen.

A search can be performed by a product number or by a product

description. TOUCH either the check box Search by character to

perform a search by product description or Search by PLU to

perform a search by product number.

T o perform a Search by character

by Character. TOUCH the text field to the left of the check boxes

to activate it for data entry. The Alpha Keyboard will be

displayed on the screen. TYPE the letters on the keyboard

describing the product. A maximum of 4 characters may be

entered. If the search does not begin automatically, TOUCH

Done.

Using the Access Wrapping System 3-24 F-35538 (April 2010)

: TOUCH the check box Search

Page 41

Access AWS-1B Wrapping System Operator Manual

As shown on the screen below, a list of products is displayed.

TOUCH the scroll bar arrows to the right of the box containing

the product list to scroll up or down and view all of the products

listed. TOUCH the scroll bar arrows below the box to view list

entries that are wider than the box.

SELECT the desired product on the list. The Run Screen for the

selected product will be displayed.

To perform a Search by PLU Range

: TOUCH the check box

Search by PLU. TOUCH the text field to the left of the check

boxes to activate it for data entry. The Numeric Keypad will be

displayed on the screen. TYPE the product number. If the search

does not begin automatically, TOUCH Enter.

F-35538 (April 2010) 3-25 Using the Access Wrapping System

Page 42

Access AWS-1B Wrapping System Operator Manual

As shown on the screen below, a list of products is displayed.

Help Drop-Down Menu Describe this Page Screen

TOUCH the scroll bar arrows to the right of the box containing

the product list to scroll up or down and view all of the products

listed. TOUCH the scroll bar arrows below the box to view list

entries that are wider than the box.

SELECT the desired product on the list. The Run Screen for the

selected product will be displayed.

The Describe this Page Screen will give you tips about the current

screen.

From any screen, TOUCH Help. TOUCH Describe this Page.

You should now be on the Describe this Page Screen.

To exit this screen

Using the Access Wrapping System 3-26 F-35538 (April 2010)

: TOUCH Back.

Page 43

Help Drop-Down Menu Questions Screen

Access AWS-1B Wrapping System Operator Manual

The Questions Screen will show a list of frequently asked

questions regarding the Access Wrapping System operation and

maintenance.

From any screen, TOUCH Help. TOUCH Questions. You should

now be on the Questions Screen.

Help Drop-Down Menu Operator Note Screen

T o view Questions

: TOUCH the scroll bar on the right of the list

of questions to scroll up and the down the list of questions.

To exit this screen

: TOUCH Back.

From any screen, TOUCH Help. TOUCH Operator Note. You

should now be on the Operator Note Screen. This is only

available if there is a note.

To exit this screen

F-35538 (April 2010) 3-27 Using the Access Wrapping System

: TOUCH Back.

Page 44

Access AWS-1B Wrapping System Operator Manual

Help Drop-Down Menu About Access Screen

From any screen, TOUCH Help. TOUCH About Access. You

should now be on the About Access Screen.

Help Drop-Down Menu Weights & Measures Screen

To exit this screen

: TOUCH Back.

From any screen, TOUCH Help. TOUCH Weights & Measures.

You should now be on the Weights & Measures Screen.

Note

The information on this screen will vary depending on the

peripherals attached.

To exit this screen: TOUCH Back.

Using the Access Wrapping System 3-28 F-35538 (April 2010)

Page 45

Chapter 4: Maintenance & Cleaning

Cleaning and Maintaining your System

Access AWS-1B Wrapping System Operator Manual

This durable Access Wrapping System has been designed and

manufactured to resist corrosion, scratches, stains, alkaline, protein and food acid when cared for properly. Improper care can

permanently damage the wrapper, electronics and printer.

Proper cleaning prolongs the life and productivity of the machine.

This machine should be thoroughly cleaned on a daily basis

(more often, if necessary). If the system is not cleaned on a

regular basis it may not run consistently and will cause service

problems. Failure to follow use, care and maintenance as noted

may void your Hobart warranty.

About Proper Care

Enemies of Stainless Steel

The following information was derived from the brochure STAINLESS STEEL EQUIPMENT CARE AND CLEANING

(F-24845) distributed by NAFEM.

Corrosion of metals is everywhere. We recognize it on iron and

steel as rust. These are called active metals because they actively

corrode in the natural environment. Stainless steels are passive

metals because they contain other metals, like chromium and

nickel.

There are three basic components which can break down your

stainless steel’s passivity layer (micro-thin film) and allow

corrosion:

Component Explanation

Mechanical

Abrasions

Deposits and Water Water comes out of the tap in varying

Items that will scratch the steel’s surface.

Steel pads, wire brushes, and scrapers are

prime examples.

degrees of hardness. Depending on what

part of the country you live in, you may

have hard or soft water. Hard water may

leave spots. Also, when heated, hard

water leaves deposits behind that, if left

to sit, will break down the passive layer

and rust your stainless steel.

Other deposits from food preparation

and service must be properly removed.

Chlorides Chlorides are found nearly everywhere.

They are in water, food, and table salt.

One of the worst perpetrators of

chlorides can come from household and

industrial cleaners.

F-35538 (April 2010) 4-1 Maintenance & Cleaning

Page 46

Access AWS-1B Wrapping System Operator Manual

Steps to help prevent stainless steel from rusting or pitting:

1. Use the proper tools. Soft cloths and plastic scouring pads

will not harm the stainless steel’s passive layer.

2. Clean with the polish lines.

3. Use alkaline, alkaline chlorinated or non-chloride contain-

ing cleaners. Also, avoid cleaners containing quaternary

salts as they can attack stainless steel and cause pitting and

rusting.

4. Treat your water. If you are not sure of the proper water

treatment, call a treatment specialist.

5. Keep your food equipment clean. Clean frequently to avoid

buildup of hard stubborn stains.

6. Rinse, Rinse, Rinse. If chlorinated cleaners are used you

must rinse and wipe dry immediately. The sooner you wipe

off standing water, especially when it contains cleaning

agents, the better. After wiping the equip ment down, allow it

to air dry for the oxygen helps maintain the stainless steels’

passivity film.

7. Never use hydrochloric acid on stainless steel.

Guidelines

All food-contact surfaces must be washed, rinsed, and sanitized:

• after each use

• when you begin working with another type of food

• anytime you are interrupted during a task

• at four hour intervals, if the items are in constant use

Other components should be cleaned and sanitized at least once

each day and whenever they become soiled.

Before using cleaning solvent, all food products and

packaging materials must be removed from the area or

carefully protected. All odor of the cleaner must dissipate

before food products or packaging materials are exposed.

Refer to manufacturers instructions.

• FDA Code of Regulations Vol. 21 require solutions

containing chlorine to be of no greater concentration than

200 ppm. Solutions containing concentrations greater than

200 ppm chlorine will accelerate corrosion of metals.

• Proper cleaning solvent is available from your local Hobart

service office for all rubber surfaces. Observe the instructions on the bottle.

Maintenance & Cleaning 4-2 F-35538 (April 2010)

Page 47

Access AWS-1B Wrapping System Operator Manual

Cleaning/Rinsing Guidelines

Do Don’t

Refer to the following Cleaning and Rinsing guidelines.

use products formulated to be safe on stainless steel

DO

(mild soap and water are recommended)..

DON’T dampen labels, electronic parts, or

connections.

DON’T

clean the system.

DON’T

ment with relative humidity levels consistently in

excess of 70%.

DON’T

• Chloride-Based cleaners

• Formula 409

• Glass Cleaners (i.e. Scotty’s Glass Cleaner)

• Citrus-Based Cleaners (i.e. Citro-Sol or Bio-T)

• Caustic Cleaners with high pH (i.e. Butchers

Block, concentrated Lysol or Pinesol)

DON’T

concentrations for detergent.

Sanitizing Guidelines

Do Don’t

use steam or a high pressure water spray to

operate and/or store the system in an environ-

use:

exceed chemical manufacturer’s recommended

use 5% Chlorine Bleach (5.25% Sodium

DO

Hypochlorite).

Ratio

Bleach Water Concentration

1 : 250 1 tsp. 1 gal. 200 ppm

1 : 500 1/2 tsp. 1 gal. 100 ppm

1 : 1000 1/4 tsp. 1 gal. 50 ppm

1 : 2000 1/8 tsp. 1 gal. 25 ppm

DON’T exceed chemical manufacturer’s recommended

concentrations for sanitizer.

DON’T

use solutions of greater than 200 ppm

concentration of chlorine cleaners.

F-35538 (April 2010) 4-3 Maintenance & Cleaning

Page 48

Access AWS-1B Wrapping System Operator Manual

Cleaning Instructions

Prior to cleaning, power down the touch screen, printer and wrapper. See Shutting Down the System. Unthread the film from the

film selector.

Disconnect power source to wrapper before cleaning.

Use of high pressure washing system will cause damage to the

wrapper.

Cleaning Each Component

Component Cleaning Table

T o appropriately clean each component of the system, refer to the

following component cleaning table.

Component Explanation

Rear Film Chamber Clean as needed with a soft cloth moistened with a mild detergent and water.

Rinse and allow to air dry.

Maintenance & Cleaning 4-4 F-35538 (April 2010)

Page 49

Access AWS-1B Wrapping System Operator Manual

Component Explanation

Canopy and Film Chamber

Doors

Clean as needed with a soft cloth moistened with a mild detergent and water.

Rinse and allow to air dry.

Covers (External - Plastic) Clean as needed by using a soft cloth moistened with a mild detergent and

water. Rinse and allow to air dry.

Sealer Belt

Hot surface. Do not touch.

Clean as needed by using a soft cloth moistened with a mild detergent and

water. Rinse and allow to air dry.

Intake Conveyor Area and

Weigher Rods

Clean as needed by using a long-handled brush or a moist cloth. Weigher rods

can be removed and cleaned in a sink with mild detergent and water. Use the

long-handled brush for additional cleaning of the belts. Replace weigher rods

after cleaning. Rinse and allow to air dry.

Side Panels (Stainless Steel) Clean as needed by using a soft cloth moistened with a mild detergent and

water. Rinse and allow to air dry.

F-35538 (April 2010) 4-5 Maintenance & Cleaning

Page 50

Access AWS-1B Wrapping System Operator Manual

Component Explanation

Package Hold Down Lift upward and clean as needed with a soft cloth moistened with a mild deter-

gent and water. Rinse and allow to air dry.

Rubber Pads, Side Clamp

Clean as needed with Hobart cleaning solvent or isopropyl alcohol.

Gripper

Rubber Roller (in film selector) Clean as needed with Hobart cleaning solvent or isopropyl alcohol.

Front, Rear and Side

Underfolders

Clean as needed by using a soft cloth moistened with a mild detergent and

water. Rinse and allow to air dry.

Elevator Area Clean as needed by using a soft cloth. Open the canopy and the side doors to

get access to the elevator area. Rinse and allow to air dry. A soft brush may be

required to reach confined areas.

Once cleaning is complete and any steam in the room has

dissipated, restore power to the printer and wrapper. See Power

Up the System.

Before restoring power, insure there is no water remaining on

the weigher. This could result in the system coming up out of

zero range.

Maintenance & Cleaning 4-6 F-35538 (April 2010)

Page 51

Removing Labels

Access AWS-1B Wrapping System Operator Manual

To remove labels from the printer:

1. Open the printer label access door.

2. Pull the printhead positioning lever toward the printhead to

lower the printhead.

3. Push and hold in the label door release located on the interior

back wall behind the roller and lower the label door.

F-35538 (April 2010) 4-7 Maintenance & Cleaning

Page 52

Access AWS-1B Wrapping System Operator Manual

4. Remove the take-up spool key.

5. Remove the label backing paper from the take-up spool and

the label roll from the hub.

Maintenance & Cleaning 4-8 F-35538 (April 2010)

Page 53

Loading Labels

Access AWS-1B Wrapping System Operator Manual

Note

Before loading labels:

•See Cleaning the Printhead.

•See Setting the Label Size Plate.

To load labels in the printer

:

1. Remove labels from the first 12 inches of the new label roll.

This will create a leader to attach to the take-up spool.

2. Pull the printhead positioning lever toward the printhead to

lower the printhead.

F-35538 (April 2010) 4-9 Maintenance & Cleaning

Page 54

Access AWS-1B Wrapping System Operator Manual

3. Push and hold in the label door release located on the interior

back wall behind the roller and lower the label door.

4. Place the label roll on the hub. The leader feeds from the

bottom of the roll in a clockwise direction.

5. Remove the take-up spool key.

6. Wrap the leader under the black label guide, around the roller

and the take-up spool and insert the take-up spool key. Insert

the short side of the key first and catch the leader under the

long side of the key.

7. Take up the leader slack and align the leader on the spool.

Maintenance & Cleaning 4-10 F-35538 (April 2010)

Page 55

Access AWS-1B Wrapping System Operator Manual

8. Close the label door on the front of the printer.

9. Pull the printhead positioning lever away from the printhead

to raise the printhead into position. The printer will

automatically advance the labels through the printhead

setting the labels in the ready position.

10. Close the printer label access door.

F-35538 (April 2010) 4-11 Maintenance & Cleaning

Page 56

Access AWS-1B Wrapping System Operator Manual

Setting the Label Size Plate

To set the label size plate:

1. Lift the label plate and set it in the slots for the size labels

being used.

2. Move the lever on the hub to the slot for the size labels being

used.

Note

If you change the label size, make sure to adjust the printer settings (see Printer Settings Screen).

Maintenance & Cleaning 4-12 F-35538 (April 2010)

Page 57

Cleaning the Printhead

Access AWS-1B Wrapping System Operator Manual

The printhead of your Access Wrapping System Printer should be

cleaned approximately once each week, or whenever labels are

obstructed due to a residue buildup on the printhead and/or roller.

It is a good idea to clean the printhead roller whenever a new

roll of labels is installed. To obtain a Printhead Cleaning Kit,

contact your local Hobart Representative; request

Part Number 00-184326.

Do not use a metal tool on the printhead. This could scratch or

break the printhead. In addition, monitor the printer to look for

labels stuck on the printer parts. If found, remove these labels at

once following the instructions given below.

To clean the printhead

:

1. With the label door lowered, the labels removed and the

printhead in the lowered position, check to see if the

printhead is clean and free of label stock and label adhesive.

2. Use the plastic scraper from the Printhead Cleaning Kit to

remove stuck-on label stock.

3. To remove burnt-on adhesive, gently rub the printhead

surface with the eraser from the Printhead Cleaning Kit.

4. Using the cleaner and a swab from the Printhead Cleaning

Kit, scrub the printhead until all of the residue is removed.

5. Clean the roller with the cleaner and swabs.

6. Allow the printhead and roller to dry before loading the

labels.

F-35538 (April 2010) 4-13 Maintenance & Cleaning

Page 58

Access AWS-1B Wrapping System Operator Manual

Maintenance & Cleaning 4-14 F-35538 (April 2010)

Page 59

Troubleshooting

Access AWS-1B Wrapping System Operator Manual

Chapter 5: Troubleshooting

In the event that your Access Wrapping System does not operate

as expected, please read through the following troubleshooting

steps before calling for service.

Tip

Properly loaded trays produce the most attractively wrapped

packages and can enhance wrapper operation by reducing rewraps, product spillage and loss, repeated shutdowns, machine

damage, etc.

To insure proper loading:

Keep all product in the tray.

Avoid top-heavy packages to prevent product from

rolling out.

Avoid stacking product whenever possible.

Use appropriate sized tray.

Keep loose product flat in the tray.

An improperly loaded tray has the following attributes:

Product exceeds height requirement and is unstable. You

should hand wrap oversized items to avoid possible

machine damage.

Product is unstable or overhanging tray. Use larger and

deeper tray or hand wrap.

These guidelines can improve product appearance, case life, and

overall productivity.

If the machine has shutdown because of an error, correct the

problem, cycle the stop switch, and push the START button. The

error message displays again if the error is not corrected.

F-35538 (April 2010) 5-1 Troubleshooting

Page 60

Access AWS-1B Wrapping System Operator Manual

Reviewing System Errors

Message What should I do?

Primary conveyor not at home. 1. Press the START button to home the machine.

Press the START button to home the machine. 1. Press the STOP button.

Primary intake jammed. 1. Press the STOP button.

Primary conveyor did not find home. 1. Press the STOP button.

Intake blocked. 1. Press the STOP button.

The following system error messages display at the console, if

problems occur.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Package is too long or too short. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Package did not trip the elevator sensor. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Secondary intake jammed. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Centering conveyor not at home. 1. Press the START button to home the machine.

Centering conveyor jammed. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Package is too far left. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Package is too far right. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Troubleshooting 5-2 F-35538 (April 2010)

Page 61

Access AWS-1B Wrapping System Operator Manual

Message What should I do?

Centering conveyor did not find home. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Secondary shift lost control. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Elevator not at home. 1. Press the START button to home the machine.

Elevator stalled. 1. Press the STOP button.

2. Check that the package is 15 lbs. or less.

3. Remove any packages, labels, debris in the machine.

4. Press the START button.

Elevator position error. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Elevator did not find home. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Elevator did not find top. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Elevator sensor is not working. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Package will not wrap with selected film. 1. Press the STOP button.

2. Select a larger size film.

3. Remove any packages, labels, debris in the machine.

4. Press the START button.

Film not pulled. 1. Press the STOP button.

2. Check to make sure film is properly loaded and the gripper

and film selector are clear of debris.

3. Press the START button.

Gripper not at home. 1. Press the START button to home the machine.

Gripper position error. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

F-35538 (April 2010) 5-3 Troubleshooting

Page 62

Access AWS-1B Wrapping System Operator Manual

Message What should I do?

Gripper jammed. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Gripper did not find home. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Side clamps not at home. 1. Press the START button to home the machine.

Side clamps jammed. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Side clamps did not find home. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Side folders did not find home. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Side folders not at home. 1. Press the START button to home the machine.

Side folders jammed. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Rear folder did not find home. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Rear folder not at home. 1. Press the START button to home the machine.

Rear folder jammed. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Front folder did not find home. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Front folder not at home. 1. Press the START button to home the machine.

Front folder jammed. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Pusher did not find home. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Troubleshooting 5-4 F-35538 (April 2010)

Page 63

Access AWS-1B Wrapping System Operator Manual

Message What should I do?

Pusher not at home. 1. Press the START button to home the machine.

Pusher jammed. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Sealer belt jammed. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Label applier did not find home. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Label applier not at home. 1. Press the START button to home the machine.

Label applier did not find home. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Wrapper lost CAN communications. 1. Cycle the circuit breaker. Press the START button.

Canopy open. 1. Please close the canopy.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Right-side access door open. 1. Please close the door.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Left-side access door open. 1. Please close the door.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Rear film door open. 1. Please be sure both film doors are closed.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Package stopped on intake. 1. Press the STOP button.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

Wrapper did not respond. 1. Cycle the circuit breaker.

2. Remove any packages, labels, debris in the machine.

3. Press the START button.

An invalid Sealer belt temperature was

1. The previous value will be restored.

entered.

F-35538 (April 2010) 5-5 Troubleshooting

Page 64

Access AWS-1B Wrapping System Operator Manual

Possible System Problems

Problem Possible Cause Action/Solution

If you are experiencing problems with the wrapper, label applier

or printer, review the following scenarios.

There is no display on the

display unit.

The Operator ID was not

accepted.

Product number was not

found.

System prompts you to take

a label. No label is present.

Y ou may not have power running to the

system.

Verify the following connections:

• Power cord is plugged into a working electrical outlet.

• Power cord is plugged into the

rear of the printer.

• Display unit power cord is plugged

into the printer.

• Display unit power cord is plugged

into the display unit.

• USB cable is plugged into the

printer.

• USB cable is plugged into the

display unit.

You may have entered the wrong ID. Verify that you are entering the proper

ID. If correct, have your supervisor

check the ID number.

You may have entered an invalid prod-

Verify the product number.

uct number.

A portion of the label may be ‘hidden’

Make sure that the label exit is clear.

in the label exit.

Partial non-printed label is

exposed.

System prints blank labels or

partially printed labels.

The package has an open side

(incomplete wrap).

The labels may be improperly

threaded.

The labels may be improperly threaded

or the printhead or roller may be dirty.

Verify that labels are properly

threaded.

Check to see that labels are threaded

properly. If the problem persists,

clean the printhead using the Hobart

Printhead Cleaning Kit.

The film is not threaded correctly or

centered correctly.

The side clamp pads are dirty causing

film to slip out when being stretched.

Refer to Loading Film for correct

threading procedures.

Clean as required. Refer to Cleaning

and Maintaining for detailed

procedures.

The product is outside the tray. Rearrange product.

Film roll turning on film arbor. Tighten film collars.

Troubleshooting 5-6 F-35538 (April 2010)

Page 65

Access AWS-1B Wrapping System Operator Manual

Problem Possible Cause Action/Solution

The package has an open side

or end (incomplete wrap).

There are holes in the film on

the bottom of the package

(tear or burn).

The film selector rubber rollers are

dirty.

The tray or film is too slick or wet

Refer to Cleaning and Maintaining for

detailed procedures.

Change the film or tray.

preventing the film from sticking.

Improper film size or the type of film is

Change the film.

not suitable for machine wrapping.

The sealer belt temperature is too high. Verify sealer belt temperature.

Normally , the sealer belt does not need

to be hotter than 325° F (163° C).

The elevator or side under folders are

dirty.

The film gripper pads and/or side

clamp pads are dirty. --OR-- Foreign

Refer to Cleaning and Maintaining for

detailed procedures.

Refer to Cleaning and Maintaining for

detailed procedures.

material is stuck inside the plates, causing film to slip out when being

stretched.

Damaged or defective film. This may

be caused by improper storage,

improper handling or excessive age.

Verify the film storage conditions. The

film should be stored at a temperature

between 50° F (10° C) and 70° F

(21° C) and at a relative humidity of

50% to 85%.

Package is not sealed or

closed on the bottom.

Improper film size or the type of film is

Change the film.

not suitable for machine wrapping.

The sealer belt temperature is set too

low or off.

Adjust the temperature. Refer to

Wrapper Screen for detailed proce-

dures.

Foreign material in gripper or the grip-

per is dirty.

Too many layers of film on the bottom

Refer to Cleaning and Maintenance for

detailed procedures.

Verify the film selection.

of the package. A small tray may have

been wrapped with wide film.

The film selector rubber rollers are

dirty.

Improper film size or type of film is

Refer to Cleaning and Maintenance for

detailed procedures.

Change the film.

not suitable for machine wrapping.

Film roll is loose on film arbor. Tighten film collars..

F-35538 (April 2010) 5-7 Troubleshooting

Page 66

Access AWS-1B Wrapping System Operator Manual

Problem Possible Cause Action/Solution

Package has tails. The film gripper pads are dirty. Refer to Cleaning and Maintenance for

detailed procedures.

The elevator is dirty causing trays to

slide too far onto the elevator.

Improper film size or type of film is

Refer to Cleaning and Maintenance for

detailed procedures.

Change the film.

not suitable for machine wrapping.

Package rolls on the intake. The package was loaded incorrectly. Verify the package height versus the

package length.

The package was placed too far off

center.

The product was hanging over the

Center the package on the intake

sensor.

Re-adjust the product on the tray.

edges of the tray.

The intake shelf is dirty. Refer to Cleaning and Maintenance for

detailed procedures.

Package jams. The product was loaded on the tray

Re-adjust the product on the tray.

incorrectly.

The film is not threaded correctly. Refer to Loading Film for detailed

procedures.

The package was placed too far off