Page 1

Page 2

INSTRUCTION MANUAL FOR DISHWASHERS

Page 1 of 15

GB

CONTENTS

CHAP 1 PREFACE....................................................................................................................2

CHAP 2 INSTALLATION...........................................................................................................2

2.1 U

NPACKING.......................................................................................................................2

2.2 P

OSITIONING .....................................................................................................................2

2.3 E

LECTRICAL CONNECTION..................................................................................................3

2.4 P

LUMBING CONNECTION.....................................................................................................3

2.5 C

ONNECTION TO THE DRAIN LINE ........................................................................................4

CHAP 3 RISKS AND IMPORTANT WARNINGS.......................................................................4

CHAP 4 MACHINE USE ............................................................................................................5

4.1 C

ONTROL PANEL AND LEGEND............................................................................................5

4.2 S

TARTING .........................................................................................................................5

4.3 F

ILLING.............................................................................................................................5

4.4 H

EATING ...........................................................................................................................5

4.5 W

ASHING CYCLE................................................................................................................6

4.5.1 Infinite cycle (

∞

)......................................................................................................6

4.6 T

URNING OFF THE MACHINE................................................................................................6

4.7 E

MPTYING THE MACHINE ....................................................................................................6

4.7.1 Machine witho ut disch ar ge pump.............................................................................6

4.7.2 Machine wit h discharge pump ..................................................................................6

4.8 R

ESIN REGENERATION .......................................................................................................6

4.9 E

ND OF SERVICE................................................................................................................8

4.10 S

ELF-TEST AND INDICATION OF ANOMALIES .........................................................................8

CHAP 5 MAINTENANCE...........................................................................................................9

5.1 C

LEANING AND HYGIENE.....................................................................................................9

5.2 R

OUTINE MAINTENANCE (DAILY)..........................................................................................9

5.3 W

EEKLY MAINTENANCE....................................................................................................10

5.4 A

NNUAL MAINTENANCE....................................................................................................10

CHAP 6 ADJUSTMENT AND CONTROLS.............................................................................10

6.1 M

EASURING DEVICES.......................................................................................................10

6.1.1 Rinse aid measuring device ...................................................................................10

6.1.2 Models with no detergent metering unit..................................................................12

6.1.3 Appliance with detergent measuring device (available on request).........................12

6.2 S

ETTINGS........................................................................................................................12

6.2.1 Number of cycles for resin regeneration.................................................................13

CHAP 7 DEINSTALLATION....................................................................................................13

CHAP 8 DISPOSAL.................................................................................................................14

CHAP 9 REPAIR OPERATIONS.............................................................................................14

9.1 S

PECIAL PRECAUTIONS....................................................................................................14

9.2 R

ESTORING THE SAFETY THERMOSTAT.............................................................................14

9.3 R

EPLACING THE DETERGENT DISPENSER PIPE ..................................................................14

9.4 R

EPLACING THE TANK PRESSURE SWITCH ........................................................................14

9.5 R

EMOVING THE RINSE AGENT DISPENSER REGULAT OR.....................................................15

In legal terms, the manufacturer reserves the property of this document. It is forbidden to reproduce it or divulge it with any means

without prior written authorisation.

The manufacturer reserves the right to introduce changes in order to achieve the improvements it deems necessary without prior notice.

Page 3

INSTRUCTION MANUAL FOR DISHWASHERS

Page 2 of 15

GB

Chap 1 PREFACE

Failure to follow the instructions provided in the attached documentation may jeopardize

safety of the appliance and immediately cancel the warranty.

The warnings contained in this manual provide important information regarding

safety during the various installation, operation and maintenance stages.

Carefully store all documentation near the appliance; give it to the technicians and operators who

will be using it.

It is the operator’s duty to read, understand and learn this manual before

starting any operation on the machine.

The appliance is intended for the professional washing of

dishes for communities, so installation, use and maintenance must in all cases to be performed by

trained personnel who follow the manufacturer’s instructions. Do not leave within the reach of

chil

dren. The choice of materials, construction in conformity with CE safety directives and complete

testing ensure the quality of this machine. In addition to this manual, you will find in the machine :

• wiring diagram

• topographic table

The manufacturer declines all responsibility for damage to things or injuries to persons

deriving from failure to comply with the instructions given or from improper use of the

machine.

Chap 2 INSTALLATION

Proper installation is essential in order for the machine to operate well. Some

of the data neede d for

machine installation can be found on the data plate placed on the right side

of the machine and in

duplicate on the cover of this manual.

Only qualified, authorised technicians must install the machine.

2.1 Unpacking

Check that the packing is in perfect condition and write down any damage found on the delivery

note. After you have removed the packing, make sure the appliance is intact

. If the machine is

damaged, immediately notify the dealer by fax or by reg

istered letter with advice of receipt and the

haulage contractor that transported it. If the damage is such as to jeopardize machine safety, do not

install an d/or us e unti l a qualified tec hnic i a n ser vi ces it.

The packing compon

ents (plastic bags, foam polystyrene, nails, etc. ...) must not be

left within the reach of children and pets as they may be dangerous.

2.2 Positioning

•

Check that there are no objects and materials in

the installation area that can

be damaged by steam

that may exit the machine during operation, or at

least that they are s u ffici e ntl y pr ot ec t ed .

•

In order to ensure stability, install and balance the

machine on it s four fee t.

•

Different installation solutions must be agreed upon

and approved by the manufacturer.

Page 4

INSTRUCTION MANUAL FOR DISHWASHERS

Page 3 of 15

GB

Mod.

V~ Hz kW

A

S/N

H2O

kPa °C

2.3 Electrical connection

•

There must be an omnipolar type of main

switch that disconnects all contacts, including

the neutral, with a distance of at least 3 mm

between the open contacts and with safety

cir

cuit breaker tripping or connected with

fuses

, to be sized or calibrated in conformity with

the power indicated on the machine’s dat a plate.

•

The main switch must be located on the electric

line close to the installation, and it must serve only

one appliance at a time.

•

Electric network voltage and frequency must

coincide with those given on the data plate.

•

There must be an effective earthing system in

conformity with the prevention standards in force

for operator and equipm e nt sa fety .

• The power supply cable (type H07RN-

F only) must

not be pulled or crushed during normal operation or

routine maintenance.

•

The unipotential terminal fastened to the body must

be connected to a unipotential cable having a

section suited to the application.

• Respect the polarities in

dicated in the wiring

diagram.

•

Consult that attached wiring diagram for additional

information.

Do not use adaptors, multiple socket-

outlets or cables of inadequate type and

section or with extension connections not compliant w

ith plant engineering

standards in force.

2.4 Plumbing connection

The appliance is to be connected to the water network

with a hose. There must be a slide on-

off, ball or ga te

valve

able to quickly and completely turn off the

water if n e c essa r y

between th e wa te r ne t work an d the

appliance’s solenoid valve. The on-

off valve must be on

the line near and right before the appliance.

•

If the system is new or barely used, have the water run a long time before making the

connection.

• The water supply, temperature and pressure must be comp at ible

with what is indicated on the

machine’ s t ech ni c al da ta pl a te.

•

If the water’s hardness is greater than 14 F (8 dH), we recommend you use the machine with

internal water softener (available on request).

If the w ater ’s ha rdne ss is grea ter t han 35 F ( 19.5

dH), we recommend you install an external water softener upline of the solenoid valve.

Page 5

INSTRUCTION MANUAL FOR DISHWASHERS

Page 4 of 15

GB

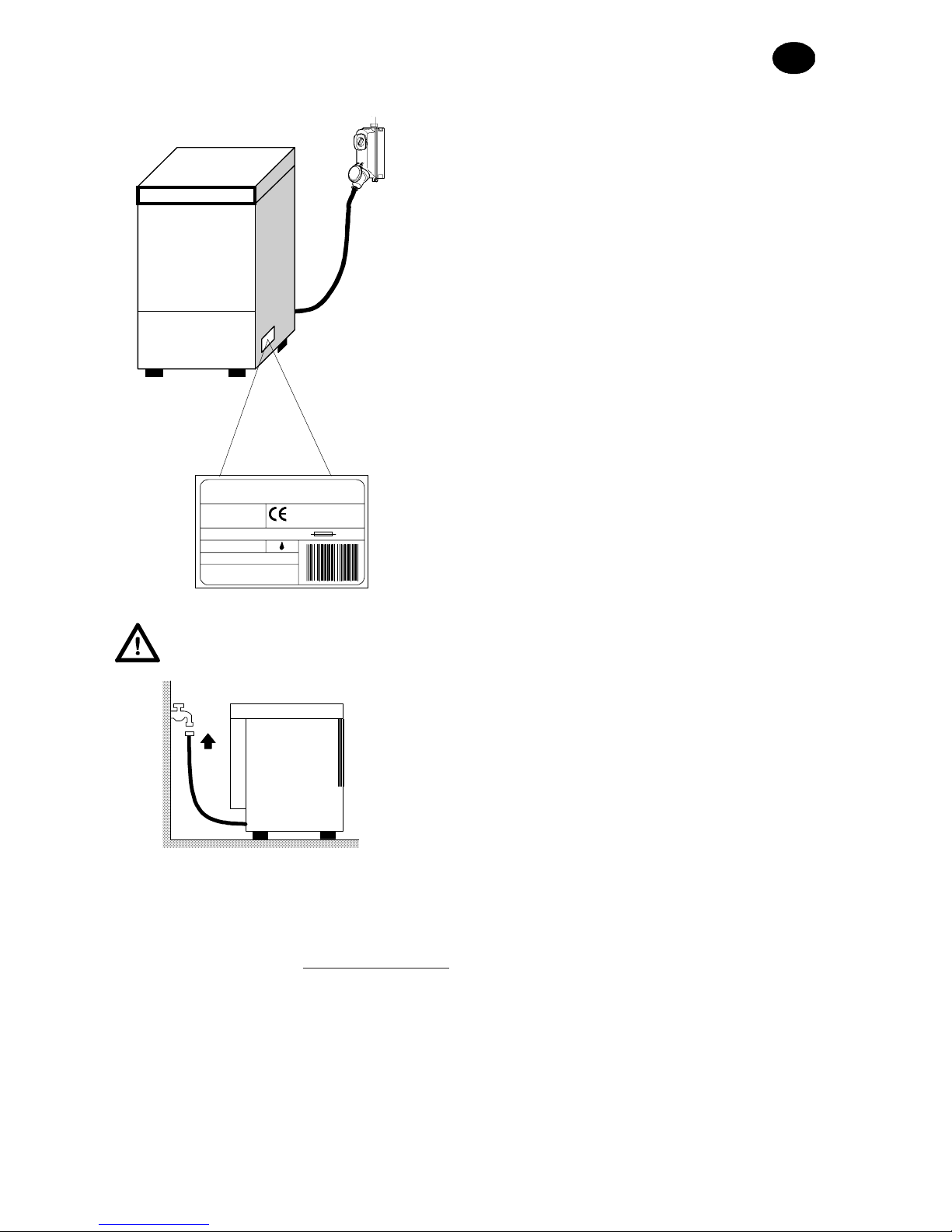

Free drain

2.5 Connection to the drain line

•

The drain line must be made up of a free water

trap

of a size proportionate to the delivery of the

drain pipe supplied with the machine. The pipe

must be able to reach the water trap

without

being p ulle d, sque ezed , be nt, c rush ed, p ressed

or forced by anything.

• The tank empties by gravity, so the drain m

ust be

at a lower level than the base machine.

Max.

1 m

With discharge pump (available on

request)

•

If the drain is not at a lower level than the base of

the machine, you can use the version equipped

with a discharge pump (available on request).

• In this case the maximum drain height is 1 m.

•

Always check that the drain works properly and

that i t is not clogged.

•

All ot her s olut ions mu st be previ ously ag reed up on

and approved by the manufacturer.

Chap 3 RISKS AND IMPORTANT WARNINGS

• This applianc

e is to be used only for the use for which it was expressly designed. All other uses

are to be considered unfit and therefore dangerous.

•

The specialised personnel who will install the machine is obliged to appropriately instruct

the user on the appliance’

s operation and any safety measures that are to be complied

with, also by providing practical demonstrations.

•

Any type of service done on the mach ine, also in the case of failure, must be performed only by

the manufacturer or by an authorised service centre and by qualified personnel,

using only

original spare parts.

•

Always disconnect or separate the machine from the electric and water networks before

performing maintenance, repairs or cleaning.

• Untrained personnel must NOT use the machine.

• The machine must NOT remain live when it is not used.

• NEVER open the machine door quickly if it has not finished the cycle.

• NEVER use the machine without the factory-installed safety attachments.

• NEVER use the machine for washing object of a type, shape, size or materi

al not guara nte ed for

machine washing or not perfectly intact.

• NEVER use the appliance or its parts as a ladder or support for people, things or animals.

• NEVER overload the open door of front-

loading machines, which are sized to support only the

rack loaded with kitchenware.

• NEVER immerse bare hands in the washing solutions.

• NEVER turn the machine over after installation.

Page 6

INSTRUCTION MANUAL FOR DISHWASHERS

Page 5 of 15

GB

Chap 4 MACHINE USE

4.1 Control panel and legend

Indicator lamp off

Indicator lamp

blinking

START

BOILER

TANK

Indicator lamp on

The following images, describing the operation of

the appliance refer to the control panels of

dishwashers. Glass-

washers have one washing

cycle only.

TANK

4.2 Starting

1.

Open the wate r netwo rk tap an d switc h on the main

power switc h.

2. Check the presence of the overflow, if necessary.

3.

Press the on / off button as shown at the side (the

corresponding indicator lamp turns on).

4.3 Filling

•

Whenever the first filling is carried out with the boiler empty, the Quick ready

function must not be activated (as p er factory settings).

• On CRP models only, the Quick ready function must always be active

, even

when the boiler is empty (see chapter “Adjustments and Settings”).

TANK

START

TANK

BOILER

•

If the discharge pump or water softener is present,

to fill the machine select a wash cycle by pressing

the program cycle button (the correspond

ing

indicator lamp turns on) and press the start button

as sho wn at the s ide. Ot herwise, f illing starts when

it is turned on.

With break tan k present and bo iler

empty, wait about 15 seconds after the starting

stage.

• The machine ready indicator lamp may bli

nk or be

off during the filling stage.

•

The indicator lamp remains on and green when the

machine is ready (full tank and tank and boiler

temperatures reached).

TANK /

BOILER /

4.4 Heating

When the resistances are heating, a green dot appears

on the

displa y next to th e tempe rature ind icator . When

the optimum

set temperatures (approx. 55°C for the

tank and approx. 85°C for the boiler) are reached, the

corresponding dot turns off.

Page 7

INSTRUCTION MANUAL FOR DISHWASHERS

Page 6 of 15

GB

4.5 Washing cycle

• Check to make sure there is d

etergent and rinse

aid. Information about the type of products to be

used and the dosage (automatic or manual) is

found in the chapter “Adjustment and controls ”.

•

Use a suitable rack, f illing it without overloading it

and without placing the dishes one on t

op of the

other. Always clean off the dishes beforehand

,

and do not load dishes with dry or solid residue on

them.

• Place the empty containers upside-

down on the

rack. Put the plates and similar kitchenware into

the special inclined rack, with the internal

surface

facing upwards. Put the mixed silverware into the

special basket with the handles facing downwards.

• Wash items intended for dishwasher use only.

•

It is advisable to wash the dishes immediately after

use, in order to prevent any residuals from

hardening and sticking on them.

For versions with rotating basket:

•

If possible, run the cycle only with the basket full,

evenly distributing the dishes.

•

Place the lightest dishes near the middle of the

rack, and the heaviest ones near the outside.

• Place the

smallest dishes near the middle of the

rack, and the largest ones near the outside.

• Load the rack into the machine and close the door.

• For versions with rotating basket,

make sure the basket turns freely, lightly spinning it

clockwise, then close the door and start the cycle.

• To avoid breakage, use only dishes that are intact and guaranteed for machine washing.

•

Do not place silver and stainless steel silverware in the same silverware basket. Burnishing of

the silver and probable corrosion of the steel would result from it.

TANK

Among the available cycles, select a washing cycle

suitable for the items to be washed, by repeatedly

pressing the cyclic program button, shown here, until

the corresponding warning light turn on.

START

TANK

BOILER

To start the cycle, press the start / start cycle button

shown at the side. The corresponding cycle indicator

lamp blinks.

After the washing stage, the rinsing and drain stages

start, and the cycle comes to an end. The indicator

lamp goes back to being on and not blinking.

•

If the door is accidentally opened during the cycle, the machine stops automatically. All you have

to do is close the door again in order to resume from the point it was interrupted.

• In order to get rapid drying, immedia

tely remove the rack from the machine at the end of the

cycle.

• If you want to stop the washing cycle in advance, press the on / off button.

•

If the washing solution should prove too dirty or if you notice residues of grime on the

tank filter, perform the routine maintenance as described in the chapter “Maintenance”.

Page 8

INSTRUCTION MANUAL FOR DISHWASHERS

Page 7 of 15

GB

• Perform the operations described in the paragraph “Washing cycle

” again to run

subsequent cycles.

START

TANK

BOILER

4.5.1 Infinite cycle ( ∞

)

It is enabled by selecting the cycle indicat

ed by the

symbol

∞

and pressing the start cycle button shown

at the side. The machine continues to wash. To start

the rinse and drain stages, press the start cycle button

again. The cycles stops automatically.

TANK

4.6 Turning off the machine

Press the on / off button as shown at the side (the

corresponding indicator lamp turns off).

4.7 Emptying the machine

4.7.1 Machine without discharge pump

Turn off the machine and remove the overflow. Wait for

the tank to become completely empty.

Turn off the machine every time the overflow is

removed. Clean the machine as described in the

chapter “Maintenance”.

TANK

4.7.2 Machine with discharge pump

1.

With the machine on, keep the cycle selection button

shown at the s

ide pressed until the indicator lamp

corresponding to the drain cycle turns on.

2. Remove the overflow and close the door.

START

BOILER

3.

Press the start / start cycle button. The machine

turns off at the end.

4. Clean the machine as described in t

he chapter

“Maintenance”.

TANK

4.8 Resin regeneration

When th e correspond ing ind icator lamp turns red, you

have to run a resin regeneration cycle in order to

restore proper operation of the internal water softener.

Proceed as follows:

•

Empty and clean the machine as described in the

paragraph “Emptying the machine”.

• Open the salt container inside the tank.

•

Pour approx. 300 g of regeneration salt into the

container (kitchen salt without additives in 1 or 2-

mm

diameter granules).

• Close the container again with force.

• Make sure that the overflow has been removed.

Page 9

INSTRUCTION MANUAL FOR DISHWASHERS

Page 8 of 15

GB

START

BOILER

TANK

• Close the door and turn on the machine.

•

With the cycle selection button shown at the side,

select the resin regeneration cycle (the

corresponding indicator lamp turns green).

START

BOILER

TANK

•

To start the cycle that lasts about 20 minutes, press

the start / start cycle button shown at the side (the

corresponding indicator lamp blinks). The machine

turns off by itself when the cycle ends.

• To

change the number of cycles between one

regeneration and the next, refer to the chapter

“Adjustment and controls”.

4.9 End of service

•

At the end of the day always drain the machine as

described in the “Machine draining” section.

• Disconnect the power supply

by means of the

main switch and close the external water cock.

•

Perform routine maintenance and clean the

machine as described in the “Maintenance” section.

• If possible, leave the door ajar to prevent the

formation of bad sm ell s insid e.

4.10 Self-test and indication of anomalies

The machine has a set of devices for the control and safety of operation. The anomaly or alarm

condition is indicated on the tank and boiler temperature displays.

The user must check whether

or not malfunctioning has occurred and take c

onsequent action. If the assistance of a

qualified technician is necessary, you must turn off the machine, disconnect it from the

electric line and shut off the tap. The user must NOT meddle with the machine.

CAUTION! Turning off and then turning on the m

achine “resets” the indication, which

afterwards will reappear if the problem has not been solved

Message displayed Anomaly or alarm found

Line indicator lamp is blinking (*)

: the inco ming water control is not

working. To reac

tive the control, you have to disconnect and reconnect

the machine to the electric line.

If the indication appears again, contact

a qualified technician.

TANK /

BOILER /

Insufficient water delivery (*)

: the quantity of incoming water is not

su

fficient for complete rinsing. When the problem has been solved, run

a complete washing cycle.

If the indication appears again, contact a

qualified technician.

TANK / BOILER /

Excessive water pressure or delivery (*)

: if the message appears

often, it is necessary

to have the water supply checked by a qualified

technician.

TANK / BOILER /

Lack of incoming water (*)

: rinsing not carried out. When the problem

has been solved, run a complete washing cycle.

If the indication

appears again, contact a qualified technician.

TANK / BOILER /

Discharge time out

: The tank has not drained completely. Check the

overflow cap has been removed. Try performing another discharge

cycle. Should the problem persist, contact a qualified technician.

Page 10

INSTRUCTION MANUAL FOR DISHWASHERS

Page 9 of 15

GB

TANK / BOILER /

Thermostop time-out

. For more information, refer to the chapter

“Adjustment and controls”.

If the indication appears again, contact a

qualified technician.

TANK / BOILER /

Tank loading time-out: the tank has

not filled up. Try to turn off and

turn back on the machine and run a new loading.

Check that the

overflow is present if it is necessary for machine operation.

If the indication appears again, contact a qualified technician

.

TANK / BOILER /

Tank probe broken (open). Contact a qualified technician

.

TANK / BOILER /

Tank probe broken (short-circuit). Contact a qualified technician

.

TANK / BOILER /

Boiler probe broken (open). Contact a qualified technician

.

TANK / BOILER /

Boiler probe broken (short-circuit). Contact a qualified technician

.

TANK /

BOILER /

Boiler loading time-out

: the bo iler has not filled up . It is not possible to

rinse. Check that the water tap upline of the machine is open. Run

a

new complete cycle.

If the indication appears again, contact a qualif ied

technician.

TANK /

BOILER /

Tank temperature too high. Contact a qualified technician

.

TANK /

BOILER /

Boiler temperature too high. Contact a qualified technician

.

TANK / BOILER /

Electromechanical safety:

the safety thermostats of the boiler or tank

have tripped or the tank safety pressure switch has tripped.

Contact a

qualified technician.

(*) these messages can be deactivated by a qualified technician on request.

Chap 5 MAINTENANCE

Completely empty the machine as described in the paragraph “Machine Emptying”,

turn off the electricity with the main external switch and close the external water

valve before starting any maintenance operation.

5.1 Cleaning and hygiene

To guarantee machine hygiene the routine (daily), weekly and yearly maintenance operations

indicated below must be regularly performed. Also carry out a periodical sanitising treatment with

suitable non-corrosive products available on the market.

5.2 Routine maintenance (daily)

When you notice residue of grime on the tank filter:

• Remove and clean the racks, the overflow if present and the filter.

• Do not use abrasive products or objects for cleaning the steel tank.

Instead use a slightly soapy

damp cloth.

• Do not use pressurised jets of water because they could damage the electric system.

Page 11

INSTRUCTION MANUAL FOR DISHWASHERS

Page 10 of 15

GB

5.3 Weekly maintenance

• Perform routine maintenance.

• Remove and clean the wash and rinse arms and nozzles.

Illustrated below are the possible configurations of upper and lower wash/rinse arms.

(*) Spray closed. Nozzle not present.

• Clean the arm rotation pins and the wash and rinse water

outlet zone.

• Carefully clean the tank and machine, using non-abrasive

disinfecta nt pr o ducts.

• Correctly refit the nozzles, arms and filters, paying attention

to the inclination and coupling of the arms in their respective

seats.

5.4 Annual Maintenance

Have your appl i a nc e car e ful l y in sp ec te d by an au t hor i se d t ech ni ci a n, and in partic ular :

• Remove residues from the bottom of the tank.

• Remove and deep clean wash arms and diffusers.

• Thoroughly clean the weir inserted in the lower wash arm shaft and the water exit area.

Page 12

INSTRUCTION MANUAL FOR DISHWASHERS

Page 11 of 15

GB

• Correctly refit weir, pivoting pins and wash arms.

• Inspect the

conditions of the sealing gaskets and the wear of other components such as pumps,

dispensers, etc.

• Inspect the settings of washing detergent and rinse agent dispensers.

• Inspect and eventually clean the resistors.

If the appliance is not used for periods o

f time, it is necessary to have it adequately setup. If you

have any suspects about the presence of ice, do not run the appliance until an authorised technician

has inspected boiler and pipes.

Chap 6 ADJUSTMENT AND CONTROLS

Only qualified and authorised personnel may perform the following adjustment and

control operations. They must be extremely careful, pay utmost attention and take the

necessary precautions if they must cut out the machine’s safety devices.

6.1 Measuring devices

The measuring device or devices

and supply pipes

must be full before performing the calibration

.

Calibration is done using the corresponding adjustment

screws that are accessible when the front panel

beneath the tank door is removed. Calibration is done

using the corresponding adjustment

screws that are

accessible when the front panel beneath the tank door

is removed and horizontally positioning the support of

the electrical components.

•

The warranty does not cover damages resulting from incorrect use of the

measuring device or devices or in the event manual dosing is incorrect.

•

The choice and dosing of the deterge nt and rinse aid are c ritical in order to get

good washing results and a long life of the a p pliance. Use onl y liquid products

for industrial washing with controlled suds.

•

The adjustments are to be made with the machine warm and with the product

dosed correctly.

6.1.1 Rinse aid measuring device

The level of rinse aid in the container must be high enough. It must never fall as low as

empty or be topped off wi

th corrosive or impure products. To fill the supply pipe and

measuring device, turn on the machine, start the washing cycle, wait about 20 seconds

and press the stop button. Wait another 20 seconds and run the se quence again another 4-

5 times.

Wait another 20 seconds and run the turning on and off sequence again another 4-5 times.

•

The quantity of rinse aid dispense decreases when the

adjustment screw is turned clockwise, whereas it

increases if you turn it counter-clockwise.

• R

efer to the doses indicated by the selected product’s

manufa cturer

in order get an idea of the quantity of

product needed for the first calibration.

•

Adjustment is to be sharpened after assessing the

rinsing results obtained after at least three cycles

,

which are necessary for stabilising the results.

•

Streaks on the dishes and the formation of foam in the washing solution indicate too much rinse

aid is used. Dishes covered with drops of water and a fairly long drying time indicate there is

not enough rinse aid.

• In order to get optimum results, use only rinse aids the manufacturer-

recomme nded dose s of

Page 13

INSTRUCTION MANUAL FOR DISHWASHERS

Page 12 of 15

GB

which are lower than 1.5 g/ litre.

• 7.9 cm of pipe = 1 ml of pr oduc t ( = 1 g of pr od uct wi th densi ty e qui val en t to 1 kg/ dm

3

). The water used

for rinsing is about 3 l itres/cycle.

•

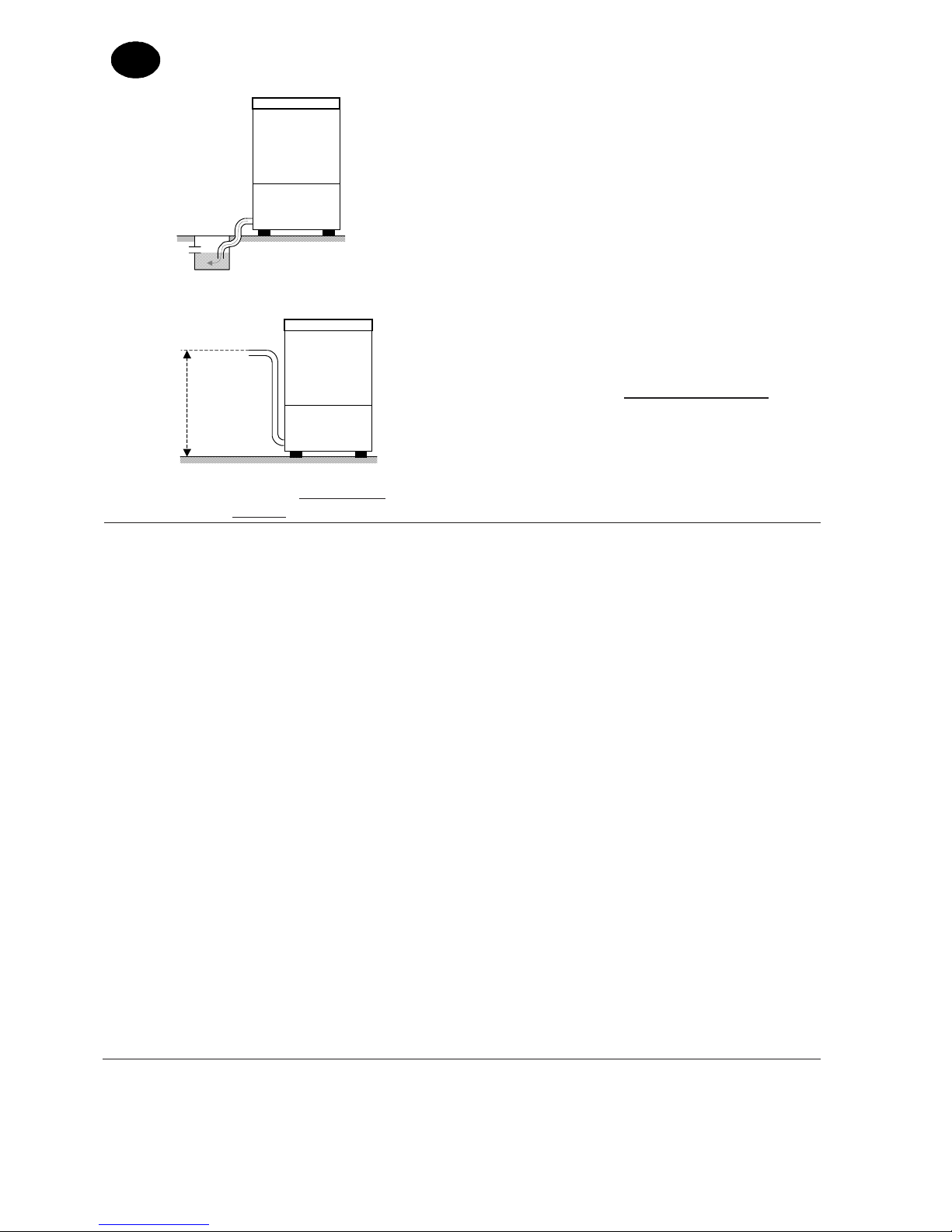

Do not change the difference of height between the tank and the base of the machine after

having set the dosa ge.

•

If the d if feren ce of height bet ween the con taine r and t he base of the machi ne is greate r th an 80 cm,

the me asuri n g devi c e may not operate prop erl y.

• If rinse aid is not used, completely close the dispenser adjustment screw.

6.1.2

Models with no detergent metering unit

Manual feed is discouraged

as it does not guarantee

the optimal results offered by an automatic

system. If ,

however, an automatic dispenser is not used, introduce

the detergent in the pump intake filter area every five

cycles,

according to the dosage suggested by the

manufacturer of the detergent, and in relation to the

quantity of water in the tank

and the amount of water

used for rinsi n g.

Installation of an automatic detergent measuring device is always recommended.

6.1.3 Appliance with detergent measuring device (available on request)

The level of detergent in the containe

r must be high enough. It must never fall as low as

empty or be topped off with corrosive or impure products. All you have to do to load the

supply pipe is turn on the machine and carry out the first charging with the measuring device

connected.

•

The amount of detergent dispensed decreases when

the adjustment screw is turned counter-

clockwise,

while it increases when the screw is turned clockwise

(from 1 to 1.5 ml per rinse per notch that

corresponds to about 1.2 to 1.8 g of pro

duct with

density equivalent to 1.2 kg/dm3).

Check the

appliance’s technical specifications to find out

about the amount of water in the tank.

•

Refer to the doses indicated by the selected

product’s manufacturer

in order get an idea of the

quantity of product need ed for th e firs t cal ibr a ti o n.

•

Adjustment is to be sharpened after assessing the

washing results obtained after at least three cycles

,

which are necessary for stabilising the results.

• Suds must not be present in the ta nk a t the end of a cycle.

• In th

e event there are suds, the first thing to check is the type of detergent used and if necessary,

replace it wit h a more suita ble detergent. If there are still suds, ch eck that the te mperature of the

water in the tank is correct and if necessary, reduce the

dosage of detergent until the suds are

completely eliminated.

• It is necessary to use only detergents the manufacturer-

recommended dose of which is less

than 5 g/litre.

6.2 Settings

Only a qualified technician must make the following settings.

Several func ti ons can be selec te d on th e machine at the time of inst al l ation or afterw ar ds :

• Quick ready (For the CRP versions the function must always be enabled):

o if the function is enabled, the tank is filled with pre-heated water from the

boiler and the

Page 14

INSTRUCTION MANUAL FOR DISHWASHERS

Page 13 of 15

GB

machine read y indicator lamp blinks red. The machin e ready time decreases.

o If the function is not enabled

, the tank starts to fill directly from the line and the machine

ready indicator lamp blinks green.

• Energy-Saving: allows electric energy to be saved in the case of stand-

by while keeping the

water temperature at a value strictly dependent on the chosen cycle.

• Thermostop

: allows the optimum rinsing temperature to be reached before the end of the

washing cycle in progress.

• Tank operating temperature: can be set between 45°C and 70°C.

• Boiler operating temperature: can be set between 65 °C and 90 °C.

6.2.1 Number of cycles for resin regene ration

The number of cycles between one regeneration and the next has to be established based on the

hardness of the wa ter in the installation area, following the table given below.

dH F

No.

Cycles

dH F

No.

Cycles

dH F

No.

Cycles

dH F

No.

Cycles

8,0 14 100 11,0 20 65 14,5 26 47 18,0 32 29

8,5 15 90 12,0 21 62 15,0 27 44 18,5 33 26

9,0 16 77 12,5 22 59 15,5 28 41 19,0 34 23

9,5 17 74 13,0 23 56 16,0 29 38 19,5 35 20

10,0 18 71 13,5 24 53 17,0 30 35

10,5 19 68 14,0 25 50 17,5 31 32

To change the number of cycles:

1. Turn off and turn back on the machine while keeping the on/off button

pressed for about 5

seconds.

2.

The message “SET” alternating with the tank and boiler setting temperatures appears on the

display.

3. Press the on/off button once again to make the number of set cycles appear.

START

BOILER

TANK

-

+

4. “Cycle selection” butt

on to reduce the number of set

cycles (min = 1);

5.

“Cycle start” button to increase the number of set

cycles (max = 99);

6. Set the number of cycles to zero to deactivate the regeneration indicator.

7. Press the on/off button to return to the machine ready condition.

8. Run a final regeneration cycle.

Chap 7 DEINSTALLATION

Only qualified and authorised technical personnel can perform deinstallation.

• Turn off the power to the machine with the external main switch.

• Shut off the external water supply tap.

• Completely disconnect the machine from the electric and water supply networks.

• Empty, clean and completely prepare all the internal water circuits, measuring devices, pumps

and boiler.

• Completely empty the detergent and rinse aid dispensers and tubes connected to them, making

sure to correctly dispose of the detergent and rinse aid (contact the supplier of the products

used)

Page 15

INSTRUCTION MANUAL FOR DISHWASHERS

Page 14 of 15

GB

Chap 8

DISPOSAL

There are no materials on our machines that require special disposal procedures.

Chap 9 REPAIR OPERATIONS

9.1 Special Precautions

•

Before performing any operation always unplug appliance from outlet and detach

from water mains. Always wear protective gloves.

•

Always refer to the technical documentation and specifications enclosed with

appliance.

• At the end of any intervention, replace all safety features previously removed.

• Do not leave foreign objects inside appliance.

• Do not tip over appliance after setup.

9.2 Restoring the Safety Thermostat

To resume the operation, eliminate the

cause of the

problem and press the red button on the thermostat to

reengage.

9.3 Replacing the Detergent Dispenser Pipe

The silicon pipe from the detergent dispenser is subject to wear and must therefore be replaced

periodic all y . Proceed as follows:

1) Remove the clear

cap

2) Loosen th e pipe by

turning the gear

3) Replace the silicone

pipe

4) Shut the clear cap

9.4 Replacing the Tank Pressure Switch

If replacing the pres

sure switch, or its drum, or in the case of the appliance accidentally tipping over,

proceed as follows:

1) The pressure switch is

situated eit her at the back or top

of appliance

2) Rem ove the tube and, if

necessary, replace the

pressure switch.

3) Blow inside the tube to eliminate

condensatio n. Refit the components

in reverse order.

Page 16

INSTRUCTION MANUAL FOR DISHWASHERS

Page 15 of 15

GB

9.5 Removing the Rinse Agent Dispenser Regulato

r

The internal components (boot, …) are subject to wear, therefore they must be periodically replaced.

In case of intervention on the rinse a id dispen ser, carry out the following steps:

1) Drain the appliance as

described in “Discharging

the appliance”.

2) Loosen th e four

screws holding the

dispenser.

3) Replace any faulty

components.

4) Refit the dispenser

correctly centring the

rubber bellow.

Loading...

Loading...