Page 1

Manuals and Instructions

Brought to your courtesy of

wechillit.com Ltd

Sales Team : 01743 284918

Page 2

CLF 26

Installation & Operation

Page 3

-

Contents

GENERAL INFORMATION ______________________________________________________ 2

1.

Documentation supplied with the machine

____________________________________________ 2

2.

General notes

___________________________________________________________________ 2

3.

Important safety notes

____________________________________________________________ 3

GETTING TO KNOW YOUR MACHINE____________________________________________ 4

1.

Control panel

___________________________________________________________________ 4

2.

Installation data

_________________________________________________________________ 4

INSTALLATION________________________________________________________________ 5

1.

Glossary

________________________________________________________________________ 5

2.

Unpacking the appliance

__________________________________________________________ 6

3.

Positioning

_____________________________________________________________________ 6

4.

Connections

_____________________________________________________________________ 6

5.

Dispenser settings

________________________________________________________________ 8

6.

Operator training

_______________________________________________________________ 10

USE AND MAINTENANCE _____________________________________________________ 11

1.

Safety notes

____________________________________________________________________ 11

2.

Preparation of the machine

_______________________________________________________ 12

3.

First cycle

_____________________________________________________________________ 13

4.

Subsequent cycles

_______________________________________________________________ 14

5.

Emptying the machine

___________________________________________________________ 15

6.

Before the daily shutdown

________________________________________________________ 15

7.

Maintenance

___________________________________________________________________ 16

8. Solutions to the most common problems _____________________________________________ 17

Page 4

GENERAL INFORMATION

Page 2

GENERAL INFORMATION

F

AILURE TO COMPLY WITH THE INSTRUCTIONS PROVIDED MAY COMPROMISE THE

SAFETY OF THE APPLIANCE AND WILL INVALIDATE THE WARRANTY WITH

IMMEDIATE EFFECT

.

1. Documentation supplied with the machine

This manual contains important information regarding safety during the installation,

use and maintenance of the appliance.

To ensure that you obtain the maximum safety, hygiene

and performance, keep all the documents supplied in a safe place near the appliance and ensure that

they are available for consultation by all the personnel assigned to the installation, operation and

maintenance of the machine.

I Manual

This manual is divided into various sections and contains instructions covering the entire service

life of the appliance:

• installation reserved for qualified technicians

• use and maintenance addressed to the user

•

•

II Technical documentation

In addition to this manual, the following documents are supplied with the appliance:

• electrical circuit diagram

• layout diagram

2. General notes

The quality of this machine is ensured by the use of high-quality materials, construction

according to EC safety directives and by fully testing each appliance.

• Adherence to the recommendations contained in this manual

is essential for the safety

of the

installation and the user.

• The manufacturer, the dealer and the authorized service centers are available for any further

clarification regarding the use and installation of the appliance.

• The manufacturer reserves the right to make any modifications to the appliance deemed

necessary without prior notice.

Page 5

GENERAL INFORMATION

Page 3

3. Important safety notes

The appliance is designed for professional use and notwithstanding the manufacturer’s efforts to

simplify its operation, installation and maintenance, the appliance is

designed for operation by

trained personnel

in compliance with the manufacturer’s instructions. Do not allow children to

operate or play with the machine.

Failure to comply with the manufacturer’s instructions contained in the documentation

supplied with the machine may compromise the safety of the appliance and will render the

warranty void with immediate effect.

T

HE MANUFACTURER ACCEPTS NO LIABILITY FOR ANY DAMAGE TO OBJECTS OR

PERSONAL INJURY ARISING FROM FAILURE TO COMPLY WITH THE INSTRUCTIONS

PROVIDED

.

T

HE FOLLOWING OPERATIONS ARE EXPRESSLY PROHIBITED

:

• The installation or deinstallation, maintenance, adjustment, repair of the appliance or any other

type of operation which requires the removal of the protective panels, unless

carried out by

qualified and authorized personnel

in compliance with the manufacturer’s instructions; such

persons must always disconnect the machine from the electrical power supply and the water

supply before undertaking any such operation and take the necessary precautions if they exclude

the safety devices installed by the manufacturer.

•

Installations of an inferior standard or temporary nature

or any installation in which

adequate protection is not provided for the electrical power supply (e.g. fuses, main switch,

EARTH CONNECTION

) or the water supply (e.g. stop cock, waste trap).

•

Modifications or the installation of additional devices

which alter the operation of the

machine.

•

Use of non-original replacement parts

.

• Installation or repositioning in environmental conditions which do not comply with the

manufacturer’s prescriptions.

• Use of the appliance to wash items of a type or size other than that prescribed by the

manufacturer.

• Use of corrosive, impure or dry products in the dispensers.

The servicing and repair of the machine must be carried out by qualified and

authorized technicians only.

Page 6

GETTING TO KNOW YOUR MACHINE

Page 4

GETTING TO KNOW YOUR MACHINE

1. Control panel

[1] = Power on/off switch and pilot light»

[2] = Start button

[3] = “Wash cycle” pilot light

[4] = “Heating” pilot light

[5] = Cold rinse (optional)

[6] = Drain pump (optional)

[7] = Cycle selection (optional)

2. Installation data

For correct installation, follow all the instructions in the section “Installation”.

All the data necessary for correct installation of the appliance can be found on the data plate affixed

to the machine. A copy of this data plate is printed on the cover of this manual for quick reference.

The appliance must be installed correctl y in order to function properly. Installation of

the appliance should be carried out by qualified and authorized technicians only.

Page 7

INSTALLATION

Page 5

INSTALLATION

T

HE MANUFACTURER ACCEPTS NO LIABILITY FOR ANY DAMAGE TO OBJECTS OR

PERSONAL INJURY ARISING FROM INSTALLATIONS WHICH FAIL TO COMPLY WITH

THE INSTRUCTIONS PROVIDED

.

1. Glossary

In this document, the terms

Main switch, water supply stop cock

and

Drain line

are defined

as follows:

M

AIN SWITCH

:

Must be of the type which

disconnects all conductors of the supply circuit including the

neutral

, with a distance between the open contacts of at least 3 mm, incorporating a thermal

magnetic circuit breaker or fuses, to be sized or calibrated in accordance with the power rating

indicated on the appliance data plate.

The main switch must be located near to the installation and

must serve only one machine.

WATER SUPPLY STOP COCK:

This must be a slide, ball or gate stop valve

capable of rapid and complete shut-off of the water

supply

, of sufficient dimensions to ensure the flow rate and pressure indicated on the machine data

plate.

If the water supply pressure exceeds the prescribed maximum, a pressure regulator must be installed

upstream of the machine. If the supply pressure is below the prescribed minimum, a pressure

booster pump must be installed upstream of the machine.

If the temperature of the incoming water is below the recommended minimum, additional steps

must be taken to obtain good washing results (see chapter “USE AND MAINTENANCE”)

The stop cock must be installed on the water supply pipe near to and

immediately upstream of the

appliance

.

D

RAIN LINE

Must comprise an

open trap

of sufficient dimensions to discharge at least double the required

supply flow.

It must be installed within reach of the discharge pipe supplied with the machine without this being

subject to

tension, kinking or joints

.

Page 8

INSTALLATION

Page 6

2.

Unpacking the appliance

Before removing the packaging, check for any signs of damage, noting any defects found on the

carrier’s delivery note

After removing the packaging

inspect the appliance for signs of damage;

if damaged, notify your

dealer by fax or registered post immediately and, if the damage is such as to compromise the safety

of the machine,

do not

proceed with the installation until the appliance has been checked by a

qualified technician.

Packing materials (plastic bags, expanded pol ystyrene, nails, etc.) must not b e left within

reach of children and pets as they potentially very dangerous.

3. Positioning

Ensure that there are no objects or materials near the

installation site which could be damaged by water vapor or

splashes of detergent solution which might be produced by the

machine during operation.

The appliance must be leveled using the four adjustable feet so

that it is

perfectly stable

; any other type of installation must

be agreed and approved by the manufacturer.

4. Connections

I Electrical supply

A

Main Switch

must be provided for connection (see “Glossary”).

There must be an efficient EARTH CIRCUIT to which the

machine is to be connected

.

Do not use adapters, multiple sockets, cables of insufficient

cross-sectional area or with extension connections which do not

comply with specifications prescribed by EN 60335-1 and EN

60335-2-58.

•

The electrical power supply

must be compatible with the indications on the data plate. For

details on electrical operation consult the electrical circuit diagram.

•

The supply cable

must not be pulled or crushed during normal operation or routine

maintenance.

•

The equipotential bonding terminal

fixed to the body of the machine must be connected in

accordance with the requirements of standards EN 60335-1 and EN 60335-2-58 (using a cable

with a cross-sectional area of between 2.5 and 6 mm2)

Page 9

INSTALLATION

Page 7

II Water supply

A water supply pipe with a

“Stop cock”

(see “Glossary”) must be provided for each machine.

The water supply line must conform to the specifications indicated

in the section “Installation data”, even when other appliances are

connected to the supply line.

If the water supply system

is new or has not been used for a

prolonged period, run the water before connecting the

appliance

so as to eliminate any impurities or air pockets which

could soil or damage the machine.

Connect the filling solenoid valve to the stop cock with a flexible

pipe.

III Drain line

A suitable

“Drain line”

must be provided (see “Glossary”).

To ensure unrestricted discharge the pipe must reach the trap

without being put under tension,

kinked, crushed, pressed or forced.

(Model CLF 26 - supplied with Drain Pump as standard)

If the discharge pipe is connected to a trap in the floor, the

highest point of the pipe must be at least 300 mm above floor

level to prevent the machine from emptying.

The highest point of the discharge pipe should be less than 1

meter above floor level.

Page 10

INSTALLATION

Page 8

5. Dispenser settings

I Rinse-aid dispenser

Before starting the washing cycle, the dispenser and the delivery

pipe must be full.

Check that there is sufficient rinse-aid in t he container and top up

if necessary.

The rinse-aid container must never be allowed to empty

completely and must not be topped up with corrosive or impure

products.

The warranty does not extend to any damage arising from incorrect use of the dispenser.

The dispenser is

not

factory-set; the dispenser must be calibrated by a qualified technician.

The dispenser is calibrated by adjusting a screw which is

accessed by removing the front panel under the wash chamber

door.

With the panel removed, without pulling the connection pipe, fill

the delivery pipe with rinse-aid, and then fully close the adjuster

screw, without forcing.

To determine the dosage for the preliminary setting,

refer to the

information provided by the product manufacturer.

Once you have determined the required dosage, open the adjuster screw until this quantity is obtained.

Electric dispenser (DB-2)

One full turn of the adjuster screw is approximately equivalent to 0.06 grams of product per

dispenser pulse, given that when fully open (16 turns of the screw), the dispenser delivers 1

gram/pulse. If the machine has 3 pulses per cycle, it can thus dispense from a maximum 3x1=3

grams/cycle (16 turns of the screw) down to a minimum of 0.06x3=0,18 grams/cycle (1 turn of

the screw).

After this preliminary calibration, any subsequent adjustment is to be made on the basis of the

rinsing results obtained after at least 3 cycles.

Turn the screw counter-clockwise to increase and clockwise to reduce the dosage.

Bluish streaks on dishes and the formation of foam in the washing solution indicate too much rinse-

aid.

Drops of water on items and slow drying indicate too little rinse-aid.

In the event of imperfect washing, (at incorrect temperature or with too little detergent), an

invisible, non-toxic patina of grease or starch may form on the tableware. This patina will prevent

the rinse-aid from doing its job properly and in this case, increasing the dosage of the rinse-aid will

Page 11

INSTALLATION

Page 9

not lead to any significant improvement. To remove this patina, the tableware is to be left to soak in

a water and soap solution (10:1) for about 30 minutes and then washed again.

II Detergent dispenser (optional)

Never allow the detergent container to empty completely and

never top up with corrosive or impure products.

The warranty does not extend to damage arising from

incorrect use of the dispenser.

The detergent dispenser is factory-set; any subsequent adjustment

to the dispenser setting should carried out by a qualified

technician.

Refer to the dosage indicated by the detergent manufacturer

, taking into account:

• characteristics of the water in your area;

• the type of items to be washed: glass, plastic, ceramic, decorated or plain porcelain, metal,

cutlery or cooking utensils;

• type and quantity of food residue;

• intensity of use (number of wash cycles per hour ).

Electronic dispenser EV-400

Carefully clean the machine

.

Adjust the detergent potentiometer on the electronic control card (consult layout diagram), turning it

fully counter-clockwise to obtain zero detergent dosage.

Start a wash cycle, with no dishes in the machine, and allow the chamber to fill with water.

Page 12

INSTALLATION

Page 10

On completion of the filling cycle and before the wash cycle has

started, open the door and pour the previously determined quantity of

detergent into the chamber in the region of the wash pump suction

filter.

About 10 seconds after the start of the wash cycle, start turning the

potentiometer in a clockwise direction until you hear a buzzing which

indicates that the dispenser is delivering detergent to the chamber. At

this point the dispenser is calibrated to the previously determined

dosage.

Any subsequent adjustment to the dosage should be made on the basis of the results obtained after a

number of real wash cycles

(turn the potentiometer clockwise to increase the dosage and

counter-clockwise to decrease it.).

6. Operator training

The installer is required to

provide the users with suitabl e instruction on the operation of

the appliance and on th e safety precautions

. He/she must also give practical demonstrations of

the use of the appliance and ensure that he/she is in possession of all the documentation supplied

with the appliance.

Note that to obtain the best performance and longest service life from the appliance, it must be used

in accordance with the operating instructions

, which must be kept in a safe place,

with

particular attention to maintenance

(routine, periodic and major) and to periodic sanitation using

non-corrosive commercial products.

Page 13

USE AND MAINTENANCE

Page 11

USE AND MAINTENANCE

1. Safety notes

T

HE MANUFACTURER ACCEPTS NO LIABILITY FOR ANY DAMAGE TO OBJECTS OR

PERSONAL INJURY ARISING FROM FAILURE TO COMPLY WITH THE INSTRUCTIONS

PROVIDED

.

I Precautions

The correct operation and the service life of the appliance depend on external factors including

preventive maintenance

, the characteristics of the water supply and the products used for washing,

rinsing and cleaning.

Maintenance should be carried out at the recommended intervals and in the manner

prescribed.

The characteristics of the water supply (in particular the hardness and pressure) are the main factors

to be taken into consideration when deciding whether or not to install an additional rinse pump,

water softener, filters or purifiers to improve washing results or reduce detergent consumption.

Consult your installation technician

for advice.

II Safety

In case of malfunction, seek assistance from qualified and authorized technicians only.

Prior to all maintenance, adjustment, repair and cleaning operations and in the case of

malfunction,

always disconnect the appliance from the electrical power supply

at the external

main switch, and

shut off the water supply

at the supply tap.

Do not

clean the appliance using:

• pressurized water jets, as water could get into the electrical system and damage it;

• scouring pads, wire brushes or corrosive or abrasive cleaning products which could damage

surfaces and rubber parts.

A soft damp cloth with a small quantity of detergent is all that is required to get the appliance

perfectly clean.

III Warnings regarding use of the appliance

•

NEVER

open the door before the cycle has terminated and the machine has stopped to prevent

the possibility of splashes of alkaline washing solution being thrown out of the machine and to

allow the moving parts to come to a complete stop.

•

NEVER

climb or stand on any part of the appliance or use it as a support for objects or animals.

•

NEVER

overload the open door of a front-loading appliance; the door is only designed to

support the weight of the rack loaded with tableware.

•

NEVER

use the machine to wash items of a type, shape, size or material not compatible with

the manufacturer’s recommendations..

We recommend that you do not wash items which are not guaranteed suitable for dishwashers or

which are cracked or fragile through use.

Page 14

USE AND MAINTENANCE

Page 12

IV Hygiene

To ensure the hygiene of the machine, it is important to carry out the periodic

maintenance operations

indicated in the relative section of this manual. The appliance must also

be regularly

sanitized

using suitable non-corrosive commercial products.

The internal components of the appliance should be periodically cleaned and checked by a qualified

technician.

To ensure the

hygiene of the tableware

, apply the following basic rules:

•

remove dry or solid food particles

from items before washing;

•

change the washing solution

, in accordance with the number of cycles performed, but always

at

least three time a day

;

• to avoid contamination of clean tableware

do not use: rotary brushes, dish cloths or tea towels

which are not sterile

, or place washed items on sponge or other materials which may be

contaminated with bacteria.

Use disposable materials or draining racks

;

•

frequently clean all surfaces

where dishes may be placed, using commercial disinfectant

products.

2. Preparation of the machine

I Detergents

The type and quantity of detergen t used d etermine the w ash in g resu lts obtain ed from the

appliance and the length of its service life.

Detergents are not supplied with the appliance; we suggest that you contact a reputable detergent

manufacturer who can advise you on the type of detergent suitable for your particular requirements.

Use the dosage recommend by the detergent manufacturer; incorrect dosages may give

unsatisfactory results or cause unnecessary pollution.

To avoid damage to the appliance and to protect the environment, do not use corrosive or pollutant

products.

The appliance uses

two types of detergent

:

− Washing detergent

− Rinse-aid

Both powder and liquid products are available; only choose

low foaming industrial products.

Some detergents are age and temperature sensitive; these must not be stored for too long or in

very hot or cold ambient temperatures.

Detergents and rinse-aids are potentially hazardous chemical products.

NEVER immerse

you bare hands in the washing solution

; use protective gloves when necessary. In case of contact

with eyes, rinse with copious amounts of running water and seek medical assistance, indicating the

type of detergent..

II Checking the machine

Page 15

USE AND MAINTENANCE

Page 13

Before starting the machine, check that it has been installed correctly by a qualified

technician in compliance with all the indications contained in the documentation supplied

with the appliance.

Dispensers

for rinse-aid and detergent (optional)

Before starting the wash cycle, the dispensers and the

dispensing pipes must be full.

Check the levels of rinse-aid and detergent and top up if

necessary.

Never allow the rinse-aid and detergent containers to empty

completely. Do not top up with corrosive or impure products.

The warranty does not cover any damage or injury arising from the incorrect use of

dispensers.

3. First cycle

1. Turn on the external water stop cock.

2. Connect the power supply to the appliance by operating the external main switch.

3. Set the machine to “wash” mode by pressing switch [1]. The wash chamber will automatically

start to fill.

For appliances without detergent dispensers only.

Add detergent in the region of the pump suction filter every 5 cycles in

the amount recommended by the manufacturer. An average dosage

might be 1-2g/litre for powder detergents or double this amount for

liquid products. On first filling, and then at each subsequent changing

of the washing solution (at least three times per day), the dosage must

be sufficient for the amount of water in the chamber plus that used in

the next five rinses, as indicated in the section “installation data”. For

subsequent dosages only add the detergent required for the rinses.

4. Load the items to be washed into the racks: use racks suitable for the

type of item (long-stemmed glasses, tumbler, cups, ordinary plates,

large plates, cutlery, etc.) without overloading.

5. Remove large food particles; do not load dishes with dried-on or solid residue.

Page 16

USE AND MAINTENANCE

Page 14

6. Only load items which are guaranteed suitable for dishwashers and which are free from cracks.

7. Load the rack into the appliance and close the door.

8. Select the desired cycle with button [7]. Press button [2] to start the wash cycle.

9. Light [3] will illuminate to indicate that washing cycle is in progress.

If the door is accidentally opened during the washing cycle, the machine will stop

immediately. To resume the cycle from the point at which it was interrupted, simply re-

close the door.

Even though the cycle will stop immediately if the door is opened accidentally, some splashes

of alkaline washing solution may be thrown out of the appliance.

10. L Pilot light [3] switches off to indicate that the washing and rinsing phases have been

completed.

For appliances with the “cold rinse” option only.

If washed items are to be used immediately and require a cold rinse (beer glasses, ice

cream dishes), press button [5] for 10 - 20 seconds to perform a further rinse cycle

using fresh water drawn directly from the mains supply without heating.

11. Remove the rack immediately from the appliance to allow the items to dry properly.

12. When removing the tray, tilt it slightly to allow excess water to drain from the dishes.

13. Leave the dishes in the rack for a few seconds to allow the last drops of water to

evaporate.

14. Remove the items from the rack. Ensure that your hands and the surfaces where the items

are placed are perfectly clean to prevent contamination of the washed items.

4. Subsequent cycles

Check the washing solution

; if it is too dirty or the filters are clogged with residue from previous

washes:

• empty the wash chamber as described in the section “Emptying the machine”;

• clean the machine as described in the section “Maintenance”;

• renew the washing solution.

The washing solution must in any event be renewed at least

three times per day.

Page 17

USE AND MAINTENANCE

Page 15

For appliances without detergent dispensers only.

If five cycles have already been performed, add detergent in the

region of the washing pump suction filter in the amount indicated

by the detergent manufacturer and the installation manual.

Follow the instructions given for the first wash cycle from point 6 “Load the items to be washed

into the racks” onwards.

5. Emptying the machine

I Appliances without drain pumps

Switch off the machine at the power on/off switch [1].

Remove the overflow plug from the machine and wait until the chamber is completely

empty before proceeding to clean as described in the section “Maintenance”.

II Appliances with drain pumps

To drain the machine:

I. Clean the filters.

II. Remove the overflow plug.

III.Press the “drain pump” button [6] to drain, releasing it when the chamber is empty.

6. Before the daily shutdown

• Remove the overflow plug and empty the machine as described in the section “Emptying the

machine”.

• Clean the machine as described in the section “Maintenance”.

• Switch the machine off at the power on/off switch [1]

•

Disconnect the power supply to the machine

at the external main switch.

•

Turn off the external water stop cock

.

• Leave the door slightly ajar to prevent unpleasant odors forming in the chamber.

7. Maintenance

I Daily maintenance

The following operations are to be carried out

two or three times a day

when residue

accumulates around the chamber filter.

•

Drain

the water off completely as described in the section “Emptying the machine”.

•

Disconnect the power supply at the external main switch

.

•

Turn off the external water stop cock

.

• Remove the racks, filters and overflow plug from the chamber.

Page 18

USE AND MAINTENANCE

Page 16

• Clean the machine using a damp rag with a little detergent.

•

Do not use

scouring pads, wire brushes or abrasive cleaning products to clean the steel

surfaces.

If the machine is not to be used for a period, leave the door slightly ajar to prevent unpleasant odors

from forming.

II Periodic maintenance

The following operations are to be carried out

every two or three days

, after routine maintenance.

Remove and clean the wash and rinse arms

as shown below:

• Unscrew the ring nut and pull off the wash and rinse arms.

Thoroughly clean the chamber and the machine

, using a non-abrasive disinfectant product.

Refit the nozzles and arms, taking care to insert the arms properly in their respective mountings.

Refit all the filters.

III Major maintenance

Once a year

, or whenever limescale deposits are noted in the machine, call a

specialist technician

to:

• Remove limescale deposits from the chamber and heating elements.

• Dismantle and thoroughly clean the wash and rinse arms/nozzles.

• Check the condition of the seals and other components subject to wear such as pumps.

dispensers, level switches and programmers and replace parts when necessary.

• Adjust the settings of the rinse-aid dispenser and detergent dispenser (optional).

When the appliance is to remain

idle for a long period

, apply Vaseline oil to the steel surfaces

and call a

specialist technician to prepare the water circuits and the dispensers for storage.

.

If you suspect that

ice

may have formed in the appliance,

DO NOT USE IT

until

a qualified technician has inspected the boiler and the pipes.

Page 19

USE AND MAINTENANCE

Page 17

8. Solutions to the most common problems

I Dishes not clean

P

ROBLEM

R

EMEDY

Wash arms stuck. The arms should rotate easily by hand. Pull arms off and clean

carefully. Check and clean the arms supply pipe in the

machine.

Nozzles of spray arms obstructed Remove the spray arms and clean carefully to remove

obstructions.

Nozzles of rinse arms clogged with limescale Pull off the rinse arms and descale in a separate c ontainer.

Check that the water softener is operating correc tly (if fitted).

Too much or too little detergent. Check detergent dosage, referring to relative section in this

manual.

Filter clogged Remove, empty and clean filte r

Wash cycle too short. Select a longer cycle if possible, or repeat the cycle.

II Dishes not perfectly dry

P

ROBLEM

R

EMEDY

Too little rinse-aid Increase dosage (see instructions).

Grease or starch not completely removed Too little detergent. Incre ase dosage as per instructions in

relative section of this manual.

Wrong type of detergent Choose a more effective product.

Washing solution too dirty. Drain the wash chamber, clean filters and chamber. Remove

more residue prior to washing.

Rack unsuitable for type of tableware. Use a suitable rack and allow water to drain from tableware.

Tableware left in machine after c y cle has finished. Remove from machine immediately after the cycle finishes to

allow to dry.

Glassware surface rough and porous, or opaque

through corrosion.

Renew glasses and use suitable racks. Glasses should be

prevented from coming into contact with each other during the

wash cycle.

Streaks and spots on tableware. Too much rinse-aid. Reduce the dosage (see instructions).

Water too hard or containing too high a

concentration of dissolved minerals.

Ask local water board for information about water quality and

compare with values indicated on the machine’s data plate

Page 20

USE AND MAINTENANCE

Page 18

III Water softener(Optional)

P

ROBLEM

R

EMEDY

Excess salt in rinse water.

Salt left in container af ter regeneration.

Only fill container

immediately before starting the regeneration cycle with the

quantity of salt indicated in the ope rating instructions.

Wrong size salt grains.

Use salt with a grain size of 1 - 2 mm

Excessive salinity after resin regeneration.

External water softener.

Rinse the resin at the end of the

regeneration cycle, draining the water container in the water

softener.

Built-in water softener.

Salt container cap not fully tig htened.

Open container, remove salt usi ng hot water, replace cap and

screw on tightly..

Limescale deposits in machine

Regeneration not performed correctly at right time.

perform two or three consecutive regeneration cycles, adding

salt each time.

Descale the machine.

Water supply filter clogged.

Clean or, if necessary, replace

with a higher capacity filter.

IV Miscellaneous problems

P

ROBLEM

R

EMEDY

Tableware broken by impact during wash cycle. Use suitable racks for the type of tableware and do not

overload.

Machine stops in middle of cycle. Machine interconnected with other appliances. Provide

separate power supply for the machine with a switch or fuses

suitably rated for the current indicated on the data plate.

If the problem recurs, have the system checked by a qualified

electrician.

Machine fails to start after a period of inactivity. Have a qualified technician turn the pump motor over using

the splines on the opposite end of the shaft to the pump

impeller.

The cycle does not stop when the door is opened. Have a qualified technician repair the door safety switch and

check the magnetic contact and its circuit.

Page 21

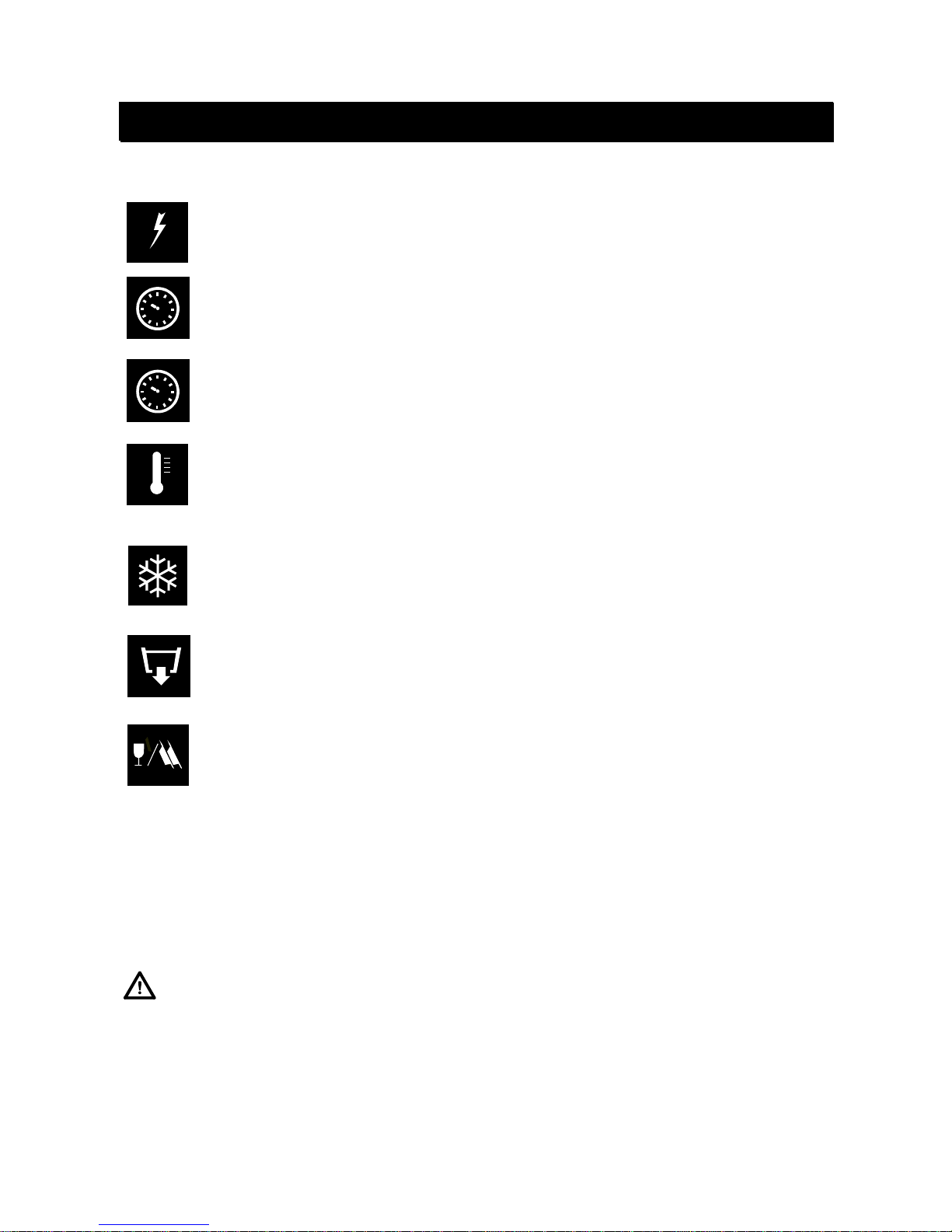

D

M6

109

139

Y7

E

B11

C2

M4

109

FG

A

B

B

B

F

Y5

109

N01

123

M3

S3

151

102

109

151

N03

N02

C

N03

E1 E3

B3

PE

N

L3

L2

BRBK

201

204

203

205

202

B1

H4

N01

122

116

114

115

110

137

101

BL

L1

C1

ML

K11

B10

B5

S1

MV

K4

A1

1

K4 A1 A1M1Y2 H3

116

A1

2

3

A1

4

A1K4 S16

F1

109

K4

120

122

N01

111

116

116

122

K11

BK

Z1

K11

206

103

N02

Z1

116

109

Y4H1

S14

S14

YE-GR

F10

150

121

108

109

102

102

P

P P

ML

20'

MV

60"

1234

Fragnan L.

Ersetzt

Supds. dwg.

Remplace

Sostit. il

File

File

File

File

Datum

Date

Date

Data

Gezeichn

Dwn.by

Dessine

Disegn.

Mod.

Mod.

Mod.

Mod.

Zeichnungh n.

Drawing n.

Dessin n.

Disegno n.

784MANON.CAD 13-06-2001

CLF 26

.

784/Sc

BR

BL

NL3L2L1PE

D

With detergent pump

Mit dosiergeraet reiniger

Avec doseur produit de lavage

Con dosatore detergente

E

With break tank

Mit break tank

Avec break tank

Con break tank

G

With DB2

Mit DB2

Avec DB2

Con DB2

With drain pump

Mit umwaelzpumpe

Avec pompe de vidange

Con pompa scarico

F

C

B

A

Without drain pump

Ohne umwaelzpumpe

Sans pompe de vidange

Senza pompa scarico

Without break tank

Ohne break tank

Sans break tank

Senza break tank

With regeneration

Mit regenerieren

Avec regeneration

Con rigenerazione

MARRONEBRAUNBROWN MARRONBR

BLUBLAU BLEUBLUEBL

I

NERO

GIALLO-VERDE

D

SCHWARZ

JAUNE-VERSYELLOW-GREEN

NOIRBLACK

GB F

BK

BK

BL

BR

BK201

N01

101

BK

BRBLBK

2"

60"/180"

2"2"

17"

2

3

4

1

POWER

SUPPLY

INSIDE

MACHINE

OUTSIDE

MACHINE

230V ~230V 3~

N

N

PE

L1

L2

L3

L3L2L1PE

YE-GRYE-GR

GELB-GRUENYE-GR

BK

BL

BR

BK201

N01

101

BK

BRBLBK

400V 3N~

NL3L2L1PE

YE-GRYE-GR

BK

BL

BR

BK201

N01

101

BK

BRBLBK

NL3L2L1PE

YE-GRYE-GR

230V ~

201

N01

101

Page 22

GB D F I E P

A1 Cycle timer Programmschaltwerk Programmateur de cycle Timer ciclo Programador de ciclo Programador ciclo

B1 Boiler thermostat

Temperaturbegrenzer

Durchlauferhitzer

Thermostat surchauffeur Termostato boiler Termostato del calderin Regolador de temperatura caldeira

B3 Tank thermostat Tanktemperaturbegrenzer Thermostat cuve Termostato vasca Termostato del deposito Regolador de temperatura tanque

B5 Door switch Reed- Türsicherheitkontaktschalter Micro contact de porte Micro porta Interruptor de puerta Micro-interruptor porta

B10 Tank level control Tankniveauschalter Pressostat de cuve Controllo livello vasca Interruptor del nivel en la cuba Interruptor de nivel tanque

B11 Air gap level control "Air Gap" Niveauschalter Pressostat niveau "Air Gap" Controllo livello "Air Gap" Comprobación de nivel "Air Gap" Interruptor de nivel "Air Gap"

C1 Wash pump noise filter Fünkenstörfilter Umwälzpumpe Condensateur pompe de lavage Condensatore pompa lavaggio Condensador bomba de lavado Condensator bomba lavagem

C2 Rinse booster pump noise filt.

Fünkenstörfilter

Drucksteigerungspumpe

Condensateur pompe auxiliaire Condensatore pompa ausiliaria

Condensador bomba de aumento

presion

Condensator bomba do aumento de

pressão

E1 Boiler heating element Heizkörper Durchlauferhitzer Resistance du surchauffeur Resistenza boiler Resistencia del calderin Resisténcias caldera

E3 Tank heating element Tankheizung Resistance de cuve Resistenza vasca Resistencia de la cuba Resisténcia cuba

F1 Boiler safety thermostat

Durchlauferhitzer

Temperaturbegrenzer

Thermostat securite surchauffeur Termostato sicurezza boiler Limitador de temperatura del calderin Rgolador de temperatura caldera

F10 Tank level safety switch Überlaufschutz Tankniveauschalter Pressostat de contrôle niveau Cuve Sicurezza livello vasca Interruptor de nivel agua en la cuba Segurança de nivel tanque

H1 Power lamp Netz Kontrolleuchte Voyant reseau Spia di linea Lámpara de piloto alimentación Làmpada indicadora tenção

H3 Cycle lamp Spülprogramm Kontrolleuchte Voyant de cycle Spia ciclo Lámpara de piloto ciclo Làmpada indicadora ciclo

H4 Heating lamp Heizkörper Kontrolleuchte Voyant de chauffage Spia riscaldamento Lámpara de piloto calefacción Làmpada indicadora aquecimento

K4 Door security relay Türsicherheit Relais Relais securite de porte Relè sicurezza porta Relé de de segurancia puerta Relé de segurança porta

K11 Heating control relay

ReIais Versorgung Heizkörper (evt.

Schütz)

Relais contrôle chauffement Relè controllo riscaldamento Relé limitador de temperatura Relé limitador de temperatura

M1 Wash pump motor Motor UmwäIzpumpe Moteur pompe lavage Motore pompa lavaggio Motor bomba lavado Motor bomba de lavagem

M3 Drain pump motor Motor Laugenpumpe Moteur pompe vidange Motore pompa scarico Motor bomba de desagüe Motor bomba de esgoto

M4 Rinse booster pump motor Motor Drucksteigerungspumpe Moteur pompe auxiliaire Motore pompa ausiliaria

Motor bomba para aumentar la

presión

Motor bomba de enxágue

M6 Detergent pump motor Dosiergerät Reiniger Moteur pompe produit lavage Dosatore detergente Dosificador por el detergente Doseador de detergente

S1 Start cycle push button START- Taste SpüIprogramm Poussoir mise en cycle Pulsante avvio ciclo Pulsador de principio ciclo Botões arranque ciclo

S3 Drain push button Taste Laugenpumpe (EntIeeren) Poussoir pompe vidange Pulsante pompa scarico Pulsador bomba de desagüa Botões bomba de esgoto

S14 Machine main switch

UmschaIter Betriebs / RuhesteIIung Regenerieren

Sélecteur lavage / arrêt - regeneration

Deviatore servizio / riposorigenerazione

Conmutadore conex. / desconex regeneración

Comutador arranque / interrupçáo-

regeneração

S16 Wash time selector WahIschaIter Spülprogrammdauer Sélecteur durée cycle Selettore tempi Selector de tiempo de lavado

Manipulo para selecionar o tempo do

ciclo

Y2 Rinse agent dispenser Dosiergerät KIarspüImittei DB2 Doseur produit rinçage Dosatore brillantante Dosificador líquido tensioactivo Doseador do produto de enxágue

Y4 Fill / hot rinse solenoid valve

EIektromagnetventiI Füllen /

Klarspülung warm

Electrovanne remplissage Elettrovalvola carico / risciacquo caldo

Válvula magnetica de entrada /

enjuague caliente

Válvula magnetica de entrada /

enxague quente

Y5 Regeneration solenoid valve EIektromagnetventiI Regenerieren Electrovanne regeneration Elettrovalvola rigenerazione Válvula magnetica de regeneración Válvula magnetica de regeneração

Y7 Break tank solenoid valve

NiveaueIektromagnetventiI für "Air

Gap"

Electrovanne niveau "Air Gap" Elettrovalvola livello "Air Gap" Válvula magnetica de "Air Gap" Válvula magnetica de "Air Gap"

Z1 Interference suppression filter Funkenstörfilter Filtre antiparasite Filtro antidisturbo Filtro antiparasitario Filtro de ruídos

CLF 26

Page 23

DISHWASHER TECHNICAL SPECIFICATIONS

CHG25 CHF40 CHH50 CLG25 CLF26

Drain size 20MM 22MM 50MM 18MM 22MM

Drain hose length 2,5M 1,5M 1,80M 1,5M 1,5M

Water connection 3/4" 3/4" 3/4" 3/4" 3/4"

Water hose length 1,5M 1,5M 2M 1,5M 1,5mt

Water pressure 1-4BAR 1-4BAR 1-4BAR 1-4BAR 1-4BAR

Water temp 50-55C 15-55C 15-55C 50-55C 50-55C

Total KW loading 3P N/A N/A 6.8KW N/A N/A

Total KW loading 1P 2,85KW 2,7KW/6,7KW 4.8KW 2,85KW 2,7KW/6,7KW

Mains cable length 3,0M 3,0M 1,60M 3,0M 3,0M

Mains cable size 3x1,5mm 3x4mm 5x2,5mm 3x1,5mm 3x4mm

Det pipe length N/A 1,50M 1,50M 1,50M

R/aid pipe length 1,50M 1,50M 1,50M 1,50M 1,50M

Programme times. secs 150 60-120-180 60-120-180 150 60-180

Wat/consumption,cycle 2,6L 3,3L 3L 2,6L 3.3L

W/tank capacity 11L 33L 20L 11L 33L

R/tank capacity 2.6L 6L 12L 2.6L 6L

Drain pump YES YES NO NO YES

W/pump rating 0.15kw 0.8KW 0.8KW 0.15KW 0.8KW

W/pump flow rate 105L/min 330L/min 380lt/min 105L/min 330L/min

R/pump rating 0,45KW 0,45KW 0,15kw 0,45KW 0,45KW

R/pump flow rate 11L/min 11L/min 36L/min 11L/min 11L/min

Voltage 3P N/A N/A 400/50/3/N N/A N/A

Voltage 1P 230/50/1 230/50/1 230/50/1 230/50/1 230/50/1

Noise level(dB) 63db 67db 66dB 63db 67db

Rinse time 15 sec 17 sec 15 sec 17 sec 17 sec

Page 24

As continued product improvement is a policy of HOBART, specifications are subject to change without notice.

Ce catalogue n’est pas contractuel. HOBART se réser ve le droit, et sans préavis, d’apporter toutes modifications

ou améliorations à ses matériels.

HOBART behält sich das Recht vor, an allen Produkten technische Änderungen und Verbesserungen ohne

Ankündigung vorzunehmen.10.03.2003-Issue-1

Loading...

Loading...