Page 1

INSTRUCTION MANUAL

.

.

.

with Replacement Parts

DISHWASHER

(INCLUDES MOTOR PARTS)

THlS MANUAL REPLACES AND SHOULD BE USED

INSTEAD OF FORM

PRIOR ML'S COVERED

12364C

IN

(9-80)

THlS MANUAL:

A

product

FORM

13830 15-81

of

HOBART CORPORATION

TROY,

OHIO

45374

Page 2

pue

slapow ayl

zt-~\d

~zL-I/u\~

.sAayseMys!p asu !A Aa$eM ysaA4 '3!$ecuolne

-!was aAe

1

aY1

y$!~

pue

'01)

z

1-fly

OM$

AO$OU

'a~n~e~ad

e

e

a$e~od~o3u! hay

$UOAJ

pa3ueleq~a$uno3-uou

.s~aua$se4 ou sa~!nb

3!~01$3a13 apls p!los

-II!~ paw!$ pue uo!~a$o~d

'5)

s~oop ap!s pa3ueleq~a$uno3

10~~~103

-wa$ Aa$eM 'apA3 paw!$ ayl sa$elnEia~ y3!y~ cua$sAs

AayseMys!p n~y~$y6!e~$s e s! lapow

(1

'6!j

~oop uo!$3adsu!

-aA jaued ~uoi4 pJE?pue$s ayl'(l '6!j

Page 3

INSTRUCTIONS

AM-12

HEATER PROTECTION

A float

turn off the heat supply if the water level

low. Once the water level returns to

the heating circuit

is

located in the wash tank to automatically

a

safe level,

is

operational if heat

is

is

too

de-

manded.

is

Tank water

heated by steam, gas, or electricity.

REDUCED VOLTAGE CONTROL (STANDARD)

is

A control transformer

used to provide low

voltage for the solid state control circuits. This

control transformer also supplies 1 15 V.A.C. to the

control components.

INSTALLATION

LOCATION

Adequate space must be available to open and

(6,

Fig. 1

).

service the control box

is

mounted 4-518" below the dish table height

when shipped from the factory. It can be changed

12-518" below the dish table by removing two

to

bolts and reinstalling in the two lower holes

provided.

Set the dishwasher in

its

desired location. Adjust

the height and level by turning the threaded feet

(7, Fig. 1). Make sure the dishwasher

making plumbing connections.

The control box

is

level before

Drain

Connect the drain to the sewer using

Left-hand drain

is

standard. Interchange plug

for a right-hand drain. If a grease trap

by code,

of 42 gallons per minute.

it

should have a minimum flow capacity

.

2" pipe.

is

required

Water Supply

The supply water should have a temperature of

180"-195" F. minimum and have a flow pressure

of 15 to 25

P.S-I. at the pressure gauge tee beside

the fill (solenoid) valve.

Use

314" pipe for connecting the water supply line

to line strainer which

is

assembled directly ahead

of the fill (solenoid) valve. The line strainer pre-

vents foreign matter from reaching the solenoid

25

valve. If flow pressure exceeds

P.S.I., a pressure

reducing valve (not furnished) must be installed in

the water supply line.

Gas Heat

Check gas data plate (9, Fig.

1) attached to dish-

washer or tag attached to gas burner tubing for

type of

Connect gas burner to

gas

to be used.

gas

supply. Check gas burner

compression fittings to assure they have not

loosened during shipment.

Dish tables (1, Fig. 2) should be turned down and

fit into the dishwasher. Use a sealer between table

and tank lip to prevent leakage. Fasten the dish

tables to the tank lip with truss head screws.

Plumbing connections must comply with applicable sanitary, safety and plumbing codes.

U

Fig.

2

is

A capped "tee" (not supplied)

recommended to

catch loose particles in front of the valve.

The burner

not adjustable. If line pressure

is

is

above 7" W.C. (natural gas) or 1 1 " W.C. (L.P. gas),

an additional regulator valve (not supplied) must

be installed.

The burner

circuitry. There

is

ignited automatically by solid state

is

no pilot light. Gas flow

is

regu-

lated by the temperature control circuit through a

solenoid valve.

If a failure occurs in the gas heat control board or

gas pressure, the reset button, located on the side

of the gas burner control box, will pop out. This

completely shuts off the gas heat system. To reset,

push the button in. If system does not reset,

contact an authorized Hobart service office.

Steam Heat

The steam supply must be between 15 and 50 P.S.

flowing pressure. Steam flow

solenoid valve

as

well

as

a

is

controlled by

mechanical globe valve.

I.

a

Page 4

AM-1 2 INSTRUCTIONS

A

314"

union connection, for steam supply line,

is located behind the control box.

A solid state circuit board controls the steam valve

is

to provide shut-off. When the dishwasher

not in

use, close the globe valve in the line ahead of the

solenoid valve.

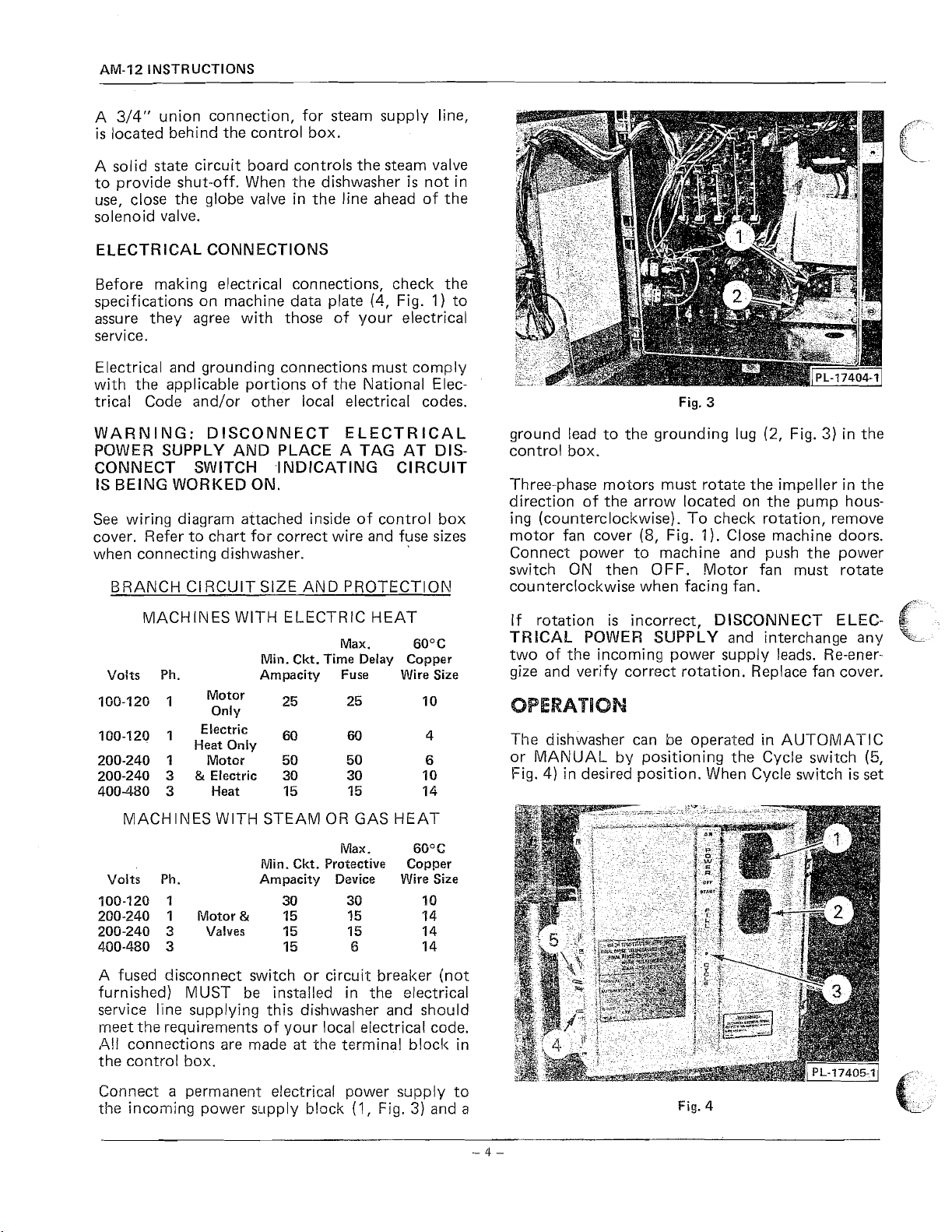

ELECTRICAL COhINECTIONS

Before making electrical connections, check the

(4,

Fig.

1)

specifications on machine data plate

to

assure they agree with those of your electrical

service.

Electrical and grounding connections must comply

with the

trical

a~~licable ~ortions of the National Elec-

cod;' and/or 'other local electrical codes.

Fig.

3

WARNIIVG: DISCONNECT ELECTRICAL

POWER SUPPLY AND PLACE A TAG AT DISCONNECT SWITCH

.INDICATING CIRCUIT

IS BEING WORKED ON.

See wiring diagram attached inside of control box

cover. Refer to chart for correct wire and fuse sizes

when connecting dishwasher.

CI

BRANCH

MACHINES

Volts Ph.

100-120

100-120

200-240

200-240

400480

RCUlT SIZE AND PROTECTION

WITH ELECTRIC HEAT

Max.

25

60 4

1

1

3

3

Motor

Only

Electric

Heat Only

Motor

&

Electric

Heat

Min. Ckt. Time Delay Copper

Ampacity Fuse Wire Size

25

50 50

30 30 10

15 15 14

60°C

6

MACHIkIES WITH STEAM OR GAS HEAT

Volts Ph.

100-120

200-240

2013-240

4.00-480 3 15

I

1

3

Motor

Valves

Min. Ckt. Protective Copper

Ampacity Device Wire Size

30

15

&

15 15 14

Max.

30

15

6

6G°C

a

o

14

14

ground lead to the grounding lug

(2,

Fig.

3)

in the

control box.

Three-phase motors must rotate the impeller in the

direction of the arrow located on the pump hous-

ing (counterclockwise). To

(5,

motor fan cover

Fig.

check rotation, remove

1

).

Close machine doors.

Connect power to machine and push the power

switch ON then OFF. Motor fan must rotate

counterclockwise when facing fan.

If rotation is incorrect,

TRlCAh POWER SUPPLY

DISCONNECT ELEC-

and interchange any

two of the incoming power supply leads. Re-energize and verify correct rotation. Replace fan cover.

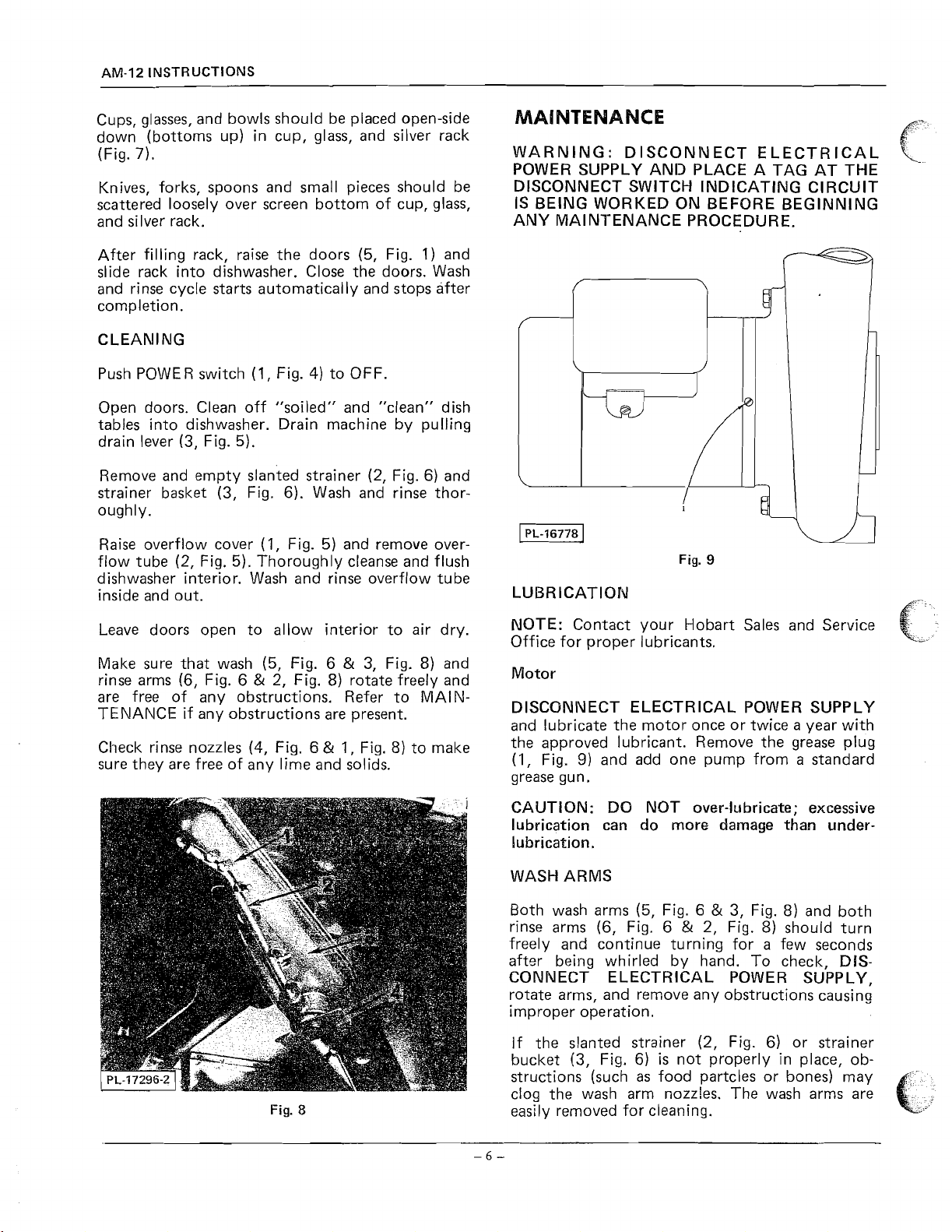

OPERATION

The dishwasher can be operated in AU-TORIIATIC

or MANUAL by positioning the Cycle switch

Fig.

4)

in desired position. When Cycle switch

is

(5,

set

$-

k-

A fused disconnect switch or circuit breaker (not

furnished) MUST be instailed in the electrical

service

l'ine supplying this dishwasher and should

meet the requirements of your local electrical c~de.

,411

connections are made

at

the terminal blocl< in

the control box.

Connect

the incoming power

a

permanent electrical power supply to

sr-lpply b!ock

(1,

Fig.

3)

and

a

Fig.

4

Page 5

for AUTOMATIC, the WASHIRINSE switch (4,

Fig. 4) must be in the OFF position. When Cycle

switch

accomplished when WASHIR INSE switch

is

set

for MANUAL, wash operation

is

is

in

WASH position. To rinse in MANUAL operation,

WASH/R\NSE switch in RINSE position for

hold

desired rinse time.

When operating the dishwasher in AUTOMATIC

1)

setting, close door (5, Fig.

(3,

Fig.

4)

pilot light

If cycle

is

interrupted, such as opening and closing

the door to add

goes off, cycle

a

dish, the timer resets and starts

new cycle. This feature provides

to start cycle. When

is

comp!eted.

a

complete

cycle to insure proper cleaning ~f an added article.

6efore opening the door during a cycle, first turn

off POWER switch;

then wait

10

seconds to avoid

water splashing from the wash arms.

a

INSTRUCTIONS

Fig.

6

AM-12

model, the front inspection door (10, Fig.

I)

must

be closed before counterbalanced doors can be

lowered.

Push POWER switch

release timed

Fl LL switch

(1, Fig.

automatic fill operation. Wait a full 2 minutes

4)

to ON. Push and

(2,

Fig. 4) to start

18

seconds for the timed fill cycle to complete and

shut off.

The wash thermometer

(1, Fig. 1) should register

150"-168" F. during wash cycle. The rinse ther-

mometer

(1 1, Fig.

I),

during rinsing operation,

should register 180"-195" F. minimum. These tem-

pera-tures are necessary for dishwashing and sanitization.

Fig.

5

PREPARATION

Place overflow tube

(2,

Fig.

5),

overflow cover (1,

Scrape the dishes to remove large partic!es of food

and debris. Water-scrape the dishes by means of

spray of water from the water system or by

Fig. 5), end cover (1, Fig. 6), slanted strainer (2, stream of recirculating water before or after

Fig. 6) and strainer bucket

(3,

Fig. 6) in position.

Scatter the initial charge of detergent on the When racking dishes DO

slanted strainer. Replenish as needed unless

auto-

matic detergent dispenser has been added by others.

racking the dishes.

NOT stack one on top of

another. Water must have free access to both sides

of every dish.

a

a

Close the counterbalanced doors (5, Fig. 1) which

automatically closes the drain. On straight-thru

Stand plates and flat dishes up edgewise in mixed

dish rack (Fig.

7).

Page 6

AM-12

INSTRUCTIONS

Cups, glasses, and bowls should be placed open-side

down (bottoms up) in cup, glass, and silver rack

7).

(Fig.

Knives, forks, spoons and small pieces should be

scattered loosely over screen bottom of cup, glass,

and silver rack.

After filling rack, raise the doors (5, Fig. 1) and

slide rack into dishwasher. Close the doors. Wash

and rinse cycle starts automatically and stops after

completion.

CLEANING

Push POWER switch (1, Fig.

4)

to OFF.

Open doors. Clean off "soiled" and "clean" dish

tables into dishwasher. Drain machine by pulling

drain lever (3, Fig. 5).

Remove and empty slanted strainer (2, Fig. 6) and

strainer basket (3, Fig. 6). Wash and rinse thoroughly.

Raise overflow cover (1, Fig. 5) and remove over-

(2,

flow tube

Fig. 5). Thoroughly cleanse and flush

dishwasher interior. Wash and rinse overflow tube

inside and out.

MAINTENANCE

WARNING: DISCONIVECT ELECTRICAL

POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING CIRCUIT

IS BEING WORKED ON BEFORE BEGINNING

ANY MAINTENANCE PROCEDURE.

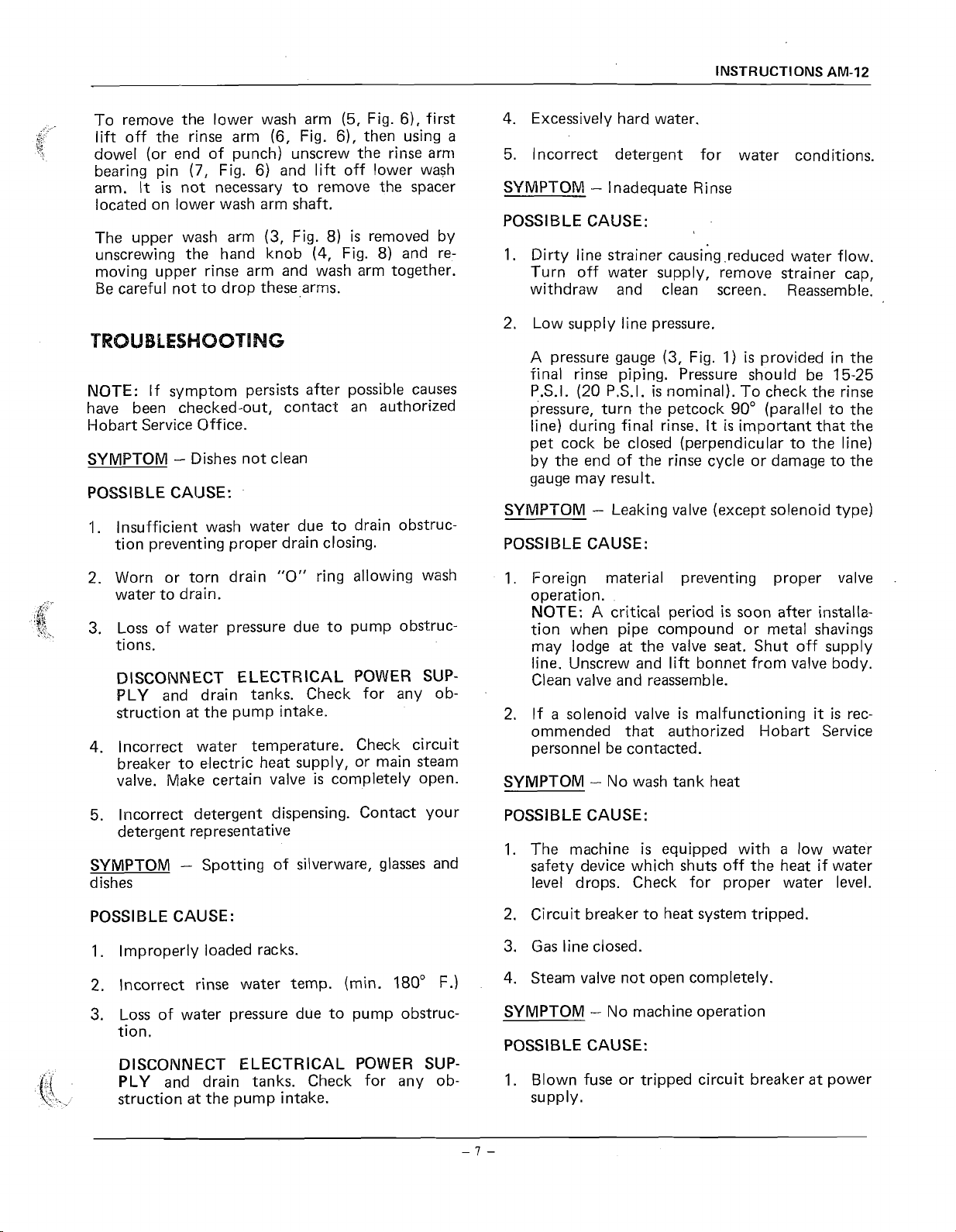

Fig.

9

LUBRICATION

B

\

Leave doors open to allow interior to air dry.

Make sure that wash (5, Fig. 6

&

rinse arms (6, Fig. 6

2, Fig. 8) rotate freely and

&

3, Fig. 8) and

are free of any obstructions. Refer to MAINTENANCE if any obstructions are present.

Check rinse nozzles

(4,

Fig. 6 & 1, Fig. 8) to make

sure they are free of any lime and solids.

Fig.

8

NOTE: Contact your Hobart Sales and Service

Office for proper lubricants.

Motor

DISCONIVECT ELECTRICAL POWER SUPPLY

and lubricate the motor once or twice a year with

the approved lubricant. Remove the grease plug

(1,

Fig.

9)

and add one pump from a standard

grease gun.

:

CAUTION

lubrication can do more damage than

DO NOT over-lubricate; excessive

under-

lubrication.

WASH ARMS

Both wash arms

rinse arms (6, Fig. 6

(5,

Fig. 6 & 3, Fig. 8) and both

&

2, Fig.

8)

should turn

freely and continue turning for a few seconds

after being whirled by hand. To check, DISCONNECT ELECTRICAL POWER SUPPLY,

rotate arms, and remove any obstructions causing

improper operation.

If the slanted strainer

bucket (3, Fig. 6)

structions (such

as

(2,

Fig. 6) or strainer

is

not properly in place, ob-

food partcles or bones) may

clog the wash arm nozzles. The wash arms are

easily removed for cleaning.

Page 7

To remove the lower wash arm (5, Fig.

lift off the rinse arm

dowel (or end of punch) unscrew the rinse

bearing pin

arm. It

located on lower wash arm shaft.

The upper wash arm (3, Fig. 8)

unscrewing the hand knob

moving upper rinse arm and wash arm together.

Be careful not to drop these arms.

(7,

Fig. 6) and lift off lower wash

is

not necessary to remove the spacer

(6, Fig.

6),

is

(4,

Fig. 8) and re-

6),

first

then using a

arni

removed by

TROUBLESHOOTING

NOTE: If symptom persists after possible causes

have been checked-out, contact an authorized

Hobart Service Office.

-

SYMPTOM

POSSIBLE CAUSE:

Insufficient wash water due to drain obstruc-

'I.

tion preventing proper drain closing.

Dishes not clean

INSTRUCT1 ONS

4.

Excessively hard water.

5. lncorrect detergent for water conditions.

SYMPTOM

POSSIBLE CAUSE:

1. Dirty line strainer causing .reduced water flow.

Turn off water supply, remove strainer cap,

withdraw and clean screen. Reassemble.

2.

Low supply line pressure.

A

final rinse piping. Pressure should be 15-25

P.S.I. (20 P.S.I.

pressure, turn the

line) during final rinse.

pet cock be closed (perpendicular to the line)

by the end of the rinse cycle or damage to the

gauge may result.

SYMPTOM

POSSIBLE CAUSE:

-

Inadequate Rinse

pressure gauge (3, Fig. 1)

is

nominal). To check the rinse

petcock

It

is

-

Leaking valve (except solenoid type)

is

provided in the

90"

(parallel to the

important thst the

AM-12

2.

b

.

&.

2.

Worn or torn drain

water to drain.

3. Loss of water pressure due to pump obstructions.

DlSCONNECT ELECTRICAL POWER SUPPLY and drain tanks. Check for any obstruction

4.

lncorrect water temperature. Check circuit

breaker to electric heat supply, or main steam

valve. Make certain valve

Iiicorrect detergent dispensing. Contact your

5.

detergent representative

SYMPTOM

dishes

POSSIBLE CAUSE:

l mproperly loaded racks.

1.

2.

lncorrect rinse water temp. (min. 180"

3. Loss of water pressure due to pump obstruction.

DISCONNECT ELECTRICAL POWER SUPPLY and drain tanks. Check for any ob-

struction

at

the pump intake.

-

Spotting of silverware, glasses and

at

the pump intake.

"0"

ring allowing wash

is

completely open.

F.)

1. Foreign material preventing proper valve

operation.

NOTE:

tion when pipe compound or metal shavings

may lodge at the valve seat. Shut off supply

line. Unscrew and lift bonnet from valve body.

Clean valve and reassemble.

If a solenoid valve

2.

ommended that authorized Hobart Service

personnel be contacted.

SYMPTOM

POSSIBLE CAUSE:

1. The machine

safety device which shuts off the heat if water

level drops. Check for proper water level.

2.

Circuit breaker to heat system tripped.

3. Gas line closed.

4.

Steam valve not open completely.

SYMPTOM

POSSIBLE CAUSE:

1. Blown fuse or tripped circuit breaker

supply.

A

critical period

is

malfunctioning

-

No wash tank heat

is

equipped with a low water

-

No machine operation

is

soon after installa-

it

is

at

power

rec-

Page 8

Page

9

11

13

15

17

19

2 1

23

2

5

2 6

27

29

3

1

33

35

36

37

38

39

4

1

43

45

47

49

5

1

5 3

5 5

5 6

Description

Conduit (R.H. Controls)

Conduit (L.H. Controls)

Control Box

AM-12 Motor

AM-1 2A Motor

Motor Parts

Lower Wash Arm (Thrust Washer Type)

Lower Wash Arm (Ball Bearing Type)

Upper Wash Arm (Thrust Washer Type)

Upper Wash Arm (Ball Bearing Type

Upper Wash Arm (Ball Bearing Type

Outside Rinse Piping

lnside Rinse Piping

Inside Rinse Piping (Low Water Consumption)

Door Interlock

Door (Straight

Door (Corner)

Door Lift Unit (Straight

Door Lift Unit (Corner)

Strainers

Track Unit

Miscellaneous

Low Water Protection

Electric Heat

Gas Burner Unit

Flue

&

Igniter Control (Gas)

Steam Injector

Dish Racks

&

&

&

-

Thru)

Drain

Pump

Pump

-

Thru)

WIStationary Rinse)

WIRotating Rinse)

Page 9

REPLACEMENT PARTS

AM-12

ILLUS.

PL-16176

"*lo P-77657-39

**I2 FE-8-23

**I4 FE-8-11

PART

NO.

1 P-77657-38

2 FE-8-25

3 FE-8-11

4 FE-8-24

5 FE-8-11

**6 FE-8-25

*7 FE-8-33

**8 FE-8-11

*9 FE-8-12

*11 C-104192-9

*13 FE-8-31

*15 FE-8-12

CONDUIT

(R.H.

CORITROLS)

NAME

Conduit - 314" x 32" (Waterproof)

Connector 90' "Sealtite" (314" Male Thd. x 314" Flex. Cnd.)

314" Gasket Assy

Connector

314" Gasket Assy

Con~lector - 90' "Sealtite" (314" Male Thd. x 314" Flex. Cnd.)

Connector 90' "Sealtite" (1" Male Thd. x 1" Flex. Cnd.)

314" Gasket Assy ............................................. 1

1" Gasket Assy

Conduit

Conduit

Connector -Straight "Sealtite" (314" Male Thd. x 314" Flex. Cnd.)

Connector - Straight "Sealtite" (1" Male Thd. x

314" Gasket Assy

1"

*110-120

**200

.

.............................................

-

45' "Sealtite" (314" Male Thd. x 314" Flex. Cnd.)

.............................................

.

..............................................

-

314" x 10" (Waterproof)

-

1"

x 9-114" (Waterproof)

.............................................

Gasket Assy .............................................. 1

v.

V.

&

Above.

OF

PART AMT.

...................................

..................

..................

..................

.....................

...................................

..................................

................

1"

Flex. Cnd.)

..................

1

1

1

1

1

1

1

1

1

1

1

1

1

(i,

Page 10

Page 11

CONDUIT

(L.H. CONTROLS)

REPLACEMENT PARTS AM-12

I

LLUS

.

PL-16177

1

2

3

4

5

PART

NO

.

FE-8-11

'

FE-8-25

P-77657-1

FE-744

FE-7-32

C-119190-1

FE-8-11

FE-7-35

FE-8-11

FE-7-35

C-119190-2

FE-646

SC-21-23

WL-6-7

FE-7-32

FE-7-44

P-77657-5

FE-8-24

FE-8-11

FE-8-12

FE-8-32

C-104192-10

FE-14-37

FE-7-33

B-122915

B-119311-1

FE-7-33

FE-7-30

FE-7-33

B-119311-2

FE-8-12

FE-7-36

NAME

OF

PART AMT

314" Gasket Assy

Connector 90' "Sealtite" (314" Male Thd x 314" Flex Cnd.)

Conduit 314" x 18" (Waterproof) 1

Connector Straight "Sealtite" (314" Female Thd x 314" Flex Cnd.)

Connector -Straight (314" Male Thd x 314" Thinwall)

Conduit 314" Thinwall (Control Box to Coupling) 1

314" Gasket Assy

Ell 90' Short (314" Male Thd x 314" Thinwall) 1

314" Gasket Assy

Ell . 90' Short (314" Male Thd . x 314" Thinwall)

Conduit . 314" Thinwall (Control Box to Coupling)

Clamp

Mach . Screw . #lo-24 x 112" Rd Hd

Lock Washer

Connector . Straight (314" Male Thd . x 314" Thinwall)

Connector -Straight "Sealtite" (314" Female Thd . x 314" Flex . Cnd.)

Conduit

Connector . 45' "Sealtite" (314" Male Thd . x 314" Flex Cnd.)

Connector . 45' "Sealtite" (1" Male Thd

Conduit . 1"

Connector -Straight (1" Female Thd . x 1" Flex . Cnd.)

Connector -Straight (1" Male Thd

Clamp

Conduit . 1"

Connector -Straight (1" Male Thd . x 1" Thinwall)

Ell

Connector

Conduit

Ell

.

.

.

.

314" Conduit

.

314" Gasket Assy

Gasket Assy

1"

.

1"

.

90' x 1" Pulling

1" Gasket Assy

.

.

90' Short (1" Male Thd

.............................................

.

.

.

..................

...................................

.

.

.

..............

....................... .

.........................

.............................................

.

..........................

.............................................

..........................

.........................

..........................................

.

.

#

10 Medium

.......................................

.................................

.......................

..............

314" x 22" (Waterproof)

...................................

.

..................

.............................................

...............................................

x 24-112" (Waterproof)

1"

Flex Cnd.)

.

.

x

..................................

....................

.......................

Conduit

x 16" (Thinwall)

...........................................

1" Thinwall)

.....................................

..........................

.

x

..........................

...........................................

.

Straight (1" Male Thd . x 1" Thinwall)

1" x 4" (Thinwall) (Pulling Ell to Control Box)

..........................

......................

..............................................

.

x

1" Thinwall)

.............................

.

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

*110-120

**200

V

.

&

v

.

Above

.

Page 12

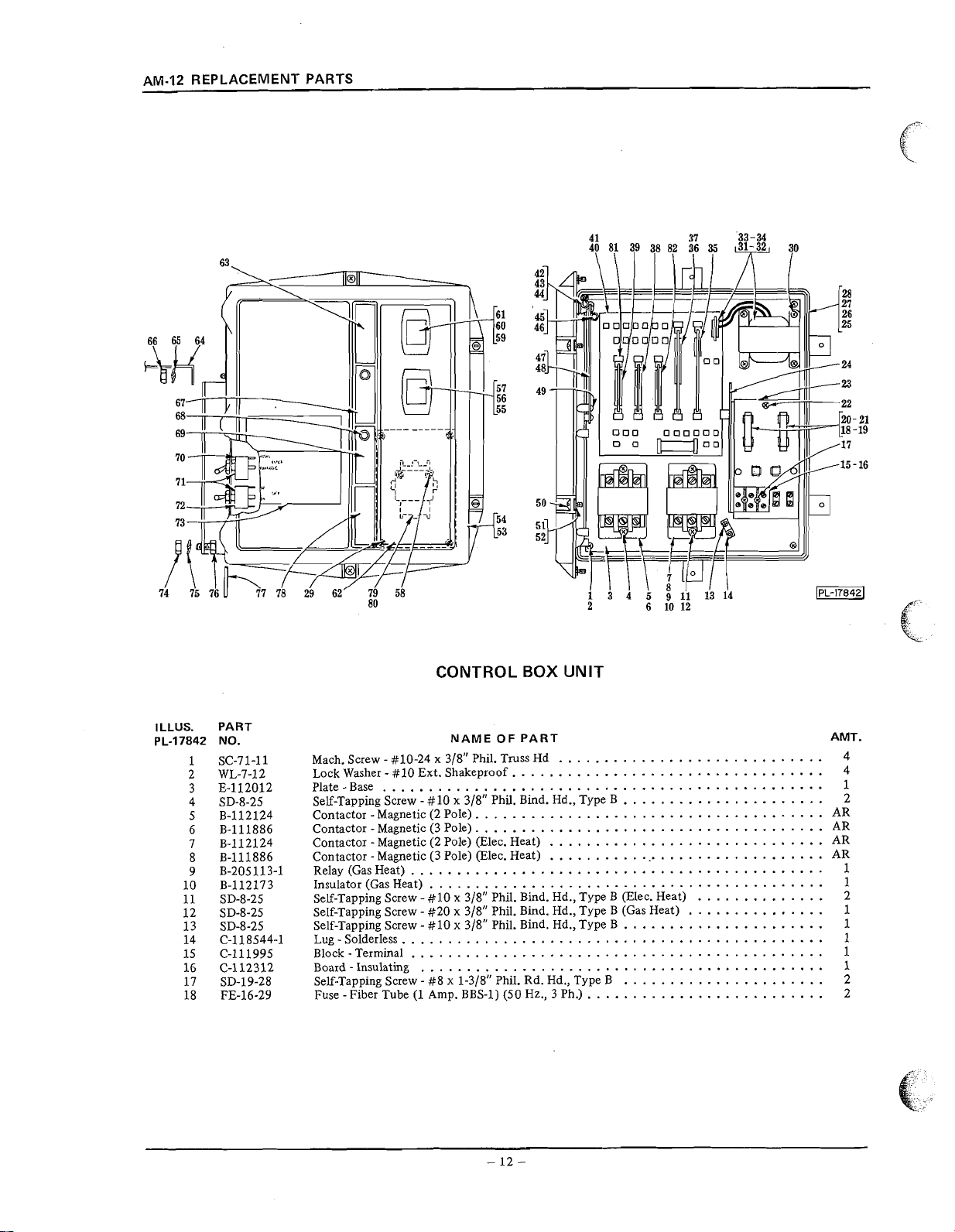

AM-12 REPLACEMENT PARTS

ILLUS. PART

PL-17842 NO.

1

SC-71-11

2 WL-7-12

3 E-112012

4 SD-8-25

5 B-112124

6 B-111886

7 B-112124

8 B-111886

9 B-205113-1

10 B-112173

11 SD-8-25

12 SD-8-25

13 SD-8-25

14 C-118544-1

15 C-111995

16 C-112312

17 SD-19-28

18 FE-16-29

CONTROL BOX UNIT

NAME OF PART AMT.

Mach. Screw - #lo-24 x 318" Phil. Truss Hd

Lock Washer - #10 Ext. Shakeproof.

Plate-Base

Self-Tapping Screw

Contactor - Magnetic (2 Pole)

Contactor

Contactor - Magnetic (2 Pole) (Elec. Heat)

Contactor

Relay (Gas Heat)

Insulator (Gas Heat)

Self-Tapping Screw

Self-Tapping Screw

Self-Tapping Screw - #10 x 318" Phil. Bind. Hd., Type B

Lug - Solderless

Block

Board - Insulating

Self-Tapping Screw - #8 x 1-318" Phil. Rd. Hd., Type B

Fuse

................................................

-

#

10 x 318" Phil. Bind. Hd., Type B

.

. . .

-

Magnetic (3 Pole)

-

Magnetic (3 Pole) (Elec. Heat)

. . . .

.

. . . . . . .

. . .

.

-

$10 x 318" Phil. Bind. Hd., Type B (Elec. Heat)

-

#20 x 318" Phil. Bind. Hd., Type B (Gas Heat)

-

. . . . .

Terminal

-

Fiber Tube (1 Amp. BBS-1) (SO Hz., 3 Ph.)

. . .

. . . .

. . . . . . . . . . . . . . . . . . . . .

.

.

.

. . .

.

.

. .

. .

. . . . . . . .

.

.

. . . . . . .

. . . . .

. . . . . . .

.

.

. . .

. . . . .

.

. . . .

. . . . . .

. .

.

. .

. . . .

. . . .

. .

.

.

.

. . .

.

. .

.

. .

.

. . . . . . . . . . . . .

. . . . . . . , . . . . . . . . . . . . . . .

.

.

. .

. . . . . . .

.

.

.

. . . . . .

. . . . .

.

. . . .

. . . . . . . .

. . . . . .

.

. .

. .

. . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . .

. .

. .

.

..

.

. . . . . . .

. . .

. .

.

. .

.

. . . .

.

.

. . . . . . .

. . . . .

. . . .

. .

. . .

.

. . . . . .

. . . . .

. . . . . . . . . . . . .

. . .

. . . . .

.

.

. . . .

.

. . .

. . .

.

. .

. . . . . .

. .

. . . . . . . . . . .

. . . . . .

. . . . . . . .

. . . . . .

.

. . . . .

. . . . .

.

.

.

.

. . . . . .

. . . . . . . . . .

.

.

. . .

. . . . .

. . . . . . . . . .

. .

. . . . . . . . .

. . . . . . . . .

.

. . . . . .

. .

. . .

.

. .

. . . . .

. . . .

. .

.

. .

.

. . . .

. . . . . . . . .

.

. . . . . . . . . .

.

. . .

.

. . . . .

.

.

. .

.

.

.

.

.

.

.

4

4

1

2

AR

AR

AR

AR

1

1

2

1

1

1

1

1

2

2

Page 13

I

LLUS

.

PL-17842

19

20

2 1

22

23

24

"

"25

*:"6

*27

"28

29

30

31

PART

.

NO

FE-16-30

FE-19-48

FE-19-50

SD-8-18

C-118300

D-112059

E-119092-1

E-119138-1

E-119309

D-119182

SD-12-4

SD-8-25

C-111983-1

REPLACEMENT PARTS AM-12

CONTROL BOX UNIT (Cont.)

NAME OF PART AMT

Fuse . Fiber Tube (2 Amp . BBS-2) (50 Hz.. 1 Ph.)

Fuse -Fiber Tube (.8 Amp

Fuse -Fiber Tube (1.6 Amp

Self-Tapping Screw

Terminals

Insulator

Control Box (R.H. Controls)

Control Box

Control Box (R.H. Controls)

Control Box (L.H. Controls)

Self-Tapping Screw - $8-32 x 318" Phil . Truss Hd., Type 23

Self-Tapping Screw

Power Input Board Assy

Circuit)

Power Input Board Assy

3Ph.)

Power Input Board Assy

Power Input Board Assy

Power Supply Board

Timer Board Assy

Timer Board Assy

Motor Protector Board Assy

Temperature Control Board Assy

Master Board Assy

Master Board Assy

Retainer

Clamp-Wire

Self-Tapping Screw

Clamp-Wire

Self-Tapping Screw

Reed Mounting Board Assy

Switch-Reed

Self-Tapping Screw

Screw - Captive 4

Retainer

Spacer - Lid 4

Lid

Gasket

Start Switch Assy

Self-Tapping Screw

Lock Washer

Self-Tapping Screw

On/Off Switch Assy . (Maintained)

Self-Tapping Screw . #6-19 x 318" Phil . Pan Hd . "Plastite"

Lock Washer

Plate

Plate

Bracket -Control Box

Lock Washer

Full Nut

Plate

Solid State Pilot Light Assy . (Timed Fill)

Plate - Identification (Cycle) (Timed Fill)

Toggle Switch

Lock Washer

Toggle Switch

Plate-Data

Full Nut

Lock Washer

Cap Screw

Pin

Plate

Contactor (Soap Dispenser)

Insulator

Edge Guide

Timed Fill Board Assy

Wiring Harness (Not Shown)

Fuse (3 Amp., 32

&

Mounting Board Assy

-

Terminal Board

(L.H. Controls)

..................................................

...................................................

.

.

.

Clamp

.............................................

...............................................

...............................................

...............................................

..............................................

-

Captive Screw

.................................................

&

Gasket Assy . (Incls . item #54)

-

Control Box

.

.

#6 Ext . Shakeproof

-

.

.

.

#6 Ext . Shakeproof

Base (Dispenser Contactor)

Identification (Power)

-

114" Light

.

114"-20 Hex Fin

Identification (Fill) (Timed Fill)

&

Label Assy . (Cycle)

-

112" Int . Shakeproof

&

Label Assy . (On/Off)

................................................

.

5116"-18 Hex Fin

-

511 6" Light

.

5116"-18 x 314" Hex Hd . (Control Box to Support)

.

Control Box & Lid

.

Identification (Blank)

..................................................

-

P.C. Board

V.)

.

BBS.8) (60'Hz., 3 Ph.)

.

-

BBS.1.6) (60 Hz., 1 Ph.)

#8 x 318" Phil . Bind . Hd., Type B

...................................

........................................

.............................

......................................

......................................

......................................

.

#

10 x 318" Phil . Bind . Hd., Type B

.

(110-120

.

(200-230

.

(115

.

(220

Assy

........................................

(ML-18500 & ML-18501)

(ML-31819 & ML-31820)

V.,

60 Hz., 1 Ph.) (200-230

V.,

60 Hz., 3 Ph

V.,

50 Hz., 1 Ph.) (220

V.,

50 Hz.. 3 Ph

......................................

...................................

.

(ML-18500 & ML-18501)

.

(ML-31819 & ML-31820)

.

#8 x 318" Phil . Bind . Hd., Type B

-

#8-32 x 112'' Phil . Truss Hd., Type 23

.

(Incls . item #48)

.

#8-32 x 318" Phil . Truss Hd., Type 23

........................................

.................................

..........................................

(Momentary) (Timed Fill)

.

#6-19 x 318" Phil . Pan Hd . "Plastite"

..................................

-

#10 x 318" Phil . Bind . Hd., Type B

...................................

..................................

...................................

......................................

..........................................

........................................

.......................................

................................

.................................

..................................

................................

......................................

.......................................

.........................................

......................................

.......................................

.........................................

..........................................

......................................

(Use in Power Input Board) 1

..........................

.........................

.......................

.......................

;

........

.....................

.....................

V.,

.

.

W/Pilot Circuit) (400-460

V.,

..

W/Pilot Circuit) (380

50 Hz., 1 Ph

60 Hz., 1 Ph

..

V.,

.

.

W/Pilot

V.,

60 Hz.,

W/Pilot Circuit)

50 Hz., 3Ph.)

...

....

.............................

.............................

.............................

............................

.......................

....................

............................

....................

............................

.....................

......................

.....................

...............................

...............................

..................

..........................

:

10

.

2

2

2

1

1

1

1

1

1

1

4

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

2

2

4

1

1

1

2

2

2

1

2

2

1

1

1

2

2

1

1

1

1

2

1

1

2

2

2

3

1

1

1

1

1

*110-120

**200

V

.

&

v

.

Above

.

-

13

-

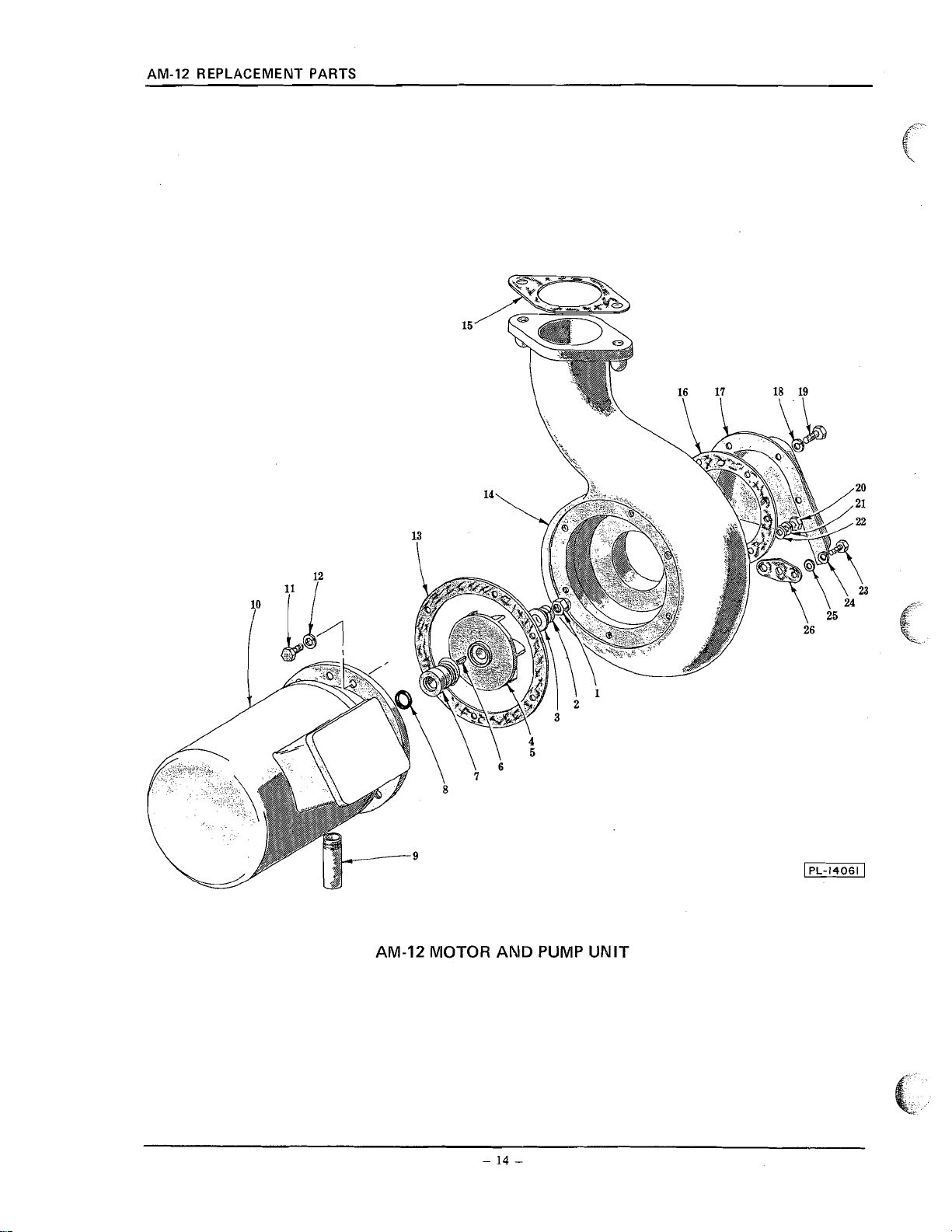

Page 14

Page 15

REPLACEMENT PARTS AM-12

PART

.

NO

NS-246

WL-6-32

WS-21-1

D-118968

D-121567-2

KW-3-3

A-104329

D-67500-7

FP-64-15

ML-18491

SC41-11

WL-6-22

B-119265

E-118961

C-119054

C-119050

C-118960

WL-6-22

SC-41-11

SC41-11

WL-6-22

WS-17-8

SC41-5

WL-6-17

WS-348

B-119051

B-119299-1

B-119299-2

B-119299-3

B-1192994

AM-12 MOTOR

PRIOR TO SERIAL NO . 23-028-320 (AM-12)

NAME OF PART AMT

Acorn Nut . 7116"-20

Lock Washer . 7/16" Light

Washer

...................................................

Impeller (60 Hz.)

Impeller (50 Hz.).

Key . #404 Woodruff

Shaft Seal Assy

-0"Ring

Nipple . 318" x 2-114" Lg . (S.T.O.E.)

Motor (Give Electrical Spec.)

Cap Screw . 5/16"-18 x 314" Hex Hd

Lock Washer

Gasket Kit (Motor to Pump) (One Set consists of: 1 Blue

and 1 Yellow

Shell-Pump

Gasket . Pump Discharge

Gasket . Pump Intake

Shroud . Pump Intake

Lock Washer . 5/16" Light

Cap Screw 5116"-18 x 314" Hex Hd 4

Cap Screw

Lock Washer

Washer

Cap Screw

Lock Washer

Washer

Gasket

AM-12 Motor & Impeller Assy . (60 Hz., 1 Ph.) (Incls . items #1,2,3,4,6,7,

AM-12 Motor & Impeller Assy . (60 Hz., 3 Ph.) (Incls . items

AM-12 Motor & Impeller Assy . (50 Hz., 1 Ph.) (Incls . items #1,2, 3,5,6,7, 8 & 10)

AM-12 Motor & Impeller Assy . (50 Hz., 3 Ph.) (Incls . items #l,2, 3,5,6,7, 8 & 10)

.................................................

.

5/16" Light

(.020" Thk.))

...............................................

.

.

5116"-18 x 314" Hex Hd

.

5/16" Light

...................................................

.

114"-20 x 518" Hex Hd

.

...................................................

.

Pump Drain Hole

........................................

.......................................

.............................................

............................................

..........................................

..

518"

..........................................

.......................................

.......................................

........................................

..........................................

..........................................

.......................................

.......................................

114" Medium

........................................

AND PUMP UNIT

12-052-786 (AM-1 2)

12-052-922 (AM-1 2C)

..................................

......................................

.................................

(.005" Thk.); 1 Brown (.OIOn Thk.);

.................................

.................................

..................................

......................................

8

&

10)

#I,

2,3,4,6,7, 8 & 10)

.....

.....

.....

.....

1

Set

.

1

1

1

1

1

1

1

1

1

1

6

6

1

1

1

1

4

2

2

2

2

2

2

1

1

1

1

1

*Select gasket to obtain . 005" to . 015" clearance between pump and impeller

.

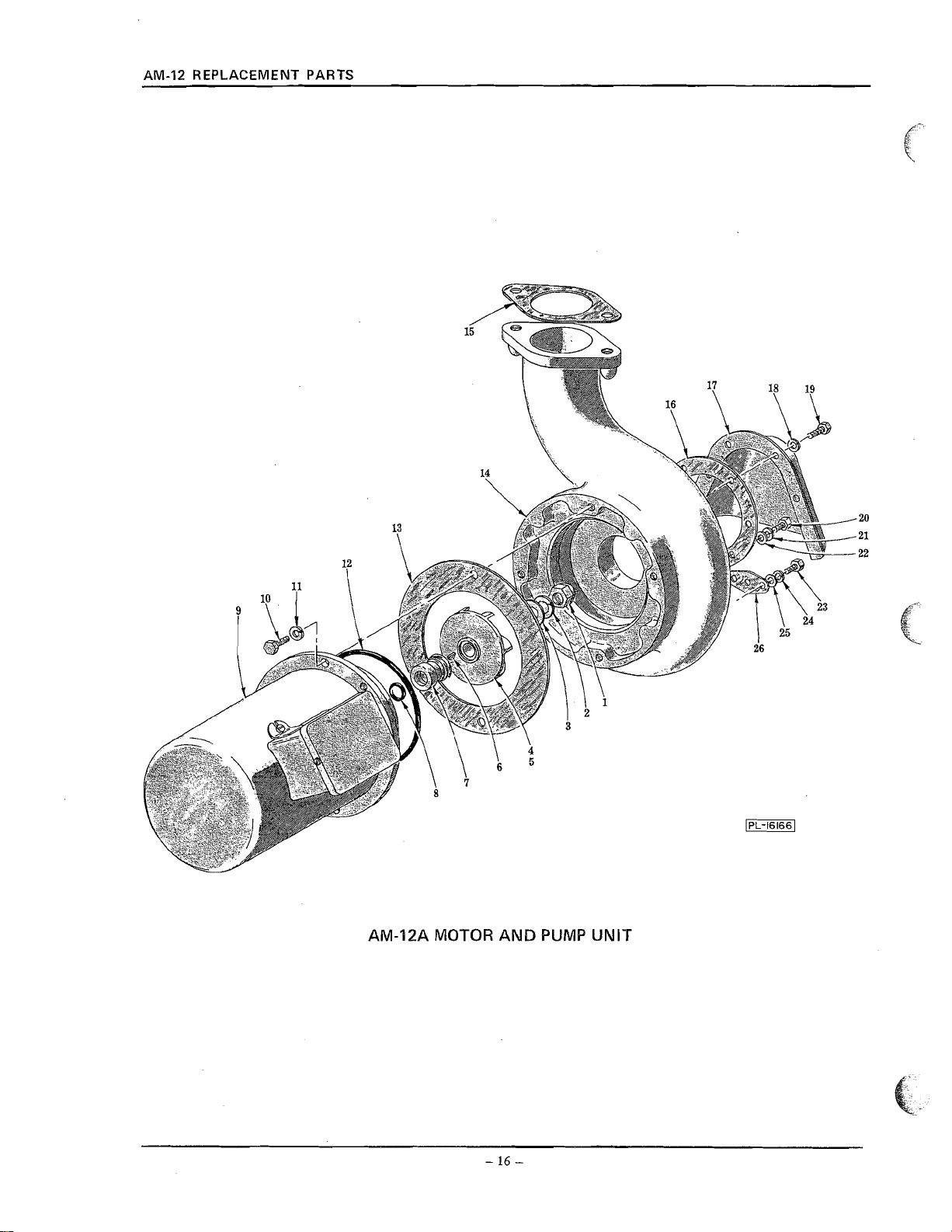

Page 16

SlkiVd lN3VU33VId3tl ZL-VUV

Page 17

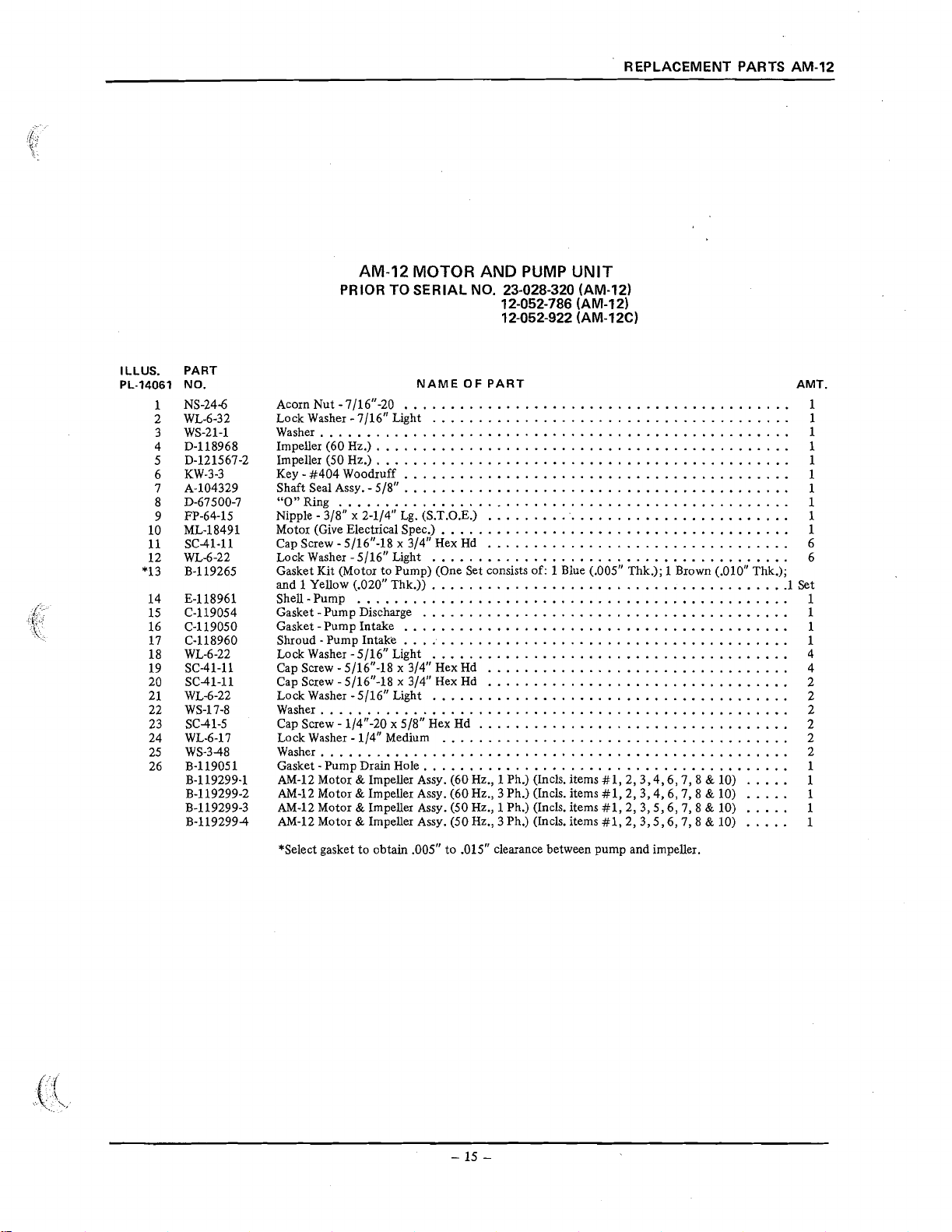

AM-12A MOTOR AND PUMP UNIT

FIRST SERIAL NO . 23-028-320 (AM-12)

12-052-786 (AM-1 2)

12-052-922 (AM-IZC)

REPLACEMENT PARTS AM-12

l-

\

ILLUS . PART

PL-16166 NO

1

2 WL-6-32

3 WS-21-1

4 D-118968

5 D-121567-2

6 KW-3-3

7 A-104329

8 D-67500-7

9 ML-34217

10 SC-41-29

11 WL-6-27

12 D-67500-97

*13 B-277836

14 E-276281

15 C-119054

16 C-119050

17 C-118960

18 WL-6-22

19

20 SC-41-11

21 WL-6-22

22 WS-17-8

23 SC-41-5

24 WL-6-17

25 WS-3-48

26 B-119051

.

NS-24-6

SC-41-11

B-277786-1

B-277786-2

B-277786-3

B-277786-4

NAME

OF

PART AMT .

Acorn Nut . 7116"-20

Lock Washer . 7/16" Light

Washer

...................................................

Impeller (60 Hz.)

Impeller (50 Hz.)

Key . #404 Woodruff

Shaft Seal Assy

"0"Ring

Motor (Give Elec

Cap Screw 318"-16 x 718" Hex Hd

Lock Washer

"0"Ring

Shim Kit (Motor to Pump) (One Set consists of: 1 Blue (.005" Thk.); 1 Brown (.010" Thk.);

and 1 Yellow

Shell-Pump

Gasket -Pump Discharge

Gasket . Pump Intake

Shroud -Pump Intake

Lock Washer

Cap Screw 5116"-18 x 314" Hex Hd 4

Cap Screw

Lock Washer

Washer

Cap Screw

Lock Washer

Washer

Gasket

AM-12A Motor & Impeller Assy . (60 Hz.. 1 Ph.) (Incls . items #1.2.3.4.6,7.8. 9 & 12)

AM-12A Motor &Impeller Assy

AM-12A Motor & Impeller Assy . (50 Hz., 1 Ph.) (Incls . items #1.2.3.5.6,7.8. 9 & 12)

AM-12A Motor &Impeller Assy . (50 Hz., 3 Ph.) (Incls . items #1.2.3.5.6.7.8,

.................................................

.

.

.................................................

(.020" Thk.))

.

511 6" Light

.

.

5116"-18 x 314" Hex Hd

-5116" Light

..................................................

.

114"-20 x 518" Hex Hd

.

...................................................

-Pump Drain Hole

..........................................

.......................................

.............................................

..............................................

..........................................

..

518"

..........................................

.

Spec.)

........................................

..................................

318" Light

........................................

.......................................

...............................................

........................................

........................................

..........................................

........................................

.................................

.................................

.......................................

..................................

114" Medium

......................................

........................................

...

.

(60 Hz., 3 Ph.) (Incls. items #1.2. 3.4,6,7.8. 9 & 12)

9

...

...

&

12)

...

1 Set

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

4

2

2

2

2

2

2

1

1

1

1

1

*Select shims to obtain . 005" to . 012" clearance between pump and impeller

.

Page 18

Page 19

REPLACEMENT PARTS AM-12

MOTOR

(AM-1 2A = M L-34217)

(AM-1 2

PART

NO

.

C-119858-2 Switch Starting (Stationary Part) 1

SC-949

D-114379-3 Bracket

D-114379-2 Bracket

D-111493-1 Fan . Ventilating

R-77067 Cover -Motor End

SC-9-65

SL-24 Loading Spring

RR4-17 Retaining Ring

BB-20-18 Ball Bearing

SC-81-76 Mach Screw #lo-24 x 7" Rd Hd 4

WL-8-13 Lock Washer #10 Int Shakeproof 4

D-113403 Box

SD-15-27

WL-7-12 Lock Washer #10 Ext Shakeproof 2

SD-1245

M-60395 Grommet

M-79118 Bushing

M-80369 Bushing . Snap (Field Ring)

SD-1245 Self-Tapping Screw #8-32 x 5/16" Pan Hd., Type 23 2

C-113405 Cover -Terminal Box

B-114811 Gasket . Terminal Box Cover

C-113417 Connector Block Assy

C-113552 Terminal Block Base Assy

D-65477-147-1 Stator Assy (100-1 15 V.1200.230 V 60 Hz.) 1

D-65477-147-2 Stator Assy (110-120 V.1220.240 V 50 Hz.) 1

D-65478-110-1 Stator Assy (200-230 V./400-460 V 60 Hz.) 1

D-65478-112-1 Stator Assy (200-240 V./346-415 V 50 HZ.) 1

C-22275-208 Rotor Assy

C-22275-207 Rotor Assy (100-120 V./200.240 V 50 Hz.)

C-15747-288 Rotor Assy (200-230 V./400.460 V 60 Hz.) (200-240 V.1346.415 V 50 Hz.) 1

B-104725 Capacitor Cover

D-704876 Capacitor

M-89258 Retainer . Capacitor

SD-15-3 Self-Tapping Screw #lo-24 x 114" Pan Hd "Taptite" 2

WS-2-15 Washer (Shims screw to prevent bottoming) 2

BB-20-18 Ball Bearing

E-121191-1 Bracket Bearing (Pump End) (60 Hz.) (AM-12A Only) 1

E-121191-2 Bracket Bearing (Pump End) (50 Hz.) (AM-1 2A Only) 1

E-118969-1 Bracket Bearing (Pump End) (60 Hz.) (AM-12 Only) 1

E-118969-2 Bracket Bearing (Pump End) (50 Hz.) (AM-1 2 Only) 1

B-118070-1

.

.

Screw . #6-32 x 318" Rd . Hd

Mach

.

Bearing (Fan End)

.

Bearing (Fan End)

.............................................

.

Screw . #8-32 x 1/4" Rd . Hd

Mach

............................................

.

N.D. #S-17

..............................................

.

N.D. #77503

.

.

.

.

Terminal

Self-Tapping Screw

Self-Tapping Screw

..............................................

.

.

.

.................................................

.

Snap (Field Ring)

.

. ..

.

.

.

.

(1

00-1 20 V./200.230 V 60 HZ.) 1

.

.

&

Insulator Assy

................................................

.

.

N.D. #77503

.

.

.

Plug (Not Shown) (Use with items

.

NAME

......................................

......................................

......................................

.......................................

.

.

#lo-24 x 5/16" Pan Hd . "Taptite"

.

#8-32 x 5/16" Pan Hd., Type 23

.......................................

.......................................

..........................................

......................................

..........................................

........................................

...........................................

.......................................

UNIT

=

ML-18491)

OF

PART AMT

...................................

..................................

..................................

..................................

..................................

......................

..................................

.......................

.......................

............................

..

..

..

..

..

..

............................

............................

............................

............................

............................

..

........

...................................

.

.......................

.............................

......................

......................

.......................

#38,39, 40 & 41)

.......................

........................

.

2

1

1

1

1

2

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

*1 Phase

**3 Phase

.

.

Page 20

LNUV HSVM U3MO1

llNn

Page 21

REPLACEMENT PARTS AM-12

ILLUS . PART

PL-16196

NO

.

1 D-119032

2 D-67500-57

3 SC-41-30

4 WL-6-28

5 E-118973-2

6 B-119034

7 B-119229

8 C-119222

9 B-119227

10 D-119198

11 WL-6-7

12 SC-21-21

13 M-24160

14 M-22731-3

15 M-74046

16 R-89159

17 C-119087

18 M-21110

19 V-21137

20 SC-21-14

21 D-67500-57

22 WL-6-1

23 SC-50-26

24 R-89158

C-119113

LOWER WASH ARM

UNIT

(THRUST WASHER TYPE)

NAME

OF

PART

Tube-Wash

"0"Ring

Cap Screw 318"-16 x 1" Hex Hd

Lock Washer

Tee . Lower Wash

Shaft . Lower Wash Arm

Spring . Compression

HubAssy

Washer . Thrust

Wash Arm & Hub Assy . (Incls . items #8,9, 11 & 12)

Lock Washer #10 Medium

Mach Screw #lo-24 x 114" Rd Hd

Rinse Arm Bearing Pin & Thrust Washer Assy

Nozzle Rinse

Plug Rinse Arm

Arm

Rinse Arm Body Assy . (Incls . item #18)

Bearing . Rinse Arm

Plate . Pivot Bearing

Mach Screw #8-32 x 318" Rd Hd

"0"Ring

Lock Washer #8 Light

Set Screw #lo-24 x 318" Sq Hd., Cup Pt

Arm Outside Rinse

Lower Rinse Arm Assy

................................................

.................................................

.

.

318" Medium

...................................

......................................

............................................

........................................

..........................................

.................................................

..............................................

.

.

.

.......................................

.

.................................

............................

.

.

.

Inside Rinse

..............................................

..............................................

............................................

...............................

...........................................

...........................................

.

.

.

..................................

.................................................

.

.

.

.........................................

.

..............................

...........................................

.

(Incls . items #14 thru 20,22, 23 & 24)

........................

..................

AMT

1

.

Page 22

Page 23

REPLACEMENT PARTS AM-12

LOWER WASH ARM

UNIT

(BALL BEARING TYPE)

ILLUS . PART

PL-17806-1

i

:

\

.

NO

.

1

D-119032

D-67500-57

2

3 SC-41-30

WC6-28

4

5 E-118973-2

6 B-119034

7 B-286944

8 D-286948

9 BA-2-40

10 D-67500-19

11 C-286947

12 D-287987

13 WL-6-7

14 SC-21-23

15 B-286946

16 B-122440

17 M-22731-3

18 C-122443-2

19 D-122633

20 V-21137

21 SC-21-14

22 D-67500-57

23 WL-6-1

SC-110-44

24

25 C-122442-2

D-122635-2

Tube-Wash

"0"Ring

Cap

Screw . 318"-16

Lock Washer

Tee

.

Shaft

Spacer

Hub

.

Ball

uO"Ring

Retainer

Wash Arm &Hub Assy . (Incls . items #8, 9.10.11. 13 & 14)

Lock Washer

Mach

Bearing Pin & Washer Assy

Pug-RinseArm

Nozzle . Rinse

Arm

Body

Plate

Mach . Screw . #8-32 x 318" Rd . Hd

"OWRing

Lock Washer . #8 Light

Set Screw

Arm

Lower Rinse Arm Assy . (Incls . items #16 thru 21.23, 24 & 25)

................................................

.................................................

.

Lower Wash

.

318'' Medium

............................................

Lower Wash Arm

...................................................

....................................................

114" Dia

.............................................

.................................................

.

Ball

..............................................

.

#

.

Screw

10 Medium

.

#

10-24 x 112" Rd . Hd

.............................................

..............................................

.

Rinse (4 Nozzle Holes)

.

Lower Rinse Arm

.

Pivot Bearing

.................................................

.

5116"-18 x 318" Soc . Hdls., Cone Pt

.

Rinse

(5

Nozzle Holes)

x

1"

Hex Hd

NAME

OF

PART AMT

...................................

......................................

........................................

...................

.......................................

.................................

.

:

.....................................

......................................

........................................

...........................................

..................................

.........................................

...........................

......................................

..................

.

1

1

2

2

1

1

1

1

13

1

1

1

2

2

1

2

9

1

1

1

4

1

4

2

1

1

Page 24

H3ddfl

HSVM

WtJV

LINT\

(MA1 kl3HSWM 1SnklHl)

Page 25

REPLACEMENT PARTS AM-12

PART

NO

.

SC-41-9

WL-6-22

E-118972-2

C-119033

C-119222

B-119227

D-119198

WL-6-7

SC-21-21

C-118978

R-14524

P-103952

UPPER

Cap Screw . 5/16"-18 x 112" Hex Hd

Lock Washer

.

Upper Wash

Ell

Shaft . Upper Wash Arm

HubAssy

Washer-Thrust

Wash Arm & Hub Assy . (Incls . items #5.6. 8 & 9)

Lock Washer . #10 Medium

Mach

Nut -Wash Arm

Core . Rinse Nozzle

Top . Rinse Nozzle

.

5/16" Light

.............................................

.................................................

............................................

.

Screw . #lo-24 x 114" Rd . Hd

.............................................

...........................................

............................................

WASH ARM

(THRUST WASHER TYPE)

NAME

OF

PART AMT

.................................

.......................................

.........................................

........................................

.................................

UNIT

.........................

.

2

2

1

1

1

1

1

2

2

1

1

1

Page 26

AM-12 REPLACEMENT PARTS

ILLUS. PART

PL-17075-1 NO.

1 SC-41-9

2 WL-6-22

3 E-118972-2

4 C-119033

5 D-286948

6 D-67500-19

7 BA-2-40

8 C-286947

9 D-286943

10 WL-6-7

11 SC-21-23

12 C-118978

13 R-14524

14 P-103952

UPPER

(WITH STATIONARY RINSE)

Cap Screw - 5116"-18 x 112" Hex Hd

Lock Washer - 5/16" Light

Ell - Upper Wash

Shaft - Upper Wash Arm.

Hub

....................................................

"0"Ring

Ball - 1/4" Dia

Retainer - Ball

Washer Arm & Hub Assy. (Incls. itmes #5,6,7,8, 10 & 11)

Lock Washer - #10 Medium

Mach. Screw

Nut-WashArm

Core - Rinse Nozzle

Top - Rinse Nozzle

. .

. . . . . . . .

.................................................

.

. . . . . . . . .

.

. . . .

-

#

10-24 x 1/2" Rd. Hd

.............................................

. . . . .

. . . . . .

WASH

(BALL BEARING TYPE)

NAME OF PART

.

. .

. . . . . . . . . . . . . . . . . . .

. . . .

.

.

. . .

. . .

. .

ARM

UNIT

.

. . . . .

. .

. . . . . . . . . . . . . . .

. .

. . . . . . . . . .

. . . .

. . . . . .

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

.

. . . . .

. .

.

.

. .

. . . . . . . . . . . .

. . . . . .

. .

. . . . .

. . . . . . . . . . .

. . . . . . . . .

.

.

.

. . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. .

. . . . . .

. . . . . . .

. . .

. .

.

.

. .

. . . . . . . . . . . . . .

.

. . . . .

. . . . .

.

. . . . . .

. . . . . . .

. . . . . . .

. . . . .

. .

. .

.

. . .

.

.

. .

. . .

. . . . . . . . . . . .

. . .

. . . . . . . . .

.

. . . . .

. . . .

.

. . .

. . . . . . . . .

. . .

. . . . . . .

. . . . .

. .

. . . .

. .

.

. . . .

. . . .

. .

.

.

. .

.

.

.

.

.

AMT.

2

2

1

1

1

1

13

Page 27

REPLACEMENT PARTS AM-12

-1

@-

2

3

.

ILLUS

.

PL-17106-2

PART

1 SC-41-9

2 WL-6-22

3 E-118972-2

4

B-122437

5 D-286948

6 D-67500-19

7 BA-240

8 C-286947

9 D-287987

10 WL-6-7

11 SC-21-23

12 B-122438

13 D-122401

1.4 C-287908

15 B-122440

16 SC-11044

17 B-122632

18 C-122445

19 RR-11-3

20 M-22731-3

21 C-287913

C-287932-2

NO

UPPER

WASH

ARM

UNIT

(BALL BEARING TYPE)

(WITH

.

Cap Screw . 5/16"-18 x 112" Hex Hd

Lock Washer

.

Upper Wash

Ell

Shaft

Hub

"0"Ring

Ball . 1/4" Dia

Retainer

Washer Arm & Hub Assy . (Incls . items #5.6.7.8. 10 & 11)

Lock Washer . #10 Medium

Mach

Upper Rinse Shaft Assy

Hub-RinseArm

Arm

Plug . Rinse Arm

Set Screw 5/16"-18 x 3/8" Soc Hdls., Cone Pt "Nylok"

Washer -Thrust

Handle

Retaining Ring

Nozzle

Arm

Rinse Arm Assy

.

5/16" Light

.............................................

.

Upper Wash Arm

....................................................

.................................................

..............................................

.

Ball

..............................................

.

Screw . #lo-24 x 112" Rd . Hd

.............................................

.

Outside Rinse (5 Nozzle Holes)

.............................................

.

..............................................

...................................................

..............................................

.

Rinse

-Inside Rinse (6 Nozzle Holes)

..............................................

.

(Incls . items #12 thru 21)

ROTATING RINSE)

NAME

OF

PART AMT

.................................

.......................................

.........................................

....................

.......................................

.................................

.........................................

.................................

.

.

.....................

..................................

.............................

2

2

1

1

1

1

1

3

1

1

2

2

1

1

1

2

2

1

1

1

11

1

1

.

Page 28

Page 29

OUTSIDE RINSE PlPllVG UNIT

REPLACEMENT PARTS AM-12

PART

NO

.

C-119290

A-119127

SC41-13

WL-6-22

D-67500-12

SC41-16

WS-17-8

SC41-5

WS-3-48

WL-6-17

NS-15-1

D-119292

D-67500-12

P-63262-26

WL-6-22

NS-15-11

A-106468-5

P-86218

C-119066

A-102516

M-82231

A-102517

M-82236

M-82238

D-67500-59

FE-8-10

FE-6-45

D-119004-2

FE-645

FE-76

P-6819068

FE-7-3

FE-8-10

C-277915

NS-15-11

WL-6-22

SC41-15

C-276678

B-277 11 2

B-118270

C-119291

M-74338

A-104729

*M-74343

B-112062-1

NAME OF PART AMT

Connector Assy . (Rinse to Vacuum Breaker)

.

118" Sq

.

Plug

Cap Screw

Lock Washer

"0"Ring

Cap Screw . 5/16"-18 x 1-318" Hex Hd

Washer

Cap Screw

Washer

Lock Washer

Full Nut

Bracket

"0"Ring

Flange & Nipple Assy

Lock Washer

Full Nut . 5116"-18 Hex Fin

Solenoid Valve

Pet Cock

.....................................................

Tee

Line Strainer (314") (Incls . items #21,22, 23, 24 & 25)

Screen

.

Plate

Clamp

Thumb Screw

"0"

Ring (314" Line Strainer)

112" Gasket Assy

Connector

Conduit

Connector

Connector . Straight "Sealtite" (112" Female Thd

Conduit . 3/23'' x 25" (Waterproof)

Connector . 90' "Sealtite" (112" Male Thd . x 318" Flex Cnd.)

112" Gasket Assy

Gauge -Water Pressure

Full Nut . 5/16"-18 Hex Fin

Lock Washer

Cap Screw . 5116"-18 x 1-114" Hex Hd

Connector Assy . (Vacuum Breaker to Solenoid)

Vacuum Breaker . 314" (Incls . item #40)

Float Assy & Bonnet Gasket Service Kit (Vacuum Breaker)

Connector Assy . (Vacuum Breaker to Solenoid) 1

Vacuum Breaker

Cap

.

Vacuum Breaker

Vacuum Breaker Float

.

Solenoid (1 15 V.)

Coil

Hd . Pipe

.

5116"-18 x 1" Hex Hd

.

5/16" Light

.................................................

..................................................

.

114"-20 x 518" Hex Hd

..................................................

.

114" Medium

.

114"-20 Hex Fin

.

Outside Rinse Piping

.................................................

.

5/16" Light

.

.

114"

(314" Line Strainer)

Seal (314" Line Strainer)

(314" Line Strainer)

......'.........................................

.

Straight (112" Male Thd . x 112" Thinwall)

.

112" (Low Water Protection Box to Coupling)

.

Straight (112" Male Thd . x 112" Thinwall)

.

5/16" Light

.

.........................................

...................................

.......................................

......................................

.......................................

.....................................

..........................................

.......................................

.......................................

314" (1 15

V.,

50160

..............................................

.......................................

....................................

.......................................

.....................................

.............................................

...................................

.............................................

..........................................

......................................

.......................................

.

314" (Incls . item #43)

..........................................

&

Seal Assy

.........................................

.............................

................................

..................................

Hz.)

..............................

......................

.......................

......................

.......................

.

x

318" Flex . Cnd.)

.

..............

..................

................................

...........................

...............................

....................

...........................

...............................

..................................

.

'

1

1

2

2

1

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

*Use with SLOAN Vacuum Breaker

**Use with WATTS Vacuum Breaker

.

.

Page 30

SltlVd lN3VU33Vld3tl ZL-WV

Page 31

ZL-INV SlHVd .LN3VU33Vld3H

srni

I

T

Z

E

L

OT

ZT

E

T

LT

OZ

IHV~

'ON

1-9LOLL-ld

ZZ-12-3s

L-9-TM

P668IT-'3

OLO6IT-3 P

IT-ST-SN S

ZZ-9-?M 9

ZZ-9-TM 8

OPTV3S 6

PZSPT-ZI

ZS6EOT-d 11

01-TV3S

ZZ-9-TM

6-OOSL9-a PT

PE89LZ-a ST

7-S6681T-3

6-OOSL9-a 81

ZZ-9-?M 67

01-IV3S

~301

ZT-OOSL9-a

ZT-OOSL9-a 91

"0.9

aro3

do^

de3

"O,,

"O,,

"O,,

-

j~oddns

-

JnN Ttnd

%ux

Ma13S de3

-

-

-

~u!ZI

2ux

ZU!~

Mal3S de3

-

Mal3S 'Y3eH

-

IaqseM

-

ra9seM Wo'I

-

WseM Vo?

-

-

Mal3S

-

IazlseM Wo?

-

IaqseM V0-I

-

/S

rol3auuo3 asu!x

T

OT#

Lssv ad!d as48 ~addn

,,9T/S

aIzzoN asy

a1zzoN asux

9

Lssv ropauuo3 asu!X

'

mn!paK

ad!d asurx raddn

u!d XaH 81-,,9T/S

lzl8!1,,9

l@!?

l9%!1,,9 I/S

Lssv alue~d

lzl211 ,,9T/S

dO

3WVN

PH 'PZI ,,8/£ x PZ-OT#

PH XaH ,,8/S x 81-,,9T/S

.

PH XaH ,,8/S x 81-,,9I/S

PH XaH ,,8/S x 81-,,91/S

IHVd

.................................

......................................

.........................................

.......................................

......................................

.......................................

.................................................

.......................................

.................................

...........................................

............................................

................................

.......................................

.................................................

.....................................

.................................................

...........................................

.................................................

.......................................

.................................

Page 32

Page 33

INSIDE RllUSE PIPING UNIT

(LOW WATER CONSUMPTION)

REPLACEMENT PARTS AM-12

ILLUS. PART

PL-17807-1 NO.

1

D-67500-12

2 WL-6-22

3 SC-41-10

4 D-287947

5 SC-41-9

6 WL-6-22

7 D-67500-9

8 D-276834

9 D-67500-9

10 WL-6-22

11 SC-41-9

NAME OF PART AMT.

"0"Ring

Lockwasher-5/16"Light

Cap Screw

Upper Rinse Pipe Assy

Cap Screw - 5/16"-18 x 112" Hex

Lock Washer

"0"Ring

Rinse Connector

"0"Ring

Lock Washer - 5/16" Light

Cap Screw

.................................................

-

5116"-18 x 518" Hex Hd

-

5/16" Light

. . . . . . . . . . . .

. .

.

. .

.

.

.................................................

&

Flange Assy

.................................................

.

-

5/16"-18 x 112" Hex Hd

.

. . . .

. . .

.

. . . .

.

..

. . .

.

.

.

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hd

.

.

. . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . .

. . . .

. . . . .

. .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

.

.

. .

.

. .

. . . . . .

. . .

.

. .

.

. .

. . . .

.

.

.

. . . . . . . . . .

. . .

.

. . . . . . . . . . . .

. . .

.

.

. . . . . . . . . .

. . . . . . . . . . . . . . .

.

.

. . . . .

. .

.

.

.

..

. . . .

.

. .

. . .

.

. .

.

.

. . . . .

.

. .

.

.

. .

. .

. .

.

.

.

.

.

. .

1

.

2

.

2

.

1

.

2

2

1

1

1

.

2

2

Page 34

Page 35

DOOR INTERLOCK UNIT

REPLACEMENT PARTS AM-12

PART

NO

.

13-119062

VJL-6-17

NS-15-1

FE-8-10

FE-6-45

D-119004-1

B-119065-1

FE-6-45

FE-7-6

P-68190-5

FE-7-1

WL-6-7

WS-19-6

SC-21-34

D-288490

SC-2 1-25

B-288455

WS-29-10

WL-6-7

NS-11-18

B-106803

B-288456

SD-25 -1 2

B-119075

C-119057

B-119300

SD-12-35

NAME OF PART AMT

Retainer . Conduit

Lock Washer

Full Nut

112" Gasket Assy

Connector . Straight (112" Male Thd

Conduit . 112" Thinwall (Heat Box to Coupling)

Bracket

Connector

Connector

Conduit . 318" x 11" (N"v'terproof)

Connector

Lock Washer

Washer

Mach

Housing

Mach

Spacer

Washer

Lock Washer

Mach

Gasket

Interlock Switch

Self-Tapping Screw

Retainer

Magnet -Door Interlock Switch

Gasket

Self-Tapping Screw

.

114"-20 Hex Fin

.

Conduit

.

.

.

...................................................

.

Screw . #lo-32 x 1-314" Rd . Hd

.

Interlock Switch

.

Screw

&

Insert Assy

...................................................

.

Nut . #lo-24 Hex

.

Interlock Switch

.

Magnet

.

Magnet Retainer

............................................

.

114'' Medium

......................................

.......................................

.............................................

.

x

1/2" Thinwall)

.......................

...........................

............................................

Straight (112" Male Thd . x 112" Thinwall)

Straight "Sealtite" (112" Male Thd . x 318'' Flex . Cnd.)

.......................

................

...................................

Straight "Sealtite" (112'' Male Thd . x 318'' Flex . Cnd.)

.

#10 Medium

.......................................

................

................................

.......................................

.

#

10-24 x 314" Rd . Hd

.................................

...........................................

.

#

10 Medium

.......................................

........................................

........................................

&

Cover Assy

.

#8-18 x 112" Phil . Pan Hd . "Shakeproof"

.....................................

..................

............................................

....................................

........................................

.

#8-32 x 1/2" Phil . Pan Hd., Type 23

.....................

.

1

1

1

1

1

1

1

1

1

1

1

2

2

2

1

2

1

2

2

2

1

1

2

1

1

1

2

Page 36

AM-12 REPLACEMENT PARTS

PART

NO.

E-119006-2

B-119103

PC-5-2

C-119236

D-112378-23

E-119006-1

D-119133

NS-18-6

WS-17-8

C-119168

SC-21-23

WL-6 -7

C-119086

B-119007

DOOR

(STRAIGHT THRU INSTALLATION)

NAME

Door

-

Counterbalanced (L.H.) .

-

Flat Hd

Rivet

Cotter Pin

Latch - Inspection Door

Guide-Door

Door - Counterbalanced (R.H.)

Door

&

Jam Nut

Washer

Bracket

Mach. Screw - #lo-24 x 1/2" Rd. Hd

Lock Washer

Bumper -Door Stop

Door Stop Assy

. . . .

-

1/16" x 112"

. . . . . . .

.

.

. . . . . . . . . .

.

. .

.

..............................................

Lift Assy. (NonCounterbalanced) .

-5116"-18 Hex Fin . .

..................................................

-

Door Lock .

-

.

. . .

#I0 Medium.

.

. . . .

. . . . . .

. .

. . . . .

. .

.

. . .

UNIT

OF

PART AMT

. . . . .

. . . . . . . . . . . . . . . .

. . .

. .

. . . . .

. . . . .

. . . .

.

. . . . .

. . . . . . .

. . .

. .

.

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. .

. . . . . .

. . .

.

. . . . . . . .

. .

.

. . . .

. .

. .

. . . . . . . . . . . . . . . . . . .

. . .

. . .

. . .

. . .

. . . . . . . . . . . .

. . .

. .

. . . . . . . . . . . . . . . .

. . . . .

. . .

. . . . . . . . .

. . . . . . . .

. . . . . . . . . . .

. .

. . .

. . . . .

. .

.

. .

. . . . . . . .

. . .

. .

. . . . .

. .

.

.

. . . . .

.

. .

.

. . .

.

. . . . .

. . . .

. . . . . . . . . . . . . . . .

.

.

.

. . . .

. . . .

. . . . . . . .

. .

.

. . . . . . . . . . .

. .

. .

. .

. . . .

. .

. . . . . .

. . . . .

. .

. . .

. .

. . . . .

. . .

.

.

. . . . . . . .

. . . . . . . . . .

. . .

. .

. . .

. . . . . . . . .

.

. 1

.

.

.

1

1

1

6

1

1

2

2

1

2

2

2

2

Page 37

REPLACEMENT PARTS AM-12

ILLUS. PART

PL-14405

NO.

1 E-119005

2 E-119098

3 E-119006-1

4 D-112378-23

5 SC-21-23

6 WL-6-7

7 C-119086

8 B-119007

Door - Inspection.

Door

-

Counterbalanced (Front)

-

Counterbalanced (R.H.)

Door

Guide-Door

Mach. Screw

Lock Washer

Bumper

Door Stop

...............................................

-

#lo-24 x 112" Rd. Hd

-

#10 Medium

-

Door Stop

Assy

. . . . . . .

DOOR