Page 1

AHP SERIES ROLL-IN PROOF BOXES

MODEL

Proofers

AHP1S

AHP2S

AHP3S

AHP1D

AHP2D

Proofer-Retarders

AHPR1S

AHPR2S

AHPR3S

AHPR1D

AHPR2D

Thaw Proofers

AHTP1S

AHTP2S

AHTP3S

AHTP1D

AHTP2D

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 19410 Rev.A (Aug. 2000)

Page 2

Table of Content

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ACCOMMODATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PLUMBING CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

WATER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DRAIN CONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

ELECTRICAL CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembly Drawings

Models AHP2S, AHPR2S, & AHTP2S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Models AHP3S & AHPR3S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Models AHP1D, AHPR1D, & AHTP1D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Models AHP2D & AHPR2D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Models AHPR- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AHP Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AHPR Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AHTP Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Temperature Controller (E5CX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 DAY TIME SWITCH (H5S) — Model AHPR Proofer-Retarder only . . . . . . . . 23

To Erase Times Stored in P1 and P2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Timer Memory Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setting the Current Day-of-the-Week and Time-of-Day. . . . . . . . . . . . . . . . . 24

Programming Start and Stop Times for P1: Proofer Functions . . . . . . . . . . . 25

Programming Start and Stop Times for P2: Retarder Functions. . . . . . . . . . 27

Programming a Pause or Time Delay Between Two Programs . . . . . . . . . . 29

Planning Your Weekly Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Programming an Operation For Longer Than One Day. . . . . . . . . . . . . . . . . 30

Reviewing and Changing the Set Times for either P1 or P2 . . . . . . . . . . . . . 30

Reviewing the Set Times for Both P1 and P2 from the Run Position . . . . . . 30

Day Override: Temporarily Copying Program(s) from One Day-Of-The-Week

to Another. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Running a Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

In Case of Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

HUMIDIFIER, HEATER, AIR FILTER, AND FAN UNIT. . . . . . . . . . . . . . . . . . . . . . . 33

DOOR CLOSER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

RETARDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

PROOFING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

– 2 –

Page 3

Installation, Operation, and Care of

AHP SERIES PROOFERS

SAVE THESE INSTRUCTIONS

GENERAL

The AHP Series Roll-In Proof Boxes proof racks of dough products under controlled temperature and

humidity prior to baking. The proof boxes have three basic equipment options: Proofers (AHP models)

are equipped to proof dough only; Thaw-Proofers (AHTP models) are equipped to proof and/or to

re-awaken frozen dough; and Proofer-Retarders (AHPR models) are equipped to proof the dough and

then chill it or slowly thaw and then proof the dough prior to delayed baking. A programmable 7 day

time switch controls proof and retard cycles on AHPR models; two individual timers, operating

sequentially, control thaw and then proof cycles on AHTP models. All AHP Series Proofers have easyto-clean stainless steel interior and exterior panels with sandwiched urethane foam insulation.

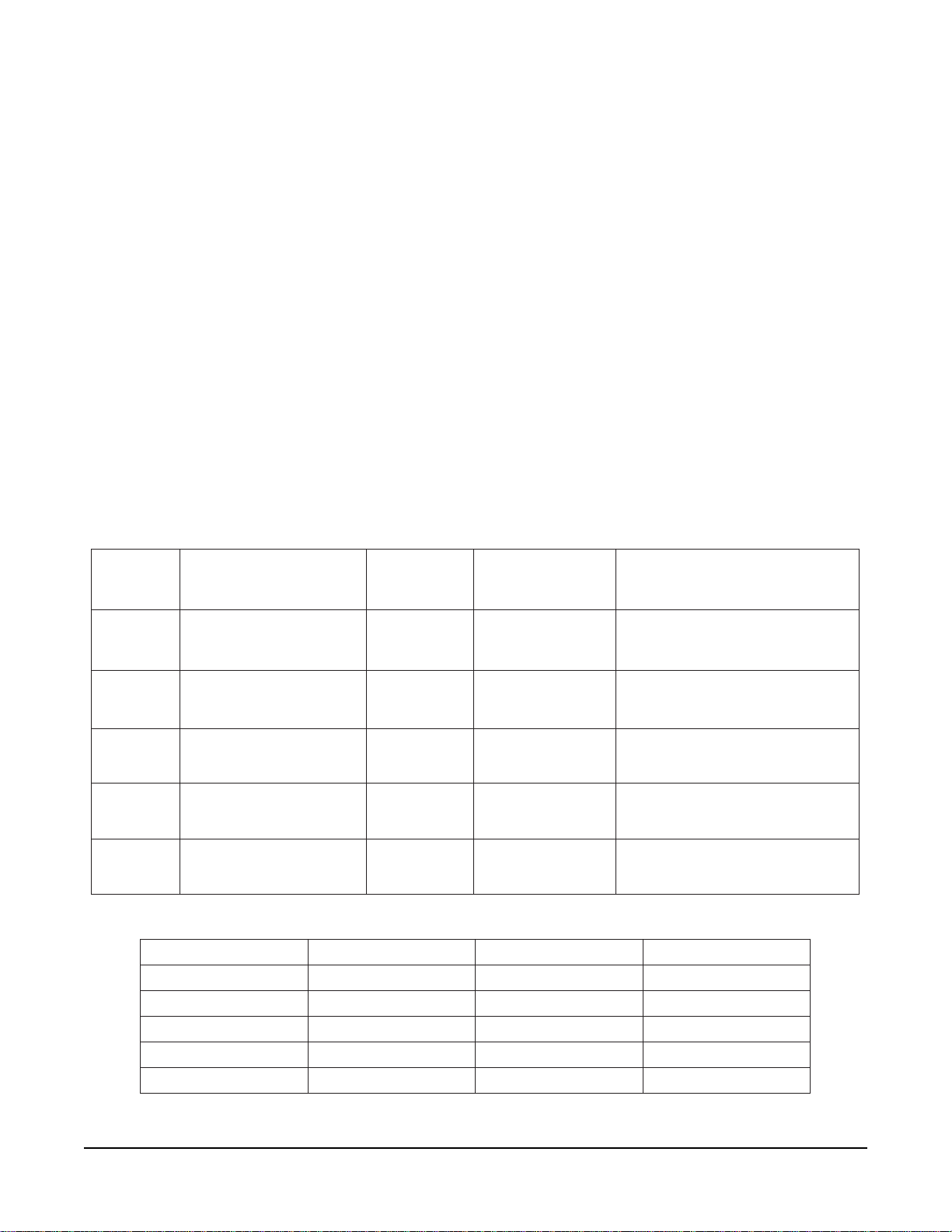

Different size proof boxes accommodate rack(s) as follows:

NOITADOMMOCCA

SNOISNEMIDREBMAHC

LEDOM

)sehcni()sehcni(

)sehcni()sehcni(

)sehcni(

S1PHA

S1PTHA

S1RPHA

S2PHA

S2PTHA

S2RPHA

S3PHA

S3PTHA

S3RPHA

D1PHA

D1PTHA

D1RPHA

D2PHA

D2PTHA

D2RPHA

ledoMegatloVPHtnaregirfeR

S1RPHA5113/1431R

S2RPHA0222/1431R

S3RPHA0224/3431R

D1RPHA0222/1431R

D2RPHA0224/3431R

thgieHxhtpeDxhtdiWthgieHxhtpeDxhtdiW

thgieHxhtpeDxhtdiWthgieHxhtpeDxhtdiW

thgieHxhtpeDxhtdiW

57x9.23x5.321

57x9.23x5.322

57x9.23x5.323

57x52.64x52.331

57x52.64x52.332

FOREBMUN

SREBMAHCSREBMAHC

SREBMAHCSREBMAHC

SREBMAHC

SNOISNEMIDNAP

htdiWxhtgneLhtdiWxhtgneL

htdiWxhtgneLhtdiWxhtgneL

htdiWxhtgneL

)sehcni()sehcni(

)sehcni()sehcni(

)sehcni(

ro62x81

03x02

ro62x81

03x02

ro62x81

03x02

ro62x81

03x02

ro62x81

03x02

epyTtnaregirfeR&snoitacificepStinUrosserpmoC

SKCARFOREBMUN

DETADOMMOCCADETADOMMOCCA

DETADOMMOCCADETADOMMOCCA

DETADOMMOCCA

kcaRelgniS1

skcaRelgniS2

skcaRelgniS3

skcaRelgniS2roelbuoD1

elgniS4ro,skcaRelbuoD2

2sulpkcaRelbuoD1ro,skcaR

skcaRelgniS

– 3 –

Page 4

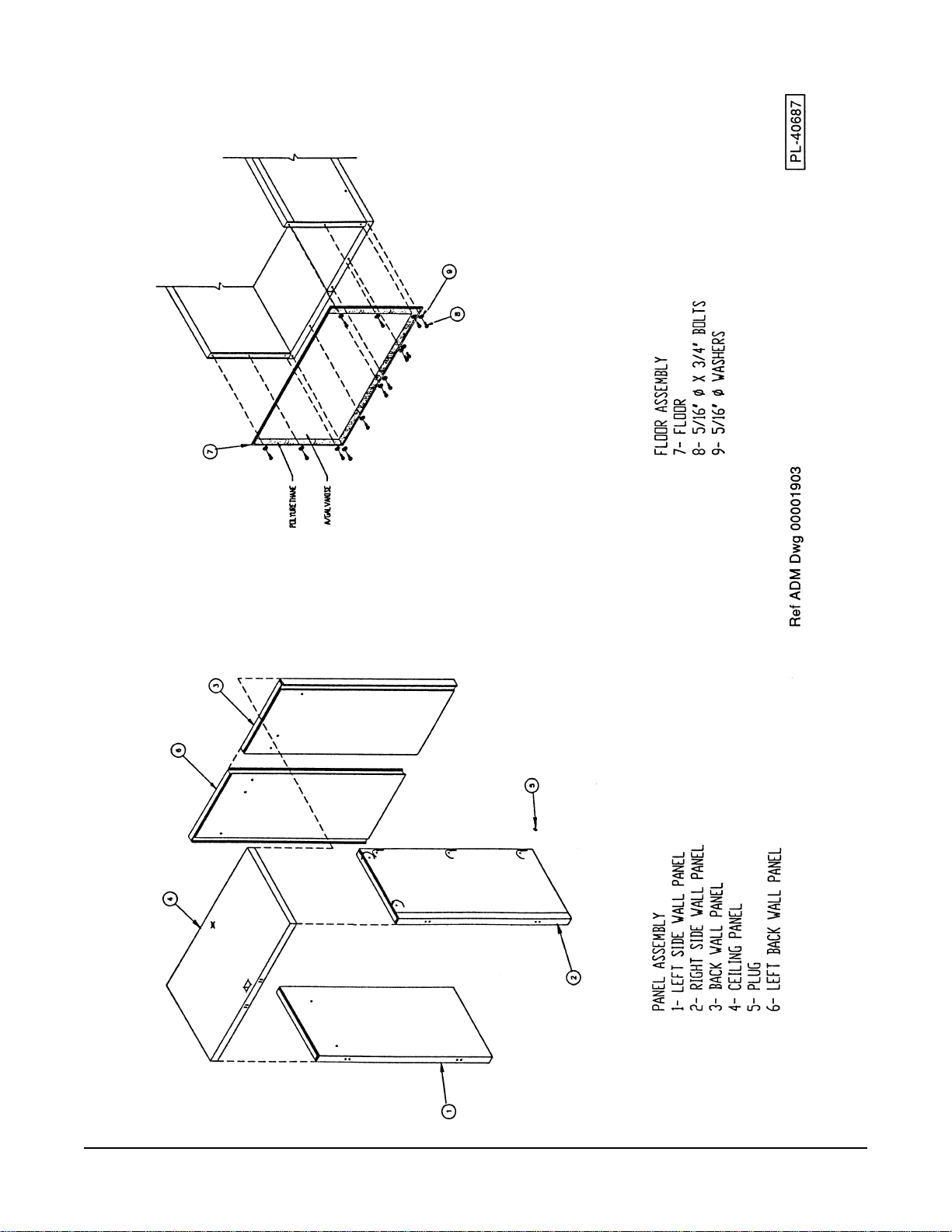

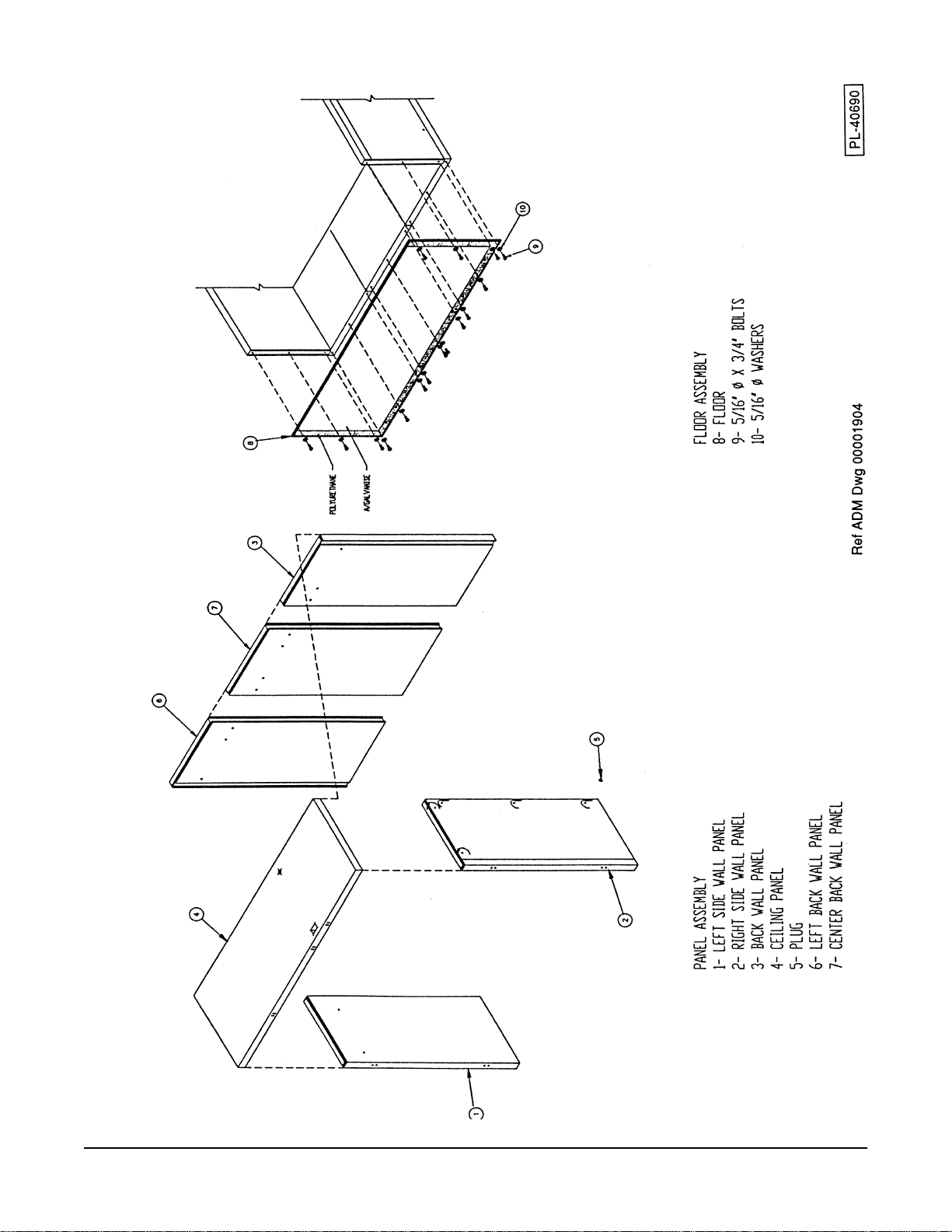

INSTALLATION

ASSEMBLY

Models AHP1S, AHPR1S, and AHTP1S are shipped completely assembled from the factory. Other

AHP Series Proofers are shipped knocked-down for installation on the job site. Ceiling and wall panels

are locked together with cam-locks; the floor is fastened to the wall panels with stainless steel screws.

Correctly install proofers following these step-by-step instructions:

1. If there are two or more back panels, place the back panels [B] in vertical, upright position. Insert

the hex wrench in the lock hole and turn clockwise until the locking arm strikes the pin in the adjacent

panel, locking panels together. If lock fails to engage, turn wrench counterclockwise and again turn

wrench clockwise until panels are properly locked together.

2. Tilt the assembled back panel(s) and lay them on the floor with the exterior side down.

3. Select the left side wall panel [S1]; place it in position with the back panel assembly; and, lock them

together with the cam lock by turning the hex wrench clockwise. Make sure top and bottom edges

of side and back panels are flush.

4. Repeat step 3 with the right side wall panel [S2].

5. Fasten the floor to the bottom of the back and side panels with stainless steel screws.

6. Place the roof panel [C] in position with the walls. First lock the roof panel [C] and the left side wall

panel [S1] by turning the hex wrench clockwise; then, lock the roof panel [C] and the right side wall

panel [S2] by turning the hex wrench counterclockwise.

7. The proofer box can now be put in an upright position.

8. For AHP and AHTP models: Lock the roof panel [C] to the back wall assembly by turning the hex

wrench clockwise.

9. For AHPR models:

a. Unlock the roof and side panel cam locks and install the mullion module (see pages 19 – 21).

b. Lock the roof and side panel cam locks.

c. Seal all joints between panels, ceiling, and floor with an NSF approved sealant, provided.

d. Assemble brass couplers, sight glass, and filter to the refrigeration lines on the evaporator and

condensing unit.

e. Install permagum around the refrigeration lines, add fiberglass insulation, and install sheet metal

covers on the ceiling (inside) and roof (outside) where refrigeration lines go through the ceiling.

f. Set the condensing unit on the top of the cabinet with the condensing coil facing front and the

refrigeration lines aligned. Fasten the condensing unit in place.

g. Connect the electric wires from the condensing unit to the controls: Pass wires through ceiling

to the opening for the controls and attach them to the terminal block. (220Volt: Wire 12 to

Wire 16 to

h. After completing steps 11 - 21, charge the refrigeration system with appropriate R22 or R134

refrigerant and install the condensing unit cover to the front at the top of the cabinet. For all

models: Low pressure Cut-Out = 13 psig; High pressure Cut-In = 22 psig.

10. For AHP and AHTP models: Seal all joints between panels, ceiling, and floor with an NSF approved

silicone sealant, provided. Slide the humidifying unit into place and fasten it to the ceiling and the

floor; the top and bottom cover plates of the control panels should be removed to allow access to

the mounting slots. It is recommended that the side cover of the humidifying unit be removed during

installation. On completion, seal humidifying unit at ceiling and floor using an NSF approved

silicone sealant, provided.

TB16, and Gnd to Gnd. 120Volt: Wire N to TBN, Wire 16 to TB16 and Gnd to Gnd).

TB12,

– 4 –

Page 5

Steps 11 - 22 apply to all models:

11. Mount the bumper(s) at the upper part of the humidifying unit; fasten at front and back of control

panel by screwing bracket(s) to the wall with two stainless steel screws, each. Also mount the

bumpers on the back and side panels. Seal bumpers to walls and doors with an NSF approved

silicone sealant, provided.

12. Mount the hinge pin assembly to the front side wall(s). Place one nylon spacer behind each hinge

pin assembly.

13. Mount the white plastic halves with spacers on the door(s) but do not tighten screws.

14. Hang the door on the hinge pin assemblies: Carefully align the door with the door frame; press

against the door to make sure the seals are tight against the frame; and, tighten the white plastic

halves of the hinges making sure they are straight. If there are two or more doors, mount them in

the same way.

15. Mount the outside door handle/bumper and the inside bumper by screwing to the door and sealing

with an NSF approved silicone sealant, provided.

16. Mount the bracket for the door closer on the top of the door. Mount the hydraulic door closer (see

Fig. 47 on page 33.

17. Place the drain pan at the bottom of the humidifying unit. Fasten the plastic hose to the drain pan

with a hose clamp. Remove insulation from the knockout on either the left or right side wall panels;

pass the hose through the hole and continue to a floor drain. Refer to page 6.

18. Install the water supply line and solenoid assembly. A water filter (not supplied) is recommended

to remove particulates ahead of the spray nozzles in the humidifier. The water pressure should be

at least 43 psig (2 kg/cm

2

). Refer to page 6.

19. Install ramp(s).

20. Refer to page 6 for Electrical Connection information.

21. When the proofer has been set and leveled in its final installed position, seal all around the proofer

perimeter where it contacts the building floor with an NSF approved silicone sealant, provided.

Wipe off any excess sealant.

Refer to the drawings for your proofer:

Size (model number suffix) 2S — see pages 7 – 9.

Size (model number suffix) 3S — see pages 10 – 12.

Size (model number suffix) 1D — see pages 13 – 15.

Size (model number suffix) 2D — see pages 16 – 18.

Models AHPR — see pages 19 – 21.

– 5 –

Page 6

PLUMBING CONNECTIONS

WARNING: PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY,

AND PLUMBING CODES.

WATER SUPPLY

Water must be proper hardness and pH. The recommended hardness is 4 – 6 grains per gallon. The

recommended pH is 6.5 – 8.0. Consult your local water company and/or water conditioner dealer

before installing the AHP Series Roll-In Proof Box to make sure the water supply meets these

conditions.

Connect potable water supply to the

1

/4" NPT supply connection; the flow rate is 2 gallons per hour.

DRAIN CONNECTION

The drain hose connects to the 1" O.D. fitting at the bottom of the drain pan on the humidifying unit.

Overflow drain knockouts are provided on both ends of the cabinet to allow drain installation on either

end. Run the hose to a floor drain.

ELECTRICAL CONNECTION

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE DISCONNECT

SWITCH INDICATING THAT YOU ARE WORKING ON THE CIRCUIT.

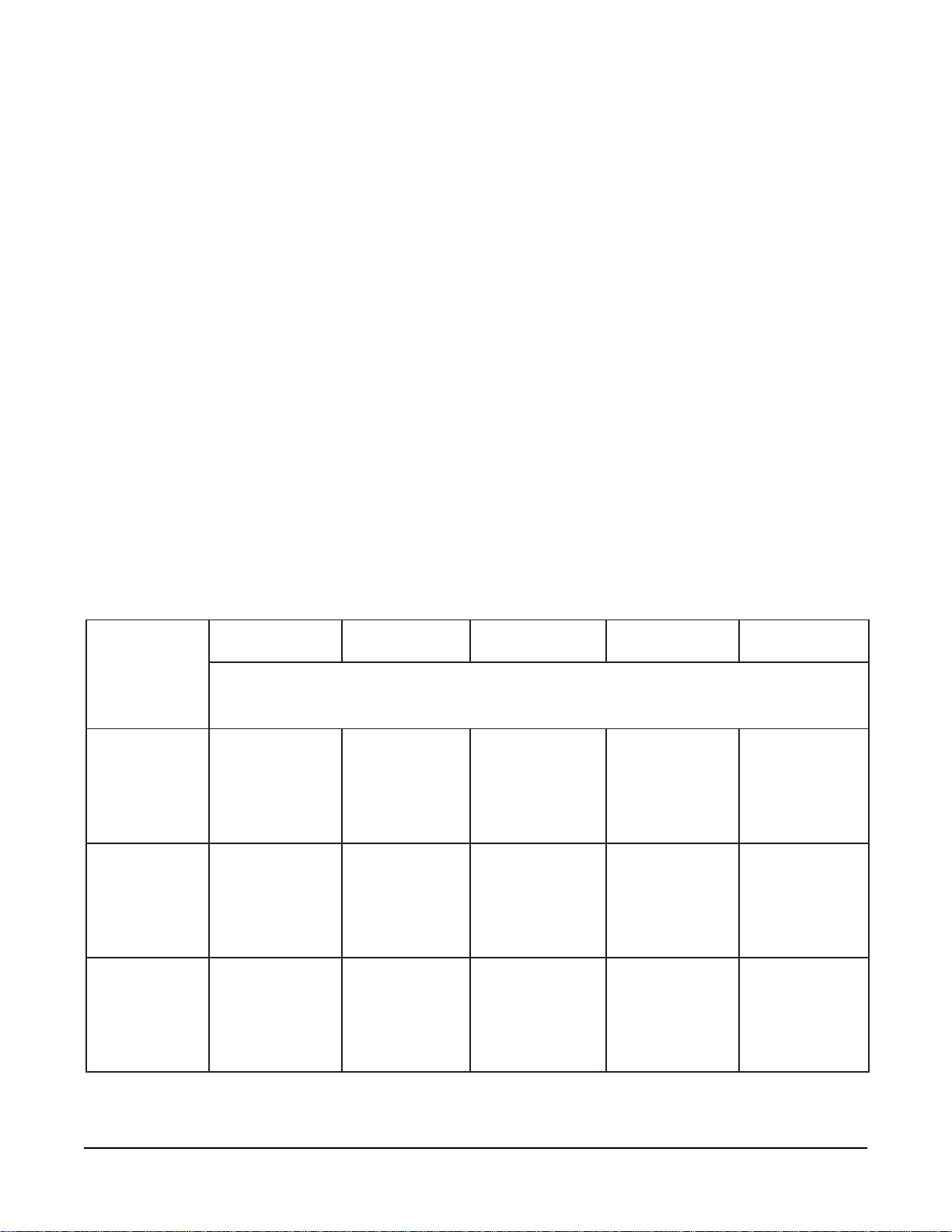

ATADLACIRTCELE

esahP-ztreH-stloV

1-06-802/0211-06-802/021

1-06-802/0211-06-802/021

1-06-802/021

:srefoorP

S1PHA

S2PHA

S3PHA

D1PHA

D2PHA

:sredrateRrefoorP

S1RPHA

S2RPHA

S3RPHA

D1RPHA

D2RPHA

:srefoorPwahT

S1PTHA

S2PTHA

S3PTHA

D1PTHA

D2PTHA

0252AN

esahP-ztreH-stloV

1-06-042/0211-06-042/021

1-06-042/0211-06-042/021

1-06-042/021

02

02

03

02

03

02

03

02

03

03

03

04

03

04

esahP-ztreH-stloV

1-06-8021-06-802

1-06-8021-06-802

1-06-802

yticapmAtiucriCmuminiM

eciveDevitcetorPmumixaMeciveDevitcetorPmumixaM

eciveDevitcetorPmumixaMeciveDevitcetorPmumixaM

SPMASPMA

SPMASPMA

SPMA

eciveDevitcetorPmumixaM

52

52

04

52

04

AN

52

04

52

04

04

04

05

04

05

esahP-ztreH-stloV

1-06-0421-06-042

1-06-0421-06-042

1-06-042

51

51

02

51

02

AN

AN

02

AN

02

02

02

52

02

52

esahP/ztreH/stloV

1-06-0841-06-084

1-06-0841-06-084

1-06-084

– 6 –

.)noitidetsetal,07APFN(edoClacirtcelElanoitaNehthtiwecnadroccanidelipmoC

Page 7

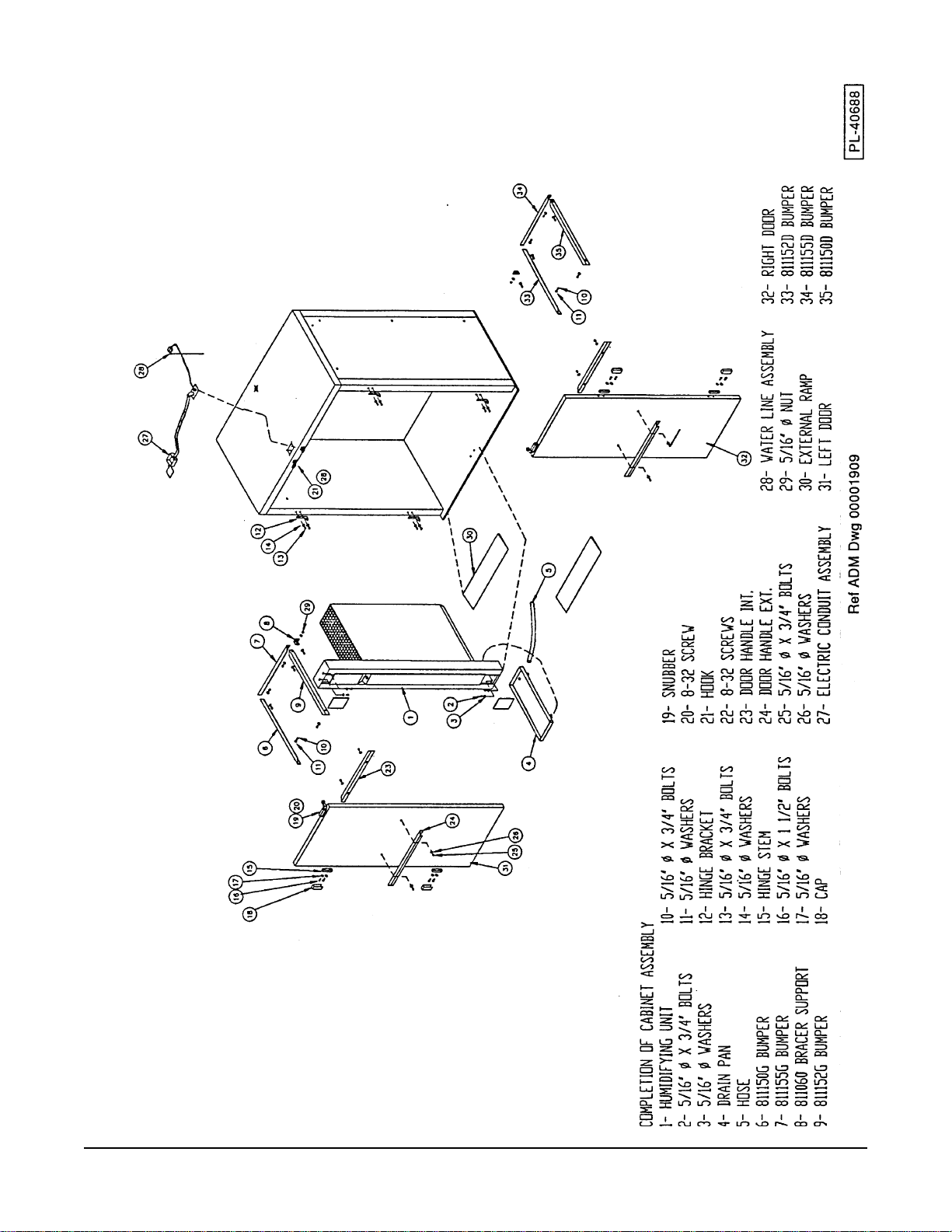

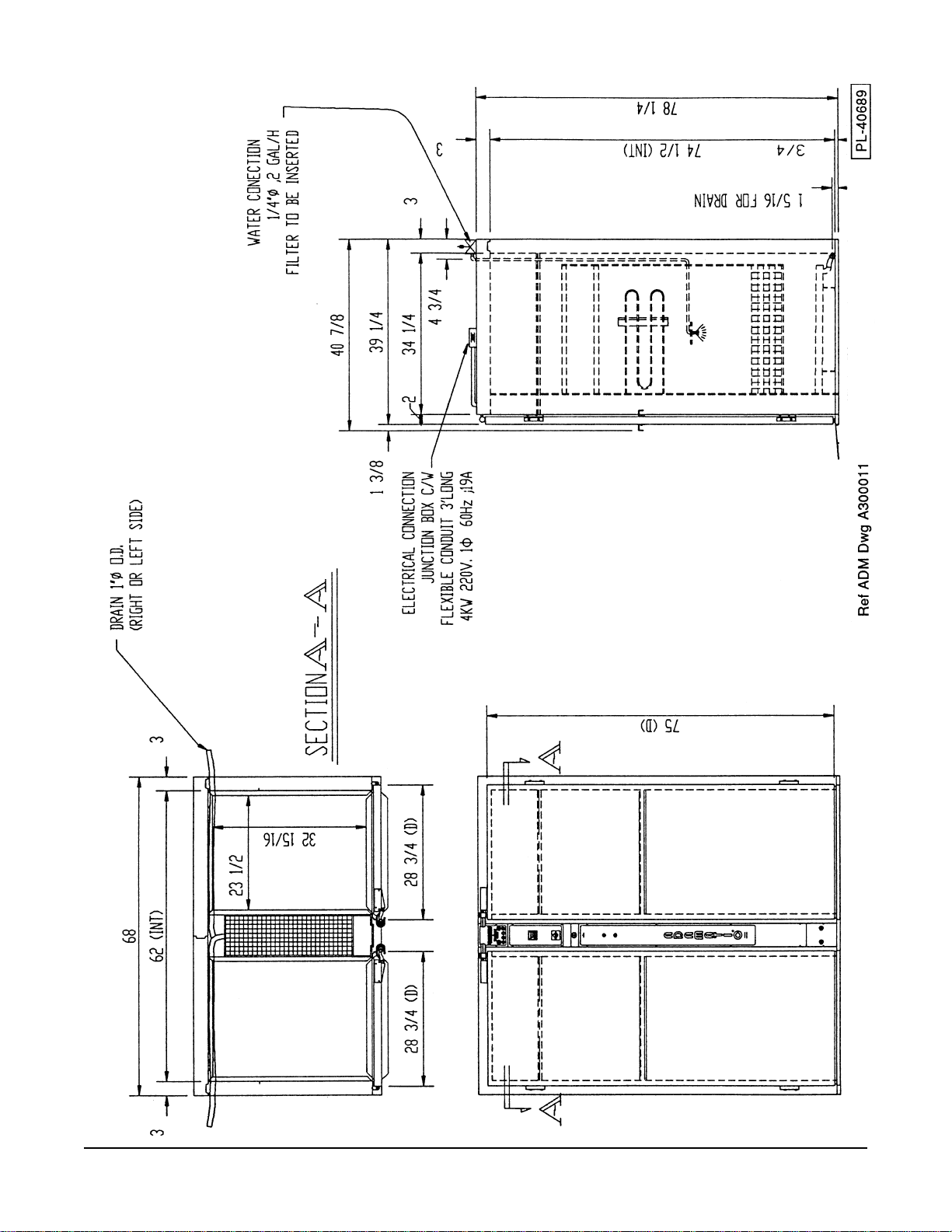

MODELS AHP2S, AHPR2S, & AHTP2S

– 7 –

Page 8

MODELS AHP2S, AHPR2S, & AHTP2S

– 8 –

Page 9

MODELS AHP2S, AHPR2S, & AHTP2S

– 9 –

Page 10

MODELS AHP3S & AHPR3S

– 10 –

Page 11

MODELS AHP3S & AHPR3S

– 11 –

Page 12

MODELS AHP3S & AHPR3S

– 12 –

Page 13

MODELS AHP1D, AHPR1D, & AHTP1D

– 13 –

Page 14

MODELS AHP1D, AHPR1D, & AHTP1D

– 14 –

Page 15

MODELS AHP1D, AHPR1D, & AHTP1D

– 15 –

Page 16

MODELS AHP2D & AHPR2D

– 16 –

Page 17

MODELS AHP2D & AHPR2D

– 17 –

Page 18

MODELS AHP2D & AHPR2D

– 18 –

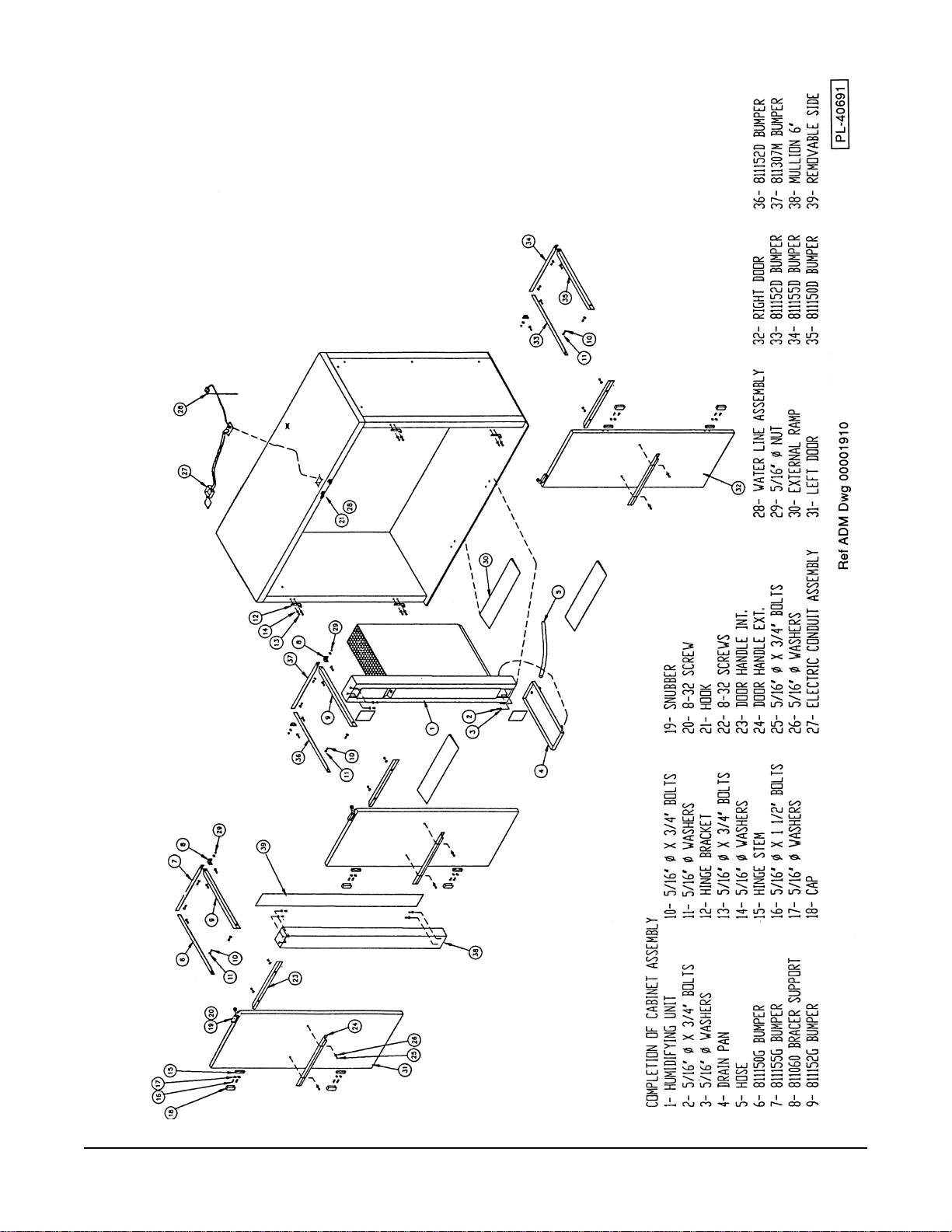

Page 19

MODEL AHPR2D SHOWN

– 19 –

Page 20

MODEL AHPR2D SHOWN

– 20 –

Page 21

MODELS AHPR2S, AHPR3S, AHPR1D, AHPR2D

– 21 –

Page 22

OPERATION

CONTROLS (Figs. 1, 2, & 3)

AHP models AHPR models AHTP models

Proofer Temperature

Main On-Off Switch

% Humidity

Pilot Light

Reset Button

On position uses the Proofer

Temperature Controller (E5CX)

and % Humidity.

7 Day Time Switch

Retarder Temperature

Proofer Temperature

Auto / Man Proof / Man Retard

Selector Switch

% Humidity

Main On-Off Switch

Pilot Light

Reset Button

Auto uses the 7 Day Time Switch discussed

on pages 23 – 32. Retard uses P2 and the

Retarder Temperature Controller (E5CX).

Proof uses P1, the Proofer Temperature

Controller (E5CX) and % Humidity.

Man Proof uses the Proofer Temperature

Controller (E5CX) and % Humidity.

Man Retard uses the Retarder Temperature

Controller (E5CX).

Thaw Temperature

Proofer Temperature

Auto / Off / Manual

Selector Switch

Proofer % Humidity

Thaw % Humidity

Pilot Light

Reset Button

Thaw Timer

Proofer Timer

Auto selects Timed Thawing followed by

Timed Proofing: Thawing uses Thaw

Timer and Thaw Temperature Controller

(E5CX); Proofing uses Proofer Timer,

Proofer Temperature Controller (E5CX),

and % Humidity.

Manual Proof uses the Proofer Temperature

Controller (E5CX) and % Humidity.

Fig. 1

Temperature Controller (E5CX) . . . For proofing, retarding, or thawing.

Actual Temperature

1234

Set Temperature

Use the Up and Down arrow keys

1234

OUT AT HB ALM

∨

∨

▲

∨

∨

Fig. 2

AT

to set the temperature.

Changed data becomes

effective 2 seconds after the

Up or Down key is released.

– 22 –

Page 23

7 Day Time Switch (H5S) — Models AHPR: Proofer-Retarder only (pages 23 – 32)

ON

Indicator Light

Write Key

Check Key

P1 - On Auto Off

Selector Switch

P2 - On Auto Off

Selector Switch

Time Adjust Key

Mode Selector

(Not Used)

SUN MON TUE WED THU FRI SAT

OUT

1 OUT 2

ON

AUTO

OFF

TIMER 1 2 MAN

MODE BOOT

■■

PULSE 1 2 AUTO

Cycle / Pulse Key

■

(Not Used)

SHIFT

DAY

SET/RESET

PROG

CHECK WRITE

TIME ADJ

CYCLE /PULSE COPY CLR

P1

P2

RUN

Copy Key

h

m

Day Shift Key

Day Set / Reset Key

Hour Set Key

Minutes Set Key

P1 P2 Run

Selector Switch

Clear Key

Fig. 3

NOTE: Times stored in P1 control Proofer functions; P2 time settings control the Retarder. The timer

prevents P1 (Proofer) and P2 (Retarder) set times from overlapping.

TO ERASE TIMES STORED IN P1 AND P2

RUN

P1

P2

P1

P2

RUN

P1

P2

RUN

Select P1 and press the CLR (Clear) key — this erases P1 memory.

Select P2 and press the CLR (Clear) key — this erases P2 memory.

NOTE: Use the RUN position during automatic operations to control the

Proofer-Retarder using the programmed start and stop times for each day

of the week.

TIMER MEMORY CAPACITY

The timer can be programmed for up to 24 events

in all. An event is a start date-time or a stop datetime. A start date-time and a stop date-time are the

two required events for every program. When 12

programs have been entered, the Event Number

(Fig. 4) will be reduced to 0 and no more programs

can be entered.

NOTE: The zero hour (0:00) on this timer is the

twelfth hour on most clocks. For example: 0:01 0:59 AM is 12:01 - 12:59 AM, just after midnight.

Also, 0:01 - 0:59 PM is 12:01 - 12:59 PM, afternoon.

SUN MON TUE WED THU FRI SAT

▼

— — — — — — —

— : — —

____________

_____↑

— : — — — : — —

Fig. 4

↓____24

Event

Number

1

PROG

– 23 –

Page 24

SETTING THE CURRENT DAY-OF-THE-WEEK AND TIME-OF-DAY

P1

P2

RUN

• Press the Time Adjust key for 2 to 3 seconds. The clock flashes (Fig. 6).

• Press the Day Shift key until the arrow,

• Press the Day Set / Reset key once to accept the Day-of-the-Week (Fig. 7).

Select the RUN position.

The display indicates the day

and time: Fig. 5 indicates it is

Tuesday, 8:15 am. If this is not

the correct Date and Time, reset

as follows:

SUN MON TUE WED THU FRI SAT

▼

— — — — — — —

▼

, is positioned on today's Day-of-the-Week.

SUN MON TUE WED THU FRI SAT

— — — — — — —

AM

_____↑

SUN MON TUE WED THU FRI SAT

— — — — — — —

8 : 1 5

___________ _

— : — — — : — —

Fig. 5

▼

↓____

AM

• Press the Hour Set key until the hour (and AM or PM) is displayed.

• Press the Minutes Set key until the minutes are displayed (Fig. 8).

• Press the Write key to validate (accept) the date and time (Fig. 9).

SUN MON TUE WED THU FRI SAT

— — — — — — —

PM

8 : 1 5

Fig. 6 Fig. 7

▼

2 : 2 1

AM

SUN MON TUE WED THU FRI SAT

— — — — — — —

PM

_____↑

8 : 1 5

▼

2 : 2 1

___________ _

↓____

— : — — — : — —

Fig. 8 Fig. 9

– 24 –

Page 25

PROGRAMMING START AND STOP TIMES FOR P1: PROOFER FUNCTIONS

P1

P2

RUN

Select the P1 position.

The display (Fig. 10) indicates that 24 events

SUN MON TUE WED THU FRI SAT

▼

— — — — — — —

or 12 programs can be entered (no programs

have been entered). The

P1-P2-RUN switch is

positioned on P1, indicated by

.

1

BLINKING

_____↑

— : — —

____________

The flashing date line and up arrow,↑,

indicate that the start date and time can be

— : — — — : — —

programmed. Once the start date and time

have been programmed, the flashing down

Fig. 10

arrow, ↓, prompts for the stop date and time.

▼

☞ Press the Day Shift key until the arrow,

, is positioned on the start day-of-week (Fig. 11).

• Press the Day Set / Reset key once to accept the start day-of-week (Fig. 12).

↓____24

1

PROG

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

____________

BLINKING

_____↑

— : — — — : — —

Fig. 11 Fig. 12

↓____24

1

PROG

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

____________

BLINKING

_____↑

— : — — — : — —

↓____24

1

PROG

• Press the Hour Set key until the start hour and AM or PM are displayed.

• Press the Minutes Set key until the start minutes are displayed (Fig. 13).

• Press the Write key to validate (accept) the start date and time (Fig. 14). The event number

changes from 24 to 23.

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

AM

8 : 2 0

____________

BLINKING

_____↑

— : — — — : — —

Fig. 13 Fig. 14

↓____24

1

PROG

_____↑

— : — —

____________

AM

8 : 2 0 — : — —

Programming the stop date and time for P1 continues on the next page.

– 25 –

BLINKING

↓___ _ 23

1

PROG

Page 26

NOTE: Skip the next two steps if the stop day-of-week is the same as the start day-of-week.

▼

• Press the Day Shift key until the arrow,

, is positioned on the stop day-of-week (Fig. 15).

• Press the Day Set / Reset key once to accept the stop day-of-week (Fig. 16).

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

_____↑

AM

___________ _

8 : 2 0 — : — —

Fig. 15

BLINKING

↓____ 23

1

PROG

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

_____↑

AM

___________ _

8 : 2 0 — : — —

Fig. 16

BLINKING

↓____ 23

1

• Press the Hour Set key, beginning at the start time (Fig. 17) and continue pressing

until the stop hour and AM or PM are displayed (Fig. 18).

SUN MON TUE WED THU FRI SAT

— — — — — — —

AM

_____↑

AM

▼

8 : 2 0

___________ _

8 : 2 0 — : — —

BLINKING

↓____ 23

PROG

1

SUN MON TUE WED THU FRI SAT

— — — — — — —

PM

_____↑

AM

▼

4 : – –

___________ _

↓____ 23

8 : 2 0 — : — —

BLINKING

1

PROG

PROG

Fig. 17 Fig. 18

• Press the Minutes Set key until the stop minutes are displayed (Fig. 19).

• Press the Write key to validate (accept) the stop date and time (Fig. 20). The display reverts

to Fig. 10 with the event number changed from 23 to 22.

SUN MON TUE WED THU FRI SAT

— — — — — — —

PM

_____↑

AM

▼

4 : 5 0

___________ _

8 : 2 0 — : — —

Fig. 19 Fig. 20

BLINKING

↓____ 23

PROG

1

The program is now complete. To enter another P1 program, repeat from ☞ on page 25; or, exit P1.

– 26 –

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

____________

_____↑

AM

8 : 2 0 4 : 5 0

↓____ 22

PM

PROG

1

Page 27

PROGRAMMING START AND STOP TIMES FOR P2: RETARDER FUNCTIONS

SUN MON TUE WED THU FRI SAT

▼

— — — — — — —

RUN

P1

P2

Select the P2 position.

Fig. 21 indicates 18 events (9

programs) can yet be programmed.

P1-P2-RUN switch is set on P2.

The

The flashing date line and up arrow,↑,

_____↑

— : — —

____________

BLINKING

↓____18

indicate that the start date and time can be

programmed. Once the start date and time

— : — — — : — —

have been programmed, the flashing down

arrow, ↓, prompts you to program the stop

Fig. 21

date and time.

▼

☞ Press the Day Shift key until the arrow,

, is positioned on the start day-of-week (Fig. 22).

• Press the Day Set / Reset key once to accept the start day-of-week (Fig. 23).

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

2

PROG

BLINKING

_____↑

____________

↓____18

2

PROG

— : — — — : — —

Fig. 22 Fig. 23

_____↑

____________

BLINKING

— : — — — : — —

↓____18

2

PROG

• Press the Hour Set key until the start hour and AM or PM are displayed.

• Press the Minutes Set key until the start minutes are displayed (Fig. 24).

• Press the Write key to validate (accept) the date and time (Fig. 25). The event number

changes from 18 to 17.

SUN MON TUE WED THU FRI SAT

— — — — — — —

PM

▼

5 : 3 0

___________ _

BLINKING

_____↑

— : — — — : — —

↓ ____18

2

PROG

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

_____↑

PM

____________

5 : 3 0 — : — —

BLINKING

↓____ 17

2

PROG

Fig. 24 Fig. 25

Programming the stop date and time for P2 continues on the next page.

– 27 –

Page 28

NOTE: Skip the next two steps if the stop day-of-the-week is the same as the start date.

▼

• Press the Day Shift key until the arrow,

, is positioned on the Day-of-the-Week (Fig. 26).

• Press the Day Set / Reset key once to accept the new Day-of-the-Week (Fig. 27).

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

_____↑

PM

___________ _

5 : 3 0 — : — —

Fig. 26

BLINKING

↓____ 17

2

PROG

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

_____↑

PM

___________ _

5 : 3 0 — : — —

Fig. 27

BLINKING

↓____ 17

2

• Press the Hour Set key, beginning at the start time (Fig. 28) and continue pressing

until the 'stop' hour and AM or PM are displayed (Fig. 29).

SUN MON TUE WED THU FRI SAT

— — — — — — —

PM

_____↑

PM

5 : 3 0

___________ _

5 : 3 0 — : — —

▼

BLINKING

↓____ 17

PROG

2

SUN MON TUE WED THU FRI SAT

— — — — — — —

AM

_____↑

7 : – –

___________ _

PM

5 : 3 0 — : — —

▼

BLINKING

↓____ 17

2

PROG

PROG

Fig. 28 Fig. 29

• Press the Minutes Set key until the stop minutes are displayed (Fig. 30).

• Press the Write key to validate (accept) the stop date and time (Fig. 31). The display reverts

to Fig. 10 with the event number changed from 17 to 16.

SUN MON TUE WED THU FRI SAT

— — — — — — —

AM

_____↑

7 : 3 0

___________ _

5 : 3 0 — : — —

PM

Fig. 30

▼

BLINKING

↓____ 17

PROG

2

The program is now complete. To enter another P2 program, repeat from ☞ on page 27; or, exit P2.

– 28 –

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

— : — —

___________ _

_____↑

PM

5 : 3 0 7 : 3 0

Fig. 31

↓____ 16

AM

PROG

2

Page 29

PROGRAMMING A PAUSE OR TIME DELAY BETWEEN TWO PROGRAMS

To program a pause between the stop time of one program and the start time of the next, set the stop

time prior to the next start time as shown in the following examples:

EXAMPLE MODE START DAY START TIME STOP DAY STOP TIME

1 P1: Proofer Monday 8:00 AM Monday 5:00 PM

2 P2: Retarder Monday 5:30 PM Tuesday 7:30 AM

3 P1: Proofer Tuesday 8:00 AM Tuesday 5:00 PM

Between the stop time for example 1 and the start time for example 2, a 30 minute delay has been

scheduled. Also, a 30 minute delay is scheduled between the stop time for example 2 and the start

time for example 3. During this time delay, the fans will continue to run for a maximum of 30 minutes.

PLANNING YOUR WEEKLY SCHEDULE

If several days of the week have the same schedule, they can all be in the same program. When

selecting the start days of the week, merely repeat the selection (use the Day Shift key followed by the

Day Set / Reset key repeatedly). Then select the start hour and minutes only once since they are to

be the same. Do the same for the stop days of the week and the stop hours and minutes. For example,

if the P1 Proofer function were to be the same as example 1 above for Monday, Tuesday, Wednesday,

Thursday, and Friday the final set displays would look like Figs. 32, 33.

SUN MON TUE WED THU FRI SAT

— — — — — — —

AM

8 : 0 0

▼

___________ _

_____↑

AM

8 : 0 0 – : – –

Fig. 32 Fig. 33

↓____ 23

PROG

1

SUN MON TUE WED THU FRI SAT

— — — — — — —

PM

5 : 0 0

▼

___________ _

_____↑

AM

8 : 0 0 5 : 0 0

↓____ 22

PM

PROG

1

If scheduling example 2 for five overnight retarder mode functions, the final set displays would look like

Figs. 34, 35. Notice the removal of Monday and inclusion of Saturday in the stop day selection.

SUN MON TUE WED THU FRI SAT

— — — — — — —

PM

5 : 3 0

▼

___________ _

_____↑

AM

5 : 3 0 – : – –

↓____ 21

PROG

2

SUN MON TUE WED THU FRI SAT

— — — — — — —

AM

7 : 3 0

▼

___________ _

_____↑

5 : 3 0 7 : 3 0

↓____ 20

AMPM

PROG

2

Fig. 34 Fig. 35

– 29 –

Page 30

PROGRAMMING AN OPERATION FOR LONGER THAN ONE DAY

The timer can be programmed to start one day and stop several days later. For example, to start at

8:30 AM Monday and stop at 11:30 AM Wednesday, the final set displays would look like Figs. 36 & 37.

Use the Day Set / Reset key to remove the Monday designation when setting the stop day. Then use

the Day Shift key twice and the Day Set / Reset key once to fix the stop day on Wednesday.

SUN MON TUE WED THU FRI SAT

SUN MON TUE WED THU FRI SAT

▼

— — — — — — —

AM

8 : 3 0

___________ _

_____↑

AM

8 : 3 0 – : – –

Fig. 36 Fig. 37

BLINKING

↓____ 23

— — — — — — —

AM

_____↑

PROG

1

AM

▼

1 1 : 3 0

____________

↓____ 22

8 : 3 0 1 1 : 3 0

AM

REVIEWING AND CHANGING THE SET TIMES FOR EITHER P1 OR P2

P1

P2

RUN

The set times for P1 can be reviewed and changed, if necessary, by setting the P1-P2-

UN switch on P1 and pressing the Write key. If necessary, change the settings using

R

the appropriate keys; then, press the Write key to continue. Each time the Write key is

pressed, the set times are displayed in the sequence they were set. Press the Write key

P1

P2

RUN

after all set times have been displayed.

Set the P1-P2-R

UN switch on P2 to review and change the settings for P2.

REVIEWING THE SET TIMES FOR BOTH P1 AND P2 FROM THE RUN POSITION

PROG

1

P1

P2

RUN

P1

P2

RUN

The set times for today can be reviewed with the P1-P2-R

UN switch on Run, by pressing

the Check key. First, the set times for P1 are displayed, starting from the earliest start

time. Then the set times for P2 are displayed. Press the Check key after all the set times

have been reviewed to return to the Run display. If the control is left untouched for 20

seconds, the Run display automatically returns.

To review the set times for a day-of-the-week other than today, press the Day Shift key

▼

until the arrow,

, is positioned on the desired day-of-week; then press the Day Set key.

Press the Check key to step through the

set times for this day in sequence. The

start times and stop times for P1 are

displayed beginning with the earliest start

SUN MON TUE WED THU FRI SAT

— — — — — — —

▼

times (Fig. 38). Then the start and stop

times for P2 are displayed. After all set

times have been displayed, the display

returns to the Run display. If the control

is left untouched for 20 seconds, the Run

display automatically returns.

– 30 –

___________ _

_____↑

AM

8 : 3 0 1 1 : 3 0

Fig. 38

AM

↓____ 22

1

PROG

Page 31

DAY OVERRIDE: Temporarily Copying Program(s) From One Day-Of-The-Week To Another

Both P1 and P2 program(s) can be copied from one day-of-the-week to another; the original settings

are restored after one week. This allows you to temporarily copy Sunday's program(s) to a holiday that

falls in the middle of the week and resume the normal schedule the next week. After copying, review

the settings as described on the previous page. The example copies Sunday's program(s) to

Wednesday.

UN switch positioned on Run, (display looks like Fig. 39), hold down the

RUN

With the P1-P2-R

P1

P2

Copy key for at least one second. Fig. 40 should display.*

Select the day you want to copy to (Wednesday); use Day Shift and Day Set / Reset keys

to select the day. Fig. 41 displays. Press the Write key. Fig. 42 displays.

Select the day you want to copy from (Sunday); use Day shift and Day Set / Reset keys

to select the day. Fig. 43 displays. Press the Write key. Fig. 44 displays.

*

NOTE: If Fig. 42 displays, a day override for the week has already been programmed; this can be cleared and reset.

SUN MON TUE WED THU FRI SAT

▼

— — — — — — —

AM

8 : 3 0

SUN MON TUE WED THU FRI SAT

▼

— — — — — — —

BLINKING

___________ _

_____↑

AM

9 : 0 0 5 : 0 0

Fig. 39 Fig. 40

SUN MON TUE WED THU FRI SAT

PM

↓____ 11

PROG

1

SUN MON TUE WED THU FRI SAT

PROG

— — — — — — —

SUN MON TUE WED THU FRI SAT

▼

— — — — — — —

▼

Fig. 41 Fig. 42

Fig. 43 Fig. 44

PROG

PROG

▼▼▼▼▼▼▼

BLINKING

— — — — — — —

SUN MON TUE WED THU FRI SAT

▼

— — — — — — —

AM

8 : 4 1

____________

_____↑

AM

9 : 0 0 5 : 0 0

↓____ 11

1

PM

PROG

PROG

– 31 –

Page 32

RUNNING A PROGRAM (Fig. 45)

SUN MON TUE WED THU FRI SAT

P1 (Proofing) is ON

P1 & P2 Switches on AUTO

▼

— — — — — — —

AM

_____↑

■■

AM

■

OUT

1

1 OUT 2

ON

AUTO

OFF

TIMER 1 2 MAN

MODE BOOT

PULSE 1 2 AUTO

Boot Switch on AUTO

9 : 3 0

____________

↓____ 11

9 : 0 0 5 : 0 0

PM

CHECK WRITE

Fig. 45

1

TIME ADJ

SHIFT

DAY

SET/RESET

h

m

PROG

RUN Position

P1

P2

RUN

The Current Time is 9:30 AM Monday.

P1 (Proofing) is operating. It started at 9:00

AM and will stop at 5:00 PM.

NOTE: When P2 (Retarding) is ON, 2 is displayed in the OUT and PROG boxes.

NOTE: When neither P1 nor P2 is running and P1 (Proofing) is the next program to be started,

1 is displayed in the PROG box and the programmed start and stop times are displayed. When

neither P1 nor P2 is running and P2 (Retarding) is the next program to be started, 2 is displayed

in the PROG box and the programmed start and stop times are displayed.

IN CASE OF POWER FAILURE

The Time Switch maintains memory during a power failure but there is no output, the display is off, and

the ON indicator light is not lit. With the BOOT switch on AUTO, the time switch resumes its operation

as programmed after power recovery. If the BOOT switch is on MANUAL, the keyhole indicator blinks

on the display screen after power recovery and the output does not turn on until the BOOT switch is

set on the AUTO position.

– 32 –

Page 33

HUMIDIFIER, HEATER, AIR FILTER, AND FAN UNIT (Fig. 46)

TEMPERATURE AND HUMIDITY PROBE

IS LOCATED IN RETURN AIR STREAM.

FANS CIRCULATE AIR DOWN

THROUGH HEATING ELEMENTS

AND THE AIR IS HEATED.

THE HEATED AIR STREAM

FLOWS THROUGH A FINE

MIST WATER SPRAY,

PICKING UP MOISTURE.

ANY LARGE WATER DROPS ARE

TRAPPED BY THE AIR FILTER.

HOT MOIST AIR IS DELIVERED TO

THE PROOFING CHAMBER.

CONTINUOUS RECIRCULATION

GENTLY REPEATS THE CYCLE.

EXCESS WATER

FLOWS TO DRAIN.

DOOR CLOSER (Fig. 47)

Fig. 46

Fig. 47

– 33 –

Page 34

RETARDING

The retarder temperature is usually set at 38°F. Defrosting frozen dough at retarder temperatures

takes 6 hours minimum; dough products can be stored for as long as 48 hours in the retarder using the

cool humid air so dough products do not dry out. Dough should not be refrozen after thawing. The

retarder slows the yeast fermentation process, reduces gas formation, and inhibits raising of dough.

Products removed from the retarder should be left at room temperature for 5 – 7 minutes before being

put in the proofer. This will reduce moisture condensation when cold metal pans are placed in the warm

humid proofer.

PROOFING

Controlled temperature and humidity in the proofer promotes yeast fermentation which generates gas

and causes the dough to rise. Proofing takes from 45 – 60 minutes depending on the product. A

temperature setting of 95°F and humidity at 85% are typical but will vary slightly depending on the

product being proofed. The chart below is for guidelines only — ask your dough supplier for technical

product reports to set up your own chart.

Proofing Baking

Product

Rolls 95°F 85% 55 min 375°F 12 sec 12 min

French Crust Bread

14 oz

French Crust Bread

10 oz

Bagels 85°F 85% 50 min 400°F 20 sec 15 min

Croissants 75°F 70% 30 min 360°F 0 12 min

Temperature

°F

90°F 90% 45 min 375°F 15 sec 20 min

90°F 85% 45 min 360°F 12 sec 18 min

% Humidity

Proof Time

Minutes

Temperature°FSteam Time

Seconds

Bake Time

Minutes

CLEANING

Clean the inside of the cabinet and the doors weekly with a warm water solution of mild household liquid

dishwashing detergent (such as Palmolive green or Ivory). Do not use anything containing grit,

abrasive materials, bleach, or harsh chemicals. Be cautious with new or improved formulas; use only

products approved for stainless steel. Rinse thoroughly and dry with a clean soft cloth. Do not use

steel wool to clean surfaces.

Remove the filter and rinse clean weekly. Replace filter when necessary.

NOTE: Failure to follow use, care and maintenance instructions may void your Hobart warranty.

– 34 –

Page 35

SERVICE

Contact your local Hobart-authorized service office for any repairs or adjustments needed on this

equipment.

– 35 –

Page 36

NOTES

FORM 19410 Rev.A (Aug. 2000) PRINTED IN U.S.A.

– 36 –

Loading...

Loading...