Page 1

Global LCD Panel Exchange Center

TECHNICAL DATA

CONTENTS

TX36D88VC1CAA

www.panelook.com

Hitachi Displays, Ltd.

Date; Sep. 18, 2007

No.

— DPBCL0001618-1

—

—

1 DPBCL0001618-1

2 DPBCL0001618-1

3 DPBCL0001618-1

4 DPBCL0001618-1

5 DPBCL0001618-1

7 DPBCL0001618-1

8 DPBCL0001618-1

9 DPBCL0001618-1

10

COVER 1-1/1

RECORD OF REVISION 2-1/1

APPLICATIONS 3-1/1

ABSOLUTE MAXIMUM RATINGS 4-1/2 - 2/2

OPTICAL CHARACTERISTICS 5-1/2 - 2/2

ELECTRICAL CHARACTERISTICS 6-1/1

BLOCK DIAGRAM 7-1/1

INTERFACE PIN CONNECTION 8-1/4 - 4/4

INTERFACE TIMING 9-1/4 - 4/4

DIMENSIONAL OUTLINE 10-1/1

DESIGNATION OF LOT MARK 11-1/2 - 2/2

COSMETIC SPECIFICATIONS 12-1/3 - 3/3

PRECAUTIONS 13-1/4 - 4/4

DPBCL0001618-1

DPBCL0001618-1

DPBCL0001618-16

DPBCL0001618-1

PageSheet No.Item

Hitachi Displays, Ltd. DPBCL0001618-1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Page

1-1/1

www.panelook.com

Page 2

Global LCD Panel Exchange Center

RECORD OF REVISION

The upper section : Before revision

The lower section : After revision

Sheet No. Page

www.panelook.com

SummaryDate

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

2-1/1

www.panelook.com

Page 3

Global LCD Panel Exchange Center

APPLICATIONS

This specification is applied to the following TFT Liquid Crystal Display Module

with Back-light unit and LVDS (Low Voltage Differential Signaling) Interface.

Note: Inverter device for Back-light is not built in and so it needs to

be prepared on your side.

www.panelook.com

Type name

Display Area : (H)285.7 × (V)214.3 [mm]

Display Pixels : (H)1,024 × (V)768 pixels

(Display Dots) (H(1024 × 3) × V768 [dots])

Power Supply Voltage : 3.3 V

Pixel Pitch : (H)0.279 × (V)0.279 [mm]

Color Pixel Arrangement : R•G•B Vertical Stripe

Display Mode : Transmissive &

Color Number : 262k Colors

Direction with Wider : Lower side of 6 o'clock

Viewing Angle

: TX36D88VC1CAA

Normally White Mode

(Azimuth I = 270°)

Dimensions Outlines : (H)298.5 × (V)225.5 typ. × (t)6.0max [mm]

Weight : 480typ. [g]

Interface : 1ch-LVDS

Back-light : One Cold Cathode Fluorescent Lamp

(Lower side)

Back-light inverter is not contained in Module.

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

3-1/1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

1. ABSOLUTE MAXIMUM RATINGS

1.1 ENVIRONMENTAL ABSOLUTE MAXIMUM RATINGS

Item

Ambient Temperature 0 40 -20 60 °C 1)

Humidity 2) 2) %RH 1)

Vibration – (0.5G) – (2G)

Shock – (3G) – (50G)

Corrosive Gas Not Acceptable Not Acceptable –

Illumination at

LCD Surface

Notes 1) Environmental temperature and humidity of this unit, not of system installed with this unit.

At low temperature the brightness of CFL drop and the life time of CFL become to be short.

2) Ambient temp. Ta d 40°C : 85%RH MAX. without condensation.

Ta > 40°C : Absolute humidity must be lower than the saturated vapor of

3) Vibration frequency : 20~50Hz. (Except resonance frequency) 3min/cyc

4) 7ms of pulse width.

5) With mounting protective spacer (ref. page 4-2/2)

www.panelook.com

Operating Storage

Min. Max. Min. Max.

4.9

29.4

––

85%RH at 40°C. Without condensation.

50,000

19.6

490

50,000

Unit

m/s

m/s

lx

Note

2

2

3), 5)

4), 5)

1.2 ELECTRICAL ABSOLUTE MAXIMUM RATINGS

(1) TFT Liquid Crystal Display Module Vss=0V

Item Symbol Min. Max. Unit Note

V

V

V

ESD0

ESD1

DD

0 4.0 V

±100 V 1), 2)

±8 kV 1), 3)

Power Supply Voltage

Electrostatic Durability

Notes 1) Discharge circuit: 200pF-250:, Surrounding: 25°C-70%RH.

2) The specification is applicable to I/F Connector pins.

3) The specification is applicable to metal bezel and LCD glass.

(2) Back Light unit GND=0V

ITEM Symbol Min. Max. Unit

Lamp Current

Lamp Voltage

I

L

V

L

0 7.0 mArms

0 2,000 Vrms

Hitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

Date Page

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

4-1/2

www.panelook.com

Page 5

Global LCD Panel Exchange Center

A

A

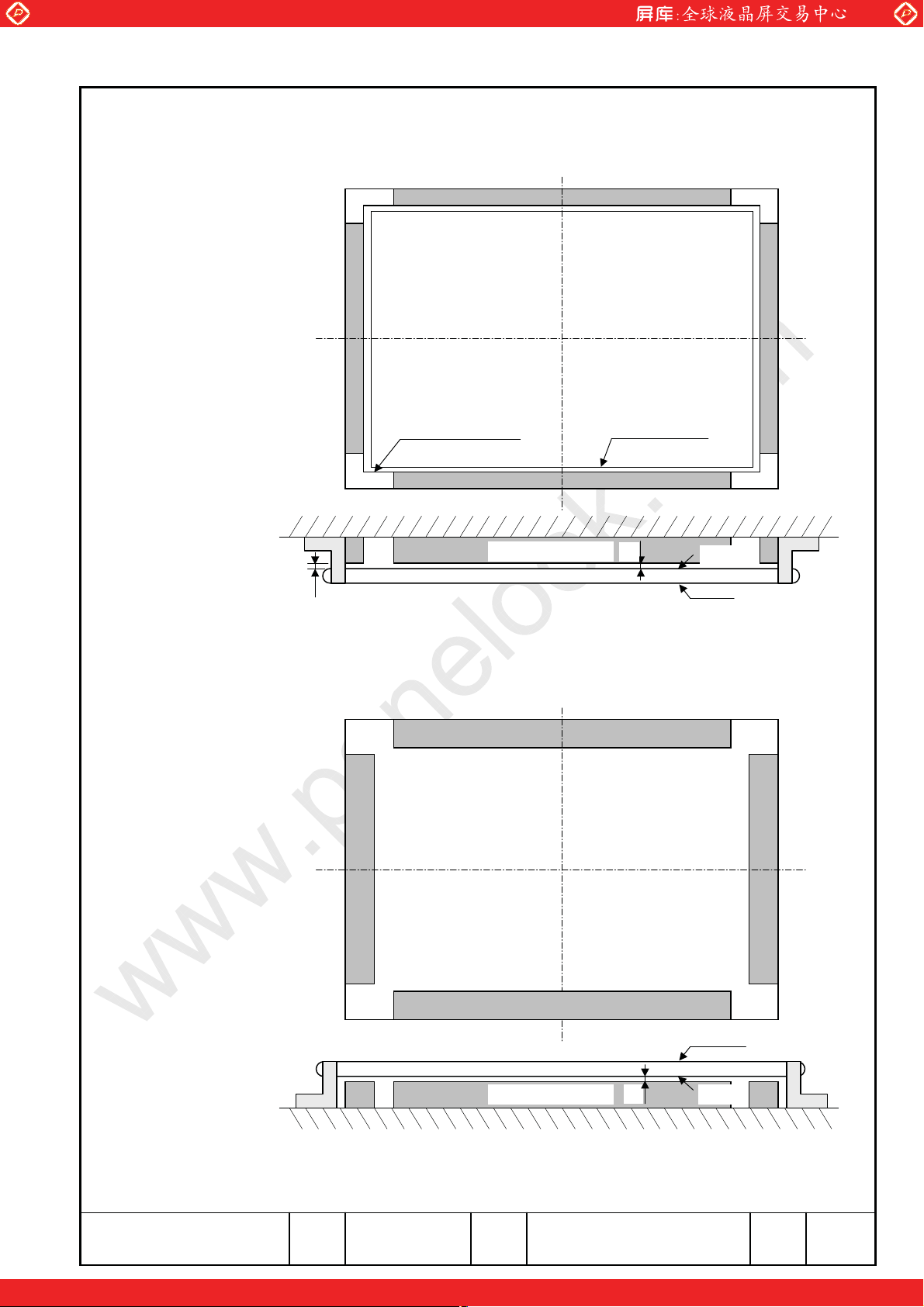

Adding protective spacer at shock & vibration test

(1) This protective

spacer is to be added

at shock and vibration

test on the front side

www.panelook.com

(2) This protective spacer

is to be added shock and

vibration test on the

back side

Window of Bezel

Protective Spacer

(1)

Display Area

(1)

Front

Back

Front

Protective Spacer

(1)

Back

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1Date

4-2/2

www.panelook.com

Page 6

Global LCD Panel Exchange Center

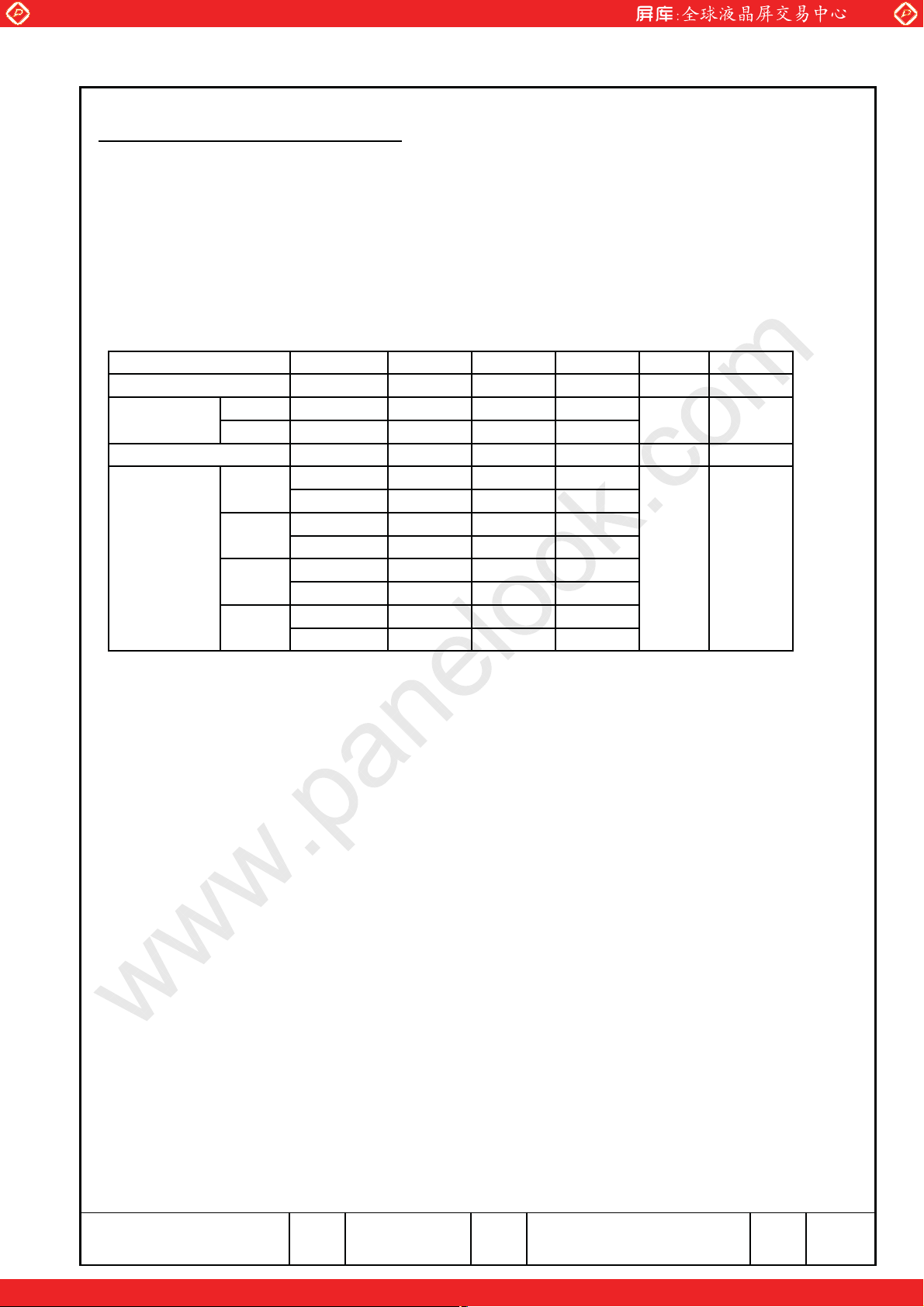

2. OPTICAL CHARACTERISTICS

The following items are measured on the conditions that this unit operation (TFT panel

and Back-light) and measuring systems are stable. (more than 30minites' operation)

The ambient light excluding The Back-light unit is nothing.

•Measuring equipment : TOPCON BM-7, Prichard 1980A, or equivalent

•Measuring point : Active area center

Item Symbol Min. Typ. Max. Unit Note

Contrast Ratio CR – 150 – – 1)

Response Rise tr – 50 –

Time Fall tf – 30 –

Brightness (white) Bwh – 150 –

Red

Color of CIE y – 0.56 – –

Green

Blue

White

www.panelook.com

Temperature of LCD=25°C, VDD=3.3V, fV=60Hz, IL=6.0mA

ms 2)

2

cd/m

x – 0.58 –

y – 0.33 –

x – 0.30 –

x – 0.15 –

y – 0.14 –

x – 0.32 –

y – 0.33 –

Hitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

Date Page

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

5-1/2

www.panelook.com

Page 7

Global LCD Panel Exchange Center

f

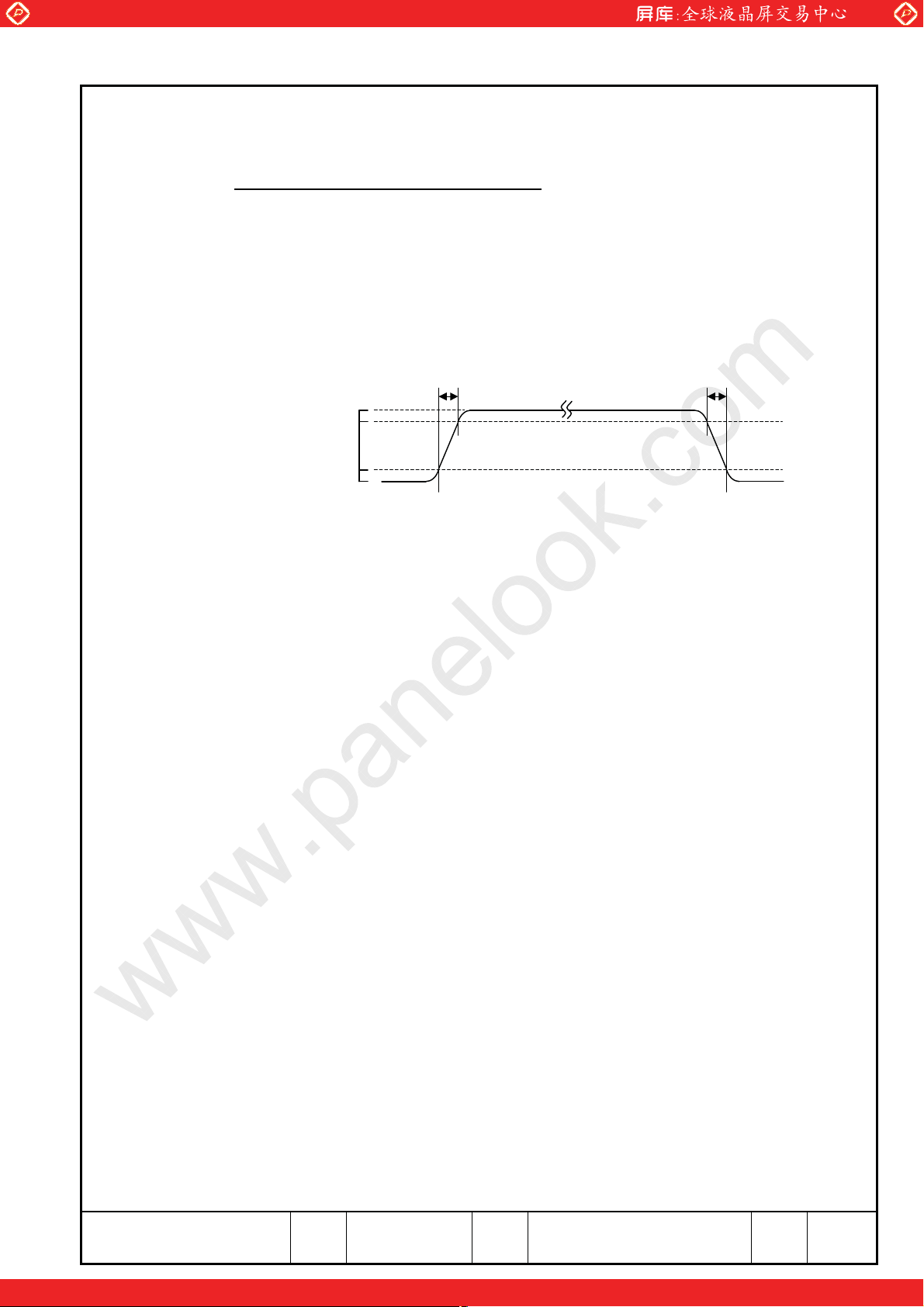

Notes 1) Definition of Contrast Ratio (CR)

CR =

2) Definition of Response Time

Brightness when displaying White raster

Brightness when displaying Black raster

These Brightness is measured on the center of screen.

* Measurement in the darkroom.

www.panelook.com

Optical Response

Relative

luminance

100

90

10

%

tr t

0

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1Date

5-2/2

www.panelook.com

Page 8

Global LCD Panel Exchange Center

3. ELECTRICAL CHARACTERISTICS

3.1 TFT LIQUID CRYSTAL DISPLAY MODULE Ta=25°C, Vss=0V

Power Supply Voltage

Differential Input Voltage

for LVDS Receiver Threshold

Power Supply Current

Vsync Frequency

Hsync Frequency

DCLK Frequency

Notes 1) VCM=+1.25V

fv=60Hz, f

2)

Typical value is measured when displaying vertical 64 gray scale.

Maximum is measured when displaying Vertical-stripe (Black-Gray 7).

=65MHz, VDD=3.3V, DC Current.

CLK

DC Ampere Meter

V

DD

Hi

Lo

www.panelook.com

Symbol

V

V

V

I

f

f

f

CLK

I

DD

DD

IH

IL

DD

V

H

V

V

Min.Item

3.0

– – +100

-100

–

–

–

–

TFT/LCM

DD

SS

Typ.

3.3

–

300

60

48.5

65

Max. Unit Note

3.6

–

600

65

52.4

67

V

mV 1)

mA

Hz

kHz

MHz

2), 3)

4)

4)

4)

Current capacity for V

3)

4) For LVDS Transmitter Input

power source should be larger than 2A.

DD

3.2 BACK-LIGHT UNIT Ta=25°C

Item Symbol Min. Typ. Max. Unit Note

Lamp Current

Lamp Voltage

Frequency

I

L

V

L

f

L

Starting Lamp Voltage Vs Vrms

Notes 1) Higher IL cause the short life time of CFL.

2) DC current cause irregular fluorescence and the short life of CFL.

3) Lamp frequency may produce interference with Hsync frequency,

causing beat or flicker on the display. There fore lamp frequency

shall be as different as possible from Hsync frequency, to avoid interference.

4) Starting Lamp Voltage applied be more than Vs (Min).

5) Ta=10°C

6) Reducing Lamp current increases Lamp voltage and generally increases Lamp frequency.

So all the parameters of an inverter should be carefully designed so as not to

produce to much leakage current from high-voltage output of the inverter.

7) Must be high considering to the loss of the ballast capacitor in the inverter.

3.5 5.0 6.0 mArms

– – 11 mA0-peak

1), 2), 6)

– 650 – Vrms

50 – 70 kHz 3)

1100 – – 4)

1400 – – 4), 5), 7)

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1Date

6-1/1

www.panelook.com

Page 9

Global LCD Panel Exchange Center

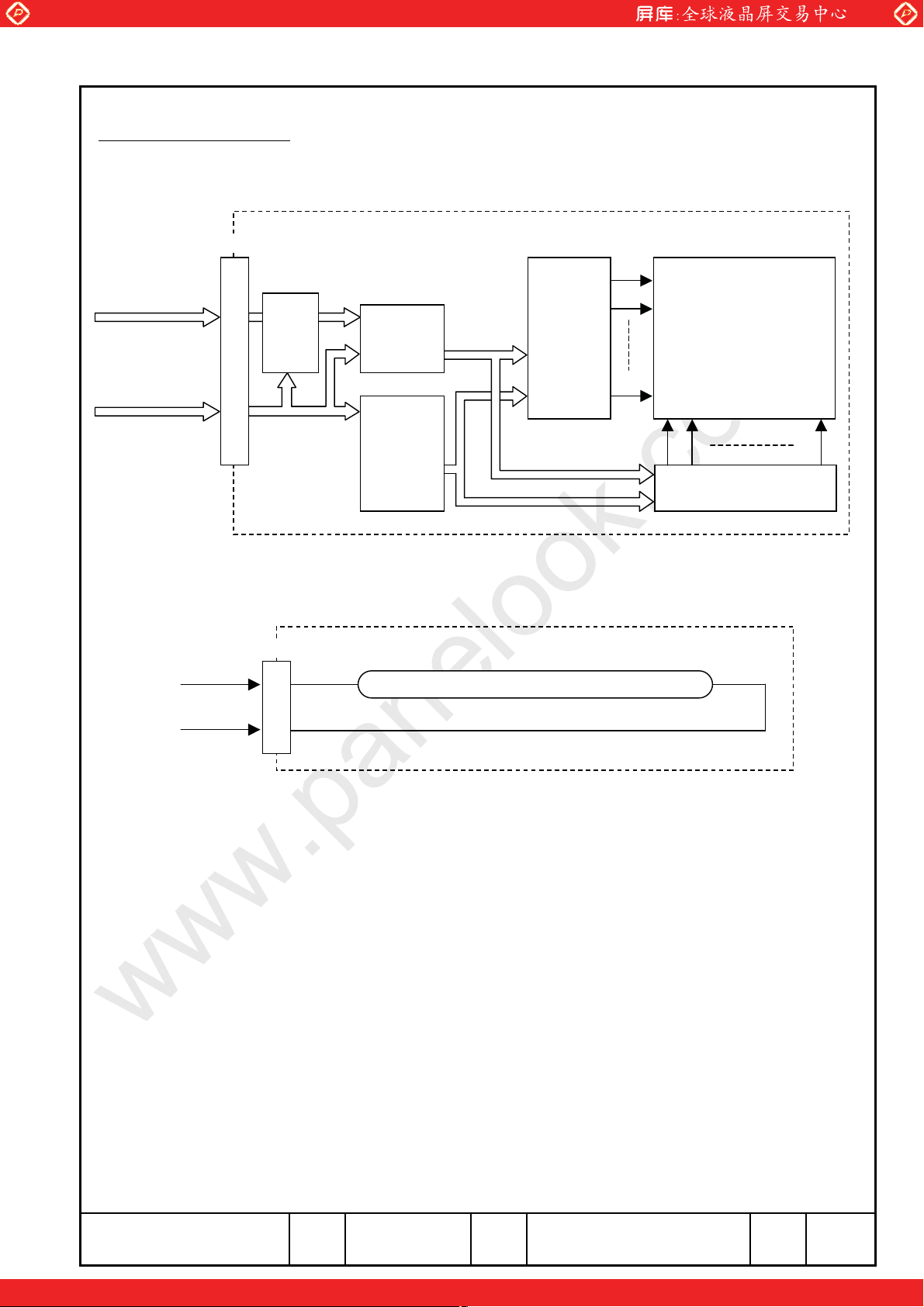

4. BLOCK DIAGRAM

4.1 TFT LIQUID CRYSTAL DISPLAY MODULE

Connector

CN1 G1

Timing signal

Display data

LVDS

Receiver

www.panelook.com

Timing

Converter

Gate

Driver

G2

TFT-LCD

DC Power

supply

4.2 BACK-LIGHT UNIT

Connector

V

L

GND

CN2

LCD

Drive

Circuit

Lamp

G768

D1

D2

D3072

Drain Driver

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

7-1/1

www.panelook.com

Page 10

Global LCD Panel Exchange Center

5. INTERFACE PIN CONNECTION

5.1 TFT LIQUID CRYSTAL DISPLAY MODULE

CN1 <<JAE FI-SEB20P-HF13 or equivalent>>

Pin No. Symbol Function

1 VDD Power Supply 3.3V nominal

2 VDD Power Supply 3.3V nominal

3 VSS Ground

4 VSS Ground

5 Rin0- Receiver Signal (-)

6 Rin0+ Receiver Signal (+)

7 VSS Ground

8 Rin1- Receiver Signal (-)

9 Rin1+ Receiver Signal (+)

10 VSS Ground

11 Rin2- Receiver Signal (-)

12 Rin2+ Receiver Signal (+)

13 VSS Ground

14 CLK- Clock Signal (-)

15 CLK+ Clock Signal (+)

16 VSS Ground

17 – NC

18 – NC

19 VSS Ground

20 VSS Ground

Notes 1) All VSS pins should be connected to GND (0V).

Metal bezel is connected internally to VSS.

2) All VDD pins should be connected to +3.3V.

3) All NC pins should be kept Open.

www.panelook.com

5.2 BACK-LIGHT UNIT

CN2 <<JST BHSR-02VS-1>>

Pin No. Symbol Function

1 VL Power Supply

2 GND GND (0V)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1Date

8-1/4

www.panelook.com

Page 11

Global LCD Panel Exchange Center

LVDS INTERFACE

PC Side TFT-LCD Side

www.panelook.com

CN1

2) 1)

R0~R5

G0~G5

B0~B5

Hsync

Vsync

DTMG

CLK

Host

Graphics

Controller

6

6

6

TFT

Parallel-to-LVDS

PLL

IN0+

IN0IN1+

IN1IN2+

IN2-

CLK+

CLK-

LVDS-to-TTL

PLL

6

6

6

Parallel

R0~R5

G0~G5

B0~B5

Hsync

Vsync

DTMG

LCD Panel

Controller

CLK

Notes 1) LVDS cable impedance is 100 ohms per signal line when two are used differentially...

2) Transmitter: TI SN75LVDS84, or equivalent.

Transmitter is not contained in Module.

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

8-2/4

www.panelook.com

Page 12

Global LCD Panel Exchange Center

LVDS Input Signal

V

V

V

www.panelook.com

Rin0

Rin1

Rin2

diff=0V

G0 R5 R4 R3 R2 R1 R0

B1 B0 G5 G4 G3 G2 G1

DTMG Vsync Hsync B5 B4 B3 B2

Prior cycle Signal for 1 DCLK cycle Next cycle

Pin connection in case of using

TI SN75LVDS84

INPUT Transmitter Interface connecter (CN1)

SIGNAL PC Module

R0 IN0(44)

R1 IN1(45) OUT0+ IN0+

L R2 IN2(47)

R3 IN3(48)

D R4 IN4(1)

S R5 IN5(3) OUT0- IN0-

G0 IN6(4)

G1 IN7(6)

G2 IN8(7) OUT1+ IN1+

G3 IN9(9)

G4 IN10(10)

G5 IN11(12)

B0 IN12(13) OUT1- IN1B1 IN13(15)

B2 IN14(16)

B3 IN15(18) OUT2+ IN2+

B4 IN16(19)

B5 IN17(20)

HSYNC IN18(22)

VSYNC IN19(23) OUT2- IN2DTMG IN20(25)

DCLK CLK IN(26) CLK OUT+ CLK IN+

CLK OUT- CLK IN-

Note 1) The ( ) valve of the transmitter show IC pin No.

diff=0VCLK+

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1Date

8-3/4

www.panelook.com

Page 13

Global LCD Panel Exchange Center

RELATIONSHIP BETWEEN DISPLAY COLORS AND INPUT DATA

www.panelook.com

Color

Basic

Color

Red

Green

Input data

MSB LSB MSB LSB MSB LSB

Black 0

Red (63) 000000

Green (63) 0

Blue (63) 111111

Cyan 1

Magenta 111111

Yellow 0

White 111111

Black 0

Red (1) 0

Red (2) 0

…

…

Red (61) 0

Red (62) 000000

Red (63) 0

Black 0

Green (1) 0

Green (2) 0

…

…

111111

000000

111111

111111

000001

000010

…

…

111101

111110

000000

000000

000000

…

…

R Data G Data B Data

G1 G0G5 G4 G3 G2R0R4 R3 R2 R1

00000000000000

000000

11001111000000

000000

11111111000000

000000

11001111111111

111111

0000000000000

0

00000000

00000000

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

…

00000000

000000

0000000111111

00000000

01000000

10000000

…

…

…

0

…

…

00

0

00

0

11

1

00

0

000

000

000

…

…

…

…

…

…

000

000

000

000

000

…

…

…

…

…

…

B0B3 B2 B1B5 B4R5

…

…

…

…

Green (61) 000000

Green (62) 0

Green (63) 000000

Black 0

Blue (1) 1

Blue (2) 0

…

Blue

Notes 1) Definition of gray scale :

Color (n) --- number in parenthesis indicates gray scale level.

Larger number corresponds to brighter level.

2) Data Signal : 1: High, 0: Low

…

Blue (61) 1

Blue (62) 0

Blue (63) 1

000000

000000

000000

000000

…

…

…

…

…

…

…

…

…

…

…

…

000000

000000

000000

…

…

…

…

…

…

011111

10001111000000

111111

0000000000000

00000000

00000000

…

…

…

…

010000

010000

001

0

…

…

…

…

01

01

0

000

000

001

…

…

…

…

110

111

10000

111

00

…

…

…

…

…

…

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1Date

8-4/4

www.panelook.com

Page 14

Global LCD Panel Exchange Center

6. INTERFACE TIMING

V

V

K

V

6.1 LVDS RECEIVER TIMING

(Interface of TFT module)

Rx6

Rx5 Rx4 Rx3 Rx2 Rx1 Rx0RinX

www.panelook.com

t

t

RP4

t

RP5

t

RP6

t

RP0

t

RP1

RP3

t

RP2

CLK

RinX=(RinX+)–(RinX-) (X=0,1,2)

CLK=(CLK+)–(CLK-)

Item Symbol Min. Typ. Max. Unit Note

DCLK FREQUENCY

RinX 0 data position

(X=0,1,2) 1st data position

2nd data position

3rd data position

4th data position

5th data position

6th data position

1/t

t

t

t

t

t

t

t

CLK

PR1

PR0

PR6

PR5

PR4

PR3

PR2

t

CL

diff=0V

60 65 68 MHz

-0.49 0 +0.49

1/7t

2/7t

3/7t

4/7t

5/7t

6/7t

–0.49 1/7t

CLK

–0.49 2/7t

CLK

–0.49 3/7t

CLK

–0.49 4/7t

CLK

–0.49 5/7t

CLK

–0.49 6/7t

CLK

CLK

CLK

CLK

CLK

CLK

CLK

1/7t

2/7t

3/7t

4/7t

5/7t

6/7t

CLK

CLK

CLK

CLK

CLK

CLK

+0.49

+0.49

+0.49

+0.49

+0.49

+0.49

diff=0V

ns

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1Date

9-1/4

www.panelook.com

Page 15

Global LCD Panel Exchange Center

V

6.2 TIMING CONVERTER TIMING

(Input timing for transmitter)

Hsync

t

SV

Vsync

t

WH

Hsync

t

HBP

DTMG

www.panelook.com

t

HP

t

WI

t

HV

t

HfP

t

VP

t

W

Vsync

t

IP

Hsync

t

VBP

DTMG

The timings except mentioned above are referred to the specifications

of your transmitter.

t

VfP

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

9-2/4

www.panelook.com

Page 16

Global LCD Panel Exchange Center

Item Symbol Min. Typ. Max. Unit Note

Hsync

Vsync

DTMG Horizontal Back Porch

Note 1)

Period

Width-Active

Setup time

Hold time

Period

Width-Active

Display lines

Display clocks

Horizontal Front Porch

Vertical Back Porch

Vertical Front Porch

t

+ t

VFP

t 3t

HP

VBP

www.panelook.com

t

t

t

t

t

t

t

t

HP

WH

t

SV

HV

t

VP

WV

t

IP

t

WI

HBP

HFP

VBP

VFP

1,142 1,344 2,400

8 136 160

-2 – –

0––

771 806 1,000

1 6 120

768 768 768

1,024 1,024 1,024

32 – 416

4––

0––

1––

t

t

t

t

t

t

t

CLK

CLK

HP

HP

CLK

CLK

HP

For Hsync

1)

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

9-3/4

www.panelook.com

Page 17

Global LCD Panel Exchange Center

6.3 TIMING BETWEEN INTERFACE SIGNAL AND POWER SUPPLY

3.0V 3.0V

www.panelook.com

Power supply

V

(t)

DD

Interface signal

(t)

V

I

Back-Light

0V

0.8V

Note 1)

t

1t2

POWER ON

t1 d 15ms

0 < t

0 < t

2

3

0.1s d t

t

4

d 45ms

d 5ms

4

0.8V

VALID

t

3

t

Note 1)

t

t

3

5

t

6

7

t

8

ON

POWER OFF

Notes 1) t2: Hi-Z(Hi-impedace)state

2) t3: Signal transition time from Hi-Z state to Valid state specified by 3-1, 6-1 and 6-2.

3) Recommended value

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

9-4/4

www.panelook.com

Page 18

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

8. DESIGNATION OF LOT MARK

Y

8.1 LOT MARK

Lot Mark is consisted of 4 digits for production lot and 7 digits for production control.

www.panelook.com

5907

Month 2)

ear 1)

Notes

1) Year Mark 2) Month Mark Month Mark 3) Week (Days) Mark

2006 6 1 01 7 07 1~7 1

2007 7 2 02 8 08 8~14 2

2008 8 3 03 9 09 15~21 3

2009 9 4 04 10 10 22~28 4

2010 0 5 05 11 11 29~31 5

H

Optional Mark 5)

Hitachi internal use 4)

Week 3)

6061212

Serial No.

4) H Made in JAPAN

C Made in CHINA

Optional Mark for Hitachi.

5)

8.2 SERIAL NO.

Serial No. is consisted of 5 digits number (00001~99999).

Sh.

No.

PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1Date

11-1/2

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

8.3 LOCATION OF LOT MARK

Label is attached on the back side of module.

8.4 REV.

8.4.1 Made in JAPAN

www.panelook.com

Lot No. &

Production Control No.

8.4.2 Made in CHINA

Lot No. &

Production Control No.

TX36D88VC1CAA

CAUTION HIGH VOLTAGE

7095H 00001

REV

COLD CATHODE FLORESCENT LAMP IN COLOR LCD CONTAINS MERCURY.

PLEASE FOLLOW LOCAL ORDINANCES OR REGULATIONS FOR ITS DISPOSAL.

TX36D88VC1CAA

MADE IN JAPAN

L0 05 00 3 A 22 000001

CAUTION HIGH VOLTAGE

7095C 00001

REV

MADE IN CHINA

L0 05 00 3 A 22 000001

COLD CATHODE FLORESCENT LAMP IN COLOR LCD CONTAINS MERCURY.

PLEASE FOLLOW LOCAL ORDINANCES OR REGULATIONS FOR ITS DISPOSAL.

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

11-2/2

www.panelook.com

Page 21

Global LCD Panel Exchange Center

9. COSMETIC SPECIFICATIONS

A

9.1 CONDITIONS FOR COSMETIC INSPECTION

www.panelook.com

(1) Viewing zone

Viewing

zone

i) The figure shows the correspondence

between eyes (of inspector) and

TFT/LCD module.

•Td 45° when non-operating inspection

•Td 5° when operating inspection

ii) Inspection should be executed only

about

300mm

T

from front side, and only A-zone.

Cosmetic of B-zone and C-zone are

0

ignored.

(refer to 9.2 DEFINITION OF ZONE)

TFT/LCD module

(2) Environmental

i) Temperature : 25°C

When operating inspection, surface temperature of LCD panel

is 25°C.

ii) Ambient light : More than 800 [lx] and non-directive.

iii) Back-light : When non-operating inspection, Back-light should be off.

mbjent

light

(3) Operating inspection

Operating inspection should be done with 8 color mode (without gray scale).

9.2 DEFINITION OF ZONE

•A-zone : Display area (pixel area).

•B-zone : Area between A-zone and C-zone.

•C-zone : Metal bezel area.

A-zone

B-zone

C-zone

(Include I/F connector)

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

12-1/3

www.panelook.com

Page 22

Global LCD Panel Exchange Center

9.3 COSMETIC SPECIFICATIONS

When displaying condition is not stable (ex. at turn on or off),

the following specifications are not applied.

No. Item

1 Dot Defect 1dot 10 pcs 1), 2) 4)

Sparkle 2dots 4

mode 3dots 0

Black 2dots 4

mode 3dots 0

2 Line Defect Serious one

3 Uneven Brightness is no good.

4 Stain Inclusion W < 0.05 L: Ignore Ignore

Line shape W t 0.05

W: width (mm) < 0.08

L: length (mm) 0.08 d W 3.0 < L 0

5 Stain Inclusion D < 0.22 Ignore

Dot shape 0.22 d D < 0.50 5 pcs 7)

D: average dia.

6 Scratch on polarizer W < 0.05 L: Ignore Ignore

Line shape W t 0.05 L d 3.0 4

W: width (mm) < 0.10 3.0 < L 0

L: length (mm) 0.10 d W0

7 Polarizer Dent/Bubble D d 0.3 Ignore

/Peeling 0.3 < D d 0.5 10 pcs 8)

D: average dia.

8 Wrinkles on Polarizer Serious one

(mm) 0.50 d D0

(mm) 0.5 < D d 1.0 5

www.panelook.com

Maximum acceptable number

A-zone

density 1

1dot 10 pcs 1), 3), 4)

density 1

Total 10 pcs 1)

L d 3.0

1.0 < D 0

10

is no good.

Unit

units

pcs/I10

units

pcs/I5

pcs

pcs 8)

–

Note

1), 2), 5)

1), 2), 6)

1), 3), 5)

1), 3), 6)

––

7)

–

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

12-2/3

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

Notes 1) Dot Defect

2) Sparkle mode

3) Black mode

4) 1 dot

5) N dots

R G B R G B R G B The combination of the defect dot × and

R G B R G B R G B are considered as consecutive defect dots.

: Defect area > 1/2 dot

: Brightness of dot is more than 30% at Black raster. (Visible to eye)

: Brightness of dot is less than 70% at white raster. (Visible to eye)

: defect dot is isolated, not attached to other defect dot.

: N defect dots are consecutive. (N means the number of defect dots. (N t 2))

other defects () as shown in Fig. (a)

×

R G B R G B R G B : Directory adjacent to ×

RGBRGBRGB

Fig. (a)

6) Density : Number of defect dots inside of specified diameter.

7) Those stains which can be wiped out easily are acceptable.

8) Polarizer area inside of B-zone is not applied.

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

12-3/3

www.panelook.com

Page 24

Global LCD Panel Exchange Center

10. PRECAUTIONS

Please pay attention to the followings when you use this TFT/LCD module with

Back-light unit.

10.1 MOUNTING PRECAUTION

(1) You must mount Module using mounting holes (4 holes at side of Module) tightly.

(2) You should consider the mounting structure so that uneven force (ex. twisted stress)

is not applied to Module.

And the case which Module is mounted should have sufficient strength so that

external force is not transmitted directly to Module.

(3) To improve the strength of module against the mechanical shock the space between

module and the case should be less than 1.0mm.

www.panelook.com

TFT Module

case

1.0mm max.

(4) You should adopt radiation structure to satisfy the temperature specification.

(5) Acetic acid type and chlorine type materials for the cover case should not be used.

Because the former generate corrosive gas of attacking the polarizer at high

temperature and the latter causes circuit break by electro-chemical reaction.

(6) Do not touch, push or rub the exposed polarizers with glass, tweezers or anything

harder than HB pencil lead. And please do not rub by dusty clothes with chemical

treatment.

Do not touch the surface of polarizer with bare hand or greasy close.

(Some cosmetics are detrimental to the polarizer.)

(7) When the surface becomes dusty, please wipe gently with absorbent cotton.

IPA (Isopropyl Alcohol) is recommended for cleaning the adhesives used to

attach front/rear polarizers. Don't use acetone, toluene, and alcohol because

they cause chemical damage to polarizer

(8) Wipe off saliva or water drops as soon as possible. Their long time contact with

polarizer causes deformations and color fading.

(9) Do not open the case because inside circuits have not sufficient strength.

(10) Use fingerstalls of soft gloves in order to keep clean display quality,

when you handle the device for incoming inspection and assembly.

(11) Do not pull or do not fold the CFL cable.

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

Sh.

No.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

13-1/4

www.panelook.com

Page 25

Global LCD Panel Exchange Center

10.2 OPERATING PRECAUTION

(1) Response time depends on the temperature. (In lower temperature, it becomes longer).

And also Transmittance and Color depend on the temperature.

(2) Brightness depends on the temperature. (In lower temperature, it becomes lower).

And in lower temperature, response time (required time that brightness is stable

after turn on) becomes longer.

(3) Optical characteristics (eg. Luminance, uniformity, color coordinate etc.)

gradually change by operating condition, especially low temperature change faster,

because LCD module has Cold Cathode Fluorescent Lamp.

(4) Be careful for condensation at sudden temperature change.

Condensation make damage to polarizer or electrical contact part.

And after fading condensation, smear or spot will occur.

(5) When fixed patterns are displayed at long times, afterimage is likely to occur.

(6)

The Module have high frequency circuit. If you need to shield the electromagnetic

noise, please do in yours.

(7)

When Back-light unit is operating, it sounds.

If you need to shield the noise, please do in yours.

(8)

Please connect the Back-light connector to the inverter circuit directly.

The long cable between CFL and the inverter may cause the brightness drop of CFL

and may cause the rise of starting lamp Voltage (VS).

(9) Do not connect or remove the module from main system with power applied.

www.panelook.com

10.3 ELECTROSTATIC DISCHARGE CONTROL

(1) Since Module is composed with electronic circuit, it is not strong to electrostatic

discharge. Make certain that treatment persons are connected to ground through

list band etc.. And don't touch I/F pin directly.

(2) When the polarizer protection film is peeled off, electrostatic discharge occurs.

Please peel it of slowly.

10.4 PRECAUTION FOR STRONG LIGHT EXPOSURE

Strong light exposure causes degradation of polarizer and color filter.

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

13-2/4

www.panelook.com

Page 26

Global LCD Panel Exchange Center

10.5 STORAGE

When storing Module as spares for long time, the following precautions are necessary.

(1) Store them in a dark place ; do not expose then to sunlight or fluorescent light.

Keep the temperature between 5°C and 35°C at normal humidity.

(2) The polarizer surface should not come in contact with any other object.

It is recommended that they be stored in the container in which they were shipped.

10.6 HANDLING PRECAUTIONS FOR PROTECTIVE FILM

(1) When the protective film is peeled off, static electricity is generated between the

film and the polarizer.

This film should be peeled off slowly and carefully by people who are electrically

grounded and with well ion-blown equipment or in such a condition, etc.

(2) The protective film is attached to the polarizer with a small amount of glue.

If some stress is applied to rub the protective film against the polarizer during

the time you peel off the film, the glue is apt to remain more on the polarizer.

So please carefully peel off the protective film without rubbing it against the polarizer.

(3) When the Module with protective film attached is stored for long time,

sometimes there remains a very small amount of glue, still on the polarizer after the

protective film is peeled off.

Please refrain from storing the Module at the high temperature and high humidity

for glue is apt to remain in these condition.

(4) The Glue may be taken for the Modules failure, but you can remove the Glue easily.

When the glue remains on the polarizer surface or its vestige is recognized,

please wipe them off with absorbent cotton waste or other soft material soaked with

IPA (Isopropyl Alcohol).

www.panelook.com

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

13-3/4

www.panelook.com

Page 27

Global LCD Panel Exchange Center

10.7 SAFETY

(1) If Module is broken, be careful to handle not to injure. (TFT/LCD and Lamp are

made of glass.)

Please wash hands sufficiently when you touch the liquid crystal coming out from

broken LCDs.

(2) As Back-light unit has high voltage circuit internal, do not open the case and do

not insert foreign materials in the case.

(3) The LCD Modules include Cold Cathode Fluorescent Lamp (CFL).

CFL contains a small amount of mercury. Please follow local ordinances or

regulations for disposal.

(4) The CFL inverter should be designed to include the function of output shutdown

in case the output over current happens due to any backlight trouble.

The shutdown function should be assured to work in abnormal condition at the

actual system.

www.panelook.com

Date PageHitachi Displays, Ltd. Sep. 18, 2007 DPBCL0001618-1

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

13-4/4

www.panelook.com

Loading...

Loading...