Basic

HITACHI SJ Series

Guide

I

nverter

Read this “Basic

P1

Guide

”, and keep it handy for future reference.

If you have any

Refer to

or

C

ontact

for Inverter.

When making a contact, inform

the reference number on below.

Introduction

Contents

Chapter 1

:

Chapter 2

:

Chapter 4

:

Chapter 3

:

I/O Adjustment

Chapter 5

:

Chapter 6

:

Chapter 7

:

Index

inquiry or problem

Chapter 5 Troubleshooting

to

the Technical Inquiry Service

List of contact information

NT

Safety Instructions

Installation and Wiring

Settings

Operation Setting and Examples of

Troubleshooting

Maintenance and Inspection

Specifications

NT2511B

2511

,

X

0-1

Introduction Introduction/Cautions

/Warranty & Contact us

Introduction

Thank you for purchasing Hitachi SJ Series P1 Inverter.

This is a user guide for basic handling and maintenance of

Hitachi SJ Series P1 Inverter.

For the purpose of reduction of paper usage and

provision of the latest information, we enclose the Basic

Guide only while providing the User's Guide for more

detailed description through electronic means instead of

CD or a printed document.

About the Basic Guide (this document)

The Basic Guide provides the minimum information

necessary for handling the product. Please make sure to

read this document as well as the User's Guide with more

detailed information.

About the User's Guide

The User's Guide provides detailed information necessary

for handling the product. Please make sure to read the

User's Guide for proper use.

If future updates make any difference from the Basic

Guide, the description in the User's Guide will have higher

priority. You should use the inverter by observing

specifications described in User's Guide. You should also

prevent risks by performing proper inspection and

maintenance.

Please refer to the following link for download:

Hitachi Industrial Equipment Systems' Website

http://www.hitachi-ies.co.jp/

Please follow as below on the Website.

Product Information -> Inverter -> Download of

technical data

Handling an optional products

If you use the inverter with optional products, also you

should read the instruction enclosed in those products.

Cautions

Proper use of the inverter

Please read the Basic Guide, User's Guide and optional

products instruction before handling. Read carefully the

Basic Guide, User's Guide or optional product instruction

before handling or performing maintenance of the

product.

Before attempting installation, operation, maintenance,

and inspection work, you should understand the

knowledge of equipment, information of safety,

precaution and how to use and service the inverter.

Cautions

No part of this document may be reproduced or reformed

in any form without the publisher's permission.

The contents of the document are subject to change

without prior notice.

If you lose the Basic Guide and need another one in

printed form, you will be charged for resupply, so please

keep it carefully.

You "CANNOT DO" what is not described in Basic Guide or

User's Guide. We are not responsible for any impact from

operations regardless of unexpected failure or accident

due to the operation or handling of the product in a

manner not specified in Basic Guide or User's Guide. We

apologize in advance for any inconvenience this may

cause.

If you find any unclear or incorrect description, missing

description, or misplaced or missing pages, please takes

time to inform Hitachi inverter technical service office.

Note that, the Basic Guide, User's Guide and the

instruction for each optional product enclosed, should be

delivered to the end user of the inverter. And also make

sure to be accessible any other guides or instruction to

the end user.

0-2

Introduction Introduction/Cautions

/Warranty & Contact us

Method of Inquiry and Product Warranty

Method of Inquiry about Product

• For an inquiry about product damage or faults or a question

about the product, notify your supplier or Hitachi inverter

technical service office.

Product Warranty

• The product SJ series P1 inverter will be warranted by Hitachi

Industrial Equipment Systems Co., Ltd., afterward "Hitachi",

during the warranty period from your date of purchase only

under proper usage of product.

• Furthermore, the warranty expressed here is covered only for

the product delivered from Hitachi, and will not be

responsible for others damage or loss of products like a

motor or any equipment or systems damage caused by

improper usage of the product. Minimize the consequence

on equipment or system by applying safety design which is

able to notify a hazard alarm to the user in case of

malfunction or damage of the delivered product. The

selection and application of delivered product must be done

with sufficient margin on performance, as well as other

equipment or system with sufficient redundancy design. Also,

the compatibility of the product with the customer's

intended use is not warranted, hence the validation test

should be done by the customer by their responsibility

before put in operation.

• In case of delivery a defective product, or encountered a

defects on quality during a manufacturing process, Hitachi

will repair or exchange with free of charge, only when the

product is in warranty period (afterward, we call "warranty

service").

• The product will be warranted for one year from your date of

purchase. However, depending on case, sending technical

assistance for repairing will be charged to the customer. Also,

Hitachi will not be responsible of any readjustment or testing

on site.

• After warranty service, the exchanged or repaired part will be

warranted for 6 month from date of warranty service. Hitachi

will be responsible for repair or exchange of defective part

only for the exchanged or repaired part only during this

warranty period.

• In order to receive warranty service, you should present the

recipe issued by product supplier or any other document that

permit to check the purchase date. However, any defects,

damage, malfunction or any other failure caused by one of

the following facts will not be covered by warranty service.

(1) Cannot confirm the purchase date.

(2) The damage or fault resulted from improper usage or

inadequate handling of the product and not conforming

usage described into the user's guide or basic guide.

(3) Incorrect usage of product, inadequate setting of

product and optional product, remodeling or inadequate

repair and repair carried out by unqualified repair

center.

(4) Deterioration and wear resulted from normal operation.

(5) Fault resulted from natural disaster, such as earthquake,

fire disaster, lightning strike, pollution, salt pollution, or

abnormal voltage or any others external factor.

(6) Shock, falling, or Vibration resulted during

transportation or displacement after purchase.

(7) Damage or fault resulted from remodeling firmware by

unqualified personal not belonging to Hitachi.

(8) Damage or fault resulted from customer's made

programing function (EzSQ).

(9) For overseas use.

• By warranty service, might lose the data stored inside the

product, as well as, customers made (EzSQ) program. Make

sure to back up by own responsibility. However, in case of

malfunction resulting from the circuit board of the storage

devices, the backup wil not be possible. It is recommended

to keep a backup during the testing phase by using VOP or PC

software ProDriveNext.

Liability Limitation

• Neither Hitachi-IES, Affiliated company nor related dealer are

liable to the written and unwritten public requirement

including the common sense of the product or requirement

in specific application

• Even more, Hitachi, affiliated company or related dealer are

not responsible of any incidental damage, special damage,

direct loss, or indirect loss (even predictable or not) resulted

on customer because of product defect.

■ Inverter Model: It beginning with P1- in specification label.

■ Manufacturer Number(MFG No.): It shows in specification label.

■ Date of purchase: Customer's purchased period.

■ Inquiry contents:

・ Inform us the defective point and its condition.

・ Inform us the suspicious content and its detail.

0-3

Introduction Introduction/Cautions

/Warranty & Contact us

Warranty Service

• The customer is able to receive a warranty service from

product supplier or service station, if the product does not

meet the function described on basic guide or user's guide.

Moreover, in case of any mismatch occurred between user's

guide and basic guide, user's guide content will take a

priority.

• Contact to your supplier or local Hitachi distributor or service

station for fare-paying services.

Change on Product Specification

• We are sorry because any information described in Brochure,

Basic Guide, User's Guide or Technical Document would be

modified without notice.

Precaution for Product Application

• The product should apply following the condition of use,

handling method and precautions described in User's Guide.

• The installed product should be confirmed previously by own

that the product installation has done as intended in the

customer system.

• When using Hitachi inverter consider on below

(1) Select inverter with sufficient capacity for rate current

and performance.

(2) Safety design, for example, redundant system design.

(3) Equipment design where minimize hazard in case of

inverter failure.

(4) For safety precautions, make a system configuration that

alarms the hazard to user.

(5) Periodic maintenance of Hitachi inverter and customer's

equipment.

• Hitachi inverter is designed and manufactured intentionally

to be applied for general industrial equipment application.

It is not intended to be used for the applications listed

below therefore. In case inverter is used for these

applications, it is out of warranty unless there is a special

written agreement. Otherwise, the product will not be

warranted.

(1) Special application such as aircraft, spacecraft, nuclear,

electric power, passenger transportation, medical,

submarine repeater, etc.

(2) For application such as elevator, amusement equipment,

medical equipment which might have a big effect on

human life and property.

• Even for above application, in case there is an agreement for

the limitation of the purpose and quality, please contact to

our sales office. Further study will be carried out to check

whether inverter is applicable for that specific application or

not.

• For applications that involve human life, or have risk of

important loss, make sure to avoid a critical accident by

installing a fail-safe device, protecting device, detecting

device, alarm device, or spare device, etc.

• This inverter is only for three phase induction motor [IM] or

three phase synchronous motor [SM(SMM)].

• For any other application make inquiries.

Supplement

• Refer to "Chapter 7 Specification" for short lifespan

component.

• For optional product refer attached instruction.

• This warranty term will not restrict a legal right of customer

who has purchased the product.

• Contact to the local supplier for warranty of purchased

product sales in oversea.

Contact Information

Hitachi America, Ltd. (Charlotte Office)

Industrial Components and Equipment Division

6901 Northpark Blvd., Suite A, Charlotte, NC 28216,

U.S.A

TEL : +1(704) 494-3008

FAX : +1(704) 599-4108

Hitachi Europe GmbH

Industrial Components & Equipment Group

Am Seestern 18 (Euro Center),

D-40547 Dusseldorf,

Germany

TEL : +49-211-5283-0

FAX : +49-211-5283-649

Hitachi Asia Ltd.

Industrial Components & Equipment Division

No.30 Pioneer Crescent, #10-15 West Park Bizcentral,

Singapore 628560,

Singapore

TEL : +65-6305-7400

FAX : +65-6305-7401

Hitachi Australia Ltd.

Level 3, 82 Waterloo Road

North Ryde, N.S.W.2113

Australia

TEL : +61-2-9888-4100

FAX : +61-2-9888-4188

Hitachi Industrial Equipment Systems Co., Ltd.

AKS Building, 3, Kanda

Nereibei-cho, Chiyoda-ku,

Tokyo, 101-0022

Japan

TEL : +81-3-4345-6910

FAX : +81-3-4345-6067

●

●

●

●

Contents

Quick start

Introduction/instructions

Types of Warnings

Description of Safety Symbols

Precautions for Installation

Precautions for Wiring

Precautions

Check the Inverter

Install the Inverter

Dimensions Drawing

Inverter Wiring

Wiring of

Recommended

Operation Setting and Examples of IO

Keypad

overview

Monitor

Troubleshooting

Cautions for Maintenance/Inspection

Daily and Periodic Inspections

Method of Checking the Inverter and Converter

Circuits

................................

Specifications Table

Appendix Index

Quick start

Chapter 1 Safety Instructions

Chapter 2 Installation and Wiring

Chapter 3 Operation Setting and Examples of IO Adjustment

Chapter 4 Settings

Chapter 5 Troubleshoot

Chapter 7 Specifications

Chapter 6

................................

................................

to Run

and Test Running

................................

................................

................................

................................

the main circuit

wire gauges, accessories etc.

................................

naming

................................

................................

................................

................................

................................

Inspection and

..............................

................................

..............................

................................

................................

................................

..............................

................................

.................

ing

Maintenance

.......

................

.

........

.................

................

................

.............

.....................

.....

.......

Adjustment

..................

..................

4

....................

..................

..

..............

...........

index

Appendix

0-4

0-1

0-2

1-1

1-1

1-2

1-2

1-3

2-1

2-2

2-4

2-6

2-7

2-8

3-1

4-1

-10

5-1

6-1

6-2

6-4

7-1

-1

-1

●

●

Precautions

Precautions for

Other Cautions

Compliance

Compliance

Applicable Circuit Breaker

Ch

opper Breaking Resistor

Wiring

Wiring of the Control Circuit

Control Circuit Wiring Section

Residual Risk

Parameters

DC

-

Output of Life Warning

Methods of Measuring the Input/Output Voltages,

Current, and Power

Method of Inquiry and Product Warranty

Contents

................................

for Maintenance/Inspection

Dispolsal

................................

to European Directive (CE)

to UL standards

................................

................................

naming

Bus Capacitor Life

................................

................................

................................

................................

................................

................................

................................

................................

Curve

................................

................................

................................

...............................

.................

............................

......................

.............................

...................

.....................

Contents

.......... 0-3

0-4

1-4

.......... 1-4

1-4

1-5

....... 1-7

......... 2-10

........ 2-12

....... 2-13

..... 2-17

... 2-19

2-24

4-13

........ 6-5

............... 6-5

6-6

0-5

Contents

Contents

(Memo)

Chapter 1

1.1

In the Basic Manual, the severity levels of

precautions and residual risks are classified as:

"

Display

Even more, that "

to a serious risk depend on the circumstances. Be sure to

follow the instruction because whichever contains

important safety description.

Chapter 1

Safety Instructions

Types of Warnings

WARNING"

and

m

eanings

Indicates that incorrect handling may cause hazardous

situations, which would most likely result in serious

personal

injury or death,

loss or damage.

Indicates that incorrect

situations, which may result in serious personal injury or

death, and may result in major

Indicates that incorrect handling may cause hazardous

situations,

which may result in moderate or slig

personal

injury or damage, and may result

loss or damage.

"

CAUTION

and may result in major physical

WARNING

handling may cause hazardous

CAUTION

CAUTION

".

DANGER

physical loss or damage.

" level description may lead

safety

"

DANGER

ht

only

physical

1-1

",

1.2

It describes annotation of t

to follow and pay attention of content.

Symbols

1.3 Description of Safety Symbols

Read carefully following safety instruction for handling.

Description of Safety Symbols

m

eaning

Indicates a danger, warning or caution notice

for

fire, electric shock and high temperature

while handling the product

Details are indicated in or near

or words.

Indicates “what you must not do”

the described acts

product.

Indicates “what you must do”

the instructions

product.

Safety Instructions

he

s

The

drawing on the left indicates

non-

specific and general

caution”.

The drawing on the left indicates

possible

damage

shock”.

in the operation of the

s

ymbols in context

.

due to electric

in the

operation of the

according to

. Be sure

by pictures

“a

danger or

“a

to prohibit

Chapter 1

1.3.1

Caution

•

•

1.3.2

Precautions for installation

●

•

•

•

•

●

•

1.3.3 P

recautions for Wiring

●

•

•

•

●

•

Caution

Practice

Fire

Injury

Prohibited

Electric

shock Fire

Practice

Failure

Prohibited

Practice

Prohibited

Incorrect handling may result in personal

or severe injury, or may result in damage to

inverter, motor or the whole system.

Be sure to read this Basic Manual and

documents thoroughly

operating, maintaining, inspecting or

inverter.

You run the risk of fire!

Do not place flammable materials near

installed inverter.

Prevent foreign matter (e.g., cut pieces of wire,

sputtering welding materials, iron chips, wire,

and dust) from

Install the inverter on a non

such as, metal

Install the inverter in a well

site

not exposed to direct sunlight.

where the inverter is exposed to high

temperature,

high humidity, condensation, dust,

explosive gases,

gases, g

rinding fluid mist,

You run the risk of injury!

Do not install and operate the inverter

damaged or its parts are missing.

You run the risk of electric shock or

fire!

Be sure to ground

Commit wiring work to

Before wiring, make sure that the power supply

is off.

You

run the risk of failure of the

inverter!

Do not pull the wire after wiring.

before installing, wiring,

penetrating into

-

surface.

corrosive gases, flammable

or salt water.

the inverter.

a qualified electrician.

death

appended

using the

to

the inverter.

flammable surface,

-

ventilated indoor

Avoid places

if it is

WARNING

D

DANGER

1-2

the

the

Failure

Prohibited

AN

GER

Caution

Fall

Injury

Prohibited

Practice

Electric

shock

Injury

Short

circuit

Ground

Prohibited

Practice

Practice

•

Many of the drawings

inverter with covers and/or parts

as removed to

•

Do not operate the inverter in the status shown in

those drawings. If you have removed the

and/or parts, be sure to reinstall them in their

original positions before starting operation,

follow all instructions when operating the inverter.

●

You run the risk of injury due to the

inverter falling

•

Do not hold its cover parts w

inverter.

•

Install the inverter on a structure able to bear

the weight specified in this Basic

•

Install the inverter on a vertical wall that is free

of vibrations.

●

You run the risk of failure of the inverter!

•

The inverter is precision equipment.

allow it to fall or be subject to high impacts.

•

Also do not step on it, or place a heavy load on

it.

●

You run the risk of electric shock and

injury!

•

Perform wiring

●

You run the risk of short circuit and ground

fault!

•

Do not remove rubber bushings from the wiring

section.

may damage the wire.

Safety Instructions

illustrate the details.

only after installing the inverter.

Otherwise, the edges of the wiring cover

in the Basic

blocking your view

hen carrying the

Guide show

the

covers

and

Guide.

Do not

Chapter 1

●

●

1.3.4 P

recautions

●

●

●

Injury

Fire

Practice

Electric

shock

Injury

Prohibited

Electric

shock

Fire

Prohibited

Prohibited

Electric

shock

Prohibited

Injury

Fire

Practice

You run the risk of injury or fire!

•

Do not connect AC power supply to

output terminals (U, V, and W)

•

Make sure that the voltage of AC power supply

matches the rated voltage of your inverter.

You run the risk of electric shock

and injury!

•

Before operating slide switch SW in the

inverter, be sure to turn off the power supply.

•

Since the inverter supports two modes of

cooling-

fan operation, the inverter power is

not always off, even when the cooling fan is

stopped.

Therefore, be su

the power supply is off before wiring.

to

Run and

You run the risk of electric shock or

fire!

•

While power is supplied to the

touch any internal part or terminal of the

inverter. Also do not check signals, or connect

or disconnect any wire or connector.

•

While power is supplied to the inverter, do not

touch any internal part of the in

not insert a

m

You run the risk of electric shock!

•

Be sure to close the terminal block cover

before turning on the inverter power.

open the terminal block cover

being supplied to the inverter or

remains inside.

•

Do not operate switches

You run the risk of injury or fire!

•

While power is supplied to the inverter,

touch the

terminal of the inverter,

has stopped.

Test Running

aterial such as a rod

with wet hands.

any of the

.

re to confirm that

inverter, do not

verter. Also do

and etc.

Do not

while power is

voltage

do not

even if it

WARNING

DANGER

1-3

.

Prohibited

Injury

Damage

Prohibited

Injury

Prohibited

Practice

Practice

●

•

Do not use a single

•

Do not connect a resistor directly to any of the

DC terminals (PD, P, and N).

•

Do not use

the primary and secondary sides of the inverter

to stop its operation.

•

Tighten each screw to the specified torque.

•

No screws must be left loose.

•

Connect an earth

input circuit.

•

Use only the power cables, earth

breaker, and magnetic contactors that have

specified capacity (ratings).

●

• Do

not select the retry mode for controlling an

elevating or traveling device because free

status occurs in retry mode.

●

•

If the retry mode has been selected, the inverter

will restart suddenly after a break in the tripping

status.

the inverter when the inverter is under such

circumstances.

safety can be ensured,

restarts sudden

•

The [STOP] key on the operator keypad is effective

only when its function is enabled by setting.

Prepare an emergency

•

If an operation command has been input to

inverter

inverter may

recovery.

danger,

inverter

•

If an operation command has been input to the

inverter before the inverter enters alarm status,

the inverter will restart suddenly when the alarm

status is reset.

make sure that no operation command

input.

Fire

Safety Instructions

You run the risk of fire!

the magnetic contactor installed on

-

You run the risk of injury and damage to

machine.

You run the risk of injury!

Stay away from the machine controlled by

(Design the machine so that human

ly.)

before a short

restart operation after the power

If such a restart may put persons in

design a control circuit that disables the

rom restarting after power recovery.

Before resetting the alarm status,

-phase input.

-

leakage breaker

even when the inverter

stop switch separately.

-term

power failure, the

to the po

wer

-

leakage

the

-

running

the

has been

Chapter 1

●

1.3.5

Precautions for

●

1.3.6

Precautions for disposal

●

1.3.7 O

ther Cautions

●

•

Injury

Damage

Practice

Electric

shock

Practice

Electric

shock

Fire

Injury

Prohibited

Injury

Explosion

Practice

You run the

machine.

•

The inverter

speed of

operating

capacity and ratings

before operating

•

When you run the motor at a high frequency,

check

and confirm to each manufactures of a

permitting revolution of

and machine

• Check the

rotate

sound,

and vibrations

Maintenance/Inspection

You run the risk of electric shock!

•

Before inspecting the inverter, be sure to turn

off the power supply and

or more.

(Before inspection, confirm

Charge lamp

voltage between terminals P and N is

less.)

You run the risk of injury and

explosion!

•

For disposal of the inverter, outsource to a

qualified

industrial waste disposal contractor.

Disposing of the inverter on your own may

result in an explosion of the capacitor or

produce poisonous gas.

•

Contact us or your distributor

inverter.

You run the risk of electric shock, fire

and injury!

Never modify the inverter.

DANGER

risk of injury and damage to

easily

allows you to

motor.

of the motor or machine

.

the

.

motor

direction

while operating

wait for 10 minutes

on the inverter is off and

c

ontrol the

C

onfirm the

respective

motor

, abnormal

.

that the

the DC

45 V or

for fixing the

WARNING

DANGER

DANGER

1-4

Burn

I

njury

Prohibited

Injury

Practice

Prohibited

Practice

Life cycle

Practice

●

You run the risk of burn injury.

•

Inverter heat sink will heat up during operation.

Do not touch the heat sink

●

You run the risk of injury!

•

Install an external brake system

•

Commit only a designated person to

maintenance,

of parts.

metal accessories, e.g., bracelets,

maintenance and inspection work and to use

insulated tools

•

A qualified waste disposer includes

industr

ind

the

the

c

leansing

●

You run the risk of

the

•

Sterilizing and disinfecting a packaging

materials

fumigation method.

the fumigation treatment,

receive a critical damage

steams

(including fluorine, chlorine, bromine and

iodine)

Safety Instructions

inspection, and the replacement

(Be sure to remove wristwatches and

for the

ial waste collector/transporter

ustrial waste disposal operator

act related to

waste

m

for

disposing of the inverter.

life cycle of

a

use a means other than

.

Especially,

can cause corrosion in

CAUTION

.

if needed.

work.)

procedures stipulated in

anagement and

significantly

product!

If the product is included in

electronic parts

from emitted gases or

halogen disinfectants

the capacitor.

before

and

. Follow

p

ublic

shortening

wood

wood

1.4

(CE)

Compatibility)

The SJ series P1 inverter conforms to requirements of

Electromagnetic Compatibility (EMC) Directive (2014/30/EU).

However, when using the

with the following specifications and requirements to meet the

EMC Directive and other standards in Europe:

1. Power supply requirements

2. Installation requirement

3. Wiring requirements

4. Environmental requirements

Chapter 1

Compliance

1.4.1

Caution for EMC (Electromagnetic

WARNING: This equipment must be installed, adjusted,

and maintained by qualified engineers who have expert

kno

wledge of electric work, inverter operation, and the

hazardous circumstances that can occur. Otherwise,

personal injury may result.

a. Voltage fluctuation must be

b. Voltage imbalance must be ±3% or less.

c. Frequency variation must be ±4% or less.

d. Total harmonic distortion (THD) of voltage must be ±10% or

less.

a. SJ series P1 includes a built

filter must be activated.

b.

According to EN61800

any inverter with only C3 filter inside may NOT be

connected to a low voltage public power supply in

residential areas since for these installations C1 is required.

c.

In case of external filter

required according to EN61800

emit

high frequency interference in residential areas which

may require additional EMC measures”.

d. According to the EN6100

DC choke should

power line.

a. A shielded wire (screened cable) must be used for motor

wiring, and the length of the cable must be according to the

following table (Table 1 on page 1

b. The carrier frequ

following table to meet an EMC requirement (Table1 on

page 1-12).

c. The main circuit wiring must be separated from the control

circuit wiring.

(When an

EMC

a. SJ series P1

must be according to SJ series P1 specifications.

to European Directive

inverter in Europe, you must comply

-

3 it is mandatory to mention that

for

-

3

be installed

ency must be set according to the

filter is used)

inverter that is activated built

-

15% to +10% or less.

-

in EMC filter. The built

C2, an additional note is

-

3 that “this product may

3

-12, an

additional

for reducing harmonics in

-12).

-

in EMC

AC reactor or

-in EMC filter

1-5

Safety Instructions

1-6

Chapter 1

Safety Instructions

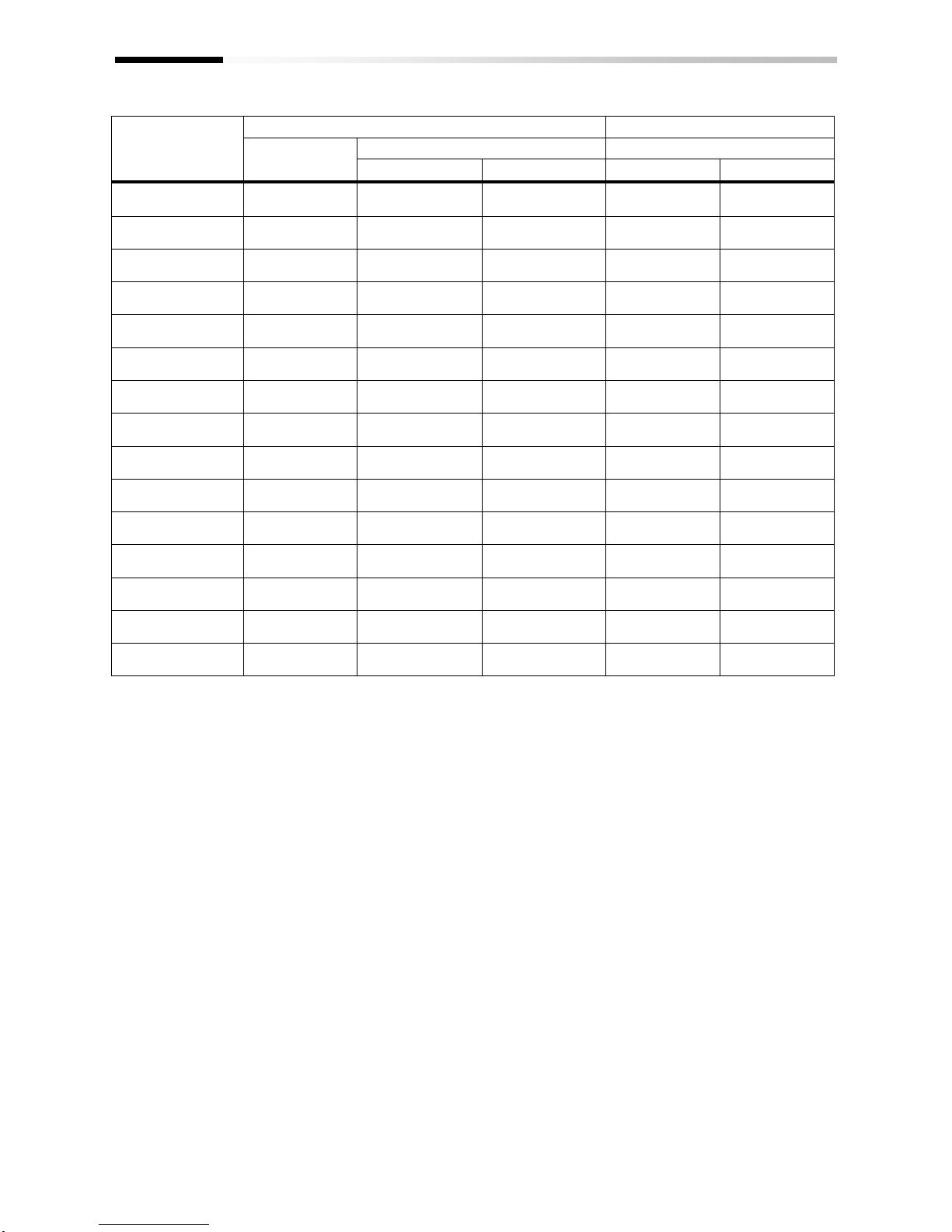

Table 1

Model Cat.

Cable

Length

(m)

Carrier

Frequency

(kHz)

Model Cat.

Cable

Length

(m)

Carrier

Frequency

(kHz)

P1-00044-L

(P1-004L)

C3 10 2 - - - -

P1-00080-L

(P1-007L)

C3 10 2

P1-00041-H

(P1-007H)

C3 10 2

P1-00104-L

(P1-015L)

C3 10 2

P1-00054-H

(P1-015H)

C3 10 2

P1-00156-L

(P1-022L)

C3 10 2

P1-00083-H

(P1-022H)

C3 10 2

P1-00228-L

(P1-037L)

C3 10 2

P1-00126-H

(P1-037H)

C3 10 2

P1-00330-L

(P1-055L)

C3 5 2

P1-00175-H

(P1-055H)

C3 5 2

P1-00460-L

(P1-075L)

C3 5 2

P1-00250-H

(P1-075H)

C3 5 2

P1-00600-L

(P1-110L)

C3 5 2

P1-00310-H

(P1-110H)

C3 5 2

P1-00800-L

(P1-150L)

C3 10 1

P1-00400-H

(P1-150H)

C3 10 2

P1-00930-L

(P1-185L)

C3 10 1

P1-00470-H

(P1-185H)

C3 10 2

P1-01240-L

(P1-220L)

C3 10 1

P1-00620-H

(P1-220H)

C3 10 2

P1-01530-L

(P1-300L)

C3 5 2

P1-00770-H

(P1-300H)

C3 5 2

P1-01850-L

(P1-370L)

C3 5 2

P1-00930-H

(P1-370H)

C3 5 2

P1-02290-L

(P1-450L)

C3 5 2

P1-01160-H

(P1-450H)

C3 5 2

P1-02950-L

(P1-550L)

C3 5 2

P1-01470-H

(P1-550H)

C3 5 2

- - - -

P1-01760-H

(P1-750H)

C3 5 2

- - - -

P1-02130-H

(P1-900H)

C3 5 2

- - - -

P1-02520-H

(P1-1100H)

C3 5 2

- - - -

P1-03160-H

(P1-1320H)

C3 5 2

1-7

Chapter 1

Safety Instructions

1.5 Compliance to UL standards

1.5.1 UL CAUTION

GENERAL:

SJ series Type P1 inverter is open type AC Inverter with

three phase input and three phase output. It is intended

to be used in an enclosure. It is used to provide both an

adjustable voltage and adjustable frequency to the AC

motor. SJ-P1 automatically maintains the required

volts-Hz ratio as a function to control motor speed. It is

multi-rated device and the ratings are selectable

according to load types by operator with key pad

operation.

Markings:

Maximum Surrounding Temperature:

- ND (Normal Duty): 50degC

- LD (Low Duty): 45degC

- VLD (Very Low Duty): 40degC

Storage Environment rating:

- 65degC (for transportation)

Instruction for installation:

- Pollution degree 2 environment and Overvoltage

category III

Electrical Connections:

- See “7.5 Main circuit terminal wiring” of user's

guide

Interconnection and wiring diagrams:

- See “7.7 Control circuit terminal wiring” of user's

guide

Short circuit rating and overcurrent protection device

rating:

P1-L series models

- Suitable for use on a circuit capable of delivering not

more than 5,000 rms symmetrical amperes, 240 V

maximum”.

P1-H series models

- Suitable for use on a circuit capable of delivering not

more than 5,000 rms symmetrical amperes, 500 V

maximum”.

Integral:

- Integral solid state short circuit protection does not

provide branch circuit protection. Branch circuit

protection must be provided in accordance with the

National Electrical Code and any additional local

codes

1-8

Chapter 1

Safety Instructions

Terminal size and terminal tightening torque for field

wiring:

- Use 75degC only for temperature rating of field

wiring.

- Use Cupper conductors only.

Model Load Type

Required

Torque

(N.m)

Conductor

size

(AWG)

Model Load Type

Required

Torque

(N.m)

Conductor

size

(AWG)

P1-00044-L

(P1-004L)

VLD

1.4 14

LD

ND

P1-00080-L

(P1-007L)

VLD

1.4 14

P1-00041-H

(P1-007H)

VLD

1.4 14

LD LD

ND ND

P1-00104-L

(P1-015L)

VLD

1.4 14

P1-00054-H

(P1-015H)

VLD

1.4 14

LD LD

ND ND

P1-00156-L

(P1-022L)

VLD

1.4 10

P1-00083-H

(P1-022H)

VLD

1.4 14

LD LD

ND ND

P1-00228-L

(P1-037L)

VLD

1.4 10

P1-00126-H

(P1-037H)

VLD

1.4

12

LD LD

14

ND ND

P1-00330-L

(P1-055L)

VLD

3 8

P1-00175-H

(P1-055H)

VLD

3 10

LD LD

12

ND ND

P1-00460-L

(P1-075L)

VLD

3 6

P1-00250-H

(P1-075H)

VLD

3 8

LD

8 LD

10

ND ND

P1-00600-L

(P1-110L)

VLD

4

4

P1-00310-H

(P1-110H)

VLD

4 8

LD LD

ND 6 ND

P1-00800-L

(P1-150L)

VLD

2.5 – 3.0

3

P1-00400-H

(P1-150H)

VLD

4 8

LD LD

ND 4 ND

P1-00930-L

(P1-185L)

VLD

2.5 – 3.0

1

P1-00470-H

(P1-185H)

VLD

4

6

LD 2 LD

ND 3 ND 8

P1-01240-L

(P1-220L)

VLD

5.5 – 6.6

2/0

P1-00620-H

(P1-220H)

VLD

4

4

LD 1/0 LD

ND 1 ND 6

P1-01530-L

(P1-300L)

VLD

6.0

Parallel of 1/0

P1-00770-H

(P1-300H)

VLD

6.0

1

LD LD 2

ND ND 3

P1-01850-L

(P1-370L)

VLD

15.0

Parallel of 1/0

P1-00930-H

(P1-370H)

VLD

15.0 1

LD

Parallel of 1/0

LD

ND 4/0 ND

P1-02290-L

(P1-450L)

VLD

6.0 – 10.0

Parallel of 2/0

P1-01160-H

(P1-450H)

VLD

6.0 – 10.0

Parallel of 2/0

LD

Parallel of 1/0

LD

Parallel of 1/0

ND

Parallel of 1/0

ND 1

P1-02950-L

(P1-550L)

VLD

19.6

Parallel of 3/0

P1-01470-H

(P1-550H)

VLD

6.0 – 10.0

Parallel of 1/0

LD

Parallel of 3/0

LD

Parallel of 1/0

ND 350kcmil

ND

2/0

1-9

Chapter 1

Safety Instructions

Required protection by Fuse and circuit-breakers:

P1-L series models

Model

Fuse Circuit Breaker

Type

Maximum Rating Maximum Rating

Voltage (V) Current (A) Voltage (V) Current (A)

P1-00044-L

(P1-004L)

Class J or T 600 50 - -

P1-00080-L

(P1-007L)

Class J or T 600 50 - -

P1-00104-L

(P1-015L)

Class J or T 600 50 - -

P1-00156-L

(P1-022L)

Class J or T 600 50 - -

P1-00228-L

(P1-037L)

Class J or T 600 50 - -

P1-00330-L

(P1-055L)

Class J or T 600 100 - -

P1-00460-L

(P1-075L)

Class J or T 600 150 - -

P1-00600-L

(P1-110L)

Class J or T 600 150 - -

P1-00800-L

(P1-150L)

Class J or T 600 150 - -

P1-00930-L

(P1-185L)

Class J or T 600 200 - -

P1-01240-L

(P1-220L)

Class J or T 600 200 - -

P1-01530-L

(P1-300L)

Class J or T 600 300 - -

P1-01850-L

(P1-370L)

Class J or T 600 300

- -

P1-02290-L

(P1-450L)

Class J or T 600 300

- -

P1-02950-L

(P1-550L)

Class J or T 600 350

- -

1-10

Chapter 1

Safety Instructions

P1-H series models

(Memo)

Model

Fuse Circuit Breaker

Type

Maximum Rating Maximum Rating

Voltage (V) Current (A) Voltage (V) Current (A)

P1-00041-H

(P1-007H)

Class J or T 600 30 - -

P1-00054-H

(P1-015H)

Class J or T 600 30 - -

P1-00083-H

(P1-022H)

Class J or T 600 30 - -

P1-00126-H

(P1-037H)

Class J or T 600 30 - -

P1-00175-H

(P1-055H)

Class J or T 600 75 - -

P1-00250-H

(P1-075H)

Class J or T 600 75 - -

P1-00310-H

(P1-110H)

Class J or T 600 75 - -

P1-00400-H

(P1-150H)

Class J or T 600 100 - -

P1-00470-H

(P1-185H)

Class J or T 600 100 - -

P1-00620-H

(P1-220H)

Class J or T 600 100 - -

P1-00770-H

(P1-300H)

Class J or T 600 200 - -

P1-00930-H

(P1-370H)

Class J or T 600 200 - -

P1-01160-H

(P1-450H)

Class J or T 600 200 - -

P1-01470-H

(P1-550H)

Class J or T 600 250 - -

2.1

Check the contents in the package, and

inverter

The model of the product is as follows:

E

(1)

(2)

(3)

(4)

(5)

(6)

•

Chapter 2

Chapter 2

Installation and Wiring

Check the Inverter

model

.g.: 200V

class input voltage for Japan

Applicable motor capacity for ND rating is 3.7kW

ND rated current 17.5A

LD rated current 19.6A

VLD

rated current 22.8A

Series name

Motor maximum rate

00001: 0.1A to 99999: 9999.9A

Input power specification

L: three-

phase 200V class;

H: three-

phase

Panel

B: no operat

F: panel equipped

Region

(None): J

E: Europe/Southeast Asia;

U: North America;

C: China

In case of (None), blank field is omitted.

Integrated noise filter

F: integrated noise filter equipped;

CB: conduit

When both F and CB are equipped, it is indicated as

FCB.

S

pecification label

Description example

(*) means eigenvalues

P1

-

(2)

Inverter model

Input ratings

(Frequency/voltage/No. of

phases/Current)

Output

(Frequency/voltage/No. of

phases/Rate current)

MFG No.; factory serial No.

Inverter

with a

specification label.

P1

d current (at VLD rated current

400V class

or keypad

equipped;

apan;

box equipped

example

for P1-

00228

00228

(3)

ratings

confirm

-LFF

L

F

(4)

(5)

-

Basic

(T

his

the

F

(6) (6)

Guide

document)

Wire separation plate

2-1

Model: P1-

00228

Hitachi Industrial Equipment

Systems Co.,

Input/Entrée:50Hz,60Hz 200

Output/Sortie:0

MFG No. 62AA****** BB001

SJ series type P1

Terminal block

Backing plate

Control circuit

terminal block

Optional slots

Refer to each optional product

instruction

M3×8

screw

S

pacer 4

P1-

01240

Con

figuration and description

depending on the model.

Refer to User

If the

inverter is

products,

optional

P1-00228-

LFF example illustration in below.

-LFF

Ltd.

MADE IN JAPAN

INVERTER

–

240V 3ph 27.1/23.3/20.8A

-590Hz 200–

240V 3ph

cover

Operator keypad

for detail.

USB (Micro-

B)

4pcs

pcs

-L(P1-220L)

Installation and Wiring

'

s Guide for

shipped incorporated with optional

instruction

22.8/19.6/17.5A

Eye bolts for hanging the inverter

P1-

01850L/

(enclosed in the package)

Specification label

contents

more

details.

will be enclosed

Ver.2.00

Date:****

NE18361

-

***

-

00930H or above

Heat sink

Main circuit

terminals

vary

.

2.2 Install the Inverter

Chapter 2

T

ransportation

•

The inverter

carrying the inverter, handle it carefully to prevent

damage to the parts.

•

Do not carry the inverter by holding the front or

terminal block cover. Doing so may

inverter to fall.

•

Do not install and operate the inverter if it is

damaged or its parts are missing.

A

mbient temperature

•

Avoid installing the inverter in a place where the

ambient temperature goes above or below the

allowable range defined by

specification.

Ambient temperature:

ND rated

LD rated

VLD rated

•

Keep

Measure the temperature in a position about 5 cm

distant from the bottom

inverter, and check that the measured

temperature

Operating the inverter at a temperature outside

this range will shorten the inverter life (especially

the capacitor life), resulting in damage to the

inverter.

Do not install

h

umidity

•

Avoid installing the inverter in a place where the

relative humidity goes above or below the range

(20% to 90% RH), as defined by the standard

inverter specification. Avoid a p

inverter is subject to condensation.

•

Condensation inside the inverter will result in

short circuits, which may c

inverter.

exposed to direct sunlight.

is made of plastics

: -

10 to 50°C

: -

10 to 45°C

: -

10 to 40°C

suffici

ent space around the inverter.

is within the allowable range.

on

or easily condensa

Also avoid places where the inverter is

component

the standard inverter

-

center poi

a high temperature, high

ause

. When

cause the

nt of the

tion

area

lace where the

damage

to the

2-2

Air flow

For

P1-

00044

(P1

-

or

P1-

00041

(P1

-

or more

I

nstall inverter on

(e.g.

metal) surface.

•

The inverter will reach a high temperature (up to

about 150°C) during operation. Install the inverter

on a vertical wall surface made of nonflammable

material (e.g., metal) to avoid the risk of fire.

•

In particular, keep

inverter and other heat sources (e.g., braking

resistors and reactors) if they are installed in the

vicinity.

Inverter

Wall

-L to P1-

02950

004L to P1-

550L)

-H to P1-

01800

007H to P1-

550H)

In

order to replace life cycle parts on following models require

a clearance of 22cm or more:

• P1-00800-

L (P1

• P1-00380-

H (P1

In order to replace life cycle parts on following models is

required to

remove the installed units:

• P1-00044-

L (P1

• P1-00041-H (P1

5 cm

10 cm

or more

10 cm

or more

Installation and Wiring

nonflammable

sufficient distance between the

•

Keep enough clearance

between the inverter and the

above and below

to prevent

ventilation from

For dimension drawing of

inverter

-L

-H

-150L) to P1

-

-

150H) to P1

-004L) to P1

-

-

007H) to P1

5 cm

or more

For

P1

(P1

see

chapter

01240-L (P1-

220L)

-00620-H (P1-

220H)

00600-L (P1-

110L)

-

00310-H (P1-110H)

30 cm

or more

30 cm

or more

5 cm

or more

-02160-

H to P1

-750H to P1-

1320H)

wiring ducts

cooling air

obstructing.

2-5.

5 cm

or more

-03610-H

Chapter 2

Installation environment

•

Avoid installing the inverter in a place where the

inverter is subject to dust, corrosive gases,

explosive

mist, or salt water.

•

Foreign

failure

.

dusty environment, install the inverter inside a

totally enclosed panel.

Installation method and position

•

Install the inverter vertically and securely with

screws or bolts on a surface that is free from

vibrations and that can bear the inverter weight.

•

If the inverter is not installed properly, its cooling

performance may be degraded and tripping or

inverter damage may result.

Mounting in an enclosure

•

When mounting multiple inverters in an enclosure

with a ventilation fan, carefully design the layout

of the ventilation fan, air intake port, and inverters.

An inappropriate layout will reduce t

inverter

temperature.

inverter ambient temperature will remain within

the range specified in the specification table.

When

the

the incoming dust may

a position to avoid this falling dust

(Acceptable)

Inverter

Screw

S

crew

gases, flammable gases, grinding fluid

particles entering the i

If you use the inverter in a considerably

-

cooling effect and

Plan the layout

inverter is installed

adhere to

Ventilation

Position of ventilation fan

nverter will cause

raise the ambient

properly

below ventilatio

the inverter.

.

(Unacceptable)

Inverter

Screw

Screw

so that the

n fan,

P

lace in

Ventilation

2-3

of

he

Reduction of enclosure size

•

External heat sink installation may reduce internal

heat emission

•

External heat sink mounting for the inverter

P1-00044

-

and

P1-00041

-

requires an optional

•

Other models than above can be installed with the

originally attached metal

inverter

enclosure panel according to the specified cutting

dimensions.

•

The cooling s

positioned outside the enclosure has a cooling fan.

Therefore, do not place the enclosure in any

environment where it is exposed to water

oil mist, or dust.

•

T

he heat sink part reaches a high temperature.

Install a pr

Installation and Wiring

and reduce the enclosure si

L to P1-

00228

H to P1-

00126

metal

for external heat sink, cut out the

ection (including the heat sink)

otection cover as needed.

-L (P1-

004L to P1

-H (P1-

007H to P1

fitting.

fitting

. To mount the

ze.

-

037L)

-

037H)

drops,

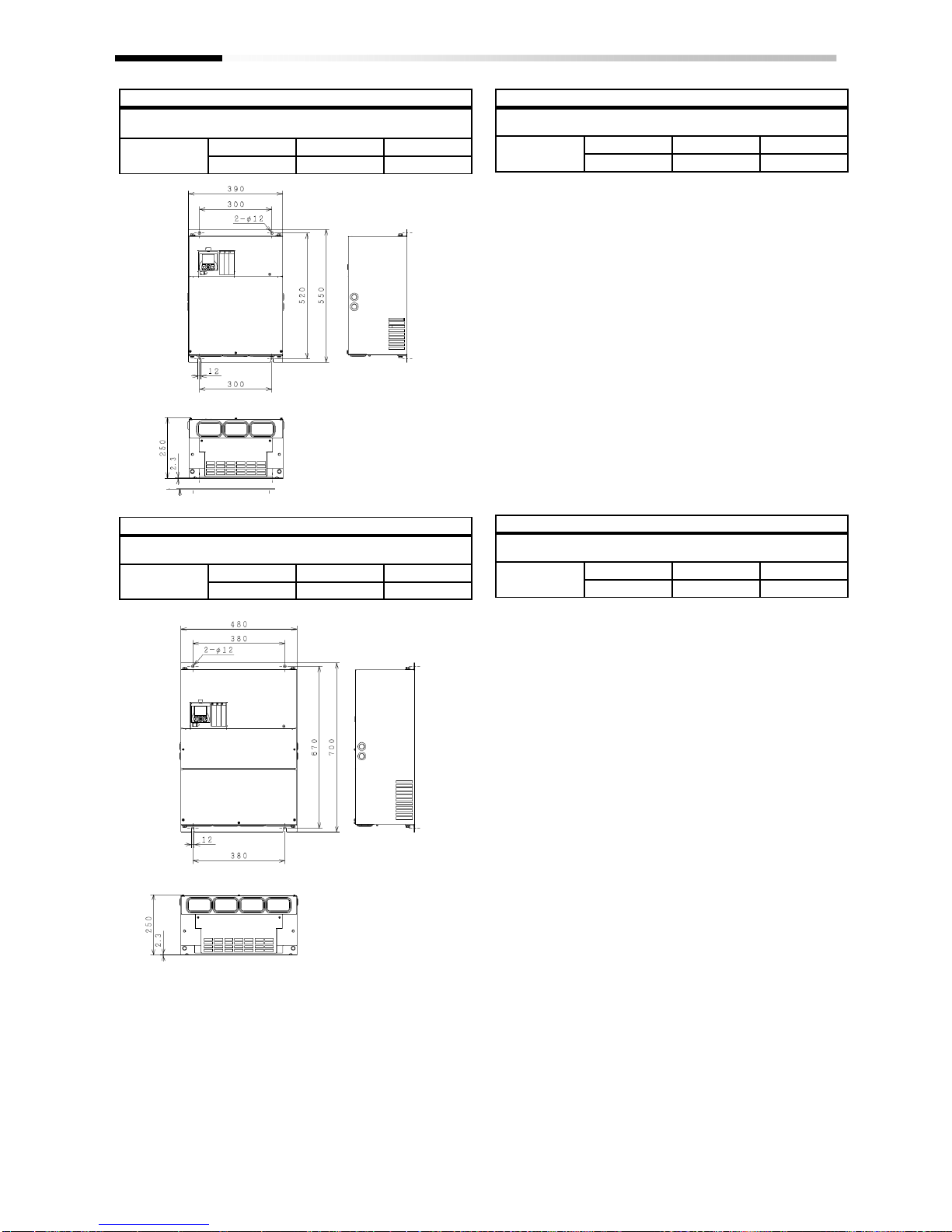

2.3 Dimension Drawing

Chapter 2

If you add optional parts to the inverter, some extra

space is required in the direction of the depth of the

inverter d

clearance of 50 mm or more.

instruction manual for each optional product.

Model P1-

*****

200V class:

00044

0104

400V class:

00041

00126

Dimension

Model P1-

*****

200V class:

00330

400V class:

00175

Dimension

epending on the wiring layout.

-* (P1-

*****

-

L(004L)

, 00080

-L(015L),

00156

-H(007H),

00054

-H(037H)

W(mm)

150

-* (P1-

*****

-

L(055L), 00460

-

H(055H), 00250

W(mm)

210

For details, refer

-*)

-

L(007L),

-

L(022L), 00228

-H(015H),

00083

H(mm)

255

-*)

-

L(075L), 00600

-H(075H),

00310

H(mm)

260

Keep

to the

-L(037L)

-H(022H),

D(mm)

140

-

L(110L)

-H(110H)

D(mm)

170

2-4

a

(E

g.

VLD rated current

(ND rat

class

Model (P1

200V class:

400V class

Dimension

Model P1

200V class:

400V class:

Dimension

) See "C

hapter 7

ed

motor capacity is

,

while H indicates 400V class.

-

*****

00800

:

00400

-*****

-

01530

00770

Installation and Wiring

Specifications

for 00046-

L(004L) is 4.6A

0.4kW), and L indicates 200V

-*)

-

L(150L), 00930

-

H(150H), 00470

W(mm)

245

* (P1-*****-

*)

-

L(300L)

-H(300H)

W(mm)

540

"

for details.

-

L(185L), 01240

-H(185H),

00620

H(mm)

390

H(mm)

300

,

-

L(220L)

-H(220H)

D(mm)

190

D(mm)

195

2-5

Chapter 2

Installation and Wiring

Model P1-*****-* (P1-*****-*)

200V class: 01850

-

L(370L), 02290

-

L(450L),

400V class: 00930-H(370H),01160-H(450H),01470-H(550H)

Dimension

W(mm) H(mm) D(mm)

550 390 250

Model P1-*****-* (P1-*****-*)

200V class: 02950-L(550L)

Dimension

W(mm) H(mm) D(mm)

700 480 250

Model P1-*****-* (P1-*****-*)

400V class: 01760-H(750H), 02130-H(900H)

Dimension

W(mm) H(mm) D(mm)

700 390 270

(in preparation)

Model P1-*****-* (P1-*****-*)

400V class: 02520-H(1100H), 03160-H(1320H)

Dimension

W(mm) H(mm) D(mm)

740 480 270

(in preparation)

2.

Chapter 2

4

Inverter Wiring

Applicable peripheral equipment

R S T

R0

T0

Power

supply

U

V

W

PD

P

N

Motor

M

RB

INV

<12>

<13>

<1>

<2>

<3>

<4>

<5>

<6>

<7>

<8>

<9>

<10>

<11>

<12>

<13>

<14>

No.

<1> Electric wire

<2> Earth-leakage circuit breaker EL

MCCB

<3> Magnetic contacto

<4> Input

AC

(For harmonic control, power supply

coordination, and power factor

correction)

<5> Noise

filter for inverter

<6> Radio noise filter

(Zero-

phase reactor)

<7> Radio noise filter on the input side

(Capacitor filter)

<8> DC

Choke

<9> Braking resistor

<10> Regenerative braking unit

<11> Noise filter on the output side

<12> Radio noise filter

(Zero-

phase reactor)

<13> Output

For reducing vibrations and

preventing thermal relay

malfunction

<14> LCR filter

Notes:

•

The description of peripheral equipment is for Hitachi 3

•

Select breakers with proper interrupting capacity. (Use inverter

•

Use

•

Use copper electric wire (HIV cable) with allowable temperature rating 75°C or more.

•

If the power line exceeds 20 m, use cable with ma

•

Tighten each termina

Loose terminal screws may cause short circuits and fire.

Excessive tightening torque may cause damage to the terminal block or inverter body.

•

When selecting a rated sensitivity current for earth

separated breaker considering a total cable length of between Inverter

Inverter

Use a delayed

•

When using a CV cable for wiring through a metal conduit, the average current leakage

would be 30mA/km.

•

When using a high relative dielectric constant cable such as IV cable, the leakage current is

about eight times as high as the standard cable. Therefore, when using an IV cable, use

ELCB with rated sensitivity current by eight times

cable length exceeds 100 m, use a CV cable.

•Do not pull the power line cable after wiring. Doing so may cause screw loosening.

Name

r MC

reactor

AC reactor

earth-

leakage circuit breakers

–

Motor distance. Do not use a high

-

type circuit breaker, because the high

2-6

See "Recommended cable

terminals” on Page 2

C

B or

Use

voltage imbalance exceeds 3% or more, or

capacity is

change rapidly. This reactor also improves the power factor.

This noise filter reduces the conductive noise that is generated by

the inverter and transmitted in cables. Connect this noise filter to

the primary side (input side) of the inverter.

The inverter may generate radio noise through power supply wiring

during operation.

Use this noise filter to reduce the radio noise (radiant noise).

Use this noise filter to reduce the radiant

cables.

Use

Use these devices to increase the braking torque of the inverter for

operation in which the inverter turns the connected

very frequently or decelerates the load running with a high moment

of inertia.

Connect this noise filter between the inverter and motor to reduce

the radiant noise

the electromagnetic interference with radio and television reception

and preventing malfunctions of measuring equipment and sensors.

Use this noise filter to

side of the inverter. (This noise filter can be used on both the input

and output sides.)

I

nverter drive

commercial power supply direct

Connect

the pulsation of motor. Also, connect

cable length between

to prevent thermal relay malfunction due to the harmonic waves

generated by switching operation o

relay can be replaced with a current sensor to avoid the

malfunction.

Connect

the inverter output into a sinusoidal waveform and to reduce the

motor vibration, motor noise and the radiant noise radiated from

cables. Surge voltage can be also controlled.

l screw with the specified tightening torque.

input reactor

over

500 kVA or more, or when the power voltage may

DC

chokes

to

nverter drive

n motor may cause large vibrations compared

Output

AC reactor between inverter and motor to lessen

this noise filter between the inverter and motor to convert

(ELB or MCB)

-

speed type of earth

Installation and Wiring

Total cable length

100 m or less

300 m or less

Function

gauges, wiring accessories, and crimp

-9.

for

harmonic wave

reduce

the harmonic generated by the inverter.

radiated from cables for the purpose of reducing

reduce the noise generated on the output

start

inverter and mo

-

phase, 4

to ensure safety.

j

or wire size for the power line.

-

leakage circu

-

speed typ

higher

in the table bel

Sensitivity current (mA)

control, or when power supply

when the power supply

noise radiated from input

motor.

output

AC reactor, when the

tor is long

er

f

inverter. Note that the thermal

-

pole squirrel

-

ready breakers)

it breaker, use a

-

Power supply and

-

leakage circuit breaker.

e may malfunction.

ow. If the total

50

100

load on and off

to

(10 m or more),

-cage motor.

2-7

Chapter 2

Installation and Wiring

2.5 Wiring of the main circuit

Wire the main circuit of the inverter.

The following illustration shows the power supply and

wiring connections to a motor only.

Open a terminal block cover to wire the terminal block in

the main circuit.

Explanation of main circuit terminal block

See “Chapter 1 Safety Instructions” for response to CE and UL

standards.

The screw size may vary depending on terminal. Refer to Page

2-8/2-9 for the size of the terminal screw for the power line cable

while for other terminals, refer to the drawings of the wiring on

Page 2-13 or later.

The tables on Page 2-8/2-9 list the specifications of cables, crimp

terminals, and terminal screw tightening torques for reference.

Recommended wire gauges vary depending on the rated load

settings (ND/LD/VLD).

Symbol

Terminal name

Description

R,S,T

(L1,L2,L3)

Main power input

Connect to the AC power supply. Leave these terminals unconnected

when using a regenerative converter.

U,V,W

(T1,T2,T3)

Inverter output Connect a Three-phase motor.

PD,P

(+1,+)

DC

choke

connection terminal

Remove the

PD-P

jumper from terminals, and connect the opt

ional

DC

choke for power factor improvement.

P,RB

(+,RB)

External

chopper

braking resistor

connection terminal

Connect the optional external braking resistor. See “Chapter 7

Specifications” for built-in braking circuit inverter models.

P,N

(+,-)

Regenerative

braking

unit connection

terminal

Connect the optional regenerative braking unit.

Inverter ground

terminal

This serves as a ground terminal for the inverter

chassis

to ground.

Connect 200V class and 400V class models to Type-D grounding and

Type-C grounding, respectively.

ELB

Earth-leakage

circuit breaker

Magnetic

contactor

MC

Three-

phase

AC power

supply

P+

R/L1

S/L2

T/L3

R0

T0

U/T1

V/T2

W/T3

Control circuit

power supply

Type-D grounding

(200 V class model)

Type-C grounding

(400 V class model)

J51 connector

Three

-

phase

M

Main circuit

terminal section

3φ

P

/+ PD

/+1

RB

N/-

Jumper

Internal EMC filter

Jumper or terminal

Disable

Enable

200V class:

200 to 240Vac

400V class:

380 to 500Vac

2-8

Chapter 2

Installation and Wiring

2.6 Recommended wire gauges, wiring

accessories, and crimp terminals

200V class

The wire gauges in the above table shows the designed values

based on HIV cables (with thermal resistance of 75°C).

Please use the round type crimp terminals (for the UL standard)

suitable for the use electric wire when you connect the electric

wire with the main circuit terminal block. Please put on pressure

to the crimp terminals with a crimp tool that the crimp terminal

maker recommends.

Applicable P1

inverter model

P1-*******

Rating

setting

Power line cable

AWG(mm2)

R,S,T,U,V,W,

P,PD,N

Grounding

cable

AWG(mm2)

External braking

resistor

between P and

RBAWG(mm2)

Power line cable

Terminal screw

size

Crimp

terminal

Tightening

torque

N•m

P1-00044-L

(P1-004L)

ND

14(2.1) 14(2.1) 14(2.1) M4 2-4/2-4 1.4 LD

VLD

P1-00080-L

(P1-007L)

ND

14(2.1)

14(2.1)

14(2.1) M4 2-4/2-4 1.4 LD

VLD

P1-00104-L

(P1-015L)

ND

14(2.1)

14(2.1)

14(2.1) M4 2-4/2-4 1.4 LD

VLD

P1-00156-L

(P1-022L)

ND

14(2.1) 14(2.1) 14(2.1)

M4

2-4/2-4

1.4 LD

VLD 10(5.3) 10(5.3) 10(5.3) 5.5-4/5.5-4

P1-00228-L

(P1-037L)

ND

10(5.3) 10(5.3) 10(5.3) M4 5.5-4/5.5-4

1.4 LD

VLD

P1-00330-L

(P1-055L)

ND

8(8.4) 8(8.4) 8(8.4) M5 8-5/8-5 3.0 LD

VLD

P1-00460-L

(P1-075L)

ND

8(8.4)

6(13.3)

8(8.4)

M5

8-5/8-5

3.0 LD

VLD 4(21.2) 6(13.3) 14-5/8-5

P1-00600-L

(P1-110L)

ND 6(13.3)

6(13.3)

6(13.3)

M6

14-6/14-6

4.0 LD

4(21.2) 4(21.2) 22-6/14-6

VLD

P1-00800-L

(P1-150L)

ND 4(21.2)

6(13.3)

4(21.2)

M6

22-6/14-6

2.5 to 3.0 LD

3(26.7) 3(26.7) 38-6/14-6

VLD

P1-00930-L

(P1-185L)

ND 3(26.7)

6(13.3)

3(26.7)

M6

38-6/14-6

5.5 to 6.6 LD 2(33.6) 2(33.6)

60-6/14-6

VLD 1(42.4) 1(42.4)

P1-01240-L

(P1-220L)

ND 1(42.4)

6(13.3)

1(42.4)

M8

60-8/14-6

5.5 to 6.6 LD 1/0(53.5) 1/0(53.5)

VLD 2/0(67.4) 2/0(67.4) 70-8/14-6

P1-01530-L

(P1-300L)

ND 2/0(67.4)

4(21.2) ― M8

70-8/22-8

6.0 LD

1/0×2(53.5×2) 60-8/22-8

VLD

P1-01850-L

(P1-370L)

ND 4/0(107.2)

4(21.2) ― M8

100-8/22-6

15.0 LD

1/0×2(53.5×2) 60-8/22-6

VLD

P1-02290-L

(P1-450L)

ND

1/0×2(53.5×2)

4(21.2) ― M8

60-8/22-6

6.0 to 10.0 LD

VLD 2/0×2(67.4×2) 70-8/22-6

P1-02950-L

(P1-550L)

ND 350kc(177)

3(26.7) ― M10

180-8/38-6

19.6 LD

3/0×2(85.0×2) 80-8/38.6

VLD

2-9

Chapter 2

Installation and Wiring

400V class

The wire gauges in the above table shows the designed values

based on HIV cable (with thermal resistance of 75°C).

Please use the round type crimp terminals (for the UL standard)

suitable for the use electric wire when you connect the electric

wire with the main circuit terminal block. Please put on pressure

to the crimp terminals with a crimp tool that the crimp terminal

maker recommends.

Applicable P1

inverter model

P1-*******

Rating

setting

Power line cable

AWG(mm2)

R,S,T,U,V,W,

P,PD,N

Grounding

cable

AWG(mm2)

External braking

resistor

between P and

RBAWG(mm2)

Power line cable

Terminal screw

size

Crimp

terminal

Tightening

torque

N•m

P1-00041-H

(P1-007H)

ND

14(2.1) 14(2.1) 14(2.1) M4 2-4/2-4 1.4 LD

VLD

P1-00054-H

(P1-015H)

ND

14(2.1) 14(2.1) 14(2.1) M4 2-4/2-4 1.4 LD

VLD

P1-00083-H

(P1-022H)

ND

14(2.1) 14(2.1) 14(2.1) M4 2-4/2-4 1.4 LD

VLD

P1-00126-H

(P1-037H)

ND 14(2.1) 14(2.1) 14(2.1)

M4

2-4/2-4

1.4 LD

12(3.3) 12(3.3) 12(3.3) 5.5-4/5.5-4

VLD

P1-00175-H

(P1-055H)

ND 12(3.3) 12(3.3) 12(3.3)

M5 5.5-5/5.5-5

3.0 LD

10(5.3) 10(5.3) 10(5.3)

VLD

P1-00250-H

(P1-075H)

ND 10(5.3) 10(5.3) 10(5.3)

M5

5.5-5/5.5-5

3.0 LD

8(8.4) 8(8.4) 8(8.4) 8-5/8-5

VLD

P1-00310-H

(P1-110H)

ND

8(8.4) 8(8.4) 8(8.4) M6 8-6/8-6 4.0 LD

VLD

P1-00400-H

(P1-150H)

ND

8(8.4) 8(8.4) 8(8.4) M6 8-6/8-6 4.0 LD

VLD

P1-00470-H

(P1-185H)

ND 8(8.4)

8(8.4)

8(8.4)

M6

8-6/8-6

4.0 LD

6(13.3) 6(13.3) 14-6/8-6

VLD

P1-00620-H

(P1-220H)

ND 6(13.3)

8(8.4)

6(13.3)

M6

14-6/8-6

4.0 LD

4(21.2) 4(21.2) 22-6/8-6

VLD

P1-00770-H

(P1-300H)

ND 3(26.7)

6(13.3) - M8

38-8/14-8

6.0 LD 2(33.6)

VLD 1(42.4) 60-8/14-8

P1-00930-H

(P1-370H)

ND

1(42.4) 6(13.3) - M8 60-8/14-8 15.0 LD

VLD

P1-01160-H

(P1-450H)

ND 1(42.4)

6(13.3) - M8

60-8/14-8

6.0~10.0

LD 1/0(53.5)

VLD 2/0(67.4) 70-8/14-8

P1-01800-H

(P1-550H)

ND 2/0(67.4)

4(21.2) - M8

70-8/22-8

6.0~10.0

LD

1/0×2(53.5×2) 60-8/22-8

VLD

P1-02160-H

(P1-750H)

ND

― ― ― ― ― ― LD

VLD

P1-02600-H

(P1-900H)

ND

― ― ― ― ― ― LD

VLD

P1-03250-H

(P1-1100H)

ND

― ― ― ― ― ― LD

VLD

P1-03610-H

(P1-1320H)

ND

― ― ― ― ― ― LD

VLD

2-10

Chapter 2

Installation and Wiring

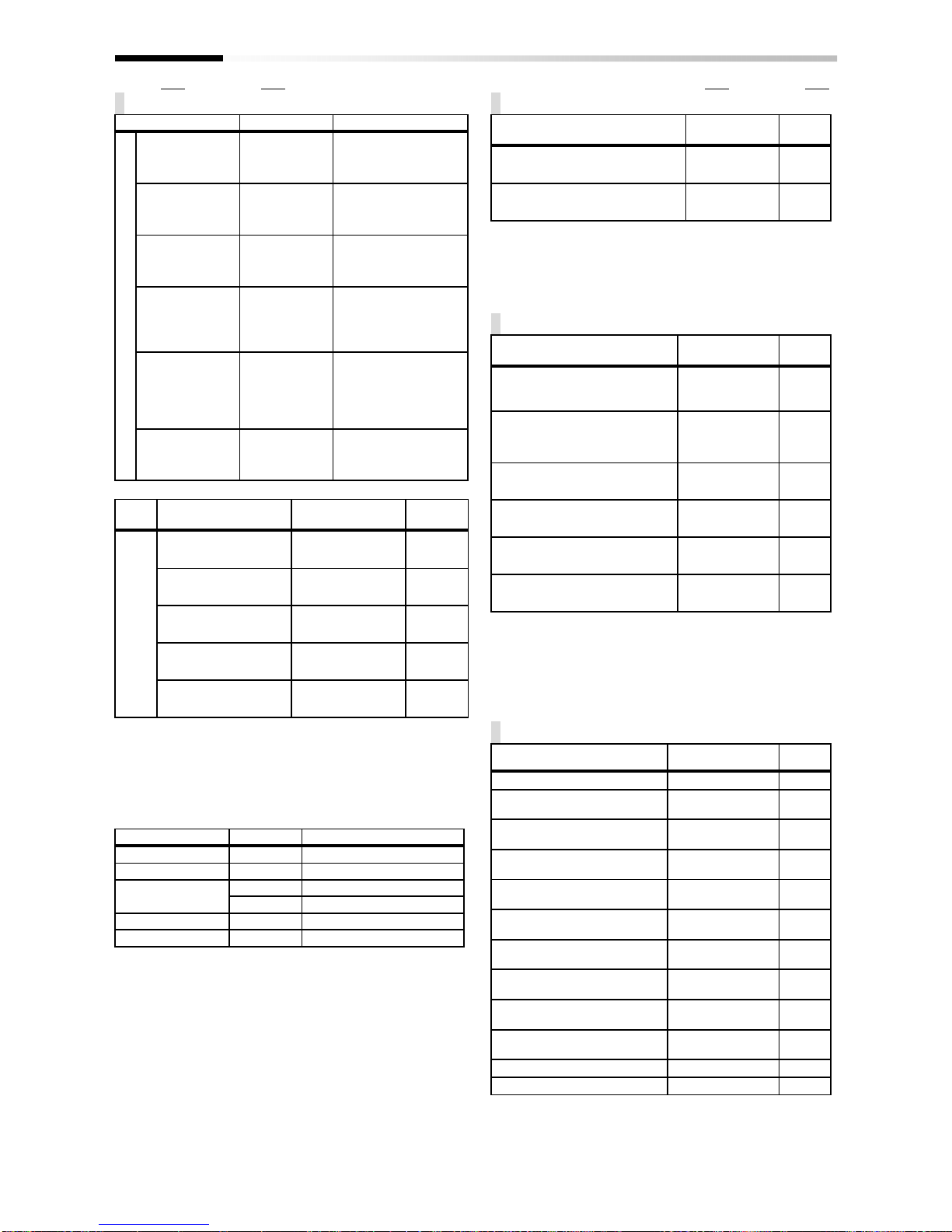

2.7 Applicable circuit breaker

200V class

• For ND rating

• For LD/VLD rating

Device model name on above table shows example selection. The

device selection should be made in base on rated current, short

circuit current capability and accordance to the local electrical

legislation.

Applicable motor capacity is based on Hitachi 200Vac, 60Hz, 4 pole

IE3 motor.

Refer to the wire gauge table on chapter 2-8 for power line cable.

Electrical endurance for AC-1 magnetic contactor is 500000 times,

however, for emergency stop in motor operation will be only 25

times.

Select AC-3 class magnetic contactor for inverter output for

application which has an emergency stop or commercial power line

operation.

When selecting oversize inverter capacity compare to motor rating,

select magnetic contactor according to the inverter capacity

Model

P1-*******

(P1-****)

Applicable

Motor

(kW)

Applicable devices (Input Voltage 200~220V)

Without reactor

(DCL or

ACL)

With reactor

(DCL or

ACL)

Earth-leakage breaker

(ELB)

Magnetic Contactor

(MC)

Earth-leakage breaker

(ELB)

Magnetic Contactor

(MC)

Example

model

Current

Rate

AC-1 AC-3

Example

model

Current

Rate

AC-1 AC-3

P1-00044-L(P1-004L) 0.4 EB-30E 5 HS8 HS8 EB-30E 5 HS8 HS8

P1-00080-L(P1-007L) 0.75 EB-30E 10 HS8 HS8 EB-30E 5 HS8 HS8

P1-00104-L(P1-015L) 1.5 EB-30E 15 HS8 HS8 EB-30E 10 HS8 HS8

P1-00156-L(P1-022L) 2.2 EB-30E 20 HS8 HS8 EB-30E 15 HS8 HS8

P1-00228-L(P1-037L) 3.7 EB-30E 30 HS8 HS20 EB-30E 20 HS8 HS20

P1-00330-L(P1-055L) 5.5 EB-50E 40 HS20 HS25 EB-30E 30 HS8 HS20

P1-00460-L(P1-075L) 7.5 EB-50E 50 HS35 HS35 EB-50E 40 HS20 HS25

P1-00600-L(P1-110L) 11 EB-100E 75 HS50 H65C EB-100E 60 HS35 HS50

P1-00800-L(P1-150L) 15 RXK125

-S

125 H65C H80C EB-100E 100 HS50 H65C

P1-00930-L(P1-185L) 18.5 RXK125

-S

125 H80C H100C

EB-

100E 100 HS50 H65C

P1-01240-L(P1-220L) 22 EXK225

150 H80C H125C

RXK125

-S

125 H65C H80C

P1-01530-L(P1-300L) 30 EXK225

200 H125C

H150C

EXK225

150 H80C H125C

P1-01850-L(P1-370L) 37 RXK250

-S

250 H150C

H200C

EXK225

200 H100C

H125C

P1-02290-L(P1-450L) 45 EX400 300 H200C

H250C

EXK225

225 H125C

H150C

P1-02950-L(P1-550L) 55 EX400 400 H200C

H300C

EX400 300 H150C

H250C

Model

P1-*******

(P1-****)

Applicable

Motor

(kW)

Applicable devices(Input Voltage 200~220V)

Without reactor

(DCL or ACL)

With reactor

(DCL or ACL)

Earth-leakage breaker

(ELB)

Magnetic Contactor

(MC)

Earth-leakage breaker

(ELB)

Magnetic Contactor

(MC)

Example

model

Current

Rate

AC-1 AC-3

Example

model

Current

Rate

AC-1 AC-3

P1-00044-L(P1-004L) 0.75 EB-30E 10 HS8 HS8 EB-30E 5 HS8 HS8

P1-00080-L(P1-007L) 1.5 EB-30E 15 HS8 HS8 EB-30E 10 HS8 HS8

P1-00104-L(P1-015L) 2.2 EB-30E 20 HS8 HS8 EB-30E 15 HS8 HS8

P1-00156-L(P1-022L) 3.7 EB-30E 30 HS8 HS20 EB-30E 20 HS8 HS20

P1-00228-L(P1-037L) 5.5 EB-50E 40 HS20 HS25 EB-30E 30 HS8 HS20

P1-00330-L(P1-055L) 7.5 EB-50E 50 HS35 HS35 EB-50E 40 HS20 HS25

P1-00460-L(P1-075L) 11 EB-100E 75 HS50 H65C EB-100E 60 HS35 HS50

P1-00600-L(P1-110L) 15 RXK125

-S

125 H65C H80C EB-100E 100 HS50 H65C

P1-00800-L(P1-150L) 18.5 RXK125

-S

125 H80C H100C

EB-

100E 100 HS50 H65C

P1-00930-L(P1-185L) 22 EXK225

150 H80C H125C

RXK125

-S

125 H65C H80C

P1-01240-L(P1-220L) 30 EXK225

200 H125C

H150C

EXK225

150 H80C H125C

P1-01530-L(P1-300L) 37 RXK250

-S

250 H150C

H200C

EXK225

200 H100C

H125C

P1-01850-L(P1-370L) 45 EX400 300 H200C

H250C

EXK225

225 H125C

H150C

P1-02290-L(P1-450L) 55 EX400 400 H200C

H300C

EX400 300 H150C

H250C

P1-02950-L(P1-550L) 75 EX600B

500 H300C

H400C

EX400 400 H200C

H300C

2-11

Chapter 2

Installation and Wiring

400V class

• For ND rating

• For LD/VLD rating

Device model name on above table shows example selection. The

device selection should be made in base on rated current, short

circuit current capability and accordance to the local electrical

legislation.

Applicable motor capacity is based on Hitachi 400Vac, 60Hz, 4 pole

IE3 motor.

Refer to the wire gauge table on chapter 2-8.

Electrical endurance for AC-1 magnetic contactor is 500000 times,

however, for emergency stop in motor operation will be only 25

times.

Select AC-3 class magnetic contactor for inverter output for

application which has an emergency stop or commercial power line

operation.

When selecting oversize inverter capacity compare to motor rating,

select according to the inverter capacity

Model

P1-*******

(P1-****)

Applicable

Motor

(kW)

Applicable devices (Input Voltage 400~440V)

Without reactor

(DCL or ACL)

With reactor

(DCL or ACL)

Earth-leakage breaker

(ELB)

Magnetic Contactor

(MC)

Earth-leakage breaker

(ELB)

Magnetic Contactor

(MC)

Example

model

Current

Rate

AC-1 AC-3

Example

model

Current

Rate

AC-1 AC-3

P1-00041-H(P1-007H) 0.75 EX50C 5 HS8 HS8 EX50C 5 HS8 HS8

P1-00054-H(P1-015H) 1.5 EX50C 10 HS8 HS8 EX50C 5 HS8 HS8

P1-00083-H(P1-022H) 2.2 EX50C 10 HS8 HS8 EX50C 10 HS8 HS8

P1-00126-H(P1-037H) 3.7 EXK50-C 15 HS8 HS10 EX50C 10 HS8 HS10

P1-00175-H(P1-055H) 5.5 EXK50-C 20 HS8 HS20 EXK50-C 15 HS8 HS20