Page 1

Embedded Computing Platform

1

HVP300

Embedded Computing Platform

User Manual

Rev 1.1 Date: January 24th, 2017

Page 2

Embedded Computing Platform

2

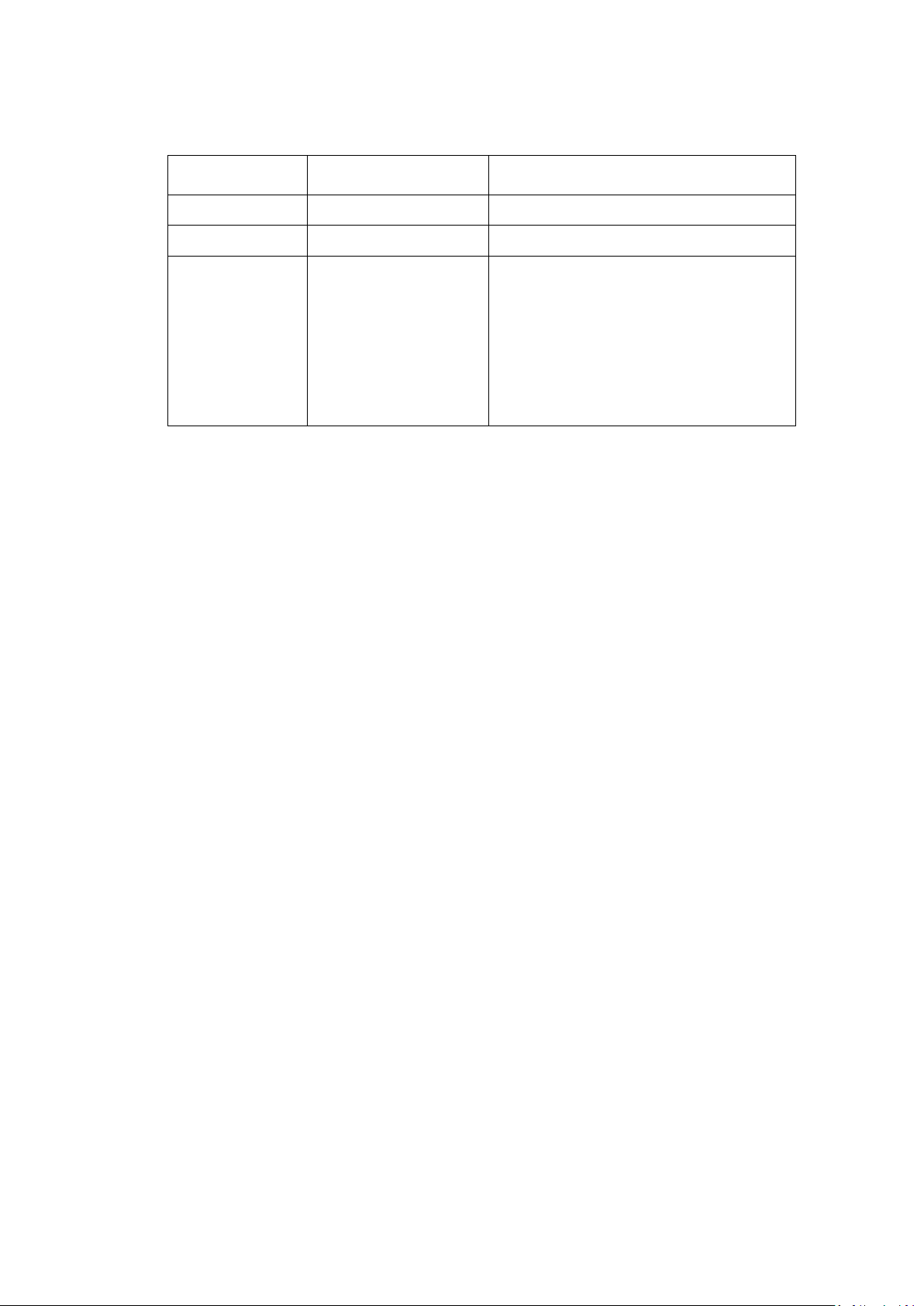

Revision

Date

Description

0.1

August 3, 2016

Preliminary

1.0

August 22, 2016

Official release

1.1

January 24, 2017

Added LTE module installation

Modified power input voltage

Modified operating temperature

Added PoE configuraiton description

Added warning statement in the installation

precaution

Added wall mounting section

Revision History

This document contains proprietary information of Lanner Electronics Inc. –and is not to be

disclosed or used except in accordance with applicable agreements.

Copyright © 2017. All Rights Reserved.

Copyright© 2017 Lanner Electronics Inc. All rights reserved. The information in this document is

proprietary and confidential to Lanner Electronics Inc. No part of this document may be

reproduced in any form or by any means or used to make any derivative work (such as

translation, transformation, or adaptation) without the express written consent of Lanner

Electronics Inc. Lanner Electronics Inc. reserves the right to revise this document and to make

changes in content from time to time without obligation on the part of Lanner Electronics Inc. to

provide notification of such revision or change.

The information in this document is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Lanner Electronics Inc. Lanner

Electronics Inc. assumes no responsibility or liability for any errors or inaccuracies that may

appear in this document or any software that may be provided in association with this document.

Page 3

Embedded Computing Platform

3

Resource

Website

Lanner

www.lannerinc.com

Product Resources

www.lannerinc.com/support/download-center

RMA

http://eRMA.lannerinc.com

Online Resources

The listed websites are links to the on-line product information and technical support.

Acknowledgement

Intel®, Pentium and Celeron are registered trademarks of Intel® Corp.

Microsoft Windows and MS-DOS are registered trademarks of Microsoft Corp.

All other product names or trademarks are properties of their respective owners.

Compliances and Certification

CE Certification

This product has passed the CE test for environmental specifications. Test conditions for passing included

the equipment being operated within an industrial enclosure. In order to protect the product from being

damaged by ESD (Electrostatic Discharge) and EMI leakage, we strongly recommend the use of

CE-compliant industrial enclosure products.

FCC Class A Certification

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

EMC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case users will be required

Page 4

Embedded Computing Platform

4

to correct the interference at their own expense.

Safety Guidelines

Follow these guidelines to ensure general safety:

Keep the chassis area clear and dust-free before, during and after installation.

Do not wear loose clothing or jewelry that could get caught in the chassis. Fasten your tie or scarf and

roll up your sleeves.

Wear safety glasses/goggles if you are working under any conditions that might be hazardous to your

eyes.

Do not perform any action that creates a potential hazard to people or makes the equipment unsafe.

Disconnect all power by turning off the power and unplugging the power cord before installing or

removing a chassis or working near power supplies

Do not work alone if potentially hazardous conditions exist.

Never assume that power is disconnected from a circuit; always check the circuit.

LITHIUM BATTERY CAUTION:

Risk of explosion could occur if battery is replaced by an incorrect type. Please dispose of used batteries

according to the recycling instructions of your country.

Operating Safety

Electrical equipment generates heat. Ambient air temperature may not be adequate to cool

equipment to acceptable operating temperatures without adequate circulation. Be sure that the

room in which you choose to operate your system has adequate air circulation.

Ensure that the chassis cover is secure. The chassis design allows cooling air to circulate effectively.

An open chassis permits air leaks, which may interrupt and redirect the flow of cooling air from

internal components.

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD damage occurs

when electronic components are improperly handled and can result in complete or intermittent failures.

Be sure to follow ESD-prevention procedures when removing and replacing components to avoid these

problems.

Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact. If no wrist strap is

available, ground yourself by touching the metal part of the chassis.

Periodically check the resistance value of the antistatic strap, which should be between 1 and 10

megohms (Mohms).

Installation only by a trained electrician or only by an electrically trained person who knows all the

applied or related installation and device specifications..

Do not carry the handle of power supplies when moving to other place.

Page 5

Embedded Computing Platform

5

The machine can only be used in a fixed location such as labs or computer facilities.

Mounting Installation Environment Precaution

1. Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than room ambient. Therefore, consideration

should be given to installing the equipment in an environment compatible with the maximum ambient

temperature (Tma) specified by the manufacturer.

2. Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of air flow

required for safe operation of the equipment is not compromised.

3. Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition

is not achieved due to uneven mechanical loading.

4. Circuit Overloading - Consideration should be given to the connection of the equipment to the supply

circuit and the effect that overloading of the circuits might have on over-current protection and supply

wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing this

concern.

5. Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular

attention should be given to supply connections other than direct connections to the branch circuit (e.g.

use of power strips).”

6. Warning: the unit must be installed indoors. The unit, AC power adapter, and its cables are not

designed for outdoor use.

Consignes de sécurité

Suivez ces consignes pour assurer la securite generale :

Laissez la zone du chassis propre et sans poussiere pendant et apres l’installation.

Ne portez pas de vetements amples ou de bijoux qui pourraient etre pris dans le chassis. Attachez

votre cravate ou echarpe et remontez vos manches.

Portez des lunettes de securite pour proteger vosmyeux.

N’effectuez aucune action qui pourrait creer un dangermpour d’autres ou rendre l’equipement

dangereux.

Coupez completement l’alimentation en eteignant l’alimentation et en debranchant le cordon

d’alimentation avant d’installer ou de retirer un chassis ou de travailler a proximite de sources

d’alimentation.

Ne travaillez pas seul si des conditions dangereuses sont presentes.

Ne considerez jamais que l’alimentation est coupee d’un circuit, verifiez toujours le circuit. Cet

appareil genere, utilise et emet une energie radiofrequence et, s’il n’est pas installe et utilise

conformement aux instructions des fournisseurs de composants sans fil, il risque de provoquer des

Page 6

Embedded Computing Platform

6

interferences dans les communications radio.

Avertissement concernant la pile au lithium

Risque d’explosion si la pile est remplacee par une autre d’un mauvais type.

Jetez les piles usagees conformement aux instructions.

L’installation doit etre effectuee par un electricien forme ou une personne formee a l’electricite

connaissant toutes les specifications d’installation et d’appareil du produit.

Ne transportez pas l’unite en la tenant par le cable d’alimentation lorsque vous deplacez l’appareil.

La machine ne peut etre utilisee qu’a un lieu fixe comme en laboratoire, salle d’ordinateurs ou salle

de classe.

Sécurité de fonctionnement

L’equipement electrique genere de la chaleur. La temperature ambiante peut ne pas etre adequate

pour refroidir l’equipement a une temperature de fonctionnement acceptable sans circulation

adaptee. Verifiez que votre site propose une circulation d’air adequate.

Verifiez que le couvercle du chassis est bien fixe. La conception du chassis permet a l’air de

refroidissement de bien circuler. Un chassis ouvert laisse l’air s’echapper, ce qui peut interrompre et

rediriger le flux d’air frais destine aux composants internes.

Les decharges electrostatiques (ESD) peuvent endommager l’equipement et gener les circuits

electriques. Des degats d’ESD surviennent lorsque des composants electroniques sont mal manipules

et peuvent causer des pannes totales ou intermittentes. Suivez les procedures de prevention d’ESD

lors du retrait et du remplacement de composants.

- Portez un bracelet anti-ESD et veillez a ce qu’il soit bien au contact de la peau. Si aucun bracelet n’est

disponible, reliez votre corps a la terre en touchant la partie metallique du chassis. Verifiez regulierement

la valeur de resistance du bracelet antistatique, qui doit etre comprise entre 1 et 10 megohms (Mohms).

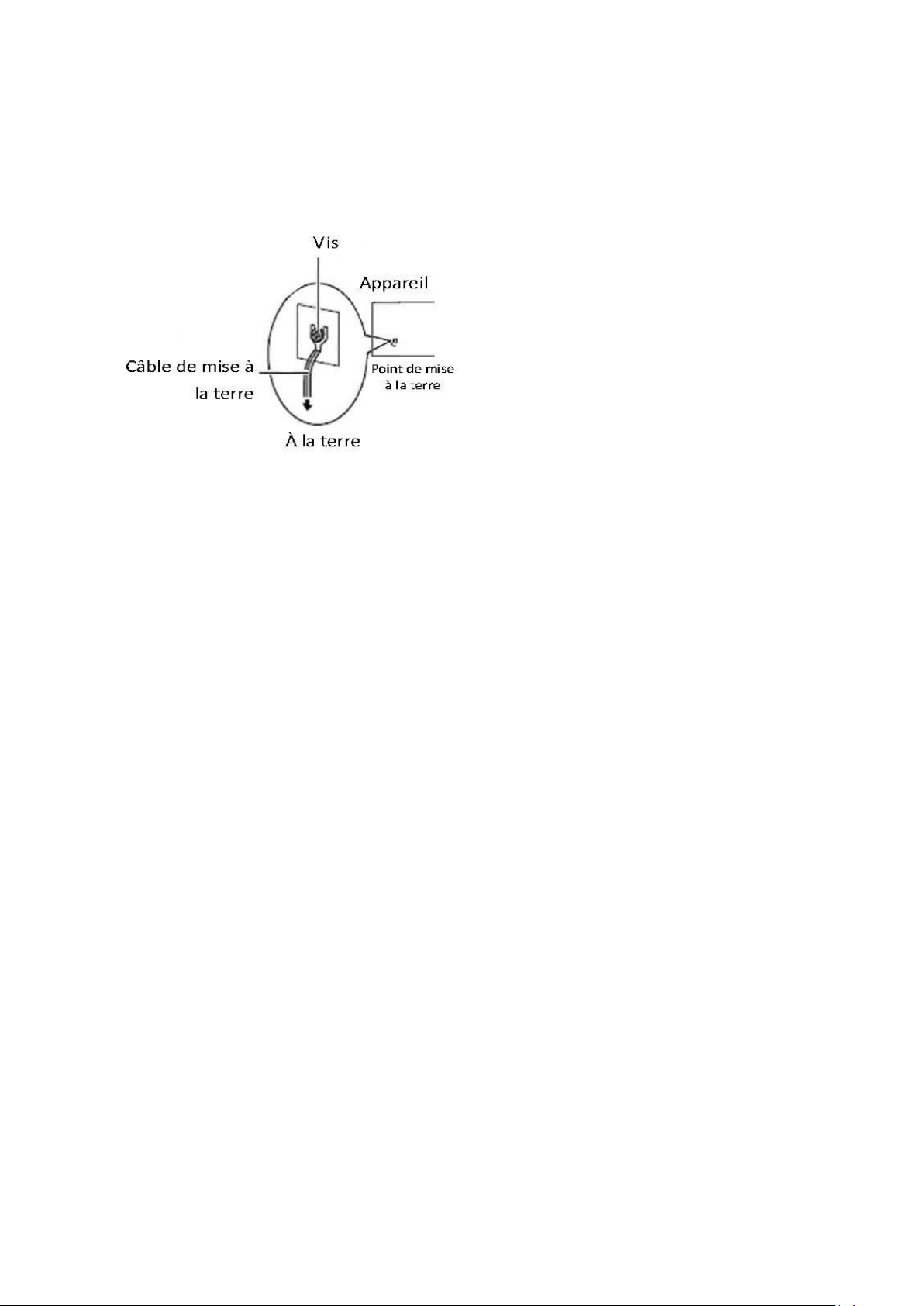

Consignes de sécurité électrique

Avant d’allumer l’appareil, reliez le cable de mise a la terre de l’equipement a la terre.

Une bonne mise a la terre (connexion a la terre) est tres importante pour proteger l equipement

contre les effets nefastes du bruit externe et reduire les risques d’electrocution en cas de foudre.

Pour desinstaller l’equipement, debranchez le cable de mise a la terre apres avoir eteint l’appareil.

Un cable de mise a la terre est requis et la zone reliant les sections du conducteur doit faire plus de 4

mm2 ou 10 AWG.

Procédure de mise à la terre pour source d’alimentation CC

• Desserrez la vis du terminal de mise a la terre.

• Branchez le cable de mise a la terre a la terre.

• L’appareil de protection pour la source d’alimentation

Page 7

Embedded Computing Platform

7

CC doit fournir 30 A de courant. Cet appareil de protection doit etre branche a la source

d’alimentation avant l’alimentation CC.

Page 8

Embedded Computing Platform

8

Table of Contents

Chapter 1: Introduction ...................................................................................................... 9

Specifications .............................................................................................................. 9

Ordering Information ................................................................................................ 10

Chapter 2: System Overview ..............................................................................................11

Mechanical Drawing ...................................................................................................11

Front I/Os .................................................................................................................. 12

Rear I/Os .................................................................................................................... 13

Chapter 3: Board Layout ................................................................................................... 14

Jumper Settings & Connector Pinout (Motherboard) .............................................. 14

Chapter 4: Hardware Setup............................................................................................... 22

Installing SO-DIMM Memory .................................................................................... 23

Installing mSATA and Mini-PCIe Module ................................................................... 24

Installing LTE Wireless Network Module .................................................................. 25

Installing Disk Drives ............................................................................................... 26

Wall Mounting .......................................................................................................... 28

Appendix 1: Watchdog Timer ........................................................................................... 29

Page 9

Embedded Computing Platform

9

Processor

Onboard Intel Skylake-U SoC processor options:

Intel® Core™ i7-6600U (15W)

Memory

2x DDR3L 1333/1600MHz SO-DIMM sockets

supporting up to 16GB

BIOS

AMI SPI Flash BIOS

Serial

4 x D-Sub9 COM ports with RS-232/422/485 signals

USB

4 x USB 3.0 Type-A ports in dual double-stacked form

2 x USB 2.0 Type-A ports in double-stacked form

Display

Intel Integrated HD Graphic Engine

2 x HDMI ports

Storage

1x mSATA mini socket

1 x dual 2.5” SATA HDD/SSD drive bay

Chapter 1: Introduction

Thank you for choosing HVP300. This industrial embedded system is empowered by Intel® Core™

i7-6600U SoC processors (codenamed Skylake-U). The I/O features include four RS-232/422/485 serial

ports, four USB 3.0, two USB 2.0 ports and two HDMI ports. For networking communications, the HVP300

comes with two 10/100/1000 Mbps Ethernet ports and four PoE ports for even greater flexibility.

Product Features:

Intel® Core™ i7-6600U SoC

2 x DDR3L 1333/1600MHz SO-DIMM sockets supporting up to 16GB

Intel® HD Graphics

2x HDMI display output ports

6x RJ45 (HVP300) or 2x RJ45 & 4x PoE (HVP300P)

4x USB 3.0 and 2x USB 2.0

2x 2.5” HDD/SSD with RAID 0/1

4x Serial Ports with RS-232/422/485 signals

0°C ~ +40°C Wide Operating Temperature Range

2 x mini-PCIe sockets (1 x full-size and 1 x half-size) with PCIe and USB signals (the full-size socket is

compatible with LTE module)

1 x mSATA socket for internal storage

Please refer to the following table for detailed specifications

Specifications

Page 10

Embedded Computing Platform

10

Expansion

1x standard mini-PCI express socket (full size) with

SIM card reader, compatible with LTE module

1x half-sized mini-PCI express socket

1x mSATA mini socket

Antenna

2 x SMA antenna holes (sealed by default)

Networking

Ethernet Controller

1x Intel i219

5x Intel i210

Ethernet Ports

6 x RJ-45 10/100/1000Mbps ports

PoE

4 x RJ-45 LAN ports with PoE function

LEDs

2 x LED for Power-on status(Green) and Storage

access status(Yellow)

2 x LED for 3G & WiFi communication access

Physical

Characteristics

Dimensions

164.5 x 143.0 x 30.0, unit: mm

Mounting

Wall mount, VESA mount

Power

Input

1x 2pin terminal block, support DC +24V input

Adapter

24V/5A, 120W with PoE

Reliability Tool

Automatic Reboot

Setting

Lanner Watchdog Timer 1~255 level per second or

minute

Environment

Operating

Temperature

0°C - 40°C

Non-operating

Temperature

-20 - 70℃

Humidity

5 to 95% (non-condensing)

Green

RoHS

Operating System Supported

WES 7 E/P, Win 7 Pro FES, WE 8.1 Industry Pro, Win10

IOT

Standards &

Regulations

EMC

CE, FCC Class A

HVP300

Embedded industrial PC with Intel i7-6600U w/ 4-ports PoE

Ordering Information

Page 11

Embedded Computing Platform

11

Unit: mm

Chapter 2: System Overview

Mechanical Drawing

Page 12

12

F1 LAN

6 x 10/100/1000 mbps RJ-45 LAN ports

LAN3-LAN6 are PoE ports

F2 USB 3.0

4 x USB3.0 Type-A ports in dual double-stacked form

F3 LED

2 x LED for Power-on status(Green) and Storage access

status(Yellow)

2 x LED for 3G & WiFi communication access

F4 Reset

1 x Reset button

F5 Antenna

2 x SMA antenna holes (sealed by default)

F1

F2

F3

F4

F5

F5

Front I/Os

Embedded Computing Platform

Page 13

13

R1 Power Input

1 x2-pin terminal block, support DC +24V input

R2 Remote Power On/Off

1x 2pin terminal block for remote power on/off

R3 COM

4 x D-sub COM ports with RS-232/422/485 signals

R4 USB

2 x USB 2.0 Type-A ports in double-stacked form

R5 HDMI

2 x HDMI ports

R1

R2

R3

R4

R5

Rear I/Os

Embedded Computing Platform

Page 14

Embedded Computing Platform

14

Pin No.

Description

Pin No.

Description

1

DATA2+

2

GND

3

DATA2-

4

DATA1+

5

GND

6

DATA1-

7

DATA0+

8

GND

9

DATA0-

10

CLK+

11

GND

12

CLK-

13

N.C

14

N.C

15

DDC CLK

16

DDC DAT

17

GND

18

HDMI_VCC

19

HPD

Pin No.

Description

Pin No.

Description

1

DATA2+

2

GND

3

DATA2-

4

DATA1+

5

GND

6

DATA1-

7

DATA0+

8

GND

9

DATA0-

10

CLK+

11

GND

12

CLK-

13

N.C

14

N.C

15

DDC CLK

16

DDC DAT

17

GND

18

HDMI_VCC

19

HPD

Chapter 3: Board Layout

Jumper Settings & Connector Pinout (Motherboard)

HDMI1: High-Definition Multimedia Interface connector

HDMI2: High-Definition Multimedia Interface connector

Page 15

Embedded Computing Platform

15

Pin No.

Description

1

TXD+

MD0+

2

TXD-

MD0-

3

RX+

MD1+

4

T45

MD2+

5

T45

MD2-

6

RX-

MD1-

7

T78

MD3+

8

T78

MD3-

9

10-/100-/1000+

10

10+/100+/1000-

11

Active LED+

12

Active LED-(yellow)

LAN1-6: LAN Connectors (RJ-45 connectors with LED) at 10/100/1000Mbps for Ethernet

connectivity. LAN3 to LAN6 are PoE ports.

USB1-2: 4 x USB3.0 Type-A Connectors in dual double-stacked form

Page 16

Embedded Computing Platform

16

PIN NO.

DESCRIPTION

1

USB_VCC1

2

-USB

3

+USB

4

GND

0

USB_VCC2

6

-USB

7

+USB

8

GND

Pin No.

Description

Pin No.

Description

1

USB_VCC1

2

USB1_D-

3

USB1_D+

4

GND

5

USB1_RX-

6

USB1_RX+

7

GND

8

USB1_TX-

9

USB1_TX+

10

USB_VCC1

11

USB1_D-

12

USB1_D+

13

GND

14

USB1_RX-

15

USB1_RX+

16

GND

17

USB1_TX-

18

USB1_TX+

USB3

5

8 4 1

USB3: USB2.0 Type-A Connectors in double-stacked form

COM1/COM2: 4 x DB-9 COM ports with RS-232/422/485 signals (COM1-4 on the panel)

Page 17

17

Pin

Signal

Pin

Signal

1

Data Carrier Detect (DCDA#)

6

Data Set Ready (DSRA#)

2

Receive Data (RXDA)

7

Request To Send (RTSA#)

3

Transmit Data (TXDA)

8

Clear To Send (CTSA#)

4

Data Terminal Ready (DTRA#)

9

Ring Indicator (RIA#)

5

GND

Pin

RS-232

RS-422

RS-485

1

DCD

TX-

RTX-

2

RXD

TX+

RTX+

3

TXD

RX+

4 DTR

RX- 5

GND

6

DSR

7

RTS

8

CTS

9

RI

RS-232/422/485

Embedded Computing Platform

Page 18

Embedded Computing Platform

18

Pin

Description

Pin

Description

1

WAKE#

2

+3.3V

3

RSVD

4

GND

5

RSVD

6

+1.5V

7

CLKREQ#

8

UIM_PWR

9

GND

10

UIM_DATA

11

REFCLK-

12

UIM_CLK

13

REFCLK+

14

UIM_RESET

15

GND

16

UIM_VPP

KEY

17

RSVD

18

GND

19

RSVD

20

W_DISABLE#

21

GND

22

PERST#

23

PERn0

24

+3.3V

25

PERp0

26

GND

27

GND

28

+1.5V

29

GND

30

SMB_CLK

31

PETn0

32

SMB_DATA

33

PETp0

34

GND

35

GND

36

USB_D+

37

GND

38

USB_D-

39

+3.3V

40

GND

41

+3.3V

42

LED_WWAN#

43

GND

44

LED_WLAN#

45

RSVD

46

LED_WPAN#

47

RSVD

48

+1.5V

49

RSVD

50

GND

51

RSVD

52

+3.3V

MPCIE1

MPCIE1: mini-PCIe slot with USB signals and SIM card reader (Full Size) for wireless

module

Page 19

Embedded Computing Platform

19

Pin

Description

Pin

Description

1

WAKE#

2

+3.3V

3

RSVD

4

GND

5

RSVD

6

+1.5V

7

CLKREQ#

8

UIM_PWR

9

GND

10

UIM_DATA

11

REFCLK-

12

UIM_CLK

13

REFCLK+

14

UIM_RESET

15

GND

16

UIM_VPP

KEY

17

RSVD

18

GND

19

RSVD

20

W_DISABLE#

21

GND

22

PERST#

23

PERn0

24

+3.3V

25

PERp0

26

GND

27

GND

28

+1.5V

29

GND

30

SMB_CLK

31

PETn0

32

SMB_DATA

33

PETp0

34

GND

35

GND

36

USB_D+

37

GND

38

USB_D-

39

+3.3V

40

GND

41

+3.3V

42

LED_WWAN#

43

GND

44

LED_WLAN#

45

RSVD

46

LED_WPAN#

47

RSVD

48

+1.5V

49

RSVD

50

GND

51

RSVD

52

+3.3V

MPCIE2: half-sized mini-PCIe slot with PCIe and USB signals for wireless modules

Page 20

Embedded Computing Platform

20

Pin

Description

Pin

Description

1

N.C 2 +3.3V

3

N.C 4 GND

5

N.C 6 N.C 7 N.C 8 N.C 9 GND

10

N.C

11

N.C

12

N.C

13

N.C

14

N.C

15

GND

16

N.C KEY

17

N.C

18

GND

19

N.C

20

N.C

21

GND

22

N.C

23

SATA_RXp

24

+3.3V

25

SATA_RXn

26

GND

27

GND

28

N.C

29

GND

30

N.C

31

SATA_TXn

32

N.C

33

SATA_TXp

34

GND

35

GND

36

N.C

37

GND

38

N.C

39

+3.3V

40

GND

41

+3.3V

42

N.C

43

GND

44

N.C

45

N.C

46

N.C

47

N.C

48

N.C

49

N.C

50

GND

51

N.C

52

+3.3V

MSATA1: mSATA mini slot for storage device (half-sized form)

Page 21

Embedded Computing Platform

21

PIN

DESCRIPTION

1

DC_IN (-)

2

DC_IN (24V)

Short Pins

Description

1-2

Normal (Default)

2-3

Clear CMOS

Short Pins

Description

1-2

Normal (Default)

2-3

Flash ME

PIN

DESCRIPTION

PIN

DESCRIPTION

1

SPI_HOLD

2

N.C 3 SPI_CS#

4

SPI_VCC

5

SPI_MO

6

N.C 7 N.C 8 SPI_CLK

9

GND

10

SPI_MI

Clear CMOS

Normal(Def)

CMOS1

1

2

3

CMOS1

1

2

3

1

2

3

2

SPI1

9

10

1

Flash ME

Normal(Def)

ME1

1

2

3

ME1

1

2

3

1

2

3

DCIN1: DC Power input through 2-pin 5.0mm Phoenix connector

JCMOS1: Clear CMOS setting

JME1: flash ME (Manageability Engine)

SPI1: SPIROM pin header for debug purpose

Page 22

Embedded Computing Platform

22

Chapter 4: Hardware Setup

Accessing the Inside of HVP300

To access some components and perform certain service procedures, you must perform the following

procedures first.

WARNING:

To reduce the risk of personal injury, electric shock, or damage to the equipment, please remove all

power sources.

Please wear ESD protected gloves before conducting the following steps.

Do NOT pile items on top of the system to prevent damages due to this improper use. Lanner is not

liable for damages caused by improper use of the product.

1. Power off HVP300 and remove the power cord.

2. Rotate and remove the four rubber pads at the bottom compartment.

2. Lift and open the chassis.

Page 23

Embedded Computing Platform

23

Installing SO-DIMM Memory

The system is designed with two SO-DIMM sockets supporting up to 16GB DDR3L 1333/1600MHz. Please

follow the steps below for proper installations.

1. Locate the SO-DIMM sockets on the motherboard.

2. Select the socket for installing the module. Align the memory module’s key with the SO-DIMM socket’s

key.

3. Insert the SO-DIMM module.

4. Press the module down until it is locked by the two clips at each side.

Page 24

Embedded Computing Platform

24

Mini-PCIe

(full-sized)

Mini-PCIe

(half-sized)

mSATA mini

Installing mSATA and Mini-PCIe Module

The system provides one mSATA mini socket and two mini-PCIe sockets (one full-sized and another

half-sized) for storage and wireless modules. Please follow the steps below for installations.

1. Locate the mSATA and the mini-PCIe sockets.

2. Select the socket for installing the module. Align the mechanical notches between the module and the

socket.

3. Insert the module into the socket.

4. Secure the installed module with two screws.

Page 25

Embedded Computing Platform

25

Installing LTE Wireless Network Module

The mini-PCIe socket of the system is compatible with LTE wireless network module. Please follow the

steps below for installations.

1. Locate the mini-PCIe sockets.

2. Align the mechanical notches between the module and the socket.

3. Insert the LTE wireless network module (Sierra M7354 in this case) into the socket.

4. Secure the installed module with two screws.

Page 26

Embedded Computing Platform

26

Installing Disk Drives

The system supports 1 x dual 2.5” SATA HDD/SSD drive bay as data storage (SSD is

recommended due to heat and vibration concerns). Please follow the steps below for installation.

1. Locate the dual 2.5” SATA HDD/SSD drive bay at the back of the bottom compartment.

2. Place disk drives onto the drive bay and apply two screws on each side of a SATA disk drive.

3. Connect the SATA 7-pin signal cable and the SATA 4-pin power cable to their corresponding

connectors on the motherboard.

Page 27

Embedded Computing Platform

27

4. Plug the standard 7+15 SATA connector to the SSD.

Page 28

Embedded Computing Platform

28

Wall Mounting

The system can be mounted on a flat surfaced wall. Please take the following into considerations

when mounting the system onto the wall.

1. Ensure the wall brackets are properly fixed onto the chassis, as illustrated in the drawings

below.

2. Please pay close attention to the dimensional parameters in the drawings below such as the

distance between each screw hole of a bracket piece. The parameter values serve as important

reference for applying standoffs on the wall.

Page 29

Embedded Computing Platform

29

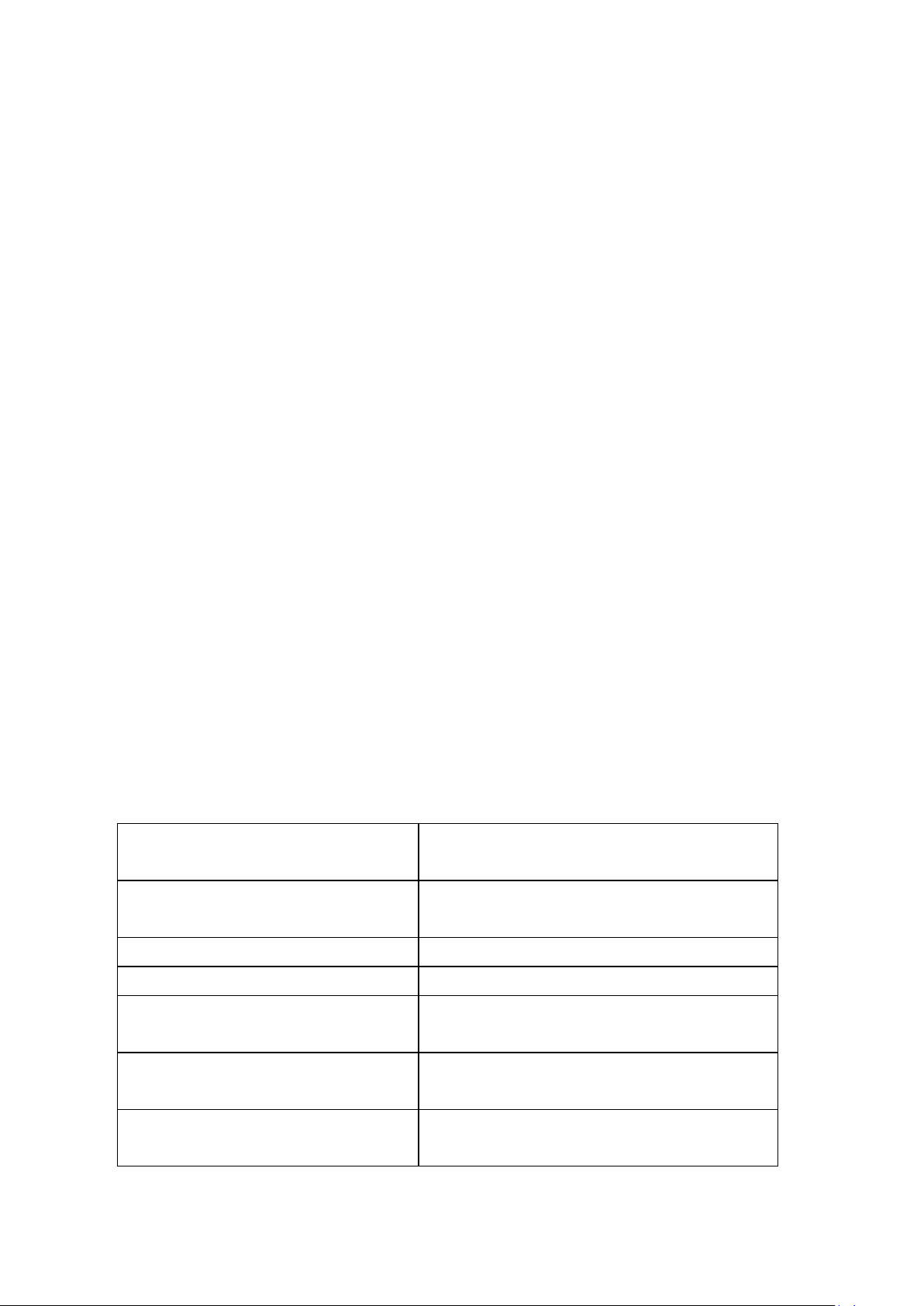

Processor

Watchdog Timer

Reset

Restart

Clock

Appendix 1: Watchdog Timer

A watchdog timer is a piece of hardware that can be used to automatically detect system anomalies and

reset the processor in case there are any problems. Generally speaking, a watchdog timer is based on a

counter that counts down from an initial value to zero. The software selects the counter’s initial value and

periodically restarts it. Should the counter reach zero before the software restarts it, the software is

presumed to be malfunctioning

and the processor’s reset signal is asserted. Thus, the processor will be restarted as if a human operator

had cycled the power.

To download sample watchdog code, please refer to our official website at www.lannerinc.com.

Page 30

Embedded Computing Platform

30

Federal Communications Commission

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to pro-vide reasonable protection against harmful

interference when the equipment is operate din a commercial environment. This equipment generates,

uses, and can radiate radiofrequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

FCC Caution: Any changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate this equipment.

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment.

This equipment should be installed and operated with minimum distance 20cm between the radiator &

your body.

Loading...

Loading...