Hitachi CPX2102MS Schematic

No. 0420

SERV IC E M A N UA L

M A N UEL D 'E N TR ETIE N

W A RTU N GSH A N D BU CH

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

CPX2102MS

Data contained within this Service

manual is subject to alteration for

improvement.

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

NAMES»

SPECIFICATIONS AND PAR TS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

Monitor

December 1999

SERVICE

MANUAL

21 "F" CHASSIS

1. Precautions

--------------------------------- 3

1-1. Safety Precautions --------------------- 3

1-2. Servicing Precautions ----------------- 5

1-3. Precautions for Electrostatically

Sensitive Devices(ESDs) ---------------- 6

2. Specifications

------------------------------ 7

3. Description of Controls

----------------- 9

4. Exploded View

----------------------------- 10

5. Alignment and Adjustments

---------- 12

5-1. Preadjustment -------------------------- 12

5-2. Factory/Service Mode ---------------- 12

5-3. Other Adjustments --------------------- 16

6. Using Devices and Description

------20

6-1. Main Signal Processor(TDA8842) --20

6-2. Vertical Output(TDA8351) ----------- 24

6-3. Video Output Amplifier

(TDA6101Q) -------------------------------- 25

6-4. Audio Output Amplifier(KA2201) --- 26

6-5. Power(STR-F6656) -------------------- 27

6-6. Video Select switch(CD4053BE) --- 28

6-7. Audio Select switch(CD4066BP) --- 28

7. Technical Study(SMPS Operation)

-- 29

7-1. VIN terminal(pin 4)

: Start-up circuit ---------------------------- 29

7-2. OCP/F.B. terminal(pin 1)

: Oscillator and constant voltage

control circuit -------------------------------- 31

7-3. OCP/F.B. terminal(pin 1)

OCP circuit ---------------------------------- 33

7-4. Drive circuit -------------------------------34

7-5. Latch circuit -------------------------------34

7-6. Thermal shutdown circuit -------------35

7-7. Overvoltage protection circuit ------- 35

8. Trouble Shooting

------------------------- 36

8-1. No Power -------------------------------- 36

8-2. No Raster -------------------------------- 37

8-3. No Sound -------------------------------- 38

9. Block Diagram

----------------------------- 39

10. Pcb Layout

-------------------------------- 40

11. Parts List

----------------------------------- 42

12. Circuit Diagram

--------------------------- 47

CONTENTS

2

1. Precautions

Follow these safety, servicing and ESD precautions to prevent

damage and protect against potential

hazards, such as electrical shock and X-rays.

1-1. Safety Precautions

1. Be sure that all of the built-in protective devices are replaced.

Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be sure to restore all protective devices,

including

nonmetallic control knobs and compartment covers.

3. Make sure that there are no cabinet openings through which people-particularly children-might

insert fingers and contact dangerous voltages. Such opening include the spacing between

the picture tube and the cabinet mask, excessively wide cabinet ventilation slots, and improperly fitted back covers.

If the measured resistance is less than 1.0 megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected before the unit is returned to the customer.

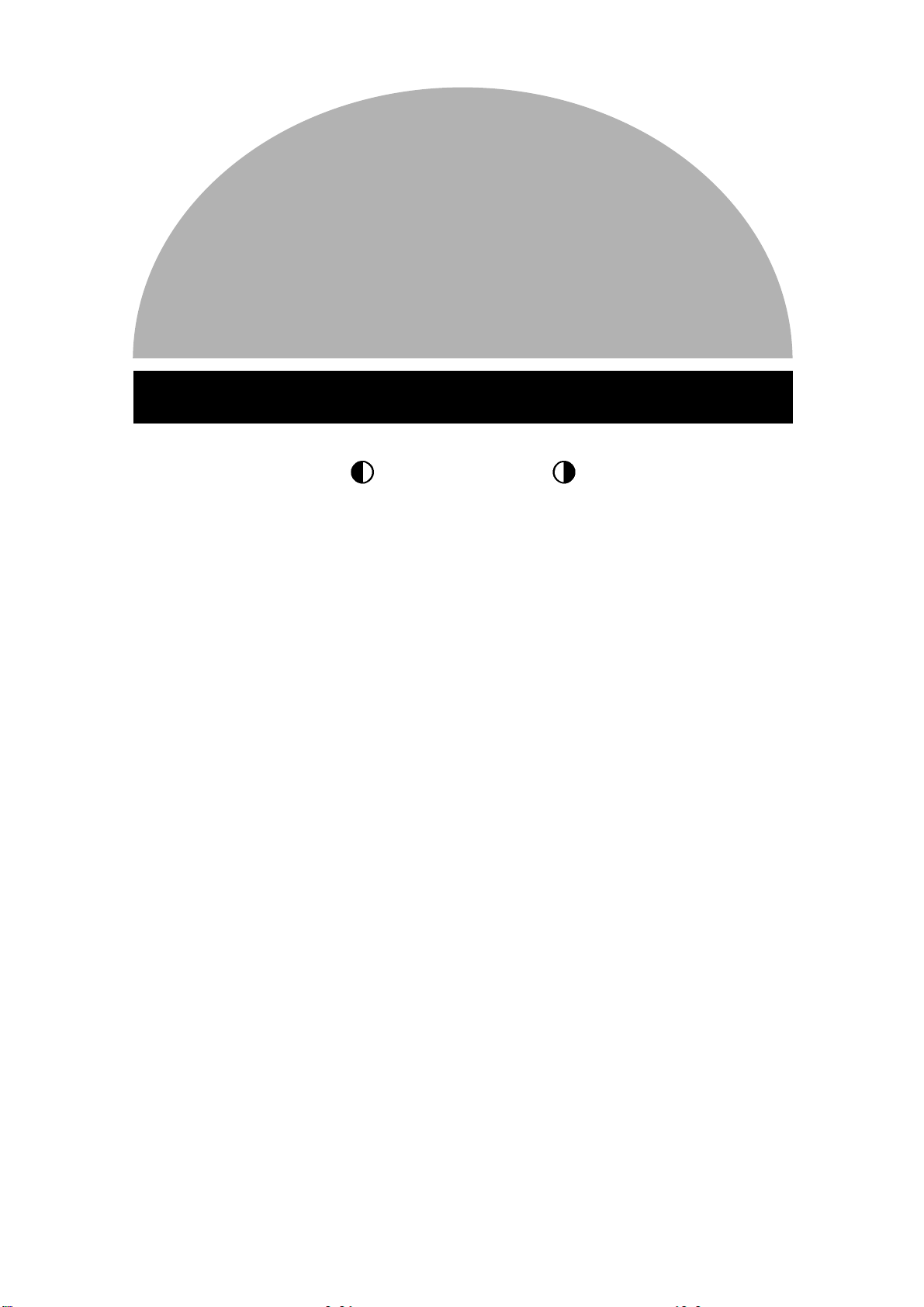

4. Leakage Current Hot Check (Figure 1-1)

Warning Do not use an isolation transformer during this test. Use a leakage current

tester or a metering system that complies with International Electrotechnical Commission

65.(IEC 65)

3

ALSO TEST WITH

PLUG REVERSED

POWER

CORD

TEST ALL

EXPOSED METAL

SURFACES

EARTH

GROUND

READING SHOULD NOT

BE ABOVE

<0.7mA PEAK AC<2mA DC.

FIGURE 1-1

AC LEAKAGE TEST

DEVICE

UNDER

TEST

LEAKAGE

CURRENT

TESTER

5. With the unit completely reassembled, plug the AC line cord directly to the power outlet.

With the unit s AC switch first in the ON position and then OFF, measure the current

between a known earth ground (metal water pipe, conduit, etc.) and all exposed metal

parts, including

handle brackets, metal cabinets, screwheads and control shafts.

The current measured should not exceed < 0.7 mA peak AC < 2mA DC.

Reverse the power-plug in the AC outlet and repeat the test.

6. X-ray Limits

The picture tube is especially designed to prohibit X-ray emissions.

To ensure continued X-ray protection, replace the picture tube only with one that is the

same type as the original. Carefully reinstall the picture tube shields and mounting

hardware these also provide X-ray protection.

7. High Voltage Limits

High voltage must be measured each time servicing is done on the +B, horizontal

deflection or high voltage circuits.

8. High voltage is maintained within specified limits by close-tolerance, safety-related

components and adjustments. If the high voltage exceeds the specified limits, check

each of the special components.

9. Design Alteration Warning

Never alter or add to the mechanical or electrical design of this unit.

Example Do not add auxiliary audio or video connectors. Such alterations might

create a safety hazard. Also, any design changes or additions will void the

manufacturer s warranty.

10. Components, parts and wiring that appear to have overheated or that are otherwise

damaged should be replaced with parts that meet the original specifications. Always

determine the cause of damage or overheating, and correct any potential hazards.

11. Observe the original lead dress, especially near the following areas

Antenna wiring, sharp edges, and especially the AC and high voltage power supplies.

Always inspect for pinched, out-of-place, or frayed wiring.

Do not change the spacing between components and the printed circuit board. Check

the AC power cord for damage. Make sure that leads and components do not touch

thermally hot parts.

12. Picture Tube Implosion Warning

The picture tube in this receiver employs

"

integral implosion"protection.

To ensure continued implosion protection, make sure that the replacement picture tube

is the same as the original.

13. Do not remove, install or handle the picture tube without first putting on shatterproof

goggles equipped with side shields.

Never handle the picture tube by its neck. Some

"

in-line"picture tubes are equipped

with permanetly attached diflection yoke do not try to remove such "permanently

attached

"

yokes from the picture tube.

4

14. Product Safety Notice

Some electrical and mechanical parts have special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they give might be lost if the replacement

component differs from the original-even if the replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are indicated in the circuit diagram by

shading( )

Use replacement components that have the same ratings, especially for flame

resistance and dielectric strength specifications. A replacement part that does not have

the same safety characteristics as the original might create shock, fire or other hazards.

1-2. Servicing Precautions

Warning 1 First read the "Safety Precaution"section of the manual.

If some unforeseen circumstance creates a conflict between the servicing and

safety precautions, always follow the safety precaution.

Warning 2

An electrolytic capacitor installed with the wrong polarity might explode.

1. Servicing Precautions are printed on the cabinet. Follow them.

2. Always unplug the unit

s AC power cord from the AC power source before attempting

to

(a) Remove or reinstall any component or assembly, (b) Disconnect an electrical

plug or connector, (c) Connect a test component in parallel with an electrolytic capacitor.

3. Some components are raised above the printed circuit board for safety.

An insulation tube or tape is sometimes used. The internal wiring is sometimes clamped

to prevent contact with thermally hot components.

Reinstall all such elements to their original position.

4. After servicing, always check that the screws, components and wiring have been

correctly reinstalled. Make sure that the portion around the serviced part has not been

damaged.

5. Check the insulation between the blades of the AC plug and accessible conductive parts

(examples metal panels,. input terminals).

6. Insulation Checking Procedure

Disconnect the power cord from the AC source and

turn the power switch ON. Connect an insulation resistance meter (500V) to the blades of

the AC plug.

The insulation resistance between each blade of the AC plug and accessible conductive

parts (see above) should be greater than 1 megohm.

7. Never defeat any of the B+ voltage interlocks. Do not apply AC power to the unit (or any

of its assemblies) unless all solid-state heat sinks are correctly installed.

5

8. Always connect a test instrument s ground lead to the instrument chassis ground before

connecting the positive lead always remove the instrument s ground lead list.

1-3. Precautions for Electrostatically Sensitive Devices (ESDs)

1. Some semiconductor ("solid state") devices are easily damaged by static electricity.

Such some components are called Electrostatically Sensitive Devices (ESDs) examples

include integrated circuits and some field-effect transistors. The following techniques will

reduce the occurrence of component damage caused by static electricity.

2. Immediately before handling any semiconductor components or assemblies, drain the

electrostatic charge from your body by, touching a known earth ground. Alternatively,

wear the discharging wrist-strap device. (Be sure to remove it prior to applying powerthis is an electric shock precaution)

3. After removing an ESD-equipped assembly, place it on a conductive surface such as

aluminum foil to prevent accumulation of electrostatic charge.

4. Do not use freon-propelled chemicals. These can generate electrical charges that

damage ESD

S.

5. Use only a grounded-tip soldering iron when soldering or unsoldering ESDS.

6. Use only an anti-static solder removal device. Many solder removal devices are not rated

as "anti-static" these can accumulate sufficient electrical charge to damage ESDS.

7. Do not remove a replacement ESD front its protective package until you are ready to

install it. Most replacement ESDs are packaged with leads that are electrically shorted

together by conductive foam, aluminum foil or other conductive materials.

8. Immediately before removing the protective material from the leads of a replacement

ESD, touch the protective material to the chassis or circuit assembly into which the

device will be installed.

9. Minimize body motions when unpackaged replacement ESDs. Motion, such as brushing

clothes together, or lifting a foot from a carpeted floor can generate, enough static

electricity to damage an ESD.

6

2. Specifications

MODEL : CT21AF

DESCRIPTION : 21 INCH CCTV WITH 2 CH CAMERA INPUT &

HORIZONTAL RESOLUTION 450 LINES

1) SPECIFICATIONS

COLOR SYSTEM : NTSC 3.58 / PAL-B

POWER INPUT : AC 100-240V(50/60 Hz)

POWER CONSUMPTION : 67W

VIDEO IMPEDANCE : 75Ohm BNC

SOUND OUTPUT : 1.0

0.2W 8 Ohm

SPEAKER SIZE : 70mm

40mm

VIDEO OUTPUT LEVEL : 1.0V

p-p 10% at 75 Ohm

VIDEO INPUT LEVEL : 1.0V

p-p 10% at 75 Ohm

AUDIO OUTPUT LEVEL : RCA JACK TYPE

300

50mVrms

AUDIO INPUT LEVEL : RCA JACK TYPE

300

50mVrms

SOUND DISTORTION : Less Than 10%

HUM : Less Than 10mVrms

BUZZ : Less than 200mV

p-p

2) FEATURES

BLUE BACK AT NO SIGNAL

PROTECTION CIRCUIT FOR X-RAY

S-VHS INPUT

VIDEO THROUGH-OUT

3) CONTROLS & SWITCHES

MAIN AC POWER S/W : PUSH LOCK FRONT

PICTURE CONTROL : ROTARY FRONT

(CONTRAST, BRIGHTNESS, TINT, COLOR, SHARPNESS)

VOLUME CONTROL : ROTARY FRONT

S-VHS/CAMERA SELECTION : TACT SWITCH FRONT

VIDEO IMPEDANCE : SLIDE SWITCH BACK

7

4) LIGHTINGS

INDICATOR : POWER ON (GREEN)

: VIDEO 1 (GREEN)

: VIDEO 2 (GREEN)

: Y/C (GREEN)

5) JACK & TERMINALS

4 BNC : VIDEO INPUT/OUTPUT

4 AUDIO RCA : AUDIO INPUT/OUTPUT

S-VHS MINI DIN : S-VHS INPUT

AC INLET : AC INPUT

6) ACCESSORIES

WARRANTY CARD

OWNER’S MANUAL

POWER CORD

7) CABINET SIZE

476(W) 432(H) 468(D)

8) PACKING

BOX OUT : 566(W) 555(H) 562(D)

Q’TY SET PER 40 FOOT FCL : 336 SETS

Q’TY SET PER 20 FOOT FCL : 160 SETS

9) REMARKS

WEIGHT : 26Kg

8

9

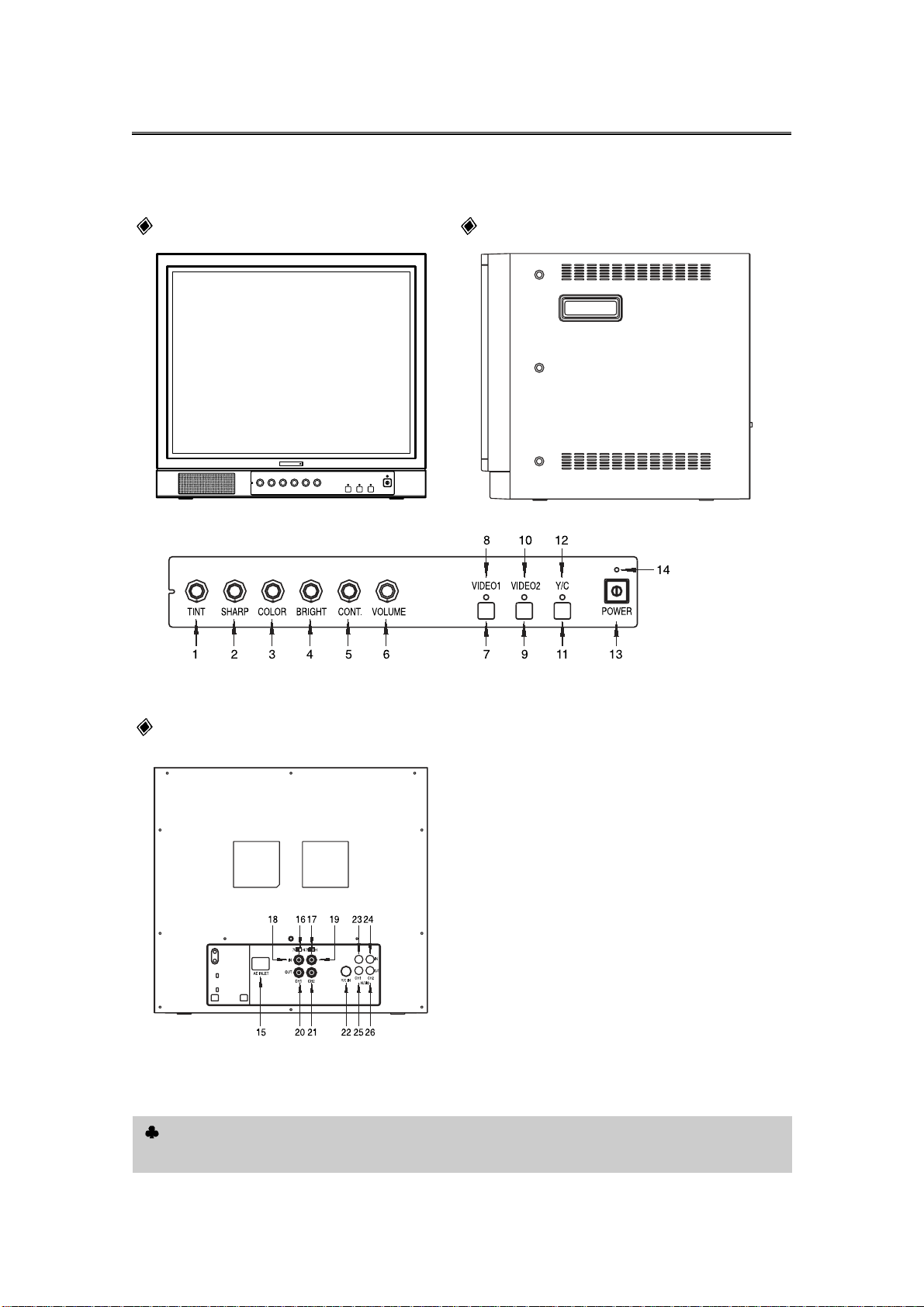

3. Description of controls

WARNING : TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS

CCTV TO RAIN OR MOISTURE

Front View Side View

Rear View

1. TINT

2. SHARPNESS

3. COLOR

4. BRIGHTNESS

5. CONTRAST

6. VOLUME

7. VIDEO 1

8. VIDEO 1 LED LAMP

9. VIDEO 2

10. VIDEO 2 LED LAMP

11. Y/C

12. Y/C LED LAMP

13. POWER BUTTON

14. POWER LED LAMP

15. POWER INLET

16. IMPEDANCE (SLIDE S/W)

17. IMPEDANCE (SLIDE S/W)

18. CHANNEL 1 IN(BNC)

19. CHANNEL 2 IN(BNC)

20. CHANNEL 1 OUT(BNC)

21. CHANNEL 2 OUT(BNC)

22. Y/C IN(DIN)

23. CHANNEL 1 AUDIO IN(RCA)

24. CHANNEL 2 AUDIO IN(RCA)

25. CHANNEL 1 AUDIO OUT(RCA)

26. CHANNEL 2 AUDIO OUT(RCA)

10

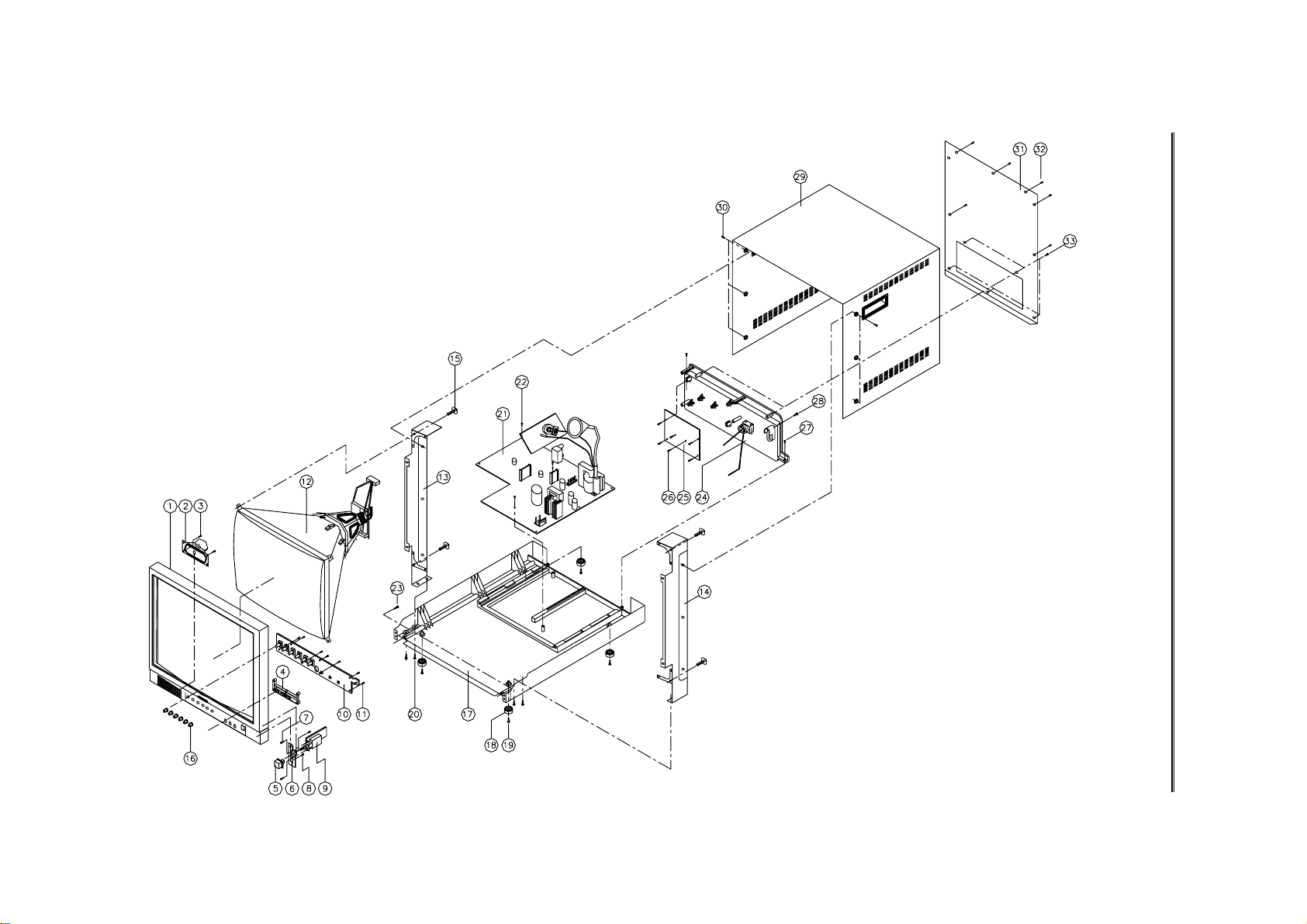

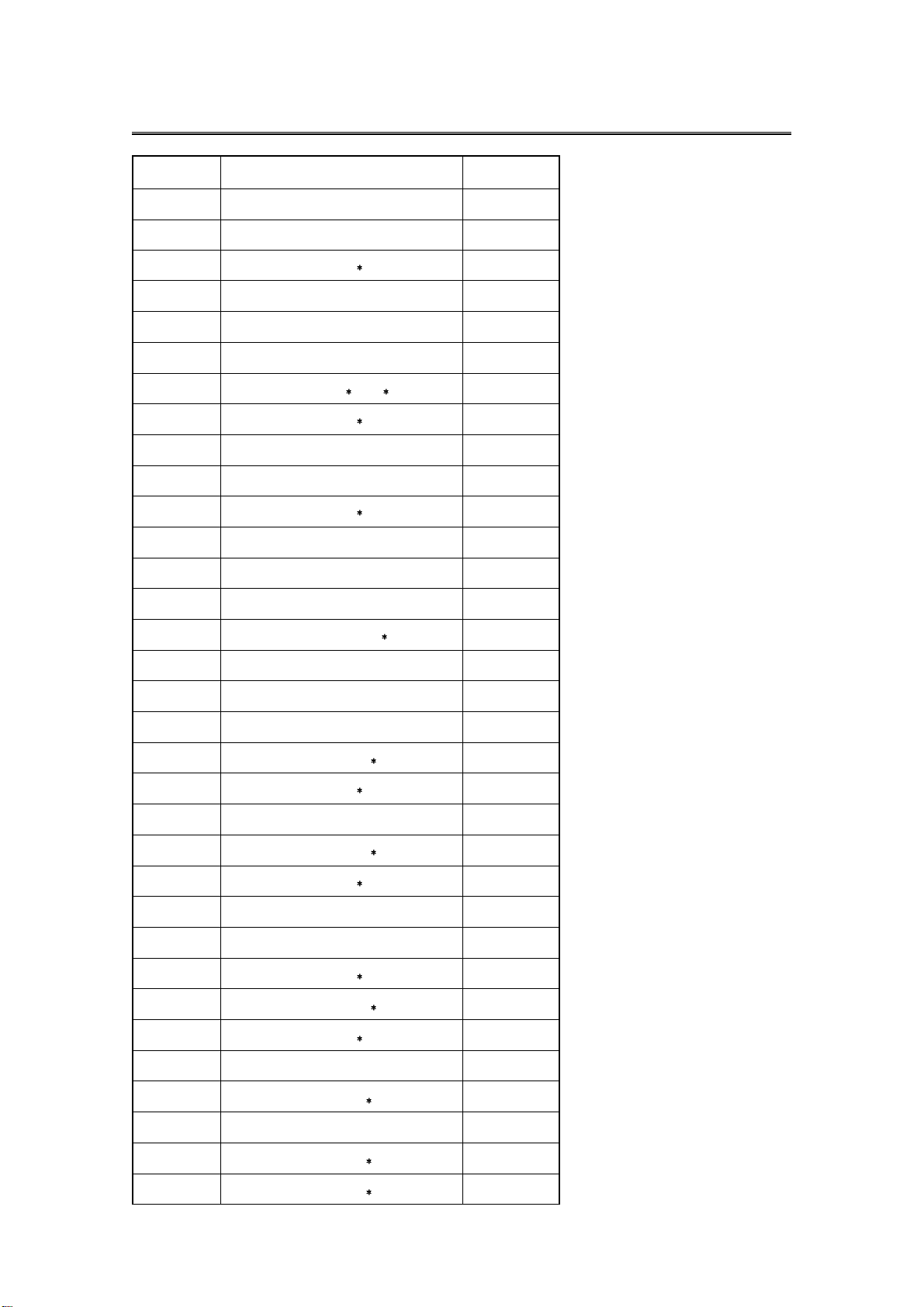

4. EXPLODED VIEW

NO ITEM

Q’TY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

FRONT PANEL ASS’Y

SPEAKER SYSTEM

SCREW BTB 3

10

KNOB, BLOCK

KNOB, POWER

BRACKET, POWER

SCREW PB 3 0.5 6

SCREW BTB 3 10

POWER S/W, MTR

CONTROL, MONITOR

SCREW BTB 3 10

CPT ASS’Y

BRACKET, LEFT

BRACKET, RIGHT

SCREW HTTBW 6 30

KNOB, VOLUME ASS’Y

BOTTOM COVER

RUBBER FOR LEG

SCREW BTBW 3

12

SCREW BTB 4

12

MAIN, CCTV

SCREW BTBW 3

12

SCREW BTB 4

12

BACK PANEL ASS’Y

BACK BOARD

SCREW BTB 3 10

SCREW BTBW 3 12

SCREW BTB 4 12

TOP COVER

SCREW BTTB 4 8

BRACKET, REAR

SCREW BTTS 3 8

SCREW PBTB 3

12

1

1

2

1

1

1

2

2

1

1

7

1

1

1

4

6

1

4

4

4

1

3

2

1

1

6

2

1

1

6

1

7

5

11

5. Alignment and Adjustments

5-1. Preadjustment

5-1-1. Factory Mode

1. Do not attempt these adjustments in the VIDEO mode.

2. The Factory Mode adjustments are necessary when either the EEPROM(Q002) or the CPT

is replaced.

3. Do not tamper with the "Adjustment" screen of the Factory Mode menu. The screen is intended

only for factory use.

5-1-2. When EEPROM (Q002) is replaced

1. When Q002 is replaced all adjustment data revert to their initial values. It is necessary to reprogram this data.

2. After Q002 is replaced, warm up the CCTV SET for 10 seconds.

5-1-3. When CPT is replaced

1. Make the following adjustments after setting up purity and convergence:

White Balance

Vertical center

Vertical size

Horizontal size

5-2. Factory / Service Mode

5-2-1. Procedure for the "Adjustment" Mode

1. This mode uses the standard remote control. The Factory (Service) Mode is activated by

pressing the "Factory" key on the remote control.

2. The Factory Mode will be displayed. The Factory Mode has four components: Screen adjustment,

Position adjustment, White balance, and Volume Adjust.

3. Access the Adjustment Mode by pressing the VOLUME keys (Up or Down). The adjustment

Parameters adjusted are listed in the accompanying table, and they are selected by pressing

the PROGRAM keys (Up or Down).

4. The VOLUME keys increase or decrease the adjustment values, which are stored in the nonvolatile memory as soon as the adjustment is cancelled.

5. Cancel the Adjustment Mode by pressing the OUT CONDITION key.

12

13

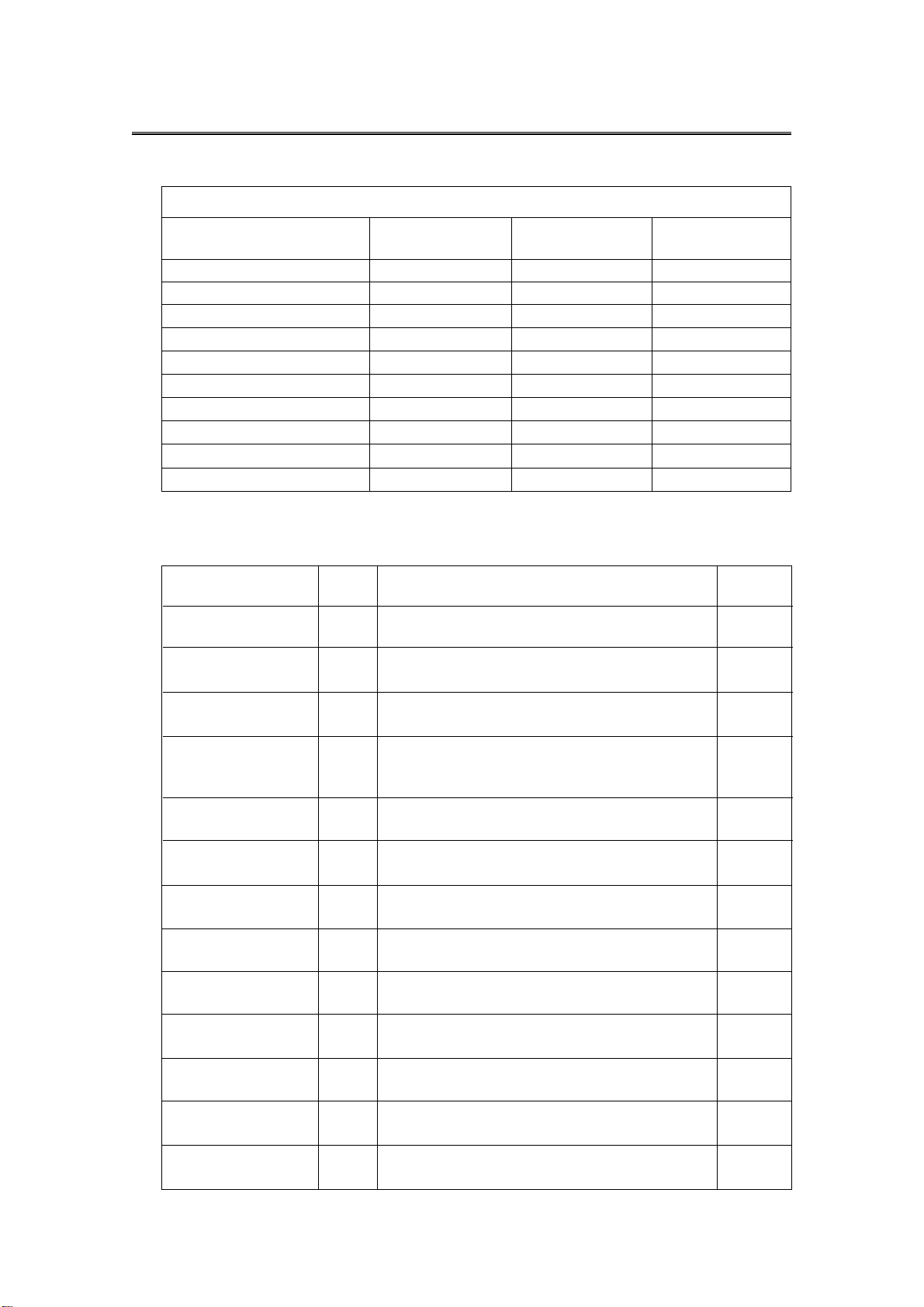

5-2-2. Service Adjustment Parameter

Main Adjustment Parameter

FUNCTION

OSD

ABBREVIATION

RANGE INITIAL DATA

SCREEN VOLTAGE

INCH OPTION

HORIZONTAL SHIFT

VERTICAL AMPLITUDE

VERTICAL SHIFT

VERTICAL SLOPE

RED CUTOFF

GREEN CUTOFF

BLUE CUTOFF

VOLUME OUTPUT

Screen ADJ

Inch

Hrs

Height

VRS

VS

R

G

B

Volume Adjust

---

21

0 ~ 63 Step

0 ~ 63 Step

0 ~ 63 Step

0 ~ 63 Step

0 ~ 63 Step

0 ~ 63 Step

0 ~ 63 Step

0 ~ 63 Step

---

21 inch

50

40

33

32

32

32

32

47

5-2-3. Factory Adjustment Parameter

FUNCTION OSD DESCRIPTION

INITIAL

DATA

IF Sensitivity

Modulation standard

Video mute switch

Search tuning mode

Video ident mode

AFC Window

PLL demodulator

frequency adjust

X-tal definition

Synchronisation

Phase 1 time constant

Video ident mode

Long blanking mode

Interlace

IFS

MOD

VSW

STM

VIM

AFW

LFA

XA

XB

POC

FOA

FOB

VID

LBM

DL

Off : Normal sensitivity

On : Maximum gain reduced by 20dB

Off : Negative modulation

On : Positive modulation

Off : Normal operation

On : IF video signal switched off

Off : Normal operation

On : Reduced dynamic sensitivity of

coincidence detector

Off : Ident coupled to CVBS

INT

On : Ident coupled to selected CVBS or Y/C

Off : Nominal window

On : Enlarged window

Off : Normal IF frequency

On : Frequency shift for L standard

0,0 : 3.6MHz, 3,6MHz, 0,1 : 3.6MHz, Open

1,0 : Open, 3,6MHz, 1,1 : 3.6MHz, 4.4MHz

Off : Active

On : Not active

0,0 : Normal, 0,1 : Slow

1,0 : Slow/Fast, 1,1 : Fast

Off : Phase 1 loop switched on and off

On : Not active

Off : Adapted to standard (50 or 60Hz)

On : Fixed in accordance with 50Hz standard

Off : Interlace

On : De-interlace

Off

Off

Off

Off

Off

Off

Off

1,1

Off

Normal

Off

Off

Off

14

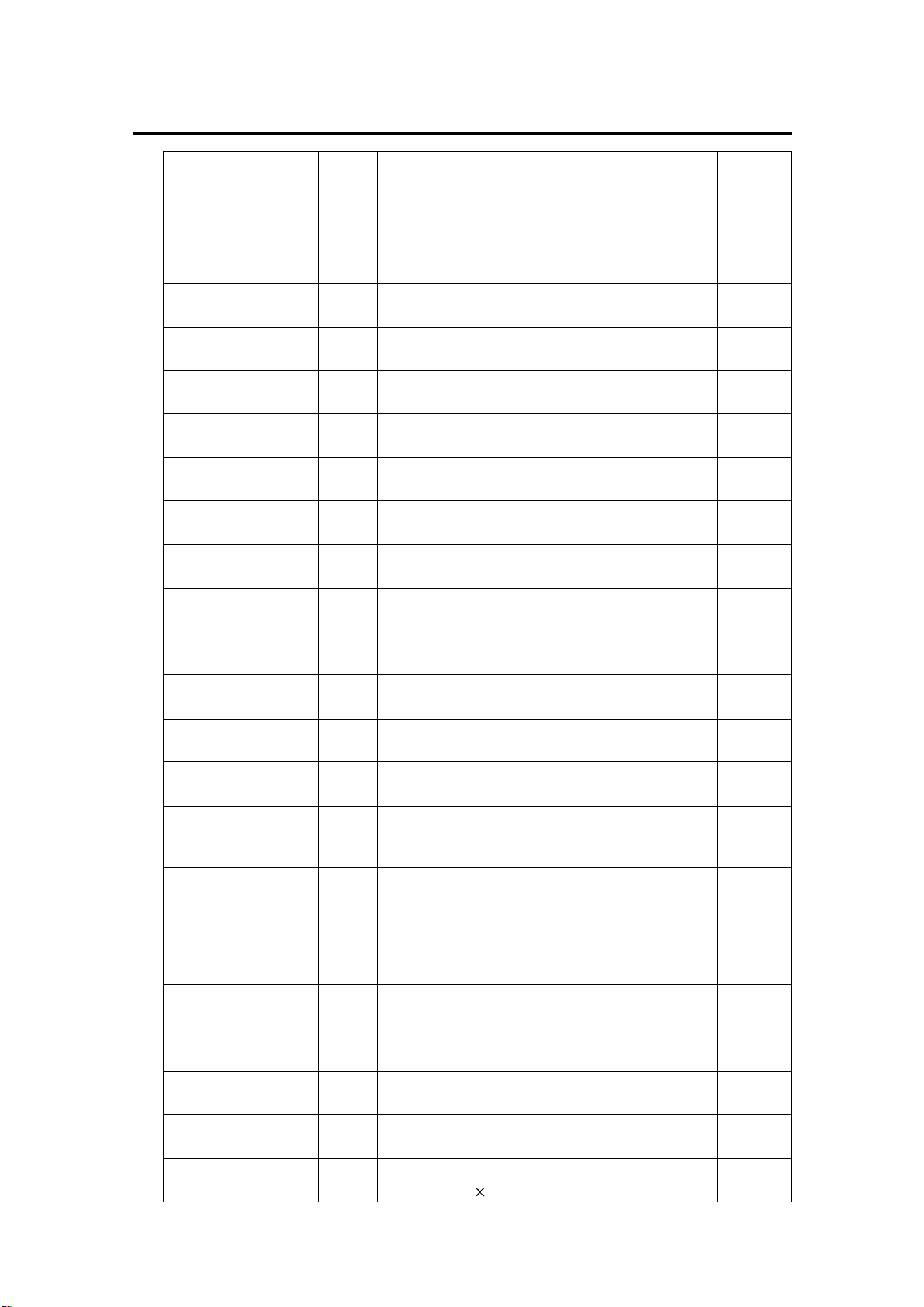

Forced field frequency

Vertical divider mode

Vertical overscan

Vertical scan disable

Helper output blanking

Enable vertical guard

Service blanking

Cathode drive level

Auto kine biasing

Automatic start up

RGB Blanking

Blue stretch

Black stretch

Enable fast blanking

Gain of luminance channel

Y-delay adjustment

Input source select

Fixed audio volume

Sound mute

Auto. volume leveling

Auto. Color limiting

Chroma bandpass

centre frequency

FORF

FORS

NCIN

OSO

VSD

HOB

EVG

SBL

CL 0

1 2

AKB

AST

RBL

BLS

BKS

IE1

GAI

YD

0123

IN

ABC

FAV

SM

AVL

ACL

CB

0,0 : Auto 60Hz, 0,1 : 60Hz forced

1,0 : Keep last detected freq., 1,1 : Auto 50Hz

Off : Normal

On : Switched to large search window

Off : Switch-off undefined

On : Switch-off in vertical overscan

Off : Vertical scan active

On : Vertical scan disabled

Off : Not active

On : Active

Off : Not active

On : Active

Off : Not active

On : Active

0 0 0 : 57V, 0 0 1 : 63V, 0 1 0 : 70V, 0 1 1 : 77V

1 0 0 : 84V, 1 0 1 : 91V, 1 1 0 : 99V, 1 1 1 : 107V

Off : Active

On : Not active

Off : Automatic mode

On : Switch on under control of u-processor

Off : Not active

On : Active

Off : Not active

On : Active

Off : Not active

On : Active

Off : Not active

On : Active

Off : Normal gain

On : High gain

0 0 0 0 : 0ns, 0 0 1 0 : 40ns, 0 1 0 0 : 80ns

0 1 1 1 : 12ns, 1 0 0 0 : 160ns, 1 0 1 1 : 200ns

1 1 0 0 : 240ns, 1 1 1 0 : 280ns, 1 1 1 1 : 320ns

0 0 0 : Int CVBS + audio

0 0 1 : Ext CVBS + audio

0 1 0 : Y/C + Ext audio

0 1 1 : CVBS3 + Ext audio

1 0 0 : Y/C + Int audio

1 1 0 : Y/C + Ext audio

Off : Normal Volume control

On : Audio level output fixed

Off : Not active

On : Active

Off : Not active

On : Active

Off : Not active

On : Active

Off : Fsc

On : On : 1.1

Fsc

1,0

Off

On

Off

Off

Off

Off

0 0 0

Off

Off

Off

Off

On

Off

Off

1 1 1 0

0 0 1

Off

On

On

On

Off

Loading...

Loading...