Page 1

SERVICE MANUAL

SM0064

Mod. PD1 A

CMP4121HDE

CMP4202E

42PMA400E

Be sure to read this manual before servicing. To assure safety from fire, electric shock, injury,

harmful radiation and materials, various measures are provided in this Plasma display.

Be sure to read cautionary items described in the manual to maintain safety before servicing.

1. Since Panel Module and Front Filter are made of glass, handling of the broken Module and

Filter shall be handled carefully in order not to be injured.

2. Replacment work shall be started after the Panel Module and the AC/DC Power supply become

Caution

Serviceman Warning

*

sufficiently cool.

3. Special care shall be taken to the display area in order not to damage its surface.

4. The Panel Module shall not to be touched with bare hand to protect its surface from stains.

5. It is recommended using clean soft gloves during the replacment work in order to protect not

only the display area of the Panel Module but also the serviceman himself.

6. The Chip Tube of Panel Module (located upper left of the back) and flexible cables connecting

Panel glasses to drive circuit PWBs are very weak, so sufficient care should be taken so as

not to break them. If you break the Chip Tube, the Panel will not display any more.

Contents

1. Features

2. Specifications

3. Lead free solder・・・・・・・・・・・・・・・・・・3

4. Names of each part・・・・・・・・・・・・・・・4

5. Trouble shooting・・・

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

・・・・・・・・・・・

・・・

・・

・・・・・・・・・・・・・・・

・・

・・・・・・・・・

・・・・・

・・・・・・・・・・・・5

2

2

6. Block diagram・

7. Disassembly Diagram・・・・・・・・・・・・15

8. Re-Adjustment ・・・・・・・・・・・・・・・・・18

9. Wiring Drawing・・・・・・・・・・・・・・・・・・22

10. Replacement Parts list・・・・・・

・・・・・・・・・・

・・・・・・・・14

・・・・・

24

Plasma Display

October 2002

Page 2

1. Features

42 inches Hi-Vision compatible high-definition color plasma display panel.

Newly developed Multi-scanning converter provides a multi-scan coverage of TV signals

through to PC analog signals (15 kHz to UXGA(107 kHz)).

Large high-quality display images free from color miss-convergence and display distortion, as

well as from geomagnetic effect and the magnetic effect of ambient power lines.

Multimedia input support

Two minis D-sub terminal have been provided for RGB input. It is possible to switch between

RGB signals and component signals* from the Menu screen or the remote controller,

therefore use is possible with equipment ranging from personal computer to imaging device.

*It is possible when the VIDEO unit is inserted.

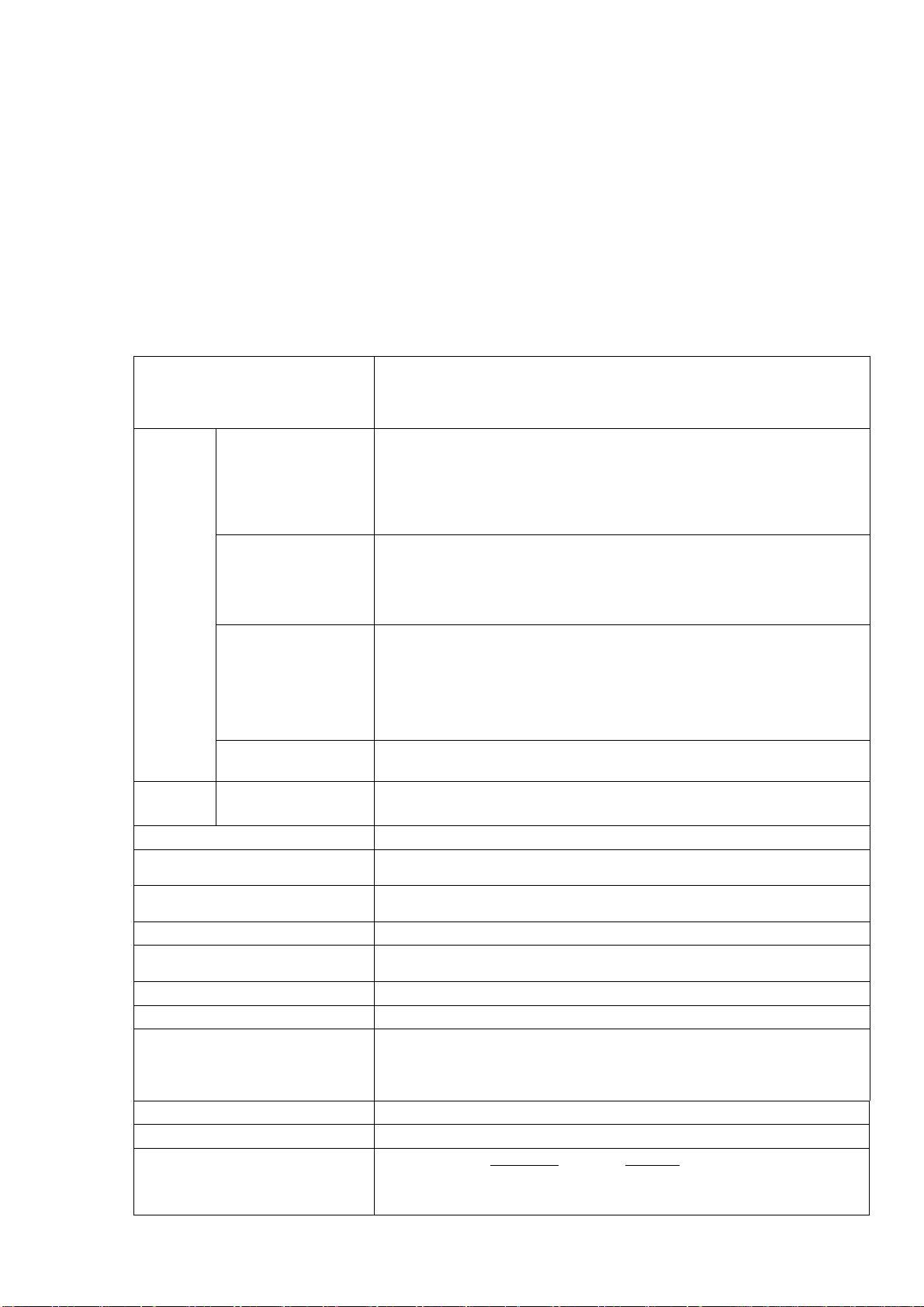

2. Specifications

PDP Module

Input

Signal

RGB 1

RGB 2

(mD-sub15p) x 2

Video 1

(RCAx1,

S-terminalx1)

Video 2

(RCAx3)

SCART

(VIDEO1,VIDEO2)

Output

Signal

Video 1

(RCAx1)

Colors

Synchronization

Resolution

Viewable Image Size

Viewable Image Area

Color Temperature

Warm-up Time

Power Supply

Dimensions

Weight

Environmental Condition

42 inch ALIS PDP panel (aspect ratio 16:9)

Description FPF42C128128UB

Pixel pitch 0.90 mm(H) x 0.51 mm(V)

Pixel structure RGB striped

Video : 0.7 Vp-p

Sync. : Separate H/V, TTL level

Composite H/V, TTL level

Sync. on Green at 0.30 Vp-p

*: A Component input is attained at a D-sub terminal.

Composite Video or S-video (forS1, S2)

NTSC3.58, NTSC4.43, PAL, M-PAL, N-PAL, PAL60,SECAM

Video : Composite 1.0 Vp-p

S-video Y: 1.0 Vp-p, C:0.29Vp-p

Sync. : Composite sync

Component Video

Y,P

B,PR

or Y,CB,CR:

(480I, 480P, 576I, 576P, 720P, 1080I, 1035I)

Video: Y : 1.0 Vp-p

Pb/Cb,Pr/Pr : 0.7 Vp-p

Sync. : Superimposed with Y signals

PAL,NTSC Video : R/G/B 0.7Vp-p (Video2)

Sync : Composite Sync 1.0Vp-p (Video1)

Composite Video

Loop-through of input video 1 signal

16.777 million

Horizontal : 15 –107 kHz

Vertical : 50 – 85 Hz

Horizontal : 1024 dots (max.)

Vertical : 1024 lines (max.)

42 inches (1060 mm), diagonal (typical)

Horizontal : 922 mm (typical)

Vertical : 522 mm (typical)

1: Cool 2: Normal 3: Warm 4:User

30 minutes to reach optimum performance level.

AC 100 - 120 / 200 – 240 V (3.7A /2.0A) 50/60 Hz

(automatically selected)

Power Consumption : 350 W (typical, without sound)

(provided with power save circuit.)

1030 (W) × 636 (H) × 89 (D) mm

31 kg (approx.) exclude option stand

Operation Storage

Temperature 5ºC to 35ºC -15ºC to 60ºC

Humidity 20% to 80% 20% to 90%

2

Page 3

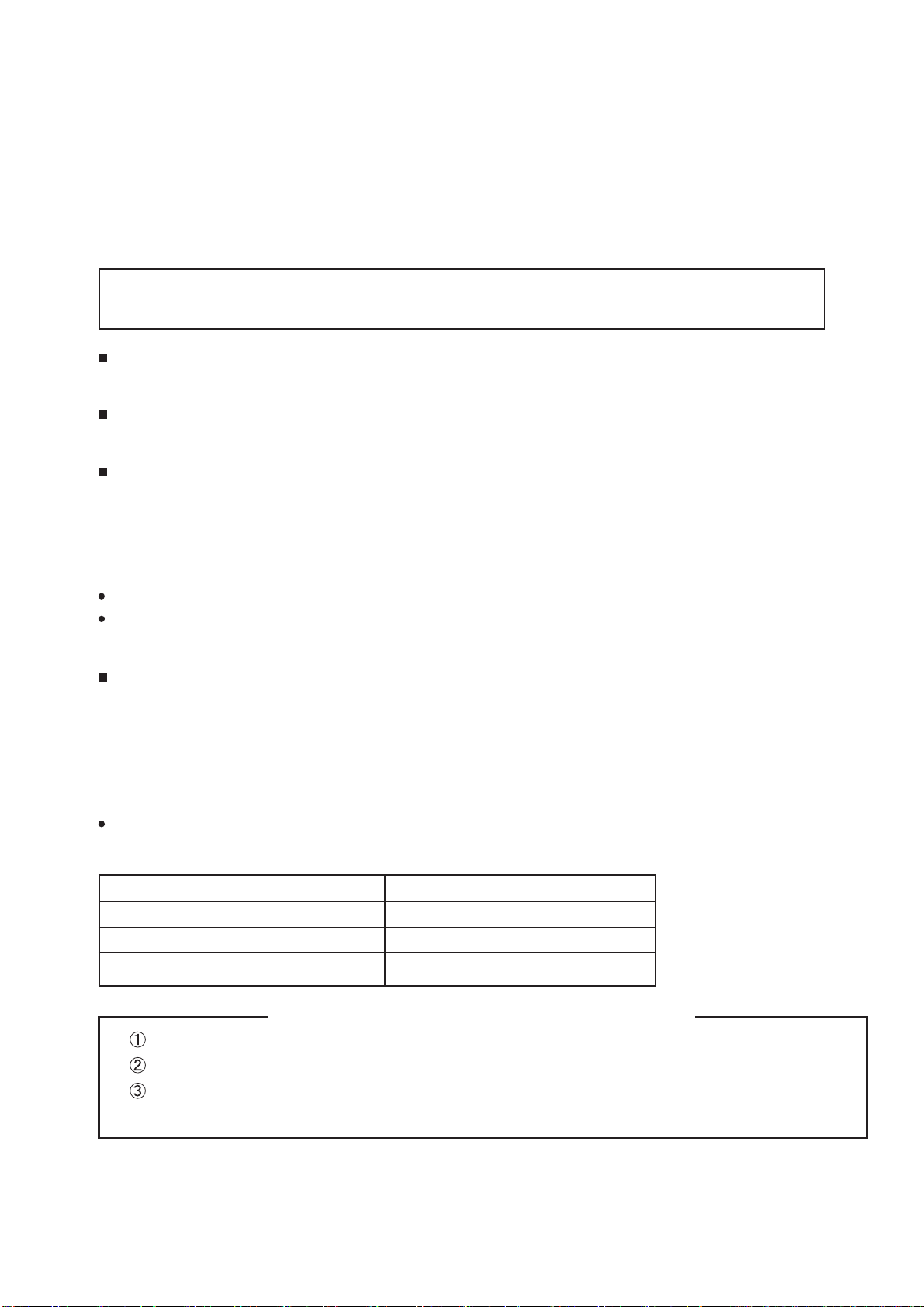

3. Lead free solder

This product uses lead free solder (unleaded) to help preserve the environment. Please read these instructions

before attempting any soldering work.

Caution: Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead

free solder can splatter at high temperatures (600

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F."

Properties of lead free solder

The melting point of lead free solder is 40-50 higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not taking

these precautions may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the lead

free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320 r

Mounting (chips) on empty PCB 380 r

Chassis, metallic shield, etc. 420 r

The PWB assembly which has used lead free solder

SIGNAL board

VIDEO board

JOINT board

ԛ

AUDIO board/FILTER board/LED,RECEIVER board/TACT SW board/SPEAKER terminal board

3

Page 4

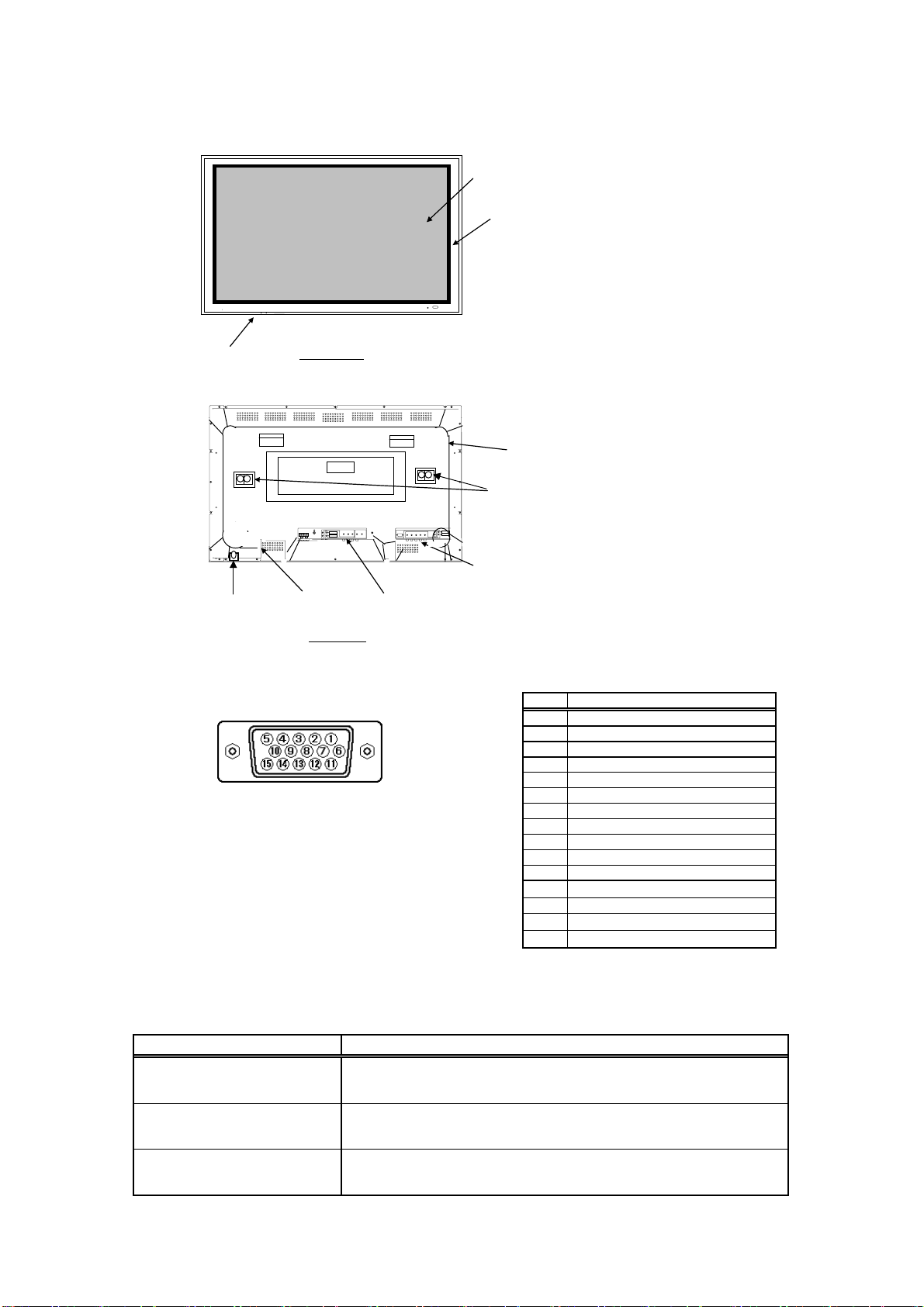

4. Names of each part

( )

Outlook

HITACHI

HITACHI

HITACHIHITACHI

S U B - P O W E R S E L E C T M E N U R G B /

V O L U M E

V I D E O

Filter

Panel

Front

Frame

Control

Switches

FRONT VIEW

Speaker

Terminals

AC Switch

A U D I O I N

S P E A K E R

T E R M I N A L

( 8 Ω 8 W )

L / M O N O

R

- - + +

R L

AC Inlet

REAR VIEW

P H 0 7 6 9 1

V I D E O 2

V I D E O 1

N e a r e r t e r m i n a l

C O M P O S I T E I N

C O M P O N E N T I N

手 前 側 端 子

F u r t h e r t e r m i n a l

S P / C P / C B B R R V I D E O Y

奥 側 端 子

Video Input Terminals

A U D I O I N

R G B 1

L / M O N O

D - S U B I N

R G B 2

R

R G B H V

RGB Input Terminals

Input terminal(D-sub connector)

Rear

Cover

PinNo Signal

1 Red Video, ( PR/CR )

2 Green Video (Sync. optional), (Y)

3 Blue Video (PB/CB)

4 No connection

5 No connection

6 Red Ground ( PR / CR Ground)

7 Green Ground ( Y Ground)

8 Blue Ground ( PB / CB Ground)

9 No connection

10 Ground

11 No connection

12

[SDA]

13 H.Sync. or H/V composite

14

V.Sync. [V.CLK]

15

[SCL]

:with RGB component input.

Message table

☛ Onscreen display

Indication Condition

The monitor indicates the

message

“NO SYNC SIGNAL”.

The monitor indicates the

message

“POWER SAVE”.

The monitor indicates the

message

“OUT OF FREQUENCY”.

The monitor detects no sync signal.

After a state whereby it does not sense a sync signal for 5 seconds

continued.

The monitor detects a sync signal which is out of specification, or

unstable.

4

Page 5

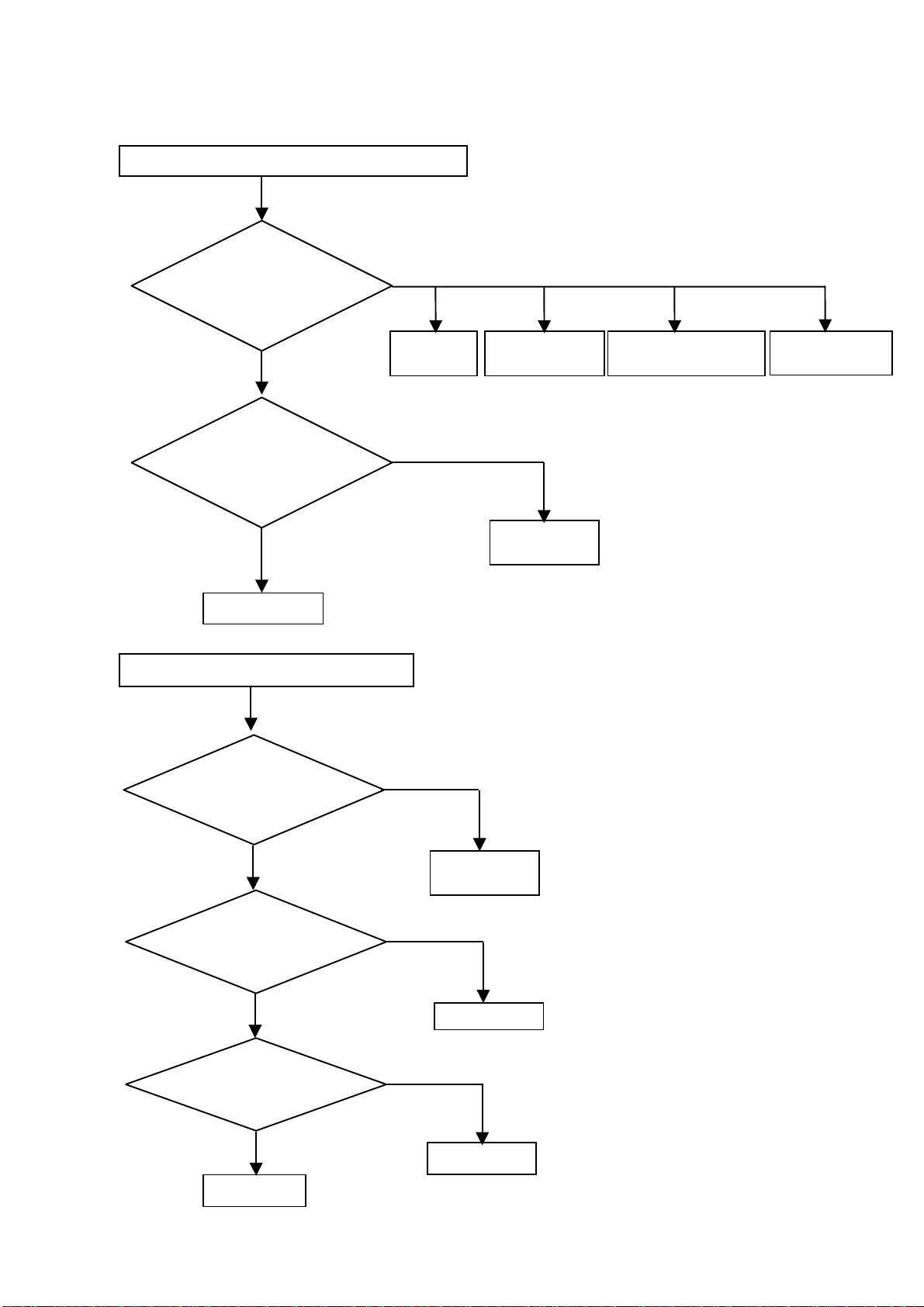

5. Trouble shooting

)

5.1 Trouble Shooting of Plasma Monitor

Power can not be turned on (LED is not light

Is the input voltage

applied to the AC/DC

Power unit ?

(CN61 ①, ③)

Yes

Are

Voltage

applied to pins ④⑦,⑪(PW01)

of the Signal PWB

④ +12V

Yes

Signal PWB

⑦ +6V

⑪ +4.5V

⑨ GND

No

AC inlet

No

Power switch

AC/DC

Power unit

AC Fuse

F901 T6.3AH 250V

FILTER PWB

Picture is displayed. But no sound

applied to pins ① (PVA)

of the Audio PWB

applied to

(PVA1)of the Audio PWB

there

Speaker Terminals

Are

Voltage

① +22~28V

Yes

Are Signal

Yes

④ GND

pin ⑤⑧ and ⑨⑪

Are

signals on

No

No

No

AC/DC

Power unit

Signal PWB

Yes

Speaker

Audio PWB

5555

Page 6

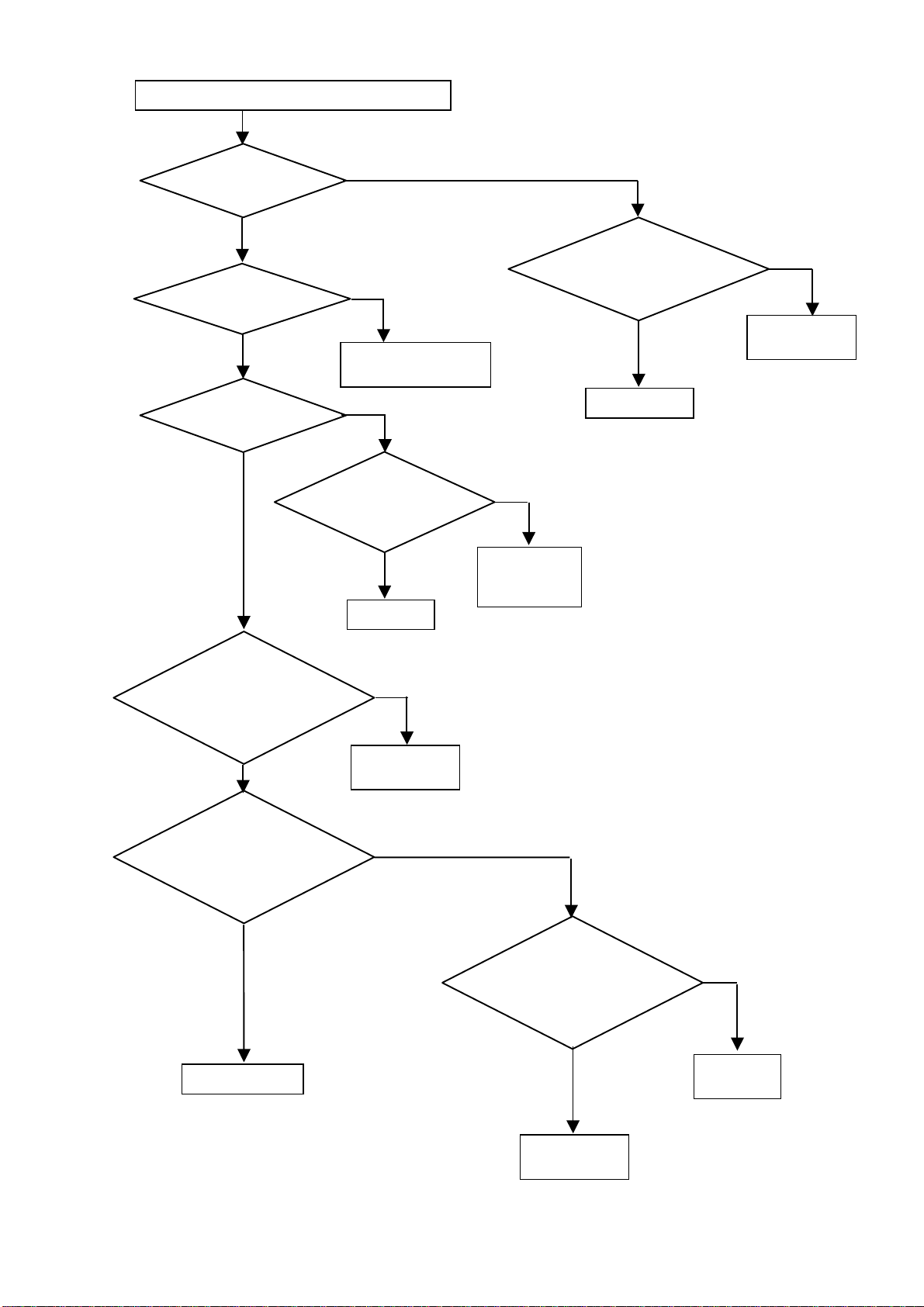

g)

Picture is not displayed (LED is lightin

Is the LED red or

green/orange

green/orange

Is it the power

saving mode?

No

Do the Fans

rotate?

Yes

CN304 and PFAN1

red

Yes

Input signal Cable

or Signal PWB

No

Is pin① of

7V more?

Yes

DC Fan

No

AC/DC Power

unit or Signal

PWB

Are

Voltage

applied to pins ⑦ (PW01)

of the Signal PWB

Yes

Signal PWB

⑦ +6V

⑨ GND

No

AC/DC

Power unit

Is Voltage

of the pin ⑥ (CN68)

on the AC/DC Power

unit 5V

Yes

Are Voltages

of the pin ①、⑩(CN64)

on the AC/DC Power

unit collect ?

Yes

① +50~70V

⑩ +75~90V

⑥ GND

Panel Module

No

AC/DC

Power unit

No

Is Voltage

of the pin ① (CN68)

on the AC/DC Power

unit collect ?

Yes

① +3V

③ GND

No

Panel

Module

AC/DC

Power unit

6666

Page 7

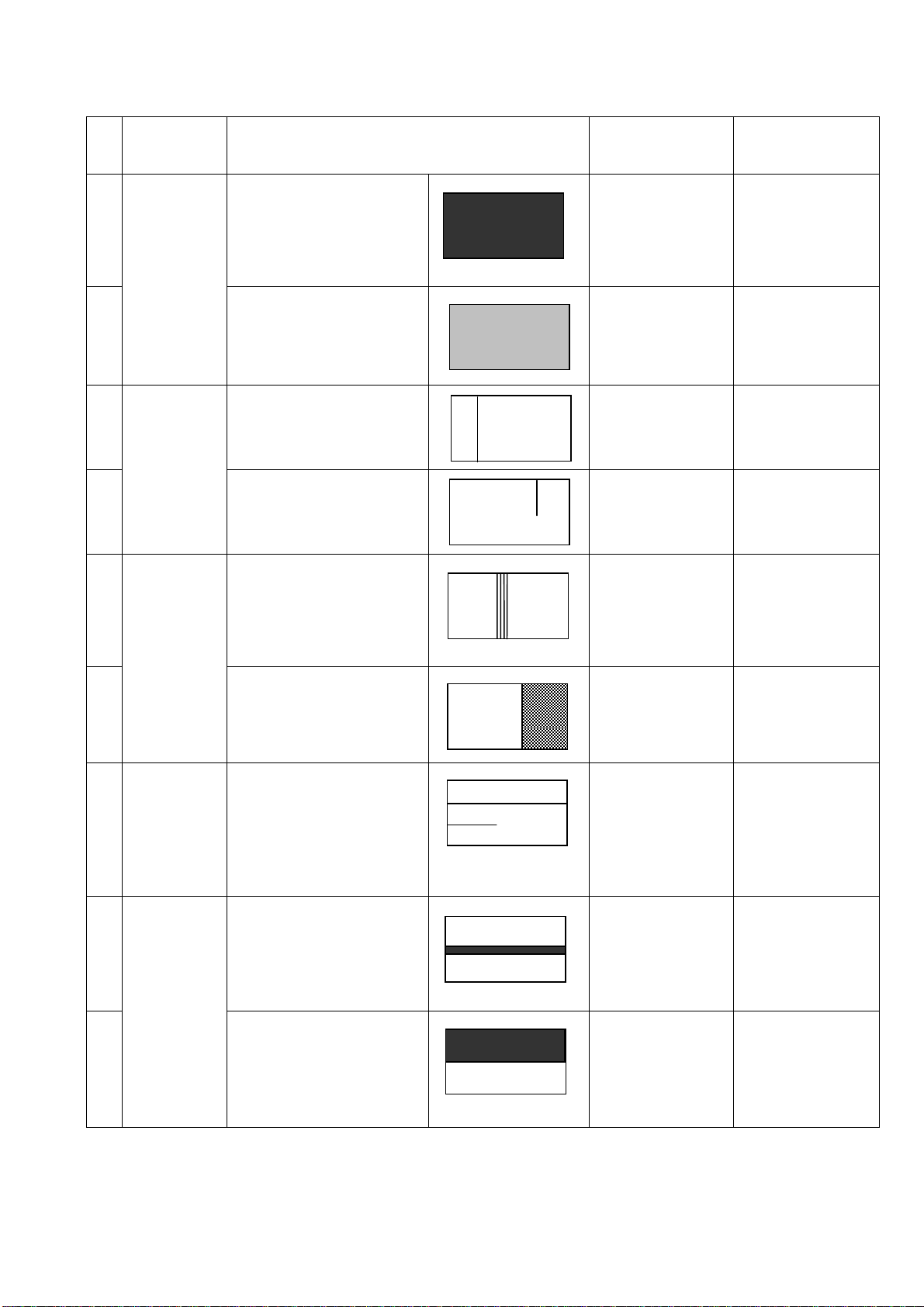

5.2 Trouble Shooting of Panel Module from the point view of Fault Symptom

NO

1

Entire

screen does

not light.

Fault

contents

After momentarily going

on, the screen becomes

black immediately or after

a few seconds. (Main

power is turned off.)

Fault status Suspected fault

location

X-SUS

Y-SUS

Panel chassis

LOGIC

ABUSL

ABUSR

Analysis

procedure

and measure

2

Vertical line

3 Single vertical line (of

4

5

Vertical bar

6

7 Horizontal

line

8 Horizontal

bar

9

Screen lights dimly even

on the back screen.

different color)

Vertical line from the

middle of effective scan

area (Vertical line of

different color)

Bar width of 1/7 of

horizontal size or in

multiples of 1/7, is

displayed. Abnormal

display.

Bar width of 3/7 or 4/7 of

the screen width, is

displayed. Abnormal

display. (Vertical line of

different color)

Single horizontal line (No

light) Or single horizontal

line does not light among

the effective scanning

area.

Single horizontal line

does not light.

Bar width of 1/8 or

multiples of 1/8 of the

screen height, is

displayed.

Abnormal (Screen does

not light)

Bar width of 1/2 of the

screen height.

Abnormal display

(Screen does not light)

LOGIC

Panel chassis

LOGIC

Panel chassis

Panel chassis

ABUSL

ABUSR

LOGIC

Above boards are

connected

ABUSL

ABUSR

LOGIC

Above boards are

connected

Panel chassis

Panel chassis

Panel chassis

Y-SUS

X-SUS

Above boards are

connected.

.

.

Replace LOGIC

board

Replace panel

chassis

Replace panel

chassis

Replace panel

chassis

7

Page 8

contents

sticking

Fault

Fixed display contents

are always displayed.

having abnormal

luminance are scattered

in the upper or lower part

of screen.

NO

10 Image

11 Stains Oval-shaped points

Fault status Suspected

fault

location

ABCDE

Panel

chassis

Panel

chassis

5.3 Trouble Shooting of Panel Module by using a Personal Computer

5.3.1 Setting up computer

Install the

panelinf.exe file

provided by DMD to the hard-disk of your PC.

Analysis procedure

and measure

Perform all white heat

run. After judgment,

replace panel chassis

Perform all white heat

run. After judgment,

replace panel chassis

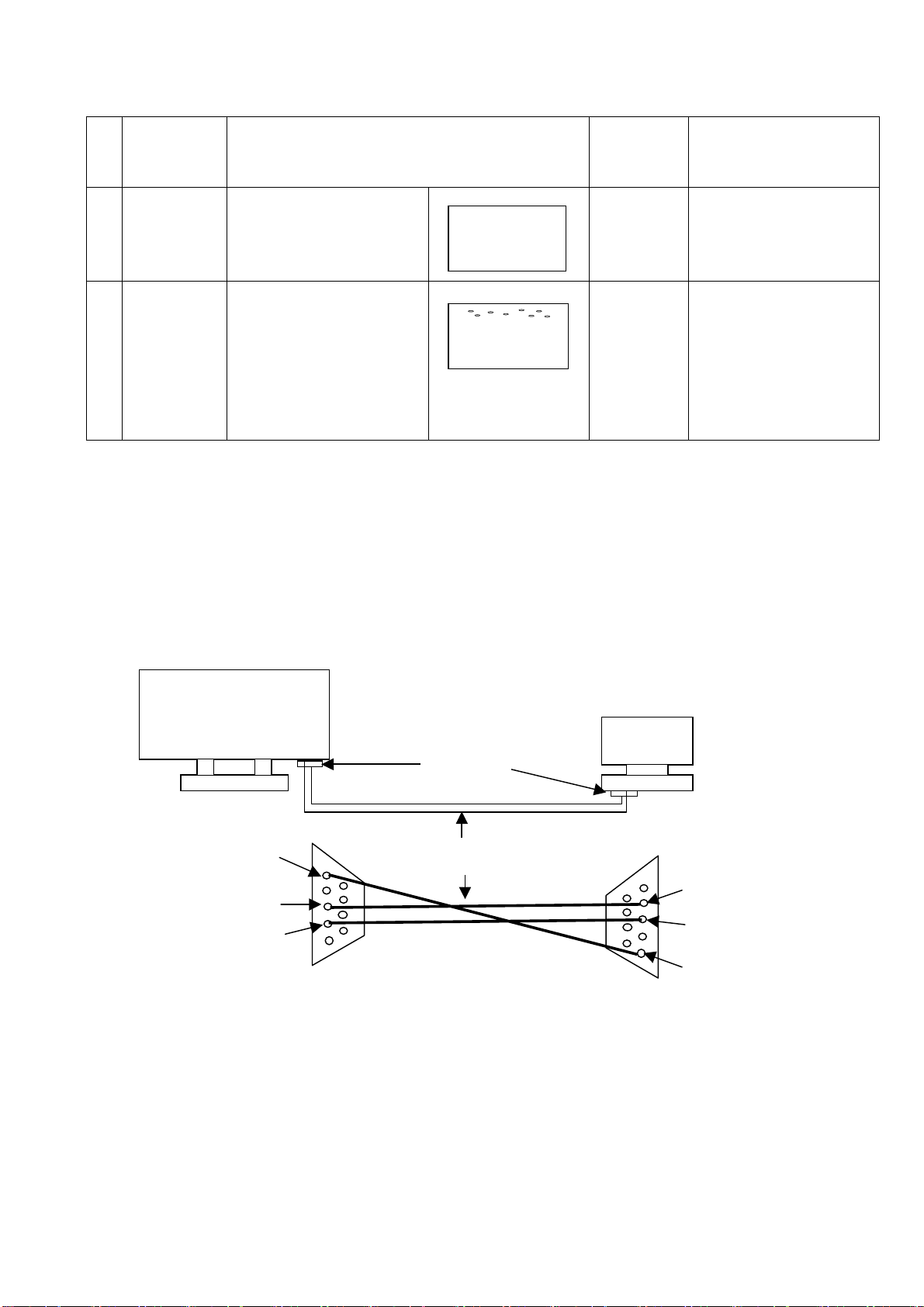

5.3.2 Connecting a computer

Plasma Monitor

PC

RS232C

Connector

⑤

③

RS232C

Cable

②

③

②

D-sub 9P

(female)

D-sub 9P

(female)

⑤

(1) Connect the RS-232C terminal of the computer to the RS-232C terminal of the plasma monitor, using

RS232C cable as above.

(2) Turn on the main power of the computer.

(3) Turn on the main power of the plasma monitor

.

8

Page 9

(4) For computer running WINDOWS:

Select

For computer running DOS/V:

(5) The following screen appears.

panelinf.exe

C : ¥ >panelinf

01:::: COND [Hex] xx

** 02:::: ERRC(CURRENT) [Hex] xx

03:::: ERRC(BEFORE1) [Hex] xx

04:::: ERRC(BEFORE2) [Hex] xx

05:::: ERRC(BEFORE3) [Hex] xx

06:::: ERRC(BEFORE4) [Hex] xx

07:::: ERRC(BEFORE5) [Hex] xx

08:::: ERRC(BEFORE6) [Hex] xx

09:::: ERRC(BEFORE7) [Hex] xx

10:::: ERRC(BEFORE8) [Hex] xx

11:::: ERRC(BEFORE9) [Hex] xx

12:::: ERRC(BEFORE10) [Hex] xx

13:::: ERRC(BEFORE11) [Hex] xx

14:::: ERRC(BEFORE12) [Hex] xx

15:::: ERRC(BEFORE13) [Hex] xx

16:::: ERRC(BEFORE14) [Hex] xx

17:::: ERRC(BEFORE15) [Hex] xx

18:::: OPERATION HOURS [Dec] xx

EXIT

from Explorer or My Computer →

<Enter>

→

PANEL DATA READ

*1 : Use COM1: the computer's communication port.

*2 : Set the communication setup as follows.

Speed : 9600 bps

Data : 7 bits

Parity : none

Stop bit : 1 bit

*3 : If the program starts up while the monitor power is not yet on, the menu

screen will not be displayed. At that time, turn on the monitor power, then the program

start up again.

5.3.3 Problem Analysis Procedure

(1) Check the error code (ERRC xx : hexadecimal number) from the CURRENT, (and BEFORE**)

error code read-out menu and detect the faulty position from the following table.

ERRC 00 is not valid.

<Enter>

<

Double Crick>

or

.

(2) Using the ↑ key or ↓ key, move the ** mark to EXIT and press <ENTER> key then

the screen returns to the WINDOWS or DOS screen.

9

Page 10

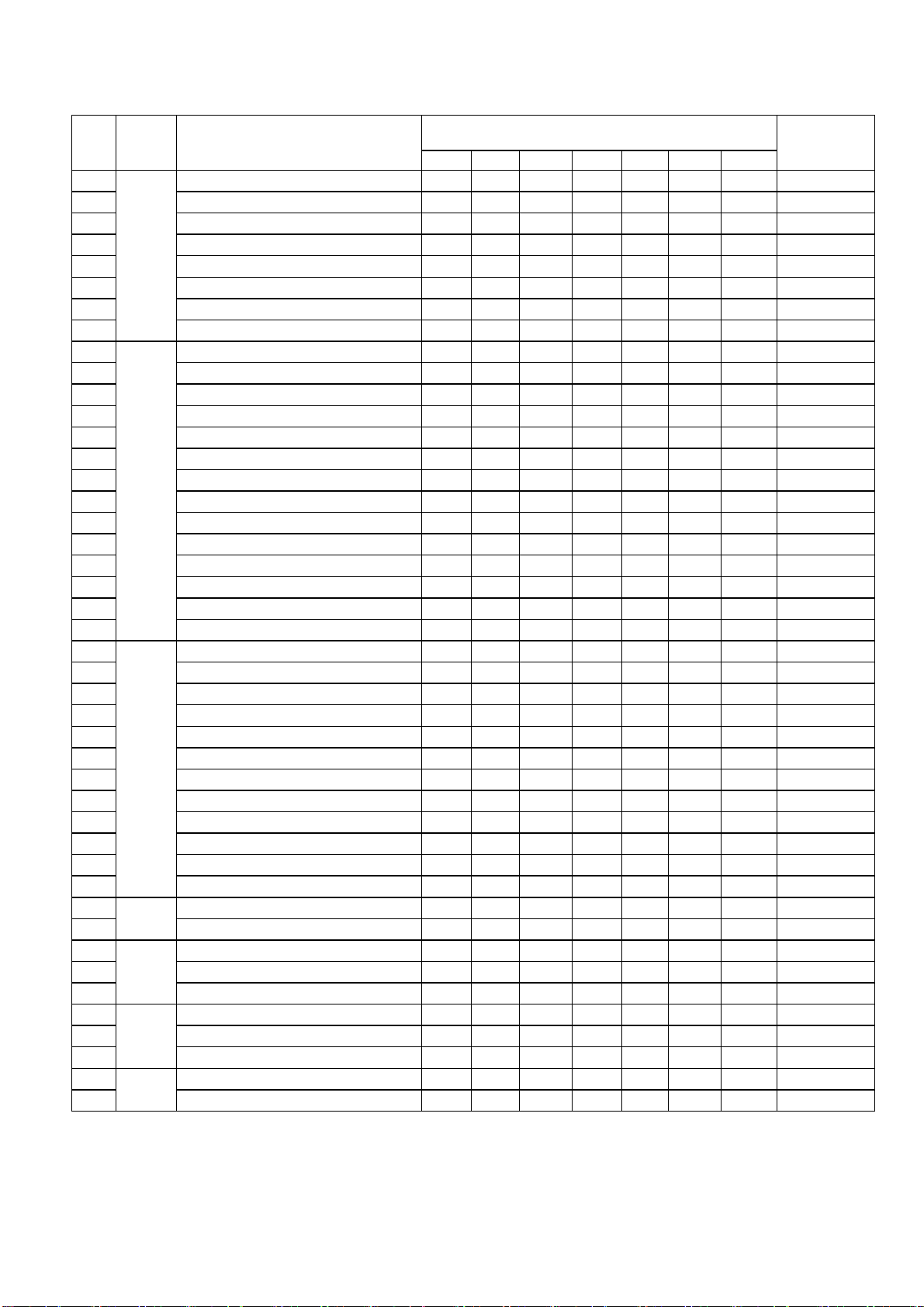

Error code table (H1 panel)

ERR

Code

Detect

position

(board)

04 LOGIC 3.3V power voltage has dropped LOGIC PSU

06 3.3V power startup is faulty X-SUS Y-SUS ADM1 - 8 PSU ABUS-L ABUS-R LOGIC

18 Internal I2C_SCL1_LOW level LOGIC

19 Internal I2C_ACK does not respond LOGIC

1C EEPROM initial setting is defective LOGIC

1D EEPROM write-down is defective LOGIC

1E EEPROM user initial setting is defective LOGIC

1F EEPROM factory setting reading is defective LOGIC

24 X-SUS Vex power voltage has decreased X-SUS LOGIC

25 Vex power voltage is excessive X-SUS

26 Vex power startup is faulty. X-SUS LOGIC

28 Vx power voltage has dropped X-SUS LOGIC

29 Vx power voltage is excessive X-SUS

2A Vx power startup is faulty. X-SUS LOGIC

2C Vpx voltage has dropped X-SUS LOGIC

2D Vpx voltage is excessive X-SUS LOGIC

30 Vpx1 voltage has dropped X-SUS LOGIC

31 Vpx1 voltage is excessive X-SUS LOGIC

34 Vpx2 voltage has dropped X-SUS LOGIC

35 Vpx2 voltage is excessive X-SUS LOGIC

39 Vs power current is excessive (during operation) X-SUS Panel LOGIC

3B Vs power current is excessive (during startup) X-SUS Panel LOGIC

44 Y-SUS Vey power voltage has dropped Y-SUS LOGIC

45 Vey power voltage is excessive Y-SUS

46 Vey power startup is faulty. Y-SUS LOGIC

4C Vpy voltage has dropped Y-SUS LOGIC

4D Vpy voltage is excessive Y-SUS LOGIC

50 Vpy1 voltage has dropped Y-SUS LOGIC

51 Vpy1 voltage is excessive Y-SUS LOGIC

54 Vpy2 voltage has dropped Y-SUS LOGIC

55 Vpy2 voltage is excessive Y-SUS LOGIC

59 Vs power current is excessive (during operation) Y-SUS Panel LOGIC

5B Vs power current is excessive (during startup) Y-SUS Panel LOGIC

5D Vs power current is excessive (during operation) Y-SUS SDM Panel LOGIC

61 PSU Vs power voltage is excessive PSU LOGIC

62 Vs power startup is faulty. X-SUS Y-SUS PSU LOGIC

X-SUS

64 Vex and Vpy power voltage has dropped LOGIC X-SUS Y-SUS

Y-SUS

65 Vex and Vey power voltage is excessive X-SUS Y-SUS

66

68 X-SUS Vw power voltage has dropped Y-SUS X-SUS LOGIC

69 Vw power voltage is excessive X-SUS

6A Vw power startup is faulty. Y-SUS X-SUS LOGIC

X-SUS

6C Vpx and Vpy voltage has dropped LOGIC X-SUS Y-SUS

Y-SUS

6D

Vex and Vey power startup is faulty. LOGIC X-SUS Y-SUS

Vpx and Vpy voltage is excessive LOGIC X-SUS Y-SUS

Contents

Suspected faulty board

(In the order of higher probability of defect)

(1) (2) (3) (4) (5) (6) (7)

Remarks

10

Page 11

ERR

Code

Detect

position

( board)

81 PSU Va power voltage is excessive PSU LOGIC

82 Va power startup is faulty. ADM1 - 8 PSU LOGIC ABUS-L ABUS-R

99 Va power current is excessive (during operation) ADM1 - 8 ABUS-L ABUS-R PSU LOGIC

9B Va power current is excessive (during startup) ADM1 - 8 ABUS-L ABUS-R PSU LOGIC

Contents

(In the order of higher probability of defect)

(1) (2) (3) (4) (5) (6) (7)

Suspected faulty board

Remarks

9D Va power current is excessive

(during operation)

A5 ADM1 ADM1 has abnormal heat generation. ADM1 PSU LOGIC

A9 ADM2 ADM2 has abnormal heat generation. ADM2 PSU LOGIC

AD ADM3 ADM3 has abnormal heat generation. ADM3 PSU LOGIC

B1 ADM4 ADM4 has abnormal heat generation. ADM4 PSU LOGIC

B5 ADM5 ADM5 has abnormal heat generation. ADM5 PSU LOGIC

B9 ADM6 ADM6 has abnormal heat generation. ADM6 PSU LOGIC

BD ADM7 ADM7 has abnormal heat generation. ADM7 PSU LOGIC

C5 ADM8 ADM8 has abnormal heat generation. ADM8 PSU LOGIC

E2 LOGIC 5V power startup is faulty. X-SUS Y-SUS PANEL PSU ABUS-L ABUS-R LOGIC

ADM1 - 8 ABUS-L ABUS-R PSU LOGIC Excess current is

detected In

ACCC operation.

It can possibly

occur depending

on screen

display.

11

Page 12

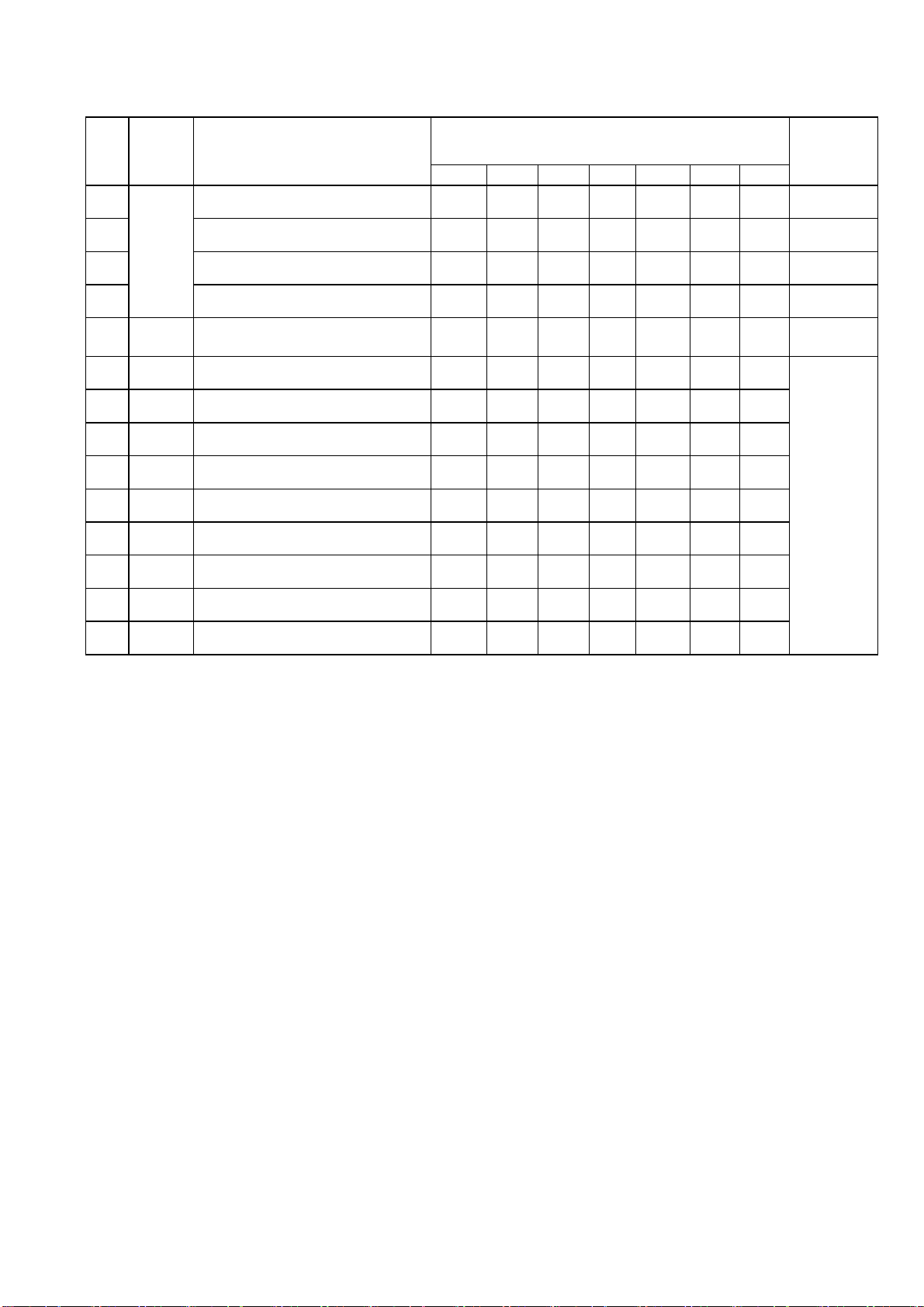

Error code table (H2 panel)

ERR

Code

Estimate

Detect

position

Detection position The states in error

Contents Remarks

generation

(board)

02 Wavy pattern ROM In startup Wavy pattern ROM data errors

04 The ordinary time 3.3V power voltage has dropped

06

18 Internal I2C_SCL1_LOW level (SCL1 error)

19

1C Initialization non-execution EEPROM initial setting is defective

1D Verify error EEPROM write-down is defective

1E User sum error EEPROM user initial setting is defective

1F

24 Vex power voltage has dropped

25

26

28 Vx power voltage has dropped

29

2A

2C Vpx 1,2 power voltage has dropped

2D

30 Vpx1 power voltage has dropped

31

34 Vpx2 power voltage has dropped

35

39 The ordinary time Isx power current is excessive

3B

44 Vey power voltage has dropped

45

46

4C Vpy1,2 power voltage has dropped

4D

50 Vpy1 power voltage has dropped

51

54 Vpy2 power voltage has dropped

55

59 The ordinary time Isy power current is excessive

5B

5D

61 The ordinary time Vs power voltage is excessive

62

64 Ve power voltage has dropped

65

66

68 Vw power voltage has dropped

69

6A

6C Vp power voltage has dropped

6D Vp power voltage is excessive

81

82

99 The ordinary time Ia power current is excessive

9B

9D

A5 ADM1 ADM1 has abnormal heat generation.(shutdowns)

A9 ADM2 ADM2 has abnormal heat generation.(shutdowns)

AD ADM3 ADM3 has abnormal heat generation.(shutdowns)

B1 ADM4 ADM4 has abnormal heat generation.(shutdowns)

B5 ADM5 ADM5 has abnormal heat generation.(shutdowns)

B9 ADM6 ADM6 has abnormal heat generation.(shutdowns)

BD

C5 The ordinary time ADM8 has abnormal heat generation.(shutdowns)

E2

LOGIC

3.3V

Internal I2C -

EEPROM

X-SUS

Y-SUS

X-SUS

Y-SUS

ADM

ADM ADM8

Vex

Vx

Vpx The ordinary time

Vpx1 The ordinary time

Vpx2 The ordinary time

Isx

Vey

Vpy The ordinary time

Vpy1 The ordinary time

Vpy2 The ordinary time

Isy

Isp The ordinary time SDM power current is excessive

Vs

Ve

Vw

Vp

Ia

ACCC The ordinary time IaACCC power current is excessive

ADM7

In startup Without starting with 3.3 V voltage.

Internal I2C_ACK does not respond (SDA1 error)

Factory sum error EEPROM factory setting reading is defective

The ordinary time

Vex power voltage is excessive

In startup Vex power startup is faulty.

The ordinary time

Vx power voltage is excessive

In startup Vx power startup is faulty.

Vpx 1,2 power voltage is excessive

Vpx1 power voltage is excessive

Vpx2 power voltage is excessive

In startup Isx power current is excessive (in startup)

The ordinary time

Vey power voltage is excessive

In startup Vey power startup is faulty.

Vpy1,2 power voltage is excessive

Vpy1 power voltage is excessive

Vpy2 power voltage is excessive

In start Isy power current is excessive (in startup)

In startup Vs power startup is faulty.

The ordinary time

Ve power voltage is excessive

In start Ve power startup is faulty.

The ordinary time

Vw power voltage is excessive

In startup Vw power startup is faulty.

The ordinary time

Va power voltage is excessive

In startup Va power startup is faulty.

In startup Ia power current is excessive (during startup)

The ordinary time

ADM7 has abnormal heat generation.(shutdowns)

In startup Vcc power startup is faulty.

12

Page 13

5.4 Checking serial ID number of Panel Module (14 digits

The serial ID number of the panel module that is brought in for service and that of the completed panel

chassis has the structure as shown below.

)

The serial ID number is shown on the bar code label that is attached to the rear of the chassis (aluminum).

P7A

51---H1 panel, 71,75---H2 panel

A-Z (excluding I and O)

Lot No.: 001-999

A-Z (excluding I and O)

1-3

Production week code: 01-53

Production year (low digit): 0-9

Product code: P7A model 42 type

Model

Panel

Module

H1 panel

Module

H2 panel

Module

2 36 131D2 01 - 51

CMP4121HDU-

512/512S/

512SH/512SA

○ ○

Version No.: 01-99

CMP

4121HDE-

302/303S

CMP

4201U/J

○ ○ ○

42PMA

400E/A/B

CMP

4202U/E

CMP

4203W

○

13

Page 14

14

to

to

toto

chassis

chassis

chassischassis

VIDEO 1

VIDEO 1

VIDEO 1VIDEO 1

OUT

OUTPUT

PUT

OUTOUT

PUTPUT

VIDEO 1

VIDEO 1

VIDEO 1VIDEO 1

INPUT

INPUT

INPUTINPUT

(COMPOSITE)

(COMPOSITE)

(COMPOSITE)(COMPOSITE)

VIDEO 1

VIDEO 1

VIDEO 1VIDEO 1

INPUT

INPUT

INPUTINPUT

(S

(S----VIDEO)

VIDEO)

(S(S

VIDEO)VIDEO)

VIDEO 2

VIDEO 2

VIDEO 2VIDEO 2

INPUT

INPUT

INPUTINPUT

(COMPONENT)

(COMPONENT)

(COMPONENT)(COMPONENT)

VIDEO 1

VIDEO 1

VIDEO 1VIDEO 1

AUDIO

AUDIO

AUDIOAUDIO

INPUT

INPUT

INPUTINPUT

VIDEO 2

VIDEO 2

VIDEO 2VIDEO 2

AUDIO

AUDIO

AUDIOAUDIO

INPUT

INPUT

INPUTINPUT

L+

L+

L+L+

GND

GND

INLET

INLET

INLETINLET

GNDGND

GND

GND

GNDGND

EXT.

EXT.

EXT.EXT.

SPEAKER

SPEAKER

SPEAKERSPEAKER

terminal

terminal

terminalterminal

AC

AC

ACAC

AC100V~240V

SIGNAL FLOW

6. BLOCK DIAGRAM (CMP4121HDE/CMP4202E/42PMA400E)

RGB 1

RGB 1

RGB 1RGB 1

AUDIO

AUDIO

AUDIOAUDIO

INPUT

INPUT

INPUTINPUT

JOINT

VIDEO

VIDEO

VIDEOVIDEO

PPPPV1

V1

V1V1

A+5V

AUDIO L,R

AUDIO L,R

AUDIO L,RAUDIO L,R

AUDIO L,R

AUDIO L,R

AUDIO L,RAUDIO L,R

SP L

SP L

SP LSP L

PAS3

PAS3

PAS3PAS3

SP R

SP R

SP RSP R

R+

R+

+

+

PF1

PF1

PF1PF1

PAS4

PAS4

PAS4PAS4

FILTER

FILTER

FILTERFILTER

POWER SW

POWER SW

POWER SWPOWER SW

PAS1

PAS1

PAS1PAS1

PFA

PFA

PFAPFA

CN61

CN61

CN61 CN 61

AUDIO

AUDIO

AUDIOAUDIO

JOINT

JOINTJOINT

+9V +12V

STB +5V

PVA

PVA

PVAPVA

CN

CN10

102222

CNCN

1010

AC100V~240V

CN30

CN30

CN30CN30

+12V

MMMMFN

FN2222

FNFN

(FAN2)

(FAN2)

(FAN2) (FAN2)

+4.5V

+5.6V

STB +5V

PA

PAV1

PAPA

+25V

POWER

POWER (AC

(AC----DC)

POWERPOWER

(AC(AC

FAN

CONNECTOR

V1

V1V1

PPPPVA

VA

VAVA

DC)

DC)DC)

CN66

CN66

CN66CN66

PPPP002

002

232C)

232C)23 2C)

RGB 2

RGB 2

RGB 2RGB 2

INPUT

INPUT

INPUTINPUT

RGB 1

RGB 1

RGB 1RGB 1

INPUT

INPUT

INPUTINPUT

CN64

CN64

CN64CN64

002002

PW0

PW0

PW0PW0

PA

PA01

PAPA

PPPPSE

SE

SESE

(RS

(RS232C)

(RS(RS

PS

PSF P001

F P001

PSPS

F P001F P001

01

0101

STAND

STAND----BY

STANDSTAND

REG.

REG. 4.5V,

REG.REG.

3.3V

REG.

REG. 25V

REG.REG.

12V

10~12V

5V(Vcc)

REG.

REG. 60V(Va)

REG.REG.

82V(Vs)

SIGNAL

SIGNAL

SIGNALSIGNAL

RGB 2

RGB 2----IN(

RGB 2RG B 2

RGB

RGB

RGB RGB

BY. 5. 6V

BYBY

CN68

CN68

CN68 CN68

RS232C

IN(DDDD----Sub15P

IN(IN(

Sub15P))))

Sub15PSub15P

CN65

RGB 2

RGB 2

RGB 2RGB 2

AUDIO

AUDIO

AUDIOAUDIO

INPUT

INPUT

INPUTINPUT

+4.5V

+5.6V

+12V

PPPPW01

W01

W01W01

CN101

CN101

CN101CN101

CN65 CN67

CN65 CN65

CN67

CN67 CN67

MFN1

MFN1

MFN1MFN1

+12V

+12V

+12V+12V

(FAN1)

(FAN1)

(FAN1)(FAN1)

PFAN1

PFAN1

PFAN1PFAN1

Pk01

Pk01 PSC1

Pk01 Pk01

PPPPL01

L01

L01L01

YYYY----SUS

PP01

PP01

PP01PP01

CN69

CN69

CN69CN69

ADDRESS

ADDRESS BUS L

ADDRESS ADDRESS

CN52

CN52

CN52CN52

TACT SW

TACT SW

TACT SWTACT SW

STB +5V

PSC1

PSC1PSC1

SUS

SUSSUS

BUS L

BUS L BUS L

CN33

CN33

CN33CN33

PSC2

PSC2

PSC2PSC2

CN32

CN32 CN22

CN32CN32

CN7

CN7

CN7CN7

VOLTAGE SUPPLY FLOW

CONNECTOR

CIRCUIT BOARD

LED

LED/RECEIVER

LEDLED

STB +5V

PANEL MODULE

PANEL MODULE

PANEL MODULEPANEL MODULE

(REAR VIEW)

CN1

CN1

CN1CN1

LOGIC

LOGIC

LOGICLOGIC

CN6

CN6

CN6CN6

SIGNAL FLOW

SIGNAL FLOW SIGNAL FLOW

VOLTAGE SUPPLY FLOW

VOLTAGE SUPPLY FLOW VOLTAGE SUPPLY FLOW

CONNECTOR

CONNECTOR CONNECTOR

CIRCUIT BOARD

CIRCUIT BOARD CIRCUIT BOARD

/RECEIVER

/RECEIVER/RECEIVER

CN22

CN22CN22

ADDRESS BUS R

ADDRESS BUS R

ADDRESS BUS RADDRESS BUS R

XXXX----SUS

CN23

CN23

CN23CN23

SUS

SUSSUS

CN42

CN42

CN42CN42

Page 15

7. Disassembly diagram

(1) Remove Back Cover

Lay down the Plasma display so that

the face is down on the soft thick (over

50mm) cushion.

Be careful not to be damaged the face

of Front Filter.

Remove 28screws(a) then remove

Back Cover.

At this time be careful not to be

damaged edges of Back Cover and its

coated face.

(2) Remove Filter PWB

Remove 2screws(b) and remove

"Insulation Cover".

Remove 2screws(c) of earth wires.

Disconnect PFA(EV-6P) and

PF1(EV-3P) connectors.

Remove 2screws(d) of AC Power

Switch Folder and remove 4screws(e)

and remove Filter P.W.B.

Remove 2 screws(f) and remove AC

Power Switch.

(3) Remove Signal PWB with PWB MTL,

;Signal PWB

Disconnect PP01(LVDS),

PW01(EH-13P), P001(FHR-50),

PA01(PH-13P),

PL01(PH-6P),PK01(PH-5P),PW02(

PH-7P),PFAN1(PH-3P)and

P002(PH-12P) connectors.

Be careful not to be damaged the PP01

and P001 connector holders.

Remove 4screws(i) then remove Signal

P.W.B with SIG PWB MTL.

(4)-1 Video Unit/JOINT PWB and

Audio PWB with PWB MTL.

;JOINT PWB

Disconnect PAV(PH-7P), PSE(PH-12P),

and PSF(FHR-50) connectors.

;

Audio PWB

Disconnect PVA, PAS1, and PAV1

connectors.

Remove 6 screws(k) then remove

VIDEO PWB MTL.

(4)-2 VIDEO Unit

Remove 2screws(j) then pull out Video

Unit.

Screw(e)

Screw(c)

Screw(d)

AC Power SW

Screw(k)

Audio P.W.B

Screw(j)

Screw(a)

Screw(b)

JOINT P.W.B.

VIDEO Unit

××××

28

Insulation Cover

Screw(f)

SIGNAL P.W.B

Screw(c)

Filter PWB

Screw(i)

.

15

Page 16

(5) Remove Front Frame

(

(

Remove 18screws(m) then remove

Front Frame.

Be careful not to fall down the Front

Frame when remove 18screws(m).

(6) Remove Front Filter (Glass)

Remove 8screws(n), and remove Filter

Fix Metal then remove Front Filter.

When attach the new Front Filter to the

Front Frame, locating the conducting

electrode side to the inside, and attach

Filter Fix Metal.

(7) Remove Fan (MFN1)

Remove 1screw(o) and disconnect

PFAN1(PH-3P) connector,

then remove Fan. (only H1 panel)

(8) Remove Main Frame

Lay down the Plasma Display so that

the face is down on the soft thick (over

50mm) cushion. Be careful not to be

damaged the face of Display Panel.

Disconnect CN61(EV-6P) connector.

(H1 panel)

Remove 8 screws(q) and 5screws(r)

then disconnect CN1(LVDS) connector

which is attached Panel Module's Logic

Board. Remove Main Frame.

(H2 panel)

Remove 8 screws(q) then disconnect

CN1(LVDS) connector which is

attached Panel Module's Logic Board.

Remove Main Frame.

Screw(m)×18

Screw(n)×8

Screw(r)

Filter Fix Metal

Front Filter

Screw(q)×8

Screw(r)

Screw(o)

Screw(q)

Screw(q)

Screw(r)

Screw(r)

H1 panel)

Screw(q)×8

Screw(r)

H2 panel)

16

Page 17

(9) Remove Power Unit P.W.B.

(y)

)

Disconnect CN101(EH-13P),

CN102(EH-6P)CN64(VH-10P),

CN65(VH-9P),CN66(PH-7P),

CN67(PH-7),CN68(PH-6P) and CN69

( FLAT Cable).

Be careful not to be damaged the

CN69 connector folder. Remove 10

screws(v) then remove Power Unit

P.W.B.

(10) Remove Fan (H1/H2 panel)

Disconnect CN304 connector.

Remove 2screws(p) then remove Fan

fix metal.

(11) Remove Panel LOGIC P.W.B.

Disconnect CN1, CN2, CN3, CN4, CN5,

CN6 and CN7 connectors. Be careful

not to be damaged the CN2, CN3, CN4,

CN5 and CN7 connector folders.

Remove 4screws(w) then remove

Panel LOGIC P.W.B.

(12) Remove Panel X-SUS P.W.B.

Disconnect CN21, CN22 and CN23

connectors. Be careful not to be

damaged the CN21 connector folder.

Remove 9screws(x) then remove Panel

X-SUS P.W.B. pulling out from CN24

and CN25 connectors.

(13) Remove Panel Y-SUS P.W.B.

Disconnect CN31, CN32 and CN33

connectors. Be careful not to be

damaged the CN31 connector folder.

CN34 and CN35 connector Remove 9

screws(y) then remove Panel Y-SUS

P.W.B. pulling out from CN34 and

CN35 connectors

Screw

×9

Screw(v)×10

Y SUS

ABUS L

Screw(z1)×11 Screw(z2)×11

Screw(p)×2

Power Unit

LOGIC

Screw(w)×4

ABUS R

Screw(x

X SUS

×9

(14) Remove Panel ABUS R P.W.B

Disconnect CN41, CN42, CN43, CN44, CN45 and CN46

Connectors. Be careful not to be damaged the CN41,

CN43, CN44, CN45 and CN46 connectors folders.

Remove 11 screws (z2), then remove Panel ABUS R P.W.B.

(15) Remove Panel ABUS L P.W.B

Disconnect CN51, CN52, CN53, CN54, CN55 and

CN56 connectors. Be careful not to be damaged

the CN51, CN53, CN54, CN55 and CN56 connector folders.

Remove 11 screws (z1), then remove Panel ABUS L P.W.B.

17

Page 18

8. Re-Adjustment

After

changing the Panel Module, re-adjustment is needed according to the item 8.1.to 8.5.

For Power Unit, item 8.1; for Signal Board, item 8.2 to 8.5* and for Video Board, item 8.2,

8.4,8.5 are needed.

It is recommended to start re-adjustment after 30 minutes warm-up with the Burn-in signal.

*) When it is not inserted into VIDEO Unit of optional Board in Signal Board replacement,

VIDEO Unit becomes necessary. In this case, insert the dummies' VIDEO unit and execute the above

adjustment item.

How to set to Burn-in signal

(red, green, blue, white, yellow, cyan, magenta, black signal)

Turn off the sub power button (or power button on the Remote Controller), then turn on the

SUB POWER button for more than 5 seconds while you keep pushing VOLUME▼ and

RECALL buttons located on the bottom of the set.

When you fall out from Burn-in mode, turn off the sub power button (or power button on the

Remote Controller),then turn on the SUB POWER button for more than 5 seconds while you

Keep pushing VOLUME▼ button located on the bottom of the set.

8.1 Vs and Va voltage adjustment on Power Unit

How to prepare

1.Connect the DC Voltmeter to the Vs test point and

the GND point (or the Va test point and the GND point)

on the Power Unit.

2.Connect VGA (75), no-setup, and all black signal to

RGB input terminal.

3.Check the amount of Vs and Va voltages printed on the

label located lower left side on the Panel Module.

How to adjust

1.If the difference of the printed voltage of Vs and the

value of DC Voltmeter of Vs is over ±0. 4 V, adjust

the Vs ADJ Volume located upward on the Power Unit

to within ±0. 4 V.

2. If the difference of the printed voltage of Va and the

value of DC Voltmeter of Va is over ±0. 4 V, adjust

the Va ADJ Volume located upward on the Power Unit to within ±0. 4 V.

Label

Power Unit

Y-sus

VR51Vs ADJ.(IC591)

PIN301 Va

VR51 Va ADJ.(IC391)

Power

Unit

Panel Module

Rear View

PIN502 GND

PIN501 Vs

X-sus

18

Page 19

8.2 Personal Computer (PC) input and Video input Automatic amplitude adjustment

How to set to service adjustment mode

Turn off the sub power button (or power button on the

Then turn on the SUB POWER button for more than 5 seconds while you keep pushing

INPUT SELECT and RECALL buttons located on the bottom of the set.

Preparation

1. Indicate service adjustment mode.

2. Select SHIP.2, then press [RECALL] button more than 3 seconds by

(The screen disappears, and EEPROM is initialized.)

A service adjustment mode screen appears after initialization end again.

* : Select items : Press [ ▲▲▲▲, ▼▼▼▼ ] botton of Remote Controller.

Adjust Data : Press [

Memorize the data : Press [ ENTER] botton of Remote controller.

Adjustment Signal

How to adjust (VIDEO input)

1.Input 525p(480p) adjustment signal into VIDEO2 input terminal.

2.Change CONTRAST of the MENU screen from DYNAMIC to LINEAR.

3.Service adjustment mode screen again

4.Select No.259. (RGB ADJ.)

5.Press [ENTER] button more than 2 seconds. * Start the automatic adjustment.

6.Complete the adjustment after disappear ADJUSTMENT indication.

7.Change CONTRAST of the MENU screen from LINER to DYNAMIC again.

How to adjust (PC input)

1.Input VGA (60Hz) adjustment signal into RGB input terminal.

2.Indicate service adjustment mode.

3.Select No.259. (RGB ADJ.)

4.Press [ENTER] button more than 2 seconds. * Start the automatic adjustment.

5.Complete the adjustment after disappear ADJUSTMENT indication.

*Never adjust without use our specify signal.

If press [ENTER]button at No.259 by mistake, the picture becomes abnormal (Black level,

Contrast and Color.)

0.7V

*Fig.1 Adjustment Signal

Black White

,

] botton of Remote controller.

Black pattern : Set pedestal level.

This signal must not insert character.

Remote Controller

),

Remote Controller.

19

Page 20

8.3 Color temperature adjustment for PC

How to prepare

Set signal generator output signal to Full White.

1.

2.Signal condition

VGA (75): 0.7Vp-p, Set up level: 0V

3.Input the signal into RGB (D-sub) terminal.

4.Set Picture setting up to reference.

How to adjust

1.Indicate service adjustment mode and adjust as follows by Remote Controller.

2.Measurement probe of CRT Color Analyzer CA-100 is set on the center of screen.

3.Adjust color temperature as follows by reducing one or two numbers of No.9, 10, 11.

(

At least one of these datas should be 255.)

PC color temperature (COOL)

x=0.285±±±±0.005, y=0.294±±±±0.005, at 9300 K

4. Adjust color temperature as follows by reducing one or two numbers of No.12, 13, 14.

(At least one of these datas should be 255.)

PC color temperature (NORMAL)

x=0.300±±±±0.005, y=0.298±±±±0.005, at 7600 K

5.Adjust color temperature as follows by reducing one or two numbers of No.15, 16, 17.

(At least one of these datas should be 255.)

PC color temperature (WARM)

x=0.314±±±±0.005, y=0.327±±±±0.005, at 6500 K

Suggestion

1.Luminance of panel surface is less than 20 lux to arrange adjustment environment.

2.Adjstment is reduce value adjustment only. (Impossible to increase value adjustment.)

3.Color select mode is automatically set to COOL while adjustment No.9, 10 and 11.

4.Color select mode is automatically set to NORMAL while adjustment No.12, 13 and 14.

5.Color select mode is automatically set to WARM while adjustment No.15, 16 and 17.

8.4 Color temperature adjustment for Video

How to prepare

Set signal generator output signal to Full White.

1.

2.Signal condition

3.Input the signal into VIDEO2 terminal.

4.Set Picture setting up to reference.

5.Make sure that CONTRAST is LINEAR.

6.Do after color temperature adjustment of PC.

480i/60Hz Component signal

Video level: 0.714Vp-p,

Sync level: 0.286Vp-p

Set up level: 0V

20

Page 21

How to adjust

1.Indicate service adjustment mode and adjust as follows by Remote Controller.

2.Measurement probe of CRT Color Analyzer CA-100 is set on the center of screen.

3.Adjust color temperature as follows by reducing one or two numbers of No.0, 1, 2.

(At least one of these datas should be 255.)

VIDEO color temperature (COOL)

x=0.285±±±±0.005, y=0.294±±±±0.005, at 9300 K

4. Adjust color temperature as follows by reducing one or two numbers of No.3, 4, 5.

(At least one of these datas should be 255.)

VIDEO color temperature (NORMAL)

x=0.300±±±±0.005, y=0.298±±±±0.005, at 7600 K

5.Adjust color temperature as follows by reducing one or two numbers of No.6, 7, 8.

(At least one of these datas should be 255.)

VIDEO color temperature (WARM)

x=0.314±±±±0.005, y=0.327±±±±0.005, at 6500 K

Suggestion

1.Luminance of panel surface is less than 20 lux to arrange adjustment environment.

2.Adjstment is reduce value adjustment only. (Impossible to increase value adjustment.)

3.Color select mode is automatically set to COOL while adjustment No.0, 1 and 2.

4.Color select mode is automatically set to NORMAL while adjustment No.3, 4 and 5.

5.Color select mode is automatically set to WARM while adjustment No.6, 7 and 8.

8.5 Reset adjustment

Always set to factory Setting mode, to prevent error picture, Reset should be done.

When above adjustment is finished, turn off the SUB POWER button (or power button on

the

Remote Controller

How to set to factory Setting

Receive a signal in RGB1.

Turn off the SUB POWER button (or power button on the

Then turn on the sub power button for more than 5 seconds while you keep pushing

SIZE and RECALL buttons located on the bottom of the set.

You fall out from factory Setting mode, turn off the SUB POWER button (or power button on

the Remote Controller).

) and Main power Switch.

Remote Controller

),

21

Page 22

9 Wiring Drawing

9.1 Panel Module and Power Unit section

POWER UNIT

PANEL YSUS

CN33

EJ203

CN32

CN22-CN32間コネクタ布線注意:

電源基板1次側に接触しない様スタイルどりし、

(CN22)側に出来るだけ手繰りよせ布線のこと。

ESP

EAP

TO AUDIO P.W.B

(PVA)

CN69

(*1) (*1) (*1)

CN7

ECN7

(*8)

TO SIGNAL P.W.B

(PW01)

CN102

CN68

(*1)

EJ206

PANEL LOGIC

CN65

CN67

CN101

CN66

CN6

CN1

CN64

(*7)

EJ202

CN22

CN23

ECN1

TO SIGNAL P.W.B

(PP01)

NCN11

Ferrite Core

フェライト・コア(中型)

(*2)(*3)

PANEL XSUS

PANEL L-ADR

CN52

EJ205

EJ204

The lead must run onto the fram e of a chassis.

MAIN FRAME(#402)取付時

ケーブルをはさみ込まないよう注意のこと。

CN42

PANEL R-ADR

22

Page 23

(φ8)

9.2 Plasma Monitor((((H1/H2 panel))))

SP端子は、CLOSE

状態にすること。

SP TERM.R

P.W.B

ESC2

For H2 panel

FLOW

MFN2

POWER UNIT

Roll 3 times

3回巻くこと.

CN304

N020

パースロック(φ8.0)

Pathlook

MF2

CN64

CN65

FLOW

MFN1

For H1 panel

EFP

パースロック(φ15)

)(

EAP

From Power Unit

(CN102)

PVA

PAV1

Z007

EVA

N21

パースロック(φ15)

Pathlook(φ15)

(*1)

AUDIO

P.W.B

VIDEO P.W.B

The lead must not run onto

ヒートシンクに接触しないよう

EAS1

the frame of a chassis.

また、フレームとバックカバーとで

挟み込まないようスタイルどりのこと。

(*1)

PAS4

E1

(*1)

E906

ネジ止め

Safety Ground

(安全アース)

C903

ダイキャストフレームの

The lead must not run onto the

ボス部品に乗り上げないよう

frame of a chassis.

スタイルどりのこと。

(*1)

PFA

FILTER

P.W.B

E905

ネジ止め

(*1)

(E905)

PF1

(*1)

CN61

(*1)

(*1)

(*1)

Pathlook(φ15)

From Power Unit

(CN101)

H1 Panel

N019

ESP

余長リードは

ここで弛ませること。

(*1)(*1)

フェライト・コア

Ferrite

EVP1

PSE

(中型)(*2)

JOINT P.W.B

N017

パースロック(φ8)

Pathlook(φ8)

NVS21

フェライト・ コア

Ferrite Core

(中型)(*2)

Z005

(*1)

NCN11

PVA

(*4)

EVS1

PSF

EVS2

FLOW

MFN1

(*7)

(*1)

(*1)

(*1)

(*1)

EF1

NCN12

フェライト・コア(小型)

Ferrite Core

PP01

ECN1

P001

NVS2

P002

(*1)

PFAN1

(*2)

From Panel Logic(CN1)

Ferrite Core

(フラット)

(Flat)

フェライト・コア

(*4)

15±2

The position of FAN only differs.

SP端子は、CLOSE

(

状態にすること。

SP TERM.L

P.W.B

PAS3

(*1)

PW02 PW01

PA01

EVA

ESC2

SIGNAL P.W.B

(L=30mm)

テープにて EAS1 ケーブルを

アルミフレームに固定のこと。

PL01

Z006

TAPE

)

(*1)

(*1)

PK01

Z004

テープ貼り

TAP E

*電源スイッチの

半田付部に当たらない

ように弛みがないこと。

*テープが#451

The tape must not run onto the

(POW BOTTOM PANEL)

POWER BOTTOM HOLDER.

に乗り上げない様に付線注意のこと。

LED/RECEIVER P.W.B

PSC2

(*9)

POWER SWITCH

AC

INLET

N018

パースロック(φ8)

Pathlook(φ8)

ヒューズホルダに接触しないよう、又

Does not touch Fuse Holder.

C903 に乗り上げないようスタイルどりのこと。

PAS1

10±2

Z003

パーマセルテープ 幅19(L=70)で

TAPE TAPE

EAS1 ケーブルを固定のこと。

10±2

Z002

パーマセルテープ 幅19 (L=70)で

EAS1 ケーブルを固定のこと。

(*1)

ESC1

PSC1

Z001

パーマセルテープ 幅19(L=100)で

TAPE

EAS1 ケーブルを固定のこと。

23

(*1)

TACT SW P.W.

Page 24

THE UPDATED PARTS LIST

FOR THIS MODEL IS

AVAILABLE ON ESTA

Page 25

SM0064

Power Supply Block Diagram

HITACHI

Page 26

SM0064

Panel Connectors

HITACHI

Page 27

NO P OWE R

NO•P OWE R

NO V s ,Va,Vcc,S T B

OK

S T B

OK

NO PICTURE

& S OUND

F U S E

NG

under 130V

NO V s,V a,Vcc

S T B

NG

check voltage

D011(k ) -J13

Q103,R 005

NG

over 130V

D161,IC101,Q104,

Q108,etc

impedance check

D001

OK

impedance checkQ003/Q004

OK

impedance check

Q201

OK

impedance check

Q301

S ee NO P OWE R

NG

D001

NG

Q003/Q004,

etc

NG

Q201,IC201

D210,Q202,etc

NG

Q301,IC301

D301,Q303,etc

V a : n o u p r i s e

V s : d o w n a f t e r u p

I C 3 0 1 , Q 3 0 3 ,

P C 3 0 1 , P C 3 0 2

D 3 1 0 , I C 3 9 1 ,

etc

OK

V cc

NO PICTURE

i m p e d a n c e c h e c k

V s L I N E

OK

i m p e d a n c e c h e c k

V a L I N E

OK

S W O N

V s : n o u p r i s e

V a : d o w n a f t e r u p

I C 5 9 1 , Q 5 0 1 ,

I C 5 0 1 , D 5 3 2 ,

Q 5 3 0 , P C 5 0 1 ,

P C 5 0 2 , D 2 8 0 ,

D 2 8 1 , e t c

NGOK

NG

NG

C N 6 4 , C N 6 6CN67

check voltage

J58 - J13

u n d e r 3 0 0 V

over 300V

I C 0 0 1,D005•D008,

R L 0 0 1 , PC003,Q010,etc

N O V s , V a

o p e n c o n nector

i m p e d a n c e check

V a L I N E

OK OK

open connector

NG

P D P module Va

D 3 5 1 D551,D552

NG

IC201,Q202,P C201,

P C202,P C252,P C256,

D210,etc

CN64,CN65

impedance check

Vs L INE

NG

P D P module Vs

NG

SM0064

Power Supply Unit Troubleshooting

HITACHI

Page 28

SM0064

Power Supply Circuit Board

HITACHI

Page 29

SM0064

Power Circuit Schematic - 1 of 5

HITACHI

Page 30

SM0064

Power Circuit Schematic - 2 of 5

HITACHI

Page 31

SM0064

Power Circuit Schematic 3 0f 5

HITACHI

Page 32

SM0064

Power Circuit Schematic - 4 of 5

HITACHI

Page 33

SM0064

Power Circuit Schematic - 5 of 5

HITACHI

Page 34

Hitachi, Ltd. Tokyo, Japan

International Sales Division

THE HITACHI ATAGO BUILDING,

No. 15 –12 Nishi Shinbashi, 2 – Chome,

Minato – Ku, Tokyo 105-8430, Japan.

Tel: 03 35022111

HITACHI EUROPE LTD,

Whitebrook Park

Lower Cookham Road

Maidenhead

Berkshire

SL6 8YA

UNITED KINGDOM

Tel: 01628 643000

Fax: 01628 643400

Email: consumer-service@hitachi-eu.com

HITACHI EUROPE GmbH

Munich Office

Dornacher Strasse 3

D-85622 Feldkirchen bei München

GERMANY

Tel: +49-89-991 80-0

Fax: +49-89-991 80-224

Hotline: +49-180-551 25 51 (12ct/min)

Email: HSE-DUS.service@hitachi-eu.com

HITACHI EUROPE srl

Via Tommaso Gulli N.39, 20147

Milano, Italia

ITALY

Tel: +39 02 487861

Tel: +39 02 38073415 Servizio Clienti

Fax: +39 02 48786381/2

Email: customerservice.italy@hitachi-eu.com

HITACHI EUROPE S.A.S

Lyon Office

B.P. 45, 69671 BRON CEDEX

FRANCE

Tel: 04 72 14 29 70

Fax: 04 72 14 29 99

Email: france.consommateur@hitachi-eu.com

HITACH EUROPE AB

Egebækgård

Egebækvej 98

DK-2850 Nærum

DENMARK

Tel: +45 43 43 6050

Fax: +45 43 60 51

Email: csgnor@hitachi-eu.com

Hitachi Europe Ltd

Bergensesteenweg 421

1600 Sint-Pieters-Leeuw

BELGIUM

Tel: +32 2 363 99 01

Fax: +32 2 363 99 00

Email: sofie.van.bom@hitachi-eu.com

www.hitachidigitalmedia.com

HITACHI EUROPE S.A.

364 Kifissias Ave. & 1, Delfon Str.

152 33 Chalandri

Athens

GREECE

Tel: 1-6837200

Fax: 1-6835964

Email: service.hellas@hitachi-eu.com

HITACHI EUROPE S.A.

Gran Via Carlos III, 86, planta 5

Edificios Trade - Torre Este

08028 Barcelona

SPAIN

Tel: 93 409 2550

Fax: 93 491 3513

Email: atencion.cliente@hitachi-eu.com

HITACHI Europe AB

Box 77 S-164 94 Kista

SWEDEN

Tel: +46 (0) 8 562 711 00

Fax: +46 (0) 8 562 711 13

Email: csgswe@hitachi-eu.com

HITACHI EUROPE LTD (Norway) AB

STRANDVEIEN 18

1366 Lysaker

NORWAY

Tel: 67 5190 30

Fax: 67 5190 32

Email: csgnor@hitachi-eu.com

HITACHI EUROPE AB

Neopoli / Niemenkatu 73

FIN-15140 Lahti

FINLAND

Tel : +358 3 8858 271

Fax: +358 3 8858 272

Email: csgnor@hitachi-eu.com

HITACHI EUROPE LTD

Na Sychrove 975/8

101 27 Pr aha 10 – Bohdalec

CZECH REPUBLIC

Tel: +420 267 212 383

Fax: +420 267 212 385

Email: csgnor@hitachi-eu.com

Loading...

Loading...