Page 1

SERVICE MANUAL

MANUEL D'ENTRETIEN

WARTUNGSHANDBUCH

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

No. 0533

CML190SXW

CML190SXWB

Data contained within this Service

manual is subject to alteration for

improvement.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

1. Introduction ..................................................................................................................................2

2. Electrical Requirements ...............................................................................................................3

3. Vl-901 Display Control Board ...................................................................................................18

4. VK901 Control Panel Board ......................................................................................................23

5. Inverter Board.............................................................................................................................24

6. DC/DC Power and Audio Ckt Vm-902 .....................................................................................26

7. Troubleshooting..........................................................................................................................28

8. Mechanical Requirements ..........................................................................................................33

9. Power Line Transient Test (Iec 61000-4-4 Fast Transients/Burst) ............................................39

10. Power Line Surge Test (IEC 61000-4-5 Surge) .........................................................................42

11. Enviroment Requirement ...........................................................................................................43

12. Regulation Compliance..............................................................................................................44

13. Quality and Reliability ...............................................................................................................46

Appendix A: PCBA Assembly................................................................................................... 47

Appendix B: DISPLAY UNIT ASSEMBLY............................................................................. 55

Parts Lists.................................................................................................................................... 60

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

TFT LCD MONITOR

July 2002

Page 2

1. INTRODUCTION

1.1 Scope

This specification defines the requirements for the 19” MICRO-PROCESSOR based Multimode supported high resolution color LCD monitor, This monitor can be directly connected

to general 15 pin D-sub VGA connector and DVI-D digital connector, eliminates the

requirement of optional special display card. It also supports VESA DPMS power

management and plug & play function. There is a build-in stereo audio amplifier with

volume control to drive a pair of speakers.

1.2 Description

The LCD monitor is designed with the latest LCD technology to provide a performance

oriented product with no radiation. This will alleviate the growing health concerns. It is also

a space saving design, allowing more desktop space, and comparing to the traditional CRT

monitor, it consumes less power and gets less weight in addition MTBF target is 20k

hours or more.

2

Page 3

2. ELECTRICAL REQUIREMENTS

2.1 Standard Test Conditions

All tests shall be performed under the following conditions, unless otherwise specified.

Ambient light

Viewing distance

Warrn up time

: 225 lux

: 50 cm in front of LCD panel

All specifications: 30 minutes

Fully functional: 5 seconds

Measuring Equipment

: Chroma 2250 signal generator or equivalent, directly

Connected to the monitor under test.

Minolta CA100 photometer, or equivalent

Control settings

User brightness control: Maximum (unless otherwise specified )

User contrast control: Typical (unless otherwise specified )

User red/white balance,

Green/white balance and

Blue/white balance control: In the center (unless otherwise specified )

Power input

Ambient temperature

Analog input mode

: 110Vac or 230Vac

: 20 ± 5 ˚C ( 68 ± 9 ˚ F)

: 1280 x1024 /60 Hz

2.1.1 MEASUREMENT SYSTEMS

The units of measure stated in this document are listed below:

1 gamma = 1 nano tesla

1 tesla = 10,000 gauss

cm = in x 2.54

lb = kg x 2.2

degrees F = [°C x 1.8] + 32

degrees C = [°F - 32]/1.8

u' = 4x/(-2x + 12y + 3)

v' = 9y/(- 2x + 12y + 3)

x = (27u'/4)/[(9u'/2) - 12v ' + 9]

y = (3v')/[(9u' /2) - 12v' + 9]

nits = cd/(m2) = Ft-L x 3.426

lux = foot-candle x 10.76

2.2 LCD monitor General specification

Panel Type : 19 “ active matrix color TFT LCD

1). FUJITSU FLC48SXC8V

Display size : 376.32mm(H) x 301.056mm(V)

Display mode : VGA 720 X 400 (70 Hz)

VGA 640 X 480 (60/66/70/72/75 Hz)

SVGA 800 X 600 (60/70/72/75 Hz)

3

Page 4

XGA 1024 X 768 (60/70/75 Hz)

SXGA 1280 X 1024 (60/70/75 Hz) standard resolution

Pixel pitch : 0.098x3mm(H) x 0.294mm(V)

Display Dot : 1280 x (RGB) x 1024

Pixel Clock : 25.2 – 135.0MHz

θ

Contrast ratio:

Brightness: 250 cd/m

Response time (Tr/Tf) : 15 /10 msec

Display color : 16777216 (8 bite color)

Viewing angle: L / R 85 / 85 ( 170 degrees horizontal typical)

U / D 85 / 85 ( 170 degrees vertical typical)

Luminance Uniformity : > 70 %

Pc interface: 1). Video : RGB analog 0.7V peak to peak

= 0˚ 500 : 1 (typical)

2

(typical)

Sync : TTL positive or negative

2). Digital TMDS

Signal connector : 15 pin Mini D type, (standard VGA video)

DVI-D connector

Front control : power on/off with LED select (up, down) adjustment (+,-)

Interface frequency

Horizontal Frequency 24KHz --80KHz(analog), 31.5– 80KHz(digital)

Vertical Frequency 56Hz ----75Hz

Plug & play : Support VESA DDC2B functions

Power Input voltage : Single phase, 50/60HZ, 100VAC to 240VAC ±10%

Total output power : 60 Watt max.

2.3 LCD Panel Specification

2.3.1 LCD Panel Model (FUJITSU FLC48SXC8V)

• Display Type active matrix color TFT LCD

• Resolution 1280 x 1024 pixels

• Display Dot 1280 x (RGB) x 1024

• Display Area 376.32mm(H) x 301.056mm(V)

• Pixel Pitch 0.098x3mm(H) x 0.294mm(V)

• Display Color 16777216

4

Page 5

• Lamp Voltage 700 Vrms typ.

• Lamp Current 7mA rms.( typ). 4 Lamp

• Weight 3200g .

• Optical Specifications

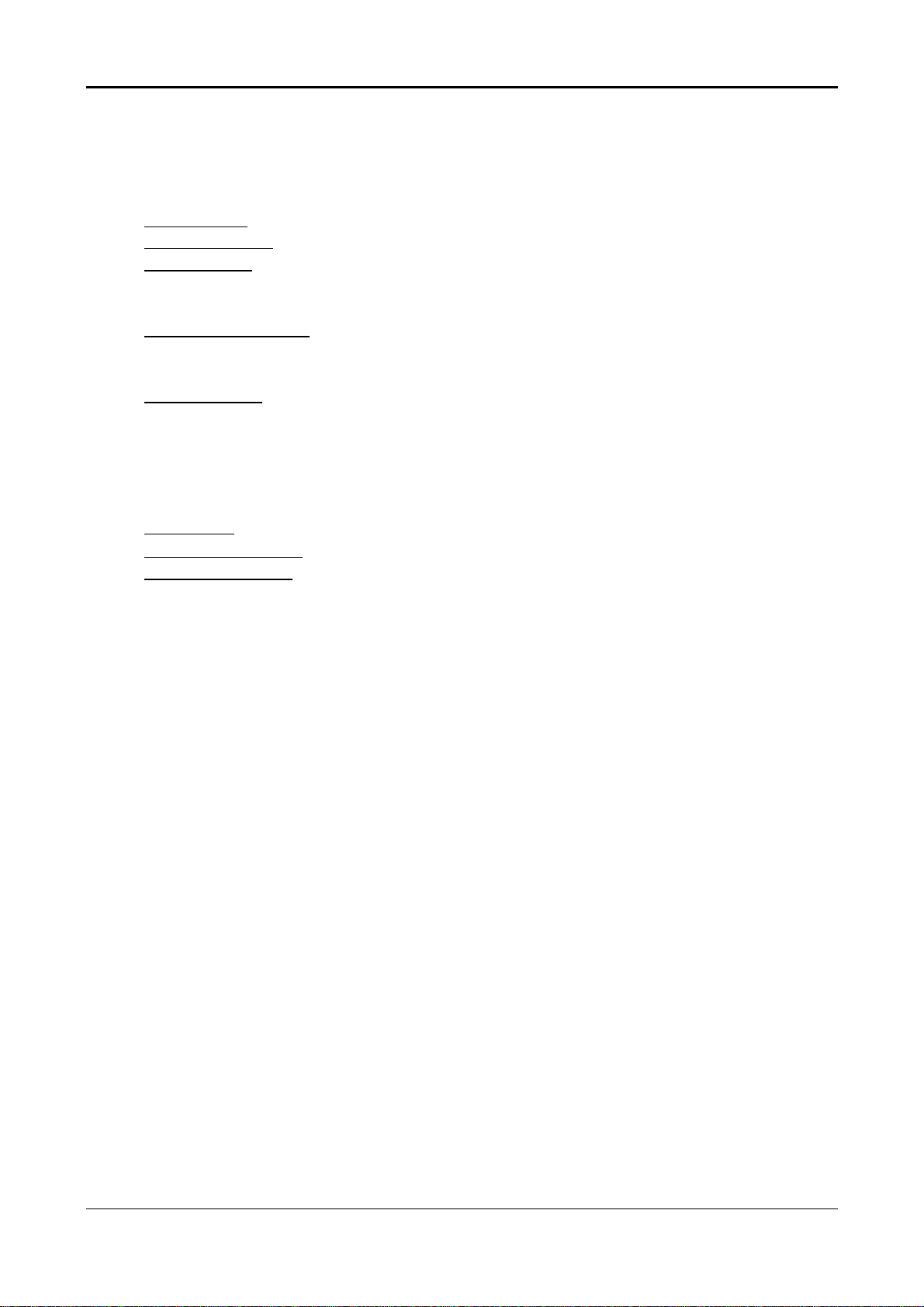

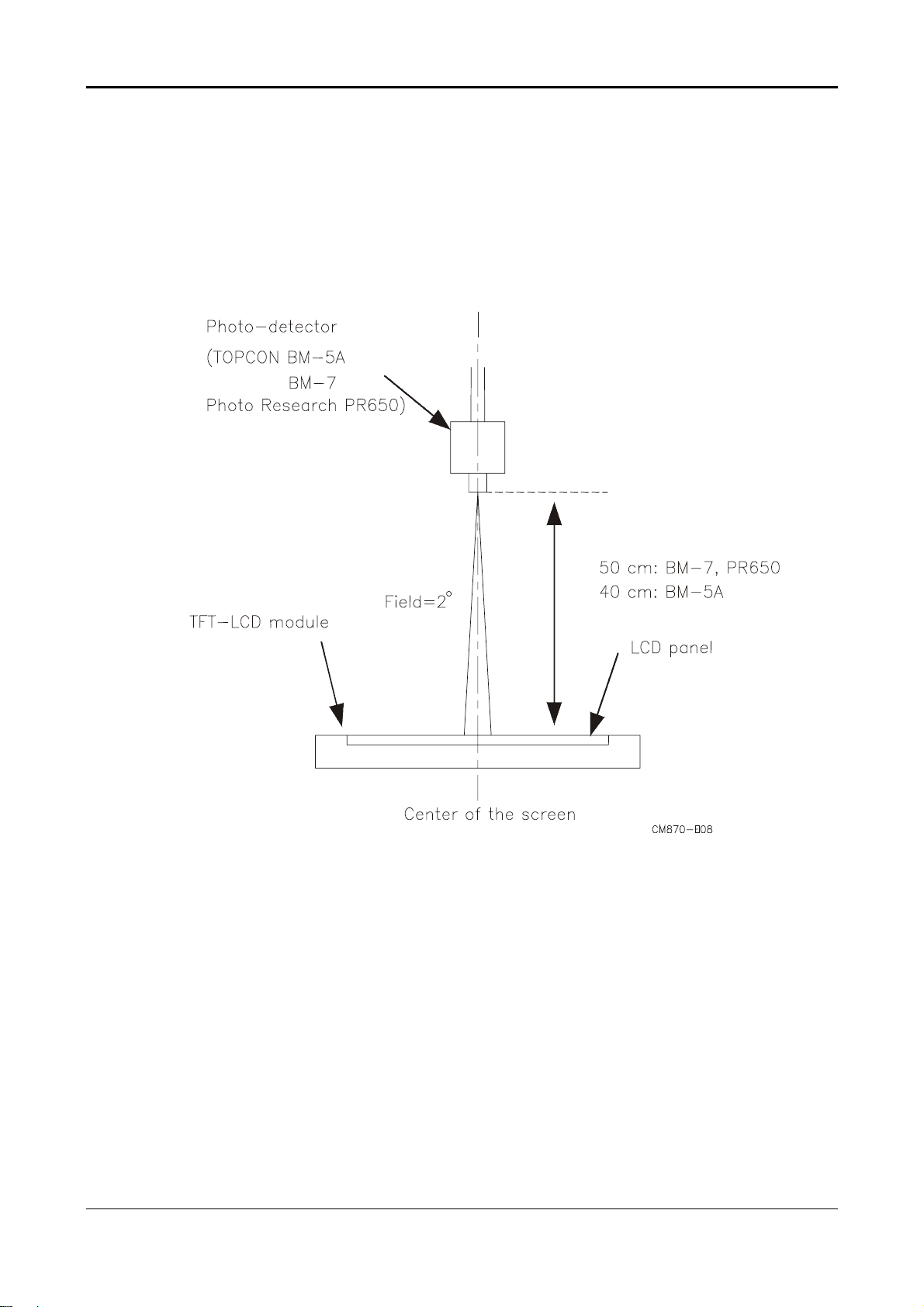

The following items are measured under stable conditions. The optical characteristics

should be measured in a dark room or equivalent state with the methods shown in

Note(4).

Measuring equipment : TOPCON BM-5A, BM-7, PHOTO RESEARCH PR650

(Inverter Freq. : 54kHz) *Ta =25 ± 2°C, VDD=5V, fv=60 Hz, fDCLK=54 MHz, IL= 6.5mArms

Item Symbol Condition Min. Typ. Max. Unit Note

Contrast Ratio

(Center of screen)

Response

Time

Luminance of White

(Center of screen)

Color

Chromaticity

(CIE 1931)

Viewing

Angle

Brightness Uniformity

(9 points)

Rising TR - 15 30

Falling T

Red

Green

Blue

White

Hor.

Ver.

CR

F - 10 25

Y

L

Rx 0.648

Ry 0.346

Gx 0.292

Gy 0.602

Bx 0.150

By 0.130

Wx 0.313

Wy

θ

L

θ

R

φ

H

φ

L

B

UNI

Normal

φ

θ

Viewing

Angle

CR≥10

T.B.D 500 -

= 0˚

= 0˚

70 - -

200 250 -

TYP.

-0.03

0.329

85 - 85 - 85 - 85 - -

TYP.

+0.03

msec

cd/m2

Degrees

%

(1)(2)(4)

BM-5A

(1)(3)

BM-7

(5)

BM-5A

(1)(4)

PR650

(1)(4)

BM-5A

(6)

BM-5A

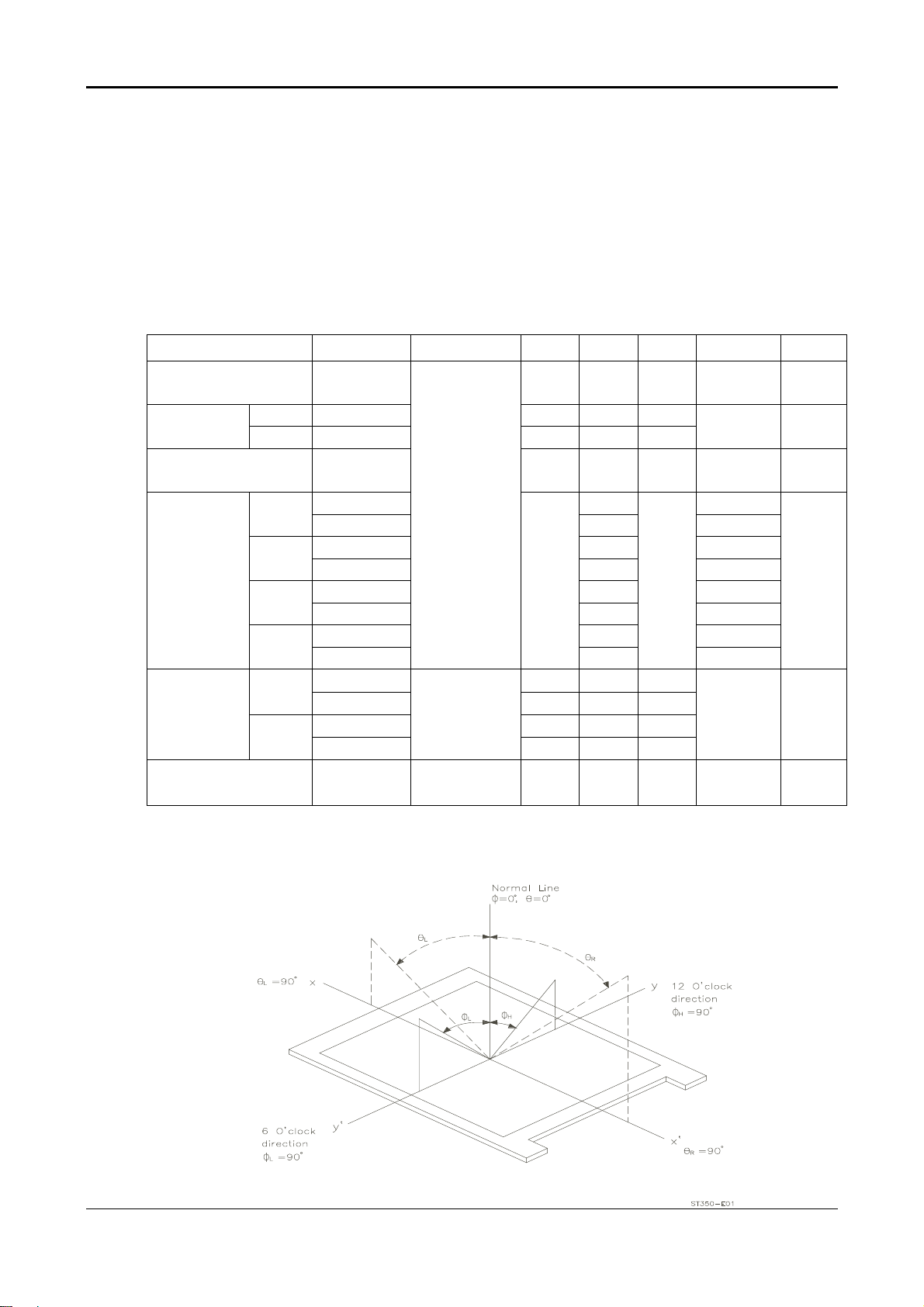

Note 1) Definition of Viewing Angle: Viewing angle range (10≤CR)

5

Page 6

Note 2) Definition of Contrast Ratio (CR): Ratio of gray max(Gmax),gray min(Gmin) at the

center point of panel.

Luminance with all pixels white (Gmax)

CR=

Luminance with all pixels black (Gmin)

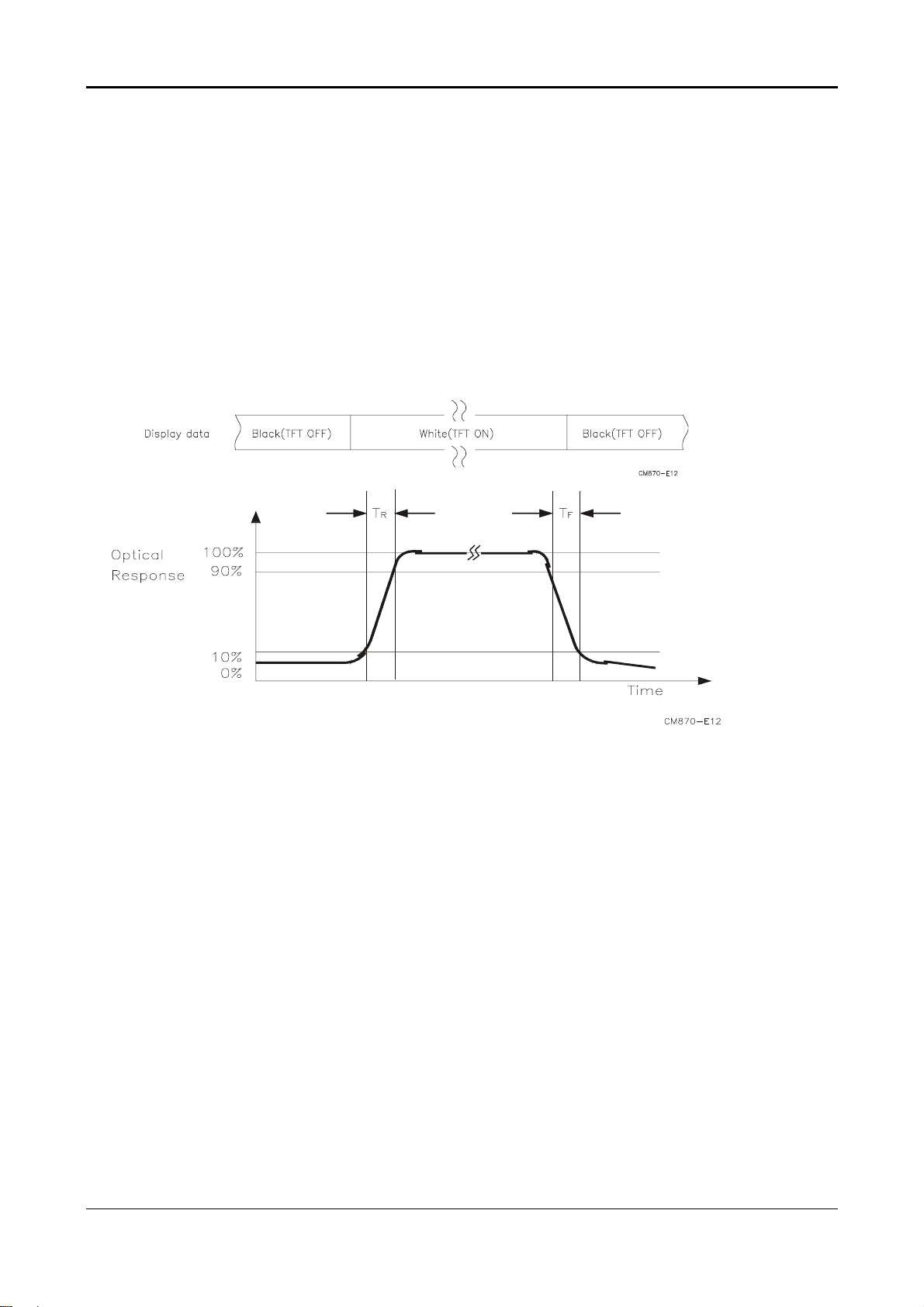

Note 3) Definition of Response time: Sum of T

, TF

R

6

Page 7

Note 4) After stabilizing and leaving the panel alone at a given temperature for 30 min, the

measurement should be executed .Measurement should be executed n a stable,

windless ,and dark room.30 min after lighting the back-light. This should be

measured in the center of screen. Dual lamp current :13.0mA(6.5mA x2)(Refer to

the note(1) in the page 14 for more information ).

Environment condition :Ta=25±2°C

Optical characteristics measurement setup

7

Page 8

Notes 5) Definition of Luminance of White : measure the luminance of white at center point.

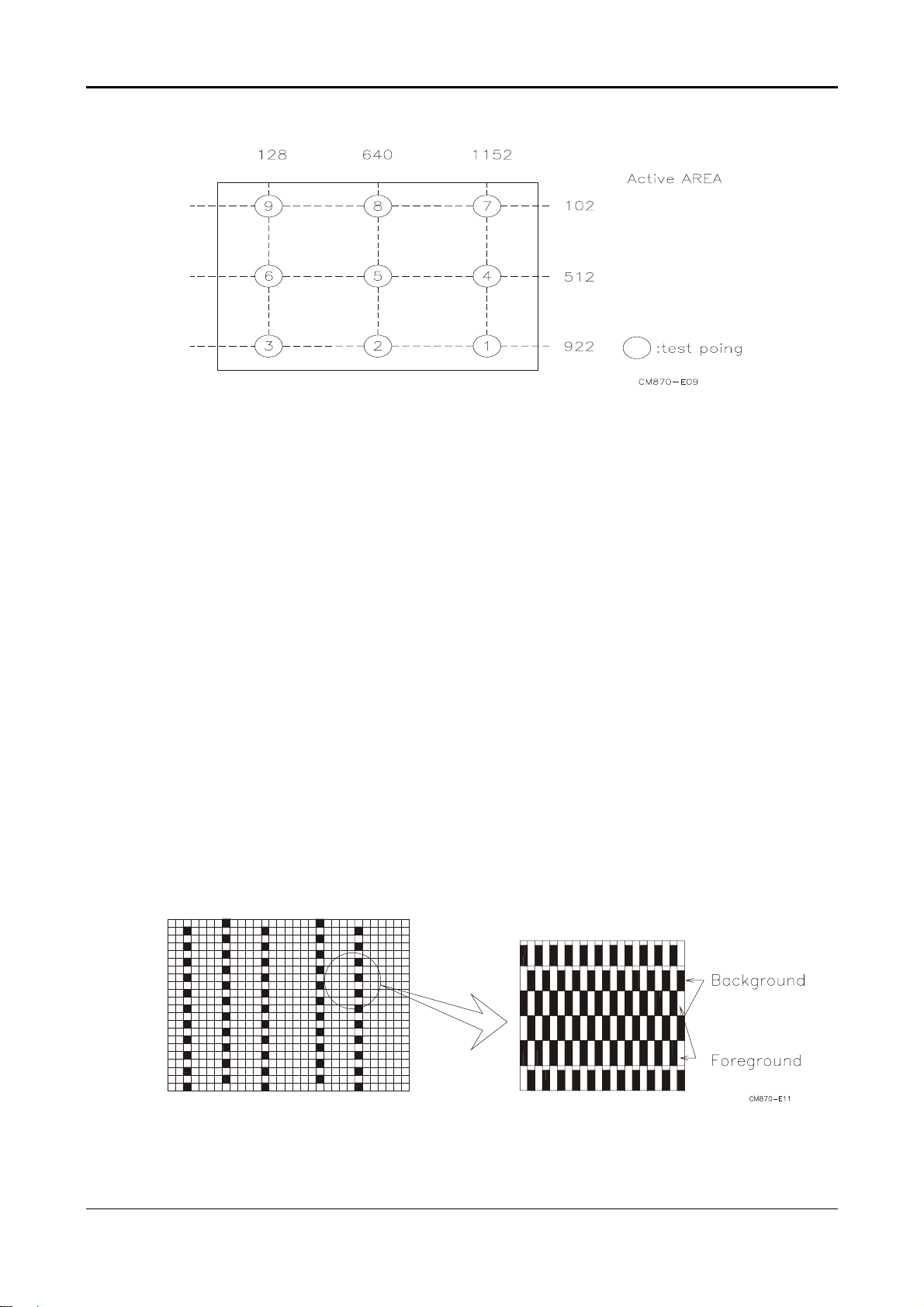

Notes 6)Definition of 9 points brightness uniformity (Measuring points: Refer to the Note 5)

Bmin

B

=100∗∗∗∗

UNI

Bmax

Bmax: Maximum brightness

Bmin: Minimum brightness

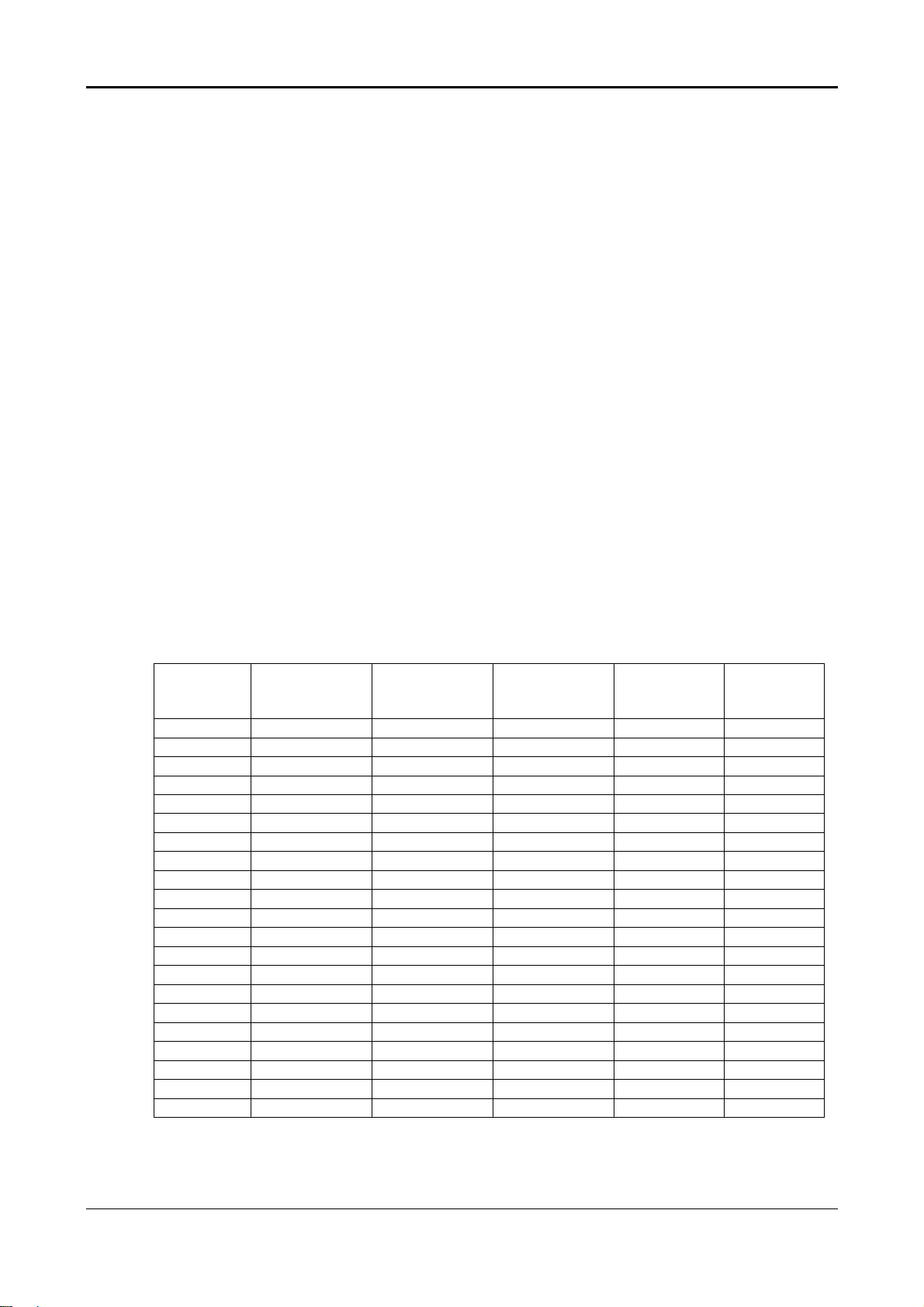

Notes 7) Definition of Flicker level

Flicker Voltage

pp

F = x 100 %

LMD Voltage

dc

♦♦♦♦ One maximum value of three estimated values.

♦♦♦♦ For this test ,an LMD(Light Measurement Device)is needed with adequate response time

to track any visible rate flicker component and with a voltage level output proportional

To luminance intensity.

♦♦♦♦ Test Pattern: For dot inversion Driving(Gray levels of foreground dots on the test panel

Are G22,G32,and G45)

♦♦♦♦ Test Point :Center point of the display area

8

Page 9

Note 8) Definition of Crosstalk (Refer to the VESA STD)

The calculation for shadowing is made from the 2 luminance measurements Gbkg and Lsh,

as follows:

Lmax -Lmin

C

= x100 %

T

Lmin

Where Lmax is the larger value of Gbkg or Lsh , and Lmin is the smaller of the two.

♦ To determine background and foreground levels (colors),first set the background to any

gray scale or color level suitable for shadowing determination.(Note that it may take

several iterations of adjusting background level and box levels to determine the proper

value for the background .Next display the box levels to determine the proper value for the

background level. Look for shadowing in any direction from box E. Independently vary the

gray level (or color) of the background and box E until the worst case shadowing is

observed. This defines the background (Gbkg) and foreground (Gfg) levels to be

maintained for the remainder of the test.

♦ One point only (the target) will be measured. To determine that point proceed as follows

Using the background and foreground gray levels of step1 (Gbkg and Gfg). Turn on each

box at a time. Look for the case with the worst shadowing. The box causing the worst case

is the shadowing source, or Bsrc. Use Bsrc and the box opposite from it that lies directly in

the shadow path. That is the target box, or Btgt. Note that box Eight be either Bsrc or Btgt,

depending on the shadowing conditions, but typically Bsrc and Btgt will be a pair of

opposite boxes, A&C or B&D. Btgt will only be displayed for aligning the LMD. It will be

turned off for the actual measurement.

♦♦♦♦ The target box point (Btgt) will be measured with the source box (Bsrc) turned on then off.

(Btgt is for alignment purpose only) Display the background only at level Gbkg. Display

Btgt determined in step 2 above. Using the correct distance, angle, and measurement

aperture, align the LMD to the center of the Btgt. Turn off Btgt. With Gbkg set to its proper

level, measure the luminance (or color). Next,turn on the source box Bsrc. Again measure at

the center point of Btgt (without Btgt present.). In this case the LMD will be measuring the

shadowing level, Lsh.

9

Page 10

2.4 Input Signals

2.4.1 Video input

• Type Analog R, G, B., Digital TMDS

• Input Impedance 75 ohm +/- 2%

• Polarity Positive

• Amplitude 0 - 0.7 +/- 0.05 Vp

• Display Color same as LCD panel

2.4.2 Sync input

• Signal separate horizontal and vertical sync, or composite sync

which are TTL compatible

• Polarity positive and negative.

2.4.3 Interface frequency

The following frequency range is generalized by supported timing. If the entered

mode does not match the supported timing the display optimization will not be

assured.

• Horizontal Frequency 24KHz --80KHz(analog), 31.5– 80KHz(digital)

• Vertical Frequency 56Hz ---------75Hz

DISPLAY MODES

MONITOR

MODE NO.

1 640x350 31.5 + 70.0 - 25.0 VGA

2 640X400 24.83 - 56.4 - 21.05 NEC

3 640X400 31.5- 70.0+ 25.0 VGA

4 640X400 31.5- 70.1- 25.19 NEC

5 640X480 31.5 - 60.0 - 25.0 Defacto

6 640X480 35.0- 66.67- 30.24 MAC

7 640X480 37.86- 72.80- 31.5 VESA

8 640X480 37.5- 75.0- 31.5 VESA

9 720X400 31.5 - 70.0 + 28.0 Text Defacto

10 832X624 49.72- 74.55 - 57.28 MAC

11 800X600 35.16+ 56.25+ 36.0 SVGA

12 800X600 37.8 + 60.0 + 40.0 VESA

13 800X600 48.07 + 72.18 + 50.0 VESA

14 800X600 46.87+ 75.0+ 49.5 VESA

15 1024X768 48.4 - 60.0 - 65.0 VESA

16 1024X768 53.96 + 66.13 + 71.66 XGA

17 1024X768 56.47 - 70.07 - 75.0 VESA

18 1024X768 60.0 + 75.0 + 78.75 VESA

19 1024x768 60.24- 75.02- 80.0 MAC-768

20 1280X1024 64.0 + 60.0 + 108.5 SXGA

21 1280X1024 80.0 + 75.0 + 135.0 Defacto

SCREEN

RESOLUTION

HORIZONTAL

SYNC RATE

(kHz)

VERTICAL

SYNC RATE

(Hz)

VIDEO CLK

(MHz)

STANDARD

10

Page 11

Supported Timing

TIMING

FV(HZ) POLARITY (DOT/LINE) (DOT/LINE) WIDTH PORCH PORCH FOREQ.(MHZ)

(DOT/LINE) (DOT/LINE) (DOT/LINE)

640x350 31.469 + 800 640 96 16 48 25.175

VGA-350 70.087 – 449 350 2 37 60

640x400 24.83 – 848 640 64 64 80 21.05

NEC PC9801 56.42 – 440 400 8 7 25

640x400 31.469 – 800 640 96 16 48 25.175

VGA-GRAPH 70.087 + 449 400 2 12 35

640x400 31.5 – 800 640 64 16 80 25.197

NEC PC9821 70.15 – 449 400 2 13 34

640x480 31.469 – 800 640 96 16 48 25.175

VGA-480 59.94 – 525 480 2 10 33

640x480 35.00 – 864 640 64 64 96 30.24

APPLE MAC480

640x480 37.861 – 832 640 40 16 120 31.5

VESA-480-72Hz 72.809 – 520 480 3 1 20

640x480 37.5 – 840 640 64 16 120 31.5

VESA-480-75Hz 75 – 500 480 3 1 16

720x400 31.469 – 900 720 108 18 54 28.322

VGA-400-TEXT 70.087 + 449 400 2 12 35

832x624 49.725 – 1152 832 64 32 224 57.2832

APPLE MAC800

800x600 35.156 + 1024 800 72 24 128 36

SVGA 56.25 + 625 600 2 1 22

800x600 37.879 + 1056 800 128 40 88 40

VESA-600-60Hz 60.317 + 628 600 4 1 23

800x600 48.077 + 1040 800 120 56 64 50

VESA-600-72Hz 72.188 + 666 600 6 37 23

800x600 46.875 + 1056 800 80 16 160 49.5

VESA-600-75Hz 75 + 625 600 3 1 21

1024x768 48.363 – 1344 1024 136 24 160 65

XGA 60.004 – 806 768 6 3 29

1024x768 53.964 + 1328 1024 176 16 112 71.664

COMPAQ-XGA 66.132 + 816 768 4 8 36

1024x768 56.476 – 1328 1024 136 24 144 75

VESA-768-70Hz 70.069 – 806 768 6 3 29

1024x768 60.023 + 1312 1024 96 16 176 78.75

VESA-768-75Hz 75.029 + 800 768 3 1 28

1024x768 60.24 – 1328 1024 96 32 176 80

APPLE MAC768

1280x1024 64 + 1688 1280 112 48 248 108

VESA-102460Hz

1280x1024 80 + 1688 1280 144 16 248 135

VESA-102475Hz

If the input timing is not a supported timing listed above but within the supported frequency

range (Horizontal: 80KHz,Vertical: 75Hz), this monitor will select a closest mode instead. But

the display quality may not be optimized.

If the input timing over the supported frequency range, a message “Input Signal Out of Range”

will be shown.

FH(KHZ) SYNC TOTAL ACTIVE SYNC FRONT BACK PIXEL

66.67 – 525 480 3 3 39

74.55 – 667 624 3 1 39

75.02 – 803 768 3 3 29

60 + 1066 1024 3 1 38

75 + 1066 1024 3 1 38

11

Page 12

2.4.4 85Hz refresh rate Support

Monitor should display 85Hz refresh rate mode as emergency mode.

Monitor should display “Out of Range” warning menu at this mode.

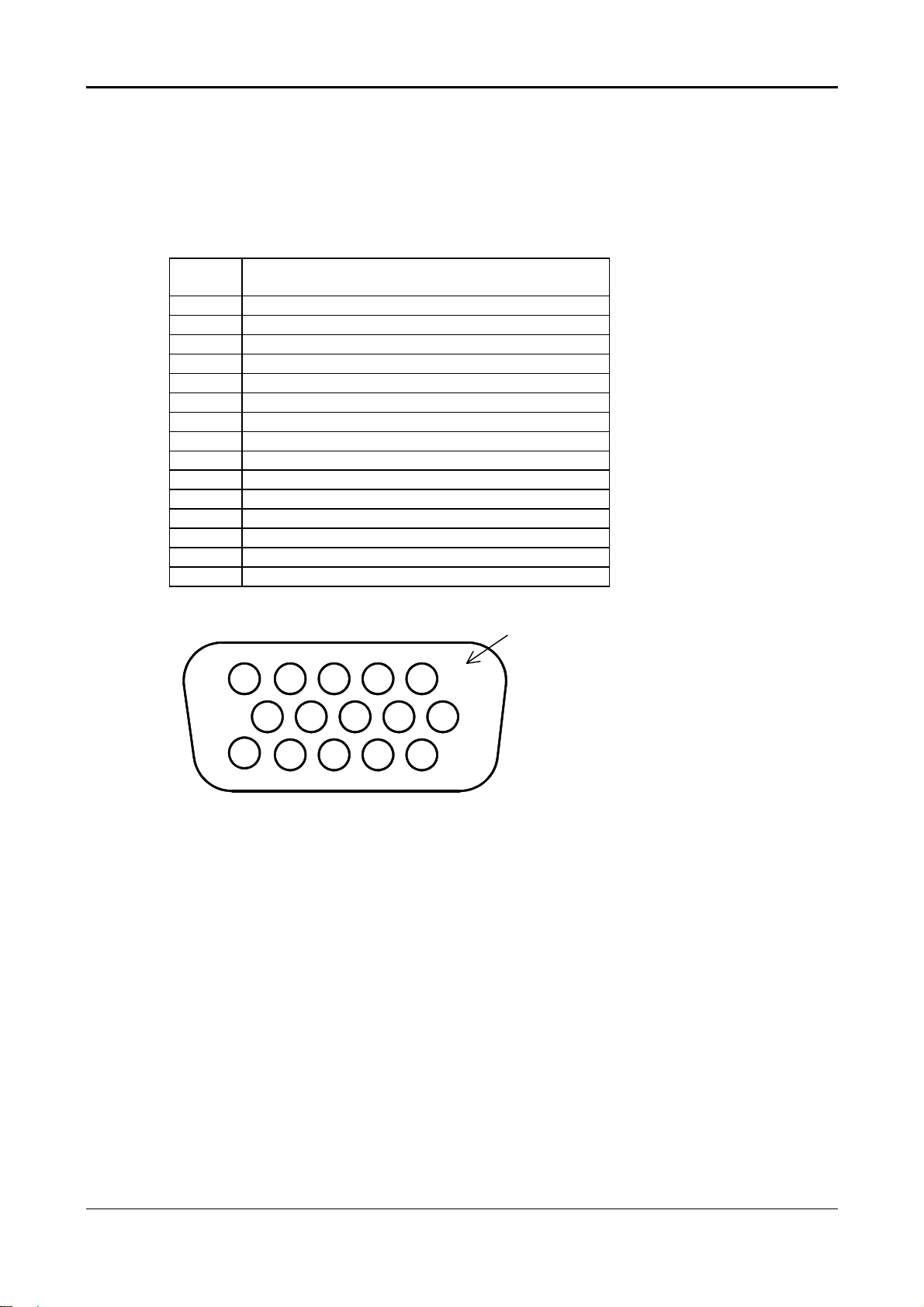

2.4.5 Video input Connector

Analog Video input Connector: 15pins mini D-Sub

Table 2.4.5. Pin assignment for D-sub connector

PIN NO. Separate Sync

1 RED VIDEO

2 GREEN VIDEO

3 BLUE VIDEO

4 GROUND

5 GROUND

6 RED GROUND

7 GREEN GROUND

8 BLUE GROUND

9 PC5V (+5V DDC)

10 CABLE DETECTION

11 GROUND

12 SDA

13 H.SYNC

14 V.SYNC

15 SCL

Color of plastic parts: Blue

5 1

10

15

D-sub connector

6

11

12

Page 13

Digital Video input Connector: DVI-D (T.B.D)

Table 4-3-3. Pin assignment for DVI-D (24pin) connector

Pin – Assignment of DVI –D connector :

1 TX2- 9 TX1- 17 TX02 TX2+ 10 TX1+ 18 TX0+

3 Shield (TX2 / TX4) 11 Shield (TX1 / TX3) 19 Shield (TX0 / TX5)

4 NC 12 NC 20 NC

5 NC 13 NC 21 NC

6 DDC-Serial Clock 14 +5V power *) 22 Shield (TXC)

7 DDC-Serial Data 15 Ground (+5V) 23 TXC+

8 No Connect 16 Hot plug detect 24 TXC-

*) In case, the power of the PC unit is switched off and the power of the monitor is switched on,

no voltage may occur at pin 14.

13

Page 14

2.5 CONTROLS

2 3 6 1 4 5

2.5.1 Control panel (monitor front panel)

1. Power LED, will be green when monitor is on; be amber when in power saving mode.

2. Adjust decrease.

3. Adjust increase.

4. Function select counter-clockwise.

5. Function select clockwise.

6. Power ON/OFF switch, push to ON and push to OFF. (toggle switch)

Note: When OSD Menu is off, press button 2 and 3 at the same time can activate “Auto

Adjustment” immediately.

2.5.2 OSD Functions

• OSD Format: Refer to following figure.

• OSD Border: Cyan color

• OSD Tunable Item: The 16 icons that around the border.

• Selected Item: Yellow background

• Comment: Magenta foreground, Blue background

page format :

14

Page 15

Description:

• Brightness: Brightness adjustment, the range from 0 to 100.

• Contrast: Contrast adjustment, the range from 0 to 100.

• H. Position: Horizontal position adjustment.

• V. Position: Vertical position adjustment.

• Phase: Focus adjustment, the range from 0 to 31,32 steps.

• OSD position: OSD position adjustment.

• Auto Adjustment: This feature will automatically adjust size, position, clock and phase.

It takes 3-5 seconds to finish. When auto start, it shows “Auto

Adjusting….” message.

• Clock: Frequency tracking adjustment. The max range from -48 to +48, but

some modes the range will be limited.

• Graph Text: 640x400(GRAPH) or 720x400(TEXT) mode select.

• Language: 5 kinds of language for description, including (English, German,

French, Spanish, Italian)

• Recall: Recall the default value.

• Color Temp: Color temperature for standard 9300,6500, 7500 or user defined.

User:

User R: Red signal gain by user defined.

User G: Green signal gain by user defined.

User B: Blue signal gain by user defined.

7500: Set CIE coordinate at 7500°K color temperature.

6500: Set CIE coordinate at 6500°K color temperature.

9300: Set CIE coordinate at 9300°K color temperature.

• Exit: Exit OSD menu function.

Sharpness : Adjust the scale-up effect(smoother or sharper.)

OSD Transparency: Adjust the transparency level of OSD. The range is from 0 to 100 scales.

Comment:

• 1280x1024: Current mode resolution.

• 60 HZ: Current mode vertical frequency±1Hz.

• VER 1.00: Firmware revision.

15

Page 16

Other features:

Intellectual-Auto LCM999 can start the Auto-Adjustment automatically when input a new

display mode at first time. After the adjustment, LCM999 will remember this mode and

switch to optimized condition automatically for this mode whenever encounter this mode

again. Total 21 recent used modes are recorded into LCM999.

VESA DPMS Functionality When signaled by the host CPU, LCM999 show a black

screen about 3 seconds. If no further signal, then it shows “No Signal” and enter power

saving mode.

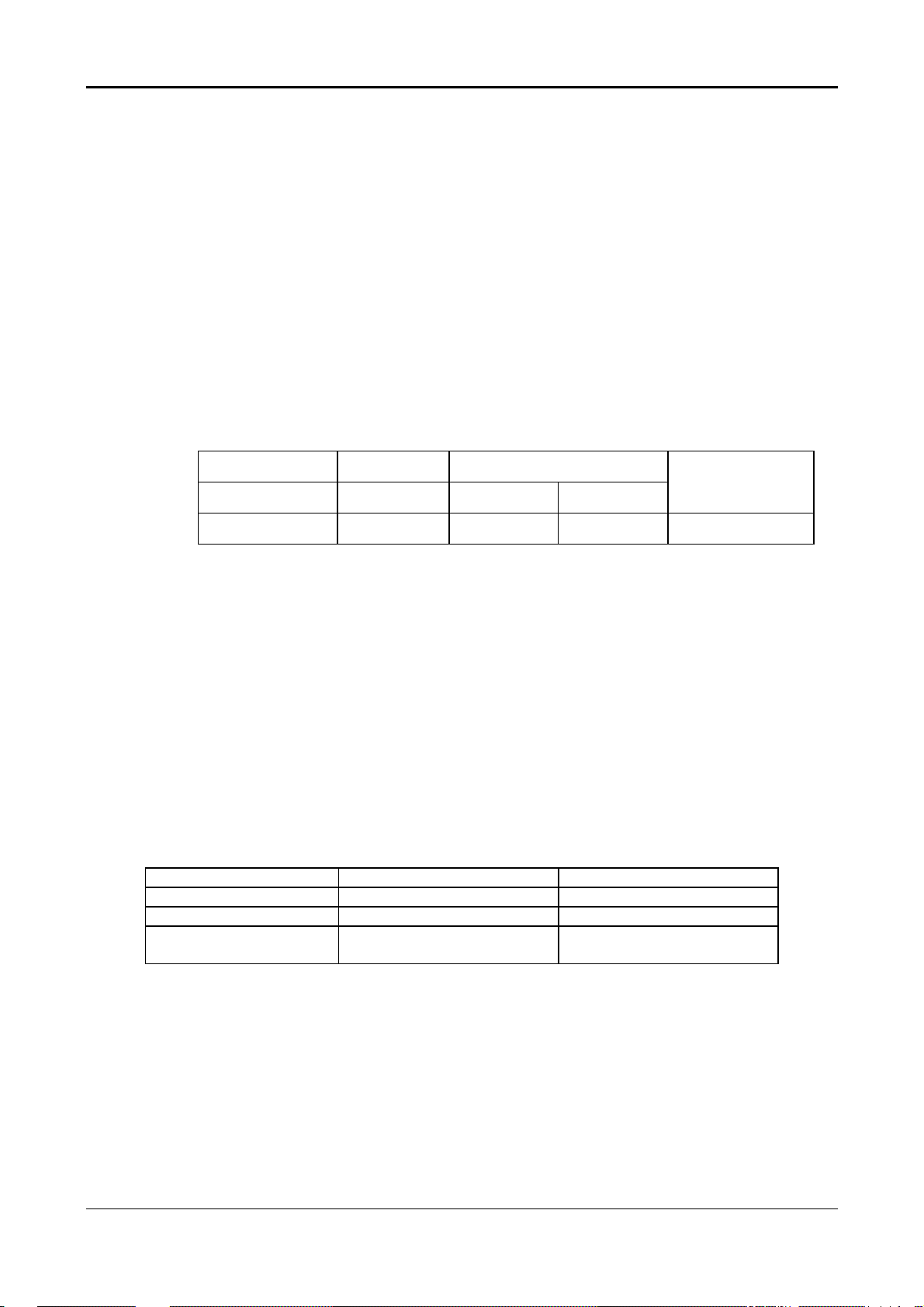

2.6 White Color Temperature

White color temperature is 4 preset as 9300, 7500,6500 and User,

Default value of user color should be user which is maximum setting for panel.

Target of color setting

Color

Temp.

9300K 0.281 0.311 +0.03 0.189 0.446 u’v’ < 0.01*

7500K 0.300 0.315 +0.03 0.194 0.459 u’v’ < 0.01*

6500K 0.315 0.325 +0.03 0.198 0.468

User - - - - -

User should follow “Microsoft Windows Color Quality Specification for Liquid Crystal Display OEM’s”.

(http://www.microsoft.com/hwd ev/tech/color/ColorTest.asp)

Color Coordinate T olerance Color Coordinate Tolerance

x y u’ v’

*) TCO’0X A.2.6.1 requirement

u’v’ <

0.01*

16

Page 17

2.7 POWER SUPPLY

2.7.1 input Voltage Range

The monitor shall operate within specification over the range of 90 to 265 VAC power supply.

2.7.2 Input Frequency Range

Input power frequency range shall be from 47.5 to 63 Hz over the specified input voltage range.

2.7.3 Quick specification review

• Input current

1.5A (max) at 90VAC input and full load ,

0.75A (max) at 264 VAC input and full load.

• Inrush current @ cold start

30A(0-peak)@ 110Vac ,50A(0-peak) @ 220Vac

(measured when switched off for at least 10 mins.)

• Output

Tolerance Output Current

Output Volt - MIN MAX

+12Vdc ±5% 0A 5A 11.4~12.6Vdc

Volt Tolerance

• Total output power: 60 Watt max.

• Withstanding voltage : 1.5Kvac or 2.2KVdc for 1 minute.

• Leakage current : < 0.25mA/100Vac , <3.5mA/230Vac

• Efficiency : 80% min. @115V/230VAC, maximum load.

2.7.4 Power Management

2.7.4.1 Meet VESA DPMS proposal

The monitor must comply with the Microsoft On Now specification, with a minimum of three power

management states, as defined by the VESA DPMS document. The front panel of the monitor must

appropriately display the DPMS state, For example:

DPMS ON : The power LED is Green

DPMS OFF : The power LED is Amber

2.7.5 Power Consumption

On mode 54 Wmax Green

Off mode 4 Wmax Amber

DC power off 4 Wmax Dark

disconnection 4 Wmax

Power saving states are measured with speakers attached but not worked.

The recovery time from stand by /suspend/off mode to on mode is 3 seconds maximun.

Dark (DC power off)

Amber (DC power on)

2.7.6 Power Connector

All units shall have an IEC/CEE-22 type male power receptacle.

2.8 Plug & Play(EDID)

The monitor will be capable of sending a VESA standardized EDID file through the DDC (pins 12,

15 of the VGA connector).

17

Page 18

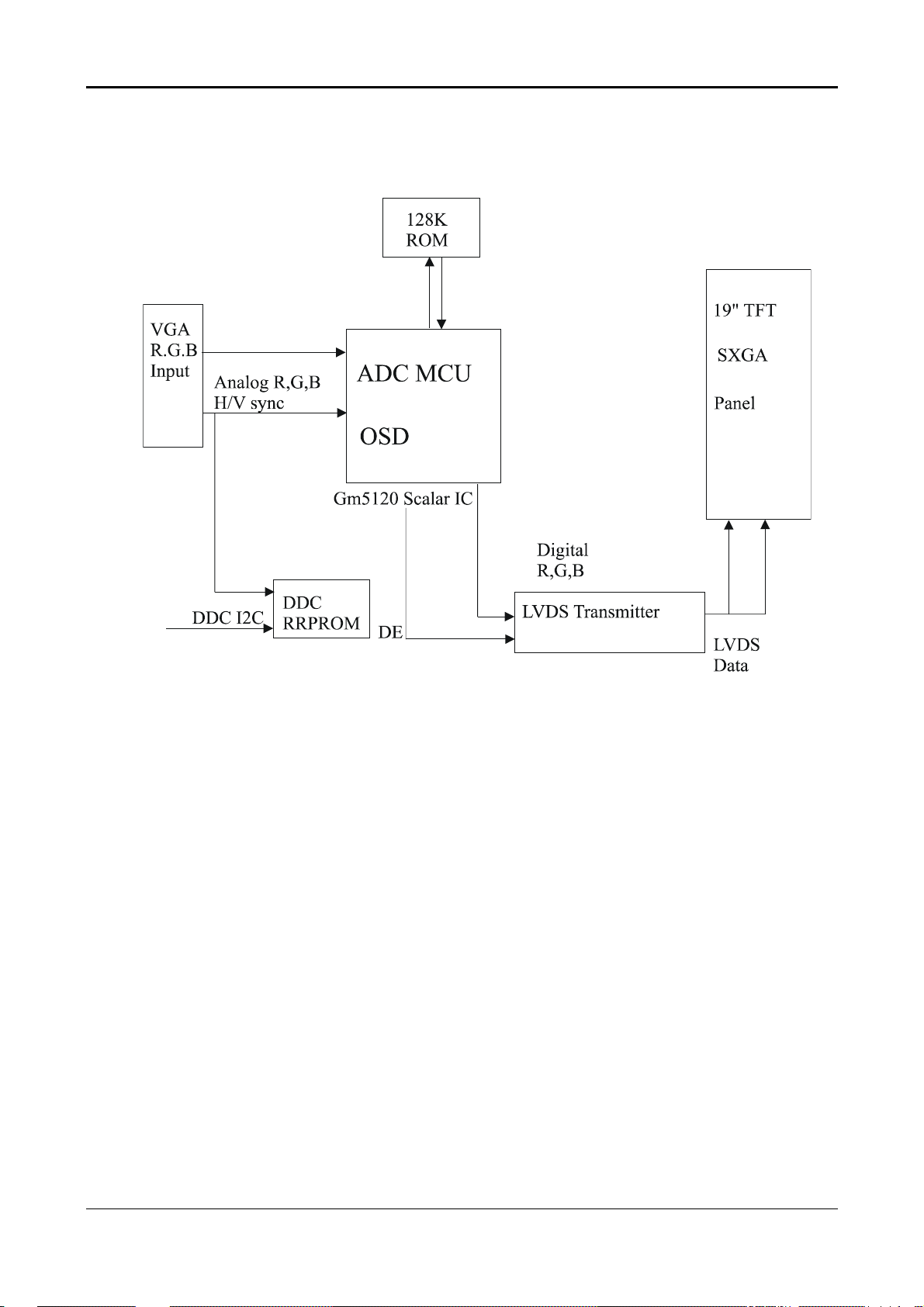

3. VL-901 DISPLAY CONTROL BOARD

3.1 Description

The VL-901 display control board is design to directly convert the analog RGB signals from

standard VGA display card to optimum LCD timing signals so as to construct a high display

quality LCD monitor.

3.2 Features

•

On board embedded micro-processor to detect display timings and control user

functions.

• Using Genesis gm5120 design to generate optimum LCD timings.

• Using E

2

PROM to memorize every adjusted parameter.

• support up to 22 display modes from VGA to SXGA.

• Offer full screen expansion function on non-SXGA mode (automatic).

• flexible color temperature selection function including 9300,6500,7500 and user

mode.

• Support OSD functions.

• Support VESA DPMS function.

• Support DDC2B functions.

• Support 5 languages for OSD description.

• The longest time for mode change is 3 seconds.

18

Page 19

3.3 BLOCK DIAGRAM

19

Page 20

3.4 Connector Locations

3.5 Connector Type

Location Type Maker Number of pins

CN1 74320-4004 MOLEX 24

CN2 1211-15 E&T 15

CN4 6905-40 E&T 40

J1 4300-10 E&T 10

J2 4500-07 E&T 07

3.6 Connector pin assignment

3.6.1 CN2

Pin NO. Signal Comment

1 R-Video Red Video Input.

2 G-Video Green Video Input.

3 B-Video Blue Video Input.

4 N. C.

5 Ground Ground.

6 Ground Ground.

7 Ground Ground.

8 Ground Ground

9 5VCC DDC Power Input.

10 PCDETECT PCDETECT Input.

11 NC NC

12 SDA DDC 2B

13 HS Horizontal Sync Input.

14 VS Vertical Sync Input.

15 SCL DDC 2B

20

Page 21

3.6.2 CN4

Terminal No. Symbol Function

36,37,38 VDD 5V POWER SUPPLY

1 TXE0- LVDS EVEN OUTPUT DATA PAIRS

2 TXE0+ LVDS EVEN OUTPUT DATA PAIRS

4 TXE1- LVDS EVEN OUTPUT DATA PAIRS

5 TXE1+ LVDS EVEN OUTPUT DATA PAIRS

7 TXE2- LVDS EVEN OUTPUT DATA PAIRS

8 TXE2+ LVDS EVEN OUTPUT DATA PAIRS

10 TXECLK- LVDS EVEN OUTPUT DATA PAIRS

11 TXECLK+ LVDS EVEN OUTPUT DATA PAIRS

13 TXE3- LVDS EVEN OUTPUT DATA PAIRS

14 TXE3+ LVDS EVEN OUTPUT DATA PAIRS

16 TXO0- LVDS ODD OUTPUT DATA PAIRS

17 TXO0+ LVDS ODD OUTPUT DATA PAIRS

19 TXO1- LVDS ODD OUTPUT DATA PAIRS

20 TXO1+ LVDS ODD OUTPUT DATA PAIRS

22 TXO2- LVDS ODD OUTPUT DATA PAIRS

23 TXO2+ LVDS ODD OUTPUT DATA PAIRS

25 TXOCLK- LVDS ODD OUT PUT DATA PAIRS

26 TXOCLK+ LVDS ODD OUTPUT DATA PA IRS

28 TXO3- LVDS ODD OUTPUT DATA PAIRS

29 TXO3+ LVDS ODD OUTPUT DATA PAIRS

03,06,09, 12 GND Ground

15, 18, 21, 24 GND Ground

27, 30, 34, 35 GND Ground

39,40 GND Ground

3.6.3 J2

Pin NO. Signal Comment

1,2 5 VCC 5V Power Input

3,4,5 GND GND

6 BLON Bright Light ON/OFF.

7 BRIGHT Brightness Adjustment.

21

Page 22

3.6.4 J1

Pin NO. Signal Comment

1 NC NC

2 LED-Y Power saving mode

3 LED-G Monitor is ON

4 GND GND

5 KEY-POWER Power ON/OFF key

6 KEY-DOWN Function select counter-clockwise key

7 KEY-R Adjust up key

8 KEY-L Adjust down key

9 KEY-UP Function select counter-clockwise key

10 GND GND

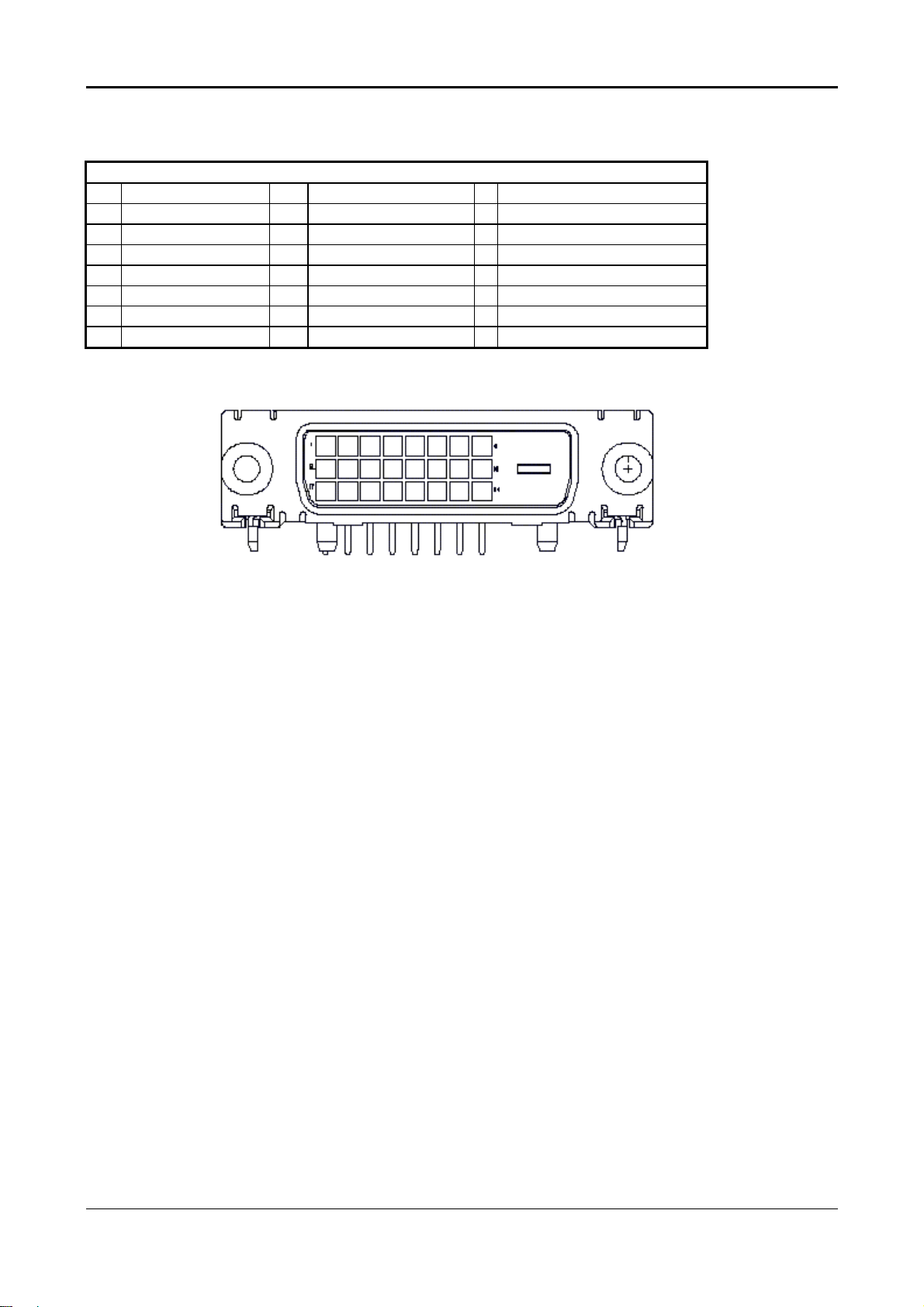

3.6.5 CN1 Digital Video input Connector: DVI-D

Pin-Assignment of DVI-D(24 pin) connector

1 TX2- 9 TX1- 17 TX02 TX2+ 10 TX1+ 18 TX0+

3 Shield (TX2 / TX4) 11 Shield (TX1 / TX3) 19 Shield (TX0 / TX5)

4 NC 12 NC 20 NC

5 NC 13 NC 21 NC

6 DDC-Serial Clock 14 -5V Power *) 22 Shield (TXC)

7 DDC-Serial Data 15 Ground (+5V) 23 TXC8 No Connect 16 Hot plug detect 24 TXC+

*)In case, the power of the PC unit is switched off and the power the monitor is switched

on, no voltage may occur at pin 14.

22

Page 23

4. VK901 Control Panel Board

4.1.1 Description

The VK-901 is designed to offer a user interfaced control panel which passes and receives

signals to and from VL-901 display control board.

4.1.2 Connector and Switch Locations

4.1.3 Connector type

Location Type Maker Number of pins

J1 4500-10 E&T 10

4.1.4 Connector pin Assignment

4.1.5 J1

Pin NO. Signal Comment

1 NC NC

2 LED-Y Power saving mode

3 LED-G Monitor is ON

4 GND GND

5 KEY-POWER Power ON/OFF key

6 KEY-DOWN Function select counter-clockwise key

7 KEY-R Adjust up key

8 KEY-L Adjust down key

9 KEY-UP Function select counter-clockwise key

10 GND GND

4.1.6 Switch definition

Location Definition

S5 Power ON/OFF

S1 Function select by clockwise direction

S4 Function select by counter-clockwise direction

S3 Adjust up

S2 Adjust down

4.1.7 LED definition

Location Definition

D1 Green for ON mode; Yellow for OFF mode; yellow for Power Saving

mode; Dark for DC power OFF mode.

23

Page 24

5. INVERTER BOARD

5.1 Description

The Inverter board is designed for lighting up the back-lights of LCD module.

5.2 Electrical characteristics

5.2.1 FOR Fujitsu PANEL FLC48SXC8V

MIN. TYP. MAX. COMMENT

INPUT VOLTAGE 11.4V 12.0V 12.6V 12V±5%

INPUT CURRENT -------- 2A _

Normal BACKLIGHT

VOLTAGE

LAMP CURRENT

DRIVING

FREQUENCY

EFFICIENCY -------- 80% --------

Vin ON/OFF sequence -------- 1s --------

OLP TIME -------- 3S _

BRIGHTNESS

RANGE

Brightness control 0V _ 3.3V

Brightness _ 220cd/m

Strike voltage at 0°C 1600 Vrms _ _

Operating life time 20,000 hrs _ _ (note)

Note:

-------- 700V rms. --------

--------. 7mA rms 8mA rms

KHz 50KHZ KHz

10% -------- 100%

2

_

Vin=12V,

Vbrite=3.3V

Total two lamps for

Unipac

Vin = 12V,max

brightness

Open lamp

protection time

0V, brightness

Life time (hr) can be defined as the time in which it continues to operate under the condition:

Ta=25±2°C, IL =7 mArms until one of the following event occurs:

1. When the brightness becomes 50 %

2. When the startup voltage (Vs) at 0°C becomes higher than the maximal value of Vs specified above.

24

Page 25

5.3 Connector locations

5.3.1 Connector type

J2 J1

J3 J4

CM999-E04

Location Type Maker Number of pins

JN2, JN3, SM02 (8.0)B-BHS ST 2

JN4, JN5

JN1 85205-1200 E&T 12

5.3.2 Connector pin assignment

5.3.2.1 J2,J3,J4,J5

Pin NO. Signal Comment

1 HV High voltage for lamp

J5

5.3.2.2 JN1

Pin NO. Signal Comment

3.3 V for max. brightness (for Fujitsu model)

3 LV Low voltage (common)

1, 2, 3,4 BP+ +12V

7 BLT_ON Back-light ON/OFF control, high active (3.3V)

5, 6, 10, 11, 12 GND

8 +5VS +5VS

9 BRITE BRITE Brightness (0-3.3V) control from I/F

25

Page 26

6. DC/DC POWER and Audio CKT VM-902

6.1 Input:

+12V/5A from AC adapter

6.2 Output:

ITEM Output Voltage Max Load. Min Load Tolerance Ripple & Noise(max)

VCC +5V 2.1A 0.1A ±5 % 200mVpp

6.3 Efficiency: 80 % min at Maximum Load.

6.4 Connector Locations

6.4.1 Connector type for VM-902

Location Type Maker Number of pins

J801 DC-IN SC 2

J802 4500-12 E&T 12

J803 4500-07 E&T 7 (for LCM999 only)

J2 4500-11 E&T 11

6.4.2 Connector pin Assignment

6.4.3 J801 DC 12V Input

Pin No Signal Comment

Pin 1 +12V From adapter output cable

Pin 2 GND From adapter output cable

26

Page 27

6.4.3.1 J802 FOR I/F CKT

Pin No Signal Comment

Pin 1,2,3,4 +12V From adapter +12V power

Pin

5,6,10,11,12

GND GND

Pin 8 +5V Supply for I/F CKT

Pin 7 ON/OFF

Pin 9 BRIGHT

6.4.3.2 J803 FOR M/B CKT

Pin No Signal Comment

Pin 1,2 +5V For M/B +5V power

Pin 3,4,5 GND GND

Pin 6 BLON Bright Light On/ Off

Pin 7 BRIGHT Brightness Adjustment

6.4.3.3 J3 FOR Audio input(for CM999 only)

Pin No Signal Comment

Pin 1 GND GND

Pin 2 Audio IN (1) From Audio output (1)

Pin 3 Audio IN (2) From Audio output (2)

ON/OFF Control ON>3.0V OFF <2.0V

Lamp Current Control (0V to 3.3V) ,

3.3V for max brightness

6.4.3.4 J2 TO Speaker CKT(for CM999 only)

Pin No Signal Comment

Pin 1 VOL Volume ON/OFF control

Pin 2 GND GND

Pin 3 RIN1 Audio volume adjust line INR

Pin 4 LIN1 Audio volume adjust line INL

Pin 5 RIN2 Audio volume a djust line OUTR

Pin 6 LIN2 Audio volume adjust line OUTL

Pin 11 GND

Pin 7 R-EAR EAR phone out R

Pin 8 L-EAR EAR phone out L

Pin 9 ROUT Speaker out R

Pin 10 LOUT Speaker out L

27

Page 28

7. TROUBLESHOOTING

7.1 Main Procedure

28

Page 29

7.1.1 Power Circuit Troubleshooting

29

Page 30

7.1.2 Backlights Troubleshooting

30

Page 31

7.1.3 Performance Troubleshooting

31

Page 32

7.1.4 Function Troubleshooting

32

Page 33

8. MECHANICAL REQUIREMENTS

8.1 Vibration and Shock

All testing shall be done in each of three mutually perpendicular axes, referenced to the

position of the system as it is in front of the user (i.e., front-to back, side-to-side, and top-tobottom).

8.1.1 Non-Operating

The unit should suffer minimal visible cosmetic damage or damage that presents a safety

hazard, or impairs the setup and operation of the system after testing.

Sinusoidal Vibration: 0.75 G zero-to-peak, 10 to 500Hz, 0.5 octave / minute sweep rate.

This requires one sweep, 10 to 500 to 10Hz, along each of the three axes.

Random Vibration: 0.008 G

one hour for each of the three axes.

Half Sine Wave Shock: 120 G peak, half sine pulse, 2 ms pulse duration. Testing shall

consist of one shock in each direction in each axis, for a total of 6 shock inputs.

Square Wave Shock: 40 G peak acceleration, 160 inches / second velocity change. There

shall be one shock in each direction in each axis, for a total of 6 shock inputs.

2

/Hz, 10 to 500 Hz, nominal 2 GRMS. The test shall be for

8.2 Package Drop Specification

Listed below are standards of drop heights for monitor product

Product Weight height Specs

<9.1 kg 0.76 m

9.2~18.2 kg 0.66 m

18.3~27.2 Kg 0.61 m

27.3~45.4 Kg 0.46 m

8.2.1 Drop Test Sequence

Drop Order Drop point Drop Times

1 Right Front Bottom Corner 1

2 Right Bottom Edge 1

3 Right Front Edge 1

4 Front Bottom Edge 1

5 Bottom Side 1

6 Top Side 1

7 Front Side 1

33

Page 34

8 Back Side 1

9 Left Side 1

10 Right Side 1

8.3 Dimension Size and Weight

Dimension size 433 (W) x 447 (H) x 235 (D)

Net Weight 6.5Kg

Gross Weight 8.5Kg

34

Page 35

8.4 Gap Spec.

8.4.1 The step between front bezel and back cover shall be within specification.

Back Cover & Bezel Gap

0.8 mm ≤ A ≤ 1.2 mm

Back Cover & Bezel Alignment

0 mm ≤ D ≤ 0.8 mm

Back Cover & Cable Cover Gap

0.8 mm ≤ B ≤ 1.2 mm

35

Page 36

Back Cover & Cable Cover Gap

0.8 mm ≤ B ≤ 1.2 mm

36

Page 37

Base Cover & Neck Cover Gap

0.8 mm ≤ C ≤ 1.2 mm

8.4.2 LCD Horizontally

The angle between front bezel and LCD unit in bottom side should not be larger than 1.0mm.

37

Page 38

The distance of the LCD display unit from left side to right should not be larger than

E - F<=4.0mm.

Tilt Base Rotation

Tilt up 25 ± 1°/ down 5 ±1°

8.5 Swivel Base Rotation

Swivel Right 45 ±1° / Left 45 ±1°

8.6 Plastic Material

Front Bezel ABS 94HB, 94V-0

Back Cover ABS 94HB, 94V-0

The Others ABS 94HB

TCO’ 99(Optional)

Front Bezel PC + ABS 94 - V0

BACK COVER PC + ABS 94 – V0

The others ABS 94 HB

38

Page 39

8.7 GAP Spec.

Gap between panel with bezel is 0 mm < gap < 1.5 mm

CM999

9. Power Line Transient Test (IEC 61000-4-4 Fast Transients/Burst)

TEST CONDITIONS & PROCEDURE: (Follow IEC 61000-4-4)

Test Condition :

The condition is based on operating with 50Ω load.

39

Page 40

9.1 Peak Voltage:

2 KV (applies the Level 3 typical Industrial Environment” of IEC

61000-4-4)

9.2 Polarity : + / -

9.3 Repetition Frequency of the impulse : 5 KHz.

±±±±

9.4 Rise-Time : 5ns

30%

9.5 Impulse Duration: 50 nS

±±±±

30%

9.6 Relation to Power Supply: Asynchronous

±±±±

9.7 Burst Duration: 15 ms

9.8 Burst Period: 300 ms

20%

±±±±

20%

9.9 Climatic Conditions:

- Ambient Temperature: 15°C to 35°C

- Relative Humidity: 45% to 75%

- Atmospheric Pressure: 86 kPa to 106 kPa

9.10 Test Procedure:

The monitor Display set high-resolution mode, AC input use AC 240V.

Note :

9.10.1

IEC 61000-4-4 defines that power supply, I/O line, and control line all shall be performed

the transient test, but the I/O line and control line is applied with only half of peak voltage

(1 KV).

9.10.2

For the comparison of wave-shape generated by different generator, so the test must uses

a scope with at least 400 MHz bandwidth, and coupled to 50

impulse, duration, and repetition rate of the impulses within one burst.

40

Ω

to monitor the rise-time,

Page 41

WAVESHAPE

41

Page 42

10. Power Line Surge Test (IEC 61000-4-5 Surge)

10.1 Climatic Condition

The climatic conditions shall be within the following ranges:

10.1.1 Ambient Temperature: 15

10.1.2 Relative Humidity: 10% to 75%

10.1.3 Atmospheric Pressure 86kPa(860 mbar)to 106kPa (1060mbar)

Note: The temperature and relative humidity should be recorded in the test report.

°°°°

C to 35

°°°°

C

10.2 Test Conditions:

10.2.1 Wave-shape of the current surge: (refer to IEC 61000-4-5)

Open circuit voltage: (1.2 / 50 µs)

Short circuit current: (8 / 20 µs)

10.2.2 Polarity: positive / negative

10.2.3 Phase shifting:in a range between 0º to 270º versus the AC line phase angle

10.2.4 Repetition rate:at least 1 per minute

10.2.5 Number of tests: at least 5 positive and 5 negative at the selected points.

10.3

The surge will be applied between lines and between lines and ground.

10.4

If not otherwise specified, the surge to power supply circuits shall be applied synchronized

to the voltage phase at the zero crossing and the peak value of the AC voltage wave.

(Positive and negative)

10.5

The surge voltage for test is from 1 KV and increases 1 kV for each step.

10.6

The recommended severity levels for the surge voltage test is 2.0 KV, and without any

degradation or loss of function that is not recoverable due to damage of component or

software allowed.

10.7 Display set high-resolution mode, AC input use AC 240V.

42

42

Page 43

11. ENVIRONMENTAL REQUIREMENTS

11.1 Operating

Temperature 5°C ~ 40°C

Relative Humidity 20% to 80%

Altitude Sea level to 8000ft

11.2 Storage or Shipment

Temperature -20°C ~ +60°C

Relative Humidity 5% to 85%

Altitude Sea level to 40,000ft

11.2.1 TEST PROCEDURE:

• Put in temperature chamber under 60°C Time:24 hours

• Back to room temperature Time: 4 hours

• Put in temperature chamber under -20°C Time:24 hours

• Back to room temperature Time:4 hours

• The process repeat 2 times.

43

Page 44

12. REGULATION COMPLIANCE

12.1 This product comply to the most current revisions of following regulations:

UL/CUL

{UL 1950/ CSA C22.2 NO950}

EN 60950/CB Scheme Safety of Information Technology Equipment including Electrical

MPR 1990:8 Test methods for visual display units.

MPR 1990:10 User handbook for evaluation visual display units.

ISO 9241-3: Ergonomic requirements for office work with visual display terminals

ISO 9241-7: Ergonomic requirements for office work with visual display terminals

ISO 9241-8: Ergonomic requirements for office work with visual display terminals

NUTEK/EPA Requirements of power saving according to NUTEK Spec.

TCO 1999 (option) Requirements for Environmental Labeling of Personal Computers.

TUV/GS Safety regulation for displays work places in the office sector.

FCC 47 CFR, Chapter 1,

Subchapter A, Part 15, Subpart B

Standard fo r Safety of Information Technology Equipment including

Electrical Business Equipment

Business Equipment

(VDTs)-Visual display requirements.

(VDTs)-Requirements for display with reflections.

(VDTs)-Requirements for displayed colours.

803299/94/96, EPA Energy star.

Test methods for Ergonomic, Emission, Energy Efficiency, safety.

A digital device that is marketed for use in a residential environment

not withstanding use in commercial, business and industrial

environments.

CISPR 22 Limits and methods of measurements of radio interference

characteristics of information technology equipment.

CE LVD Directive (73/23/EEC) Safety: EN60950

CE EMC Directive (89/336/EEC)

IEC 61000-4

VCCI (option) Specification for limits and methods of measurement of radio

BSMI (option)

EMI: EN55022 class B

Harmonics: EN61000-3-2

Voltage Fluctuation/Flicker: EN61000-3-3

Immunity: EN55024

IEC 61000-4-2 Electrostatic Discharge

IEC 61000-4-3 Radiated Electromagnetic Field

IEC 61000-4-4 Fast Transients/Burst

IEC 61000-4-5 Surge

IEC 61000-4-6 Conducted Disturbance, Induced by Radio

Frequency Fields

IEC 61000-4-8 Power Frequency Magnetic Field

IEC 61000-4-11 Voltage DIP/Interruption

interference characteristics of information technology equipment.

Class B conformity verification report from the VCCI

CNS 13438, Class B

44

Page 45

12.2 Electrostatics Discharge (ESD)

E.S.D Test

This test follow the IEC 61000-4-2

Discharge Voltage Level :

Criteria Contact Discharge (KV) Air Discharge(KV)

Class C ±4 ±4

Class B ±6 ±8

Class A ±8 ±15

Class A : Temporary degradation or loss of function or performance which requires

operator Intervention or system reset.

Class B : Temporary degradation or loss of function or performance which is self-

recoverable

Class C : Normal performance within the specification limits

Discharge times: 20 times for each discharge point, time interval 1 second.

In the case of acceptance tests, the test program and the interpretation of the test results are

subject to

agreement between manufacturer and user.

The test documentation shall include the test conditions and the test results.

45

Page 46

Ambient temperature : 15°C to 35°C

Relative humidity : 30% to 60%

13. QUALITY AND RELIABILITY

13.1 QUALITY ASSURANCE

Unless otherwise specified in this specification or the applicable purchase order, the supplier shall

be responsible for maintaining a statistical process program or performing inspections that are

sufficient to assure that the parts supplied meet the requirements specified herein.

13.2 RELIABILITY

The product shall have a designed MTBF of greater than 20,000 hours during its useful life.

46

Page 47

Appendix A: PCBA Assembly

47

Page 48

DC-JACK +12V

J801

2

1

104 50V CC5D

C801

L801

BEAD/DIP

104 50V/CC5D

C804

+12V

SI8051S/DIP/TO-220

1

VI

U801

3

CM999 P/B - I/B

H-CON SET

J802

1

2

3

4

5

6

7

10

11

12

J802

10

11

12

8

9

1

2

3

4

5

6

7

8

9

CM988 P/B - I/B

(PIN to PIN)

H-CON-SET

+12V

C802

104 50V CC5D

2

GNDSWVSVEN

45

D803

SB140

1 2

+

C803

470U/16V LOW-ESR

L802

56UH/DIP

D804

SB140

1 2

ZD801

6.2B

+

C810

1000U/10V

+5V

BLKON

C805

104 50V/CC5D

J802

1

2

3

4

5

6

7

8

9

10

11

12

E&T_98115-1203/DIP/2.0mm

E&T_4500-12/DIP/2.0mm

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

J803

1

2

3

4

5

6

7

E&T_98115-1003/DIP/2.0mm

E&T_4500-07/DIP/2.0mm(CM999)

E&T_4500-10/DIP/2.0mm (CM988)

J803

1

2

3

4

5

6

7

8

9

10

<>

BRIGHTNESS

+5V

BLK_on_off

BRIGHTNESS

Bri_ADJ

No. 0533

Audio and D/D

48

HITACHI

Page 49

LVDS_IF

ER[0..7]

EG[0..7]

EB[0..7]

OR[0..7]

OG[0..7]

OB[0..7]

DVS

DHS

DEN

DCLK

LVDS_EN

LCDON

LVDS_EN

RED+

RED-

GREEN+

GREEN-

BLUE+

BLUE-

RXC+

RXCRX2+

RX2-

RX1+

RX1-

RX0+

RX0-

HS

VS

DDC_SCL

DDC_SDA

HCLK

HFSn

SCL

SDA

PCDETECTA

PCDETECTD

RED+

REDGREEN+

GREENBLUE+

BLUE-

RXC+

RXCRX2+

RX2RX1+

RX1RX0+

RX0-

HS

VS

DDC_SCL

DDC_SDA

HCLK

HFSn

SCL

SDA

gm5115

ER[0..7]

EB[0..7]

RED+

REDGREEN+

GREEN-

BLUE+

BLUE-

RXC+

RXC-

RX2+

RX2RX1+

RX1-

RX0+

RX0-

HSYNC

VSYNC

DDC_SCL

DDC_SDA

HCLK

HFSn

SCL AUDIO_ON

SDA

PCDETECTA

PCDETECTD

LVDS_EN

OR[0..7]

OG[0..7]

KEY DOWN

KEY RIGHT

KEY UP

KEY LEFT

KEY ONOFF

EG[0..7]

OB[0..7]

DVS

DHS

DEN

DCLK

LED_Y

LED_G

ER[0..7]

EG[0..7]

EB[0..7]

OR[0..7]

OG[0..7]

OB[0..7]

DVS

DHS

DEN

DCLK

GPIO8/IRQINn

GPIO21/IRQn

GPIO7

GPIO6

GPIO3/TIMER1

GPIO2/PWM2

GPIO1/PWM1

6. LVDS_IF

Display

ER[0..7]

EG[0..7]

EB[0..7]

OR[0..7]

OG[0..7]

OB[0..7]

DVS

DHS

DEN

DCLK

AUDIO_ON

LED_Y

LED_G

KEY DOWN

KEY RIGHT

KEY UP

KEY LEFT

KEY ONOFF

Power

3. Input Connectors

No. 0533

4. gm5115

PPWR

PBIAS

BRI_ADJ

LCDON

BLKON

GPIO0/PWM0

Ctrl/B VL-901 - VGA Input - 1

49

PPWR

5. Display

PBIAS

BRI_ADJ

7. Power

HITACHI

Page 50

CN1

Shell

Shell

DDC_5V

DVI-D

RX2-

RX2+

GND

RX4-

RX4+

SCL

SDA

VS

RX1-

RX1+

GND

RX3-

RX3+

5V

GND

HP

RX0-

RX0+

GND

RX5-

RX5+

GND

RXC+

RXC-

RED

GRN

BLU

HS

GND

D3 EC10QS04

D4 EC10QS04

D5 EC10QS04

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

C1

C2

C3

C4

C5

GND

SCL_IN

SDA_IN

DVI_5V

L8 STC222B

STS2125

R1 10K

HOT_PLUG

DVI_5V

12

VGA_5V

12

+5V

12

PCDETECTD

R5 100

R6 100

D1

5.6V

GND

DDC_5V

GND

GND

C1

0.1uF

1

2

3

4

U1

NC

NC

NC

GND

24LC21A

VCC

VCLK

SCL

SDA

R4

47K

8

7

6

5

R2

R3

47K

47K

D2

5.6V

1 3

1 3

RX2- SHT-4

RX2+ SHT-4

RX1- SHT-4

RX1+ SHT-4

RX0- SHT-4

RX0+ SHT-4

RXC+ SHT-4

RXC- SHT-4

DDC_SCL SHT-4

DDC_SDA SHT-4

GND

1

2

3

4

DDC_5V

C2

R7

0.1uF

47K

GND

U2

NC

NC

NC

GND

24LC21A

8

VCC

7

VCLK

6

SCL

5

SDA

3.3V_DVDD

VGA_BLU VGA_GRN

PCDETECTA

R8

R9

47K

47K

D6

D7

5.6V

5.6V

1 3

1 3

GND

NC/ZD1 DALC208SC6

1

6

52

3

4

GND

VGA_RED

VGA_SDA

VGA_SCL

HCLK SHT-4

HFSn SHT-4

R12 100

R15 100

Hsync

CN2

11

12

13

14

15

VGA

Pins 6/7/8 are R/G/B

return lines resp.

Vsync

GND

VGA_5V

C101

0.1uF

S1S2

1

6

2

7

3

8

4

9

5

10

PCDETECTA

GND

VGA_RED

VGA_GRN

VGA_BLU

PCDETECTA

GND

R23

510

R18

75

GND

R21 100

R22 100

C10

220pF

C3 0.01uF

C4 0.01uF

C5 0.01uF

C6 0.01uF

C7 0.01uF

C8 0.01uF

3.3V_DVDD

C120

0.1uF

GND

SN74LVC14APWR

14

U3F

13 12

7

SN74LVC14APWR

14

U3A

1 2

7

SN74LVC14APWR

14

U3E

11 10

7

SN74LVC14APWR

14

U3B

3 4

7

RED+ SHT-4

RED- SHT-4

GREEN+ S HT-4

GREEN- SHT-4

BLUE+ SHT-4

BLUE- SHT-4

VS SHT-4

IN

HS SHT-4

R10 20 1%

R11 56.2 1%

R13 20 1%

R14 56.2 1%

R16 20 1%

R17 56.2 1%

C9

220pF

R20

75

D9

5.6V

1 3

R19

75

D8

5.6V

1 3

No. 0533

Ctrl/B VL-901 - VGA Input - 2

50

HITACHI

Page 51

C11

C12

0.1uF

0.1uF

GND

GND

U5

VCCA0

SCL

SDA

22uF

6.3V

C46

22uF

6.3V

GND

GND

81

7

6

5

Reset

Circuit

C25

0.1uF

C37

0.1uF

C47

0.1uF

GND

C26

0.1uF

C38

0.1uF

C48

100pF

R24

10K

GND

U7

MCP809-300

BAV99L SIZE

+3.3V

L1

BLM21P300S C24

+2.5V 2.5V_AVDD

L3

BLM21P300S

3.3V_DVDD

C51

0.1uF

2

A1A2WP

3

4

GND

AT24C16-10SC-1.8

GND

C13

0.1uF

C27

0.1uF

C39

0.1uF

R25

10K

SCL

RMADDR[0..15]

RMADDR15

RMADDR14

RMADDR13

RMADDR12

RMADDR11

RMADDR10

RMADDR9

RMADDR8

RMADDR7

RMADDR6

RMADDR5

RMADDR4

RMADDR3

RMADDR2

RMADDR1

RMADDR0

SW1

SW PUSHBUTTON

3

VCC

2

Reset

1

GND

R30 NC/10K

R31 10K

R32 NC/10K

R33 NC/10K

R34 NC/10K

R35 NC/10K

R36 10K

R37 10K

R40 NC/10K

R41 NC/10K

R42 NC/10K

R43 NC/10K

R44 NC/10K

R45 NC/10K

R46 NC/10K

R47 NC/10K

3.3V_DVDD

GND

C14

0.1uF

C28

0.1uF

C40

0.1uF

C15

0.1uF

C29

0.1uF

C41

0.1uF

3.3V_DVDD

RM-15

RM-14

OSC-SEL

RM-A12

RM-A11

RM-A10

OCM-START

H-PORT-EN

H-PROTO

SCLPOL

RM-A5

RM-A4

RM-A3

RM-A2

RM-A1

RM-A0

/RESET

C16

0.1uF

C30

0.1uF

C42

0.1uF

C17

0.1uF

C31

0.1uF

C43

0.1uF

C18

0.1uF

C32

0.1uF

C44

0.1uF

C19

0.1uF

2.5V_VDD

A17

A16

C20

0.1uF

C33

0.1uF

C45

0.1uF

R29 NC/0

+5V

R38

10K

C34

0.1uF

3.3V_AVDD

R39

10K

R48 10K

C21

0.1uF

C35

0.1uF

C49

22pF

3.3V_DVDD

C22

0.1uF

3.3V_AVDD

C36

0.1uF

X1

14.318MHz

+5V

RMADDR15

RMADDR14

RMADDR13

RMADDR12

RMADDR11

RMADDR10

RMADDR9

RMADDR8

RMADDR7

RMADDR6

RMADDR5

RMADDR4

RMADDR3

RMADDR2

RMADDR1

RMADDR0

FLASH_OEn

3.3V_AVDD

R2810K

GND

C50

22pF

XTAL

R26

0R

/WR

U6 AT49HF/F010-45JC

31

WE

30

NC/A17

2

A16

3

A15

29

A14

28

A13

4

A12

25

A11

23

A10

26

A9

27

A8

5

A7

6

A6

7

A5

8

A4

9

A3

10

A2

11

A1

12

A0

24

OE

22

CE

32-Pin PLCC Socket

DQ7

DQ6

DQ5

DQ4

DQ3

DQ2

DQ1

DQ0

VCC

GND

CVSS

135

148

144

VDD_DPLL_3.3

VDD_SDDS_3.3

CVSS

202

123

3.3V_DVDD

22053678197111

139

RVDD

RVDD

VDD_DDDS_3.3

GND1_ADC

GND2_ADC

GND_RX2

GND_RX1

156

154

177

183

129

37

RVDD

RVDD

RVDD

RVDD

RVDD

RVDD

RVDD

DCLK

PD47/OB7

PD46/OB6

PD45/OB5

PD44/OB4

PD43/OB3

PD42/OB2

PD41/OB1

PD40/OB0

PD39/OG7

PD38/OG6

PD37/OG5

PD36/OG4

PD35/OG3

PD34/OG2

PD33/OG1

PD32/OG0

PD31/OR7

PD30/OR6

PD29/OR5

PD28/OR4

PD27/OR3

PD26/OR2

PD25/OR1

PD24/OR0

PD23/EB7

PD22/EB6

PD21/EB5

PD20/EB4

PD19/EB3

PD18/EB2

PD17/EB1

PD16/EB0

PD15/EG7

PD14/EG6

PD13/EG5

PD12/EG4

PD11/EG3

PD10/EG2

PD9/EG1

PD8/EG0

PD7/ER7

PD6/ER6

PD5/ER5

PD4/ER4

PD3/ER3

PD2/ER2

PD1/ER1

PD0/ER0

TCON_OSP

TCON_OPOL

TCON_OINV

TCON_ESP

TCON_EPOL

TCON_EINV

TCON_RSP2

TCON_RSP3

TCON_RCLK

GPIO10/TCON_ROE3

GPIO9/TCON_ROE2

TCON_ROE

GPIO4/UART_D1

GPIO5/UART_D0

GPIO13/NVRAM_SCL

GPIO12/NVRAM_SDA

GPIO21/IRQINn

GPIO21/IRQn

GPIO7/TCON_TDIV

GPIO6/TCON_SHC

GPIO3/TIMER1

GPIO2/PWM2

GPIO1/PWM1

GPIO0/PWM0

CLKOUT

Int_Test

Reserved

Reserved

GND_RX0

VSS_DPLL

VSS_SDDS

VSS_DDDS

189

147

143

138

+3.3V

DEN

DVS

DHS

BLM21P300S

118

115

117

116

110

109

108

107

106

105

104

103

102

101

100

99

96

95

94

93

92

91

90

87

86

85

84

83

80

79

78

77

76

75

74

73

72

71

70

69

66

65

64

63

62

61

60

59

58

57

56

55

119

120

121

122

123

124

125

126

127

49

48

128

44

45

52

51

39

4

47

46

43

42

41

40

201

200

N/C

142

N/C

132

131

L2

R63 0

R65 0

R64 0

OB7

OB6

OB5

OB4

OB3

OB2

OB1

OB0

OG7

OG6

OG5

OG4

OG3

OG2

OG1

OG0

OR7

OR6

OR5

OR4

OR3

OR2

OR1

OR0

EB7

EB6

EB5

EB4

EB3

EB2

EB1

EB0

EG7

EG6

EG5

EG4

EG3

EG2

EG1

EG0

ER7

ER6

ER5

ER4

ER3

ER2

ER1

ER0SDA

LVDS_EN

RXD

TXD

GPIO13/NVRAM_SCL

GPIO12/NVRAM_SDA

GPIO8/IRQINn

GPIO21/IRQn

GPIO7

GPIO6

GPIO3/TIMER1

GPIO2/PWM2

GPIO1/PWM1

GPIO0/PWM0

GND

DCLK SHT-5,6

DEN SHT-5,6

DVS SHT-5,6

DHS SHT-5,6

OB[0..7] SHT-5,6

OG[0..7] SHT-5,6

OR[0..7] SHT-5,6

EB[0..7] SHT-5,6

EG[0..7] SHT-5,6

ER[0..7] SHT-5,6

LVDS_EN

AUDIO_ON SHT- 5

SCL SHT-3

SDA SHT-3

LED_Y SHT-5

LED_G SHT- 5

KEY DOWN

KEY RIGHT

KEY ONOFF SHT-5

KEY LEFT SHT-5

KEY UP SHT -5

BRI_ADJ SHT-5

SHT-5

SHT-5

SHT-5

2.5V_VDD

3.3V_AVDD

2.5V_AVDD

3.3V_DVDD

R66

R67

10K

10K

GND

PPWRSHT-5

PBIASSHT-7

TCLK

PCDETECTASHT-3

PCDETECTDSHT-3

HFSnSHT-3

HCLKSHT-3

DDC_SCLSHT-3

DDC_SDASHT-3

RED+SHT-3

RED-SHT-3

GREEN+SHT-3

GREEN-SHT-3

BLUE+SHT-3

BLUE-SHT-3

HSYNCSHT-3

VSYNCSHT-3

RXC+SHT-3

RXC-SHT-3

RX2+SHT-3

RX2-SHT-3

RX1+SHT-3

RX1-SHT-3

RX0+SHT-3

RX0-SHT-3

RMDATA7

21

RMDATA6

20

RMDATA5

19

RMDATA4

18

RMDATA3

17

RMDATA2

15

RMDATA1

14

RMDATA0

13

+5V+5V

1

NC

32

16

GND

3.3V_DVDD

RMDATA[0..7]

LCDON

BLKON

TCLK

XTAL

A17

A16

/RESET

R27 1K

RMADDR15

RMADDR14

RMADDR13

RMADDR12

RMADDR11

RMADDR10

RMADDR9

RMADDR8

RMADDR7

RMADDR6

RMADDR5

RMADDR4

RMADDR3

RMADDR2

RMADDR1

RMADDR0

RMDATA7

RMDATA6

RMDATA5

RMDATA4

RMDATA3

RMDATA2

RMDATA1

RMDATA0

ROM_OEn

gm5115 Family

+5V

C52

0.1uF

GND

PQFP208

141

146

150

173

181

187

193

196

164

168

172

160

199

175

178

184

190

197

198

157

158

161

165

169

149

145

140

113

114

152

151

206

207

208

205

204

171

170

167

166

163

162

137

136

159

194

195

179

180

185

186

191

192

174

1%

U4

AVDD_DDDS

AVDD_SDDS

AVDD_RPLL

AVDD_IMB

AVDD_RX2

AVDD_RX1

AVDD_RX0

AVDD_RXC

AVDD_BLUE

AVDD_GREEN

AVDD_RED

AVDD_ADC

VDD_RXPLL_2.5

AGND_IMB

AGND_RX2

AGND_RX1

AGND_RX0

AGND_RXC

AGND_RXPLL

SGND_ADC

AGND_ADC

AGND_BLUE

AGND_GREEN

AGND_RED

AVSS_RPLL

AVSS_SDDS

AVSS_DDDS

PPWR

PBIAS

TCLK

XTAL

GPIO20

GPIO19

GPIO18

1

GPIO17

GPIO16/HFSn

GPIO22/HCLK

6

DDC_SCL

7

DDC_SDA

5

RESETn

50

GPIO11/ROM_WEn

RED+

REDGREEN+

GREENBLUE+

BLUEHSYNC

VSYNC

ADC_TEST

RXC+

RXCRX2+

RX2RX1+

RX1RX0+

RX0-

REXT

8

ROM_ADDR15

9

ROM_ADDR14

10

ROM_ADDR13

11

ROM_ADDR12

12

ROM_ADDR11

13

ROM_ADDR10

14

ROM_ADDR9

15

ROM_ADDR8

16

ROM_ADDR7

17

ROM_ADDR6

18

ROM_ADDR5

19

ROM_ADDR4

22

ROM_ADDR3

23

ROM_ADDR2

24

ROM_ADDR1

25

ROM_ADDR0

28

ROM_DATA7

29

ROM_DATA6

30

ROM_DATA5

31

ROM_DATA4

32

ROM_DATA3

33

ROM_DATA2

34

ROM_DATA1

35

ROM_DATA0

36

ROM_OEn

153

VDD2_ADC_2.5

3.3V_A

AGND

RVSS

RVSS

RVSS

3213854688298

GND

155

176

182

188

VDD_RX2_2.5

VDD_RX1_2.5

VDD_RX0_2.5

VDD1_ADC_2.5

RVSS

RVSS

RVSS

RVSS

112

TXD

RXD

2688134

203

CVDD_2.5

CVDD_2.5

CVDD_2.5

CVDD_2.5

RVSS

RVSS

CVSS

CVSS

CVSS

13089133

27

NC/CN3 E&T 96113-0512

4

No. 0533

Ctrl/B VL-901 - VGA Input - 3

51

HITACHI

Page 52

SHT-4

SHT-4

SHT-4

KEY UP

KEY LEFT

KEY ONOFF

KEY RIGHTSHT-4

KEY DOWNSHT-4

3.3V_DVDD

R50

470

C53

0.1uF

GND

R51

470

C54

0.1uF

R52

470

C55

0.1uF

R53

470

C56

0.1uF

R54

470

R72 100

R73 100

R71 100

R74 100

R75 100

C57

0.1uF

+5V

SHT-4

SHT-4

LED_Y

LED_G

R56

47K / 4.7K

R59

47K / 4.7K

3.3V_DVDD

B

3.3V_DVDD

B

E

Q1

C

2N3906 / NC

E

Q2

C

2N3906 / NC

R61 75 / 100

SHT-4

AUDIO_ON

NC/4.7uF/10V 0805

GND GND

C63

470pF

GND GND

C58

C64

470pF

R55 NC/820

C59

NC/0.1uF

KEY ONOFF

KEY DOWN

KEY RIGHT

KEY LEFT

KEY UP

GND

J1

1

2

3

4

5

6

7

Keyboard Connector

8

9

10

Molex_53261-1090

PANEL_VDD

PANEL_VDD

C62

18pF

GND

GND

U8

1

S1

2

S2

3

S3

4 5

GD 1

SI9435_SO8

Q3

2SC2411K

8

D4

7

D3

6

D2

L4 BLM21P300S

C61

+

47uF

C60

680uF/16V DIP

GND

PPWRSHT-4

LCDON

R60 10K

+

C65

NC/47uF

R57

10KR58 75 / 100

+

GND

No. 0533

Ctrl/B VL-901 - VGA Input - 4

52

HITACHI

Page 53

LCDONSHT-4

LCDON

ER0

ER1

ER2

ER3

ER4

ER5

ER6

ER7

EB0

EB1

EB2

EB3

EB4

EB5

EB6

EB7

EG0

EG1

EG2

EG3

EG4

EG5

EG6

EG7

OR0

OR1

OR2

OR3

OR4

OR5

OR6

OR7

OB0

OB1

OB2

OB3

OB4

OB5

OB6

OB7

OG0

OG1

OG2

OG3

OG4

OG5

OG6

OG7

DHS

DVS

DEN

DCLK

RP1 22

8

7

6

8

7

6

RP2 22

RP5 22

8

7

6

8

7

6

RP6 22

RP3 22

8

7

6

8

7

6

RP4 22

RP7 22

8

7

6

8

7

6

RP8 22

RP11 22

8

7

6

8

7

6

RP12 22

RP9

8

7

6

8

7

22

6

RP10 22

U9

DS90CF383MTD

DARED0

DARED1

R62

100

DARED2

DARED3

DARED4

DARED5

DARED6

DARED7

DAGRN0

DAGRN1

DAGRN2

DAGRN3

DAGRN4

DAGRN5

DAGRN6

DAGRN7

DABLU0

DABLU1

DABLU2

DABLU3

DABLU4

DABLU5

DABLU6

DABLU7

DHS

DVS

DEN

DISP_CLK

DARED0

1

DARED1

2

DARED2

3

DARED3

45

DARED4

1

DARED5

2

DARED6

3

DARED7

45

DABLU0

1

DABLU1

2

DABLU2

3

DABLU3

45

DABLU4

1

DABLU5

2

DABLU6

3

DABLU7

45

DAGRN0

1

DAGRN1

2

DAGRN2

3

DAGRN3

45

DAGRN4

1

DAGRN5

2

DAGRN6

3

DAGRN7

45

DCLK

DBRED0

1

DBRED1

2

DBRED2

3

DBRED3

45

DBRED4

1

DBRED5

2

DBRED6

3

DBRED7

45

DBBLU0

1

DBBLU1

2

DBBLU2

3

DBBLU3

45

DBBLU4

1

DBBLU5

2

DBBLU6

3

DBBLU7

45

DBGRN0

1

DBGRN1

2

DBGRN2

3

DBGRN3

45

DBGRN4

1

DBGRN5

2

DBGRN6

3

DBGRN7

45

10pF

C74

LVDS_GND

GND

DBRED0

DBRED1

DBRED2

DBRED3

DBRED4

DBRED5

DBRED6

DBRED7

DBGRN0

DBGRN1

DBGRN2

DBGRN3

DBGRN4

DBGRN5

DBGRN6

DBGRN7

DBBLU0

DBBLU1

DBBLU2

DBBLU3

DBBLU4

DBBLU5

DBBLU6

DBBLU7

DHS

DVS

DEN

DISP_CLK

50

2

51

52

54

55

56

3

8

10

4

6

7

11

12

14

16

18

15

19

20

22

23

24

25

27

28

30

31

TXIN27

TXIN5

TXIN0

TXIN1

TXIN2

TXIN3

TXIN4

TXIN6

TXIN10

TXIN11

TXIN7

TXIN8

TXIN9

TXIN12

TXIN13

TXIN14

TXIN16

TXIN17

TXIN15

TXIN18

TXIN19

TXIN20

TXIN21

TXIN22

TXIN23

TXIN24

TXIN25

TXIN26

TXCLKIN

U10

DS90CF383MTD

TSSOP56

50

TXIN27

2

TXIN5

51

TXIN0

52

TXIN1

54

TXIN2

55

TXIN3

56

TXIN4

3

TXIN6

8

TXIN10

10

TXIN11

4

TXIN7

6

TXIN8

7

TXIN9

11

TXIN12

12

TXIN13

14

TXIN14

16

TXIN16

18

TXIN17

15

TXIN15

19

TXIN18

20

TXIN19

22

TXIN20

23

TXIN21

24

TXIN22

25

TXIN23

27

TXIN24

28

TXIN25

30

TXIN26

31

TXCLKIN

1917

VVV

ODD

26

V

1917

VVV

EVEN

PWRDWN

TXOUT0-

TXOUT0+

TXOUT1-

TXOUT1+

TXOUT2-

TXOUT2+

TXOUT3-

TXOUT3+

TXCLKOUT-

TXCLKOUT+

LVDSVCC

LVDSGND

LVDSGND

LVDSGND

PLLVCC

PLLGND

PLLGND

GND

GND

GND

GND

GND

C75

0.1uF

26

V

TXCLKOUT-

TXCLKOUT+

PWRDWN

TXOUT0+

TXOUT1+

TXOUT2+

TXOUT3+

LVDSVCC

LVDSGND

LVDSGND

LVDSGND

DHSSHT-4

DVSSHT-4

DENSHT-4

DCLKSHT-4

ER[0..7]SHT-4

EB[0..7]SHT-4

EG[0..7]SHT-4

OR[0..7]SHT-4

OB[0..7]SHT-4

OG[0..7]SHT-4

ER[0..7]

EB[0..7]

EG[0..7]

OR[0..7]

OB[0..7]

OG[0..7]

C66

0.1uF

32

48

47

46

45

42

41

38

37

40

39

44

49

43

36

34

35

33

53

29

21

13

5

TXOUT0-

TXOUT1-

TXOUT2-

TXOUT3-

PLLVCC

PLLGND

PLLGND

GND

GND

GND

GND

GND

C76

0.1uF

C67

0.1uF

TXO0TXO0+

TXO1TXO1+

TXO2TXO2+

TXO3TXO3+

TXOCLKTXOCLK+

GND

32

48

47

46

45

42

41

38

37

40

39

44

49

43

36

34

35

33

53

29

21

13

5

C68

0.1uF

C70

0.1uF

C72

0.1uF

LVDS_GND

C77

0.1uF

TXE0TXE0+

TXE1TXE1+

TXE2TXE2+

TXE3TXE3+

TXECLKTXECLK+

C79

0.1uF

C81

0.1uF

GND

C78

0.1uF

GND

LVDS_GND

C69

0.1uF

C71

0.01uF

C73

0.01uF

C80

0.01uF

C82

0.01uF

PANEL SIGNAL OUTPUT

LVDS_ENSHT-4

PANEL_VDD

Connect LVDS grounds to GND

at one single point only.

TXE0TXE0+

TXE1TXE1+

TXE2TXE2+

TXECLKTXECLK+

TXE3TXE3+

TXO0TXO0+

TXO1TXO1+

TXO2TXO2+

TXOCLKTXOCLK+

TXO3TXO3+

PANEL_VDD

LVDS_GNDGND

CN4

1

RXO0-

2

RXO0+

3

GND

4

RXO1-

5

RXO1+

6

GND

7

RXO2-

8

RXO2+

9

GND

10

RXOC-

11

RXOC+

12

GND

13

RXO3-

14

RXO3+

15

GND

16

RXE0-

17

RXE0+

18

GND

19

RXE1-

20

RXE1+

21

GND

22

RXE2-

23

RXE2+

24

GND

25

RXEC-

26

RXEC+

27

GND

28

RXE3-

29

RXE3+

30

GND

31

NC

32

PD

33

NC

34

GND

35

GND

36

VDD

37

VDD

38

VDD

39

GND

40

GND

E&T_6701-40p-0.50m

No. 0533

GND

GND

LVDS_3.3V

Ctrl/B VL-901 - VGA Input - 5

53

HITACHI

Page 54

J2

1

2

3

4

5

6

7

CON7

GND

C90

100uF

GND

+

BLKON

L6

BLM21P300S

PBIAS

C91

0.01uF

5VCC

+5V

+5V

+

U12

APL1117-25uC

C84

0.1uF

ADJ

1

VOVI

VO

GND

23

4

C83

100uF

GND

C92

+

100uF

GND GND GND GND

U11

APL1085-3.3CE

3

IN

OUT

1

GND

C93

0.1uF

+2.5V

+

2

C94

100uF

C87

0.1uF

L7 BLM21P300S

L5 BLM21P300S

C88

0.01uF

GND GND GND

C95

0.1uF

GND GND

+

100uF

2.5V_VDD

C96

+

100uF

C85

C86

0.1uF

3.3V_DVDD+3.3V

C89

+

100uF

47uF

C102

GND

R70 1K

+

BRI_ADJ SHT-4

1

ADJ/GND

1

ADJ/GND

4 Vout

APL1117

SOT-223

2

OUT

4 Vout

APL1085

-33CE

SOT-252

2

OUT

3

IN

3

IN

+5V

C97

100uF

+

GND GND

C98

0.1uF

U13

APL1117-3.3V

VOVI

VO

ADJ

1

GND

23

4

C99

0.1uF

GND GND

+

C100

100uF

LVDS_3.3V

No. 0533

Ctrl/B VL-901 - Power

54

HITACHI

Page 55

Appendix B: DISPLAY UNIT ASSEMBLY

55

Page 56

56

Page 57

57

Page 58

58

Page 59

59

Page 60

THE UPDATED PARTS LIST

FOR THIS MODEL IS

AVAILABLE ON ESTA

Page 61

Hitachi, Ltd. Tokyo, Japan

International Sales Division

THE HITACHI ATAGO BUILDING,

No. 15 –12 Nishi Shinbashi, 2 – Chome,

Minato – Ku, Tokyo 105-8430, Japan.

Tel: 03 35022111

HITACHI EUROPE LTD,

Whitebrook Park

Lower Cookham Road

Maidenhead

Berkshire

SL6 8YA

UNITED KINGDOM

Tel: 01628 643000

Fax: 01628 643400

Email: consumer-service@hitachi-eu.com

HITACHI EUROPE GmbH

Munich Office

Dornacher Strasse 3

D-85622 Feldkirchen bei München

GERMANY

Tel: +49-89-991 80-0

Fax: +49- 89-991 80-224

Hotline: +49-180-551 25 51 (12ct/min)

Email: HSE-DUS.service@hitachi-eu.com

HITACHI EUROPE srl

Via Tommaso Gulli N.39, 20147

Milano, Italia

ITALY

Tel: +39 02 487861

Tel: +39 02 38073415 Servizio Clienti

Fax: +39 02 48786381/2

Email: customerservice.italy@hitachi -eu.com

HITACHI EUROPE S.A.S

Lyon Office

B.P. 45, 69671 BRON CEDEX

FRANCE

Tel: 04 72 14 29 70

Fax: 04 72 14 29 99

Email: france.consommateur@hitachi -eu.com

HITACH EUROPE AB

Egebækgård

Egebækvej 98

DK-2850 Nærum

DENMARK

Tel: +45 43 43 6050

Fax: +45 43 60 51

Email: csgnor@hitachi-eu.com

Hitachi Europe Ltd

Bergensesteenweg 421

1600 Sint- Pieters-Leeuw

BELGIUM

Tel: +32 2 363 99 01

Fax: +32 2 363 99 00

Email: sofie.van.bom@hitachi-eu.com

www.hitachidigitalmedia.com

HITACHI EUROPE S.A.

364 Kifissias Ave. & 1, Delfon Str.

152 33 Chalandri

Athens

GREECE

Tel: 1-6837200

Fax: 1-6835964

Email: service.hellas@hitachi -eu.com

HITACHI EUROPE S.A.

Gran Via Carlos III, 101- 1

08028 Barcelona

SPAIN

Tel: 93 409 2550

Fax: 93 491 3513

Email: atencion.cliente@hitachi -eu.com

HITACHI Europe AB

Box 77 S-164 94 Kista

SWEDEN

Tel: +46 (0) 8 562 711 00

Fax: +46 (0) 8 562 711 13

Email: csgswe@hitachi-eu.com

HITACHI EUROPE LTD (Norway) AB

STRANDVEIEN 18

1366 Lysaker

NORWAY

Tel: 67 5190 30

Fax: 67 5190 32

Email: csgnor@hitachi-eu.com

HITACHI EUROPE AB

Neopoli / Niemenkatu 73

FIN-15140 Lahti

FINLAND

Tel : +358 3 8858 271

Fax: +358 3 8858 272

Email: csgnor@hitachi-eu.com

HITACHI EUROPE LTD

Na Sychrove 975/8

101 27 Praha 10 – Bohdalec

CZECH REPUBLIC

Tel: +420 267 212 383

Fax: +420 267 212 385

Email: csgnor@hitachi-eu.com

Loading...

Loading...