Page 1

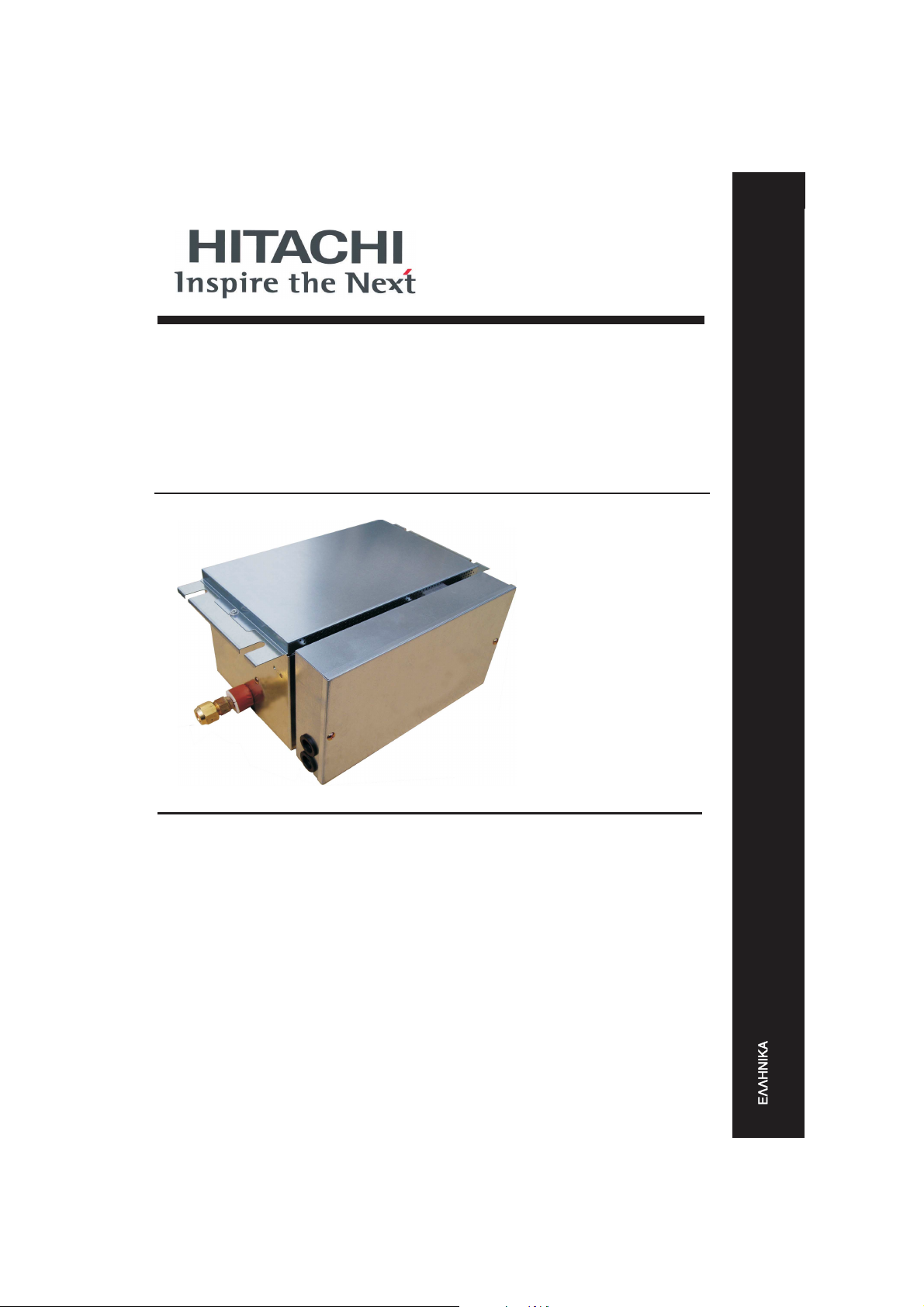

CH-UNIT

ENGLISH

INSTALLATION AND OPERATION MANUAL

MANUAL DE INSTALACIÓN Y FUNCIONAMIENTO

INSTALLATIONS- UND BETRIEBSHANDBUCH

MANUEL D’INSTALLATION ET DE

FUNCTIONNEMENT

MANUALE D’INSTALLAZIONE E D’USO

MANUAL DE INSTALAÇÄO E DE

FUNCIONAMENTO

BRUGER- OG MONTERINGSVEJLEDNING

INSTALLATIE- EN BEDIENINGSHANDLEIDING

HANDBOK FÖR INSTALLATION OCH ANVÄNDING

ΕΓΧΕΙΡΙΔΙΟΕΓΚΑΤΑΣΤΑΣΗΣΚΑΙΛΕΙΤΟΥΡΓΙΑΣ

MODELS:

CH-4.0NE

CH-8.0NE

CH-12.0N

ESPAÑOL

DEUTCH

FRANÇAIS

ITALIANO

PORTUGUESDANSK

Do not perform installation work, without referring to our installation manual.

No realice la instalación de este equipo, sin antes consultar este manual de instalación.

Bei der Installation unbedingt die Hinweise in der Installationsanleitung beachten.

Consulter notre manuel avant de réaliser une quelconque installation.

Realizzare l’installazione, seguendo quanto indicato in questo manuale.

Nao inicie os trabalhos de montagem, sem consultar o nosso manual de montagem.

Udfor ikke installationsarbejder uden forst at donsultere vores vejledning.

Voer geen enkele handeling uit om de apparatuur alvorens deze hadleiding te hebben

doorgelezen.

Utför inte nagra installationsarbeten utan att först läsa var installationsmanual

Μην ήσετε στην εγκατάσταση, χωρίς πριν να έχετε συμβουλευθεί αυτo το εγχειρίδιο εγκατάστασης

NEDERLANDS

SVENSKA

Page 2

Page 3

Specifications in this catalogue are subject to change without notice in order that

HITACHI may bring the latest innovations to their custo me rs

Whi lst ever y effort is m ade to en sure that all dimensions and specifi catio ns are c or rect,

any printers' errors not rectified are outside the control of HITACHI, who cannot be held

responsible for same

Page 4

Page 5

DANGER – Immediate hazard which WILL result in severe injury or death.

Õ

PELIGRO – Riesgos inmediatos que PRODUCIRÁN lesiones personales graves e incluso

la muerte.

GEFAHR – Unmittelbare Gefahrenquellen, die zu schweren Verletzungen oder zum Tod

führen.

DANGER – Dangers instantanés de blessures corporelles sévères ou de mort.

PERICOLO – Pericolo immediato che PRODURRÀ ferite gravi o la morte.

PERIGO – Problemas imediatos que IRÃO resultar em graves ferimentos pessoais ou

morte.

FARE – Overhængende fare, som VIL resultere i alvorlig personskade eller dødsfald.

GEVAAR – Onmiddellijke risico's die ernstige persoonlijke verwondingen of de dood ten

gevolge kunnen hebben.

FARA – Omedelbar risk som medför svår personskada eller död.

KINAYNO – Άµεσος κίνδυνος που ΘΑ έχει ως αποτέλεσµα σοβαρές σωµατικές βλάβες ή

θάνατο.

WARNING – Hazards or unsafe practices which COULD result in severe personal injuries

Ô

or death.

AVISO – Riesgos o prácticas poco seguras que PODRÍAN producir lesiones personales e

incluso la muerte.

WARNUNG – Gefährliche oder unsichere Anwendung, die zu schweren

Körperverletzungen oder zum Tod führen kann.

ATTENTION – Utilisation dangereuse ou sans garantie de sécurité qui PEUT provoquer de

sévères blessures personnelles ou la mort.

AVVISO – Pericoli o azioni pericolose che POTREBBERO avere come esito lesioni fisiche

gravi o il decesso.

AVISO – Riesgos o prácticas poco seguras que PUEDEN producir lesiones personales e

incluso la muerte

ADVARSEL – Farer eller farlig brug, som KAN resultere i alvorlig personskade eller

dødsfald.

WAARSCHUWING – Gevaren of onveilige praktijken die ernstig persoonlijk letsel of de

dood tot gevolg KUNNEN hebben.

VARNING – Risker eller osäkra tillvägagångssätt som KAN leda till svåra personskador

eller dödsfall.

ΠΡΟΕΙ∆ΟΠΟΙΗΣΗ – Κίνδυνοι ή επικίνδυνες πρακτικές, οι οποίες ΜΠΟΡΕΙ να έχουν ως

αποτέλεσµα σοβαρές σωµατικές βλάβες ή θάνατο.

ESPAÑOLDEUTSCHFRANÇAISPORTUGÊSDANSKNEDERLANDSSVENSKA ITALIANOEΛΛHNIKA ENGLISH

CAUTION – Hazards or unsafe practices which COULD result in minor personal injury or

product or property damage.

PRECAUCIÓN – Riesgos o prácticas poco seguras que PODRÍAN provocar lesiones

personales de menor importancia o daños en el producto u otros bienes.

VORSICHT – Gefährliche oder unsichere Anwendung, die geringfügigen Personen-,

Produkt- oder Sachschaden verursachen kann.

PRECAUTION – Utilisation dangereuse ou sans garantie de sécurité qui PEUT provoquer

des blessures mineures ou des dommages au produit ou aux biens.

ATTENZIONE – Pericoli o azioni pericolose che POTREBBERO avere come esito lesioni

fisiche minori o danni al prodotto o ad altri beni.

CUIDADO – Perigos e procedimentos perigosos que PODERÃO PROVOCAR danos

pessoais ligeiros ou danos em produtos e bens.

FORSIGTIG – Farer eller farlig brug, som KAN resultere i mindre skade på personer,

produkt eller ejendom.

LET OP – Gevaren of onveilige praktijken die licht persoonlijk letsel of beschadiging van

het product of eigendommen tot gevolg KUNNEN hebben.

VARSAMHET – Risker eller farliga tillvägagångssätt som KAN leda till mindre

personskador eller skador på produkten eller på egendom.

ΠΡΟΣΟΧΗ – Κίνδυνοι ή επικίνδυνες πρακτικές, οι οποίες ΜΠΟΡΕΙ να έχουν ως

αποτέλεσµα την πρόκληση ελαφρών σωµατικών βλαβών ή καταστροφή περιουσίας.

Page 6

Page 7

SAFETY SUMMARY

1. SAFETY SUMMARY

Ô WARNING:

- Do not perform installation work, refrigerant piping work and electrical wiring connection

without referring to our installation manual.

- Check that the ground wire is securely connected.

- Connect a fuse of specified capacity.

CAUTION:

- Do not install the CH unit and cable within approximately 3 meters from strong

electromagnetic wave radiators such as medical equipment.

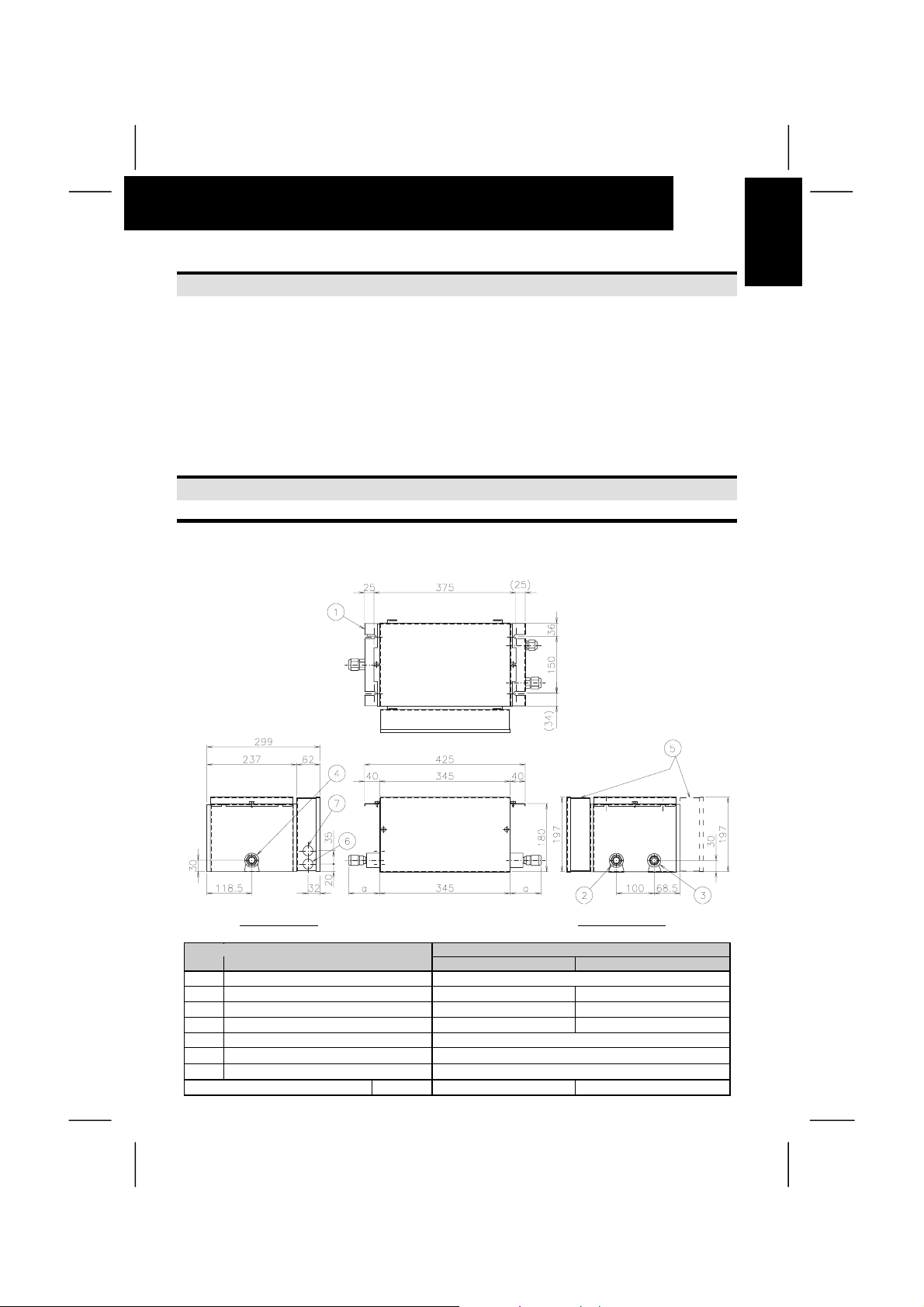

2. STRUCTURE

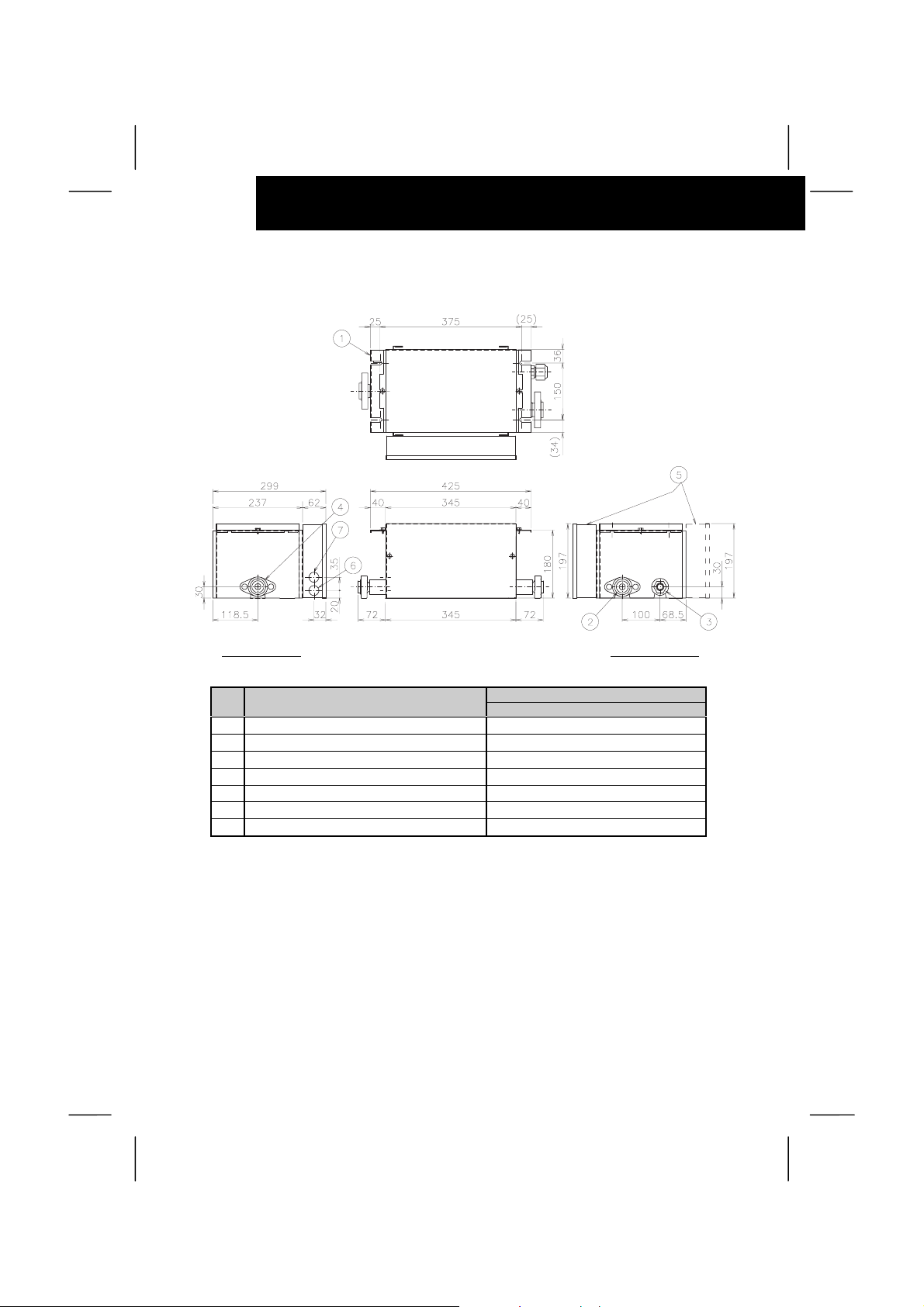

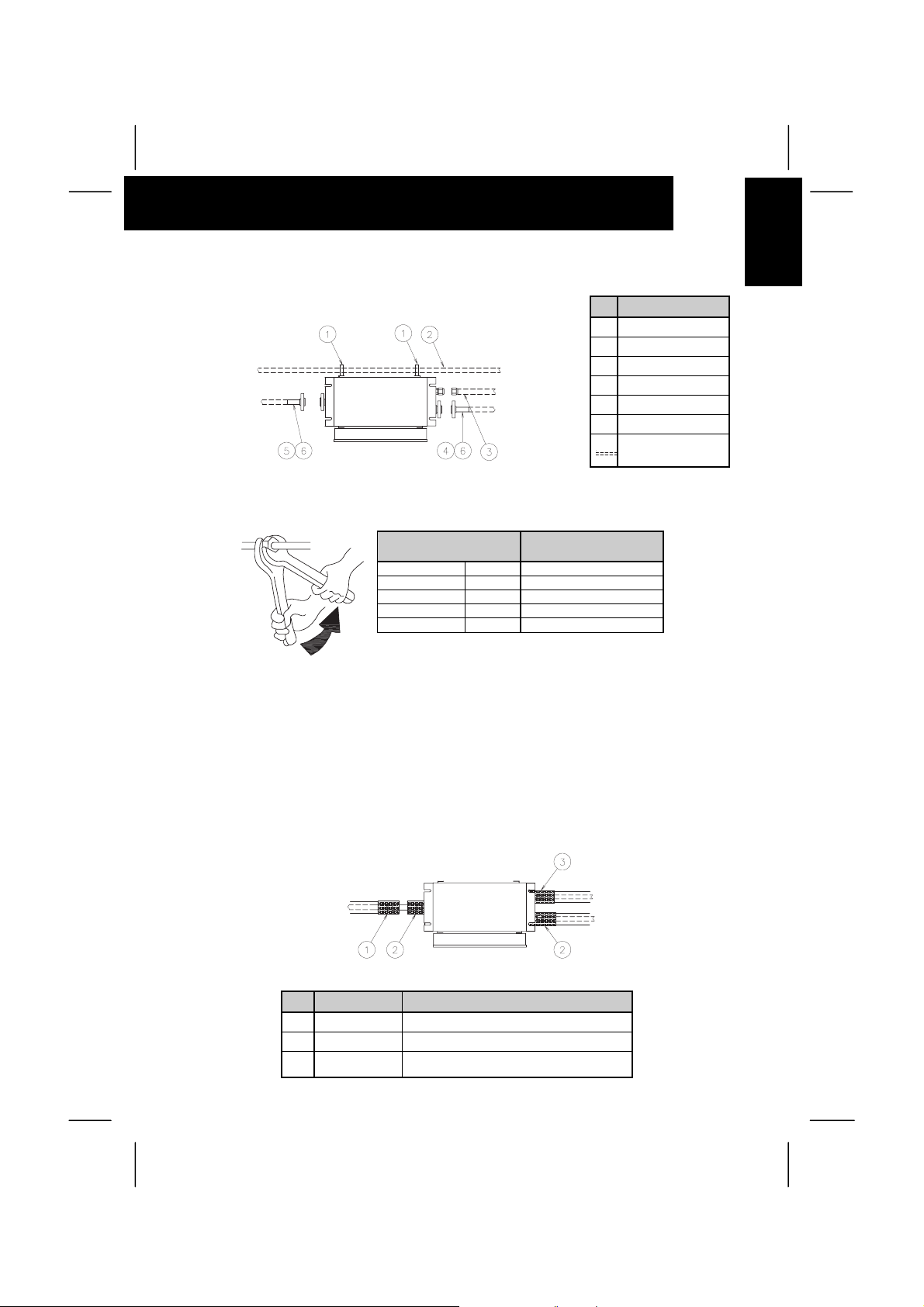

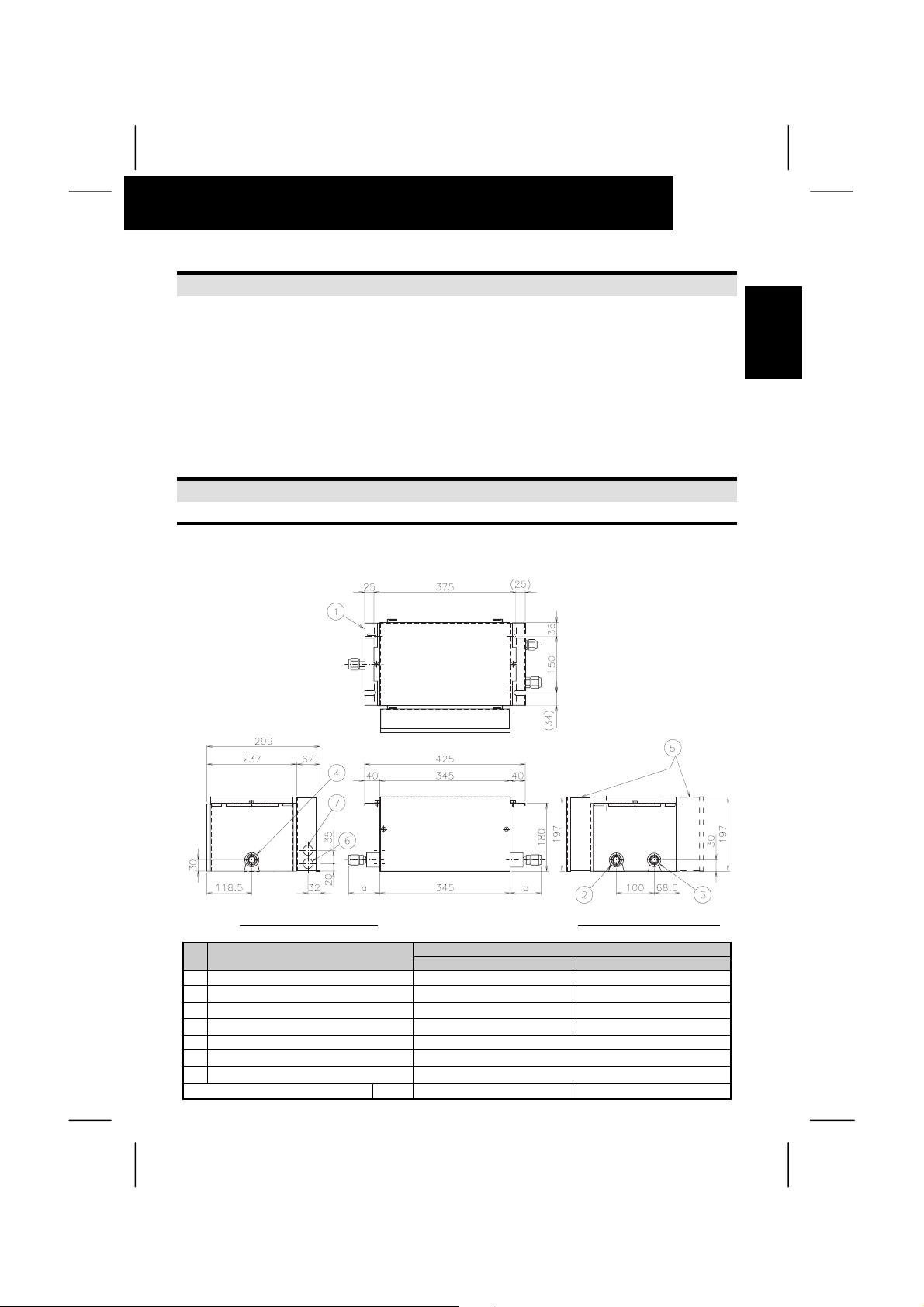

2.1. DIMENSIONS

2.1.1. Model: CH Unit – CH-(4.0/8.0)NE

1

ENGLISH

Unit:mm

To Indoor Unit To Outdoor Unit

No Description

1 Suspension Bracket For M8 or W5/16 Bolt

2 Refrigerant Gas (Low) Pipe connection

3 Refrigerant Gas (High) Pipe connection

4 Refrigerant Gas Pipe connection

5 Electrical Control Box (Available attachment in the both sides)

6 Hole for operating Line

7 Hole for power supply Line

Dimension a 78mm 82mm

CH-4.0NE CH-8.0NE

∅15.88 Flare connection ∅19.05 Flare Connection

∅12.7 Flare connection ∅15.88 Flare Connection

∅15.88 Flare connection ∅19.05 Flare connection

Remarks

∅26.5

∅26.5

Page 8

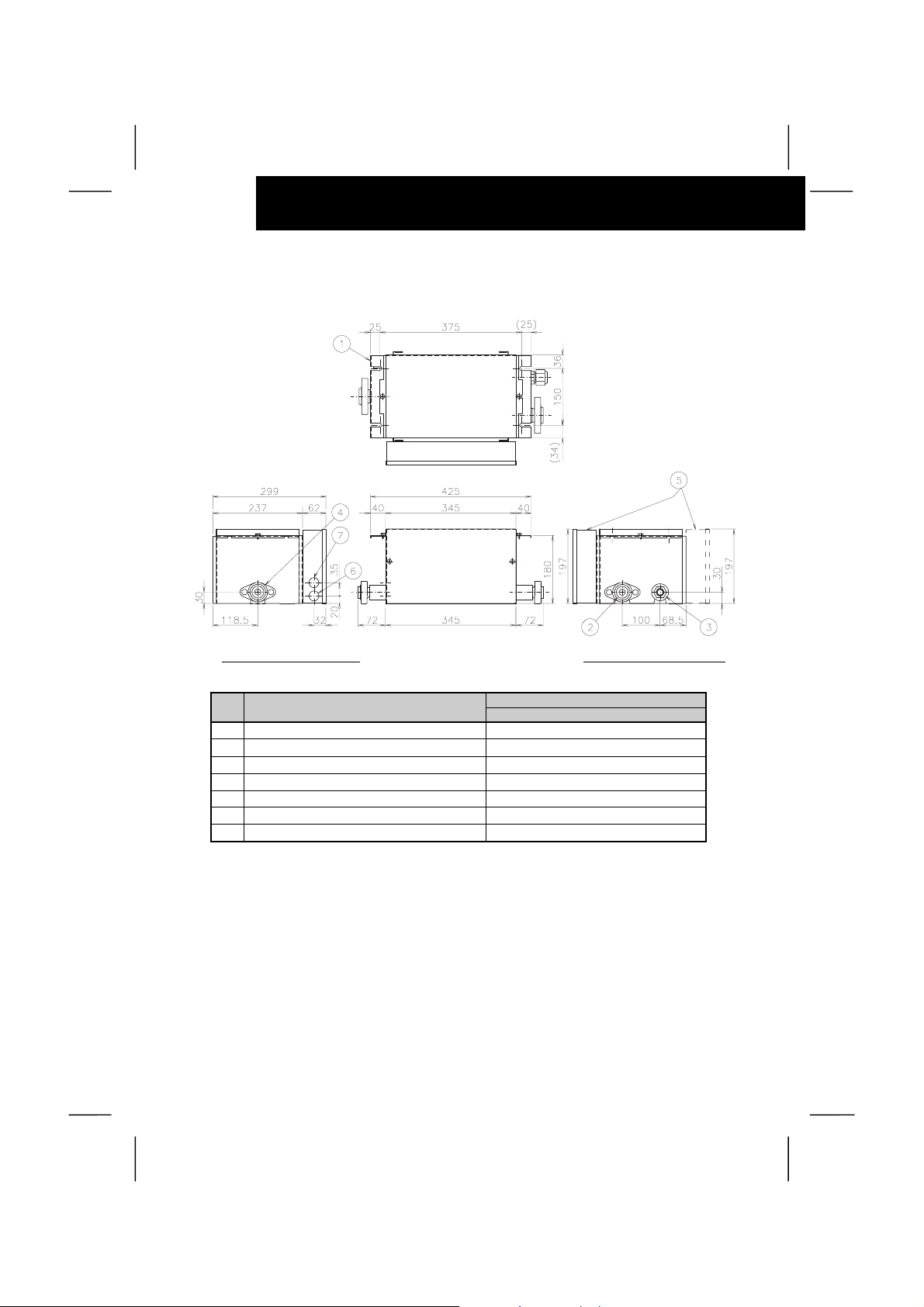

2

STRUCTURE

2.1.2. Model: CH Unit – CH-12.0N

To Indoor Unit To Outdoor Unit

Unit:mm

No Description

1 Suspension Bracket For M8 or W5/16 Bolt

2 Refrigerant Gas (Low) Pipe connection

3 Refrigerant Gas (High) Pipe connection

4 Refrigerant Gas Pipe connection

5 Electrical Control Box (Available attachment in the both sides)

6 Hole for operating Line

7 Hole for power supply Line

Remarks

CH-12.0N

∅22.2 Flange connection

∅19.05 Flare connection

∅22.2 Flange connection

∅26.5

∅26.5

Page 9

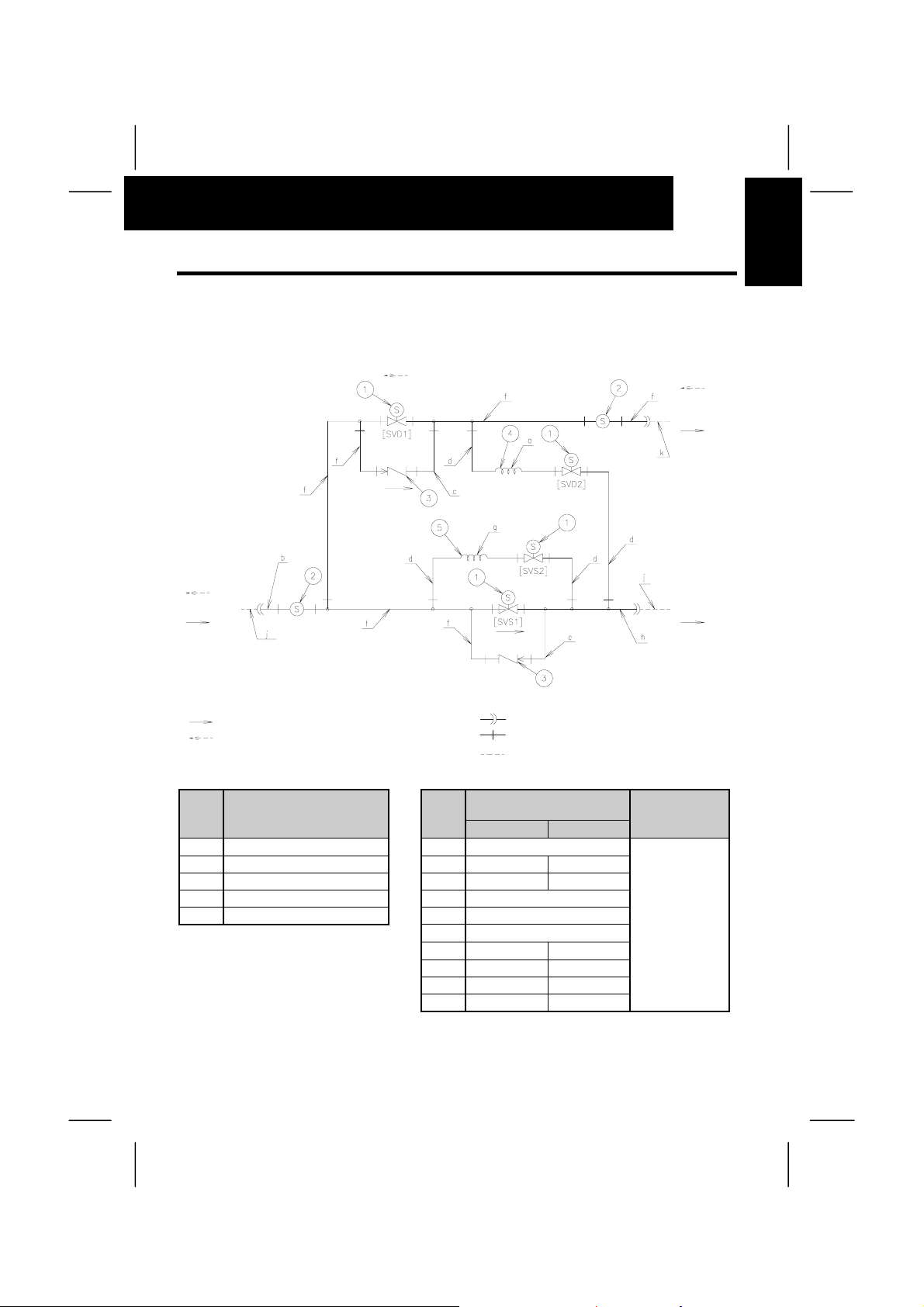

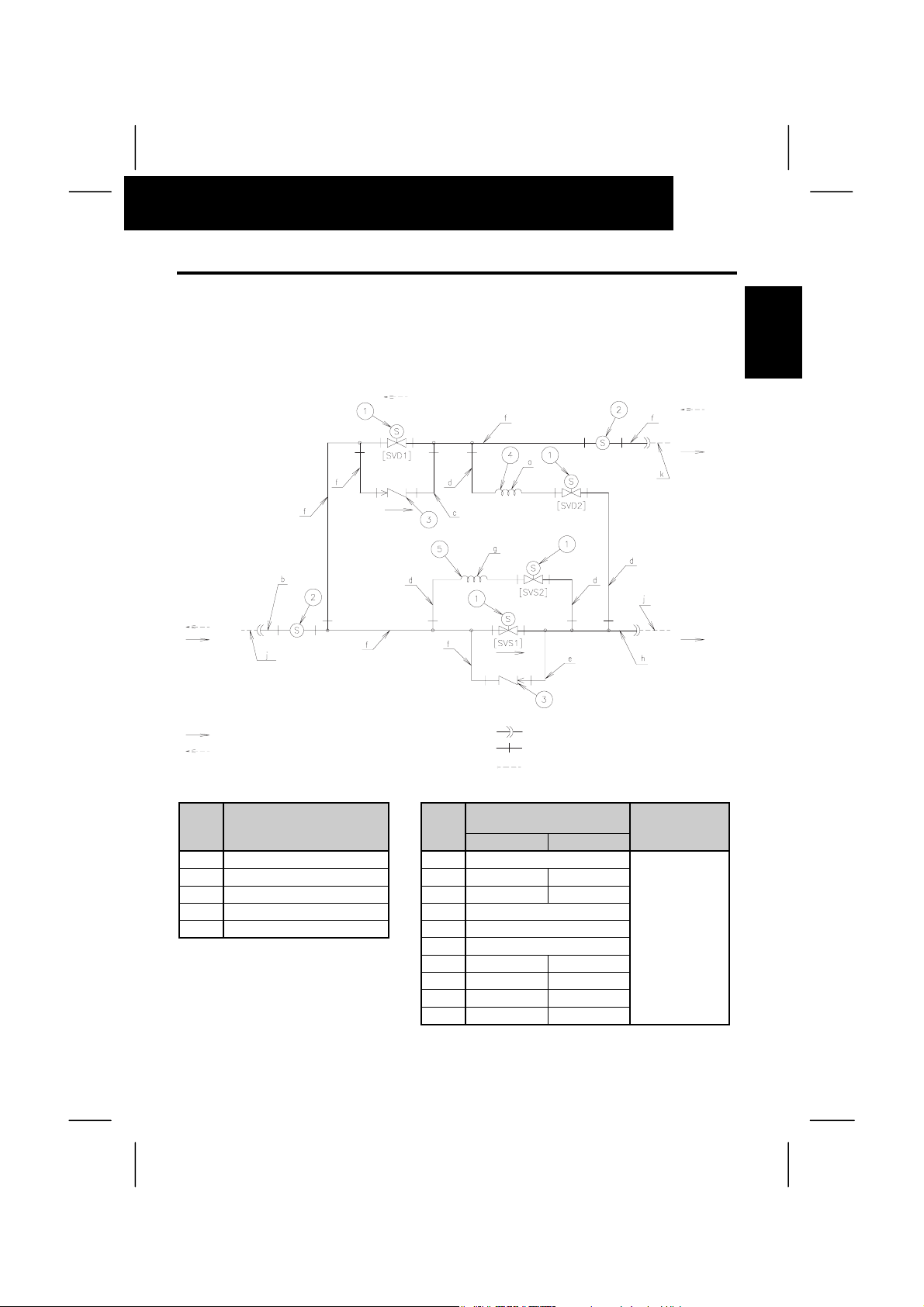

2.2. REFRIGERANT CYCLE

2.2.1. CH Unit - CH-(4.0/8.0)NE

To Indoor Unit To Outdoor Unit

Õ

High

Pressure

Gas Line

STRUCTURE

High Pressure

3

ENGLISH

Ö

Gas Line

Low

Pressure

Gas Line

Low

Pressure

Gas Line

Refrigerant Flow Direction (Cooling Operation)

Refrigerant Flow Direction (Heating Operation)

No Description Mark

1 Solenoid Valve (AC) a

2 Strainer b

3 Check Valve c

4 Capillary Tube d

5 Capillary Tube e

O.D.(mm) × thickness (mm)

CH-4.0NE CH-8.0NE

∅12.7×1.0 ∅15.88×1.0

∅9.53×0.8 ∅12.7×1.0

f

g

h

∅12.7×1.0 ∅15.88×1.2

j

k

NOTE:

The mark of inside "[ ]" is shown in the electrical wiring diagram.

Flare Connection

Brazing Connection

Field Refrigerant Piping

Material Size

∅2.5x0.7

∅6.35×1.07

∅9.53×0.8

∅12.7×1.0

∅4.0x0.8 ∅4.0x0.5

∅15.88 ∅19.05

∅12.7 ∅15.88

Low

pressure

gas line

Material

Copper Tube

C1220T-O

Page 10

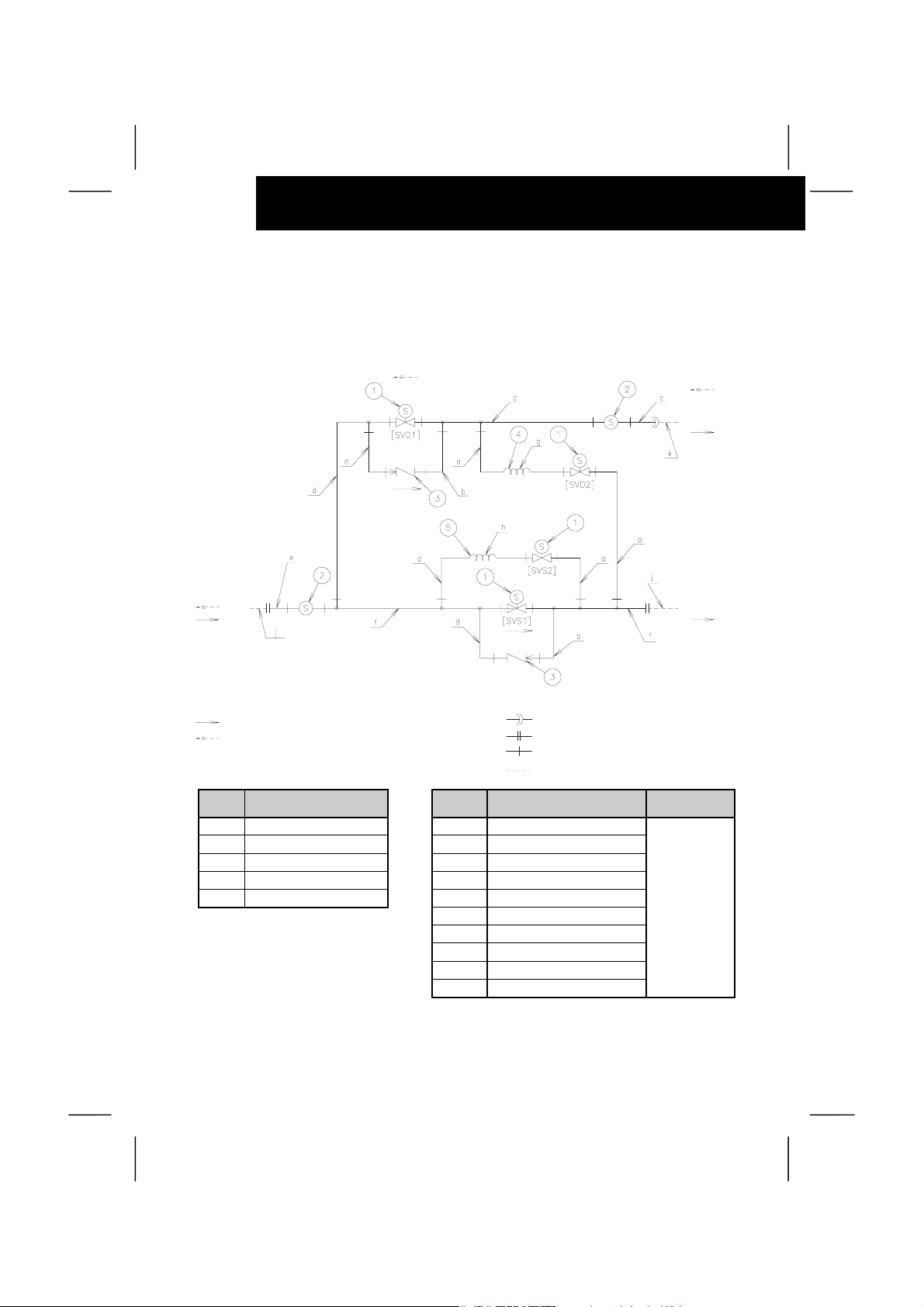

4

STRUCTURE

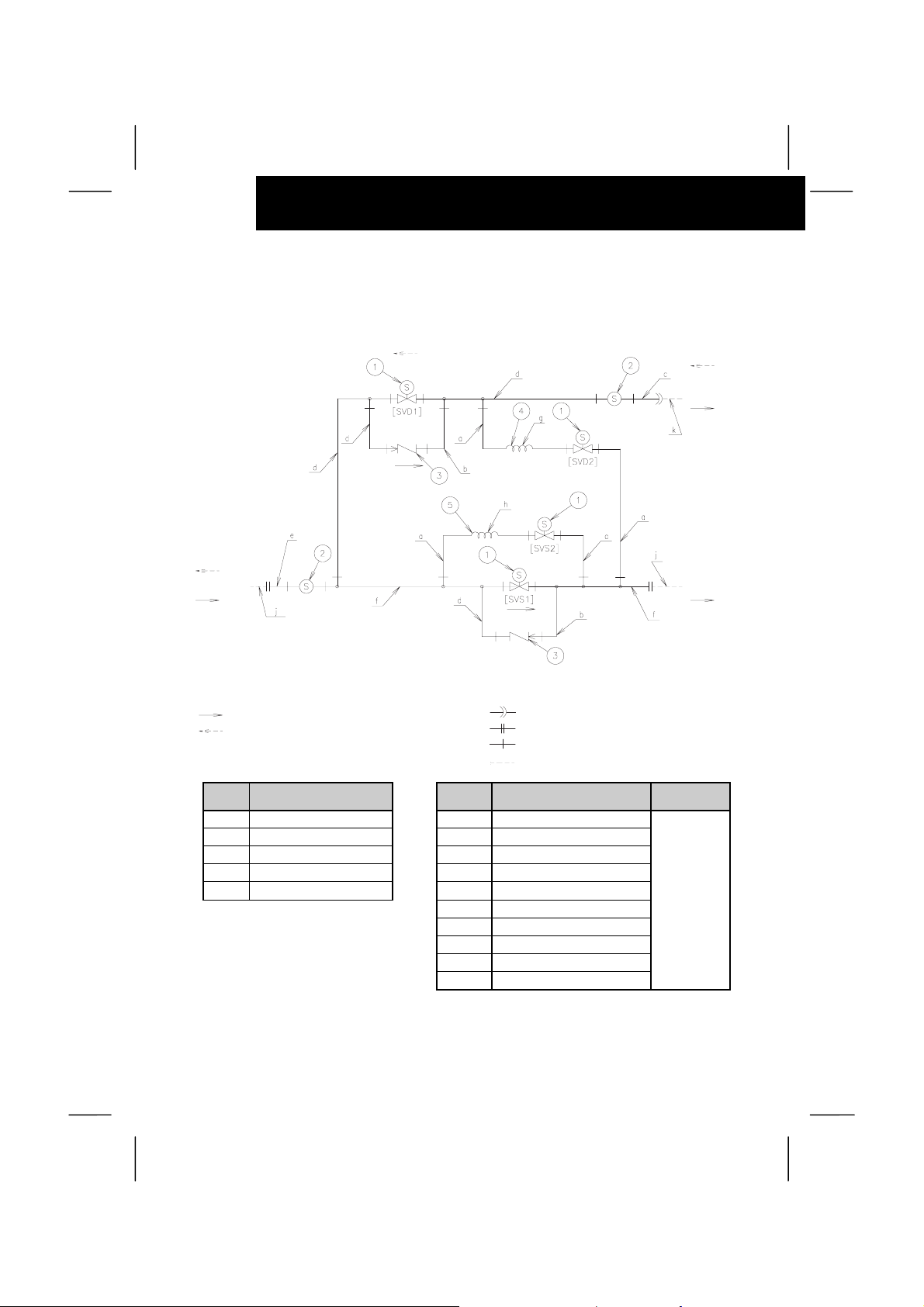

2.2.2. CH Unit – CH-12.0N

To Indoor Unit To Outdoor Unit

Õ

High

Pressure

Gas Line

Ö

High Pressure

Gas Line

Low

Pressure

Gas Line

Low

Pressure

Gas Line

Refrigerant Flow Direction (Cooling Operation) Flare Connection

Refrigerant Flow Direction (Heating Operation) Flange Connection

No Description Mark

1 Solenoid Valve (AC) a

2 Strainer b

3 Check Valve c

4 Capillary Tube d

5 Capillary Tube e

f

g

h

j

k

NOTE:

The mark of inside "[ ]" is shown in the electrical wiring diagram.

Brazing Connection

Field Refrigerant Piping

Material Size

O.D.(mm) × thickness (mm)

∅6.35 x 1.07

∅12.7 x 1.0

∅15.88 x 1.0

∅15.88 x 1.2

∅19.05 x 1.2

∅19.05 x 1.65

∅3.0 x 0.8

∅4.0 x 0.5

∅22.2

∅19.05

Low

Pressure

Gas Line

Material

Copper Tube

C1220T-O

Page 11

TRANSPORTATION AND HANDLING

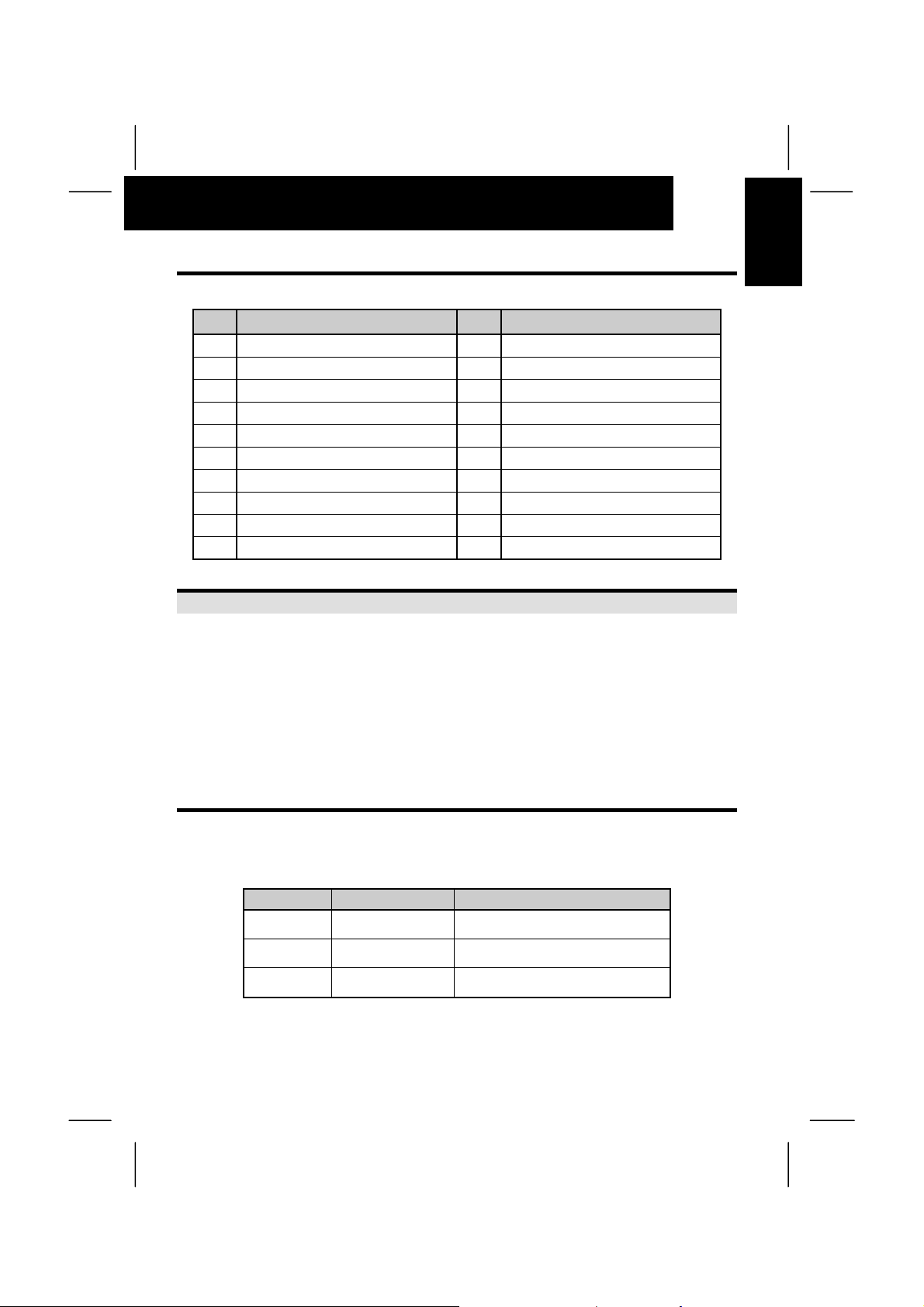

2.3. NECESSARY TOOLS AND INSTRUMENT LIST FOR INSTALLATION

No. Tool No. Tool

1 Handsaw 11 Spanner

2 Phillips Screwdriver 12 Charging Cylinder

3 Vacuum Pump 13 Gauge Manifold

4 Refrigerant Gas Hose 14 Cutter for Wires

5 Megohmmeter 15 Gas Leak Detector

6 Copper Pipe Bender 16 Leveler

7 Manual Water Pump 17 Clamper for Solderless Terminals

8 Pipe Cutter 18 Hoist (for Indoor Unit)

9 Brazing Kit 19 Ammeter

10 Hexagon Wrench 20 Voltage Meter

3. TRANSPORTATION AND HANDLING

Transport the product as close to the installation location as practical before unpacking

5

ENGLISH

Ô WARNING:

Do not put any foreign material into the CH Unit and check to ensure that none exists in the

outdoor unit before the installation and test run. Otherwise, a fire or failure, etc. may occur.

Ó CAUTION:

Do not put any material on the product.

Be careful not to damage on insulation materials of unit’s surface when lifting.

3.1. COMBINATION CH UNIT AND INDOOR UNIT

The CH Unit is Installed indoors for the SET-FREE FXN(E) system, between the outdoor unit and

Indoor unit. The combination of the CH Unit and indoor Unit is as follows.

Model Indoor Unit Quantity Total Indoor Capacity (HP)

CH-4.0NE 1 to 5

CH-8.0NE 1 to 8

CH-12.0N 1 to 5

Smaller than 4.0

(excluding 4.0)

4.0~8.0 (including 4.0

and excluding 8.0)

8.0~12.0 (including 8.0

and including 12.0)

Page 12

6

CH UNIT INSTALLATION

4. CH UNIT INSTALLATION

Õ DANGER:

Do not install the Indoor Unit in a flammable environment to avoid fire or an explosion.

Ô WARNING:

Check to ensure that the ceiling slab is strong enough.

Do not install the CH Unit outside. If installed outdoors, an electric hazard electric leakage will

occur.

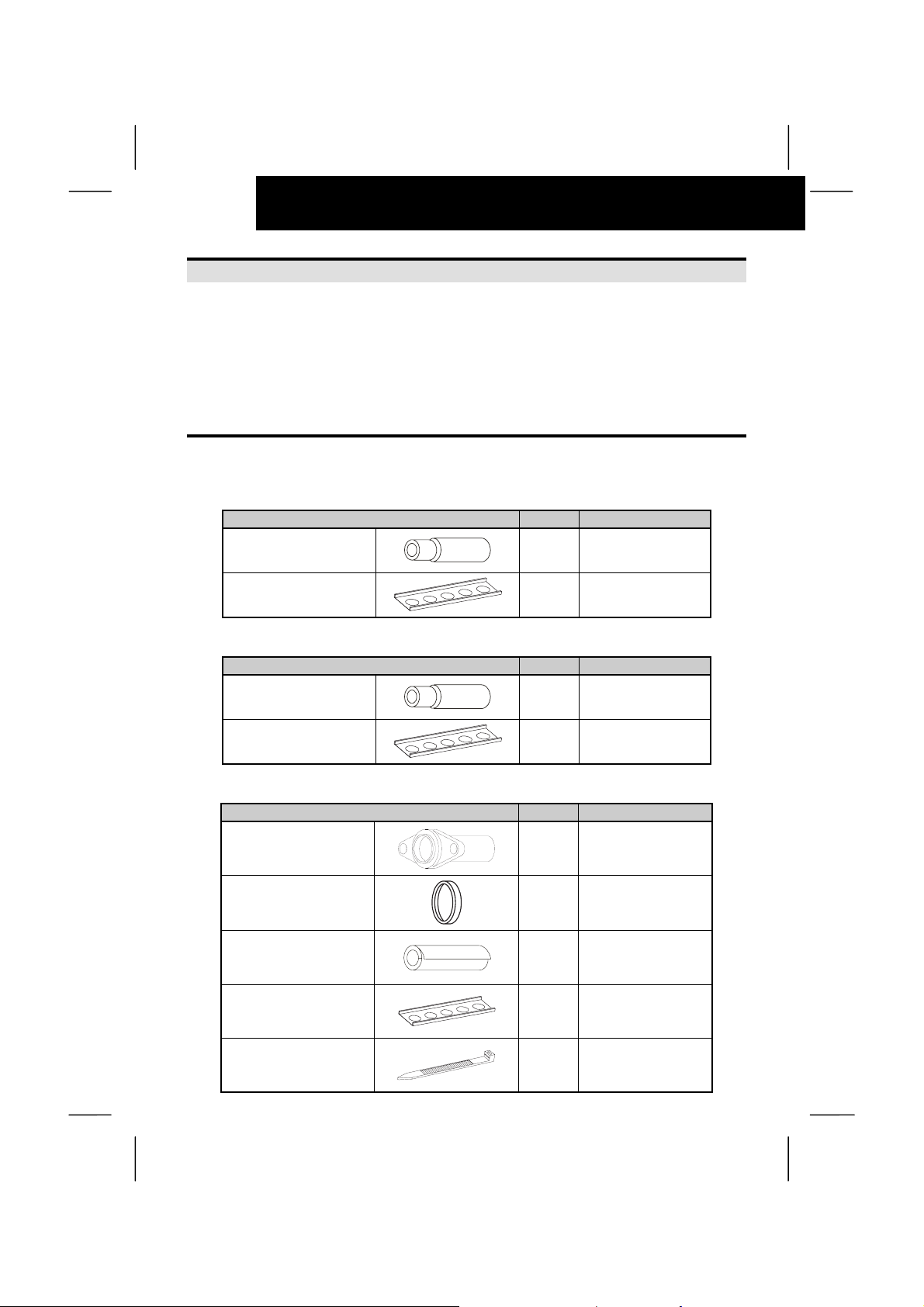

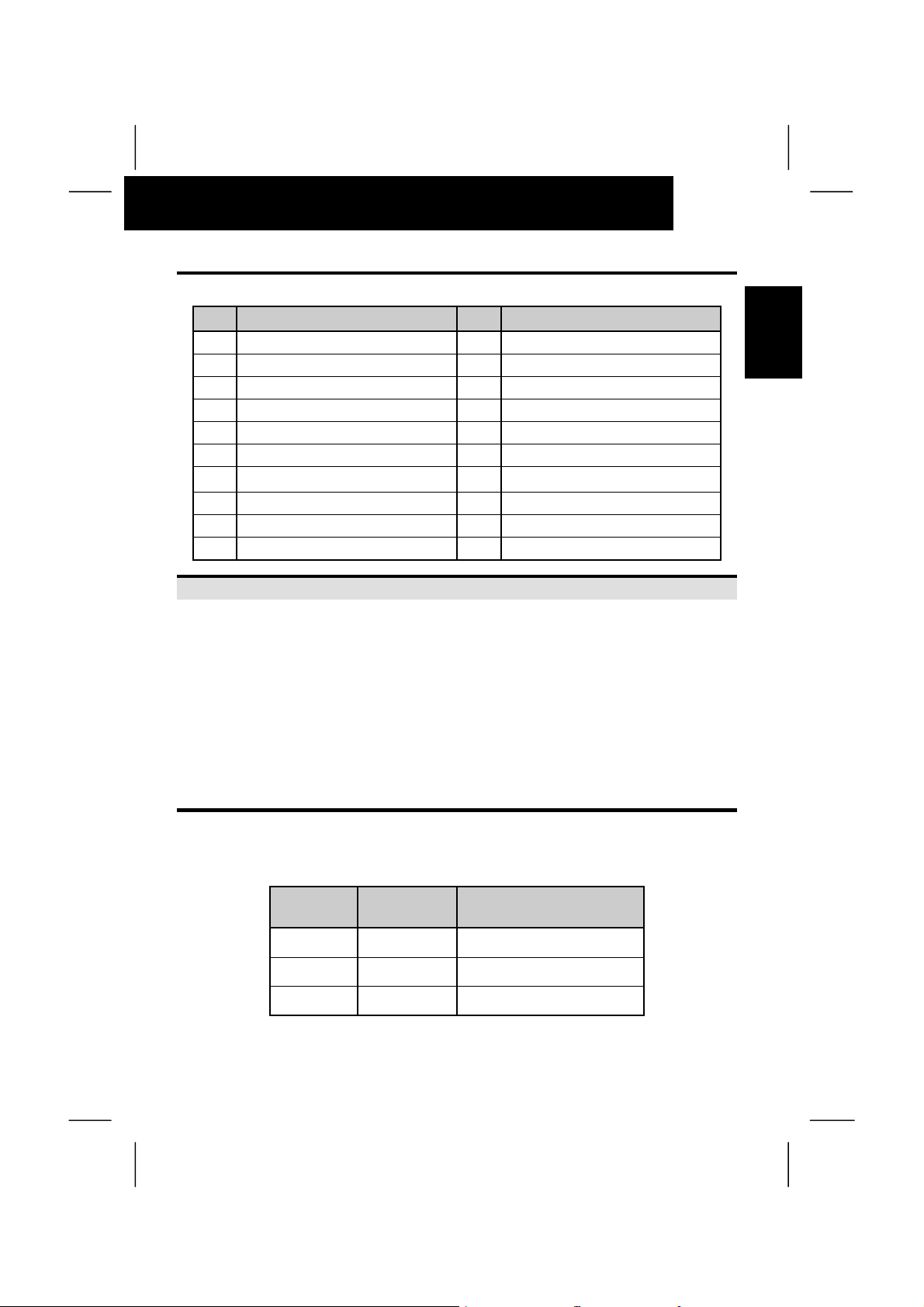

4.1. FACTORY-SUPPLIED ACCESSORIES

Check to ensure that the following accessories are packed with the CH Unit.

Factory Supplied Accessories - For CH-4.0NE.

Accessory Q´ty Purpose

To Connect ∅12.7 liquid

Reducer (∅15.88 to ∅12.7)

Pipe Fixing Band 2 To Fix Liquid Pipe

Factory Supplied Accessories - For CH-8.0NE.

Accessory Q´ty Purpose

Reducer (∅19.05 to ∅15.88)

1

piping of Indoor Unit

To Connect ∅15.88

1

liquid piping of Indoor

Unit

Pipe Fixing Band 2 To Fix Liquid Pipe

Factory Supplied Accessories - For CH-12.0N.

Accessory Q´ty Purpose

Flange Piping Size (∅22.2)

Packing for Flange 2 Flange sealing

Insulation (∅38 ID)

Pipe Fixing Band 2 To Fix Liquid Pipe

Band 8

2

1

For Gas (High) Piping

from Outdoor Unit

For Refrigerant Piping

Connection

To fix Insulation for

Refrigerant Piping

Page 13

CH UNIT INSTALLATION

7

4.2. INITIAL CHECK

4.2.1. Install the CH unit with a proper clearance around it for maintenance working space, as

shown in below figure:

Service Space

No Description

Electrical Box

o

Service Access Panel

p

View from A

Mark Dimension (Min).

Model CH-4-0/8.0 CH-12.0

a 250mm 350mm

b 100mm

4.2.2. Flowing sound of refrigerant may be heard from the CH unit when the solenoid valve in

the CH unit is activated. Therefore, take the following action to minimize the sound.

- Install the CH unit inside the ceiling. As for the ceiling material, select a material like a plaster

board which minimizes operation sound.

- Do not install the CH unit in near a bed room or hospital room.

- Do not install the CH unit in a hot or humid place like kitchen to prevent dew condensation on the

outer surface of the CH unit.

ENGLISH

4.2.3. Pay attention to the following points when the CH is installed in a hospital or other

facilities where there are electronic waves from medical equipment.

- Do not install the CH unit where the electromagnetic wave is directly radiated to the electrical box

or intermediate wiring (operating line).

- Install the CH unit and components as far as practical or at least 3 meters from the

electromagnetic wave radiator.

- Install a noise filter when the power supply emits harmful noises.

Page 14

8

CH UNIT INSTALLATION

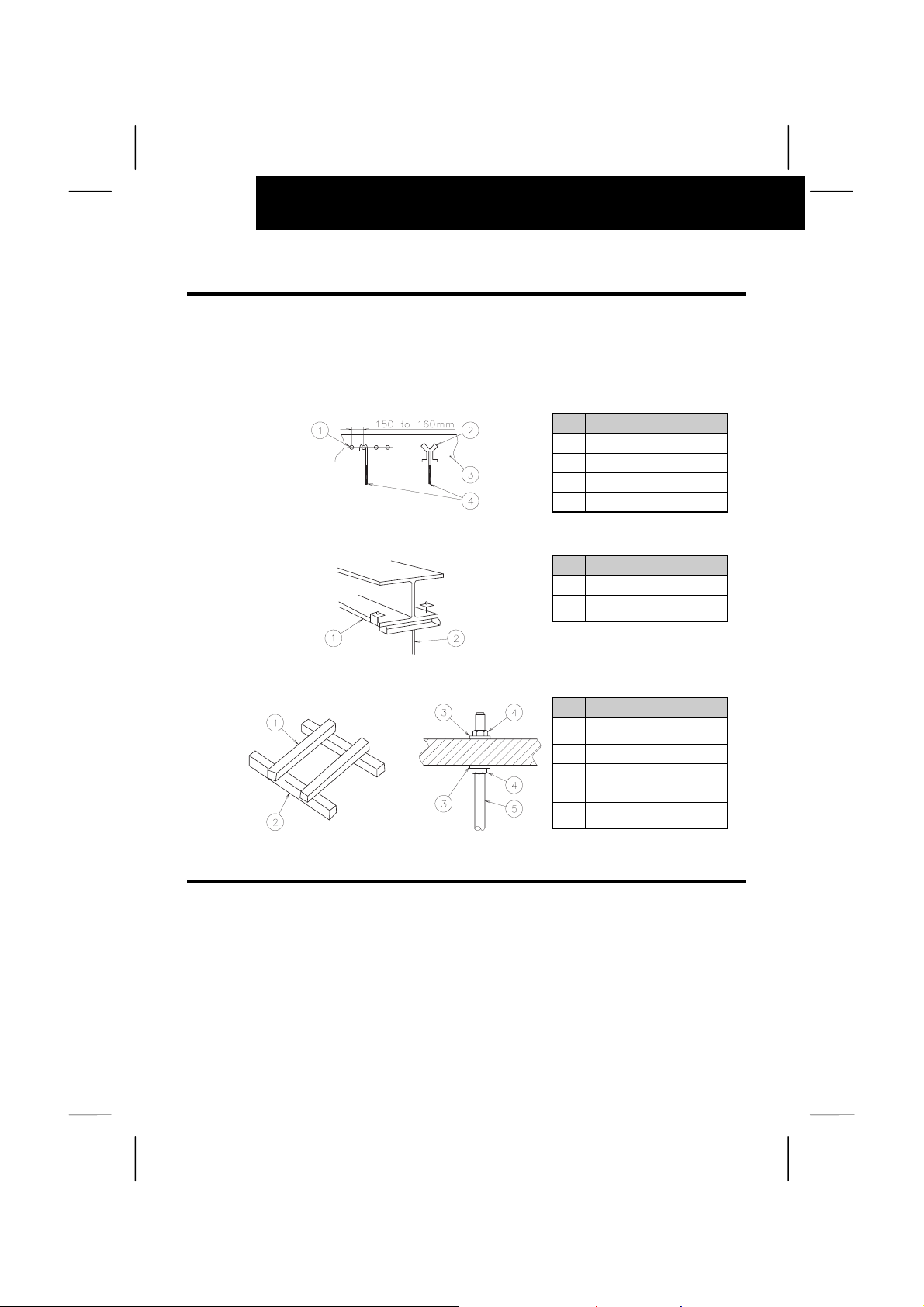

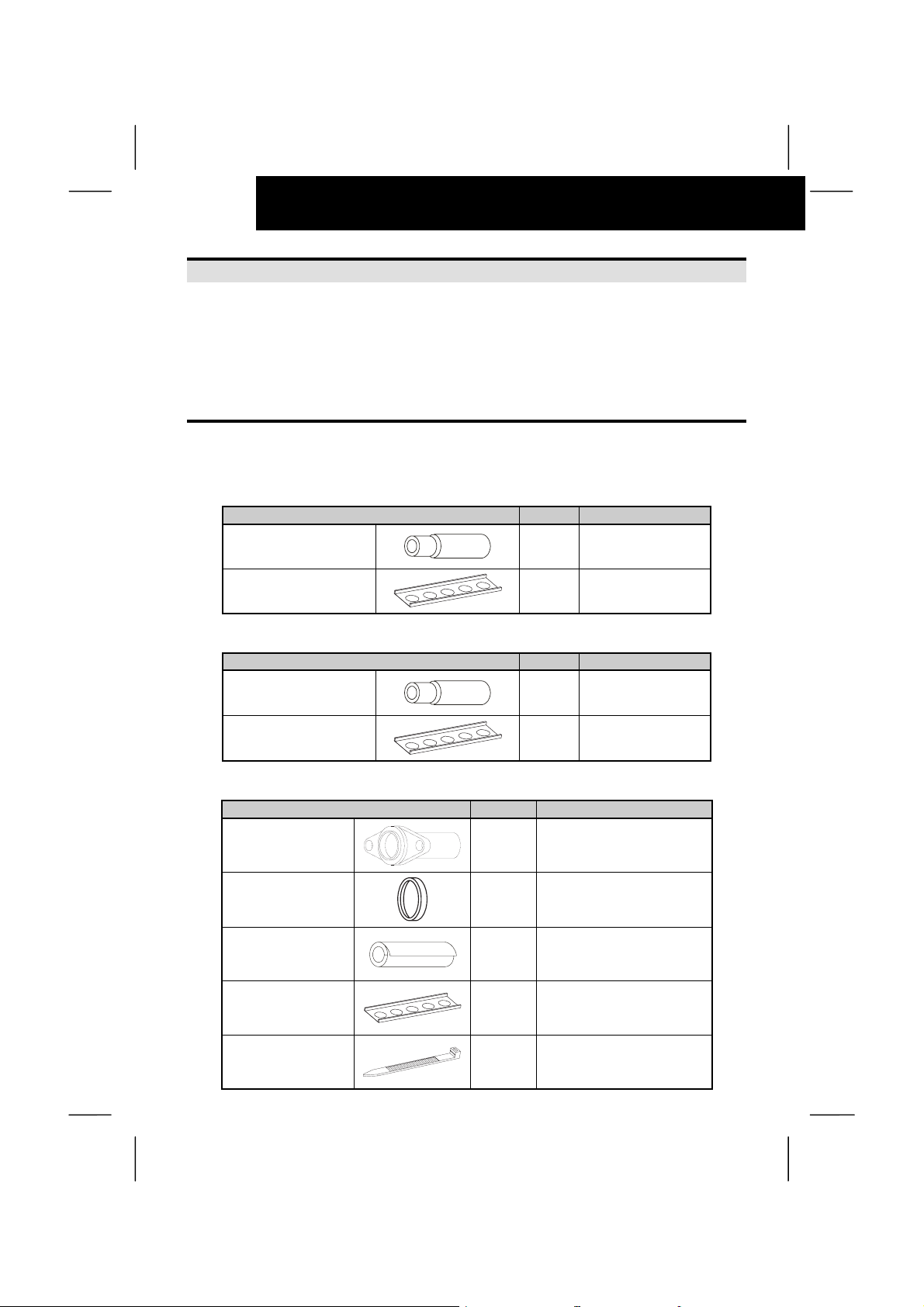

4.3. SUSPENSION BOLTS

- Select final location and installation direction of the indoor unit paying careful attention to the

space for the piping, wiring and maintenance.

- Mount suspension bolts, as shown below:

- For Concrete Slab:

No Description

Steel

o

Insert (100 to 150kg)

p

Concrete

q

Anchor Bolt (W3/8 or M10)

r

- For Steel Beam:

No Description

I Beam

o

Suspension Bolt

p

(W3/8 or M10)

- For Wooden Beam Suspension:

No Description

Wooden Bar

o

(60~90mm Square)

Wooden Beam

p

Square Washers

q

Nuts

r

Suspension Bolts

s

(W3/8 or M10)

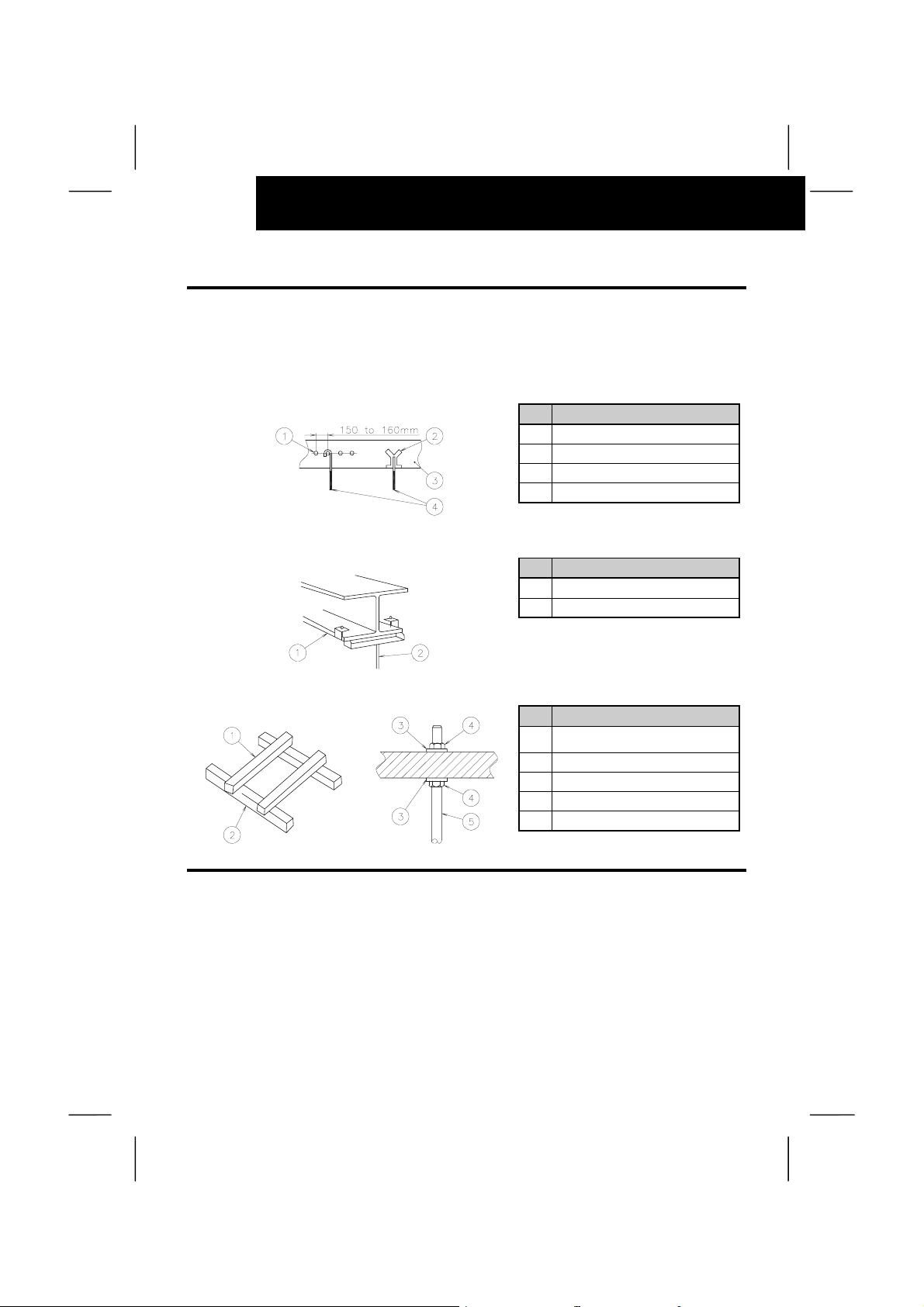

4.4. INSTALLATION

4.4.1. Marking Position of the Suspension Bolts and Piping Connections

- Mark position of the Suspension bolts, refrigerant piping connections and drain connection.

- See Installation dimensions in chapter 2.1.

Page 15

CH UNIT INSTALLATION

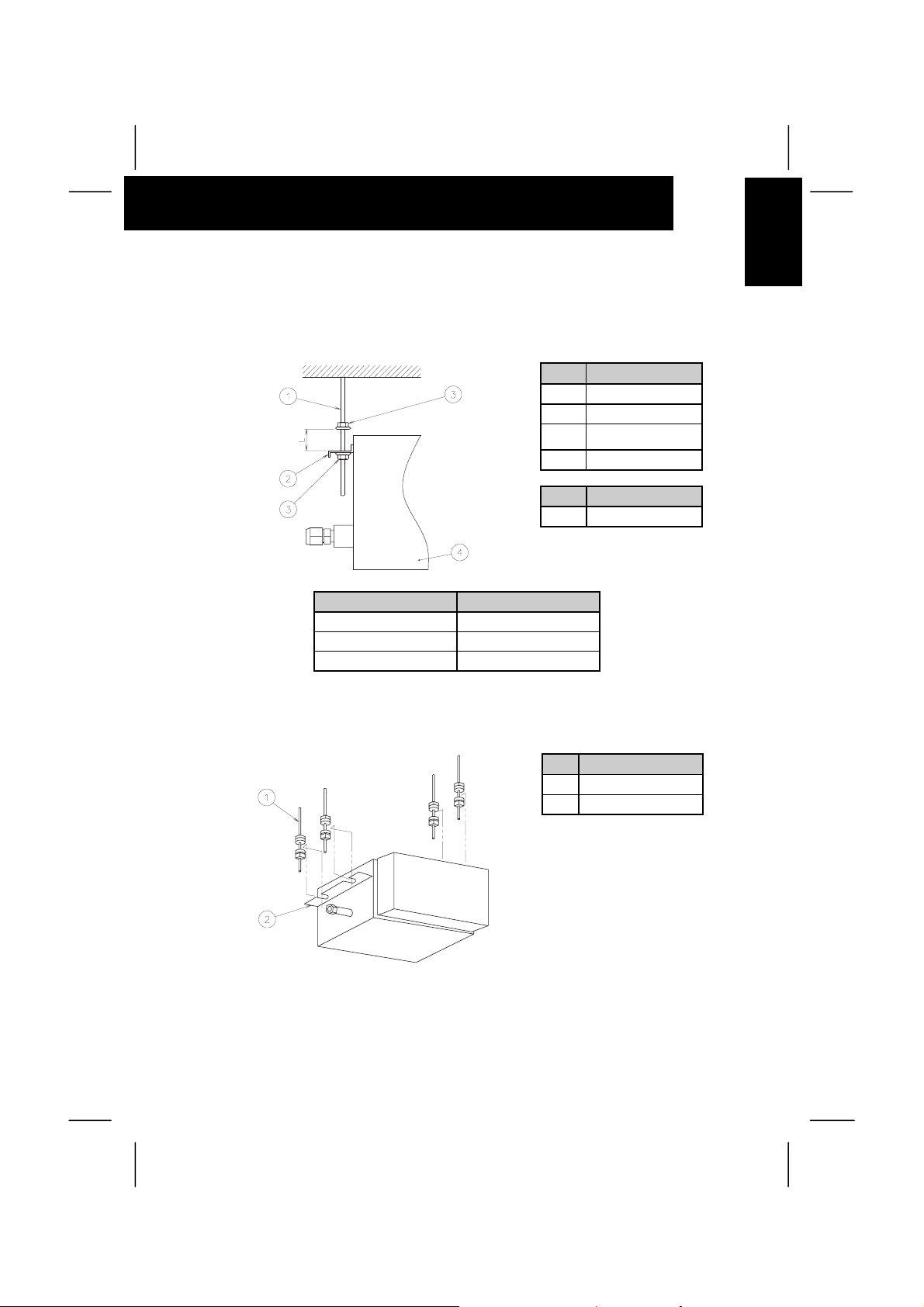

4.4.2. Mounting the CH Unit

How to put Nuts

Put nuts on each of the four suspension bolts before suspending the CH unit, as shown below

No Description

Suspension Bolt

o

Suspension Bracket

p

Nut & Washer

q

(Field-Supplied)

CH-Box

r

Mark Dimension

L 30~50mm

Field-Supplied Parts CH-(4.0/8.0/12.0)N(E)

Suspension Bolts 4-M10 or W-3/8

Nut 8-M10 or W-3/8

Washer 8-M10 or W-3/8

9

ENGLISH

Suspension the CH Unit

Hook suspension bracket to the nut and washer of each suspension bolt, as shown below.

Check that the nuts and washers are correctly fixed by the retainers of the suspension bracket.

No Description

Suspension Bolt

o

Suspension Bracket

p

Page 16

10

REFRIGERANT PIPING WORK

4.4.3. Adjusting of the Unit Level

How to put Nuts

In order to avoid an incorrect unit operation, check the level of the unit using a water level in a

transparent Vinyl tube containing water.

No Description

Vinyl Tube

o

Level Scale

p

Tighten the bolts of the suspension nuts with the suspension brackets after adjustment is completed.

Special plastic paint must be applied to the bolts in order to prevent them from loosening.

5. REFRIGERANT PIPING WORK

Õ DANGER:

Use refrigerant R410A in the refrigerant cycle. Do not charge oxygen, acetylene or other

flammable and poisonous gases into the refrigerant cycle when performing a leakage test or

an air-tight test. These types of gases are extremely dangerous and can cause an explosion. It

is recommended that compressed air, nitrogen or refrigerant be used for these types of tests.

5.1. PIPING MATERIALS

1. Prepare locally-supplied copper pipes.

2. Select clean copper pipes. Make sure there is no dust and moisture inside. Before connecting

pipes, blow the inside of the pipes with nitrogen or dry air, to remove any dust or foreign

materials.

3. Select the piping size from dimensional drawing

5.2. PIPING CONNECTION

1. Position of piping connection is shown in dimensional drawing.

2. Connect the accessories as shown in the Diagram bellow:

CH-(4.0/8.0)NE

No Description

Pipe Fixing Band

To

Indoor

Unit

{

Outdoor

}

To

Unit

o

Liquid Pipe

p

Low Gas Pipe

q

High Gas Pipe

r

Gas Pipe

s

Reducer

t

Field-Supplied Piping

Page 17

REFRIGERANT PIPING WORK

}

CH-12.0N

No Description

To

Indoor

Unit

{

3. When tightening the Flare nut, use two spanners as shown in below figure.

Pipe Size Tightening Torque (N.m)

∅6.35

∅9.53

∅12.7

∅15.88

∅19.05

(1/4) 2

(3/8) 4

(1/2) 6

(5/8) 8

(3/4) 10

To

Outdoor

Unit

Pipe Fixing Band

o

Liquid Pipe

p

High Gas Pipe

q

Low Gas Pipe

r

Gas Pipe

s

Pipe Flange

t

Field-Supplied

Piping

11

ENGLISH

4. After connecting the refrigerant piping, seal the refrigerant pipes by using the field-supplied

insulation materials as shown in figure below.

Use the factory-supplied pipe with a flange to connect low-pressure gas piping. The gasket at the

unit gas piping inlet should be replaced to the one supplied with your unit.

(Thermal insulator over the flange connection should be field-supplied).

NOTE:

The factory-supplied flange should be welded with the connection pipe before connecting the

valve. Mount the Insulation’s after the pipe brazing. Take particular care upon connecting

flange so that Insulation is correctly located.

To

Indoor

{}

Unit

No Description Remarks

Insulation - Field Supplied – CH-4.0NE unit

o

Insulation - Field Supplied – CH-(4.0/8.0/12.0)NE units

p

Insulation

q

- Field Supplied – CH-(4.0/8.0)NE

- Included in CH-12.0N unit as accessory.

To

Outdoor

Unit

Page 18

12

ELECTRICAL WIRING

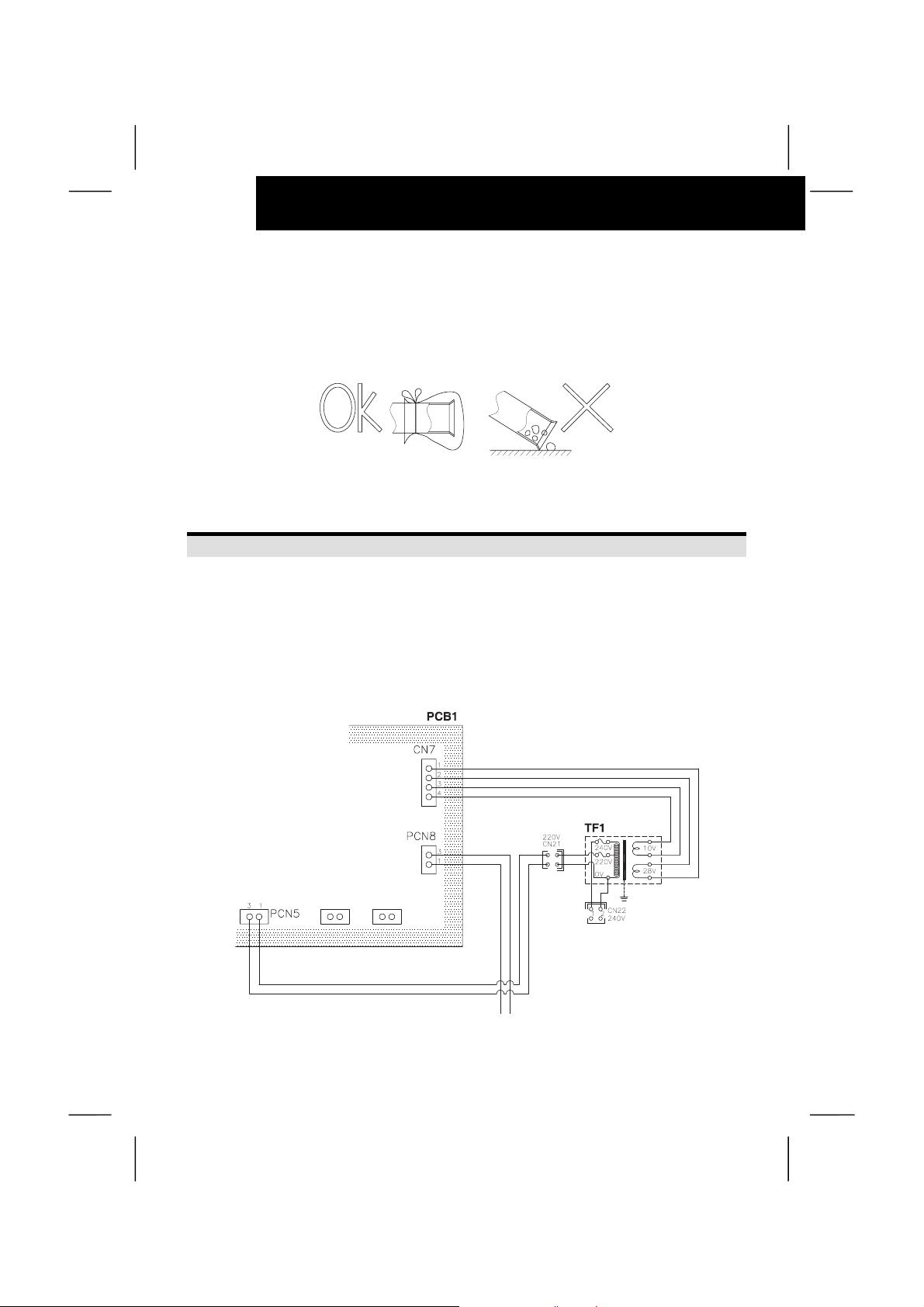

CAUTION:

- Cover the end of the pipe if the pipe has to be inserted through a hole.

- Do not put pipes on the ground directly without a cap or vinyl tape at the end of the pipe.

- Remove all the flammable materials around the units. If not, it will cause a fire.

Correct Incorrect

5. Evacuation and refrigerant charging procedures should be performed according to “Installation

and Operation Manual” of Outdoor unit – Chapter: “Piping and Refrigerant Charge”.

6. ELECTRICAL WIRING

ÔWARNING:

- Turn OFF the main power switch to the CH unit, the indoor unit and the outdoor unit before

electrical wiring work or a periodical check is performed.

- Protect the wires, electrical parts, etc. from rats or other vermin.

- Check the item below before turning ON the main switch.

In case that the power source for indoor unit 240V (nominal voltage), change CN21 (connector)

to CN22 of transformer (TF1) in the electrical control box as shown below.

CAUTION:

- Wrap the accessory packing around the wires, and plug the wiring connection hole with the

seal material to protect the product from any condensate water or insects.

- Tightly secure the wires with the cord clamp inside the electrical box.

Page 19

ELECTRICAL WIRING

13

6.1. GENERAL CHECK

- Make sure that the field-selected electrical components (main power switches, circuit breakers,

wires, conduit connectors and wire terminals) have been properly selected according to the

electrical data indicated in Technical Catalogue. Make sure that the components comply with

National Electrical code (NEC)

- Check to ensure that the power supply voltage is within ±10% of rated voltage.

- Check the power source capacity is too low, the system cannot be started due to the voltage drop.

- Check to ensure that the ground wire is connected.

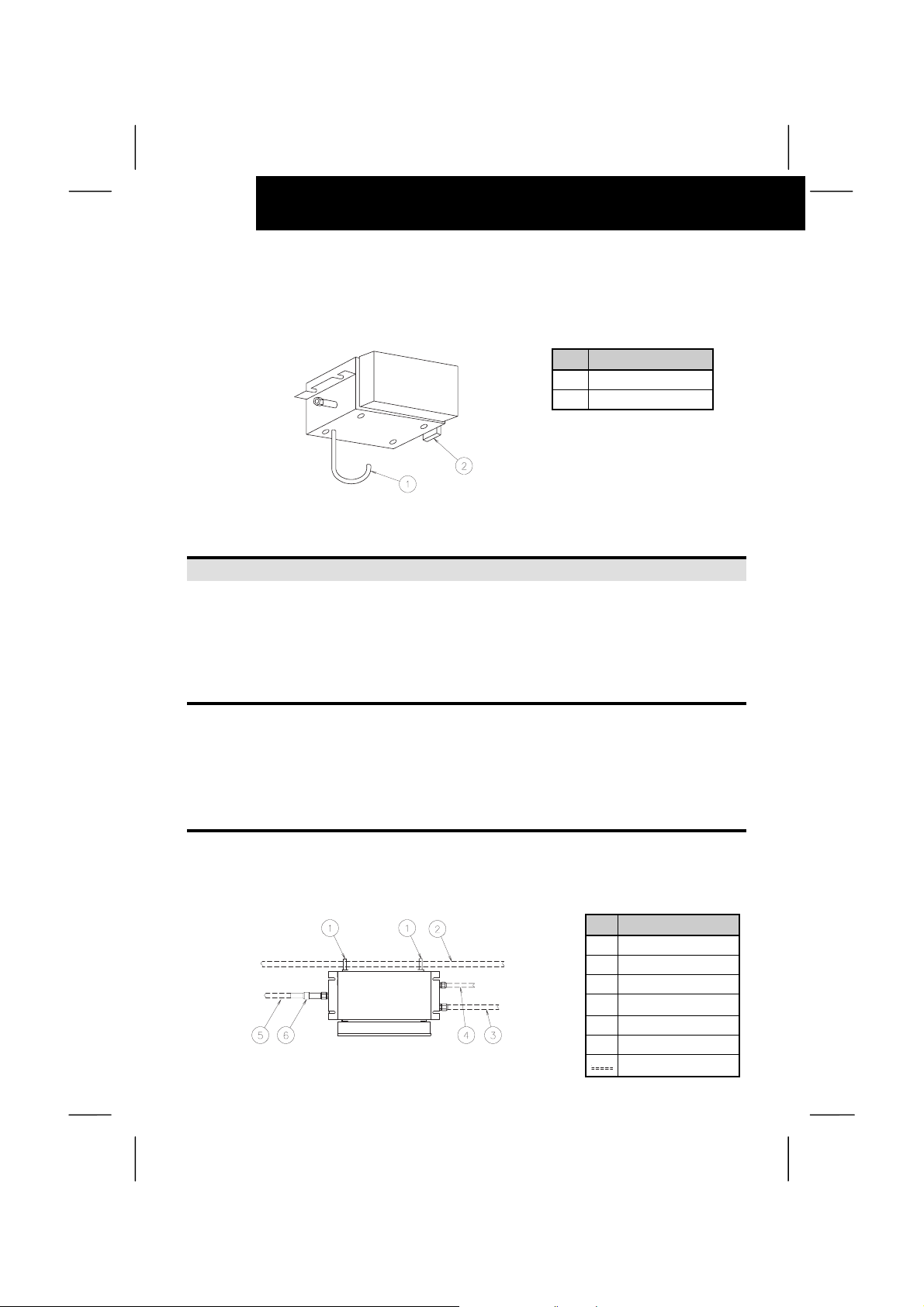

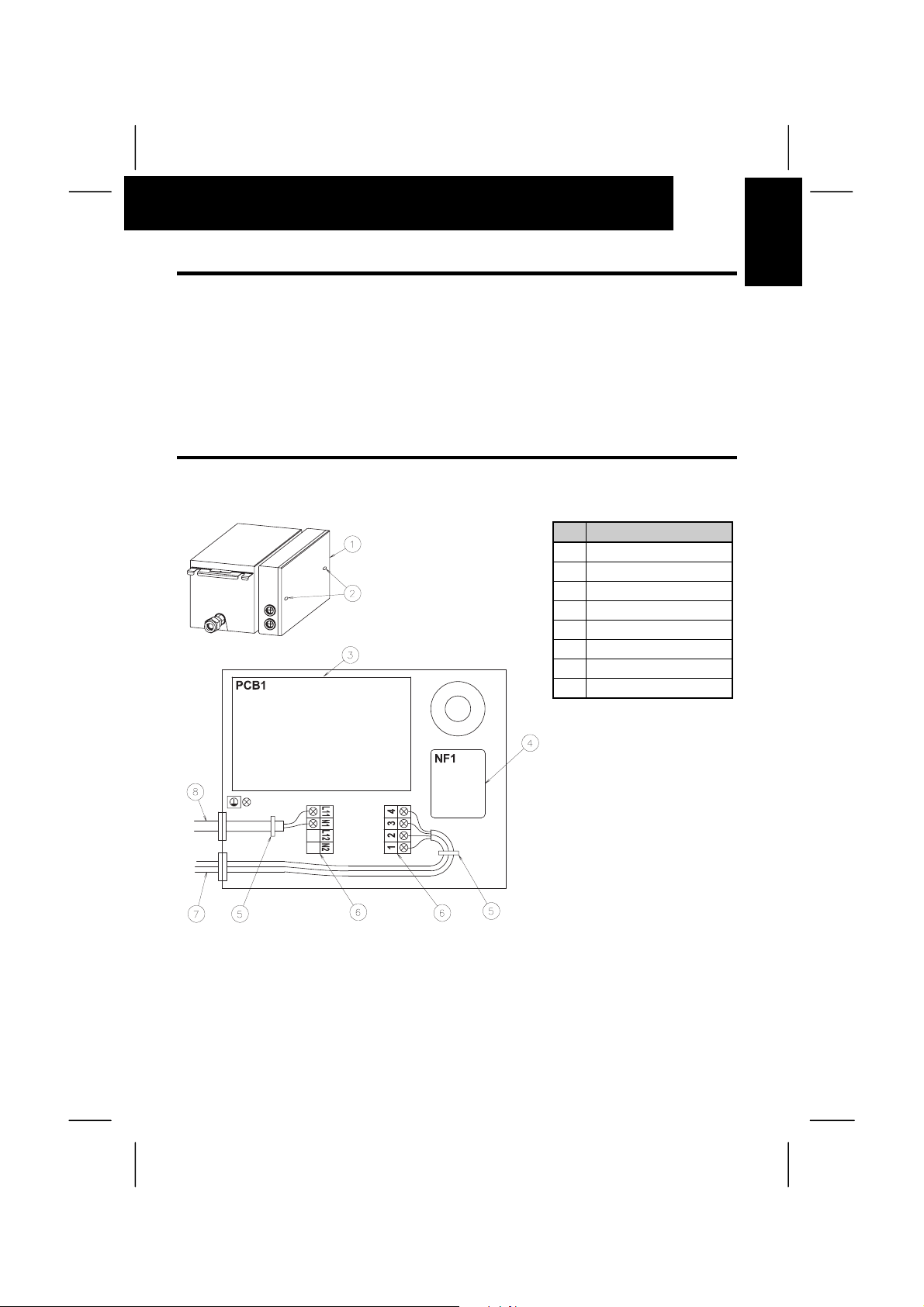

6.2. ELECTRICAL WIRING CONNECTION

The electrical wiring connection is shown in below figure.

No Description

Electrical Box Cover

o

Fixing Screw

p

Printed circuit Board

q

Noise Filter

r

Cord Clamp

s

Terminal Board

t

Operating Line

u

Power Supply Line

v

ENGLISH

NOTE:

At the terminal board 2, the

connectors 1 and 2 are for

H Link system, and the

connectors 3 and 4 are for

going to the Indoor Unit

from the CH-Box setting of

dip switches

1. Turn OFF the main power switch and take off the electrical box cover of CH unit.

2. Cut out the center of the rubber bushing in the wiring connection hole, as shown below.

3. Connect the power supply and earth wires to the terminals in the electrical box.

4. Connect the wires of the operating line to the terminals in the electrical box.

Page 20

14

ELECTRICAL WIRING

5. Tightly clamp the wires using the cord clamp inside the electrical box.

6. Fix the electrical box cover after wiring work.

No Description

Rubber Bushing

o

Cut Inside

p

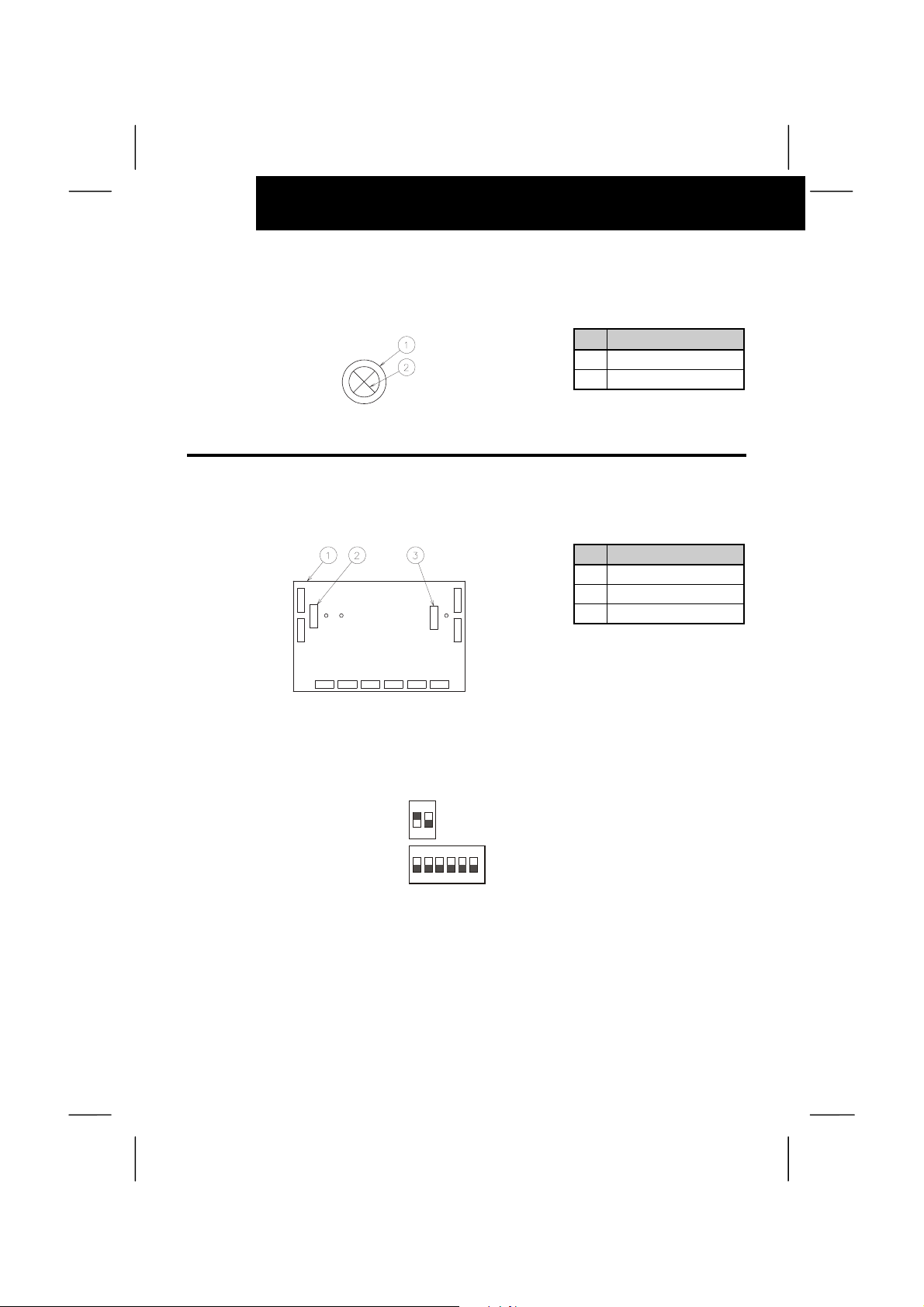

6.3. SETTING OF DIP SWITCHES

Position of Dip Switches

The PCB1 in the electrical box of CH unit is equipped with 2 types of dip switches (DSW2, DSW5),

as shown in the figure below.

No Description

PCB1

o

DSW5

p

DSW2

q

Setting of Dip Switches

The dip switches are set before shipment and no setting in the field is required. These are utilized for

the self-diagnosis of PCB.

Factory Setting Position (Dip Switch)

¥ DSW5

¥ DSW2

NOTE:

The "" mark indicates position of dip switches. The above figures show the setting before

shipment.

ON

1 2

ON

1 2 3 4 5 6

CAUTION:

Before setting dip switches, firstly turn OFF power source and set the position of the dip

switches. If the switches are set without turning OFF the power source, the switch can not

function.

Page 21

TEST RUN

7. TEST RUN

Test run should be performed according to “Installation & Operation Manual” of Outdoor unit.

Ô WARNING:

Do not operate the system until all the check points have been cleared.

- Check to ensure that the electrical resistance is more than 1 M

resistance between ground and the terminal of the electrical parts. If not, do not operate the

system until the electrical leakage is found and repaired.

- Check to ensure that the stop valves of the outdoor unit are fully opened, and then start the

system.

- Check to ensure that the switch on the main power source has been ON for more than 12

hours, to warm the compressor oil by the crankcase heater.

Pay attention to the following items while the system is running.

- Do not touch any of the parts by hand at the discharge gas side, since the compressor

chamber and the pipes at the discharge side are heated higher than 90Cº.

- DO NOT PUSH THE BUTTON OF THE MAGNETIC SWITCH(ES). It will cause a serious

accident.

Ω

, by measuring the

15

ENGLISH

Page 22

Page 23

RESUMEN DE SEGURIDAD 17

1. RESUMEN DE SEGURIDAD

Ô ADVERTENCIA:

- Al realizar la instalación y conectar la tubería de refrigerante y el cableado eléctrico, siga las

instrucciones de nuestro manual de instalación.

- Compruebe que la toma de tierra está bien conectada.

- Conecte un fusible de la capacidad especificada.

PRECAUCIÓN:

- Cuando instale la unidad CH y el cable, procure que la distancia mínima hasta la fuente más

próxima de ondas electromagnéticas, como los equipos médicos, sea de 3 metros

aproximadamente.

2. ESTRUCTURA

2.1. DIMENSIONES

2.1.1. Modelo: Unidad CH-(4.0/8.0)NE

ESPAÑOL

Unidad:mm

Hacia la maquina Interior Hacia la maquina Exterior

Nº Descripción

1 Soporte de Suspensión Para pernos M8 o W5/16

2 Conexión tubería gas refrigerante (Baja)

3 Conexión tubería gas refrigerante (Alta)

4 Conexión del tubo de gas refrigerante

5 Accesorios (Disponible sujetarla en ambos lados)

6 Orificio para la línea de servicio

7 Orificio para la línea de alimentación

Dimensiones a 78mm 82mm

15.88 Conexión abocardada 19.05 Conexión abocardada

15.88 Conexión abocardada 19.05 Conexión abocardada

CH-4.0NE CH-8.0NE

12.7 Conexión abocardada 15.88 Conexión abocardada

Observaciones

26.5

26.5

Page 24

18 ESTRUCTUR

A

2.1.2. Modelo: Unidad CH-12.0N

Hacia la maquina Interior Hacia la maquina Exterior

Unidad:mm

Nº Descripción

1 Soporte de Suspensión Para pernos M8 o W5/16

2 Conexión tubería gas refrigerante (Baja)

3 Conexión tubería gas refrigerante (Alta)

4 Conexión del tubo de gas refrigerante

5 Accesorios (Disponible sujetarla en ambos lados)

6 Orificio para la línea de servicio

7 Orificio para la línea de alimentación

Observaciones

CH-12.0N

∅22.2 Conexión con brida

∅19.05 Conexión abocardada

∅22.2 Conexión con brida

∅26.5

∅26.5

Page 25

2.2. CICLO FRIGORÍFICO

2.2.1. Unidad (CH-4.0/8.0NE)

Hacia unidad

interior

Õ

Alta

presión

Tubería

de Gas

ESTRUCTURA 19

Hacia unidad

exterior

Ö

Alta

presión

Tubería

de Gas

Baja

presión

Tubería

de Gas

ESPAÑOL

Baja

presión

Tubería

de Gas

Dirección del Flujo de refrigerante (modo enfriamiento)

Dirección del Flujo de refrigerante (modo calefacción)

Nº Descripción Marca

1 Válvula Solenoide (AC) a

2 Filtro b

3 Válvula de Comprobación c

4 Tubo Capilar d

5 Tubo Capilar e

f

g

h

j

k

O.D.(mm) × grosor (mm)

CH-4.0NE CH-8.0NE

∅12.7×1.0 ∅15.88×1.0

∅9.53×0.8 ∅12.7×1.0

∅4.0x0.8 ∅4.0x0.5

∅12.7×1.0 ∅15.88×1.2

∅15.88 ∅19.05

Conexión abocardada

Conexión soldada

Tuberías de refrigerante

Dimensión Material

∅2.5x0.7

∅6.35×1.07

∅9.53×0.8

∅12.7×1.0

∅12.7 ∅15.88

NOTA:

La inscripción entre corchetes "[ ]" aparece en el diagrama del cableado eléctrico.

Baja

presión

Tubería

de Gas

Material

Tubo de Cobre

C1220T-O

Page 26

20 ESTRUCTUR

A

2.2.2. Unidad CH-12.0N

Hacia maquina

interior

Õ

Alta

presión

Tubería

de Gas

Hacia maquina

exterior

Ö

Alta

presión

Tubería

de Gas

Baja

presión

Tubería

de Gas

Baja

presión

Tubería

de Gas

Dirección del Flujo de refrigerante (modo enfriamiento) Conexión abocardada

Dirección del Flujo de refrigerante (modo calefacción) Conexión con brida

Conexión soldada

Tuberías de refrigerante

Nº Descripción Marca

1 Válvula solenoide (AC) a

2 Filtro b

3 Válvula de Comprobación c

4 Tubo Capilar d

5 Tubo Capilar e

f

g

h

j

k

Dimensión Material

O.D.(mm) × grosor (mm)

∅6.35 x 1.07

∅12.7 x 1.0

∅15.88 x 1.0

∅15.88 x 1.2

∅19.05 x 1.2

∅19.05 x 1.65

∅3.0 x 0.8

∅4.0 x 0.5

∅22.2

∅19.05

NOTA:

La inscripción entre corchetes "[ ]" aparece en el diagrama del cableado eléctrico.

Baja

presión

Tubería

de Gas

Material

Tubo de Cobre

C1220T-O

Page 27

TRANSPORTE Y MANEJO 21

2.3. LISTA DE HERRAMIENTAS E INSTRUMENTAL NECESARIOS PARA LA INSTALACIÓN

Nº Herramienta Nº Herramienta

1 Sierra de mano 11 Llave inglesa

2 Destornillador Phillips 12 Cilindro de carga

3 Bomba de vacío 13 Colector del manómetro

4 Manguera gas refrigerante 14 Corta cables

5 Megaohmímetro 15 Detector de escapes de gas

6 Curvador para tubos de cobre 16 Nivel

7 Bomba de agua manual 17

8 Corta tubos 18 Cabria (para izar la unidad interior)

9 Equipo de soldadura 19 Amperímetro

10 Llave allen 20 Medidor de voltaje

Grapa para terminales de fijación sin

soldadura

3. TRANSPORTE Y MANEJO

Antes de desempaquetar el producto, transpórtelo lo más cerca posible del lugar de instalación.

Ô ADVERTENCIA:

No introduzca ningún objeto extraño dentro de la unidad CH y compruebe que no se ha

introducido ninguno en la unidad interior antes de llevar a cabo la instalación y la prueba de

funcionamiento. De lo contrario, puede provocarse un incendio o una avería.

ESPAÑOL

Ó PRECAUCIÓN:

No coloque ningún tipo de material sobre el producto.

Al izar la unidad, tenga precaución para no dañar los materiales aislantes de la superficie.

3.1. COMBINACIÓN DE LA UNIDAD CH Y LA UNIDAD INTERIOR

La unidad CH se instala en el interior para dar soporte al sistema SET-FREE FXN(E), entre la

unidad exterior y la interior. La combinación de la unidad CH y la interior es como sigue:

Modelo

CH-4.0NE 1 a 5

CH-8.0NE 1 a 8

CH-12.0N 1 a 5

Nº unidades

interiores

Capacidad total interior (HP)

Inferior a 4.0

(sin incluir 4.0)

4.0 ~ 6.5 (incluyendo 4.0

y excluyendo 8.0)

8.0 ~ 12.0 (incluyendo 8.0

e incluyendo 12.0)

Page 28

22 INSTALACIÓN DE LA UNIDAD CH

4. INSTALACIÓN DE LA UNIDAD CH

Õ PELIGRO:

No instale la unidad interior en lugares inflamables para evitar incendios y explosiones.

Ô ADVERTENCIA:

Compruebe que las placas del techo son suficientemente resistentes.

No instale la unidad CH en el exterior. Si lo hace, hay riesgo de dispersión eléctrica.

4.1. PARA FIJAR EL AISLANTE DEL TUBO REFRIGERANTE SUMINISTRADOS DE FÁBRICA

Compruebe que el paquete de la unidad CH incluye los siguientes Para fijar el aislante del tubo

refrigerante:

Para fijar el aislante del tubo refrigerante suministrados de fábrica (para CH-4.0NE)

Accesorios Cantidad Propósito

Para conectar el tubo de

Reductor (∅15.88 a ∅12.7)

Brida fijadora de tubo 2

Para fijar el aislante del tubo refrigerante suministrados de fábrica (para CH-8.0NE)

Accesorios Cantidad Propósito

Reductor (∅19.05 a ∅15.88)

Brida fijadora de tubo 2

1

liquido ∅12.7 de la

unidad interior

Para fijar el tubo de

liquido

Para conectar el tubo de

1

liquido ∅15.88 de la

unidad interior

Para fijar el tubo de

liquido

Para fijar el aislante del tubo refrigerante suministrados de fábrica (para CH-12.0N)

Accesorios Cantidad Propósito

Tubo con brida.

Tamaño: (∅22.2)

Obturador para brida 2 Sellado con brida

Aislante (∅38 ID)

Brida fijadora de tubo 2 Para fijar el tubo de liquido

Brida Flexible 8

Para conectar el tubo de gas

2

(alto) procedente de la unidad

exterior

Para conectar los tubos de

1

refrigerante

Para fijar el aislante del tubo

refrigerante

Page 29

INSTALACIÓN DE LA UNIDAD CH 23

4.2. COMPROBACIONES INICIALES

4.2.1. Cuando instale la unidad CH, procure que haya suficiente espacio a su alrededor para

trabajar, tal como se indica en la figura:

Panel de Acceso

Nº Descripción

Caja eléctrica

o

Panel de Acceso

p

Vista desde A

Marca Dimensiones (Min)

Modelo CH-4.0/8.0 CH-12.0

a 250mm 350mm

b 100mm

4.2.2. Al activar la válvula solenoide de la unidad CH es posible que se escuche el ruido que

produce el refrigerante. Para reducir al mínimo este ruido, tome las siguientes medidas:

- Instale la unidad CH empotrada en el techo. Como material para el techo, escoja uno del tipo de

las placas de escayola, que reduce al mínimo el ruido del aparato en funcionamiento.

- No instale la unidad CH cerca de un dormitorio o en una sala de hospital.

- No instale la unidad CH en ningún lugar húmedo, como una cocina, para evitar que se condense

rocío en la superficie exterior de la unidad CH.

ESPAÑOL

4.2.3. Si ha de instalar la unidad CH en un hospital u otro tipo de local donde haya ondas

eléctricas generadas por equipos médicos, preste atención a los siguientes puntos:

- No instale la unidad CH en lugares donde la Accesorios o los cables intermedios reciban

directamente la radiación electromagnética.

- Instale la unidad CH y los componentes tan lejos como sea posible de la fuente de radiaciones

electromagnéticas o, como mínimo, a 3 metros de distancia.

- Instale un filtro antirruido cuando la fuente de alimentación emita ruidos molestos.

Page 30

24 INSTALACIÓN DE LA UNIDAD CH

4.3. PERNOS DE SUSPENSIÓN

- Escoja el lugar definitivo y la dirección en que desea instalar la unidad interior, con especial

atención al espacio destinado a los tubos, el cableado y el mantenimiento.

- Monte los pernos de suspensión, tal como indica la figura.

- Para placas de hormigón:

Nº Descripción

Acero

o

Insertar (100 a 150kg)

p

Hormigón

q

Perno de anclaje (W3/8 a M10)

r

- Para vigas de acero

Nº Descripción

Viga en doble T

o

Perno de suspensión (W3/8 a M10)

p

- Para suspensión en viguetas de madera:

Nº Descripción

Barra de madera (60~90mm

o

Cuadrada)

Vigueta de madera

p

Arandelas cuadradas

q

Tuercas

r

Perno de suspensión (W3/8 a M10)

s

4.4. INSTALACIÓN

4.4.1. Señalización de los puntos para los pernos de suspensión y las conexiones de los

tubos

- Marque los puntos exactos de los pernos de suspensión, las conexiones de los tubos de

refrigerante y de desagüe

- Ver las Dimensiones de Instalación en el apartado 2.1.

Page 31

INSTALACIÓN DE LA UNIDAD CH 25

4.4.2. Montaje de la unidad CH

Cómo colocar las tuercas

Coloque las tuercas en cada uno de los cuatro pernos de suspensión antes de suspender la

unidad CH, tal como muestra la figura.

Nº Descripción

Perno de suspensión

o

Soporte de Suspensión

p

Tuerca & Arandela

q

(Suministrado Instalador)

CH-Box

r

Marca Dimensiones

L 30~50mm

ESPAÑOL

Piezas no incluidas de

fabrica

Perno de suspensión 4-M10 a W-3/8

Tuerca 8-M10 a W-3/8

Arandela 8-M10 a W-3/8

CH-(4.0/8.0/12.0)N(E)

Suspensión de la unidad CH

Cuelgue los soportes de suspensión del juego de tuerca y arandela de cada uno de los pernos de

suspensión, como muestra la figura.

Compruebe que las tuercas y las arandelas están bien sujetas por los retenes de los soportes de

suspensión.

Nº Descripción

Perno de suspensión

o

Soporte de Suspensión

p

Page 32

26 INSTALACIÓN DE LOS TUBOS DE REFRIGERANTE

{

4.4.3. Ajuste del nivel de la unidad

Cómo colocar las tuercas

Para evitar el mal funcionamiento de la unidad, compruebe el nivel de la maquina con un medidor de

nivel, un tubo de vinilo transparente con agua dentro.

Nº Descripción

Tubo de vinilo

o

Escala de nivel

p

Una vez realizado el ajuste, apriete los pernos de las tuercas de suspensión a sus soportes.

Aplíquese pintura plástica especial a los pernos con el fin de evitar que se aflojen.

5. INSTALACIÓN DE LOS TUBOS DE REFRIGERANTE

Õ PELIGRO:

Para el circuito de refrigerante, utilice R410A. No cargue oxígeno, acetileno ni ningún otro gas

inflamable ni venenoso en el circuito cuando compruebe si hay fugas o haga pruebas de

estanqueidad. Estos tipos de gases son extremadamente peligrosos y pueden provocar una

explosión. Recomendamos utilizar aire comprimido, nitrógeno o refrigerante para realizar este

tipo de pruebas.

5.1. MATERIALES DE LAS TUBERÍAS

1. Prepare tubos de cobre (no suministrados).

2. Seleccione tuberías de cobre limpias. Asegúrese de que no haya polvo ni humedad en su

interior. Antes de conectar los tubos, insufle nitrógeno o aire seco al interior de los tubos para

eliminar cualquier resto de polvo o sustancias extrañas.

3. Seleccione el tamaño de tubo en el dibujo acotado.

5.2. CONEXIÓN DE LA TUBERÍA

1. En el dibujo acotado podrá ver la posición de las conexiones de los tubos.

2. Conecte los filtros Para fijar el aislante del tubo refrigerante y los manguitos reductores, tal como

indica la siguiente figura.

CH-(4.0/8.0)NE

No Descripción

Brida fijadora de tubo

o

Tubo de liquido

Hacia

unidad

interior

}

Hacia

unidad

exterior

p

Tubo de Gas Bajo

q

Tubo de Gas Alto

r

Tubo de Gas

s

Reductor

t

Tubo suministrado

por el instalador

Page 33

INSTALACIÓN DE LOS TUBOS DE REFRIGERANTE 27

CH-12.0N

No Descripción

Brida fijadora de tubo

o

Tubo de Liquido

p

Tubo de Gas Alto

Hacia

unidad

interior

{

3. Apriete la tuerca abocardada con dos llaves inglesas, tal como indica la figura.

Tamaño de tubería Par de Apriete (N.m)

∅6.35

∅9.53

∅12.7

∅15.88

∅19.05

4. Una vez conectados los tubos de refrigerante, séllelos con el material aislante que lo suministra

el instalador, tal como muestra la siguiente figura.

Para conectar el gas a baja presión, utilice el tubo con brida que es suministrado por fábrica.

Retire la junta obturadora de la entrada del tubo de gas de la unidad por otra, que se suministra

con el equipo.

(El aislante térmico que recubre la conexión embridada no se suministra de fábrica; deberá

adquirirlo en un establecimiento).

Hacia

unidad

exterior

}

(1/4) 2

(3/8) 4

(1/2) 6

(5/8) 8

(3/4) 10

q

Tubo de Gas Bajo

r

Tubo de Gas

s

Tubo con brida

t

Tubo suministrado

por el instalador

ESPAÑOL

NOTA:

La brida que se suministra de fábrica debe soldarse al tubo de conexión antes de conectar la

válvula. Tras soldar el tubo, monte la junta de obturación. Preste especial atención a la

conexión embridada; asegúrese de que la junta obturadora queda correctamente colocada.

Hacia

unidad

interior

Nº Descripción Observaciones

o

p

q

{ }

Aislante - Suministrado por el instalador – CH-4.0NE

Aislante - Suministrado por el instalador – CH-(4.0/8.0/12.0)NE

Aislante

- Suministrado por el instalador – CH-(4.0/8.0)NE

- Incluido en la unidad CH-12.0N como accessorio.

unidad

exterior

Hacia

Page 34

28 CABLEADO ELÉCTRICO

PRECAUCIÓN:

- Si tiene que introducir el tubo por un agujero, ponga un tapón en el extremo.

- No coloque tuberías directamente sobre el suelo sin haber colocado un tapón o cinta de vinilo

en el extremo de la misma.

- Retire todas las sustancias inflamables de las cercanías de las unidades. Pueden provocar

un incendio.

Correcto Incorrecto

5. El vaciado y cambio del refrigerante se debe realizar según las instrucciones del “Manual de

instalación y funcionamiento” de la unidad exterior.

6. CABLEADO ELÉCTRICO

ÔADVERTENCIA:

- Desconecte el interruptor principal de la unidad CH, la unidad interior y la exterior antes de

comenzar a instalar el cableado y cada vez que se lleve a cabo una comprobación periódica.

- Proteja los cables y demás componentes eléctricos de las ratas y demás alimañas.

- Preste atención a la siguiente información antes de conectar el interruptor principal.

En caso de que la fuente de alimentación de la unidad interior, tenga un voltaje nominal de 240

V cambie el conector CN21 al CN22 del transformador TF1 de la caja de control eléctrico, tal

como indica la figura.

ATENCIÓN:

- Proteja los cables con el embalaje accesorio y tape el orificio de conexión con el material de

sellado para así proteger el producto de la condensación de agua y los insectos.

- Sujete con firmeza los cables con la abrazadera dentro de la Accesorios.

Page 35

CABLEADO ELÉCTRICO 29

6.1. COMPROBACIONES GENERALES

- Asegúrese de que todos los componentes eléctricos (interruptores principales, disyuntores,

cables, conectores para las canaletas y terminales para cable) son los adecuados, según los

datos eléctricos que figuran en el catálogo técnico. Compruebe que todos los componentes

cumplen las normas nacionales en materia de electricidad.

- Compruebe que la tensión de la fuente de alimentación está dentro del +/-10% de la tensión

nominal.

- Compruebe la capacidad de la fuente de alimentación; si es demasiado baja, el sistema no podrá

arrancar por la bajada de tensión.

- Asegúrese de que el cable de toma de tierra está conectado.

6.2. CONEXIÓN DEL CABLEADO ELÉCTRICO

En esta figura le indicamos las conexiones del cableado eléctrico.

Nº Descripción

Caja eléctrica

o

Tornillo de fijación

p

Placa de circuitos impresos

q

Filtro de sonido

r

Brida sujeta cables

s

Placa de bornes

t

Línea de funcionamiento

u

Alimentación

v

ESPAÑOL

NOTA:

En la placa de bornes 2, los

conectores 1 y 2

corresponden l sistema H

Link y los 3 y 4, van a la

unidad interior desde la caja

CH.

1. Desconecte el interruptor principal y retire la tapa de la Accesorios de la unidad CH.

2. Corte el centro del forro de goma del orificio de conexión de los cables, tal como indica la figura.

3. Conecte los cables de alimentación y tierra a las terminales correspondientes de la caja.

4. Conecte los cable de la línea operativa a los terminales de la Accesorios.

Page 36

30 CABLEADO ELÉCTRICO

5. Sujete bien los cables con la abrazadera, dentro de la Accesorios.

6. Tras terminar el cableado, vuelva a colocar la tapa de la Accesorios.

Nº Descripción

Forro de goma

o

Cortar dentro

p

6.3. CONFIGURACIÓN DE LOS CONMUTADORES DIP

Posición de los conmutadores DIP

La PCB1 de la Accesorios de la unidad CH está equipada con dos tipos de conmutadores DIP

(DSM2 y DSM5), tal como muestra la figura.

Nº Descripción

PCB1

o

DSW5

p

DSW2

q

Configuración de los conmutadores DIP

Los conmutadores DIP está ya configurados de fábrica, por lo que no es necesario volver a hacerlo.

Se utilizan para el autodiagnóstico de la PCB.

Configuración de fabrica (Conmutador Dip)

¥ DSW5

¥ DSW2

NOTA:

La señal "" indica la posición de los conmutadores DIP. En las anteriores figuras le

mostramos la configuración antes del envío del material.

ON

1 2

ON

1 2 3 4 5 6

PRECAUCIÓN:

Antes de configurar los conmutadores DIP, desconecte la alimentación y configure la posición

correcta de los conmutadores. Si se configuran los conmutadores sin desconectar la corriente,

no podrán funcionar.

Page 37

MODO DE PRUEBA 31

7. MODO DE PRUEBA

Deberá realizar una prueba de funcionamiento, según las instrucciones del “Manual de instalación y

funcionamiento” de la unidad exterior.

Ô ADVERTENCIA:

No ponga en funcionamiento el sistema hasta que se hayan verificado todos los puntos de

comprobación.

- Compruebe que la resistencia eléctrica es de más de 1 M

tierra y el terminal de los componentes eléctricos. Si no fuera así, no haga funcionar el

sistema hasta haber localizado y reparado la fuga eléctrica.

- Compruebe que las válvulas de servicio de la unidad exterior están completamente abiertas

y luego encienda el sistema.

- Compruebe que el conmutador de la fuente de alimentación principal ha estado encendido

durante más de 12 horas para calentar el aceite del compresor con el calentador de aceite.

Preste atención a los siguientes aspectos mientras el sistema está en funcionamiento.

- No toque con las manos ninguna de las piezas en la zona de descarga del gas, ya que la

cámara del compresor y las tuberías de dicha zona se calientan hasta alcanzar una

temperatura superior a los 90ºC.

- NO PULSE EL BOTÓN DEL CONMUTADOR O CONMUTADORES MAGNÉTICOS. Puede

provocar graves accidentes.

Ω

, midiendo la resistencia entre la

ESPAÑOL

Page 38

Page 39

SICHERHEITSANWEISUNGEN

1. SICHERHEITSANWEISUNGEN

Ô WARNUNG:

- Führen Sie keine Montage-, Kühlmittelleitungs- oder Elektroinstallationsarbeiten

ohne Befolgung der Anweisungen in diesem Handbuch durch.

- Prüfen Sie, dass die Erdung korrekt angeschlossen ist.

- Fügen Sie eine Sicherung mit den geforderten Werten in die Leitung ein.

VORSICHT:

- Installieren Sie die CH-Einheit und deren Kabel nicht in weniger als 3 m Entfernung von

starken elektromagnetischen Quellen wie medizinischen Geräten.

2. STRUKTUR

2.1. ABMESSUNGEN

2.1.1. Modell: CH-Einheit CH(4.0/8.0)NE

33

DEUTSCH

Unit:mm

Zur Inneneinheit Zur Außeneinheit

Nr Bezeichnung

1 Halterung für Schrauben M8 oder W5/16

2 Kühlgasleitungsanschluss (Niederdruck)

3 Kühlgasleitungsanschluss (Hochdruck)

4 Kühlgasleitungsanschluss

5 Anschlussbox (Verfügbare Befestigung auf beiden Seiten)

6 Durchführung für Betriebsleitungen

7 Durchführung für Netzkabel

Abmessungen a 78mm 82mm

CH-4.0NE CH-8.0NE

∅15.88 Flanschverbindung ∅19.05 Flanschverbindung

∅12.7 Flanschverbindung ∅15.88 Flanschverbindung

∅15.88 Flanschverbindung ∅19.05 Flanschverbindung

Anmerkungen

∅26.5

∅26.5

Page 40

34

STRUKTUR

2.1.2. Model: CH Unit – CH-12.0N

Zur Inneneinheit Zur Außeneinheit

Unit:mm

Nr Bezeichnung

1 Halterung für Schrauben M8 oder W5/16

2 Kühlgasleitungsanschluss (Niederdruck)

3 Kühlgasleitungsanschluss (Hochdruck)

4 Kühlgasleitungsanschluss

5 Anschlussbox (Verfügbare Befestigung auf beiden Seiten)

Durchführung für Betriebsleitungen

6

Durchführung für Netzkabel

7

Anmerkungen

CH-12.0N

∅22.2 Flanschrohrbindung

∅19.05 Flanschverbindung

∅22.2 Flanschrohrbindung

∅26.5

∅26.5

Page 41

2.2. KÜHLMITTELKREISLAUF

2.2.1. CH-Einheit (CH-4.0/8.0NE)

Zur Inneneinheit Zur Außeneinheit

Õ

STRUKTUR

Ö

Hoher Druck

Gasleitung

35

Hoher

Druck

Gasleitung

Ansaugdruck

Gasleitung

Kühlmittelflussrichtung (Kühlbetrieb)

Kühlmittelflussrichtung (Heizbetrieb)

Nr Teilebezeichnung

1 Magnetventil (AC) a

2Sieb b

3 Prüfhahn c

4 Kapillarrohr d

5 Kapillarrohr e

Markier-

ung

f

g

h

j

k

Stülpverbindung

Lötstelle

Vor Ort beigestellte Kühlmittelleitung

Außendurchmesser Material

O.D.(mm) × Stärke (mm)

CH-4.0NE CH-8.0NE

∅2.5x0.7

∅12.7×1.0 ∅15.88×1.0

∅9.53×0.8 ∅12.7×1.0

∅6.35×1.07

∅9.53×0.8

∅12.7×1.0

∅4.0x0.8 ∅4.0x0.5

∅12.7×1.0 ∅15.88×1.2

∅15.88 ∅19.05

∅12.7 ∅15.88

Ansaugdruck

Gasleitung

Ansaugdruck

Gasleitung

Material

Kupferrohr

C1220T-O

DEUTSCH

HINWEIS:

Die Markierung der Innenseite "[ ]" geht aus dem Stromlaufdiagramm hervor.

Page 42

36

STRUKTUR

2.2.2. CH-Einheit – CH-12.0N

Zur Inneneinheit Zur Außeneinheit

Õ

Hoher Druck

Gasleitung

Ö

Hoher Druck

Gasleitung

Ansaugdruck

Gasleitung

Ansaugdruck

Gasleitung

Kühlmittelflussrichtung (Kühlbetrieb) Stülpverbindung

Kühlmittelflussrichtung (Heizbetrieb) Flanschrohrbindung

Lötstelle

Vor Ort beigestellte Kühlmittelleitung

Nr Teilebezeichnung

1 Magnetventil (AC) a

2Sieb b

3 Prüfhahn c

4 Kapillarrohr d

5 Kapillarrohr e

Markier-

Außendurchmesser Material

ung

f

g

h

j

k

O.D.(mm) × Stärke (mm)

∅6.35 x 1.07

∅12.7 x 1.0

∅15.88 x 1.0

∅15.88 x 1.2

∅19.05 x 1.2

∅19.05 x 1.65

∅3.0 x 0.8

∅4.0 x 0.5

∅22.2

∅19.05

HINWEIS:

Die Markierung der Innenseite "[ ]" geht aus dem Stromlaufdiagramm hervor.

Ansaugdruck

Gasleitung

Material

Kupferrohr

C1220T-O

Page 43

TRANSPORT UND HANDHABUNG

2.3. LISTE DER ZUR MONTAGE NOTWENDIGEN WERKZEUGE UND INSTRUMENTE

Nr. Werkzeug Nr. Werkzeug

1 Handsäge 11

2 Phillips-Schraubendreher 12 Ladeflasche

3 Vakuumpumpe 13 Mehrfachanschlussstück

4 Kühlmittelschlauch 14 Kabelschneider

5 Widerstandsmessgerät 15 Gasleckdetektor

6 Rohrkurvenwerkzeug 16 Wasserwaage

7 Manuelle Wasserpumpe 17 Klemmzange für lötfreie Verbinder

8 Rohrschneider 18 Winde (für Inneneinheit)

9 Lötgerät 19 Amperemeter

10 Schraubenschlüssel 20 Voltmeter

Klemme

3. TRANSPORT UND HANDHABUNG

Transportieren Sie das Gerät vor dem Auspacken so nahe zur Aufstellungsstelle wie praktisch

möglich.

37

DEUTSCH

Ô WARNUNG:

Bringen Sie keinerlei Fremdkörper in die CH-Einheit ein und prüfen Sie vor der Installation und

dem Testlauf, dass auch in der Außeneinheit keine solchen vorhanden sind. Sonst besteht

akute Feuer- und Fehlfunktionsgefahr.

Ó VORSICHT:

Legen Sie nichts auf die Geräte.

Seien Sie beim Entfernen der Gehäuseteile vorsichtig, um die Isolierung nicht zu beschädigen.

3.1. KOMBINATION CH-EINHEIT UND INNENEINHEIT

Die CH-Einheit für das SET-FREE FXN(E) System ist in einem Innenraum zwischen Außen- und

Inneneinheit zu installieren. Die CH-Einheit und Inneneinheiten werden wie folgt kombiniert:

Modell

CH-4.0NE 1 bis 5

CH-8.0NE 1 bis 8

CH-12.0N 1 bis 5

Anzahl

Inneneinheiten

Gesamtleistung Inneneinheiten (PS)

Weniger als 4.0

(unter Ausschluss von 4.0)

4.0~8.0 (i einschließlich 4.0

und ausschließlich 8.0)

8.0~12.0 (i einschließlich 8.0

und ausschließlich 12.0)

Page 44

38

MONTAGE DER CH-EINHEIT

4. MONTAGE DER CH-EINHEIT

Õ GEFAHR:

Installieren Sie die CH-Einheit nicht in explosionsgefährdeter Umgebung.

Ô WARNUNG:

Prüfen Sie, dass die Deckenaufhängung stark genug ist.

Installieren Sie die CH-Einheit nicht im Freien. Bei Montage im Freien sind Stromschläge zu

erwarten.

4.1. MITGELIEFERTES ZUBEHÖR

Prüfen Sie, dass das folgende Zubehör mitgeliefert wurde.

Mitgeliefertes Zubehör (für CH-4.0NE).

Schaltuhr Stk Zweck

Reduzierstück

(∅15.88 to ∅12.7)

Rohrbefestigungsband 2

Mitgeliefertes Zubehör (für CH-8.0NE).

Schaltuhr Stk Zweck

Reducer (∅19.05 to ∅15.88)

Rohrbefestigungsband 2

Zum Anschluss der ∅12,7

1

mm Kühlmittelleitung von

der Inneneinheit

Zur Befestigung der

Flüssigkeitsleitung

Zum Anschluss der ∅15,88

1

mm Kühlmittelleitung von

der Inneneinheit

Zur Befestigung der

Flüssigkeitsleitung

Mitgeliefertes Zubehör (für CH-12.0N).

Schaltuhr Stk Zweck

Rohrflansch, Größe

(∅22.2)

Paket für Flansch 2 Flanschdichtung

Isolierung (∅38 ID)

Rohrbefestigungsband 2 Zur Befestigung der Flüssigkeitsleitung

Kabelschlaufe 8 Zur Fixierung der Kühlmittelrohrisolierung

Für Kühlmittelleitung (Hochdruck) von der

2

Außeneinheit

1 Für Kühlmittelleitungsanschluss

Page 45

MONTAGE DER CH-EINHEIT

4.2. PRÜFUNG VOR DEM START

4.2.1. Montieren Sie die CH-Einheit allseitig mit ausreichendem Wartungsabstand. Siehe

folgende Abbildung:

Zugangspaneel

Nr Bezeichnung

Anschlussbox

o

Zugangspaneel

p

39

DEUTSCH

Ansicht A

Markier

-ung

Modell CH-4-0/8.0 CH-12.0

a 250mm 350mm

b 100mm

Abmessungen (Min.)

4.2.2. Nach Einschalten des Magnetventils in der CH-Einheit können

Kühlmittelflussgeräusche auftreten. Zur Geringhaltung dieser ist wie folgt vorzugehen.

- Installieren Sie die CH-Einheit in der Decke. Wählen Sie ein Deckenmaterial wie z. B. Gipsplatten,

das die Betriebsgeräusche dämpft.

- Installieren Sie die CH-Einheit nicht in Bettnähe oder Krankenhauszimmern.

- Installieren Sie die CH-Einheit nicht an heißen oder feuchten Stellen wie in einer Küche, um

Kondensationen an den Außenflächen zu vermeiden.

4.2.3. Beachten Sie bei der Montage der CH-Einheit in Krankenhäusern und ähnlichen

Einrichtungen mit elektromagnetischer Strahlung wie von medizinischen Geräten bitte

folgende Punkte:

- Montieren Sie die CH-Einheit nicht, wo direkter elektromagnetischer Einfluss auf die Anschlussbox

oder die Kabelverbindung besteht.

- Installieren Sie die CH-Einheit und ihre Komponenten so weit weg wie praktisch möglich aber

mindestens 3 m entfernt von elektromagnetischen Störquellen.

- Installieren Sie einen Störfilter, falls die Netzversorgung Interferenzen verursacht.

Page 46

40

MONTAGE DER CH-EINHEIT

4.3. AUFHÄNGESCHRAUBEN

- Wählen Sie die Montagestellung und Ausrichtung der Inneneinheit auch im Hinblick auf

ausreichenden Platz für Rohrleitungen, Kabel und Wartung.

- Die Aufhängeschrauben wie folgt montieren.

- Für Betonplatten

Nr Bezeichnung

Ankerschrauben

o

Einsatz (100 bis 150kg)

p

Beton

q

Aus Stahl (W3/8 bis M10)

r

- Für Stahlträger

Nr Bezeichnung

Träger

o

Aufhängeschrauben

p

(W3/8 bis M10)

- Für Aufhängung an Holzbalken

Nr Bezeichnung

Holzleisten

o

(60~90mm quadratisch)

Holzbalken

p

Unterlegscheiben

q

Muttern

r

Ösenchraube

s

(W3/8 bis M10)

4.4. MONTAGE

4.4.1. Markieren der Positionen der Aufhängeschrauben und Rohranschlüsse

- Markieren Sie die Lage der Aufhängeschrauben, Kühlmittelrohr- und Abwasseranschlüsse.

- Siehe Abmessungen für die Installation in Kapitel 2.1.

Page 47

MONTAGE DER CH-EINHEIT

4.4.2. Montage der CH-Einheit

Anbringen der Muttern

Die Muttern der vier Aufhängeschrauben sind, wie unten zu sehen, schon vor Aufhängen der CHEinheit anzubringen

Nr Bezeichnung

Aufhängeschraube

o

Halterung

p

Scheibe und Mutter

q

(Vor Ort beigestellt)

CH-Box

r

Mark Abmessungen

L 30~50mm

Field-Supplied Parts CH-(4.0/8.0/12.0)NE

Aufhängeschrauben 4-M10 oder W-3/8

Mutter 8-M10 oder W-3/8

Unterlegscheibe 8-M10 oder W-3/8

41

DEUTSCH

Aufhängung der CH-Einheit

Die Halteklammern unter die Scheibe und Mutter der Aufhängeschrauben einsetzen, wie unten

gezeigt.

Prüfen, dass die Scheiben und Muttern korrekt von den Halteklammern fixiert werden.

Nr Bezeichnung

Aufhängeschraube

o

Halterung

p

Page 48

42

A

{

4.4.3. Einstellung der Lage der Einheit

Stellung der Muttern

Um einen fehlerhaften Betrieb des Geräts zu vermeiden, sollte die Ausrichtung des Geräts mit einer

Wasserwaage in einem durchsichtigen Vinylrohr, das Wasser enthält, geprüft werden.

Nach Abschluss der Justierung die Schrauben der Aufhängemuttern mit den Halteklemmen

festziehen.

Die Schrauben müssen mit speziellem Schraubenkleber gegen ungewolltes Lösen geschützt

werden.

RBEIT AN DEN KÜHLMITTELROHREN

Nr Bezeichnung

o

p

Plastikschlauch

Ansatz Wasserwaage

5. ARBEIT AN DEN KÜHLMITTELROHREN

Õ GEFAHR:

Nur Kühlmittel R407C im Kühlkreislauf benutzen. Niemals zur Leckprüfung Sauerstoff,

Azetylen oder andere brennbare oder gifte Gase in den Kreislauf einführen. Diese Art von

Gasen sind äußerst gefährlich und können Explosionen hervorrufen. Für solche Tests nur

Druckluft, Stickstoff oder Kühlmittel benutzen.

5.1. ROHRMATERIAL

1. Ort bereitgestelltes Kupferrohr vorbereiten.

2. Nur sauberes Kupferrohr verwenden. Versichern Sie sich, dass die Rohre innen frei von Schmutz

und Feuchtigkeit sind. Die Rohre vor Einbau gründlich mit Stickstoff oder getrockneter Luft

durchblasen, um alle Art von Staub und Fremdkörpern zu entfernen.

3. Die Rohrgrößen sind aus der Abmessungszeichnung zu entnehmen

5.2. ROHRANSCHLUSS

1. Die Lage der Rohranschlüsse geht aus der Abmessungszeichnung hervor.

2. Schließen Sie die Zubehörteile an, so wie es in nachfolgendem Schaltplan abgebildet ist.

CH-(4.0/8.0)NE

Nr Bezeichnung

Rohrbefestigungsband

Zur

Innene

inheit

Außen

}

Zur

einheit

o

Flüssigkeits-leitung

p

Ansaugdruck Gasleitung

q

Hoher DruckGasleitung

r

Gasleitung

s

Reduzierstück

t

Vor Ort beigestellte

Kühlmittelleitung

Page 49

A

RBEIT AN DEN KÜHLMITTELROHREN

CH-12.0N

Nr Bezeichnung

Rohrbefestigungsband

o

Flüssigkeits-leitung

p

Hoher DruckGasleitung

Zur

Innene

inheit

{ }

3. Zum Festziehen der Flanschmuttern zwei Schlüssel benutzen, wie unten gezeigt.

Rohrgröße Anzugdrehmoment (N.m)

∅6.35

∅9.53

∅12.7

∅15.88

∅19.05

(1/4) 2

(3/8) 4

(1/2) 6

(5/8) 8

(3/4) 10

Zur

Außen

einheit

q

Ansaugdruck Gasleitung

r

Gasleitung

s

Flanschrohrbindung

t

Vor Ort beigestellte

Kühlmittelleitung

43

DEUTSCH

4. Nach Anschluss der Kühlmittelrohre diese, wie unten zu sehen, mit dem lieferumfang

Isolationsmaterial isolieren.

Das mitgelieferte Flanschrohr zum Anschluss des Niederdruck-Gasrohrs benutzen. Die Dichtung

am Gasrohreinlass der Einheit sollte durch die mit der Einheit mitgelieferte ausgetauscht werden.

(Der Flanschanschluss ist mit vor Ort beigestelltem Material thermisch zu isolieren).

HINWEIS:

Der mitgelieferte Flansch ist vor Anschluss des Ventils mit dem Anschlussrohr zu

verschweißen. Die Dichtung erst nach dem Verlöten des Rohrs einsetzen. Beim Anschluss

des Flanschs besonders auf die korrekte Lage der Dichtung achten.

Zur

Innenein

heit

{ }

Nr Bezeichnung Anmerkungen

Isolierung - Nicht mitgelieferte – CH-4.0NE unit

o

Isolierung - Nicht mitgelieferte – CH-(4.0/8.0/12.0)NE units

p

Isolierung

q

- Nicht mitgelieferte – CH-(4.0/8.0)NE

- Mitgeliefertes Zubehör CH-12.0N

Zur

Außenei

nheit

Page 50

44

KABELVERLEGUNG

VORSICHT:

- Vor Einführen eines Rohrs durch ein Loch dessen Öffnung verstopfen.

- Das Rohrmaterial nicht ohne Stopfen oder Umkleben der Enden auf den Boden legen.

- Alle entflammbaren Materialien aus der Umgebung der Einheiten entfernen. Sonst besteht

akute Feuergefahr.

Richtig Falsch

5. Die Kühlmittelent- und -Beladung ist nach den Anweisungen im "Installations- und

Betriebshandbuch" der Außeneinheit durchzuführen.

6. KABELVERLEGUNG

Ô WARNUNG:

- Schalten Sie die Stromversorgung zur CH-, Außen- und Inneneinheit vor Beginn von

Kabelarbeiten oder Inspektionen aus.

- Die Kabel, Elektroteile etc. vor Ratten und anderen Nagern schützen.

- Die unten stehenden Punkte vor Einschalten des Hauptschalters prüfen.

Bei einer Netzspannung der Inneneinheit von 240V (Nennspannung), wie unten zu sehen, in der

Schaltbox den Stecker CN21 am Trafo (TF1) zur Klemme CN22 wechseln

VORSICHT:

- Wickeln Sie das zusätzliche Isolationsmaterial um die Kabel und verstopfen Sie die

Kabeldurchführung mit der Siegelmasse, um das Gerät vor Kondenswasser oder Insekten zu

schützen. Binden Sie die Kabel in der Anschlussbox mit dem Kabelbinder zusammen.

Page 51

KABELVERLEGUNG

45

6.1. ALLGEMEINE ÜBERPRÜFUNG

- Sichern Sie ab, dass die vor Ort beigestellten Elektroteile (Hauptschalter, Sicherungen, Kabel,

Stecker und Klemmen) den Anforderungen im technischen Katalog entsprechend ausgewählt

wurden. Außerdem müssen alle diese Elektroteile den örtlichen und internationalen Normen

entsprechen.

- Versichern Sie sich, dass die Netzspannung nicht mehr als ±10% von der Nennspannung

abweicht.

- Prüfen Sie die Versorgungsleistung. Ist sie zu niedrig, kann das System wegen zu starkem

Spannungsabfall beim Einschalten nicht starten.

- Prüfen Sie, dass die Erdung angeschlossen ist.

6.2. ELEKTRISCHE VERKABELUNG

Die Verkabelung wird in dem folgenden Schaltbild dargestellt.

Nr Bezeichnung

Anschlussbox

o

Befestigungsschraube

p

Schaltplatine

q

Störfilter

r

Kabelbinder

s

Klemmenleisten

t

Steuerleitung

u

Netzversorgung

v

DEUTSCH

HINWEIS:

Auf der Klemmenplatte

dienen die Klemmen 1 und

2 für das H-Link-System

und die Klemmen 3 und 4

für die Verbindung

zwischen Inneneinheit und

CH-Einheit.

1. Schalten Sie die Stromversorgung aus und entfernen den Deckel von der Anschlussbox der CHEinheit.

2. Schneiden Sie das Zentrum der Gummitülle zur Kabeldurchführung ab, wie im folgenden gezeigt.

3. Schließen Sie das Netz- und das Erdungskabel an die Klemmen in der Anschlussbox an.

4. Schließen Sie die Steuerleitung an ihre Klemmen in der Anschlussbox an.

Page 52

46

KABELVERLEGUNG

5. Binden Sie die Kabel mit einem Kabelbinder in der Anschlussbox ordentlich zusammen.

6. Setzen Sie den Deckel der Anschlussbox wieder auf.

Nr Bezeichnung

Gummitülle

o

Einschneiden

p

6.3. EINSTELLUNG DER DIP-SCHALTER

Stellung der DIP-Schalter

Die PCB1-Platine in der Anschlussbox der CH-Einheit ist mit zwei DIP-Schaltern (DSW2, DSW5)

ausgestattet, wie aus folgender Abbildung hervorgeht.

Nr Bezeichnung

PCB1

o

DSW5

p

DSW2

q

Einstellung der DIP-Schalter

Die Werkseinstellung der DIP-Schalter braucht nicht vor Ort geändert zu werden. Diese sind nur zur

Selbstdiagnose der PCB notwendig.

Werkseinstellung (Dip-Schalter)

¥ DSW5

¥ DSW2

HINWEIS:

Die Markierung "" zeigt die Stellung der DIP-Schalter. Die obige Abbildung zeigt die

Werkseinstellung

ON

1 2

ON

1 2 3 4 5 6

VORSICHT:

Vor Verändern der DIP-Schalter ist die Stromversorgung zu unterbrechen. Die Änderung der

Schalterstellungen bei eingeschalteter Netzspannung sind unwirksam.

Page 53

TESTLAUF

7. TESTLAUF

Führen Sie einen Testlauf durch, wie im "Installations- und Betriebshandbuch" der Außeneinheit

beschrieben.

Ô WARNUNG:

Nehmen Sie das System nicht in Betrieb, bevor nicht alle Checkpunkte geprüft wurden.

- Prüfen Sie durch eine Widerstandsmessung zwischen Masse und den elektrischen

Anschlussklemmen, dass der Widerstand höher als 1 M

das System auf keinen Fall einschalten, bevor die Stromflussstelle gefunden und behoben

wurde.

- Versichern Sie sich, dass die Verschlusshähne an der Außeneinheit komplett geöffnet sind

und starten dann das System.

- Prüfen Sie dass die Hauptstromversorgung vor Inbetriebnahme mindestens 12 Stunden

eingeschaltet war, um das Kompressoröl vorzuwärmen.

Achten Sie bei laufendem Gerät auf die folgenden Punkte:

- Fassen Sie keine Teile im Gasentladebereich an, da die Kompressorkammer und die Rohre

in diesem Bereich heißer als 90ºC werden können.

- NICHT DEN TASTER DES MAGNETSCHALTERS BETÄTIGEN. Dies würde zu einem

ernsthaften Unfall führen.

Ω

ist.Ist der Widerstand geringer,

47

DEUTSCH

Page 54

Page 55

CONSIGNES DE SÉCURITÉ

1. CONSIGNES DE SÉCURITÉ

Ô ATTENTION:

- Ne pas procéder aux travaux d'installation, tuyauterie frigorifique et câblage électrique

sans se référer à notre manuel d'installation.

- Vérifier que le câble de mise à la terre est branché fermement.

- Connecter un fusible de la puissance spécifiée.

PRECAUTION :

- Ne pas installer l'unité CH et le câble dans un rayon de 3 mètres de radiateurs à fortes ondes

électromagnétiques (matériel médical par exemple).

2. STRUCTURE

2.1. DIMENSIONS

2.1.1. Modèle : Unité CH -(4.0/8.0)NE

49

FRANÇAIS

Unit:mm

Vers l’unité intérieure Vers l’unité extérieure

Nº Nom

1 Support de suspension Pour boulon M8 ou W5/16

2 Raccord du tuyau du gaz frigorigène (en bas)

3 Raccord du tuyau du gaz frigorigène (en haut)

4 Raccord du tuyau du gaz frigorigène

5 Boîtier de commande électrique (Fixation disponible des deux côtés)

6 Orifice pour la ligne de fonctionnement

7 Orifice pour la ligne d'alimentation électrique

Dimension a 78mm 82mm

CH-4.0NE CH-8.0NE

∅15.88 Raccord évasé ∅19.05 Raccord évasé

∅12.7 Raccord évasé ∅15.88 Raccord évasé

∅15.88 Raccord évasé ∅19.05 Raccord évasé

Remarques

∅26.5

∅26.5

Page 56

50

STRUCTURE

2.1.2. Modèle : Unité CH-12.0N

Vers l’unité intérieure Vers l’unité extérieure

Unit:mm

Nº Nom

Support de suspension

1

Raccord du tuyau du gaz frigorigène (en bas)

2

Raccord du tuyau du gaz frigorigène (en haut)

3

Raccord du tuyau du gaz frigorigène

4

Boîtier de commande électrique

5

Orifice pour la ligne de fonctionnement

6

Orifice pour la ligne d'alimentation électrique

7

Remarques

CH-12.0N

Pour boulon M8 ou W5/16

∅22.2 Joint à brides

∅19.05 Raccord évasé

∅22.2 Joint à brides

(Fixation disponible des deux côtés)

∅26.5

∅26.5

Page 57

2.2. CYCLE DE FLUIDE FRIGORIGENE

2.2.1. Unité CH(4.0/8.0NE)

Vers l’unité intérieure Vers l'unité extérieure

Õ

Haute

pression

Conduite

de gaz

STRUCTURE

Haute pression

Conduite de gaz

51

Ö

Basse

pression

Conduite

de gaz

FRANÇAIS

Basse

pression

Conduite

de gaz

Sens de circulation du frigorigène (mode Froid)

Sens de circulation du frigorigène (mode Chauffage)

Nº Nom

1 Electrovanne (C.A.) a

Epurateur

2

3 Check Valve c

4 Tuyau capillaire d

5 Tuyau capillaire e

Repèr

Diamètre ext. (mm) ×

e

b

f

g

h

j

k

épaisseur (mm)

CH-4.0GE CH-8.0GE

∅12.7×1.0 ∅15.88×1.0

∅9.53×0.8 ∅12.7×1.0

∅4.0x0.8 ∅4.0x0.5

∅12.7×1.0 ∅15.88×1.2

∅15.88 ∅19.05

∅12.7 ∅15.88

Raccord Flare

Connexion par brasage

Tuyauterie de fluide frigorigène

sur site

∅2.5x0.7

∅6.35×1.07

∅9.53×0.8

∅12.7×1.0

REMARQUE :

"Le symbole à l’intérieur des ""[ ]"" est montré dans le schéma de câblage électrique."

Basse

pression

Conduite

de gaz

Matériau

Tube en cuivre

C1220T-O

Page 58

52

STRUCTURE

2.2.2. Unité CH-12.0N

Vers l’unité

intérieure

Õ

Haute

pression

Conduite

de gaz

Vers l’unité

extérieure

Ö

Haute pression

Conduite de gaz

Basse

pression

Conduite

de gaz

Low

Pressure

Gas Line

Sens de circulation du frigorigène (mode Froid) Raccord Flare

Sens de circulation du frigorigène (mode Chauffage) Connexion par bride

Connexion par brasage

Tuyauterie de fluide frigorigène

sur site

Nº Nom Repère

Electrovanne (C.A.) a

1

2 Epurateur b

Vanne de service c

3

4 Tuyau capillaire d

5 Tuyau capillaire e

f

g

h

j

k

Diamètre ext. (mm) ×

épaisseur (mm)

∅6.35 x 1.07

∅12.7 x 1.0

∅15.88 x 1.0

∅15.88 x 1.2

∅19.05 x 1.2

∅19.05 x 1.65

∅3.0 x 0.8

∅4.0 x 0.5

∅22.2

∅19.05

REMARQUE :

"Le symbole à l’intérieur des ""[ ]"" est montré dans le schéma de câblage électrique."

Low

Pressure

Gas Line

Matériau

Tube en

cuivre

C1220T-O

Page 59

Transport et manipulation

2.3. LISTE DES OUTILS ET INSTRUMENTS NECESSAIRES POUR L’INSTALLATION

No. Outil No. Outil

1 Scie égoïne 11 Clé

2 Tournevis cruciforme 12 Cylindre de charge

3 Pompe à vide 13 Manifold

4 Flexible pour le gaz frigorigène 14 Cutter pour les câbles

5 Mégohmmètre 15 Détecteur de fuites de gaz

6 Cintreuse pour tuyaux en cuivre 16 Planeuse

7 Pompe à eau manuelle 17 Attache-fils pour bornes non soudées

8 Cutter pour tuyaux 18 Élévateur (pour l’unité intérieure)

9 Kit de brasage 1 9 Ampèremètre

10 Clé à six pans 20 Tensiomètre

3. TRANSPORT ET MANIPULATION

Amenez le produit le plus près possible du site d’installation avant de le déballer.

53

FRANÇAIS

Ô AVERTISSEMENT :

N’introduisez aucun matériel étranger dans l’unité CH et assurez-vous qu’il n’y a rien à

l’intérieur avant l’installation et le passage des tests. Sans cette précaution, l’appareil pourrait

prendre feu ou subir des défaillances.

Ó ATTENTION :

Ne déposez aucun matériel sur l’appareil.

Faites attention à ne pas endommager les matériaux d’isolation qui recouvrent l’unité lorsque

vous la soulevez.

3.1. COMBINAISON UNITE CH ET UNITE INTERIEURE

Dans le cas du système SET-FREE FXN(E), l’unité CH est installée à l’intérieur, entre le groupe

extérieur et l’unité intérieure. Les unités CH et unités intérieures peuvent être combinées comme

suit :

Modèle

CH-4.0NE 1 à 5 Inférieure à 4.0(excluant 4.0)

CH-8.0NE 1 à 8 4.0~8.0 (incluant 4.0 et excluant 8.0)

CH-12.0N 1 à 5 8.0~12.0 (incluant 8.0and incluant 12.0)

Nbre d’unités

intérieures :

Puissance totale intérieure (CV)

Page 60

54

INSTALLATION DE L'UNITÉ CH

4. INSTALLATION DE L'UNITÉ CH

Õ DANGER :

Afin d'éviter tout danger d'incendie ou d'explosion, n'installez pas les unités intérieures dans

un environnement inflammable.

Ô AVERTISSEMENT :

Assurez-vous que la plaque du plafond est suffisamment résistante.

N'installez pas les unités CH à l'extérieur. Installées à l'extérieur, un danger électrique ou une

fuite pourraient se produire.

4.1. ACCESSOIRES FOURNIS EN STANDARD

Assurez-vous que les accessoires suivants sont livrés avec l’unité CH.

Accessoires fournis en standard - Pour CH-4.0NE

Accessoire Qté Utilisation

Connexion de la

Réducteur (∅15.88 à ∅12.7)

Bande de fixation de

tuyauterie

Accessoires fournis en standard - Pour CH-8.0NE

Accessoire Qté Utilisation

Réducteur (∅19.05 à

∅15.88)

Bande de fixation de

tuyauterie

1

tuyauterie liquide ∅12.7

de l’unité intérieure

Pour la fixation de la

2

tuyauterie de liquide

Connexion de la

tuyauterie liquide

1

∅15.88 de l’unité

intérieure

Pour la fixation de la

2

tuyauterie de liquide

Accessoires fournis en standard - Pour CH-12.0N

Accessoire Qté Utilisation

Taille du tuyau à bride

(Ø22,2)

Garniture pour la bride

Isolation (∅38 ID)

Bande de fixation de

tuyauterie

Collier

2

2

1 Raccord des tuyauteries frigorifiques

2

8

Pour tuyauterie gaz (haute) à partir de

l’unité extérieure

Scellement de la bride

Pour la fixation de la tuyauterie de

liquide

Fixation de l’isolation des tuyauteries

frigorifiques

Page 61

INSTALLATION DE L'UNITÉ CH

55

4.2. VERIFICATION INITIALE

4.2.1. Installez l'unité CH dans un espace suffisamment dégagé pour permettre la

maintenance, comme montré sur la figure ci-dessous :

Vide technique

Nº Nom

Boîte électrique

o

Trappe de maintenance

p

Vue à partir de A

Repère Dimension (Min.)

Modèle CH-4-0/8.0 CH-12.0

a 250mm 350mm

b 100mm

4.2.2. Le bruit d’écoulement du frigorigène peut être entendu depuis l’unité CH lorsque

l’électrovanne de cette unité est activée. Prenez les mesures suivantes pour minimiser le

bruit :

- -{}-Install the CH unit inside the ceiling. As for the ceiling material, select a material like a plaster

board which minimizes operation sound.

- Do not install the CH unit in near a bed room or hospital room.

- Ne pas installer l'unité CH dans un endroit chaud ou humide come la cuisin, a fin d'eviter

l'apparition de condensation sur la surface externe de l'unité.

FRANÇAIS

4.2.3. Prêtez attention aux points suivants lorsque l'unité CH est installée dans un hôpital ou

autres lieux subissant des ondes électroniques provenant d’équipements médicaux.

- N'installez pas l'unité CH là où les radiations électromagnétiques peuvent atteindre directement la

boîte électrique ou le câblage intermédiaire (ligne de service).

- Installez l'unité et ses composants aussi loin que possible ou du moins à 3 mètres de la source

des radiations électromagnétiques.

- Installez un filtre antiparasite lorsque la source d'alimentation émet des nuisances sonores.

Page 62

56

INSTALLATION DE L'UNITÉ CH

TIGES DE SUSPENSION

- Déterminez l'emplacement final et le sens d'installation de l'unité intérieure en veillant

particulièrement à l'espace réservé aux tuyauteries, câblage et maintenance.

- Mettez en place les tiges de suspension, comme illustré ci-dessous:

- Dalle de béton:

Nº Nom

Acier

o

Cheville (100 à 150 kg)

p

Béton

q

Boulon d’ancrage (W3/8 ou

r

M10)

- Poutre d’acier:

Nº Nom

Profilé en I

o

Tige de suspension

p

(W3/8 ou M10)

- Suspension à poutre en bois:

Nº Nom

Poutre en bois

o

(60~90mm carré)

Poutre en bois

p

Rondelles carrées

q

Écrous

r

Tige de suspension

s

(W3/8 ou M10)

4.3. INSTALLATION

4.3.1. Marquage des emplacements des tiges de suspension et des raccords des tuyauteries

- Marquez les emplacements des tiges de suspension et des raccords des tuyauteries frigorifiques

et de l'écoulement.

- Voir les dimensions de l’installation, chapitre 2.1.

Page 63

INSTALLATION DE L'UNITÉ CH

4.3.2. Montage de l’unité CH

Comment placer les écrous

Put nuts on each of the four suspension bolts before suspending the CH unit, as shown below

57

Nº

o

p

q

r

Repère Dimension

L 30~50mm

Pièces fournies sur site CH-(4.0/8.0/12.0)N(E)

Tiges de suspension 4-M10 ou W-3/8

Ecrou 8-M10 ou W-3/8

Rondelle 8-M10 ou W-3/8

Nom