Page 1

Designed for operating in USA & Canada only.

When this product is used in areas other than the USA & Canada,

we cannot guarantee the product quality and performance.

Grass Trimmer

CG 23ECP (SL)

Coupe-Herbes

Motoguadañas

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and understand this manual

BEFORE operating the power tool. Please keep this manual available for other users and owners before they

use the power tool. This manual should be stored in safe place.

INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner la mort ou de

sérieuses blessures corporelles !

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce produit. Prière de

lire et de comprendre ce mode d’emploi AVANT d’utiliser l’outil motorisé. Garder ce mode d’emploi à la

disponibilité des autres utilisateurs et propriétaires avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi

doit être conservé dans un endroit sûr.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede provocar lesiones

graves o la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y comprenda este

manual ANTES de utilizar la herramienta eléctrica. Guarde este manual para que puedan leerlo otras

personas antes de utilizar la herramienta eléctrica. Este manual debe ser guardado en un lugar seguro.

Page 2

English

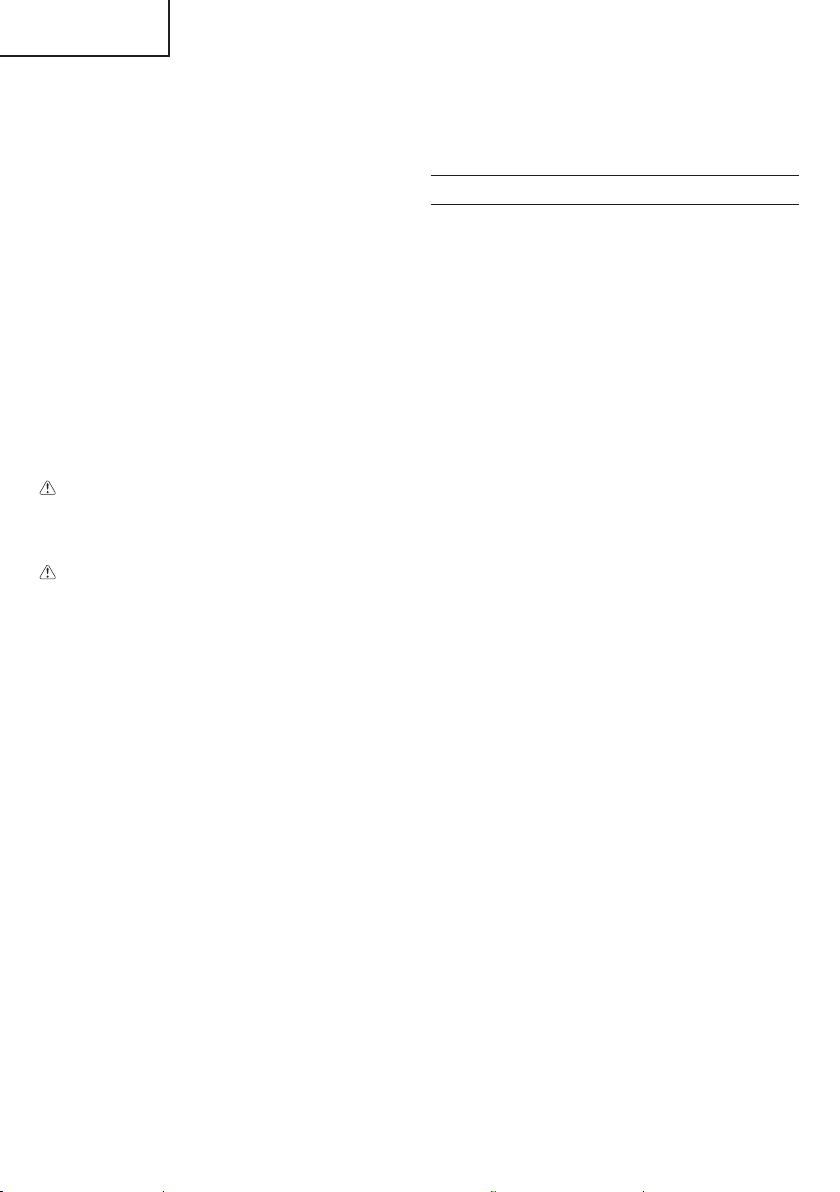

MEANINGS OF SYMBOLS

NOTE: Some units do not carry them.

Symbols

WARNING

The following show symbols used for the machine. Be sure that you understand

their meaning before use.

It is important that you read,

fully understand before use, and

observe the following safety

precautions and warnings.

Careless or improper use of the

unit may cause serious or fatal

injury.

Read, understand and follow all

warnings and instructions in this

manual and on the unit.

START

Choke - Run position (Open)

Choke - Start position

(Closed)

On/Start

Always wear eye, head and ear

protectors when using this unit.

STOP

Do not use metal/rigid blades

when this sign is shown on the

unit.

Keep all children, bystanders

and helpers 15 m away from

the unit. If anyone approaches

you, stop the engine and cutting

attachment immediately.

Be careful of thrown objects.

Shows maximum shaft speed. Do

not use the cutting attachment

-1

min

whose max rpm is below the

shaft rpm.

Gloves should be worn

when necessary, e.g., when

assembling cutting equipment.

Use anti-slip and sturdy footwear.

Before using your machine

• Read the manual carefully.

• Check that the cutting equipment is correctly assembled and adjusted.

• Start the unit and check the carburetor adjustment. See “MAINTENANCE”.

Off /Stop

Fuel and oil mixture

Idle speed adjustment

Priming pump

Hot surface – Contact with

hot surface can cause serious

burns.

Indicate handle location.

Arrows which show limits for

handle positioning.

Indicates cutting attachment

guard location for a trimmer

head or semi-auto cutting

head.

2

Page 3

English

Contents

WHAT IS WHAT ....................................................3

WARNINGS AND SAFETY INSTRUCTIONS ........ 4

WARRANTY .......................................................... 6

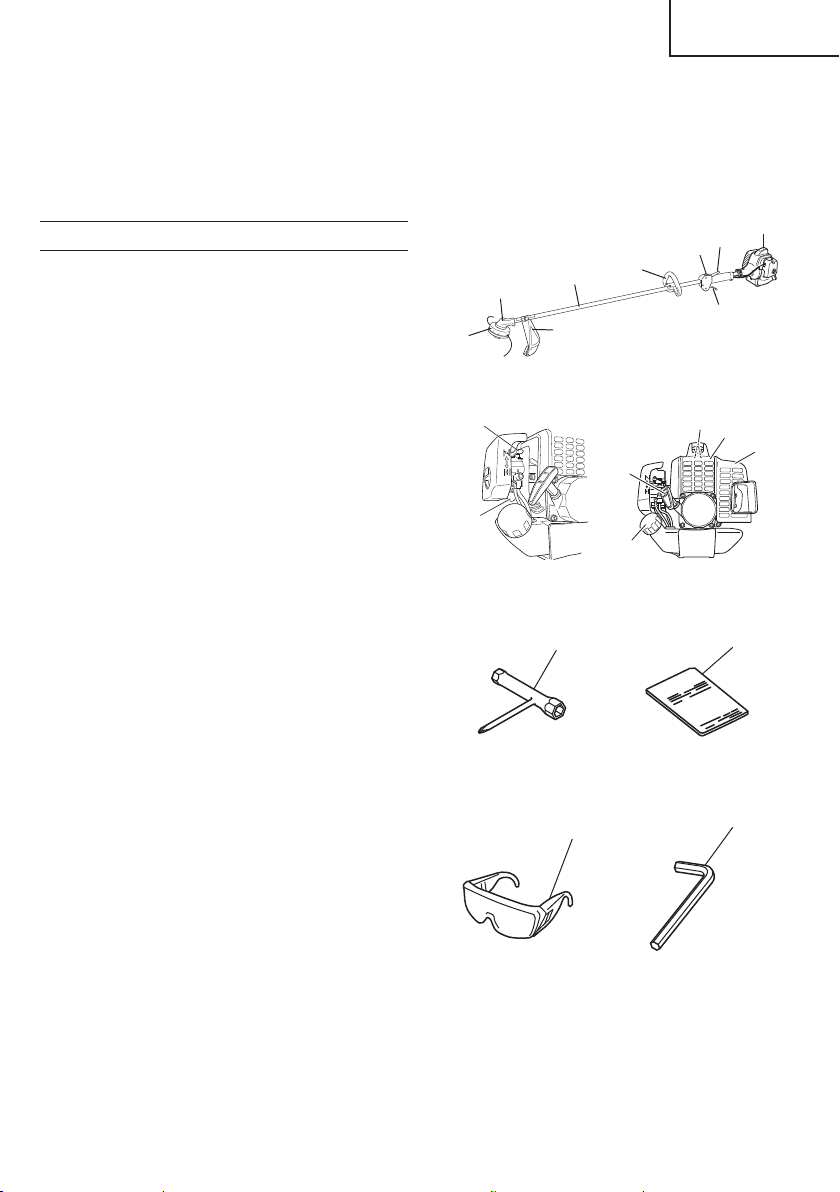

WHAT IS WHAT

Since this manual covers several models, there may

be some diff erence between pictures and your unit.

Use the instructions that apply to your unit.

1. Fuel cap

2. Throttle trigger

3. Starter handle

4. Cutting attachment guard

5. Cutting attachment

6. Drive shaft tube

7. Handle

8. Ignition switch

9. Spark plug

10. Priming pump

11. Throttle trigger lockout

12. Choke lever

13. Engine

14. Gear case

15. Combi box spanner

16. Handling instructions

17. Goggles

18. Hex bar wrench

19. Top cover

SPECIFICATIONS ................................................. 7

ASSEMBLY PROCEDURES .................................8

OPERATING PROCEDURES ................................ 9

MAINTENANCE .................................................. 12

13

11

8

14

5

12

10

6

4

15

7

2

9

13

3

1

19

16

17

18

3

Page 4

English

WARNING

The engine exhaust from this product contains

chemical known to the State of California to cause

cancer, birth defects or other reproductive harm.

WARNINGS AND SAFETY

INSTRUCTIONS

Pay special attention to statements preceded by the

following words:

WARNING

Indicates a strong possibility of severe personal

injury or loss of life, if instructions are not

followed.

CAUTION

Indicates a possibility of personal injury or

equipment damage, if instructions are not

followed.

NOTE

Helpful information for correct function and use.

Operator safety

○ Always wear a safety face shield or goggles.

○ Approved protective goggles comply with

standard ANSI Z87.1 in the USA.

○ Always wear heavy, long pants, non-slip boots,

gloves and a long-sleeve shirt. Do not wear

loose clothing, jewelry, short pants, sandals or

go barefoot. Secure hair so it is above shoulder

length.

○ Do not operate this tool when you are tired,

ill or under the infl uence of alcohol, drugs or

medication.

○ Never let a child or inexperienced person operate

the machine.

○ Wear approved hearing protection.

Long-term exposure to noise can result in

permanent hearing impairment.

Pay attention to your surroundings. Be aware of

any bystanders who may be signaling a problem.

Remove safety equipment immediately upon

shutting off engine.

○ Wear head protection.

○ Never start or run the engine inside a closed

environment, such as a room or building.

Breathing carbon monoxide exhaust fumes can

kill.

○ Keep handles free of oil and fuel.

○ Keep hands away from cutting equipment.

○ Do not grab or hold the unit by the cutting

equipment.

○ When the unit is turned off , make sure the cutting

attachment has stopped before the unit is set

down.

4

○ When operation is prolonged, take a break from

time to time so that you may avoid possible

Hand-Arm Vibration Syndrome (HAVS) which is

caused by vibration.

○ Do not operate the tool at night or under bad

weather conditions when visibility is poor. And do

not operate the tool when it is raining or right after

it has been raining.

Working on slippery ground could lead to an

accident if you lose your balance.

○ Do not start the engine if there are any

fl ammables such as dry leaves, waste paper or

fuel in the vicinity.

○ Gloves should be worn when installing or

removing the cutting attachment. Failure to do so

may result in injury.

WARNING

● Always operate the tool with proper

protective equipment and clothing. Failure to

do so may result in accidents such as burns

or injuries.

● Do not touch the spark plug area or high

voltage during operation. Doing so may

result in electric shock.

● Do not allow children near the tool during

operation.

● Do not touch the engine, top cover or

exhaust vent during or shortly after

operation. Doing so may result in burn or

injury.

● Antivibration systems do not guarantee that

you will not sustain Hand-Arm Vibration

Syndrome or carpal tunnel syndrome.

Therefore, continual and regular users

should monitor closely the condition of

their hands and fi ngers. If any symptoms

of the above appear, seek medical advice

immediately.

● If you are using any medical electric/

electronic devices such as a pacemaker,

consult your physician as well as the device

manufacturer prior to operating any power

equipment.

Unit/machine safety

○ Inspect the entire unit/machine before each use.

Replace damaged parts. Check for fuel leaks

and make sure all fasteners are in place and

securely tightened.

○ Replace parts that are cracked, chipped or

damaged in any way before using the unit/

machine. Faulty parts may increase the risk of

accidents and may lead to an injury.

○ Make sure the cutting attachment is properly

installed and securely fastened.

Page 5

English

○ Make sure the cutting attachment guard and

harness are properly attached. Do not operate

if cutting attachment guard and harness is not

properly attached.

○ Keep others away when making carburetor

adjustments.

○ Use only accessories as recommended for this

unit/machine by the manufacturer.

○ Before operation, make sure that there are no

tools such as the adjustment key or spanner still

attached to the unit.

WARNING

● Never modify the unit/machine in any way.

Do not use your unit/machine for any job

except that for which it is intended.

● Non-authorized modifi cations and/or

accessories may result in serious personal

injury or the death of the operator or others.

Fuel safety

○ Mix and pour fuel outdoors where there are no

sparks and fl ames.

○ Use a container approved for fuel.

○ Move at least 10 ft (3 m) away from fueling site

before starting engine.

○ Slowly remove the fuel cap only after stopping

the engine. Do not remove the fuel cap during

operation.

○ Empty the fuel tank before storing the unit/

machine. It is recommended that the fuel be

emptied after each use. If fuel is left in the tank,

store so fuel will not leak.

WARNING

● Fuel is easy to ignite or get explosion or

inhale fumes, so that pay special attention

when handling or fi lling fuel.

● Do not smoke or allow smoking near fuel

or the unit/machine or while using the unit/

machine and fueling or mixing fuel.

● Wipe up all fuel spills before starting engine.

● Store unit/machine and fuel in area where

fuel vapors cannot reach sparks or open

fl ames from water heaters, electric motors or

switches, furnaces. etc.

● When using the unit in dry areas, make sure

that fi re extinguishing equipment is readily

available.

● If you shut off the engine for refueling, make

sure the unit has cooled down before adding

fuel.

Cutting safety

○ Do not cut any material other than grass and

brush.

○ Clear the area to be cut before each use.

Remove objects which can be thrown or become

entangled in the cutting attachment.

○ For respiratory protection, wear an aerosol

protection mask when cutting the grass after

insecticide is scattered.

○ Keep others including children, animals,

bystanders and helpers outside the 50 ft (15 m)

hazard zone. There is still a risk of injury from

thrown object. Bystanders should be encouraged

to wear eye protection. Stop the engine

immediately if you are approached.

○ Please exercise caution as engine startup may

be delayed after pulling the starter handle.

○ Always keep the engine on the right side of your

body.

○ Hold the unit/machine fi rmly with both hands.

○ Keep fi rm footing and balance. Do not over-

reach.

Losing your balance during work may lead to an

injury.

○ Keep all parts of your body away from the muffl er

and cutting attachment when the engine is

running.

○ Keep cutting attachment below knee level.

○ Please exercise caution when operating in areas

where electrical cables or gas pipes are present.

○ Do not operate the cutting attachment for

anything but clearing grass or bushes. Avoid

operations where the cutting attachment may

touch water such as puddles or dig into dirt.

Failure to do so may result in injury or damage to

the unit.

○ Avoid prolonged use at low speed range in which

vibration is high. Doing so may result in engine

damage.

○ When relocating to a new work area, or

inspecting, adjusting or exchanging the unit’s

cutting attachments, accessories, etc., be sure

to shut off the machine and ensure that all cutting

attachments are stopped.

○ Never place the machine on the ground when

running.

○ Never touch the cutting attachment when it is

rotating.

○ Always ensure that the engine is shut off and any

cutting attachments have completely stopped

before clearing debris or removing grass from the

cutting attachment.

○ Always carry a fi rst-aid kit when operating any

power equipment.

○ Turn o

ff the engine and make sure the cutting

attachment has come to a full stop before

removing the unit from your body or before

leaving the unit unattended.

5

Page 6

English

○ If you accidentally bump or drop the unit,

inspect it immediately to make sure there are no

damage, cracks or deformations.

○ If the tool is operating poorly and produces

strange noise or vibrations, turn off the engine

immediately and ask your dealer to have it

inspected and repaired.

Continued use under these conditions could lead

to injury or tool damage.

○ Use in accordance with local laws and

regulations.

Maintenance safety

○ Maintain the unit/machine according to

recommended procedures.

○ Disconnect the spark plug before performing

maintenance except for carburetor adjustments.

○ Keep others away when making carburetor

adjustments.

○ Use only genuine Hitachi replacement parts as

recommended by the manufacturer.

CAUTION

Do not disassemble the recoil starter. There

is a possibility of personal injury with recoil

spring.

WARNING

Improper maintenance could result in

serious engine damage or in serious

personal injury.

Transport and storage

○ Carry the unit/machine by hand with the engine

stopped and the muffl er away from your body.

○ Allow the engine to cool, empty the fuel tank

before storing or transporting.

Secure the machine during transport to prevent

loss of fuel, damage or injury.

○ Empty the fuel tank before storing the unit/

machine. It is recommended that the fuel be

emptied after each use. If fuel is left in the tank,

store so fuel will not leak.

○ Store unit/machine out of the reach of children.

○ Clean and maintain the unit carefully and store it

in a dry place.

○ Make sure engine switch is off when transporting

or storing.

○ When transporting and storing, either remove the

cutting attachment or place the blade cover over

the blade.

○ You have to secure the machine during transport

to prevent loss of fuel, damage or injury.

○ If a warning label cannot be read, peels off or

becomes indistinct, replace it with a new one. To

purchase new labels, contact Hitachi Authorized

Service Centers.

If situations occur which are not covered in this

manual, take care and use common sense. Contact

Hitachi Authorized Service Centers if you need

assistance.

WARRANTY

The warranties provided by Hitachi Koki U.S.A., Ltd.

are explained in the warranty card enclosed with this

product titled “Hitachi Outdoor Power Equipment

Limited Warranty”.

6

Page 7

SPECIFICATIONS

Engine Size (cu. in.) 1.37 (22.5 ml)

English

Model CG23ECP (SL)

Spark Plug

Fuel Tank Capacity (fl . oz) 16.2 (0.48 l)

Dry Weight (Ibs) 10.8 (4.9 kg)

Sound pressure level

LpA (dB (A))

(ISO22868)

Measured sound

power level LwA

(dB (A))

Guaranteed sound

power level LwA

(dB (A))

Vibration level (m/s2)

(ISO22867)

Equivalent (Front / Left handle)

Equivalent (Rear / Right handle)

Uncertainty

NOTE

Equivalent noise level/vibration level are calculated as the time-weighted energy total for noise/vibration

levels under various working conditions with the following time distribution:

* 1/2 idle, 1/2 racing.

All data subject to change without notice.

Equivalent

(

ISO

22868)

Racing

(

ISO

22868)

Racing

TORCH AC6RA

(NGK CMR6A)

95.3

112

115

6.0

6.3

1.5

7

Page 8

English

ASSEMBLY PROCEDURES

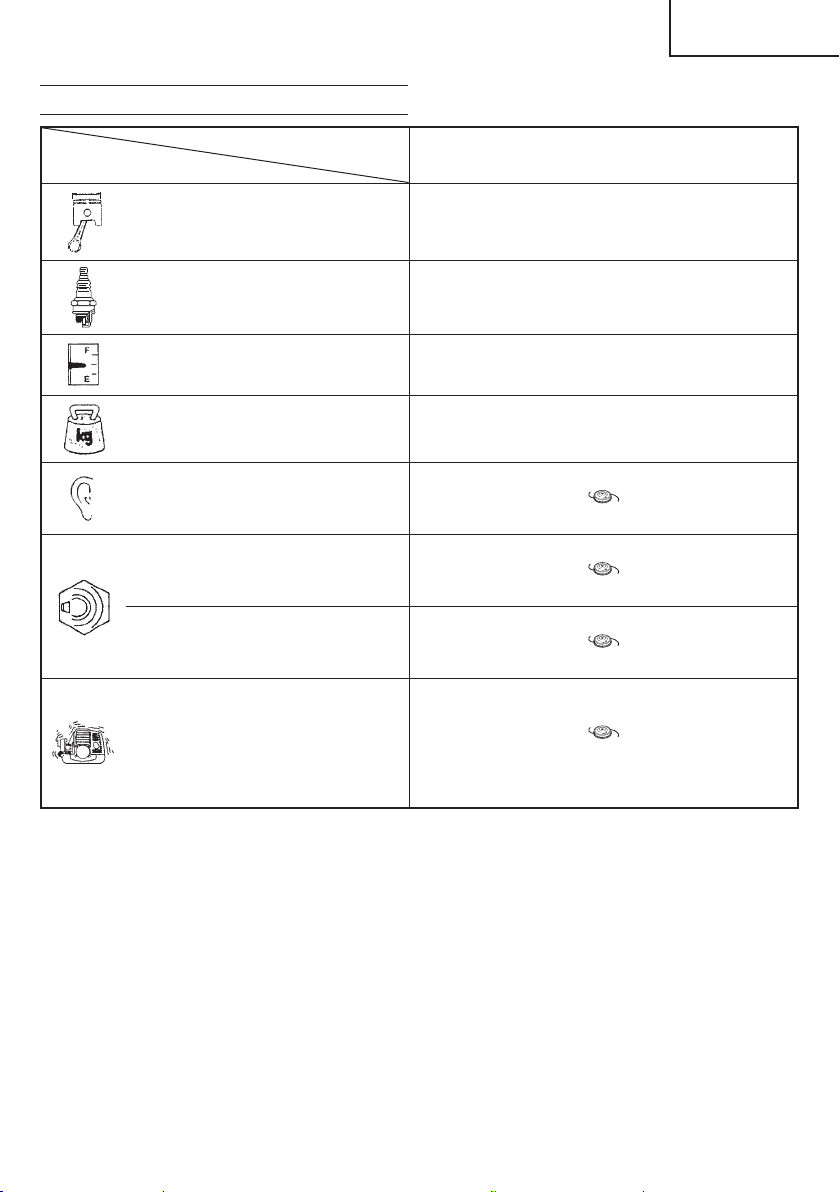

Installation of handle (Fig. 1)

Attach the handle to the drive shaft tube.

Adjust the location to the most comfortable position

before operation.

Make sure to securely attach the handle with the 4

bolts.

1

Fig. 1

NOTE

If your unit has handle location label (1) on drive

shaft tube, follow the illustration.

WARNING

Do not use metal or plastic blade cutting

attachments.

Installation of cuttingt attachment guard

WARNING

● Do not start or operate unit unless each

guard is properly assembled to unit.

● If an incorrect or faulty guard is fi tted, this

may cause serious personal injury.

CAUTION

Some cutting attachment guards are

equipped with sharp line limiters. Be careful

with handling it.

Aligning to the position indicated by the guard

location label (2), fi rmly secure the cutting

attachment guard to the drive shaft tube with the bolt

(3) and guard bracket (4). (Fig. 2)

3

4

2

WARNING

● lf unit is operated without a sharp line

limiters, the line will become too long, the

engine will overheat, and engine damage

may occur.

● Check sharp line limiters surely cut nylon

line when operating.

Installation of cutting attachment

WARNING

● Install the cutting attachment properly

and securely as instructed in the handling

instructions.

If not attached properly or securely, it may

come off and cause serious and/or fatal

injury.

● Do not install or remove cutting attachments

while the engine is running.

● Always use genuine Hitachi cutting

attachments and metal fi ttings.

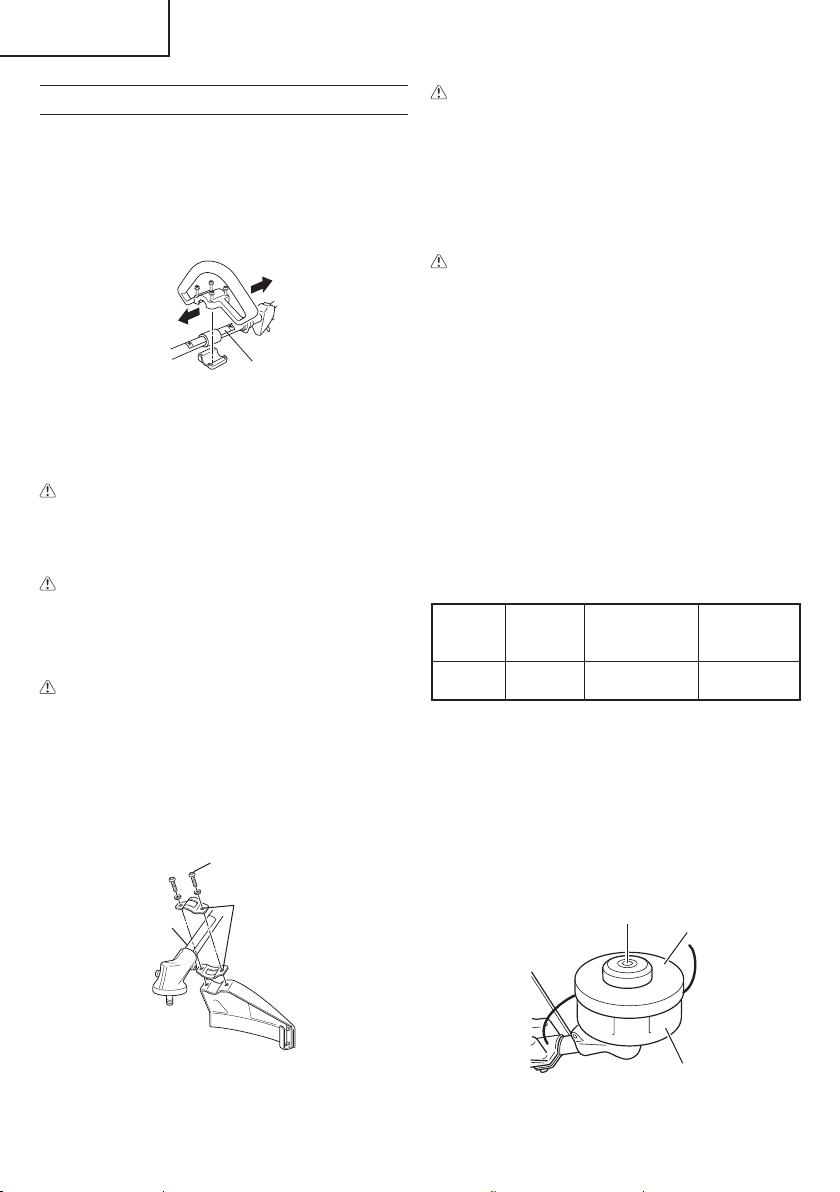

Installation of semi-auto cutting head

1. Function

Automatically feeds more nylon cutting line

when it is tapped at low rpm (not greater than

6,000 min–1).

Specifi cations

Code No.

6600570

Applicable nylon cord

2. Precautions

○ The case must be securely attached to the cover.

○ Check the cover (5), case (6) and other

○ Check the case and button for wear.

If there is a hole in the bottom (7) of the button,

Type of

attaching

screw

Female

screw

Cord diameter: 3/22˝ (Φ2.4 mm) Length: 16.3 ft (5 m)

components for cracks or other damage. (Fig. 3)

change the new parts immediately. (Fig. 3)

Direction of

rotation

Counterclockwise

7

Size of

attaching

screw

M10×P1.25LH

6

Fig. 2

Fig. 3

8

5

Page 9

English

○ The cutting head must be securely mounted to

the unit’s gear case/cutter case.

○ If the cutting head does not feed cutting line

properly, check that the nylon line and all

components are properly installed. Contact

Hitachi Authorized Service Centers if you need

assistance.

WARNING

For Hitachi heads, use only fl exible,

non-metallic line recommended by the

manufacturer. Never use wire or wire ropes.

They can break off and become a dangerous

projectile.

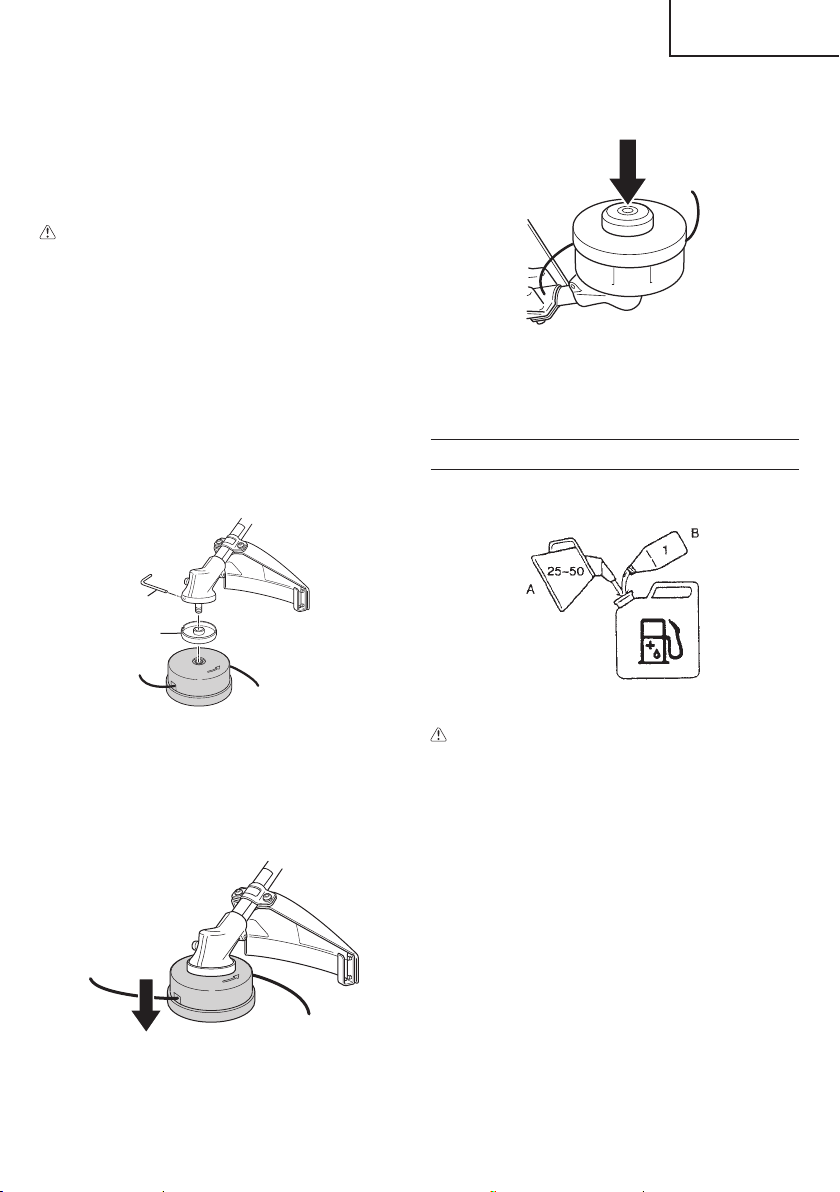

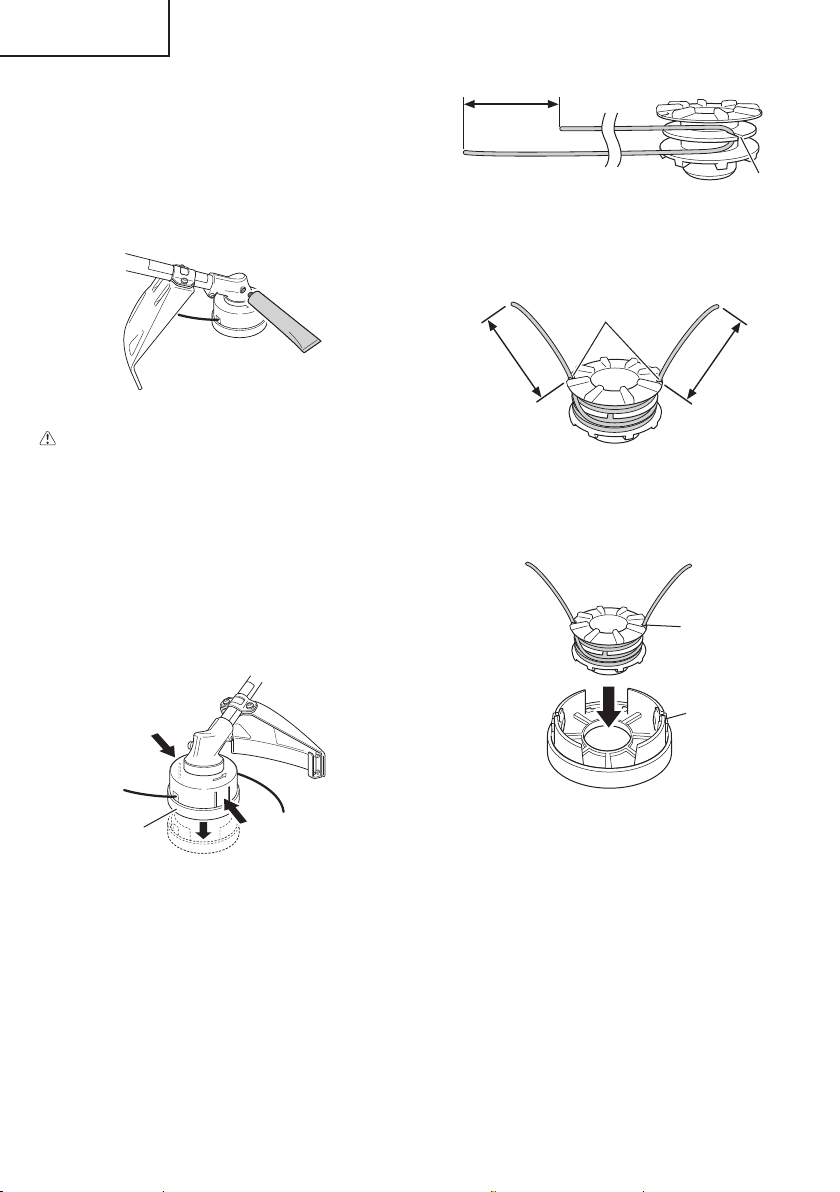

3. Installation (Fig. 4)

Insert the Hex bar wrench (8) into the hole of the

gear case and groove of the Cutter holder (9) in

order to lock the shaft.

Install cutting head on gear case of grass

trimmers. The mounting nut is left-handthreaded. Turn clockwise to loosen/counterclockwise to tighten.

8

9

Also, you can extend the nylon line by hand but

the engine must be completely stopped. (Fig. 6)

Fig. 6

Adjust the nylon line to the proper length

of 4-11/32˝–5-1/2˝ (11–14 cm) before each

operation.

OPERATING PROCEDURES

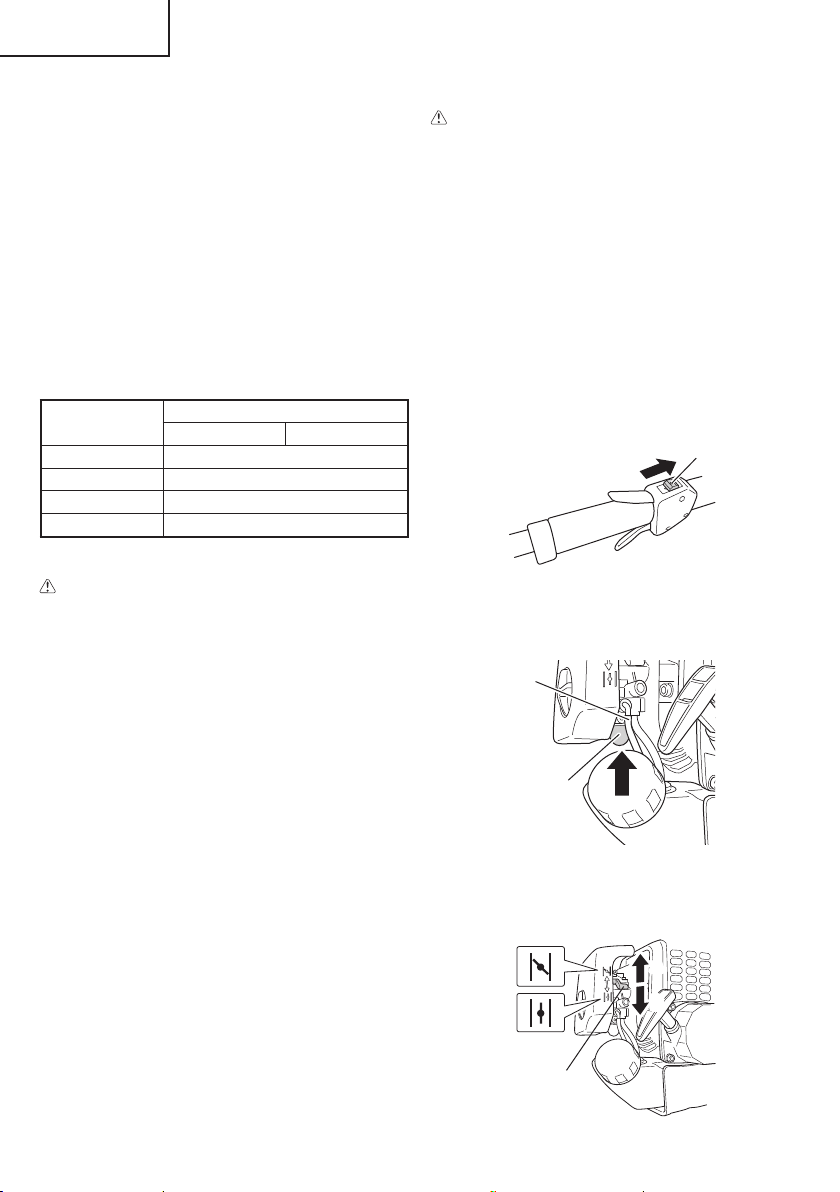

Fuel (Fig. 7)

Fig. 4

4. Adjusting line length

Set the engine speed as low as possible and tap

the head on the ground. The nylon line will be

drawn out about 1-3/16˝ (3 cm) with each tap.

(Fig. 5)

Fig. 5

Fig. 7

WARNING

● The trimmer is equipped with a two-stroke

engine. Always run the engine on fuel, which

is mixed with oil.

Provide good ventilation, when fueling or

handling fuel.

● Fuel contains highly fl ammable and it is

possible to get the serious personal injury

when inhaling or spilling on your body.

Always pay attention when handling fuel.

Always have good ventilation when handling

fuel inside building.

Fuel

○ Always use branded 89 octane unleaded

gasoline.

○ Use genuine two-cycle oil or use a mix between

25:1 to 50:1, please consult about the mixture

ratio to Hitachi Authorized Service Centers.

○ Only for the state of California at 50:1.

9

Page 10

English

○ If genuine oil is not available, use an anti-oxidant

added quality oil expressly labeled for air-cooled

2-cycle engine use (JASO FC GRADE OIL or

ISO EGC GRADE). Do not use BIA or TCW

(2-stroke water-cooling type) mixed oil.

○ Never use multi-grade oil (10 W/30) or waste oil.

○ Never mix fuel and oil in machine’s fuel tank.

Always mix fuel and oil in a separate clean

container.

Always start by fi lling half the amount of gasoline,

which is to be used.

Then add the whole amount of oil. Mix (shake) the

fuel mixture. Add the remaining amount of gasoline.

Mix (shake) the fuel-mix thoroughly before fi lling the

fuel tank.

Mixing amount of two-cycle oil and gasoline

Gasoline (Liter)

0.5 10 ——— 20

1 20 ——— 40

2 40 ——— 80

4 80 ——— 160

Fueling

WARNING

● Always shut off the engine and let it cool for

a few minutes before refueling.

Do not smoke or bring fl ames or sparks near

the fueling site.

● Slowly open the fuel tank, when fi lling up

with fuel, so that possible over-pressure

disappears.

● Tighten the fuel cap carefully, after fueling.

● Always move the trimmer at least 10 ft (3 m)

from the fueling area before starting.

● Always wash any spilled fuel from clothing

immediately with soap.

● Be sure to check for any fuel leakage after

refueling.

● Before fueling, in order to remove static

electricity from the main body, the fuel

container and the operator, please touch the

ground that is slightly damp.

Before fueling, clean the tank cap area carefully,

to ensure that no dirt falls into the tank. Make sure

that the fuel is well mixed by shaking the container,

before fueling.

Two-cycle oil (ml)

Ratio 50:1 Ratio 25:1

Starting

WARNING

● Before starting the tool, ensure that the

cutting attachment is not touching any

objects or the ground.

Otherwise, the cutting attachment may

unexpectedly rotate and cause an injury.

● Ensure that the cutting attachment does not

rotate while the engine is idling. If it does

rotate, adjust the idle speed according to the

instructions in “Idle speed adjustment” in

the “MAINTENANCE” section. If the cutting

attachment still rotates after this adjustment,

immediately stop the engine and cease use,

then bring the tool to the nearest Hitachi

Authorized Service Center.

1. Starting the cold engine

(1) Set ignition switch (10) to ON position. (Fig. 8)

10

Fig. 8

(2) Push priming bulb (11) several times so that fuel

fl ows through return pipe (12). (Fig. 9)

12

11

Fig. 9

(3) Set choke lever (13) to START position (closed)

(A). (Fig. 10)

AA

B

B

13

10

Fig. 10

Page 11

(4) Pull recoil starter briskly, taking care to keep the

handle in your grasp and not allowing it to snap

back. (Fig. 11)

Fig. 11

(5) When you hear the engine want to start, return

choke lever to RUN position (open) (B). (Fig. 10)

(6) Pull recoil starter briskly again. (Fig. 11)

NOTE

If engine does not start, repeat procedures from

2 to 5.

(7) Then allow the engine about 2–3 minutes to

warm up before subjecting it to any load.

(8) Check that the cutting attachment does not rotate

when the engine is idling.

2. Starting the warm engine

Use only 1, 6 and 8 of the starting procedure for a

cold engine.

If the engine does not start, use the same starting

procedure as for a cold engine.

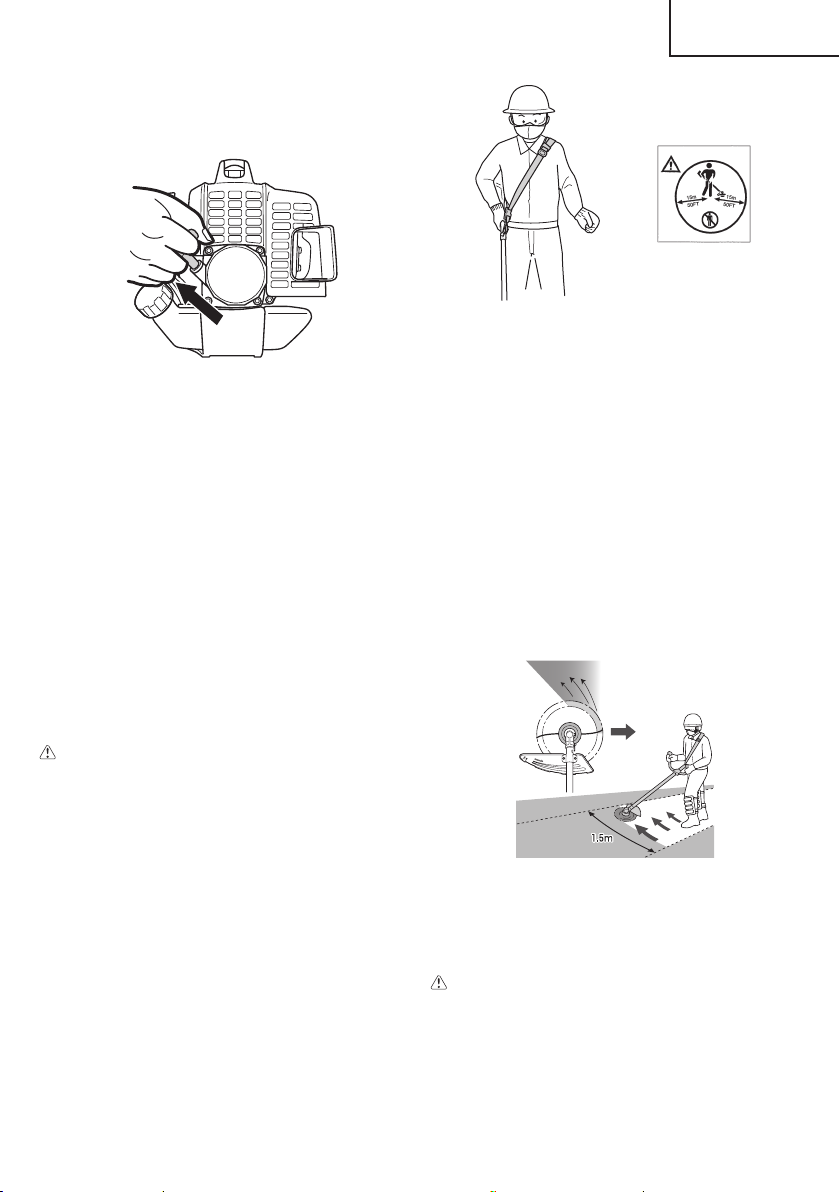

Cutting

WARNING

● Always use the harness (if so equipped)

and wear the proper attire and protective

equipment when operating the unit. (Fig. 12)

● Keep others including children, animals,

bystanders and helpers outside the 15 m

hazard zone. Stop the engine immediately if

you are approached. (Fig. 13)

● When grass or vines wrap around

attachment, stop engine and attachment

and remove them. Continuing operation

with grass or vines wrapped around the

attachment may result in damages such as

early abrasion of the clutch.

English

Fig. 12 Fig. 13

NOTE

Use in accordance with local laws and

regulations.

Using a semi-auto cutting head

○ Set the engine at high speed when using this

attachment.

○ Cut grass from left to right. The cut grass will

be discharged away from the body, minimizing

transfer to your clothes. (Fig. 14)

○ Cut grass from right to left as the cutting

attachment of the curved drive shaft tube model

rotates clockwise.

○ With nylon cord, use about 3/4” (2 cm) of the end

of the cord to cut grass. Using the full length of

the cord will reduce rotation speed and make

cutting diffi cult.

Fig. 14

NOTE

Automatically feeds more nylon cutting line

when it is tapped at low rpm (not greater than

6,000 min-1).

WARNING

● This product is equipped with a line limiter

that will automatically cut any excess cord.

When operating the unit, do not remove the

guard or line limiter.

As the resistance is greater for nylon cords

as opposed to blades, mishandling could

increase engine load and result in damage.

11

Page 12

English

● Do not use with the engine set at low

speeds. If the engine speed is low, grass

may wrap around the attachment, causing

the clutch to slip which could result in clutch

abrasion.

● With nylon cord cutters, always use over

5-7/8” (15 cm) of cord. If the length of

the cord is too short, rotation speed will

increase and may cause damage to the

nylon cord cutter. As the curved drive shaft

tube model in particular is not equipped with

a deceleration mechanism, the possibility

of increased rotation speed for the cutting

attachment is high.

Stopping (Fig. 15)

Decrease engine speed and run at an idle for a few

minutes, then turn off ignition switch (10).

10

Fig. 15

WARNING

A cutting attachment can injure while it

continues to spin after the engine is stopped

or Throttle trigger is released. When the

unit is turned off , make sure the cutting

attachment has stopped before the unit is

set down.

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR

OF THE EMISSION CONTROL DEVICES AND

SYSTEMS MAY BE PERFORMED BY ANY NONROAD ENGINE REPAIR ESTABLISHMENT OR

INDIVIDUAL.

Carburetor adjustment (Fig. 16)

Fig. 16

The carburetor is a precision part that mixes air and

fuel, and it is designed to ensure high performance

from the engine. Before the tool is shipped from

the factory, its carburetor is adjusted during a

test run. Only make adjustments if it is necessary

because of environmental conditions (the climate or

atmospheric pressure), the type of fuel, the type of

two-cycle oil, etc.

WARNING

● Because the carburetor is manufactured

with a high degree of precision, do not

disassemble it.

● For this product, the only setting of the

carburetor that can be adjusted is the idle

speed (T).

● Never start the engine without the complete

clutch cover and tube assembled! Otherwise

the clutch can come loose and cause

personal injuries.

T = Idle speed adjustment screw.

Idle speed adjustment (T)

WARNING

● When the engine is stopped, do not

excessively turn the idle speed adjustment

screw (T) in a clockwise direction.

Otherwise, when the engine starts, the

cutting attachment may unexpectedly rotate

and cause an injury.

● Do not adjust the idle speed adjustment

screw (T) for any reason other than to adjust

the idling.

12

Page 13

English

Run the engine while adjusting the idling.

(1) If the engine stops during idling

Start the engine, and slowly turn the idle speed

adjustment screw (T) in a clockwise direction

until it is in a position at which the engine rotates

smoothly. At that time, ensure that the cutting

attachment is not spinning.

(2) If the cutting attachment rotates during idling

Slowly turn the idle speed adjustment screw (T)

in a counter-clockwise direction until it is in a

position at which the cutting attachment does not

rotate. At that time, ensure that the rotation of the

engine is smooth.

WARNING

If the cutting attachment still rotates after

adjustment of the idle speed adjustment

screw (T), immediately stop the engine and

cease use, then contact the nearest Hitachi

Authorized Service Center.

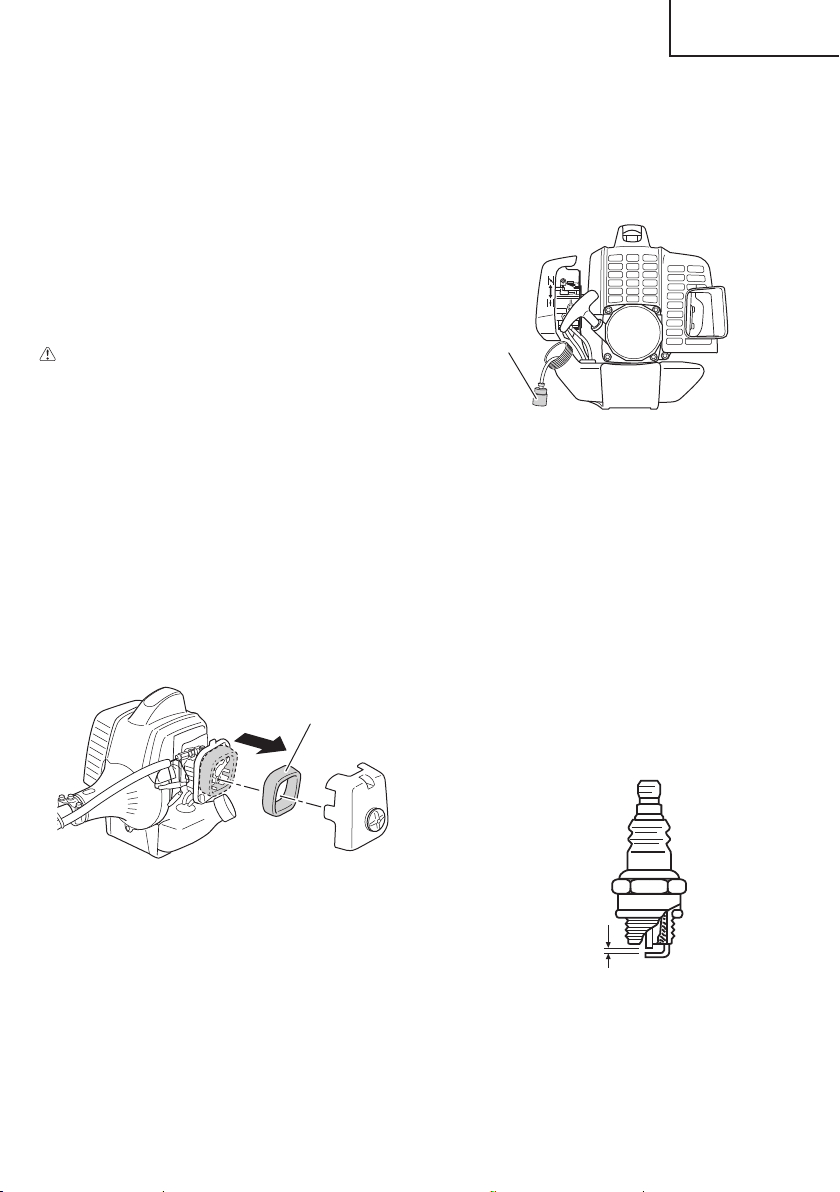

Air fi lter (Fig. 17)

The air fi lter (14) must be cleaned from dust and dirt

in order to avoid:

○ Carburetor malfunctions

○ Starting problems

○ Engine power reduction

○ Unnecessary wear on the engine parts

○ Abnormal fuel consumption

Clean the air fi lter daily or more often if working in

exceptionally dusty areas.

14

Fuel fi lter (Fig. 18)

Remove the fuel fi lter (15) from the fuel tank, and

replace it if it is dirty.

NOTE

A blocked fuel fi lter (15) can prevent the supply of

fuel and cause a rotation malfunction of the engine.

15

Fig. 18

Spark plug (Fig. 19)

The spark plug condition is infl uenced by:

○ An incorrect carburetor setting

○ Wrong fuel mixture (too much oil in the gasoline)

○ A dirty air fi lter

○ Hard running conditions (such as cold weather)

These factors cause deposits on the spark plug

electrodes, which may result in malfunction and

starting diffi culties. If the engine is low on power,

diffi cult to start or runs poorly at idling speed, always

check the spark plug fi rst. If the spark plug is dirty,

clean it and check the electrode gap. Re-adjust

if necessary. The correct gap is 0.024˝ (0.6 mm).

The spark plug should be replaced after about 100

operation hours or earlier if the electrodes are badly

eroded.

Fig. 17

Cleaning the air fi lter

Open the air fi lter cover and remove the air fi lter

(14). Clean it.

Check that the fi lter is dry before reassembly.

An air fi lter that has been used for some time cannot

be cleaned completely. Therefore, it must regularly

be replaced with a new one. A damaged fi lter must

always be replaced.

NOTE

To put the air fi lter cover back into place, hook it

on the upper tabs and then attach it.

0.024˝

(0.6 mm)

Fig. 19

NOTE

In some areas, local law requires using a resistor

spark plug to suppress ignition signals. If this

machine was originally equipped with resistor

spark plug, use same type of spark plug for

replacement.

13

Page 14

English

Gear case (Fig. 20)

Check gear case or angle gear for grease level

about every 50 hours of operation by removing the

grease fi ller plug on the side of gear case.

If no grease can be seen on the fl anks of the

gears, fi ll the gear case with quality lithium based

multipurpose grease up to 3/4. Do not completely fi ll

the gear case.

Fig. 20

CAUTION

● Make sure to remove any dirt or grit when

attaching the plug to its original position.

●

Before attempting inspection or maintenance

of the gear case, make sure the case has

cooled.

Semi-auto cutting head

Nylon line replacement

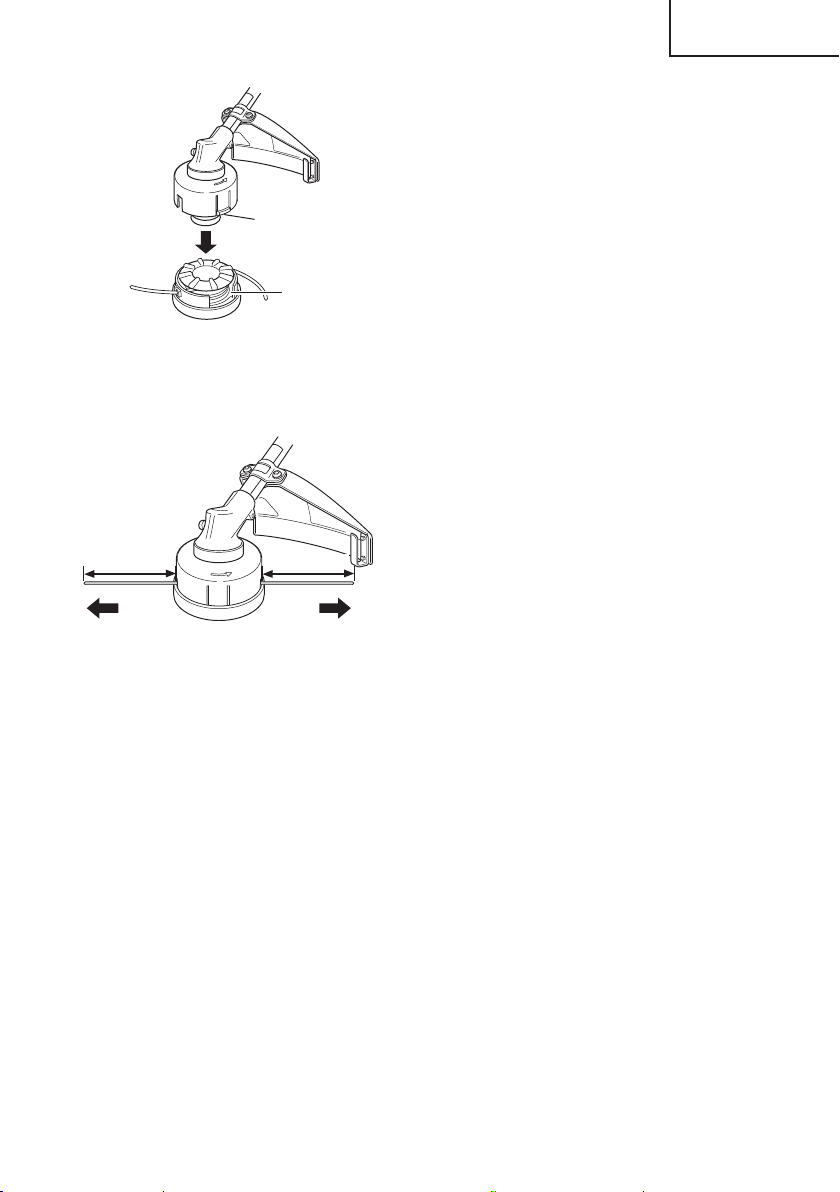

(1) Remove the case (16) by fi rmly pushing inward

the locking tabs with your thumbs as shown in

Fig. 21.

4˝ (10 cm)

17

Fig. 22

(4) Push each line into the stopper holes (18),

leaving the loose ends approx. 4˝ (10 cm) in

length. (Fig. 23)

18

4˝ (10 cm)

4˝ (10 cm)

Fig. 23

(5) Insert both loose ends of the line through the

cord guide (19) when placing the reel in the case.

(Fig. 24)

18

16

Fig. 21

(2) After removing the case, take out the reel and

discard the remaining line.

(3) Fold the new nylon line unevenly (approx. 10 cm)

in half as shown in picture.

Hook the U-shaped end of the nylon line into the

groove (17) on the center partition of the reel.

Wind both halves of the line on the reel in the

same direction, keeping each half of the line on

its own side of the partition. (Fig. 22)

14

19

Fig. 24

NOTE

When placing a reel in the case, try to line up the

stopper holes (18) with the cord guide (19) for

easier line release later.

(6) Place the cover over the case so that the cap

locking tabs (20) on the cover meet the long

holes (21) on the case. Then push the case

securely until it clicks into place. (Fig. 25)

Page 15

20

21

Fig. 25

(7) The initial cutting line length should be approx.

4-11/32˝–5-1/2˝ (11–14 cm) and should be equal

on both sides. (Fig. 26)

4-11/32˝–5-1/2˝

(11-14 cm)

4-11/32˝–5-1/2˝

English

○ Check that nuts and screws are suffi ciently

tightened.

○ Check that the unit is undamaged and free of

defects.

Weekly maintenance

○ Check the starter, especially the cord.

○ Clean the exterior of the spark plug.

○ Remove the spark plug and check the electrode

gap. Adjust it to 0.024˝ (0.6 mm), or change the

spark plug.

○ Check that the angle gear is fi lled with grease up

to 3/4.

○ Clean the air fi lter.

Monthly maintenance

○ Rinse the fuel tank with gasoline.

○ Clean the exterior of the carburetor and the

space around it.

○ Clean the fan and the space around it.

Fig. 26

For long-term storage

Drain all fuel from the fuel tank. Start and let engine

run until it stops. Repair any damage which has

resulted from use. Clean the unit with a clean rag, or

the use of high pressure air hose. Put a few drops

of two-cycle engine oil into the cylinder through the

spark plug hole, and spin the engine over several

times to distribute oil.

Cover the unit and store it in a dry area.

Maintenance schedule

Below you will fi nd some general maintenance

instructions. For further information please contact

Hitachi Authorized Service Centers.

Daily maintenance

○ Clean the exterior of the unit.

○ Check the cutting attachment guard for damage

or cracks. Change the guard in case of impacts

or cracks.

○ Check that the cutting attachment is properly

centred, sharp, and without cracks. An off -centre

cutting attachment induces heavy vibrations that

may damage the unit.

○ Check that the cutting attachment nut is

suffi ciently tightened.

15

Page 16

English

TROUBLESHOOTING

Use the inspections in the table below if the tool does not operate normally. If this does not remedy the

problem, consult your dealer or the Hitachi Authorized Service Center.

Condition Cause Remedy

Engine does

not start

Fuel

system

Electrical

system

Other

Fuel tank is empty or fuel level is

low

Fuel tank contains old fuel (off ensive

odor)

Too much fuel is absorbed and

spark plug is wet

Fuel fi lter is clogged with dirt Clean the fuel fi lter

Fuel pipe is bent or disconnected Ensure that the fuel fl ows smoothly

Carburetor malfunction

Stop switch lead has shortcircuited

Spark plug is dirty Replace or clean the spark plug

Electrode gap is too big Adjust the gap to 0.6 mm

Poor connection between high

tension cable and spark plug

Electrical system malfunction

Muffl er exhaust port is clogged

with carbon

Fill the fuel tank with the correct fuel mix

(25:1-50:1)

Replace with new fuel

1.

Disconnect the spark plug and allow

to dry

2. Pull the starter handle 5 or 6 times to

remove the surplus fuel

3. Attach the spark plug

4. Set the choke lever to RUN position

and pull the starter handle

Contact Hitachi Authorized Service

Centers

Contact Hitachi Authorized Service

Centers

Reconnect

Contact Hitachi Authorized Service

Centers

Contact Hitachi Authorized Service

Centers for repair

16

Page 17

Condition Cause Remedy

Fuel tank is empty or fuel level is

low

Fuel tank contains old fuel (off ensive

odor)

Fuel

system

Engine starts

but cuts out

straightaway

Engine is apt to

cut out

Abnormal vibration

Engine is running but blade

does not move

Movement is poor

Engine does not stop Stop switch failure

Engine stops when throttle

is closed

Blade continues rotating

when throttle is closed

Electrical

system

Other

Two-cycle oil has not been added

Choke lever is in START position Set the choke lever to RUN position

Air has got into fuel system Reconnect the fuel pipe or joint

Carburetor malfunction

Ignition failure

Spark plug failure Replace with new spark plug

Electrical system failure

Engine overheating

Wrong spark plug model

Dirty air cleaner Clean

Carbon clogging (muffl er exhaust

port)

Insuffi cient compression (piston,

piston ring, cylinder)

Cutting attachment is not properly

installed

Handle, handle bracket or other

fastening part is loose

Grass is wrapped round gear case Remove grass

Grass is wrapped round gear case Remove grass and dirt

Idle speed is too low

Idle speed is too high

Throttle wire is too taut

Fill the fuel tank with the correct fuel mix

(25:1-50:1)

Replace with new fuel

Contact Hitachi Authorized Service

Centers

Contact Hitachi Authorized Service

Centers

Contact Hitachi Authorized Service

Centers

Replace with designated part

See “SPECIFICATIONS”

Clean

Contact Hitachi Authorized Service

Centers

See “Installation of cutting attachment”

Check and tighten

Set the choke lever to START position

to stop the engine

Cease use immediately and contact

Hitachi Authorized Service Centers

Contact Hitachi Authorized Service

Centers

Contact Hitachi Authorized Service

Centers

English

17

Page 18

Français

SIGNIFICATION DES SYMBOLES

REMARQUE:

Avant l’utilisation de votre nouvelle machine

• Lisez attentivement le manuel d’utilisation.

• Vérifi ez que l’équipement de coupe est monté et réglé correctement.

• Démarrez la machine et vérifi ez le réglage du carburateur. Voir la section “ENTRETIEN”.

Certains appareils n’en sont pas pourvus.

Symboles

ATTENTION

Les symboles suivants sont utilisés pour l’outil. Bien se familiariser avec leur

signifi cation avant d’utiliser l’outil.

Il est important que vous lisiez

et compreniez bien avant

utilisation et que vous respectiez

Utilisez des chaussures

antidérapantes et solides.

les précautions de sécurité

et avertissements suivants.

L’utilisation inattentive ou

Etranglement – Position

marche (ouverte)

inadéquate de cet appareil peut

provoquer des blessures graves

voire mortelles.

Etranglement – Position de

démarrage (fermé)

Lisez attentivement et respectez toutes

les instructions et tous les avertissements

donnés dans ce manuel et sur le produit.

START

Marche/Allumer

Utilisez toujours des lunettes de

protection ainsi qu’un casque et

des protections d’oreilles lorsque

STOP

Arrêt/Eteindre

vous utilisez ce produit.

N’utilisez pas de lames métalliques/

rigides lorsque ce signe apparaît sur

Mélange carburant/huile

la machine.

Maintenez les enfants, spectateurs

et aides à plus de 15 m de l’appareil.

Réglage du ralenti

Si quelqu’un s’approche de vous,

coupez immédiatemment le moteur

et arrêtez l’outil de coupe.

Pompe à amorcer

Surface chaude – Tout

Faites attention aux projections

d’objets.

contact avec une surface

chaude peut provoquer de

graves brûlures.

Indique la vitesse maximale de

l’arbre. N’utilisez pas d’outil de coupe

dont la vitesse de rotation (nombre

-1

min

de tours/minute) est inférieure à la

vitesse de rotation de l’arbre.

Indique l’emplacement

de la poignée. Flèches

pour indiquer les limites

concernant le positionnement

de la poignée.

Indique l’emplacement de

Au besoin, utilisez des gants,

notamment lors du montage de

l’équipement de coupe.

la protection de l’outil de

coupe pour un coupe-herbe

ou une tête de coupe semi-

automatique.

18

Page 19

Français

Sommaire

DESCRIPTION ..................................................... 19

PRÉCAUTIONS ET CONSIGNES DE SÉCURITÉ

GARANTIE ........................................................... 22

....... 20

DESCRIPTION

Ce manuel étant commun à plusieurs modèles, vous

constaterez peut-être certaines diff érences entre

les images et votre appareil. Suivez les instructions

relatives à votre modèle.

1. Bouchon de réservoir de carburant

2. Manette d’accélérateur

3. Poignée du démarreur

4. Protection de l’outil de coupe

5. Outil de coupe

6. Tube de transmission

7. Poignée

8. Contacteur d’allumage

9. Bougie

10. Pompe d’amorçage

11. Manette de verrouillage

12. Levier d’étranglement

13. Moteur

14. Boîte de vitesse

15. Clé à douille multiple

16. Mode d’emploi

17. Lunettes

18. Clé Allen

19. Couvercle supérieur

CARACTÉRISTIQUES ......................................... 23

MONTAGE ........................................................... 24

UTILISATION ........................................................ 25

ENTRETIEN ......................................................... 29

13

11

8

14

5

12

10

6

4

15

7

2

9

13

3

1

19

16

17

18

19

Page 20

Français

ATTENTION

Les gaz d'échappement du moteur de ce produit

contiennent des substances chimiques connues

dans l'État de la Californie pour causer le cancer, des

malformations congénitales ou d'autres anomalies

reproductives.

PRÉCAUTIONS ET CONSIGNES

DE SÉCURITÉ

Faites particulièrement attention aux stipulations

introduites par les mots ci-dessous:

AVERTISSEMENT

Information de première importance pour éviter

des dommages corporels graves ou mortels.

ATTENTION

Information importante afi n d’éviter des

dommages corporels ou matériels.

REMARQUE

Information utile pour une utilisation et un

fonctionnement corrects de la machine.

Sécurité de l’utilisateur

○ Portez toujours une visière et des lunettes de

protection.

○ Les lunettes étanches de protection agréées sont

conformes à la norme ANSI Z87.1 aux États Unis.

○ Portez toujours un pantalon épais, des chaussures

antidérapantes, des gants et une chemise à

manches longues. Évitez les vêtements amples,

les shorts, les sandales et les pieds nus. Veillez

à ce que vos cheveux ne descendent pas audessous des épaules.

○ Utilisez cette machine uniquement si vous êtes

en pleine possession de vos moyens physiques.

Évitez strictement la consommation d’alcool, de

drogue ou de médicaments.

○ Ne laissez jamais un enfant ou une personne

inexpérimentée se servir de ces machines.

Portez un dispositif de protection auditive agréé (3).

○

L’exposition prolongée à des sons forts peut

entraîner une défi cience auditive permanente.

Restez vigilant à tout ce qui vous entoure. Restez

attentif dans l’éventualité où une personne située

à proximité vous signalerait un problème.

Retirez les équipements de sécurité

immédiatement après avoir coupé le moteur de

l’outil.

○ Protégez-vous la tête.

○ Ne mettez jamais le moteur en marche dans un

environnement fermé, comme dans une pièce

ou à l’intérieur d’un bâtiment. L'inhalation de gaz

d’échappement au monoxyde de carbone peut

être mortelle.

20

○ Nettoyez les poignées de toute trace d’huile ou de

carburant.

○ N’approchez jamais les mains du guide-chaîne et

de la chaîne.

○ N’attrapez jamais et ne tenez jamais la machine

par l’extrémité du guide-chaîne.

○ Après l’arrêt de la machine, attendez l’arrêt

complet de l’outil de coupe avant de poser la

machine.

○ Lors d’une utilisation prolongée, veillez à pratiquer

des pauses régulières afi n d’éviter des troubles

éventuels provoqués par les vibrations.

○ Ne pas utiliser l’outil de nuit ou sous de mauvaises

conditions météorologiques lorsque la visibilité

est mauvaise. Et n’utilisez pas l’appareil lorsqu’il

pleut ou tout de suite après une averse.

Travailler sur un sol glissant peut conduire à un

accident si vous perdez l’équilibre.

○ Ne démarrez pas le moteur s’il y a des matières

infl ammables telles que des feuilles sèches, de

vieux papiers ou du carburant dans les alentours.

○ Au besoin, utilisez des gants, lors du montage

ou du dégagement de l’outil de coupe. Le nonrespect de cette précaution peut provoquer des

blessures.

ATTENTION

● Toujours utiliser l’outil avec un équipement

de protection et des vêtements. Le nonrespect de cette consigne pourrait entraîner

des accidents comme des brûlures ou des

blessures.

Ne touchez pas à la zone d’étincelle ou à la zone

●

de haute tension pendant le fonctionnement.

Cela peut entraîner un choc électrique.

● Ne laissez pas les enfants près de l’outil

pendant le fonctionnement.

● Veuillez ne pas toucher le couvercle supérieur

du moteur ni le conduit d'aération pendant

ou tout de suite après l'utilisation. Cela peut

entraîner des brûlures ou des blessures.

● Les systèmes anti-vibrations ne préviennent

pas de la maladie des doigts blancs, ni du

syndrome du canal carpien. Par conséquent,

en cas d’utilisation régulière et continue de

votre machine, surveillez soigneusement

l’état de vos mains et de vos doigts. Si l’un des

symptômes ci-dessus venait à apparaître, il

serait indispensable de vous faire examiner

immédiatement par votre médecin.

● Si vous êtes équipé d’un appareillage médical

électrique/électronique tel qu’un stimulateur

cardiaque, consultez votre médecin et le

fabricant de cet appareillage avant d’utiliser

tout appareil électrique.

Page 21

Français

Règles de sécurité concernant l’utilisation de la

machine.

○ Contrôlez entièrement votre machine avant

chaque utilisation. Remplacez les pièces

endommagées. Vérifi ez l’absence de fuites de

carburant et assurez-vous que tous les dispositifs

de fi xation sont en place et solidement fi xés.

○ Remplacez les pièces qui présentent des

fi ssures, des ébréchures ou toute autre avarie

avant d’utiliser l’outil/la machine. Les pièces

défectueuses peuvent augmenter les risques

d’accident et provoquer des blessures.

○ Assurez-vous que l’outil de coupe est

correctement installé et solidement fi xé.

○ Assurez-vous que la protection de l’accessoire de

coupe et le harnais sont correctement attachés.

Ne pas faire fonctionner l’appareil si la protection

et le harnais de l’accessoire de coupe ne sont pas

correctement attachés.

○ Ne laissez personne s’approcher lorsque vous

réglez le carburateur.

○ Utilisez uniquement les accessoires

recommandés par le constructeur pour cette

machine.

○ Avant l’utilisation, assurez-vous qu’il n’y a pas

d’outils tels que la clé de réglage ou la clé encore

fi xées à l’appareil.

ATTENTION

● Ne modifi ez en aucun cas la machine.

N’utilisez jamais la débroussailleuse pour

un autre usage que celui pour lequel elle est

prévue.

● Toute modifi cation non autorisée et/ou

des accessoires pourraient entraîner de

graves blessures corporelles ou la mort de

l’opérateur ou d’autres.

Sécurité au niveau du carburant

○ Faites le mélange et le plein à l’air libre, à distance

de toute étincelle et fl amme.

○ Utilisez un récipient agréé pour l’essence.

○ Pour démarrer la débroussailleuse, écartez-vous

d’au moins 10 pieds (3 mètres) de l’endroit où

vous avez fait le plein.

○ Retirez lentement le bouchon du réservoir de

carburant uniquement après avoir arrêté le

moteur. Ne retirez pas le bouchon de carburant

pendant le fonctionnement.

○ Vidangez le réservoir de carburant avant de ranger

la machine. Cette opération est recommandée

après chaque utilisation. Si le réservoir n’est pas

vide, rangez alors la machine dans une position

empêchant toute fuite de carburant.

ATTENTION

● Le carburant peut s’enfl ammer facilement ou

exploser et l’inhalation de ses vapeurs est

dangereuse. Faites particulièrement attention

lorsque vous manipulez le carburant ou faites

l’appoint du réservoir.

● Ne fumez pas et ne laissez personne fumer à

proximité du carburant ou de la machine ou

pendant que vous utilisez la machine et faites

le mélange de carburant ou le plein.

● Essuyez soigneusement toutes les traces de

carburant avant de démarrer le moteur.

● Rangez la machine et le carburant dans un

endroit où les vapeurs d’essence ne risquent

pas d’entrer en contact avec des étincelles ou

une fl amme en provenance d’un chauff e-eau,

d’un moteur électrique, d’un commutateur,

d’une chaudière, etc.

●

Lorsque vous utilisez l’appareil dans des zones

sèches, assurez-vous que des extincteurs

d'incendie sont facilement accessibles.

●

Si vous coupez le moteur au réapprovisionnement

en carburant, assurez-vous que l’appareil a

refroidi avant d’ajouter du carburant

Sécurité au niveau de la coupe

○ Ne coupez rien d’autre que de l’herbe et des

broussailles.

○ Nettoyez la zone de coupe avant chaque

utilisation. Enlevez les objets susceptibles d’être

projetés ou de s’enchevêtrer dans l’outil de coupe.

○ Pour la protection des voies respiratoires, portez

un masque de protection contre les aérosols lors

de la coupe d’une végétation traitée avec des

insecticides.

○ Veillez à ce que personne (enfants, animaux,

spectateurs ou aides) ne se tienne à l’intérieur

d’un périmètre de sécurité de 50 pieds (15

mètres). Il y a toujours un risque de blessure

en cas de projections d’objets. Les spectateurs

devraient être invités à porter un protecteur

pour la vue. Arrêtez immédiatement le moteur si

quelqu’un s’approche de vous.

○ Soyez prudent car le démarrage du moteur peut

être retardé après avoir tiré sur la poignée de

démarrage.

○ Tenez toujours le moteur à votre droite.

○ Maintenez fermement la machine des deux

mains.

○ Tenez-vous bien en équilibre sur les deux jambes.

Ne travaillez jamais en porte-à-faux.

Perdre l’équilibre pendant le travail peut mener à

une blessure.

○ Restez toujours éloigné du silencieux

d’échappement et de l’ensemble de coupe

lorsque le moteur est en marche.

.

21

Page 22

Français

○ Maintenez l’outil de coupe en-dessous du niveau

du genou.

○ Soyez prudent lors de l’utilisation dans des

endroits où des câbles électriques ou des

conduites de gaz sont présents.

○ N’utilisez l’accessoire de coupe pour rien d’autre

que le débroussaillage d’herbes ou de buissons.

Évitez les opérations où l’accessoire de coupe

pourrait entrer en contact de l’eau, comme des

fl aques, ou de creuser dans la saleté. Le nonrespect de cette précaution peut provoquer des

blessures ou d’endommager l’appareil.

○ Evitez une utilisation prolongée à basse vitesse

dans laquelle le mouvement de vibration est

élevé. Cela peut endommager le moteur.

○ Quand vous déplacez l’outil de coupe dans un

autre lieu de travail, lorsque vous faites des

réglages ou lorsque vous échangez les outils

de coupes, accessoires, etc., assurez-vous que

l’appareil n’est pas sous tension et assurez-vous

que tous les outils de coupe sont à l’arrêt.

○ Ne posez jamais l’appareil sur le sol lorsque le

moteur tourne.

○ Ne jamais toucher l’outil de coupe lorsqu'il tourne.

○ Assurez-vous toujours que le moteur est

arrêté et que tous les accessoires de coupe

sont complètement à l’arrêt avant de nettoyer

l’accessoire principal de coupe de tout débris ou

amas d’herbe.

○ Lors de l’utilisation de n’importe quel appareil

électrique/thermique, emportez toujours avec

vous une trousse de premiers soins.

○ Éteindre le moteur et vérifi er que l’accessoire de

coupe est à l’arrêt complet avant de vous séparer

ou avant de laisser l’appareil sans surveillance.

○ Si vous appuyez accidentellement sur une

bosse ou laissez tomber l’appareil, le contrôler

immédiatement et assurez-vous de l'absence de

dommages, fi ssures ou de déformations.

○ Si l’outil fonctionne mal et produit des bruits

étranges ou des vibrations, arrêtez le moteur

immédiatement et contactez votre revendeur pour

le faire inspecter et réparer.

Une utilisation continue dans ces conditions

peut entraîner des blessures ou endommager

l’appareil.

○ Utiliser selon les réglementations et lois locales.

Sécurité au niveau de l’entretien

○ Entretenez votre machine selon les

recommandations du constructeur.

○ Débranchez la bougie avant toute intervention

d’entretien, à l’exception des opérations de

réglages du carburateur.

○ Ne laissez personne s’approcher lorsque vous

réglez le carburateur.

22

○ Utilisez uniquement les pièces de rechange

d’origine Hitachi.

ATTENTION

Ne démontez pas le lanceur à retour automatique.

Son ressort risque de vous blesser.

AVERTISSEMENT

Un entretien incorrect peut entraîner des

avaries importantes du moteur ou des

blessures graves.

Transport et rangement

○ Portez la machine avec moteur arrêté et silencieux

orienté vers l’extérieur.

○ Laisser le moteur refroidir, vider le réservoir de

carburant avant le rangement ou le transport.

Bien attacher la machine pendant le transport pour

éviter des pertes de carburant, des dommages ou

des blessures.

○ Vidangez le réservoir de carburant avant de ranger

la machine. Cette opération est recommandée

après chaque utilisation. Si le réservoir n’est pas

vide, rangez alors la machine dans une position

empêchant toute fuite de carburant.

○ Rangez la machine hors de portée des enfants.

○ Nettoyez soigneusement la machine avant de

l’entreposer dans un endroit sec.

○ Assurez-vous que le commutateur d’arrêt du

moteur est bien sur la position « stop » lors du

transport ou du rangement de la machine.

○ Lors du transport et du rangement, retirez l’accessoire

de coupe ou placez la protection sur la lame.

○

Vous devez bien attacher la machine pendant le

transport pour éviter les pertes de carburant, des

dommages ou des blessures.

○

Si une étiquette d’avertissement ne peut pas être

lue, si elle s’écaille ou devient illisible, remplacez

la par une autre. Pour acheter de nouvelles

étiquettes, veuillez contacter un service aprèsvente Hitachi agréé.

Dans l’éventualité de situations qui ne seraient pas prises

en compte par le présent manuel, redoublez d’attention

et usez de bon sens. Si vous avez besoin d’assistance,

contactez un centre de service Hitachi autorisé.

GARANTIE

Les garanties fournies par Hitachi Koki U.S.A., Ltd.

sont indiquées sur le bon de garantie accompagnant

ce produit intitulé “Garantie limitée applicable aux

appareils électriques extérieurs Hitachi”.

Page 23

CARACTÉRISTIQUES

Français

Modèle CG23ECP (SL)

Taille du moteur

(cu. in.)

Bougie d’allumage

Contenance du réservoir de carburant

(fl . oz)

Poids à sec (livre) 10.8 (4.9 kg)

Niveau de pression

acoustique

LpA (dB (A)) (

Niveau de puissance

acoustique mesuré

LwA (dB (A))

Niveau de puissance

acoustique garanti

LwA (dB (A))

Niveau de vibrations (m/s2) (ISO22867)

Équivalent (Poignée avant / gauche)

Équivalent (Poignée avant / droite)

Incertitude

ISO22868

Équivalent

)

(

ISO

Vitesse de

course

(

ISO

Vitesse de

course

22868)

22868)

1.37 (22.5 ml)

TORCH AC6RA

(NGK CMR6A)

16.2 (0.48 l)

95.3

112

115

6.0

6.3

1.5

REMARQUE

Les niveaux de bruit/vibrations équivalents sont calculés comme total d’énergie pondérée en fonction du

temps pour les niveaux de bruit/vibrations dans diverses conditions de travail avec la répartition temporelle

suivante:

*1/2 ralenti, 1/2 vitesse de course.

Toutes les données sont susceptibles d’être modifi ées sans préavis.

23

Page 24

Français

MONTAGE

Montage de la poignée (Fig. 1)

Fixez la poignée au tube de transmission.

Choisissez la position la plus pratique avant la mise

en marche.

Assurez-vous d’attacher la poignée fermement avec

les 4 boulons.

1

Fig. 1

REMARQUE

Si le tube de l’arbre moteur comporte une étiquette

(1) indiquant la position de la poignée, suivez les

indications fournies.

AVERTISSEMENT

Ne pas utiliser d’outils de coupe avec des

lames en métal ou en plastique.

Installation de la protection de l’outil de coupe

AVERTISSEMENT

● Ne démarrez pas l’appareil et ne l’utilisez pas

tant que tous les dispositifs de protection ne

sont pas correctement installés.

● Si une protection mauvaise et défectueuse

est installée, cela peut provoquer des

blessures corporelles.

ATTENTION

Certaines protections d’outils de coupe sont

équipées de limiteurs aiguisés. Prenez garde

lorsque vous les maniez.

Alignez sur l’emplacement désigné par l’étiquette

indiquant la position de la protection (2), fi xez

solidement la protection de l

tube de transmission au moyen de la vis (3) et du

crochet de garde (4). (Fig. 2)

’

outil de coupe sur le

3

4

2

Fig. 2

AVERTISSEMENT

● Si l’appareil est utilisé sans limiteur aiguisé,

le fi l de coupe sera trop long, provoquant une

surchauff e du moteur pouvait entraîner une

dégradation.

● Vérifi ez que les limiteurs aiguisés coupent le

fi l de coupe en nylon en toute sécurité quand

l'appareil est en fonction.

Installation de l’outil de coupe

AVERTISSEMENT

● Installez l’outil de coupe correctement

et fermement comme indiqué dans les

instructions de manutention.

S’il n’est pas fi xé correctement ou fermement,

il peut se détacher et provoquer de graves et/

ou de fatales blessures.

● Ne pas installer ou enlever les accessoires de

coupe lorsque le moteur est en marche.

● Toujours utiliser des accessoires de coupe

d'origine Hitachi et des éléments en métal.

Montage de la tête de coupe semi-automatique

1. Fonction

Fait avancer automatiquement le fi l de coupe en

nylon lorsqu’elle est tapotée à bas régime (au plus

6,000 min

Caractéristiques

N° de

code

6600570 Vis creuse

-1

).

Type de

vis de

fi xation

Sens de la

rotation

Sens

antihoraire

Taille de vis

de fi xation

M10×P1.25LH

Cordon de nylon applicable

Diamètre du cordon :

Longueur :

2. Précautions

○ Le boîtier doit être attaché solidement au

couvercle.

24

16.3 pieds (5 m)

3/22˝ (Φ2.4 mm)

Page 25

Français

○ Vérifi ez s'il y a des fi ssures ou d'autres dommages

sur le couvercle (5), le boîtier (6) et les autres

composants. (Fig. 3)

○ Vérifi ez si le boîtier et le bouton sont usés.

S’il y a un trou au bas du bouton (7), changez

immédiatement les nouvelles pièces. (Fig. 3)

7

Fig. 3

○ La tête de coupe doit être montée solidement sur

le boîtier d’engrenages de l’appareil.

○ Si le fi l de coupe n’avance pas bien dans la

tête de coupe, vérifi ez si le fi l nylon et tous les

composants sont bien installés. Si vous avez

besoin d’assistance, contactez un centre de

service Hitachi autorisé.

AVERTISSEMENT

Pour les têtes Hitachi, utilisez uniquement des

fi ls fl exibles, non métalliques recommandés

par le fabricant. N’utilisez jamais de fi l de fer

ou de câble métallique. Ils peuvent se rompre

et devenir de dangereux projectiles.

3. Installation (Fig. 4)

Insérez la clé de forme hexagonale (8) dans le

trou du boîtier d’engrenage et dans la rainure du

support de découpe (9) afi n de bloquer l’arbre.

Installez la tête de coupe sur le boîtier

d’engrenages de la débroussailleuse. L’écrou de

montage est muni d’un fi letage à gauche. Tournez

dans le sens des aiguilles d’une montre pour

desserrer et dans le sens inverse pour serrer.

6

5

4. Ajustement de la longueur du fi l

Réglez le moteur sur la vitesse la plus faible

possible et tapotez la tête de coupe contre le sol.

Le fi l nylon avancera d’environ 1-3/16˝ (3 cm)

pour chaque coup donné. (Fig. 5)

Fig. 5

Vous pouvez également étendre le fi l nylon à la

main, mais uniquement après l’arrêt complet du

moteur. (Fig. 6)

Fig. 6

Ajustez le fi l nylon à une longueur comprise entre

4-11/32˝–5-1/2˝ (11 et 14 cm) avant chaque

utilisation.

UTILISATION

Carburant (Fig. 7)

8

9

Fig. 7

Fig. 4

25

Page 26

Français

AVERTISSEMENT

● La débroussailleuse est équipée d’un moteur

deux temps. Veillez à toujours l’alimenter en

mélange essence/huile.

Veillez à une bonne aération pendant

l’opération de remplissage du réservoir.

● Le carburant contient des substances

hautement infl ammables. Vous risquez des

blessures sévères en cas d’inhalation de

vapeurs ou d’éclaboussure accidentelle

du produit sur votre corps. Faites toujours

très attention lorsque vous manipulez le

carburant. Si vous prévoyez de manipuler le

carburant en intérieur, faites-le dans un local

bien ventilé.

Essence

○ Utilisez toujours de l’essence sans plomb avec un

indice d’octane de 89.

○ Utilisez une huile pour moteur à deux temps

d’origine ou un mélange variant de 25:1 à 50:1,

veuillez consulter un service après-vente Hitachi

agréé pour la proportion du mélange.

○ Et une proportion 50:1 pour l’Etat de la Californie

uniquement.

○ Si vous n’utilisez pas une huile d’origine, utilisez

une huile de qualité contenant un antioxydant

recommandé pour être utilisé avec un moteur à

deux temps refroidi à l’air (JASO FC GRADE OIL

ou ISO EGC GRADE). N’utilisez jamais d’huiles

mélangées BIA ou TCW (pour les moteurs à

essence 2 temps à refroidissement par eau).

○ N’utilisez jamais d’huile Multigrade (10 W/30), ni

d’huile usagée.

○ Ne mélangez jamais le carburant et l’huile dans le

réservoir de carburant de la machine. Eff ectuez

toujours le mélange dans un récipient propre.

Commencez toujours par verser la moitié de

l’essence à mélanger.

Versez ensuite la totalité de l’huile. Mélangez en

agitant le récipient. Ajoutez le reste de l’essence.

Puis agitez le récipient afi n de mélanger

soigneusement le carburant avant de faire le plein.

Quantité de mélange d’huile pour moteur à deux

temps et d’essence

Essence (litre)

0.5

1

2

4

Huile pour moteur à deux temps (ml)

Rapport 50:1 Rapport 25:1

10 ——— 20

20 ——— 40

40 ——— 80

80 ——— 160

Faire le plein

AVERTISSEMENT

● Coupez toujours le moteur et laissez-le

refroidir pendant quelques minutes avant de

refaire le plein.

Ne fumez pas et n’approchez pas de fl ammes

ou d'étincelles à proximité de l’endroit où

vous faites le plein.

● Desserrez lentement le bouchon du réservoir

de carburant pour eff ectuer le remplissage

afi n d’évacuer une éventuelle surpression.

● Serrez le bouchon soigneusement après

avoir rempli le réservoir de carburant.

● Avant de redémarrer le moteur, éloignezvous toujours d’au moins 10 pieds (3 mètres)

de l’endroit où vous avez fait le plein de

carburant.

● En cas de projection accidentelle de carburant

sur vos vêtements, lavez immédiatement ces

derniers avec du savon.

● Après chaque appoint de carburant, vérifi ez

toujours l’absence de fuite.

● Avant de faire le plein, afi n de décharger

le corps principal, le bidon d’essence et

l’opérateur de toute électricité statique,

touchez un sol légèrement humide.

Avant le remplissage, essuyez autour du bouchon

du réservoir afi n d’éviter que des corps étrangers ne

pénètrent dans le réservoir. Veillez à l’homogénéité

du mélange en agitant à intervalle régulier le récipient

avant et pendant le remplissage.

Démarrage

AVERTISSEMENT

● Avant de démarrer l'outil, assurez-vous que

l'accessoire de coupe ne touche aucun objet

ni le sol. Dans le cas contraire, l’accessoire

de coupe peut tourner sans que vous ne vous

y attendiez et provoquer des blessures.

● Vérifi ez que l’accessoire de coupe ne tourne

pas lorsque le moteur est au ralenti. S'il

ne tourne pas, réglez le ralenti selon les

instructions de « Réglage du ralenti » dans

la section « ENTRETIEN ». Si l’accessoire de

coupe tourne encore après cet ajustement,

arrêtez immédiatement le moteur et cessez

d'utiliser l'outil, puis présentez-le au centre

de service agréé Hitachi le plus proche.

26

Page 27

Français

1. Démarrage du moteur froid

(1) Placez l’interrupteur de marche/arrêt (10) en

position “marche” (ON). (Fig. 8)

10

Fig. 8

(2) Pressez la poire de la pompe d’amorçage (11) à

plusieurs reprises pour que le carburant puisse

s’écouler par le tuyau de retour (12). (Fig. 9)

12

11

Fig. 9

(3) Réglez le levier du starter (13) à la position de

démarrage (fermé) (A). (Fig. 10)

AA

B

B

13

Fig. 10

(4) Tirez vivement sur la corde du lanceur en

accompagnant son retour, sans relâcher

brusquement la poignée. (Fig. 11)

Fig. 11

(5) Dès les premiers soubresauts du moteur, ramenez

le starter en position ouverte (B). (Fig. 10)

(6) Puis tirez à nouveau d’un coup sec sur le

démarreur à lanceur. (Fig. 11)

REMARQUE

Si le moteur ne démarre pas, répétez la procédure

décrite entre les points 2 et 5.

(7) Laissez ensuite le moteur chauff er pendant

2 à 3 minutes avant de le soumettre à un eff ort

quelconque.

(8) Vérifi ez que l’outil de coupe ne tourne pas lorsque

le moteur tourne au ralenti.

2. Démarrage du moteur chaud

Appliquez uniquement les étapes 1, 6, et 8 de la

procédure de démarrage pour un moteur froid.

Si le moteur ne démarre pas, appliquez la même

procédure que celle pour moteur froid.

Coupe

AVERTISSEMENT

● Toujours utiliser le harnais (le cas échéant)

et porter la bonne tenue de travail et des

équipements de protection lors de l’utilisation

de l’appareil. (Fig. 12)

● Veillez à ce que personne (enfants, animaux,

passants ou assistants) ne se tienne à

l’intérieur d’un périmètre de sécurité de 15

mètres. Coupez immédiatement le moteur si

quelqu’un s’approche. (Fig. 13)

● Lorsque des herbes ou des plantes

grimpantes s'enroulent autour de l’outil de

coupe, arrêtez le moteur, attendez que la

lame s’arrête de tourner et retirez les herbes

et plantes grimpantes. Si vous poursuivez

l’utilisation avec de l’herbe ou des plantes

grimpantes enroulées autour de l’équipement

cela peut entraîner des dommages comme

une usure précoce de l’embrayage.

27

Page 28

Français

Fig. 12 Fig. 13

REMARQUE

Utiliser selon les réglementations et lois locales.

Utilisation d’une tête de coupe semi-automatique

○ Réglez le moteur à vitesse élevée lors de

l’utilisation de cet équipement.

○ Coupez l’herbe de gauche à droite. L’herbe

coupée sera rejetée loin de votre corps, ce

qui minimise le transfert de matières sur vos

vêtements. (Fig. 14)

○ Coupez l’herbe de droite à gauche car l’accessoire

de coupe sur le modèle d’arbre de transmission

incurvé tourne dans le sens des aiguilles d’une

montre.

○ Avec un fi l de nylon, utilisez environ 3/4” (2 cm)

de l’extrémité du fi l pour eff ectuer la coupe.

L’utilisation de la longueur complète de la corde

aura pour conséquence une réduction de la

vitesse de rotation et la vitesse de coupe sera

rendue diffi cile.

AVERTISSEMENT

●

Ce produit est équipé d’un limiteur de ligne

qui coupe automatiquement tout excès de

cordon. Lors du fonctionnement de l’unité, ne

pas retirer la protection ou le limiteur de ligne.

Comme la résistance est de plus pour les

cordes de nylon pour une manipulation

incorrecte, ce qui risque d’augmenter la charge

du véhicule et de causer des dommages.

● Ne pas utiliser le projecteur sans le

paramétrage du moteur à basse vitesse. Si

la vitesse du moteur est basse, l’herbe peut

s'enrouler autour de l’outil de coupe causant

un glissement de l’embrayage qui pourrait

mener à une usure de l’embrayage.

● Avec des lames en fi l de nylon, utilisez toujours

plus de 7/8” (15 cm) de fi l. Si la longueur du

câble est trop courte, la vitesse de rotation

augmentera et risque d’endommager la lame

en fi l de nylon. Comme le modèle d’arbre de

transmission incurvé, en particulier, n’est

pas équipé d’un mécanisme de décélération,

la possibilité d’augmentation de la vitesse

de rotation pour l’accessoire de coupe est

élevée.

Arrêt de la débroussailleuse (Fig. 15)

Ralentissez le moteur et faites-le fonctionner au

ralenti quelques minutes puis mettez l’interrupteur

de marche-arrêt (10) sur la position “stop”.

10

Fig. 14

REMARQUE

Fait avancer automatiquement le fi l de coupe en

nylon lorsqu’elle est exploitée à bas régime (au

-1

plus 6,000 min

28

).

Fig. 15

AVERTISSEMENT

Un outil de coupe peut blesser lorsqu’il

continue de tourner après l’arrêt du moteur

ou lorsque la commande d’accélérateur

est relâchée. Après l’arrêt de la machine,

attendez l’arrêt complet de l’outil de coupe

avant de poser la machine.

Page 29

Français

ENTRETIEN

L’ENTRETIEN, LE REMPLACEMENT OU LA

RÉPARATION DES DISPOSITIFS ET SYSTÈMES

DE CONTRÔLE DE L’ÉCHAPPEMENT PEUVENT

ÊTRE EFFECTUÉS PAR N’IMPORTE QUEL

ATELIER DE RÉPARATION OU MÉCANICIEN DE

MOTEUR NON AUTOMOBILE.

Réglage du carburateur (Fig. 16)

Fig. 16

Le carburateur est une pièce de précision qui

mélange l'air et le carburant, et il est conçu pour

assurer une haute performance du moteur. Avant

que l'outil soit expédié de l'usine, son carburateur est

réglé au cours d'un essai. Ne faites des ajustements

que si cela est nécessaire en raison des conditions

environnementales (le climat ou la pression

atmosphérique), du type de carburant, du type d'huile

à deux temps, etc.

AVERTISSEMENT

● Comme le carburateur est fabriqué avec un

haut degré de précision, ne le démontez pas.

● Pour ce produit, le seul réglage du carburateur

qui peut être réglé est la vitesse de ralenti (T).

● N'essayez jamais de démarrer le moteur tant

que le carter de protection de l'embrayage

et le tube ne sont pas parfaitement en place.

Dans le cas contraire l'embrayage risquerait

de se détacher, entraînant ainsi des blessures

corporelles.

T = Vis de réglage du ralenti.

Réglage du ralenti (T)

AVERTISSEMENT

● Lorsque le moteur est à l'arrêt, ne pas trop

tourner la vis de réglage du ralenti (T) dans

le sens des aiguilles d'une montre. Dans le

cas contraire, lorsque le moteur démarre,

l’accessoire de coupe peut tourner sans que

vous ne vous y attendiez et provoquer des

blessures.

● Ne pas régler la vis de réglage du ralenti (T)

pour toute autre raison que pour régler le

ralenti.

Faites tourner le moteur pendant le réglage du ralenti.

(1) Si le moteur s'arrête pendant le ralenti

Démarrez le moteur, puis tournez lentement la

vis de réglage du ralenti (T) dans le sens horaire

jusqu’à ce qu’elle soit sur une position à laquelle