Page 1

MODEL DUST COLLECTION CIRCULAR SAW

MODÈLE

MODELO

C 7YA

SCIE CIRCULAIRE AVEC COLLECTEUR DE POUSSIERE

SIERRA CIRCULAR CON TOWA DE ASPIRACION

INSTRUCTION MANUAL AND SAFETY INSTRUCTIONS

WARNING

Improper and unsafe use of this power tool can result in death or serious bodily

injury!

This manual contains important information about product safety. Please read

and understand this manual before operating the power tool. Please keep this

manual available for others before they use the power tool.

MODE D’EMPLOI ET INSTRUCTIONS DE SECURITE

AVERTISSEMENT

Une utilisation incorrecte et dangereuse de cet outil motorisé peut entraîner la

mort ou de sérieuses blessures corporelles!

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de

ce produit. Prière de lire et de comprendre ce mode d’emploi avant d’utiliser l’outil

motorisé. Garder ce mode d’emploi à la disponibilité des autres utilisateurs avant

qu’ils utilisent l’outil motorisé.

MANUAL DE INSTRUCCIONES E INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

¡La utilización inapropiada e insegura de esta herramienta eléctrica puede resultar

en lesiones serias o en la muerte!

Este manual contiene información importante sobre la seguridad del producto.

Lea y comprenda este manual antes de utilizar la herramienta eléctrica. Guarde

este manual para que puedan leerlo otras personas antes de que utilicen la

herramienta eléctrica.

DOUBLE INSULATION

DOUBLE ISOLATION

AISLAMIENTO DOBLE

Page 2

English

IMPORTANT INFORMATION ..................... 3

MEANINGS OF SIGNAL WORDS............... 3

SAFETY ............................................................ 4

SAFETY RULES ........................................... 4

SERVICE AND REPAIRS ............................. 9

REPLACEMENT PARTS .............................. 9

POLARIZED PLUGS .................................... 9

USE OF EXTENSION CORD ..................... 10

DOUBLE INSULATION FOR SAFER

OPERATION .......................................... 11

FUNCTIONAL DESCRIPTION ....................... 12

NAME OF PARTS ...................................... 12

SPECIFICATIONS ...................................... 12

CONTENTS

Page

ASSEMBLY AND OPERATION ..................... 13

Page

APPLICATIONS ......................................... 13

PRIOR TO OPERATION ............................. 13

ADJUSTING THE SAW PRIOR TO USE ... 14

CUTTING PROCEDURES ......................... 16

MOUNTING AND DISMOUNTING THE

SAW BLADE ......................................... 17

USE OF DUST BAG ................................... 18

USE OF DUST GUIDE ............................... 18

MAINTENANCE AND INSPECTION ............. 20

ACCESSORIES .............................................. 22

STANDARD ACCESSORIES ..................... 22

OPTIONAL ACCESSORIES ....................... 22

PARTS LIST ................................................... 66

Français

INFORMATIONS IMPORTANTES ............ 23

SIGNIFICATION DES MOTS

D’AVERTISSEMENT ............................. 23

SECURITE ...................................................... 24

REGLES DE SECURITE ............................. 24

SERVICE APRES-VENTE ET REPARATIONS

PIECES DE RECHANGE ............................ 30

FICHE POLARISEES .................................. 30

UTILIZATION D'UN CORDON DE RALLONGE

DOUBLE ISOLATION POUR UN

FONCTIONNEMENT PLUS SUR ......... 32

DESCRIPTION FONCTIONNELLE................. 33

NOM DES PARTIES................................... 33

SPECIFICATIONS ...................................... 33

TABLE DES MATIERES

Page

...... 30

... 31

Español

INFORMACIÓN IMPORTANTE ................. 44

SIGNIFICADO DE LAS PALABRAS DE

SEÑALIZACIÓN ....................................44

SEGURIDAD .................................................. 45

NORMAS DE SEGURIDAD ..........................

SERVICIO Y REPARACIÓN ....................... 51

PIEZAS DE REEMPLAZO .......................... 51

ENCHUFES POLARIZADOS ...................... 51

UTILIZACIÓN DE UN CABLE PROLONGADOR

AISLAMIENTO DOBLE PARA OFRECER

UNA OPERACIÓN MÁS SEGURA ....... 53

DESCRIPCIÓN FUNCTIONAL ....................... 54

NOMENCLATURA ..................................... 54

ESPECIFICACIONES .................................. 54

Página

...... 52

ÍNDICE

45

ASSEMBLAGE ET FONCTIONNEMENT ...... 34

APPLICATIONS ......................................... 34

AVANT L’UTILISATION ............................ 34

REGLAGE DE LA SCIE AVANT L'UTILISATION ..

PROCEDURES DE COUPE ........................ 37

MONTAGE ET DEMONTAGE DE LA LAME DE SIE .

UTILISATION DU SAC À POUSSIÈRE ..... 39

UTILISATION DU GUIDE-POUSSIÈRE .... 40

ENTRETIEN ET INSPECTION ....................... 41

ACCESSOIRES .............................................. 43

ACCESSOIRES STANDARD ..................... 43

ACCESSOIRES SUR OPTION ................... 43

LISTE DES PIECES ........................................ 66

MONTAJE Y OPERACIÓN ............................ 55

APLICACIONES ......................................... 55

ANTES DE LA OPERACIÓN ...................... 55

AJUSTE DE LA SIERRA ANTES DE UTILIZARLA ..

PROCEDIMIENTOS DE CORTE................. 58

MONTAJE Y DESMONTAJE DE LA

CUCHILLA DE LA SIERRA ................... 59

USO DE LA BOLSA PARA EL POLVO ...... 60

USO DE LA GUIA PARA EL POLVO ......... 61

MANTENIMIENTO E INSPECCIÓN .............. 62

ACCESORIOS ................................................ 64

ACCESORIOS ESTÁNDAR ....................... 64

ACCESORIOS OPCIONALES .................... 64

LISTA DE PIEZAS .......................................... 66

Page

Página

56

35

38

Page 3

English

IMPORTANT INFORMATION

Read and understand all of the operating instructions, safety precautions and warnings in

the Instruction Manual before operating or maintaining this power tool.

Most accidents that result from power tool operation and maintenance are caused by the

failure to observe basic safety rules or precautions. An accident can often be avoided by

recognizing a potentially hazardous situation before it occurs, and by observing appropriate

safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Instruction Manual and

in the sections which contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by

WARNINGS on the power tool and in this Instruction Manual.

Never use this power tool in a manner that has not been specifically recommended by

HITACHI, unless you first confirm that the planned use will be safe for you and others.

MEANINGS OF SIGNAL WORDS

WARNING indicates a potentially hazardous situations which, if ignored, could result in

serious personal injury.

CAUTION indicates a hazardous situations which, if ignored, could result in moderate

personal injury, or could cause machine damage.

NOTE emphasizes essential information.

3

Page 4

English

SAFETY

SAFETY RULES

WARNING: Death or serious bodily injury could result from improper or unsafe use

of power tools. To avoid these risks, follow these basic safety instructions:

READ ALL INSTRUCTIONS

1. NEVER TOUCH MOVING PARTS.

Never place your hands, fingers or other body parts near the tool’s moving parts.

2. NEVER OPERATE WITHOUT ALL GUARDS IN PLACE.

Never operate this tool without all guards or safety features in place and in proper

working order. If maintenance or servicing requires the removal of a guard or safety

feature, be sure to replace the guard or safety feature before resuming operation of the

tool.

3. ALWAYS WEAR EYE AND EAR PROTECTOR.

Protect yourself from flying or expelled wood chips, metal particles or other debris by

using protective goggles or equivalent eye protector. Wear ear protector to protect

yourself from excessive noise.

4. PROTECT YOURSELF AGAINST ELECTRIC SHOCK.

Prevent body contact with grounded surfaces such as pipes, radiators, ranges and

refrigeration enclosures. Never operate the tool in damp or wet locations.

5. DISCONNECT TOOLS.

Never leave the tool connected to a power source. Always disconnect the tool from its

power source before servicing, inspecting, maintaining, cleaning and before changing

or checking any parts.

6. AVOID UNINTENTIONAL STARTING.

Don’t carry the tool while it is connected to its power source. Don’t carry the tool with

your finger near the power switch. Be sure the power switch is in the ‘“off” position

before connecting the tool to its power source.

7. STORE TOOL PROPERLY.

When not in use, the tool should be stored in a dry place. Keep out of reach of children.

Lock-out the storage area.

8. KEEP WORK AREA CLEAN.

Cluttered areas and benches invite injuries. Clear all work areas and work benches of

unnecessary tools, debris, furniture, etec.

9. CONSIDER WORK AREA ENVIRONMENT.

Don’t expose power tools to rain. Don’t use power tools in damp or wet locations. Keep

work area well lit and well ventilated.

Don’t use tool in presence of flammable liquids or gases.

Power tools produce sparks during operation. They also spark when switching ON/

OFF. Never use power tools in sites containing lacquer, paint, benzine, thinner,

gasoline, gases, adhesive agents, and other materials which are combustible or

explosive.

4

Page 5

10. KEEP CHILDREN AWAY.

Do not let visitors contact tool or extension cord.

All visitors should be kept safely away from work area.

11. DON’T FORCE TOOL.

It will do the job better and safer at the rate for which it was intended.

12. USE RIGHT TOOL.

Don’t force small tool or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended—for example—don’t use circular saw for cutting

tree limbs or logs.

13. DRESS PROPERLY.

Do not wear loose clothing or jewelry. They can be caught in moving parts.

Rubber gloves and non-skid footwear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

14. USE FACE, DUST MASK OR RESPIRATOR IF OPERATION IS DUSTY.

All persons in the area where power tools are being operated should also wear face, dust

mask or respirator.

15. DON’T ABUSE CORD.

Never carry tool by cord or yank it to disconnect from receptacle.

Keep cord from heat, oil and sharp edges.

16. SECURE WORK.

Use clamps or a vise to hold work. It’s safer than using your hand and it frees both hands

to operate tool.

17. DON’T OVERREACH.

Keep proper footing and balance at all times.

18. MAINTAIN TOOLS WITH CARE.

Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories.

Inspect tool cords periodically and if damaged, have repaired by an authorized service

center. Inspect extension cords periodically and replace if damaged.

Keep handles dry, clean, and free from oil and grease.

19. REMOVE ADJUSTING KEYS AND WRENCHES.

Keys and adjusting wrenches remove from tool before turning it on.

20. OUTDOOR USE EXTENSION CORD.

When tool is used outdoors, use only extension cord intended for use outdoors and so

marked.

21. STAY ALERT.

Watch what you are doing. Use common sense. Do not operate tool when you are tired.

Tools should never be used by you if you are under the influence of alcohol, drugs or

medication that makes you drowsy.

22. CHECK DAMAGED PARTS.

Before further use of the tool, a guard or other part that is damaged should be carefully

checked to determine that it will operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or replaced by an

authorized service center unless otherwise indicated elsewhere in this Instruction

Manual.

English

5

Page 6

English

Have defective switches replaced by the authorized service center.

Do not use tool if switch does not turn it on and off.

23. NEVER USE A POWER TOOL FOR APPLICATIONS OTHER THAN THOSE SPECIFIED.

Never use a power tool for applications other than those specified in the Instruction

Manual.

24. HANDLE TOOL CORRECTLY.

Operate the tool according to the instructions provided herein. Do not drop or throw the

tool. Never allow the tool to be operated by children, individuals unfamiliar with its

operation or unauthorized personnel.

25. CHECK FOR LIVE WIRES.

Avoid the risk of severe electrical shock by checking for live electrical wires that may be

buried in walls, floors or ceilings. The wires should be de-energized before work begins.

26. KEEP ALL SCREWS, BOLTS AND COVERS TIGHTLY IN PLACE.

Keep all screws, bolts, and plates tightly mounted. Check their condition periodically.

27. DO NOT USE POWER TOOLS IF THE PLASTIC HOUSING OR HANDLE ARE CRACKED.

Cracks in the tool’s housing or handle can lead to electric shock. Such tools should not

be used until repaired.

28. BLADES AND ACCESSORIES MUST BE SECURELY MOUNTED TO THE TOOL.

Prevent potential injuries to yourself or others. Blades, cutting implements and accessories which have been mounted to the tool should be secure and tight.

29. KEEP MOTOR AIR VENT CLEAN.

The tool’s motor air vent must be kept clean so that air can freely flow at all times. Check

for dust build-up frequently.

30. OPERATE POWER TOOLS AT THE RATED VOLTAGE.

Operate the power tool at voltages specified on their nameplates.

If using the power tool at a higher voltage than the rated voltage, it will result in

abnormally fast motor revolution and may damage the unit and burn out the motor.

31. NEVER USE A TOOL WHICH IS DEFECTIVE OR OPERATING ABNORMALLY

If the tool appears to be operating unusually, making abnormal noises, or otherwise

appears defective, stop using it immediately and arrange for repairs by a Hitachi

authorized service center.

32. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF.

Don’t leave tool until it comes to a complete stop.

33. CAREFULLY HANDLE POWER TOOLS.

Should a power tool be dropped or struck against hard materials inadvertently it may

be deformed, cracked, or damaged.

34. DO NOT WIPE PLASTIC PARTS WITH SOLVENT.

Solvents such as gasoline, thinner, benzine, carbon tetrachloride, and alcohol may

damage and crack plastic parts. Do not wipe them with such solvents.

Wipe plastic parts with a soft cloth lightly dampened with soapy water and dry

thoroughly.

35. WHEN REPLACING A COMPONENT PART, ADOPT THE SAME TYPE. When replacing a

component part with a new one, adopt the same type of new part. Also, never attempt

to repair a power tool yourself.

36. KEEP GUARDS IN PLACE AND IN WORKING ORDER. Never wedge of tie lower guard

open. Check operation of lower guard before each use. Do not use if lower guard dose

not close briskly over saw blade.

CAUTION: If saw is dropped, lower guard may be bent, restricting full return.

6

Page 7

English

37. KEEP BLADES CLEAN AND SHARP. Sharp blades minimize stalling and kickback.

38. DANGER: KEEP HANDS AWAY FROM CUTTING AREA. Keep hands away from blades.

Do not reach underneath work while blade is rotating. Do not attempt to remove cut

material when blade is moving.

CAUTION: Blades coast after turn off.

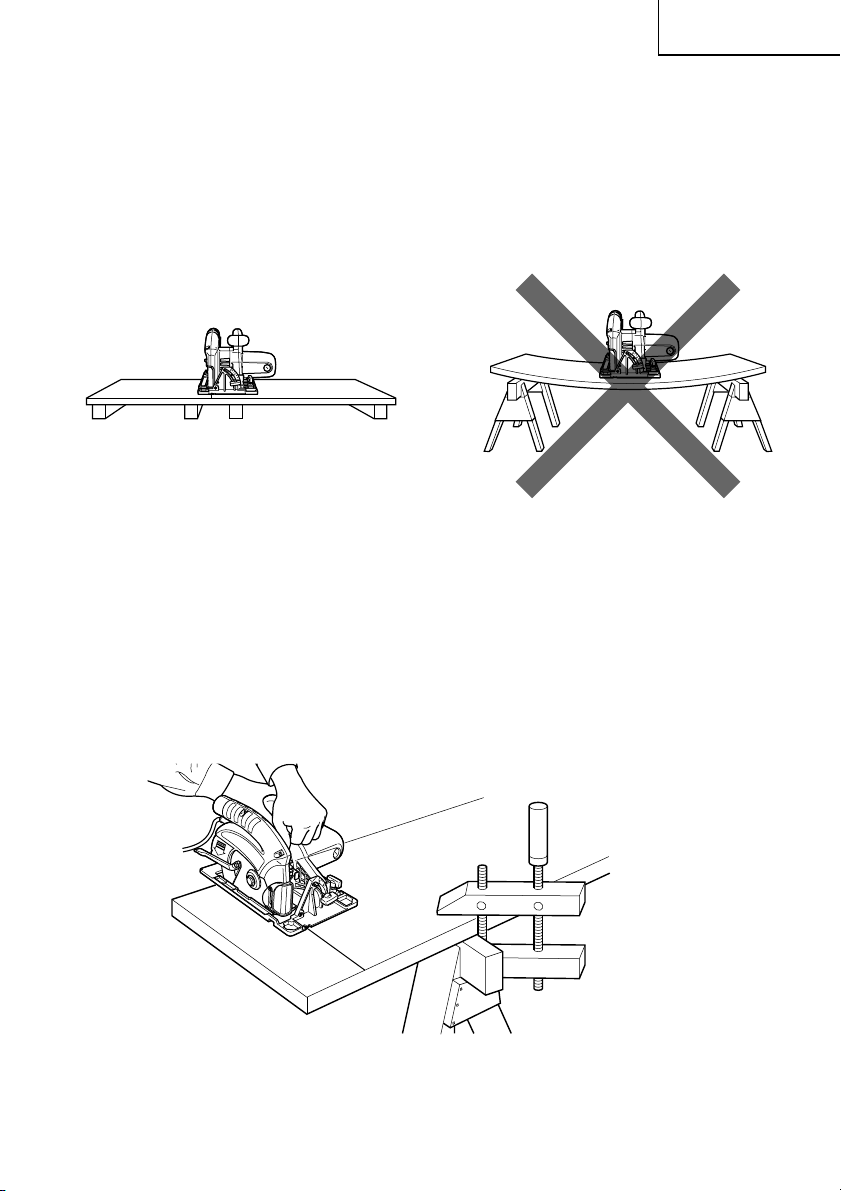

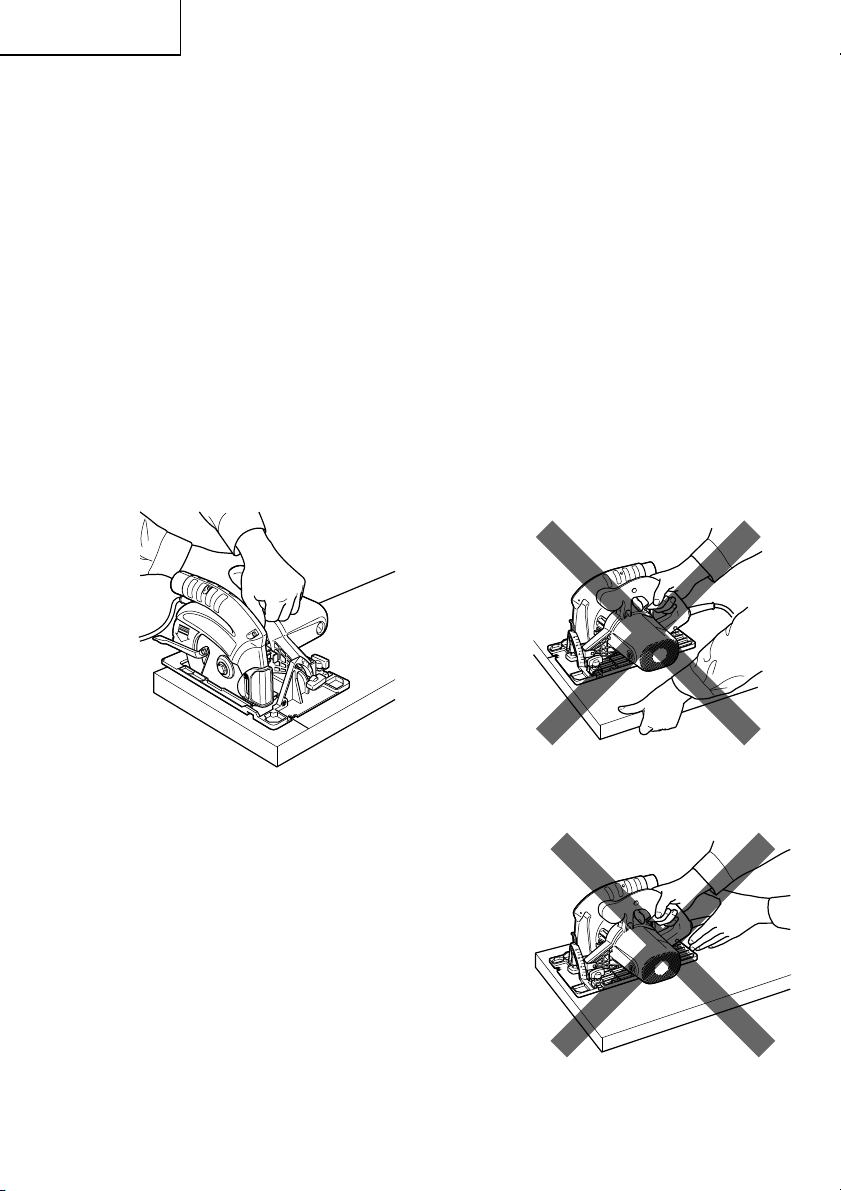

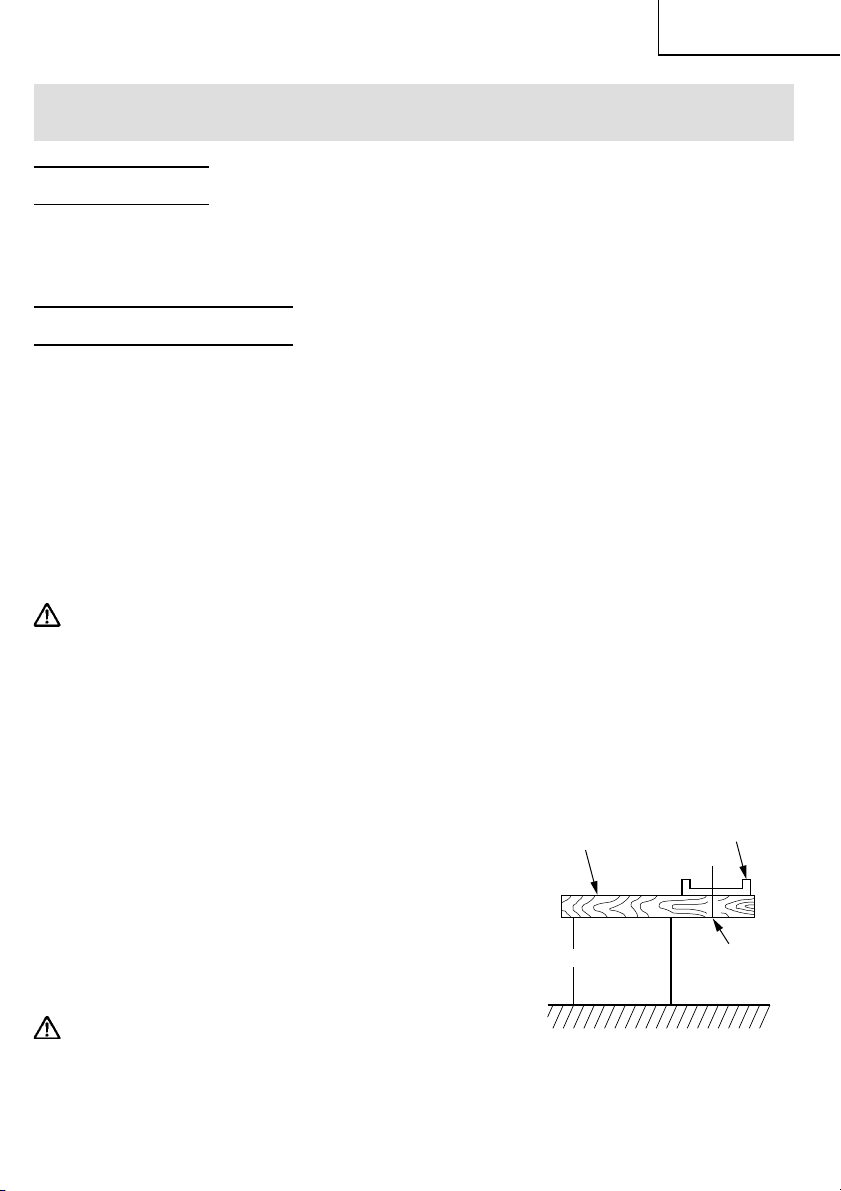

39. SURRPORT LARGE PANELS. Large panels must be supported as shown in Fig. 1 to

minimize the risk of blade pinching and kickback. When cutting operation requires the

resting of saw on the work piece, the saw shall be rested on the larger portion and the

smaller piece cut off.

To avoid kickback, do support board Don't support board or panel away

or panel near the cut. from the cut.

Fig. 1 Fig. 2

40. USE RIP FENCE. Always use a fence or straight edge guide when ripping.

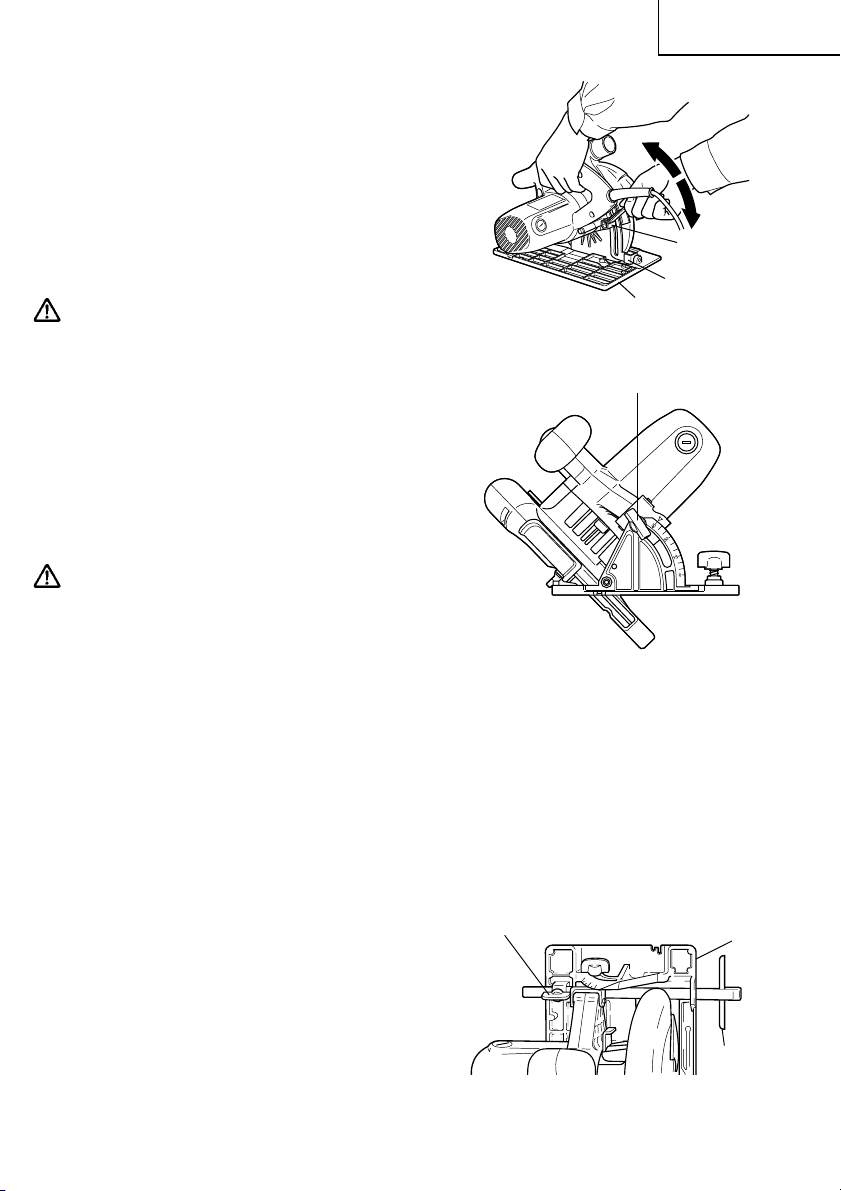

41. WARNING: It is important to support the work piece properly and to hold the saw firmly

to prevent loss of control which could cause personal injury. Fig. 3 illustrates typical

hand support of the saw. When operating the saw, keep the cord away from the cutting

area and position it so that it will not be caught on the work piece during the cutting

operation.

A TYPICAL ILLUSTRATION OF PROPER HAND SUPPORT.

WORK PIECE SUPPORT, AND SUPPLY CORD ROUTING

Fig. 3

42. GUARD AGAINST KICKBACK. Kickback occurs when the saw stalls rapidly and is driven

back towards the oprator. Release switch immediately if blade binds or saw stalls.

7

Page 8

English

Keep blades sharp.

Support large panels as shown in Fig. 1.

Use fance or straight edge guide when ripping.

Don't fence tool.

Stay alert exercise control.

Don't remove saw from work during a cut while the blade is moving.

43. LOWER GUARD. Raise lower guard with the retracing handle (Lever).

44. ADJUSTMENTS. Before cutting be sure depth and bevel adjustments are tight.

45. USE ONLY CORRECT BLADES IN MOUNTING. Do not use blade with incorrect size

holes.

Never use defective or incorrect blade washers or bolts.

46. AVOID CUTTING NAILS. Inspect for and remove all nails from work piece before

cutting.

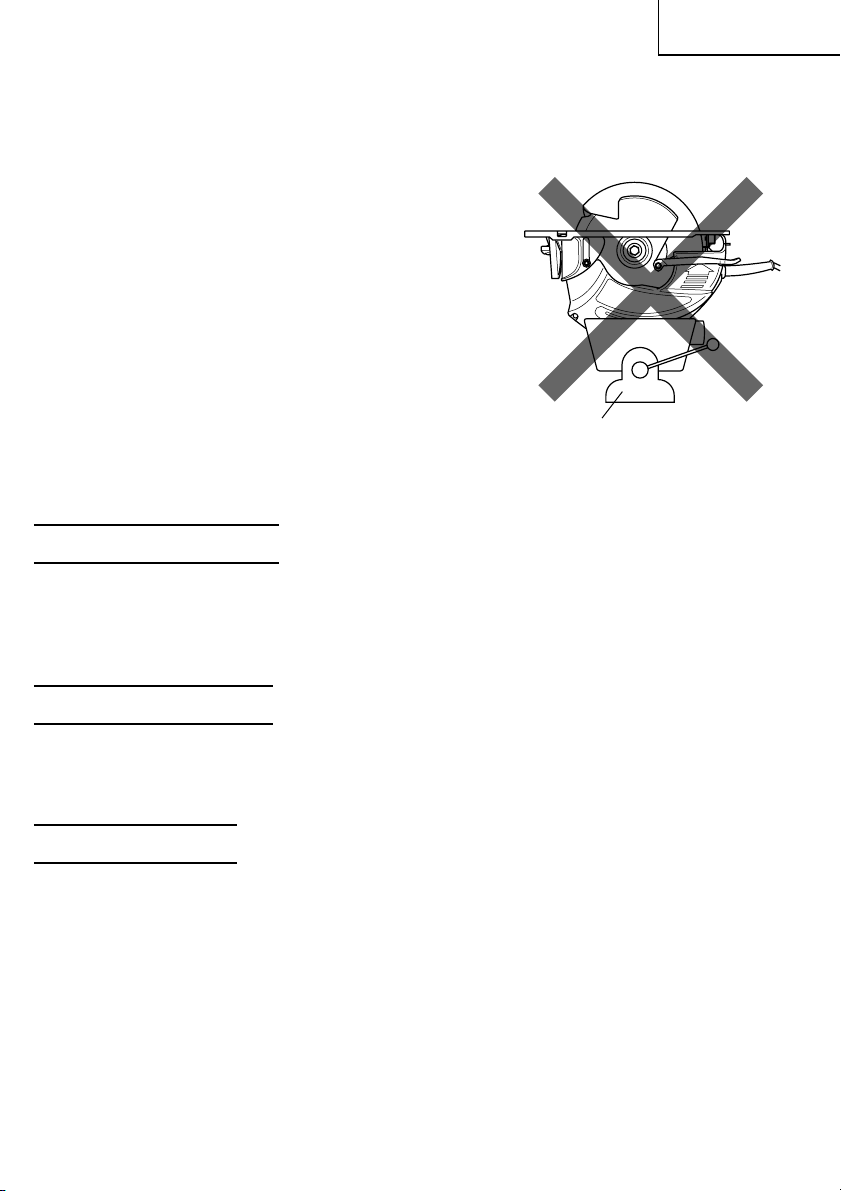

47. DO NOT RUN THE SAW WHILE CARRYING IT AT YOUR SIDE.

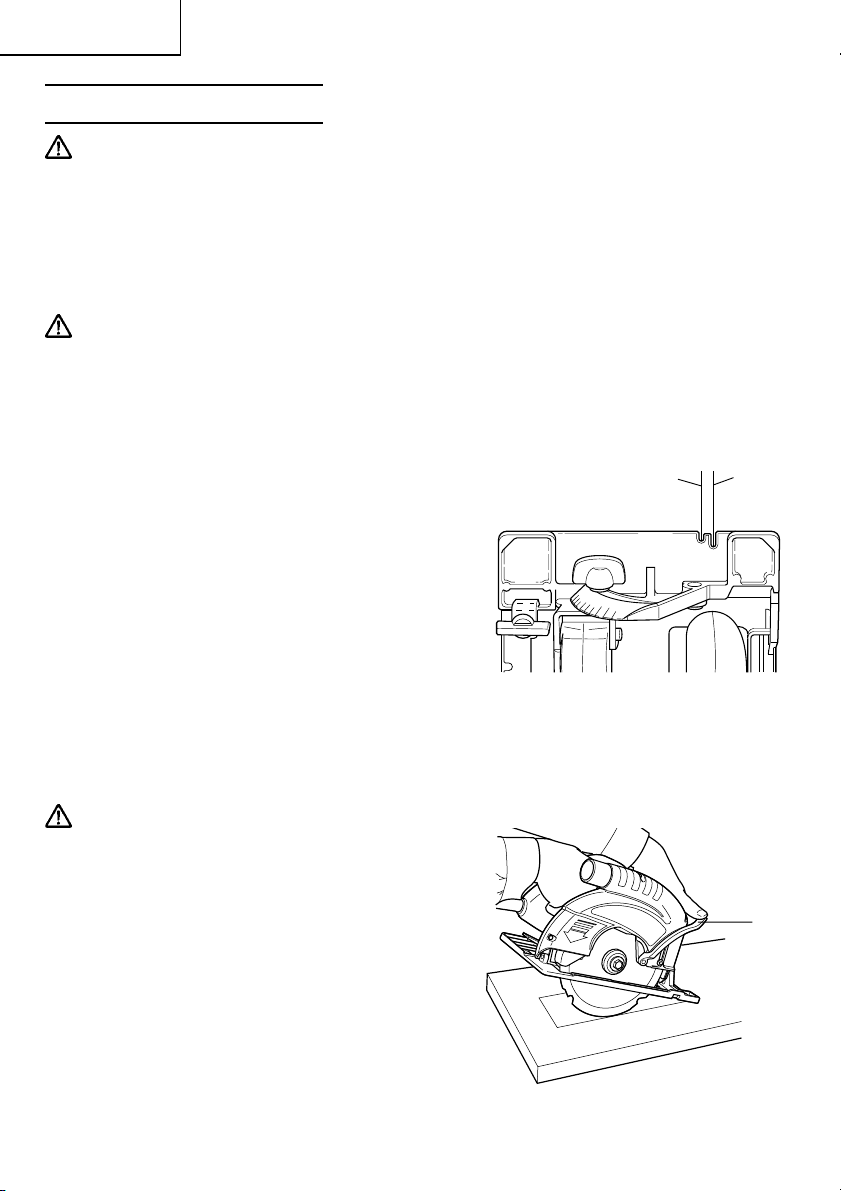

48. Place the wider portion of the saw base on that part of the work piece which is solidly

supported, not on the section that will fall off when the cut is made. As examples, Fig.

4 illustrates the RIGHT way to cut off the end of board, and Fig. 5 the WRONG way. If the

work piece is short or small, clamp is down.

DON’T TRY TO HOLD SHORT PLACES BY HAND!

Fig. 4 Fig. 5

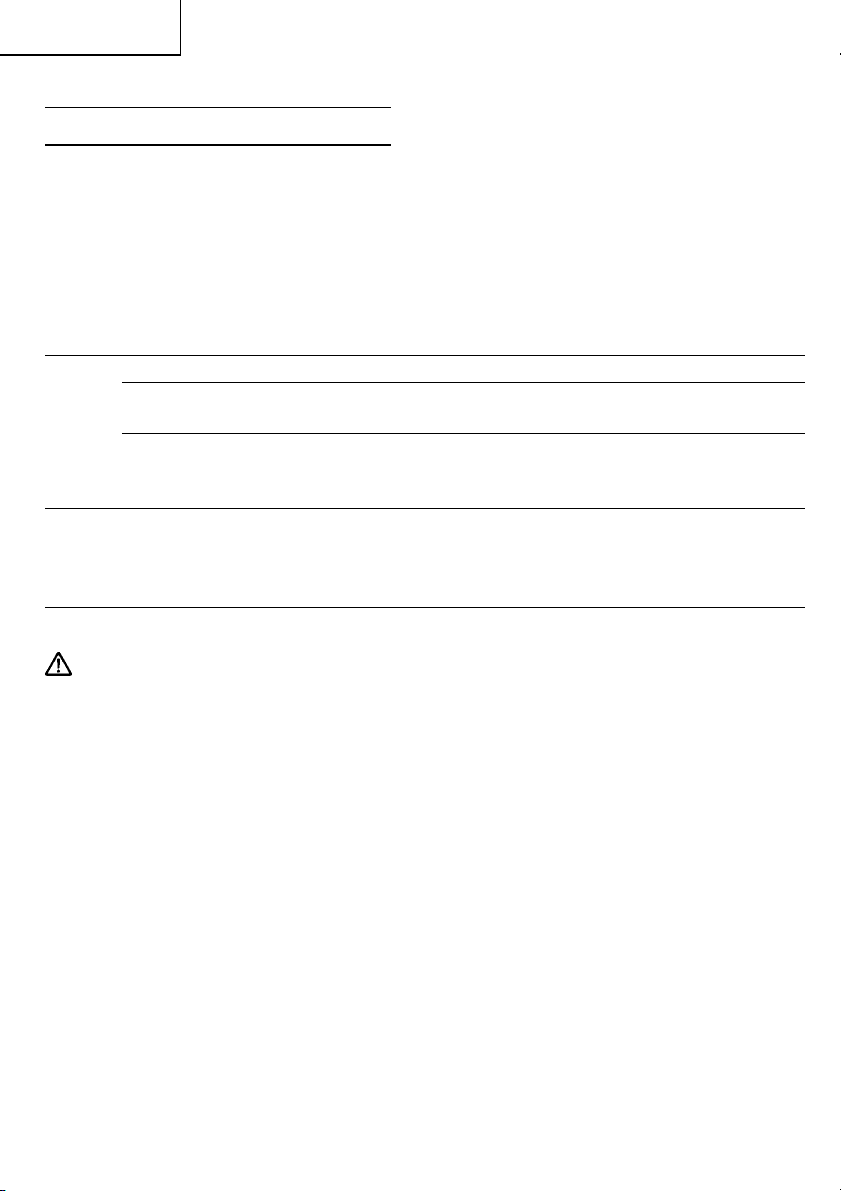

49. Use extra caution when making a “Pocket

Cut” into existing walls or other blind areas.

The protruding blade may cut objects that can

cause KICKBACK.

NEVER place your hand or fingers behind the

saw. If kickback occurs, the saw could easily

jump backwards over your hand, possibly

causing severe injury.

8

Fig. 6

Page 9

English

50. Before setting the tool down after completing a cut, be sure that the lower (telescoping)

guard has closed and the blade has come to a complete stop.

51. Never attempt to saw any material like metal and so on that give off sparks. Such action

can lead to fire or injury.

52. Never attempt to saw with the circular saw

held upside down in a vise. This is extremely

dangerous and can lead to serious accidents.

(Fig. 7)

Vise

Fig. 7

SERVICE AND REPAIRS

All quality power tools will eventually require servicing or replacement of parts because of

wear from normal use. To assure that only genuine replacement parts will be used, all service

and repairs must be performed by a HITACHI AUTHORIZED SERVICE CENTER, ONLY.

REPLACEMENT PARTS

When servicing use only identical replacement parts.

Repairs should be conducted only by a Hitachi authorized service center.

POLARIZED PLUGS

To reduce the risk of electrick shock, this equipment has a polarized plug (one blade is wider

than the other).

This plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician to install the proper outlet.

Do not change the plug in any way.

9

Page 10

English

USE OF EXTENSION CORD

Make sure your extension cord is in good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your product will draw.

An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. Table shows the correct size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the

heavier the cord.

MINIMUM GAGE FOR CORD SETS

Total Length of Cord in Feet (Meter)

0 – 25 26 – 50 51 – 100 101 – 150

(0 – 7.6) (7.9 – 15.2) (15.5 – 30.5) (30.8 – 45.7)

Ampere Rating AWG

More Not More

Than Than

0 – 618161614

6 – 10 18 16 14 12

10 – 12 16 16 14 12

12 – 16 14 12 Not Recommended

WARNING: Avoid electrical shock hazard. Never use this tool with a damaged or

frayed electrical cord or extension cord.

Inspect all electrical cords regularly. Never use in or near water or in any

environment where electric shock is possible.

10

Page 11

English

DOUBLE INSULATION FOR SAFER OPERATION

To ensure safer operation of this power tool, HITACHI has adopted a double insulation

design. “Double insulation “ means that two physically separated insulation systems have

been used to insulate the electrically conductive materials connected to the power supply

from the outer frame handled by the operator. Therefore, either the symbol “

“Double insulation” appear on the power tool or on the nameplate.

Although this system has no external grounding, you must still follow the normal electrical

safety precautions given in this Instruction Manual, including not using the power tool in wet

environments.

To keep the double insulation system effective, follow these precautions:

䡬 Only HITACHI AUTHORIZED SERVICE CENTER should disassemble or assemble this

power tool, and only genuine HITACHI replacement parts should be installed.

䡬 Clean the exterior of the power tool only with a soft cloth moistened with soapy water,

and dry thoroughly.

Never use solvents, gasoline or thinners on plastic components; otherwise the plastic

may dissolve.

” or the words

SAVE THESE INSTRUCTIONS

AND

MAKE THEM AVAILABLE TO

OTHER USERS OF THIS TOOL!

11

Page 12

English

FUNCTIONAL DESCRIPTION

NOTE:

The information contained in this Instruction Manual is designed to assist you in the safe

operation and maintenance of the power tool.

Some illustrations in this Instruction Manual may show details or attachments that differ

from those on your own power tool

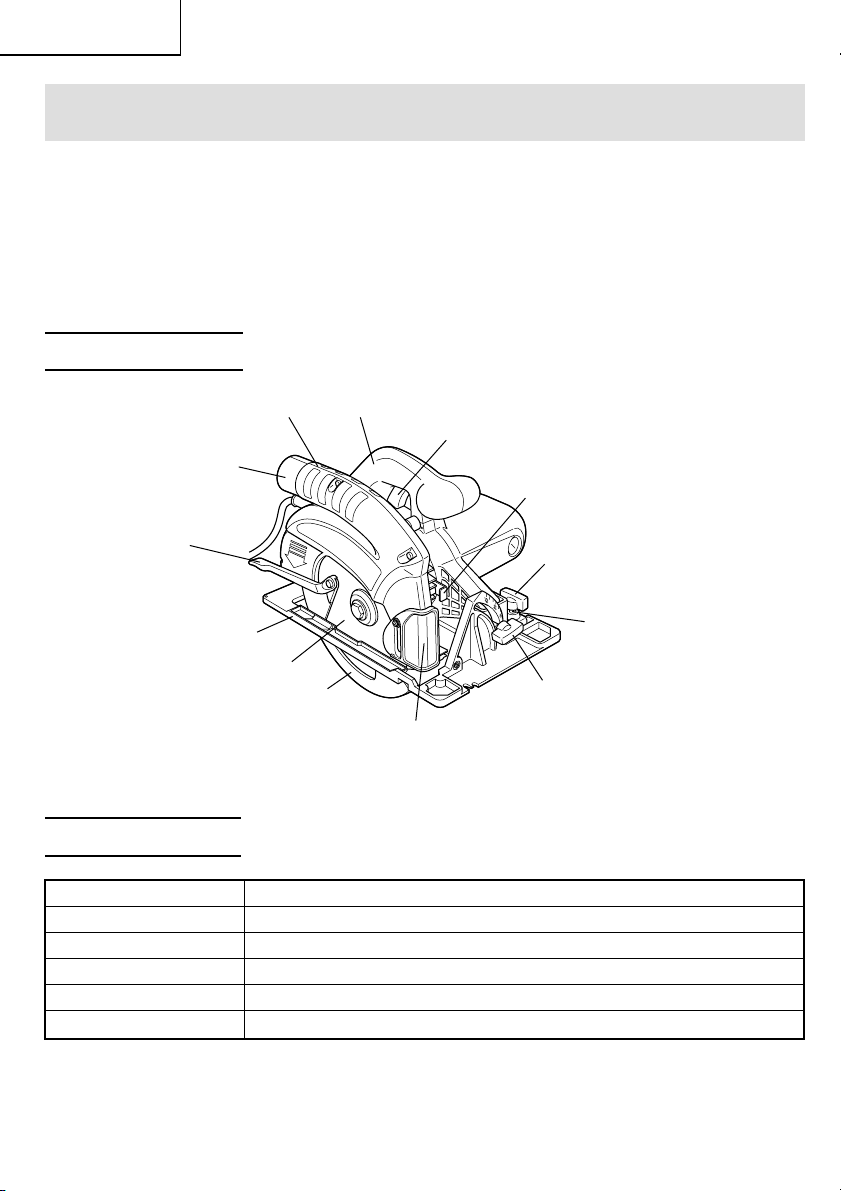

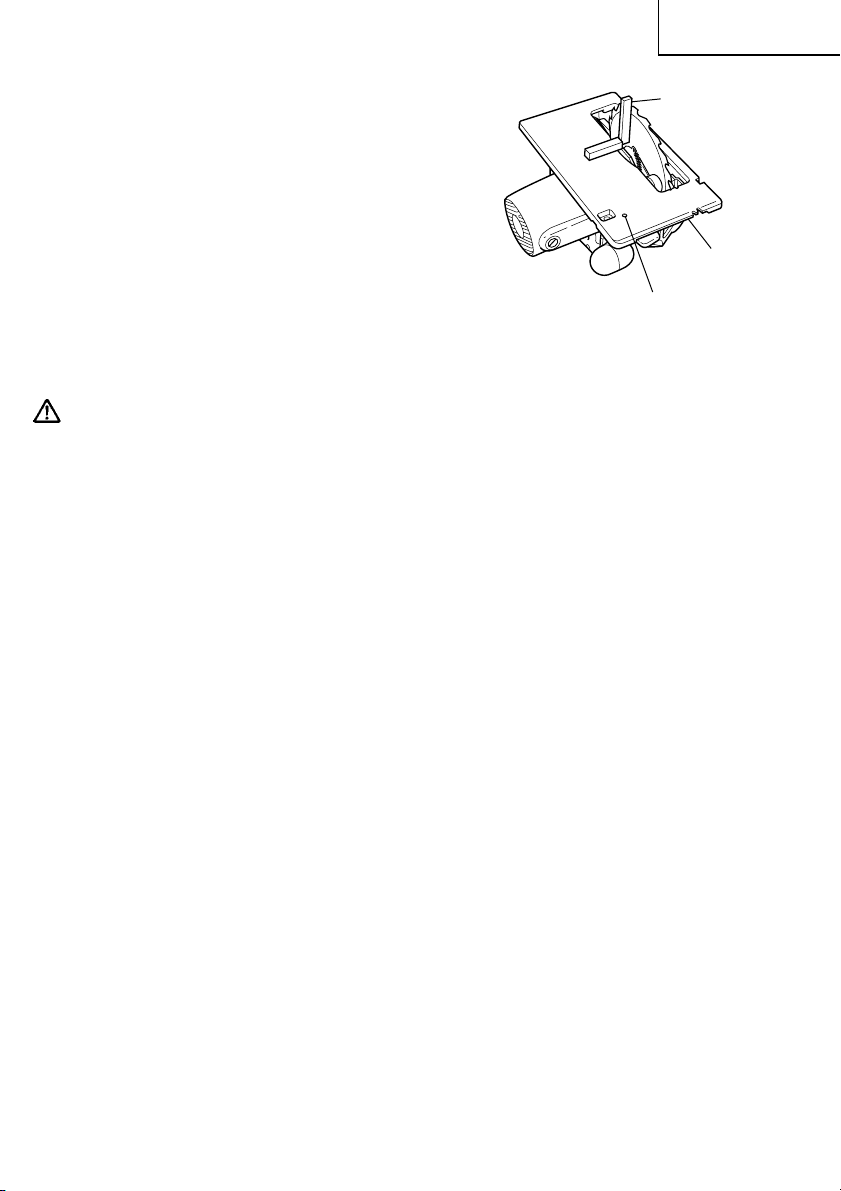

NAME OF PARTS

Gear Cover

Saw Cover

Lever

(Retracting

Handle)

Base

Saw Blade

Safety Cover

(Lower Guard)

Handle

Switch

Lock Lever

Wing Bolt (B)

Lock Spring

Wing Bolt (A)

Slide Cover

Fig. 8

SPECIFICATIONS

Motor Single-Phase, Series Commutator Motor

Power Source Single-Phase 120V AC 60Hz

Max. Cutting Depth 2-3/8" (60mm)

Current 13 A

No-Load Speed 5500/min.

Weight (without cord) 11.3 lbs (5.1 kg)

12

Page 13

English

ASSEMBLY AND OPERATION

APPLICATIONS

䡬 Cutting fiber cement board

(Ex. HARDI PLANK, HARDI PANEL)

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms to the power source requirements

specified on the product nameplate.

2. Power switch

Ensure that the switch is in the OFF position. If the plug is connected to a receptacle while

the switch is in the ON position, the power tool will start operating immediately and can

cause serious injury.

3. Extension cord

When the work area is far away from the power source, use an extension cord of sufficient

thickness and rated capacity. The extension cord should be kept as short as practicable.

WARNING: Damaged cord must be replaced or repaired.

4. Check the receptacle

If the receptacle only loosely accepts the plug, the receptacle must be repaired. Contact

a licensed electrician to make appropriate repairs.

If such a fautly receptacle is used, it may cause overheating, resulting in a serious hazard.

5. Confirming condition of the environment:

Confirm that the work site is placed under appropriate conditions conforming to

prescribed precautions.

6. Prepare a wooden workbench (Fig. 9)

Since the saw blade will extend beyond the

lower surface of the work piece, place the work

piece on a workbench when cutting. If a square

block is utilized as a workbench, select level

ground to ensure it is properly stabilized. An

unstable workbench will result in hazardous

operation.

CAUTION:

To avoid possible accident, always ensure that

the portion of work piece remaining after cutting

is securely anchored or held in position.

Work piece Base

Workbench

Fig. 9

Saw Blade

13

Page 14

English

7. Check if clamp lever and wing bolt are tightened.

If the wing bolt to adjust cutting depth (Fig. 12) and wing bolt to adjust angle of inclination

(Fig. 13) are loose, injury can result. Make sure that they are tightened securely.

8. Check performance of safety cover

WARNING: Make absolutely sure that the safety cover is not fixed. Also, check and

see if it can move smoothly. If the saw blade is kept exposed injury can

result.

The safety cover (refer to Fig. 8) serves to protect your body from coming into contact with

the saw blade. Make absolutely certain that the cover smoothly performs to cover the saw

blade. If the safety cover should not move smoothly, never use it without repairing it.

In such a case, get in touch with the store where you bought the circular saw or the

HITACHI Authorized Service Center for necessary repair.

9. Protective glasses and dustproof mask (Fig. 10)

When you use the tool, make certain that you wear the protective glasses and the

dustproof mask.

10.Dust bag or dust guide

Make it absolutely sure when you use the tool to

mount any one of the dust bag or dust guide

that is provided as a standard accessory. For

mounting details and refer to [use of dust bag]

in Page 17, [use of dust guide] in Page 17.

11.Check if saw blade is tightened

Refer to [mounting and dismounting the saw

blade] in Page 16, and make sure that the flange

bolt is tightened securely.

Fig. 10

ADJUSTSING THE SAW PRIOR TO USE

1. Adjustment of slide cover

WARNING:

To avoid serious accidents, ensure the switch

is in OFF position, and disconnect the plug from

the receptacle.

You can move the slide cover of the tool up and

down. The slide cover is mounted in the

lowermost position when the tool is shipped

from the factory. If you use it in the originally

mounted position for right-angle cutting, you

can reduce the scattering sawdust particles.

14

Slide

Cover

Screw

Fig. 11

Page 15

When you find it difficult to inspect the blade

tip, or in case of inclined cutting, or when you

use the guide for cutting, loosen the screw,

move the slide cover upward and make

necessary adjustment before use. (For inclined

cutting, fix the slide cover in the uppermost

position.) Make sure that the screw is tightened

securely after adjustment.

2. Adjusting the cutting depth (Fig. 12)

WARNING:

If the clamp lever is loose, injury can result.

Tighten it securiely after adjustment.

To adjust cutting depth, loosen the clamp lever

and, while holding the base with one hand,

move the main body up and down to obtain the

prescribed cutting depth. After adjusting to the

prescribed cutting depth, tighten the clamp

lever securely.

3. Adjusting the angle of inclination

WARNING:

If the wing bolt is loose, injury can result.

Tighten it securiely after adjustment.

English

Loosen

Tighten

Clamp Lever

Link

Base

Fig. 12

Wing Bolt (A)

Fig. 13

NOTE: Keep the slide cover moved up to the uppermost position before making adjustment

on the angle of inclination. (Refer to [adjustment of slide cover] in Page 13)

As shown in Fig. 13 by loosening the wing-bolt on the inclined gauge, the saw blade may

be inclined to a maximum angle of 45° in relation to the base. Always ensure that the

wing-bolt is thoroughly tightened after making the desired adjustment.

4. Regulating the guide (Rip fence)

.......................................... Optional Accessory

NOTE: When mounting the guide, move the slide

cover upward to the extent where the guide

is not in touch with the slide cover. (Refer to

[adjustment of slide cover] in Page 13)

The cutting position can be regulated by moving

the guide to the left or right after loosening its

wing-bolt. The guide may be mounted on either

the right or left side of the tool. (See Fig. 14)

Wing Bolt (B), Lock Spring

Base

Guide

(Rip Fence)

Fig. 14

15

Page 16

English

CUTTING PROCEDURES

WARNING:

● Never touch the moving parts.

● Should the saw blade be stopped or make an abnormol noise during operation, turn off

the switch immediately.

● Don't remove circular saw from work piece during a cut while the saw blade is moving.

● Wear protective glasses and a dustproof mask.

● Avoid cutting any material like metal, etc., that give off sparks.

CAUTION:

● Always take care in preventing the power cord from coming near the revolving saw

blade.

● Mount either of the dust bag, or dust guide before use.

● Before starting to saw, ensure that the saw blade has reached full speed revolution.

1. Place the saw body (base) on the work piece,

and as in Fig. 15 align the intended line of cut

with the saw blade, using the notch at the front

of the base. This relationship of base to work

pieces should remain unchanged regardless of

the inclination of the base.

2. The switch should be turned to the ON position

before the saw blade comes into contact with

the work piece. The switch is turned ON when

the trigger is pulled by one’s finger, and is

turned OFF when the trigger is released.

3. Moving the saw straight at a constant speed will

produce optimum cutting.

[POCKET CUTTING]

WARNING:

● To avoid serious accident, ensure the switch is

OFF position, and disconnect the plug from the

receptacle before any adjustment.

● Never tie or wedge the safety cover in a raised

position.

1. Mark the desired cutting area clearly with lines

all side. (See Fig. 16)

2. Set depth adjustment according to material to

be cut.

3. Push the safety cover lever all the way back so

the blade is exposed as shown in Fig. 16.

4. Tilt saw forward and align the notch (Fig. 15)

with the pre-marked guide line.

16

When

Inclined

45°

Fig. 15

Fig. 16

When

not

Inclined

Lever

Page 17

English

5. Release the safety cover lever. When the safety cover contacts the work piece surface,

it will be in proper position to open freely when cutting is commencend.

6. Holding the saw in position, with the blade not contacting the work piece surface, pull

the trigger.

7. After the saw has reached full speed, gradually lower rear end of the saw until its base

rests on the work surface.

8. Advance saw along the cutting line up to the corner.

9. Release trigger and allow blade to stop completely before withdrawing the blade from

the work piece.

䡩 Never under any circumstances pull the saw backwards while the blade is in motion, as

kickback may result.

10. Use a jig saw or hand saw to cut the corners out clean.

11. When starting each new cut, repeat as above.

MOUNTING AND DISMOUNTING THE SAW BLADE

WARNING: To avoid serious accident ensure the switch is in the OFF position, and

disconnect the plug from the receptacle.

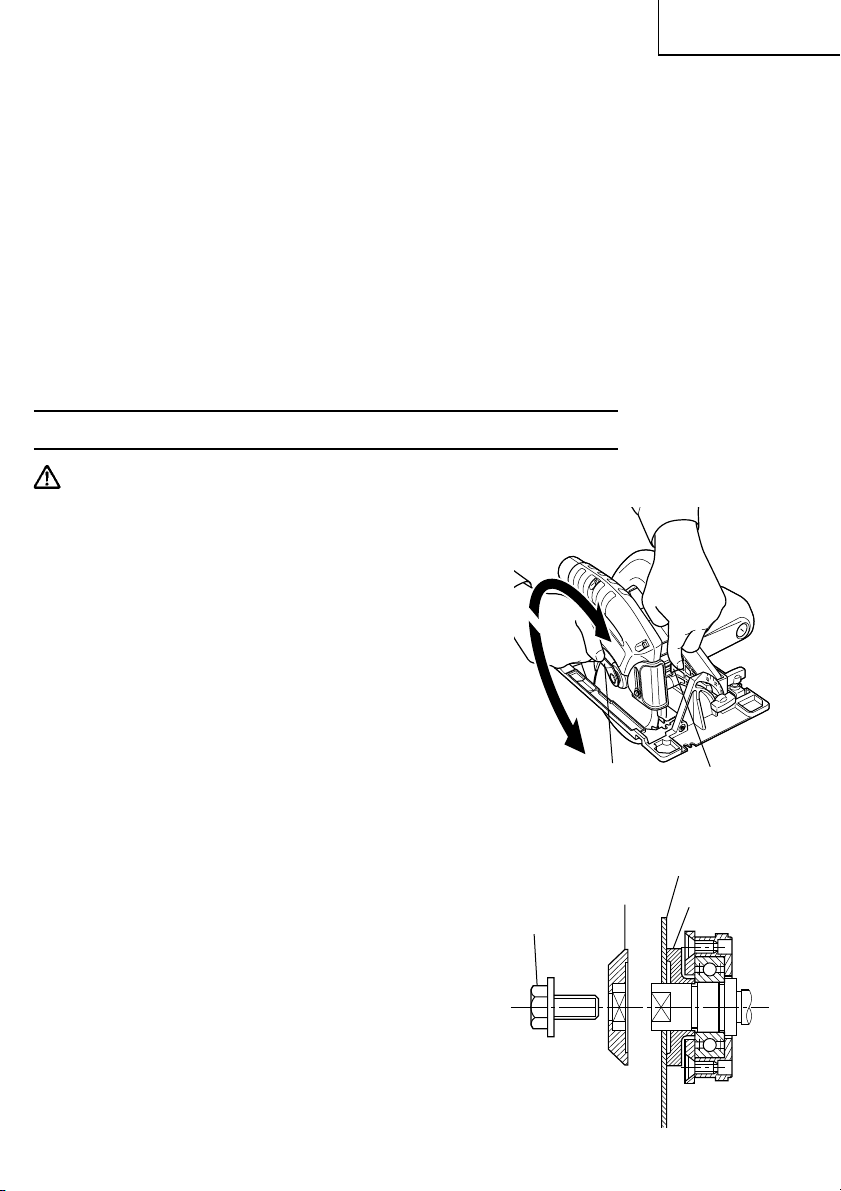

1. Dismounting the saw blade (Fig. 17)

To replace the saw blade, push the lock lever,

then loosen the hexagonal bolt with the wrench.

The blade comes off easily.

2. Mounting the saw blade

(1) Thoroughly remove any sawdust which has

accumulated on the spindle, bolt and washers.

(2) For mounting saw blade, the concave sides of

both washers (A) and (B) must be fitted to the

saw blade sides. Mount the saw blade on the

spindle, and finally affix washer (B) (See Fig. 18)

(3) To assure proper rotation direction of the saw

blade, the arrow direction on the saw blade

must coincide with the arrow direction on the

saw cover.

(4) Using the fingers, tighten the hexagonal bolt

retaining the saw blade as much as possible.

Then depress the lock lever, lock the spindle,

and thoroughly tighten the bolt.

(5) Confirm that the lock lever is in the original

position.

Tighten

Loosen

Hexagonal

Flange Bolt

Wrench

Fig. 17

Washer (B)

Lock Lever

Saw Blade

Washer (A)

Fig. 18

17

Page 18

English

USE OF DUST BAG

WARNING:

● To avoid serious accident, ensure the switch is in the OFF position, and disconnect the

plug from the receptacle.

● Never attempt to saw any material like metal and so on that give off sparks. Such action

can lead to fire or injury.

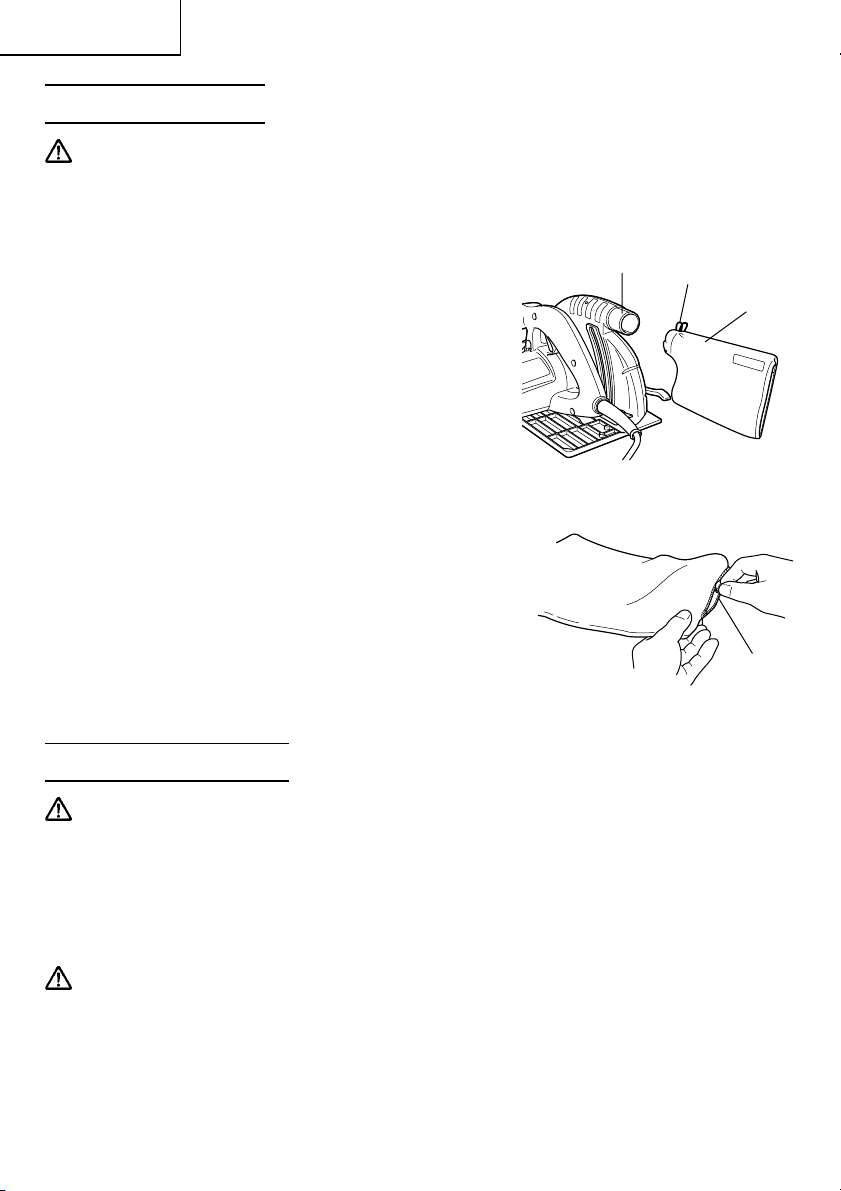

1. Mounting the dust bag

Hold the clasp of the dust bag and insert it into

the adapting mouth of the body while opening

the thrusting mouth. (Fig. 19)

2. Dumping sawdust and cleaning the

inside of dust bag

Adapting Mouth

Clasp

Dust Bag

NOTE: If too much sawdust is accumulated inside

the dust bag, the dust collector will run low

on power. Attempt to dump the sawdust as

early as you can and clean the dust bag

thoroughly so that you can enjoy your work

with strong dust collecting power.

(1) Hold the clasp, open the thrusting mouth of the

dust bag, and pull it off from the body.

(2) Open the fastener (Fig. 20) and dump the

sawdust.

Fig. 19

Fastener

Fig. 20

USE OF DUST GUIDE

WARNING:

● To avoid serious accidents, ensure the switch is in the OFF position, and disconnect the

plug from the receptacle.

● The dust guide is a component part that changes the discharge direction of sawdust and

is not a tool to collect dust. Make certain that you wear protective glasses and a

dustproof mask during the use of the dust guide.

CAUTION:

● The dust guide can change the direction of the discharge direction. Never point it in the

direction of the worker.

● Never carry the tool by the dust guide.

18

Page 19

English

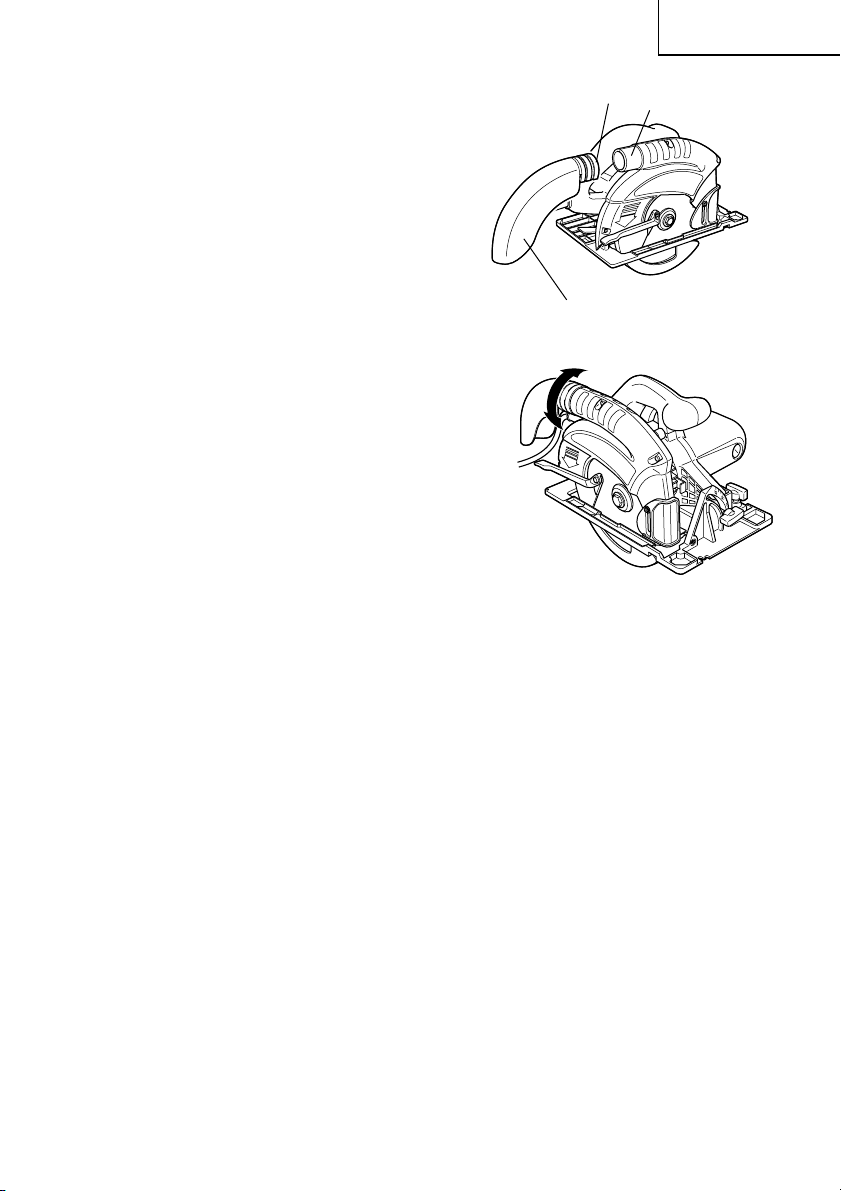

1. Mounting the dust guide

(1) Insert the dust guide’s thrusting mouth into the

adapting mouth of the body. (Fig. 21)

(2) Turn the dust guide and point it in the desired

direction to discharge sawdust. (Fig. 22)

Thrusting Mouth

Dust Guide

Fig. 21

Fig. 22

Adapting Mouth

19

Page 20

English

MAINTENANCE AND INSPECTION

WARNING: To avoid serious accident, ensure the switch is in the OFF position and

disconnect the plug from the receptacle during maintenance and

inspection.

1. Inspecting the saw blade:

Since use of a dull saw blade will degrade efficiency and cause possible motor

malfunction, sharpen or replace the saw blade as soon as abrasion is noted.

CAUTION:

If a dull saw blade is used, reactive force is increased during cutting operation. Avoid

the use of the dull saw blade without repair.

2. Check the mounting screws

Loose mounting screws are dangerous. Regularly inspect them and make sure they are

tight.

CAUTION: Using this power tool with loosened screws is extremely dangerous.

0.67"

(17mm)

Fig. 24

Wear limit

38

0.24"(6mm)

No. of carbon

brush

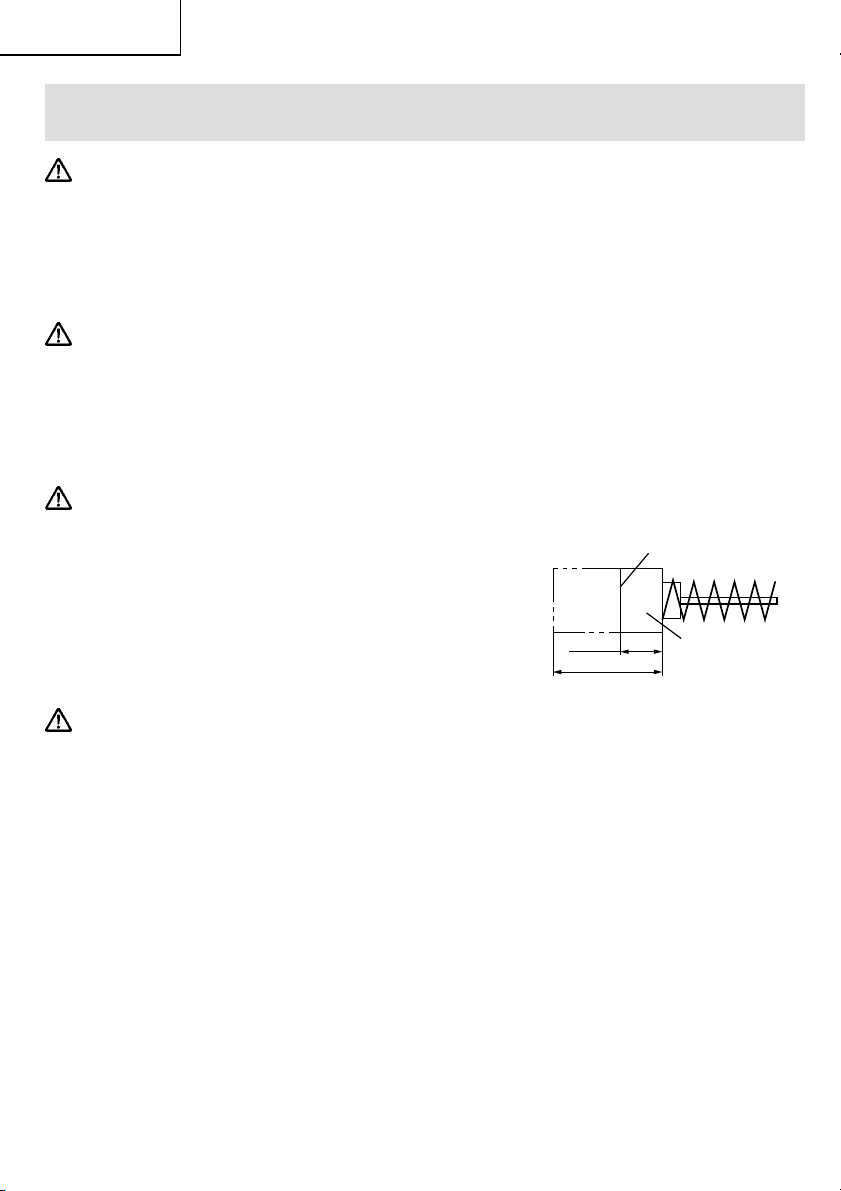

3. Inspecting the carbon brushes (Fig. 24)

The motor employs carbon brushes which are

consumable parts. Replace the carbon brush

with a new one when it becomes worn to its

wear limit. Always keep carbon brushes clean

and ensure that they slide freely within the

brush holders.

CAUTION:

Using this circular saw with a carbon brush which is worn in excess of the wear limit will

damge the motor.

NOTE: Use HITACHI carbon brush No. 38 indicated in Fig. 24.

4 Replacing carbon brushes:

Remove the brush caps with a slotted-head screwdriver. The carbon brushes can then be

easily removed.

5. Performance checkup and maintenance of safety cover

Keep the safety cover in good shape for smooth performance at all times. Be sure to make

prompt repair in case of any malfunction.

6. Adjusting the base and saw blade to maintain perpendicularity

The angle between the base and the saw blade has been adjusted to 90°, however should

this perpendicularity be lost for some reason, adjust in the following manner.

20

Page 21

English

(1) Turn the base face up (Fig. 25) and loosen the

wing-nut.

(2) Apply a square to the base and the saw blade

and, turning the slotted set screw with a slottedhead screwdriver, shift the position of the base

to produce the desired right angle.

Slotted Set Screw

Fig. 25

Square

Base

7. Service parts list

CAUTION:

Repair, modification and inspection of Hitachi Power Tools must be carried out by an

Hitachi Authorized Service Center.

This Parts List will be helpful if presented with the tool to the Hitachi Authorized Service

Center when requesting repair or other maintenance. In the operation and maintenance

of power tools, the safety regulations and standards prescribed in each country must be

observed.

MODIFICATIONS:

Hitachi Power Tools are constantly being improved and modified to incorporate the latest

technological advancements.

Accordingly, some parts (i.e. code numbers and/or design) may be changed without prior

notice.

21

Page 22

English

ACCESSORIES

WARNING: Accessories for this power tool are mentioned in this Instruction

Manual.

The use of any other attachment or accessory can be dangerous and

could cause injury or mechanical damage.

NOTE:

Accessories are subject to change without any obligation on the part of the HITACHI.

STANDARD ACCESSORIES

(1) Saw Blade ............................................................................................................................1

External Diam Hole Diam. Code No.

7-1/4" (185mm) 5/8" (15.9mm) 18008

(2) Dust Bag (Code No. 319296) ............................................................................................... 1

(3) Dust Guide (Code No. 319297) ........................................................................................... 1

(4) Wrench (Code No. 957683) ................................................................................................. 1

(5) Wing Bolt (B) (Code No. 302697) ........................................................................................1

(6) Lock Spring (Code No. 9478359) ........................................................................................ 1

OPTIONAL ACCESSORIES.......sold separately

(1) Guide (Code No. 302691)

NOTE:

Specifications are subject to change without any obligation on the part of the HITACHI.

22

Page 23

Français

INFORMATIONS IMPORTANTES

Lire et comprendre toutes les instructions de fonctionnement, les précautions de sécurité et

les avertissements dans ce mode d’emploi avant d’utiliser ou d’entretenir cet outil motorisé.

La plupart des accidents causés lors de l’utilisation ou de l’entretien de l’outil motorisé

proviennent d’un non respect des règles ou précautions de base de sécurité. Un accident

peut la plupart du temps être évité si l’on reconnaît une situation de danger potentiel avant

qu’elle ne se produise, et en observant les procédures de sécurité appropriées.

Les précautions de base de sécurité sont mises en évidence dans la section “SECURITE” de

ce mode d’emploi et dans les sections qui contiennent les instructions de fonctionnement

et d’entretien.

Les dangers qui doivent être évités pour prévenir des blessures corporelles ou un

endommagement de la machine sont identifiés par AVERTISSEMENTS sur l’outil motorisé

et dans ce mode d’emploi.

Ne jamais utiliser cet outil motorisé d’une manière qui n’est pas spécifiquement recommandée

par HITACHI sans avoir d’abord vérifié que l’utilisation prévue est sans danger pour vous et

les autres.

SIGNIFICATION DES MOTS D’AVERTISSEMENT

AVERTISSEMENT indique des situations potentiellement dangereuses qui, si elles sont

ignorées, pourraient entraîner de sérieuses blessures personnelles.

PRECAUTION indique des situations dangereuses qui, si elles sont ignorées, pourrait

entraîner de légères blessures personnelles ou endommager la machine.

REMARQUE met en relief des informations essentielles.

23

Page 24

Français

REGLES DE SECURITE

SECURITE

AVERTISSEMENT:Une utilisation incorrecte ou dangereuse des outils électriques

peut entraîner la mort ou des blessures graves.

LIRE TOUT CE MODE D’EMPLOI.

1. NE JAMAIS TOUCHER LES PARTIES MOBILES.

Ne jamais placer ses mains, ses doigts ou toute autre partie de son corps près des parties

mobiles de l’outil.

2. NE JAMAIS UTILISER L’OUTIL SANS QUE TOUS LES DISPOSITIFS DE SECURITE NE

SOIENT EN PLACE.

Ne jamais faire fonctionner cet outil sans que tous les dispositifs et caractéristiques de

sécurité ne soient en place et en état de fonctionnement. Si un entretien ou une

réparation nécessite le retrait d’un dispositif ou d’une caractéristique de sécurité,

s’assurer de bien remettre en place le dispositif ou la caractéristique de sécurité avant

de recommencer à utiliser l’outil.

3. TOUJOURS SE PROTEGER LES YEUX ET LES OREILLES.

Pour se protéger des projections de copeaux de bois, particules métalliques ou autres

débris, porter des lunettes de protection ou un masque pour les yeux. Porter des

protections anti-bruit pour se protéger du bruit.

4. SE PROTEGER CONTRE LES DECHARGES ELECTRIQUES.

Empêcher tout contact du corps avec les surfaces mises à la terre, par exemple tuyaux,

radiateurs, plaques de cuisson et enceintes de réfrigération. Ne jamais faire fonctionner

l’outil dans un endroit humide ou mouillé.

5. DEBRANCHER LES OUTILS.

Ne jamais laisser l’outil branché dans une source d’alimentation. Toujours débrancher

l’outil de la source d’alimentation avant tout travail de réparation, d’inspection, d’entretien,

de nettoyage, de remplacement ou de vérification des pièces.

6. EVITER TOUTE MISE EN MARCHE INOPINEE.

Ne pas transporter l’outil pendant qu’il est raccordé à la source d’alimentation. Ne pas

transporter l’outil avec le doigt près de l’interrupteur d’alimentation. Bien s’assurer que

l’interrupteur d’alimentation se trouve sur la position “OFF” (arrêt) avant de raccorder

l’outil à la source d’alimentation.

7. REMISER L’OUTIL CORRECTEMENT.

Lorsqu’on ne se sert pas de l’outil, le remiser dans un endroit sec. Veiller à ce qu’il soit

hors d’atteinte des enfants. Fermer le local de remisage à clé.

8. MAINTENIR L’AIRE DE TRAVAIL PROPRE.

Les aires de travail et les établis encombrés favorisent les accidents. Débarrasser l’aire

de travail et les établis des outils inutiles, débris, meubles, etc.

9. CONSIDERER L’ENVIRONNEMENT DE L’AIRE DE TRAVAIL.

Ne pas exposer les outils à la pluie. Ne pas les utiliser dans un endroit humide ou

mouillé. Veiller à ce que l’aire de travail soit bien éclairée et bien aérée.

Ne pas utiliser l’outil en présence de liquides ou de gaz inflammables.

24

Page 25

Français

Les outils projettent des étincelles pendant qu’ils fonctionnent. Ne jamais utiliser les

outils dans un lieu renfermant de la laque, de la peinture, du diluant, de l’essence, des

gaz, des produits adhésifs ni aucun autre matériau combustible ou explosif.

10. ELOIGNER LES ENFANTS.

Ne pas laisser les visiteurs toucher l’outil ou le cordon de rallonge.

Tous les visiteurs devront être suffisamment éloignés de l’aire de travail.

11. NE PAS FORCER L’OUTIL.

Il effectuera le travail le meilleur et avec la sécurité maximale au régime pour lequel il

a été conçu.

12. UTILISER L’OUTIL CORRECT

Ne pas forcer sur un petit outil ou accessoire pour faire le travail d’un outil de grande

puissance. Ne pas utiliser un outil pour un usage pour lequel il n’a pas été prévu: par

exemple, ne pas utiliser une scie circulaire pour couper des branches d’arbre ou des

bûches.

13. SE VETIR CORRECTEMENT.

Ne pas porter de vêtements lâches ni de bijoux. Ils pourraient se prendre dans les pièces

en mouvement. Il est recommandé de porter des gants en caoutchouc et des chaussures

anti-glissantes lors d’un travail à l’extérieur.

Porter un couvre-chef qui recouvre les cheveux longs.

14. PORTER UN MASQUE, UN MASQUE ANTI-POUSSIERE OU UN APPAREIL RESPIRATOIRE

SI LE TRAVAIL DOIT DEGAGER DE LA POUSSIERE.

Toutes les personnes présentes sur l’aire de travail devront également porter un

masque, un masque anti-poussière ou un appareil respiratoire.

15. NE PAS MALTRAITER LE CORDON.

Ne jamais transporter l’outil par le cordon ni tirer brusquement sur le cordon pour le

débrancher.

Eloigner le cordon de la chaleur, de la graisse et des surfaces tranchantes.

16. FIXER LA PIECE.

Utiliser des dispositifs de serrage ou un étau pour tenir la pièce. Cela sera plus sûr que

de tenir la pièce à la main et libérera les deux mains pour le travail.

17. NE PAS TROP SE PENCHER.

Garder une bonne assise et un bon équilibre à tout moment.

18. ENTRETENIR LES OUTILS AVEC SOIN.

Maintenir les outils aiguisés et propres pour optimiser le travail et la sécurité.

Suivre les instructions de graissage et de remplacement des accessoires.

Vérifier périodiquement les cordons d’outil et les faire réparer par un centre de

réparation agréé s’ils sont endommagés. Vérifier périodiquement les cordons de

rallonge et les faire remplacer s’ils sont endommagés. Maintenir les poignées sèches

et propres, et enlever toute graisse et toute huile dessus.

19. RETIRER LES CLAVETTES DE REGLAGE ET LES CLES.

Les clés et les clavettes de réglage devront être retirées de l’outil avant de sa mise en

marche.

20. CORDONS DE RALLONGE POUR UTILISATION A L’EXTERIEUR.

Si l’outil doit être utilisé dehors, utiliser exclusivement des cordons de rallonge conçus

pour un usage extérieur et marqués à cet effet.

21. RESTER SUR SES GARDES.

Bien faire attention à ce que l’on fait. Faire preuve de bon sens. Ne pas utiliser l’outil

lorsqu’on est fatigué.

25

Page 26

Français

Ne jamais utiliser l’outil si l’on est sous l’influence d’alcool, de drogues ou de médicaments

qui rendent somnolent.

22. VERIFIER S’IL Y A DES PIECES ENDOMMAGEES.

Avant de continuer à utiliser l’outil, inspecter attentivement les protections ou autres

pièces endommagées pour voir si l’outil pourra fonctionner correctement et effectuer

le travail pour lequel il est conçu. Vérifier l’alignement et le couplage des pièces mobiles,

le voilage des pièces mobiles, la présence de pièces cassées, le montage, et toute autre

condition susceptible d’affecter le bon fonctionnement.

Si une protection ou une pièce est endommagée, la faire réparer ou remplacer par un

service après-vente agréé, sauf spécification contraire dans ce mode d’emploi.

Faire remplacer les interrupteurs défectueux par un centre de réparation agréé.

Ne pas utiliser l’outil si l’interrupteur ne fonctionne pas.

23. NE JAMAIS UTILISER UN OUTIL MOTORISE POUR DES APPLICATIONS AUTRES QUE

CELLES SPECIFIEES.

Ne jamais utiliser un outil motorisé pour des applications autres que celles spécifiées

dans le mode d’emploi.

24. MANIPULER L’OUTIL CORRECTEMENT

Utiliser l’outil de la façon indiquée dans ce mode d’emploi. Ne pas laisser tomber ou

lancer l’outil. Ne jamais permettre que l’outil soit utilisé par des enfants, des personnes

non familiarisées avec son fonctionnement ou un personnel non autorisé.

25. VERIFIER S’IL Y A DES FILS SOUS TENSION.

Pour éviter tout risque de choc électrique grave, vérifier s’il y a des fils électriques sous

tension encastrés dans le mur, le plancher ou le plafond. Couper l’alimentation des fils

avant le travail.

26. MAINTENIR TOUTES LES VIS, TOUS LES BOULONS ET LES COUVERCLES FERMEMENT

EN PLACE.

Maintenir toutes les vis, tous les boulons et les couvercles fermement montés. Vérifier

leurs conditions périodiquement.

27. NE PAS UTILISER LES OUTILS MOTORISES SI LE REVETEMENT DE PLASTIQUE OU LA

POIGNEE EST FENDU.

Des fentes dans le revêtement ou la poignée peuvent entraîner une électrocution. De tels

outils ne doivent pas être utilisés avant d’être réparé.

28. LES LAMES ET LES ACCESSOIRES DOIVENT ETRE FERMEMENT MONTES

SUR L’OUTIL.

Eviter les blessures potentielles personnelles et aux autres. Les lames, les instruments

de coupe et les accessoires qui ont été montés sur l’outil doivent être fixés et serrés

fermement.

29. GARDER PROPRES LES EVENTS D’AIR DU MOTEUR

Les évents d’air du moteur doivent être maintenus propres de façon que l’air puisse

circuler librement tout le temps. Vérifier les accumulations de poussière fréquemment.

30. UTILISER L’OUTIL MOTORISE A LA TENSION NOMINALE.

Utiliser l’outil motorisé à la tension spécifiée sur sa plaque signalétique.

Si l’on utilise l’outil motorisé avec une tension supérieure à la tension nominale, il en

résultera une rotation anormalement trop rapide du moteur et cela risque d’endommager

l’outil et le moteur risque de griller.

31. NE JAMAIS UTILISER UN OUTIL DEFECTUEUX OU QUI FONCTIONNE

ANORMALEMENT.

Si l’outil n’a pas l’air de fonctionner normalement, fait des bruits étranges ou sans cela

26

Page 27

Français

paraît défectueux, arrêter de l’utiliser immédiatement et le faire réparer par un centre

de service Hitachi autorisé.

32. NE JAMAIS LAISSER FONCTIONNER L’OUTIL SANS SURVEILLANCE. LE METTRE

HORS TENSION.

Ne pas abandonner l’outil avant qu’il ne soit complètement arrêté.

33. MANIPULER L’OUTIL MOTORISE AVEC PRECAUTION.

Si un outil motorisé tombe ou frappe un matériau dur accidentellement, il risque d’être

déformé, fendu ou endommagé.

34. NE PAS ESSUYER LES PARTIES EN PLASTIQUE AVEC DU SOLVANT.

Les solvants comme l’essence, les diluants, la benzine, le tétrachlorure de carbone et

l’alcool peuvent endommager et fissurer les parties en plastique. Ne pas les essuyer

avec de tels solvants.

Essuyer les parties en plastique avec un chiffon doux légèrement imbibé d’une solution

d’eau savonneuse et sécher minutieusement.

35. LORS DU REMPLACEMENT D’UNE PIECE CONSTITUTIVE, CHOISIR UNE PIECE DU

MEME TYPE. Lors du remplacement d’une pièce constitutive par une neuve, choisir une

nouvelle pièce du même type. Par ailleurs, ne pas tenter de réparer l’outil électrique soi-

même.

36. LAISSER LES PROTECTIONS EN PLACE ET EN BON ORDRE DE MARCHE. Ne jamais

maintenir la protection inférieure ouverte en l’attachant ou en la coinçant. Vérifier le bon

fonctionnement de la protection inférieure avant chaque utilisation. Ne pas utiliser

l’outil si la protection inférieure ne se referme pas promptement sur la lame.

PRECAUTION: Si la scie tombe, la protection inférieure risque de se voiler, ce qui

l’empêchera de se refermer complètement.

37. MAINTENIR LES LAMES PROPRES ET BIEN AFFUTEES. Des lames affûtées réduiront

les calages et les retours de lame.

38. DANGER : NE PAS APPROCHER LES MAINS DE LA ZONE DE COUPE. Ne pas approcher

les mains des lames. Ne pas passer la main sous la pièce pendant que la lame tourne.

Ne pas tenter de retirer la section tronçonnée pendant que la lame tourne.

PRECAUTION: Les lames continuent à tourner quelque temps en roue libre après l’arrêt.

39. SOUTENIR LES PANNEAUX VOLUMINEUX. Les panneaux volumineux devront être

soutenus comme indiqué sur la Fig. 1 pour réduire les risques de pincement de la lame

et de retour de lame. Si l’opération de coupe demande que la scie repose sur la pièce,

poser la scie sur la section la plus grande et couper la section la plus petite.

Pour éviter tout retour de lame,

soutenir la planche ou le panneau

près de la ligne de coupe.

Fig. 1

Ne pas soutenir la planche ou

le panneau loin de la ligne de coupe.

Fig. 2

27

Page 28

Français

40. UTILISER LE GUIDE DE REFENTE. Toujours utiliser un guide de refente ou un guide à

bord rectiligne pour effectuer une refente.

41. AVERTISSEMENT : Il est important de soutenir la pièce correctement et de tenir

solidement la scie pour éviter toute perte de contrôle pouvant entraîner des blessures

physiques. La Fig. 3 donne un exemple type de soutien manuel de la scie. Lorsqu’on

utilise la scie, éloigner le cordon de la zone de coupe et le placer de façon qu’il ne se

coince pas dans la pièce pendant l’opération de coupe.

EXEMPLE TYPE DE SOUTIEN MANUEL DE LA SCIE, DE

SOUTIEN LA PIÈCE ET D’ACHEMINEMENT DU CORDON

Fig. 3

42. PROTECTION CONTRE LES RETOURS DE LAME. Il se produit un retour de lame lorsque

la scie cale brusquement et qu’elle est ramenée vers l’opérateur. Relâcher immédiatement

l’interrupteur si la lame se plie ou que la scie cale.

Maintenir les lames bien affûtées.

Soutenir les panneaux volumineux comme indiqué sur la Fig. 1.

Utiliser le guide de refente ou un guide à bord rectiligne pour effectuer une refente.

Ne pas clôturer l’outil.

Rester sur ses gardes et être maître de soi.

Ne pas retirer la lame de la pièce pendant que la lame tourne.

43. ABAISSER LA PROTECTION. Relever la protection inférieure avec la poignée de retrait.

44. REGLAGES. Avant de couper, bien vérifier que les réglages de profondeur et de

biseau sont solides.

45. UTILISER UNIQUEMENT LES LAMES APPROPRIEES. Ne pas utiliser de lames dont les

orifices ont une dimension qui ne convient pas.

Ne jamais utiliser de rondelles ni de boulons de lame défectueux ou qui ne conviennent

pas.

46. EVITER DE COUPER DES CLOUS. Avant de couper, vérifier s’il y a des clous dans le

matériau et les retirer le cas échéant.

47. NE PAS TRANSPORTER LA SCIE A LA MAIN AVEC LA LAME QUI TOURNE.

28

Page 29

Français

48. Placer la section large de l’embase de la lame sur la section de la pièce qui est

fermement soutenue, et non sur la section qui va tomber après la coupe. A titre

d’exemple, la Fig. 4 montre la façon CORRECTE de couper l’extrémité de la planche, et

la Fig. 5 montre la façon INCORRECTE. Si la pièce est courte ou petite, la serrer.

NE PAS ESSAYER DE TENIR LES SECTIONS COURTES À LA MAIN!

Fig. 4 Fig. 5

49. Faire particulièrement attention lors d’une

“coupe de poche” dans un mur existant ou

tout autre endroit aveugle. La lame pourrait

couper des objets, ce qui risque de provoquer

un RETOUR DE LAME.

NE JAMAIS passer la main ou les doigts

derrière la scie. S’il se produit un retour de

lame, la scie pourrait facilement sauter

brusquement en arrière sur la main et

provoquer des blessures graves.

Fig. 6

50. Avant de poser l’outil par terre une fois la coupe terminée, bien s’assurer que la garde

inférieure (télescopique) s’est refermée et que la lame est complètement arrêtée.

51. Ne jamais tenter de scier des matériaux, comme du métal, susceptibles de projeter des

étincelles. Cela pourrait entraîner un feu ou des blessures.

52. Ne jamais tenter de scier avec la scie circulaire

dirigée vers le bas dans un étau. Ceci serait

extrêmement dangereux et pourrait entraîner

de graves accidents. (Fig. 7)

Etau

Fig. 7

29

Page 30

Français

SERVICE APRES-VENTE ET REPARATIONS

Tous les outils motorisés de qualité auront éventuellement besoin d’une réparation ou du

remplacement d’une pièce à cause de l’usure normale de l’outil. Pour assurer que seules des

pièces de rechange autorisées seront utilisées, tous les entretiens et les réparations doivent

être effectués uniquement par UN CENTRE DE SERVICE HITACHI AUTORISE.

PIECES DE RECHANGE

Pour les réparations, utiliser exclusivement des pièces de rechange identiques.

Les réparations devront être effectuées exclusivement par un centre de service après-vente

Hitachi agréé.

FICHES POLARISEES

Pour réduire tout risque de choc électrique, l’appareil possède une fiche polarisée (l’une des

lames est plus large que l’autre).

Cette fiche ne rentrera dans une prise polarisée que dans un sens.

Si la fiche ne rentre pas dans la prise, l’inverser.

Si elle ne rentre toujours pas, faire installer une prise appropriée par un électricien qualifié.

Ne pas modifier la fiche de quelque façon que ce soit.

30

Page 31

Français

UTILISATION D’UN CORDON DE RALLONGE

Utiliser exclusivement un cordon de rallonge en bon état. Lorsqu’on utilise un cordon de

rallonge, veiller à ce qu’il soit suffisamment lourd pour supporter le courant dont l’appareil

aura besoin. Un cordon trop petit provoquera une chute de la tension de ligne, ce qui

entraînera une perte de puissance et une surchauffe. Le tableau indique le calibre à utiliser

en fonction de la longueur du cordon et de l’intensité nominale indiquée sur la plaque

signalétique. En cas de doute, utiliser un calibre supérieur. Plus le numéro du calibre est petit,

plus le cordon est lourd.

CALIBRE MINIMUM DES CORDONS

Longueur totale de cordon en pieds (mètres)

0 – 25 26 – 50 51 – 100 101 – 150

(0 – 7,6) (7,9 – 15,2) (15,5 – 30,5) (30,8 – 45,7)

Intensité nominale CALIBRE

Supérieure Non supérieure

àà

0 – 618161614

6 – 10 18 16 14 12

10 – 12 16 16 14 12

12 – 16 14 12 Non recommandé

AVERTISSEMENT:Eviter tout risque de choc électrique. Ne jamais utiliser l’outil

avec un cordon électrique ou un cordon de rallonge

endommagé ou dénudé.

Inspecter régulièrement les cordons électriques. Ne jamais

utiliser dans l’eau ou à proximité d’eau, ni dans un

environnement susceptible de provoquer un choc électrique.

31

Page 32

Français

DOUBLE ISOLATION POUR UN FONCTIONNEMENT PLUS SUR

Pour assurer un fonctionnement plus sûr de cet outil motorisé, HITACHI a adopté une

conception à double insolation. “Double isolation” signifie que deux systèmes d’isolation

physiquement séparés ont été utilisés pour isoler les matériaux conducteurs d’électricité

connectés à l’outil motorisé à partir du cadre extérieur manipulé par l’utilisateur. C’est

pourquoi, le symbole “

sur l’outil motorisé ou sur la plaque signalétique.

Bien que ce système n’ait pas de mise à terre extérieure, il est quand même nécessaire de

suivre les précautions de sécurité électrique données dans ce mode d’emploi, y-compris de

ne pas utiliser l’outil motorisé dans un environnement humide.

Pour garder le système de double isolation effectif, suivre ces précautions:

䡬 Seuls les CENTRES DE SERVICE AUTORISES HITACHI peuvent démonter et remonter cet

outil motorisé et uniquement des pièces de rechange HITACHI garanties d’origine

doivent être utilisées.

䡬 Nettoyer l’extérieur de l’outil motorisé uniquement avec un chiffon doux légèrement

imbibé d’une solution savonneuse et essuyer minutieusement.

Ne jamais utiliser des solvants, de l’essence ou des diluants sur les parties en plastique;

sinon le plastique risquerait de se dissoudre.

” ou les mots “Double insulation” (double isolation) apparaissent

CONSERVER CES INSTRUCTIONS

ET

LES METTRE A LA DISPOSITION

DES AUTRES UTILISATEURS

DE CET OUTIL!

32

Page 33

Français

DESCRIPTION FONCTIONNELLE

REMARQUE:

Les informations contenues dans ce mode d’emploi sont conçues pour assister l’utilisateur

dans une utilisation sans danger et un entretien de l’outil motorisé.

Certaines illustrations dans ce mode d’emploi peuvent montrer des détails ou des

accessoires différents de ceux de l’outil motorisé utilisé.

NOM DES PARTIES

Couvercle du pignon

Carter de lame

Levier

(Poignée de retrait)

Socle

Lame de la scie

Carter de sécurité

(Protection inférieure)

Poignée

Interrupteur

Levier de blocage

Boulon-papillon (B)

Ressort de

verrouillage

Boulon-papillon (A)

Couvercle

coulissant

Fig. 8

SPECIFICATIONS

Moteur Moteur série monophasé à collecteur

Source d’alimentation Secteur, 120V 60Hz, monophasé

Profondeur max. de coupe 2-3/8" (60mm)

Curant 13 A

Vitesse sans charge 5500/min.

Poids 11,3 lbs (5,1 kg)

33

Page 34

Français

ASSEMBLAGE ET FONCTIONNEMENT

APPLICATIONS

䡬 Coupe de fibro-ciment

(Ex. Planche HARDI, Panneau HARDI)

AVANT L’UTILISATION

1. Source d’alimentation

S’assurer que la source d’alimentation qui doit être utilisée est conforme à la source

d’alimentation requise spécifiée sur la plaque signalétique du produit.

2. Interrupteur d’alimentation

S’assurer que l’interrupteur est sur la position OFF (arrêt). Si la fiche est connectée sur

une prise alors que l’interrupteur est sur la position ON (marche), l’outil motorisé

démarrera immédiatement risquant de causer de sérieuses blessures.

3. Cordon prolongateur

Quand la zone de travail est éloignée de la source d’alimentation, utiliser un cordon

prolongateur d’épaisseur et de capacité nominale suffisante. Le cordon prolongateur

doit être aussi court que possible.

AVERTISSEMENT: Tout cordon endommagé devra être remplacé ou réparé.

4. Vérifier la prise

Si la prise reçoit la fiche avec beaucoup de jeu, elle doit être réparée. Contacter un

électricien licencié pour réaliser les réparations nécessaires.

Si une telle prise défectueuse est utilisée, elle peut causer une surchauffe entraînant des

dangers sérieux.

5. Vérification des conditions d’environnement

Vérifier que l’état de l’aire de travail est conforme aux précautions.

6. Préparer un établi de travail en bois (Fig. 9).

La lame de scie se déplaçant au-delà de la

surface inférieure du matériau, placer le

matériau sur un établi en bois pour effectuer la

coupe. Si l’on utilise un bloc carré comme établi

de travail, sélectionner un sol de niveau pour

bien stabiliser le travail. Un établi de travail

instable risque de rendre le travail dangereux.

PRECAUTION:

Pour éviter tout risque d’accident, toujours

s’assurer que la section du matériau qui reste

après la coupe est solidement ancrée ou

maintenue en place.

34

Matériau

Etabli de travail

Fig. 9

Socle

Lame de scie

Page 35

Français

7. Vérifier si le levier de serrage et le boulon à ailettes sont bien serrés.

Si le boulon à ailettes pour le réglage de la profondeur de coupe (Fig. 12) et le boulon à

ailettes pour le réglage de l’angle d’inclinaison (Fig. 13) sont desserrés, cela risque

d’entraîner des blessures. Bien s’assurer qu’ils sont serrés à fond.

8. Vérifier le bon fonctionnement du carter de sécurité

AVERTISSEMENT:Il faudra impérativement vérifier que le carter de sécurité n ’est

pas fixé. Par ailleurs, vérifier également qu’il se déplace en

douceur. Si la lame de scie reste exposée, il y a risque de

blessure.

Le carter de sécurité (voir Fig. 8) sert à protéger le corps de l’opérateur de tout contact

avec la lame de scie. Vérifier impérativement que le carter de sécurité fonctionne de façon

que la lame de scie soit toujours couverte. Si le carter de sécurité ne fonctionne pas en

douceur, ne jamais utiliser l’outil sans avoir réparé le carter.

Dans ce cas, contacter le magasin où l’on a acheté la scie circulaire ou un service après-

vente HITACHI agréé pour le faire réparer.

9. Lunettes de protection et masque anti-poussière

(Fig. 10)

Lorsqu’on utilise l’outil, bien porter les lunettes

de protection et le masque anti-poussière.

10.Sac à poussière ou guide-poussière

Lorsqu’on utilise l’outil, il faut impérativement

utiliser le sac à poussière ou le guide-poussière

qui sont livrés en standard. Pour les détails de

montage, voir [Utilisation du sac à poussière],

page 36, et [Utilisation du guide-poussière],

page 37.

11.Vérifier si la lame est serrée

Voir [Fixation et retrait de la lame de scie] à la page 35, et vérifier si le boulon à bride est

bien serré à fond.

Fig. 10

RÉGLAGE DE LA SCIE AVANT L’UTILISATION

1Réglage du couvercle coulissant

AVERTISSEMENT :

Pour éviter tout risque d’accident grave,

s’assurer que l’interrupteur est à la position

OFF et débrancher la fiche de la prise secteur.

Le couvercle coulissant de l’outil se déplace de

haut en bas. Lorsque l’outil quitte nos usines, le

couvercle coulissant est monté à la position de

Vis

Fig. 11

Couvercle

coulissant

35

Page 36

Français

descente maximale. Si l’on utilise l’outil dans sa

position de montage d’origine pour une coupe

à angle doit, cela permettra de réduire

l’éparpillement des particules de sciure.

Si l’on a du mal à inspecter le bout de la lame,

ou lors d’une coupe à angle, ou si l’on utilise le

guide-poussière pour effectuer une coupe,

desserrer la vis, déplacer le couvercle coulissant

vers le haut, et effectuer les réglages nécessaires

avant l’utilisation. (Pour une coupe à angle,

fixer le couvercle coulissant à la position de

levage maximal.) Bien s’assurer que la vis est

serrée à fond après le réglage.

2. Réglage de la profondeur de coupe (Fig. 12)

AVERTISSEMENT:

Si le levier de serrage est lâche, il y a risque de

blessure. Le serrer à fond après le réglage.

Pour régler la profondeur de coupe, desserrer le

levier de serrage et, tout en tenant le socle d’une

main, déplacer l’outil principal vers le haut ou

vers le bas de façon à obtenir la profondeur de

coupe spécifiée. Après avoir réglé la profondeur

de coupe spécifiée, resserrer le levier de serrage

à fond.

3. Réglage de l’angle d’inclinaison

Desserrer

Serrer

Levier de

serrage

Articulation

Socle

Fig. 12

Boulon à ailettes (A)

Fig. 13

AVERTISSEMENT: Si le boulon oreilles est lâche, il y a risque de blessure. Le

serrer à fond après le réglage.

REMARQUE : Laisser le couvercle coulissant relevé en position de levage maximal avant de

régler l’angle d’inclinaison. (Voir “Réglage du couvercle coulissant”, page 13.)

Comme indiqué à la Fig. 13, en desserrant le boulon à ailettes de la jauge inclinée, il est

possible d’incliner la lame de scie à un angle de 45° maximum par rapport au socle.

Toujours s’assurer que le boulon à ailettes est serré à fond après avoir effectué le réglage.

4. Réglage du guide (garde de refente)

................................... Accessoire en option

REMARQUE : Pour monter le guide, déplacer le couvercle coulissant vers le haut jusqu’à ce

que le guide ne soit plus en contact avec le couvercle coulissant. (Voir

“Réglage du couvercle coulissant”, page 32.)

36

Page 37

Français

Il est possible de régler la position de coupe en

déplaçant le guide vers la gauche ou vers la

droite après avoir desserré son boulon à ailettes.

Le guide pourra être monté sur le côté droit ou

sur le côté gauche de l’outil. (Voir Fig. 14)

PROCEDURES DE COUPE

AVERTISSEMENT

● Ne jamais toucher les pièces mobiles.

● Si la lame s’arrête ou qu’elle fait un bruit anormal pendant le fonctionnement, couper

immédiatement l’interrupteur.

● Ne pas enlever la lame de la pièce pendant la coupe alors que la lame tourne.

● Porter des lunettes de protection et un masque anti-poussière.

● Ne pas scier de matériaux, comme du métal, etc. susceptibles de projeter des étincelles.

PRECAUTION :

● Toujours veiller à ce que le cordon d’alimentation n’approche pas de la lame de scie en

rotation.

● Fixer le sac à poussière ou le guide-poussière avant l’utilisation.

● Avant de commencer à scier, s’assurer que la lame de scie a bien atteint sa vitesse de

régime.

1. Placer le corps (socle) de la scie sur le matériau,

et, comme indiqué à la Fig. 15, aligner la ligne de

coupe en pointillé sur la lame de scie, en utilisant

l’encoche gravée à l’avant du socle. Ce rapport

entre le socle et le matériau ne devra pas changer

quelle que soit l’inclinaison du socle.

2. Mettre l’interrupteur sur la position ON avant

que la lame de scie n’entre en contact avec le

matériau. L’interrupteur s’allume lorsqu’on tire

la gâchette avec le doigt, et il s’éteint lorsqu’on

relâche la gâchette.

3. Pour obtenir un rendement de coupe maximal,

déplacer la scie en droite ligne et à vitesse

constante.

Boulon à ailettes (B), ressort

de verrouillage

Fig. 14

Pas

d’inclinaison

Inclinaison à 45°

Fig. 15

Socle

Guide

(garde de

refente)

[COUPE DE POCHES]

AVERTISSEMENT :

● Pour éviter tout risque d’accident grave, s’assurer que l’interrupteur est à la position OFF

et débrancher la fiche de la prise secteur avant tout réglage.

● Ne jamais attacher ni caler le carter de sécurité en position relevée.

37

Page 38

Français

1. Marquer bien lisiblement la section à couper

avec des lignes sur tous les côtés. (Voir Fig. 16)

2. Régler la profondeur de coupe en fonction du

matériau à couper.

3. Pousser le levier du carter de sécurité à fond

vers l’arrière jusqu’à ce que la lame soit exposée,

comme indiqué à la Fig. 16.

4. Incliner la scie vers l’avant et aligner l’encoche

(Fig. 15) sur la ligne de guidage pré-marquée.

5. Relâcher le levier du carter de sécurité. Lorsque

le carter de sécurité entre en contact avec la

surface de la pièce, il sera dans la bonne position

pour s’ouvrir librement lorsqu’on commencera

à couper.

6. Tout en tenant la scie dans cette position, et alors que la lame n’est pas en contact avec

la surface de la pièce, tirer sur la gâchette.

7. Lorsque la scie a atteint sa vitesse de régime, abaisser progressivement l’extrémité

arrière de la scie jusqu’à ce que le socle repose sur la surface de la pièce.

8. Avancer la scie le long de la ligne de coupe jusqu’au coin.

9. Relâcher la gâchette et attendre que la lame se soit complètement arrêtée avant de retirer

la lame de la pièce.

䡩 En aucun cas on ne tirera la lame vers l’arrière pendant qu’elle tourne, car cela pourrait

provoquer un retour de lame.

10. Utiliser une scie sauteuse ou une scie à main pour parfaire la coupe des coins.

11. Chaque fois qu’on commence une nouvelle coupe, recommencer les opérations ci-

dessus.

Fig. 16

Levier

MONTAGE ET DEMONTAGE DE LA LAME DE SCIE

AVERTISSEMENT: Pour éviter tout risque d’accident grave, s’assurer que

l’interrupteur est à la position OFF et débrancher la fiche de la

prise secteur avant tout réglage.

1. Démontage de la lame de scie (Fig. 17)

Pour remplacer la lame, appuyer sur le levier de

verrouillage, puis desserrer le boulon hexagonal

à l’aide de la clé.

La lame s’enlève en toute facilité.

2. Montage de la lame

(1) Bien retirer toute la sciure qui s’est accumulée

sur l’axe, le boulon et les rondelles.

(2) Pour monter la lame, les côtés concaves des

deux rondelles (A) et (B) doivent rentrer dans les

côtés de la lame. Monter la lame sur l’axe, puis

fixer la rondelle (B). (Voir Fig. 18)

38

Serrer

Desserrer

Clé

Fig. 17

Levier de

verrouillage

Page 39

Français

(3) Pour s’assurer que la lame tourne dans le bon

sens, il faut que la flèche de la lame soit dirigée

dans le même sens que celle du carter de lame.

(4) Avec les doigts, serrer le boulon hexagonal qui

fixe la lame de scie au maximum. Puis, appuyer

sur le levier de verrouillage, verrouiller l’axe et

serrer le boulon à fond.

(5) Vérifier que le levier de verrouillage se trouve

sur sa position d’origine.

UTILISATION DU SAC À POUSSIÈRE

AVERTISSEMENT :

● Pour éviter tout risque d’accident grave,

s’assurer que l’interrupteur est à la position

OFF et débrancher la fiche de la prise secteur.

● Ne jamais tenter de scier des matériaux, comme

du métal, susceptibles de projeter des étincelles.

Cela pourrait entraîner un feu ou des blessures.

1. Fixation du sac à poussière

Saisir la languette du sac à poussière et l’insérer

dans l’orifice de raccordement du boîtier tout

en ouvrant l’orifice de propulsion. (Fig. 19)

Boulon à

bride

hexagonal

Orifice de

raccordement

Lame de scie

Rondelle (B)

Fig. 18

Languette

Rondelle (A)

Sac à

poussière

2. Vidage de la sciure et nettoyage de

l’intérieur du sac à poussière

REMARQUE : S’il y a trop de sciure dans le sac à

poussière, le collecteur de poussière

ne fonctionnera que faiblement.

Essayer de vider la sciure dès que

possible et bien nettoyer l’intérieur

du sac à poussière de façon à pouvoir

travailler sans problème, avec une

forte puissance de propulsion de la

poussière.

(1) Saisir la languette, ouvrir l’orifice de propulsion

du sac à poussière, et le dégager du boîtier.

(2) Ouvrir la fermeture (Fig. 20), et vider la sciure.

Fig. 19

Fermeture

Fig. 20

39

Page 40

Français

UTILISATION DU GUIDE-POUSSIÈRE

AVERTISSEMENT :

● Pour éviter tout risque d’accident grave,

s’assurer que l’interrupteur est à la position

OFF et débrancher la fiche de la prise secteur.

● Le guide-poussière est une pièce qui intervertit

le sens du rejet de la sciure ; il ne permet pas de

recueillir la poussière. Bien porter les lunettes

de protection et le masque anti-poussière

pendant l’utilisation du guide-poussière.

PRECAUTION:

● Le guide-poussière change le sens du rejet de la

sciure. Ne jamais le diriger sur des personnes.

● Ne jamais transporter l’outil par le guide-

poussière.

1. Fixation du guide-poussière

(1) Insérer l’orifice de propulsion du guide-

poussière dans l’orifice de raccordement du

boîtier. (Fig. 21)

(2) Tourner le guide-poussière et le diriger dans le

sens de rejet voulu. (Fig. 22)

Orifice de

propulsion

Guide-poussière

Orifice de

raccordement

Fig. 21

Fig. 22

40

Page 41

Français

ENTRETIEN ET INSPECTION

AVERTISSEMENT: Pour éviter tout risque d’accident grave, s’assurer que

l’interrupteur est à la position OFF et débrancher la fiche de la

prise secteur.

1. Inspection de la lame de scie