Page 1

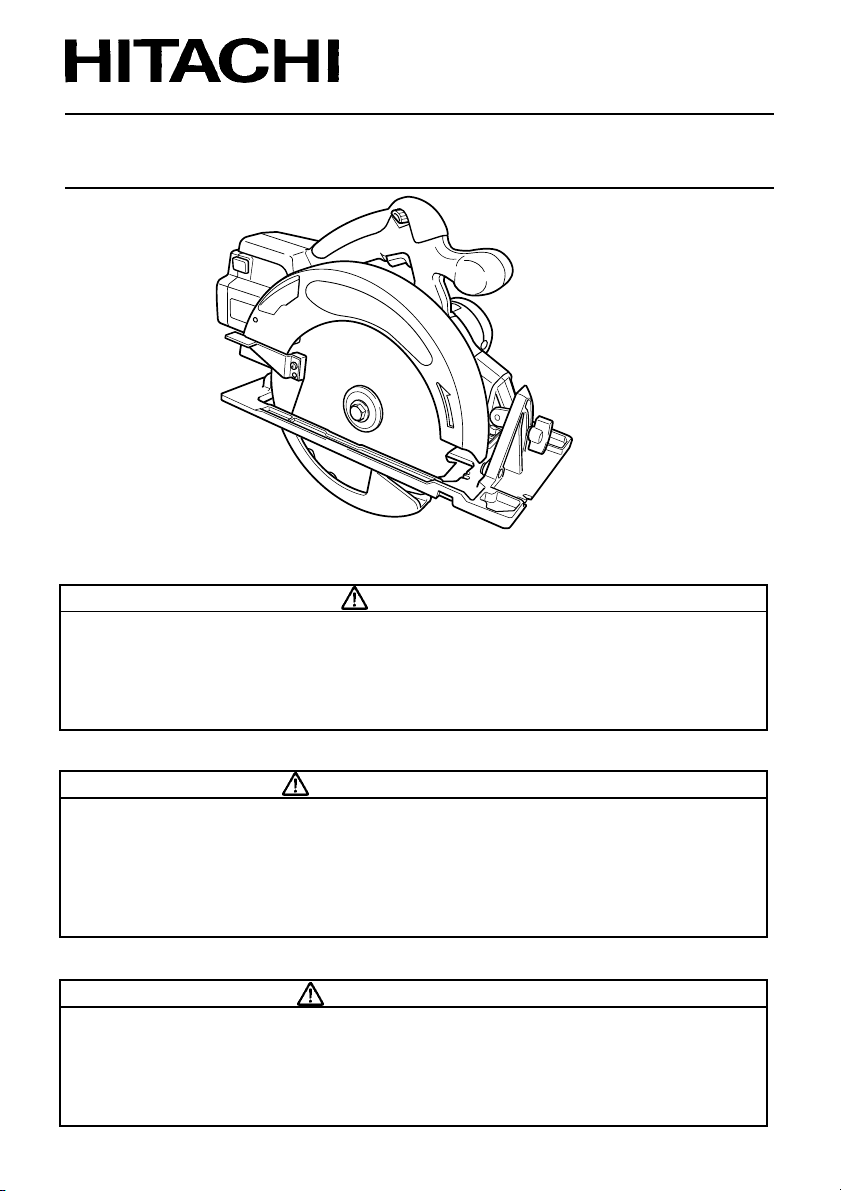

MODEL CORDLESS CIRCULAR SAW

MODÈLE SCIE CIRCULAIRE À BATTERIE

MODELO SIERRA CIRCULAR A BATERÍA

C 7D

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily

injury!

This manual contains important information about product safety. Please read

and understand this manual BEFORE operating the power tool. Please keep this

manual available for other users and owners before they use the power tool. This

manual should be stored in safe place.

English

INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner

la mort ou de sérieuses blessures corporelles!

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de

ce produit. Prière de lire et de comprendre ce mode d’emploi AVANT d’utiliser

l’outil motorisé. Garder ce mode d’emploi à la disponibilité des autres utilisateurs

et propriétaires avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi doit être

conservé dans un endroit sûr.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede

resultar en lesiones de gravedad o la muerte!

Este manual contiene información importante sobre la seguridad del producto.

Lea y comprenda este manual ANTES de utilizar la herramienta eléctrica. Guarde

este manual para que puedan leerlo otras personas antes de utilizar la herramienta

eléctrica. Este manual debe ser guardado en un lugar seguro.

1

Page 2

English

English

IMPORTANT SAFETY INFORMATION ............... 3

MEANINGS OF SIGNAL WORDS ....................... 3

SAFETY .................................................................... 4

GENERAL SAFETY RULES – FOR ALL

BATTERY OPERATED TOOLS ..................... 4

SPECIFIC SAFETY RULES ................................... 6

IMPORTANT SAFETY INSTRUCTIONS FOR

USE OF THE CORDLESS CIRCULAR SAW ...

IMPORTANT SAFETY INSTRUCTIONS

FOR BATTERY CHARGER .......................... 12

IMPORTANT SAFETY INSTRUCTIONS

FOR USE OF THE BATTERY AND

BATTERY CHARGER .................................... 13

FUNCTIONAL DESCRIPTION .................................. 15

MODEL ................................................................. 15

NAME OF PARTS ................................................ 15

SPECIFICATIONS ................................................ 16

Français

INFORMATIONS IMPORTANTES DE SÉCURITÉ

SIGNIFICATION DES MOTS D’AVERTISSEMEN

SECURITE ................................................................ 33

REGLES GENERALE DE SECURITE – POUR TOUS

LES OUTILS FONCTIONNANT SUR BATTERIE ...

REGLES DE SECURITE SPECIFIQUES ............... 35

CONSIGNES DE SÉCURITÉ IMPORTANTES POUR

L'UTILISATION DU SCIE CIRCULAIRE À BATTERIE

CONSIGNES DE SÉCURITÉ IMPORTANTES

POUR LE CHARGEUR DE BATTERIE

CONSIGNES DE SÉCURITÉ IMPORTANTES POUR L’UTILISATION

DE LA BATTERIE ET DU CHARGEUR DE BATTERIE

DESCRIPTION FONCTIONNELLE ........................... 44

MODELE ............................................................... 44

NOM DES PARTIES ............................................. 44

SPECIFICATIONS ................................................ 45

TABLE DES MATIERES

CONTENTS

Page

Page

...... 32

T .... 32

............. 41

........... 42

11

33

.. 40

ASSEMBLY AND OPERATION ............................... 17

APPLICATIONS .................................................... 17

REMOVAL AND INSTALLATION METHOD

OF BATTERY .................................................... 17

CHARGING METHOD .......................................... 17

BEFORE USE ....................................................... 20

ADJUSTING THE SAW PRIOR TO USE ............. 21

OPERATION ......................................................... 22

MOUNTING AND DISMOUNTING THE

SAW BLADE ..................................................... 25

REPLACING LIGHT BULB ................................... 26

MAINTENANCE AND INSPECTION ....................... 27

ASSEMBLAGE ET FONCTIONNEMENT ..........................

UTILISATIONS ..................................................... 46

MÉTHODE DE RETRAIT ET D’INSTALLATION

DE LA BATTERIE .......................................... 46

MÉTHODE DE RECHARGE ................................. 46

AVANT L’UTILISATION ...................................... 49

RÉGLAGE DE LA SCIE AVANT L’UTILISATION .....

UTILISATION ....................................................... 51

MONTAGE ET DÉMONTAGE DE LA LAME DE

SCIE .............................................................. 54

REMPLACEMENT DE L’AMPOULE .................... 55

ENTRETIEN ET INSPECTION .................................. 56

Page

Page

46

50

Español

INFORMACIÓN IMPORTANTE SOBRE SEGURIDAD ..

SIGNIFICADO DE LAS PALABRAS DE SEÑALIZACIÓN

SEGURIDAD ............................................................. 62

NORMAS GENERALES DE SEGURIDAD – PARA TODAS

LAS HERRAMIENTAS ALIMENTADAS CON BATERÍA

NORMAS ESPECÍFICOS DE SEGURIDAD ......... 64

INSTRUCCIONES IMPORTANTES PARA LA

UTILIZACIÓN DEL SIERRA CIRCULAR

A BATTERÍA .....................................................

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

PARA EL CARGADOR DE BATERÍAS

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

PARA LA BATERÍA Y EL CARGADOR DE BATERÍAS

DESCRIPCIÓN FUNCIONAL .................................... 73

MODELO .............................................................. 73

NOMENCLATURA ............................................... 73

ESPECIFICACIONES ............................................ 74

2

Página

................. 70

ÍNDICE

61

.. 61

.. 62

68

... 71

MONTAJE Y OPERACIÓN ....................................... 75

APLICACIONES ................................................... 75

MÉTODO DE EXTRACCIÓN E INSTALACIÓN

DE LA BATERÍA ............................................ 75

MÉTODO DE CARGA .......................................... 75

ANTES DE LA UTILIZACIÓN .............................. 78

AJUSTE DE LA SIERRA ANTES DE UTILIZARLA ......

OPERACIÓN ......................................................... 80

MONTAJE Y DESMONTAJE DE LA HOJA DE

SIERRA ......................................................... 83

FORMA DE CAMBIAR LA LÁMPARA ................. 84

MANTENIMIENTO E INSPECCIÓN ........................ 86

Página

79

Page 3

English

IMPORTANT SAFETY INFORMATION

Read and understand all of the safety precautions, warnings and operating instructions in

the Instruction Manual before operating or maintaining this power tool.

Most accidents that result from power tool operation and maintenance are caused by the

failure to observe basic safety rules or precautions. An accident can often be avoided by

recognizing a potentially hazardous situation before it occurs, and by observing appropriate

safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Instruction Manual and

in the sections which contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by

WARNINGS on the power tool and in this Instruction Manual.

NEVER use this power tool in a manner that has not been specifically recommended by

HITACHI.

MEANINGS OF SIGNAL WORDS

WARNING indicates a potentially hazardous situations which, if ignored, could result in

death or serious injury.

CAUTION indicates a potentially hazardous situations which, if not avoided, may result in

minor or moderate injury, or may cause machine damage.

NOTE emphasizes essential information.

3

Page 4

English

SAFETY

GENERAL SAFETY RULES – FOR ALL BATTERY OPERATED TOOLS

WARNING: Read and understand all instructions.

Failure to follow all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

1. Work Area

(1) Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

(2) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools create sparks which may ignite the

dust of fumes.

(3) Keep bystanders children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

2. Electrical Safety

(1) A battery operated tool with integral batteries or a separate battery pack must be

recharged only with the specified charger for the battery.

A charger that may be suitable for one type of battery may create a risk of fire when

used with another battery.

(2) Use battery operated tool only with specifically designed battery pack.

Use of any other batteries may create a risk of fire.

3. Personal Safety

(1) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use tool while tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating power tools may result in

serious personal injury.

(2) Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing and gloves away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

(3) Avoid accidental starting. Be sure switch is off position before inserting battery.

Carrying tools with your finger on the switch or inserting the battery pack into a tool

with the switch on invites accidents.

(4) Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that

is left attached to a rotating part of the tool may result in personal injury.

(5) Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enable better control of the tool in unexpected situations.

(6) Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

4

Page 5

English

4. Tool Use and Care

(1) Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to

loss of control.

(2) Do not force tool. Use the correct tool for your application. The correct tool will do

the job better and safer at the rate for which it is designed.

(3) Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be repaired.

(4) Disconnect battery pack from tool or place the switch in the locked or off position

before making any adjustments, changing accessories, or storing the tools. Such

preventive safety measures reduce the risk of starting the tool accidentally.

(5) Store idle tools out of reach of children and other untrained persons. Tools are

dangerous in the hands of untrained users.

(6) When battery pack is not in use, keep it away from other metal objects like: paper

clips, coins, keys, nails, screws, or other small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together may cause sparks, burns, or a fire.

(7) Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely to bind and are easier to control.

(8) Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the tool's operation. If damaged, have the tool serviced by

a HITACHI authorized service center before using. Many accidents are caused by

poorly maintained tools.

(9) Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on

another tool.

5. Service

(1) Tool service must be performed only by a HITACHI authorized service center. Service

or maintenance performed by unqualified personnel could result in a risk of injury.

(2) When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instruction may create a risk of electric shock or injury.

WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known [to the State of California] to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

● Lead from lead-based paints,

● Crystalline silica from bricks and cement and other masonry products, and

● Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemicals: work in a well ventilated area,

and work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

5

Page 6

English

SPECIFIC SAFETY RULES

1. DANGER! Keep hands away from cutting area and blade. Keep your second hand on

auxiliary handle or motor housing. If both hands are holding the saw, they cannot be cut

by the blade.

Keep your body positioned to either side of the saw blade, but not in line with the saw

blade. KICKBACK could cause the saw to jump backwards. (See KICKBACK)

Do not reach underneath the work. The guard can not protect you from the blade below

the work.

2. Check lower guard for proper closing before each use. Do not operate saw if lower guard

does not move freely and close instantly. Never clamp or tie the lower guard into the

open position. If saw is accidentally dropped, lower guard may be bent. Raise the lower

guard with the Retracting Handle and make sure it moves freely and does not touch the

blade or any other part, in all angles and depths of cut.-

3. Check the operation and condition of the lower guard spring. If the guard the spring are

not operating properly, they must be serviced before use. Lower guard may operate

sluggishly due to damaged parts, gummy deposits, or a buildup of debris.

4. Lower guard should be retracted manually only for special cuts such as “Pocket Cuts”

and “Compound Cuts.” Raise lower guard by Retracting Handle. As soon as blade enters

the material, lower guard must be released. For all other sawing, the lower guard should

operate automatically.

5. Always observe that the lower guard is covering the blade before placing saw down on

bench or floor. An unprotected, coasting blade will cause the saw to walk backwards,

cutting whatever is in its path. Be aware of the time it takes for the blade to stop after

switch is released.

6. NEVER hold piece being cut in your hands or across your leg. It is important to support

the work properly to minimize body exposure, blade binding, or loss of control.

7. Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring. Contact with a “live” wire will also make

exposed metal parts of the tool “live” and shock the operator.

8. When ripping always use a rip fence or straight edge guide. This improves the accuracy

of cut and reduces the chance for blade binding.

9. Always use blades with correct size and shape (diamond vs. round) arbor holes. Blades

that do not match the mounting hardware of the saw will run eccentrically, causing loss

of control.

10. Never use damaged or incorrect blade washers or bolts. The blade washers and bolt

were specially designed for your saw, for optimum performance and safety of operation.

11. Causes and Operator Prevention of Kickback:

Kickback is a sudden reaction to a pinched, bound, or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the workpiece toward the operator.

When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly back toward the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the

blade can dig into the top surface of the wood causing the blade to climb out of the kerf

and jump back toward the operator.

Kickback is the result of tool misuse and/or incorrect operating procedures or conditions

and can be avoided by taking proper precautions as given below:

6

Page 7

English

䡬 Maintain a firm grip on the saw and position your body and arm in a way that allows you

to resist KICKBACK forces. KICKBACK forces can be controlled by the operator, if proper

precautions are taken.

䡬 When blade is binding, or when interrupting a cut for any reason, release the trigger and

hold the saw motionless in the material until the blade comes to a complete stop. Never

attempt to remove the saw from the work or pull the saw backward while the blade is

in motion or KICKBACK may occur. Investigate and take corrective actions to eliminate

the cause of blade binding.

䡬 When restarting a saw in the workpiece, center the saw blade in the kerf and check that

teeth are not engaged into the material. If saw blade is binding, it may walk up or

KICKBACK from the workpiece as the saw is restarted.

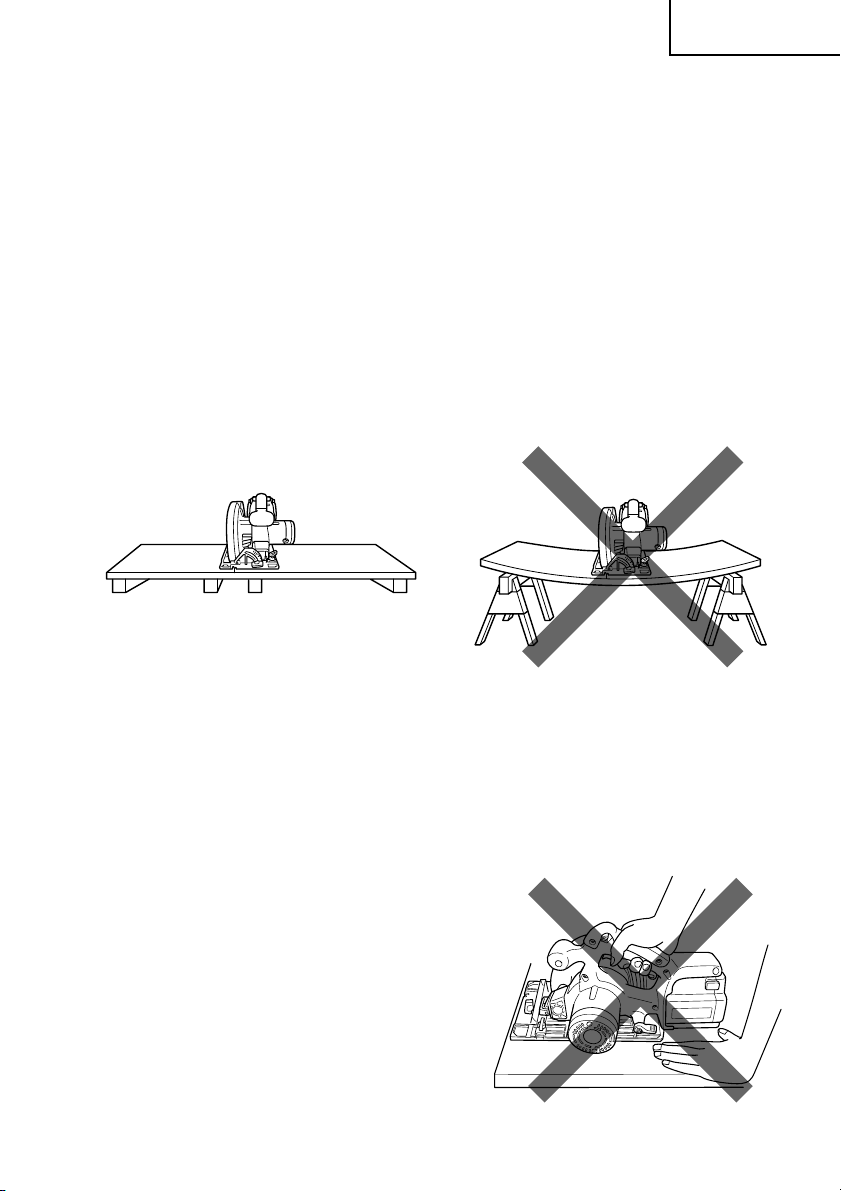

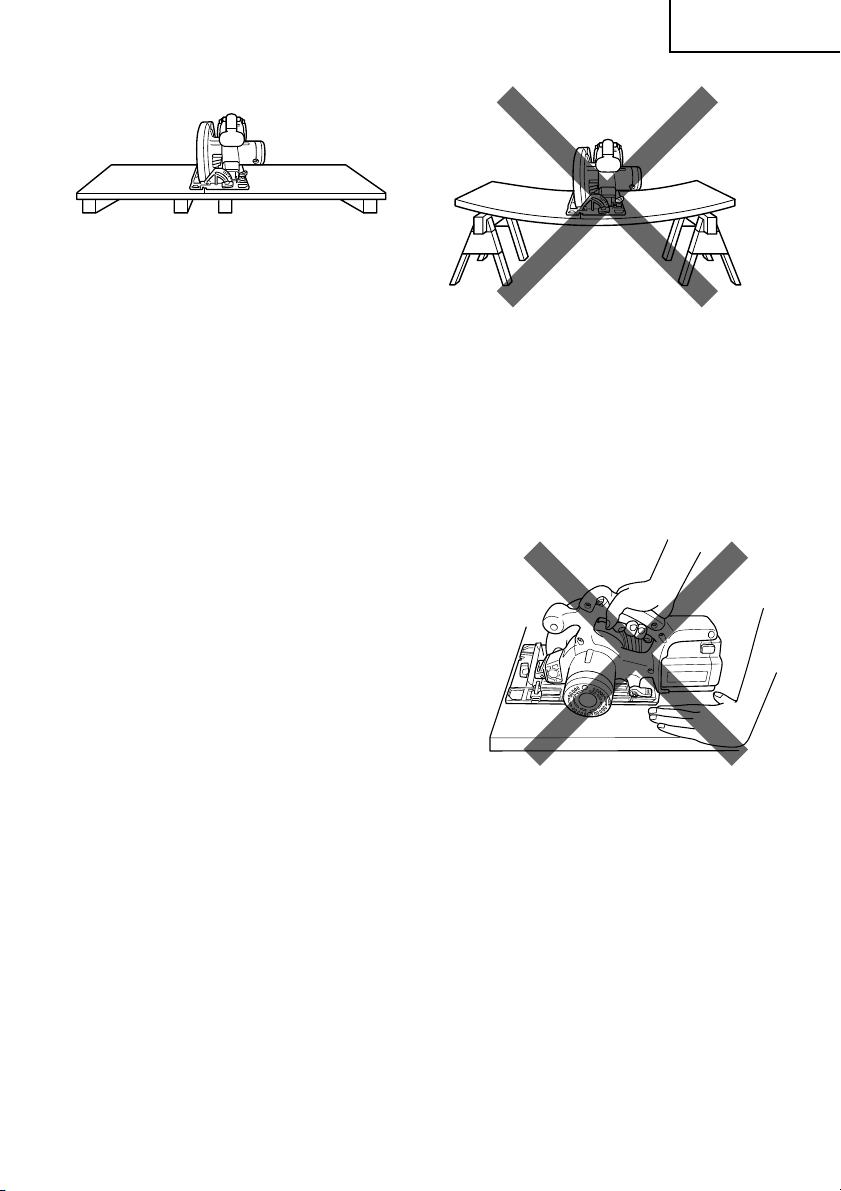

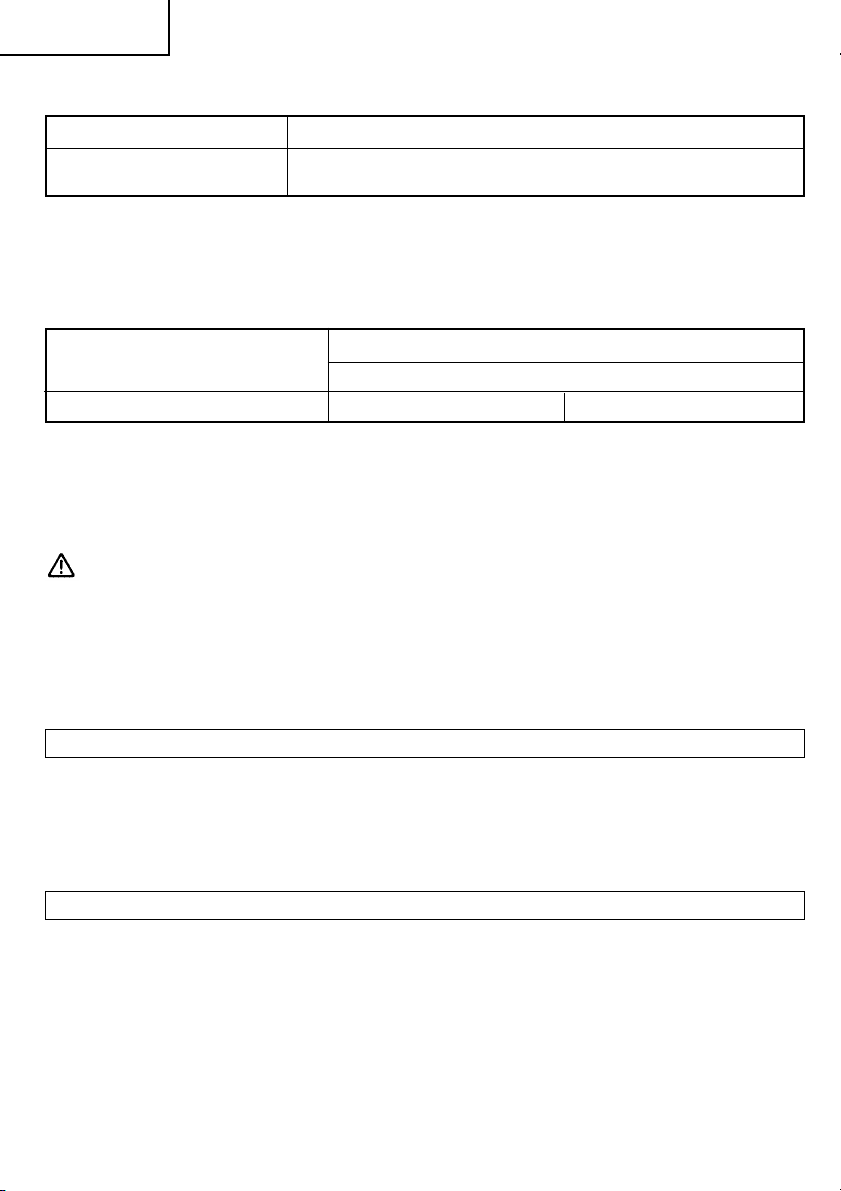

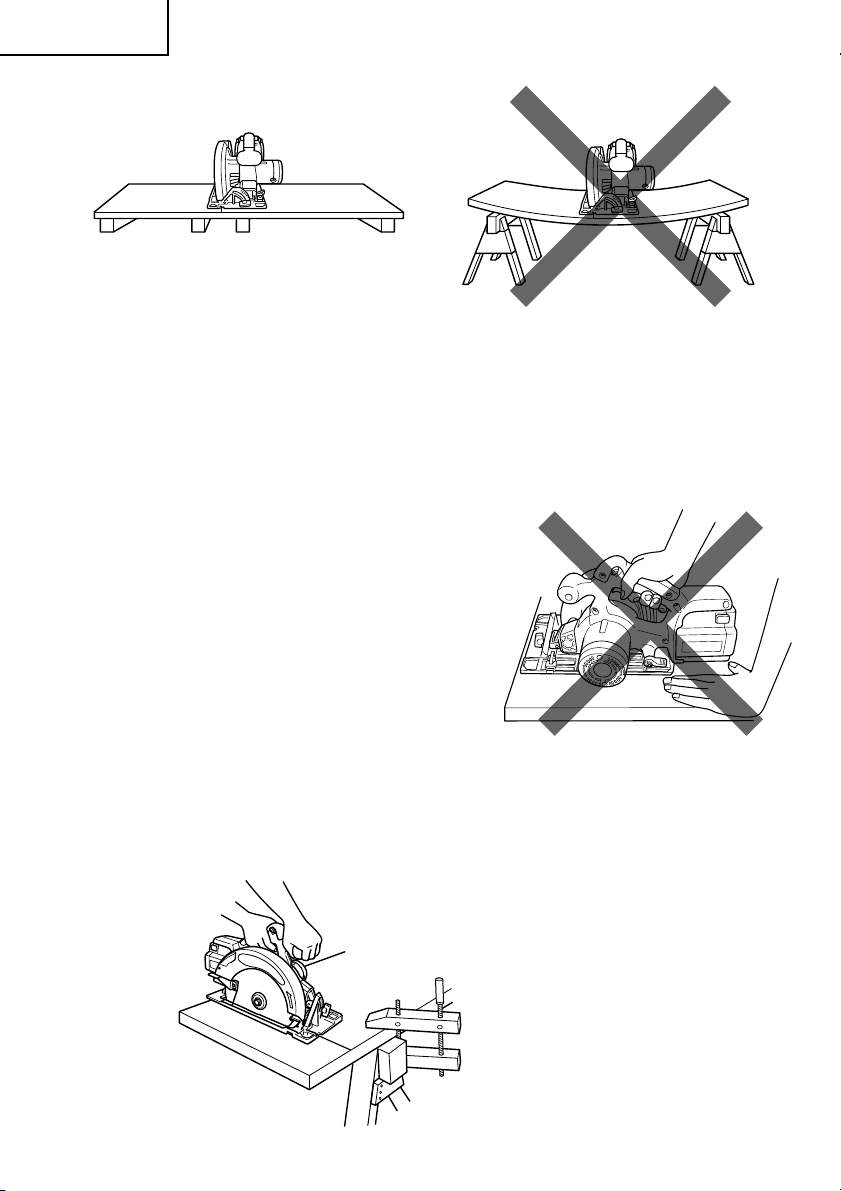

䡬 Support large panels to minimize the risk of blade pinching and KICKBACK. Large panels

tend to sag under their own weight. Supports must be placed under the panel on both

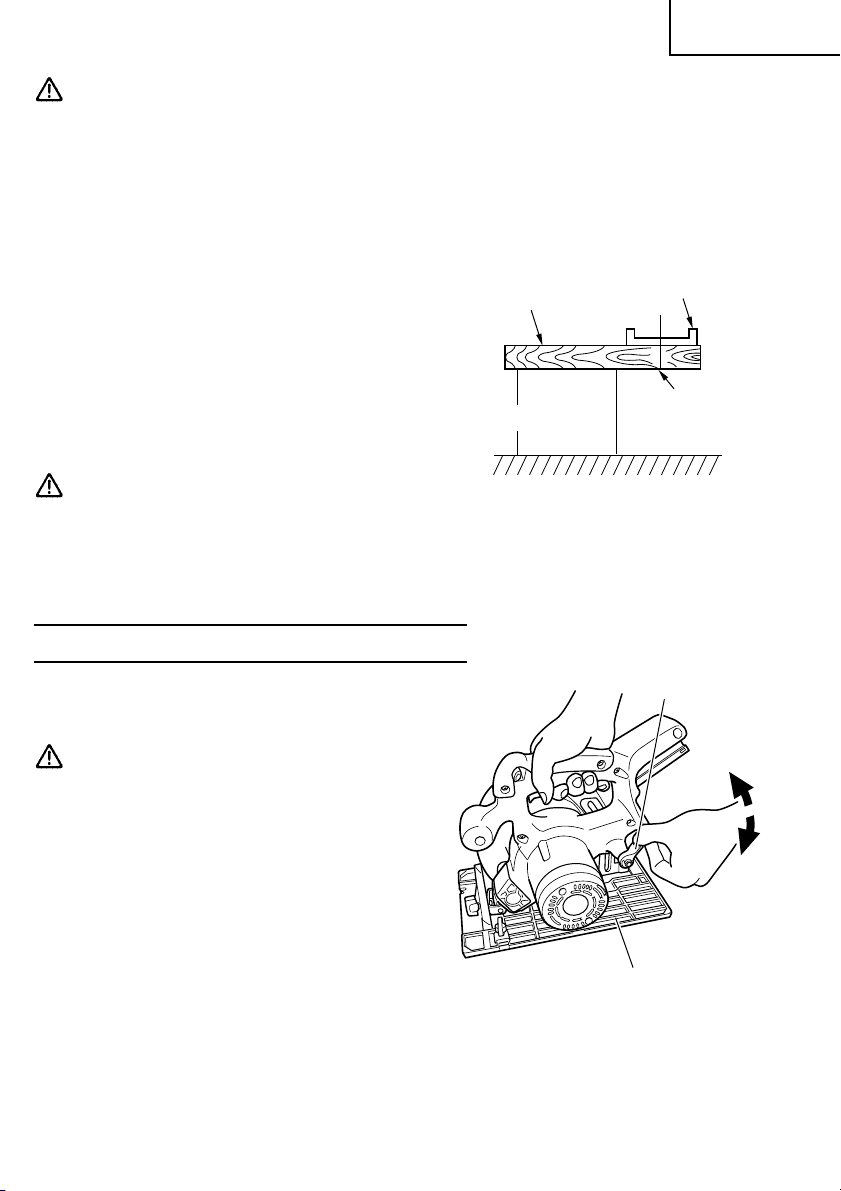

sides, near the line of cut and near the edge of the panel as shown in Fig. 1.

To minimize the risk of blade pinching and kickback. When cutting operation requires the

resting of the saw on the work piece, the saw shall be rested on the larger portion and the

smaller piece cut off.

To avoid kickback, do support board Don't support board or panel away

or panel near the cut. from the cut.

Fig. 1 Fig. 2

䡬 Do not use dull or damaged blade. Unsharpened or improperly set blades produce

narrow kerf causing excessive friction, blade binding, and KICKBACK.

䡬 Blade depth and bevel adjusting locking levers (wing bolt (A) and clamp lever) must be

tight and secure before making cut. If blade adjustment shifts while cutting, it will cause

binding and KICKBACK.

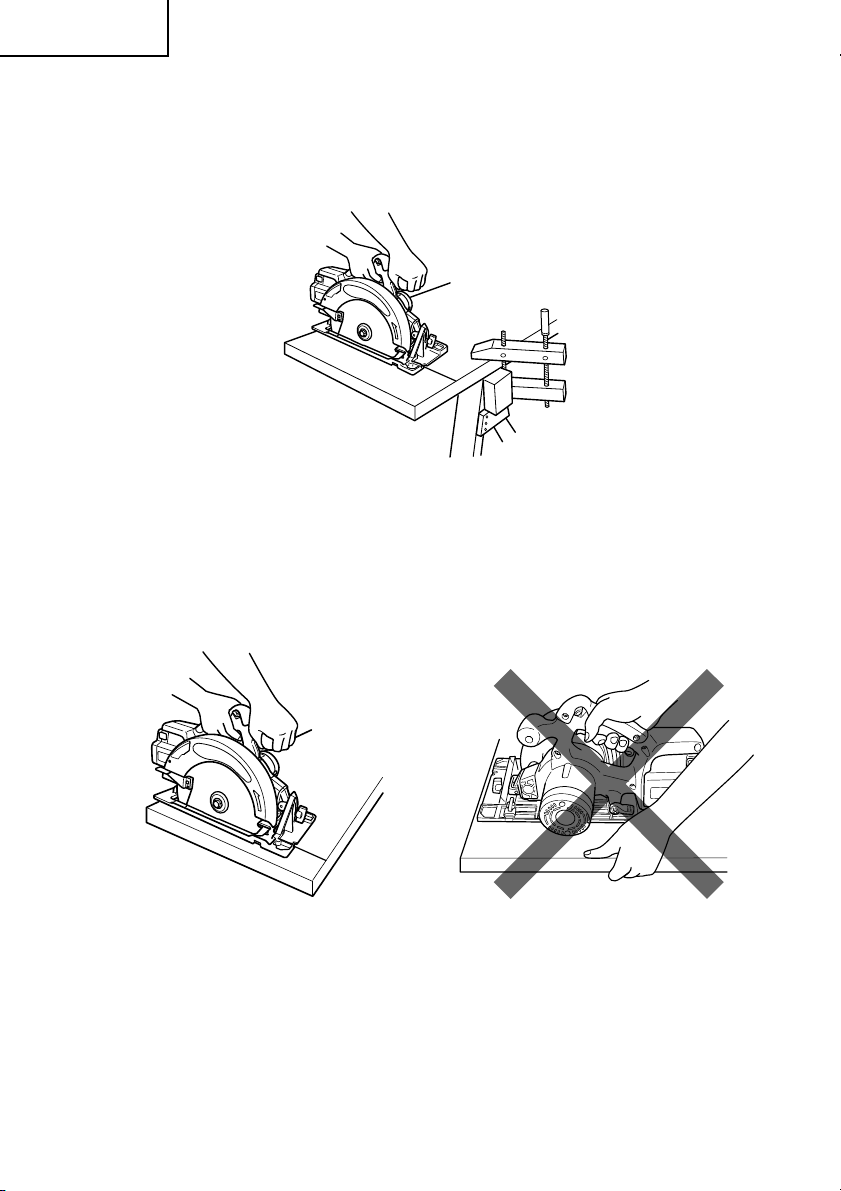

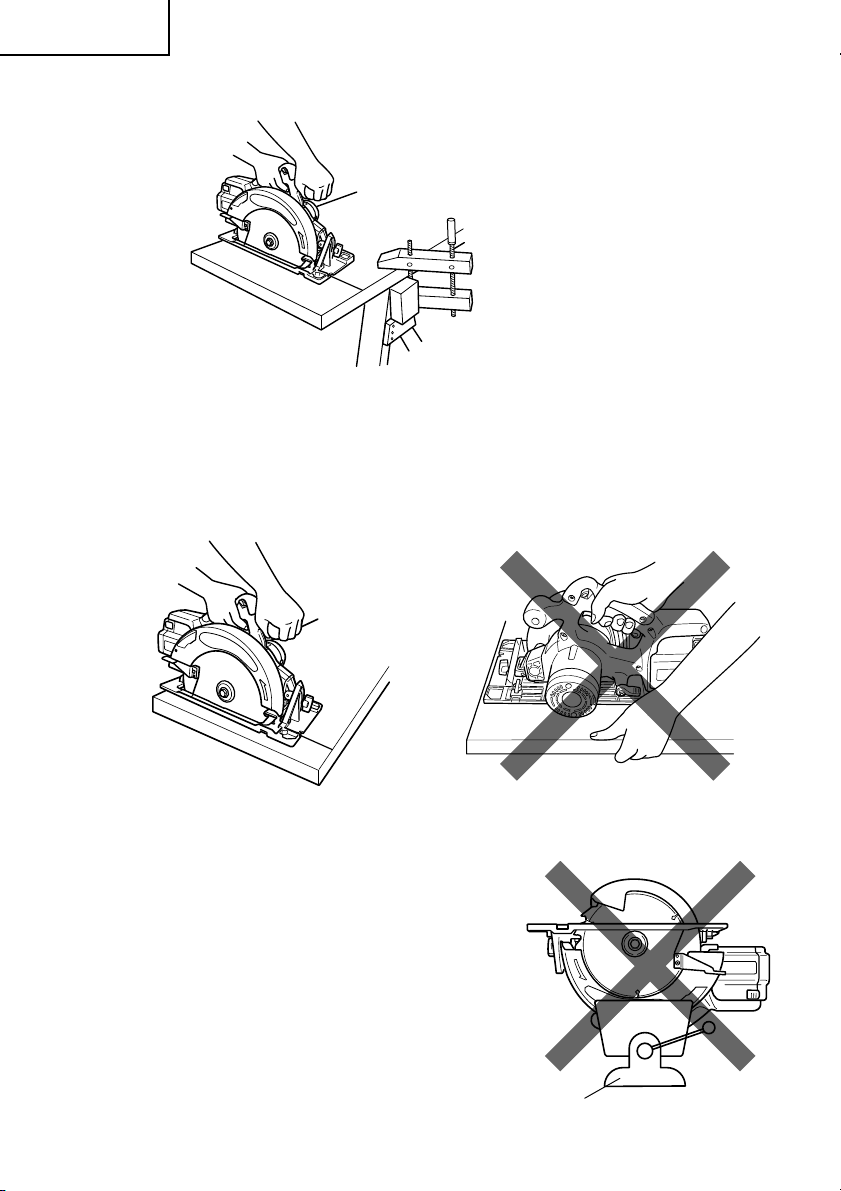

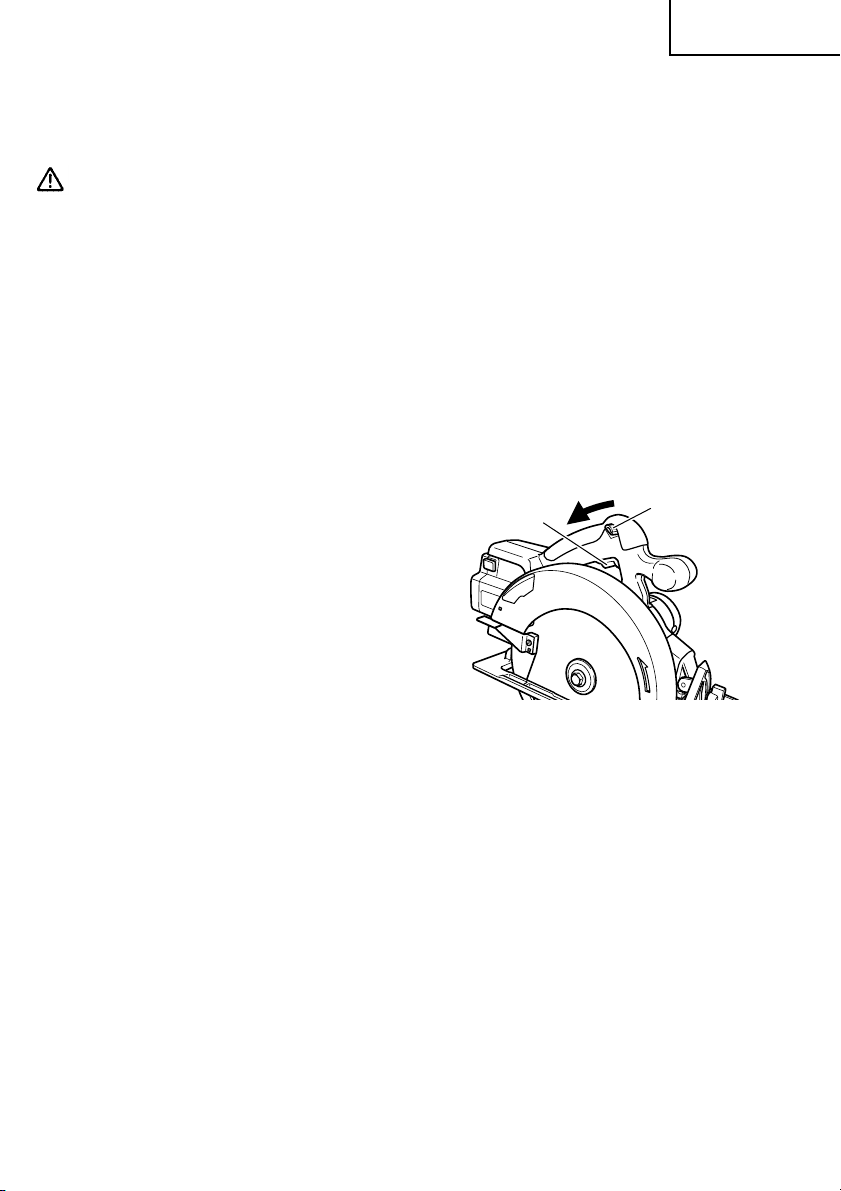

䡬 Use extra caution when making a “Pocket Cut”

into existing walls or other blind areas. The

protruding blade may cut objects that can cause

KICKBACK.

NEVER place your hand or fingers behind the

saw. If kickback occurs, the saw could easily

jump backwards over your hand, possibly

causing severe injury.

Fig. 3

7

Page 8

English

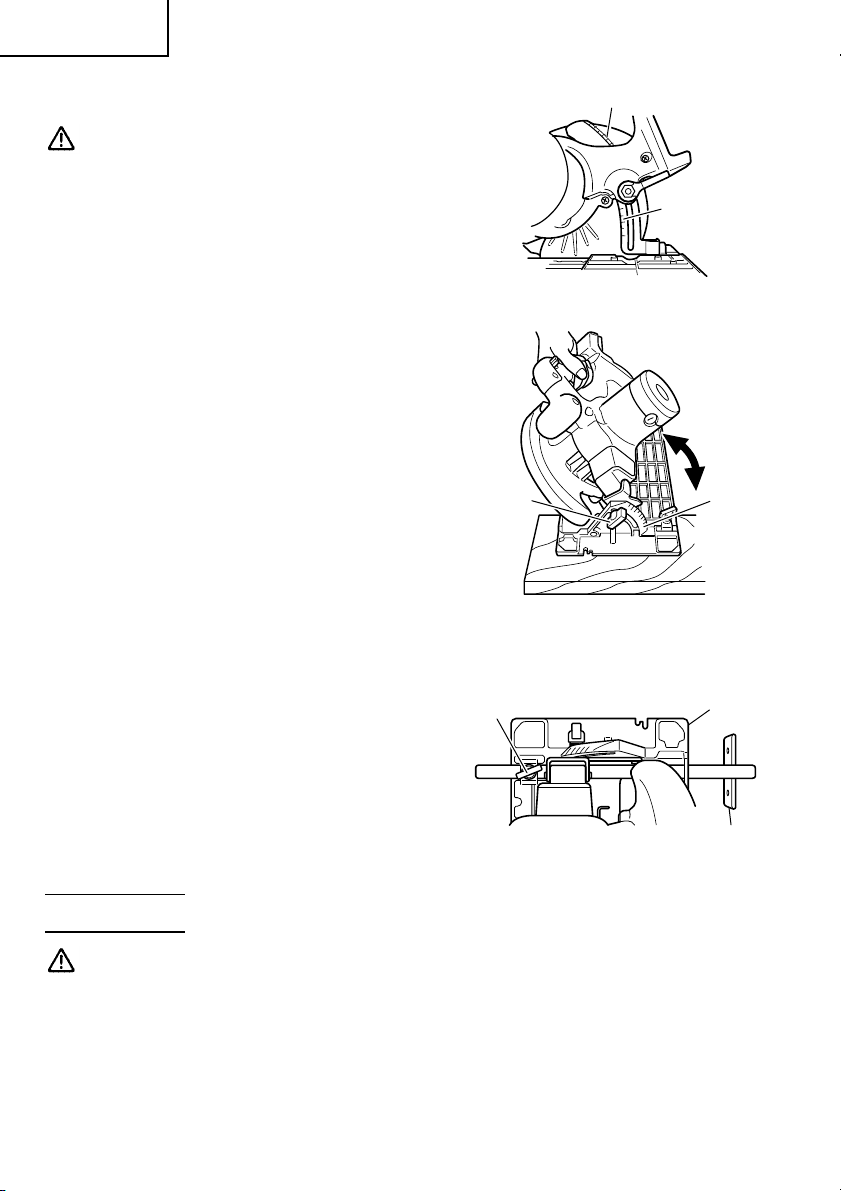

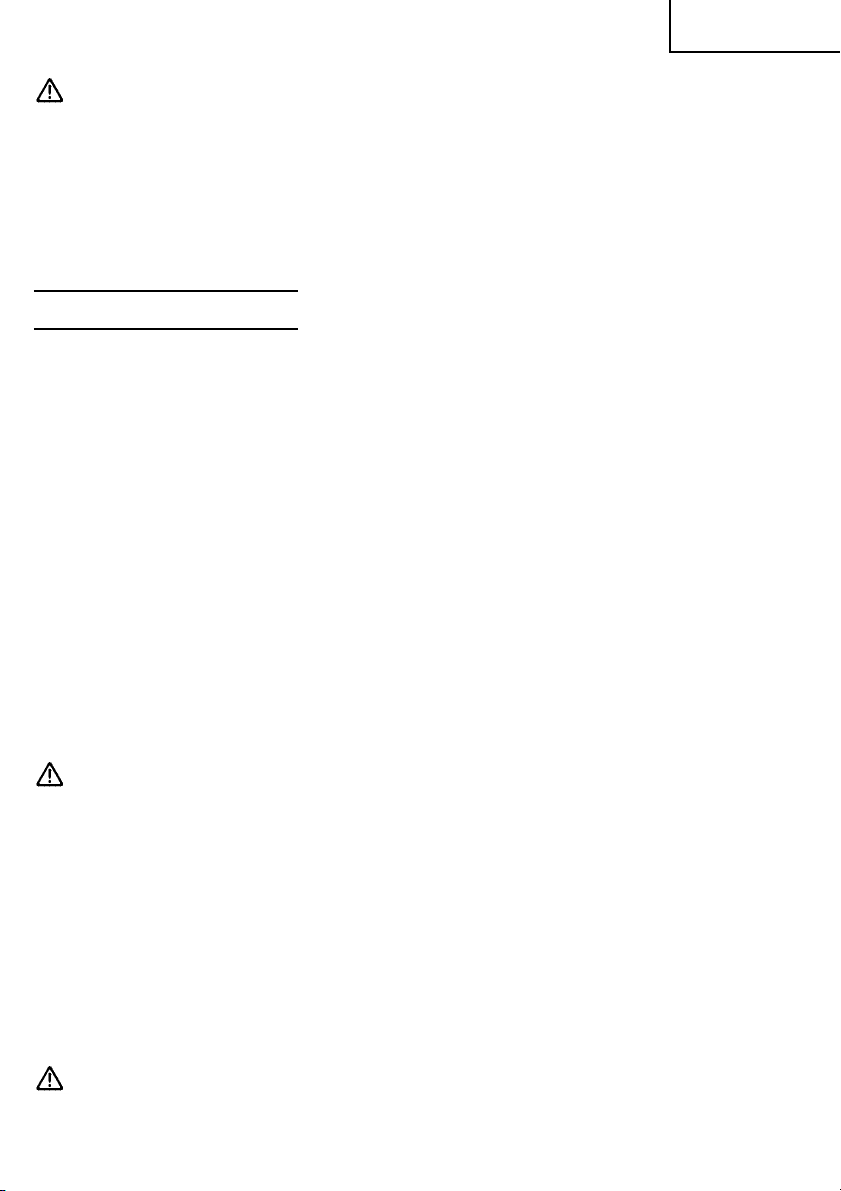

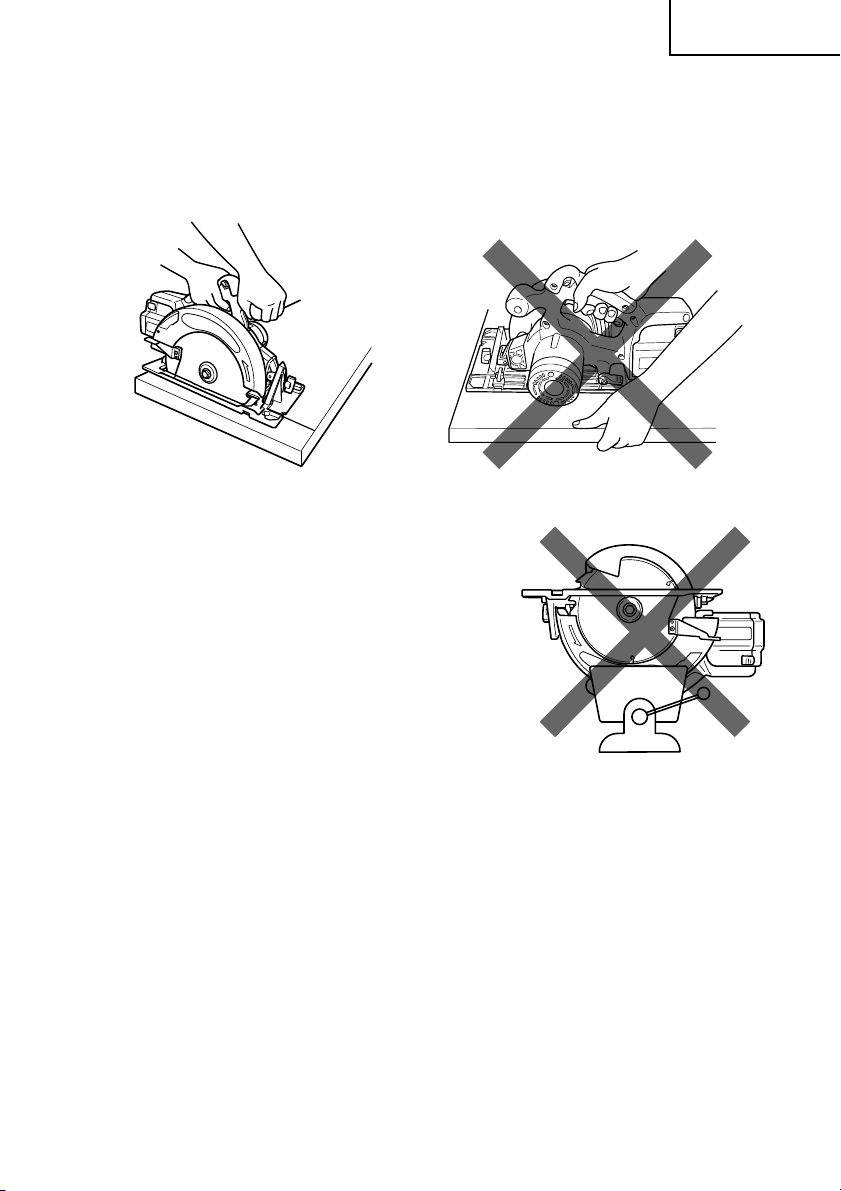

12. WARNING: It is important to support the work piece properly and to hold the saw firmly

to prevent loss of control which could cause personal injury. Fig. 4 illustrates typical hand

support of the saw.

A TYPICAL ILLUSTRATION OF PROPER HAND SUPPORT

AND WORK PIECE SUPPORT.

Fig. 4

13. Place the wider portion of the saw base on that part of the work piece which is solidly

supported, not on the section that will fall off when the cut is made. As examples, Fig.

5 illustrates the RIGHT way to cut off the end of board, and Fig. 6 the WRONG way. If the

work piece is short or small, clamp is down.

DON’T TRY TO HOLD SHORT PLACES BY HAND!

Fig. 5 Fig. 6

8

Page 9

English

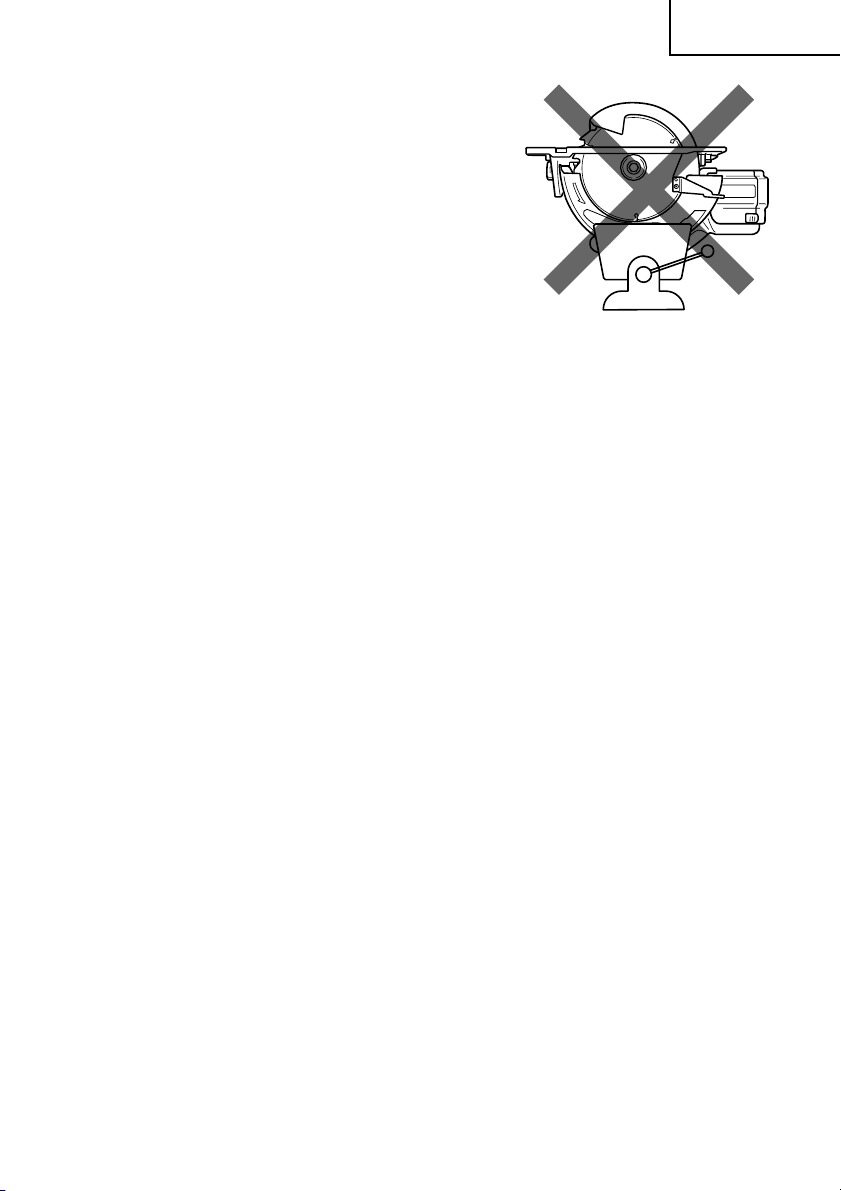

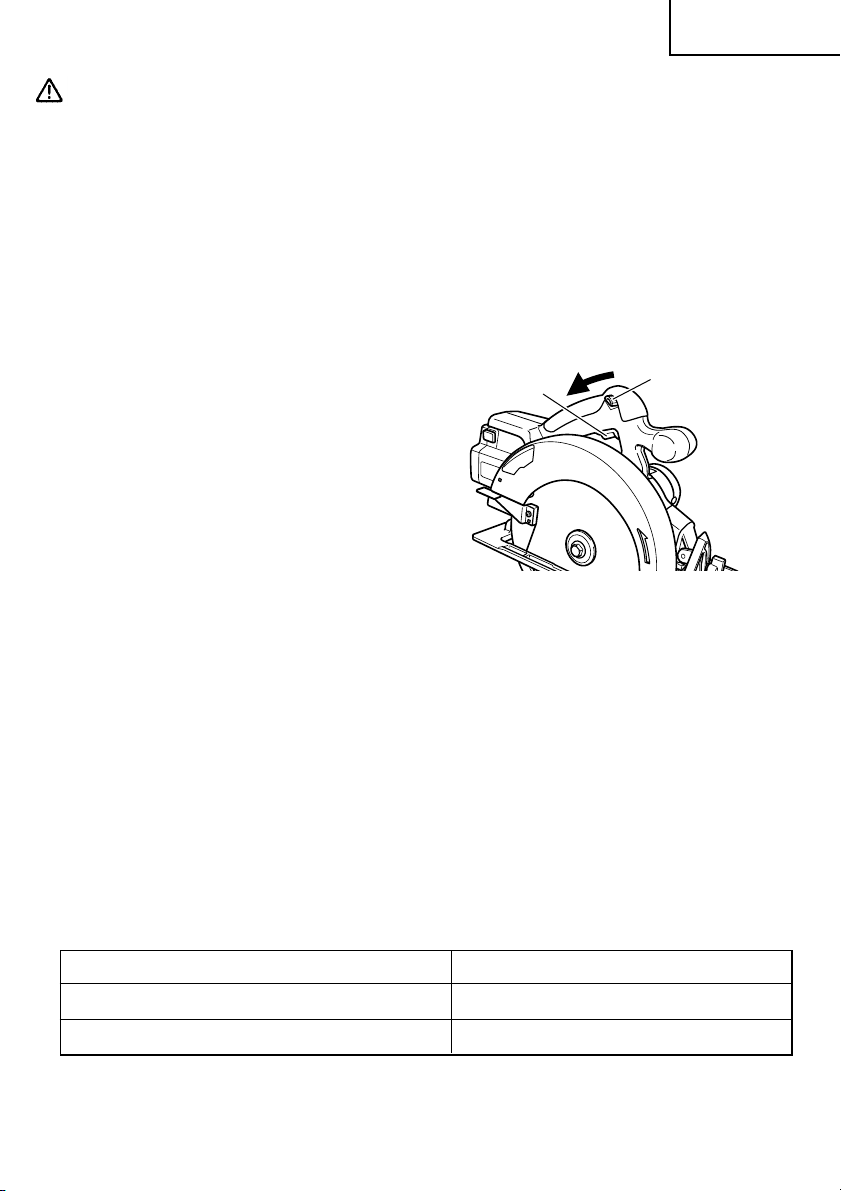

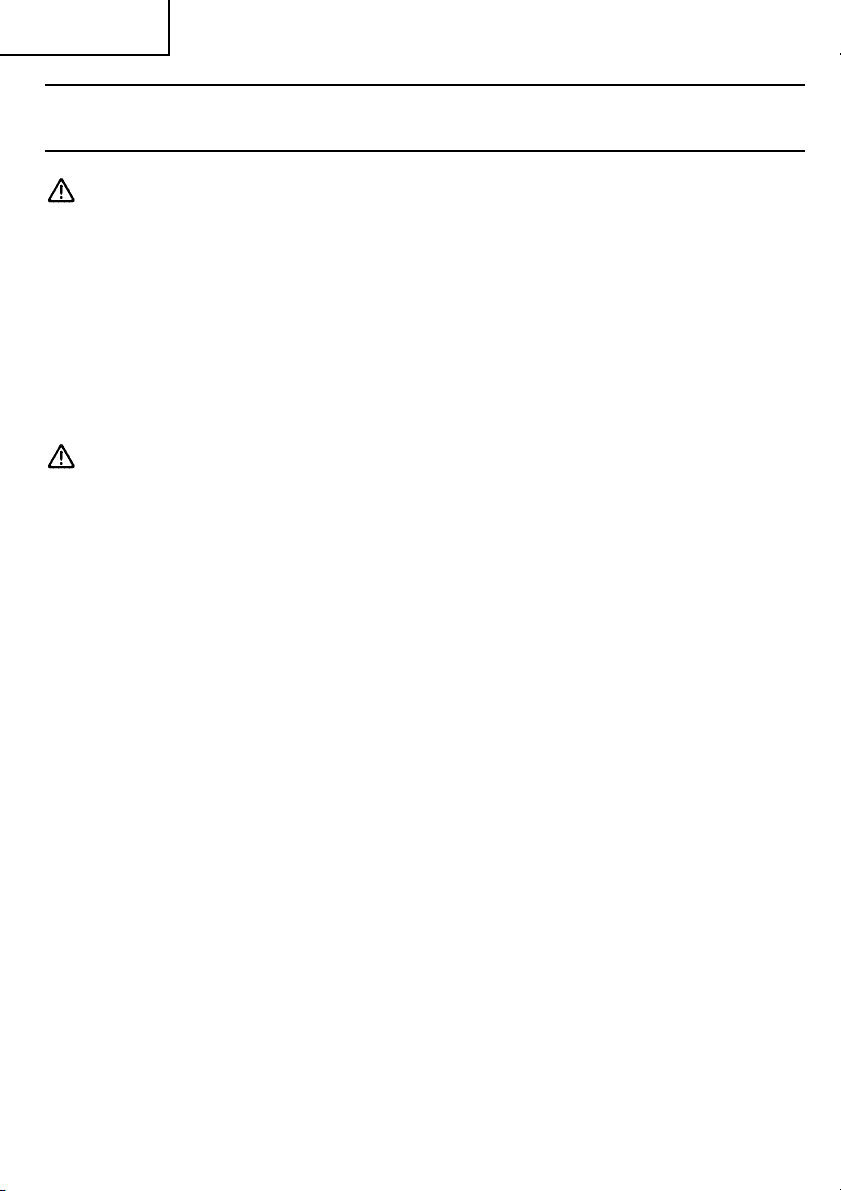

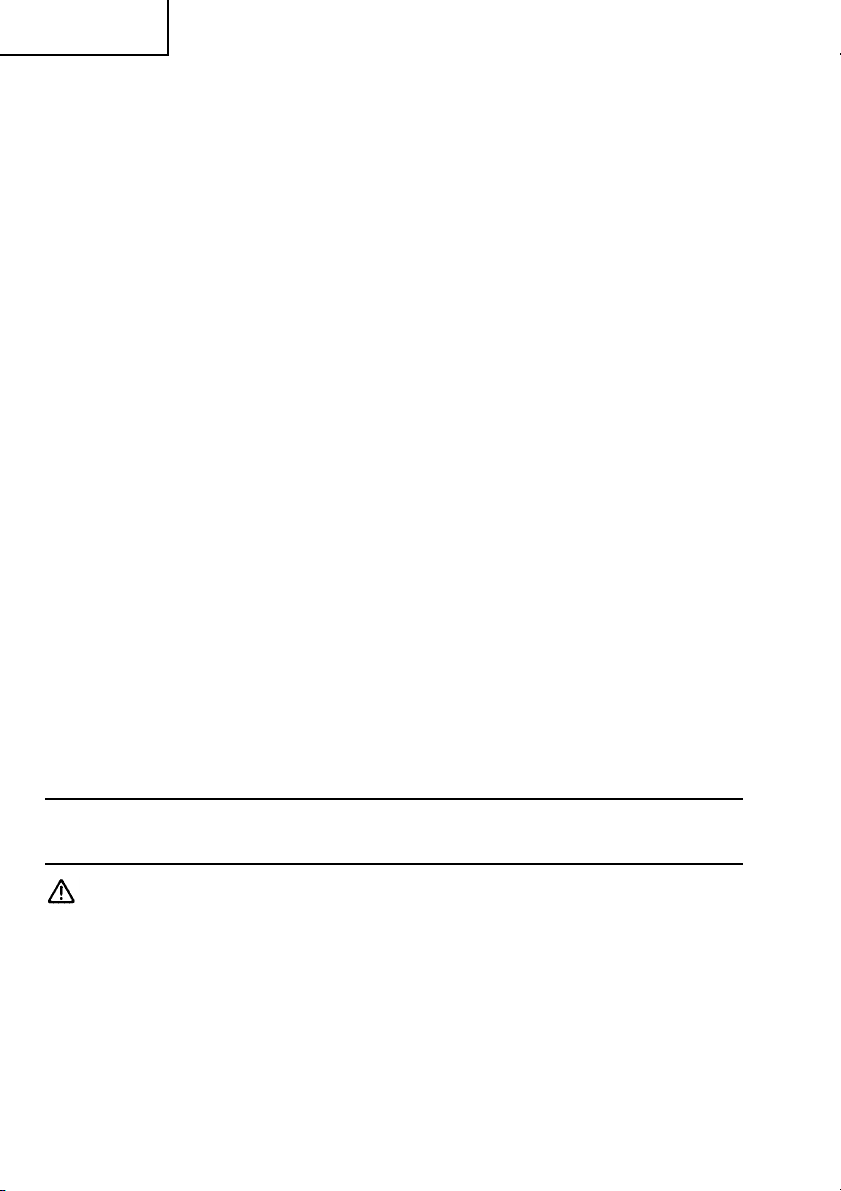

14. Never attempt to saw with the circular saw

held upside down in a vise. This is extremely

dangerous and can lead to serious accidents.

(Fig. 7)

Fig. 7

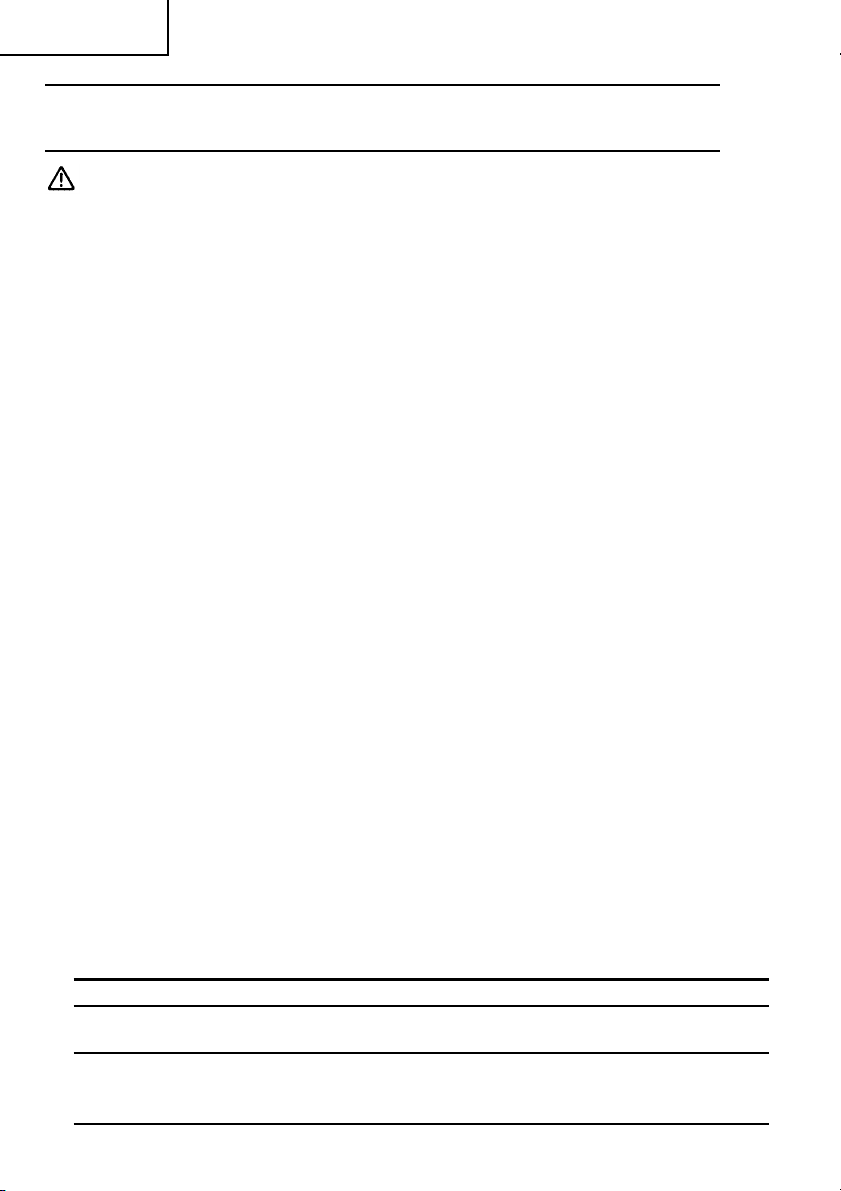

15. Never touch moving parts.

Never place your hands, fingers or other body parts near the tool’s moving parts.

16. Never operate without all guards in place.

Never operate this tool without all guards or safety features in place and in proper

working order. If maintenance or servicing requires the removal of a guard or safety

feature, be sure to replace the guard or safety feature before resuming operation of the

tool.

17. Use right tool.

Don’t force small tool or attachment to do the job of a heavy-duty tool.

Don’t use tool for purpose not intended —for example— don’t use circular saw for cutting

tree limbs or logs.

18. Never use a power tool for applications other than those specified.

Never use a power tool for applications other than those specified in the Instruction

Manual.

19. Handle tool correctly.

Operate the tool according to the instructions provided herein. Do not drop or throw the

tool. Never allow the tool to be operated by children, individuals unfamiliar with its

operation or unauthorized personnel.

20. Definitions for symbols

V ...... volts

—

................ direct current

---

................ no load speed

n

o

---/min ........ revolutions or reciprocation per minute

21. Keep all screws, bolts and covers tightly in place.

Keep all screws, bolts, and plates tightly mounted. Check their condition periodically.

22. Do not use power tools if the plastic housing or handle is cracked.

Cracks in the tool’s housing or handle can lead to electric shock. Such tools should not

be used until repaired.

23. Blades and accessories must be securely mounted to the tool.

Prevent potential injuries to youself or others. Blades, cutting implements and accessories which have been mounted to the tool should be secure and tight.

24. Never use a tool which is defective or operating abnormally.

If the tool appears to be operating unusually, making strange noises, or otherwise

appears defective, stop using it immediately and arrange for repairs by a Hitachi

authorized service center.

9

Page 10

English

25. Carefully handle power tools.

Should a power tool be dropped or struck against hard materials inadvertently, it may be

deformed, cracked, or damaged.

26. Do not wipe plastic parts with solvent.

Solvents such as gasoline, thinner benzine, carbon tetrachloride, and alcohol may

damage and crack plastic parts. Do not wipe them with such solvents.

Wipe plastic parts with a soft cloth lightly dampened with soapy water and dried

thoroughly.

10

Page 11

English

IMPORTANT SAFETY INSTRUCTIONS FOR USE OF THE

CORDLESS CIRCULAR SAW

WARNING: Death or serious bodily injury could result from improper or unsafe use

of the cordless circular saw. To avoid these risks, follow these basic

safety instructions:

1. Wear ear plugs when using the tool for extended periods. Prolonged exposure to high

intensity noise can cause hearing loss.

2. Never wedge or tie safety cover open. Check operation of safety cover before each use.

Do not use if safety cover does not close briskly over saw blade.

CAUTION: If saw is dropped, safety cover may be bent restricting full return.

3. In case the saw is accidentally dropped or hit, please confirm that there is no damage or

cracks to the saw blade or motor, etc. Damage and cracks or deformation can be the cause

of injury.

4. Never place hands or other body parts near the saw blade during operation. Hold the

circular saw by its handle only.

5. Because the cordless circular saw operates by battery power, be aware of the fact that it

can begin to operate at any time.

6. Wear eye and ear protection at all times.

7. When working at elevated locations, clear the area of other people and aware of

conditions below you.

8. It is important to support the work properly and to hold the saw firmly to prevent loss of

control which could cause personal injury.

9. Guard against kickback: Kickback occurs when the saw stalls rapidly and is driven back

towards the operator. Release switch immediately if blade binds or saw stalls.

• Keep blades sharp.

• Support the panel near the cut.

• Use guide when ripping.

• Don’t force tool.

• Stay alert exercise control

• Don’t remove saw from work during a cut while the blade is moving.

10. In operating, keep hold main body firmly.

11. Keep the light ON during cutting operation only. If it is lit ON in other cases, the main body

switch can be inadvertently turned ON, resulting in unexpected accidents.

11

Page 12

English

IMPORTANT SAFETY INSTRUCTIONS FOR BATTERY CHARGER

WARNING: Death or serious bodily injury could result from imprper or unsafe use

of battery chargers. To avoid these risks, follow these basic safety

instructions:

READ ALL INSTRUCTIONS

1. This manual contains important safety and operating instructions for battery charger

Model UC 24YFB.

2. Before using battery charger, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

3. To reduce risk of injury, charge HITACHI rechargeable battery type EB2420. Other type

of batteries may burst causing personal injury and damage.

4. Do not expose battery charger to rain or snow.

5. Use of an attachment not recommended or sold by the battery charger manufacturer may

result in a risk of fire, electric shock, or injury to persons.

6. To reduce risk of damage to electric plug and cord, pull by plug when disconnecting

battery charger.

7. Make sure cord is located so that it will not be stepped on, tripped over, or otherwise

subjected to damage or stress.

8. An extension cord should not be used unless absolutely necessary. Use of improper

extension cord could result in a risk of fire and electric shock.

If extension cord must be used make sure:

a. That blades of extension cord are the same number, size, and shape as those of plug

on battery charger:

b. That extension cord is properly wired and in good electrical condition; and

c. That wire size is large enough for AC ampere rating of battery charger as specified

in Table 1.

Table 1

RECOMMENDED MINIMUM AWG SIZE FOR

EXTENSION CORDS FOR BATTERY CHARGERS

AC Input Rating Amperes* AWG Size of Cord

Equal to or but less Length of Cord, Feet (Meter)

greater than than 25 (7.5) 50 (15) 100 (30) 150 (45)

0 2 18 18 18 16

2 3 18 18 16 14

3 4 18 18 16 14

* If the input rating of a battery charger is given in watts rather than in amperes, the

corresponding ampere rating is to be determined by dividing the wattage rating by the

voltage rating–for example:

1250watts

125 volts

12

= 10 amperes

Page 13

English

9. Do not operate battery charger with damaged cord or plug-replace them immediately.

10. Do not operate battery charger if it has received a sharp blow, been dropped, or otherwise

damaged in any way; take it to a qualified serviceman.

11. Do not disassemble battery charger; take it to a qualified serviceman when service or

repair is required. Incorrect reassembly may result in a risk of electric shock or fire.

12. To reduce risk of electric shock, unplug charger from receptacle before attempting any

maintenance or cleaning. Removing the battery will not reduce this risk.

13. This battery charger might be attached to HITACHI battery operated tools as a standard

accessory. In this case, please confirm instruction Manual of the HITACHI battery

operated tools before using the battery charger.

IMPORTANT SAFETY INSTRUCTIONS FOR USE OF THE

BATTERY AND BATTERY CHARGER

You must charge the battery before you can use the power tool. Before using the model

UC 24YFB battery charger, be sure to read all instructions and cautionary statements on it,

the battery and in this manual.

REMEMBER: USE ONLY HITACHI BATTERY TYPE EB2420. OTHER TYPES OF BATTERIES

MAY BURST AND CAUSE INJURY!

Follow these instructions to avoid the risk of injury:

WARNING: Improper use of the battery or battery charger can lead to serious injury.

To avoid these injuries:

1. NEVER disassemble the battery.

2. NEVER incinerate the battery, even if it is damaged or is completely worn out. The

battery can explode in a fire.

3. NEVER short-circuit the battery.

4. NEVER insert any objects into the battery charger’s air vents. Electric shock or

damage to the battery charger may result.

5. NEVER charge outdoors. Keep the battery away from direct sunlight and use only

where there is low humidity and good ventilation.

6. NEVER charge when the temperature is below 32°F (0°C) or above 104°F (40°C).

7. NEVER connect two battery chargers together.

8. NEVER insert foreign objects into the hole for the battery or the battery charger.

9. NEVER use a booster transformer when charging.

10. NEVER use an engine generator or DC power to charge.

11. NEVER store the battery or battery charger in places where the temperature may

reach or exceed 104°F (40°C).

12. ALWAYS operate charger on standard household electrical power (120 volts). Using

the charger on any other voltage may overheat and damage the charger.

13. ALWAYS wait at least 15 minutes between charges to avoid overheating the charger.

14. ALWAYS disconnect the power cord from its receptacle when the charger is not in use.

13

Page 14

English

SAVE THESE INSTRUCTIONS

AND

MAKE THEM AVAILABLE TO

OTHER USERS

AND

OWNERS OF THIS TOOL!

14

Page 15

English

FUNCTIONAL DESCRIPTION

NOTE: The information contained in this Instruction Manual is designed to assist you in the

safe operation and maintenance of the power tool.

NEVER operate, or attempt any maintenance on the tool unless you have first read

and understood all safety instructions contained in this manual.

Some illustrations in this Instruction Manual may show details or attachments that

differ from those on your own power tool

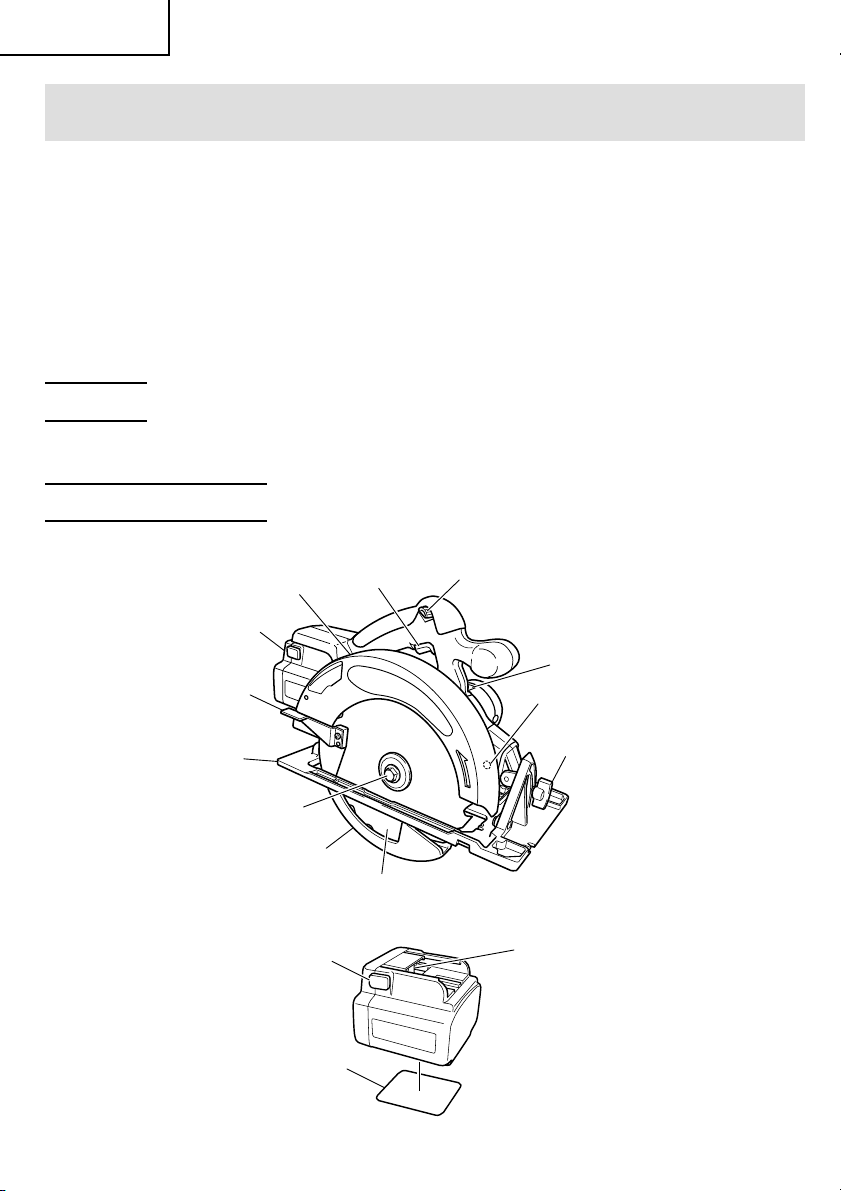

MODEL

C7D (BFK): with charger and case

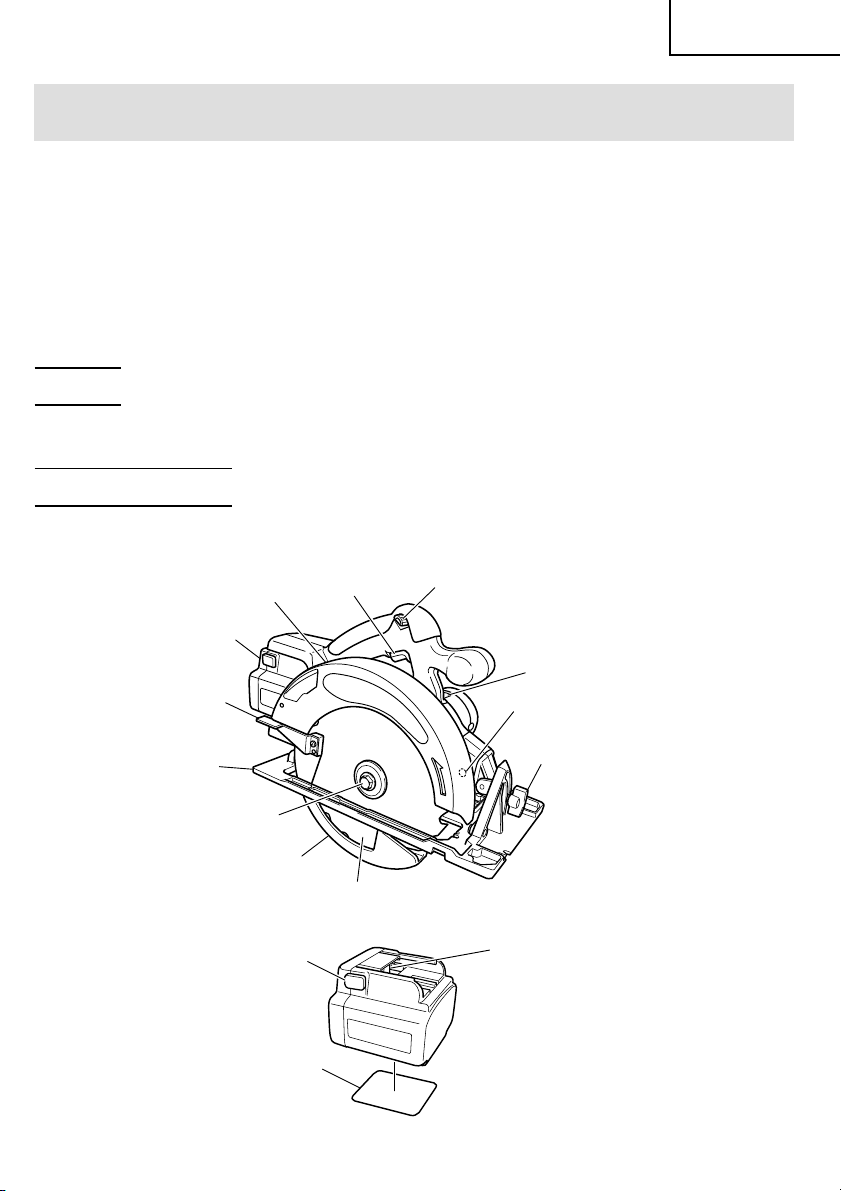

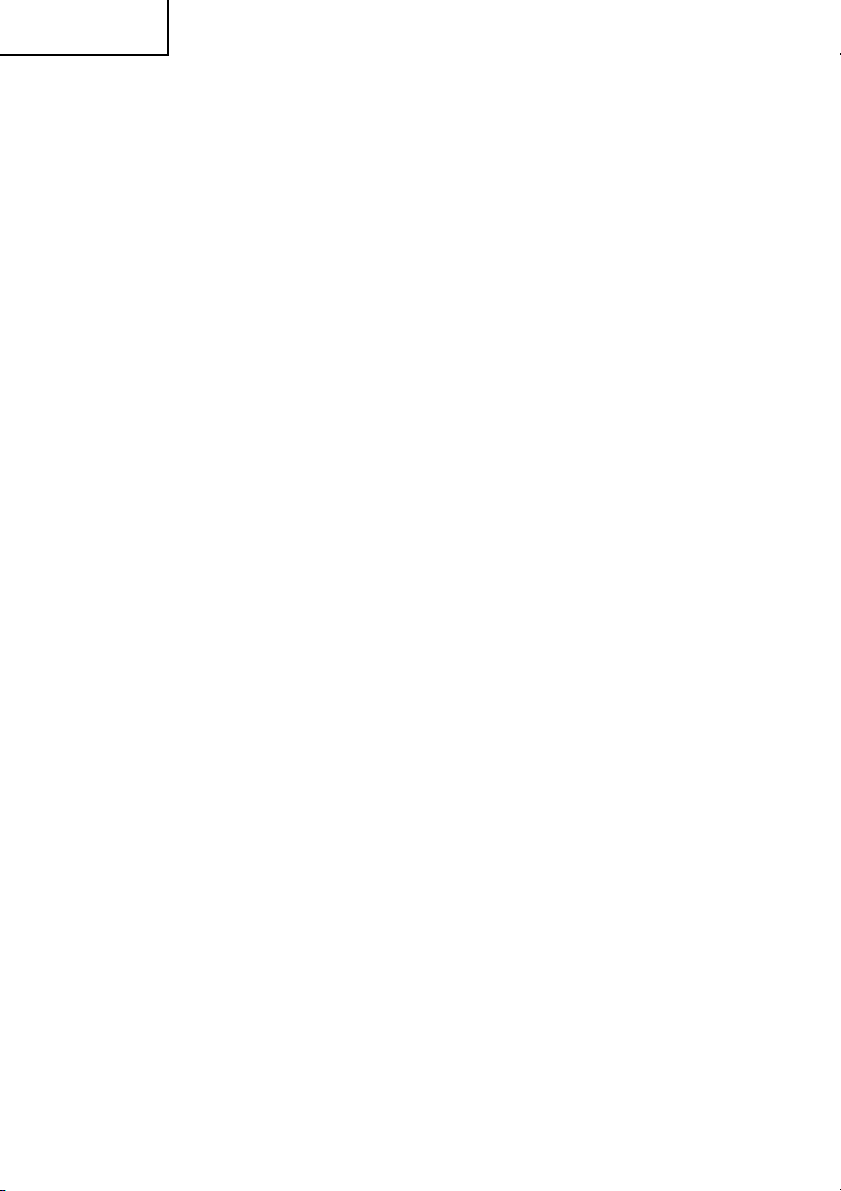

NAME OF PARTS

1. Cordless Circular Saw (C7D)

Saw Cover

Battery

Lever (RetractingHandle)

Base

Hexagonal-Flange Bolt

Safety Cover

(Lower Guard)

䡬 Battery (EB2420)

Switch Trigger

Latch

Nameplate

Saw Blade

Fig. 8

Switch Lock

Nameplate

Light

Wing Bolt (A)

Terminal Hole

15

Page 16

English

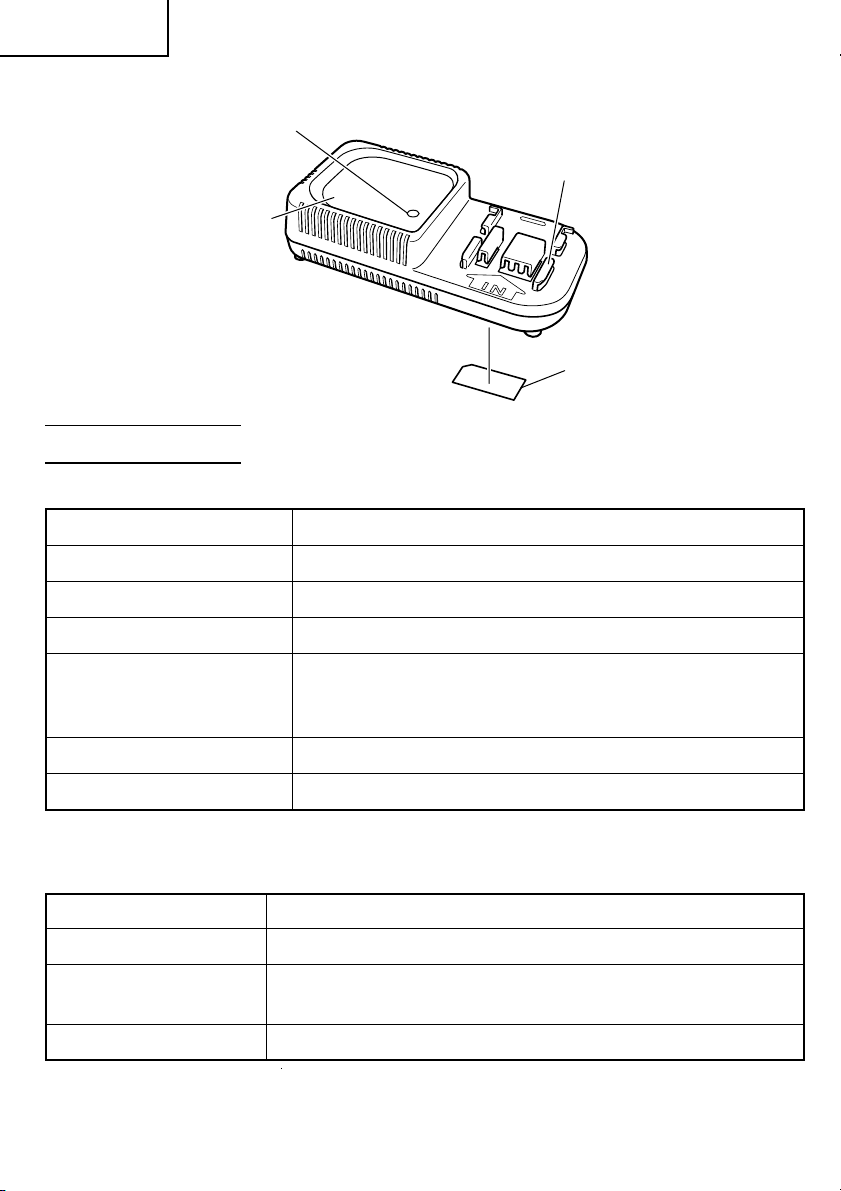

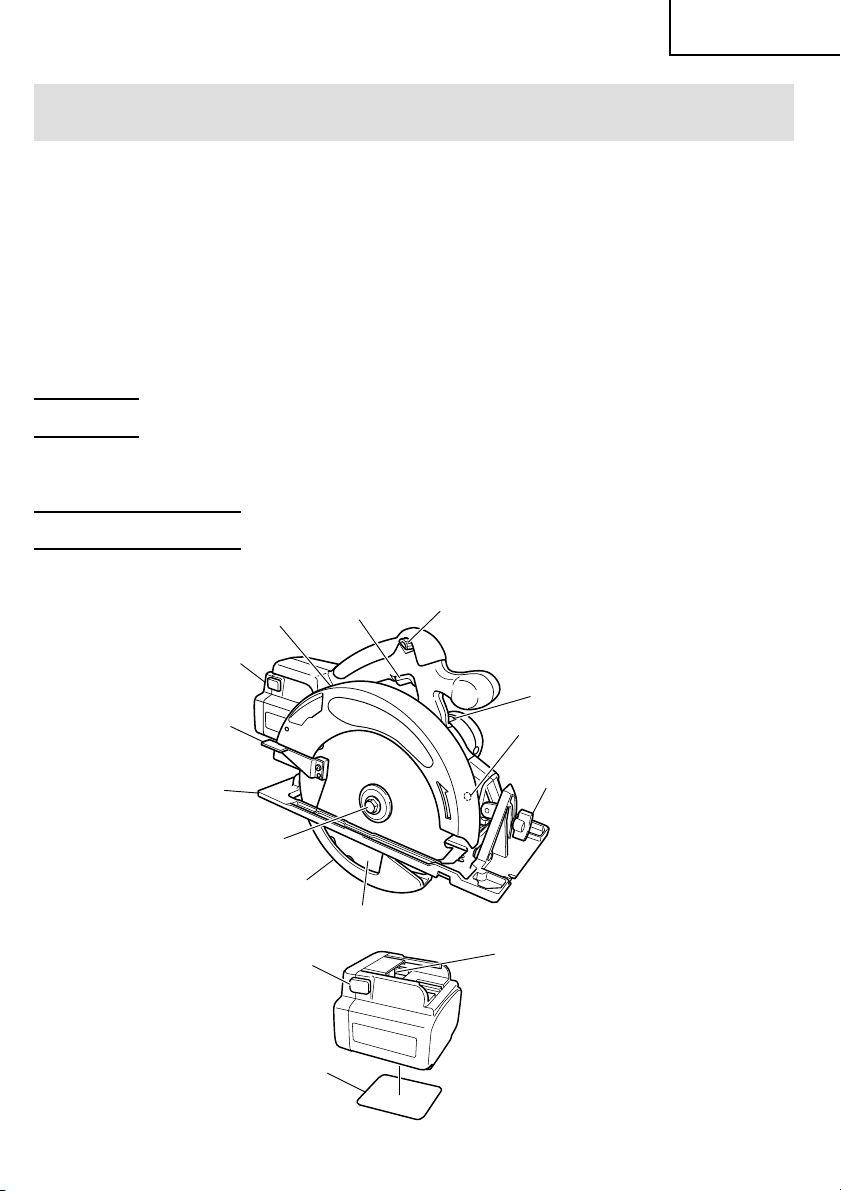

2. Battery Charger (UC 24YFB)

Pilot Lamp

Caution Plate

SPECIFICATIONS

1. Cordless Circular Saw (C7D)

Motor DC motor

No-load speed 2700/min

Max. Cutting Depth 2-3/8″ (60 mm)

Guide Rail

Nameplate

Fig. 9

Blade Size 7-1/4″ (185 mm) D × 5/8” (15.9 mm) H × 5/64” (2.0 mm) T

Battery (EB2420) Nickel cadmium battery

Voltage .................................................... DC24V

Charging and discharging frequency ... about 1000 times

Light Bulb 24V, 5W

Weight 11.0 lbs (5.0 kg)

2. Battery Charger (UC 24YFB)

Input power source Single phase: AC120V 60Hz

Charging time Approx. 50min. (At a temperature of 68°F (20°C))

Charger

Weight 1.3 lbs (0.6 kg)

16

Charging voltage ......................................... DC 24V

Charging current .......................................... DC 2.5A

Page 17

ASSEMBLY AND OPERATION

APPLICATIONS

䡬 Cutting Various types of wood.

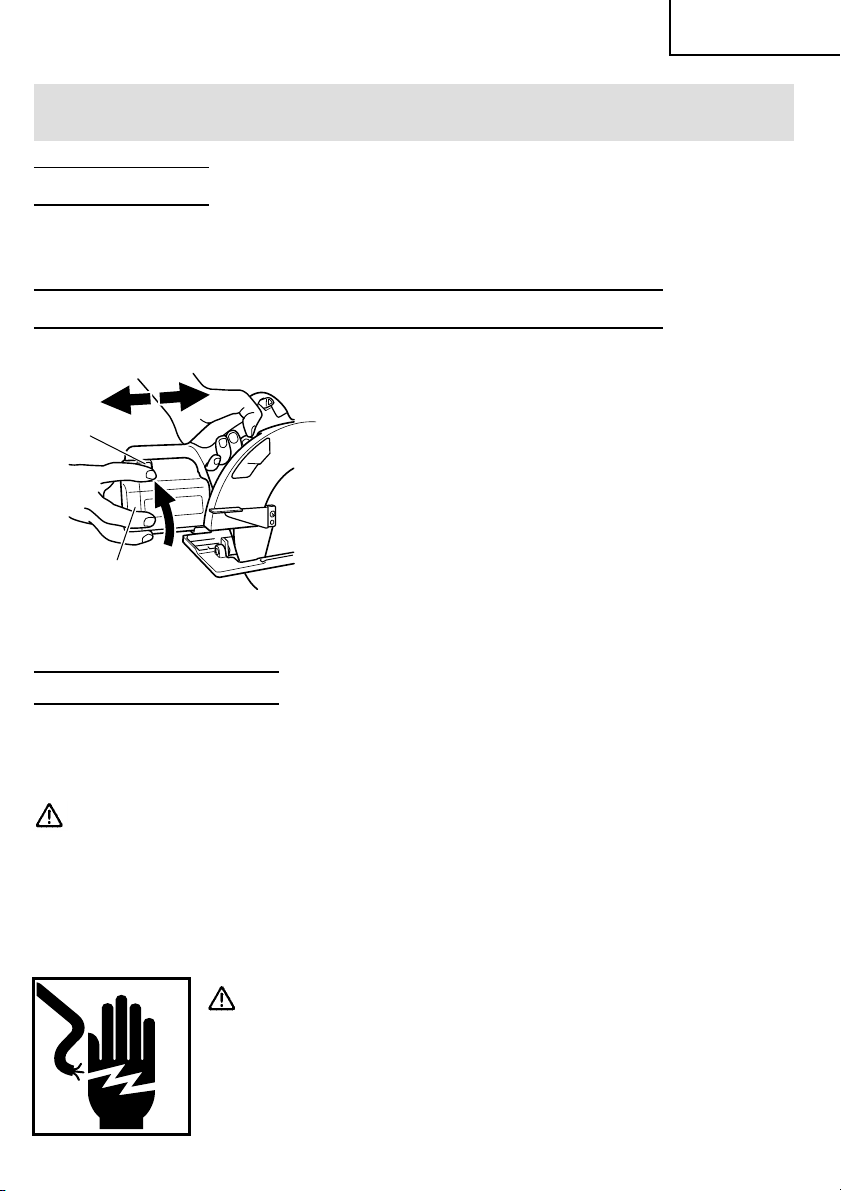

REMOVAL AND INSTALLATION METHOD OF BATTERY

English

Pull out

Latch

Battery

Insert

Push

Fig. 10

䡬 How to install the battery.

Align both guide rails of the battery and the

tool.

Always insert the battery all the way until it

locks in place with a little click, If not, it may

accidentally fall out of the tool, causing

injury to you or someone around you. (Fig.

4)

䡬 How to remove the battery.

Withdraw the battery from the tool while

pressing the latches on both sides of the

battery. (Fig. 4)

CHARGING METHOD

NOTE: Before plugging into the receptacle, make sure the following points.

䡬 The power source voltage is stated on the nameplate.

䡬 The cord is not damaged.

WARNING: Do not charge at voltage higher than indicated on the nameplate.

If charged at voltage higher than indicated on the nameplate, the

charger will burn out.

1. Insert the plug of battery charger into the receptacle.

When the plug of battery charger has been inserted into the receptacle, pilot lamp will

blink in red. (At 1-second intervals)

WARNING:

Do not use the electrical cord if damaged. Have it repaired

immediately.

17

Page 18

English

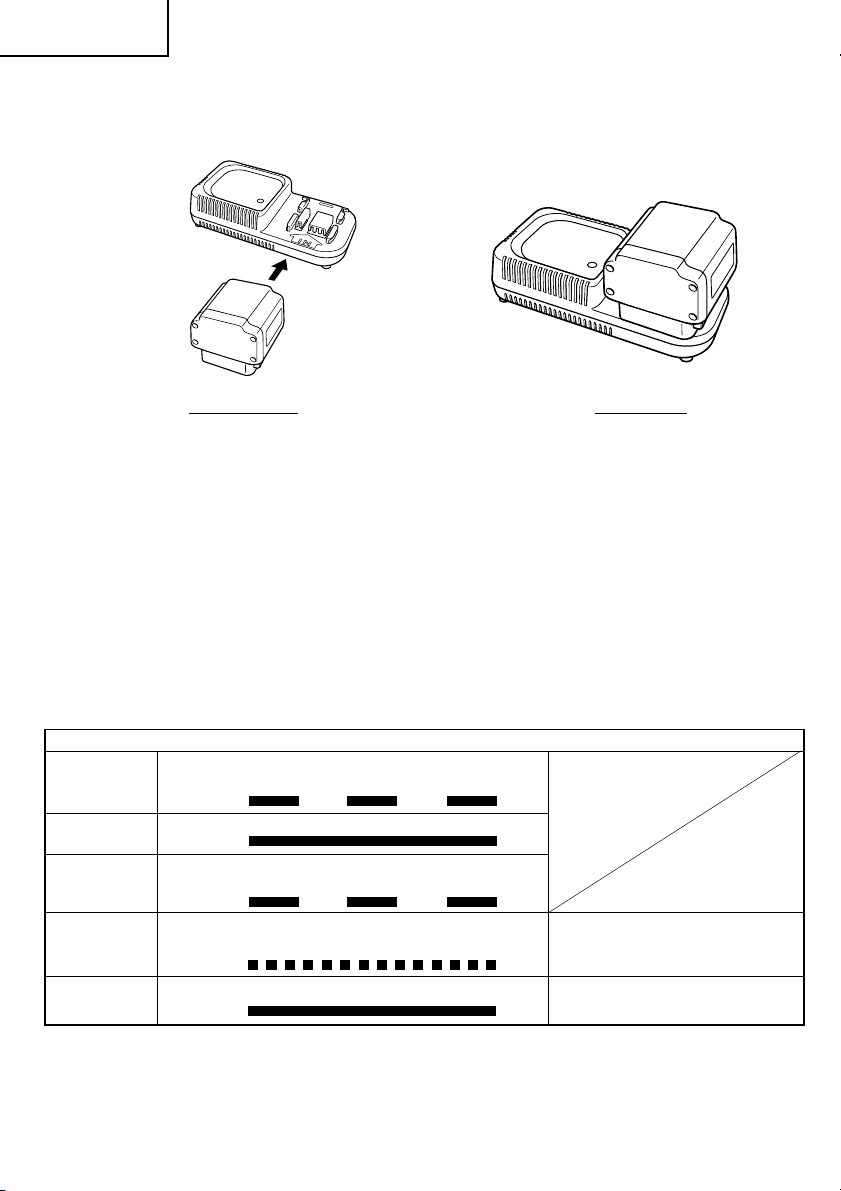

2. Insert the battery to the battery charger.

Insert the battery into the battery charger as shown in Fig. 11. Make sure the battery is

fully seated in the battery charger.

Before insert after insert

Fig. 11

3. Charging

䡬 When the battery is connected to the battery charger, charging will commence and the

pilot lamp will light in red. (See Table 2)

NOTE: If the pilot lamp flikers in red, pull out the plug from the receptacle and check if

the battery is properly mounted.

䡬 When the battery is fully charged, the pilot lamp will bilink in red slowly. (At 1-second

intervals) (See Table 2)

Table 2

Indications of the pilot lamp

Before

charging

While

charging

Charging

complete

Charging

impossible

Charging

impossible

18

Blinks

(RED)

Lights

(RED)

Blinks

(RED)

Flickers

(RED)

Lights

(GREEN)

Lights for 0.5 seconds. Does not light for

0.5 seconds. (off for 0.5 seconds)

Lights continuously

Lights for 0.5 seconds. Does not light for

0.5 seconds. (off for 0.5 seconds)

Lights for 0.1 seconds. Does not light for

0.1 seconds. (off for 0.1 seconds)

Lights continuously

Malfunction in the battery or the

charger

The battery temperature is high,

making recharging impossible.

Page 19

English

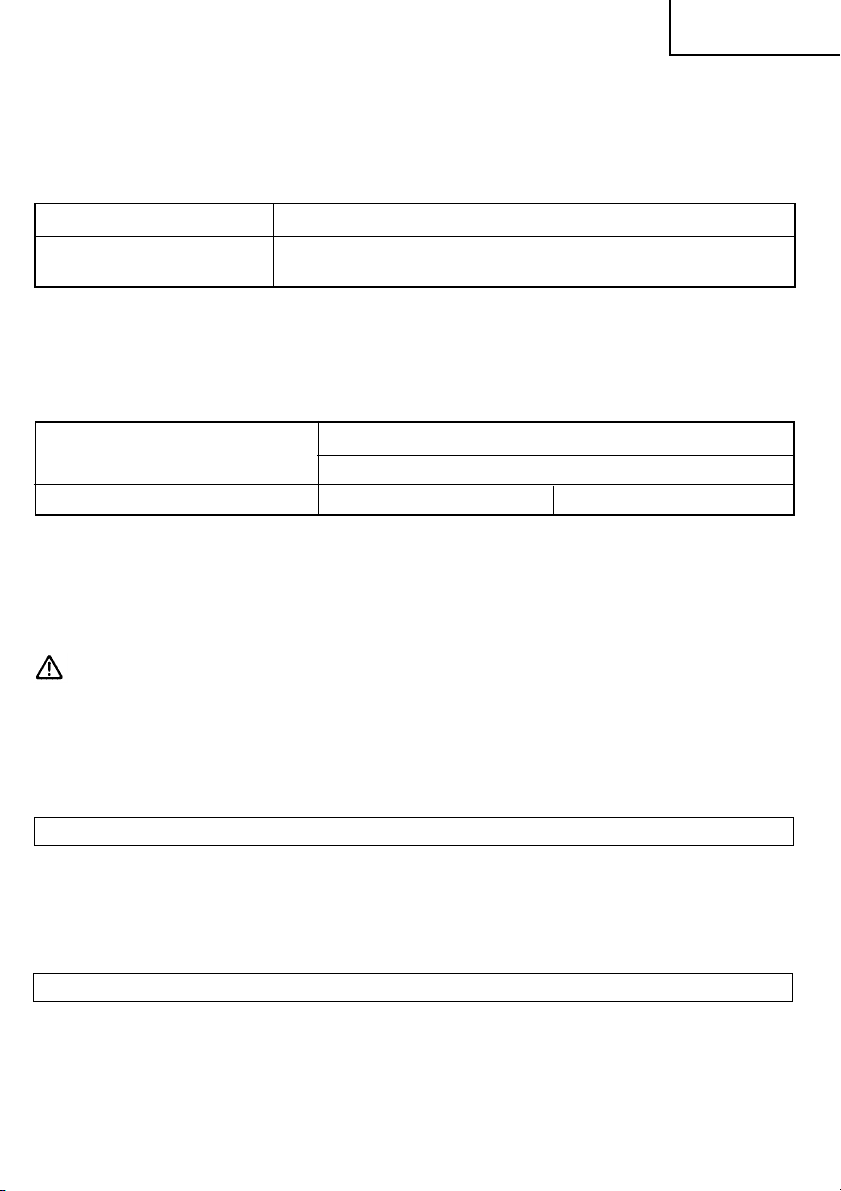

䡬 Regarding the temperature of the rechargeable battery.

The temperatures for rechargeable batteries are as shown in the table below, and

batteries that have become hot should be cooled for a while before being recharged.

Table 3

Rechargeable batteries

EB2420

䡬 Regarding recharging time

Table 4 shows the recharging time required according to the type of battery.

Table 4 Recharging time (approx. min.) at 68°F(20°C)

Battery Voltage (V)

24V EB2420 50min.

NOTE: The recharging time may vary according to ambient temperature and power

source voltage.

Temperatures at which the battery can be recharged

23°F — 140°F

(–5°C — 60°C)

Battery capacity (Ah)

2.0 Ah

4. Disconnect battery charger from the receptacle.

CAUTION:

Do not pull the plug out of the receptacle by pulling on the cord.

Make sure to grasp the plug when removing from receptacle to avoid damaging cord.

5. Remove the battery from the battery charger.

Supporting the battery charger by hand, pull out the battery from the battery charger.

Regarding electric discharge in case of new batteries, etc.

As the internal chemical substance of new batteries and batteries that have not been used

for an extended period is not activated, the electric discharge might be low when using

them the first and second time. This is a temporary phenomenon, and normal time

required for recharging will be restored by recharging the batteries 2 – 3 times.

How to make the batteries perform longer.

䡬 Recharge the batteries before they become completely exhausted.

When you feel that the power of the tool becomes weaker, stop using the tool and

recharge its battery. If you continue to use the tool and exhaust the electric current, the

battery may be damaged and its life will become shorter.

19

Page 20

English

䡬 Avoid recharging at high temperatures.

A rechargeable battery will be hot immediately after use. If such a battery is recharged

immediately after use, its internal chemical substance will deteriorate, and the battery life

will be shortened. Leave the battery and recharge it after it has cooled for a while.

CAUTION:

● When the battery charger has been continuosly used, the battery charger will heated,

thus constituting the cause of the failures. Once the charging has been completed, give

15 minutes rest until the next charging.

● If the battery is rechraged when it is warm due to battery use or exposure to sunlight,

the pilot lamp may light in green.

The battery will not be recharged. In such a case, let the battery cool before charging.

BEFORE USE

1. Check the work area environment.

Check the work area to make sure that it is clear of debris and clutter.

Clear the area of unnecessary personnel. Ensure that lighting and ventilation is adequate.

2. Check if saw blade is tightened

While the saw blade is tightened securely for immediate use when it is assembled at the

factory, be sure to check it out again for caution’s sake. A bolt can be tightened when it

is turned clockwise. Use the provided box wrench to check it out.

For further details, refer to the item of [MOUNTING AND DISMOUNTING THE SAW

BLADE] on Page 20.

3. Check if clamp lever is tightened

If the clamp lever to adjust cutting depth (Fig. 13) is loose, injury can result. Make sure

that it is tightened securely.

4. Check performance of safety cover

WARNING: Make absolutely sure that the safety cover is not fixed. Also, check and

see if it can move smoothly. If the saw blade is kept exposed, injury can

result.

The safety cover (refer to Fig. 8) serves to protect your body from coming into contact with

the saw blade. Make absolutely certain that the cover smoothly performs to cover the saw

blade. If the safety cover should not move smoothly, never use it without repairing it.

In such a case, get in touch with the store where you bought the circular saw or the

HITACHI Authorized Service Center for necessary repair.

5. Check battery insertion

WARNING: If the battery is inserted while the power switch is in the ON position,

the power tool will start operating immediately, inviting serious accident.

20

Page 21

English

CAUTION: Always insert the battery all the way until it locks in place with a little click,

if not, it may accidentally fall out of the tool causing injury to you or

someone around you.

6. Check for proper operation of the brake.

This circular saw features an electric brake that functions when the switch is released.

Before using the circular saw, ensure that the electric brake functions properly. If it does

not, bring the tool to an Hitachi Authorized Service Center.

7. Prepare a wooden work bench (Fig. 12)

Since the saw blade will extend beyond

the lower surface of the lumber, place the

lumber on a work bench when cutting. If

a square block is utilized as a work bench,

select level ground to ensure it is properly

stabilized. An unstable work bench will

result in hazardous operation.

CAUTION:

To avoid possible accident, always ensure

that the portion of lumber remaining

after cutting is securely anchored or held

in position.

ADJUSTING THE SAW PRIOR TO USE

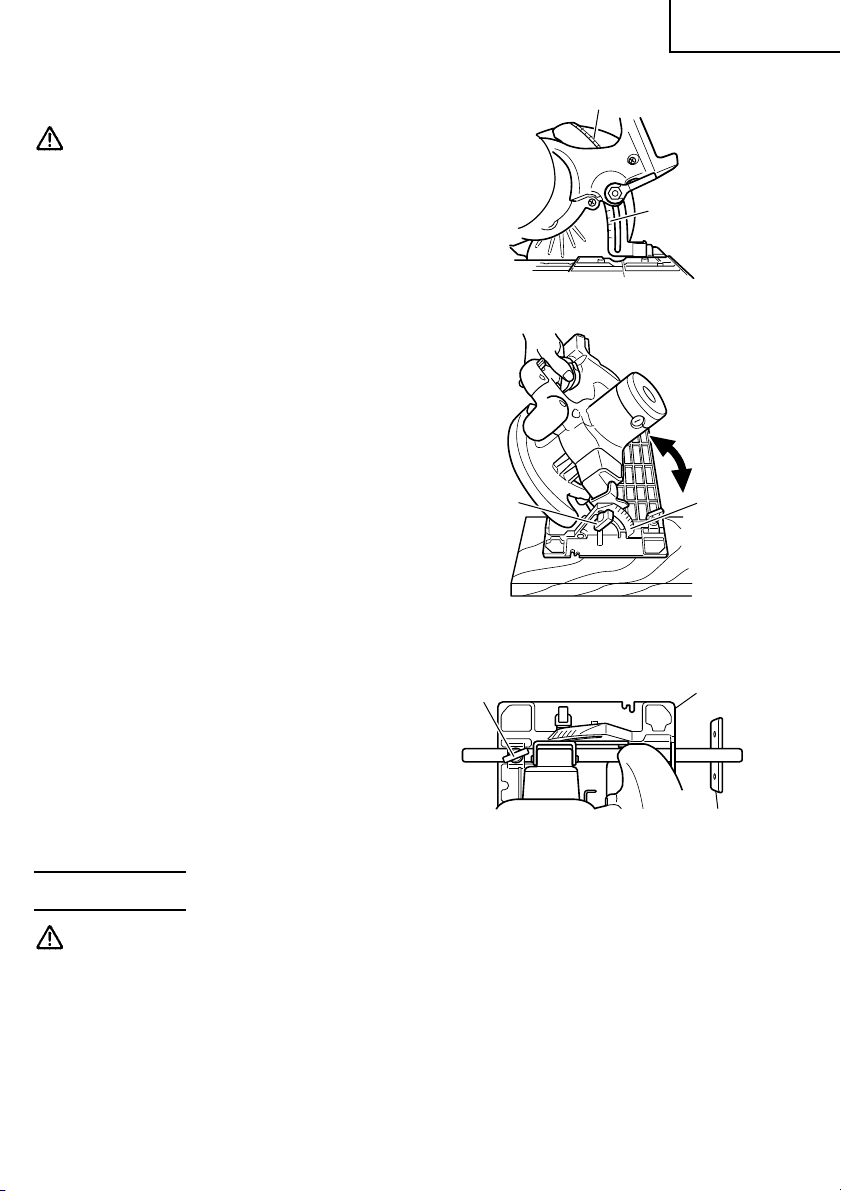

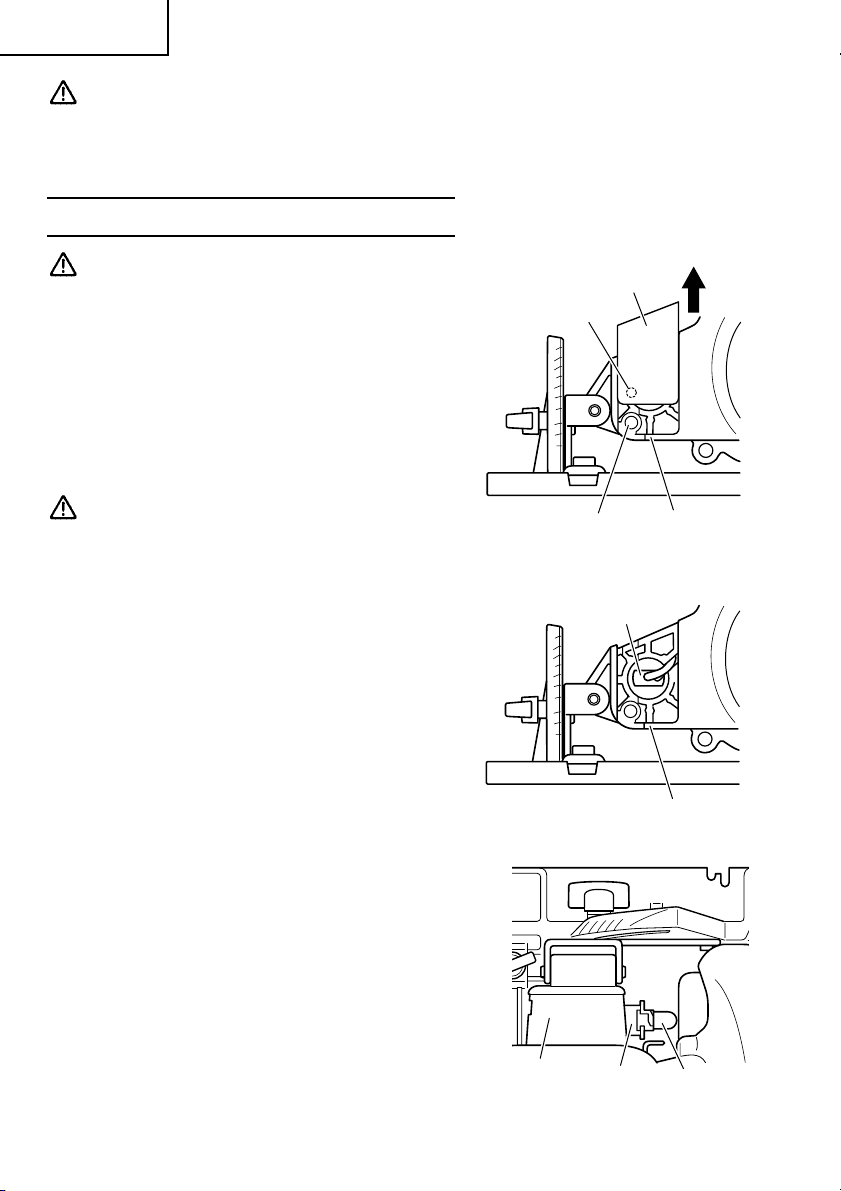

1. Adjusting the cutting depth (Fig. 13,

Fig. 14)

WARNING: If the clamp lever is loose,

injury can result. Tighten

it securely after adjustment.

Lumber

Work Bench

Base

Saw Blade

Fig. 12

Clamp Lever

Loosen

To adjust cutting depth, loosen the clmap

lever and, while holding the base with

one hand, move the main body up and

down to obtain the prescribed cutting

depth.

After adjusting to the prescribed cutting

depth, tighten the clamp lever securely.

Tighten

Base

Fig. 13

21

Page 22

English

2. Adjusting the angle of inclination

WARNING: If the wing bolt (A) is

loose, injury can result.

Tighten it securely after

adjustment.

As shown in Fig. 15 by loosening the wing

bolt (A) on the inclined gauge, the saw

blade may be inclined to a maximum

angle of 45° in relation to the base. Always

insure that the wing bolt (A) is thoroughly

tightened after making the desired

adjustment.

NOTE: Values of the inclined gauge pro-

vided on the base merely serve as

a rough guideline. For cutting

operation at an inclined posture,

use the circular saw after adjusting the angle between the base

and the saw blade with a protractor, etc.

3. Regulating the guide (Rip Fence)(Fig.

16)

................................. Optional Accessory

The cutting position can be regulated by

moving the guide to the left or right after

loosening its wing-bolt. The guide may

be mounted on either the right or left side

of the tool.

Inch Scale

Fig. 14

Wing-Bolt

(A)

Fig. 15

Wing Bolt, Lock spring

Metric Scale

Inclined

Gauge

Base

Fig. 16

Guide

(Rip Fence)

OPERATION

WARNING:

● Never touch the moving parts.

● Never operate the circular saw with the saw blade turned upward or to the side.

● Do not fix and secure the switch lock. Besides, keep your finger off the switch trigger

when the circular saw is being carried around. Otherwise, the main body switch can

be inadvertently turned ON, resulting in unexpected accidents.

● Keep the light ON during cutting operation only. If it is lit ON in other cases, the main

body switch can be inadvertently turned ON, resulting in unexpected accidents.

22

Page 23

English

CAUTION:

● Don’t remove circular saw from workpiece during a cut while the saw blade is

moving.

● Pull out the battery after completing operation.

NOTE:

Take care not to lock the motor. If the motor is locked, immediately turn the power off. If

the motor is locked for a while, the motor or battery may be burnt.

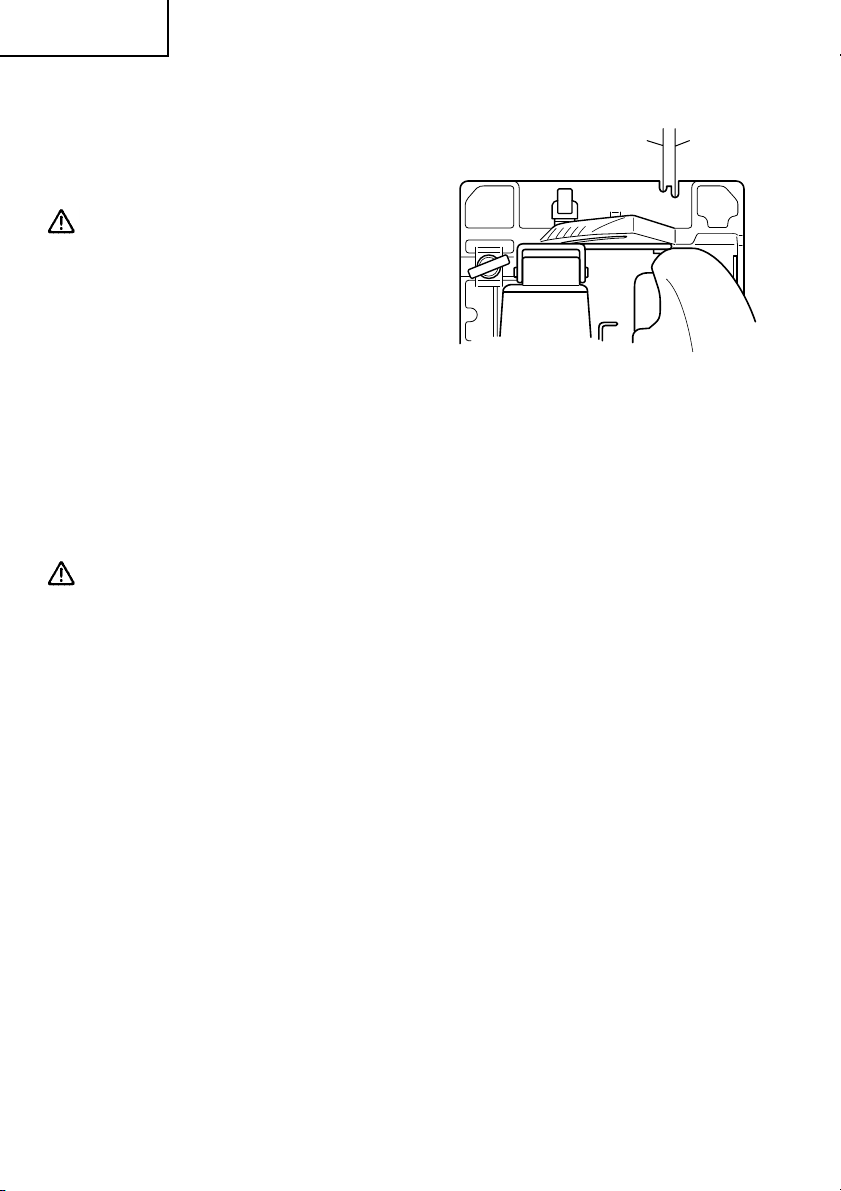

1. Operation of switch (switch trigger and light switch)

(1) For safe operation of the machine, a

“switch lock” is provided on the side of a

handle.

If the “switch lock” is pulled in a state

where it is pressed in the direction of the

arrow mark, the main switch can be

turned ON.

And the “switch lock” is used as the “light

switch”. If the “switch lock (light switch)”

is pulled in a state, the light is turned ON.

(2) After the switch is turned ON, even when

you release your hand from the switch

lock, the saw blade continues running

and the light continues being turned ON

as long as you keep on pulling the switch

trigger.

(3) If you release the switch trigger, you can turn OFF the switch and the “switch lock” returns

to the original position automatically and the light turns OFF too.

Switch Trigger

Switch Lock

(Be used as both

Switch Lock and

Light Switch)

Fig. 17

NOTE:

If the saw is set aside with the battery still installed, then depending on the orientation of

the saw, if the “Switch Lock” comes in contact with the floor surface or wall surface, the

light can remain on continuously. Please be aware that if the light is allowed to remain

on continuously, even a fully charged battery can be completely discharged in about 3

hours.

2. Working performance per single charge (Reference data)

䡬 Cutting capability differs according to the condition of lumber, type of saw blade, ambient

temperature, battery characteristics, etc.

Wood Capacity

2 × 8 (Spruce-Pine-Fir) 85 (cuts)

Concreteform plywood (1/2” (12 mm) t) 148 ft (45 m)

To improve working efficiency per single charge,

䡬 Minimize operation (no-load operation) other than cutting;

23

Page 24

English

䡬 Avoid any unreasonably forced pressure to the motor during cutting operation by

twisting or pressing the circular saw forcibly;

䡬 Avoid any use of dull saw blade.

When inclined 45°

When not

inclined

3. Cutting procedures

CAUTION:

● Recheck that the saw blade is se-

curely clamped.

● Confirm that the clamp lever for ad-

justing the slot depth, the wing-bolt

(A) for adjusting the angle of inclination.

(1) Place the saw body (base) on the lumber, and as in Fig. 18 align the intended line of cut

with the saw blade, using the notch at the front of the base. This relationship of base to

lumber should remain unchanged regardless of the inclination of the base.

(2) Ensure that the switch is turned to the ON position before the saw blade comes in contact

with the lumber. The switch is turned ON when the trigger is squeezed; and OFF when

the trigger is released.

(3) Moving the saw straight at a constant speed will produce optimum cutting.

CAUTION:

● Before starting to saw, ensure that the saw blade has reached full speed revolution.

● Should the saw blade be stopped or made an abnormal noise during operation, turn

off the switch immediately.

● When finished with a job, pull out the battery from the main body.

● Twisting and forcibly pressing the saw during cutting can result in unreasonable

pressure on the motor, so try to go straight quietly.

● In the situation where the circular saw is continuously operated while replacing the

battery with stocked spare batteries one after another, the motor tends to overheat.

Therefore, whenever the housing becomes hot, give the saw a break for a while.

● Avoid cutting operation in a state where the base bottom is afloat from the material

being cut. Otherwise, the motor can get locked.

Fig. 18

24

Page 25

MOUNTING AND DISMOUNTING THE SAW BLADE

English

CAUTION:

To avoid serious accident, ensure the

switch is in the OFF position, and pull out

the battery.

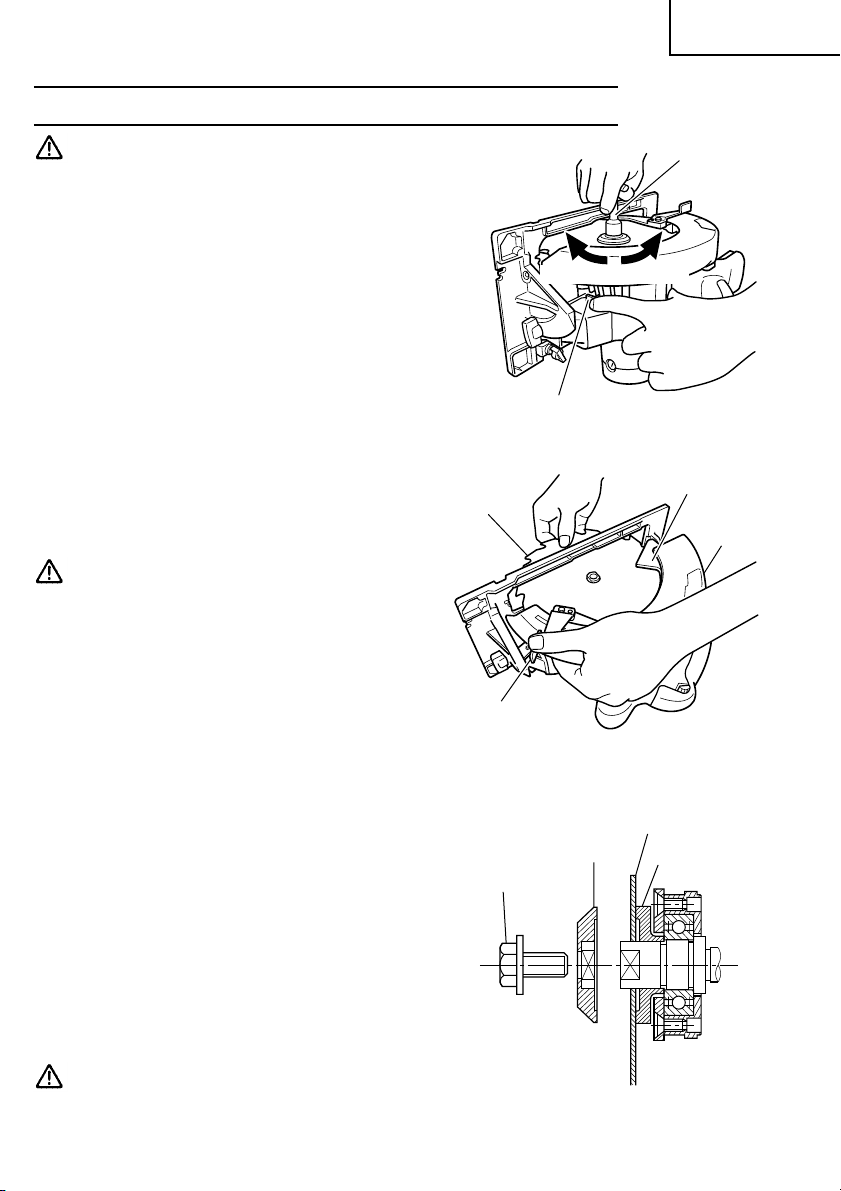

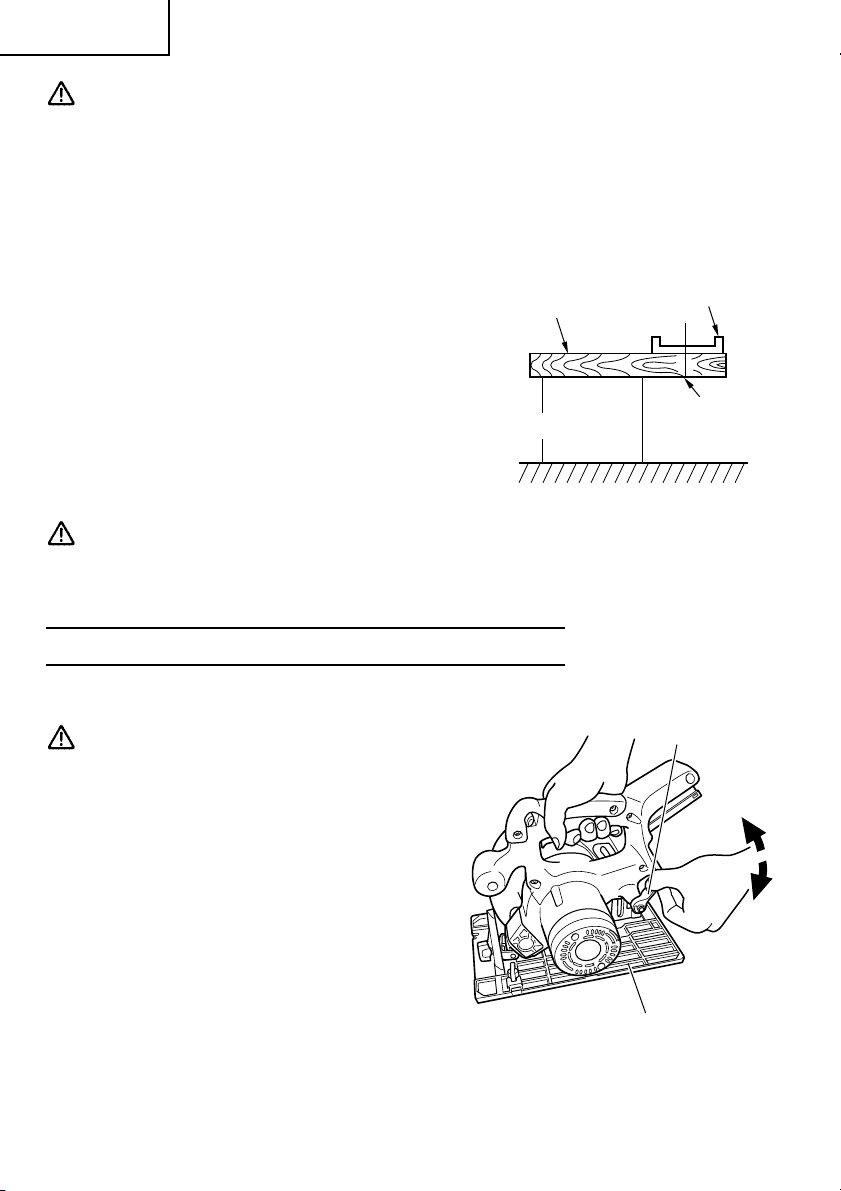

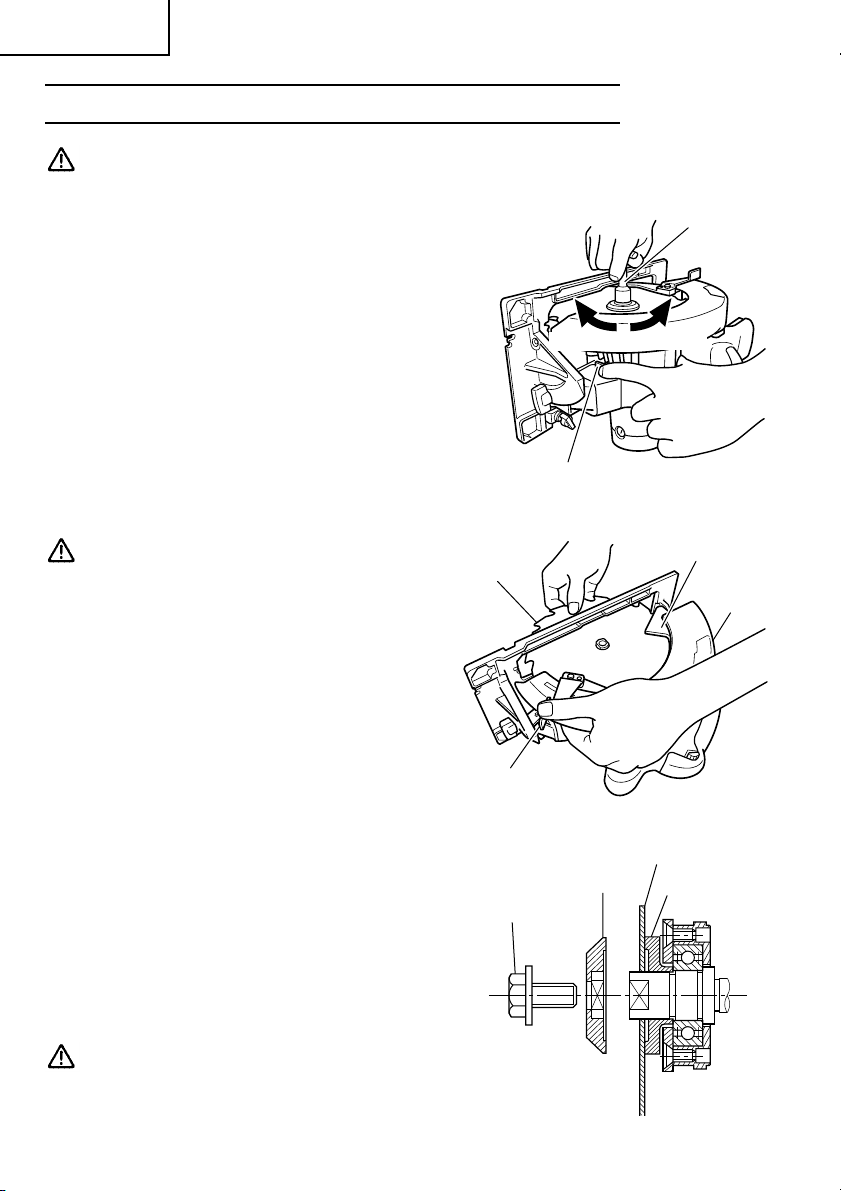

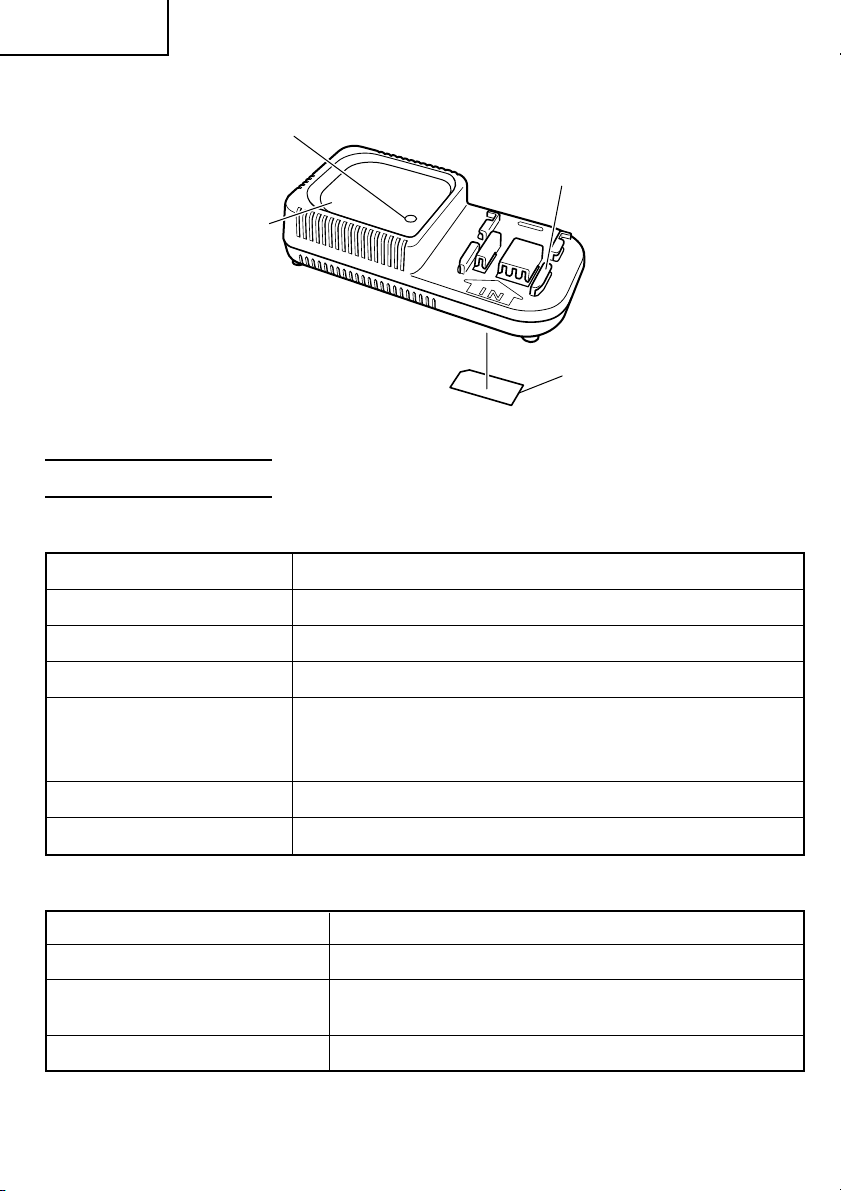

1. Dismounting the saw blade

(1) Set the cutting volume at maximum, and

place the Circular Saw as shown in

Fig. 19.

(2) Depress the lock lever, lock the spindle,

and remove the hexagonal-flange bolt

and washer(B) with the box wrench.

(3) While holding the safety cover lever to

keep the safety cover fully retracted into

the saw cover, remove the saw blade.

(Fig. 20)

2. Mounting the Saw Blade (Fig. 21)

WARNING:

If the bolt is worked using other tools

than the provided box wrench, excessive

tightening and insufficient tightening

may take place, resulting in injury.

䡬 Take procedures here that are contrary to

the detaching procedures.

Lock Lever

Saw

Blade

Safety Cover

Lever

Tighten

Fig. 19

Box Wrench

Loosen

Safety Cover

Saw Cover

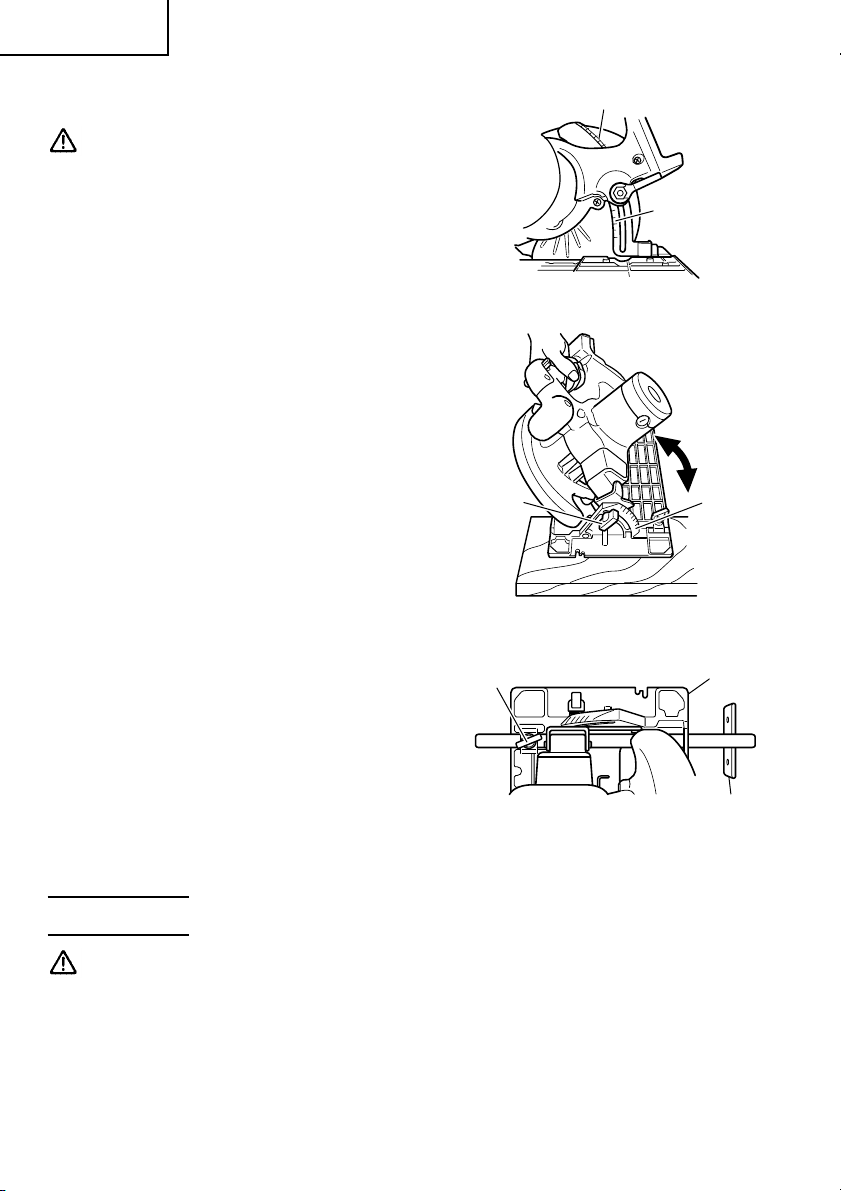

NOTE:

䢇 Thoroughly remove any sawdust which

has accumulated on the spindle, bolt and

washers.

䢇 To assure proper rotation direction of the

saw blade, the arrow direction on the saw

blade must coincide with the arrow

direction on the saw cover.

䢇 Using the fingers, tighten the hexagonal

flange bolt retaining the saw blade as

much as possible. Then depress the lock

lever, lock the spindle, and thoroughly

tighten the hexagonal flange bolt.

CAUTION:

After mounting the saw blade, reconfirm

that the lock lever is firmly secured in the

prescribed position.

Hexagonal

Flange Bolt

Fig. 20

Saw Blade

Washer (B)

Washer (A)

Fig. 21

25

Page 26

English

REPLACING LIGHT BULB

WARNING:

● Make absolutely sure that the battery is removed from the main body before

replacing the light bulb.

● Immediately after the light is turned OFF, the bulb retains high temperature. Make

sure to cool down the light bulb thoroughly before replacing it so as to prevent

burns.

CAUTION:

When replacing the light bulb, check the

shape of base as well as the rating (24 V,

5 W), and then carry out perfect mounting. Otherwise, the light bulb can come

off and/or cause overheat.

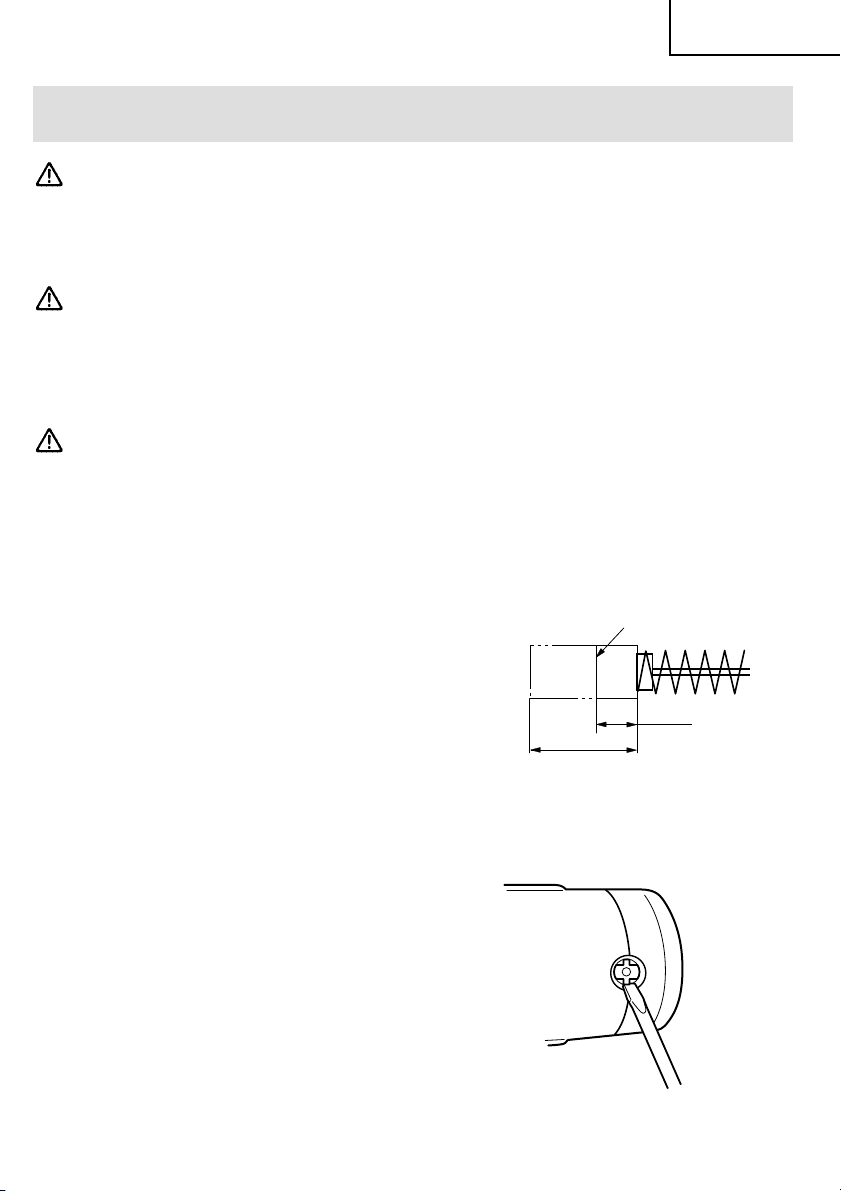

1. Detaching light bulb

(1) Remove the convex part of the light cover

from the concave part of the housing,

and then pull out the light cover in the

arrow-marked direction as shown in Fig.

22.

(2) Push the back of the socket, and remove

the socket and the light bulb together

from the housing. (Fig. 23)

(3) Remove the light bulb from the socket.

(Fig. 24)

2. Attaching light bulb

Take procedures here that are contrary

to the detaching procedures.

NOTE:

䢇 When attaching the light bulb to the

socket, insert the light bulb until it lightly

bumps against the socket.

䢇 When attaching the socket to the housing,

align the socket with the hole of housing

while watching the back of the socket

shown in Fig. 23, and insert the socket

until it lightly bumps against the housing.

Light Cover

Convex

Concave

Fig. 22 〈Side View〉

Back of the Socket

Housing

Fig. 23

Housing

Housing

26

Socket

Fig. 24 〈Top View〉

Light Bulb

Page 27

English

MAINTENANCE AND INSPECTION

CAUTION: Pull out battery before doing any inspection or maintenance.

1. Inspecting the saw blade:

Since use of a dull saw blade will degrade efficiency and cause possible motor

malfunction, sharpen or replace the saw blade as soon as abrasion is noted.

CAUTION:

If a dull saw blade is used, reactive force is increased during cutting operation. Avoid

the use of the dull saw blade without repair.

2. Check the screws

Loose screws are dangerous. Regularly inspect them and make sure they are tight.

CAUTION: Using this power tool with loosened screws is extremely dangerous.

3. Performance checkup and maintenance of safety cover

Keep the safety cover in good shape for smooth performance at all times. Be sure to make

prompt repair in case of any malfunction.

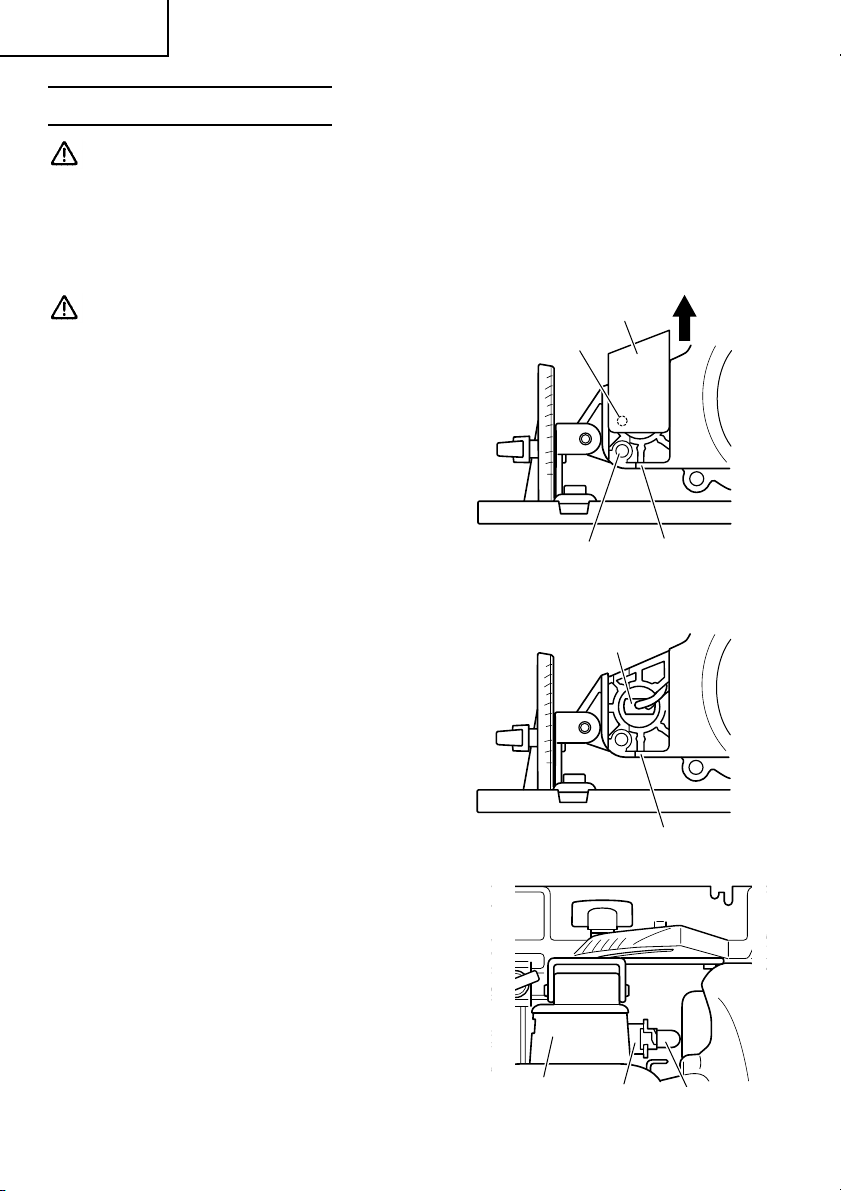

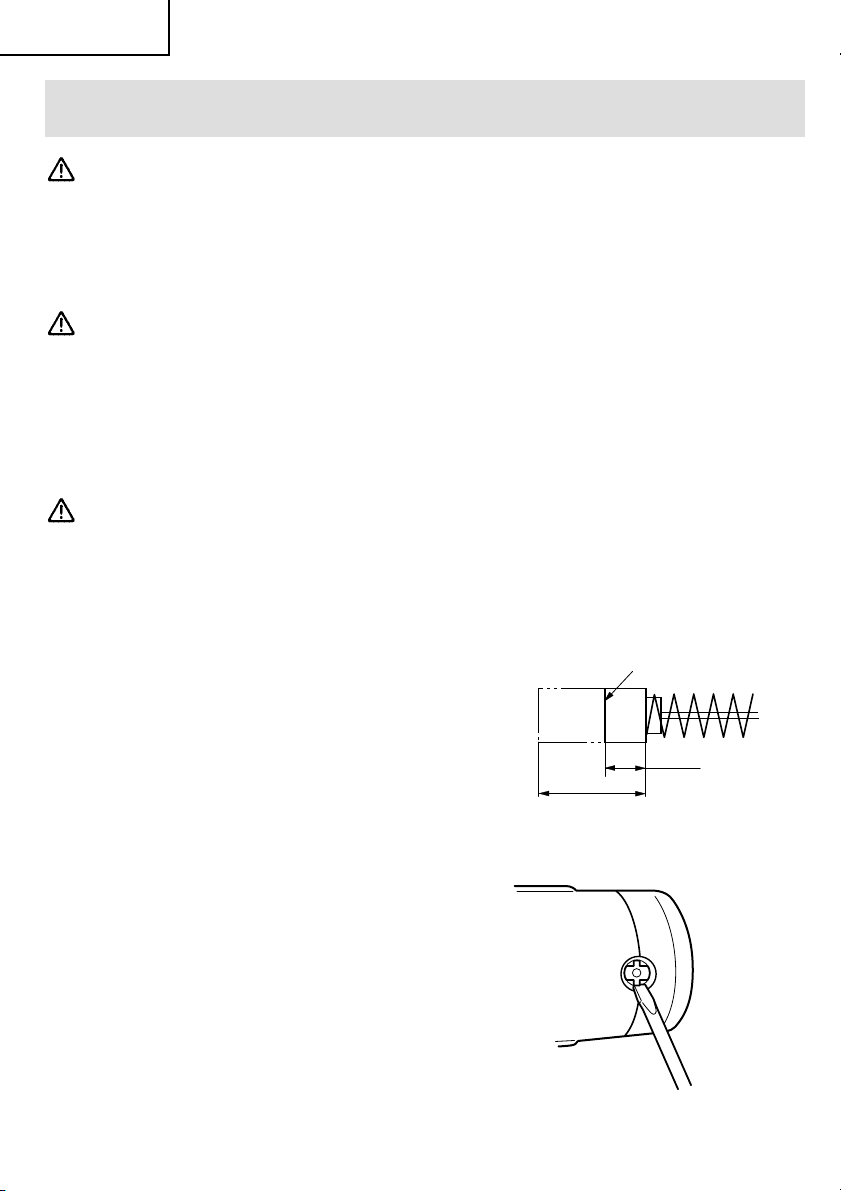

4. Inspecting the carbon brushes (Fig. 25)

The motor employs carbon brushes which

are consumable parts. Since and

excessively worn carbon brush can result

in motor trouble, replace the carbon brush

with new ones when it becomes worn to

or near the “wear limit”. In addition,

always keep carbon brushes clean and

ensure that they slide freely within the

brush holders.

NOTE:

When replacing the carbon brush with a

new one, be sure to use the Hitachi Carbon

Brush Code No. 999058.

(11.5mm)

Wear limit

0.12″ (3mm)

0.45″

Fig. 25

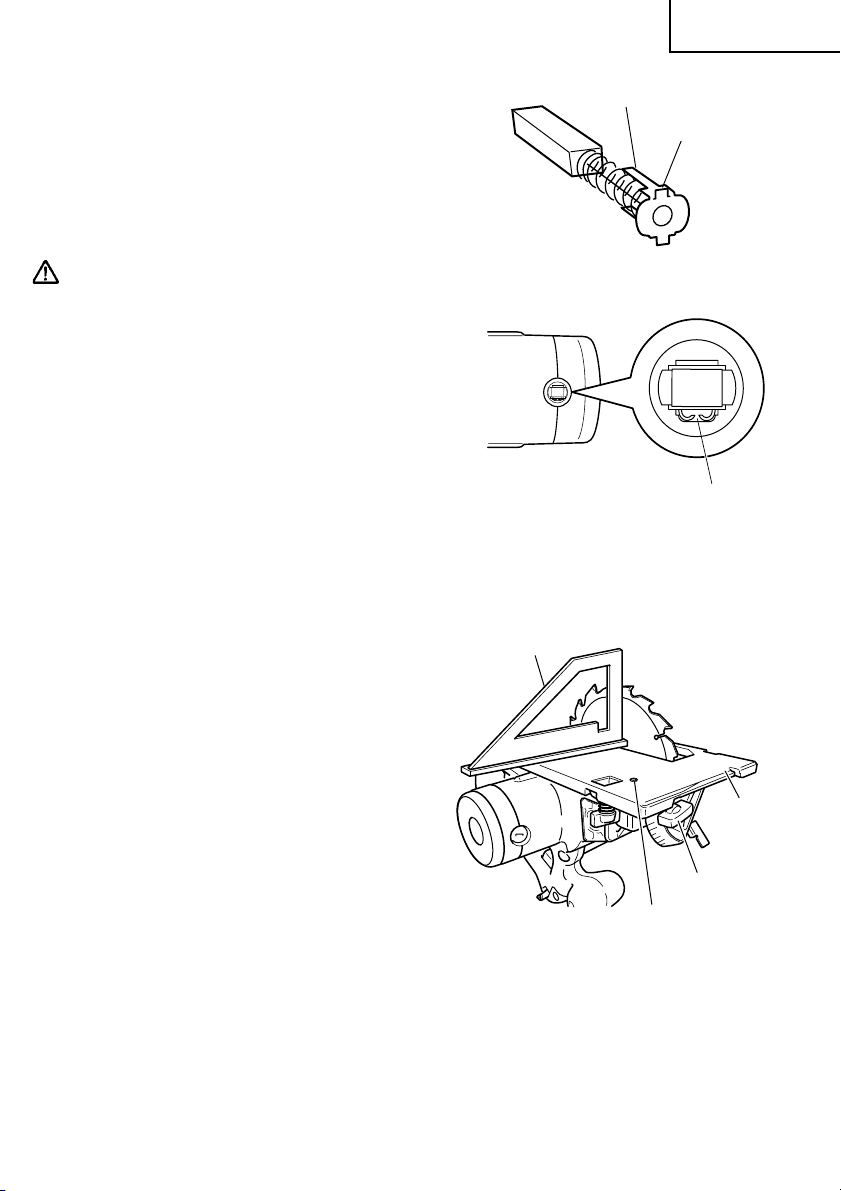

5. Replacing carbon brushes

Take out the carbon brush by first

removing the brush cap and then hooking

the protrusion of the carbon brush with a

slotted-head screw driver, etc., as shown

in Fig. 26, Fig. 27.

When installing the carbon brush, choose

the direction so that the nail of the carbon

brush (Fig. 27) agrees with the contact

portion outside the brush tube (Fig. 28).

Then push it in with a finger.

Lastly, install the brush cap.

Fig. 26

27

Page 28

English

CAUTION:

Be absolutely sure to insert the nail of the

carbon brush into the contact portion

outside the brush tube. (You can insert

whichever one of the two nails provided.)

Caution must be exercised since any error

in this operation can result in the

deformed nail of the carbon brush and

may cause motor trouble at an early

stage.

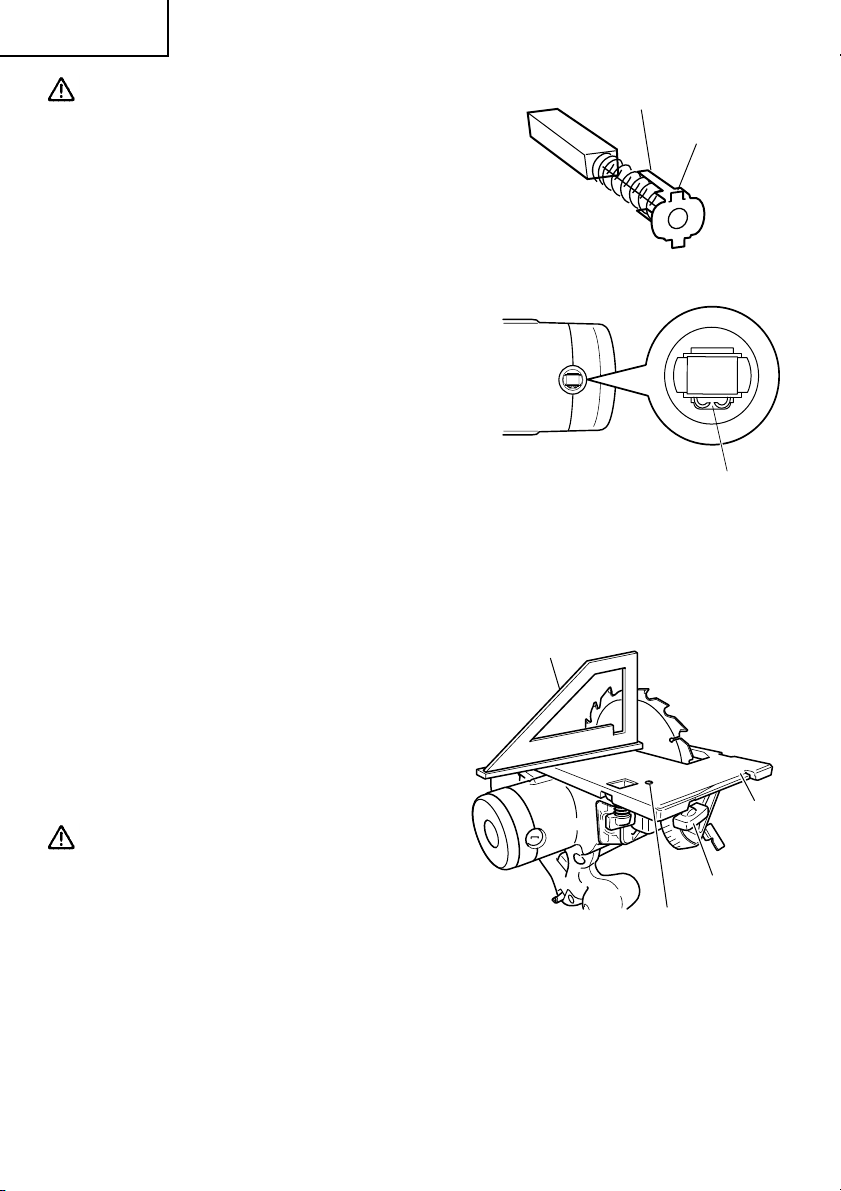

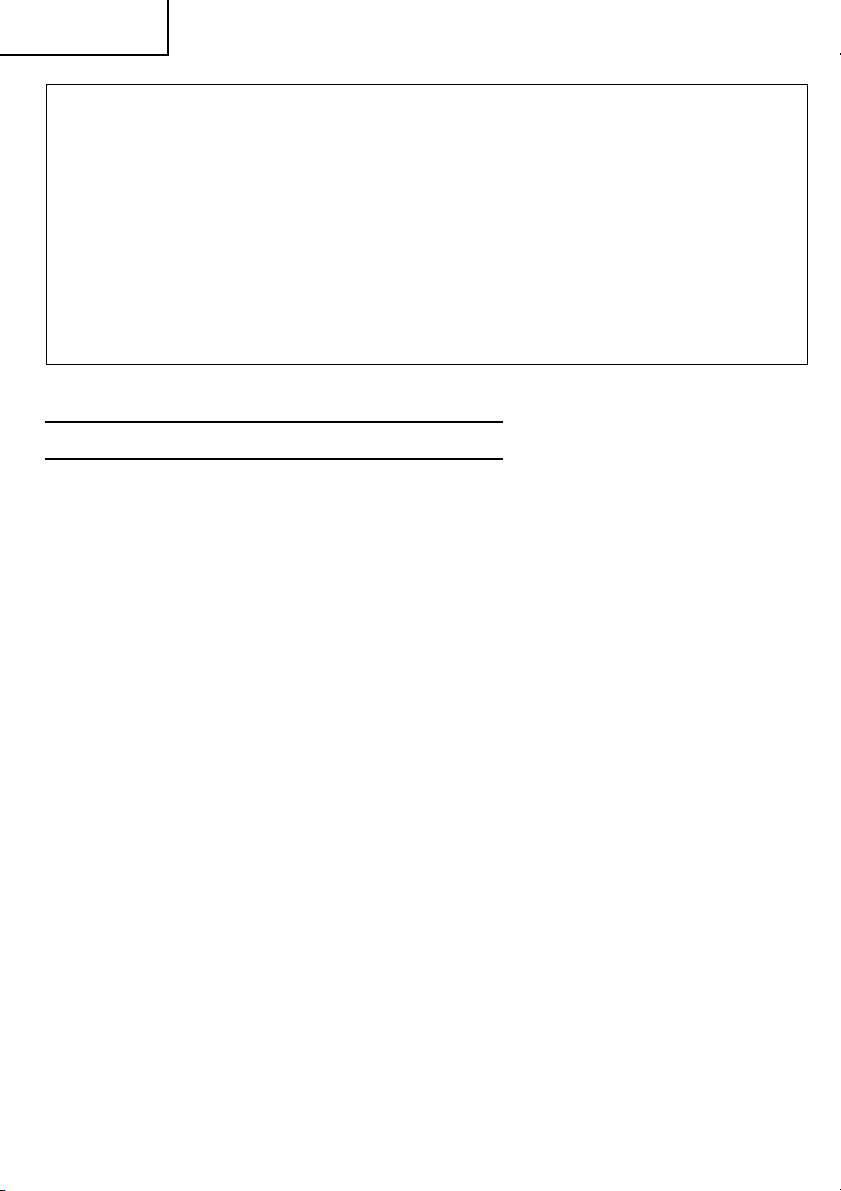

6. Adjusting the base and saw blade to

maintain perpendicularity

The angle between the base and the saw

blade has been adjusted to 90°, however

should this perpendicularity be lost for

some reason, adjust in the following

manner.

(1) Turn the base face up (Fig. 29) and loosen

the wing bolt (A).

(2) Apply a square to the base and the saw

blade and, turning the slotted set screw

with a slotted-head screwdriver, shift the

position of the base to produce the desired

right angle.

7. Check for dust

Dust may be removed with a clean rag or

a cloth dampened with soapy water.

Do not use bleach, chlorine, gasoline or

thinner, for they may damage the plastics.

Nail of Carbon Brush

Protrusion

of Carbon

Brush

Fig. 27

Contact portion

outside Brush Tube

Fig. 28

Square

8. Disposal of the exhausted battery

WARNING:

Do not dispose of the exhausted battery.

The battery must explode if it is

incinerated. The product that you have

purchased contains a rechargeable

battery. The battery is recyclable. At the

end of it’s useful life, under various state

and local laws, it may be illegal to dispose

of this battery into the municipal waste

stream. Check with your local solid waste

officials for details in your area for

recycling options or proper disposal.

28

Base

Wing-Bolt (A)

Slotted Set Screw

Fig. 29

Page 29

English

9. Storage

Storing in a place below 104°F (40°C) and out of the reach of children.

10.Service and repairs

All quality power tools will eventually require servicing or replacement of parts because

of wear from normal use. To assure that only genuine replacement parts must be used,

all service and repairs must be performed by a HITACHI AUTHORIZED SERVICE CENTER,

ONLY.

29

Page 30

30

Page 31

31

Page 32

Français

INFORMATIONS IMPORTANTES DE SÉCURITÉ

Lire et comprendre toutes les précautions de sécurité, les avertissements et les instructions

de fonctionnement dans ce mode d’emploi avant d’utiliser ou d’entretenir cet outil motorisé.

La plupart des accidents causés lors de l’utilisation ou de l’entretien de l’outil motorisé

proviennent d’un non respect des règles ou précautions de base de sécurité. Un accident

peut la plupart du temps être évité si l’on reconnaît une situation de danger potentiel avant

qu’elle ne se produise, et en observant les procédures de sécurité appropriées.

Les précautions de base de sécurité sont mises en évidence dans la section “SECURITE” de

ce mode d’emploi et dans les sections qui contiennent les instructions de fonctionnement

et d’entretien.

Les dangers qui doivent être évités pour prévenir des blessures corporelles ou un

endommagement de la machine sont identifiés par AVERTISSEMENTS sur l’outil motorisé

et dans ce mode d’emploi.

NE JAMAIS utiliser cet outil motorisé d’une manière qui n’est pas spécifiquement

recommandée par HITACHI.

SIGNIFICATION DES MOTS D’AVERTISSEMENT

AVERTISSEMENT indique des situations potentiellement dangereuses qui, si elles sont

ignorées, pourraient entraîner la mort ou de sérieuses blessures.

PRECAUTION indique des situations dangereuses potentilles qui, si elles ne sont pas

évitées, peuvent entraîner de mineures et légères blessures ou endommager la machine.

REMARQUE met en relief des informations essentielles.

32

Page 33

Français

SECURITE

REGLES GENERALE DE SECURITE – POUR TOUS LES OUTILS

FONCTIONNANT SUR BATTERIE

AVERTISSEMENT: Lire et coxmprendre toutes les instructions.

Un non respect de toutes les instructions ci-dessous peut

entraîner une électrocution, un incendie et/ou de sérieuses

blessures personnelles.

CONSERVER CES INSTRUCTIONS

1. Zone de travail

(1) Garder la zone de travail propre et bien éclairée. Les établis mal rangés et les zones

sombres invitent aux accidents.

(2) Ne pas utiliser les outils motorisés dans une atmosphère explosive, telle qu’en

présence de liquides inflammables, de gaz ou de poussières. Les outils motorisés

créent des étincelles qui risquent d’enflammer la poussière ou les vapeurs.

(3) Tenir les spectateurs, les enfants et les visiteurs éloignés, lors de l’utilisation de

l’outil motorisé. Une distraction peut faire perdre le contrôle de la machine.

2. Sécurité électrique

(1) Un outil motorisé à batterie avec batterie intégrée ou batterie séparée ne devra être

rechargé qu’avec le chargeur spécialement conçu pour la batterie. Un chargeur qui

convient pour un type de batterie donné peut présenter un risque de feu s’il est utilisé

avec une autre batterie.

(2) Utiliser l’outil motorisé à batterie exclusivement avec la batterie spécialement

conçue. L’utilisation de toute autre batterie peut présenter un risque de feu.

3. Sécurité personnelle

(1) Rester sur ses gardes, regarder ce que l’on fait et utiliser son sens commun lors de

l’utilisation d’un outil motorisé. Ne pas utiliser un outil en état de fatigue ou sous

l’influence de drogues, d’alcool ou de médicaments. Un moment d’inattention lors de

l’utilisation de l’outil motorisé peut entraîner de sérieuses blessures personnelles.

(2) S’habiller correctement. Ne pas porter des vêtements larges ou des bijoux. Attacher

les cheveux longs. Tenir ses cheveux, vêtements et ses gants éloignés des parties

mobiles. Les vêtements larges, les bijoux et les cheveux longs peuvent se prendre

dans les parties mobiles.

(3) Eviter tout démarrage accidentel. S’assurer que le l’interrupteur d’alimentation est

sur la position d’arrêt avant de brancher la machine. Transporter l’appareil avec les

doigts sur l’interrupteur d’alimentation ou brancher un outil avec l’interrupteur sur la

position marche invite aux accidents.

(4) Retirer les clefs d’ajustement ou les commutateurs avant de mettre l’outil sous

tension. Une clef qui est laissée attachée à une partie tournante de l’outil peut

provoquer une blessure personnelle.

33

Page 34

Français

(5) Ne pas trop présumer de ses forces. Garder en permanence une position et un

équilibre correct. Une position et un équilibre correct permettent un meilleur contrôle

de l’outil dans des situations inattendues.

(6) Utiliser un équipement de sécurité. Toujours porter des lunettes de protection. Un

masque à poussière, des chaussures de sécurité antidérapantes, un chapeau dur et

des bouchons d’oreille doivent être utilisés dans les conditions appropriées.

4. Utilisation de l’outil et entretien

(1) Utiliser un étau ou toutes autres façons de fixer et maintenir la pièce à usiner sur une

plate-forme stable. Tenir la pièce avec la main ou contre son corps est instable et peut

conduire à une perte de contrôle de l’outil.

(2) Ne pas forcer sur l’outil. Utiliser l’outil correct pour l’application souhaitée. L’outil

correct réalisera un meilleur et plus sûr travail dans le domaine pour lequel il a été

conçu.

(3) Ne pas utiliser un outil s’il ne se met pas sous ou hors tension avec un interrupteur.

Un outil qui ne peut pas être commandé avec un interrupteur est dangereux et doit

être réparé.

(4) Débrancher la batterie de l'outil ou mettre l'interrupteur sur la position verrouillée ou

éteinte avant d'effectuer un réglage, de remplacer un accessoire ou de ranger l'outil.

Ces mesures de sécurité préventives réduiront les risques de déclenchement accidentel

de l‘outil.

(5) Ranger les outils inutilisés hors de la portée des enfants et des autres personnes

inexpérimentées. Les outils sont dangereux dans les mains de personnes

inexpérimentées.

(6) Lorsqu’on ne se sert pas de la batterie, l’éloigner des objets métalliques, par exemple

trombones, pièces de monnaie, clous, vis, ou petits objets métalliques qui peuvent

créer une connexion entre deux bornes. Le fait de court-circuiter les bornes entre elles

peut provoquer des étincelles, des brulûres ou un feu.

(7) Conserver les outils avec soin. Garder les outils de coupe aiguisés et propres. Des

outils bien entretenus, avec des lames coupantes aiguisées risquent moins de se

gripper et sont plus faciles à contrôler.

(8) Vérifier les défauts d’alignement ou grippage des parties mobiles, les ruptures des

pièces et toutes les autres conditions qui peuvent affecter le fonctionnement des

outils. En cas de dommage, faire réparer l’outil par un centre de service HITACHI

autorisé avant de l’utiliser. Beaucoup d’accidents sont causés par des outils mal

entretenus.

(9) Utiliser uniquement les accessoires recommandés par le fabricant pour le modèle

utilisé. Des accessoires qui peuvent convenir à un outil, peuvent devenir dangereux

lorsqu’ils sont utilisés avec un autre outil.

5. Réparation

(1) La réparation de l’outil ne doit être réalisée que par un centre de revice HITACHI

autorisé. Une réparation ou un entretien réalisé par un personnel non qualifié peut

entraîner des risques de blessures.

(2) Lors de la réparation d’un outil, utiliser uniquement des pièces de rechange identiques.

Suivre les instructions de la section d’entretien de ce mode d’emploi. L’utilisation de

pièces non autorisées ou un non respect des instructions d’entretien peut créer un

risque d’électrocution ou de blessures.

34

Page 35

Français

AVERTISSEMENT:

La poussière résultant d'un ponçage, d'un sciage, d'un meulage, d'un perçage ou

de toute autre activité de construction renferme des produits chimiques qui sont

connus par l'Etat de Californie pour causer des cancers, des défauts de naissance

et autres anomalies de reproduction. Nous énumérons ci-dessus certains de ces

produits chimiques:

● Plomb des peintres à base de plomb,

● Silice cristalline des briques et du ciment et autres matériaux de maçonnerie, et

● Arsenic et chrome du bois d'oeuvre traité chimiquement.

Le risque d'exposition à ces substances varie en fonction de la fréquence d'exécution

de ce genre de travail. Pour réduire l'exposition à ces produits chimiques, travailler

dans un lieu bien ventilé, et porter un équipement de protection agréé, par exemple

un masque anti-poussière spécialement conçu pour filter les particules microscopiques.

REGLES DE SECURITE SPECIFIQUES

1. DANGER ! Ne pas approcher les mains de la zone de coupe ni de la lame. Mettre la

seconde main sur la poignée auxiliaire ou sur le carter moteur. Si les deux mains tiennent

la lame, elles risquent d’être coupées par la lame.

Placer le corps de l’un ou de l’autre côté de la lame, et non dans l’axe de la lame. Un

RETOUR DE LAME pourrait faire sauter la lame en arrière. (Voir RETOUR DE LAME.)

Ne pas passer la main sous la pièce. La protection ne protégera pas l’opérateur de la lame

sous la pièce.

2. Vérifier que la garde inférieure se referme bien avant chaque utilisation. Ne pas faire

fonctionner la lame si la protection inférieure ne se déplace pas librement et ne se

referme pas instantanément. Ne jamais fixer ni attacher la protection inférieure en

position ouverte. Si la lame tombe accidentellement, la protection inférieure risque de

se voiler. Relever la protection inférieure avec la poignée de rétraction et s’assurer qu’elle

se déplace librement et qu’elle ne touche pas la lame ni aucune autre pièce à tous les

angles et toutes les profondeurs de coupe.

3. Vérifier le fonctionnement et l’état du ressort de protection inférieure. Si la protection

et le ressort ne fonctionnent pas correctement, il faudra les faire réparer avant de les

utiliser. Le fonctionnement de la protection inférieure risque d’être lent s’il y a des pièces

endommagées, des dépôts gluants ou une accumulation de débris.

4. La protection inférieure ne devra être rétractée manuellement que pour des coupes

spéciales comme les “coupes de poche” et les “coupes composées”. Relever la

protection inférieure avec la poignée de rétraction. Dès que la lame entre en contact avec

le matériau, relâcher la protection inférieure. Pour toutes les autres opérations de coupe,

laisser la protection inférieure fonctionner automatiquement.

5. Toujours s’assurer que la protection inférieure recouvre la lame avant de poser la scie

sur un établi ou sur le sol. Une lame qui tournerait sans être protégée fera avancer la scie

vers l’arrière, et elle coupera tout ce qu’elle rencontre sur son passage. Bien évaluer le

temps nécessaire pour que la lame cesse de tourner après avoir relâché l’interrupteur.

6. Ne JAMAIS tenir la pièce à couper avec les mains ou sur le genou. Il est important de

soutenir la pièce correctement pour éviter tout risque d’exposition du corps, tout voilage

de la lame et toute perte de contrôle de l’outil.

35

Page 36

Français

7. Tenir l’outil par ses surfaces de saisie isolées lors d’un travail dans un endroit où la lame

risque d’entrer en contact avec des fils cachés. Tout contact avec un fil sous tension

transmettra également le courant aux parties métalliques et provoquera une décharge

électrique.

8. Pour tout travail de refente, toujours utiliser une garde de refente ou un guide à bord

droit. Cela améliorera la précision de coupe et réduira les risques de voilage de la lame.

9. Toujours utiliser des lames avec des orifices d’alésage de la taille et de la forme correctes

(carrés ou ronds). Des lames ne correspondant pas au système de montage de la scie

auront une rotation excentrée, ce qui provoquera une perte de contrôle de l’outil.

10. Ne jamais utiliser de rondelles ni de boulons de lame endommagés ou incorrects. Les

rondelles et le boulon de lame ont été spécialement conçus pour la scie, et ils garantiront

les performances et la sécurité maximales.

11. Causes des retours de lame et protection de l’opérateur :

Un retour de lame est la réaction brusque d’une lame pincée, coincée ou mal alignée, qui

fait que la lame, qui n’est plus contrôlée, se relève et se projette de la pièce en direction

de l’opérateur.

Lorsque la lame est pincée ou solidement coincée par la fermeture du plateau de

découpe, elle cale et la réaction du moteur entraîne rapidement l’outil vers l’arrière, c’està-dire vers l’opérateur.

Si la lame est voilée ou mal alignée sur la découpe, les dents du bord arrière de la lame

risquent de s’enfoncer dans la surface supérieure du bois, de sorte que la lame remonte

du plateau de découpe et qu’elle saute vers l’arrière, c’est-à-dire vers l’opérateur.

Le retour de lame est le résultat d’une mauvaise utilisation et/ou d’une procédure ou

d’une opération de coupe incorrectes ; on pourra l’éviter en prenant les précautions

suivantes :

䡬 Tenir la scie fermement, et placer le corps et le bras de façon à pouvoir résister aux forces

du RETOUR DE LAME. S’il prend les précautions appropriées, l’opérateur pourra

maîtriser les forces du RETOUR DE LAME.

䡬 Si la lame est voilée, ou si la coupe est interrompue pour une raison ou pour un autre,

relâcher la gâchette et tenir la scie sans bouger dans le matériau jusqu’à ce que la lame

arrive à un arrêt complet. Ne jamais tenter de retirer la scie du matériau ni tirer la scie

vers l’arrière si la lame tourne ou qu’il risque de se produire un RETOUR DE LAME.

Rechercher la cause du voilage de la lame et corriger le problème.

䡬 Lorsqu’on remet la scie en marche alors que la lame est enfoncée dans la pièce, centrer

la lame sur le plateau de découpe et vérifier que les dents ne sont pas engagées dans le

matériau. Si la lame est voilée, elle risque de se relever et de provoquer un RETOUR DE

LAME lorsque la scie sera remise en marche.

䡬 Soutenir les panneaux volumineux de façon à réduire les risques de pincement de la

lame et de RETOUR DE LAME. Les panneaux volumineux ont tendance à plier sous leur

propre poids. Il faudra placer les supports sous le panneau, des deux côtés du panneau,

près de la ligne de coupe et près du bord du panneau comme indiqué sur la Fig. 1.

Pour réduire tout risque de pincement de la lame ou de retour de lame. Lorsqu’une

opération de coupe nécessite que la scie repose sur la pièce, poser la scie sur le morceau

le plus grand et couper le petit morceau.

36

Page 37

Français

Pour éviter tout retour de lame, Ne pas soutenir la planche ou

soutenir la planche ou le panneau le panneau loin de la ligne de coupe.

près de la ligne de coupe.

Fig. 1 Fig. 2

䡬 Ne pas utiliser de lame émoussée ou endommagée. Une lame non affûtée ou

incorrectement montée engendrera des traits de scie étroits, provoquant une friction

excessive, un voilage de lame et un RETOUR DE LAME.

䡬 Les leviers de verrouillage de la profondeur de

lame et de l’angle de biseau (boulon à oreilles

(A) et levier de serrage) doivent être bien serrés

et vissés à fond avant la coupe. Si le réglage de

la lame change pendant la coupe, cela

provoquera un voilage de lame et un RETOUR

DE LAME.

䡬 Faire particulièrement attention lors d’une

“coupe de poche” dans un mur existant ou tout

autre endroit aveugle. La lame pourrait couper

des objets, ce qui risque de provoquer un

RETOUR DE LAME.

NE JAMAIS passer la main ou les doigts derrière

la scie. S’il se produit un retour de lame, la scie

pourrait facilement sauter brusquement en

arrière sur la main et provoquer des blessures

graves.

12. AVERTISSEMENT : Il est important de soutenir la pièce correctement et de tenir

solidement la scie pour éviter toute perte de contrôle pouvant entraîner des blessures

physiques. La Fig. 4 donne un exemple type de soutien manuel de la scie.

Fig. 3

37

Page 38

Français

EXEMPLE TYPE DE SOUTIEN MANUEL DE LA SCIE ET DE

SOUTIEN LA PIÈCE.

Fig. 4

13. Placer la section large de l’embase de la lame sur la section de la pièce qui est fermement

soutenue, et non sur la section qui va tomber après la coupe. A titre d’exemple, la Fig.

5 montre la façon CORRECTE de couper l’extrémité de la planche, et la Fig. 6 montre la

façon INCORRECTE. Si la pièce est courte ou petite, la serrer.

NE PAS ESSAYER DE TENIR LES SECTIONS COURTES À LA MAIN!

Fig. 5 Fig. 6

14. Ne jamais tenter de scier avec la scie circulaire

dirigée vers le bas dans un étau. Ceci serait

extrêmement dangereux et pourrait entraîner

de graves accidents. (Fig. 7)

38

Etau

Fig. 7

Page 39

Français

15. Ne jamais toucher les parties mobiles.

Ne jamais placer ses mains, ses doigts ou toute autre partie de son corps près des parties

mobiles de l’outil.

16. Ne jamais utiliser l’outil sans que tous les dispositifs de sécurité ne soient en place.

Ne jamais faire fonctionner cet outil sans que tous les dispositifs et caractéristiques de

sécurité ne soient en place et en état de fonctionnement. Si un entretien ou une réparation

nécessite le retrait d’un dispositif ou d’une caractéristique de sécurité, s’assurer de bien

remettre en place le dispositif ou la caractéristique de sécurité avant de recommencer à

utiliser l’outil.

17. Utiliser l’outil correct

Ne pas forcer sur un petit outil ou accessoire pour faire le travail d’un outil de grande

puissance. Ne pas utiliser un outil pour un usage pour lequel il n’a pas été prévu: par

exemple, ne pas utiliser une scie circulaire pour couper des branches d’arbre ou des

bûches.

18. Ne jamais utiliser un outil motorisé pour des applications autres que celles spécifiées.

Ne jamais utiliser un outil motorisé pour des applications autres que celles spécifiées

dans le mode d’emploi.

19. Manipuler l’outil correctement

Utiliser l’outil de la façon indiquée dans ce mode d’emploi. Ne pas laisser tomber ou

lancer l’outil. Ne jamais permettre que l’outil soit utilisé par des enfants, des personnes

non familiarisées avec son fonctionnement ou un personnel non autorisé.

20. Définitions pour les symboles

V ............. volts

—

............ courant continu

---

........... vitesse à vide

n

o

---/min .... rotations ou mouvements de va-et-vient par minute

21. Maintenir toutes les vis, tous les boulons et les couvercles fermement en place.

Maintenir toutes les vis, tous les boulons et les couvercles fermement montés. Vérifier

leurs conditions périodiquement.

22. Ne pas utiliser les outils motorisés si le revêtement de plastique ou la poignée est fendu.

Des fentes dans le revêtement ou la poignée peuvent entraîner une électrocution. De tels

outils ne doivent pas être utilisés avant d’être réparé.

23. Les lames et les accessoires doivent être fermement montés sur l’outil.

Eviter les blessures potentielles personnelles et aux autres. Les lames, les instruments

de coupe et les accessoires qui ont été montés sur l’outil doivent être fixés et serrés

fermement.

24. Ne jamais utiliser un outil défectueux ou qui fonctionne anormalement.

Si l’outil n’a pas l’air de fonctionner normalement, fait des bruits étranges ou sans cela

paraît défectueux, arrêter de l’utiliser immédiatement et le faire réparer par un centre de

service Hitachi autorisé.

25. Manipuler l’outil motorisé avec précaution.

Si un outil motorisé tombe ou frappe un matériau dur accidentellement, il risque d’être

déformé, fendu ou endommagé.

26. Ne pas essuyer les parties en plastique avec du solvant.

Les solvants comme l’essence, les diluants, la benzine, le tétrachlorure de carbone et

l’alcool peuvent endommager et fissurer les parties en plastique. Ne pas les essuyer avec

de tels solvants.

Essuyer les parties en plastique avec un chiffon doux légèrement imbibé d’une solution

d’eau savonneuse et sécher minutieusement.

39

Page 40

Français

CONSIGNES DE SÉCURITÉ IMPORTANTES POUR L'UTILISATION

DU SCIE CIRCULAIRE À BATTERIE

AVERTISSEMENT: Une utilisation incorrecte ou sans sécurité du scie circulaire à

batterie risque d'entraîner la mort ou des blessures graves.

Pour éviter ces risques, observer les consignes de sécurité

élémentaires suivantes:

1. Porter des protections anti-bruit quand on utilise l’outil pendant une longue session de

travail. Une exposition prolongée à un bruit de forte intensité risque d’endommager

l’ouïe.

2. Ne jamais coincer ni attacher le carter de sécurité en position ouverte. Vérifier le bon

fonctionnement du carter de sécurité avant chaque utilisation. Ne pas utiliser l’outil si le

carter de sécurité ne se referme pas complètement sur la lame de scie.

ATTENTION: Si la scie tombe, le carter de sécurité risque de se voiler, empêchant un

retour complet.

3. Dans le cas où la scie tomberait ou serait heurtée, s’assurer que la lame, le moteur, etc.

ne sont pas fissurés ou autrement endommagés. Un endommagement, une fissure ou

une déformation peuvent être la cause d’une blessure.

4. Ne jamais approcher les mains ni aucune autre partie du corps de la lame de scie pendant

le fonctionnement. Tenir la scie circulaire uniquement par sa poignée.

5. La scie circulaire fonctionnant sur batterie, bien savoir qu’elle peut se déclencher à tout

moment.

6. Toujours porter des lunettes de protection et des protection anti-bruit.

7. Lors d’un travail en hauteur, évacuer tout le monde de l’aire de travail et vérifier ce qu’il

y a en-dessous.