Page 1

Page 2

12

12

3

4

3

56

789

7

6

5

4

8

9

A

0

10 11 12D

C

5

B

E

1

F

0

5

G

6

D

Page 3

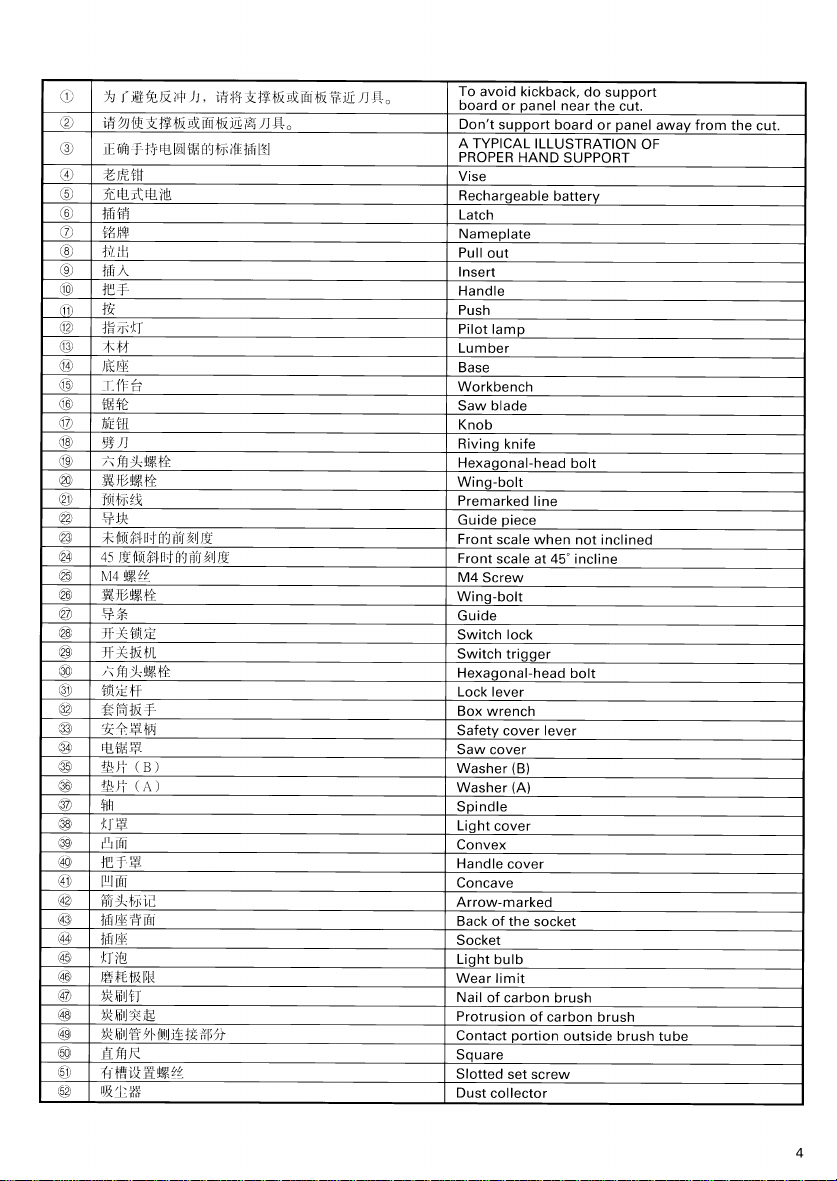

Page 4

21 22

a

`

T

23

Y

`

F

c

Z

[

24

25 26

f

3 mm

11.5 mm

27

28

]\

d

`

g

e

h

29 30

3

j

D

k

i

l

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

GENERAL OPERATIONAL PRECAUTIONS

1. Keep work area clean. Cluttered areas and benches

invite accidents.

2. Avoid dangerous environment. Don’t expose power

tools and charger to rain. Don’t use power tools

and charger in damp or wet locations. And keep

work area well lit. Never use power tools and

charger near flammable or explosive materials.

Do not use tool and charger in presence of

flammable liquids or gases.

3. Keep children away. All visitors should be kept

safe distance from work area.

4. Store idle tools and charger. When not in use,

tools and charger should be stored in dry, high

or locked-up place-out of reach of children. Store

tools and charger in a palce where the temperature

is less than 40˚C.

5. Don’t force tool. It will do the job better and safer

at the rate for which it was designed.

6. Use right tool. Don’t force small tool or attachment

to do the job of a heavy duty tool.

7. Wear proper apparel. Do not wear clothing or

jewelry. They can be caught in moving parts.

Rubber gloves and footwear are recommended

when working outdoor.

8. Use eye protection with most tools. Also use face

or dust mask if cutting operation is dusty.

9. Don’t abuse cord. Never carry charger by cord or

yank it to disconnect from receptacle. Keep cord

from heat, oil and sharp edges.

10. Secure work. Use clamps or a vise to hold work.

It’s safer than using your hand and it frees both

hands to operate tool.

11. Don’t overreach. Keep proper footing and balance

at all times.

12. Maintain tools with care. Keep tools sharp at all

times, and clean for best and safest performance.

Follow instructions for lubricating and changing

accessories.

13. When the charger is not in use, or when being

maintained and inspected, disconnect its power

cord from the AC outlet.

14. Remove chuck wrenches and wrenches. Form habit

of checking to see that wrenches are removed

from tool before turning it on.

15. Avoid accidental starting. Don’t carry tool with

finger on switch.

16. To avoid danger, always use only the specified

charger.

17. Use only original HITACHI replacement parts.

18. Do not use power tools for applications other than

those specified in the Handling Instructions.

19. To avoid personal injury, use only the accessories

or attachment recommended in these handling

instructions or in the HITACHI catalog.

20. If the supply cord of this charger is damaged, the

charger must be returned to the HITACHI

authorized service center for the cord to be

replaced. Let only the authorized service center

do the repairing. The Manufacturer will not be

responsible for any damages or injuries caused

by repair by the unauthorized persons or by

mishandling of the tool.

21. To ensure the designed operational integrity of

power tools and charger, do not remove installed

covers or screws.

22. Always use the charger at the voltage specified

on the nameplate.

23. Do not touch movable parts or accessories unless

the battery has been removed.

24. Always charge the battery before use.

25. Never use a battery other than that specified. Do

not connect a usual dry cell, a rechargeable battery

other than that specified or a car battery to the

power tool.

26. Do not use any transformer that has a booster.

27. Do not charge the battery from an engine electric

generator or DC power supply.

28. Always charge indoors. Because the charger and

battery heat slightly during charging, charge the

battery in a place not exposed to direct sunlight;

where the humidity is low and the ventilation

good.

29. When working in a high place, pay attention to

the activities below to make sure there are no

people below.

30. Use the exploded assembly drawing on this

handling instructions only for authorized servicing.

PRECAUTIONS ON USING CORDLESS

CIRCULAR SAW

1. Always charge the battery at a temperature of 0

– 40°C. A temperature of less than 0°C will result

in over charging which is dangerous. The battery

cannot be charged at a temperature higher than

40°C.

The most suitable temperature for charging is that

of 20 – 25°C.

2. When one charging is completed, leave the charger

for about 15 minutes before the next charging of

battery.

Do not charge more than two batteries

consecutively.

3. Do not allow foreign matter to enter the hole for

connecting the rechargeable battery.

4. Never disassemble the rechargeable battery and

charger.

5. Never short-circuit the rechargeable battery. Shortcircuiting the battery will cause a great electric

current and overheat. It results in burn or damage

to the battery.

6. Do not dispose of the battery in fire.

If the battery is burnt, it may explode.

7. When using this unit continuously, the unit may

overheat, leading to damage in the motor and

switch. Please leave it without using it for

approximately 15 minutes.

8. Do not insert object into the air ventilation slots

of the charger.

Inserting metal objects or inflammables into the

charger air ventilation slots will result in electrical

shock hazard or damaged charger.

9. Using an exhausted battery will damage the

charger.

10. Bring the battery to the shop from which it was

purchased as soon as the post-charging battery

life becomes too short for practical use. Do not

dispose of the exhausted battery.

11. Wear earplugs to protect your ears during

operation.

12. Always hold the handle of the power tool firmly.

Otherwise the counterforce produced may result

in inaccurate and even dangerous operation.

13. Do not use saw blades which are deformed or

cracked.

14. Do not use saw blades made of high speed steel.

15. Do not use saw blades which do not comply with

the characteristics specified in these instructions.

16. Do not stop the saw blades by lateral pressure

on the disc.

17. Always keep the saw blades sharp.

18. Ensure that the safety cover moves smoothly and

freely.

19. Never use the circular saw with its safety cover

fixed in the open position.

20. Ensure that the retraction mechanism of the guard

system operates correctly.

12

Page 14

21. The saw blades body must be thinner than the

riving knife and the width of cut, or kerf (with

teeth set) must be greater than the thickness of

the riving knife.

22. Never operate the circular saw with the saw blade

turned upward or the side.

23. Ensure that the material is free of foreign matters

such as nails.

24. The riving knife should always be used except

when plunging in the middle of the workpiece.

25. The saw blades range should be from 165 mm

to 150 mm.

26. Be careful of brake kickback.

This circular saw features an electric brake that

functions when the switch is released. As there

is some kickback when the brake functions, be

sure to hold the main body securely.

27. Avoid cutting in the state where the base has

floated up from the material.

When blade is binding, or when interrupting a cut

for any reason, release the trigger and hold the

saw motionless in the material until the blade

comes to a complete stop. Never attempt to

remove the saw from the work or pull the saw

backward while the blade is in motion or KICKBACK

may occur. Investigate and take corrective actions

to eliminate the cause of blade binding.

28. Support large panels to minimize the risk of blade

pinching and KICKBACK. Large panels tend to sag

under their own weight. Supports must be placed

under the panel on both sides, near the line of

cut and near the edge of the panel as shown in

Fig. 1.

To minimize the risk of blade pinching and kickback.

When cutting operation requires the resting of the

saw on the work piece, the saw shall be rested

on the larger portion and the smaller piece cut

off.

29. Use extra caution when making a “Pocket Cut”

into existing walls or other blind areas. The

protruding blade may cut objects that can cause

KICKBACK.

NEVER place your hand or fingers behind the saw

(Fig. 3). If kickback occurs, the saw could easily

jump backwards over your hand, possibly causing

severe injury.

30. WARNING: It is important to support the work

piece properly and to hold the saw firmly to

prevent loss of control which could cause personal

injury. Fig. 4 illustrates typical hand support of the

saw.

31. Place the wider portion of the saw base on that

part of the work piece which is solidly supported,

not on the section that will fall off when the cut

is made. As examples, Fig. 5 illustrates the RIGHT

way to cut off the end of board, and Fig. 6 the

WRONG way. If the work piece is short or small,

clamp is down.

DON’T TRY TO HOLD SHORT PLACES BY HAND!

32. Never attempt to saw with the circular saw held

upside down in a vise. This is extremely dangerous

and can lead to serious accidents. (Fig. 7)

33. When the brake becomes ineffective, replace the

carbon brushes with new ones.

SPECIFICATIONS

POWER TOOL

Model C6DD

No-load speed 2600 min

Capacity Cutting depth

Rechargeable battery Ni-Cd battery, 18V

Light bulb 12V, 5W

Weight 4.4 kg

CHARGER

Model UC24YFA

Charging voltage 7.2 – 24V

Weight 0.6 kg

13

90° 55 mm

45° 40 mm

–1

Page 15

STANDARD ACCESSORIES

1

C6DD

1 Saw Blade (mounted on tool) ................................................................................ 1

2 Box Wrench ................................................................................................................ 1

3 Guide ............................................................................................................................ 1

4 Wing-bolt ..................................................................................................................... 1

5 Charger (UC24YFA) .................................................................................................... 1

6 Plastic case.................................................................................................................. 1

Standard accessories are subject to change without notice.

2

3

OPTIONAL ACCESSORIES (sold separately)

1. Battery (EB1814, EB18B, EB1820, EB1830H)

2. Saw Blade

Use......Cutting various types of wood.

External Diam Hole Diam. No. of Teeth

165 mm 16 mm 16 pieces

165 mm 20 mm 16 pieces

165 mm 30 mm 16 pieces

3. Washer (A) .... for 16 mm (Hole dia .of saw blade)

4. Dust Collector Set (D)

Connect the suction hose to collect saw dust with

the vacuum cleaner (see Fig. 30).

Optional accessories are subject to charge without notice.

.... for 20 mm (Hole dia. of saw blade)

.... for 30 mm (Hole dia. of saw blade)

APPLICATION

Cutting various types of wood.

4

5

6

BATTERY REMOVAL/INSTALLATION

1. Battery removal

Hold the handle tightly and push the battery latches

to remove the battery (see Fig. 8,9).

CAUTION

Never short-circuit the battery.

2. Battery installation

Insert the battery while observing its polarities (see

Fig. 9).

CHARGING

Before using the power tool, charge the battery as follows.

1. Connect the charger’s power cord to a receptacle.

When the power cord is connected, the charger’s

pilot lamp will blink in red. (At 1-second intervals).

2. Insert the battery into the charger.

Firmly insert the battery into the charger till it

contacts the bottom of the charger and checking

the polarities as shown in Fig. 10.

CAUTION

䡬 If the batteries are inserted in the reverse direction,

not only recharging will become impossible, but it

may also cause problems in the charger such as

a deformed recharging terminal.

3. Charging

When inserting a battery in the charger, charging

will commence and the pilot lamp will light

continuously in red.

When the battery becomes fully recharged, the pilot

lamp will blink in red. (At 1-second intervals.) (See

Table 1)

(1) Pilot lamp indication

The indications of the pilot lamp will be as shown

in Table 1, according to the condition of the charger

or the rechargeable battery.

14

Page 16

Table 1

Before

charging

Blinks

(RED)

Indications of the pilot lamp

Lights for 0.5 seconds. Does not light for 0.5

seconds. (off for 0.5 seconds)

While

charging

Charging

complete

Charging

impossible

Charging

impossible

(2) Regarding the temperatures of the rechargeable

battery.

The temperatures for rechargeable batteries are as

shown in the table below, and batteries that have

become hot should be cooled for a while before

being recharged.

Table 2 Recharging ranges of batteries

Rechargeable batteries which the battery

EB1814. EB18B. EB1820 –5°C – 60°C

EB1830H 0°C – 45°C

(3) Regarding recharging time

Depending on the combination of the charger and

batteries, the charging time will become as shown

in Table 3.

Table 3 Charging time (At 20°C)

Battery

EB1814 Approx. 40 min.

EB18B, EB1820 Approx. 50 min.

EB1830H Approx. 70 min.

NOTE

The charging time may vary according to

temperature and power source voltage.

4. Disconnect the charger’s power cord from the

receptacle.

5. Hold the charger firmly and pull out the battery.

NOTE

After operation, pull out batteries from the charger

first, and then keep the batteries properly.

Lights

(RED)

Blinks

(RED)

Flickers

(RED)

Lights

(GREEN)

Charger

Lights continuously

Lights for 0.5 seconds. Does not light for 0.5

seconds. (off for 0.5 seconds)

Lights for 0.1 seconds. Does not light for 0.1

seconds. (off for 0.1 seconds)

Lights continuously

Temperatures at

can be recharged

UC24YFA

Malfunction in the

battery or the charger

The battery temperature

is high, making

recharging impossible.

Regarding electric discharge in case of new batteries,

etc.

As the internal chemical substance of new batteries

and batteries that have not been used for an

extended period is not activated, the electric

discharge might be low when using them the first

and second time. This is a temporary phenomenon,

and normal time required for recharging will be

restored by recharging the batteries 2 – 3 times.

How to make the batteries perform longer.

(1) Recharge the batteries before they become

completely exhausted.

When you feel that the power of the tool becomes

weaker, stop using the tool and recharge its battery.

If you continue to use the tool and exhaust the

electric current, the battery may be damaged and

its life will become shorter.

(2) Avoid recharging at high temperatures.

A rechargeable battery will be hot immediately after

use. If such a battery is recharged immediately after

use, its internal chemical substance will deteriorate,

and the battery life will be shortened. Leave the

battery and recharge it after it has cooled for a

while.

CAUTION

䡬 If the battery is charged while it is heated because

it has been left for a long time in a location subject

to direct sunlight or because the batetery has just

been used, the pilot lamp of the charger lights up

green. In such a case, first let the battery cool, then

start charging.

䡬 When the pilot lamp flickers in red (at 0.2-second

intervals), check for and take out any foreign objects

in the charger’s battery installation hole. If there are

no foreign objects, it is probable that the battery

or charger is malfunctioning. Take it to your

authorized Service Center.

䡬 Since the built-in micro computer takes about 3

seconds to confirm that the battery being charged

with UC24YFA is taken out, wait for a minimum of

3 seconds before reinserting it to continue charging.

15

Page 17

If the battery is reinserted within 3 seconds, the

battery may not be properly charged.

PRIOR TO OPERATION

1. Setting up and checking the work environment

Check if the work environment is suitable by

following the precautions.

2. Prepare a wooden workbench (Fig. 11)

Since the saw blade will extend beyond the lower

surface of the lumber, place the lumber on a

workbench when cutting. If a square block is utilized

as a workbench, select level ground to ensure it

is properly stabilized. An unstable workbench will

result in hazardous operation.

CAUTION

To avoid possible accident, always ensure that the

portion of lumber remaining after cutting is securely

anchored or held in position.

ADJUSTING THE SAW PRIOR TO USE

CAUTION

Pull out battery before doing any adjusting.

1. Adjusting the cutting depth

As shown in Fig. 12, hold the handle with one hand

while loosening the knob with the other.

The cutting depth can be adjusted by moving the

base to the desired position. In such manner adjust

the cutting depth and then securely retighten the

knob.

2. Adjusting the riving knife

Loosen the hexagonal – head bolt used to clamp

the riving knife, adjust the riving knife to the position

shown in Fig. 13 and securely retighten the bolt.

3. Adjusting the angle of inclination

As shown in Fig. 14 (A), Fig. 14 (B) by loosening

the knob on the incline gauge and the wing-bolt

on the base, the saw blade may be inclined to a

maximum angle of 45° in relation to the base. After

having completed the adjustment, reconfirm that

the knob and the wing bolt are firmly tightened.

NOTE:

Values of the inclined gauge provided on the base

merely serve as a rough guideline. For cutting

operation at an inclined posture, use the circular

saw after adjusting the angle between the base and

the saw blade with a protractor, etc.

4. Adjusting the guide piece

On the circular saw, it is possible to make fine

adjustment of the fixing position of the guide piece,

where the saw blade and the premarked line are

to be aligned.

When the saw is shipped from the factory, the

linear portion of a front scale on the guide piece

is aligned with the central position of the saw blade.

(Fig. 15)

Loosen the fixed screw on the guide piece, should

the fixing position be wrong, and make necessary

adjustment of the position.

NOTE:

For cutting operation at the inclination of 45 degrees,

make adjustment so that the notch on the guide

piece and the premarked line become aligned.

5. Regulating the guide (Fig. 16)

The cutting position can be regulated by moving

the guide to the left or right after loosening its

wingbolt. The guide may be mounted on either the

right or left side of the tool.

HOW TO USE

1. Operation of switch (Fig. 17)

(switch trigger and light switch)

(1) For safe operation of the machine, a “switch lock”

is provided on the side of a handle.

If the “switch trigger” is pulled in a state where

“switch lock” is pressed in the direction of the

arrow mark, the main switch can be turned ON.

And the “switch lock” is used as the “light switch”.

If the “switch lock (light switch)” is pressed in a

state, the light is turned ON.

(2) After the switch is turned ON, even when you

release your hand from the switch lock, the body

continues running and the light continues being

turned ON as long as you keep on pulling the

switch trigger.

(3) If you release the switch trigger, you can turn OFF

the switch and the “switch lock” returns to the

original position automatically and the light turns

OFF too.

CAUTION:

䡬 Do not fix and secure the switch lock. Besides, keep

your finger off the switch trigger when the circular

saw is being carried around. Otherwise, the main

body switch can be inadvertently turned ON,

resulting in unexpected accidents.

䡬 Keep the light ON during cutting operation only.

If it is lit ON in other cases, the main body switch

can be inadvertently turned ON, resulting in

unexpected accidents.

䡬 If the main body is left as it is with the battery

inserted, there can be a case where the [switch lock]

touches the floor and/or wall surface and lights up

continuously, depending on the direction of the

body. Be careful, since continuous lighting can easily

make a full-charged battery go dead in about 3

hours.”

2. Cutting procedures

CAUTION:

䡬 Recheck that the saw blade is securely clamped.

䡬 Confirm that the knob for adjusting the slot depth,

the knob and the wing bolt for adjusting the angle

of inclination.

(1) Place the base on the material, then align the

premarked line and the sawblade with the guide

piece front scale section at the front of the base.

(Fig. 15)

When the base is not slanted, use the large cutout

as the guide. (Fig. 15, Fig. 18(A))

If the base is slanted (45 degrees), use the small

front scale as the guide. (Fig. 15, Fig. 18(B))

(2) Ensure that the switch is turned to the ON position

before the saw blade comes in contact with the

lumber. The switch is turned ON when the trigger

is squeezed; and OFF when the trigger is released.

Moving the saw straight at a constant speed will

produce optimum cutting.

16

Page 18

CAUTIONS

䡬 Before starting to saw, ensure that the saw blade

has reached full speed revolution.

䡬 Should the saw blade be stopped or made an

abnormal noise during operation, turn off the switch

immediately.

䡬 When finished with a job, pull out the battery from

the main body.

䡬 Twisting and forcibly pressing the saw during cutting

can result in unreasonable pressure on the motor,

so try to go straight quietly.

䡬 In the situation where the circular saw is continuously

operated while replacing the battery with stocked

spare batteries one after another, the motor tends

to overheat. Therefore, whenever the housing

becomes hot, give the saw a break for a while.

䡬 Avoid cutting operation in a state where the base

bottom is afloat from the material being cut.

Otherwise, the motor can get locked.

MOUNTING AND DISMOUNTING THE SAW

BLADE

CAUTION

To avoid serious accident, ensure the switch is in

the OFF position, and pull out the battery.

1. Dismounting the saw blade

(1) Set the cutting volume at maximum, and place the

Circular Saw as shown in Fig. 19.

(2) Depress the lock lever, lock the spindle, and remove

the hexagonal-head bolt and washer (B) with the

box wrench.

(3) While holding the safety cover lever to keep the

safety cover fully retracted into the saw cover,

remove the saw blade. (Fig. 20)

2. Mounting the Saw Blade:

CAUTION:

If the bolt is worked using other tools than the

provided box wrench, excessive tightening and

insufficient tightening may take place resulting in

injury.

(1) Thoroughly remove any sawdust which has

accumulated on the spindle, bolt and washers.

(2) As shown in Fig. 21, the side of Washer (A) with

a projected center the same diameter as the inner

diameter of the saw blade and the concave side

of Washer (B) must be fitted to the saw blade sides.

* Washer (A) is supplied for 2 types of saw blades

with the hole diameters of 16 mm and 30 mm.

(When buying the Circular Saw, one type of

washer (A) is spplied.)

In case the hole diameter of your saw blade

does not correspond to that of washer (A), please

contact the shop where you purchased the

Circular Saw.

(3) To assure proper rotation direction of the saw blade,

the arrow direction on the saw blade must coincide

with the arrow direction on the saw cover.

(4) Using the fingers, tighten the hexagonal-head bolt

retaining the saw blade as much as possible. Then

depress the lock lever, lock the spindle, and

thoroughly tighten the hexagonal-head bolt.

CAUTION

After having attached the saw blade, reconfirm that

the lock lever is firmly secured in the prescribed

position.

17

REPLACING LIGHT BULB

CAUTION:

䡬 Make absolutely sure that the battery is removed

from the main body before replacing the light bulb.

䡬 Immediately after the light is turned OFF, the bulb

retains high temperature. Make sure to cool down

the light bulb thoroughly before replacing it so as

to prevent burns.

䡬 When replacing the light bulb, check the shape of

base as well as the rating (12 V, 5 W), and then

carry out perfect mounting. Otherwise, the light

bulb can come off and/or cause overheat.

1. Detaching light bulb

(1) Remove the convex part of the light cover from the

concave part of the handle cover, and then pull out

the light cover in the arrow-marked direction as

shown in Fig. 22.

(2) Push the back of the socket, and remove the socket

and the light bulb together from the handle cover

(Fig. 23).

(3) Remove the light bulb from the socket. (Fig. 24).

2. Attaching light bulb

Take procedures here that are contrary to the

detaching procedures.

NOTE:

䡬 When attaching the light bulb to the socket, insert

the light bulb until it lightly bumps against the

socket.

䡬 When attaching the socket to the handle cover,

align the socket with the hole of housing while

watching the back of the socket shown in Fig. 24,

and insert the socket until it lightly bumps against

the handle cover.

MAINTENANCE AND INSPECTION

CAUTION:

Pull out battery before doing any inspection or

maintenance.

1. Inspecting the saw blade:

Since use of a dull saw blade will degrade efficiency

and cause possible motor malfunction, sharpen or

replace the saw blade as soon as abrasion is noted.

CAUTION:

If a dull saw blade is used, reactive force is increased

during cutting operation. Avoid the use of the dull

saw blade without repair.

2. Inspecting the mounting screws:

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very "heart" of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Inspecting the carbon brushes (Fig. 25)

The motor employs carbon brushes which are

consumable parts. Since and excessively worn

carbon brush can result in motor trouble, replace

the carbon brush with new ones when it becomes

worn to or near the "wear limit". In addition, always

keep carbon brushes clean and ensure that they

slide freely whthin the brush holders.

Page 19

NOTE:

When replacing the carbon brush with a new one,

be sure to use the Hitachi Carbon Brush Code No.

999058.

5. Replacing carbon brushes

Take out the carbon brush by first removing the

brush cap and then hooking the protrusion of the

carbon brush with a flat head screw driver, etc., as

shown in Fig. 27.

When installing the carbon brush, choose the

direction so that the nail of the carbon brush agrees

with the contact portion outside the brush tube.

Then push it in with a finger as illustrated in

Fig. 28. Lastly, install the brush cap.

CAUTION:

Be absolutely sure to insert the nail of the carbon

brush into the contact portion outside the brush

tube. (You can insert whichever one of the two

nails provided.)

Caution must be exercised since any error in this

operation can result in the deformed nail of the

carbon brush and may cause motor trouble at an

early stage.

6. Performance checkup and maintenance of safety

cover

Keep the safety cover in good shape for smooth

performance at all times. Be sure to make prompt

repair in case of any malfunction.

7. Adjusting the base and saw blade to maintain

perpendicularity:

The angle between the base and the saw blade has

been adjusted to 90°, however should this

perpendicularity be lost for some reason, adjust in

the following manner:

(1) Turn the base face up (Fig. 29) and loosen the knob

and wing-nut.

(2) Apply a square to the base and the saw blade and

turning the slotted set screw with a slotted-head

screwdriver, shift the position of the base to produce

the desired right angle.

8. Check for dust

Dust may be removed with a clean rag or a cloth

dampened with soapy water.

Do not use bleach, chlorine, gasoline or thinner, for

they may damage the plastics.

9. Storage

Storing in a place below 40°C and out of the reach

of children.

10. Service and repairs

All quality power tools will eventually require

servicing or replacement of parts because of wear

from normal use. To assure that only genuine

replacement parts must be used, all service and

repairs must be performed by a HITACHI

AUTHORIZED SERVICE CENTER, ONLY.

11. Service parts list

A : Item No.

B : Code No.

C : No. Used

D : Remarks

CAUTION:

Repair, modification and inspection of Hitachi Power

Tools must be carried out by an Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools,

the safety regulations and standards prescribed in

each country must be observed.

MODIFICATIONS:

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

18

Page 20

19

Page 21

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

29

19

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

501

502

503

504

47

48

49

50

51

52

53

54

55

56

57

58

21

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

ABC D

39 319-904 1

40 – – – – 1

41 319-820 1

1 600-1VV 1 6001VVCMPS2L

2 958-130 1

3 302-742 1 "2, 5, 6"

ABC D

42 302-454 1

43 608-VVM 1 608VVC2PS2L

44 311-435 1

45 360-554 1 "1, 43, 44"

4 – – – – 1

5 961-729 1

6 949-794 2 M6x20

7 319-829 1

46 302-453 1

47 319-834 1

48 – – – – 1

8 302-433 1

9 961-807 1

10 600-3VV 1 6003VVCMPS2L

70, 71"

49 319-819 1

50 319-828 1

51 319-832 1

52 319-827 1

53 999-058 2

54 319-833 2

55 319-821 1

56 319-826 1

57 959-141 1

58 319-818 1

59 319-831 1

60 962-569 2

61 960-108 2 D4x60

63 308-479 1

64 949-686 1 D6x40

65 317-200 1 M4x8

66 316-246 1

67 302-457 1 M8x30

68 308-480 2 D6x17

69 316-443 1 "19, 21, 63, 65-68,

70 949-425 1 M6

71 302-459 1 M6x17

72 301-806 1

73 302-469 1 M6x6

501 319-836 1

502 UC24YFA 1

503 302-478 1 13MM

62 1 319-835 1 EB1820

62 2 319-765 1 EB1830H

11 302-461 1

12 302-463 1

13 302-435 1

14 990-430 2 M4x10

15 1 302-476 1 D30

15 2 302-443 1 D16

16 1 302-409 1 165MM-D30

17 302-423 1

18 302-427 1 M8x15.5

19 302-458 2

16 2 302-407 1 165MM-D16

20 676-531 1

21 949-433 2

22 319-830 1

23 303-838 1

24 302-468 1 M8x10

25 992-013 2 M5x14

26 303-800 1 M8

27 302-464 1

28 304-043 1 M4x10

29 302-086 8 D4x20

30 997-234 3 M5x35

31 319-820 1

32 319-822 1

33 319-824 1

34 319-825 1

35 958-715 1 D4x10

504 302-756 1

36 319-823 1

37 301-631 1

38 317-207 1

20

Page 22

203

Code No. C99104221

Printed in China

Loading...

Loading...