Page 1

CAUTION: Before servicing this chassis, it is important that the service technician read the “Safety Precaution”

and “Safety Notice” in this Service Manual.

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

Components having special characteristics are identified by a ! on the schematics and on the parts list in this

service data and its supplements and bulletins. Before servicing the chassis, it is important that the service

technician read and follow the “Safety Precautions” and “Safety Notice” in this Service Manual.

* For continued X-radiation protection, replace picture tube with original type or approved equivalent type.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

CONTENTS

SAFETY NOTICE···························································································· 2

SAFETY PRECAUTIONS··················································································· 3

TECHNICAL CAUTIONS···················································································· 6

SPECIFICATIONS···························································································· 7

CIRCUIT PROTECTION····················································································· 7

GENERAL INFORMATION·················································································· 8

CAUTIONS WHEN CONNECTING/DISCONNECTING THE HV CONNECTOR······················· 10

SERVICE ADJUSTMENTS················································································· 11

TROUBLE SHOOTING······················································································ 51

PROTECTION CIRCUIT BLOCK DIAGRAM······························································ 55

EXPLODED VIEW··························································································· 56

REPLACEMENT PARTS LIST·············································································· 60

BLOCK DIAGRAM··························································································· 96

BASIC CIRCUIT DIAGRAM················································································· 97

PRINTED CIRCUIT BOARD················································································· 112

WIRING DIAGRAM···························································································120

SERVICE MANUAL

MODEL: C43-FD5000 C50-FD5000

MULTI SYSTEM

DP3M CHASSIS

PROJECTION COLOR TELEVISION

Dec 2

003

P7

966139

A

CODE: FH-0302E

Page 2

2

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

For continued X-Radiation protection, replace picture tube with original type or HITACHI approved

equivalent type.

This Service Manual is intended for qualified service technicians, it is not meant for the casual

do-it-yourself. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improper performed repairs can adversely affect the safety and reliability of the product and may void

warranty. If you are not qualified to perform the repair of this product properly and safely, you should

not risk trying to do so and refer the repair to a qualified service technician.

WARNING

When servicing or handling circuit boards and other components that contain lead in solder, avoid

unprotected skin contact with solder. Also, when soldering does not inhale any smoke or fumes

produced.

Page 3

3

SAFETY PRECAUTIONS

1. Before returning an instrument to the customer,

always make a safety check of the entire instrument,

including but not limited to the following items:

a) Be sure that no built-in protective devices are

defective and/or have been deleted during servicing.

(1) Protective shields are provided on this chassis to

protect both the technician and the customer.

Correctly replace all missing protective shields,

including any removal for servicing convenience.

(2) When reinstalling the chassis and/or other

assembly in the cabinet, be sure to put back in place

all protective devices, including but not limited to

nonmetallic control knobs, insulating fish-paper,

adjustment and compartment covers shields, and

isolation resistor/capacitor networks. Do not operate

this instrument or permit it to be operated

without all protective devices correctly installed

and functioning. Service technician who

disregard safety features or fail to perform safety

checks may be liable for any resulting damage.

b) Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to

(1) spacing between the picture tube and cabinet

mask,

(2) excessively wide cabinet ventilation slots, and

(3) an improperly fitted and/or incorrectly secured

cabinet back cover.

c) Antenna Cold Check - With the instrument AC plug

source, connect an electrical jumper across the two

AC plug prongs. Place the instrument AC switch in

the ON position. Connect one lead of an ammeter to

the AC plug prongs tied together and touch the other

ohmmeter lead to each tuner antenna input,

exposed terminal screw and, if applicable, to the

coaxial connector in sequence. If the measured

resistance is less than 4.0 megohm or greater than

10 megohm, an abnormality exists that must be

corrected before the instrument is returned to the

customer. Repeat this test with the instrument AC

switch in the OFF position.

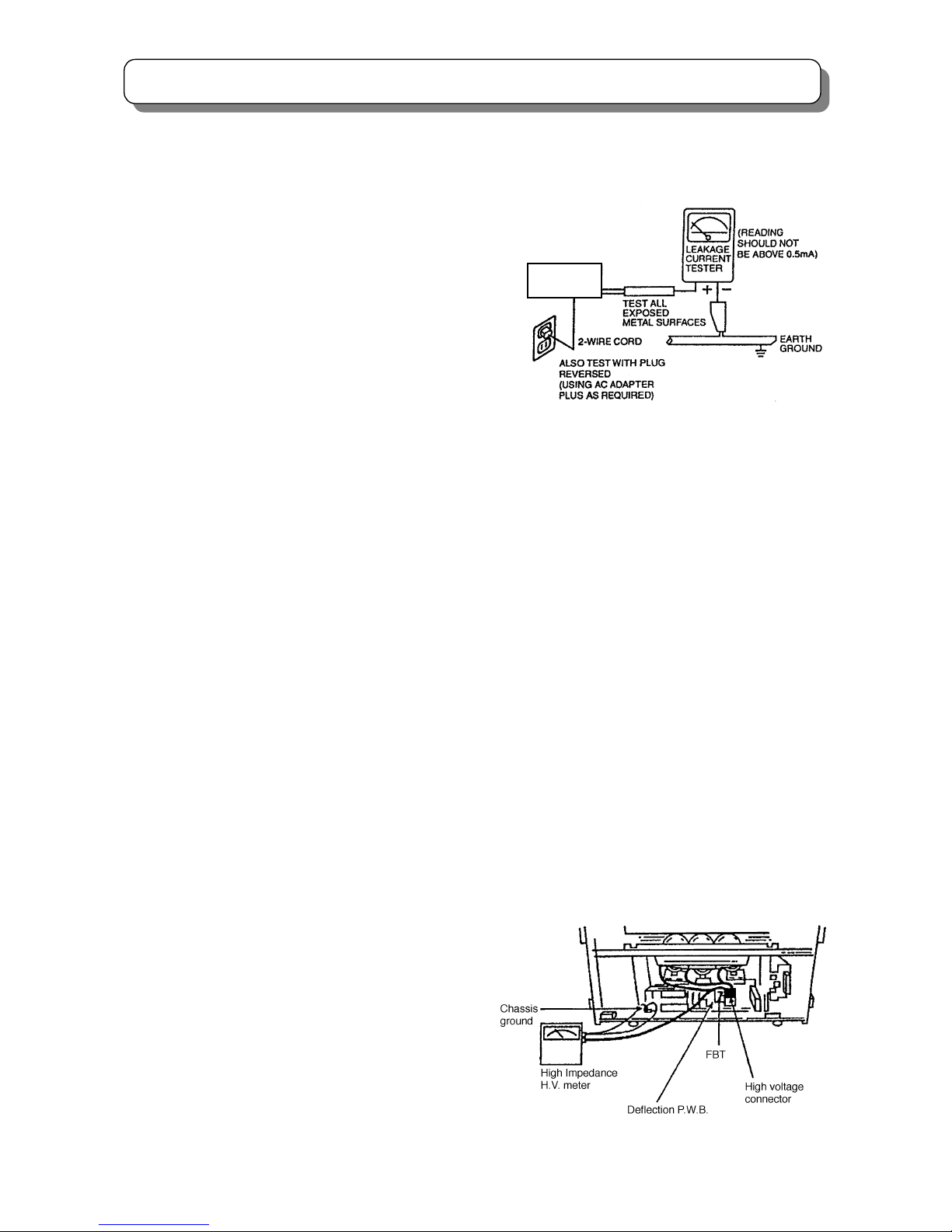

d) Leakage Current Hot Check - With the instrument

completely reassembled, plug the AC line cord

directly into a 220V outlet. (Do not use an isolation

transformer during this test.) Use a leakage current

tester or a metering system with the instrument AC

switch first in the ON position and then in the OFF

position, measure from a known earth ground (metal

water-pipe, conduit, etc.), to all exposed metal parts

of the instrument (antennas, handle bracket, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal parts that

offer an electrical return path to the chassis. Any

current measured must not exceed 0.7 milliamps.

Reverse the instrument power cord plug in the outlet

and repeat test. (See the following connection

diagram)

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE INSTRUMENT TO THE

CUSTOMER OR BEFORE CONNECTING THE

ANTENNA OR ACCESSORIES

e) High Voltage - This receiver is provided with a hold

down clearly indicating that voltage has increased in

excess of a predetermined value. Comply with all

notes described in this Service Manual regarding

this hold down circuit when servicing, so that this

hold down circuit may correctly be operated.

f) Service Warning - With maximum contrast,

operating high voltage in this receiver is lower than

31.0kV. In case if any component having influence

on high voltage is replaced, confirm that the high

voltage with maximum contrast is lower than 31.6kV.

To measure H.V use a high impedance H.V. meter.

Connect (-) to chassis earth and (+) to the CRT

anode button. (See the following connection

diagram).

Note: Must turn power switch off before the connection

to the anode button is made.

(TH01)

INSTRUMENT

UNDER TEST

Page 4

4

SAFETY PRECAUTIONS

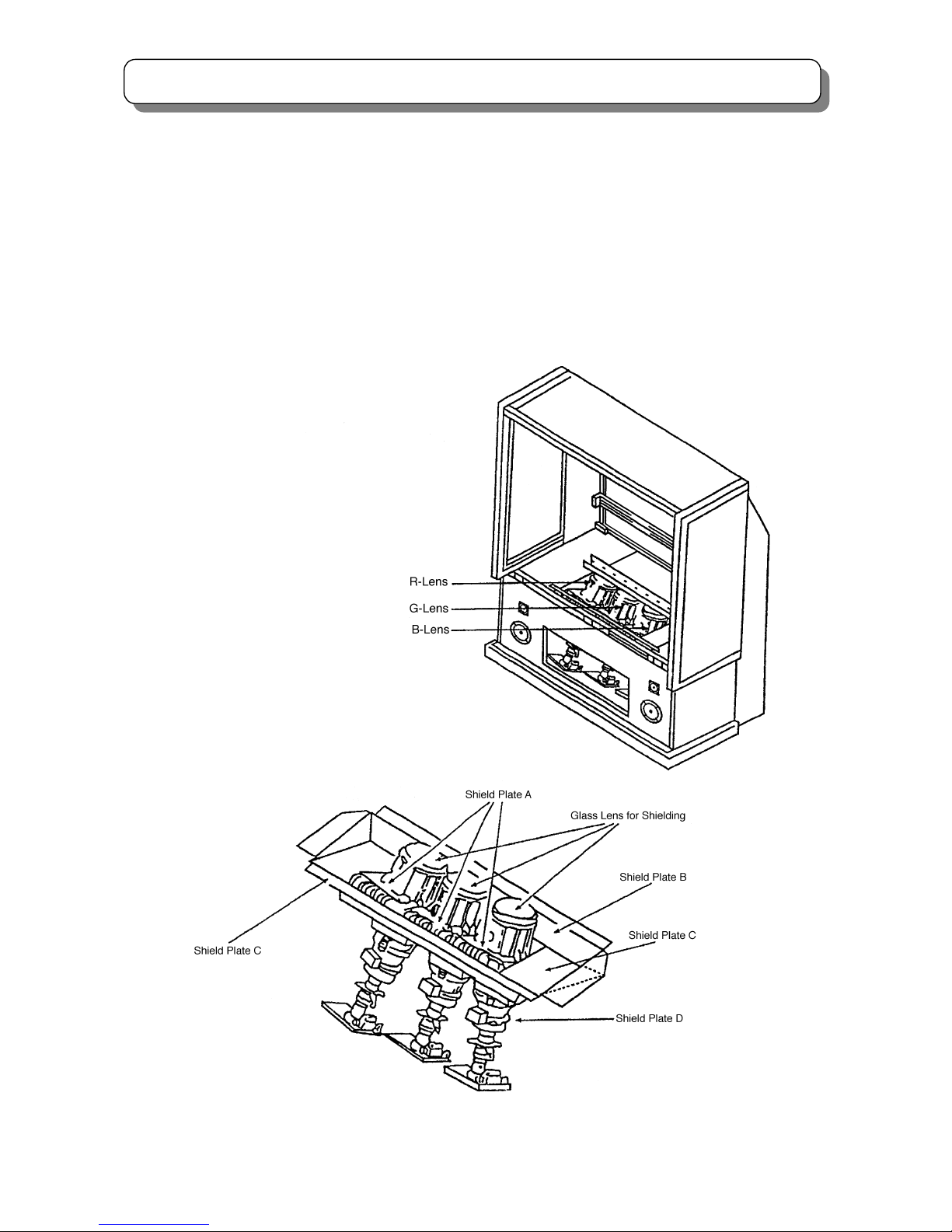

Fig. 1 X-ray shield plates

g) X-radiation (TUBE) -The primary source of

X-radiation in this receiver is the picture tube. The tube

utilized for the above mentioned function in this

chassis is specially constructed to limit X-radiation

emissions.

For continued X-radiation protection, the replacement

tube must be the same type as the original. HITACHI

approved type.

When troubleshooting and making test measurements

in a receiver with a problem of excessive high voltage,

avoid being unnecessarily close to the picture tube

and the high voltage component.

Do not operate the chassis longer than is necessary

to locate the cause of excessive voltage.

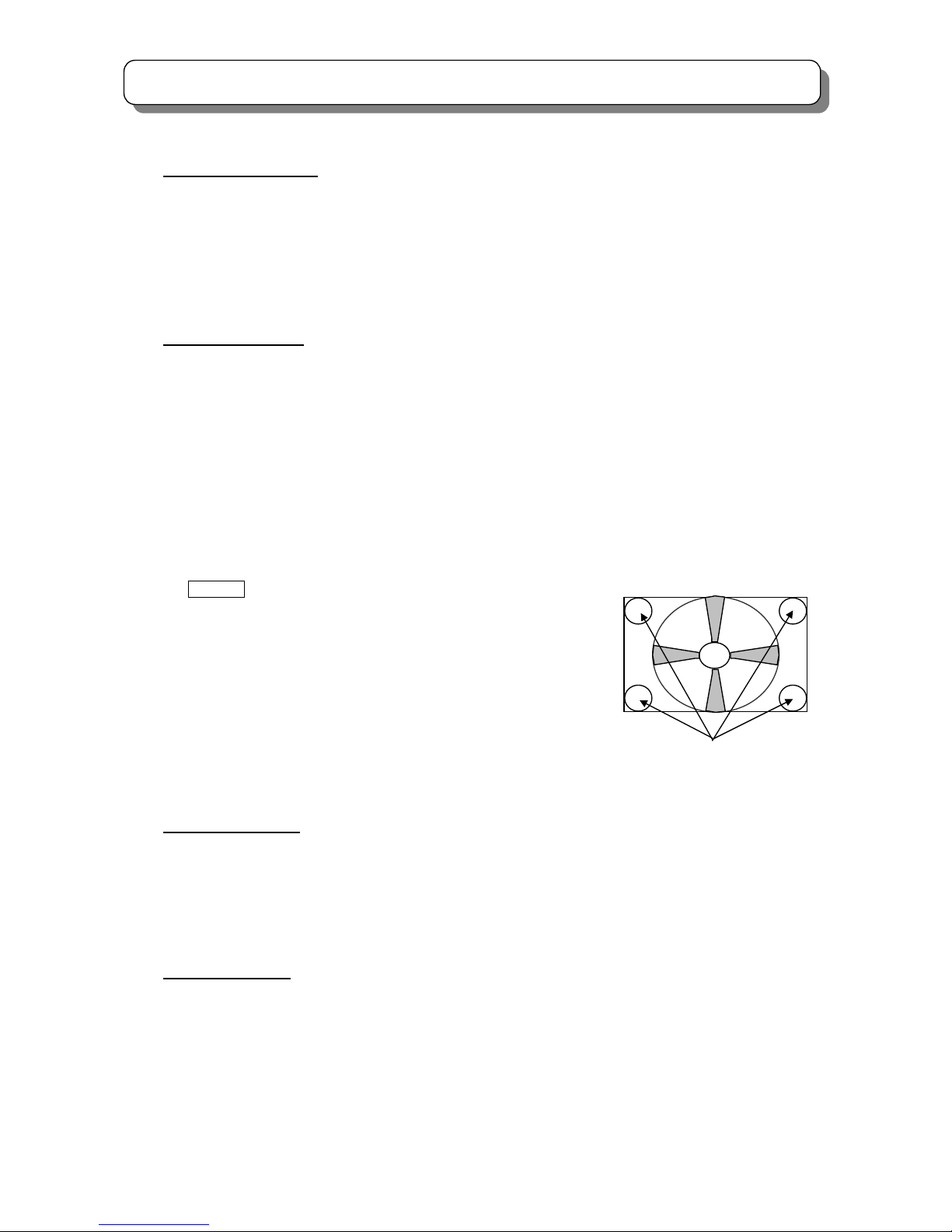

h) X-radiation Shield -This receiver is provided with

X-ray shield plates for protection against X-radiation.

Do not remove X-ray shield plates A, B, C, or D

shown in Fig.1 unnecessarily, when troubleshooting

and/or making test measurements.

To prevent X-radiation, after replacement of picture

tube and lens, confirm these components to be fixed

correctly to bracket and cabinet, and not to be taken

off easily.

Page 5

5

SAFETY PRECAUTIONS

2. Read and comply with all caution and safety-related

notes on or inside the receiver cabinet, on the

receiver chassis, or on the picture tube.

3. Design Alteration Warning - Do not alter or add to

the mechanical or electrical design of this TV receiver.

Design alterations and additions, including but not

limited to circuit modifications and the addition of

items such as auxiliary audio and/or video output

connectors, might alter the safety characteristics of

this receiver and create a hazard to the user. Any

design alterations or additions may void the

manufacturer’s warranty and may make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4. Picture Tube Implosion Protection Warning - The

picture tube in this receiver employs integral

implosion protection. For continued implosion

protection, replace the picture tube only with one of

the same type number. Do not remove, install, or

otherwise handle the picture tube in any manner

without first putting on shatterproof goggles equipped

with side shields. People not so equipped must be

kept safely away while picture tubes are handled.

Keep the picture tube away from your body. Do not

handle the picture tube by its neck.

5. Hot Chassis Warning

a) Some TV receiver chassis are electrically connected

directly to one conductor of the AC power cord and

may be safely serviced without an isolation

transformer only if the AC power plug is inserted so

that the chassis is connected to the ground side of the

AC power source. Confirm that the AC power plug is

inserted correctly with an AC voltmeter by measuring

between the chassis and a known earth ground. If a

voltage reading in excess of 1.0V is obtained, remove

and reinsert the AC power plug in the opposite polarity

and again measure the voltage potential between the

chassis and a known earth ground.

b) Some TV receiver chassis normally have 85V AC

(RMS) between chassis and earth ground regardless

of the AC plug polarity. These chassis can be safely

serviced only with an isolation transformer inserted in

the power line between the receiver and the AC power

source, for both personnel and test equipment

protection.

c) Some TV receiver chassis have a secondary ground

system in addition to the main chassis ground. This

secondary ground system is not isolated from the AC

power line. The two ground systems are electrically

separated by insulating material that must not be

defeated or altered.

6. Observe original lead dress. Take extra care to assure

correct lead dress (the AC supply, high voltage and

antenna wiring) in the following areas:

a) Near sharp edges

b) Near thermally hot parts

Be sure that leads and components do not touch

thermally hot parts. Always inspect in all areas for

pinched, out-of -plate, or frayed wiring; Do not

change spacing between components and the printed

circuit board; Check AC power cord for damage.

7. Components, parts, and/or wiring that appear to have

overheated or are otherwise damaged should be

replaced with components, parts or wiring that meet

original specifications. Additionally, determine the

cause of overheating and/or damage and, if

necessary, take corrective action to remove any

potential safety hazard.

8. PRODUCT SAFETY NOTICE - Many TV electrical

and mechanical parts have special safety-related

characteristics some of which are often not evident

from visual inspection, nor can the protection they

give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified by a

! in the replacement parts list. Use of

substitute replacement that does not have the same

safety characteristics as the recommended

replacement part in the parts list might create shock,

fire, and/or other hazards. Product safety is under

review continuously and new instructions are issued

whenever appropriate. For the latest information,

always consult the appropriate current service

literature. A subscription to, or additional copies of

service literature may be obtained at a nominal

charge from manufacturer.

Page 6

6

TECHNICAL CAUTIONS

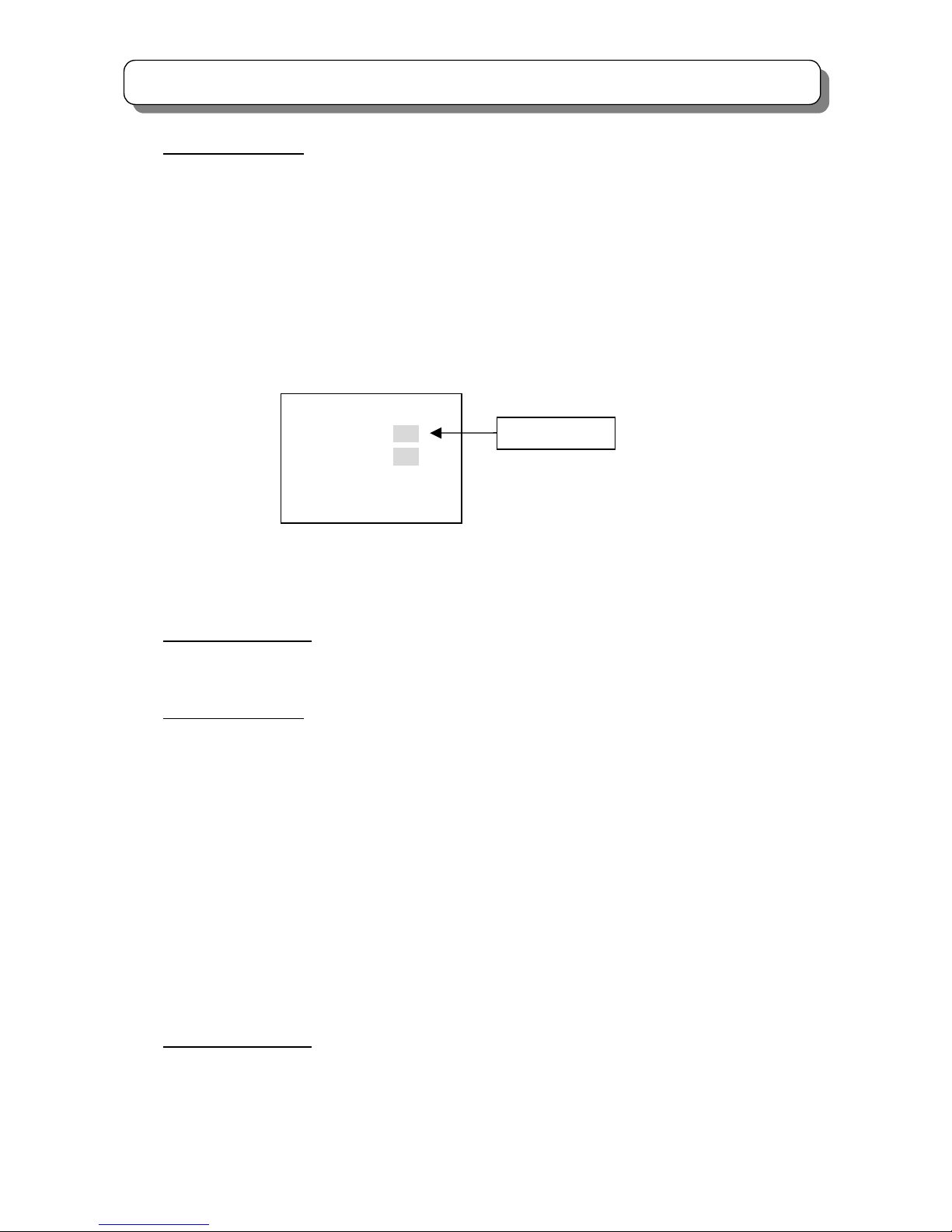

High Voltage limiter circuit operation check

1. Turn off TV and delete Resistor RH19(82KΩ)in the PWB .Add jig A to the RH19 position in the PWB,set 50 KΩ

VR fully clockwise(maximum resistance).

2. Set the AC input to 242V AC and turn on TV.

3. Confirm test pattern on PRT is a usable picture,then slowly adjust 50 KΩVR until the picture disappears and TV

shuts down.

4. When the limiter circuit is operating properly, High Voltage will be less than 36.8KV at 1.6mA when TV shuts down.

5. Turn off TV immediately after checking High Voltage limiter circuit operation. Unplug TV for one minute to reset

shutdown circuit. Remove the jig A,and the

n add resistor RH19(82KΩ)to the P.W.B.

Fig.2 High Voltage limiter circuit operation check

FBT

TH01

Jig A

50 KΩ VR

33KΩ

Connect Jig A to P.W.B between RH19.

Deflection/Convergence P.W.B

FBT

RH19

50 KΩ VR

33KΩ

RH17

Page 7

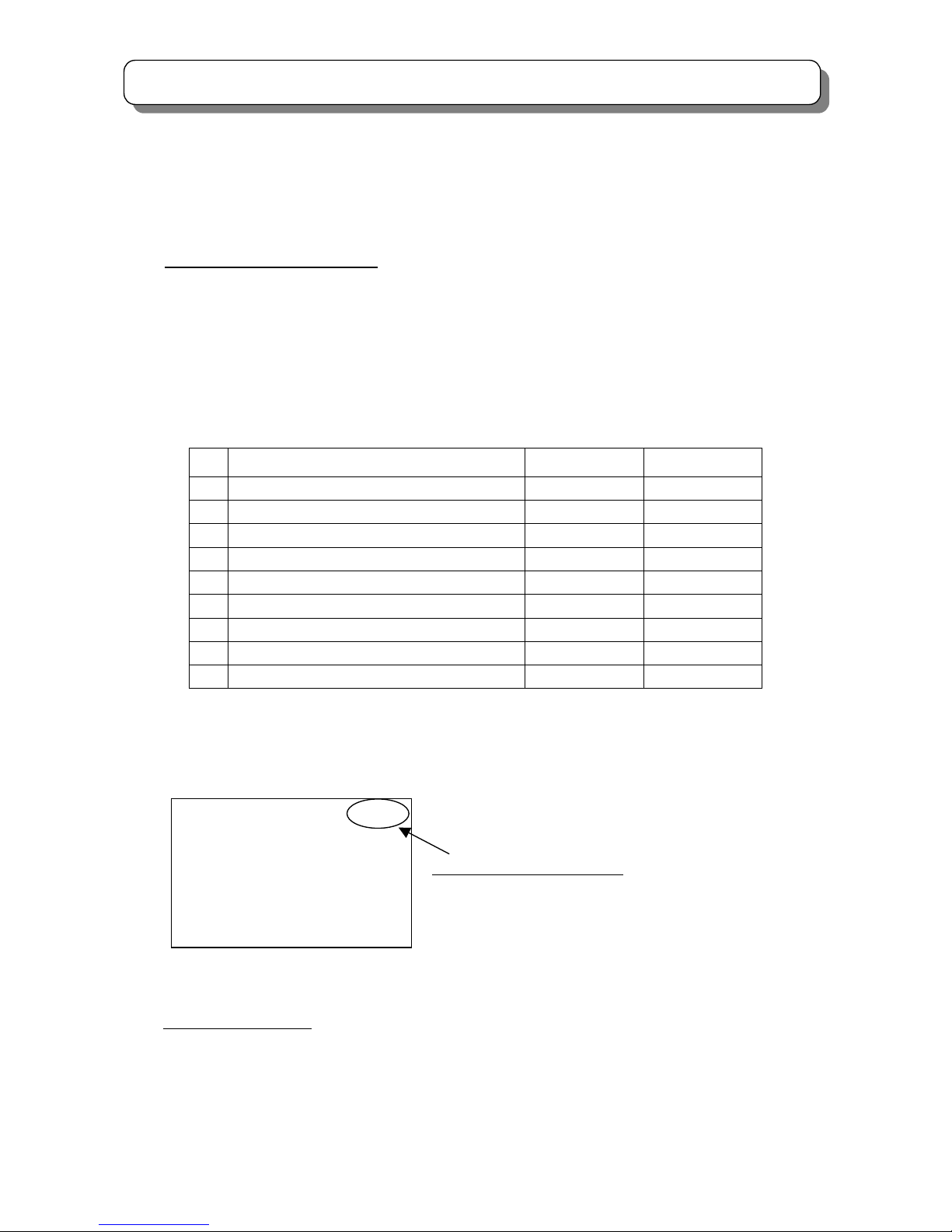

7

7

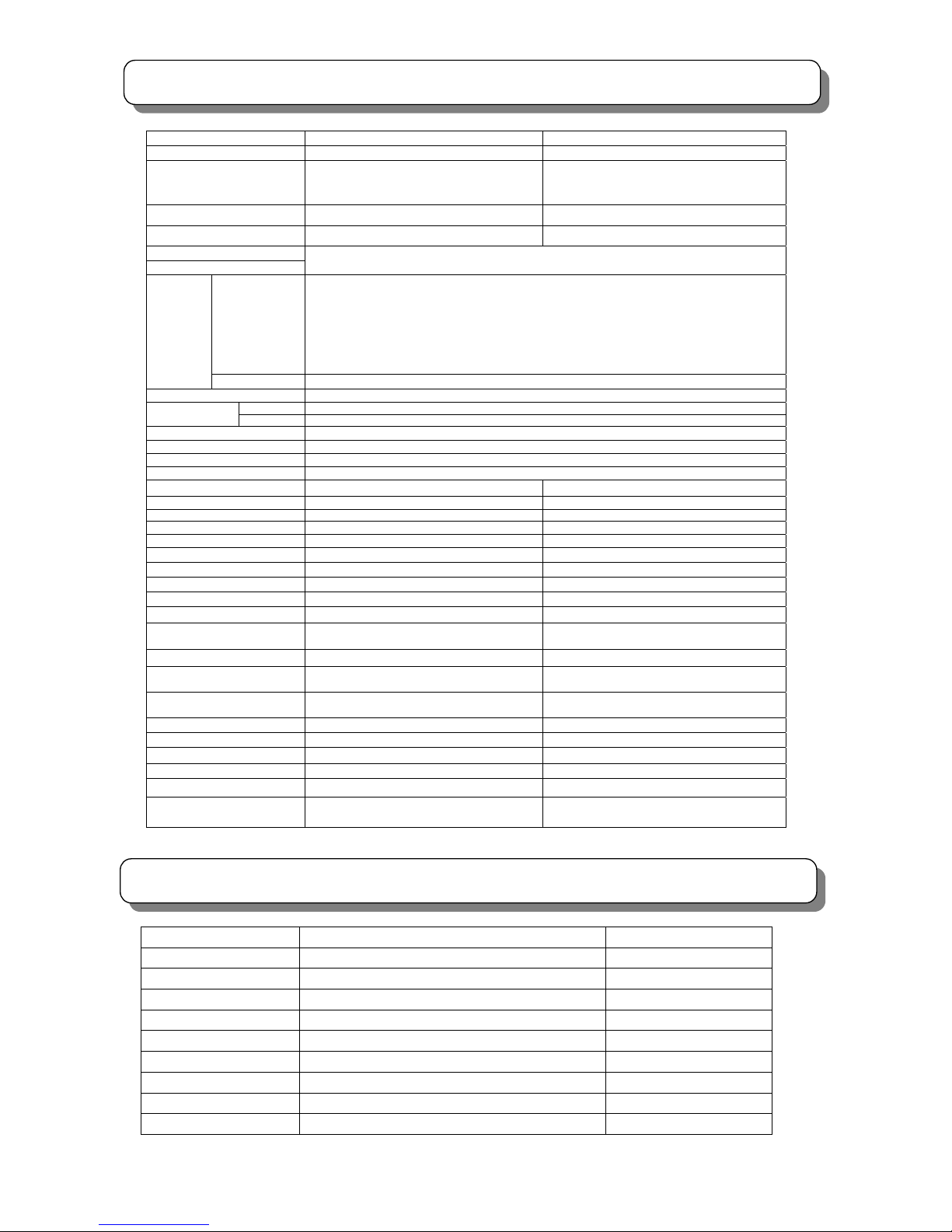

SPECIFICATIONS

CIRCUIT PROTECTION

Fuse (or Device) Circuit Protected Physical Location

F9C1 (T6.3AL/250V) Main Primary Fuse Power PWB

F903 (T3.15AL/250V) Primary Fuse Power PWB

E901 7A Fuse Protector Over Current Protector (Audio +38.5V Power Supply) Power PWB

E902 7A Fuse Protector Over Current Protector (SW +10V Power Supply) Power PWB

E903 4A Fuse Protector Over Current Protector (SW +220V Power Supply) Power PWB

E904 10 A Fuse Protector Over Current Protector (SW +28V Power Supply) Power PWB

E905 10A Fuse Protector Over Current Protector (SW -28V Power Supply) Power PWB

E906 0.5A Fuse Protector Over Current Protector (+B Error AMP) Power PWB

E907 3A Fuse Protector Over Current Protector (+B Power Supply) Power PWB

Model

C43-FD5000 C50-FD5000

Screen size

109cm 127cm

Cathode Ray Tube

R: P16LXL00RFA(C)

G: P16LXL00HHA(C)

B: P16LXL00BMB(C)

R: P16LXL00RFA(C)

G: P16LXL00HHA(C)

B: P16LXL00BMB(C)

Lens HSA SCB

Anode voltage 30.7KV 30.7KV

Power supply

Power consumption

Refer to the values as indicated on the rating label pasted at the back of the TV set.

PAL B.G/I/D.K

SECAM B.G/D.K

NTSC 50

M/NTSC

NTSC3.58-5.5/6.0/6.5

NTSC4.43-5.5/6.0/6.5

RF/VIDEO

PAL/SECAM 60

Reception

system

COMPONENT 525i/525p/625i/625p/750p/1125i

Frequency range 44MHz-863 MHz

VHF Not less than 250uVReception

sens

itivity

U

HF Not l

ess

than

350u

V

Antenna input impedance 75 Ohm non balance type

Speaker

Φ12×2 、Φ5×2

Sound output

20 W×2

Comb filter 3L(PAL)/3D(NTSC)

Digital convergence Yes Yes

Magic focus Yes Yes

Perfect volume Yes Yes

NICAM/A2 Yes Yes

BBE Yes Yes

SRS Yes Yes

P i n P Yes Yes

Tel e t ext Ye s Yes

S-VIDEO input

1 ( side),2(back

)1(

side),2 (back)

VIDEO input 1 (side),4(back) 1 (side),4(back)

Component input

(Y, PB/CB, PR/CR)

2 (back) 2 (back)

AUDIO (L, R) input 1 (side),4(back) 1 (side),4(back)

VIDEO output

(

MONITOR OUT)

1(back) 1(back)

AUDIO(L,R)output

(MONITOR OUT)

1(back) 1(back)

Headphone output jack 2 (side) 2 (side)

Variable audio (L、R) output

1(back) 1(back)

Shielding Yes Yes

Memory card slot No No

Weight 55Kg 62.5Kg

Dimension (mm)

(width×depth×height)

969 ㎜×534 ㎜×1237 ㎜ 111 9 ㎜×535 ㎜×1362 ㎜

Page 8

8

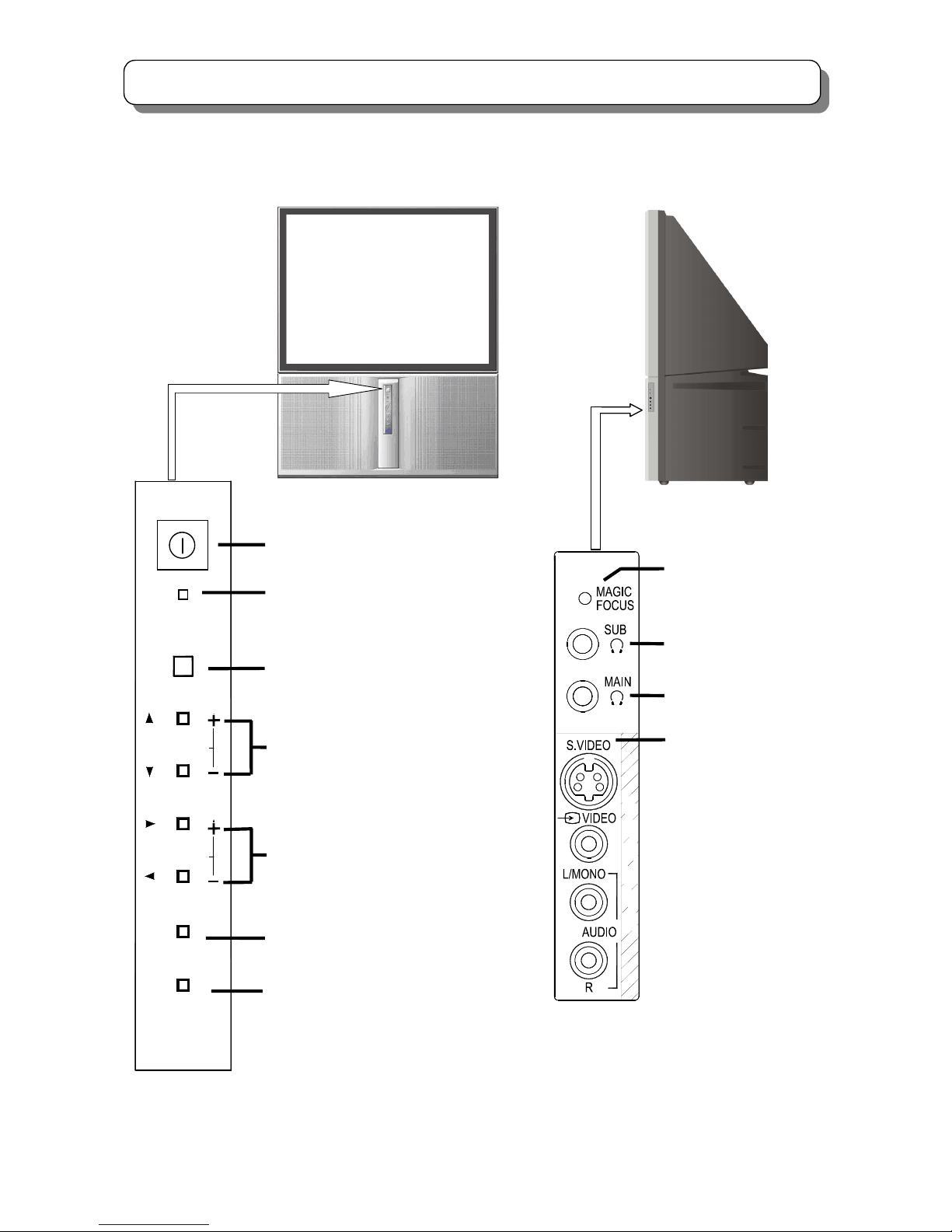

GENERAL INFORMATION

Control panel and side panel

POWER

PROGRAM

VOLUME

TV/VIDEO

MENU/RETURN

Power ON/OFF switch

Power/ standby indicator

Remote control sensor

PROGRAM UP/DOWN buttons (When

the menu appears on the screen, press

PROGRAM UP/DOWN buttons to

select the menu up and down.)

VOLUME UP/DOWN buttons (When the

menu appears on the screen, press

VOLUME UP/DOWN buttons to select

the menu right and left.)

MENU/RETURN button

TV/VIDEO selector

POWER

5

I

P

T

U

N

Main headphone jack

Sub headphone jack

Magic focus button

Side panel input jacks

(For AV5 input)

Page 9

9

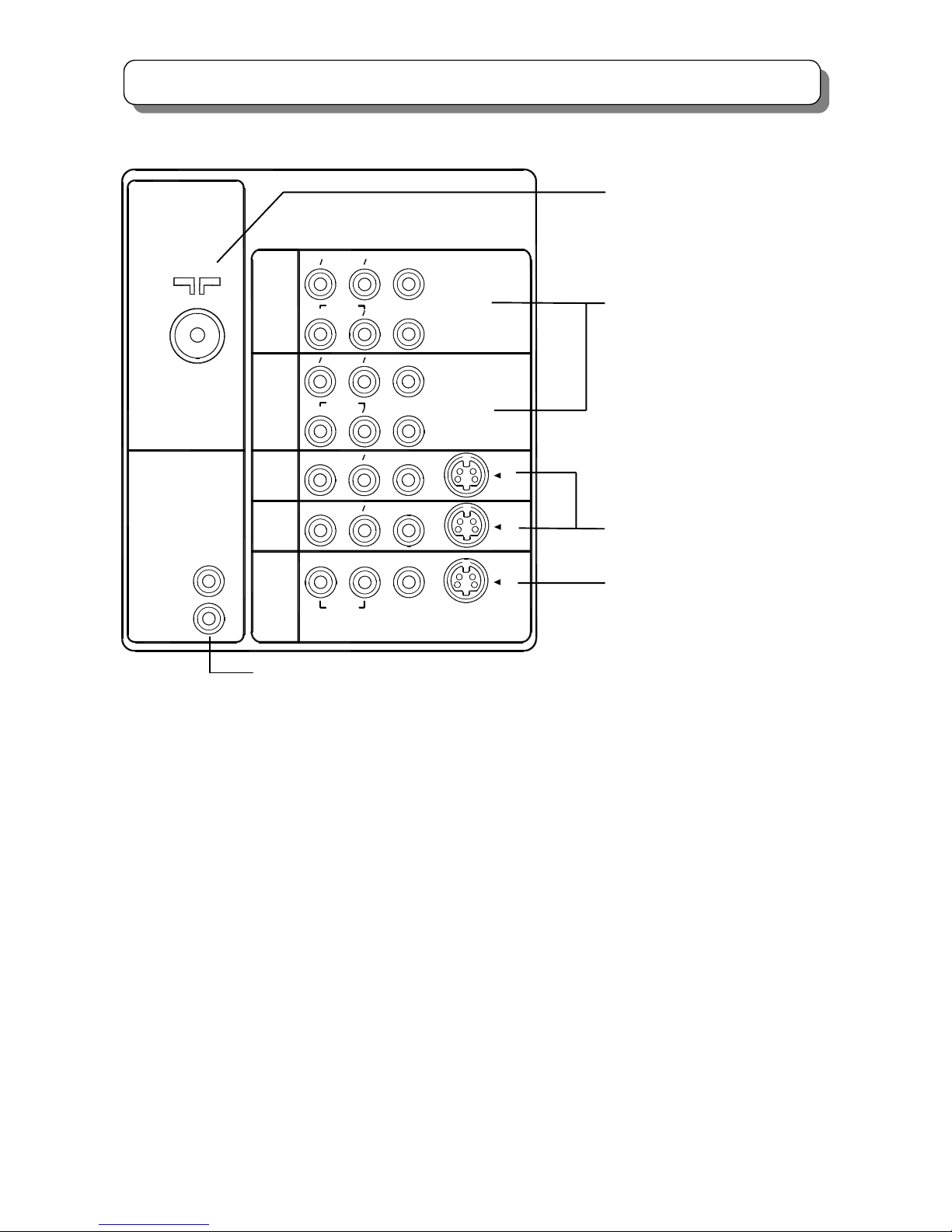

GENERAL INFORMATION

REAR PANEL

AUDIO OUT

MONITOR

R

L

OUT

AUDIO

R

LVIDEO

S-VIDEO

VARIABLE

R

(MONO)

L

INPUT 4

INPUT 3

R

L

(MONO)

INPUT 2

L

R

AUDIO

(MONO)

VIDEO S-VIDEO

VIDEO

S-VIDEO

VIDEO

B

C

INPUT 1

P

C

RR

BP

C

AUDIO

R

(MONO)

L

C

P

RR

PB

Y

VIDEO

Y

B

Variable Audio output terminals

A

ntenna terminal

Monitor output terminals

A

udio/Video input & Component

in

p

ut terminals 1,2

A

udio/Video input terminals 3,4

Page 10

10

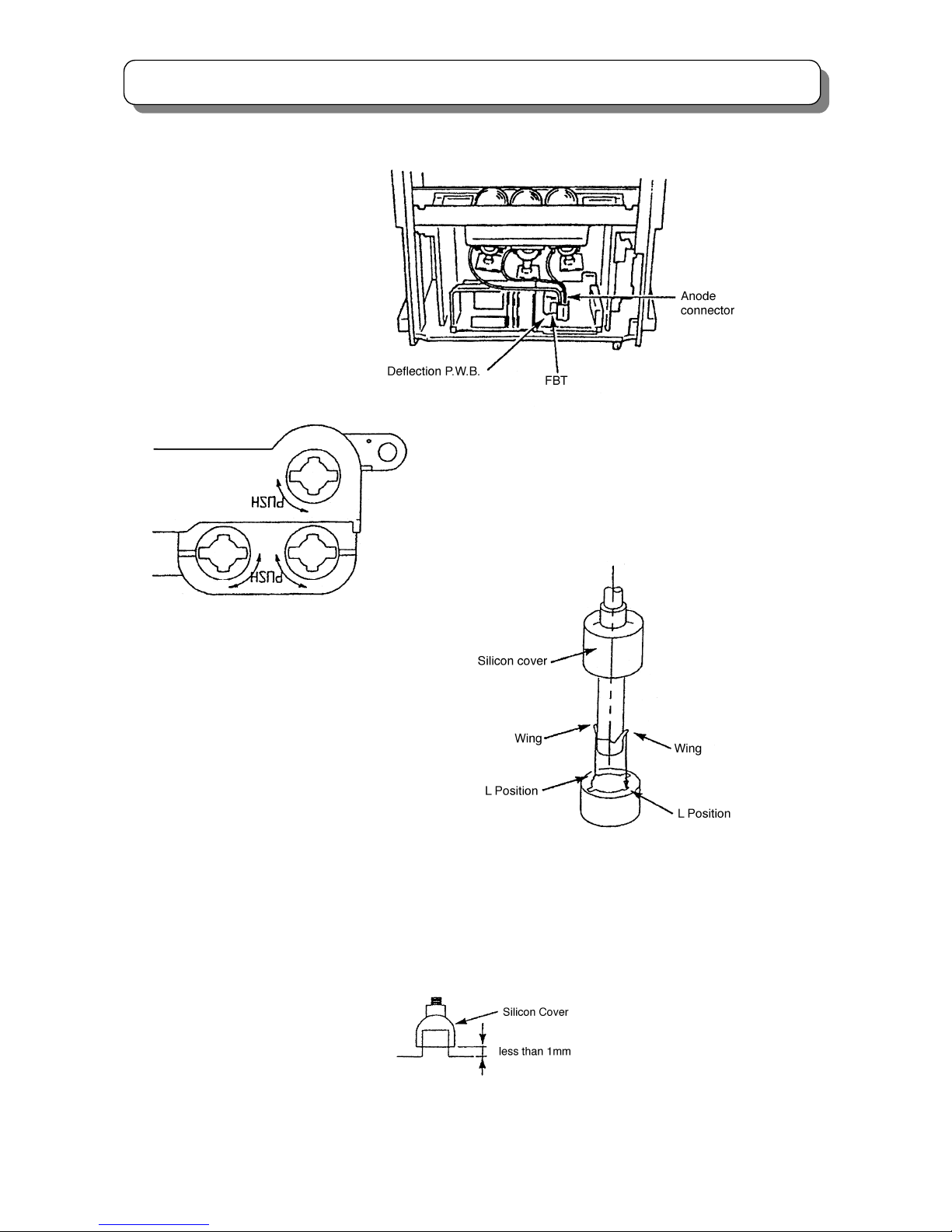

CAUTIONS WHEN CONNECTING/DISCONNECTING THE HV CONNECTOR

O

O

L L

L

Perform the following when the

HV connector (anode connector)

is removed or inserted for PRT

replacement, etc.

During Insertion

1. Please refer to direction for insertion as shown in Fig. 4 (L position). Insert connector until “CLICK” sound is heard.

2. Make sure the connector is pressed right in, so that it has a good contact with the spring.

3. Confirm the contact by pulling the connector slightly. (Don’t pull hard because it may damage the connector).

4. Cover the high voltage output by carefully pushing silicon cover onto it. (Don’t turn the connector).

(REMARK)

1. Make sure the silicon cover is

covering the high voltage output.

During Removal

1. Roll out silicon cover from FBT’s contact area slowly.

2. While turning the connector about 90 degrees following the

arrow (from L position to O position), push the connecto

r

slightly towards the case. (Fig .3)

3. Remove the connector slowly by pulling it away from the

case.

Fig. 3 Remove the anode connector

Fig. 4 Insert the anode connector

Page 11

11

SERVICE ADJUSTMENTS

SERVICE ADJUSTMENT ITEMS

1.ASSEMBLED P.W.B ADJUSTMENT……………………………………………………… (12)

1.1 MEMORY INITIALIZE…………………………………………………………………… (12)

1.2 MAIN AGC ADJUSTMENT………………………………………………………………

(12)

1.3 SUB AGC ADJUSTMENT………………………………………………………………..(13)

2.FINAL ASSEMBLY ADJUSTMENT…………………………………………………………(13)

2.1 CUT OFF ADJUSTMENT……………………………………………………………….. (13)

2.2 RASTER TILT ADJUSTMENT…………………………………………………………..(14)

2.3 DCU PHASE DATA SETTING………………………………………………………….. (14)

2.4 BEAM ALIGNMENT…………………………..…………………………………………..(15)

2.5 RASTER POSITION ADJUSTMENT………..………………………………………….(16)

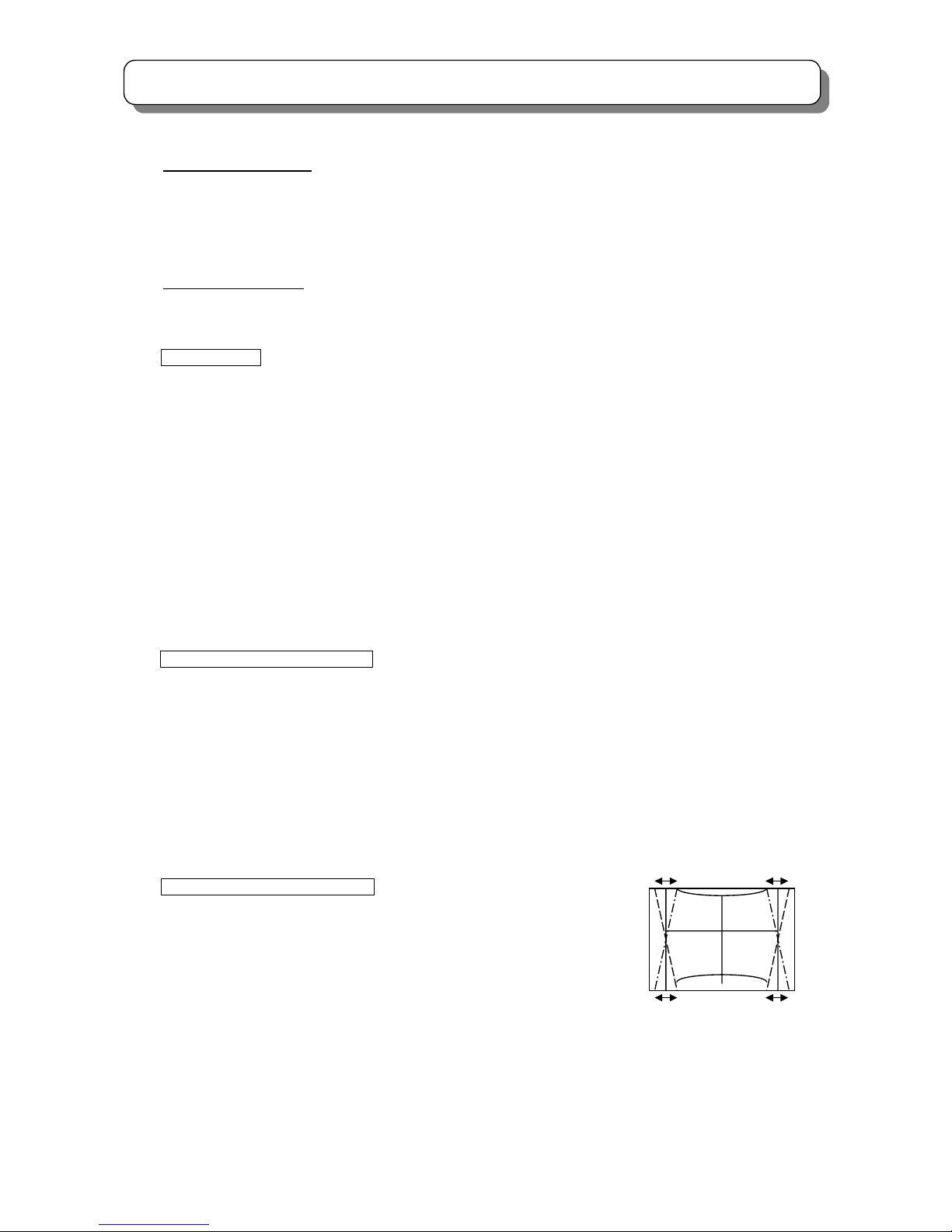

2.6 SIDE PIN DISTORTION ADJUSTMENT………..……………………………………...(17)

2.7 VERTICAL SIZE ADJUSTMENT………..………………………………………………(18)

2.8 HORIZONTAL SIZE ADJUSTMENT………..…………………………………………. (19)

2.9 TRAPEZOID DISTORTION ADJUSTMENT………..………………………………….

(20)

2.10 BEAM FORM ADJUSTMENT………..………………………………………………...(21)

2.11 LENS FOCUS ADJUSTMENT………..………………………………………………..(21)

2.12 STATIC FOCUS ADJUSTMENT………..……………………………………………..(24)

2.13 DYNAMIC FOCUS CHECK………..…………………………………………………..

(24)

2.14 DIGITAL CONVERGENCE ADJUSTMENT………..………………………………...(25)

2.15 SCANNING AREA CHECK………..…………….…………………………………... ..(34)

2.16 BLUE DEFOCUS ADJUSTMENT………..…………………………………………... (36)

2.17 WHITE BALANCE ADJUSTMENT………..………………………………………..... (36)

2.17.1 CHECK CUT OFF ADJUSTMENT………..……………………………….…..

(36)

2.17.2 WHITE BALANCE ADJUSTMENT………..…………………………………...(36)

2.18 SUB BRIGHTNESS ADJUSTMENT………..………………………………………...

(38)

2.19 SUB PICTURE WHITE BALANCE ADJUSTMENT………..………………………..

(39)

2.20 TINT ADJUSTMENT………..………………………………..……………………….. .(39)

2.21 MAGIC FOCUS INITIALIZE………..…………………………………..………….…..

(40)

2.21.1 MAGIC FOCUS INITIALIZE………..……………………………………….…. (40)

2.21.2 CONVERGENCE ERRORS………..…………………….…………….……... (41)

3. ADJUSTMENT POINT………..…………………………………..………………………....

(42)

3.1 PRT CABINET LOCATIONS…………..…..………………………………………..…..

(42)

3.2 FOCUS PACK………..……………………………………………………………….…..

(42)

3.3 MAIN P.W.B. ………..…………………………………….………………………….…..

(43)

4. SERVICE MENU………..……………………………………………………….…………....(49)

4.1 ADJUSTMENT PROCEDURE………..…………………………………………….….. (49)

4.2 SERVICE MENU………..…………………………………………………………….…..(49)

Page 12

12

SERVICE ADJUSTMENTS

● Before performing SERVICE ADJUSTMENTS, please refer to the item “TROUBLE SHOOTING”.

1. ASSEMBLED P.W.B ADJUSTMENT

1.1 MEMORY INITIALIZE

Adjustment Procedure by R/C Jig.

(1) Select item No.612 (set2) in service menu, press and hold the [RECALL] key on the remote handset until the

OSD background changes to yellow. (It takes about 3 seconds.)

(2) Wait until the OSD background color becomes normal, this means initialize is completed and each settings

become factory preset condition.

Do not unplug the outlet or perform any key operation until the initialize is completed.

Note: Other method for memory initialize: Link the PRST① and PRST② for longer than 3 seconds.

(3) Change initial-setting values according to the INITIAL-SETTING CHANGE TABLE.

(4) After set the above items in service menu, set to SHIPMENT by following method.

Select

item (set1) in service menu, press the [ENTER] key or [MUTE] key on the remote handset.

(5)

Check the setting state displayed on the upper right of a service menu.

1.2 MAIN AGC ADJUSTMENT

Adjustment Preparation

(1) To prevent circuit temperature drift, the set must apply heat run for more then 10 minutes.

(2) Check the RF signal frequency and level accuracy. (e.g. 623.25MHz, -50dBm)

(3) Confirm the function of antenna attenuation is set to OFF.

N

o. Data V203-007-898C-000112100

Color:PAL Sound:6.5

0: 0

1: 1

2: 0

3: 0

The state of Model Select setting

From the left to the 1st figure:The state of Model Select1

…

From the left to the 9th figure:The state of Model Select9

Items

C43-FD5000 C50-FD5000

1

Model Select1:ASPECT

0 0

2

Model Select2:HD

0 0

3

Model Select3:MULTI_PICTURE

0 0

4

Model Select4:DESTINATION

1 1

5

Model Select5:LANGUAGE

1 1

6

Model Select6:SOUND_SYS/COLOR_SYS

2 2

7

Model Select7:TEXT

1 1

8

Model Select8:PHOTO_MC

0 0

9

Model Select9:LIGHT

0 0

Page 13

13

SERVICE ADJUSTMENTS

Adjustment Procedure

(1) Receive ch27 China or ch40 CCIR. (623.25MHz, -50dBm) in service mode.

(2) Select item No.11 in service menu by [▲] or [▼] key.

(3-1) When the value of AGC (NO.11 in service menu) is 235 or less than 235.

(3-1-1) Push [►] key of remote control and set AGC value becomes 235 or greater than 235.

(3-1-2) Push the "MUTE" button of remote control, and then AGC adjustment is completed.

(3-2) When the value of AGC (NO.11 in service menu) is 235 or greater than 235.

(3-2-1) Set the value of AGC by [◄] key of remote control to smaller than 235.

(3-2-2) Then push [►] key of remote control and set the AGC value again to greater than and as close as 235.

(3-2-3) Push the "MUTE" button of remote control, and then AGC adjustment is completed.

1.3 SUB AGC ADJUSTMENT

Adjustment Preparation

(1) To prevent circuit temperature drift, the set must be warmed up before alignment longer than 10 minutes.

(2) Check the RF signal frequency and level accuracy. (e.g. 623.25MHz, -50dBm)

Adjustment Procedure

(1) Press [PIP] button to display sub picture, and receive the signal, ch27 China or ch40 CCIR (623.25MHz,

-50dBm) in adjustment mode.

(2) Select item No.12 in service menu by [▲] or [▼] key.

(3-1) When the value of AGC (NO.12 in service menu) is 235 or less than 235.

(3-1-1) Push [►] key of remote control and set AGC value becomes 235 or greater than 235.

(3-1-2) Push the "MUTE" button of remote control, and then AGC adjustment is completed.

(3-2) When the value of AGC (NO.12 in service menu) is 235 or greater than 235.

(3-2-1) Set the value of AGC by [◄] key of remote control to smaller than 235.

(3-2-2) Then push [►] key of remote control and set the AGC value again to greater than and as close as 235.

(3-2-3) Push the "MUTE" button of remote control, and then SUB AGC adjustment is completed.

2. FINAL ASSEMBLY ADJUSTMENT

2.1 CUT OFF ADJUSTMENT

Adjustment Preparation

(1) Pre-set (turn counterclockwise to the end) the screen VR (R, G and B) on FOCUS PACK. Then pre-heat the

set.

(2) Confirm item No. 47、48 and 49 are set to 127 in service menu.

No. V0XX

11 34 235

12 54 234

13 64

14 32

Value of AGC

Page 14

14

SERVICE ADJUSTMENTS

L

L

1

Adjustment Procedure

(1) Enter “SERVICE MENU” and select item No.10. Press [►] key to enter CUT OFF adjustment mode.

(2) Turn screen VR (R, G and B) clockwise gradually until each horizontal line (R, G or B) begins to appear.

(3) Press [◄] key to return normal mode.

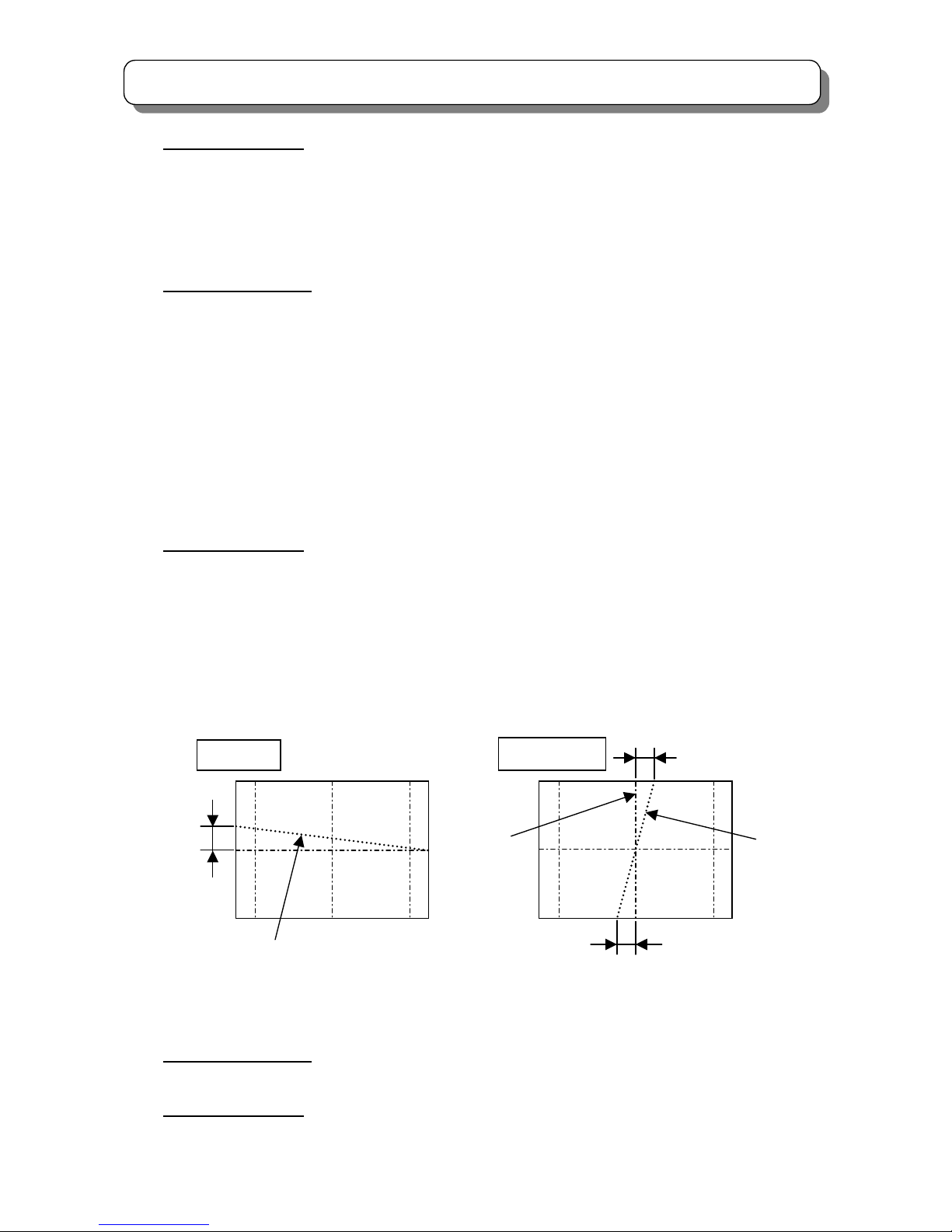

2.2 RASTER TILT ADJUSTMENT

Adjustment Preparation

(1) Face the set East or West.

(2) Receive the NTSC cross-hatch signal.

(3) Contrast should be set maximum and the other controls should be set center.

(4) The lens focus should be coarsely adjusted.

(5) The electrical focus should be coarsely adjusted.

(6) The digital convergence should not be corrected.

(7) Turn the Main power switch off.

(8) Press and hold the “SERVICE ONLY” switch on CONVERGENCE/FOCUS P.W.B. and switch on the Main

power.

Adjustment Procedure

(1) Apply covers to the R and B lenses or short the TS (2P SUB MINI Connector) on R and B on CPT P.W.B. to

project only green beam.

(2) Turn the G deflection yoke and adjust the Vertical raster inclination. (Fig. 5)

(3) Remove the cover of R or B lens and display blue light and green light together on the screen.

(4) Turn the deflection yoke of R or B and adjust the inclination of R or B light with reference to the green light as

shown on Fig. 6.

(5) After the adjustment, fix the screw of each DY with a torque of 1.18 Nm (12kgfcm).

2.3 DCU PHASE DATA SETTING

Adjustment Preparation

(1) Complete cut off adjustment.

Adjustment Procedure

(1) Receive any PAL signal and Set to 100HZ mode. (RF or VIDEO)

L2

L1, L2≦±2mm

R or B

G

L≦±2mm

Vertical center axis of cross-hatch signal

Fig. 5 Raster inclination (G)

Fig. 6 Raster inclination (R or B)

Page 15

15

SERVICE ADJUSTMENTS

(2) Contrast should be set center and the other controls should be set standard.

(3) Push the “SERVICE ONLY” switch on the CONVERGENCE P.W.B. to set the digital convergence unit to the

adjustment mode.

(4) Phase set

1) Press the [ REVEAL] key on R/C to display the green cross-hatch pattern.

2) Press the [ CHⅠ /Ⅱ ] key to recall the phase DATA on screen.

PAL 100i mode PAL 50p mode NTSC 60p mode

3) If phase data is not same as above, change the DATA by using the following R/C keys.

Press [4] or [6] key to adjust the PH-H

Press [2] or [5] key to adjust the PH-V

Press [◄] or [►] key to adjust the CR-H

Press [▲] or [▼] key to adjust the CR-V

4) Press the [REVEAL] key to exit from phase mode.

5) Press [INDEX] key on R/C twice to write the data into ROM.

6) Push the “SERVICE ONLY” switch on the CONVER P.W.B. twice to exit from adjustment mode of the

digital convergence unit.

(4) Change to PAL50p mode (Set DCU the PAL50p mode) and repeat procedure (2)-(3) for PAL50p mode.

(5) Change to NTSC mode (Set DCU to the NTSC mode) and repeat procedure (2)-(3) for NTSC mode.

2.4 BEAM ALIGNMENT

Preparation for adjustment

(1) Pre-heat 30 minutes or more before the adjustment.

(2) The static convergence data should be cleared.

(3) Raster inclination should be adjusted. Optical focus should be coarsely adjusted.

(4) Contrast should be set MAX and the other control should be set Center.

(5) Receive the NTSC cross-hatch pattern signal or Dot pattern signal.

(6) Discharge static charge from metallic parts on PRT NECK by using Short-clip-JIG.

Adjustment procedure

(1) Green (G) tube alignment: Short-circuit 2P sub-mini connectors on the red ( R ) and blue (B) CPT P.W.B.s and

project the only green beam.

(2) Set the G tube beam alignment magnet to the cancel state as shown on right.

PHASE MODE: 1

PH-H: E7

PH-V: 0C

CR-H: 35

CR-V: 1C

PHASE MODE: 6

PH-H: DD

PH-V: 07

CR-H: 33

CR-

V

: 14

PHASE MODE: 5

PH-H: E7

PH-V: 16

CR-H: 35

CR-

V

: 1C

Page 16

16

SERVICE ADJUSTMENTS

(3) Turn the static focus VR*

1

for Green fully counterclockwise and check the cross-hatch center position on the

screen.

Note : Halo state

(4) Turn the static focus VR*

1

for Green fully clockwise.

(5) Turn 2 sheets of the alignment magnet in either direction and move the cross-hatch center to the position

where is checked in step (3).

(6) Turn the static focus VR*

1

for Green and check if the picture position moves or not.

(7) Repeat steps (2) to (6) until the picture position does not move during step (6)

(8) In the same manner, adjust the Red ( VR )*

2

and the Blue (VR)*3 tube alignments.

(9) Fix the beam alignment magnet with white paint after the alignment is completed.

VR*

1

VR*

2

Static Focus VR is on focus pack UFPK

VR*3

2.5 RASTER POSITION ADJUSTMENT

Preparation for adjustment

(1) Place the set facing east or west.

(2) Receive the NTSC Hitachi circle pattern signal. (Set the NTSC mode)

(3) Contrast control should be set Maximum and the other controls should be set Center.

(4) The raster inclination and beam alignment should be adjusted.

The lens focus and electric focus adjustment should be coarsely adjusted.

(5) The convergence should be uncorrected state.

(6) Turn the Main power SW off.

(7) Press and hold the “SERVICE ONLY” SW. on CONV./FOCUS P.W.B. and switch on the Main power.

(8) Press “SERVICE ONLY” SW again to display the DCU’s cross-hatch pattern.

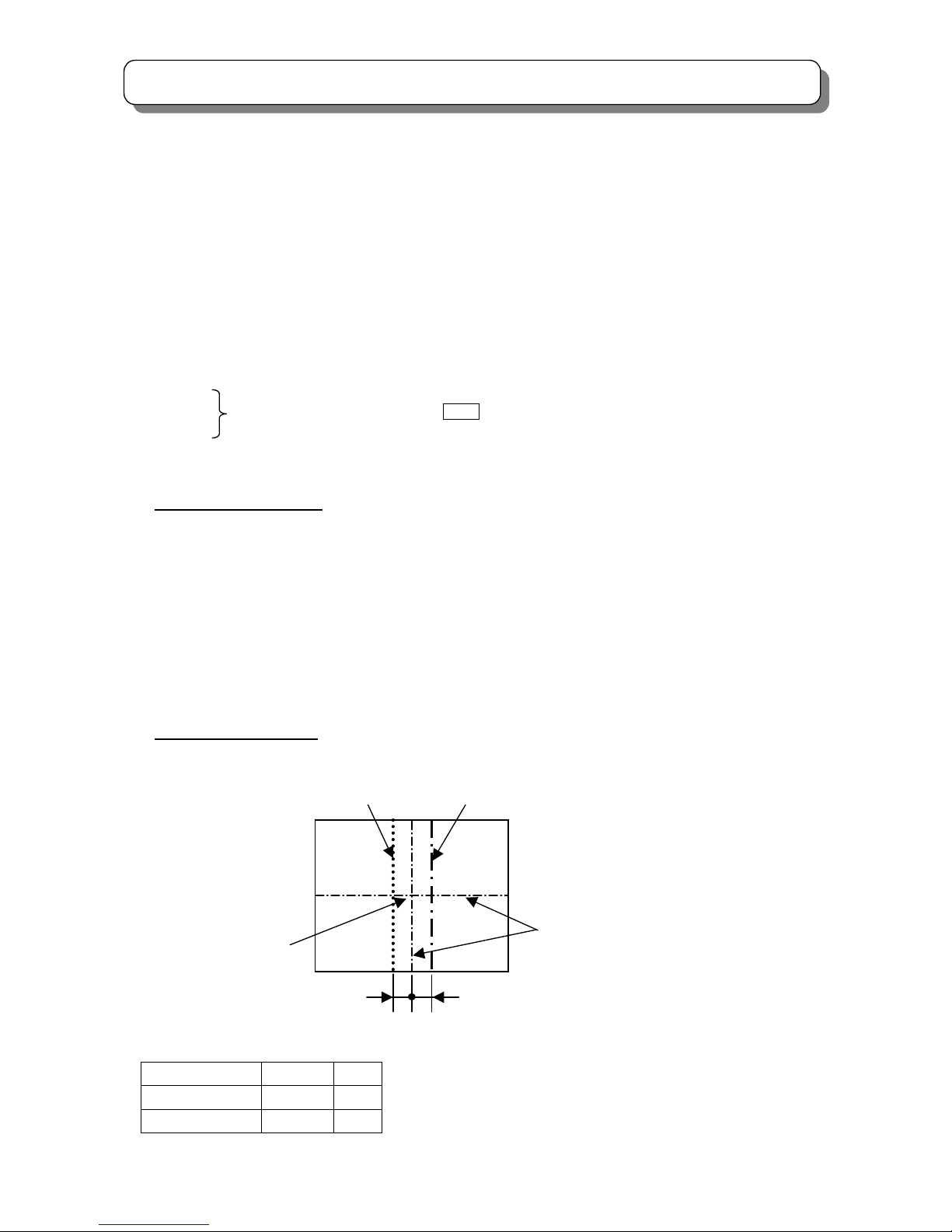

Adjustment procedure

(1) Turn the centering magnets for R, G and B to get the center point of the cross-hatch position

within specification as shown below.

R B

Geometric center of the screen

G

[Horizontal direction] Unit:mm

R: L

1

to the left from the geometric center of the screen,L1±2mm

B: L

2

to the right from the geometric center of the screen,L2±2mm

G: To geometric center of screen.

4:3 L1 L

2

43” 20 30

50” 20 30

L

2

L1

Page 17

17

SERVICE ADJUSTMENTS

[Vertical direction]

Both of the distance between the central horizontal line of R, B and the geometric center of the screen should be

within ±2mm.

(2) After the adjustment is completed, fix the R, G and B centering magnets using white paint.

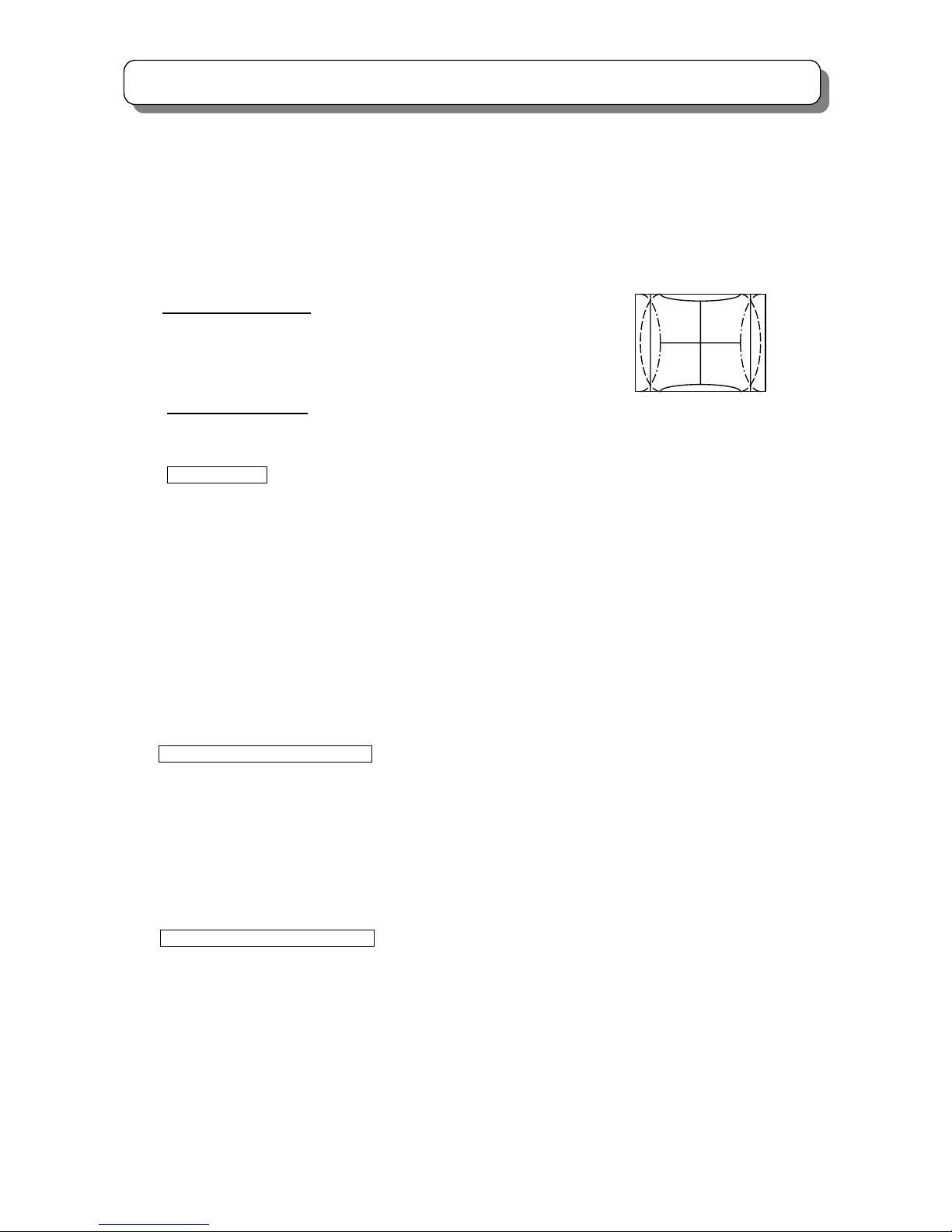

2.6 SIDE PIN DISTORTION ADJUSTMENT

Adjustment Preparation

(1) VIDEO control should be set to Factory Preset condition.

(2) Place the set facing east.

(3) DCU ROM CHECK should be completed.

Adjustment Procedure

PAL 100i MODE I2C No.15

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose FUNCTION and SCAN, and set to 100Hz mode.

(4) Press [MENU] key twice to exit from FUNCTION.

(5) Press and hold the SERVICE ONLY SW. on CONV./FOCUS P.W.B. and press [MUTE] key of Hands

-et. Green DCU cross-hatch are appeared with Conv. Data cleared.

(6) Press the [TV/VIDEO] button on the control panel, then SERVICE MENU appears.

(7) Choose SIDE PIN (EW parabola) item by using Handset up/down cursor key.

(8) Adjust SIDE PIN as following by using Handset left/right cursor key.

(9) Press [MUTE] key of handset to write the adjusted data.

(10) After adjustment, press SERVICE ONLY SW. to exit from SERVICE mode.

PAL 50Hz PROGRESSIVE MODE I

2

C No.19

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose FUNCTION and SCAN, and set to Progressive mode.

(4) Press [MENU] key to exit from FUNCTION.

(5) Adjust the same items as (5)-(10) of setting PAL 100i MODE.

NTSC 60Hz PROGRESSIVE MODE I

2

C No.23

(1) Input any NTSC signal.

(2) Adjust the same items as (5)-(10) of setting PAL 100i MODE.

Edge of vertical DCU cross-hatch line

should be straight condition.

Note: If it’s impossible to adjust the

straight line, set a little pin condition.

Page 18

18

SERVICE ADJUSTMENTS

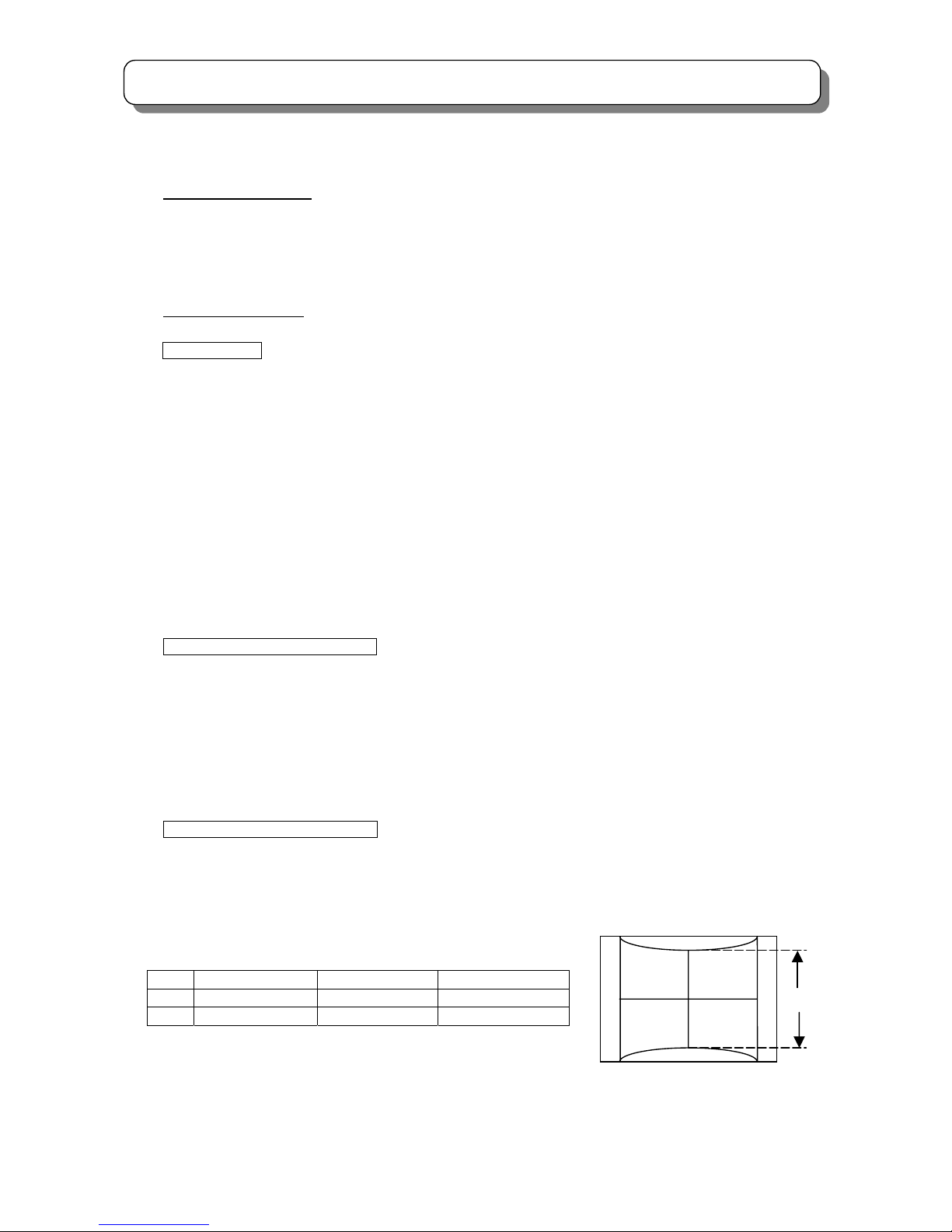

2.7 VERTICAL SIZE ADJUSTMENT

Adjustment Preparation

(1) VIDEO control should be set to Factory Preset condition.

(2) DCU ROM CHECK should be completed.

(3) Place the set facing east.

Adjustment Procedure

PAL 100i MODE I

2

C No.13

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose FUNCTION and SCAN, and set to 100Hz mode.

(4) Press [MENU] key to exit from FUNCTION.

(5) Press and hold the SERVICE ONLY SW. on CONV./FOCUS P.W.B. and [MUTE] key of Handset.

Green DCU cross-hatch are appeared with Conv. Data cleared.

(6) Press the input selector, then SERVICE MENU appears.

(7) Choose V.SIZE (amplitude) item by using Handset up/down cursor key.

(8) Adjust V.SIZE (amplitude) as following by using Handset left/right cursor key.

So that the distance between the topmost horizontal line and the bottommost horizontal line of DCU’s

cross-hatch pattern is L.

(9) Press [MUTE] key of handset to write the data.

(10) After adjustment, press SERVICE ONLY SW. for exit from SERVICE mode.

PAL 50Hz PROGRESSIVE MODE I

2

C No.17

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose FUNCTION and SCAN, and set to Progressive mode.

(4) Press [MENU] key to exit from FUNCTION.

(5) Adjust the same items as (5)-(10) of setting PAL 100i MODE.

NTSC 60Hz PROGRESSIVE MODE I

2

C No.21

(1) Input any NTSC signal.

(2) Adjust the same items as (5)-(10) of setting PAL 100i MODE.

Unit: mm Tolerance: ±5mm

L PAL 100i mode PAL 50p mode NTSC 60p mode

43” 525 525 560

50” 610 610 650

L

The distance between the topmost

horizontal line and the bottommost

horizontal line

Page 19

19

SERVICE ADJUSTMENTS

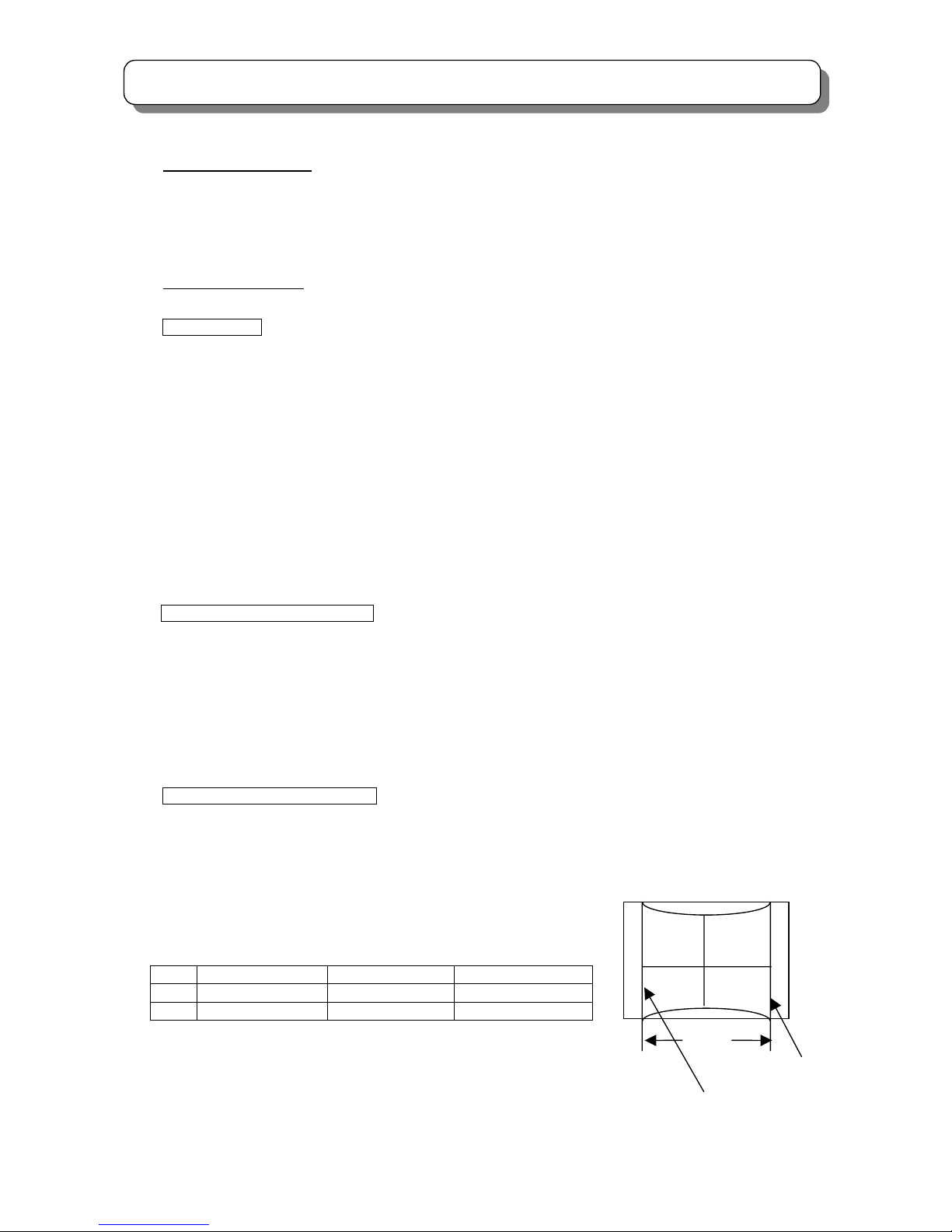

2.8 HORIZONTAL SIZE ADJUSTMENT

Adjustment Preparation

(1) VIDEO control should be set to Factory Preset condition.

(2) DCU ROM CHECK should be completed.

(3) Place the set facing east.

Adjustment Procedure

PAL 100i MODE I

2

C No.14

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose FUNCTION and SCAN, and set to 100Hz mode.

(4) Press [MENU] key twice to exit from FUNCTION.

(5) Press and hold the SERVICE ONLY SW. on CONV./FOCUS P.W.B. and [MUTE] key of Handset.

Green DCU cross-hatch are appeared with Conv. Data cleared.

(6) Press the input selector, then SERVICE MENU appears.

(7) Choose H.SIZE (EW SIZE) item by using Handset up/down cursor key.

(8) Adjust H.SIZE (EW SIZE) as following by using Handset left/right cursor key.

So that the distance between the left vertical line and the right vertical line of DCU’s cross-hatch

pattern is L.

(9) Press “MUTE” key of handset to write the data.

(10) After adjustment, press SERVICE ONLY SW. for exit from SERVICE mode.

PAL 50Hz PROGRESSIVE MODE I

2

C No. 18

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose FUNCTION and SCAN, and set to Progressive mode.

(4) Press [MENU] key to exit from FUNCTION.

(5) Adjust the same items as (5)-(10) of setting PAL 100i MODE.

NTSC 60Hz PROGRESSIVE MODE I

2

C No.22

(1) Input any NTSC signal.

(2) Adjust the same items as (5)-(10) of setting PAL 100i MODE.

Unit: mm Tolerance: ±5mm

L PAL 100i MODE PAL 50p MODE NTSC 60p MODE

43” 830 830 830

50” 965 965 965

L

The left line

The right line

Page 20

20

SERVICE ADJUSTMENTS

2.9 TRAPEZOID DISTORTION ADJUSTMENT

Adjustment Preparation

(1) VIDEO control should be set to Factory Preset condition.

(2) HORIZONTAL SIZE adjustment should be completed.

(3) Place the set facing east.

Adjustment Procedure

PAL 100i MODE I

2

C No.16

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose FUNCTION and SCAN, and set to 100i mode.

(4) Press [MENU] key twice to exit from FUNCTION.

(5) Press and hold the SERVICE ONLY SW. on CONV./FOCUS P.W.B. and [MUTE] key of Handset.

Green DCU cross-hatch are appeared with Conv. Data cleared.

(6) Press the input selector, then SERVICE MENU appears.

(7) Choose TRAPEZOID item by using Handset up/down cursor key.

(8) Adjust TRAPEZOID as following by using Handset left/right cursor key.

(9) Press “MUTE” key of handset to write the data.

(10) After adjustment, press SERVICE ONLY SW. for exit from SERVICE mode.

PAL 50Hz PROGRESSIVE MODE I

2

C No.20

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose FUNCTION and SCAN, and set to 50P mode.

(4) Press [MENU] key to exit from FUNCTION.

(5) Adjust the same items as (5)-(10) of setting PAL 100i MODE.

NTSC 60Hz PROGRESSIVE MODE I

2

C No.24

(1) Input any NTSC signal.

(2) Adjust the same items as (5)-(10) of setting PAL 100i MODE.

Vertical Screen frame line & edge

of vertical DCU cross-hatch line

should be parallel condition.

Page 21

21

SERVICE ADJUSTMENTS

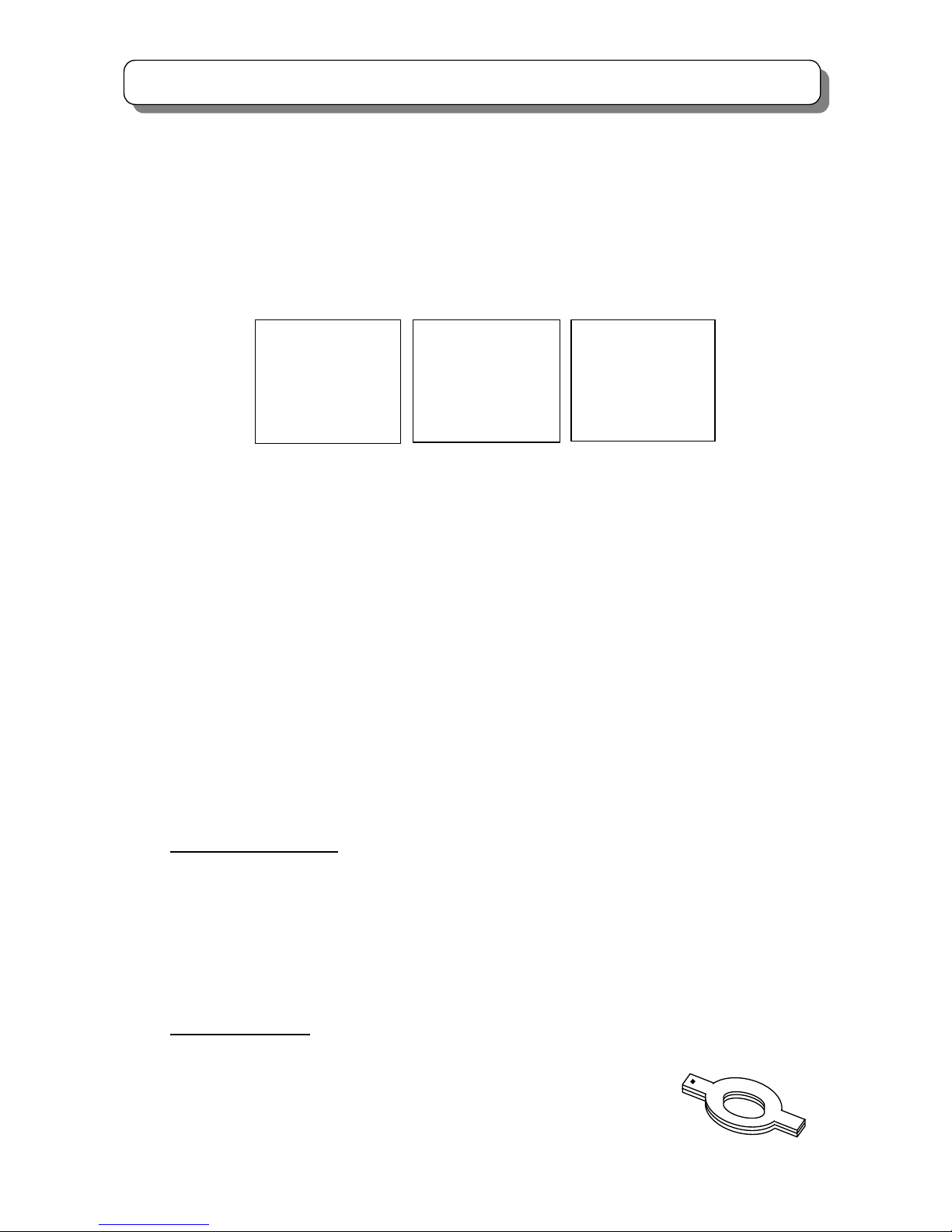

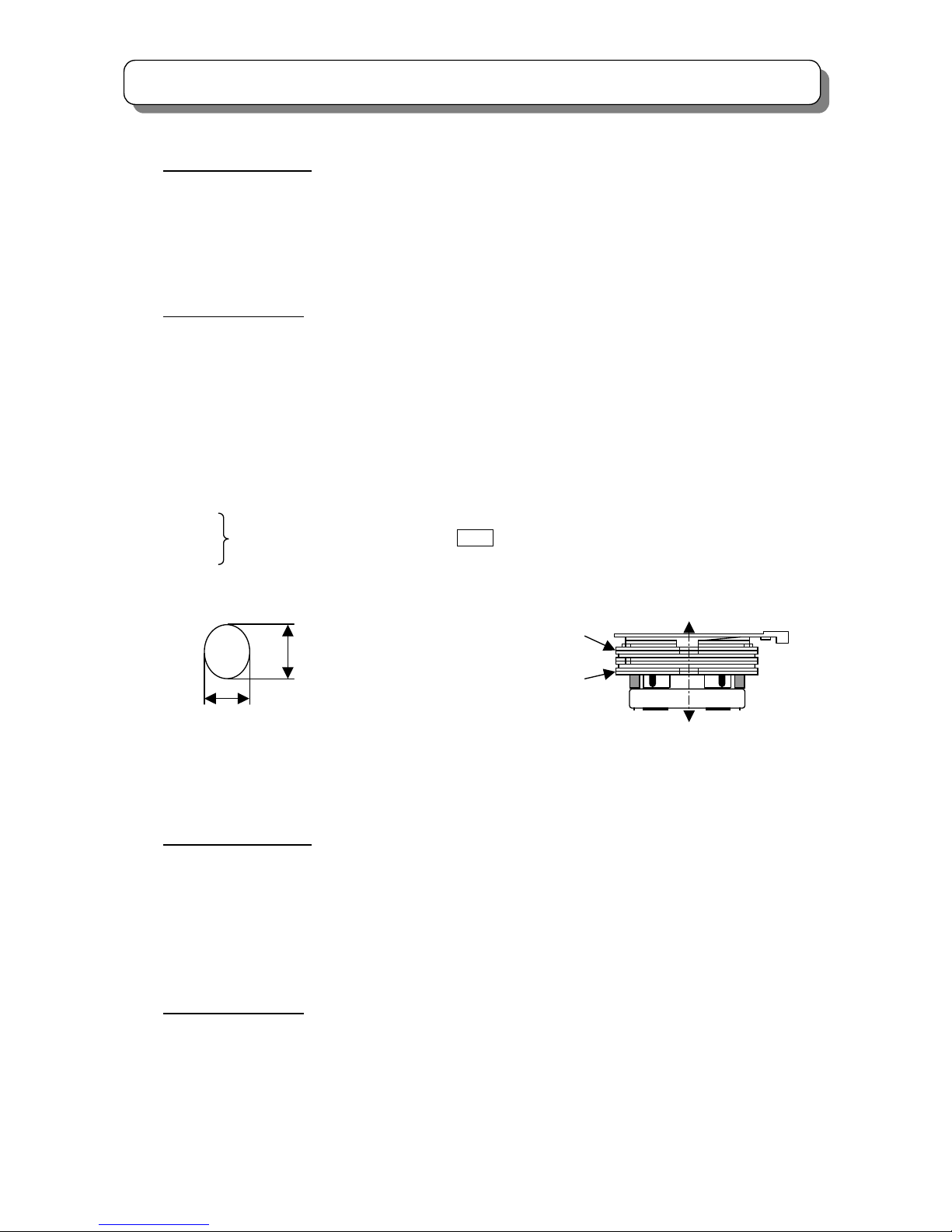

2.10 BEAM FORM ADJUSTMENT

Adjustment Preparation

(1) The beam alignment should have been completed.

(2) The raster inclination, centering, horizontal and vertical size adjustments should be completed. Optical focus

should be coarsely adjusted.

(3) VIDEO control should be set to Factory Preset condition. (Contrast: Max;other item: Center)

(4) Input the dot signal.

Adjustment Procedure

(1) Green PRT beam shape adjustment. Short-circuit 2P sub-mini connectors on Red and Blue CPT P.W.Bs. to

project only the green beam.

(2) Turn the green static VR

*1

fully clockwise.

Note : Blooming

(3) Make the dot at the screen center a true circle using the 4-pole magnet shown below.

(4) Repeat the procedure for the Red

*2

and Blue*3 PRT beam shapes

(5) After complete the adjustment, return R, G and B static VRs to the best focus point.

(6) After complete the beam alignment, fix the beam alignment magnet with white paint.

*1

*2 Static Focus VR is on FOCUS PACK UFPK

*3

2.11 LENS FOCUS ADJUSTMENT

Adjustment Preparation

(1) The orientation of PTV set is arbitrary, west, east, north and south.

(2) Centering DY inclination should be adjusted.

(3) Electrical focus adjustment should have been completed.

(4) Drive VR location adjustment should have been completed.(Red : 12 0’clock, Green : 1~2 0’clock)

(5) Receive the NTSC cross-hatch signal.

Contrast control should be set Center and Brightness control should be set minimum.

Adjustment Procedure

(1) Loosen the fixing screws or wing nuts on the lens cylinder so that the lens cylinder can be turned. (Be careful

not to loosen too much). After completing steps (4), (5), (6) below, tighten the fixing screws or wing nuts for

each lens with a torque of 0.67N.m(7Kgfcm) ~1.18N.m(12Kgfcm). (Do not turn the lens cylinder after tighten

the screws and wing nuts. Also do not over tighten the screw, otherwise the lens might be tilted or the screw

might be broken).

a

b

True circle specification

Specification : 0.9~1.1

True circle Form Ratio: a/b

PRT surface side

PRT E. gun side

4-pole beam shape

correction magnet

2-pole beam alignment

magnet

Page 22

22

SERVICE ADJUSTMENTS

Lens sass Lens sass

TYPE 1 TYPE 2

(2) Apply covers to colors of R, G and B lenses so as to project a single color beam on the screen and adjust in

sequence. (The adjustment order of R, G and B is only an example.)

(3) If the lens adjustment knob is turned clockwise (viewed from the front), the color aberration changes as

follows:

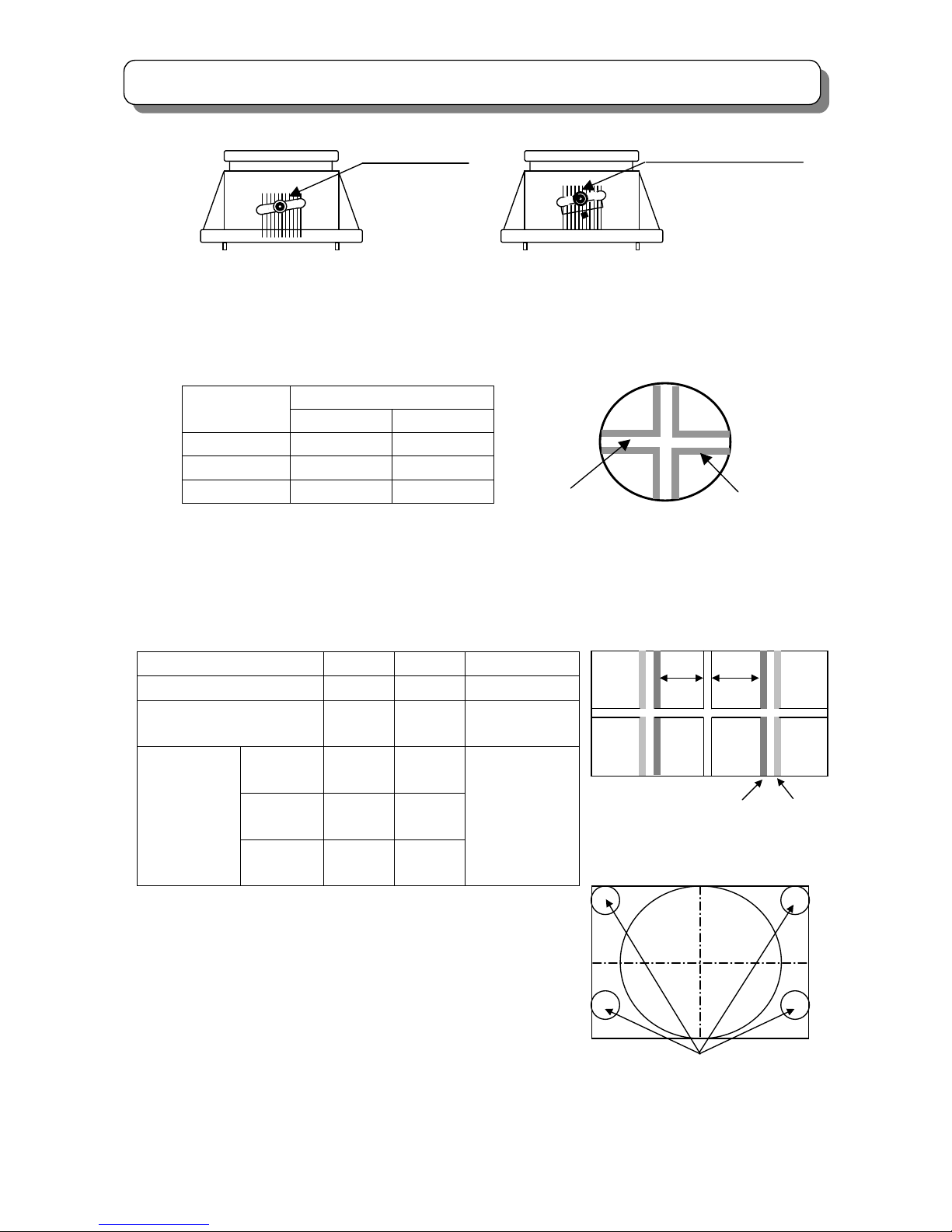

(4) In the case of G lens.

Set to the point where the chromatic aberration switches from blue to red. If the chromatic aberration

appearing all over the screen is not the same, observe the vertical bright line and adjust lens focus as specified

in table below. When the red chromatic aberration appearing at both sides of the bright line is not equal,

observe the side with larger chromatic aberration when adjusting.

HSA

SCB UNIT

SCREEN SIZE

43” 50”

INCH

L1 and L2

(PITCHES from CENTER)

3.0 3.0

CROSS-HATCH

PITCHES

BETWEEN

L1&L2

* *

I

*

(2mmMAX) * (2mmMAX)

COLOR

ABERRATION

O

**

(2mmMAX)

**

(2mmMAX)

REFER TO

NOTE BELOW

NOTE : * Slightly reddish or no color.

** Slightly bluish or no color.

Change the signal to the circular pattern and fine-adjust. Observe

the corners of the screen, especially the numbers in the small circle

when adjusting. If the focus performance at the screen center

exceeds the lower limit, it is acceptable.

NOTE1:

Since the G light is very important for picture quality and performance. Pay special attention in its adjustment. Be

careful not to touch the lens with your fingers when adjusting.

Color aberration

Cross-Hatch

Change of color aberration

Short focus Long focus

RED LENS Orange Scarlet

GREEN LENS Blue Red

BLUE LENS Purple Green

L1 L2

I O

Small circle of circle pattern

(NOTE 1)

Fixing screws

(NOTE 2)

Fixing Wing nuts

Page 23

23

SERVICE ADJUSTMENTS

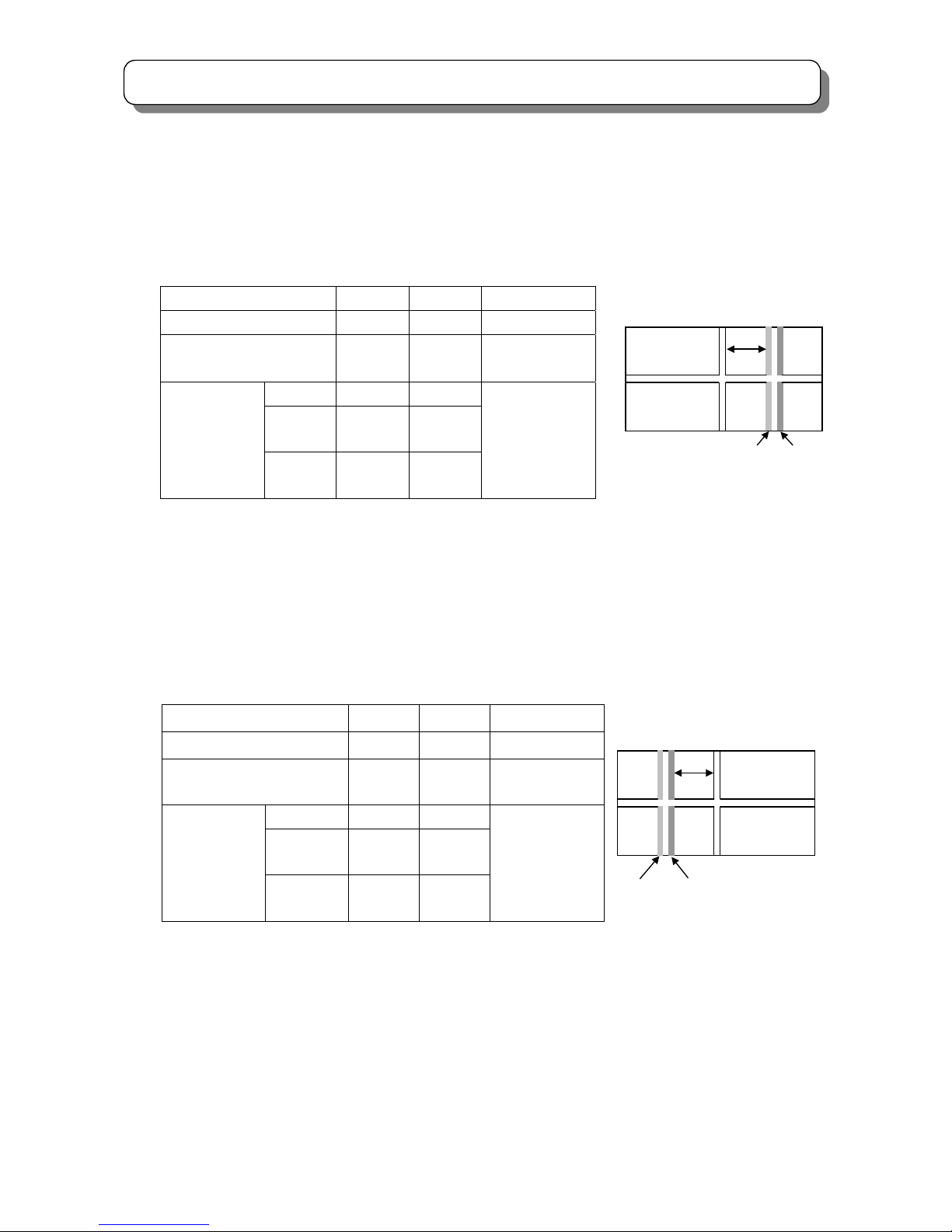

(5) In the case of R lens.

Set the position where the chromatic aberration changes from red to crimson as shown below. Observe

the vertical bright line and adjust lens focus where the crimson or red chromatic aberration slightly

appears inside and crimson or red outside (reference value: 1~3mm) at the point specified in the table

below. Change the signal and fine-adjust in the same way as the G lens.

OPTICAL FOCUSING ADJUSTMENT RED

LENS HSA SCB UNIT

SCREEN SIZE

43” 50”

INCH

PITCHES from CENTER

6.0 7.0

CROSS-HATCH

PITCHES

SIDE

* *

I

*

(2mmMAX)* (2mmMAX)

COLOR

ABERRATION

O

**

(2mmMAX)

**

(2mmMAX)

REFER TO

NOTE BELOW

NOTE: * Slightly reddish or no color ** Slightly crimson or no color

NOTE 2: Adjust to the position such that Red and crimson is optimum.

(6) In the case of B lens.

Set the position where the chromatic aberration changes from purple to green as shown below.

Observe the vertical bright line and adjust lens focus where the purple or green chromatic aberration

slightly appears inside and purple or green outside (reference value: 1~3mm) at the point specified in the

table below. Change the signal and fine-adjust in the same way as the G lens.

LENS HSA SCB UNIT

SCREEN SIZE

43” 50”

INCH

PITCHES from CENTER

6.0 5.0

CROSS-HATCH

PITCHES

SIDE

* *

I

*

(2.0mmMAX)* (2.5mmMAX)

COLOR

ABERRATION

O

**

(2.0mmMAX)

**

(2.5mmMAX)

REFER TO

NOTE BELOW

NOTE: * Slightly purple or no color ** Slightly green or no color

NOTE 3: Setting to the center between purple and green is optimum.

(7) After all colors have been adjusted, display all colors with the cross-hatch pattern signal and compare the

focus (optical focus) performance with the limit sample set.

(8) Then, select the circular pattern signal and compare the focus (optical focus) performances of each color

and all colors together with the limit sample set.

(9) If the focus performance is worse than the limit sample set, re-adjust step (1) to (6).

L

I

O

L

I

O

Page 24

24

SERVICE ADJUSTMENTS

2.12 STATIC FOCUS ADJUSTMENT

Adjustment Preparation

(1) The raster inclination, centering, horizontal/vertical amplitude and optical/electrical focus and beam alignment

should be adjusted.

(2) The digital focus data should be cleared.

(3) Contrast control should be set maximum and brightness control should be set center.

(4) Receive the Hitachi circular pattern signal G24-CH.

(5) Apply covers to the others then adjusting lenses and project only single color on the screen.

Adjustment Procedure

(1) Red static focus adjustment: Vary the static focus VR on Focus pack (UFPK) (for red) so that the right edge of

Hitachi mark on the circular pattern is the clearest. Check that the focus does not get conspicuously worse at

other check point on the cross-hatch signal.

(2) Blue static focus adjustment: Vary the static focus VR on Focus pack (UFPK) (for blue) so that the Hitachi

mark on the circular pattern is the clearest. Check that the focus does not get conspicuously worse at all

edges of the cross-hatch signal.

(3) Green static focus adjustment: Vary the static focus VR on Focus pack (UFPK) (for green) so that the Hitachi

mark on the circular pattern center is t the clearest. Check that the focus does not get conspicuously worse at

the checking point on the periphery of picture and the cross-hatch signal.

Remarks

Checking point for the periphery of picture

2.13 DYNAMIC FOCUS CHECK

Preparation for Check

(1) The raster inclination, centering, horizontal/vertical amplitude and optical/electrical focus and beam alignment

should have been adjusted.

(2) The static convergence data should be cleared.

(3) Contrast control should be set maximum and brightness control should be set center.

(4) Receive the cross-hatch pattern signal.

Checking Procedure

(1) Short-circuit the sub mini connectors of Red (R) and Blue (B) on the CPT P.W.B. and project the Green (G)

color.

(2) Turn the static focus VR for Green (G) so that the picture center is just in focus.

(3) Check that the focus does not get conspicuously worse at all edges of the picture.

Checking point

Page 25

25

SERVICE ADJUSTMENTS

Checking points for horizontal direction:

Checking points for vertical direction:

Static focus VR for green is VR on Focus pack (UFPK).

2.14 DIGITAL CONVERGENCE ADJUSTMENT

Preparation for Check

(1) Place the set facing east or west.

(2) Pre-heat 20 minutes or more before the adjustment.

(3) The horizontal/vertical amplitude should have been adjusted.

How to adjust by using remote controller

(1) Receive any PAL signal. (RF or VIDEO)

(2) Turn the set on and set it in PAL 100i mode.

(3) Push the “SERVICE ONLY” switch on the

CONVERGENCE/FOCUS P.W.B. to set digital convergence

unit to the adjustment mode.

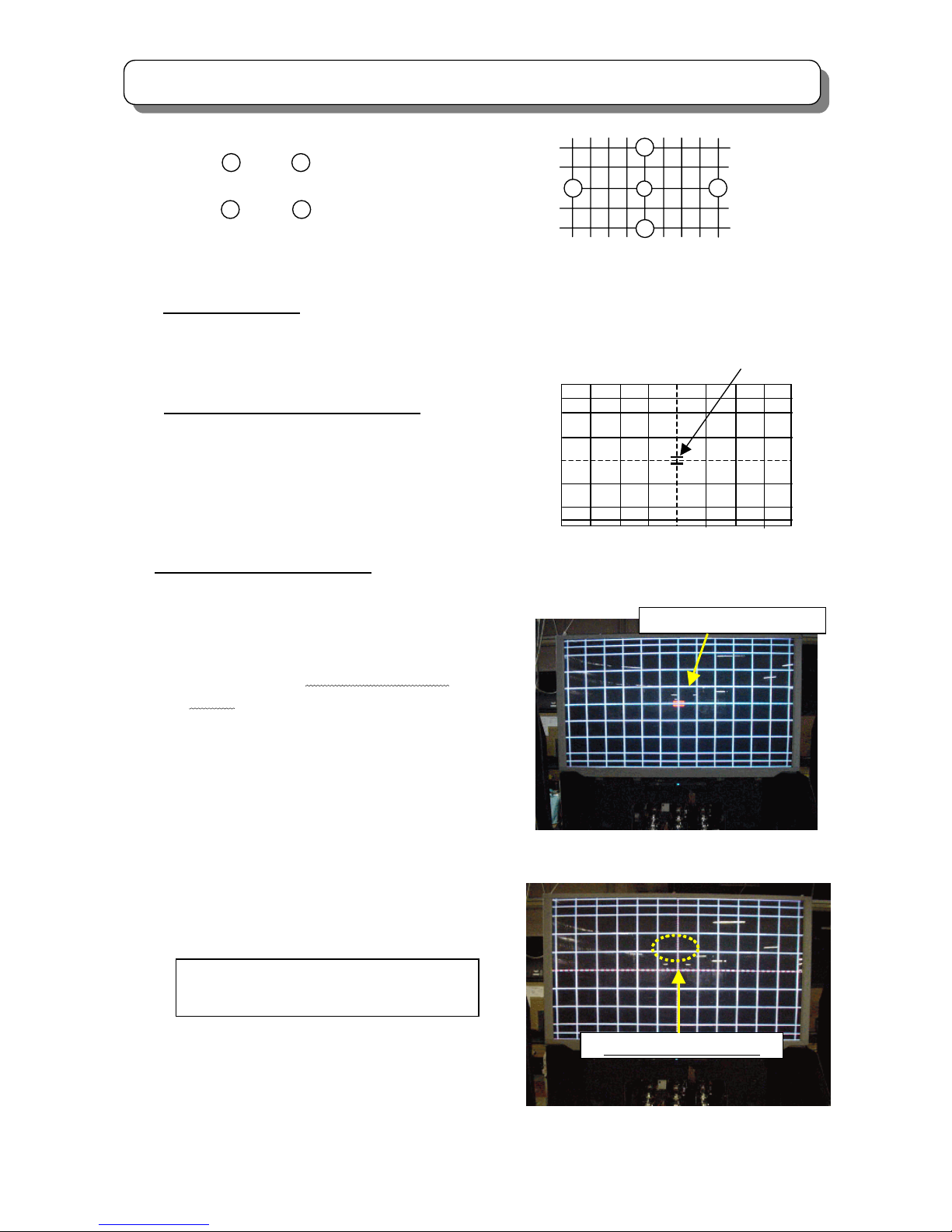

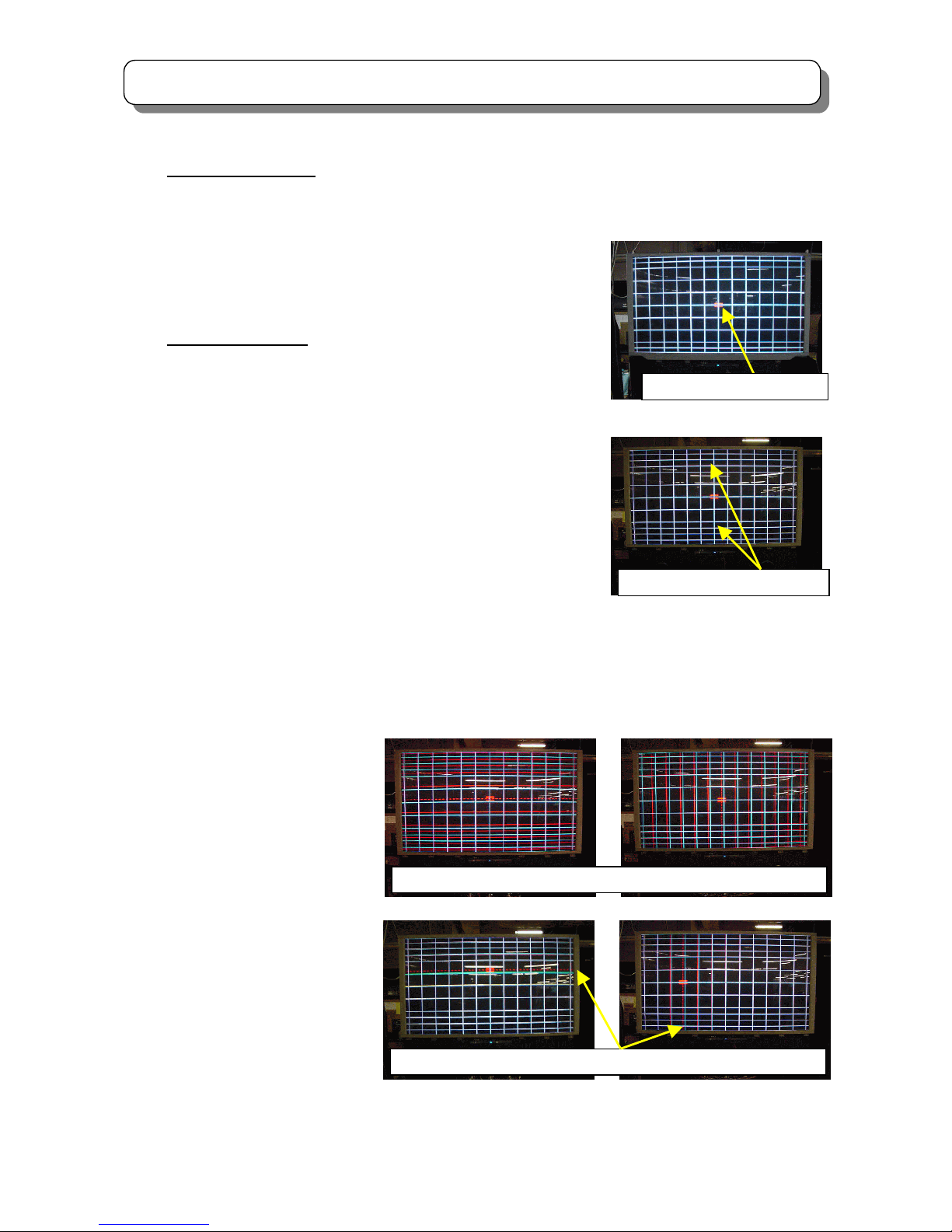

* Adjustment Point Marker ON/OFF

This function can improve view of adjustment point at CONVERGENCE adjustment mode.

a) Press Service Switch on Def/Conv. PWB to set to

CONVERGENCE adjustment mode, then display

Normal Crosshatch with "Adjustment Point

marker". (Fig.1)

b) Press [TV/TEXT] key on R/C, then display only

Normal Crosshatch, without "Adjustment Point

Marker". (Fig.2)

Adjustment Point is indicated as broken line

crossing.

c) Press [TV/TEXT] key on R/C again, then display

Normal Crosshatch with "Adjustment Point

Marker" again. (Fig.1)

(4) Phase Adjustment

See page 43, 27. DCU PHASE

(4) Phase Adjustment

See item “DCU PHASE DATA SETTING”.

3 9

6

12

C

3

9

6

12

A

djustment mode

A

djustment point

Maker is NOT displayed

Fig.1

Adj

ustment Point Marker

A

nd repeat procedure b) ~ c) by each press

[TV/TEXT] key on R/C.

Fig.2

Page 26

26

SERVICE ADJUSTMENTS

(5) Fine adjustment.

Adjustment points are 117 points. (H: 13 points x V: 9 points)

Adjustment points can be moved using [2], [4], [5], [6] keys. For better

result, adjust convergence from center to outside of the screen.

(6) Green convergence adjustment.

Press [▼/ CH down] key on R/C to select green convergence mode.

Adjust green cross-hatch line, using [▲], [▼], [◄], [►] (cursor) key.

(7) Red convergence adjustment.

Press [0] key on R/C to select red convergence mode. Adjust each red

line to green cross-hatch line, using [▲], [▼], [◄], [►] (cursor) key.

(8) Blue convergence adjustment.

Press [▲/ CH up] key on R/C to select blue convergence mode.

Adjust each blue line to green cross-hatch line, using [▲], [▼], [◄], [►]

(cursor) key.

(9) Calculation *

After complete convergence adjustment, press [MODE] key on R/C and the calculation mode starts. The

operation time takes about 2 seconds and no picture appears during this operation. This operation fills

convergence data between each adjustment points.

Check the mis-convergence; refer to

(Mis-convergence check)

. If you find mis-convergence more than this specification, adjust convergence

again.

(10) Write data to ROM

Press [INDEX] key on R/C.

First press, “ROM WRITE?” is displayed.

Second press, Data starts to write to ROM, this takes about 3 seconds and no picture appears during this

operation. If green dot pattern appears, writing operation has succeeded. Press [MUTE] key to return to the

adjustment mode. If red dot pattern appears, writing operation has failed. Replace digital convergence unit

and re-adjust. Push the “SERVICE ONLY” switch again to finish the adjustment.

* Step (9) ‘Calculation’ process can be omitted by pressing [MODE] key, because step (10) ‘ Write data to ROM’

process includes calculation process as well.

ROM WRITE by pressing [INDEX] key twice: ① Calculation process

② Writing data to ROM

(11) The digital convergence has 3 modes includes NTSC/60p , PAL/50p , PAL/100i. Change the other mode and

adjust again step (1) to (11) again.

NOTES:

(1) [CH Ⅰ/Ⅱ ] button……Cross-hatch/Video mode

Press [CH Ⅰ/Ⅱ ] 5 times to display external signal.

Press [CH Ⅰ/Ⅱ ] 5 times again to return to DCU internal cross-hatch.

(2) [MENU] button……….Remove color mode

Press [MENU] to switch between all colors displayed or adjustment color and Green only.

Press [0] then press [MENU], Red and Green displayed (Blue removed)

Press [▲/ CH UP] then press [MENU], Blue and Green displayed (Red removed)

Press [▼/ CH DOWN] then press [MENU], Only Green displayed

A

djustment point

Page 27

27

SERVICE ADJUSTMENTS

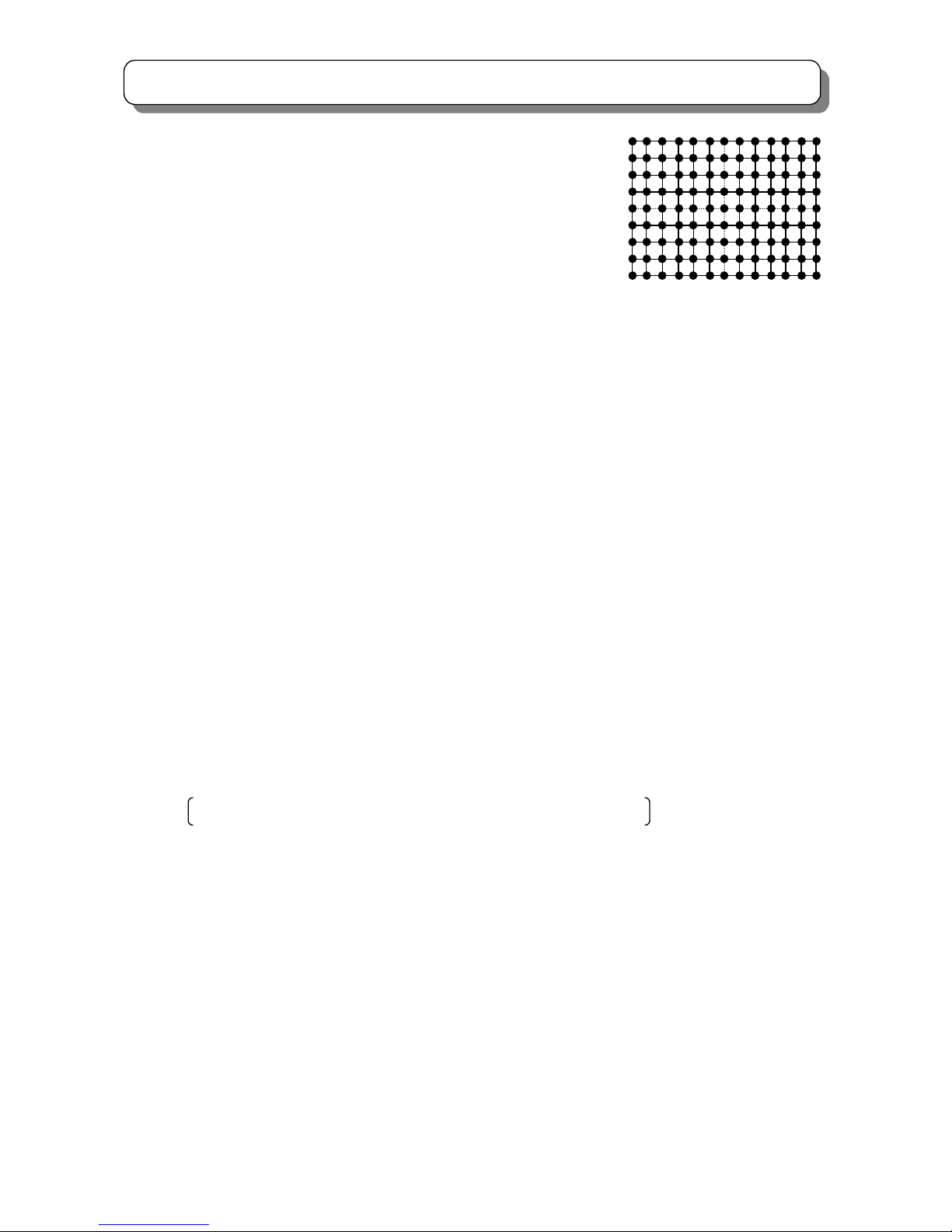

* Explanation of "Conv. For Outside Signal" function

(a) Press the “SERVICE ONLY” switch on DEF/Conv PWB, then

display "Normal Crosshatch". (Fig.1)

(b) Press [MENU] key on R/C, then display "Red + Green

Crosshatch with Red Marker" or "Green Crosshatch with

Green Marker" or "Blue + Green Crosshatch with Blue

Marker". (Fig.2)

(c) Press [MENU] key on R/C again, then display "Normal

Crosshatch" on Main Picture". (Fig.3)

(d) Press [MENU] key on R/C again, then display "Cross Marker

+ Box Marker " on Main Picture". (Fig.4)

(e) Press [MENU] key on R/C again, then display "only Box

Marker on Main Picture". (Fig.5)

(f) Press [MENU] key on R/C again, then display "Normal

Crosshatch" again. (Fig.1)

And repeat procedure (b) ~ (f) by each press [MENU] key on

R/C.

Fig.3

Marke

r

Fig.5 Fig.4

Marke

r

Marke

r

Fig.2

Fig.1

Marker (Adjustment point)

Marker

Page 28

28

SERVICE ADJUSTMENTS

(3) [SUB] button…raster position adjust

Adjustment preparation

a) Position adjustment...This will move an entire color. Use this adjustment to match colors at the center of

the screen.

b) Use the buttons below to switch color to adjust:

[▼/ CH down] : Green

[0]: Red

[▲/ CH up] : Blue

Adjustment procedure

a) Press the [SUB] button. Extra horizontal lines appear to confirm

raster position mode.

b) Use the cursor buttons to adjust position.

c) Press [SUB] again to exit from raster position mode.

Notes

: 1) Other functions cannot be accessed during the raster

position adjustment mode; Press [SUB] to exit from raster

position mode, and confirm extra horizontal lines are

disappeared.

2) Press [MENU] to switch between all colors displayed

or adjustment color and Green only.

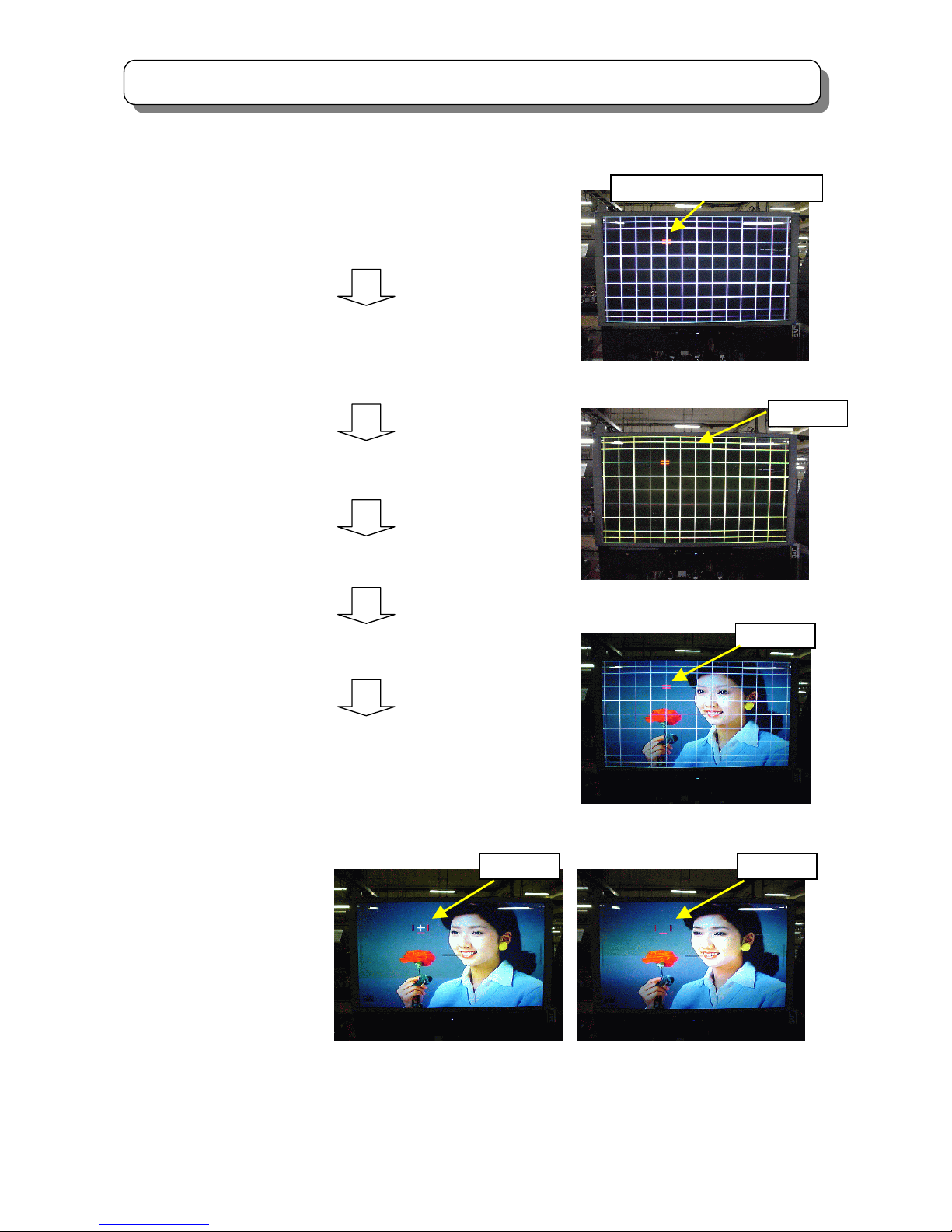

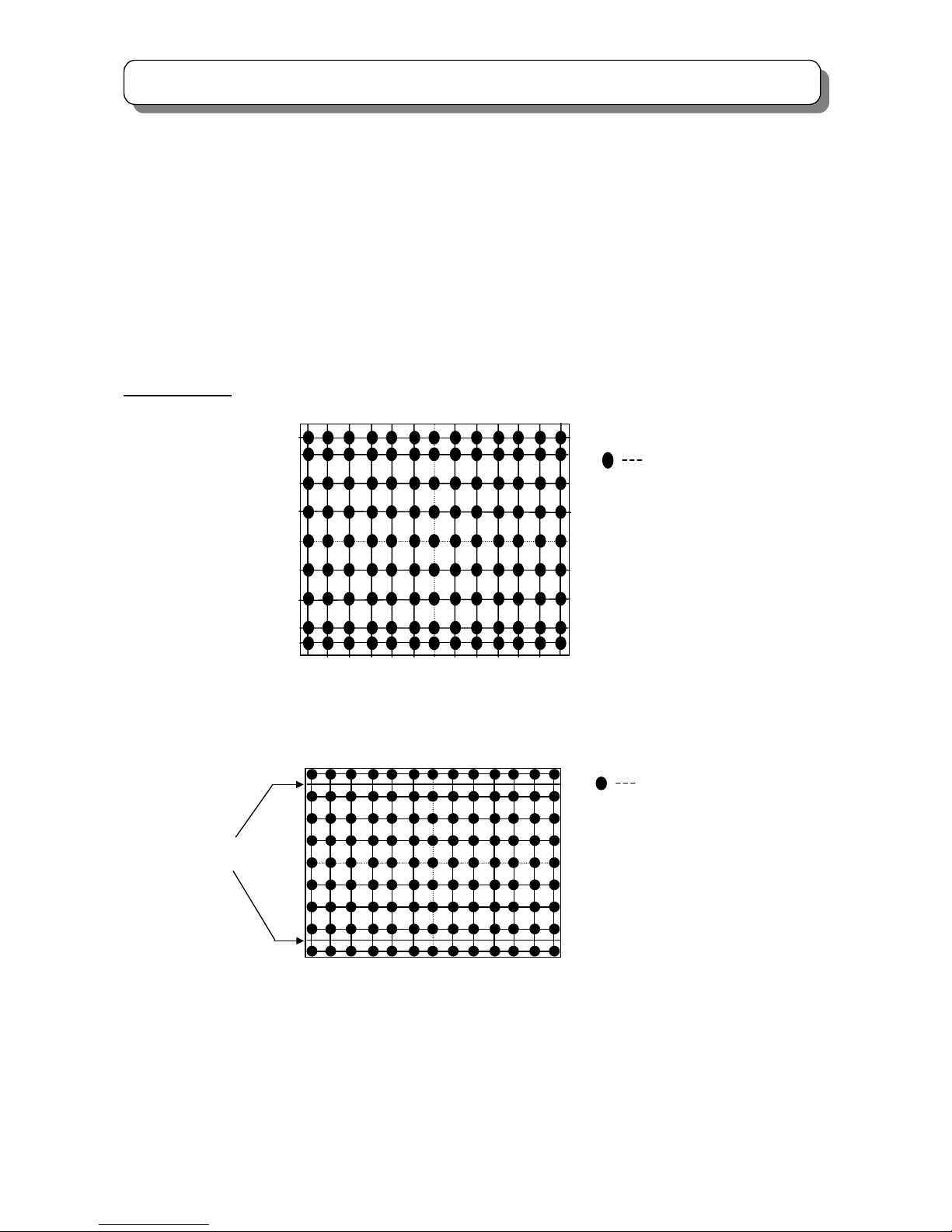

*Convergence Data Adjustment Method

This function can adjust convergence data of all of one line (or all of screen) at the same time in

CONVERGENCE adjustment mode.

a) Press the “SERVICE ONLY” switch on DEF/Conv PWB to set to CONVERGENCE adjustment mode,

and then display Normal Crosshatch with Adjustment Point Marker. (Fig.1)

b) Press [SUB] key on R/C,

then the extra horizontal

lines appeared as set to

RATER POSITION

ADJUSTMENT MODE.

(Fig.2)

1) If Adjustment Point is

on center, by press

cursor key ([↑ ], [ ← ],

[↓], [→]) on R/C, then

Convergence Data of

all of screen are

exchanged at the same

time.

ex) Fig.3 (Fig.4) : By press [↑] ([←]) key on R/C, move up (left) RED convergence data of all of

screen.

Fig.2

Extra Horizontal line is added

Fig.4 Fig.3

Convergence Data (RED) of all of screen is exchanged.

Fig.6 Fig.5

Convergence Data (RED) of all of line is exchanged.

Fig.1

Adjustment Point Marker

Page 29

29

SERVICE ADJUSTMENTS

2) If the Adjustment point is not on center, by press cursor key on R/C, then Convergence Data of all of

one line include existing Adjustment Point Marker are exchanged at the same time.

ex) Fig.5 (Fig.6) : By press [↑] ([←]) key on R/C, move up

(left) RED convergence data of all of horizontal (vertical)

line include existing Adjustment Point Marker.

c) Press [SUB] key on R/C again to exit RATER POSITION ADJUSTMENT MODE.

Adjustment point

NOTE: PAL mode can be confirmed by extra horizontal lines.

A

djustment point

9 x 13 = 117 point

A

djustment point (NTSC 60p mode)

Extra horizontal line

A

djustment point

9 x 13 = 117 point

A

djustment point (PAL 50p,PAL 100i mode)

Page 30

30

SERVICE ADJUSTMENTS

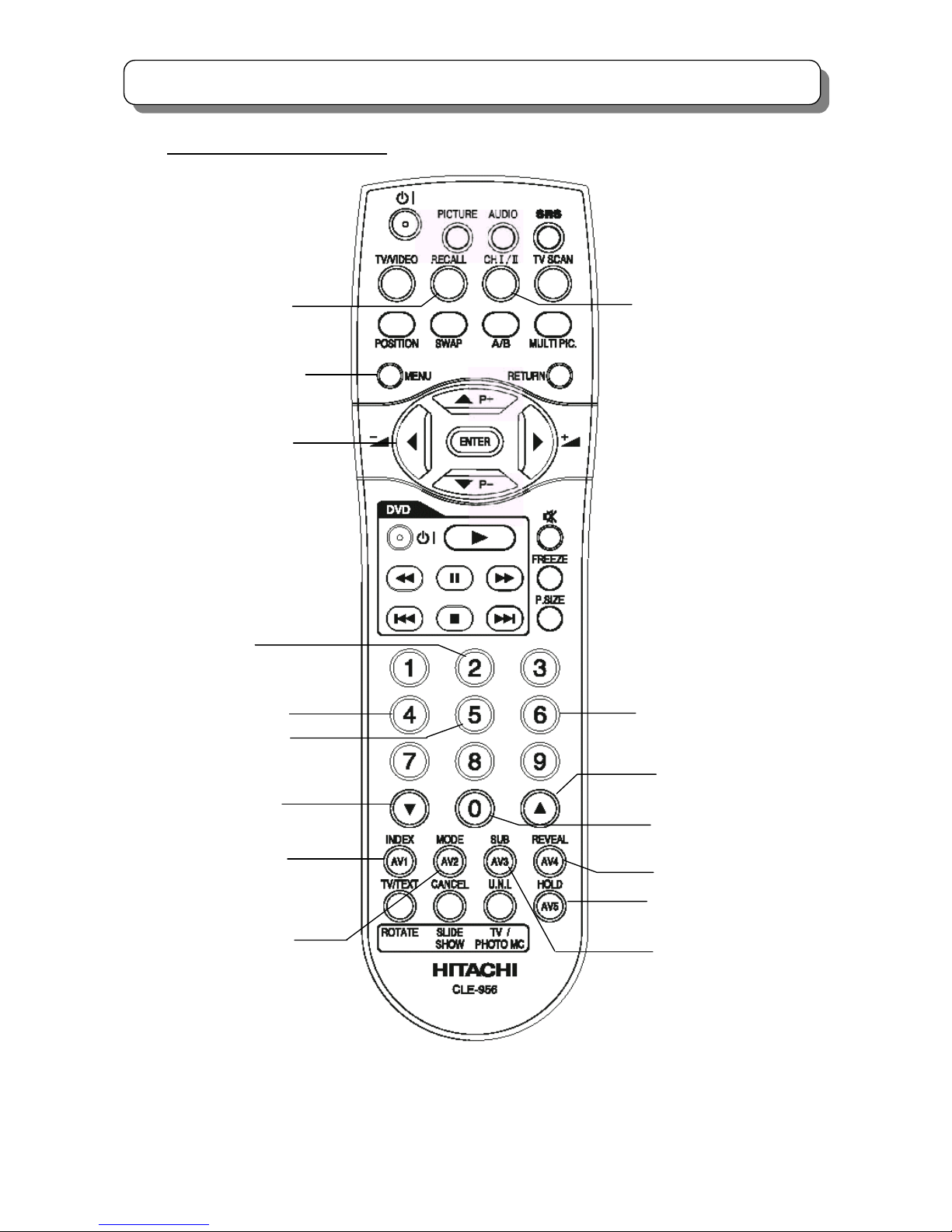

Digital convergence remote control

CURSOR UP

CURSOR LEFT

CURSOR DOWN

GREEN (3x3 ADJ.*)

REMOVE COLOR

A

DJUSTMENT

ROM WRITE

CURSOR RIGHT

RASTER POSITION

CALCULATION

INITIALIZE

PHASE

ROM READ

CROSSHATCH /

VIDEO MODE

BLUE (13×9 Fine ADJ.)

RED (5×7 ADJ.

)

NOTE: 3×3 Adjustment mode can be selected only after DCU uncorrected state.

(DCU uncorrected state: With the Power off, PRESS AND HOLD the Service Only button, then press the Powe

r

On/Off button at the same time until power is applied… Release Both.)

Page 31

31

SERVICE ADJUSTMENTS

Specification of digital convergence cross-hatch

4:3 NTSC 60p MODE

43” DIGITAL CONVERGENCE CROSSHATCH

50”

DIGITAL CONVERGENCE CROSSHATCH

UNIT:mm

876

10.2 10.2

2.0

73.3 83.9 83.9 73.3

2.0

654

71.3 71.3

83.9

71.3 71.3 71.3 71.3 71.3 71.3 71.3 71.3 71.3 71.3

83.9 83.9 83.9

UNIT:mm

1020

12.0 12.0

2.4

85.5 97.7 97.7 85.5

2.4

762

83.0 83.0

97.7

83.0 83.0 83.0 83.0 83.0 83.0 83.0 83.0 83.0 83.0

97.7 97.7 97.7

Page 32

32

SERVICE ADJUSTMENTS

4:3 PAL 100i MODE

43”

DIGITAL CONVERGENCE CROSSHATCH

50”

DIGITAL CONVERGENCE CROSSHATCH

UNIT:mm

876

5.0

78.1

9.6

654

78.1

3.0 3.0

72.5 72.5

72.5 72.5 72.5 72.5 72.5 72.5 72.5 72.5 72.5 72.5

78.1 78.1 78.1

9.6

5.0

78.1

78.1 78.1

UNIT:mm

1020

5.8

91.0

11.2

762

91.0

3.6 3.6

84.4 84.4

84.4

91.0 91.0 91.0

11.2

5.8

91.0

91.0 91.0

84.484.484.484.484.484.484.484.484.4

Page 33

33

SERVICE ADJUSTMENTS

4:3 PAL 50p MODE

43”

DIGITAL CONVERGENCE CROSSHATCH

50”

DIGITAL CONVERGENCE CROSSHATCH

UNIT:mm

1020

5.8

91.0

11.2

762

91.0

3.6 3.6

84.4 84.4

84.4

91.0 91.0 91.0

11.2

5.8

91.0

91.0 91.0

84.484.484.484.484.484.484.484.484.4

UNIT:mm

876

5.0

78.1

9.6

654

78.1

3.0 3.0

72.5 72.5

72.5 72.5 72.5 72.5 72.5 72.5 72.5 72.5 72.5 72.5

78.1 78.1 78.1

9.6

5.0

78.1

78.1 78.1

Page 34

34

SERVICE ADJUSTMENTS

2.15 SCANNING AREA CHECK

Checking condition

(1) Digital convergence adjustment should be completed.(PA L、NTSC)

(2) Receive the Hitachi circle pattern signal. (PAL 、NTSC)

(3) Contrast and Brightness should be set Factory Preset condition.

(Contrast : max Other controls : Center position)

(4) Check that the scanning area matches with the next drawing.

(5) The digital convergence has 3 modes. Change the other mode then check again.

(6) Check the horizontal center position. If the center is shifted, readjust to center position.

*Service menu No.70 : Horizontal position for PAL 100i mode.

No.71 : Horizontal position for PAL 50p mode.

No.72 : Horizontal position for NTSC 60p mode.

Page 35

35

SERVICE ADJUSTMENTS

Inner edge of the circle

H size marker

0.7~2

Outer edge of the circle

H size marker

0.7~2

53

35

Top and bottom of the circle is between outer edge and inner edge.

PAL 100i/PAL 50p/NTSC MODE

Page 36

36

SERVICE ADJUSTMENTS

2.16 BLUE DEFOCUS ADJUSTMENT

Adjustment Preparation

(1) Optical and electrical focus adjustment should be completed.

(2) The convergence adjustment should be completed.

(3) VIDEO control should be set to Factory Preset condition. (Contrast: maximum; Other items: center)

Adjustment Procedure

(1) Input cross-hatch signal to VIDEO or RF input.

(2) Turn the B FOCUS VR fully clockwise.

(3) If blue does not satisfy specification as shown in the table below, adjust it by turning the B FOCUS VR

counterclockwise.

Blue Defocus Luminance

CHASSIS DP3M UNIT

Screen size 43” 50” INCH

Blue out of specification 1.5 1.5 mm

Note: The view point should be limited to the center of the screen for this adjustment. (FOB 0.0)

2.17 WHITE BALANCE ADJUSTMENT

2.17.1 CHECK CUT OFF ADJUSTMENT

Adjustment Preparation

(1) Pre heat-run should be completed.

Adjustment Procedure

(1) Go to “SERVICE item No.10” and press [►] key to enter CUT OFF adjustment mode by using JIG R/C.

(2) Check that each line just appears.

(3) If some of lines are brighter or darker than others, apply CUT OFF adjustment again.

(4) Press [◄] key to return normal mode.

2.17.2 WHITE BALANCE ADJUSTMENT

Adjustment Preparation

(1) Pre-heat 20 minutes or more before the adjustment.

(2) VIDEO control should be set to Factory Preset condition. (Contrast: maximum; others: center)

(3) Color temp. : COOL

(4) Signal: High Light white balance adjustment: WHOLE WHITE 100 IRE

Low Light white balance adjustment: WHOLE WHITE 25 IRE

Blue out of specification

High brightness white balance Low brightness white balance

Service mode Item No. Service mode Item No.

Red : (R DRV) 45 Red : (R cut OFF) 47

Green: (G DRV) 46 Green: (G cut OFF) 48

Blue : (B cut OFF) 49

Sub Brightness should be adjusted roughly

before adjust the white balance.

Page 37

37

SERVICE ADJUSTMENTS

※ COMPONENT INPUT (input Y signal to “Y” terminal of AV1& insert a connector without signal to the

“P

R”

terminal of AV1)should be used in order to reduce digital noise.

※ Use signal without color burst. If it is not possible, use PAL signal and turn off comb filter in User Menu.

(5) BLUE defocus adjustment should be finished.

(6) The vertical incident illumination on the screen should be 20 lux or less.

Adjustment procedure

A) High Light W/B adjustment:

(1) Receive signal for High Light white balance adjustment.

(2) Adjust the white balance to 14000K+0MPCD (X, Y) = (0.266,0.270) at the screen center by using JIG R/C.

Use item No. 45 (R DRV) to adjust X, item No. 46 (G DRV) to adjust Y.

B) Low Light W/B adjustment

(1) Receive signal for Low Light white balance adjustment.

(2) Adjust the white balance to (X, Y) = (0.266,0.270) by using R/C. Use item No.47 (R CUT OFF) to adjust X,

item No.49 (B CUT OFF) to adjust X &Y. Do not change the item No.48 (G CUT OFF) setting.

C) Repeat A & B two or three times.

(Press [MUTE] button on the R/C when adjustment has completed.)

White balance adjustment flowchart

FINISH

Cut off Adj

Sub Brightness Adj (roughly)

If Bluish

Check

Low light W/B

Adjust Low light W/B

Adjust High light W/B

sub brightness Adj

START

Repeat two or three times, until no

adjustment is needed

Check

Low light W/B

High light W/B

Sub brightness

If NG

If OK

BLUE defocus Adj

Page 38

38

SERVICE ADJUSTMENTS

2.18 SUB BRIGHTNESS ADJUSTMENT

Adjustment Preparation

(1) Pre-heat 20 minutes or more before the adjustment.

(2) Receive the color bar signal.

(3) The vertical incident illumination on the screen should be 20 lux or less.

Adjustment Procedure

(1) Go to “Sub Brightness (item No. 44)” in adjustment mode by using JIG R/C.

(2) Adjust Sub brightness following the specification as shown below by using JIG. R/C.

(3) Press [MUTE] key on R/C to write the data into ROM.

REMARKS

Observe the TV SET screen directly by eye; Do not use a mirror.

Adjustment specification: Within ± 0.3 step

Quality control specification: Within ± 0.5 step

Note: During the SUB-BRIGHTNESS adjustment mode, TV Micron IC changes the CONTRAST and the COLOR

controls to Minimum, but the other controls are not changed automatically.

Make sure that the other controls are set center.

CHASSIS Sink to black Slightly for black

DP3M A0 A1

Note: Actual procedure, set A1 portion to black (same level as A0 portion) and reduce 6 steps to set A1 portion

slightly brighter.

A0 A1 A2A3A4A5A6A7A8A

9

A10

Page 39

39

SERVICE ADJUSTMENTS

2.19 SUB PICTURE WHITE BALANCE ADJUSTMENT

Adjustment Procedure

(1) Observe P852 on the CPT P.W.B. and change the SUB CONTRAST (Item No. 61) of service mode by

using jig R/C and adjust so that the amplitude of the sub-picture is the same as that of the main-picture.

(shown on below)

(2) Press [MUTE] key to write the data.

* Adjustment specification : ±1V

* Quality control specification : ±3V

* Wave form of P852 = Cathode

(Sub picture level compared with main picture level)

* Perform this adjustment after the white balance and sub-brightness adjustments of the main picture are

completed.

* White balance 14000K±0 MPCD (Color coordinates: x=0.266 y=0.270)

2.20 TINT ADJUSTMENT

(1) Preparation

Pre heat run should be finished.

(2) Input window pattern signal like below to the AV3 and AV4.

1H

CATHODE WAVE FORM

WHITE (CATHODE VOLTAGE)

MAIN PICTURE

1/2H

1/2V

INT Y = 0%

EXT Y = 0%

INT C = 100%

EXT C = 100%

INT C = -90°

EXT C = +90°

Page 40

40

SERVICE ADJUSTMENTS

(3) Enter to split mode and display AV3 and AV4.

(4) Enter to service mode.

(5) Observe “B” cathode and adjust the INT level and EXT level.

Item 64 for main, item 65 for sub.

Press [MUTE] key on R/C to write the data into ROM.

2.21 MAGIC FOCUS INITIALIZE

2.21.1 MAGIC FOCUS INITIALIZE

Adjustment Preparation

(1) Receive the PAL cross-hatch or PAL circle pattern signal and set 100Hz mode.

(2) Digital convergence adjustment should be completed.

Adjustment Procedure

(1) Press the R/C Jig. command (Jig code: 509E) to start initialize operation.

(2) Several windows appear during this operation. It takes about 45 seconds by green dots appear after

initialize operation is completed.

(3) Check that green dots appear.

(4) Turn the power switch off.

(5) Change the PAL 50p mode and repeat the procedure (1) - (3) for PAL50p mode.

(6) Change the signal to NTSC circle pattern and repeat the procedure (1) - (3) for the NTSC 60p mode.

Initialize operation

OSD: PAL 100i mode *INITIAL:1*

PAL 50P mode *INITIAL:5*

NTSC 60P mode *INITIAL:6*

NOTE: The digital convergence has 3 modes NTSC 60p, PAL 100i, PAL 50p.

Therefore this adjustment needs 3 modes.

REMARKS Another way to start the initialize operation:

(1) Press ”SERVICE ONLY” SW on CONVER/FOCUS P.W.B. to set DCU the adjustment mode.

(2) Press [INDEX] key on R/C. Then “ROM WRITE?” message is displayed to confirm the ROM writing.

(3) Press [ RECALL ] key on R/C to cancel the ROM writing and start initialization.

It takes about 45 seconds by green dots appear after initialization is completed.

(4) Check that green dots appear.

*INITIAL: 6*

Page 41

41

SERVICE ADJUSTMENTS

Note: If any error message (red) appears, refer to “CONVERGENCE ERRORS”.

CONVERGENCE ERRORS

If there is an error while performing INITIALIZE or MAGIC FOCUS, error code or message appears on the

screen as shown on the following table.

When MAGIC FOCUS operates: Error code (‘GREEN’) appears for about 1 second in bottom right corner, and

then returns to RF or video signal.

When INITIALIZE operates: Error message (RED) appears all the time.

REMARKS *1) Relation of sensor No. and screen position as shown below:

Error

Code

Error Massage Contents Countermeasure/ Check method

1 VF ERROR ! EEPROM Write Error

2

CONNECT1 !

No.01234567

OVER FLOW !

No.01234567 *1

Connection Check Error

(Pattern is not detected)

3

A/D LEVEL !

No.01234567

OVER FLOW !

No.01234567 *1

Calibration Error

(Small difference between

High and Low brightness)

Replace the DCU

Darken outside light

Check the placement of the sensor Is pattern hitting

to sensor?

Check connection and solder bridge of sensor

Replace the sensor

Sensor connector check

Sensor P.W.B. check

Adjustment check (H/V size, centering)

4 OVER FLOW !

Data over flow Error

(Saturation of corr. Dada)

5

Convergence

error(The number of

adjustment times is

more than setting.)

Convergence Error

(The number of ADJ. Times

is more than setting.)

Check the placement of the sensor

Adjustment check

(H/V size, centering)

Convergence AMP circuit check

6 LOOP COUNT ! Not use

7 OPERATION ! Make setup data error Same as error code 4

8 CHECK SUM ! Deferent SRAM-EEPROM Replace the DCU

9

CONNECT2 !

No.01234567 *1

Connect data set error(ADJ.

Parameter PORT80-87 Is

Wrong setting)

Same as error code 2

10 NOISE ! Sensor noise error

Input strong field strength signal

Check the wire dressing of connector between

sensor and DCU.

11 SYNC ! H BLK, V BLK error

Input strong field strength signal

Input standard signal NTSC or PAL

0 1 2

6 5 4

7 3

On screen

(View from front side)

sensor No. 0-7

Page 42

42

SERVICE ADJUSTMENTS

3. ADJUSTMENT POINT

3.1 PRT CABINET LOCATIONS

FRONT

3.2 FOCUS PACK

(4) 4-POLE MAGNET FOR BEAM FORM ADJUSTMENT

(5) BEAM ALIGNMENT MAGNET

(6) FOCUS PACK

(1) CENTERING MAGNET FOR RED PRT

(2) CENTERING MAGNET FOR GREEN PRT

(3) CENTERING MAGNET FOR BLUE PRT

R G B

FOCUS PACK

SCREEN GREEN

SCREEN BLUE

FOCUS BLUE

SCREEN RED

FOCUS GREEN

FOCUS RED

1 4 3

2

5

46

5

Page 43

43

SERVICE ADJUSTMENTS

3.3 MAIN P.W.B.

(1) SIGNAL P.W.B.

PSC

PH12P

PBS

VH12P

PAS1

EH10P

PFSH2

EH2P

PFSH1

PH10P

PFS

EH13P

PRST

PH2P

PJIG

EH7P

I501

I001

TERMINAL

PWB

(PIP)

U401

FLEX

CONTROL

SUB SIGNAL

PWB

U301

U302

Main

Tune

r

Sub

Tune

r

Look down view

Page 44

44

SERVICE ADJUSTMENTS

(2) SIGNAL SUB P.W.B.

IG02

IS02

IS01

IT01

IQ01

IG01

Look down view

Page 45

45

SERVICE ADJUSTMENTS

REAR VIEW

(3) DEFLECTION/CONVERGENCE P.W.B.

Look down view

DIGITAL

CONVERGENCE

“SERVICE ONLY” switch

SK01

DF1

I601

MB MG MR

Q701

IK04

IK05

TH01

QH01

Q777

PAD J

XA6P

D708

RH17

SUB DEF. PWB

Q712

Page 46

46

SERVICE ADJUSTMENTS

(4) CPT/CONTROL/LED P.W.B.

(5) CONTROL P.W.B.

(6) LED P.W.B.

P852

(Cathode)

P851

E851

GND

GREEN

3 1

P802

(

Cathode

)

P801

E801

GND

RED

3 1

P8A1

E8

A

GND

BLUE

3 1

P8A2

(Cathode)

CPT P.W.B.

(16:9 MODEL)

MENU

VOL-DOWN

CH-UP

VOL-UP

CH-DOWN

IR RECEIVER

PPL1

PCC1

PFS

POWER LED(BLUE)

PHOTO MC LED(GREEN)

TV/VIDEO

CONTROL P.W.B.

PLL2

BLUE LED

LED P.W.B.

Page 47

47

SERVICE ADJUSTMENTS

(5) AV INPUT P.W.B.

(6) AC SW P.W.B.

(7) AutoPower P.W.B ( Only for 191,982)

INPUT 5

S

MAIN

HEAD PHONE

L R V

SUB

HEAD PHONE

MAGIC

F

OCUS

PF1

PCC2

PFN

PCIA

PCIB

I9X1

R9XB

R9XA

R9XD

R9XC

Q9X1

PPX2

PPX1

Page 48

48

SERVICE ADJUSTMENTS

(8) DP3M POWER P.W.B.

IAA1

PPS1 PPS3 PPS4 PPS5 PPS6

PSP

PPD3

PPD1

PPD4 PPD1

PPC1

D901

S901

D956

Audio

E903

+220V

U901

I901

F9C1

FUSE

F903

FUSE

T901

Switching Transformer

D955

SW+5.5V

D913

SBY+5V

D912

Main

Power

I902

ACK

I903

FB

D932

+B

E907

+B

E906

+B Reg

E905

-28V

E901

Audio

E904

+28V

EAG1

Audio-GND

PPC2

Stand-by

Module

Main Power SW

Back Cover Side

(Green)

(Green)

(Green)

(Green)

(Red)

E902

+10V

PPS2

PPD2

PC1

PC2

China Model

onl

y

Page 49

49

SERVICE ADJUSTMENTS

4. SERVICE MENU

4.1 ADJUSTMENT PROCEDURE

(1) Receive signal on main picture, then turn off the main power.

(2) Press and hold the [TV/VIDEO] button on Control Panel and then Power ON to access service

adjustment mode. (Hold the [TV/VIDEO] button until service menu appears.)

(3) Adjust required items by the following table. Select item by [▲] or [▼] button on remote handset and

adjust by [►] or [◄] button.

(4) Press [MUTE] button to memorize the value.

4.2 SERVICE MENU(V203)

4.21 Below items are for service adjustment (Don’t change other items except for below.)

FACTORY ADJ. ADJUSTMENT DETAILS

No.

CODE MODE ITEM MODE

ADJ.

RANGE

INITIAL

DATA

IC

0 00 1 CH_PRESET - 0~2 0 -

1 01 1 Model Identification 1:ASPECT - 0~1 0 -

2 02 1 Model Identification 2:HD - 0~1 0 -

3 03 1 Model Identification 3:MULTI PICTURE - 0~1 0 -

4 04 1 Model Identification 4:Destination - 0~2 0 -

5 05 1 Model Identification 5:OSD Language - 0~2 0 -

6 06 1

Model Identification 6 : SOUND_SYSTEM /

COLOR_SYSTEM

- 0~5 0 -

7 07 1 Model Identification 7:TEXT - 0~8 0 -

8 08 1 Model Identification 8:MC - 0~1 0 -

9 09 1 Model Identification 9:LIGHT - 0~1 0 -

10 0A 1 CUT_OFF ADJ. - 0~1 0 -

11 0B 1 AGC ADJ. MAIN 0~255 75 CXA1875

12 0C 1 AGC ADJ. SUB 0~255 120 CXA1875

13 0D 1 V_SIZE Deflection Mode 1 0~127 38 TA1317AN

14 0E 1 H_SIZE Deflection Mode 1 0~127 53 TA1317AN

15 0F 1 Parabola Modification Deflection Mode 1 0~63 25 TA1317AN

16 10 1 Side Pin Symmetry Modification Deflection Mode 1 0~127 66 TA1317AN

17 11 1 V SIZE Deflection Mode 2 0~127 24 TA1317AN

18 12 1 H SIZE Deflection Mode 2 0~127 53 TA1317AN

19 13 1 Parabola Modification Deflection Mode 2 0~63 26 TA1317AN

20 14 1 Side Pin Symmetry Modification Deflection Mode 2 0~127 65 TA1317AN

21 15 1 V SIZE Deflection Mode 3/5 0~127 23 TA1317AN

22 16 1 H SIZE Deflection Mode 3/5 0~127 33 TA1317AN