Hitachi C47-WD8000, C50-FD8000, C57-WD8000, C43-FD8000, C43-FL8000 Service Manual

CAUTION: Before servicing this chassis, it is important that the service technician read the “Safety Precaution”

and “Safety Notice” in this Service Manual.

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

Components having special characteristics are identified by a ! on the schematics and on the parts list in this

service data and its supplements and bulletins. Before servicing the chassis, it is important that the service

technician read and follow the “Safety Precautions” and “Safety Notice” in this Service Manual.

* For continued X-radiation protection, replace picture tube with original type or approved equivalent type.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

CONTENTS

SAFETY NOTICE···························································································· 2

SAFETY PRECAUTIONS···················································································· 3

CAUTIONS WHEN CONNECTING/DISCONNECTING THE HV CONNECTOR······················· 6

TECHNICAL CAUTIONS ················································································· 7

CIRCUIT PROTECTION····················································································· 7

LEAD FREE SOLDERING GUIDE ······································································· 8

SPECIFICATIONS···························································································· 9

GENERAL INFORMATION·················································································· 10

CPU PIN_FUNCTION ··· ················································································· 15

TROUBLE SHOOTING ··· ·················································································· 16

SERVICE ADJUSTMENTS ················································································ 25

EXPLODED VIEW·························································································· 81

SERVICE MENU ··························································································· 85

REPLACEMENT PARTS LIST·············································································· 86

WIRING DIAGRAM ·························································································205

CIRCUIT DIAGRAM ·······················································································210

C47-WD8000 C57-WD8000

C43-FD8000 C50-FD8000

C43-FL8000

DP5M CHASSIS

PROJECTION COLOR TELEVISION

Oct 2005

P7

966168

A

CODE : FH-0502E

MODEL:

SERVICE MANUAL

2

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

For continued X-Radiation protection, replace picture tube with original type or HITACHI approved

equivalent type.

This Service Manual is intended for qualified service technicians, it is not meant for the casual

do-it-yourself. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improper performed repairs can adversely affect the safety and reliability of the product and may void

warranty. If you are not qualified to perform the repair of this product properly and safely, you should

not risk trying to do so and refer the repair to a qualified service technician.

WARNING

When servicing or handling circuit boards and other components that contain lead in solder, avoid

unprotected skin contact with solder. Also, when soldering does not inhale any smoke or fumes

produced.

3

SAFETY PRECAUTIONS

1. Before returning an instrument to the customer,

always make a safety check of the entire instrument,

including but not limited to the following items:

a) Be sure that no built-in protective devices are

defective and/or have been deleted during servicing.

(1) Protective shields are provided on this chassis to

protect both the technician and the customer.

Correctly replace all missing protective shields,

including any removal for servicing convenience.

(2) When reinstalling the chassis and/or other

assembly in the cabinet, be sure to put back in place

all protective devices, including but not limited to

nonmetallic control knobs, insulating fish-paper,

adjustment and compartment covers shields, and

isolation resistor/capacitor networks. Do not operate

this instrument or permit it to be operated

without all protective devices correctly installed

and functioning. Service technician who

disregard safety features or fail to perform safety

checks may be liable for any resulting damage.

b) Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to

(1) spacing between the picture tube and cabinet

mask,

(2) excessively wide cabinet ventilation slots, and

(3) an improperly fitted and/or incorrectly secured

cabinet back cover.

c) Antenna Cold Check - With the instrument AC plug

source, connect an electrical jumper across the two

AC plug prongs. Place the instrument AC switch in

the ON position. Connect one lead of an ammeter to

the AC plug prongs tied together and touch the other

ohmmeter lead to each tuner antenna input,

exposed terminal screw and, if applicable, to the

coaxial connector in sequence. If the measured

resistance is less than 4.0 megohm or greater than

7.2 megohm, an abnormality exists that must be

corrected before the instrument is returned to the

customer. Repeat this test with the instrument AC

switch in the OFF position.

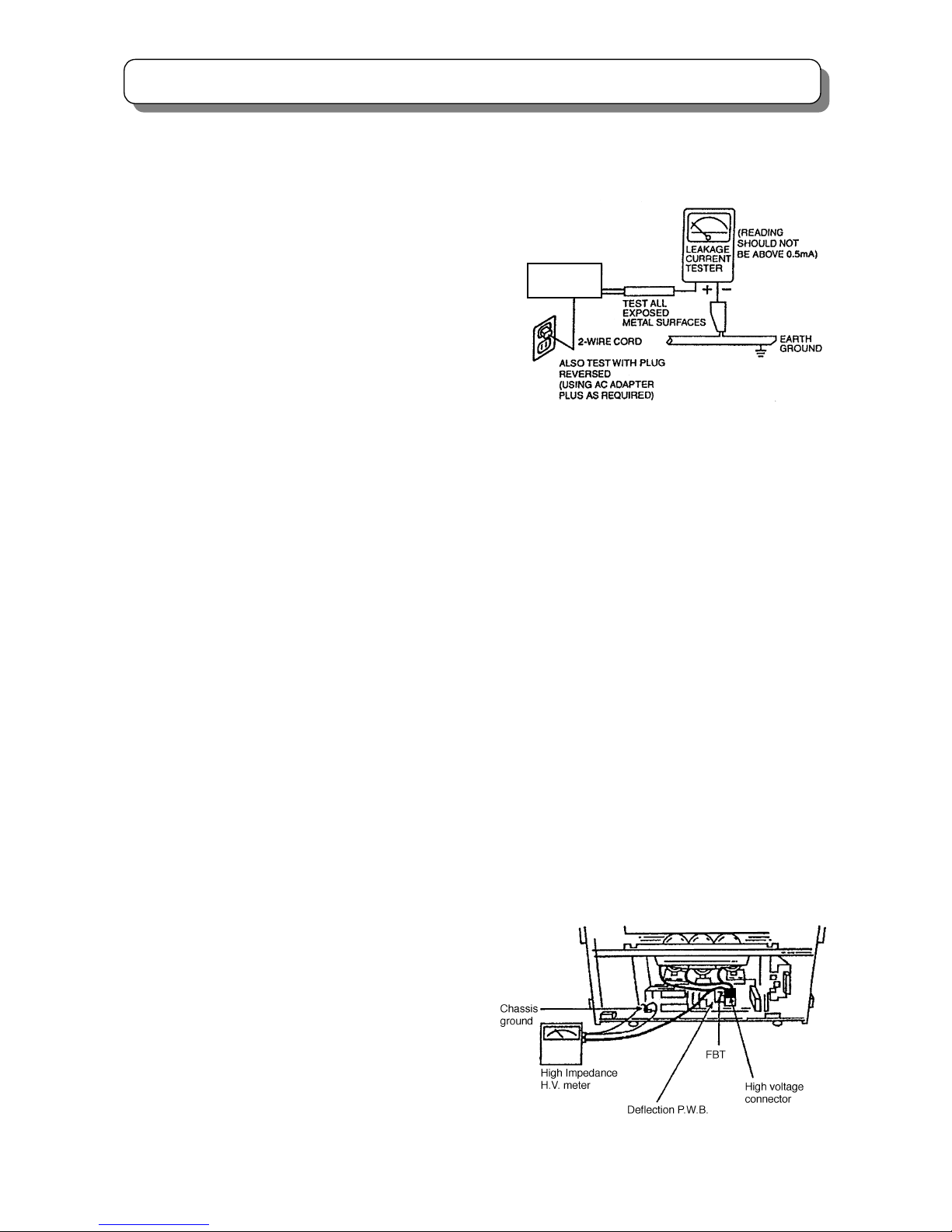

d) Leakage Current Hot Check - With the instrument

completely reassembled, plug the AC line cord

directly into a 220V outlet. (Do not use an isolation

transformer during this test.) Use a leakage current

tester or a metering system with the instrument AC

switch first in the ON position and then in the OFF

position, measure from a known earth ground (metal

water-pipe, conduit, etc.), to all exposed metal parts

of the instrument (antennas, handle bracket, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal parts that

offer an electrical return path to the chassis. Any

current measured must not exceed 0.7 milliamps.

Reverse the instrument power cord plug in the outlet

and repeat test. (See the following connection

diagram)

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE INSTRUMENT TO THE

CUSTOMER OR BEFORE CONNECTING THE

ANTENNA OR ACCESSORIES

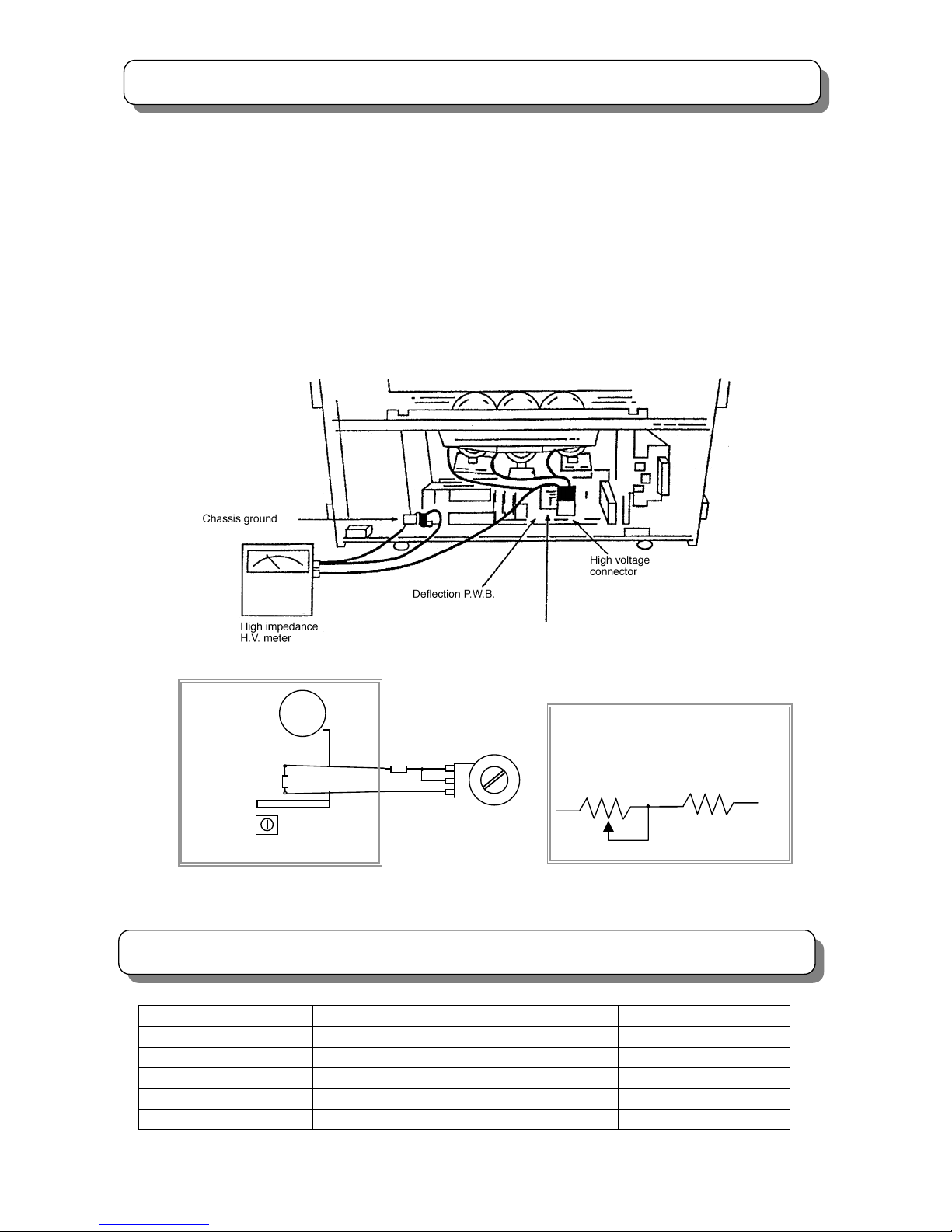

e) High Voltage - This receiver is provided with a hold

down clearly indicating that voltage has increased in

excess of a predetermined value. Comply with all

notes described in this Service Manual regarding

this hold down circuit when servicing, so that this

hold down circuit may correctly be operated.

f) Service Warning - With maximum contrast,

operating high voltage in this receiver is lower than

32kV. In case if any component having influence on

high voltage is replaced, confirm that the high

voltage with maximum contrast is lower than 32kV.

To measure H.V use a high impedance H.V. meter.

Connect (-) to chassis earth and (+) to the CRT

anode button. (See the following connection

diagram).

Note: Must turn power switch off before the connection

to the anode button is made.

(TH01)

INSTRUMENT

UNDER TEST

4

SAFETY PRECAUTIONS

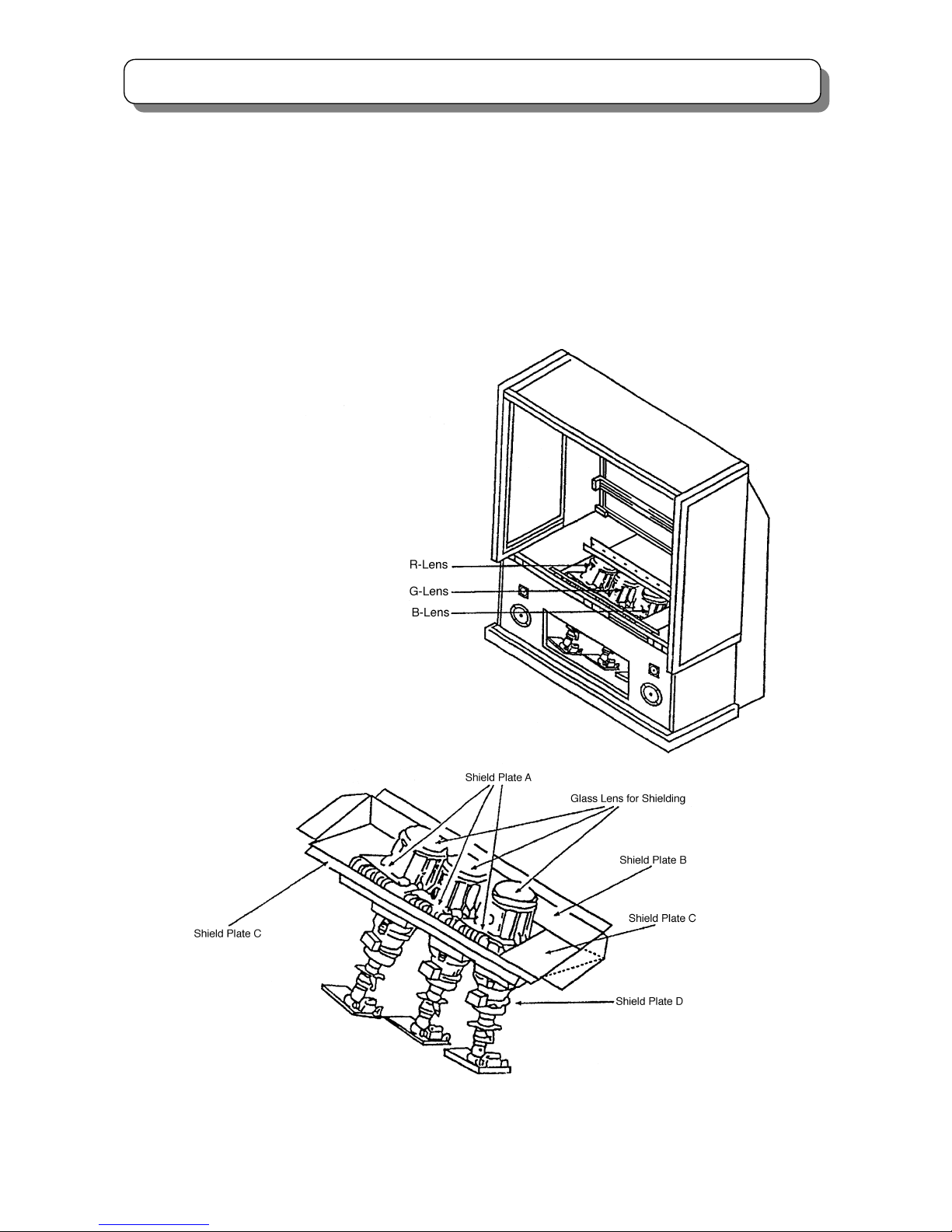

Fig. 1 X-ray shield plates

g) X-radiation (TUBE) -The primary source of

X-radiation in this receiver is the picture tube. The tube

utilized for the above mentioned function in this

chassis is specially constructed to limit X-radiation

emissions.

For continued X-radiation protection, the replacement

tube must be the same type as the original. HITACHI

approved type.

When troubleshooting and making test measurements

in a receiver with a problem of excessive high voltage,

avoid being unnecessarily close to the picture tube

and the high voltage component.

Do not operate the chassis longer than is necessary

to locate the cause of excessive voltage.

h) X-radiation Shield -This receiver is provided with

X-ray shield plates for protection against X-radiation.

Do not remove X-ray shield plates A, B, C, or D

shown in Fig.1 unnecessarily, when troubleshooting

and/or making test measurements.

To prevent X-radiation, after replacement of picture

tube and lens, confirm these components to be fixed

correctly to bracket and cabinet, and not to be taken

off easily.

5

SAFETY PRECAUTIONS

2. Read and comply with all caution and safety-related

notes on or inside the receiver cabinet, on the

receiver chassis, or on the picture tube.

3. Design Alteration Warning - Do not alter or add to

the mechanical or electrical design of this TV receiver.

Design alterations and additions, including but not

limited to circuit modifications and the addition of

items such as auxiliary audio and/or video output

connectors, might alter the safety characteristics of

this receiver and create a hazard to the user. Any

design alterations or additions may void the

manufacturer’s warranty and may make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4. Picture Tube Implosion Protection Warning - The

picture tube in this receiver employs integral

implosion protection. For continued implosion

protection, replace the picture tube only with one of

the same type number. Do not remove, install, or

otherwise handle the picture tube in any manner

without first putting on shatterproof goggles equipped

with side shields. People not so equipped must be

kept safely away while picture tubes are handled.

Keep the picture tube away from your body. Do not

handle the picture tube by its neck.

5. Hot Chassis Warning

a) Some TV receiver chassis are electrically connected

directly to one conductor of the AC power cord and

may be safely serviced without an isolation

transformer only if the AC power plug is inserted so

that the chassis is connected to the ground side of the

AC power source. Confirm that the AC power plug is

inserted correctly with an AC voltmeter by measuring

between the chassis and a known earth ground. If a

voltage reading in excess of 1.0V is obtained, remove

and reinsert the AC power plug in the opposite polarity

and again measure the voltage potential between the

chassis and a known earth ground.

b) Some TV receiver chassis normally have 85V AC

(RMS) between chassis and earth ground regardless

of the AC plug polarity. These chassis can be safely

serviced only with an isolation transformer inserted in

the power line between the receiver and the AC power

source, for both personnel and test equipment

protection.

c) Some TV receiver chassis have a secondary ground

system in addition to the main chassis ground. This

secondary ground system is not isolated from the AC

power line. The two ground systems are electrically

separated by insulating material that must not be

defeated or altered.

6. Observe original lead dress. Take extra care to assure

correct lead dress (the AC supply, high voltage and

antenna wiring) in the following areas:

a) Near sharp edges

b) Near thermally hot parts

Be sure that leads and components do not touch

thermally hot parts. Always inspect in all areas for

pinched, out-of -plate, or frayed wiring; Do not

change spacing between components and the printed

circuit board; Check AC power cord for damage.

7. Components, parts, and/or wiring that appear to have

overheated or are otherwise damaged should be

replaced with components, parts or wiring that meet

original specifications. Additionally, determine the

cause of overheating and/or damage and, if

necessary, take corrective action to remove any

potential safety hazard.

8. PRODUCT SAFETY NOTICE - Many TV electrical

and mechanical parts have special safety-related

characteristics some of which are often not evident

from visual inspection, nor can the protection they

give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified by a

! in the replacement parts list. Use of

substitute replacement that does not have the same

safety characteristics as the recommended

replacement part in the parts list might create shock,

fire, and/or other hazards. Product safety is under

review continuously and new instructions are issued

whenever appropriate. For the latest information,

always consult the appropriate current service

literature. A subscription to, or additional copies of

service literature may be obtained at a nominal

charge from manufacturer.

6

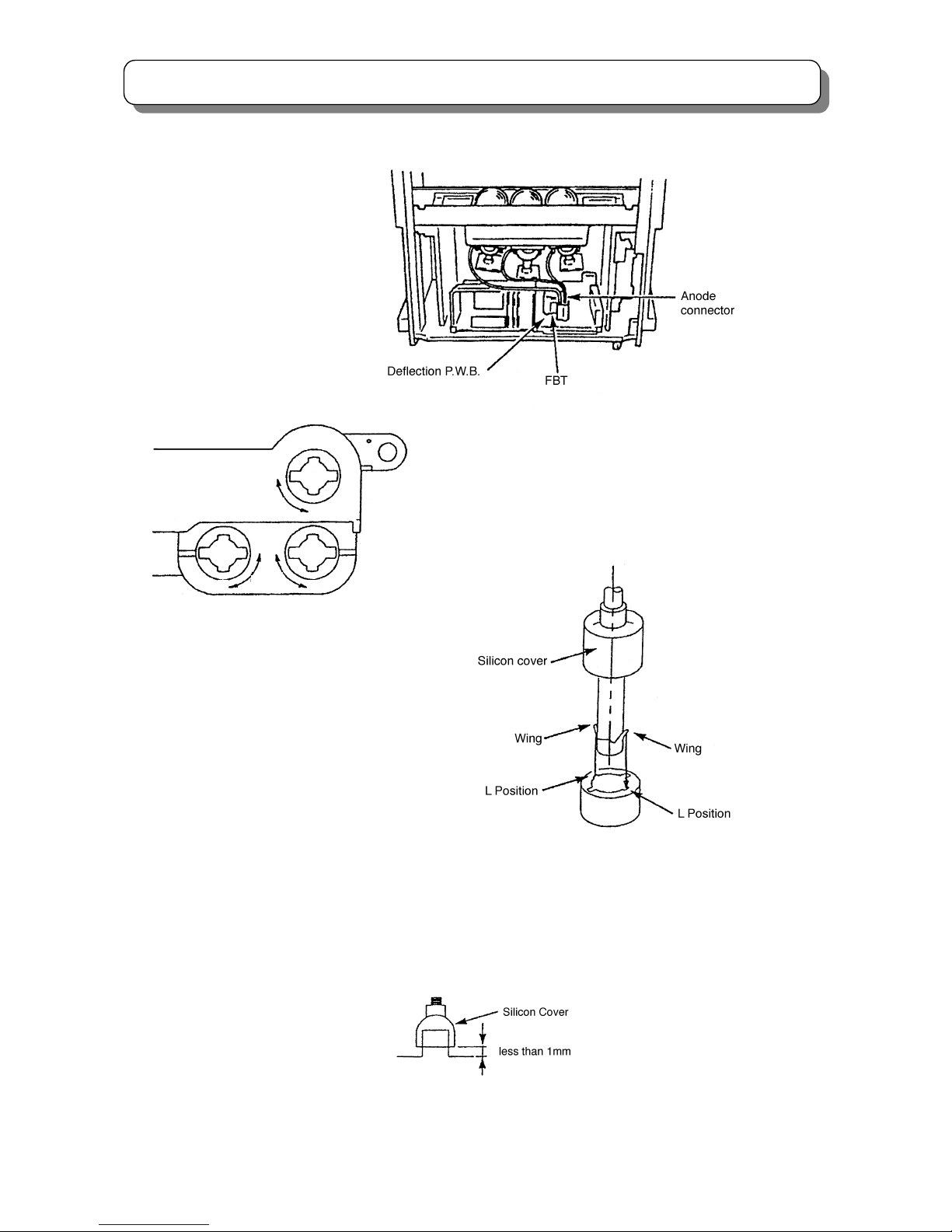

CAUTIONS WHEN CONNECTING/DISCONNECTING THE HV CONNECTOR

Perform the following when the

HV connector (anode connector)

is removed or inserted for PRT

replacement, etc.

During Insertion

1. Please refer to direction for insertion as shown in Fig. 4 (L position). Insert connector until “CLICK” sound is heard.

2. Make sure the connector is pressed right in, so that it has a good contact with the spring.

3. Confirm the contact by pulling the connector slightly. (Don’t pull hard because it may damage the connector).

4. Cover the high voltage output by carefully pushing silicon cover onto it. (Don’t turn the connector).

(REMARK)

1. Make sure the silicon cover is

covering the high voltage output.

During Removal

1. Roll out silicon cover from FBT’s contact area slowly.

2. While turning the connector about 90 degrees following the

arrow (from L position to O position), push the connecto

r

slightly towards the case. (Fig .3)

3. Remove the connector slowly by pulling it away from the

case.

Fig. 3 Remove the anode connector

Fig. 4 Insert the anode connector

O

O

L L

L

PUSH

PUSH

7

TECHNICAL CAUTIONS

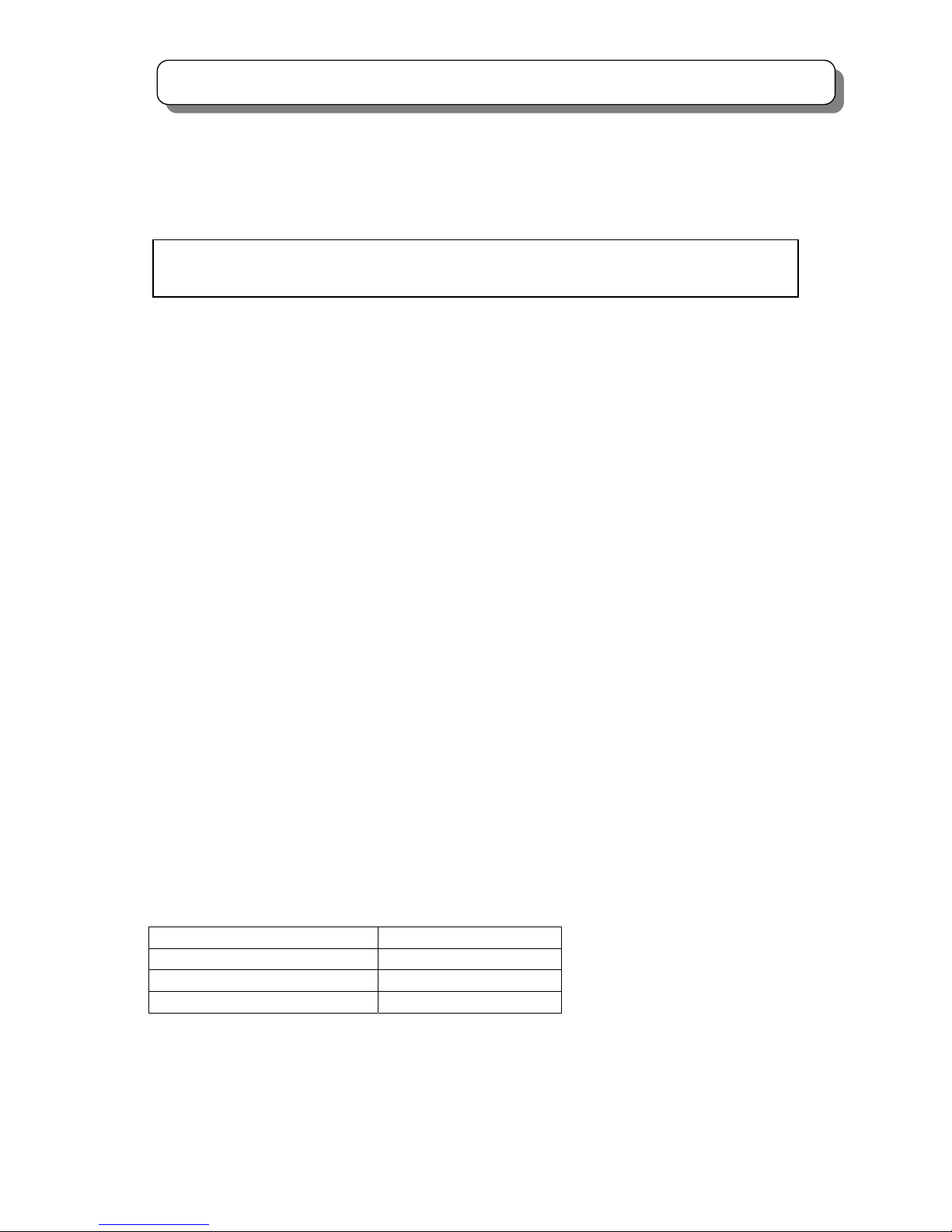

High Voltage limiter circuit operation check

1. Turn off TV and delete resistor RH19 (82KΩ) in the Power/Deflection PWB, set 50KΩ VR fully clockwise(maximum

resistance).

2. Set the AC input to 220V AC and turn on TV.

3. Confirm test pattern on PRT is a usable picture, then slowly adjust 50KΩ VR until the picture disappears and TV

shuts down.

4. When the limiter circuit is operating properly, High Voltage will be less than 35.6kV(maximum brightness and

contrast).

5. Turn off TV immediately after checking High Voltage limiter circuit operation.

6.Unplug TV for one minute to reset shutdown circuit. Remove the jig A, and then add resistor RH19(82KΩ)to the PWB.

FBT

TH01

RH19

33 KΩ

50 KΩ VR

Fig.2 High Voltage limiter circuit operation check

POWER /

DEFLECTION PWB

FBT

33 KΩ

50 KΩ VR

Connect Jig A to PWB between RH19

RH17

CIRCUIT PROTECTION

Fuse (or Device) Circuit Protected Physical Location

F901(T6.3AL/250V)

AC POWER CIRCUIIT Power Supply Unit

F902(T1AL/250V)

STAND BY CIRCUIT Power Supply Unit

F903(T3.15AL/250V)

SIGNAL POWER CIRCUIT Power Supply Unit

F904(2.2Ω/fuse)

SIGNAL POWER CIRCUIT Power Supply Unit

FP01(T3.15AL/250V)

PRIMARY POWER CIRCUIT Power / Deflection PWB

8

LEAD FREE SOLDERING GUIDE

● Lead free solder

With some exception, this product is going to use lead free solder (unleaded) to help preserve the

environment from the September of 2004. Please read these instructions before attempting any soldering

work.

Caution: Always wear safety glasses to prevent fumes or molten solder from getting into the eyes.

Lead free solder can splatter at high temperatures. (600ºC).

■ Lead free solder indicator

There is a F mark made behind the name of PWB or close to its on the printed circuit boards with lead free

solder.

■ Properties of lead free solder

The melting point of lead free solder is 40--50ºC higher than lead solder.

■ Servicing solder

Unleaded solder with an alloy composition of Sn-3.0Ag-0.5Cu is recommended. Although servicing with

leaded solder is possible, there are a few precautions that have to be taken. (Not taking these precautions

may cause the solder to not harden properly, and lead to consequent malfunctions.)

■ Precautions when using leaded solder

● Remove all lead free solder from soldered dots when replacing components.

● If leaded solder should be added to existing unleaded soldered dots , melt the leaded solder thoroughly

and mix it in the unleaded solder after the unleaded soldered dots have been completely melted. (It’s not

permitted to solder directly with soldering iron without solder)

■Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended. The

melting point of unleaded soldering tin is higher than that of leaded ones. Use a soldering iron that maintains

a high stable temperature (large heat capacity) and allows temperature adjustment according to the parts

awaiting serviced to avoid poor servicing performance.

■ Recommended soldering iron

● Soldering iron with temperature control function (temperature range:320--450ºC)

Recommended temperature range per part:

PARTS Soldering iron temperature

Mounting (chips) on mounted PCB 320ºC±30ºC

Mounting (chips) on empty PCB 380ºC±30ºC

Chassis, metallic shield, etc. 420ºC±30ºC

9

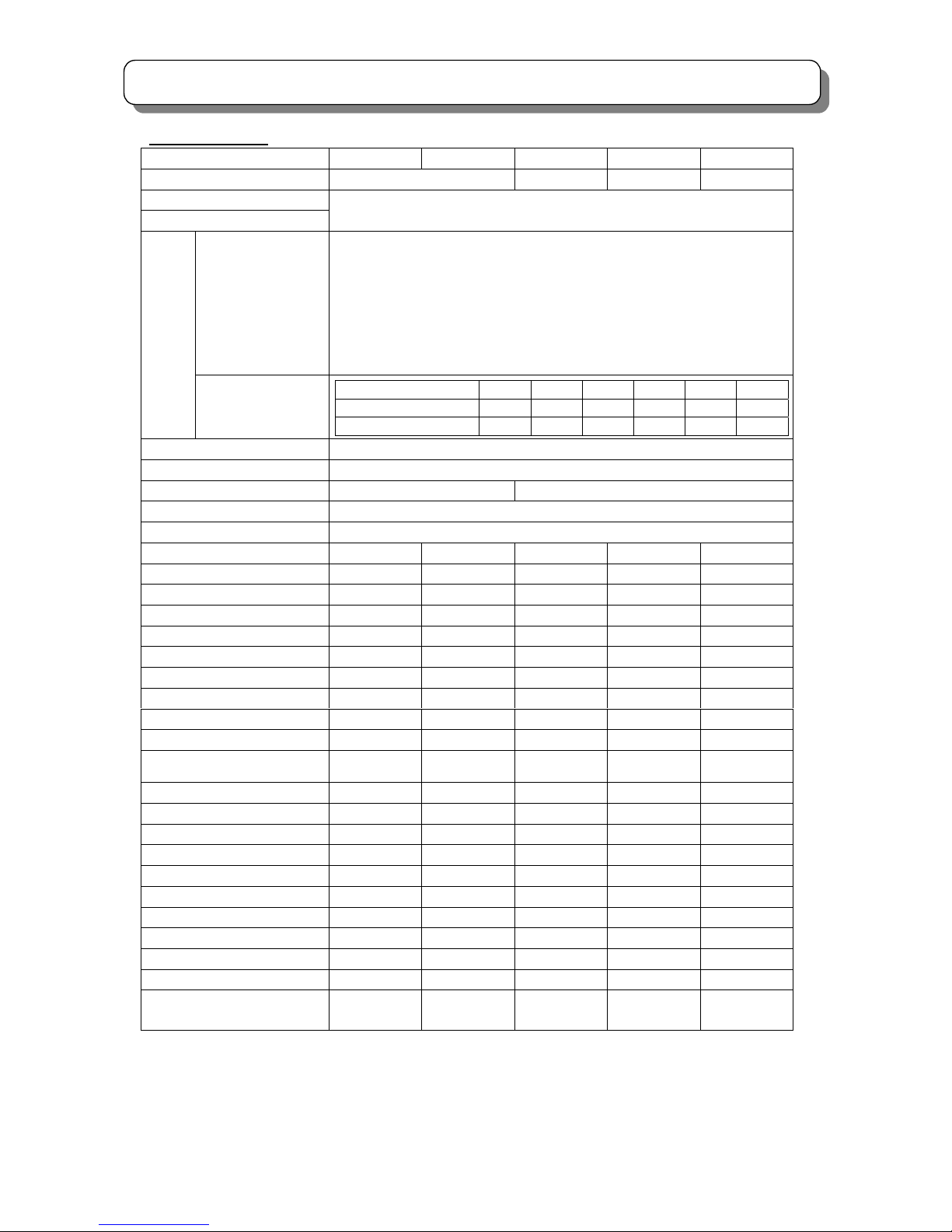

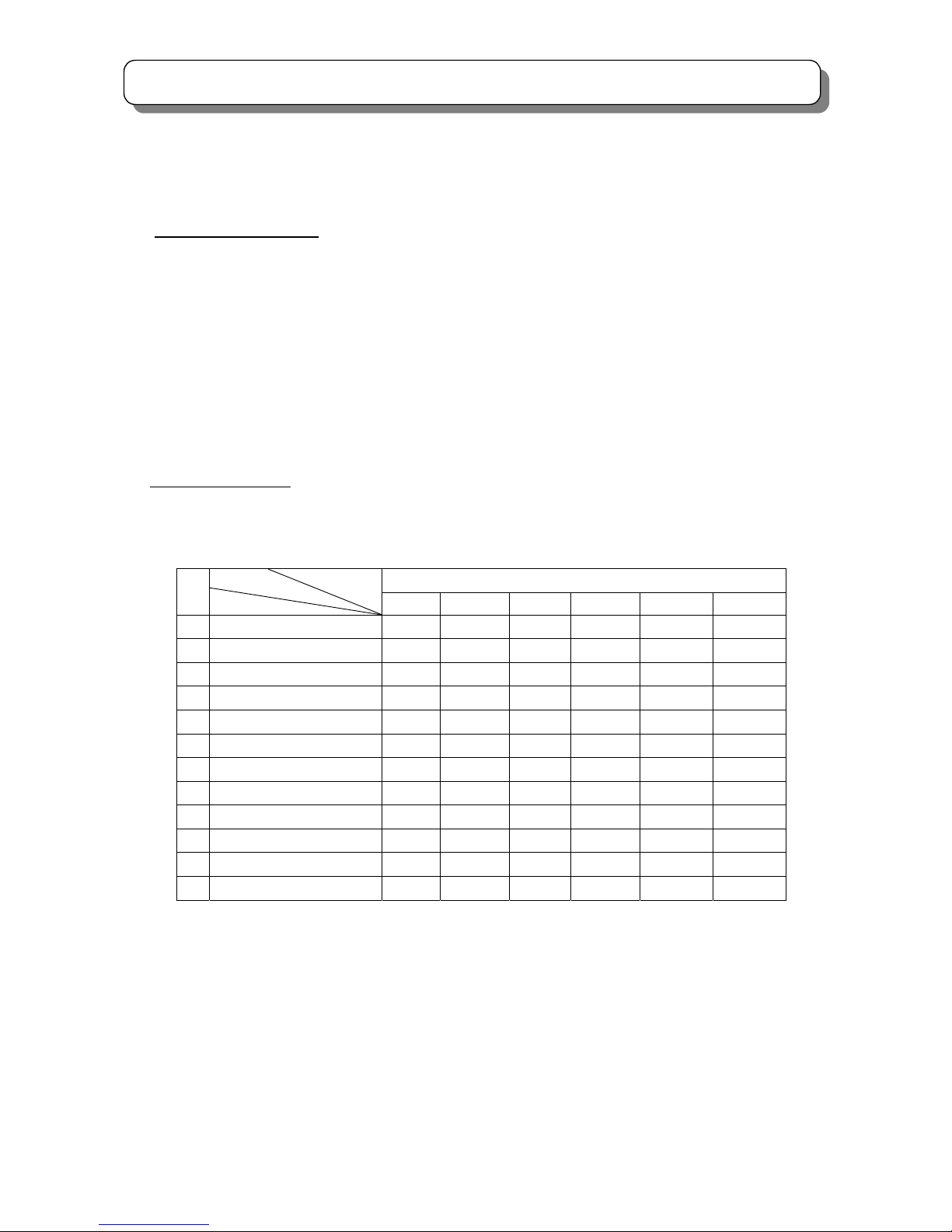

SPECIFICATIONS

Specifications

Model

C43-FL8000 C43-FD8000 C50-FD8000 C47-WD8000 C57-WD8000

Screen size 109cm 127cm 119cm 145cm

Power supply

Power consumption

Refer to the values as indicated on the rating label pasted at the back of the TV set.

PAL B.G/I/D.K

SECAM B.G/D.K

NTSC 50

M/NTSC

NTSC3.58-5.5/6.0/6.5

NTSC4.43-5.5/6.0/6.5

RF/VIDEO

PAL/SECAM 60

Reception

system

COMPONENT

Frequency range 44MHz-863 MHz

Antenna input impedance 75Ohm non balance type

Speaker Φ12×2 ,Φ5×2 Φ13×2 ,Φ5×2

Sound output 20W×2

Comb filter 3L(PAL)/3D(NTSC)

Digital convergence Yes Yes Yes Yes Yes

Magic focus No(manual) Yes Yes Yes Yes

Perfect v o l u m e Ye s Ye s Ye s Yes Ye s

NICAM/A2 Yes Ye s Ye s Ye s Ye s

BBE Yes Yes Yes Yes Yes

SRS Ye s Ye s Yes Yes Ye s

P i n P Yes Ye s Yes Yes Ye s

Tel e t ext No Yes Yes Yes Ye s

S-VIDEO INPUT 1(side),2(rear) 1(side),2(rear) 1(side),2(rear) 1(side),2(rear) 1(side),2(rear)

VIDEO INPUT 1(side),4(rear) 1(side),4(rear) 1(side),4(rear) 1(side),4(rear) 1(side),4(rear)

COMPONENT INPUT

(Y、P

B/CB、PR/CR)

2(rear) 2(rear) 2(rear) 2(rear) 2(rear)

HDMI INPUT

No

No No

1(rear) 1(rear)

BRIDGE MEDIA

No No No Ye s Yes

PC INPUT

No No No Ye s Yes

AUDIO INPUT 1(side),4(rear) 1(side),4(rear) 1(side),4(rear) 1(side),4(rear) 1(side),4(rear)

MONITOR OUT 1(rear) 1(rear) 1(rear) 1(rear) 1(rear)

HEADPHONE OUTPUT 1(side) 1(side) 1(side) 1(side) 1(side)

IR BLASTER OUT No 2(rear) 2(rear) 2(rear) 2(rear)

FIXED/VARIABLE AUDIO OUT 1(rear) 1(rear) 1(rear) 1(rear) 1(rear)

Shieldin g N o No Ye s Yes Yes

Weight 57Kg 57Kg 69Kg 68Kg 84.5Kg

Dimension (mm)

(width×height×depth)

969mm×1229mm×

456mm

969mm×1229mm

×456mm

1119mm×1362mm

×498mm

1121mm×1223mm

×485mm

1344mm×1412mm

×530mm

Note: Specifications may be subject to change without notice for improvement.

Total scan lines 1125i 750p 625p 625i 525p 525i

Active scan lines 1080i 720p 576p 576i 480p 480i

Vertical frequency(Hz)

50/60 60 50 50 60 60

10

GENERAL INFOMATION

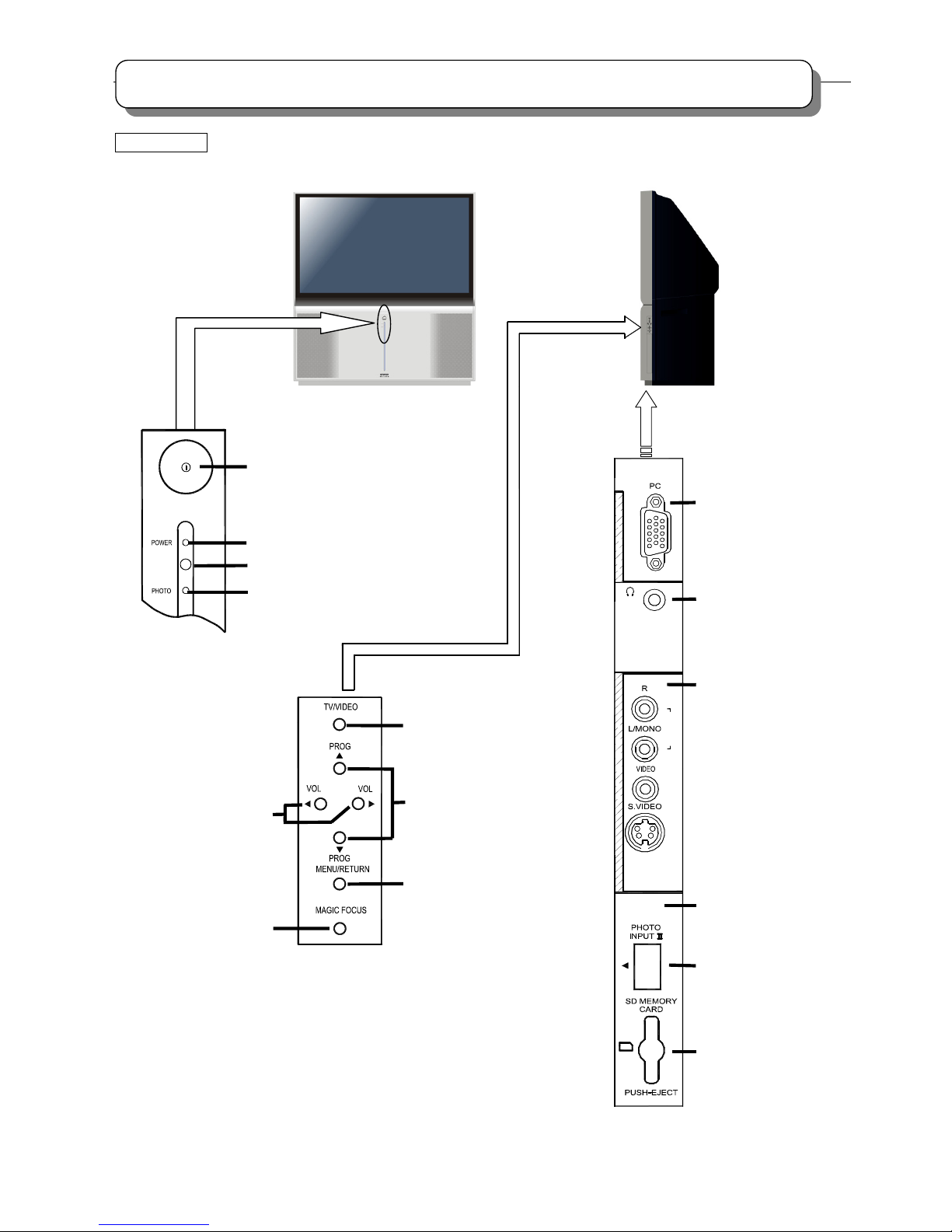

16:9 MODEL C47-WD8000 / C57-WD8000

Control panel and side panel

U

A

D

I

O

P

U

T

5

N

I

P

C

I

N

P

U

T

MENU/RETURN button

POWER button

POWER indicator

Remote control sensor

PROGRAM UP/DOWN buttons

(When the menu appears on

the screen, press PROG ▲/

PROG▼ buttons to select the

menu up and down.)

TV/VIDEO selector

BRIDGE MEDIA status indicator

HEADPHONE jack

Side panel input jacks

(For AV5 input)

PC INPUT terminal

VOLUME UP/DOWN

buttons (When the menu

appears on the screen,

press VOL◄ / VOL►

buttons to select the

menu left and right.)

MAGIC FOCUS button

BRIDGE MEDIA

INPUT terminals

USB slot

SD memory card slot

11

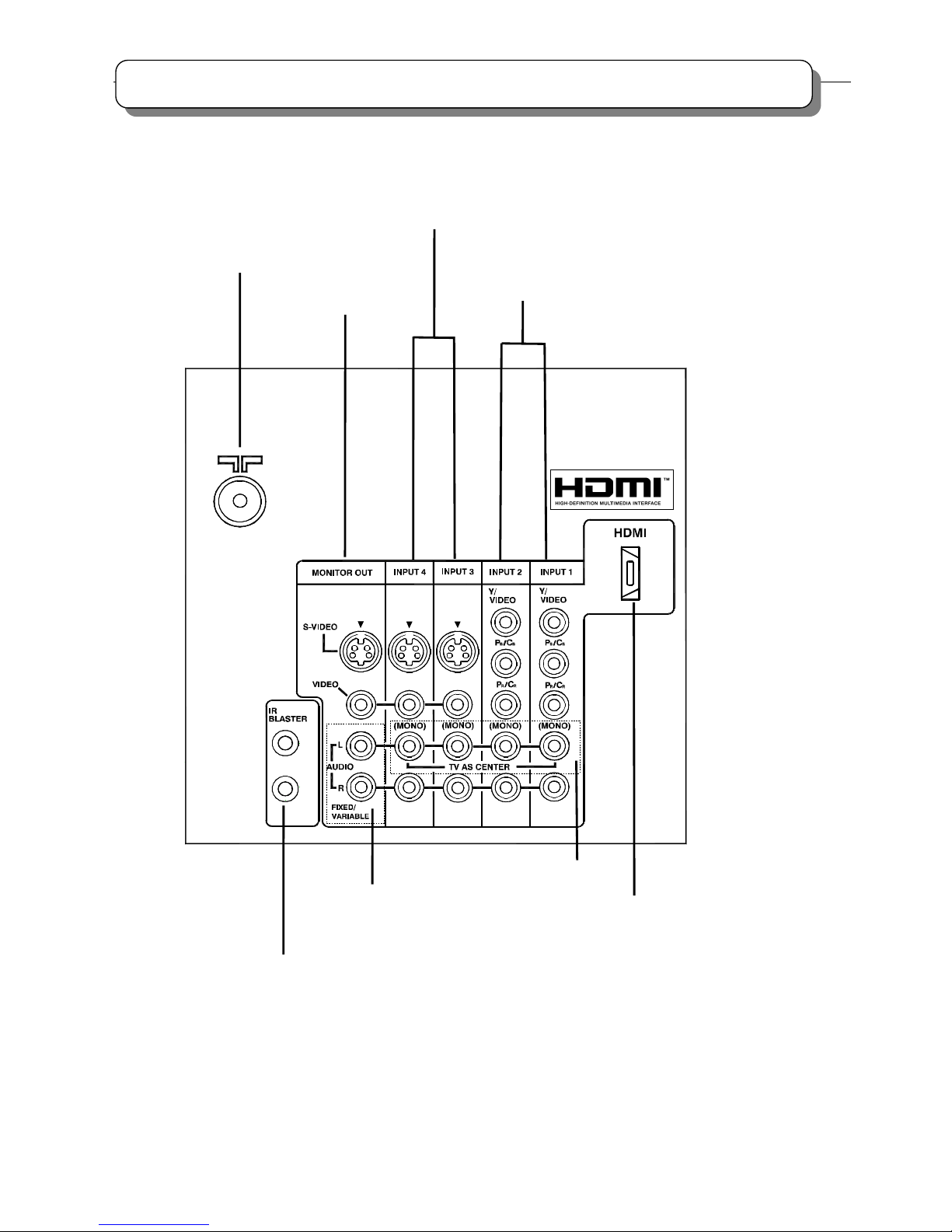

GENERAL INFOMATION

Rear panel

Fixed/Variable Audio output

terminals

A

ntenna terminal

Monitor output

terminals

A

udio/Video input terminals 3,4

A

udio/Video input & Component

input terminals 1,2

IR BLASTER output jacks

TV AS CENTER input jacks

HDMI

(High Definition Multimedia Interface)

12

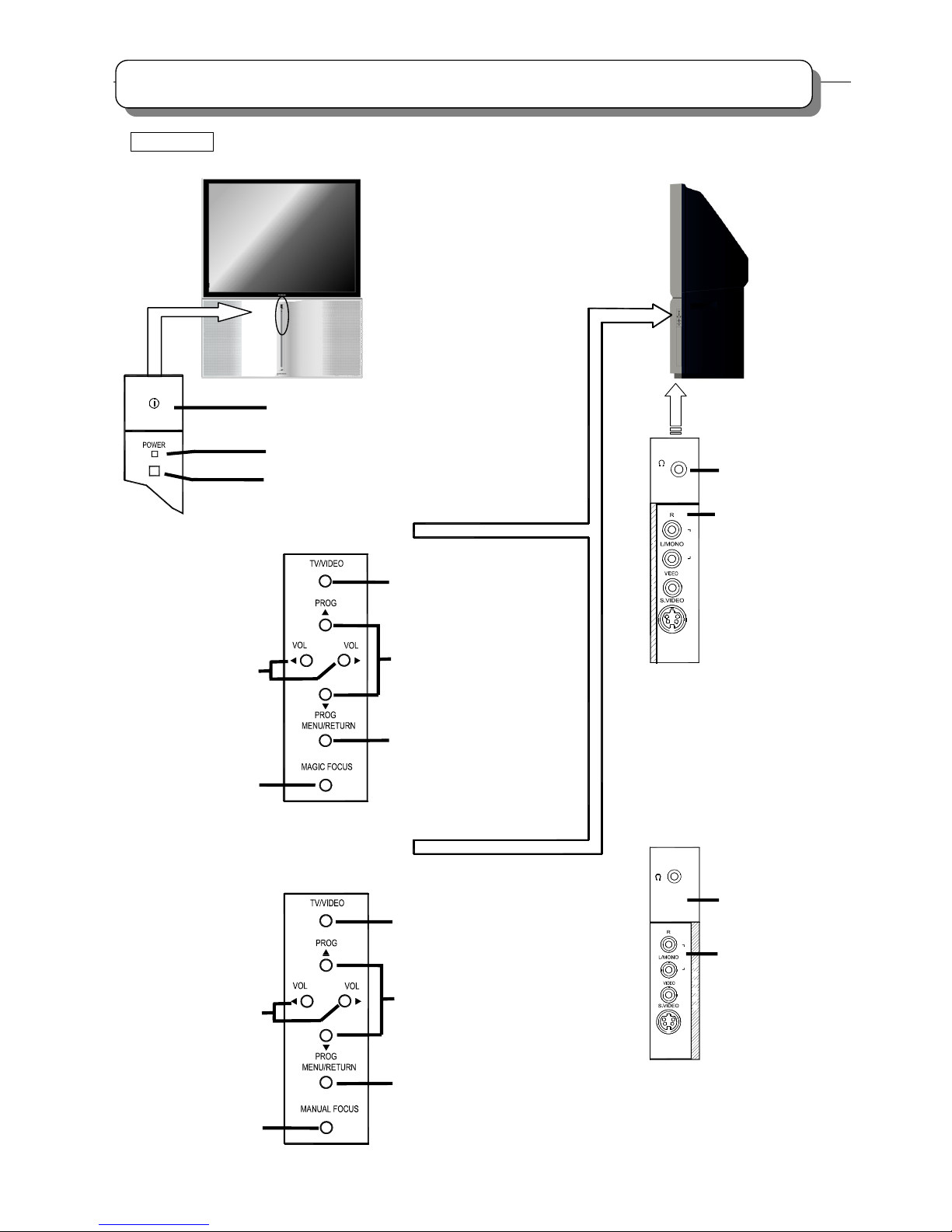

GENERAL INFOMATION

4:3 MODEL C43-FD8000 / C50-FD8000 / C43-FL8000

Control panel and side panel

I

N

5

T

U

P

O

I

D

A

U

MENU/RETURN button

POWER button

POWER indicator

Remote control sensor

PROGRAM UP/DOWN

buttons (When the menu

appears on the screen,

press PROG ▲/ PROG▼

buttons to select the menu

up and down.)

TV/VIDEO selector

HEADPHONE jack

Side panel input jacks

(For AV5 input)

VOLUME UP/DOWN

buttons (When the

menu appears on

the screen, press

VOL◄/VOL►

buttons to select

the menu left and

right.)

MAGIC FOCUS

button

Function of keys

Function of keys

(C43-FD8000, C50-FD8000)

5

T

U

P

N

I

O

I

D

U

A

or

(C43-FD8000, C50-FD8000)

MENU/RETURN button

TV/VIDEO selector

MANUAL FOCUS

button

(C43-FL8000)

PROGRAM UP/DOWN

buttons (When the menu

appears on the screen,

press PROG ▲/ PROG▼

buttons to select the menu

up and down.)

HEADPHONE jack

Side panel input jacks

(For AV5 input)

(C43-FL8000)

VOLUME UP/DOWN

buttons (When the

menu appears on

the screen, press

VOL◄/VOL►

buttons to select

the menu left and

right.)

13

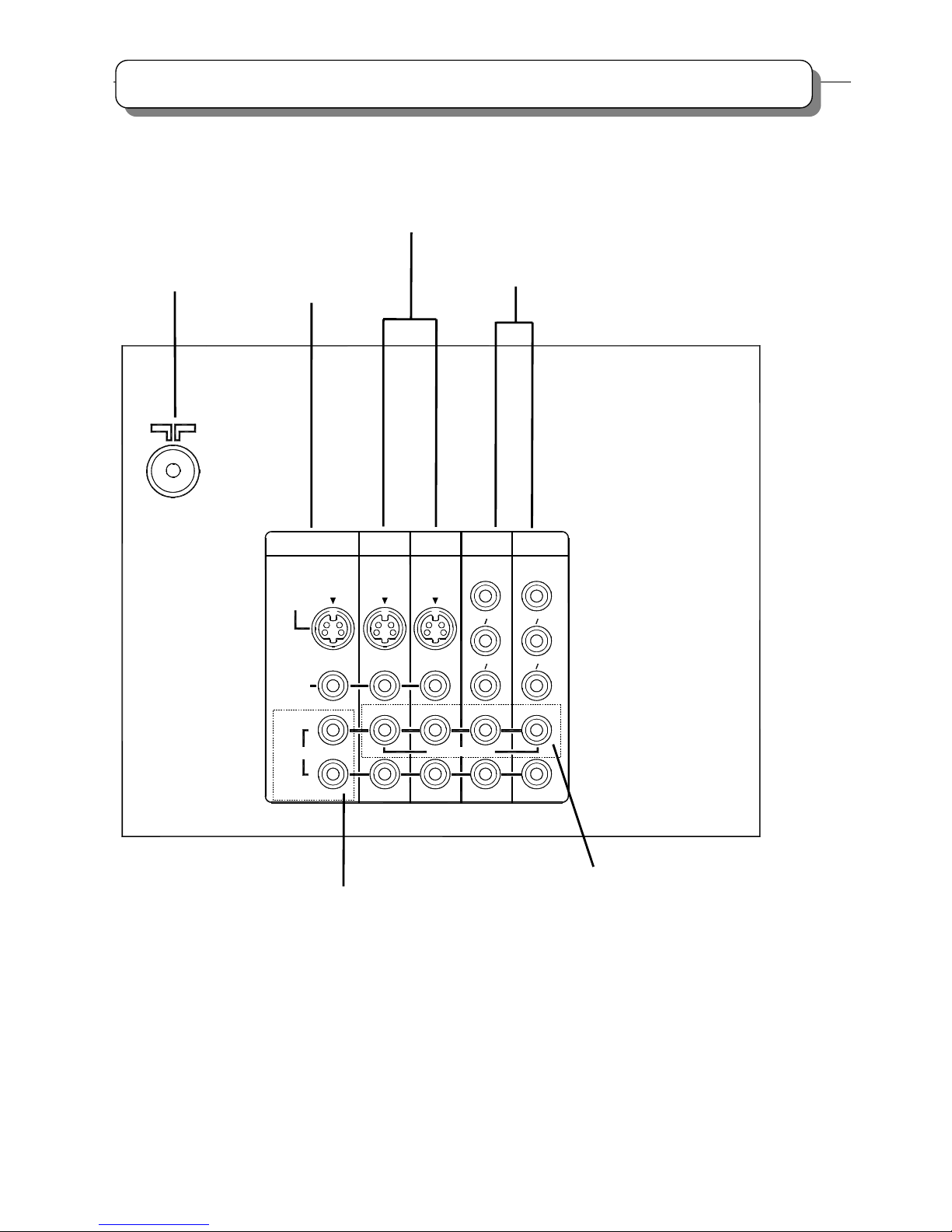

GENERAL INFOMATION

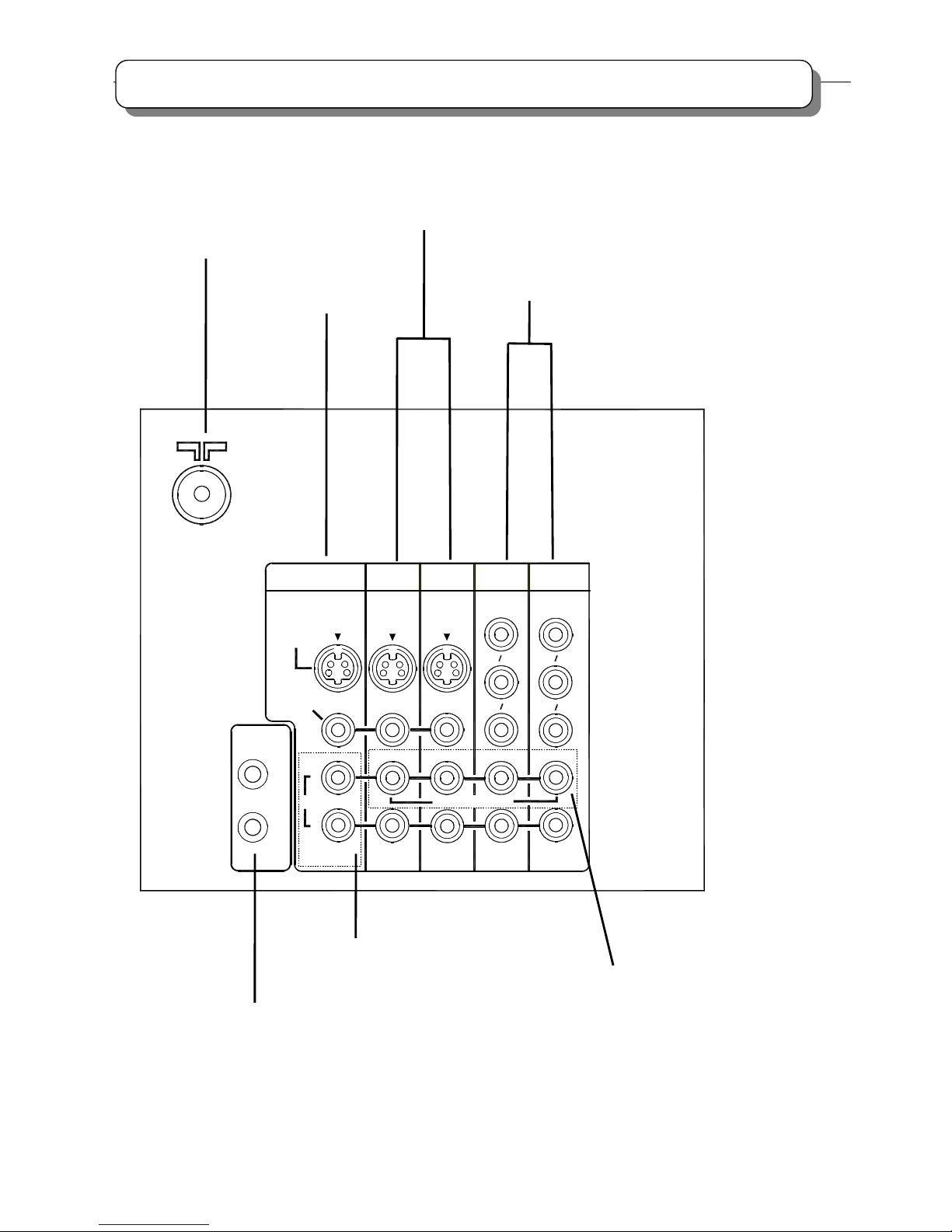

Rear panel

(The rear panel shown as below is designed for C43-FL8000 model.)

Fixed/Variable Audio output

terminals

A

ntenna terminal

Monitor output

terminals

A

udio/Video input terminals 3,4

A

udio/Video input & Component

input terminals 1,2

TV AS CENTER input jacks

L

R

VIDEO

MONITOR OUT

(MONO)

C

P

RR

C

P

BB

Y/

INPUT 4

INPUT 3

INPUT 1

INPUT 2

S-VIDEO

AUDIO

VARIABLE

FIXED/

VIDEO

C

P

RR

C

P

BB

Y/

VIDEO

TV AS CENTER

(MONO) (MONO) (MONO)

14

GENERAL INFOMATION

Rear panel

(The rear panel shown as below is designed for C43-FD8000 model and C50-FD8000 model.)

L

R

AUDIO

VARIABLE

FIXED/

BLASTER

IR

S-VIDEO

(MONO)

C

P

RR

C

P

BB

Y/

VIDEO

C

P

RR

C

P

BB

Y/

VIDEO

TV AS CENTER

(MONO)

(MONO) (MONO)

VIDEO

MONITOR OUT

INPUT 4

INPUT 3

INPUT 1

INPUT 2

Fixed/Variable Audio output

terminals

A

ntenna terminal

Monitor output

terminals

A

udio/Video input terminals 3,4

A

udio/Video input & Component

input terminals 1,2

IR BLASTER output jacks

TV AS CENTER input jacks

15

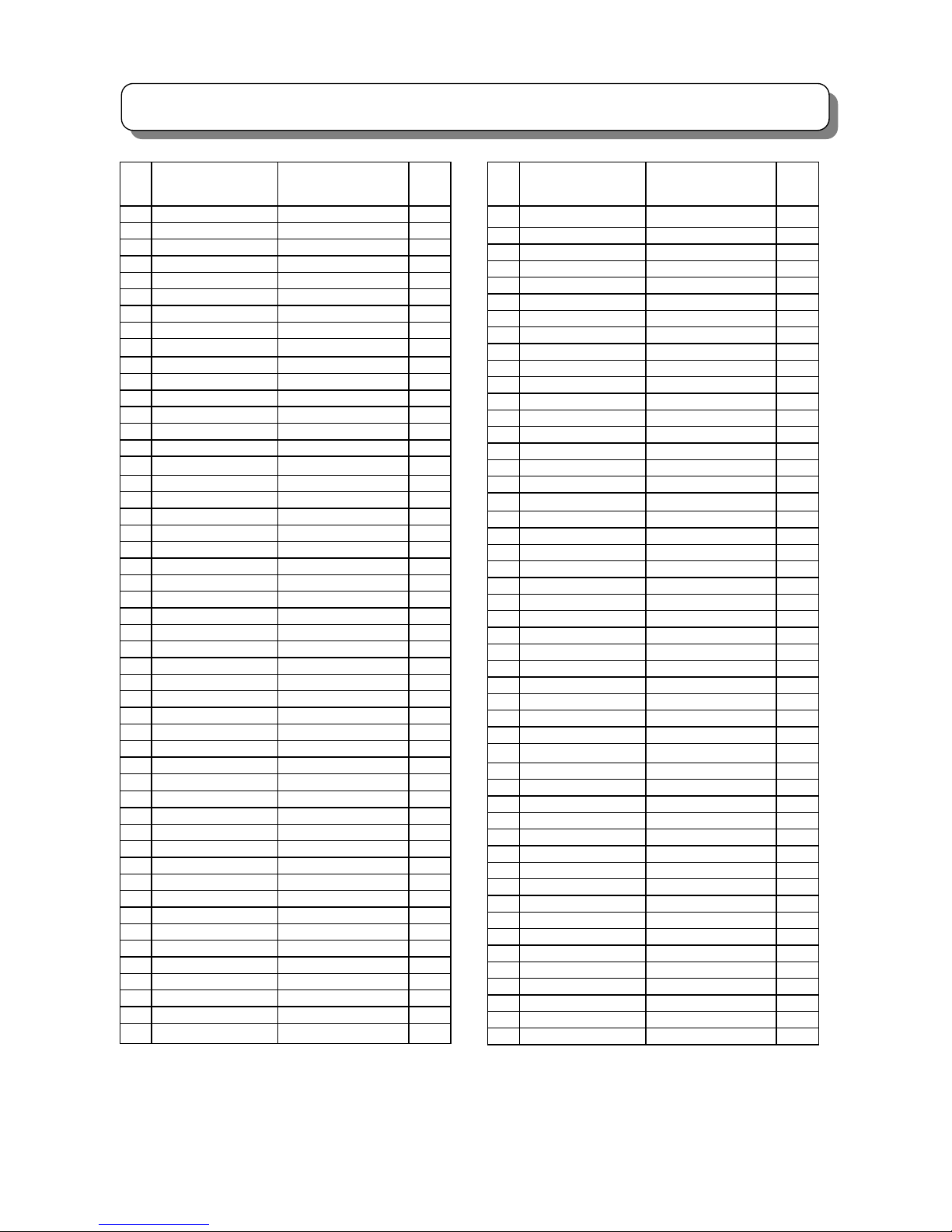

CPU(I001)PIN_FUNCTION

PIN PIN_NAME FUNCTION I/O

1 V HOLD1 Vertical Hold1 I

2 HLF Filter 1 I/O

3 IRB_RXD Communication RXD I/O

4 IRB_TXD Communication TXD I/O

5 HDMI CEC IN HDMI CEC Input I/O

6 IR_IN REMOTE IR Input I/O

7 M-S SYNC DET Sync Detect(M/S) I/O

8 BYTE Byte(GND) I

9 FLASH(CNVSS)

CNVSS(FOR PROGRAM)

I

10 SUB OSC IN SUB OSC Input I/O

11 SUB OSC OUT SUB OSC Output I/O

12 RESET Reset I

13 MAIN OSC OUT MAIN OSC Output O

14 VSS(ORIGIN) VSS(GND)

-

15 MAIN OSC IN MAIN OSC Input I

16 VCCI(+3.3V) VCCI(+3.3V)

-

17 OSC1-HLF OSC 1 I

18 OSC2 OSC 2 O

19 HDMI INI1 HDMI INI1 I/O

20 HDMI INI2 HDMI INI2 I/O

21 OSD BLK OSD BLK Output O

22 HALF TONE OSD Translucence O

23 HDMI DEMP2 HDMI DEMP2 I/O

24 HDMI CEC OUT HDMI CEC Output I/O

25 SD SELECT SYNC SELECT I/O

26 WDT CLOCK WDT CLOCK I/O

27 HDMI DEMP1 HDMI DEMP1 I/O

28 SCL2 IIC CLOCK 2 I/O

29 SCL1 IIC CLOCK 1 I/O

30 SDA1 IIC DATA 1 I/O

31 SDA2 IIC DATA 2 I/O

32 OSD_R OSD_R Output O

33 OSD_G OSD_G Output O

34 OSD_B OSD_B Output O

35 FLASH-TXD

TXD(FOR PROGRAM)

I/O

36 FLASH-RXD

RXD(FOR PROGRAM)

I/O

37 FLASH(SCLK)

SCLK(FOR PROGRAM)

I/O

38 FLASH(BUSY)

BUSY(FOR PROGRAM)

I/O

39 SCL3 IIC CLOCK 3 I/O

40 SDA3 IIC DATA 3 I/O

41 FLASH(EPM)

EPM(FOR PROGRAM)

I/O

42 DCU BUSY IN DCU BUSY Control I/O

43 DCU SIZE DCU SIZE Control I/O

44 SCL4 IIC CLOCK 4 I/O

45 SDA4 IIC DATA 4 I/O

46 FLASH (CE)

CE(FOR PROGRAM)

I/O

47 CUT OFF OUT CUT OFF Output I/O

48 HDMI HPD HDMI HPD I/O

49 V MUTE VIDEO MUTE I/O

50 HDMI RESET HDMI Reset I/O

PIN PIN_NAME FUNCTION I/O

51 FC DATA IN FC DATA Input I/O

52 FC DATA OUT FC DATA Output I/O

53 FC CLOCK CLOCK FOR FC I/O

54 FC ENABLE FC ENABLE Control I/O

55 SCL5 IIC CLOCK 5 I/O

56 SDA5 IIC DATA 5 I/O

57 MC LED MC LED I/O

58 POWER LED Power LED I/0

59 TV POWER Power ON/OFF Control I/O

60 IRB IR SELECT IR Select I/O

61 MC ENABLE MC MODE ENABLE I/O

62 OSD H SYNC IN OSD H SYNC Input I

63 MC WAKEUP OUT MC MODE CONTROL I/O

64 OSD V SYNC IN OSD V SYNC Input I

65 60Hz OUT 60Hz Output I/O

66 100Hz OUT 100Hz Output I/O

67 28KHz OUT 28KHz Control I/O

68 TEXT RESET TEXT RESET I/O

69 MSP RESET MSP RESET I/O

70 V SQUEEZE OUT Vertical Squeeze Output I/O

71 AUDIO MUTE AUDIO MUTE Output I/O

72 KEY OUT(2) KEY OUT(2) I/O

73 AV5 DET AV 5 Input Detect I/O

74 AV1 DET AV 1 Input Detect I/O

75 KEY OUT(1) KEY OUT(1) I/O

76 NC I/O

77 BM MUTE BM Mute I/O

78 HDMI SPDIF SEL HDMI SPDIF Select I/O

79 LIGHT OUT LIGHT ON/OFF I/O

80 HP DET HP DETECT I/O

81 KEY IN(2) KEY IN(2) I/O

82 KEY IN(1) KEY IN(1) I/O

83 NC I/O

84 IF SYS1(S) OUT SUB IF SYS1(S) I/O

85 IF SYS1(M) OUT MAIN IF SYS1(M) I/O

86 IF SYS2(M) OUT MAIN IF SYS2(M) I/O

87 IF SYS2(S) OUT SUB IF SYS2(S) I/O

88 IRB RESET IR BLASTER Reset I/O

89 AGC IN (S) SUB AGC Input I/O

90 AGC IN (M) MAIN AGC Input I/O

91 DIP DETECT DIP Detect I/O

92 SUB AFC IN SUB AFC Input I/O

93 MAIN AFC IN MAIN AFC Input I/O

94 AD KEY IN AD_KEY IN I/O

95 V HOLD2 Vertical Hold2 I/O

96 HLF2 Filter 2 I/O

97 SUB CCD IN SUB CCD Input I

98 TVSETB GND I

99 VCCE VCCE(5V)

-

100 MAIN CCD IN MAIN CCD Input I

16

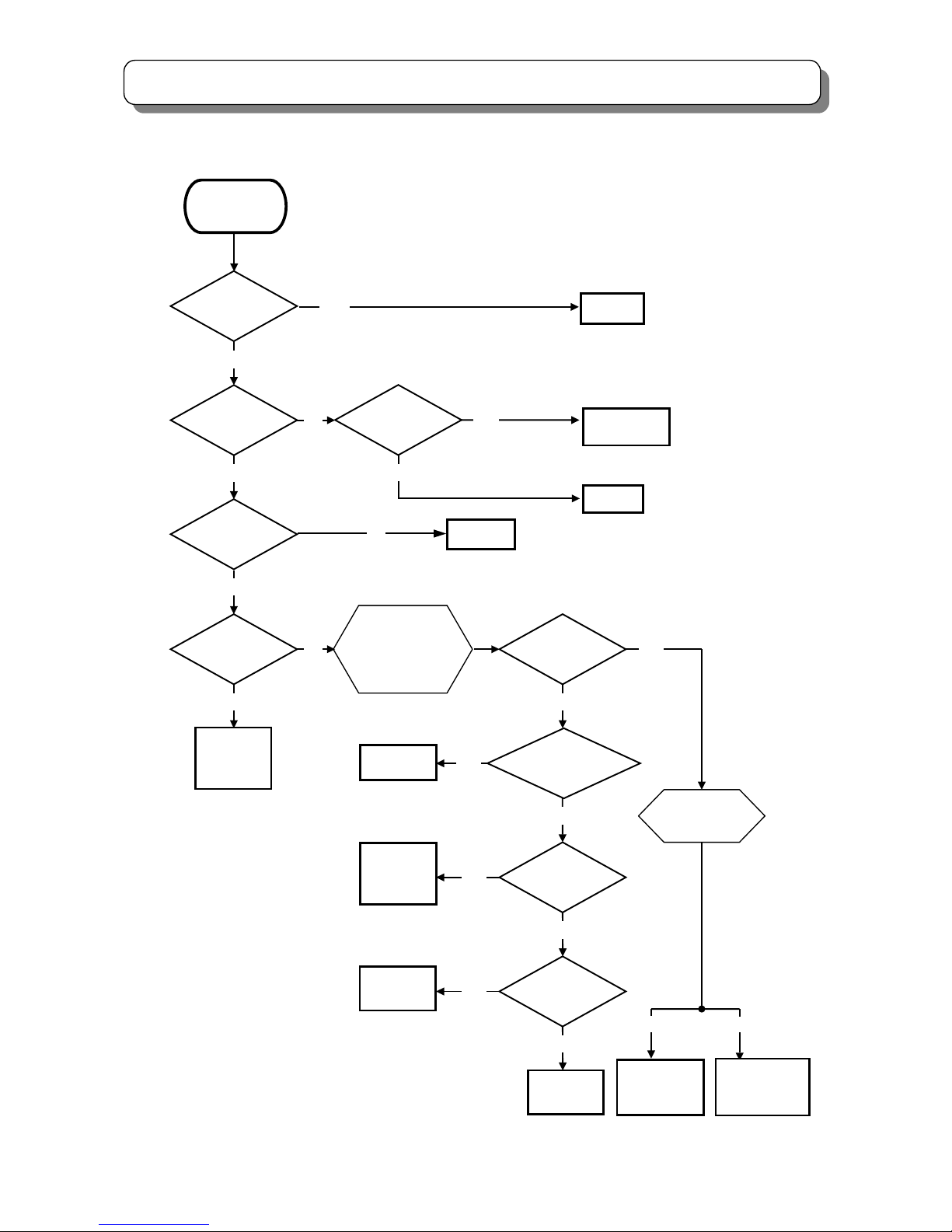

TROUBLE SHOOTING

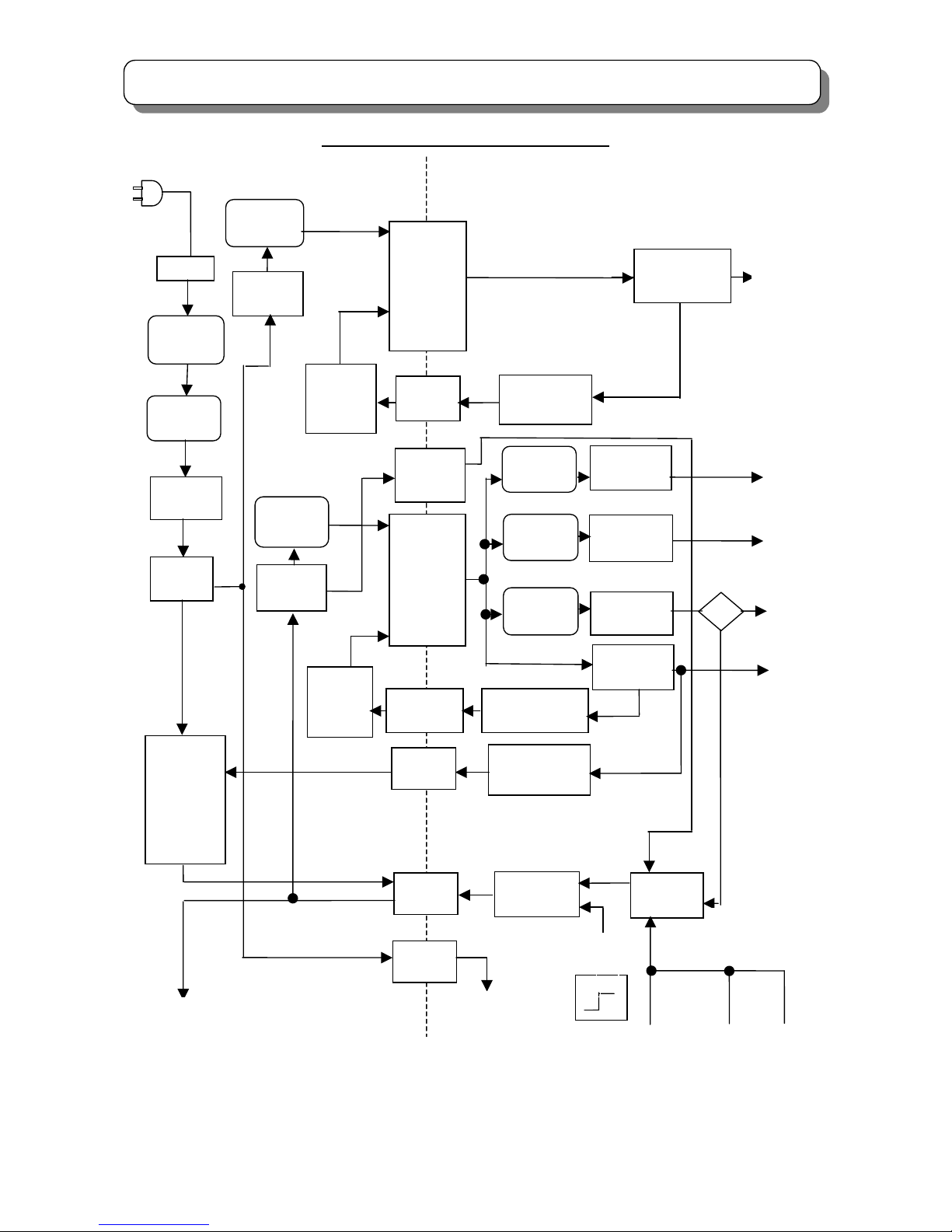

Is click sound

of Relay heard?

Are 2 Green LEDs

turned OFF at the

same time?

I901,I904,

F902 etc

Check

No

Raste

r

Is Voltage at

of D993(K)

5.8V

Has Fuse FP01

blown?

F903,I902,

I941 etc

YES

YES

YES YES

NO

Is base Voltage

of Q709 normal?

Does raste

r

appear with (7) and (17)

of PPT3 shorted?

Are Voltages

At both ends of T702

(primary side)

normal?

PDT2 pin(9)

-H out,

PDT3 pin(3)

-DEF 10.5V

etc.

T702, R748,

R730,etc.

Q777, QH01,

T701, TH01

etc.

NO

NO

YES

YES

Is Voltage

at pin(6) of PPT3

(R947) 2.5V?

Check

Check

Check

Check

Check

IP01,TP01,

DP05,DP02

etc.

Replace FP01

Check

Q944,

S903

YES

Check

uCOM

Power control

YES

Check

Find LED(s) that is

Turned dark or OFF

Earlier than the other.

(1) TROUBLE SHOOTING for POWER CIRCUIT

No raster and no power (How to check LED’s Diagnosis)

(Sig

nal Power PWB)

(Sig

nal Power PWB)

(Sig

nal Power PWB

)

(Pow Def PWB)

Check

(

Pow Def PWB)

(

Pow Def PWB

)

(Sig

nal Power PWB)

(Sig

nal Power PWB)

(Pow Def PWB)

Is Voltage

at D949(K) 5V?

SW+28/-28V line

EP40, EP41,

DP40, DP42,etc.

SW+115V line

EP45, DP46,

Q777,QH01,

Q701,TH01,

T701 etc.

Q980,Q981,

Q901 etc

(Pow Def PWB)

NO

NO

NO

YES

NO

NO

NO

1.Turn OFF

the power SW.

2.Wait for 3 seconds.

3.Turn ON again after

several seconds, and

observe green LEDs

carefully.

DP59

DP48

17

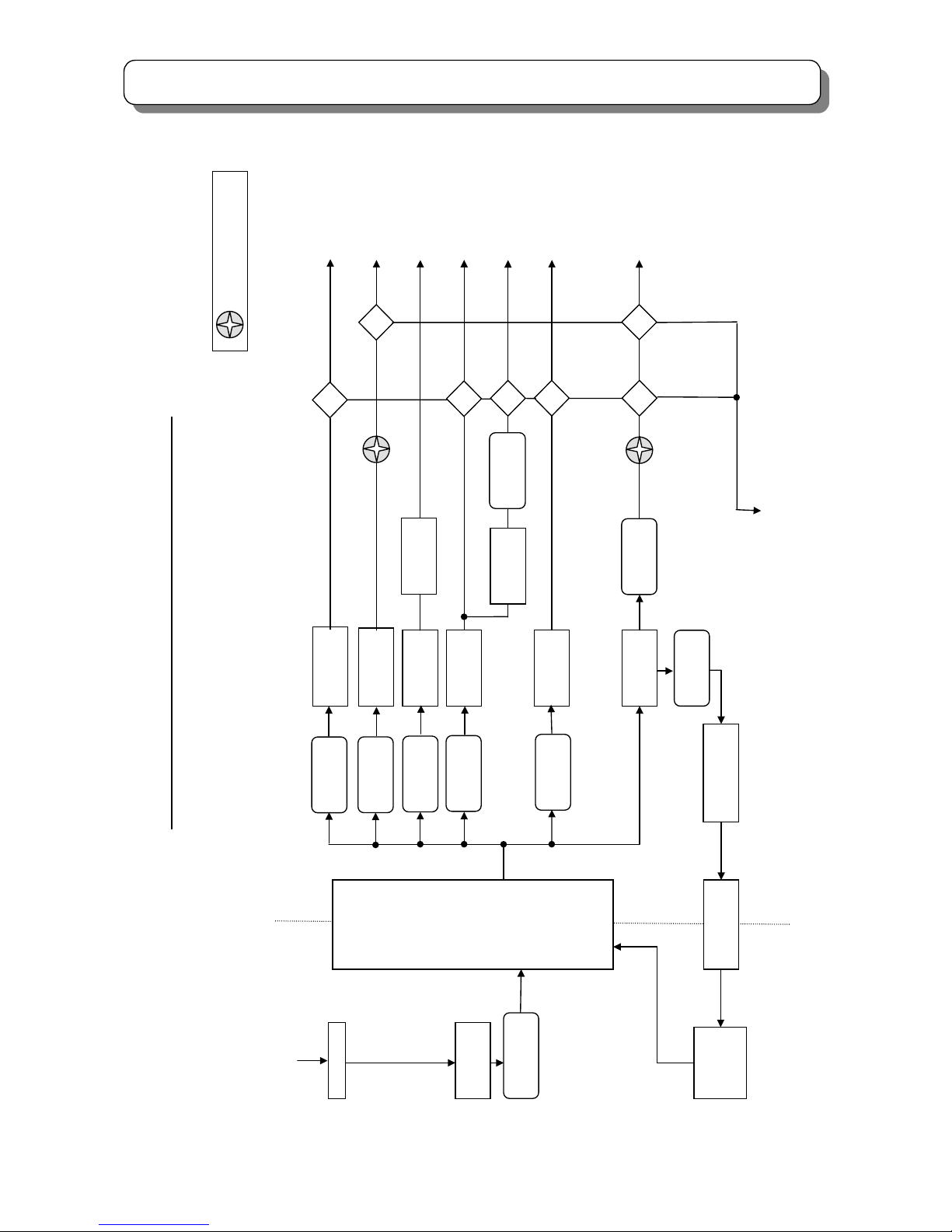

TROUBLE SHOOTING

(2) PROPTECTION CIRCUIT BLOCK DIAGRAM

DP59:+115V

Switching

Transformer

TP01

LIVE

COLD

Feed Back

IP02

Rectifier

+28V:DP40

Rectifier

+12V:DP43

Rectifier

+115V:DP46

Protecto

r

EP45:3

Rectifier

-24V:DP42

DP48:+28V

DP58:>133

QP41:>1.8A

Q

ZD

DP60:>32V

ZD

ZD

Voltage Control

+115V:IP40

Short CCT.

Detecto

r

Over Voltage

Detecto

r

= GREEN LED

DP5M Protection Circuit Block Daigram (Deflection Power Supply)

Switching

Control

IP01

AC Input

Rectifier

DP01

Fuse

FP01:T3.15A

Deflection:

DEF+115V

Conver / DCU:

DEF-28V

Conver / Vert:

DEF+28V

Video:

DEF+220V

DCU:

DEF+7.5V

Rectifier

+7V:DP44

Regulator

+6.3V:QP40

Heater:

DEF+6.3V

Protecto

r

EP47:2

From Power P.W.B

Protecto

r

EP44:4

Protecto

r

EP41:10

Protecto

r

EP43:5

Protecto

r

EP42:3

Protecto

r

EP40:10

Rectifier

+220V:DP45

D

DP63:<5V

Regulator

+10.5V:IP41

D

D

DP65:

<

5V

DP62:<5V

DP60:>-20V

Protecto

r

EP46:0.5

DEF CCT.

Protect

18

TROUBLE SHOOTING

DP5M Protection Circuit Block Daigram

Audio:

+38.5V

Signal:

SIG+10.5V

>AC300V

A

C Input

Fuse

F901:T6.3

Varistor

X901:681

Line Filter

L901

Line Filter

L902

Temperature

Limited

Fusing

Resistor

F904

Fuse

F902:T1A

Rectifier

D901

Switching

Control

I901

Switching

Transformer

T901

Feed Back

I904

AC-OVP

I905

Switching

Transformer

T902

Fuse

F903:T3.15

Rectifier

D902

Switching

Control

I902

Feed Back

I906

Protector

E940:7

Protector

E942:2

Protector

E941:5

Rectifier

+38.5V:D960

Rectifier

+35V:D961

Rectifier

+10.5V:D954

Voltage Control

+5.2V:D962

Voltage Control

+5.6V:I941

Rectifier

+5.6V:D955

ZD

Rush R On/Off

Switch:Q942

Protect

On/Off

RELAY

S901

DEF CCT

Protect

SIG CCT

Protect

CPT CCT

Protect

Over Voltage

Detecto

r

Signal:

SIG+5.6V

Signal:

SBY+5.2V

D988:>14V

Rectifier

+5.2V:D949

Power On/Off

Switch:Q944

RELAY

S903

AC Clock

I903

AC Clock

50Hz

COLD

LIVE

AC Plug

Power_1

On/Off

On

Off

(TV)

To Deflection

Power Suppl

y

19

TROUBLE SHOOTING

)

20

TROUBLE SHOOTING

21

TROUBLE SHOOTING

22

TROUBLE SHOOTING

How to Adjust 9 Point Manual Convergence

Adjustment Preparation

Receive RF or Video signal.

Adjustment Procedure

Press and hold the MAGIC/MANUAL FOCUS button for more than 3 seconds to enter the MANUAL CONVERGENCE

mode.

(Note: If you press the MANUAL FOCUS button on the side panel of C43-FL8000 model, the TV will enter the MANUAL

CONVERGENCE mode directly.)

(1) Press the ▲ ▼ ◄ ► cursor buttons to move the selection box to select the adjustment point. Press the ENTER

button to change the color of the selection box to red. Press the ▲ ▼ ◄ ► cursor buttons to adjust red convergence.

Note: Press the number buttons (2, 5, 4, 6) can also move the selection box to select the adjustment point, and then to

adjust red convergence directly.

(2) Press the ENTER button to change the selection box to blue. Press the ▲ ▼ ◄ ► cursor buttons to adjust blue

convergence.

(3) Press the ENTER button to change the selection box to white. Press the ▲ ▼ ◄ ► cursor buttons to move the

selection box to select another adjustment point, then perform (1)~(2) to adjust.

Notes: 1. During the adjustment, press the ENTER button frequently to return to the moving mode ( is shown in white,

which means the selection box is in the moving mode.) and affirm convergence of the selection box so as to get

the best convergence.

2. If you cannot insure perfect alignment, please try to get balance in alignment between and .

(4) When adjustment is done, press the MENU button and the following screen will display as below. Press the number

keys to perform the following procedure.

[0]: To cancel the adjusted data and exit from adjustment mode.

[1]: To save the adjusted data and exit from adjustment mode.

[2]: To return to manual convergence mode.

[3]: To recall the adjusted data from previous auto convergence

and return to manual convergence mode.

Notes:

1) During the adjustment, you are suggested to adjust again and again, and confirm

the alignment of the selection box in the moving mode.

2) If there is no operation for 3 minutes from the remote control unit, the TV will exit from MANUAL CONVERGENCE

mode.

Release the MAGIC

FOCUS button.

Press and hold the MAGIC

FOCUS button more than

3 seconds.

MANUAL FOCUS

PLEASE

ENTER NUMBER

CANCEL :[ 0 ]

DONE :[ 1 ]

BACK :[ 2 ]

RESET :[ 3 ]

23

TROUBLE SHOOTING

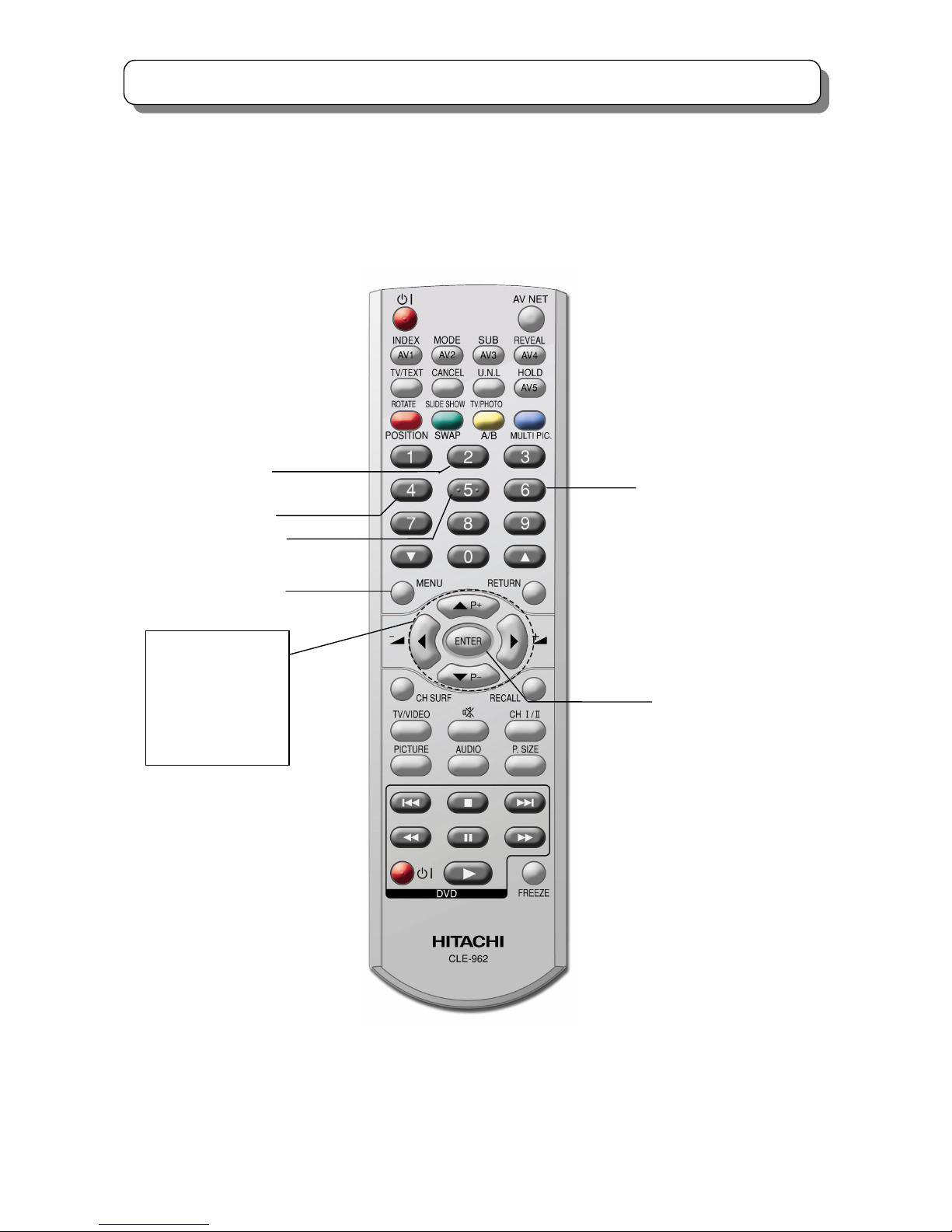

9 Point Manual Adjustment remote control

CURSOR LEFT

CURSOR DOWN

MENU

CURSOR RIGHT

CHANGE COLOR

(

Red & Blue)

ADJUSTMENT

[▲]:UP

[▼]:DOWN

[◄]:LEFT

[►]:RIGHT

CURSOR UP

24

TROUBLE SHOOTING

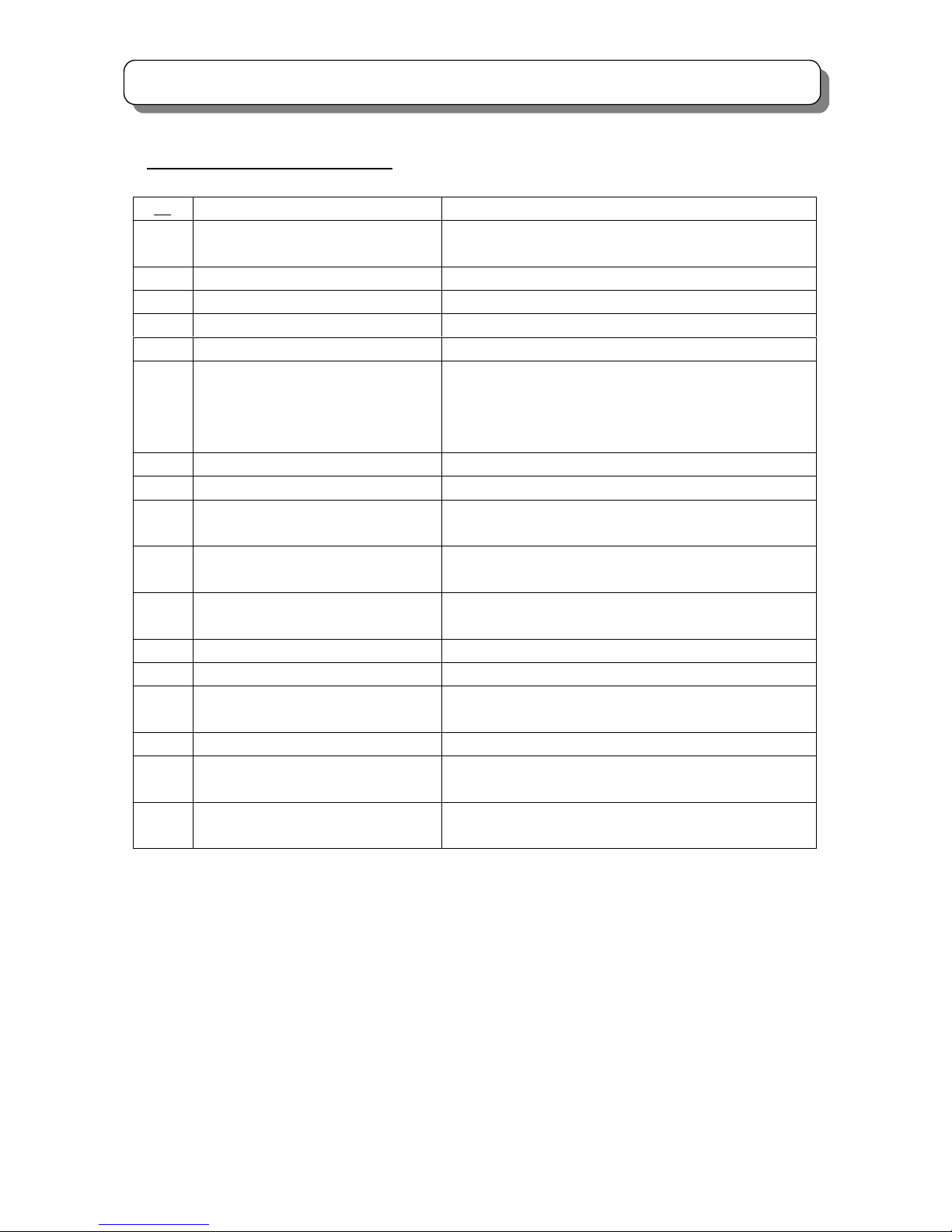

Trouble Shooting Guide for DP5M

No

Changed Parts Adjustment necessary(refer to page 25)

1 Signal PWB

No. 1.1/1.2/2.2/2.5/2.6/2.7/2.8/2.9/2.14/2.16/2.17/2.18/2.19/

2.20

2 Tuner (Main/Sub) No adjustment necessary

3 Microprocessor (I001) No adjustment necessary

4 FC unit No adjustment necessary

5 Sub signal PWB No adjustment necessary

6

Audio control / amplifier,NICAM/A2

I305(MSP3415G)

IA02(TA8258H)

IA01 (NJW1177V)

No adjustment necessary

7 EEPROM (I002) No. 1.1/1.2/2.6/2.7/2.8/2.9/2.14/2.16/2.17/2.18/2.19/2.20

8 Video chroma IC IV01,IW03 No. 2.19

9

Deflection Control/RGB IC

IX01

No. 2.14.2/2.16/2.17

10

Power / Deflection PWB

Sub Deflection PWB

No. 2.1/2.5/2.6/2.7/2.8/2.9/2.12/2.13/2.14/2.15/2.20

11

DCU circuit

IS06 / IT01 / IS01 / IS03

No. 2.2/2.5/2.14/2.20

12 Sub Signal PWB; Power PWB No adjustment necessary

13 Sensor PWB, Sensor No. 2.14/2.20

14 PRT tube

No. 1.3/2.1/2.3/2.4/2.5/2.6/2.7/2.8/2.9/2.10/2.11/2.12/2.13/

2.14/2.15/2.16/2.17/2.20

15 CPT PWB No. 2.1/2.12/2.13/2.14/2.15/2.16/2.17/2.20

16 DY

No. 1.3/2.3/2.4/2.5/2.6/2.7/2.8/2.9/2.10/2.12/2.13/2.14/2.15/

2.20

17

Deflection Control IC

IH01 (M62501P), FBT (TH01)

High voltage adjustment

25

SERVICE ADJUSTMENTS

SERVICE ADJUSTMENT ITEMS:

1.1 MEMORY INITIALIZE ……………………………………………………………………………………. 26

1.2 MODEL SETUP …………………………………………………………………………………………... 26

1.3 PREHEAT RUN CONDITION …………………………………………………………………………… 28

2.1 CUT OFF ADJUSTMENT ……………………………………………………………………………….. 28

2.2 DCU PHASE DATA SETTING ………………………………………………………………………….. 29

2.3 RASTER TILT ADJUSTMENT ………………………………………………………………………….. 30

2.4 BEAM ALIGNMENT ……………………………………………………………………………………… 32

2.5 RASTER POSITION ADJUSTMENT …………………………………………………………………... 33

2.6 SIDE PIN DISTORTION ADJUSTMENT ………………………………………………………………. 34

2.7 VERTICAL SIZE ADJUSTMENT ……………………………………………………………………….. 35

2.8 HORIZONTAL SIZE ADJUSTMENT …………………………………………………………………… 36

2.9 TRAPEZOID DISTORTION ADJUSTMENT ………………………………………………………….. 38

2.10 BEAM FORM ADJUSTMENT ………………………………………………………………………….. 39

2.11 LENS FOCUS ADJUSTMENT ………………………………………………………………………….. 40

2.12 STATIC FOCUS ADJUSTMENT ……………………………………………………………………….. 44

2.13 DYNAMIC FOCUS CHECK …………………………………………………………………………….. 45

2.14 DIGITAL CONVERGENCE ADJUSTMENT …………………………………………………………… 46

2.15 BLUE DEFOCUS ADJSUTMENT ……………………………………………………………………… 65

2.16 WHITE BALANCE ADJUSTMENT …………………………………………………………………….. 66

2.17 SUB BRIGHTNESS ADJUSTMENT …………………………………………………………………… 68

2.18 SUB PICTURE ADJUSTMENT …………………………………………………………………………. 69

2.19 TINT ADJUSTMENT …………………………………………………………………………………….. 70

2.20 MAGIC FOCUS INITIALIZE …………………………………………………………………………….. 71

3.1 PRT CABINET LOCATION ……………………………………………………………………………… 73

3.2 FOCUS PACK …………………………………………………………………………………………….. 73

3.3 MAIN P.W.B ……………………………………………………………………………………………….. 74

26

SERVICE ADJUSTMENTS

Before performing SERVICE ADJUSTMENTS★ ,please refer to the “TROUBLE SHOOTING”。

1.1 Memory initialize

When replacing signal P.W.B or EEPROM(I004), it requires perform Memory Initialize operation.

Adjustment Procedure

(1)Link the PRST① and PRST② for longer than 3 seconds.

(Please refer to page 74.)

(2)Wait until the OSD “1” is displayed (It takes several 10 seconds.) , this means initialization is

completed and each settings become factory preset condition.

Do not unplug the outlet or perform any key operation until the initialization is completed.

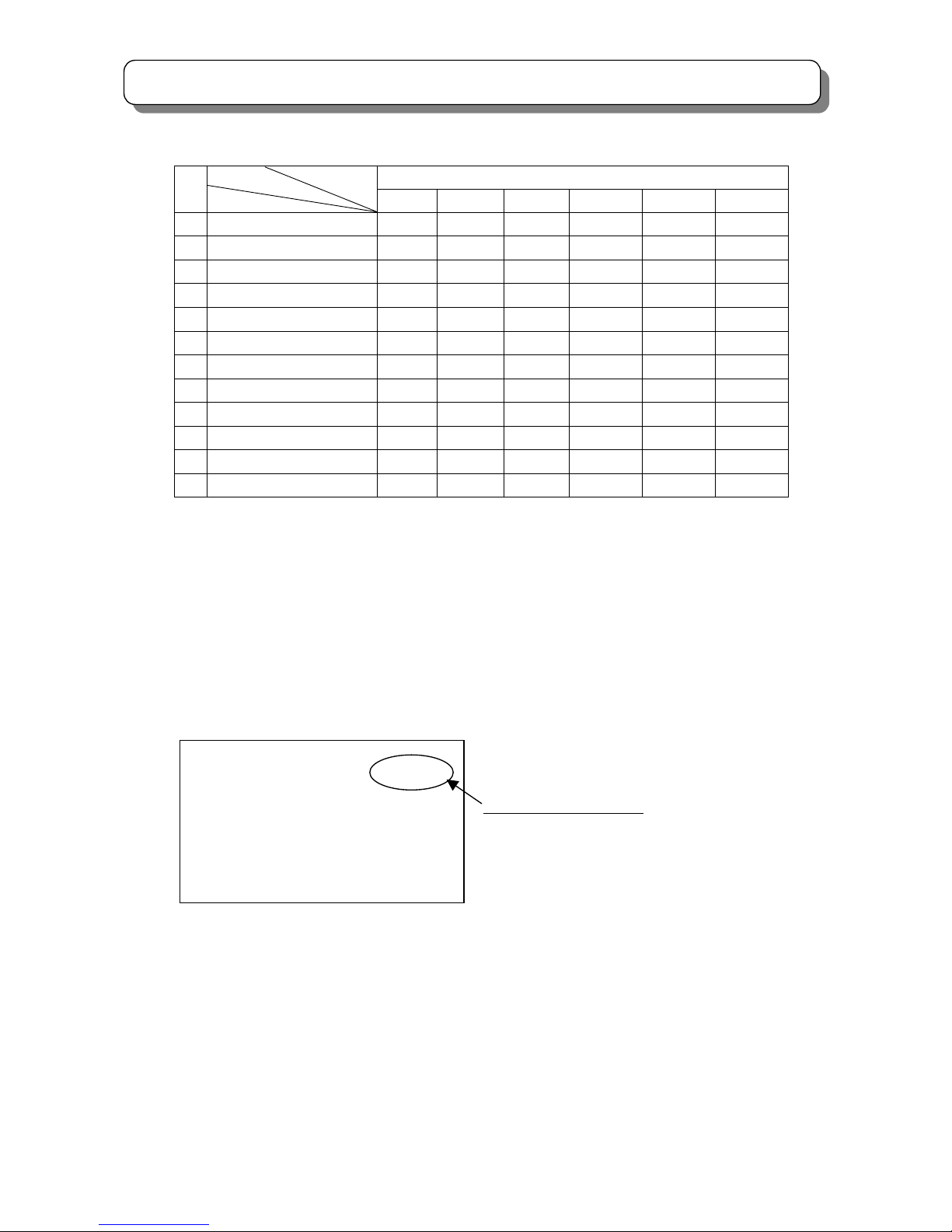

1.2 Model Setup

Adjustment Procedure

(1) Set following items in service menu according to respective model.

[4:3 Model]

4:3

No.

FD8000 FL8000

1 Model Select1:ASPECT

0 0

2 Model Select2:DESTINATION

1 1

3 Model Select3:LIGHT

1 0

4 Model Select4:MULTI_PICTURE

1 1

5 Model Select5:COLOR_MANAGER

1 1

6 Model Select6:PC

0 0

7 Model Select7:IR_BLASTER

1 0

8 Model Select8:PHOTO

0 0

9 Model Select9:TEXT

2 0

10 Model Select10:HDMI

0 0

11 Model Select11:SUB-Y/C

1 1

12 Model Select12:SRS

1 1

Models

Value

Items

27

SERVICE ADJUSTMENTS

[16:9 Model]

(2) After set the Items according to the above tables.

(a) Select item No.837(INIT3) in service menu and press and hold the [recall] key on the remote handset until the

OSD background changes to yellow. (It takes about 3 seconds.)

(b) Wait until the OSD background color becomes normal (It takes several 10 seconds.) , this means initialization

is completed and each settings become preset condition according to the model .

Do not unplug the outlet or perform any key operation until the initialization is completed.

(3) Check the setting state displayed on the upper right of the service menu.

V100-FFFF FC100-FFFF MC100 001111110011

No. Data

0: 0

1: 0

2: 0

3: 1

The state of Model Select setting

・From the left to the 1st figure:The state of Model Select1

……

・From the left to the 12th figure:The state of Model Select12

16:9

No.

WD8000

1 Model Select1:ASPECT 1

2 Model Select2:DESTINATION 1

3 Model Select3:LIGHT 1

4 Model Select4:MULTI_PICTURE 1

5 Model Select5:COLOR_MANAGER 1

6 Model Select6:PC 1

7 Model Select7:IR_BLASTER 1

8 Model Select8:PHOTO 1

9 Model Select9:TEXT 2

10 Model Select10:HDMI 1

11 Model Select11:SUB-Y/C 1

12 Model Select12:SRS 1

Models

Val ue

Items

28

SERVICE ADJUSTMENTS

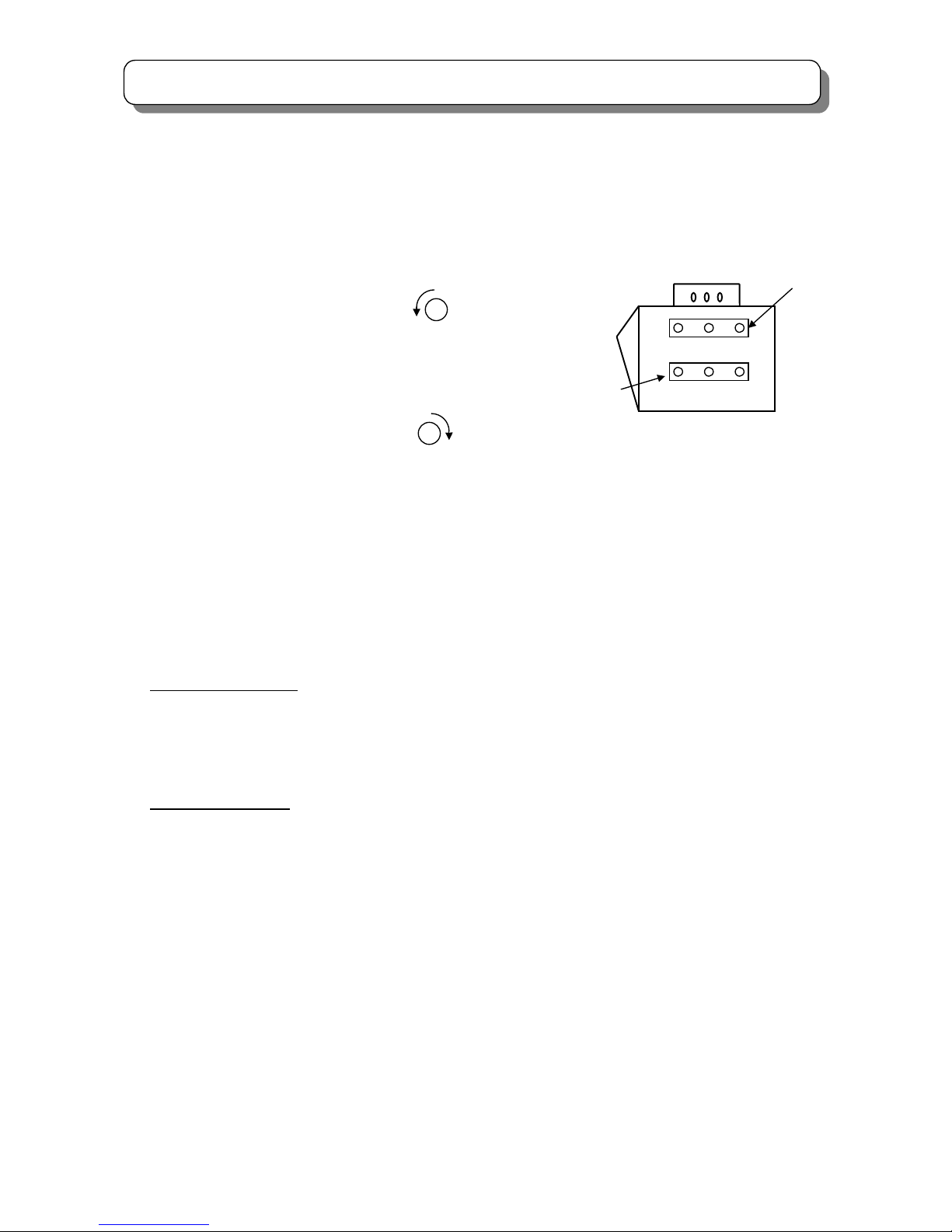

1.3 PREHEAT RUN CONDITION

* Preset each VR as in the following figure before PREHEAT RUN.

(1) SCREEN VR ON FOCUS PACK.

<PRESET> Turn counterclockwise to the end.

(2) STATIC FOCUS VR ON FOCUS PACK.

<PRESET>Turn clockwise to the end.

2.1 CUT OFF ADJUSTMENT

Adjustment preparation

(1) Preheat run should be finished.

(2) Confirm item No.54(R cut off), 55(G cut off) and 56 (B cut off) are set to 127 in service menu.

(3) Confirm item No.52(R DRV) and No. 53(G DRV) are set to 63 in service menu.

Adjustment procedure

(1) Select item No. 20 in service menu by using the remote controller.

Press [►] key to enter CUT OFF adjustment mode.

(2) Screen VR (R, G and B) should be turned clockwise gradually and set the condition that the each horizontal

line is just beginning to appear.

(3) Press [◄] key to return normal mode.

Screen VR

Focus VR

R G B

R G B

Screen VR

Static Focus VR

<Focus Pack>

29

SERVICE ADJUSTMENTS

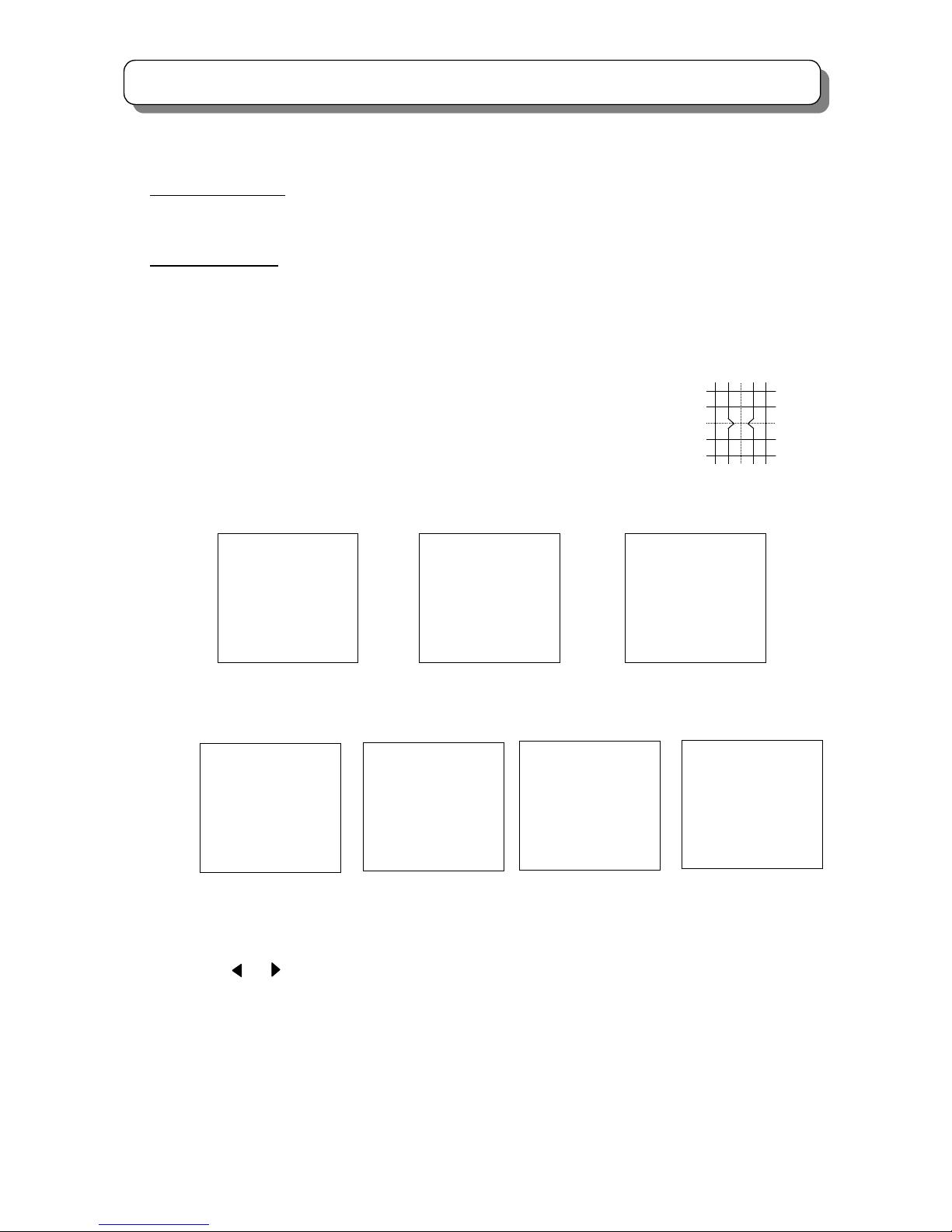

2.2 DCU PHASE DATA SETTING

Adjustment preparation

(1) Cut off adjustment should be finished.

Adjustment procedure

(1) Receive PAL signal (RF or VIDEO) and set to 100Hz mode. (User MENU

FUNCTION \ SCAN MODE

\ 100Hz) Contrast should be set center and other control be set normal.

(2) Push the “SERVICE ONLY” switch on the SIGNAL P.W.B. to enter the adjustment mode of the digital

convergence unit.

(3) Phase set.

(3-1) Press the [REVEAL] key on R/C to display the green cross-hatch pattern.

(3-2) Press the [CH Ⅰ/Ⅱ] key to recall the phase DATA on screen.

【4:3】

【16:9】

(3-3) If phase data is not the same as above, change the DATA by using the following R/C keys.

Press [4] or [6] key to adjust the PH-H

Press [2] or [5] key to adjust the PH-V

Press [ ] or [ ] key to adjust the CR-H

Press [▲] or [▼] key to adjust the CR-V

(3-4) Press the [REVEAL] key to exit from phase mode.

(3-5) Press [INDEX] key on R/C twice to write the data into ROM.

(3-6) Push the “SERVICE ONLY” switch on the SIGNAL P.W.B. twice to exit from adjustment mode of the digital

convergence unit.

PAL 50p mode NTSC 60p mode

PHASE MODE: 6

PH-H: EC

PH-V: 09

CR-H: 34

CR-V: 14

PHASE MODE: 5

PH-H: F3

PH-V: 19

CR-H: 37

CR-V: 1C

PAL 100i mode

PHASE MODE: 1

PH-H: F3

PH-V: 0D

CR-H: 37

CR-V: 1C

PAL 50p mode

NTSC 60p mode

PHASE MODE: 6

PH-H: ED

PH-V: 06

CR-H: 31

CR-V: 14

PHASE MODE: 5

PH-H: F6

PH-V:16

CR-H: 36

CR-V: 1C

PAL 100i mode

PHASE MODE: 1

PH-H: F6

PH-V: 0A

CR-H: 36

CR-V: 1C

PAL HD mode

PHASE MODE: 2

PH-H: F5

PH-V: 03

CR-H: 33

CR-V: 14

30

SERVICE ADJUSTMENTS

(3-7) Change to PAL50p mode (PAL signal input, User Menu setting FUNCTION \ SCAN MODE \

PROGRESSIVE) and repeat procedure (2)-(3) for PAL50p mode.

(3-8) Change to NTSC60p mode (NTSC signal input, User Menu setting

FUNCTION \ SCAN MODE \

PROGRESSIVE) and repeat procedure (2)-(3) for NTSC60p mode.

[16:9 model only]

(3-9) Change to PAL HD (1080i/50) mode, and repeat procedure (2)-(3) for PAL HD mode.

(*)Setting procedure of PAL HD mode.

(a) Receive 1080i(50Hz).

(b) Set the Scan Mode to HD.

(c) Set the Picture Mode to Favorite.

Film Mode : Off

Dynamic Contrast : Off

Color Manager : Off

(d) Set Picture Size to 16:9 mode.

2.3 RASTER TILT ADJUSTMENT (DEFLECTION YOKE ADJUSTMENT)

Adjustment preparation

(1) Face the set East or West.

(2) Receive the NTSC cross-hatch signal.

(3) Contrast should be set MAX and the other controls should be set CENTER.

(4) The lens focus should be coarsely adjusted.

(5) The electrical focus should be coarsely adjusted

(6) The digital convergence should not be corrected.

(7) Turn the main power switch off.

(8) Press and hold the “SERVICE ONLY” switch on SIGNAL P.W.B. and switch on the power.

Adjustment procedure

(1) Apply covers to the R and B lenses or short the TS (2P EH Connector) on R and B CPT P.W.B. to project only

green beam.

(2) Then loose Dys’ screws (R, G, B) before start alignment of raster tilt.

DY

PRT GUN

SCREW

Loading...

Loading...