Page 1

FH 0202E

DP2M CHASSIS

SERVICE MANUAL

MODEL: C43-FD2000 C50-FD2000

CAUTION: Before servicing this chassis, it is important that the service technician read the “Safety Precaution”

SAFETY NOTICE···························································································· 2

SAFETY PRECAUTIONS··················································································· 3

TECHNICAL CAUTIONS···················································································· 6

SPECIFICATIONS···························································································· 7

CIRCUIT PROTECTION····················································································· 7

G EN ERAL I N FO RM AT IO N·················································································· 8

CAUTIONS WHEN CONNECTING/DISCONNECTING THE HV CONNECTOR······················· 10

S ERVIC E A DJ US TMEN TS ················································································· 11

T RO UB LE SH OO TING ······················································································ 51

PROTECTION CIRCUIT BLOCK DIAGRAM······························································ 55

EXPLODED VIEW··························································································· 56

REPLACEMENT PARTS LIST·············································································· 60

BLOCK DIAGRAM··························································································· 96

BASIC CIRCUIT DIAGRAM················································································· 97

PRINTED CIRCUIT BOARD················································································· 112

WIRING DIAGRAM···························································································120

and “Safety Notice” in this Service Manual.

CONTENTS

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

Components having special characteristics are identified by a ! on the schematics and on the parts list in this

service data and its supplements and bulletins. Before servicing the chassis, it is important that the service

technician read and follow the “Safety Precautions” and “Safety Notice” in this Service Manual.

* For continued X-radiation protection, replace picture tube with original type or approved equivalent type.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

PROJECTION COLOR TELEVISION

Page 2

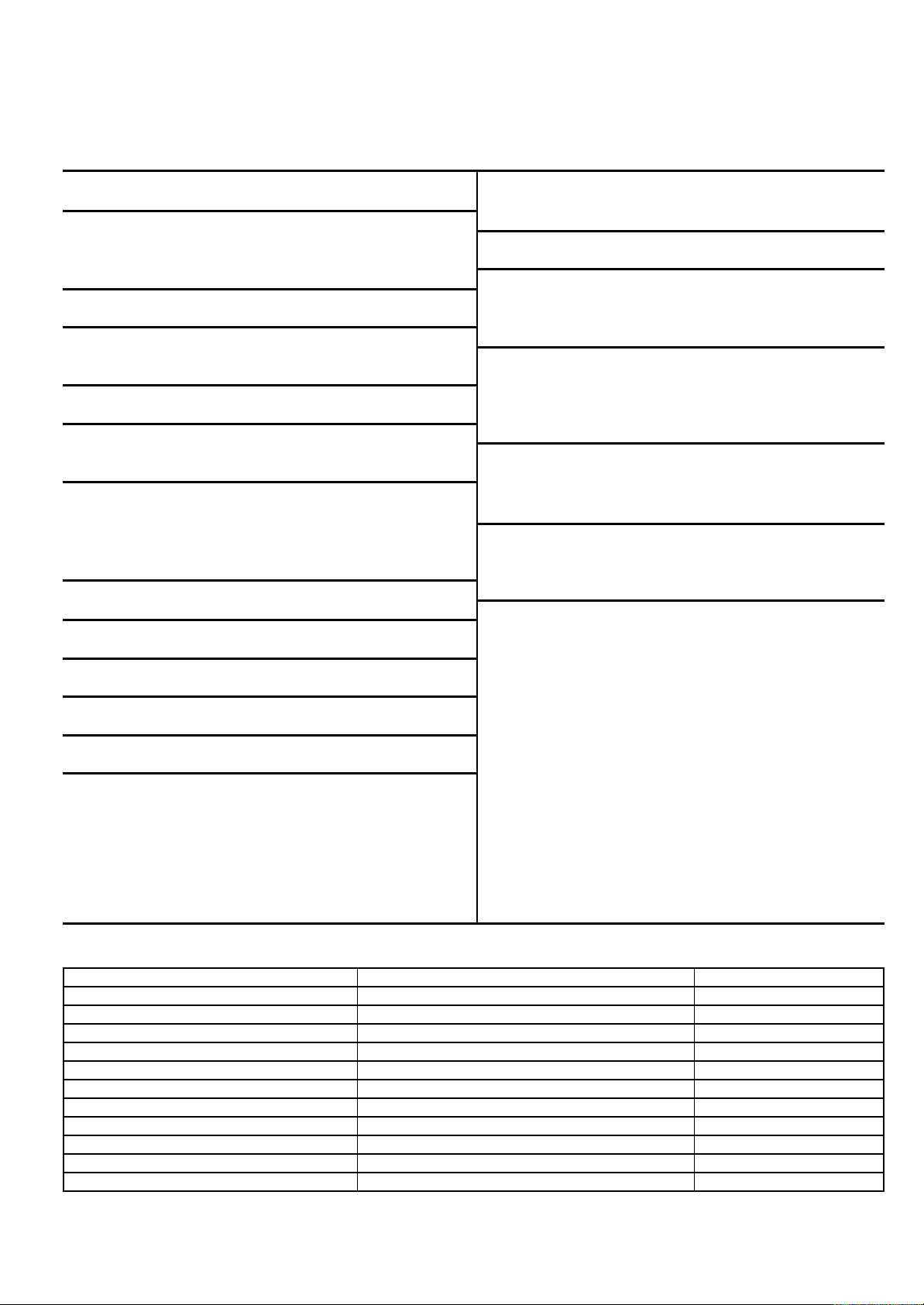

C43-FD2000 SPECIFICATIONS

Sreen Size : 43 - inch Brightness : 200 cd/m

(white screen)

Cathode Ray Tube : R P16LXL00

G P16LXL00 Anode Voltage : 30.9kV

B P16LXL00

Speakers :

Power Supply : 220 - 240V AC, 50/60 Hz Front L/R : 12cm x 2

Tweeter: 5cm x 2

Power Consumption : 235W (Operating)

Dimension : Height (mm) 1231

Width (mm) 1098

Antenna Impedance : 75 ohm unbalanced Depth (mm) 570

Weight (kg) 66

Receiving Channel : CH (MHz)

43MHz - 863MHz Terminals (Input): Video Audio (L/R) x 5

S-Video x 3

Intermediate Frequency:

Picture I-F Carrier 38.9MHz

Sound I-F Carrier 32.4MHz Terminals (Output): Monitor

Color Sub Carrier 34.47MHz (Video,Audio [L/R]) x 1

Program Selection : 200

Circuit Board Assemblies :

Video Input : 1V 75 ohm

Video Output : 1V 75 ohm C.P.T. (G) P.C.B.

Audio Input : 470mVrms, 47k ohm Convergence P.C.B.

Stereo Audio Output : 470mVrms, 1k ohm Power/Deflection P.C.B.

Audio Output Power : 30Watt Power Sup P.C.B.

Front : 15W x 2 Power switch P.C.B

Component x 2(Y1, CB, CR)

Headphone x 1

C.P.T. (B) P.C.B.

C.P.T. (R) P.C.B.

Signal Sub P.C.B

Signal P.C.B.

Terminal P.C.B.

Side Terminal P.C.B

Sensor P.C.B

Control P.C.B

2

CIRCUIT PROTECTION

Fuse (or Device) Circuit Protected Physical Location

F908 4A/25V AC Main primary Fuse Power Sub

F902 3.5A/250V AC Primary Fuse- Signal Power Supply Power Sub

FP01 3.15A/250V AC Primary Fuse - Deflection Power Supply Power Deflection

E903 5A Fuse Protector Over Current Protector Audio +30V Power Supply Power Sub

E904 5A Fuse Protector Over Current Protector SW+11W Power Supply Power Sub

E905 5A Fuse Protector Over Current Protector StandBy Power Supply Power Sub

EP33 5A Fuse Protector Over Current Protector SW+8V Power Supply Power Deflection

EP31 10A Fuse Protector Over Current Protector SW+28V Power Supply Power Deflection

EP32 10A Fuse Protector Over Current Protector SW-28V Power Supply Power Deflection

EP36 0.5A Fuse Protector Over Current Protector (+B Error AMP) Power Deflection

EP35 3A Fuse Protector Over Current Protector (+B Power Supply) Power/Deflection

Page 3

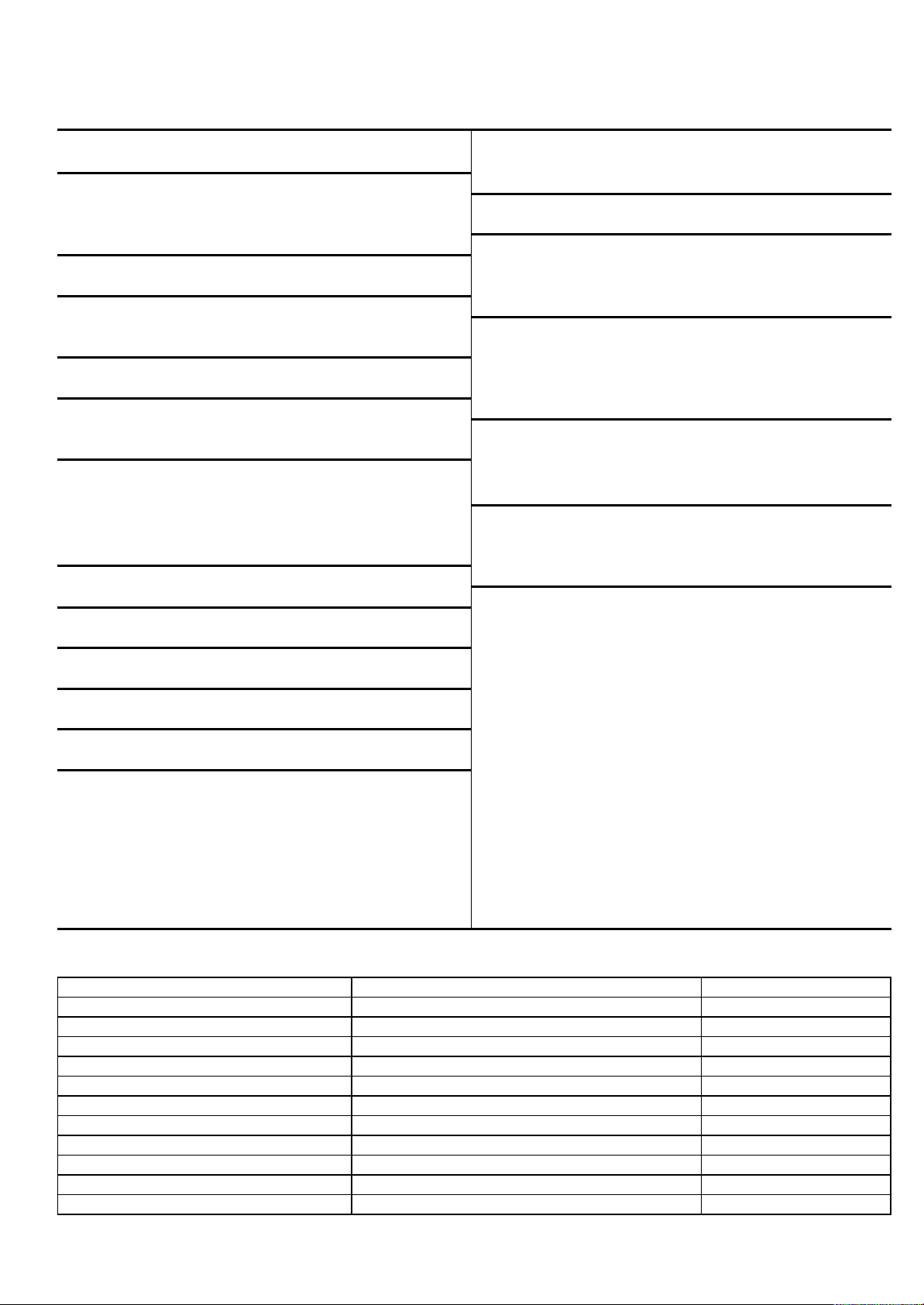

C50-FD2000 SPECIFICATIONS

Sreen Size : 50 - inch Brightness : 200 cd/m

(white screen)

Cathode Ray Tube : R P16LXL00

G P16LXL00 Anode Voltage : 30.9kV

B P16LXL00

Speakers :

Power Supply : 220 - 240V AC, 50/60 Hz Front L/R : 12cm x 2

Tweeter: 5cm x 2

Power Consumption : 235W (Operating)

Dimension : Height (mm) 1341

Width (mm) 1262

Antenna Impedance : 75 ohm unbalanced Depth (mm) 616

Weight (kg) 103

Receiving Channel : CH (MHz)

43MHz - 863MHz Terminals (Input): Video + Audio (L/R) x 5

S-Video x 3

Intermediate Frequency: Component x 2(Y1, CB, CR)

Picture I-F Carrier 38.9MHz

Sound I-F Carrier 32.4MHz Terminals (Output): Monitor

Color Sub Carrier 34.47MHz (Video,Audio [L/R]) x 1

Headphone x 1

Program Selection : 200

Circuit Board Assemblies :

Video Input : 1V 75 ohm

C.P.T. (B) P.C.B.

Video Output : 1V 75 ohm C.P.T. (G) P.C.B.

C.P.T. (R) P.C.B.

Audio Input : 470mVrms, 47k ohm Convergence P.C.B.

Signal Sub P.C.B

Stereo Audio Output : 470mVrms, 1k ohm Power/Deflection P.C.B.

Signal P.C.B.

Audio Output Power : 30Watt Power Sup P.C.B.

Terminal P.C.B.

Front : 15W x 2 Power switch P.C.B

Side Terminal P.C.B

Sensor P.C.B

Control P.C.B

2

CIRCUIT PROTECTION

Fuse (or Device) Circuit Protected Physical Location

F908 4A/25V AC Main primary Fuse Power Sub

F902 3.5A/250V AC Primary Fuse- Signal Power Supply Power Sub

FP01 3.15A/250V AC Primary Fuse - Deflection Power Supply Power Deflection

E903 5A Fuse Protector Over Current Protector Audio +30V Power Supply Power Sub

E904 5A Fuse Protector Over Current Protector SW+11W Power Supply Power Sub

E905 5A Fuse Protector Over Current Protector StandBy Power Supply Power Sub

EP33 5A Fuse Protector Over Current Protector SW+8V Power Supply Power Deflection

EP31 10A Fuse Protector Over Current Protector SW+28V Power Supply Power Deflection

EP32 10A Fuse Protector Over Current Protector SW-28V Power Supply Power Deflection

EP36 0.5A Fuse Protector Over Current Protector (+B Error AMP) Power Deflection

EP35 3A Fuse Protector Over Current Protector (+B Power Supply) Power/Deflection

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

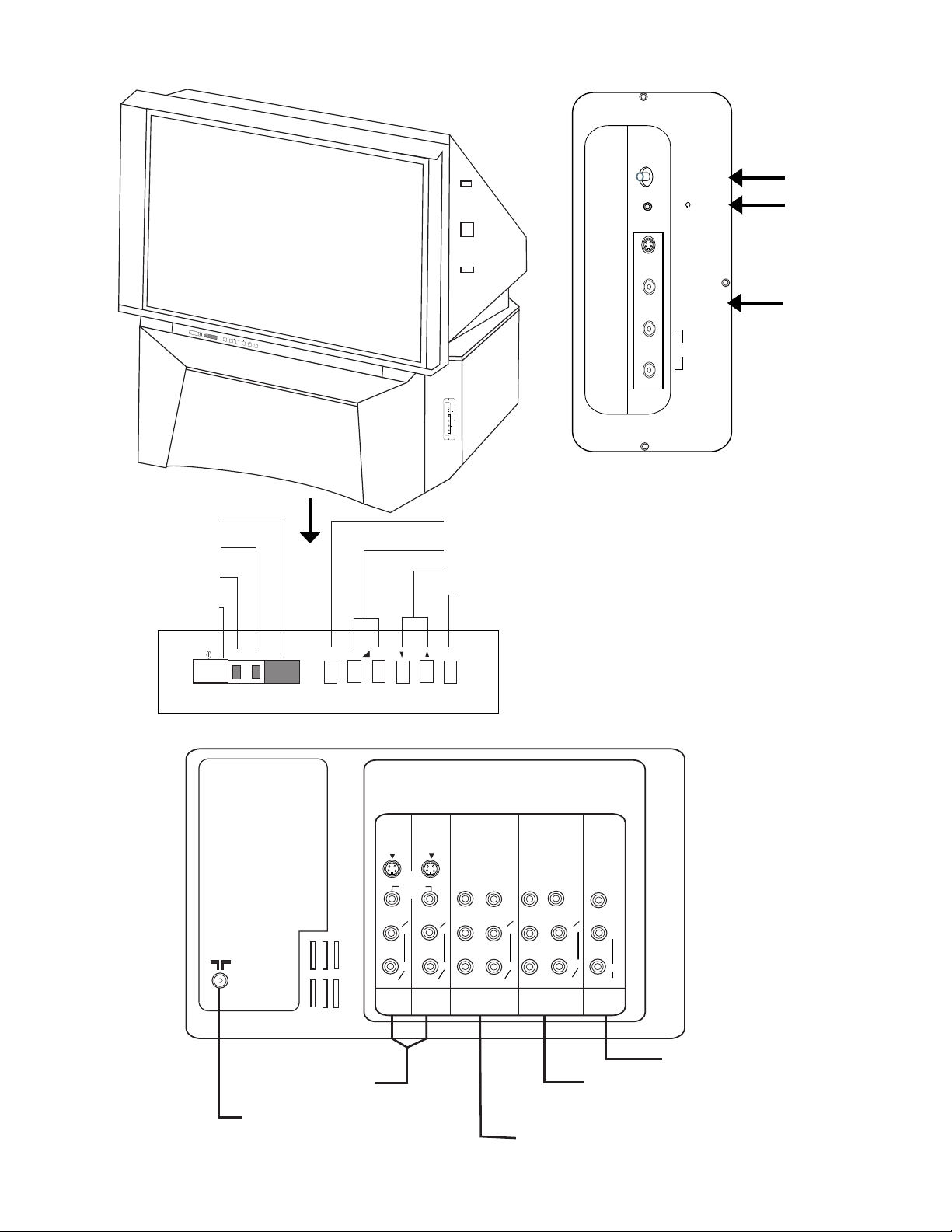

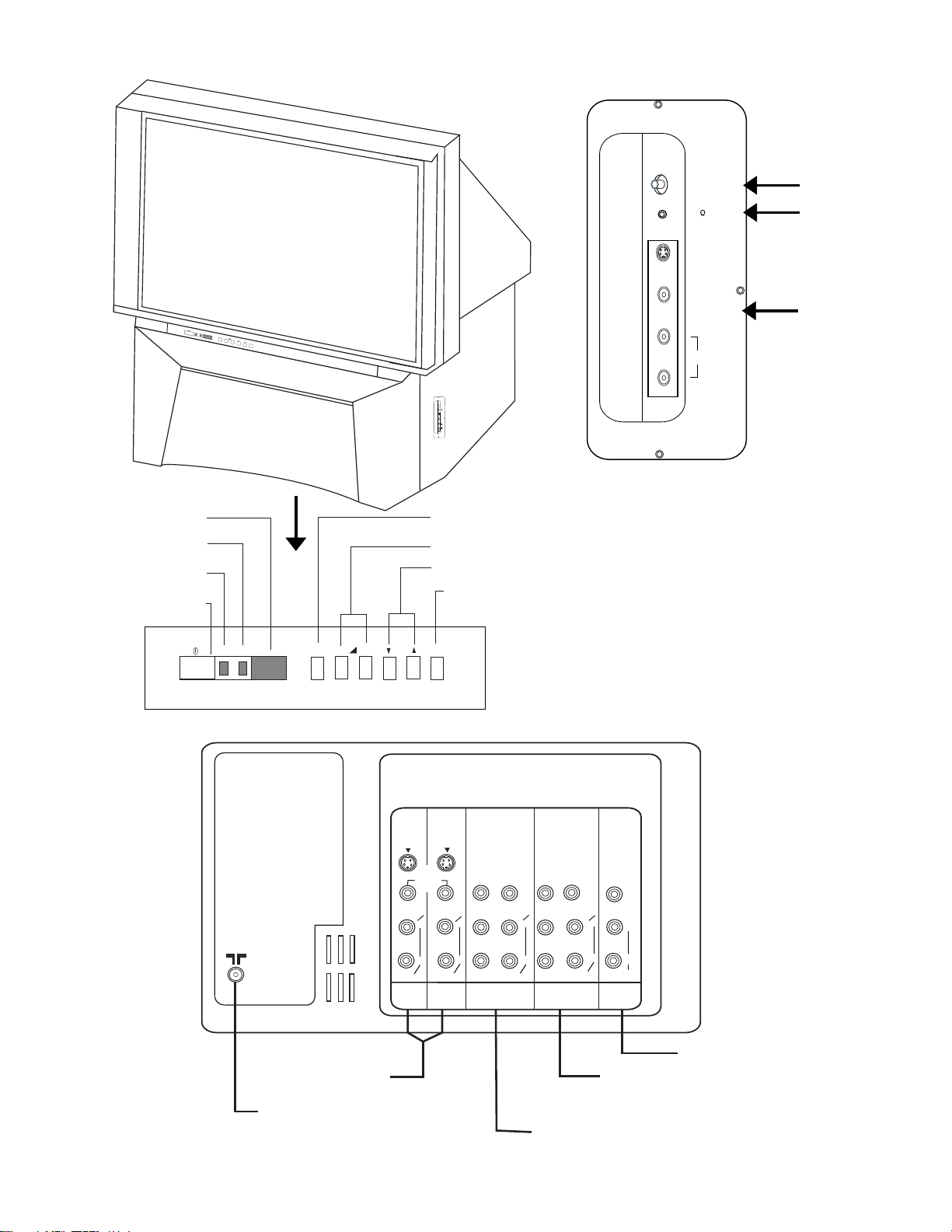

GENERAL INFORMATION C43-FD2000

ON

STAND

REMOTE CONTROL SENSOR

STANDBY INDICATOR

ON INDICATOR

POWER ON/OFF SWITCH

MAGIC FOCUS

AUTO DIGITAL

CONVERGENCE

HEADPHONE JACK

S-VIDEO

VIDEO

SIDE INPUT JACKS

( For INPUT 3)

BY

TV/VIDEO

– +

PROG

ME

NU

MAGIC FOCUS

S-VIDEO

VIDEO

L /(MONO)

AUDIO

R

L /(MONO)

AUDIO

R

SIDE CONTROL PANEL (INPUT 3)

INPUT SELECTION

VOLUME LEVEL BUTTON

CHANNEL SELECTOR

MENU BUTTON

ON

STANDBY

– +

TV/VIDEO

FRONT CONTROL PANEL

AUDIO/VIDEO

INPUTS 1,2

AERIAL TERMINAL

REAR PANEL CONNECTIONS

S-VIDEO

(MONO)

AUDIO

INPUT 1

PROG

VIDEO

L

R

S-VIDEO

(MONO)

AUDIO

INPUT 2

MENU

Y

PB/CB

L

PR/CR

R

COMPOSITE OR

(

Y P

(MONO)

AUDIO

INPUT 4

B

/

C

VIDEO

B

P

R

/

L

R

)

C

R

Y

PB/CB

PR/CR

INPUT 5

COMPOSITE OR

(

Y P

B

VIDEO

(MONO)

AUDIO

/

C

VIDEO

L

R

AUDIO

MONITOR

OUT

)

B

P

R

/

C

R

AUDIO/VIDEO INPUT 5 AND

COMPONENT INPUT

AUDIO/VIDEO INPUT 4 AND

COMPONENT INPUT

L

R

MONITOR OUTPUT

Page 15

GENERAL INFORMATION C50-FD2000

REMOTE CONTROL SENSOR

STANDBY INDICATOR

ON INDICATOR

POWER ON/OFF SWITCH

MAGIC FOCUS

AUTO DIGITAL

CONVERGENCE

HEADPHONE JACK

S-VIDEO

VIDEO

ON

STANDBY

TV/VIDEO

– +

PROG

ME

NU

MAGIC FOCUS

S-VIDEO

VIDEO

L /(MONO)

AUDIO

R

L /(MONO)

AUDIO

R

SIDE INPUT JACKS

( For INPUT 3)

SIDE CONTROL PANEL (INPUT 3)

INPUT SELECTION

VOLUME LEVEL BUTTON

CHANNEL SELECTOR

MENU BUTTON

ON

STANDBY

– +

TV/VIDEO

FRONT CONTROL PANEL

AUDIO/VIDEO

INPUTS 1,2

AERIAL TERMINAL

REAR PANEL CONNECTIONS

PROG

S-VIDEO

(MONO)

AUDIO

INPUT 1

VIDEO

L

R

MENU

S-VIDEO

(MONO)

AUDIO

INPUT 2

PB/CB

L

PR/CR

R

COMPOSITE OR

(

Y P

Y

INPUT 4

B

/

VIDEO

(MONO)

AUDIO

C

B

P

R

/

C

R

Y

PB/CB

L

PR/CR

R

COMPOSITE OR

)

(

Y P

INPUT 5

B

VIDEO

(MONO)

AUDIO

/

C

VIDEO

L

R

AUDIO

MONITOR

OUT

)

B

P

R

/

C

R

AUDIO/VIDEO INPUT 5 AND

COMPONENT INPUT

AUDIO/VIDEO INPUT 4 AND

COMPONENT INPUT

L

R

MONITOR OUTPUT

Page 16

P IN P FUNCTIONS

The P IN P feature is convenient when you want to watch more than one program at the

same time. You can watch a TV program while viewing other programs from the antenna or

any of the video inputs.

1. Press the MULTI PIC. button and a sub-picture

will appear in one of the four different modes

(SPLIT , 1, 4 or 12), depending on the last selection

of the P in P mode.

To change the P in P mode, press the M. MODE

to cycle through the four different modes.

If you wish to change the volume or channel

between the main and sub-picture, press the A/B

button. A symbol will appear to indicate your

selection. Press the CHANNEL UP/DOWN or

VOLUME UP/DOWN button to change channel

or volume for the selected picture.

SPLIT mode : The main picture and the sub-pic-

ture split evenly on the screen

Mode 1 : Sub-picture will appear in one

of the three different modes,

depending on the last selection

of the P in P mode.

Mode 4 : The main and 3 sub picture

appear on the right of the

screen.

Mode 12 : In this mode all the active chan-

nels numbers (those set in

memory) will scanned and displayed as sub-picture on the

screen.

1

SPLIT mode

MODE 1

MODE 4

2 1

5

9

6

10

2

1

2

2

1

3

2

3

4

7

8

11

12

MODE 12

Note: For P in P mode 1 and mode 4 , it is not possible to select the component

input as the sub-picture if the component input is progressive.

CAUTION:

When using Picture in Picture function, the sub-picture should not be left

permanently in one corner of the screen or a “P ATTERN BURN” may develop

over a long period of time.

Page 17

P IN P FUNCTIONS

NOTE: Some P in P buttons only function in a certain mode.

Please refer to the column below.

Remote Control

Buttons

MULTI. PIC Switch ON/OFF the P in P sub-window features.

P+ / P- Increase/decrease P in P main and sub-picture channel. This

button applies only to SPLIT , mode 1 and mode 4 selection.

In mode 4, press the P+/P– button to change channel for main

picture.

If sub-picture is selected, press the P+/P– button to select between

the sub-pictures. Press the button to change the channel.

SWAP The main and sub-picture will be exchanged. This button

applies only to SPLIT and mode 1 selection.

M. MODE To change the four different P in P modes (SPLIT, 1, 4, 12).

Pressing this button will cycle through these modes.

A/B Press this button to select between main or sub-picture to

change channel or volume. A symbol will appear to indicate

your selection.This button will only operate in SPLIT , mode 1

and mode 4 selection.

FREEZE Pressing this button will split screen to main and sub-picture.

The sub-picture will be in freeze mode.

POSITION Press this button repeatedly to select position of sub-

picture. This button apply only to P in P mode 1 selection.

Details

3 ➛ 4

➛

2 1

➛

➛

Page 18

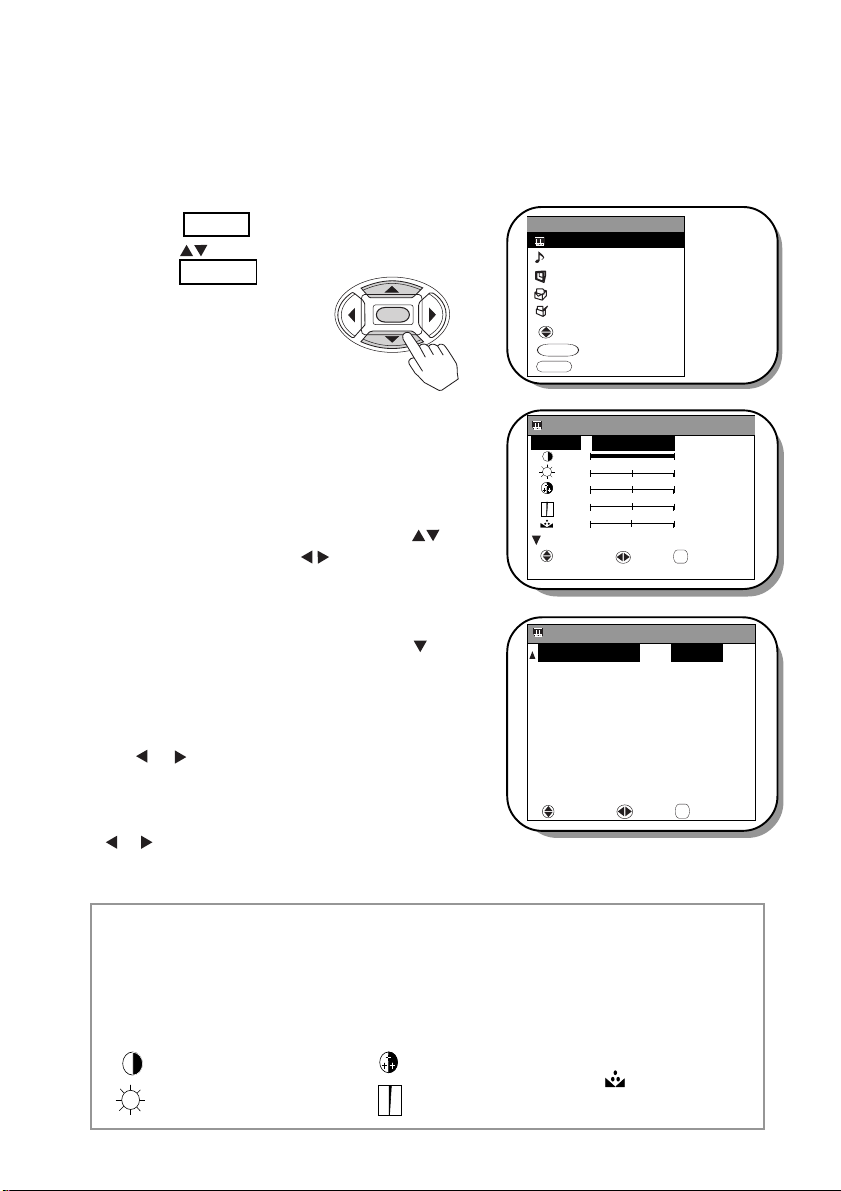

PICTURE & AUDIO SETTINGS

PICTURE SETTINGS :The PICTURE menu allows the user to select various controls,

such as mode , brightness, color, contrast and tint. To adjust these various controls, follow

the guide below.

1.

Press the MENU button.

Use the button to select PICTURE, then

press the ENTER button.

ENTER

2. The PICTURE menu is shown (right).

This menu allows the user to select and set various

standard picture controls such as MODE ( where

you can customize this mode to DYNAMIC,

NATURAL, THEATER or FAVORITE),

CONTRAST, BRIGHTNESS, COLOR,

SHARPNESS and TINT. Press the button

to select and press the button to adjust the

various setting to your desired level.

3.

In addition to these picture menu, the TV also

incorporates other controls. Press the button,

the OSD will go to page 2 of the PICTURE menu

containing controls such as COLOR TEMP,

COMB, FILM THEATER, SUPER CONT.,

NR, VM, CTI and BLACK STRETCH.

the or button to adjust the controls to your desired

level.

These features enhance and improve the

visual condition of the picture.

NOTE: If you select REFERENCE and press

or button, the setting will return to factory default

setting.

Press

the

MENU

PICTURE

AUDIO

TIMER

FUNCTION

SET UP

SELECT

ENTER

SET

MENU

EXIT

PICTURE [ 1 / 2 ]

MODE: : FAVORITE

+ 63

:

:

0

:

0

:

0

:

0

REFERENCE

SELECT SET RETURN

PICTURE

COLOR TEMP . : COOL

COMB : ON

FILM THEATER : OFF

SUPER CONT. : ON

NR : OFF

VM : ON

CTI : LOW

BLACK STRETCH : ON

REFERENCE

SELECT SET RETURN

RETURN

[2 / 2]

RETURN

DYNAMIC :

This ensures a sharp clear picture from corner to corner.

NATURAL : This mode is suitable for enjoying ordinary TV programs.

THEATER : This mode will add more realism experience.

FAVORITE : This is for your personal setting preference.

Contrast Color

Brightness Sharpness

Tint

Page 19

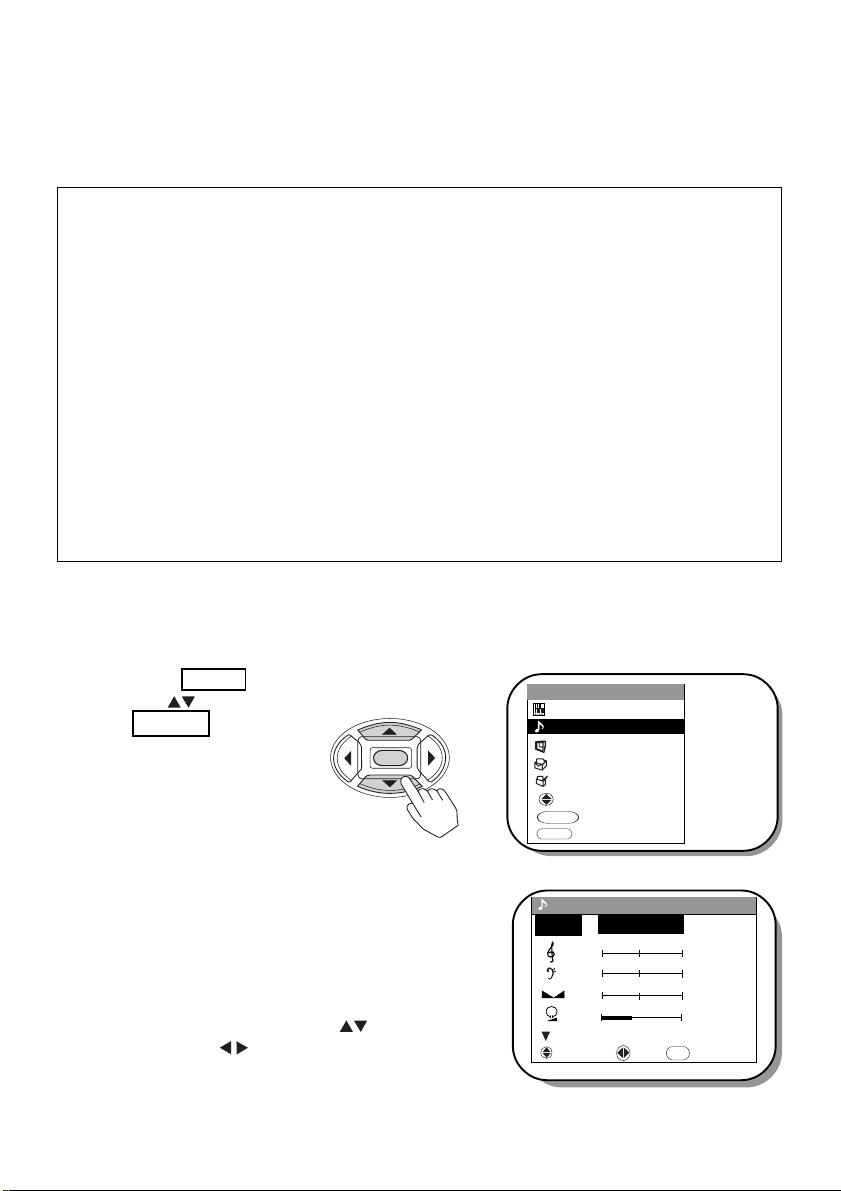

PICTURE & AUDIO SETTINGS

NOTE :

TINT

is only selectable when

NTSC

is detected.

SUPER CONT ., NR, VM and CTI

are selectable when the Picture mode is in FAVORITE.

FILM THEA TER is selectable when the Picture mode is in THEATER or FAVORITE.

COLOR TEMP. :Set this to WARM for hotter colors with more red or COOL for

less intense colors with more blue or NORMAL for standard color .

COMB : This function is used when using PAL system or when picture has

cross color.

FILM THEATER : Use this function when watching movies from film (cinema sources).

This is to smooth jagged edges.

SUPER CONT . : Turn on SUPER CONTRAST to improve picture detail in areas

of high brightness.

NR :

The NR function automatically reduces conspicuous noise in the

picture without degrading picture quality.

VM

:The VM function improves the sharpness of the picture to produce

clearest resolution and superb picture quality.

CTI :The CTI function improves color resolution at the edges to produce

clear and distinct colors.

BLACK :This function is to enhance the darker portions of the picture for

STRETCH

AUDIO SETTINGS

such as mode,treble, bass, balance and headphone volume. To adjust these various controls,

follow the guide below.

1. Press the MENU button.

Use the button to select AUDIO, then press

the ENTER button.

added realism and overall picture quality.

: The AUDIO menu allows the user to select various audio controls

MENU

PICTURE

AUDIO

ENTER

TIMER

FUNCTION

SET UP

SELECT

ENTER

SET

MENU

EXIT

2. The AUDIO menu is shown (right).

This menu allows the user to select and set various

standard audio controls such as MODE (where you

can customize this mode to FAVORITE,

THEATER, MUSIC or NARRATION),

TREBLE, BASS, BALANCE and HEADPHONE VOLUME. Press the buttons to select

and press the buttons to adjust the various

setting to your desired level.

AUDIO [ 1 / 2 ]

:

MODE

:

: +20

REFERENCE

SELECT SET RETURN

: 0

:

0

0

FAVORITE

RETURN

Page 20

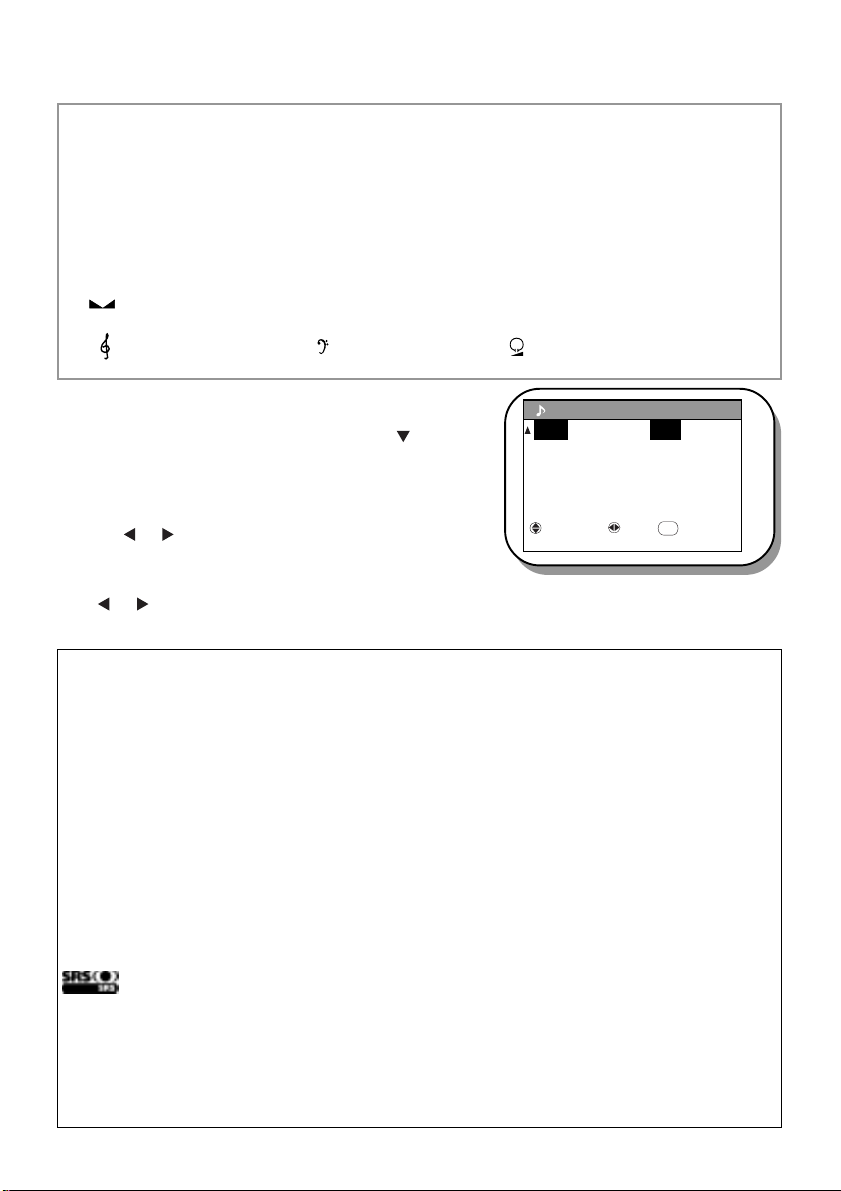

PICTURE & AUDIO SETTINGS

FAVORITE : Use this mode for your personal setting preference.

THEATER : Use this mode to improve audio performance when watching

MUSIC :

NARRATION : Use this mode for outstanding vocal clarity.

Speaker (Left/Right) Balance

Treble Bass Headphone Volume

movies based sources.

Use this mode for enhanced high frequency.

3.

In addition to these audio menu, the TV also

incorporates other controls. Press the button,

the OSD will go to page 2 of the AUDIO menu

containing controls such as SRS, BBE,

PERFECT VOLUME and LOUDNESS. Press

the or button to adjust the controls to your

AUDIO [2 / 2]

SRS : OFF

BBE : ON

PERFECT VOL. : OFF

LOUDNESS : ON

REFERENCE

SELECT SET RETURN

RETURN

desired level.

NOTE: If you select REFERENCE and press the

or button, the setting will return to factory

default setting.

SRS

The SRS surround sound expands the audio listening field wider and deeper to create ex ceptional sound quality from the TV’s speakers.

BBE

The BBE system enhance the clarity of high-frequency sound.

PERFECT VOL.

When the volume is markedly different among stations, it can be automatically adjusted

by setting this function to [ON].

LOUDNESS

The function which corrects a small sound in the clear quality of sound.

is a trademarks of SRS Labs, Inc.

SRS technology is incorporated under license from SRS Labs, Inc.

Manufactured under license from BBE Sound, Inc. Licensed by BBE Sound

Inc. under USP4638258 and 4482866. BBE and BBE symbol are registered

trademarks of BBE Sound, Inc.

Page 21

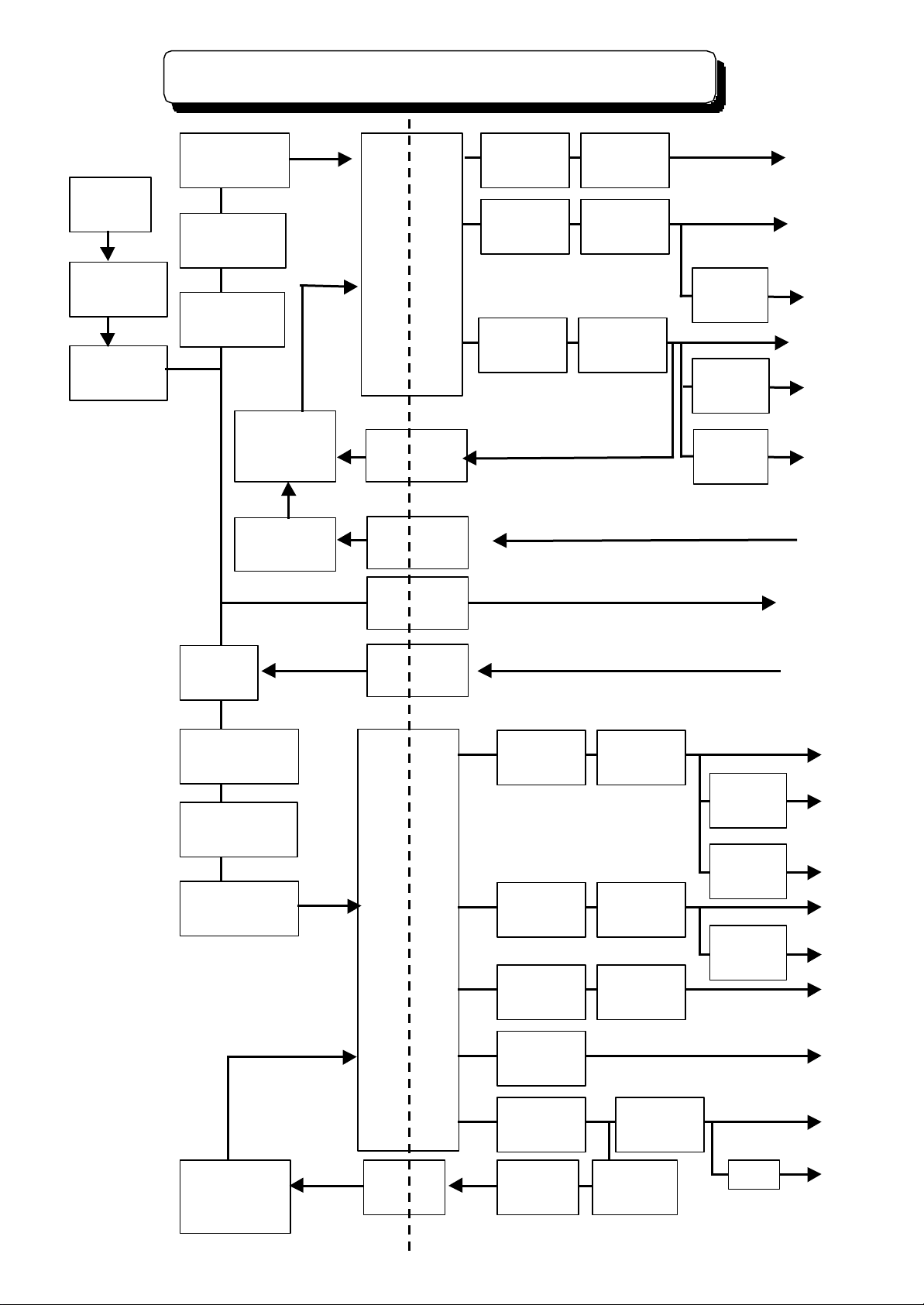

PROTECTION CIRCUIT BLOCK DIAGRAM

Hot

Cold

PROTECTION CIRCUIT BLOCK DIAGRAM

AC Cord

E901

Fuse

T4AL : F908

Noise Filter

L901, L902

Fuse

T3.15AL:F902

Rectifier

D901

Noise Filter

L911

Switching

Control

I901

Protect

Q902, Q903

Switching

Transformer

T901

Feedback

I902

Protect

I903

ACK

I904

Protector

E903 : 5000

Protector

E904 : 5000

Protector

E905 : 5000

Rectifier

29V : D931

Rectifier

11V: D932

Rectifier

7V : D935

Regulator

I907

Regulator

I905

Regulator

I906

AUD+30V

SW+11V

FC 3.3V

SBY+7V

SBY+5V

FB+5V

VM

Protector

Relay

S901

Noise Filter

L905

Rectifier

DP01

Fuse

T3 15AL: FP01

Relay Drive

Q932

Switching

Transformer

TP01

Protector

EP33:5000

Protector

EP31:10K

Protector

EP32:10K

Rectifier

220V:DP32

Rectifier

+8V:DP35

Rectifier

+28V:DP33

Rectifier

-28V:DP34

Regulator

-7V:IP05

Regulator

6.3V:IP06

Regulator

12V:IP04

TV ON/OFF

SW+8V

SW-8V

Heater

+28V

SW+12V

-28V

220V

Switching

Control

IP01

Feedback

IP02

Rsctifier

120V:DP31

Error Amp

IP03

Protector

EP35 :3000

EP36 : 500

+B

RP44Protector

SW+33V

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

System Control Circuit

Tuner Circuit

Description

Cir#

Pin

Voltage (V)

Description

Cir#

Pin

Voltage (V)

Cir#

Pin

Voltage(V)

Description

Cir#

Pin

Voltage (V)

Description

Cir#

Pin

Voltage (V)

Cir#

Pin

Voltage(V)

H8S/2238W

I00110.14

H8S/2238W

I001860.00

Q001C5.20

NJW1137M

I40114.50

MSP3455G

I101200.00

Q101C0.0020.14870.00B4.7024.50210.00B0.7435.00884.70E4.0034.50225.00E1.4340.00894.70

Q002C0.0044.50230.00

Q102C0.0055.00900.00B5.3054.50240.00B0.7865.00915.00E5.2064.50250.00E1.4675.00925.00

Q006C5.2074.50260.00

Q103C5.0085.00935.00B0.0084.50270.00B1.0095.00945.00E0.0090.95280.00E0.38105.00955.00

Q007C5.20104.50290.00

Q104C9.00115.00960.00B0.00113.40303.80B5.00125.00970.00E0.00123.40313.80E4.50135.00980.00

Q009C8.02134.70320.00

Q105C9.00140.00990.00B0.09144.80338.40B4.10150.00

100

0.00E0.00150.00347.40E3.50160.00

CAT24WC32J1

I00210.00

Q010C0.00169.00350.00

Q106C9.00170.0020.00B8.30170.00363.70B4.10180.0030.00E0.01185.00373.70E3.50190.0040.00

Q011C10.49193.40383.70

Q108C0.00200.0055.00B0.00203.20390.00B2.00210.0065.00E0.00214.50403.70E2.60220.0070.00

Q012C5.20224.50413.70

Q109C0.03230.0085.00B0.00234.50422.60B0.62242.50

MB90096

I00311.20E0.00244.50433.70E0.00252.5020.00

Q013C4.40254.50440.00

Q110C0.00265.0031.20B0.00264.50B0.00275.0040.00E0.00274.50E0.00280.0055.00

Q014C5.00284.50

Q401C0.00290.0065.00B0.00294.50B0.00305.0070.00E0.00304.50E0.00315.0084.40

NJM2198M

I40210.00

Q402C0.00325.0090.0024.50B0.00335.00105.0034.50E0.00345.00110.0044.50

Q403C12.92355.00124.4054.50B0.00365.00135.0064.50E0.00375.00144.4074.50

Q404C0.00385.00150.0084.50B0.00395.00160.0094.50E0.00401.90170.00109.00

Q405C0.25415.00180.00110.00B36.00421.90190.00124.60E36.00430.00200.00130.00

Q406C39.30442.40213.00140.00B0.04450.00225.00154.50E0.00460.00230.00164.50

Q407C0.04470.00245.00174.50B0.62482.40255.00184.50E0.00492.70265.00190.00502.30275.00204.50513.80283.00214.50525.00

HD74HC08FP

I00410.00224.50535.0020.00234.50545.0030.00244.50555.0040.00

TA8258H

I40312.40565.0055.0022.60570.0060.0030.00580.0070.0042.60595.0080.0052.40605.0095.00612.30615.00100.00719.00625.00110.0085.00632.50125.00939.50640.00130.00100.00652.50145.00114.30660.00

HD74HC08FP

I00510.001219.00675.0020.00

MSP3455G

I10115.00680.0030.0021.50690.0040.0031.50700.0055.0040.00710.0060.0052.30720.0070.0062.00735.0080.0070.00740.0095.0080.00750.00100.0090.00760.00110.00100.00775.00125.00115.00785.00130.00125.00795.00145.00135.00805.00

PST994D-T

I00615.00140.00815.0020.00150.00825.0035.00160.00835.00170.00845.00180.00855.00195.00

Page 46

Video Chroma Circuit

Teletext Circuit

Headphone Amplifier Circuit

Focus Circuit

Sensor Distribution Circuit

Description

Cir#

Pin

Voltage (V)

Description

Cir#

Pin

Voltage (V)

Cir#

Pin

Voltage(V)

Description

Cir#

Pin

Voltage (V)

Description

Cir#

Pin

Voltage (V)

Cir#

Pin

Voltage(V)

Cir#

Pin

Voltage(V)

TB1274AF

I50112.23

BA055FP-E2

I50313.20

Q503C0.00

AT24C04

IT0310.00

BA35BOFS

IA0110.00

QF02C10.70

QL10C0.4021.9327.00B1.5920.0022.70B11.20B4.7031.2030.00E2.2330.0035.07E643.00E0.0044.6045.00

Q504C0.0040.0042.70

QF03C3.00

QL11C0.4052.2050.00B1.7653.3050.00B3.50B4.7064.96E2.4063.3060.00E8.90E0.0072.45

Q505C0.0070.0072.70

QL12C0.4080.00B1.7183.3080.00B4.7090.31E2.40

SAA5264

IT0514.6799.00E0.00104.00

Q506C0.0024.70102.72

QL13C0.40112.23B4.5434.73110.00B4.70125.00E5.1944.70125.55E0.00134.20

Q507C6.4054.60132.70

QL14C0.40143.73B0.0064.54145.08B4.70150.00E0.0074.54152.70E0.00160.00

Q511C0.0084.50162.72

QL15C0.40170.00B1.5894.46B4.70180.00E2.23104.50E0.00191.58

Q512C0.00114.55

QL16C0.40201.76B1.77124.48B4.70211.70E2.40130.00E0.00221.70

Q513C0.00143.30

QL17C0.40231.70B1.78153.30B4.70240.00E2.42164.48E0.00252.43

Q514C0.00174.50262.43B2.13184.48272.43E2.79194.46280.00

Q516C6.35204.58292.21B0.00214.70302.16E0.00220.00311.35

Q517C0.00231.10324.85B1.65240.00332.04E2.31250.67342.30

Q518C0.00261.62352.32B2.30270.00360.00E2.14280.00374.85

Q519C4.70294.46383.83B0.00304.44391.64E0.00313.25402.73

Q520C5.06320.00411.87B3.60330.00424.85E2.94340.00431.67

Q521C5.06352.80442.11B3.59362.00454.61E2.93372.50465.01

Q522C0.00380.00473.72B2.31393.25481.63E2.13400.00

TB1274AF

I50212.86

Q523C4.67411.7021.93B0.06421.6031.20E0.00430.0044.95

Q524C8.93443.2552.87B3.50454.6264.97E4.03464.6072.40

Q525C8.93474.6080.00B6.39484.5390.31E5.72494.83104.00

Q526C5.01504.70112.23B3.61514.20125.00E2.90524.20135.00

Q527C0.00144.80B2.15

Cir#

Pin

Voltage(V)

15

0.00E1.48

QT02C0.00160.00

Q528C5.01B1.47170.00B3.61E2.11180.00E2.97

QT09C0.00191.40

Q529C0.00B0.00202.40B1.49E5.00211.58E2.15

QT10C0.00221.75

Q530C5.00B0.00231.77B2.48E5.00240.00E1.80

QT11C0.00252.43

Q531C0.00B0.00262.43B0.93E5.00272.43E1.58280.00

Q532C5.01292.20B3.71302.18E3.08311.38

Q533C0.00324.85B1.54332.20E2.19342.30

Q534C5.01352.31B3.50360.00E2.86374.85

Q535C0.00383.83B1.44391.66E2.09403.34

Q536C8.94412.24B4.05422.60E4.13431.50

Q537C8.94442.12B6.34454.95E5.66462.21473.73481.46

Page 47

AV Switch / Terminal Circuit

YC - Separator/ Comb Filter Circuit

Description

Cir#

Pin

Voltage (V)

Cir#

Pin

Voltage(V)

Description

Cir#

Pin

Voltage (V)

Description

Cir#

Pin

Voltage (V)

Cir#

Pin

Voltage(V)

Cir#

Pin

Voltage(V)

CXA2069Q

I20113.85

QA01C8.36

TC90A69N

I30111.30

UPD64083GF-3BA

I3A1400.00

Q301C8.90

Q339C3.0024.38B4.4023.16

3DYC410.00B5.00B2.2733.85E3.7435.00420.00E4.30E1.7844.38

QA02C4.8942.50430.00

Q302C8.90

Q340C0.0054.37B8.3650.00440.00B2.20B2.9860.00E8.9561.84452.44E1.60E3.2874.83

QA03C8.3772.23462.40

Q305C0.00

Q341C3.0083.85B4.4080.00471.06B3.10B0.0094.38E3.7590.00481.13E3.80E0.00103.85

QA04C4.51100.00490.00

Q307C9.00

Q3A1C0.00114.38B8.37115.00501.45B2.70B1.53124.37E8.95120.00510.00E2.13E2.20130.00

QA05C5.34135.00520.00

Q308C0.00

Q3A6C0.00144.84B0.00140.00532.40B3.70B1.37153.85E0.00154.22540.00E4.30E9.00164.38

QA06C0.00163.73550.00

Q310C9.00

Q3A8C9.00173.85B5.19170.00560.00B7.70B5.12184.38E5.55180.00573.27E2.10E4.46194.37

Q201C8.90192.53580.00

Q311C9.00

Q3A9C0.00200.00B4.20205.00594.27B1.10B1.45215.18E3.50210.00603.73E5.00E9.00223.85

Q202C8.90223.00610.00

Q312C9.00

Q3E2C8.98234.38B4.30233.00623.28B2.00B5.20244.00E3.70243.40632.42E1.60E4.54254.37

Q203C8.90253.16642.40

Q313C0.00264.37B4.30260.00650.00B3.16270.00E3.60273.70660.00E3.80284.84

Q204C8.90281.56672.45

Q315C9.00294.38B3.14

TC90A69N

I30311.30680.00B2.70303.85E2.5023.16690.00E2.00314.38

Q205C8.9035.00700.00

Q316C0.00320.00B4.3042.50710.00B3.50334.24E3.6050.00720.00E4.30343.70

Q206C0.0061.84730.00

Q318C9.00350.00B1.4072.23740.00B2.75364.36E2.1080.00750.00E2.13374.37

Q207C7.4090.00762.98

Q319C2.71384.40B2.18100.00770.00B8.30393.60E1.40115.00780.00E9.00404.40

Q208C0.00120.00790.00

Q320C8.30414.27B1.45135.00800.00B2.70428.84E2.10140.00812.40E2.70434.40

Q210C8.90154.81821.00

Q321C2.70444.16B4.40164.76831.45B8.35454.40E3.70170.00841.36E9.00463.60

Q211C8.90180.00850.00

Q322C8.35474.36B5.30192.53860.00B2.78480.04E4.70205.00870.00E2.21494.02

Q214C8.90210.00881.00

Q323C0.00504.40B5.30223.00890.70B1.61514.36E4.60233.00900.70E2.26524.40

Q215C8.90243.42911.20

Q324C0.00534.27B5.30253.16922.40B1.61544.40E4.60260.00932.40E2.26553.60

Q217C8.90273.70940.00

Q325C2.77563.14B4.40281.63950.00B8.35570.00E3.70

UPD64083GF-3BA

I3A110.00961.06E9.00584.27

Q218C8.90

3DYC20.00970.00

Q326C8.35594.37B5.3030.00980.00B2.78604.47E4.6040.00990.00E2.21614.38

Q221C8.9050.00

100

2.44

Q327C2.74624.37B5.2060.00

PST9227NR

13A210.50B8.35634.17E4.6070.0020.00E9.00644.37

Q222C8.9080.0030.00

Q328C8.35652.50B5.3090.0045.27B2.78

MM1113

I20514.93E4.60100.0053.28E2.2120.00

Q230C7.40110.00

TK11125CS

13A413.27

Q329C6.1234.95B2.10120.0020.00B8.3340.00E1.44130.0031.28E9.0054.95

Q231C0.05140.0042.50

Q330C8.3468.83B0.60150.0053.28B2.7874.22E0.00160.00E2.2180.00

Q232C4.40170.00

Q331C5.20B5.00180.00B8.33E0.00190.00E8.98

Q233C8.90200.00

Q332C8.33B4.28210.00B2.81E3.60220.00E2.24

Q237C0.00230.00

Q334C0.00B1.50240.00B2.28E2.10250.00E2.87

Q238C8.80260.00

Q335C0.00B4.20270.00B2.30E3.50280.00E2.90290.00

Q336C8.90300.00B2.15312.40E2.30322.40

Q337C0.00330.00B2.36340.00E3.02350.00

Q338C0.00360.00B2.36370.00E3.03383.30390.00

I201 Pin 52 Vpp : 720.0mv 1v/div

I201 Pin 54 Vpp : 720.0mv 1v/div

I201 Pin 38 Vpp : 720.0mv 1v/div

I201 Pin 40 Vpp : 720.0mv 1v/div

I201 Pin 53 Vpp : 2.440v 1v/div

I201 Pin 56 Vpp : 2.440v 1v/div

I201 Pin 41 Vpp : 2.440v 1v/div

I301 Pin 7 Vpp : 640.0mv 1v/div

I301 Pin 25 Vpp : 1.800v 1v/div

I301 Pin 27 Vpp : 640.0mv 1v/div

I303 Pin 7 Vpp : 1.000v 1v/div

I303 Pin 25 Vpp : 2.040v 1v/div

I303 Pin 27 Vpp : 640.0mv 1v/div

Page 48

Convergence Circuit

Deflection Circuit

Description

Cir#

Pin

Voltage (V)

Cir#

Pin

Voltage(V)

Description

Cir#

Pin

Voltage (V)

Cir#

Pin

Voltage(V)

Description

Cir#

Pin

Voltage (V)

BA17805

IK0117.50

QK01C0.00

LA7845N

I60110.00

Q604C0.30

6P-MINI

PMB114.6020.00B1.5920.00B27.00214.60

3

5.00E2.23314.50E27.504120.00

PST994D

IK0214.50

QK02C0.00426.60

Q706C11.806120.00

2

0.00B1.7653.00B0.90

6P-MINI

PMG114.60

3

5.00E2.4063.00E1.50214.60

STK392-120

IK0410.00

QK03C0.00727.00

Q707C0.034120.00

2

0.00B1.7181.40B0.706120.00

3

-31.00E2.409-E0.00

6P-MINI

PMR114.604-32.10

QK06C0.0010-

Q708C15.00214.60

5

32.50B4.54

TA1317AN

I70114.90B0.034120.00

6

0.50E5.1920.40E0.006120.00

7

0.32

QK07C6.4030.00

Q709C15.00

7P-JP

PSD110.008-27.50B0.0043.00B0.3620.00

9

0.38E0.0054.90E0.0030.00

10

27.30

QK08C0.0064.50

Q710C1.2040.00110.00B1.5879.50B0.0050.00

12

-27.30E2.2380.86E0.0065.0013-0.1090.00

Q711C0.0070.00

14

-0.05104.70B27.00

13P-JP

PSD211.20

15

-0.10111.30E0.0021.50

16

-0.10121.00

Q712C5.0030.0017-27.50134.80B0.00412.50

18

-0.10144.80E0.0050.00

STK392-120

IK0510.00150.00

Q754C0.4060.0020.00163.60B6.5070.00

3

-30.90174.00E6.0080.60

4

-30.10183.40

Q777C120.00

9

0.005-32.50194.50B0.06105.20

6

0.10201.20E0.00110.70

7

0.10215.20

QH01C250.00

12

5.10

8

-27.50224.20B1.50130.0090.20234.00E0.22

13P-JP

PSD310.001027.30242.60

QH02C1.5024.80

11

-0.20

M62501P

IH0116.50B0.6030.00

12

-27.50211.60E0.0044.80

13

-0.2030.80

QN01C0.6050.0014-0.2042.40B0.0069.50

15

0.0051.60E0.0070.00

16

0.006-

QN02C5.8080.3017-27.5070.00B11.3090.00

18

0.0080.00E11.501014.60

9

7.10

QN03C11.40110.00107.10B0.20120.00

11

7.10E0.001331.00

12

7.10

QN04C11.40

7P-JP

PDK110.00132.80B0.9020.00

14

2.00E0.6030.00

15

5.00

QN05C11.7040.00

16

0.00B0.0050.00E0.0065.00

QN06C0.0070.00

B

0.00

JP-11P

PDK310.00

E

0.0020.00

3

7.604-7.3050.7060.0071.5080.309-0.50105.10

11

0.00

7P-JP

PDK4112.0020.0033.404-53.6060.00

7

-

PDS Pin 13 (BV)

PDS Pin 14 (BH)

PDS Pin 16(GV)

PDS Pin 17 (GH)

PDS Pin 19 (RV)

PDS Pin 20 (RH)

Q709 Colector Pin Vpp : 42v 200v/div

QH01 Colector Pin Vpp : 400v 200v/div

QH01 Base Pin Vpp : 10.08v 200v/div

PSD2 Pin 1 Vpp : 3.360v 200v/div 10us/div

I701 Pin 4 Vpp : 1.200v 200v/div 5ms/div

I601 Pin 3 Vpp : 56v 200v/div 5ms/div

IH01 Pin 1 Vpp : 14.4v 200v/div

I601 Pin 4 Vpp : 34.80v 200v/div 5ms/div

I601 Pin 8 Vpp : 35.2v 200v/div

Q777 Colector Pin Vpp : 1.024kv 200v/div

Page 49

Signal Power Supply Circuit

Power Supply Circuit

Cir#

Pin

Voltage(V)

Description

Cir#

Pin

Voltage (V)

Description

Cir#

Pin

Voltage (V)

Cir#

Pin

Voltage(V)

Q903C19.50

STR-X6468

I9011324.00

STR-F66688

IP0111.50

QP01C45.60B0.0020.0020.00B320.00

E

0.00319.603321.00

E

320.00

Q903C0.0040.00415.00

QP02C1.20

B

19.5050.0050.00B-E19.5060.00

TLP421

IP02190.70E15.50

Q905C0.0071.30290.00

QP31C0.00

B

23.00

TLP421 FB

I90216.3031.30B120.00

E

19.5025.20414.80E120.70

Q932C0.0030.00

SE120N

IP031120.00

B

0.8042.70290.00E0.00

TLP421 PRO

I90316.0030.00

Q933C3.8026.00

NJM7812FA

IP04127.30B0.0030.0020.00

E

0.00419.50312.00

Q934C0.00

TLP421 ACK

I904166.00

PQ1CF2

IP05115.00B3.80270.0027.30

E

3.8033.4030.00

Q936C6.0045.0041.30B0.00

SI3050N

I90510.0058.20E0.002-

PQ5RD083

IP0617.60

Q939C5.4035.7026.30B4.6045.1030.00

E

5.4056.304-

Q940C0.00

SI3050N

I90610.00

XA-5P

PDC11220.00

B

3.0023.802-

E

3.0035.403272.00

Q941C0.0045.0040.00

B

0.7556.3056.30E0.00

SI8033S

I907111.20

2

3.7030.0043.40

5

2.40

XA-14P

PQS110.0020.0033.8040.0055.4060.0075.4085.4090.00100.00110.00123.50133.50

14

3.50

XA-9P

PQS216.0026.0030.00411.00511.0060.0070.0086.00

9

0.00

XA-4P

PQS3138.10238.1030.00

4

0.00

XA-6P

PQD210.0020.0030.0040.0050.55

6

0.00

PSD2 Pin 2 Vpp : 13.20v 200v/div 10us/div

PSD2 Pin 11 Vpp : 14.4v 200v/div

I901 Pin 1 Vpp : 536v 100v/div

I901 Pin 3 Vpp : 576v 100v/div

PWB Pin 1 Vpp : 36.4v 200v/div 5ms/div

PMG Pin 7 Vpp : 19.2v 200v/div 5ms/div

PMG Pin 4 Vpp : 296.0v 100v/div 5us/div

PMG Pin 6 Vpp : 1.048kv 200v/div 5us/div

PMR Pin 1 Vpp : 4.400v 200v/div 5ms/div

Page 50

Deflection Control Circuit

Power Regulator Circuit

Signal Processing Circuit

Description

Cir#

Pin

Voltage (V)

Cir#

Pin

Voltage(V)

Cir#

Pin

Voltage(V)

Description

Cir#

Pin

Voltage (V)

Description

Cir#

Pin

Voltage (V)

Description

Cir#

Pin

Voltage (V)

TA1316

IC0111.40

QC01C9.30

QCA1C9.10

SI-3018LSA

IG0113.30

TA1370FG

IL0110.00

74HC221

IL0593.9025.70B5.60B3.9022.6020.00105.0035.00E5.00E3.6033.3030.30115.0045.00

QC02C0.00

QCA2C3.6042.3745.00120.2055.00B1.66B1.9050.0050.00135.0060.00E2.30E1.2060.0060.00140.0070.16

QC03C0.00

QCA3C7.8071.8076.30152.7085.00B1.70B4.3081.8080.00165.0095.00E2.30E3.60

SI-3050F

IG0210.0095.00

MM1519XQ

IX0110.00105.00

QC04C5.60

QCA4C8.4024.50100.0020.00111.00B5.30B1.5035.00119.0030.00120.00E4.65E0.8845.00122.6049.00130.00

QC05C4.68

QCA5C4.0255.90130.0055.00142.90B8.00B8.45

SI-3090F

IG0310.00140.0060.00153.00E4.60E9.10210.88150.1374.80161.60

QC06C9.30

QCA6C0.0039.00160.6380.00171.10B5.30B4.0049.00170.0094.80180.00E4.70E4.70510.88180.00100.00199.20

QC08C9.30

QCA7C3.40

SI-3090F

IG0410.00190.00110.00206.10B9.20B7.40210.88200.00120.00215.60E8.60E8.0039.30215.00130.00226.00

QC09C9.20

QCA8C0.0049.00225.00149.00232.50B0.00B2.70510.88230.00155.00241.30E0.00E3.40242.00160.00250.00

QC10C9.20

QCA9C3.40

Cir#

Pin

Voltage(V)

25

5.30174.80261.30B1.10B7.40

QG01C0.00262.20180.00275.00E1.00E8.00B0.67270.00194.80280.00

QC13C9.10

QCB1C0.00E0.00285.00200.00292.10B0.15B2.70290.00210.00304.80E0.42E3.40300.00220.00314.80

QC14C0.00

QCB2C3.40

TA1370FG

IL0210.30230.00320.00B1.00B7.4020.00240.00334.00E1.60E8.0030.30250.00344.00

QC15C9.20

QCB3C0.0045.00263.70354.00B0.60B2.8050.00274.20360.52E1.30E3.4060.00285.00374.00

QC16C9.20

QCB6C0.0076.30290.00384.00B0.35B0.7080.00300.00394.00E1.30E0.0095.00310.00409.20

QC17C0.00100.00325.00412.80B0.00119.00330.00422.80E0.63122.60344.50432.80

QC18C0.00130.00350.00440.00B0.00140.00364.50459.20E0.63150.12370.00464.70

QC19C0.00160.63384.50474.70B0.00170.00399.00484.50E0.63180.00404.50490.00

QC20C0.00190.00410.00500.00B0.00200.00424.50510.00E0.64215.00430.00520.55

QC21C0.00225.00444.50536.20B0.00234.40459.00544.50E0.64242.00464.50559.20

QC22C0.00255.30470.00565.50B0.00262.20484.40

BU4053BCF

IC0310.00E0.64270.00490.0020.00

QC23C9.20285.00504.5030.00B8.40290.00519.0040.00E1.80300.00529.0050.00

QC24C9.20

SN74HC14NS

IL0315.00535.0060.00B0.0020.13540.0070.00E0.0030.63554.8480.00

QC25C9.2044.13560.0094.40B0.0050.63574.84104.40E0.0064.13589.00114.40

QC26C0.0070.00595.00123.20B0.2280.13600.00132.70E0.0095.00614.83142.40

QC27C5.90105.00620.00150.00B0.00110.18634.83165.00E0.00125.00640.00

QC30C9.20130.18B0.00145.00E0.00

74HC221

IL0513.9025.0035.0040.1755.0060.0072.7080.00

IC01 Pin 4 Vpp : 760.0mv 1v/div

IC01 Pin 3&8 Vpp : 760.0mv

IC01 Pin 15 Vpp : 3.520v 1v/div

IC01 Pin 31 Vpp : 5.320v 1v/div

IC01 Pin 16 Vpp : 3.680v 1v/div

IC01 Pin 30 Vpp : 5.160v 1v/div

Page 51

Trouble Shooting Guide For DP2M

No Item Changed Adjustment necessary

1 Signal PWB White Balance/ Sub-bright.

Tuner (AGC)

Horizontal phase / Vertical phase

2 Tuner (Main/ Sub) AGC

3 Micon (I001) No adjustment necessary

4 Feature Box No adjustment necessary

5 Sub Signal PWB Tint adjustment

6 Audio control/ amplifier No adjustment necessary

I101 (MSP3455G)

I403 (TA8258H)

I401 (NJW1137)

I402 (NJM2198)

IA01(BA3530FS)

I201(CXA2069Q)

7 EEPROM(I002) Micon Initialize

Same adjustment as Signal PWB

8 Video Chroma IC Tint adjustment

I501(TB1274AF)

9 Def/ RGB IC White Balance

IC01(TA1316) Horizontal Position (50Hz/ 60Hz)

Sub-bright

10 Power Deflection PWB Horizontal/ Vertical size (V. res)

Horizontal (I2C bus)

High Voltage adjustment

Cut off (screen) adjustment

11 Convergence PWB Convergence (NTSC-50p/ PAL-50p/ PAL-100i)

DCU unit (UKDG) Phase data

Focus adjustment

12 Terminal PWB, Sensor PWB, Power Sup PWB No adjustment necessary

13 PRT tube All related lens adjustment (focus, etc)

White Balance, convergence

14 CPT PWB White Balance adjustment

15 DY change All related lens adjustment (focus, etc)

Convergence

16 Synchronized Deflection Sys. Control IC High Voltage adjustment

IH01(M62501P) Cut off (screen) adjustment

FBT (TH01)

17 Deflection processor IC Horizontal adjustment

I701(TA1317AN) Vertical size adjustment

Trapezoid Distortion adjustment

Side pin adjustment

Page 52

1. No Raster and No Power

N

N

N

o raster and

No sound

TROUBLE SHOOTING

TROUBLE SHOOTING

F908 blown?

POWER SUP PWB

No

Any click

sound from

S901?

POWER SUP PWB

No

5V at I001 (62) ?

Yes

Check D901, DP01, X901 and others connected

to AC main

POWER SUP PWB

POW/DEF. PWB

Yes Yes No

Yes

S901 turns off

Immediately after switch

TV on?

No

Go to 'Pow./Def. PWB check

o TV -ON signal,

Check I001, QG01, Q939,

I905, I906 and Q932

POWER SUP PWB

flow'

Power indicator DM03

light?

Yes

Front Panel

Over current of VM.

Check QE06, QE07, QE56, QE57, QEA6,

QEA7, & others at VM circuit

CPT/VM PWB

No

SIGNAL PWB

7 at C936(+)?

Yes

SIGNAL PWB

POWER-SUP PWB

o STBY5V.

Check I905 and etc.

POWER-SUP PWB

No

SIG-POWER failure,

See 'Sub-Power check flow'

Page 53

DEF-POWER failure:

N

y

Main-Power check flow

FP01

blown?

No

Yes

Check the other

DIAGNOSIS LED

No

POW./DEF. PWB

DP09 is lit?

POW./DEF. PWB

POW./DEF. PWB

Yes

No

Over current in live side.

Check IP01, TP01, CP06, and others connected

to IP01(3)

POW/DEF. PWB

o Power for IP01.

Check IP01, DP07, DP15, DP08, QP01, RP17, RP18

and etc.

POW/DEF. PWB

Yes Yes

Some LED are lit? Some LED are not lit?

DP47 is not lit.

DP48 is not lit.

NO +B (120) for H def. and HV

Check DP31, CP32, IP03, EP35, EP36,

QH01 others connected to +B line.

POW./DEF. PWB

NO +28/-28V for V def. and Conv.

Check EP31, EP32, DP33, CP36, DP34,

CP38 and etc.

POW./DEF. PWB

No No

POW./DEF. PWB POW./DEF. PWB

Deflection circuit

Check flow

20V

0V

While the startup,

V>20V at IP01(4)

transientl

No

Check DP32, CP34, DP31

?

POW./DEF. PWB

Yes

+B error Amplider is not function

Check DP31, GP32, IP02, IP03 and EP36

POW./DEF. PWB

power on

POW./DEF. PWB

15V

10V

DP49 is not lit.

NO power for digital conv. Unit.

Check EP33, DP35, CP40, IP05, DP50,

CP48 and etc.

POW./DEF. PWB

CONV. PWB

Page 54

SIG-POWER failure:

y

N

N

Sub-Power check flow

While the startup,

V>0.5V at I903(1)

transiently

No

POWER-SUP

PWB

Yes

Over voltage of STBY5V

Shutdowned by PROTECTION:

Check I905 and short-circuit of STBY5V with

higher voltage.

POWER-SUP PWB

0.8V

I903(1)

0V

power on

F902 blown?

POWER-SUP PWB

No

V < 5V at I901(3)?

(Vin pin)

POWER-SUP PWB

No

While the startup

V > 20V at I901(3)

transientl

15V

0V

Yes

Yes

I901(3)

5V

Yes

Over current in live side.

Check I901, T901 and circuit connected to I901(3)

POWER-SUP PWB

o power for I901,

Check I901, D907, R907, R908 and etc.

POWER-SUP PWB

become higher than 10V once

ote: Vin also becomes less than 5V if shutdowned by protection.

Check I905(5) first!

power on

SIG-POWER Feedback circuit not function.

Check D930, I902, D933, E905 and etc.

POWER-SUP PWB

No

POWER-SUP PWB

20V

15V

10V

0V

power on

Check D931, D932, C934, E903,

E904 and short-circuit of

SIG-POWER cold side.

POWER-SUP PWB

Page 55

Deflection circuit

Check flow

Raster appear with

pin(1) and (2) of PQD2

shorted?

POW/DEF. PWB

No

Voltage of Q709 (B)

normal?

POW/DEF. PWB

Yes

Voltage of both ends of

T702 (primary side)

normal?

POW/DEF. PWB

Yes

Yes

No

No

Check Q933 and Q934. Try to open

DP39, DP41, DP34, QP42 and DP46.

Check one circuit at one time.

POWER-SUP PWB

Check IC01 pin(26)-Hout, pin(19)-DEF HVcc,

I908 and IG04

SIGNAL PWB

POWER-SUP PWB

Check T702, R730 and R748

POW/DEF. PWB

Check Q777, QH01, T701 and

TH01

POW/DEF. PWB

Page 56

Page 57

Page 58

Page 59

1. ASSEMBLED P.W.B ADJUSTMENT

1.1 Service menu.

Adjustment procedure

1. ‘Off’ the set. Press and hold the

‘TV/VIDEO’ button then ‘on’ the set again

until “service menu OSD” appears on the

screen.

2. Press ‘MUTE’ button on the R/C to

memorize every changes item.

3. For item number 1 ~ 9, refer to 1.2

Memory initialize (1) for memorize every

changes item.

4.

Press ‘MENU’ button on the R/C is to exit

the ‘service menu;

No. Item Value

Model Identification 1:

1

Destination

2 Shipm ent sett ing (Language)

Shipment setting (Sound

3

System)

Shipment setting (Sound

4

System)

5TEXT Yes/No

6 TEXT Language

7 OSD Language

8 4.5(K) Yes/No

9HD

10 Cut off adj.

11 AGC adj.

12 AGC adj.

13 V size

14 H size

15 Trapezoid Distortion

16 Side Pin Distortion

17 V size

18 H size

19 Parabola Modification

20 Side Pin Distortion

21 V size

2 Memory

1 Memory

1 Memory

2

1

0

0 Memory

1 Memory

0 Memory

0_

31 Main AGC

31 Sub AGC adj.

69 For PAL 100i

47 For PAL 100i

26 For PAL 100i

64 For PAL 100i

108 PAL

127 PAL

64 PAL

120 PAL

105 NTSC

Remark

initialize

initialize

initialize

Memory

initialize

Memory

initialize

Memory

initialize

initialize

initialize

initialize

adj.

progressive

progressive

progressive

progressive

progressive

No. Item Value

22 H size

23 Parabola Modification

Side Pin Symmetry

24

Modification

38 Brightness center

39 R drive

40 G drive

41 R cut off

42 G cut off

43 B cut off

55 Sub contrast

58 Tint

59 Tint

64 Horizontal position

65 Horizontal position

66 Horizontal position

607 SET 1

608 SET 2

162

60

120

128 Sub brightness

64

64

127

127

127

8 Sub picture adj.

32 Main TinT adj.

32 Sub TinT adj.

66 For PAL 100i.

71 For PAL

71

--

-

Remark

NTSC

progressive

NTSC

progressive

NTSC

progressive

adj.

For high

brightness white

balance

For high

brightness white

balance

For low

brightness white

balance

For low

brightness white

balance

For low

brightness white

balance

progressive

For NTSC

progressive.

-

Page 60

1.2 MEMORY INITIALIZE (1)

Adjustment Procedure by R/C

(1) Select item No.608 (set2) in service menu and

press and hold the recall key on the remote

handset until the OSD background changes to

yellow. (It takes about 3 seconds.)

(2) Wait until the OSD background color becomes

normal, this means initialization is completed and

each settings become factory preset condition.

Do not unplug the outlet or perform any key

operation until the initialization is co mpleted.

Note: Other method for memory initialize Link

the D007 anode and cathode for longer than 3

seconds.

(3) Select item no.1 to 9 according to service menu

& set the data accordingly.

(4) After set the above setting, then select the item

no. 607 (SET1) in service menu and press

“ENTER/MUTE” key on the R/C. The OSD

background will change to yellow.

(5) After the setting is done, then make sure all the

data setting is correct according to the below

screen shown.

No. Data VXXX-XXX

0: 1 211210010

1: 1 XXXX

2: 1

3: 2

Make sure this

data is correct

“211210010”

1.3 HIGH VOLTAGE ADJUSTMENT

TH01

(FBT)

CONV

HEATSINK

High Voltage Adjustment VR.

RH17

DEFLECTION P.W.B .

Caution

This adjustment involves very high voltage.

Please make sure all necessary equipment

is available. Do not attempt this adjustment

without the proper facility.

Adjustment Preparation

(1) Connect High Voltage meter to FBT High

Voltage output, and connect GND

of High Voltage meter to CPT GND or FBT

GND.

(2) CHECK that High Voltage adjustment VR

(RH17) is set to its mechanical

center. This VR is located behind the FBT.

(3) Receive circle pattern signal.

(4) VIDEO controls should be reset.

Adjustment Procedure

(1) Adjust High Voltage to following spec by turning

VR (RH17) slowly.

ADJ. SPEC = 30.9KV +/-0.2KV

(C43-FD2000, C50-FD2000)

(2) After the adjustment, fix VR (RH17) with Silicone

glue. (KE40RTV)

1.4 MAIN AGC ADJUSTMENT

Adjustment Preparation

(1) To prevent circuit temperature drift, the set

must be warmed up before alignment longer

than 10 minutes.

Adjust the RF signal frequency and level

(2)

accuracy to 224.25MHz and

Adjustment Procedure

(1) Receive philips pattern signal.

(2) Select item No.11 in service menu by ’

’ key.

’

(3-1) When the value of AGC of NO.11 of a service menu is

180 or less than 180,

(3-1-1) Push " " of remote control and set AGC value

becomes 180 or greater than 180.

(3-1-2) Push the "MUTE" button of remote control, then AGC

adjustment is completed.

(3-2) When the value of AGC of NO.11 of a service menu is

180 or greater than 180.

(3-2-1)Set the value of AGC by " " of remote control to

smaller than 180 at first.

-50dBm.

’or

Page 61

(3-2-2)Then push " " of remote control and set the AGC

value again to greater than and as close as 180.

(3-2-3) Push the "MUTE" button of remote control, then AGC

adjustment is completed.

No. V0XX

11 34 182

The Value of AGC

12 54 181

13 64

14 32

1.5 SUB AGC ADJUSTMENT

Adjustment Preparation

(1) To prevent circuit temperature drift, the set must be

warmed up before alignment longer than 10 minutes.

(2) Adjust the RF signal frequency and level accuracy to

224.25MHz and -50dBm.

Adjustment Procedure

(1) Press PIP button to display sub picture, and

receive the PinP sub channel point philips pattern

signal in adjustment mode.

(2) Select item No.12 in service menu by ’ ’or’ ’

key.

(3-1)When the value of AGC of NO.12 of the service menu

is 180 or less than 180,

(3-1-1)Push " " of remote control and set the AGC

value becomes 180 or greater than 180.

(3-1-2)Push the "MUTE" button of remote control, then

AGC adjustment is completed.

(3-2)When the value of AGC of NO.12 of the service menu

is 180 or greater than 180.

(3-2-1)Set the value of AGC by " " of remote control to

smaller than 180 at first.

(3-2-2)Then push " " of remote control and set the AGC

value again to greater than and as close as 180.

(3-2-3) Push the "MUTE" button of remote control, then

AGC adjustment is completed.

2. FINAL ASSEMBLY ADJUSTMENT

2.1 CUT OFF ADJUSTMENT

2.2 DCU PHASE DATA SETTING

Adjustment preparation

1) Cut off adjustment should be finished.

Adjustment procedure

(1) Receive any PAL signal and Set to 100Hz mode. (RF or

VIDEO)

(2) Push the “SERVICE ONLY” switch on the

CONVER/FOCUS P.W.B. to enter the adjustment

mode of the digital convergence unit.

(3) Phase set

1) Press the [REVEAL] key on R/C to display the

green cross-hatch pattern.

2) Press the [CH i/ii ] key to recall the phase

DATA on screen.

PAL 100i mode PAL 50p mode NTSC 60p mode

PHASE MODE: 1 PHASE MODE: 5 PHASE MODE: 6

PH-H D5 PH-H D4 PH-H D2

PH-V 0A PH-V 14 PH-V 05

CR-H 2E CR-H 2E CR-H 30

CR-V 0E CR-V 0E CR-V 0A

3) If phase data is not the same as above,

change the DATA by using the following R/C

keys.

Press [4] or [6] key to adjust the PH-H

Press [2] or [5] key to adjust the PH-V

Press [ ] or [ ] key to adjust the CR-H

Press [ ] or [ ] key to adjust the CR-V

4) Press the [REVEAL] key to exit from phase

mode.

5) Press [INDEX] key on R/C twice to write the

data into Rom.

6) Push the “SERVICE ONLY” switch on the

CONVER / FOCUS P.W.B. to exit from

adjustment mode of the digital convergence

unit.

(4) Change to PAL50p mode (Set DCU the PAL50p

mode) and repeat procedure (2)-(3) for PAL50p

mode.

(5) Change the signal to NTSC circle pattern (Set DCU

the NTSC mode) and repeat procedure(2)-(3) for

NTSC mode.

Adjustment preparation

(1) Pre heat-run should be finished.

(2) Confirm item No. 41, 42 and 43 are set to 127 in

service menu.

Adjustment procedure

(1) Go to “SERVICE” mode item No 10 by using R/C.

Press key to enter CUT OFF adjustment mode.

(2) Screen VR (R, G and B) should be turned clockwise

gradually and set the

condition that the each horizontal line is just beginning

to appear.

(3) Press key to return normal mode.

Page 62

2.3 RASTER INCLINATION

ADJUSTMENT (DEFLECTION YOKE)

(5) After the adjustment, fix the screw of each DY

with a torque of 1.18 Nm(12kgfcm).

Adjustment preparation

(1) Face the set East or West.

(2) Receive the NTSC cross-hatch signal.

(3) Contrast should be set MAX. and the other

controls should be set CENTER.

(4) The lens focus should be coarsely adjusted.

(5) The electrical focus should be coarsely

adjusted

(6) The digital convergence should not be

corrected.

(7) Turn the Main power SW. off.

(8) Press and hold the “SERVICE ONLY” SW.

on CONV./FOCUS P.W.B. and switch on the

Main power.

REMARKS

DIGITAL CONV. SERVICE

ONLY button: on the CONVER/FOCUS

P.W.B.

Adjustment procedure

(1) Apply covers to the R and B lenses and

project only green light. Or short the TS (2P

SUB MINI Connector) on R and B CPT

P.W.B. and project only green light.

(2) Turn the G deflection yoke and adjust the

Vertical raster inclination.

L<+2mm

2.4 BEAM ALIGNMENT

Preparation for adjustment

(1) Pre-heat 30 minutes or more before the

adjustment.

(2) The static convergence data should be

cleared.

(3) Raster inclination should be adjusted.

Optical focus should be coarsely adjusted.

(4) Contrast should be set MAX and the other

control should be set: Center.

(5) Receive the NTSC cross-hatch pattern signal

or Dot pattern signal.

(6) Discharge static charge from metallic parts

on PRT NECK by using Short-clip-JIG.

Adjustment procedure

(1) Green (G) tube alignment: Short-circuit 2P

sub-mini connectors on the red ( R ) and blue

(B) CPT P.W.B.s and project the only green

beam.

(2) Set the G tube beam alignment magnet to

the cancel state as shown below. Refer to

Adjustment point locations, item no.5.

L

Apply to

green DY

Vertical center axis of cross-hatch signal

(3) Then, remove the cover of R or B lens and

project red or blue light and green light

together on the screen.

(4) Turn the deflection yoke of R or B and set

so that the inclination of R or B light with

respect to the green light is as shown below

on the end sides.

Apply to Red and Blue.

L

1

L1,L2 <+ 2mm

L

2

1

(3) Turn the static focus VR*

for Green fully

counterclockwise and check the cross-hatch

center position on the screen.

Note : Halo state

(4) Turn the static focus VR*

1

for Green fully

clockwise.

(5) Turn 2 sheets of the alignment magnet in

either direction and move the cross-hatch

center to the position where is checked in

step (3).

(6) Turn the static focus VR*

1

for Green and

check if the picture position moves or not.

(7) Repeat steps (2) to (6) until the picture

position does not move during step (6)

(8) In the same manner, adjust the Red ( R )*

2

and the Blue (B)*3 tube alignments.

Fix the beam alignment magnet with white

(9)

paint after the alignment is completed.

*

1

*2

*

Static Focus VR is on

3

focus pack UFPK

2.5 LENS FOCUS ADJUSTMENT

Adjustment preparation

(1) The orientation of PTV set is arbitrary, west,

east, north and south.

(2) Centering DY inclination should be adjusted.

(3) Electrical focus adjustment should have been

completed.

(4) Receive the NTSC cross-hatch signal.

Page 63

(5) Contrast control should be set Center and

Brightness control should be set minimum.

Adjustment procedure

(1) Loosen the fixing screw or wing nut on

the lens cylinder so that the lens

cylinder can be turned. (Be careful not

to loosen too much)

After completing steps (4), (5), (6)

below, tighten the fixing screws or

wing nuts for each lens with a torque

of 1.67N.m(7Kgf cm) ~ 1.18N.m(12Kgf

cm).

(Do not turn the lens cylinder after

having a screw and wing nuts

tightened.

Also do not tighten the screw too

much, otherwise the lens will be tilted

too muchor the screw will be broken).

(2) Apply covers to each colors of R, G

and B lenses. and project a single

color beam on the screen and adjust

in sequence.

(The adjustment order of R, G and B

is only an example.)

Lens sass

NOTE1

(4) In case of G lens.

Set to the point where the chromatic

aberration switches from blue to red,

If the chromatic aberration appearing

all over the screen is not the same,

observe the vertical bright line and

adjust lens focus as specified in table

below.

When the red chromatic aberration

appearing at both sides of the bright

line is not equal, observe the side with

larger chromatic aberration when

adjusting.

L1 L2

I O

OPTICAL FOCUSING ADJUSTMENT GREEN

LENS HSA SCB UNIT

Fixing

screw

TYPE 1

Lens sass

NOTE2

Fixing

wing

nuts

TYPE 2

(3)

If the lens adjustment knob is turned

clockwise viewed from the front, the

color aberration changes as follows.

SCREEN SIZE 43” 50” INCH

L1 and L2 PITCHES from

CENTER

BETWEEN

L1&L2

COLOR

ABERRATION

3.0 (3.0) CROSS-

**

I*

(2mmMAX)*(2mmMAX)

0

**

(2mmMAX)**(2mmMAX)

HATCH

PITCHES

REFER

TO

NOTE

BELOW

(NOTE) * Slightly reddish or no color

** Slightly bluish or no color

Change the signal to the circle pattern and fine

adjust.

Observe the corner part of the screen, especially

observe number in the small circle when

adjusting.

If the focus performance at the screen center

exceeds the lower limit, it is acceptable.

Cross-Hatch Color aberration

Change of color aberration

RED LENS Orange Scarlet

GREEN

LENS

BLUE LENS Purple Green

Short focus Long focus

Blue Red

Small circle of circle pattern

Page 64

(NOTE1)

Since the G light is very important for

picture quality and performance.

Pay special attention in its adjustment.

Note: Be careful not to touch the lens with

your fingers when adjusting.

(5) In case of R lens.

Set the position where the chromatic

aberration change from red to

crimson.

As shown below, observe the

vertical bright line and adjust lens

focus where the crimson or red

chromatic aberration slightly appears

inside and crimson or

red outside (reference value :

1~3mm) at the point specified in table

below.

Change the signal and fine-adjust in

the same way as the G lens.

L

(6) In case of B lens.

Set the position where the chromatic

aberration change from purple to

green.

As shown below, observe the vertical

bright line and adjust lens focus

where the

purple or green chromatic aberration

slightly appears inside and purple or

green

outside (reference value : 1~3mm) at

the point specified in table below.

Change the signal and fine-adjust in

the same way as the G lens.

L

O I

I O

OPTICAL FOCUSING ADJUSTMENT RED

LENS HSA SCB UNIT

SCREEN SIZE 43” 50” INCH

PITCHES from CENTER 6.0 (7.0) CROSS-

SIDE * *

COLOR

ABERRATION

I*

(2mmMAX)*(2mmMAX)

0

**

(2mmMAX)**(2mmMAX)

(NOTE) * Slightly reddish or no color

** Slightly bluish or no color

(NOTE 2)

Setting to the center between Red and

crimson is optimum.

HATCH

PITCHES

REFER TO

NOTE

BELOW

OPTICAL FOCUSING ADJUSTMENT BLUE

LENS HSA SCB UNIT

SCREEN SIZE 43” 50” INCH

PITCHES from CENTER 6.0 (5.0) CROSS-

SIDE * *

COLOR

ABERRATION

I*

(2mmMAX)*(2mmMAX)

0

**

(2mmMAX)**(2mmMAX)

(NOTE) * Slightly reddish or no color

** Slightly bluish or no color

(NOTE 3)

Setting to the center between purple and

green is optimum.

(7) After all colors have been adjusted, display

all colors with the cross-hatch pattern

signal and compare the focus (optical focus)

performance with the limit sample

set.

(8) Then, select the circle pattern signal and

compare the focus (optical focus)

performances of each color and all colors

together with the limit sample set.

(9) If the focus performance is worse than the

limit sample set, re-adjust step (1) to (6).

HATCH

PITCHES

REFER TO

NOTE

BELOW

Page 65

2.6 STATIC FOCUS ADJUSTMENT

2.7 RASTER POSITION ADJUSTMENT

Preparation for adjustment

(1) The raster inclination, centering ,

horizontal/vertical amplitude and

optical/electrical focus and beam

alignment should be adjusted.

(2) Contrast control should be set MAX

and Brightness control should be set

Center.

(3) Receive the Hitachi circle pattern

signal.

(4) Apply covers to the others then adjust

lenses and project only single color on

the screen.

Adjustment procedure

(1) Red static focus adjustment.

Vary the static focus VR on Focus pack

(UFPK) so that the right edge of Hitachi

mark circle pattern is the best clear.

Check that the focus does not get

conspicuously worse at other check

point on the cross-hatch signal.

(2) Blue static focus adjustment.

Vary the static focus VR on Focus pack

(UFPK) so that the Hitachi mark on the

circle pattern center is the best clear.

Check that the focus does not get

conspicuously worse at all edges of the

cross-hatch signal.

(3) Green static focus adjustment.

Vary the static focus VR on Focus pack

(UFPK) (for green) so that the Hitachi

mark on the circle pattern center is the

best clear.

Check that the focus does not get

conspicuously worse at checking point on

the picture periphery and the cross-hatch

signal.

Remarks

Checking point for the periphery of picture.

Checking point

Preparation for adjustment

(1) Place the set facing east or west.

(2) Receive the NTSC Hitachi circle pattern

signal. (Set the NTSC mode)

(3) Contrast control should be set Maximum and

the other controls should be set Center.

(4) The raster inclination and beam alignment

should be adjusted.

The lens focus and electric focus adjustm ent

should be coarsely adjusted.

(5) The convergence should be uncorrected

state.

(6) Turn the Main power SW off.

(7) Press and hold the “SERVICE ONLY” SW.

on CONV./FOCUS P.W.B. and switch on the

Main power.

(8) Press “SERVICE ONLY” SW again to

display the DCU’s cross-hatch pattern.

Adjustment procedure

(1) Turn the centering magnets for R, G and B to

get the center point of the cross-hatch

position within specification as shown below.

R B

G

Geometric

L

1

[

Horizontal direction

L

L

1

2

L

2

]

center of the

screen

43” 20 30

50” 20 30

Unit: mm

to the left from the geometric

R: L

1

center of the screen.

+2mm

L

1

B: L2 to the right from the

geometric center of the screen.

+2mm

L

2

G: To geometric center of screen.

[Vertical direction]

Both of the distance between the central

horizontal line of R,B and the geometric

center of the screen should be within

+2mm.

(2) Immediately after the adjustment is

completed, fix the R, G and B centering

magnets using white paint.

Page 66

2.8 HORIZONTAL SIZE ADJUSTMENT

th

Adjustment Preparation

(1) VIDEO control should be set Factory Preset condition.

(2) DCU ROM CHECK should be finished.

(3) Place the set facing East.

Adjustment Procedure

(a)

PAL 100Hz INTERLACE MODE Item no.14

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose [FUNCTION] and scan, set to 100i mode.

(4) Press [MENU] key twice to exit from [FUNCTION].

(5) Press and hold the SERVICE ONLY SW. on

CONV./FOCUS P.W.B. and then press [MUTE] key

of R/C.

Green DCU cross-hatch are appeared with Conv.

Data cleared.

(6) Press the TV/Video button on the control panel, then

SERVICE MENU appears.

(7) Choose H.SIZE (item no.14) item by using Handset

up/down cursor key.

(8) Adjust H.SIZE (item no.14) as following by using

Handset left/right cursor key.

So that the distance between the vertical line at the

th

line from center line and

left 6

th

right 6

line from DCU’s cross-hatch pattern is l.

(9) Press “MUTE” key of handset to write the data.

(10)

After adjustment, press SERVICE ONLY SW. for

exit from SERVICE mode

(b) PAL 50P PROGRESSIVE MODE Item no. 18

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose [FUNCTION] and scan, set to 50P mode.

(4) Press [MENU] key twice to exit from [FUNCTION].

(5)

Adjust the same items as (5)-(10) of setting PAL

100Hz INTERLACE MODE

(c) NTSC PROGRESSIVE MODE Item no.22

(1) Input any NTSC signal.

(2) Adjust the same items as (5)-(10) of setting PAL

100Hz INTERLACE MODE.

Note:

Please do this adjustment follow sequence:

PAL 100i --!!!! PAL Progressive -!!!! NTSC Progressive

.

.

The 6

lines

from the

center

I

PAL

INTERLACE

MODE

Between the vertical lines at the

left end and the right end

PAL

PROGRESSIVE

MODE

NTSC

PROGRESSIVE

MODE

43” 800 800 840

50” 930 930 955

Tolerance: +/-5mm

Unit: mm

2.9 SIDE PIN DISTORTION ADJUSTMENT

Adjustment Preparation

(1) VIDEO control should be set Factory Preset

condition.

(2) Place the set facing East.

(3) DCU ROM CHECK should be finished.

Adjustment Procedure

(a) PAL 100Hz INTERLACE MODE Item no. 15

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose [FUNCTION] and scan, set to 100i

mode.

(4) Press [MENU] key twice to exit from

[FUNCTION].

(5) Press and hold the SERVICE ONLY SW. on

CONV./FOCUS P.W.B. and press

[MUTE] key of Handset.

Green DCU cross-hatch are appeared with

Conv. Data cleared.

(6) Press the TV/Video button on the control

panel, then SERVICE MENU appears.

(7) Choose SIDE PIN (EW parabola) item by

using Handset up/down cursor key.

(8) Adjust SIDE PIN as following by using

Handset left/right cursor key.

(9) Press “MUTE” key of handset to write the

adjusted data.

(10) After adjustment, press SERVICE ONLY SW.

for exit from SERVICE mode.

Page 67

(b) PAL 50P PROGRESSIVE MODE Item no. 19

*l

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose [FUNCTION] and scan, set to 50P

mode.

(4) Press [MENU] key twice to exit from

[FUNCTION].

(5) Adjust the same items as (5)-(10) of setting PAL

100i INTERLACE MODE.

(c) NTSC PROGRESSIVE MODE

(1) Input any NTSC signal.

(2) Adjust the same items as (5)-(10) of setting PAL

100i INTERLACE MODE.

Item no.23

(6) Press the TV/Video button on the control panel, then

SERVICE MENU appears.

(7) Choose V.SIZE (item no.13) item by using R/C

up/down cursor key.

(8) Adjust V.SIZE (item no.13) as following by using R/C

left/right cursor key.

So that the distance between the horizontal line at

the upside of 5

th

line from center line of DCU’s cross-hatch

of 5

pattern is l.

(9) Press “MUTE” key of handset to write the data.

(10) After adjustment, press SERVICE ONLY SW. for exit

from SERVICE mode.

(b) PAL 50Hz PROGRESSIVE MODE

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose [FUNCTION] and select scan, set to 50P

mode.

(4) Press [MENU] key twice to exit from [FUNCTION].

(5) Adjust the same items as (5)-(10) of setting PAL

100Hz INTERLACE MODE.

th

line from center line and underside

Item no.17

Edge of vertical DCU cross-hatch line should be straight

condition.

Note: If it’s impossible to adjust the straight line, set a little

pin condition.

Note:

Please do this adjustment follow sequence:

PAL 100i --!!!! PAL Progressive -!!!! NTSC

Progressive

2.10 VERTICAL SIZE ADJUSTMENT

Adjustment Preparation

(1) VIDEO control should be set Factory Preset condition.

(2) DCU ROM CHECK should be finished.

(3) Place the set facing East.

(c) NTSC PROGRESSIVE MODE

(1) Input any NTSC signal.

(2) Adjust the same items as (5)-(10) of setting PAL

100Hz INTERLACE MODE.

l

PAL

INTERLACE

MODE(100I)

PAL

PROGRESSIVE

MODE

Item no.21

NTSC

PROGRESSIVE

MODE

43” 525 525 560

50” 610 610 650

Tolerance: +/-5mm

Unit: mm

Top end of horizontal line.

th

(The 5

lines from the center line.)

Adjustment Procedure

(a) PAL INTERLACE MODE Item no.13

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose [FUNCTION] and scan, set to 100i mode.

(4) Press [MENU] key twice to exit from [FUNCTION].

(5) Press and hold the SERVICE ONLY SW. on

CONV./FOCUS P.W.B. and then press [MUTE] key

of Handset.

Green DCU cross-hatch are appeared with Conv.

Data cleared.

Bottom end of horizontal line.

(The 5th lines from the center line.)

*l :

Between the horizontal line

at the top end and bottom end.

Note:

Please do this adjustment follow sequence:

PAL 100i --!!!! PAL Progressive -!!!! NTSC Progressive

Page 68

2.11 TRAPEZOID DISTORTION ADJUSTMENT

b

2.12 BEAM FORM ADJUSTMENT

Adjustment Preparation

(1) VIDEO control should be set Factory Preset condition.

(2) HORIZONTAL SIZE adjustment should be finished.

(3) Place the set facing East.

Adjustment Procedure

(a) PAL INTERLACE MODE Item no.16

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose Function and scan, set to 100i mode.

(4) Press [MENU] key twice to exit from [FUNCTION].

(5) Press and hold the SERVICE ONLY SW. on

CONV./FOCUS P.W.B. and [MUTE] key of Handset.

Green DCU cross-hatch are appeared with Conv.

Data cleared.

(6) Press the TV/Video button on the control panel, then

SERVICE MENU appears.

(7) Choose TRAPEZOID item by using Handset up/down

cursor key.

(8) Adjust TRAPEZOID as following by using Handset

left/right cursor key.

(9) Press “MUTE” key of handset to write the data.

(10) After adjustment, press SERVICE ONLY SW. for exit

from SERVICE mode.

(b) PAL 50Hz PROGRESSIVE MODE

(1) Input any PAL signal.

(2) Press [MENU] key.

(3) Choose [FUNCTION] and scan, set to 50P mode.

(4) Press [MENU] key twice to exit from [FUNCTION].

(5) Adjust the same items as (5)-(10) of setting PAL 100i IN

TERLACE MODE.

Item no. 20

Preparation for adjustment

(1) The beam alignment should be completed.

(2) The raster inclination, centering, horizonta l

and vertical size adjustments should

be completed. Optical focus should be

coarsely adjusted.

(3) VIDEO control should be set the Factory

Preset condition.

(Contrast : Max, other items : Center)

(4) Input the dot signal.

Adjustment procedure

(1) Green PRT beam shape adjustment

Short-circuit 2P sub-mini connectors on

Red and Blue CPT P.W.B. to project only

the green beam.

(2) Turn the green static VR*

Note : Blooming

(3) Using the 4-pole magnet as shown below,

modify the dot pattern of the screen

center to make it to a perfect circle.