Page 1

SJ300 Series Inverter

Application Note:

Optimizing Vector Control

Hitachi America, Ltd.

AN072302-1

Please refer also to the SJ300 Inverter

Instruction Manual and the SJ-FB Option

Board Instruction Manual

© 2002 Hitachi America, Ltd.

Page 2

Application Note for Vector Control with the SJ300 Inverter

2

© 2002 Hitachi America, Ltd.

Contents

[1] Overview

[2] How to Tune Each Parameter

(2-1) Tuning target of each parameter

(2-2) SLV Control block diagram

(2-3) V2 Control block diagram

(2-4) Standard motor parameter settings for SJ300 (400V class EU version) series inverter

(2-5) Example of tuning effects (SLV mode)

[3] Positioning Under ASR mode (Orientation Function)

(3-1) Orientation Function

(3-2) Example of positioning under speed control mode (ASR) on SJ300 with SJ-FB

(3-2-1) Example of wiring

(3-2-2) Example of parameter settings

(3-2-3) Timing chart

[4] APR Control

(4-1) Example of parameter settings

(4-2) How to adjust control parameters for APR control

[5] Master Slave Control

(5-1) Example of parameter settings for Master-Slave control

(5-2) How many slaves can be connected?

(5-2-1) Parallel connection

(5-2-2) Series connection

(5-3) Explanation of each P parameter

(5-4) Explanation of each output related to V2 control

Appendix A Calculation of total inertia (reflected to the motor shaft)

(A-1) Ventilation Fan

(A-2) Truck

(A-3) Conveyer

Appendix B Calculation of load inertia

(B-1) A column

(B-2) A cylinder

(B-3) A rectangular solid

(B-4) A Cone

(B-5) Wind up (vertical linear motion)

(B-6) Horizontal linear motion

This document is a guideline for optimizing motor/inverter performance in vector mode through

parameter adjustments. Please note that actual performance of the motor depends on a combination

of many parameters, and is difficult to describe concisely. Trial & error is the customary means to

achieve good motor performance. Therefore please regard this information as just a guide only.

This document only shows technical issues related to vector control. Please refer to the SJ300

Inverter and SJ-FB manuals for detailed information for installation and operation.

Page 3

[1] Overview

ASR

Slip reference

Frequency

q axis current

Slip reference

Speed

Change over

Stability

1/s

d-axis current

d-axis

q-axis

Estimation of

Estimation of

calculation of

Output

Estimation of

3

© 2002 Hitachi America, Ltd.

This engineering note applies when using SLV , 0-SLV and V2 (closed loop) control. It is often difficult to

get optimized motor performance because many parameters interact. Please refer to this document for

getting a rough idea how to achieve good motor performance with above control modes. Please also note that

the performance WILL NOT BE like a servo drive even in the case of V2 mode.

There are 3 basic modes with which you can get high torque performance with the SJ300 inverter:

(1) SLV control (No SJ-FB is used)

High motor torque performance with open loop can be obtained in the low frequency range (~0.5Hz).

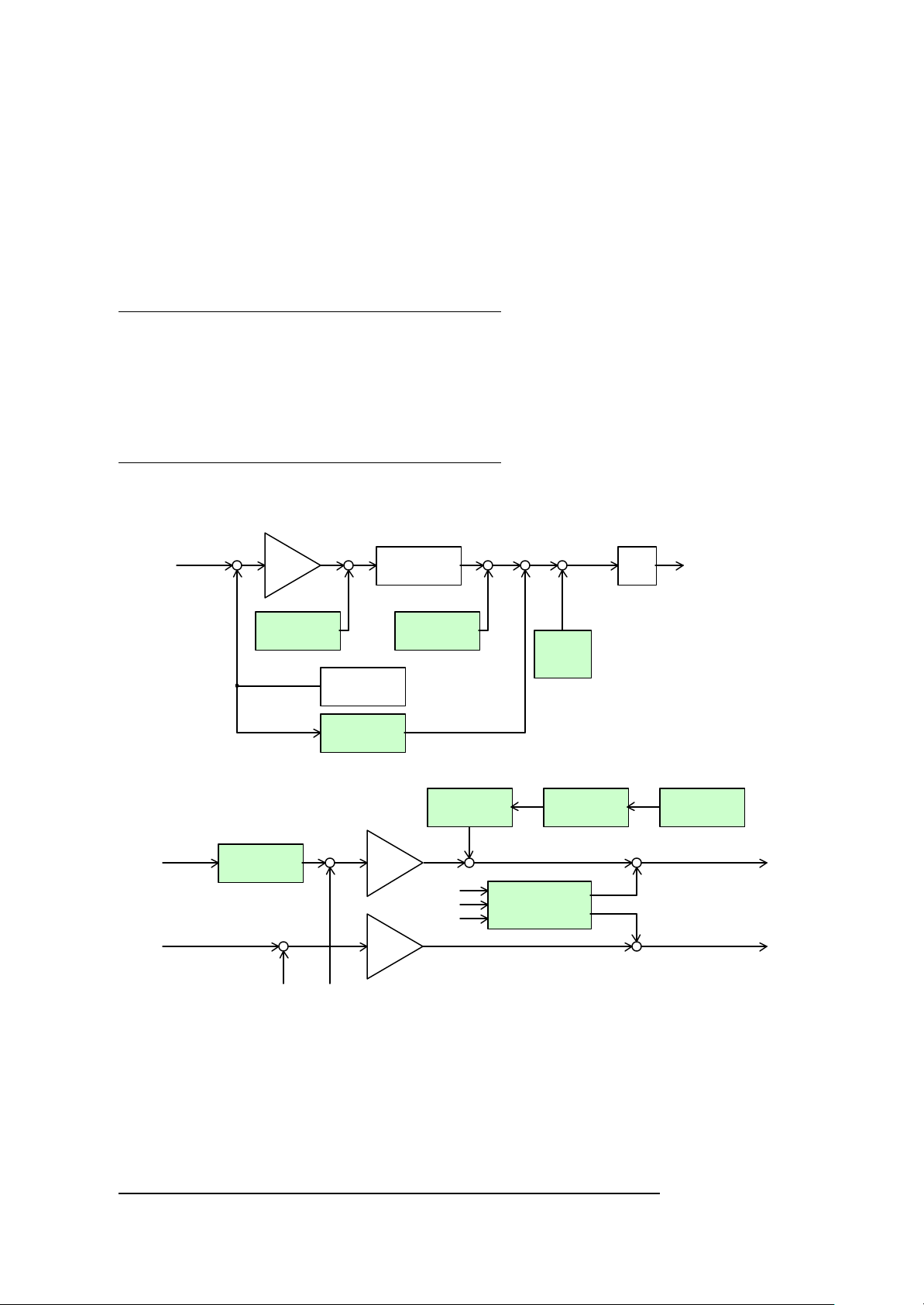

Please refer to a standard SLV block diagram in Fig 1 (section 2-2).

[H***] parameters are mainly adjusted for the control.

(2) 0-SLV control (No SJ-FB is used)

High torque performance can be obtained at around 0Hz. This does NOT mean the motor shaft will be at a

standstill. The motor rotates slightly to generate motor torque, since this is not a servo drive. Depending on the

application and tuning, you may be able to get full torque with the motor at standstill. This control algorithm is

different from SLV control.

[H***] parameters are mainly adjusted for the control.

ΠFrequency control block portion

reference

ωr*

+

-

(PI)

reference

ωr^

Iq*

+

estimation

of control

• Voltage control block portion

Magnetizing current

id*

Torque current

iq*

reference

+

id**

+

-

-

ω

s

+

+

ωs*

at 0Hz

q-axis flux

∆E

d

i

d

1

i

q

q

ACR

ACR

∆V

ω

∆V

Output frequency

+

+

control

d

Voltage Vector

ω

1

+

Motor torque

Output phase

Flux

+

+

Vd*

Vq*

+

+

V

d

voltage

V

q

i

i

q

Feedback current

d

(3) V2 control (SJ-FB is used)

High torque and stable, accurate motor performance can be achieved with the SJ300 in vector mode.

A motor encoder and a feedback option card for SJ300 (SJ-FB) are needed to use this control mode.

There are two regulation modes within the V2 control mode: ASR mode and APR mode .

ΠASR mode : Inverter is controlled by speed command input (digitally set, analog input, or RS485)

• APR mode : Inverter is controlled by pulse train input signal

[H***] and [P***] parameters are adjusted for achieving good motor control.

A suitable mode should be selected depending on the application.

Page 4

[Difference between each control]

4

© 2002 Hitachi America, Ltd.

Ø Control performance

Item SLV mode V2 mode

Speed linearity <1 % <0.01 %

Speed fluctuation <1 % <0.01 %

Control range 1 : 50 1 : 100

Speed response 15 rad/s 60 rad/s

Torque control range 1 : 50 1 : 100

Torque response 50 rad/s 500 rad/s

s Note: These are representative values only.

s

Percentages are relative to base speed

Ø Torque performance at low speed

Item SLV control 0-SLV control V2 control

Down sized motor 150% or more 150% or more 150% or more

Same kW motor 100% or more 100% or more 100% or more

s These are guaranteed minimum values with a Hitachi standard induction motor. Actual capability is greater.

Ø Torque performance at 0Hz

Item 0-SLV control V2 control

Down-sized motor 150% or more

with a small slip

Same kW motor 100% or more

with a small slip

150% or more

with standstill

100% or more

with standstill

s This has been confirmed using Hitachi standard induction motor and J2 motor (for V2 control).

Page 5

[2] How to tune each parameter

Equivalent circuit of one leg of

Small

5

(2-1) Tuning target of each parameter

There are many parameters, which influence the motor performance in SLV, 0-SLV & V2 control modes.

In some cases auto tuning is not fully sufficient to get the best motor performance because there are

various kinds of motors in the world. It is sometimes necessary to adjust by hand after the auto tuning.

Generally the performance of the motor can be determined from two criteria:

Ø Torque performance at low speed

Ø Speed response against target speed

Table 1 shows main parameters that influence the motor performance inSLV mode. The concept is the same

in 0-SLV and V2 modes as well.

Table 1. Explanation of parameters related to motor performance in SLV mode

Code Function Remarks

H001 Auto tuning mode This determines the method of auto tuning.

00 (NOR) : Auto tuning invalid

R1 L

the motor winding

R2

LM

01 (NRT) : Auto tuning with motor at standstill

02 (AUT) : Auto tuning with motor rotation

Auto tuning determines the following motor constants

automatically. (See left figure as well.)

Ÿ R1 (primary resistance)

Ÿ R2 (secondary resistance)

Ÿ L (leakage inductance)

Ÿ Io (magnetizing current at base frequency)

Ÿ J (total load inertia)

Normally better motor performance can be obtained by auto tuning

with motor rotation with an actual load on the motor. But if the

system does not allow rotating the motor, like a lift application for

example, auto tuning with motor at standstill can be used.

H002 Motor constant selection This determines which set of motor parameters is used by the drive.

00 : Motor parameters for a Hitachi standard motor

(Uses [H020] ~ [H024] )

01 : Use auto tuning data

(Uses [H030] ~ [H034] )

02 : Use auto tuning data with On-line auto tuning

On-line auto tuning occurs every time the inverter stops. It

measures R1 and R2, the main values that may change

due to a motor temperature change. The tuning period is roughly

5 seconds maximum, and if the RUN command is given during

the tuning routine, the inverter will start and tuning is aborted.

H003 Motor kW This sets the motor kW, not a kW of an inverter.

H004 Motor poles

H005

H006 Motor stability control factor This should be adjusted in case of motor instability.

H020 / H030 Primary resistance of the

H021 / H031 Secondary resistance of the

Speed response factor K

motor R1 [Ω ]

motor R2 [Ω ]

Torque

ideal

Big R2

R2

Controls the speed response

Ÿ

Large K à Quick response (Too high a value can cause instability.)

Ÿ Small K à Slow but stable response

Value is also dependent on Proportional gain (P-gain : [H050])

and Integration gain (I-gain : [H051]). ( K = f(Kp, Ki) ).

Increase / decrease depends on the situation.

Influences mainly the torque at low speed.

Ÿ Large R1 à Higher torque (Too high R1 à Over magnetizing)

Ÿ Small R1 à Smaller torque

Influence mainly on the speed change ratio (= slip compensation)

Ÿ Large R2 à Increase speed change ratio

(= Actual speed becomes faster than a target speed.)

Ÿ Small R2 à Decrease speed change ratio

(= Actual speed becomes slower than a target speed.)

Speed

Page 6

Code Function Remarks

6

See Remarks for H050

© 2002 Hitachi America, Ltd.

H022 / H032 Leakage inductance of the

motor L [mH]

H023 / H033 Magnetizing current of the

motor Io [A]

L does not influence control much compared to other

parameters, however a suitable value is recommended to be set.

Influences mainly the torque at low speed.

Ÿ Large Io à Bigger torque (Too big Io à Over magnetizing)

Ÿ Small I

à Smaller torque

o

H024 / H034 Total inertia J [kgm2] Influences mainly speed and torque response performance

This should be the total inertia (Σ J) on the motor shaft,

including the inertia of the rotor of the motor and the load. See

table 2 for information on how to tune in each case.

à

See appendix A for calculation of the total inertia.

H050 Proportional gain under

PI control mode (Kp)

(% based on [H005])

H051 Integration gain under

PI control mode (K

)

i

(% based on [H005])

Fine tuning of proportional portion of speed response factor.

Ÿ Large Kp àQuick response (Too high Kp can cause instability.)

Ÿ Small K

à Slow but stable response

p

Fine tuning of Ki portion of speed response factor.

Ÿ Large Ki à Quick response (Too high Ki can cause instability.)

Ÿ Small K

à Slow but stable response

i

H052 Proportional gain under

P control mode (Kp)

(% based on [H005])

F002 Acceleration time

F003 Deceleration time

Acc and Dec time influence the response. Even if

optimized tuning parameter values are set, actual motor speed will

change according to the set ramp time.

If a quick response is required, the ramps should be set as fast as

possible. Or, use LAC (LAD cancellation) to make the ramp invalid.

A044 Control mode Control mode should be set to 03 (SLV), 04 (0-SLV) or 05 (V2).

A045 Output gain (Vgain ) Output gain scales the duty cycle of PWM output, regardless of

the input voltage of the inverter.

Decreasing output gain can solve the problem of motor instability,

however the output torque will also decrease in this case.

A081 AVR function AVR function attempts to maintain a stable output voltage by

changing the duty cycle of the PWM output in real-time. If the input

voltage changes or bus voltage changes due to regeneration, motor

sees constant voltage. That means the motor efficiency will be better.

In some cases, disabling the AVR function can resolve motor

instability problems.

AVR function attempts to always mainain constant output voltage.

During operation, DC bus voltage is always changing, which

means AVR function is always acting to change the duty cycle of

PWM output voltage. Since it is an active control function it may

lead sometimes motor instability (unstable energy transmission).

In such cases, setting AVR OFF can solve the problem.

b022 OL restriction level Set OL level [b022] as high as possible, or else disable it

(set [b021] to “00 ”), because a rather high motor current is

required in low frequency area in the case of vector control.

b041~b044 Torque limit level Set torque limit level as high as possible, or else disable it

b083 Carrier frequency

* Second and 3rd functions ([H2**] & [H3**]) have the same meaning for 2nd and 3rd motors.

Refer to Table 3 for standard (default) motor parameter settings for SJ300 series inverter.

High torque cannot be achieved if OL restriction is preformed.

( = assign TL to an intelligent input terminal and leave it OFF),

because high motor current is required in the low frequency area

in the case of vector control.

Maximum torque cannot be achieved if torque limit is triggered.

Decreasing carrier frequency can solve the problem of motor

instability.

This is because the effect of dead time will be reduced.

Page 7

Table 2 shows suggestions for adjusting the SLV and other related parameters to correct various phenomena.

7

© 2002 Hitachi America, Ltd.© 2002 Hitachi America, Ltd.© 2002 Hitachi America, Ltd.

Table 2. Suggestions for tuning

# Phenomena Parameter How to adjust

Actual speed is faster than the target speed.

1

(Speed deviation is +)

Actual speed is slower than the target speed.

2

(Speed deviation is - )

Insufficient torque at low speed (~ few Hz) H020

3

4 Shock at start H024 Decrease J

5 Unstable motor rotation H005 Decrease speed response factor

Insufficient torque at low speed due to torque

6

limit action

H021

H021

H023

H024 Decrease J

H006

A045 Decrease output gain

A081 Set AVR function to OFF

b083 Decrease carrier frequency

b021,

b041

~b044

H005 Increase speed response factor

Decrease R2 value

(Minimum target is 80% of the preset value)

Increase R2 value

(Maximum target is 120% of the preset value)

Increase R1 value

(Maximum target is 120% of the preset value)

Increase Io value

(Maximum target is 120% of the preset value)

Increase / decrease stability control factor

(Increase or decrease depends on the situation.)

Set;

Torque limit level > Overload restriction level

7 Response is slow

Speed

8

response

overshoot due to too quick

H050 Increase P-gain of speed response factor

H051 Decrease I-gain of speed response factor

H005 Decrease speed response factor

H050 Decrease P-gain of speed response factor

H051 Increase I-gain of speed response factor

*Refer to Table 3 for a standard (default) motor parameter settings for SJ300 series inverter.

Page 8

SLV Control block diagram (Fig 1)

Magnetizing

Speed response [H005]

Magnetizing

Stabilization

Motor Constant

Motor Constant

Motor Constant

Motor Constant

Motor Constant

Motor Constant

8

© 2002 Hitachi America, Ltd.

ωr*

Speed reference

ωr^

id*

current reference

Speed

control

P gain for PI [H050]

I gain for PI [H051]

P gain for P [H052]

[H070], [H071], [H072]

Motor Constant (R1,L,Io,J)

iq*

(R1, R2, L, Io)

(R1, R2, L, Io)

iq*

id*

φd*

Voltage calculation

(Interference control)

vq*

vd*

Motor

vU* vV* vW*

Voltage conversion

(2φà3φ)

current Io

(R1, R2, L, Io)

iq*

Torque current

i

q

id*

Magnetizing

current control

i

d

d-axis secondary

id*

flux control

control

(q-ACR)

(d-ACR)

(R1, R2, L, Io)

∆

Vd∆

V

q

ω1*

∆vq0

θ

Compensation

voltage

calculation

(R1, R2, L, Io)

∆vd0

factor [H006]

iq*

φd* ω1* θ

ωr^

Frequency

calculation

φd*

Speed

estimator

i

q

ω1*

Integrator

i

d

Current converter

i

q

(3φà2φ

)

IwIu

θ

Iu

Iw

(R1, R2, L, Io)

Vector control technical information

Page 9

LAC

9

© 2002 Hitachi America, Ltd.

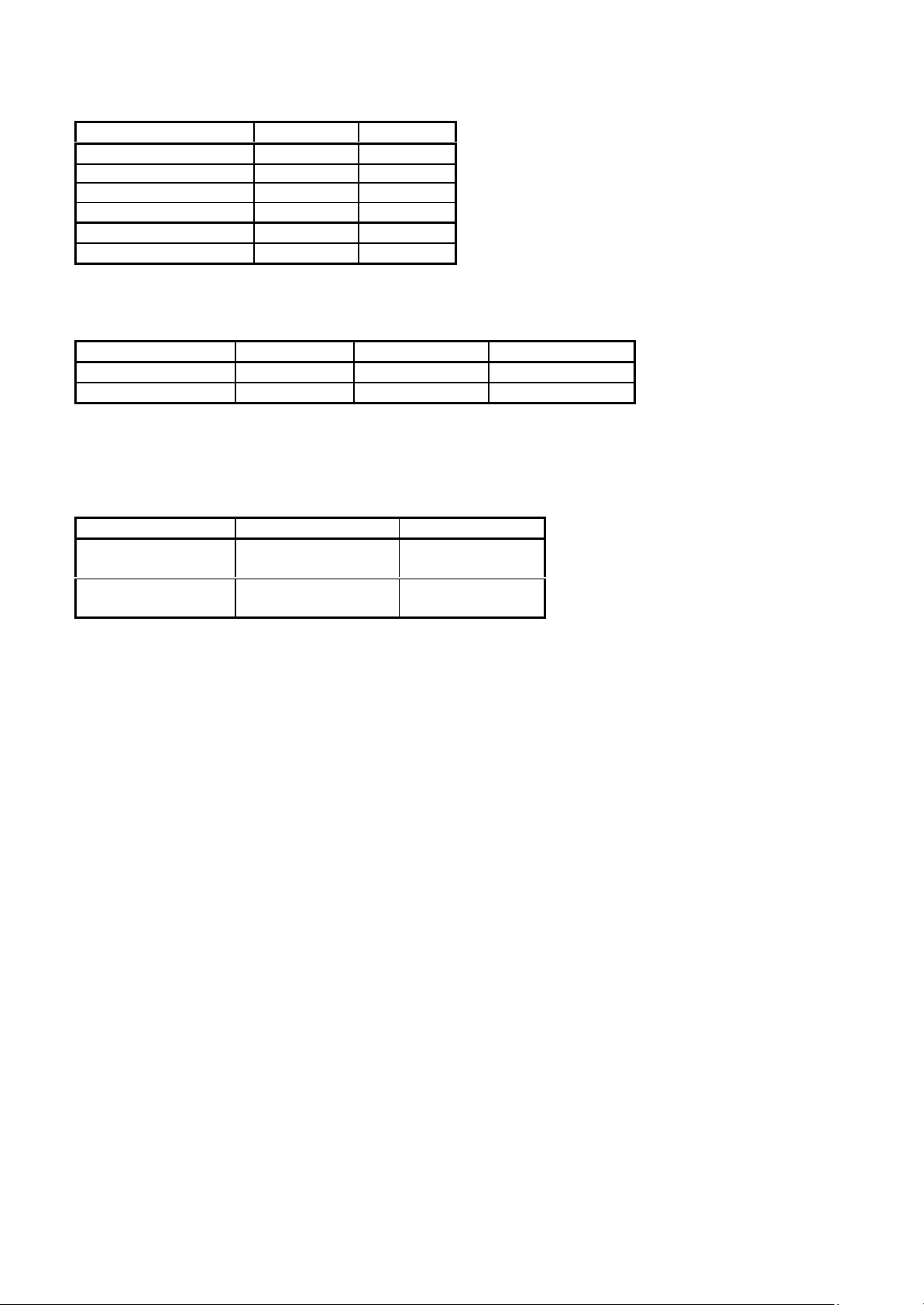

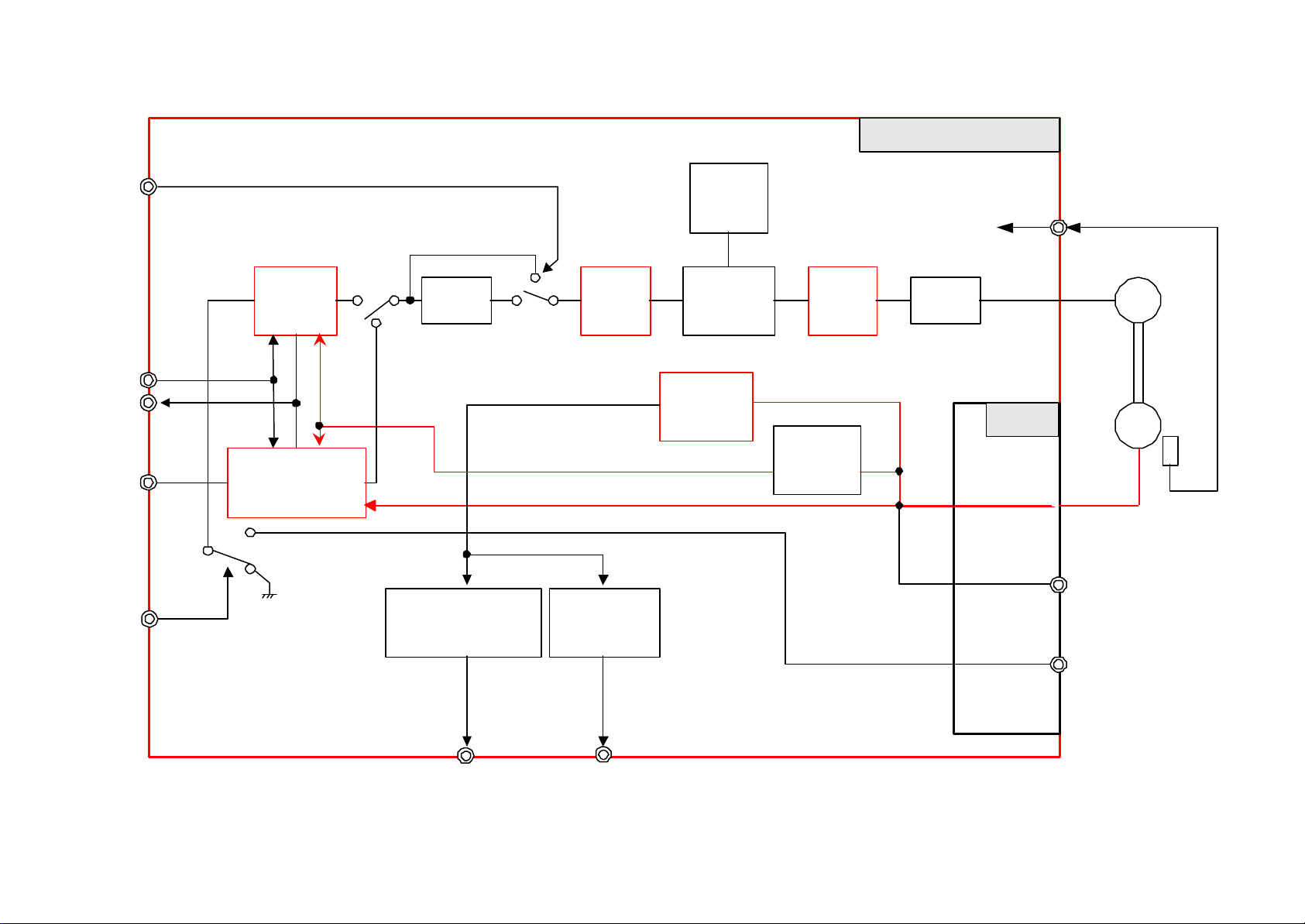

SJ-FB Option Board Block Diagram

Internal

setting

Inverter main body

TH

PCLR

POK

ORT

STAT

APR

Orientation

control

LAD

Speed deviation

excessive signal

DSE ZS

ASR

Zero speed

detection

Torque

limiter

Speed

detection

ACR

Position

detection

PWM M

SJ-FB

EAP,EAN

EBP,EBN

EZP,EZN

EP5,EG5

AP,AN

BP,BN

SAP,SAN

SBP,SBN

EC

Page 10

0.4kW

0.75kW

1.5kW

2.2kW

4kW

5.5kW

7.5kW

11kW

15kW

18.5kW

22kW

30kW

37kW

45kW

55kW

75kW

90kW

110kW

132kW

R1

24.584

9.404

3.588

2.368

1.124

0.820

0.512

0.368

0.240

0.156

0.148

0.088

0.072

0.052

0.032

0.024

0.016

0.012R26.880

2.520

1.776

1.032

0.400

0.272

0.236

0.184

0.112

0.104

0.112

0.084

0.072

0.036

0.040

0.028

0.024L83.28

24.84

13.64

7.88

7.36

5.16

2.88

2.40

2.28

1.88

Io

5.10

11.25

7.97

10.53

16.18

18.51

21.25

27.00

31.50

35.00

36.17

44.00

47.002pJ

0.003

0.011

0.012

0.039

0.049

0.059

0.095

0.116

0.276

0.313

0.551

0.613

0.713

3.001

3.438

4.625

5.625

R1

22.800

11.936

4.496

3.604

1.600

0.960

0.608

0.520

0.320

0.160

0.132

0.104

0.080

0.060

0.036

0.028

0.024

0.016

R2

11.092

3.152

1.808

0.996

0.684

0.416

0.300

0.228

0.148

0.108

0.104

0.080

0.068

0.044

0.032

0.032

0.024

L

130.56

25.12

18.64

12.60

11.28

10.40

7.44

5.16

3.64

2.40

2.32

1.92

Io

7.64

9.91

12.70

18.51

24.08

28.33

33.33

45.16

50.00

54.33

50.00

57.334pJ

0.005

0.017

0.027

0.072

0.088

0.111

0.176

0.213

0.476

0.601

1.038

1.138

1.376

3.001

3.438

6.000

7.000

R1

15.332

10.156

5.028

2.804

1.268

1.000

0.872

0.552

0.300

0.212

0.148

0.112

0.104

0.060

0.044

0.036

0.024

0.020R27.200

3.252

2.100

0.880

0.640

0.500

0.308

0.240

0.156

0.108

0.096

0.076

0.056

0.048

0.048

0.024

0.020

L

109.16

37.60

33.04

26.56

24.36

22.88

5.96

5.72

4.00

2.76

2.32

1.88

Io

6.30

11.16

14.33

20.25

28.96

33.33

38.90

43.17

58.33

58.00

81.00

68.006pJ

0.009

0.031

0.062

0.151

0.176

0.276

0.363

0.688

0.938

1.626

1.876

2.126

4.376

5.251

7.875

9.750

25.625

R1

26.668

10.244

3.532

1.708

1.000

0.900

0.804

0.536

0.412

0.232

0.168

0.092

0.060

0.052

0.040

0.024

0.020

0.016

R2

15.200

2.656

1.900

1.260

1.120

1.020

0.392

0.300

0.188

0.160

0.132

0.080

0.068

0.064

0.040

0.036

0.032

L

142.84

59.44

36.36

27.44

25.36

23.44

9.84

6.68

4.32

3.44

3.00

2.08

Io

8.40

11.97

17.66

26.73

34.83

33.80

47.50

51.33

59.33

67.00

91.47

109.178pJ

0.017

0.062

0.126

0.226

0.276

0.363

0.801

0.938

1.876

2.126

6.376

9.251

12.001

15.001

25.625

25.625

25.625

10

© 2002 Hitachi America, Ltd.

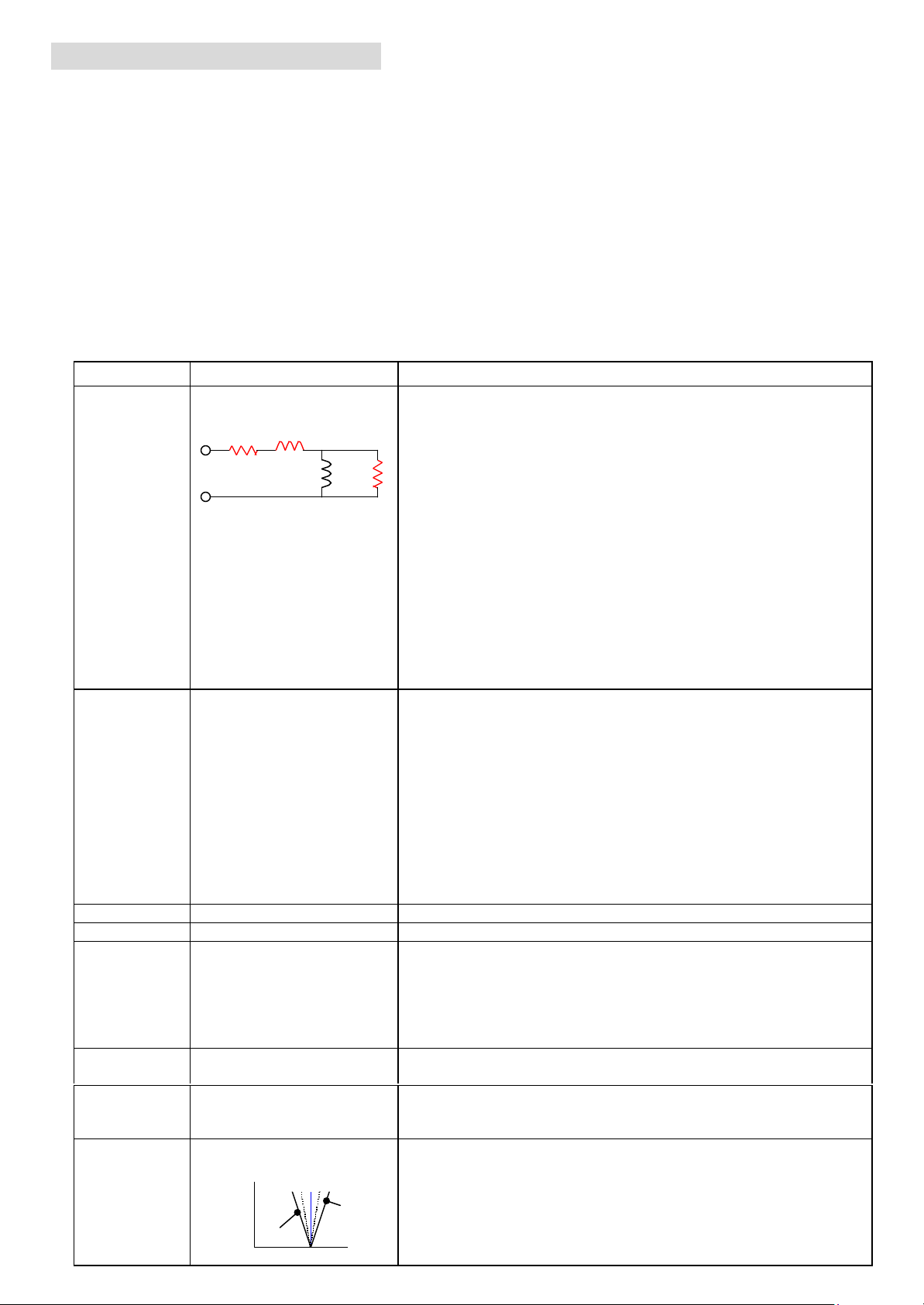

Typical Motor Constants

6.048

47.56

0.75 1.17 2.61 2.43

0.005

6.392

51.88

0.90 1.26 2.19 4.37

0.009

5.496

57.36

1.26 1.78 3.01 4.64

0.017

6.632

78.04

1.44 2.34 4.25 6.75

0.031

6.44 5.28

9.21

6.57 8.25

7.20 8.37

8.52 8.63

0.192

0.140

4.12

12.91

0.126

0.204

0.180

4.12

16.66

0.413

0.268

0.188

4.76

16.73

0.813

0.320

0.244

6.00

19.91

1.626

1.48 1.00 0.80 0.72 0.60

1.48 1.00 0.96 0.76 0.68

1.52 1.16 1.04 0.72 0.68

1.76 1.44 1.08 0.88 0.72

These parameters are based on EU motors, which have slightly different motor constants than Japanese & US motors.

Therefore the Japanese versions and US versions of SJ300 have slightly different motor parameters as default settings.

Page 11

(2-5) Example of tuning effects (SLV mode)

Data00. Default parameter

Data01. Carrier frequency 5kHzà0.5kHz / 15kHz

11

© 2002 Hitachi America, Ltd.

This section shows examples of actual effects when changing each parameter by showing motor current

waveforms. Please note that these are just examples. Actual motor performance will depend on the application.

This data is reference only! It is only intended as a guide for obtaining optimal performance.

<Summary of examples>

Common condition

Ø INV : SJ300-007HFE (rated output current = 2.5A)

Ø Motor : Hitachi standard induction motor (380V 50Hz 0.75kW 1.9A 4p 1420rpm) No load (shaft free)

s Set frequency [F001] = 3.00Hz

s Acceleration time [F002] = 0.01s, Deceleration time [F003] = 0.01s

s Control mode [A044] = 03 ; SLV mode (open loop)

s All others are default settings

Parameter

Default parameter

comparison Data number Remarks

Data00

b083 : Carrier frequency 5.0 kHz 0.5 kHz

Data01

15 kHz

H003 : Motor kW 0.75 kW 75kW Data02

H004 : Motor poles

H005 : Speed response factor K

H020 : Motor R1

H021 : Motor R2

H022 : Motor L 51.88 mH 10.00

H023 : Motor Io 1.26 A 0.3

H024 : Total J

H050 : P-gain of K

H051 : I-gain of K

4 8 Data03 OC trip

1.590 0.100

11.93

Ω

6.392

Ω

0.009 kgm

2

100 % 1

100% 1

10.00

3.000

30.00

3.000

30.00

200.0

3.0

0.001

0.100

500

200

Data04

Data05

Data06

Data07

Data08

Data09

Data10

Data11

Shock at start

OC trip

OC trip

Shock at start

Note - the graphs show steady state operation for comparison purposes only. Response characteristics cannot

be determined from this data.

1 >

1) Ref A: 1 A 200 ms

Actual frequency (average) f(ave) = 2.88Hz

IM = 1.38Arms

1 >

2 >

3 >

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

3) Ref A: 2 A 200 ms

f (ave) = 2.92 Hz / 2.88Hz

IM = 1.42 Arms / 1.38

fc = 15kHz

fc = 0.5kHz

Default parameter

Vector control technical information

Page 12

1 >

Data05. R1 [H020] = 11.93 à 3.000 / 30.00

K effects on the response so there is almost no

Data06. R2 [H021] = 6.392 à 3.000 / 30.00

12

© 2002 Hitachi America, Ltd.© 2002 Hitachi America, Ltd.

[H004] = 8

[H003] = 75

1 >

Default parameter

2 >

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

Data02. Motor kW [H003] = 0.75kW à 75kW

f (ave) = 0.87 Hz

IM = 1.57 Arms

[H005] = 10

1 >

2 >

3 >

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

3) Ref A: 2 A 200 ms

[H005] = 0.1

Data04. K [H005] = 1.590 à 0.1 / 10

f (ave) = 3.08 Hz / 2.97 Hz

IM = 1.38 Arms / 1.38 Arms

2 >

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

Default parameter

Data03. Motor poles [H004] = 4p à8p

OC trip after few seconds.

R1 = 3.00

2 >

1 >

3 >

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

3) Ref A: 2 A 200 ms

Default parameter

R1=3.00 à Bad motor performance

R1=30.0 à OC trip at start

R1 = 30.0

difference in steady state current waveform.

R2 = 30

1 >

2 >

3 >

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

3) Ref A: 2 A 200 ms

R2=3.0

Default parameter

f (ave) = 2.94 Hz / 4.25 Hz

IM = 1.37 Arms / 1.34 Arms

L=200.0 mH

1 >

2 >

3 >

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

3) Ref A: 2 A 200 ms

L=10.0 mH

Default parameter

Data07. L [H022] = 51.88 à 10.00 / 200.0

f (ave) = 2.96 Hz / 2.79 Hz

IM = 1.37 Arms / 1.40 Arms

Page 13

1 >

Data09. J [H024] = 0.009 à 0.001 / 0.100

13

© 2002 Hitachi America, Ltd.

J = 0.1

Io = 3.0 A

1 >

J = 0.001

2 >

Io = 0.3 A

3 >

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

3) Ref A: 2 A 200 ms

Default parameter

Data08. Io [H023] = 1.26 à 0.30 / 3.00

f (ave) = 2.98 Hz / -

IM = 0.40 Arms / - (OC trip)

1 >

Kp = 200

2 >

3 >

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

3) Ref A: 2 A 200 ms

Default parameter

f (ave) = 2.61 Hz / -

IM = 2.29 Arms / - (OC trip)

1 >

Ki = 200

2 >

Kp = 10

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

Data10. Kp [H050] = 100 à 10 / 200

Shock at start and then OC trip

2 >

Ki = 10

1) Ref A: 2 A 200 ms

2) Ref A: 2 A 200 ms

Data11. Ki [H051] = 100 à 10 / 200

Shock at start and then OC trip

Ø Note that these plots were made under steady state conditions, i.e. not transient data.

Transient response cannot be determined from these plots.

Ø There is no set procedure or specific order for these tuning steps, because optimal tuning depends on

the conditions and situation of the system. Refer to Table 2 in previous section for suggestions for tuning.

Page 14

[3] Positioning under ASR mode (Orientation function) (V2 mode)

Orientation speed [P015]

0

14

© 2002 Hitachi America, Ltd.

This can be implemented using SJ-FB ( feed back option card ).

(3-1) Orientation Function

The SJ300 series incorporates a function where the inverter counts the pulses from the motor encoder

and stops after a certain number of pulses. It is called the orientation function.

The Orientation function is used when an accurate stop position is required.

The SJ300 does not count encoder pulses every time, which means it is different from servo drives. The SJ300

starts counting the encoder pulses only after the Z pulse is given during orientation mode. Therefore the

SJ300 can stop the motor at a certain position.

s First, it is necessary to go into the orientation mode. (Turn the “ORT ” terminal ON on the logic

card.) During orientation period, INV stops the motor after certain pulses from Z pulse is given.

<Example of stopping 7pulses after Z pulse is given>

Orientation mode Positioning mode

ORT input

Z pulse

(1 pulse / rotation)

A pulse

• ‚ ƒ „ … †

‡

Stop!

fout

Fig 3. Example of positioning

Parameter set for this example under following condition is in table below .

- 1024 ppr encoder

- 2.0 Hz of orientation speed

- acceptable positioning range is 7±3 pulses

- give frequency command from the analog input (O-L)

- give RUN command from the digital panel

s Orientation mode starts

when the actual output

frequency reaches

the orientation speed.

s Deceleration to the

orientation speed is based on

the set deceleration time.

The ramp is based on the position loop

gain [P023], and does not follow the set

ramp time [F003].

Big [P023] results in a quick stop.

No. Code Contents Set value Remarks

1 A044 Control method 05 V2 (closed loop control)

2 P011 ppr of the encoder 1024 Depends on the encoder

3 P012 Control mode 00 ASR (Speed command base on speed)

4 P013 Mode of the pulse train input - No need to care because this is ASR mode

5 P014 Stop position while orientation 28 [P014] = 4096 * 7 / 1024 = 28

6 P015 Speed while orientation 2.0 In case of 2.0Hz for orientation speed.

7 P016 Direction of orientation 00 In case of FW rotation

8 P017 Orientation completion range 12 Allowable deviation of positioning.

9 A001 Frequency command from; 01 Terminal (O-L input)

10 A002 RUN command from; 02 “RUN” key of the operator

F002 Acceleration time 3.011

F003 Deceleration time 3.0

[P017] = 3 * 4

(Multiplying 4 is fixed as MCU calculation)

As short as the system allows.

Page 15

(3-2) Example of positioning under speed control mode (ASR) on SJ300 with SJ-FB

Belt is stopped at a certain position after passing a switch “SWZ”.

M

Required stop

SW

15

© 2002 Hitachi America, Ltd.

(3-2-1) Example of wiring

SJ300

f*

Material

O

L

P24

ORT

M

EP5

EG5

EAP

EAN

EBP

EBN

EZP

EZN

Œ

Ž

•

Allowable

deviation

n0 (pulses)

Encoder

Example of 1024ppr line driver type encoder.

EZP

EZN

n (Pulses)

•

position

In case of using external Z pulse

A

Œ Material M passes “SWO” point.

(“SWO” turns ON which means an inverter is going into an

orientation mode.)

•

Belt speed will be an orientation speed (set in

[P015]), which means it is ready for positioning

and wait for a Z pulse.

Ž After passing SWZ point, inverter starts counting the pulses

and stops at a certain position (set in [P017]).

• Inverter gives out a “positioning completion signal ; POK” from

an intelligent output terminal.

Fig 4. Example of wiring

(3-2-2) Example of parameter settings

No. Code Contents Set value Remarks

1 A044 Control method 05 V2 (closed loop control)

2 P011 ppr of the encoder 1024 Depends on the encoder

3 P012 Control mode 00 ASR (Speed command base on speed)

4 P013 Mode of the pulse train input - No need to care because this is ASR mode

5 P014 Stop position while orientation * When you want to stop at n pulses after

catching zero-pulse (after AZP/N is given);

[P014] = 4096 * n / [P011]

<Regardless the ppr of an encoder>

Stop at 300 pulses after Z pulse is given

for example;

[P014] = 4096 * 300 / 1024 = 1200

6 P015 Speed while orientation 2.0 In case of 2.0Hz for orientation speed.

7 P016 Direction of orientation 00 In case of FW rotation

8 P017 Orientation completion range * Allowable deviation of positioning.

[P017] = no * 4

9 A001 Frequency command from; 01 Terminal (O-L input)

10 A002 RUN command from; 02 “RUN” key of the operator

11 F002 Acceleration time 3.0

F003 Deceleration time 3.0

Above are the main parameters to get position control. You have to adjust other parameters ([H***] parameters)

to get good performance.

As short as the system allows.

Page 16

(3-2-3) Timing chart

ORT

Motor

N

Positioning

signal (POK)

16

© 2002 Hitachi America, Ltd.

rotation

Œ

•

2Hz Orientation

•

input

Z

A

B

MCU recognition

completion output

ON

Ž

Positioning start signal (Min. ON period = 50ms)

Start counting the pulses from the falling edge

1 2 n-2 n-1

n

Fig 5. Timing chart of example 3-2

Motor shaft rotates a bit to reverse in case it exceeds the stop position (1 ~ 2 pulses).

Refer to section [2] for adjusting each parameters to get good motor performance.

Page 17

[4] APR Control

A, B phase pulse train input

Voltage

Pulse train

APR

ASR

ACR

εθ*ω*

i*

ω

θ

i

17

© 2002 Hitachi America, Ltd.

You can control the motor by a pulse

train input on SJ300 with SJ-FB.

Make STAT terminal ON to get

(90 degrees of phase difference)

0

SJ300

EP5

EG5

M

Encoder

started. (Inverter starts to accept pulse

EAP

train input after STAT is turned ON.)

0

0

0

SAP

SAN

SBP

SBN

P24

STAT

EAN

EBP

EBN

EZP

EZN

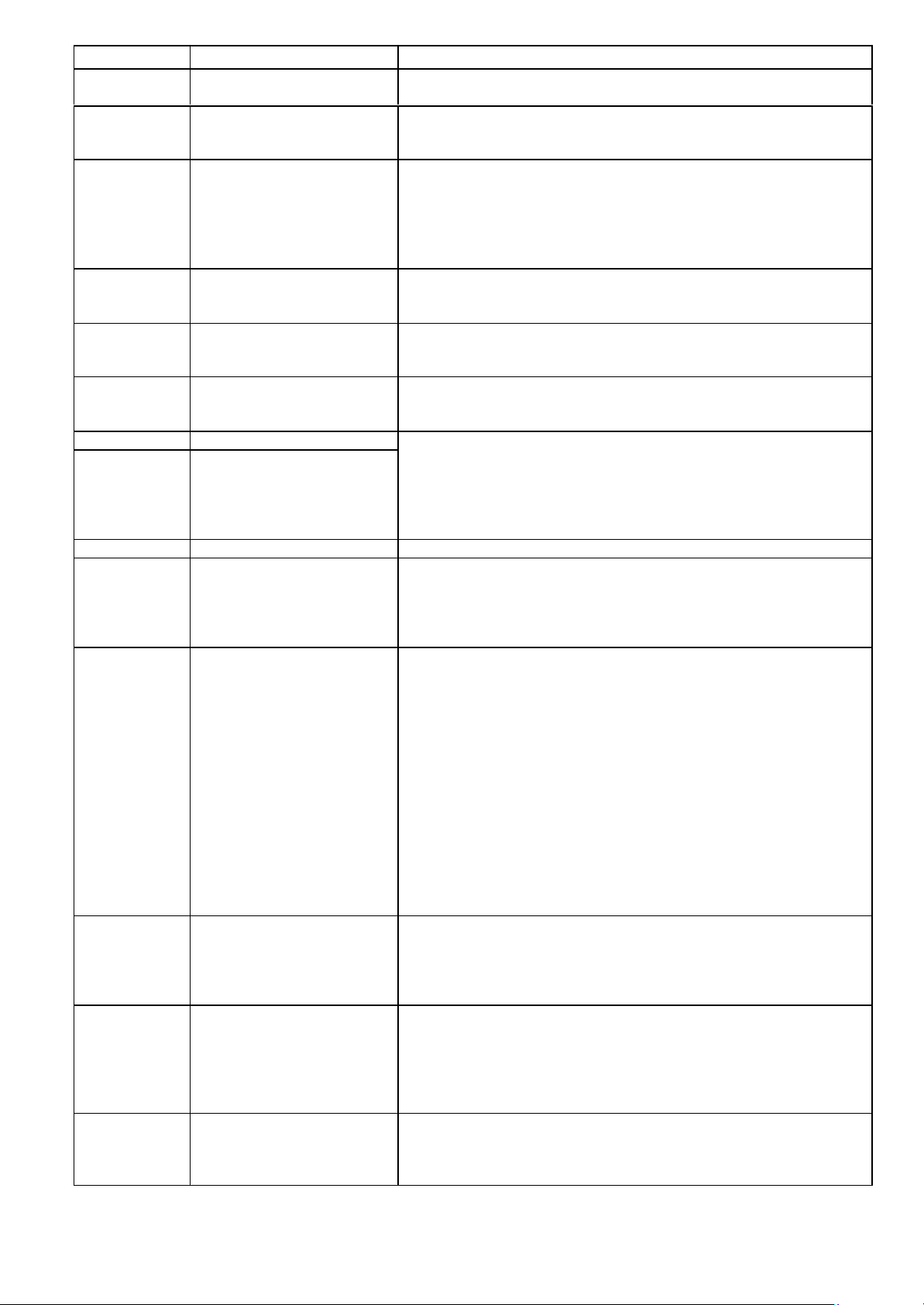

Fig 6. Idea of APR control

SJ300 controls the motor based on the pulse train input to SAP, SAN, SBP, SBN which are 90 degrees phase

difference of A, B signals. Please see below for the simplified block diagram of the control.

G1F

input

D/N

G1

+

+

+

G2

-

+

-

+

-

Position FB Speed FB Current FB

G3

control

Encoder

Motor

G1r G2r

Fig 7. Simplified control block diagram for V2 control

<Explanation of the performance>

If the control system is in a stable state, it

performs like figures shown right. Feedback will

be 1st order lag against the reference because of

PI control. (Ignoring the Overshoot.)

Making STAT signal ON while there is a

continuous pulse train input result in a constant

increasing of θ*. (θ* will not be a step change

because it is a number of pulses.) In this case

feedback θ will be fixed according to the APR

response during t1 period.

In t2 period, feedback θ will be stabilized by

APR and therefore it will be in a constant

increasing mode together with the reference (θ*).

G3r

Position

Speed

θ*

ω*

ω*

θ

ω

t

t1 t2

t1 t2

t3

Fig 8. Image of position and speed deviation

ε

t

Therefore, ω (=G1⋅(θ*-θ)), which is the output or APR block will be in a increasing (not a constant increasing)

mode during t1 period and will be stable in t2 period.

ASR block receives the ω* and controls the system to make ε (= ω* - ω) to be 0. (see above figure.) and output

of this block will be forwarded to next block.

Page 18

(4-1) Example of the parameter settings

G (P023)

Gf (P022)

AP, AN

SAP,

Speed command

Encoder

EAP, EAN

EBP, EBN

18

© 2002 Hitachi America, Ltd.

Main parameters to be set for APR control.

No. Code Contents Set value Remarks

1 A044 Control method 05 Closed loop control mode

2 P011 ppr of the encoder * Depends on an encoder

3 P012 Control mode 01 APR mode

4 P013 Mode of the pulse train input * Depends on an encoder. See manual

of SJ-FB the mode.

5 P014 Stop position while orientation 6 P015 Speed while orientation 7 P016 Direction of orientation 8 P017 Orientation completion range 9 P018 Delay time for orientation completion -

10 P019 Position of an electronic gear * Depends

11 P020 Numerator of an electronic gear * Depends

12 P021 Denominator of an electronic gear * Depends

13 P022 Feed forward gain (FFWG) * Depends

14 P023 Position loop gain (G) * Depends

No need to set since this is not

positioning.

(4-2) How to adjust control parameters for APR control

There are only two parameters to be adjusted to get good performance under APR control mode, which are feed

forward gain (P022) and position loop gain (P023).

Gf (P022) : Simply forwarding the REF value with multiplying a gain (Gf).

(Nothing to do with the actual system situation (FB).)

REF (θ* )

[P019]=01

(Feed forward gain)

N/D

+

N/D

(Position loop gain)

G (P023) : Multiplies a gain G with the deviation ε and forward.

+

+

To APR control block

(Deeply related to actual system situation (FB).)

[P019]=00

FB (θ )

Fig 9. Block diagram of position control loop

Other parameters shown in section [2] should also be adjusted to get overall good performance.

[5] Master Slave Control

With combination of ASR and APR

control, we can achieve masterslave control, which means the slave

motor follows the master motor.

SJ-FB has pulse train signal output terminals (AP,

AN, BP, BN) so that he can give them to pulse train

input terminals of another SJ-FB. The output signal

is the same as motor encoder feedback signal of the

motor belonging to him.

Ø Digital setting

Ø Analog input

Master

SJ300

SJ-FB

BP, BN

EG5

EAP, EAN

EBP, EBN

slave

SJ300

SJ-FB

SAN

SBP,

SBN

EG5

Master inverter can be either ASR or APR mode,

however the slave inverter should be in APR mode

because the slave inverter is controlled by pulse

train input from the master.

(Line driver type)

M

M

Termination resistor

Ms

Rt = ON

Rt = OFF

Fig 10. Idea of Master-Slave control

Page 19

(5-1) Example of parameter settings for Master-Slave control

Motor

Based on the

[P019]=01

19

© 2002 Hitachi America, Ltd.

<How to achieve speed 5 : 1 between master and slave>

Code Function

[A044] Main Control mode 05 (V2) 05 (V2)

[P011] Encoder pulse (ppr) 1,024 1,024

[P012] Vector control mode 00 (ASR) 01 (APR)

[P013]

[P014]

[P015] Speed while orientation 3.00 Hz [P016] Direction of orientation 00 (FW) -

[P017]

[P019]

[P020]

[P021]

[P022]

[P023] Position loop gain (G) - Depends

Mode of the pulse train

input

Stop position while

orientation

Orientation completion

range

Position of an electronic

gear

Numerator of an

electronic gear

Denominator of an

electronic gear

Feed forward gain

(FFWG)

Master Slave

* *

60 - 15 pulses * 4 = 60

20 - 5 pulses * 4 = 20

- 01 (REF side) (Note 1)

- 1,024 (Note 1)

- 5,120 1,024 * 5 (Note 1)

- Depends

Set value

(Note 1)

Remarks

Depends on the

encoder

N [P020] = 1024

D [P021] = 1024 x 5 = 5120

N/D

1

+

-

5

REF

(REF side)

Fig 11. Electronic gear of APR control

Master SJ300

P24

ORT

SJ-FB SJ-FB

SAP

SAN

SBP

SBN

EAP

EAN

EBP

EBN

EZP

EZN

EP5

EG5

AP

AN

BP

BN

Gf (P022)

FB

G (P023)

+

+

Slave SJ300

P24

STAT

SAP

SAN

SBP

SBN

EAP

EAN

EBP

EBN

EZP

EZN

EP5

EG5

AP

AN

BP

BN

APR

Common condition :

s Encoder = 1,024 ppr for both master and

slave motor

s Master is driven by ASR

s Master is stopped by positioning (3Hz of

orientation speed)

s Master stops 15 pulses after a Z pulse is

given during orientation (3 pulses for the

slave)

s Both master and slave motors stop at the

same time.

s Orientation completion range is 5 pulses

STAT

ORT

speed

Master

slave

ON

ON

Orientation

mode

set ramp time

Motor

Motor

Fig 12. Wiring and timing chart example of Master-Slave control

Page 20

(5-2) How many slaves can be connected?

20

© 2002 Hitachi America, Ltd.

There are two ways of connecting slave SJ300 to one master SJ300.

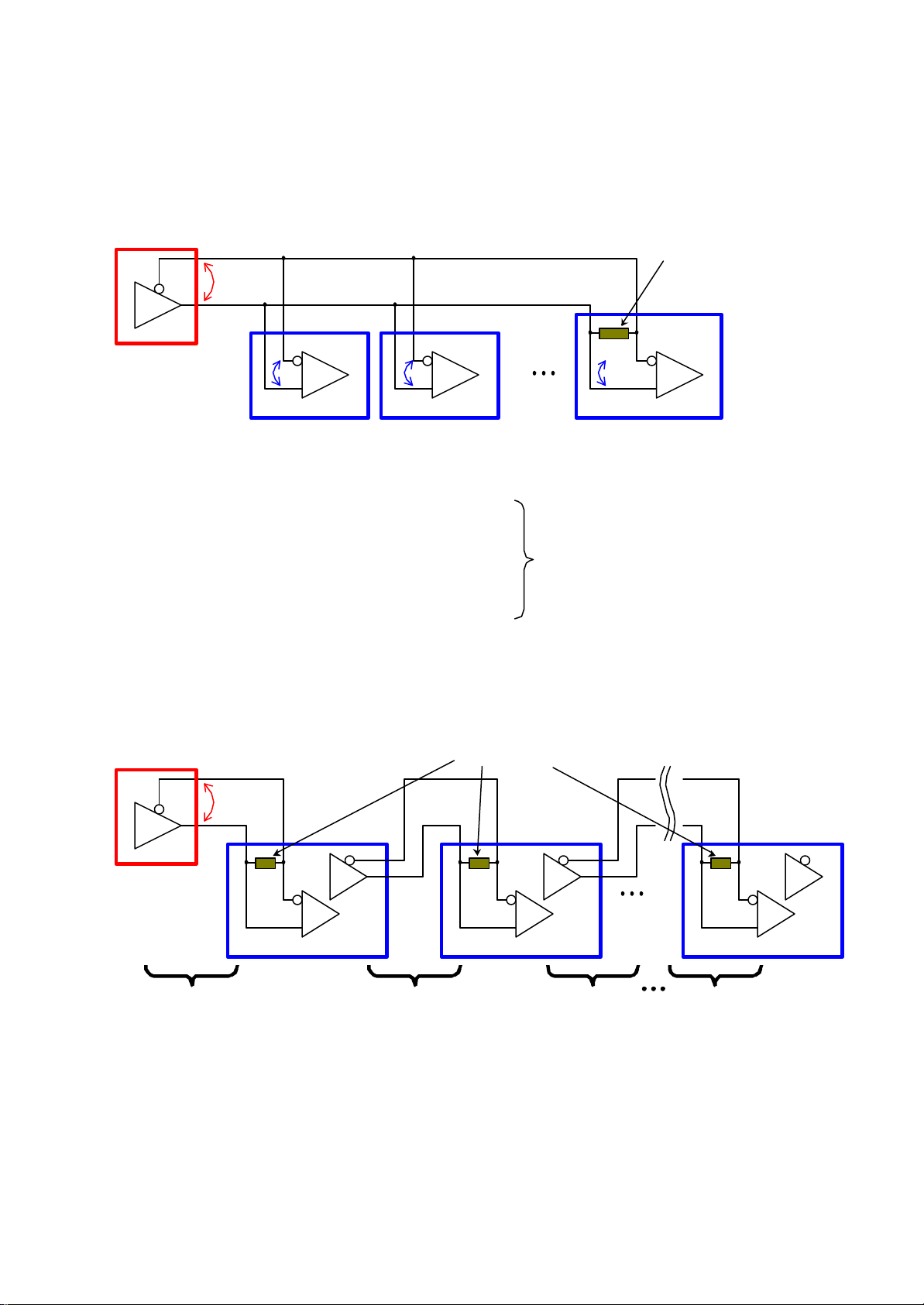

(5-2-1) Parallel connection

Maximum 10 slaves can be connected to a master based on RS422B EIAJ US. Actual capability is 32 units.

In this case, every slave follows the master with a minimum delay.

Receiver (Slave)

R

L

Termination resistor RT (Internal)

Make it ON only at the furthest place.

150 Ω

Driver

(Master)

R

1 2 32

R

i1

i2

Fig 13-1. Parallel connection of Master-Slave control

s RS422 standard

Load impedance of the driver R

Input impedance of the receiver R

> 100

L

> 4 k

in

Ω

Ω

s Actual spec of SJ-FB

Load impedance of the driver R

Input impedance of the receiver R

> 100

L

= 12 k

in

Ω

Ω

(5-2-2) Series connection

Any numbers of slaves can be connected to a master theoretically.

Delay in response will be bigger at far end.

Termination resistor RT (Internal)

Receiver (Slave)

R

L

Make it ON for every unit

R

i32

In case of 32 slaves with SJ300;

RL = (12 k

= 107 Ω > 100

∴

Capability is 32 units

Ω

/ 32) // R

T

Ω

Driver

(Master)

Delay δ1 Delay δ2 Delay δ3 Delay δn

Total delay

= δ1

Fig 13-2. Series connection of Master-Slave control

1

Total delay

= δ1+δ2

2 n

Total delay

= δ1+δ2+δ3

Total delay

= Σδn

Page 21

(5-3) Explanation of each P parameter

SAP

SAN

SBP

SBN

Detected

SAP

SAN

SBP

SBN

Detected

21

© 2002 Hitachi America, Ltd.

[P001], [P002]

What to do in case of an option error

“00” : Make inverter trip when an option error.

“01” : Make inverter ignore the error.

[P001] is for option slot 1, and [P002] is for option slot 2.

[P010]

Function display selection related to SJ-FB under user parameter [U***] mode

“00” : Parameters related to SJ-FB do not appear on the panel.

“01” : Parameters related to SJ-FB appear on the panel.

This is nothing to do with the actual performance of the motor control. It is only a display issue.

[P011]

Pulse numbers of the encoder (ppr)

Suitable number should be set depending on the encoder to be used.

[P012]

SJ-FB control mode under V2 control mode

“00” : ASR (Speed control) mode

“01” : APR (Position control) mode

[P013]

Pulse train mode of the encoder

“00” : 90° of phase difference pulse train input

pulse numbers

Forward Reverse

“01” : FW/RV pulse and pulse train

Pulse train input

FW/RV signal

pulse numbers

Forward Reverse

Page 22

“02” : FW pulse train and RV pulse train

FW pulse train

RV pulse train

Detected

SAN

SBN

Zero servo output

PWM output

POK output

ON

22

© 2002 Hitachi America, Ltd.

SAP

SBP

pulse numbers

Forward Reverse

[P014]

Stop position during orientation

Input value is 4 time of the requested stop position (pulse numbers).

<Example>

If you want to stop the motor at 15 pulses after Z pulse is given;

[P014] = 15 * 4 = 60

[P015]

Orientation speed

Low frequency is recommended to be set (1~few Hz for example), so to get stable performance of stopping.

[P016]

Orientation direction

Set the direction during orientation.

[P017]

Completion range of positioning

SJ300 keep performing positioning until the actual stop position is inside this range.

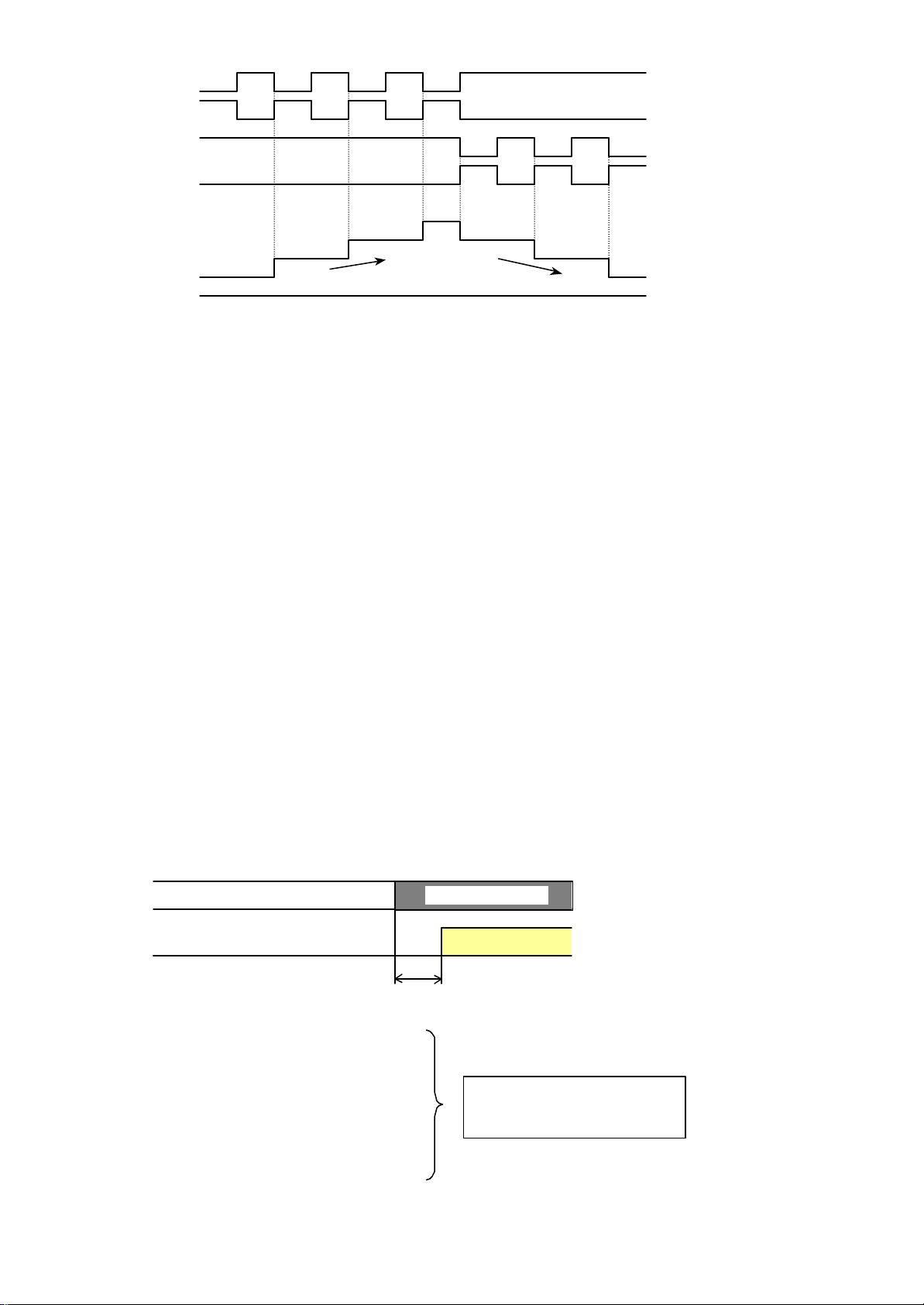

[P018]

Delay time between Completion of positioning and output of the completion signal (POK)

s This is nothing to do with the actual

motor performance, but just a delay

time of POK output signal issue.

[P018]

[P019]

[P020]

[P021]

Fig 14. Timing chart of POK output

Position of an electronic gear

Numerator of the electronic gear

Denominator of the electronic gear

Refer to section (4-2) and

(5-1) for an information.

Page 23

[P022]

Internally calculated

Detected value from thermistor

Internally calculated

Detected value from thermistor

23

© 2002 Hitachi America, Ltd.

Feed forward gain for APR control mode

[P023]

Position loop gain for APR control mode

[P025]

Secondary resistance compensation

Refer to section (4-2) for

an information.

“00” : No compensation

“01” : With compensation

• Connect a motor thermistor between TH and CM1

terminal of the control card.

‚ Set [b098] to a suitable value

s “00” : Thermistor input invalid

s “01” : PTC type

s “02“ : NTC type

ƒ Set the resistance value [Ω] you want to make it trip.

„ Set gain adjustment by [C085]

Fig 15. Example of thermistor characteristics

resistance

20kΩ

50Ω

NTC type

resistance

Small [C085]

Big [C085]

(= Pulse count numbers in MCU)

PTC type

20kΩ

50Ω

[C085] = 0[C085] = 0

Small [C085]

(= Pulse count numbers in MCU)

Big [C085]

[P026]

Over speed trip level (%) setting

Inverter trips with over speed (E 61 or E 71) when a deviation between actual speed and target speed

exceeds the level of (Maximum frequency set) x [P026].

This can happen by an overshoot caused by incorrect settings of J ([H024]/[H034]) and/or K([H005]) value.

[P027]

Over deviation detection level (Hz) setting

Inverter gives out warning (DSE output) from an intelligent input terminal when the speed deviation exceeds

this level. The calculation is based on a deviation ε in Fig 7 and Fig 8.

Page 24

• Zero speed detection : ZS (21)

24

© 2002 Hitachi America, Ltd.

SJ300 gives out this signal when;

s Actual rotation of the motor becomes less than a set value of [C063] under V2 mode .

s PWM output frequency becomes less than a set value of [C063] under other than V2 mode.

‚ Speed deviation excessive : DSE (22)

DSE signal turns ON when an actual motor speed exceeds the set value of [P027] under V2 mode.

ƒ Positioning completion : POK (23)

POK signal turns ON when the motor stop position comes to a set range of [P017] during positioning.

Once it goes out of this range the signal turns OFF and perform positioning again.

Page 25

Appendix A Calculation of total inertia (reflected to the motor shaft)

Pulley 1

Pulley 2

Motor

Gear box

Motor

Brake

Material

Mechanics

V

[m/min]

25

© 2002 Hitachi America, Ltd.

(A-1) Ventilation Fan

s Inertia of a motor = JM[kgm2]

s Inertia of a fan = JL[kgm2] : Contact a fan manufacturer for the JL value.

Total inertia ΣJ = JM + J

L

(Note) If there is a pulley inbetween them, calculation will be as follows.

Ventilation fan

Inertia JL [kgm2]

Rotation = N1 [rpm]

Inertia JM [kgm2]

Motor J

Pulley 1

Pulley 2 J

Rotation = N1 [rpm]

Inertia J1 [kgm2]

Rotation = N2 [rpm]

Inertia J2 [kgm2]

Fan J

Total - -

(A-2) Truck

Truck : W2 [kg]

s Maximum speed = V

s Maximum motor rotation = N

max

max

[m/min]

[rpm]

Inertia Rotation Converted Inertia

M

J

1

2

L

JB [kgm2]

N

1

N

1

N

2

N

2

Ÿ W3 [kg] : Possible max. weight

J

M

J

1

2

N

2

J

⋅

2

N

1

2

N

2

J

⋅

L

N

1

2

N

2

JJJ

⋅++

2M1

N

J

L

1

2

N

2

⋅+

N

1

s Inertia of a gear box = JG[kgm2] (*)

s Inertia of mechanics = Jm[kgm2] (*)

s Inertia of a motor = JM[kgm2] (*)

s Inertia of the load = JL[kgm2]

(*) Contact each manufacturer for each

J [kgm2] value.

Total inertia ΣJ = JG + Jm + JM + J

2

VW

⋅

Ÿ [kgm2]

J

=

L

max1

2

π

2

N4

⋅⋅

max

L

W1 = W2 + W3 [kg] : Total weight

Refer to Appendix B for calculation of load inertia.

JG [kgm2]

Jm [kgm2]

M B

JM [kgm2]

N

[rpm]

max

max

: Max. speed

Page 26

(A-3) Conveyor

Geared motor

26

© 2002 Hitachi America, Ltd.

W2 [kg]

V [m/min]

W3 [kg]

D1

W4 [kg]

W1 [kg]

D2

Nm [rpm]

Na [rpm]

Ÿ J

[kgm2] : gear portion

g

s Material

Ja = (W1 × V2)/(4π × N

2

)

a

s Belt conveyor

Jb = (W2 × V2)/(4π × N

2

)

a

s Drum for the belt conveyor (2 pcs)

Jc = (1/8) × (W3 × D12) × 2

s Sprocket

Jd = (1/8) × (W4 × D22)

Total inertia converted to a motor shaft ΣJm ;

Σ

Jm = (Ja+Jb+Jc+Jd) × (Na/Nm) + Jg

Jg ; Inertia for the gear portion

Page 27

Appendix B Calculation of load inertia

27

© 2002 Hitachi America, Ltd.

(B-1) A column

J = (1/8) ž W ž D2 [kgžm2]

W [kg] : Weight

D [m] : Diameter

(B-2) A cylinder

J = (1/8) ž W ž (D2 + d2) [kgžm2]

W [kg] : Weight

D [m] : Outer diameter

d [m] : Inner diameter

(B-3) A rectangular solid

J = (1/12) ž W ž (a2 + b2) [kgžm2]

W [kg] : Weight

a [m] : Length

b [m] : Length

D

W

d

D

W

a

W

b

(B-4) A Cone

J = (3/40) ž W ž D2 [kgžm2]

W [kg] : Weight

D [m] : Diameter

D

(B-5) Wind up (vertical linear motion)

J = (1/4) ž W ž D2 [kgžm2]

W [kg] : Weight of the material

D [m] : Diameter of a drum

(B-6) Horizontal linear motion

J = ( W ž D2 ) / ( 4

W [kg] : Weight of the material

V [m/min] : Speed of the material

N [rpm] : Rotation of the converted shaft

π2 ž N2 ) [kgžm2]

W

D

Drum

Material

W

V

N

Motor

W

Refer also to appendix (A-3) for detailed explanation.

Refer to Hitachi Inverter Technical Guide Book for further detailed information of inertia.

Loading...

Loading...