Page 1

M

echanical Anchoring Systems

4.3.1 HDA Undercut Anchor

4.3.1.4 Installation Instructions

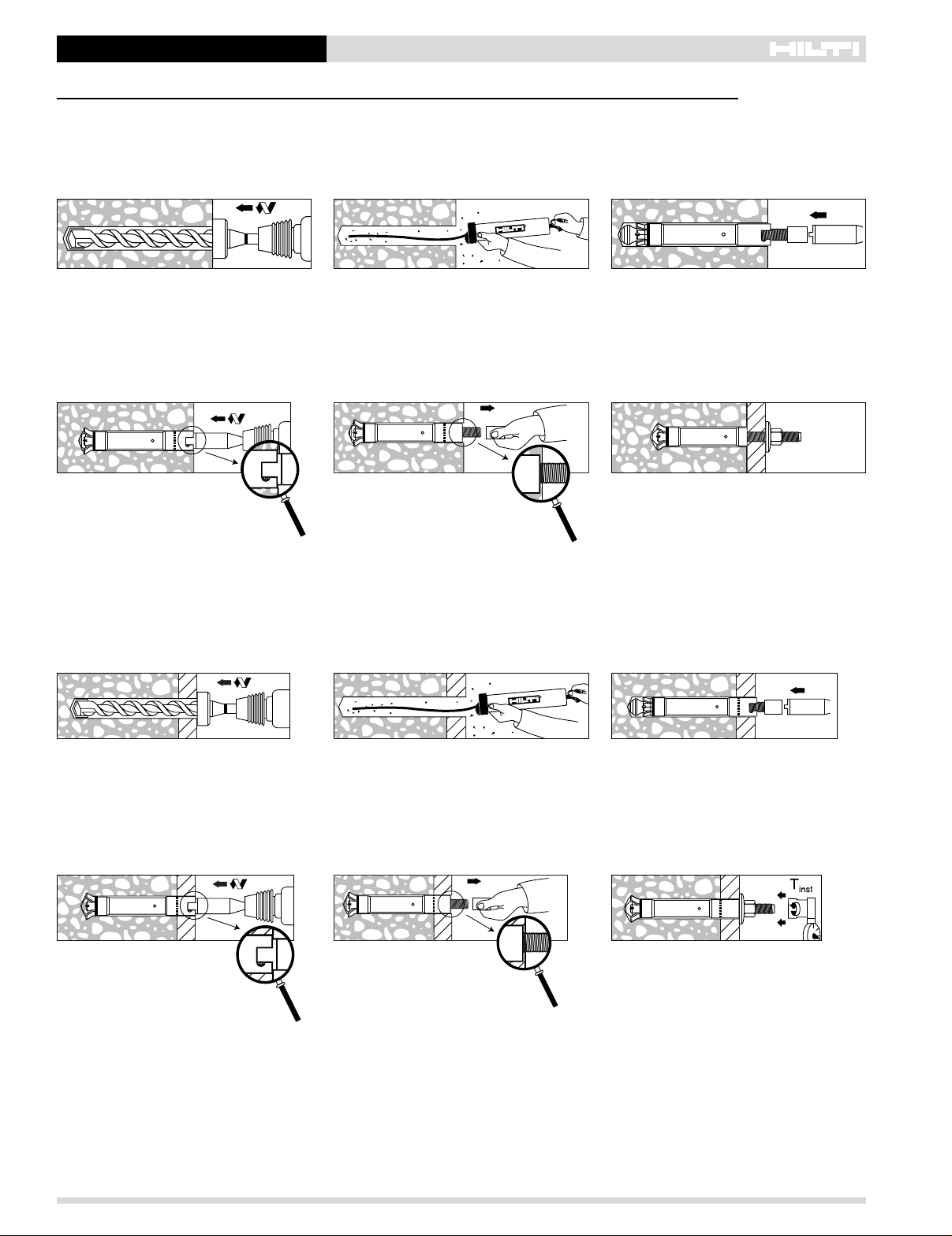

Setting Operation HDA-P/-PR/-PF (Pre-Set Style)

1. Drill a hole to the required depth using a stop drill bit

matched to the anchor,(refer to specification table

2. Clean hole with compressed air or a hand air pump

such that drilling debris is evacuated.

and ordering info.). If rebar is encountered, use a Hilti

metric matched tolerance diamond core bit to drill

through the rebar.Remove the concrete core and

finish drilling the hole with the stop drill bit.

4. The anchor is set with the hammer

drill in hammer drill mode. During

the setting procedure, both drilling and

impact energy are transferred to the sleeve

by the setting tool, causing the sleeve to slide

over the conical end of the anchor bolt while

forming the undercut in the base material. On the

setting tool, the red ring indicates the progress

of the setting operation.

5. The mark on the anchor rod

provides the indicator for correct

setting. The anchor is set and the undercut

is fully formed when the red marking on the

anchor bolt is visible above the top edge of the

sleeve. If anchor setting time exceeds 40 seconds for

M10 or M12 anchors or 60 seconds for M16 or M20

anchors, remove the anchor (see HDA removal tool

Instructions). Install a new HDA anchor.

Setting Operation HDA-T/-TR/-TF (Through-Set Style)

3. The anchor is inserted in the hole, so that the cone

sits on the bottom of the drilled hole. Do not remove

the plastic cap which protects the threaded rod.

Using the assigned setting tool and Hilti Hammer Drill

(Refer to spec. Table and Ordering Info.), the setting

tool is guided over the anchor rod and engages the

grooves in the sleeve. It is critical to use the

specified Hilti hammer drills.

6. Remove the plastic thread protector cap. Secure the

part to be fastened by using the conical spring washer and nut provided. Apply a torque not to exceed the

maximum values given in the Specification Table.

Torque is not required to set the anchor.

1. Drill a hole to the required depth using a stop drill bit

matched to the anchor,(refer to specification table

and ordering info.). If rebar is encountered, use a Hilti

metric matched tolerance diamond core bit to drill

through the rebar.Remove the concrete core and finish drilling the hole with the stop drill bit.

4. The anchor is set with the hammer

drill in hammer drill mode. During

the setting procedure, both drilling

and impact energy are transferred to the

sleeve by the setting tool, causing the sleeve

to slide over the conical end of the anchor bolt

while forming the undercut in the base material. On

the setting tool, the red ring indicates the progress of

the setting operation. When this marking is flush with

the connected part, check the anchor for proper

setting (refer to step 5).

192 Hilti, Inc. (US) 1-800-879-8000 | www

.us.hilti.com

2. Clean hole with compressed air or a hand air pump

such that drilling debris is evacuated.

3. The anchor is inserted in the hole, so that the cone

sits on the bottom of the drilled hole. Do not remove

the plastic cap which protects the threaded rod.

Using the assigned setting tool and Hilti Hammer Drill

(Refer to spec. Table and Ordering Info.), the setting

tool is guided over the anchor rod and engages the

grooves in the sleeve.

specified Hilti hammer drills.

5. The mark on the anchor rod

provides the indicator for correct

setting. The anchor is set and the

undercut is fully formed when the red

marking on the anchor bolt is visible above

6. Remove the plastic thread protector cap. Secure the

part to be fastened by using the conical spring washer and nut provided. Apply a torque not to exceed the

maximum values given in the Specification Table.

Torque is not required to set the anchor.

the top edge of the sleeve.If anchor setting time

exceeds 40 seconds for M10 or M12 anchors or 60

seconds for M16 or M20 anchors, remove the anchor

(see HDA Removal Tool instructions). Install a new

HDA anchor.

I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www

.ca.hilti.com

It is critical to use the

echnical Guide 2006

oduct T

I Pr

Loading...

Loading...